Page 1

INSTRUCTION MANUAL

SIMRAD GC80/85

EXPANDED

Gyro Compass

20221529C English

Page 2

Simrad GC80/GC85 Expanded Gyro Compass

ii 20221529 / C

Document revisions

Rev Date Written by Checked by Approved by

A 08.01.04

B 17.02.05

C 05.12.05

Document history

Rev. A First issue.

Rev. B Updated for new software release (Master compass: V.1.03, Control

unit: V.1.04).

Rev. C New procedure for how to adjust true heading, updated dimensions for

remote panel, other minor updates to text throughout the manual.

Page 3

INSTRUCTION MANUAL

20221529 / C iii

About this manual

This manual is intended as a reference guide for installing, operating and maintaining

Simrad GC80 and GC85 Expanded Gyro compasses.

The manual assumes that the operator is a qualified ship officer, or is under supervision

of a qualified person.

In this manual, references to buttons on the operator panels are written in boldface, but

in a different text style (e.g. SET button, DISP button, GYRO button).

Important text that requires special attention from the reader is emphasized as follows:

Note! Used to draw the reader’s attention to a comment or some

important information.

Caution Used for warning the reader that a risk of damage to the

equipment exists if care is not exercised.

WARNING Used when it is necessary to warn personnel

that a risk of injury or death exists if care is

not exercised.

Page 4

Simrad GC80/GC85 Expanded Gyro Compass

iv 20221529 / C

This manual is divided in the following sections:

1. System overview

An overview of the GC80/GC85 Expanded gyro system and it’s components.

2. User interface

Overview of GC80 Expanded Control unit and the user interface.

3. Operation

Main operating procedures for using the GC80/GC85 Expanded Gyro compass.

4. Maintenance

Simple maintenance procedures that should be performed by the system operator,

together with a complete procedure for how to replace the sensitive element and fuses.

5. Installation

Mechanical installation, cable connection, and software configuration for the

GC80/GC85 Expanded gyro system.

6. Advanced settings

A description of parameters that can be entered or changed in the Extension menu.

7. Technical specifications

Specifications for the system and for all separate units in the GC80/GC85 Expanded gyro

system.

8. Drawings

Outline drawings and wiring diagrams for the GC80/GC85 Expanded gyro system.

9. Spare part list

List of all standard and optional units that are used in the GC80 and GC85 Expanded

gyro systems.

10. Terminal layout

List of all terminal pins and terminal labelling with details on GTERM board in the

GC80 Control unit.

11. Dip switch settings

Drawings and references of jumpers and dip switches for the different printed circuits

boards in the Control unit.

12. Alarm messages and corrective actions

A description of how system errors are indicated, and corrective actions that can be

performed by the operator.

Page 5

INSTRUCTION MANUAL

20221529 / C v

Contents

1 SYSTEM OVERVIEW...........................................................1

1.1 Introduction.......................................................................2

1.2 Precaution in use................................................................ 3

1.3 System components............................................................4

1.4 Bearing repeaters ...............................................................4

2 USER INTERFACE ..............................................................5

2.1 GC80 Expanded Control unit ................................................6

3 OPERATION.......................................................................9

3.1 System Start-up and Shut-down......................................... 10

Start-Up .................................................................... 10

Turning the Gyro compass OFF...................................... 11

3.2 Selecting active compass ................................................... 12

3.3 Adjusting dimming level .................................................... 12

3.4 Displaying present settings ................................................ 13

3.5 Confirming present settings ............................................... 15

True bearing............................................................... 15

Latitude ..................................................................... 15

