Page 1

CAUTION!

Use of solvent based or chemical cleaners on the

displays will result in damage and invalidate the

warranty

h1000 pilot

installation

manual

HB-1000I-02 English

WARNING!

An autopilot is a very useful navigational aid, but DOES NOT under any

circumstance replace a human navigator.

Do not use automatic steering when:

x

In heavy traffic areas or in narrow waters

x

In poor visibility or extreme sea conditions

x

When in areas where use of an autopilot is prohibited by law

When using an autopilot:

x

Do not leave the helm unattended

x

Do not place any magnetic material or equipment near magnetic or

fluxgate compass used in the autopilot system

x

Verify at regular intervals course and position of vessel

x

Always switch OFF the autopilot in due time to avoid hazardous

situations

Page 2

h1000 pilot

contents 1

h1000 pilot display 4

description 4

siting the pilot head 4

mounting procedure 5

panel mounting 5

h1000 compass unit 6

description 6

siting the compass unit 6

mounting procedure 6

rudder reference unit (rru) 7

description 7

key points when installing the rru 7

linear feedback unit 11

rudder drive options 12

ram drive unit 12

description 12

hydraulic linear drives 12

contents

contents

hydraulic ram drive dimensions (T0-12V) 14

hydraulic ram drive dimensions (T1-12V, T2-12V, T2-24V) 15

size 3 hydraulic ram drive dimensions, 24V 17

ram drive unit installation 19

key points on installation 19

layout of typical ram drive unit 20

ram mounted parallel to vessel’s centre-line 21

key points on installation 22

mounting a hydraulic linear ram on a vertical bulkhead 22

vertical bulkhead installation 23

splitting the ram drive unit 24

type 1 and type 2 units 24

type 3 units 24

hydraulic drive pumps 25

description 25

pump data 25

key points on installation 25

hydraulic drive pump dimensions 26

type 1 and 2 26

type 3 26

hydraulic drive pump installation 27

Page 1

Page 3

contents

contents

h1000 pilot

hydraulic drive pump installation examples 28

single station system example 28

dual station system example 28

dual station system with bypass example 29

dual station pressurised system example 29

advanced control processor unit (acp) 30

description 30

siting the acp 30

mounting procedure 30

cable and connection information 31

emc compliance 31

general wiring notes 31

all rudder drives – heavy duty power cables 32

linear drives – clutch/valve cables 32

acp unit terminal details 32

wire colour coding and abbreviations 32

wiring connections 33

clutch voltage selection 33

acp dip switch location 34

h1000 and alarm connections 35

hand-held, mob and joystick 36

hydraulic ram drive connections 37

ram solenoid wiring details 38

hydraulic pump connections 39

continuous drive connections 40

direct paddle input connection 41

linear feedback connection 42

non-b&g paddle connection 43

furuno ad10 heading connection 44

optional accessories 46

hand-held controller 46

description 46

siting the hand-held unit 46

mounting procedure 46

man overboard button (mob) 47

description 47

siting the man overboard alarm button 47

mounting procedure 47

acp joystick 48

description 48

siting the joystick 48

mounting procedure 48

Page 2

Page 4

h1000 pilot

h1000 pilot calibration 49

pilot installation checklist 49

drive unit and steering system 49

linear hydraulic rams 49

size 3 ram installation checklist 49

hydraulic pumps 49

rotary drives 49

rudder reference unit installation 50

linear feedback unit installation 50

compass installation 50

electronics installation 50

speed calibration 51

calibrating the pilot 53

pilot calibration parameters 53

dockside calibration 53

selecting the boat type 54

setting the rudder end stops 54

setting the port rudder stop 54

setting the starboard rudder stop 54

selecting the rudder drive type 54

hardovertime 55

waterline length 55

magnetic dip angle 56

magnetic dip angle compensation chart 56

joystick control 56

seatrial calibration 57

compass calibration 58

engaging the h1000 pilot 61

setting the rudder midships position 61

boat lag 61

setting the boat lag value 62

boat lag value table 62

automatic rudder gain 62

checking the automatic rudder gain learning 62

manual rudder gain 63

rudder gain value table 63

contents

contents

trouble shooting 61

uncalibrated 61

no rudder position 61

no drive selected 62

no boat speed 62

no heading data 62

no nmea information 63

nmea data unstable 63

poor wind data 63

current trip limit 63

no pilot detected 63

pilot not steering a straight course 64

Page 3

Page 5

description/installation

h1000 pilot display

h1000 pilot

description

The h1000 pilot display is designed to be mounted above or below decks. The display head allows

control of the pilot and by installing multiple display heads, gives control at any station. It can be

connected to all other h1000 Instruments via the Fastnet

and navigational system.

Caution: it is essential that the pilot is calibrated before operati on. Details are given in the calibration

section of this manual.

In an integrated system, boat speed is supplied from the h1000 Speed/Depth Interface and wind speed

and wind angle from the h1000 Wind Interface via Fastnet

Compass and Wind modes. When a CND or NMEA position fixer is connected to the system, Navigate

mode becomes available. NMEA data is connected to the Universal Interface and then broadcast

across Fastnet

The display heads are supplied with a clip-in mounting bracket, which allows for easy installation.

Access from behind is not necessary to secure the unit in place. However to prevent theft or if removal

of the unit is not required, then locking studs and thumbnuts are supplied to allow for permanent

fixing.

2

and used by the pilot.

2

connectors to provide an integrated autopilot

2

. These allow the pilot to operate in the

siting the pilot display head

h1000 instruments are designed for mounting above or below decks. Select a display site that is:

x

At a convenient position within easy reach and view of the helmsman.

x

On a smooth and flat surface.

x

At a safe distance of 100mm (4") from any compasses.

x

Protected from physical damage.

x

Accessible from behind for fitting locking studs if required.

Page 4

Page 6

h1000 pilot

description/installation

mounting procedure

panel mounting

Ensure that the display is installed on a flat surface, and there is sufficient room behind the panel to

accommodate the fixings and connections. Using the template supplied, cut a hole in the panel in the

desired position.

Fix the mounting bracket into the hole using the screws supplied.

Note

: the sealing ring is fitted to the unit during manufacture, its purpose is to prevent moisture

penetration and reduce the effects of any vibration transmitted through the instrument panel.

Press the Pilot Display firmly into the mounting bracket; an audible ‘clic k’ will indicate that the case

is correctly located.

Secure the unit to the instrument panel by fitting the studs and thumbnuts supplied.

Caution

: To avoid damaging the casing, fixing studs must only be tightened ‘finger-tight’.

Mounting

Bracket

Sealing Ring

(Fitted at Manufacture)

Pilot Display

Unit

Protective

Cover

Page 5

Page 7

description/installation

h1000 compass unit

h1000 pilot

description

The h1000 compass is an electronic fluxgate for use with all h10 00 systems. The unit is housed in a

sealed casing constructed of high impact plastic. It is therefore suitable for on or below deck mounting.

If installed in a vessel with a steel or reinforced concrete hull it may be necessary to install the

compass unit outside the magnetic screening affect of the hull and super-structure.

Two Fastnet² connectors are provided at the base of the unit. These connectors allow connection to the

rest of the system for the supply of power and data.

siting the compass unit

Mount the compass upright on a flat vertical bulkhead where it will be:

x

A safe distance from external magnetic interference:

3m (10ft) from VHF, RDF, loudspeakers, depth sounders, engines, or power cables carrying

heavy current.

x

3m (10ft) from radar and SSB equipment.

x

Externally mounted on steel vessels.

x

Protected from physical damage.

x

Protected from water ingress (particularly bilge water).

x

Optimum positioning: as low as possible to minimise effect of pitching and rolling of boat.

mounting procedure

x

Secure the unit in the selected site using the non-magnetic self-tapping screws provided.

x

Route the Fastnet

e.g. engine starter, trim-tabs, etc.

x

Secure cables in place with cable clips or tie-wraps.

x

Avoid bending the cable through a tight radius, especially near the connector as this may damage

the wires inside the cable.

Page 6

2

cable to the rest of the system avoiding other cables carrying heavy currents,

Page 8

h1000 pilot

rudder reference unit (rru)

description/installation

description

The Rudder Reference Unit (rru) is a sealed, high specification potentiometer in a robust casing,

providing rudder position information to the pilot computer unit. The operating arm is constructed from

aluminium with three positions pre-drilled for the adjustable drag-link. The drag-link has ball-joints at

each end which connect the unit operating arm to the tiller arm or steering quadrant. The unit base has

four holes to allow for mounting. The unit is supplied with 10m (30ft) of 3-core screened cable.

key points when installing the rru

x

General consideration must be given to the steering system and its geometry before starting the

RRU installation. Many factors must be contemplated for a practical solution. The information

given here is for guidance only, although where a maximum or a minimum value is given these

must be adhered to.

x

Mount the rru on a flat surface next to the tiller arm or steering quadrant; construct a small

platform if necessary.

x

D o not lengthen the drag-link arm as this can transmit excessive vibration loads to the rru and

will invalidate the warranty.

x

The unit operating arm can be rotated through 360q; the mid-point of the potentiometer travel is

when the operating arm is opposite the cable entry point.

x

When the rudder is moved from hardover port to hardover starboard the rru arm should swing

through a minimum of 90q. This will ensure that there is sufficient voltage swing to the autopilot.

Page 7

Page 9

description/installation

h1000 pilot

rudder reference unit

Measure the voltage difference between the green and blue wires of the rru; there should be a

minimum of 1V d.c. change from hardover to hardover.

Note: If there is less than a 1V d.c. change the pilot will not commission

x

After installation check full movement of the steering system ensuring that there is no fouling

between the steering gear, rru parts and drive unit.

x

Ensure that there is no backlash in the linkage between the rru and the st eering gear, otherwise

incorrect operation of the autopilot will occur.