Speed........................................................................ 16

3.6 Pendulum function ............................................................ 18

3.7 Alarm messages ............................................................... 19

Acknowledging an alarm .............................................. 20

4 MAINTENANCE ................................................................ 21

4.1 General........................................................................... 22

4.2 Precautions...................................................................... 22

4.3 Cleaning the operator panels and the cabinet surface ............ 22

4.4 Checking the connectors.................................................... 22

4.5 Checking mechanical installation......................................... 22

4.6 Preventive maintenance intervals........................................ 23

4.7 Replacing the Sensitive element ......................................... 23

Mechanical installation ................................................. 23

Verifying the element’s tilt angle ................................... 27

Parameter updates ...................................................... 28

Page 6

Simrad GC80/GC85 Expanded Gyro Compass

vi 20221529 / C

Balancing the Horizontal ring ........................................ 29

4.8 Replacing the Fuses .......................................................... 30

Master Compass.......................................................... 30

Expanded Control unit.................................................. 31

5 INSTALLATION................................................................33

5.1 Unpacking and handling .................................................... 34

5.2 Mechanical installation ...................................................... 34

Control unit ................................................................ 35

Master compass .......................................................... 37

5.3 Cabling ........................................................................... 38

Power supply .............................................................. 39

5.4 Grounding the units .......................................................... 40

5.5 Dip-switch settings ........................................................... 40

Configuring the Control unit.......................................... 41

External heading sensor ............................................... 42

Pendulum function....................................................... 43

5.6 Installing the Sensitive element .......................................... 44

Verifying the element’s tilt angle ................................... 46

5.7 System start-up and software configuration ......................... 48

System Start-up ......................................................... 48

Configuring the gyro system ......................................... 49

Setting the Latitude input system .................................. 51

Setting the Speed input system..................................... 52

5.8 Balancing the Horizontal ring.............................................. 53

Adjusting True heading ................................................ 53

6 ADVANCED SETTINGS .....................................................55

6.1 General........................................................................... 56

6.2 Using the Extension menu ................................................. 56

6.3 The Extension menu overview ............................................ 57

7 TECHNICAL SPECIFICATION ...........................................63

7.1 Accuracy ......................................................................... 64

7.2 General specification ......................................................... 64

7.3 Input specification ............................................................ 65

7.4 Output specification .......................................................... 66

7.5 Physical Dimensions.......................................................... 67

Page 7

INSTRUCTION MANUAL

20221529 / C vii

GC80/GC85 Master Compass ........................................67

GC80 Expanded Control Unit......................................... 67

7.6 Power ............................................................................. 68

GC80/GC85 Master Compass ........................................68

GC80 Expanded Control Unit......................................... 68

7.7 Environmental Specification ............................................... 68

GC80/GC85 Master Compass ........................................68

GC80 Expanded Control unit ......................................... 68

8 DRAWINGS .....................................................................69

8.1 Drawings included ............................................................ 70

9 SPARE PART LIST............................................................77

9.1 GC80 Expanded Gyro system ............................................. 78

9.2 GC85 Expanded Gyro system ............................................. 78

9.3 Optional equipment, GC80/85 Expanded system ................... 79

10 TERMINAL LAYOUT .........................................................81

10.1 GTERM board................................................................... 82

TB1 ........................................................................... 82

TB2 ........................................................................... 84

11 DIP SWITCH SETTINGS ...................................................87

11.1 Expanded control unit .......................................................88

GPOWER board ........................................................... 89

GTERM board.............................................................. 90

SCC board.................................................................. 91

SIFC board................................................................. 95

12 ALARM MESSAGES AND CORRECTIVE ACTIONS.............101

12.1 The alarm system........................................................... 102

12.2 Acknowledging an alarm.................................................. 103

12.3 Fault finding .................................................................. 104

Main power failure..................................................... 104

Internal power failure in Control unit............................ 105

Inverter failure ......................................................... 105

Zero cross failure ...................................................... 105

System communication failure .................................... 106

GPS communication or data failure .............................. 106

Page 8

Simrad GC80/GC85 Expanded Gyro Compass

viii 20221529 / C

Internal communication failure .................................... 107

External bearing sensor failure .................................... 107

LOG (serial) communication or data failure ................... 107

Repeater failure ........................................................ 108

Failure when powering ON the gyro compass ................ 108

12.4 Complete alarm code list ................................................. 109

Page 9

SYSTEM OVERVIEW

20221529 / C 1

1 SYSTEM OVERVIEW

This section provides an overview of GC80 and GC85

Expanded Gyro compasses and their components.

Page 10

Simrad GC80/GC85 Expanded Gyro Compass

2 20221529 / C

1.1 Introduction

GC80 and GC85 Expanded Gyro compasses have been

designated for any size of vessels to enhance the navigation

capabilities and reliability. The gyro compasses eliminate the

inconvenience and limitations of magnetic compasses, and

provide a variety of electrical outputs to supply accurate and

consistent heading information to other navigational equipment.

- A GC80 Expanded gyro is designed for vessels with speed

up to 30 knots. The system complies with IMO A.424 (11)

and Wheel Mark Specifications.

- A GC85 Expanded gyro system is suitable for high speed

vessels with speed up to 70 knots. It complies with IMO

A.821 (19) HSC.