The example shown overleaf is a plan view of a typical system with a tiller arm and quadrant. When

viewed in elevation, the ram drive arm and rudder reference unit drag-link must not be more than ±9

from horizontal. Ideally, all components should be horizontally aligned as this prevents excessive

stress during operation.

.

q

Page 8

Page 10

h1000 pilot

description/installation

rudder reference unit

Page 9

Page 11

description/installation

h1000 pilot

rudder reference unit

The RRU can be mounted in a variety of positions and orientations depending on the layout of the

steering system.

If the maximum rudder angle is less than 90q then the position of the RRU or the drag-link must be

adjusted so that the operating arm of the RRU swings through a minimum of 90.

1V minimum

variation

90° MINIMUM RRU ANGLE

Page 10

Page 12

h1000 pilot

description/installation

rudder reference unit

The rudder hardover angle should only be limited by th e rudder stop s, not the rru li nkage or pilo t drive

unit. Check that when hardover, the rru arm and drag-link do not form a straight line. If this occurs the

steering system could become damaged or jammed endangering the boat and crew. This fault can

easily be rectified, by adjusting the position of the RRU.

linear feedback unit

Where installation of the conventional rudder reference unit is difficult or physically impossible, a

linear feedback unit (SEN-RUD-LFB) can be used. The linear feedback unit comprises of a tube

approximately 23mm (7/8 inch) in diameter and 300mm (12 inch) long. This assembly is attached to the

top of the B&G Blue Ram Types T1 or T2. Each end of the linear feedback unit has a small rose-joint

which is attached to corresponding pillars on the ram, the ros e-joints are retained using washers and

spring clips.

LINEAR

FEEDBACK

UNIT

Page 11

Page 13

description/installation

h1000 pilot

rudder drive options

warning

Accurate performance of the yacht’s steering system is crucial to the safety of you and your crew. B&G

always recommend that an Authorised B&G Dealer performs the installation of autopilot drive units.

caution

In line with B&G’s policy of continuous product improvement, drive units are regularly updated.

Installation data included with your drive unit will replace installation data contained in this manual.

Before undertaking any shipwright work onboard the yacht, it is essential that the installation data in

this manual be verified against your drive unit. If in doubt, consult your authorised B&G Dealer for

technical assistance. B&G cannot accept liability for differences that may occur between the drive unit

and this User Manual.

ram drive unit

description

A hydraulic pump driven from the dc electric supply combines a compact reversible pump and a

hydraulic cylinder assembly for use on boats without hydraulic steering systems. Three sizes of ram

drive units are available giving a wide range of thrust to suit all vessel types and sizes.

hydraulic linear drives

The Type 1 and Type 2 rams combine motor, pump and hydra ulic cyli nder as one unit, referred to as a n

actuator. Type 3 rams are supplied split into a separate motor/pump unit, reservoir and hydraulic

cylinder, connected by 1m (3ft) hoses. The Type 3 motor/pump unit can be mounted on a vertical

bulkhead.

.

Note: Longer hoses for the Type 3 system are available, please contact your dealer.

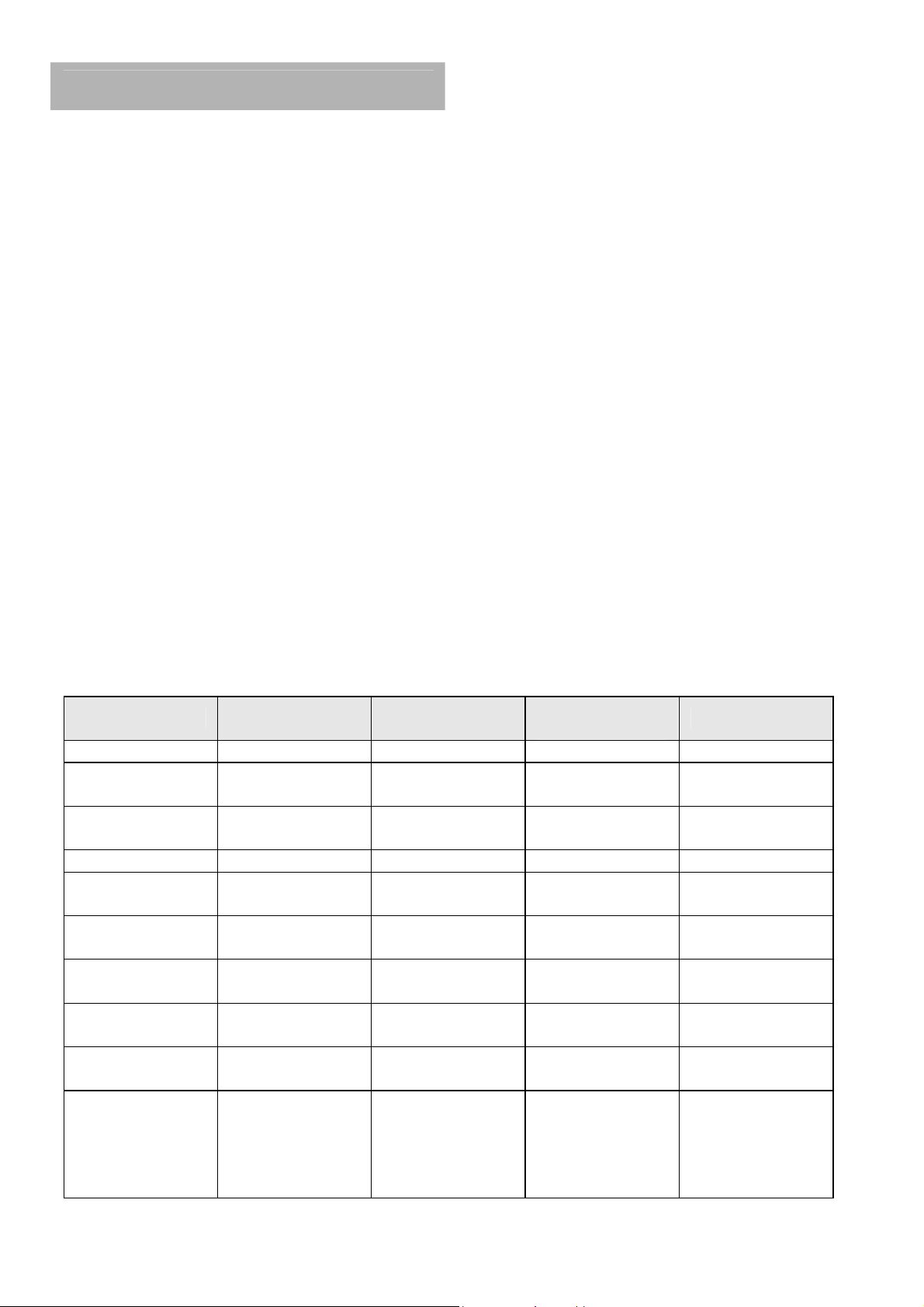

Ram Drive Type RAM-T0-12V RAM-T1-12V

Motor Supply 12V dc 12V dc 12 or 24V dc 24V dc

Solenoid Valve

Supply

Peak Thrust 300 kg force

Peak Current 20A @ 12V 20A @ 12V 25A @ 12 or 24V 17A @ 24V

Maximum

Stroke

Rod Diameter 12mm

Tiller Arm for

70q Rudder

Maximum

Torque

Weight 5.8 kg

Helm to Helm

Time

Extend

Retract

12V dc

1.25A (max)

(660 lbs force)

203mm

(8")

(0.472”)

178mm

(7")

545 Nm

(4823.65 lb.ins)

(12.7 lbs 6oz)

10.1sec

9.9 sec

(200kg force)

12V dc

1.25A (max)

680 kg force

(1496 lbs force)

254mm

(10")

16mm

(0.623”)

214mm

(8.4")

1427 Nm

(12574 lb.ins)

7 kg

(15 lbs 6oz)

15.7 sec

13.4 sec

(200kg force)

RAM-T2-12V

RAM-T2-24V

12 or 24V dc

1.25A (max)

680 kg force

(1496 lbs force)

254mm

(10”)

16mm

(0.623")

214mm

(8.4")

1427 Nm

(12566 lb.ins)

7 kg

(15 lbs 6oz)

11.9 sec

10.2 sec

(200kg force)

RAM-T3-24V

24V dc

0.8A (max)

1062 kg force

(2342 lbs force)

305mm

(12")

20mm

(0.623")

257mm

(10.16")

2688 Nm

(23780 lb.ins)

10.3 kg

(22lbs 11oz)

14.6 sec

12.6 sec

(200kg force)

Page 12

Page 14

h1000 pilot

description/installation

rudder drive options

The following tables indicate the tiller arm length required for the different types of drives.