GC80 and GC85 Expanded gyro systems have different

sensitive elements, but use the same GC80 Expanded Control

unit. The systems are identified with divergent dip switch

settings in Master compass and in the Control unit.

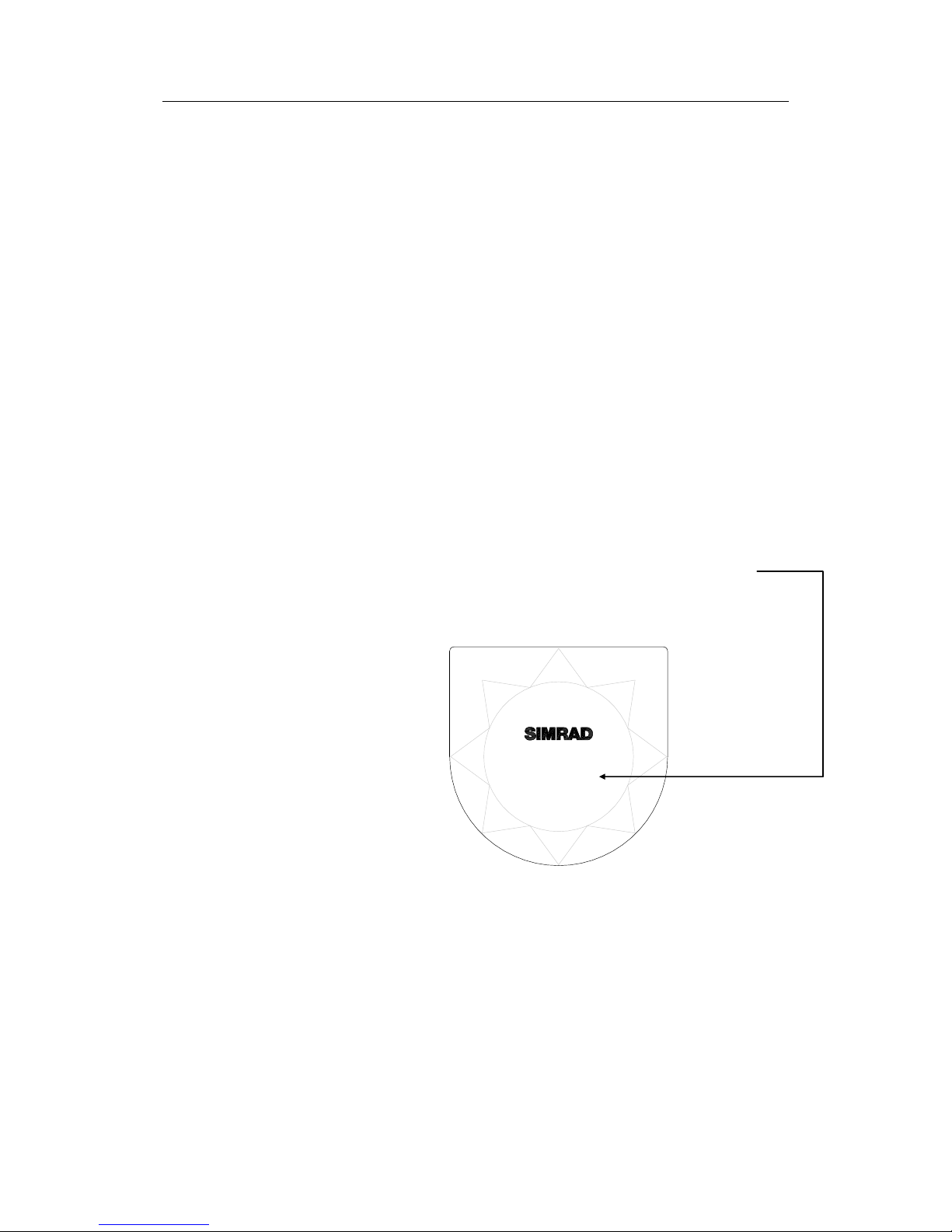

Note! A GC80 or GC85 system is identified by the labelling on top of

the Master compass’ case as shown on the figure below.

The labelling on the control unit is identical for both gyro

systems.

pfjo^a=d`UR

_lt

Page 11

SYSTEM OVERVIEW

20221529 / C 3

1.2 Precaution in use

The GC80/GC85 Expanded Gyro compass displays and outputs

bearing information. Although the system continually checks for

faults while the system is running, failures or malfunctions may

occur.