RAM T0 Hydraulic Linear Drive

RAM–T0–12V

½ Max. Rudder

Angle

q

35

RAM T1 and T2 Hydraulic Linear Drives

RAM-T1-12V

RAM-T2-12V

RAM-T2-24V

½ Max. Rudder

Angle

q

35

RAM T3 Split Hydraulic Linear Drive

RAM - T3-24V

½ Max. Rudder

Angle

q

35

Midstroke

429mm (16.9”)

Tiller Arm

178mm (7.0”)

Midstroke

575mm (22.6”)

Tiller Arm

214mm (8.4”)

Midstroke

755mm (29.7”)

Tiller Arm

257mm (10.2”)

Page 13

Page 15

description/installation

hydraulic ram drive dimensions (RAM-T0-12V)

Midstroke 429mm (16.9")

Stroke Length 203mm (8.0")

o

Movement

360

4 off Mounting Holes

9mm Dia. at 76mm Centres

223mm

h1000 pilot

76mm 66.7mm

82mm

14mm

76mm

100mm

125.6mm

73.3mm

9mm

2

16mm

12mm Dia. -0

+0.018mm

Page 14

Page 16

h1000 pilot

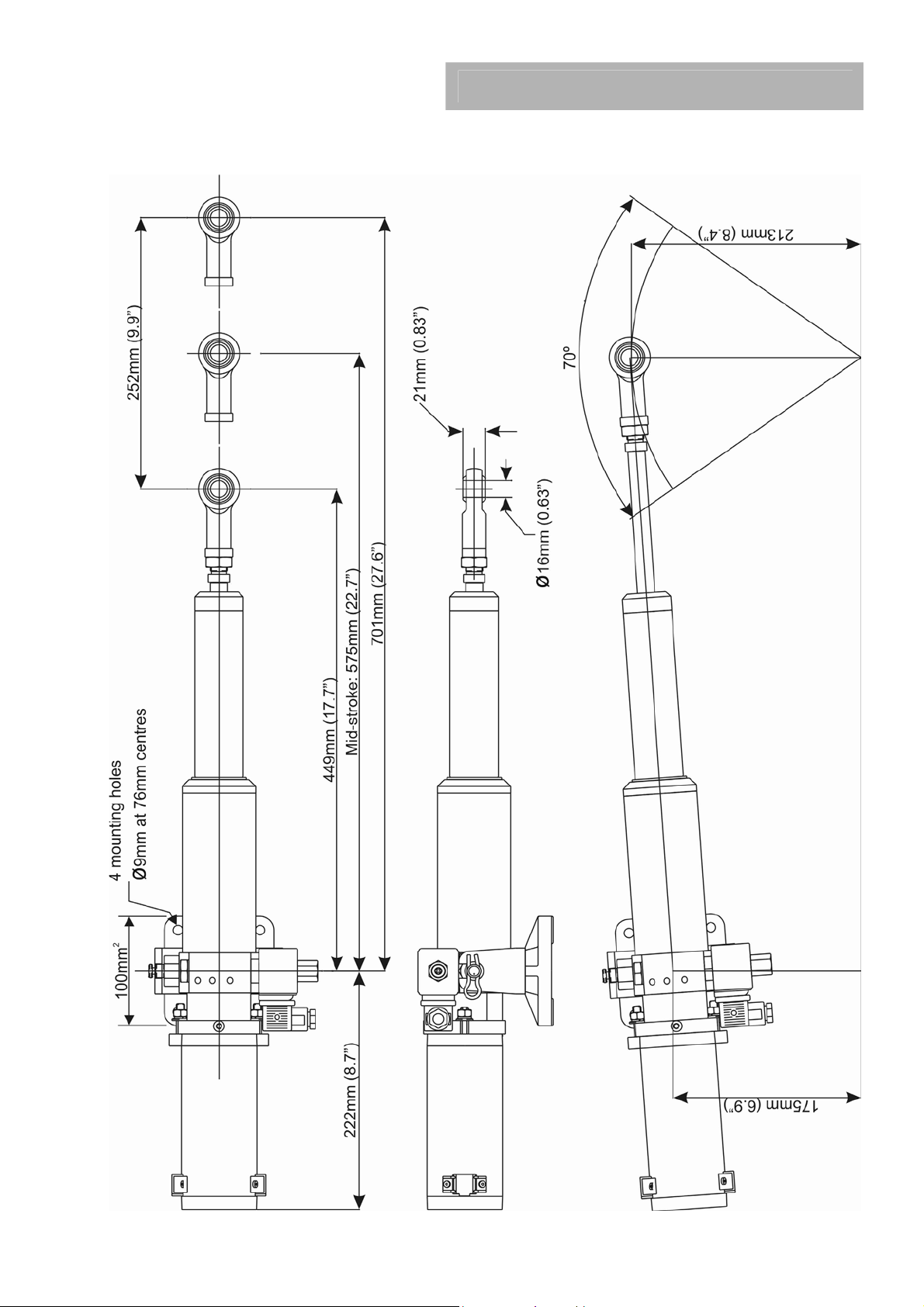

hydraulic ram drive dimensions (T1-12V, T2-12V, T2-24V)

description/installation

Page 15

Page 17

description/installation

type 1 and 2 rose joint and am bolt detail

h1000 pilot

RECOMMENDED

QUADRANT THICKNESS

ROD END

16MM

MAX

12MM

MIN

NUT TORQUE - 27NM

20 Ft.Ib

‘R’ CLIP

WASHER

TILLER BOLT

R

3773

LOCTITE

WASHER

Page 16

Page 18

h1000 pilot

description/installation

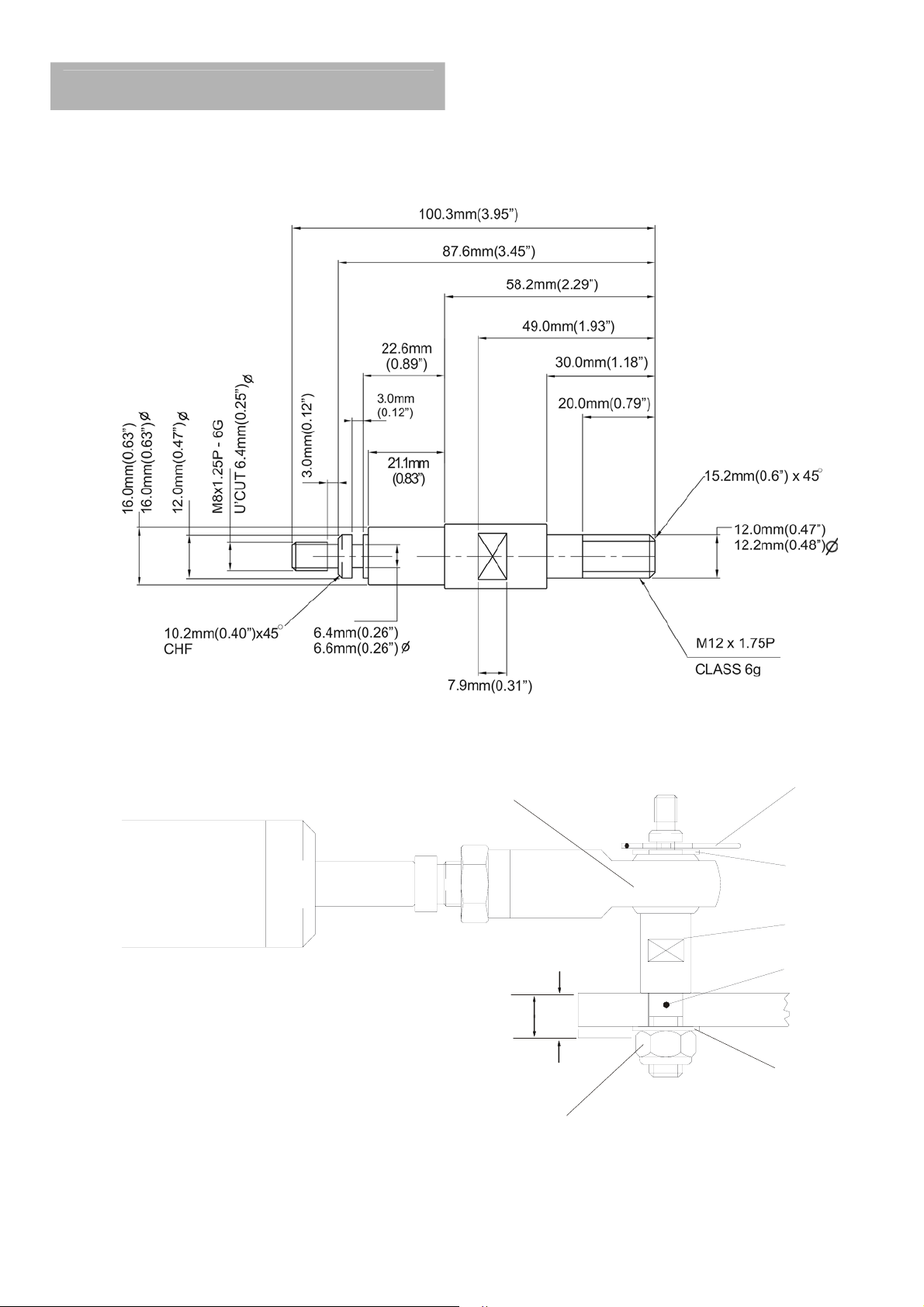

size 3 hydraulic ram drive dimensions, 24V

Page 17

Page 19

description/installation

type 3 ram bolt detail

h1000 pilot

Page 18

Page 20

h1000 pilot

‘

description/installation

ram drive unit installation

Note

: General consideration must b e given to the steering system and its geometry before starting

the installation. Many factors must be contemplated for a practical solution; the information

given here is for guidance only, although where a maximum or minimum value is given this

must be adhered to. It is essential that the unit be installed in a fully functional steering

system, with no backlash or stiffness when operating. Rectify any steering problems before

installation of the ram drive unit or the autopilot will not function correctly.

key points on installation

x

Check that the steering gear is in good condition. Rectify any steering defects prior to installation

of the ram.

x

The ram drive unit must be secured onto a flat, rigid base. It maybe necessary to construct a

platform section for the mounting plate. For angled rudderstocks, an angled platform section will

have to be constructed.

x

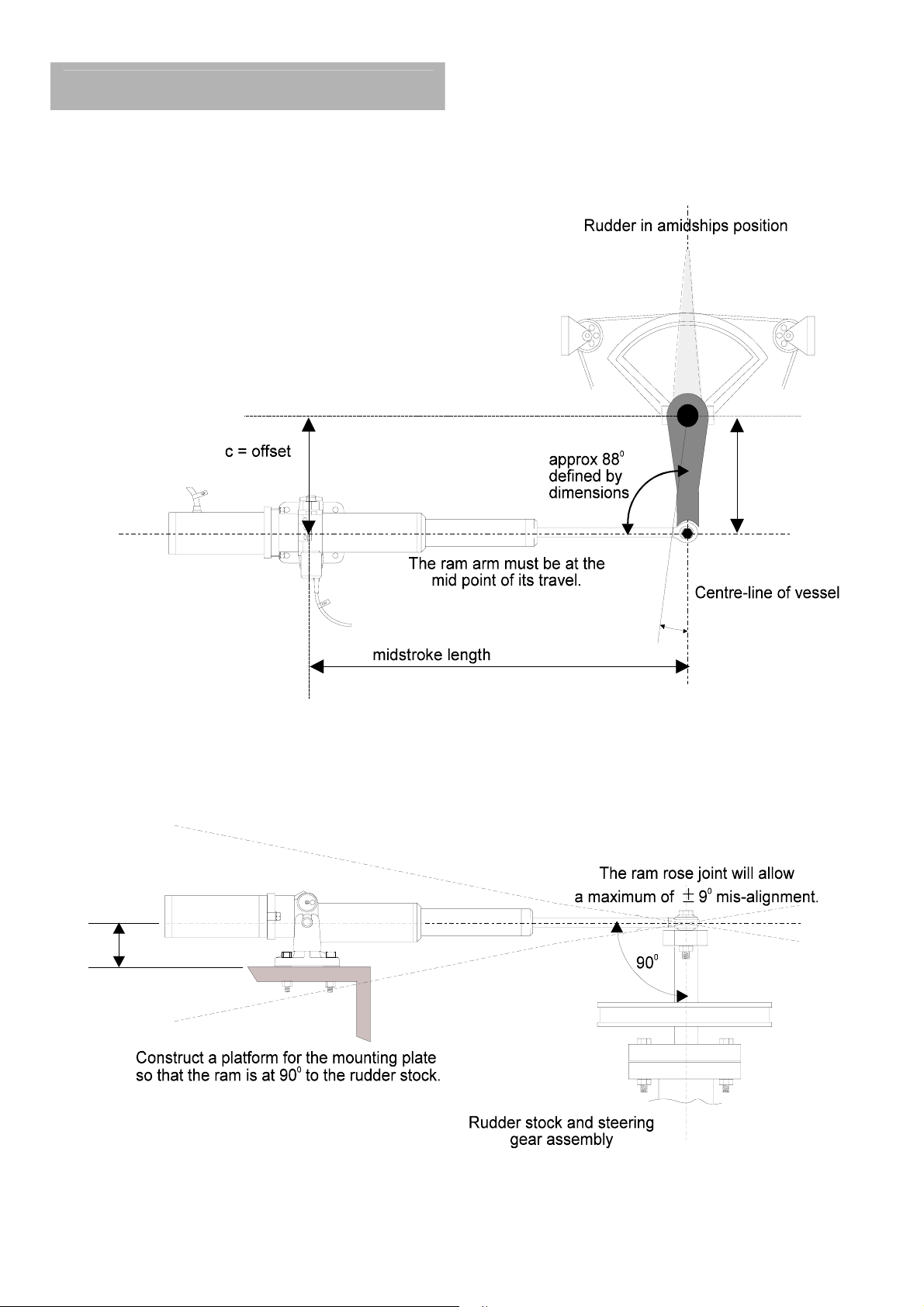

All setting-up and aligning of the ram drive unit with the steering system should be carried out

with the rudder in the amidships position and the ram arm at the centre point of its travel.

x

The angle between the ram arm and the tiller arm should be as shown in the following diagrams.

x

The ram arm should ideally be at right angles to the rudderstock. The ball-joint on the end of the

ram arm will allow a

MAXIMUM

of ±9qof vertical misalignment.

Caution: For Type 3 Ram Reservoir Installation, do not turn the black reservoir tap on or attempt to

move the piston rod until all of the following are completed:

x

The base foot of the ram and pump has been bolted into position.

x

The reservoir has been fixed to a bulkhead above the ram and pump.

x

The sealed reservoir transit cap has been replaced by the breather cap supplied.

x

The reservoir has been filled with the oil supplied.

When the checks listed above have been verified, the reservoir tap can be switched to the ‘

allowing the oil to flow between the reservoir and the pipe. (Tap “ON” position is in-line with the pipe).

ON

’ position

Page 19

Page 21

description/installation

layout of a typical ram drive unit

h1000 pilot

b=tillerarm

length

a=half max rudder angle

d

Page 20

Page 22

h1000 pilot

description/installation

ram mounted parallel to vessel’s centre-line

Page 21

Page 23

description/installation

h1000 pilot

ram mounted parallel to vessel’s centre-line

key points on installation

x

Make sure that the rudder a ngle is limited by the rudder stops and not t he limit of travel of the

ram arm. Failure to comply will damage the unit and invalidate the warranty.

x

Make sure that there is sufficient space at each end for the ram arm to extend fully. The ram

stroke length is given in the tables on Page 13 of this manual.

x

Check for full movement and security of the steering gear before applying any power to the

autopilot system. Refer to the installation checklist in the calibration section of this handbook.

mounting a hydraulic linear ram on a vertical bulkhead

Due to the restricted movement of the ram mounting foot base (+14q/-10q for the Size 1 and 2 rams and

5q for the Size 3 ram), it is important that the maximum rudder angle is carefully measured a nd the

+

positioning of the ram, tiller arm length and offset are carefully followed from the diagrams on the

following page.

Caution: Failure to comply with these dimensions may cause premature failure of the ram and

place great stress on the structure of the vessel.

Note

: The Size 1 and 2 Linear Rams may be mounted in any orientation, without the need to fit an

external reservoir. The Size 3 Linear Rams requires an external reservoir which must be

positioned such that the reservoir is always higher than the drive unit at all normal angles of

heel.

Care must be taken to ensure that the connecting pipes are not in anyway kinked or turned

through any tight bends.

Page 22

Page 24

h1000 pilot

5

description/installation

vertical bulkhead installation

b= tiller arm

=d

5

a=half max rudder angle

Page 23

Page 25

description/installation

h1000 pilot

splitting the ram drive unit

Note: when dealing with any hydraulic system great care must be taken to ensure that a high

degree of cleanliness is observed and no dirt, moisture or foreign objects are allowed to

enter the system. When filli ng or topping up the external reservoir only use a good quality

ISO 10 hydraulic oil e.g., Q8 Dynobear 10 (10cSt at 40

It is not possible to split the following linear drives:

x

RAM-T0-12V

x

RAM-T1-12V

x

RAM-T2-12V

x

RAM-T2-24V

0

C).

type 0, type 1 and type 2 units

Comprise a combined ram/pump, reservoir and hydraulic cylinder. These units cannot be split.

type 3 units

Are supplied as split units, connected by 1m (3ft) hoses. These can be supplied with quick connect

couplings and pre-filled hoses. These units do not need to be bled.

types 3 units with longer hoses are available from your dealer.

Note:

Page 24

Page 26

h1000 pilot

description/installation

hydraulic drive pumps

description

The reversible hydraulic drive pump has a small high-speed pump driven by a 12V o r 24V dc permanent

magnet motor. The pump has pilot check valves to prevent back driving and a pilot operated reservoir

valve to enable the unit to drive balanced or unbalanced cylinders. The unit has port and starboard

¼ inch BSP service ports and a ¼ inch BSP reservoir port.

pump data

Hydraulic Pump Type PMP-T1-12V PMP-T2-12V PMP-T3-24V

Pump Type Reversible

dc motor

Supply Voltage 12V dc 12V dc 24V dc

Typical Operating Current

Range

Maximum Pressure 1000 psi 1000 psi 1000 psi

Maximum Flow Rate

at continuous duty motor

loading

Cylinder Capacity 100cc to 300cc

Weight 3 kg

5A to 17.5A 5A to 22.5A 6A to 17.5A

750 cc/min

3

(46 in

/min)

(6.1 to 18.3 in

(6.6 lbs)

3

)

Reversible

dc motor

1420 cc/min

(87 in3/min)

275cc to 550cc

(16.8 to 33.6in3)

3 kg

(6.6 lbs)

Reversible

dc motor

1980 cc/min

(121 in3/min)

525cc to 750cc

(32 to 46in3)

4 kg

(8.8 lbs)

key points on installation

x

A position should be chosen convenient for the steering system hydraulic delivery lines.

x

The site should be rigid and flat to prevent excess vibration.

x

Shielded from the direct effects of the elements.

x

Minimise the lengths of the hydraulic lines from the pump to the cylinder and where possible, the

pump motor supply cables.

Page 25

Page 27

description/installation

hydraulic drive pump dimensions

h1000 pilot

type 1 and 2

80mm

(3.15)

88.9mm

(3.5)

centres

105mm

(4.13)

4 holes I 7.0mm

(0.28)

240 mm

(9. 45)

50.8mm

(2.00)

centres

type 3

Page 26

Page 28

h1000 pilot

description/installation

hydraulic drive pump installation

Note: When dealing with any hydraulic system great care must be taken to ensure that a high

degree of cleanliness is observed and no dirt, moisture or foreign objects are allowed to

enter the system. When bleeding your hydraulic steering system only use a good quality

ISO10 hydraulic oil, e.g. Q8 Dynobear or equivalent (10cSt at 40

The procedure for installing the hydraulic drive pump is as follows:

1. Drain the steering system from the lowest point, usually at a cylinder coupling.

2. Fit T-pieces into the port and starboard delivery lines, couple the lines to the appropriate service

ports of the pump using flexible hydraulic hose.

3. Couple the reservoir port to the reservoir/balance line from the helm units. A low pressure,

transparent plastic tube can be used.

Note: Ensure that this line rises gradually with no down turns.

0

C).

4. Refill the steering system as recommended by the manufacturer, using clean hydraulic fluid.

5. Fill the cylinder by temporarily removing the cylinder couplings and hoses at each end. Refit the

hoses securely.

6. Starting at the highest helm unit, fill the helm reservoir.

7. Slowly turn the steering wheel two turns to port and then to starboard, checking the level of flui d

in the helm unit reservoir at all times.

8. Next, turn the wheel fully in one direction until a slight pressure i s felt, continuously monitor the

reservoir level.

9. Repeat in the opposite direction and continue in this manner until topping up is no longer

necessary.

10. When satisfied that the steering is fully bled manually, apply power to the pump unit.

11. Turning the wheel fully from lock to lock will cause the pump to self-purge.

12. Check the fluid level in the helm unit reservoir.

13. When the system appears to be fully functional, with the pump running and the helm hardover

check for leaks.

14. Secure all hoses and cables to prevent damage.

Page 27

Page 29

description/installation

hydraulic drive pump installation examples

single station system example

h1000 pilot

dual station system example

Page 28

Page 30

h1000 pilot

hydraulic drive pump installation examples

dual station system with bypass example

description/installation

dual station pressurised system example

Page 29

Page 31

description/installation

advanced control processor unit

h1000 pilot

description

The Advanced Control Processor (ACP) Unit contai ns all the electronics for t he autopilot operation and

control of the rudder drive options. It is designed to be mounted on a vertical, flat, smooth surface. The

unit has a hinged lid to provide easy access to the electrical connections.

siting the acp unit

x

It is recom mend ed that the ACP unit be mounted with the cable entries dow nwards. It must not be

mounted with the cable entries uppermost as water may run down the cables and into the unit.

x

Ensure that there is sufficient space to allow the unit to be hinged open to make connections to

terminals inside, and that the hinges of the two halves of the case may be slid apart.

x

Select a position sheltered from the direct effects of the environment and from physical damage.

x

Do not mount the unit within 1m (3ft) of engines, starter motors and cables, and other cables

carrying heavy currents, etc., or 3m (10ft) of Radar or SSB installation cables.

mounting procedure

x

Undo the two screws at the corner of the unit, and open fully.

x

The hinges are designed to come apart. This enables the electronics to be split from the base of

the unit; i.e. the connection and terminal blocks.

x

Disconnect the cables between the two halves of the casing.

x

Firmly push the two halves of the computer unit apart.

x

Using the base of the unit as a template, mark the positions of the three mounting screw holes.

x

Using the self-tapping screws provided secure the base of the unit in position.

x

Push the two halves of the unit together again and reconnect the cables.

Page 30

Page 32

h1000 pilot

description/installation

acp unit installation

cable and connection information

emc compliance

B&G equipment is designed to be operated in leisure craft. Every care has been taken in its design and

testing to ensure compliance with the European EMC Directive, provided it is installed and operated in

accordance with the instructions as supplied, and the units and cables used are unmodified. Specific

attention is drawn to the requirements to maintain cable separation, where stated.

Transmissions from poorly installed or maintained Single Sideband equipment may adversely affect the

functioning of this equipment. On vessels fitted with SSB, it is essential that such equipment is

installed following good installation practice and as recommended by the manufacturer.

general wiring notes

x

Do not apply power to the pilot system until all units are connected and the wiring has been

checked.

x

Where spade connectors are supplied, always use the correct crimping tool to attach them to the

cable. This is extremely important where high currents are to be passed; i.e. rudder drive unit

supply cables.

x

Keep supply cables as short as possible to reduce the possibility of a voltage drop in the cables.

x

Always fit a fuse or circuit breaker in supply cables. It is recommended that heavy-duty power

cables are protected by a 25A MCB.

x

Clearly identify each cable to prevent incorrect connection.

x

Cables that have a screening braid must have the screen connected as shown on the connection

diagrams.

x

All Pilot cables should be routed at least 1m (3ft) from cables or components that carry or

generate high currents; e.g. alternators, starter motors, trim-tab cables, etc.

x

To minimise interference avoid routing Pilot cables alongside high power radio or radar cables.

x

To prevent damage to cabling always secure in position using cable clips or tie-wraps. Where

cables pass through bulkheads always protect the cable from chafing by fitting grommets.

x

Do not allow cables to rest in the bilges where prolonged immersion in water, fuel, etc. may

occur.

x

Always fit splash covers and lids on processors, computer units and junctions boxes, where

supplied.

Page 31

Page 33

description/installation

pilot drive unit cables

all rudder drives - heavy duty power cables

h1000 pilot

Total Cable Length B&G Cable

Copper Area Cable Gauge

Part No.

Up to 8m (26ft) 135-0A-128 4.0mm² 12 awg

Up to 12m (40ft) Not available 6.0mm² 10 awg

Up to 20m (65ft) Not available 10.0mm² 7 awg

linear drives - clutch/valve cables

Up to 9m (30ft) 135-0C-096 0.5mm² 22 awg

Up to 15m (50ft) 135-0B-096 0.5mm² 22 awg

acp unit terminal details

1A

-

+

DRIVE

SUPPLY

SUPPLY

IN OUT

-

DRIVE

+

BR

BL

SLV

R

BL

SLV

BL

R

SLV

C+

C-

D+

D-

SLV

CLUTCHMOBALARM

BLK

PADDLE

G

R

AD10 OUTPUT

SLV

R

W

BR

G

V

BL

Y

BLK

SLV

R

G

SLV

BL

R

JOYSTICK HANDHELD

R

BL

SLV

G

W

Y

BR

R

BLK

SLV

R

RUDDER

G

BL

SLV

wire colour coding and abbreviations

Wiring Colours

R Red V Violet

BLK Black Y Yellow

BL Blue O Orange

BR Brown W White

G Green SLV Silver (Not Used)

Page 32

Page 34

h1000 pilot

description/installation

clutch voltage selection

The h1000 pilot computer unit can output different clutch/solenoid voltages depending upon the size of

rudder drive unit fitted. The clutch/solenoid valve is only required for rams or rotary drive units. This is

achieved by setting dip-switches on the computer drive PCB. Access to the switches is obtained by

removing the four screws holding the computer PCB into the lid of the computer unit and then carefully

lifting the PCB clear.

Set the switches as per the table below. The default setting is 9V, switch 4 ON, which is suitable for Size

0, 1, and 2 12V rams.

Dip Switch Clutch Voltage Drive Size / Type

1 24V 24V Rotary

2 18V Size 2 and 3, 24V Rams

3 12V 12V Rotary

4 9V Size 0, 1 or 2 12V Rams

Page 33

Page 35

description/installation

acp dip switch location

h1000 pilot

Note:

When reassembling the computer unit ensure that the connector in the top left-hand corner

of the PCB engages correctly.

Page 34

Page 36

h1000 pilot

description/installation

h1000 and alarm connections

Red (+12v)

Blue (0v)

-

DRIVE

SUPPLY

-

+

DRIVE

SUPPLY

IN OUT

+

BR

BL

SLV

R

BL

SLV

BL

R

SLV

C+

CD+

D-

SLV

h1000

1A

R

BL

SLV

-

R

BLK

G

W

BL

ALARM

Y

SLV

BLK

G

R

SLV

R

W

BR

G

V

BL

Y

BLK

SLV

R

G

SLV

BL

R

BL

SLV

G

W

BR

BLK

SLV

G

BL

SLV

R

Y

R

R

h1000

ON OFF

-10 +10

MODE

-

Blue

Red

+

Alarm Unit

130-PK-10

Page 35

Page 37

description/installation

hand-held, mob and joystick

BR

BL

CLUTCHMOBALARMAD10

SLV

R

BL

SLV

BL

R

-

+

DRIVE

SUPPLY

IN OUT

-

+

DRIVE

SUPPLY

SLV

C+

D+

SLV

C-

PADDLEGYRO-STABILISED COMPASS

D-

1A

SLV

BLK

SLV

BLK

SLV

h1000 pilot

BR

BL

BLK

SLV

SLV

BL

R

W

G

V

Y

R

G

R

R

BL

SLV

G

W

Y

BR

R

BLK

SLV

R

RUDDER

G

BL

JOYSTICK HANDHELD

SLV

R

BL

R

G

W

BL

Y

G

R

Man Overboard

Button (MOB)

302-00-007

Handheld Controller

PLHH-ACP

Joystick and Button

545-00-060

Page 36

Page 38

h1000 pilot

description/installation

hydraulic ram drive connections

Heavy Duty

Power Supply

Black

-

Red

+

Circuit Breaker

DRIVE

SUPPLY

IN OUT

-+

DRIVE

SUPPLY

-

BR

+-

SLV

BL

1A

CLUTCH

R

RUDDER

G

BL

SLV

Rudder Reference Unit

RRF-ACP

Red

Black

Solenoid

Connector

Hydraulic Ram Drive:

RAM-T0-12V

RAM-T1-12V

RAM-T2-12V

RAM-T2-24V

RAM-T3-24V

Page 37

Page 39

description/installation

h1000 pilot

ram solenoid wiring details

the following information applies to the size 0, 1, 2 and 3 blue rams only.

1. Remove the solenoid wiring connector by unscrewing the centre screw.

2. Remove the screw from the connector housing.

3. Remove the rubber gasket.

4. Use a small screwdriver through the screw hole to carefully push against the connector block. This

will push the front of the connector block out ready for wiring.

5. Run the cable through the cable entry in the cover and then connect as follows:

Pin 1: Blue Wire

Pin 2: Brown Wire

6. The cable screen must be cut back and sleeved.

Refit the two halves of the connector together, tighten the plastic cable clamp nut, replace the rubber

seal and fit the connector onto the solenoid using the centre screw to fully secure it.

Page 38

Page 40

h1000 pilot

A

A

A

A

A

description/installation

hydraulic pump connections

Heavy Duty

Power Supply

Black

-

DRIVE

SUPPLY

IN

-+-+

DRIVE

SUPPLY

OUT

-

SLV

SLV

SLV

SLV

BR

BL

R

BL

BL

R

C+

C-

D+

D-

R

UT

BL

C

H

SLV

R

M

O

BLK

G

L

W

BL

R

Y

SLV

BLK

P

D1

G

D

R

DL

SLV

E

BR

BLK

SLV

SLV

R

W

G

V

BL

Y

R

G

BL

R

R

BL

SLV

H

G

N

W

D

H

Y

BR

R

BLK

SLV

JO

R

YS

R

TI

G

U

C

BL

D

D

SLV

1A

CL

Rudder Reference Unit

RRF-ACP

Red

+

Circuit Breaker

Hydraulic Pump

RAM-T1-12V

RAM-T2-12V

RAM-T3-24V

Page 39

Page 41

description/installation

h1000 pilot

continuous drive unit connections

These are general wiring instructions only, showing the implem entation of the ACP outputs to drive the

continuous drive pump solenoid valves. The continuous drive pump motor will also require a heavyduty supply, which is not provided. However, suitable units can be obtained from your dealer. Clutch

output is used to control the motor supply.

Note

: The ram solenoid must be designed to operate at the same voltage as the pump.

DRIVE

SUPPLY

IN

-

+

DRIVE

SUPPLY

OUT

-

1A

BLK

SLV

SLV

R

W

BR

G

V

BL

Y

R

G

BL

R

CLUTCHMOBALARMAD10

PADDLEGYRO-STABILISED COMPASS

SLV

BLK

SLV

BLK

SLV

R

BL

R

G

W

BL

Y

G

R

BR

+

SLV

SLV

SLV

SLV

BL

R

BL

BL

R

C+

C-

D+

D-

R

BL

SLV

G

W

Y

BR

R

BLK

SLV

R

RUDDER

G

JOYSTICK HANDHELD

BL

SLV

Rudder Reference Unit

RRF-ACP

Heavy Duty

Power Supply

Red

+

Black

Red

Circuit Breaker

Black

-

Continuous Drive Pump

Solenoid Valves

Page 40

PORT

STBD

RELAY

Circuit Breaker

RAM

SOLENOID(S)

Heavy Duty

Power Supply

Red

+

Black

-

Page 42

h1000 pilot

-

+

DRIVE

SUPPLY

IN OUT

-

+

DRIVE

SUPPLY

description/installation

direct paddle input connection

1A

BR

BL

SLV

R

BL

SLV

BL

R

SLV

C+

C-

D+

D-

SLV

CLUTCHMOBALARMAD10

PADDLEGYRO-STABILISED COMPASS

R

BL

SLV

R

BLK

G

W

BL

Y

SLV

BLK

G

R

SLV

R

W

BR

G

V

BL

Y

BLK

SLV

R

G

SLV

BL

R

RUDDER

JOYSTICK HANDHELD

R

BL

SLV

G

W

Y

BR

R

BLK

SLV

R

G

BL

SLV

Please consult your dealer for

the specific speed sensor and

housing suitable for your vessel

Cut back unused wires

Page 41

Page 43

description/installation

h1000 pilot

linear feedback connection

When the linear feedback unit is used, connect the linear feedback unit to the h1000 pilot terminals

using the diagram and reference table below.

Heavy Duty

Power Supply

Black

-

Red

+

Circuit Breaker

DRIVE

SUPPLY

IN OU T

-+

Black

DRIVE

SUPPLY

-

Red

+-

Solenoid

Connector

SLV

SLV

SLV

SLV

1A

BR

BL

R

BL

BL

R

C+

C-

D+

D-

R

BL

CLUTCHMOBALARMAD10

SLV

R

BLK

G

W

BL

Y

SLV

BLK

PADDLEGYRO-STABILISED COMPASS

G

R

SLV

BLK

SLV

SLV

R

W

BR

G

V

BL

Y

R

G

BL

R

R

BL

SLV

G

W

Y

BR

R

BLK

SLV

R

RUDDER

Y

JOYSTICK HANDHELD

BL

SLV

Linear Rudder Reference Unit

SEN-RUD-LFB

Hydraulic Ram Drive

RAM-T1-12V, RAM-T 2-12V, RAM-T2-24V , RAM-T3-24V

h1000 Processor Colours Function Linear Feedback Colours

Red +5V Supply Red

Blue 0V Supply Black

Green Signal (Wiper) Yellow

Page 42

Page 44

h1000 pilot

description/installation

non-B&G paddle connection

Any non-B&G speed sensor used with this system must have a speed signal output from a hall- effect

device giving positive pulses of 12V maximum.

1. Locate the cable from the speed sensor to the instrument input.

2. Cut cable (if necessary) and insert a junction box (B&G part no. 288-00-001). Connect like colour

to like colour.

3. Use a length of 2-core screened cable (B&G part no. 135-0B-098 9m/30ft) to connect the speed

signal and ground of the paddle sensor to the speed input of the ACP computer unit.

4. Calibrate the speed input in accordance with the instructions given in the Speed Calibration

section of the h1000 System User manual.

Non B&G Display

Non B&G

Paddle Unit

ACP Boat Speed

Terminals

Green Speed signal input Red wire

Red Not used Not used

Black Ground Blue wire

Silver Screen Screen

Function Cable

135-0B-098

Page 43

Page 45

description/installation

furuno ad10 heading connection

h1000 pilot

1A

-

+

DRIVE

SUPPLY

IN OUT

-

+

DRIVE

SUPPLY

C+

C-

D+

D-

SLV

AD10

Cut back unused wires

Furuno AD10

Output Cable

Furuno AD10 Compatible Display

Page 44

Page 46

h1000 pilot

description/installation

INTENTIONALLY LEFT BLANK

Page 45

Page 47

description/installation

hand-held controller

h1000 pilot

description

The hand-held remote controller is a weatherproof unit that has six function b uttons and a status LED

to indicate the operating mode of the autopilot. The unit provides palm-of-the-hand control of the pilot.

The cable has a 10m (30ft) straight section, plus a coiled length that extends from 1m to 3m.

siting the hand-held unit

x

At a convenient position within easy reach by the crew.

x

Ensure at all times the hand-held remote controller's cable cannot become snagged on any

moving parts; e.g. throttle controls.

mounting procedure

x

Heavy-duty self-adhesive Velcro® strip is supplied with the unit.

x

Clean and de-grease the site, stick the Velcro® firmly in place.

Page 46

Page 48

h1000 pilot

optional devices

man overboard button (mob)

description

The man overboard (MOB) button is a large, red, weatherproof press-switch supplied with 15m (45ft) of

two-core screened cable. Operation of this button will start the MOB sequence of operations, if fitt ed,

an audible alarm will sound when the button is pressed.

siting the man overboard alarm button

•

Select a suitable bulkhead, easily accessible to all crew in an emergency.

mounting procedure

•

With a 32mm (1¼") hole-cutter, cut a clearance hole for the button body.

•

Remove the nut and washer, then carefully feed the cable through the hole ensuring that the

sealing gasket is in place to prevent moisture ingress.

•

From behind the bulkhead, feed the washer and nut over the cabl e and tighten the nut onto the

switch body.

Page 47

Page 49

optional devices

acp joystick

h1000 pilot

description

The joystick allows direct control of the rudder vi a the autopilot control electronics. The unit is deckmountable, allowing it to be used both above a nd below decks. A 10m (30ft) 3-core screened cabl e is

used to connect the unit directly into the h1000 ACP unit.

Joystick steering is engaged and disengaged with the separate red button, whic h should b e moun ted in

the same manner as the MOB button, at a location close to the position selected for mounting the

joystick. The lever can only be moved to port or to starboard.

siting the joystick unit

•

At a convenient position within easy reach of the helmsman.

mounting procedure

•

To ensure correct steering sense the unit is marked with two indents. The unit must be installed

with these forward.

•

The unit requires at least 65mm (2.5") clearance behind the selected mounting position.

•

Use a 40mm (1 9/16") hole cutter for the joystick body.

•

Ensure the gasket is fitted under the joystick body flange.

•

Secure in place with the self-tapping screws supplied.

•

Route the cable to the ACP unit. Connect as per instruction detailed in the relevant section of this

manual.

Page 48

Page 50

h1000 pilot

calibration

h1000 pilot calibration

pilot installation checklist

Before the h1000 pilot can be used, it is necessary to set and calibrate various parameters. The

checklist below should be used prior to the calibration of the autopi lot. This will ensure that the entir e

system is correct before applying power.

drive unit and steering system

1. Drive unit securely fixed to a rigid part of the boat structure... ...................................................

2. Gauge of power cable is appropriate .............................................................................................

linear hydraulic rams

1. Boat end stops must limit the rudder movement, not the stroke of the hydraulic ram or RRU

2. Split pin that holds the pivot pin in the mounting foot is secure..................................................

3. Absence of oil leaks........................................................................................................................

4. Correct diameter bolt in universal ball joint, correct size hole in tiller.......................................

5. Ram free to move side to side & up and down..............................................................................

U

U

U

U

U

U

U

size 3 ram installation check list

1. The base foot of the ram and pump have been firmly bolted into position..................................

2. The reservoir has been fixed to a bulkhead above the ram and pump........................................

3. The sealed reservoir transit cap has been replaced by the breather cap supplied....................U

4. The reservoir has been switched to the ON position ....................................................................

6. Additional reservoir fitted (Size 3 only) ..........................................................................................

7. Reservoir at highest point (Size 3 only)..........................................................................................

Tap “ON” position is in line with the pipe.

The piston rod can now be extended or retracted and the pump run.

U

U

U

U

U

hydraulic pumps

1. Absence of oil leaks........................................................................................................................

2. Absence of air in the hydraulic steering........................................................................................

U

U

rotary drives

1. No backlash or excessive slackness in chain ...............................................................................

U

Page 49

Page 51

calibration

h1000 pilot

h1000 pilot calibration

rudder reference unit installation

1. Base securely fixed to boat structure............................................................................................

2. Arm securely fixed to boss.............................................................................................................

3. Ball joint securely fixed to arm......................................................................................................U

4. Linkage has not been over extended .............................................................................................

5. No slack or backlash in the linkage...............................................................................................

6. Linkage does not foul when rudder moved hardover to hardover...............................................

7. Arm moves through at least 90

at least 1V difference between the end stops) .............................................................................

8. Ball-joint securely fixed to quadrant/tiller ....................................................................................

0

when rudder moved hardover to hardover (there must be

linear feedback unit installation

1. Ensure that the linear feedback unit is attached correctly to the linear actuator

using the bracket kit supplied........................................................................................................

2. Ensure that the ram stroke does not exceed the stroke of the linear feedback unit..................

U

U

U

U

U

U

U

U

U

compass installation

1. Clear of sources of magnetic interference, including power cables to other equipment.

If in doubt, check 1m around with a small hand compass. Look on the other side of the

bulkhead! ........................................................................................................................................

2. Fitted as near to centre of motion of boat as other factors allow, aft of centre preferred

because usually less motion than fore of centre..........................................................................U

U

electronics installation

1. Cables secure..................................................................................................................................

2. Cables undamaged .........................................................................................................................

3. No loose bits of wire.......................................................................................................................

4. Screens connected in accordance with wiring instructions and sleeved where appropriate ....

U

U

U

U

Page 50

Page 52

h1000 pilot

g

g

g

g

calibration

speed calibration

Speed calibration sets the units of measurement, damping and speed calibration factor

units

Boat speed values can be shown in knots, kph or mph. To change the units, highlight Unit and press

ENTER. Using the UP/DOWN keys, highlight the desired choice and press ENTER to memorise.

damping

Boat speed damping allows you to slow down the response of speed readings in rou

by adjustin

damping, set th e v a l ue to 9.

adjustment

Speed adjustment calibration is necessary to compensate for hull shape and paddlewheel location on

your boat. For accurate speed and log readings, it is essential that the paddlewheel is calibrated.

adjustment - auto

This procedure will automatically calibrate the boat speed and lo

method for most boats. This procedure requires the boat to make consecutive runs, under power at a

constant speed, over a known distance.

Select two markers that are easily identifiable on the

flow is at a minimum. Measure and record the distance between the markers on the chart.

It is recommended that three runs are carried out, this accounts for tidal efforts, and improves accuracy.

However, a t ime shou ld se lect ed when th e curre nt is a t a min imum , i.e . sl a ck w ater betwe en t ide s.

1) From the

then press the ENTER key to confirm.

2) If necessary, adju st the Run Length to correspond with your measured distance an d then highlight OK,

and press ENTER to accept.

the damping value from 0 to 9. For minimum damping, set the value to 0, for maximum

readings ,and is the recommended

round and on a chart, and where the effects of tidal

Speed Calibration Menu

, highlight Adjustment , choose auto from the drop-down box, and

her conditions

3) The display will now show

speed, press ENTER when the boat is in line with the start of your measured distance. The display will

now change to show Run 1 with end highlighted.

4) When the boat is in line with the second marker of your measured distance, press the ENTER key to

temporarily halt the calibr ation.

5) Maintaining your constant boat speed, turn the boat through 180qin preparation for your second run

along the measured distance. When the boat is in line with the second marker, press the

resume the calibration procedure. The display will now show

6) When the boat is in line with the first marker, press the ENTER key. This will temporarily halt the

calibration procedure.

7) Repeat the procedure detailed above for

8) Upon completion of Run 3, highlight accept all and press ENTER. The system will now automatically

calculate the new boat speed and update the r ead ings according ly.

Run 1

and start will be highlighted. Maintaining the boat at your constant

Run 2

and start will now be shown on the screen.

ENTER

RUN 2

and end will be h ighlighted.

Run 3

.

key to

Page 51

Page 53

calibration

g

g

g

g

speed calibration

adjustment – ref

h1000 pilot

Reference speed adjustment, allows for quick and easy calibration of your boat speed readin

known calibrated source; for example, speed over the

a calibrated log.

1) From the Speed Calibration Menu, highlight Adjustment , select ref from the drop-down box and

press ENTER to select. The display will now show the Reference Speed page.

2) If speed over the

automatically detect this and display this value on the scr een with the message

accept this value, simply highlight OK and press the ENTER key.

3) If speed over the ground is not available, simply hi

UP/DOWN and ENTER keys, adjust the value to the known reference boat speed.

4) Next, highlight OK and press ENTER to complete the operation.

round data is available on the system from a GPS, the h1000 will

round from a GPS or alongside another boat with

hlight the speed value and, using the

s against a

from SOG

. To

sea temperature units

Sea temperature information can be shown in qc or qf. To change the units, highlight Sea temp and

press ENTER. Using the UP/DOWN keys, highlight the desired choice, and press the ENTER key to

memorise.

Page 52

Page 54

h1000 pilot

Secu

y

O

calibration

calibrating the pilot

Calibration

With the system ON, press ENTER and select

calibration

calibration menu

Calibration

Speed

Depth

Wind

Compass

Pilot dockside

Pilot sea trial

rit

K

The procedures for calibration can be divided into two

sections. The first is carried out at the dockside

(Dockside Calibration) and the second is carried out

or checked during the course o f a sea trial (Sea Trial

Calibration).

pilot calibration parameters

The following is a list of the pilot calibration parameters that must be set for successful pilot

operation.

Boat type Select boat type: sail, power planing, power displacement

Rudder stop port Set port rudder stop position

Rudder stop stbd Set starboard rudder stop position

Drive type Select drive type connected to pilot

Hardover time Measures the hardover port to hardover starboard time

Waterline length Set the waterline length of the boat

Dip angle Set the magnetic dip angle

Joystick control Set the joystick steering mode: normal, proportional

Rudder amidships Set the rudder amidships position

Boat lag Set the boat lag value

Rudder gain Set the rudder gain value

dockside calibration

The following parameters must be set prior to a pilot

sea trial. The procedures to do this are described in

this section of the manual:

x

Boat type

x

Rudder stop port

x

Rudder stop stbd

x

Drive type

x

Hardover time

x

Waterline length

x

Joystick control

Page 53

Page 55

calibration

dockside calibration

Dockside

Boat type

Rudder stop port

Rudder stop stbd

À

h1000 pilot

selecting the boat type

There are three selections available:

x sail:

x power disp.:

x power planing:

setting the rudder end stops

Before the h1000 pilot can be used, it must know the

position of the rudder end stops.

for all sail boats.

for power boats with displacement

hulls.

for power boats with planing

hulls.

Dockside

Boat type

Rudder stop port

Rudder stop stbd

À

Dockside

Boat type

Rudder stop port

Rudder stop stbd

À

Dockside

Rudder drive type

Rudder hardover time

Boat waterline length

Magnetic dip angle

Joystick control OK

setting the port rudder stop

Move the rudder to the hard over port position. Press

ENTER

the

position.

key and select

set

to store the port

setting the starboard rudder stop

Move the rudder to the hardover starboard position.

Press the ENTER key and select set to store the

starboard position.

selecting the rudder drive type

Depending upon the type of rudder drive unit fitted,

the pilot controls the rudder drive motor in different

ways. This optimises the autopilot steering response.

There are four selections available:

normal

1.

drives, all sizes and voltages.

2. pedestal Pedestal drive motors fitted by some

steering gear manufacturers.

3. outdrive Outdrive drive units and continuous

drive units.

special

4.

Ram drives, hydraulic pumps, rotary

Proportional drive systems.

Page 54

Page 56

h1000 pilot

Dockside

Rudder drive type

Rudder hardover time

Boat waterline length

Magnetic dip angle

Joystick control OK

calibration

dockside calibrations

hardover time

To finish the rudder end stop calibration procedure

the autopilot must calculate the rudder hardover p ort

to hardover starboard time.

The following points must observed before carrying

out the procedure:

x If the boat is equipped with hydraulic power

assisted steering the engines must be running

when setting the rudder end stops and

measuring the hardover time.

x Move rudder to midships position.

Highlight the ‘START’ command.

x

Keep clear of the wheel.

x

x Press the ENTER key to start test.

The rudder hardover to hardover time can only be

calculated with the boat stationary.

If during the hardover timing, the rudder does not

Dockside

Rudder drive type

Rudder hardover time

Boat waterline length

Magnetic dip angle

Joystick control OK

move, check:

x

The boat speed is less than 3 knots.

x

The rudder reference unit must move through an

angle of at least 90

from hardover to hardover.

x

The output variation from the rudder reference

unit is greater than 1V from hardover port to

hardover starboard.

x

Refer to the installation section for the rudder

reference unit and check the installation.

x

The separate power supply to the ACP control

unit is switched on.

0

when the wheel is turned

waterline length

Boat waterline length must be entered into the

autopilot for it to steer accurately. This value can be

entered in metres or feet.

Page 55

Page 57

calibration

h1000 pilot

dockside calibration

magnetic dip angle (for boats faster than 20 knots only)

All magnetic compasses are effected by ‘Northerly turning errors’ in the Northern Hemisphere or

‘Southerly turning errors’ in the Southern Hemisphere, which increase with boat speed and magnetic

dip angle in higher latitudes. These can cause heading instability at boat speeds greater than 20 knots

when steering with an autopilot. By entering the dip value indicated on the compensation chart, the

autopilot will be able to correct for these errors and improve the heading stability. Use the minimum

value necessary to stabilise the heading.

magnetic dip angle compensation chart

joystick control

Dockside

Rudder drive type

Rudder hardover time

Boat waterline length

Magnetic dip angle

Joystick control OK

Page 56

The joystick is an optional device that allows direct control

of the rudder. There are two joystick operating modes

available to the helmsman:

Normal: the rudder moves in the direction of the joystick.

When the joystick returns to the central position the rudder

movement stops. The greater the movement of the joystick,

the faster the response of the rudder.

Proportional: the position of the rudder follows the

position of the joystick. When the joystick returns to the

central position the rudder returns to its initial position.

Note:

autopilot should not be used to steer the boat.

Until all parameters have been set or checked the

Page 58

h1000 pilot

calibration

seatrial calibration

The following parameters should be set and checked during the initial sea trial.

x

Compass Swing

x

Rudder Amidships

x

Boat Lag

x

Rudder Gain

The sea trial calibration should be carried out in open water on a calm day. The procedures for the

remainder of the calibration involve continual course and speed changes. It is very important to

maintain a constant lookout at all times. Use proper seamanship when clearing turns to ensure the

calibration is carried out safely.

The autopilot will be initially operating from the factory default values for boat lag and rudder gain.

During the sea trial the pilot learning algorithm will automatically set and adjust the value for rudder

gain. The values for boat lag and rudder gain will be checked and adjusted to finely tune the autopilot

steering performance when necessary. The d efault values are automatically set depending upon the

type of vessel selected under boat type.

Page 57

Page 59

calibration

g

g

g

g

g

g

g

g

h1000 pilot

compass calibration

The Compass Calibration Menu sets the heading offset, damping, and swing parameters for the

h1000 fluxgate compass.

compass offset

The compass off set electronic ally compensa tes for fixed errors (mi sali

sensor and the direction of the boat. These erro rs will occur since the compass can be mounted in

any orientation within the boat.

To accurately enter a compass offset, the boat’s actual headin

reference the h1000 flux

from a chart.

To enter the compass offset value, highlight Compass from the Compass Calibration Menu and

press

between +180q and -180q.

Example:

To facilitate this procedure,

immediately be seen.

compass damping

ENTER

x

x

x

. Adjust the value using the

Boat’s actual heading is 076

h1000 display shows 092

The compass offset entered should be -016

ate against a calibrated bowl compass, or follow a known transit referenced

q

q

live heading

UP/DOWN

is shown on the screen so that the effects of the offset can

and

q

ENTER

keys. The value entered should be

nment) between the fluxgate

must be known, for example:

Compass dampin

adjusting the damping value from 0 to 9. For minimum dampin

damping value if the readings are too unstable in rough weather.

compass swing

The swin

are unique to your boat. The swin

minimal wind and waves, and away from traffic, which may require the procedure to be aborted.

The swing proc edure requi res t he boa t to b e tur ned th rough a co mplet e 360q turn, at a speed of less

than 5 knots, at about 2qper second. The entire process should take about three minutes to

complete.

To swing the compass, highlight Swing and press ENTER. The Compass Swing page will now be

displayed with start highlighted. With the boat settled on its turn, press the ENTER key to start the

swing.

The display will now show two bargraphs. The first is the

the boat has been turned through 360q. The second is the

should not be allowed to fill completely.

After completion of the swing, the message

swing, the procedure can be aborted by selecting abort and pressing the ENTER key.

procedure allows the compass to learn the effects of any magnetic deviation errors that

allows you to slow down the response of compass readings in rougher weather by

, set the value to 0. Increase the

should be performed out in open water, on a calm day, with

passed

or

Progress

Turn rate

failed

bar, which will fill completely after

bar, which, for optimum results,

will be shown. At any sta

e during the

Page 58

Page 60

h1000 pilot

calibration

compass calibration

passed

Note:

shown under the

Swing title when a

successful compass

swing has been stored

is

Page 59

Page 61

calibration

h1000 pilot

seatrial calibration

Notes:

x

On the initial sea trial

x

Always maintain a proper lookout

x

If in doubt, disengage the autopilot with the red OFF key on any pilot display or hand-held

controller, and return to manual steering

DO NOT EXCEED 15 KNOTS

Page 60

Page 62

h1000 pilot

calibration

seatrial calibration

engaging the h1000 pilot

1. Steer the boat onto a suitable heading and allow time for the boat to settle on this course.

2. Select Compass Mode by repeatedly pressing the MODE key.

3. Press the ON key on any h1000 pilot display or hand-held controller.

4. The autopilot will now be steering the boat on the selected heading.

5. Alter course in multiple increments using the 10q and rotary knob buttons on any h1000 pilot

display or hand-held controller.

Press the red

OFF

key to disengage the autopilot and return to manual steering.

Boat Lag Incorrect

setting the rudder amidships position

Due to hull design and steering characteristics, the best

rudder amidships position can only be set when underway

at normal cruising speed. Adjust the amidships position as

follows:

1. Steer the boat into the wind and maintain a steady

course.

2. Boats with twin engines must have the engine revs

balanced.

3. Boats with trim tabs must have them in the normal

cruising position.

4. Select Rudder midships from the Sea Trial menu and

choose set from the drop down menu.

boat lag

Boat lag is the time taken for the boat to respond to

changes in helm. For example, heavy displacement hulls

require a larger value for boat lag.

Boat Lag Correct

1. Engage the autopilot as previously explained in Initial

Pilot Sea Trial.

2. At a reasonably slow cruising speed (do not exceed 15

knots) change course by 90

3. Observe the autopilot steering performance. The boat

should turn onto the new heading with minimal

overshoot (a slight overshoot is acceptable).

4. If the overshoot is consistently more than 5

course changes in both directions increase the boat

lag value in steps of 0.1 until the overshoot is

corrected.

5. It is easier to observe overshoot than undershoot,

hence if no overshoot is observed decrease the boat

lag in steps of 0.1 until a small overshoot is seen.

6. Use the smallest value of boat lag to stop overshoot.

in each direction.

for

Page 61

Page 63

calibration

h1000 pilot

seatrial calibration

setting the boat lag value

The autopilot must be disengaged to adjust the

boat lag value.

boat lag value table

Boat Type Default Value Typical Value

Sail Boats 0.30 0.3 to 1.0

Power Boats 0.50 0.3 to 1.0

automatic rudder gain

When the h1000 pilot is part of an integrated h1000 system, boat speed data is supplied via the

Speed/Depth Interface unit. This allows the autopilot to automatically ‘learn’ the correct value for

rudder gain by monitoring boat speed and rate of turn. The rate of turn will be approximately 7.5q per

second.

If there is no direct speed input or the speed is being set by the manual speed band selections, then the

rudder gain value must be entered manually. Refer to

Manual Rudder Gain

.

checking the automatic rudder gain learning

1. Steer the boat onto a suitable heading and allow time for the boat to settle on this course.

2. Select

3. Press the ON key on any h1000 pilot display or hand-held controller.

4. The autopilot will now steer the boat on the selected heading.

At a speed not exceeding 15 knots

5.

multiple presses of the 10q course change buttons on any h1000 pilot display or hand-held

controller. This enables the autopilot to learn the rudder gain value.

6. When the autopilot has learnt the rudder gain val ue, the rate of turn will be approximately 7.5q per

second. (To estimate the rate of turn the display is updated every 1 second, therefore the heading

display should jump in 7q to 8q steps.)

7. Press the red OFF key to disengage the autopilot and return to manual steering.

Compass M o d e

by repeatedly pressing the

, make at least six large course changes of at least 120q, by

MODE

key.

Page 62

Page 64

h1000 pilot

calibration

seatrial calibration

manual rudder gain

1. Steer the boat onto a suitable heading and allow time for the boat to settle on this course.

2. Select Compass Mode by repeatedly pressing the MODE key.

3. Press the ON key on any h1000 pilot display or hand-held controller.

4. The autopilot will now steer the boat on the selected heading.

5. At a speed not exceeding 15 knots

the 10q course change buttons on any h1000 pilot display or hand-held controller.

6. Observe and estimate the rate of turn. It should be approximately 7q to 8q per second. (To estimate

the rate of turn th e display is upd ated every 1 second, therefo re the headi ng display should j ump

in 7q to 8q steps).

7. Observe the performance of the pilot when changing course.

8. If the rudder gain value is too low, the autopilot will understeer, causing sluggish steering. If the

rudder gain value is too high, the autopilot will oversteer, causing erratic steering and excessive

rudder movements. In high-speed boats, this could cause a jerky response and dangerous rates

of turn.

9. Adjust th e rudder g ain value fo r best ste ering perf ormance. Use the minimum value neces sary to

maintain a good response to course changes and course keeping without excessive rudder

movement.

, make course changes of at least 120q, by multiple pres ses of

setting the rudder gain manually

The autopilot must be disengaged and

calibration

mode selected to adjust the rudder gain value.

Sea Trial

rudder gain value table

Boat Type Default Value Typical Values