Any errors in input information will generate an alarm. These

errors may also cause large jumps in the output bearing from the

gyro compass. If this happens, any external equipment

depending on the bearing output from GC80/GC85 should be

operated manually or switched to other bearing sensors.

To assure long time safe operation, the following precautions

should be taken:

- Assure that the operator is familiar with the use of the

gyro compass

- Perform daily check to maintain normal system operation.

Refer MAINTENANCE, page 21 onwards

- If any unusual behavior is observed during daily

inspection, the cause should be found and corrected. If

necessary, the local Simrad dealer should be contacted

- If any alarm is generated, verify the reason for the alarm

Page 12

Simrad GC80/GC85 Expanded Gyro Compass

4 20221529 / C

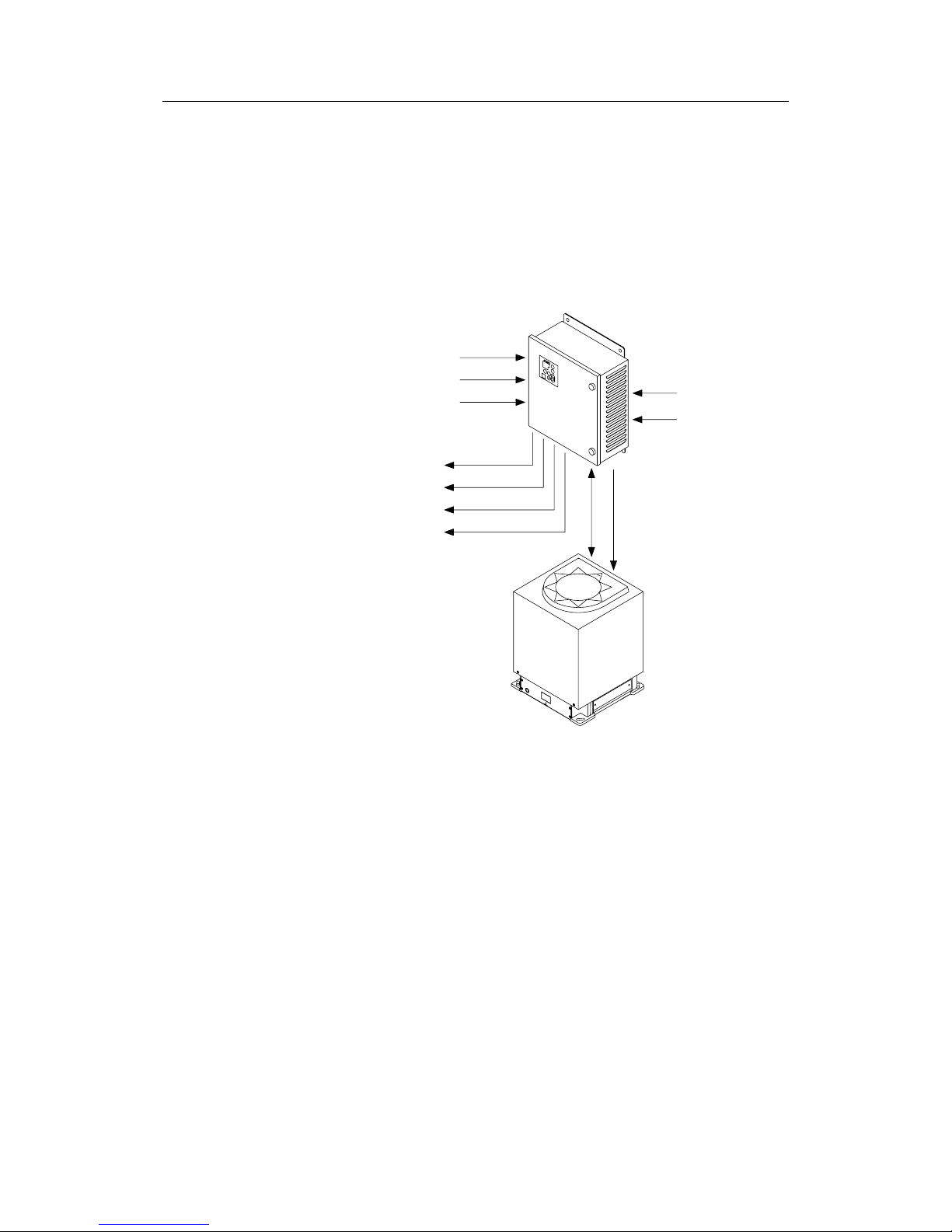

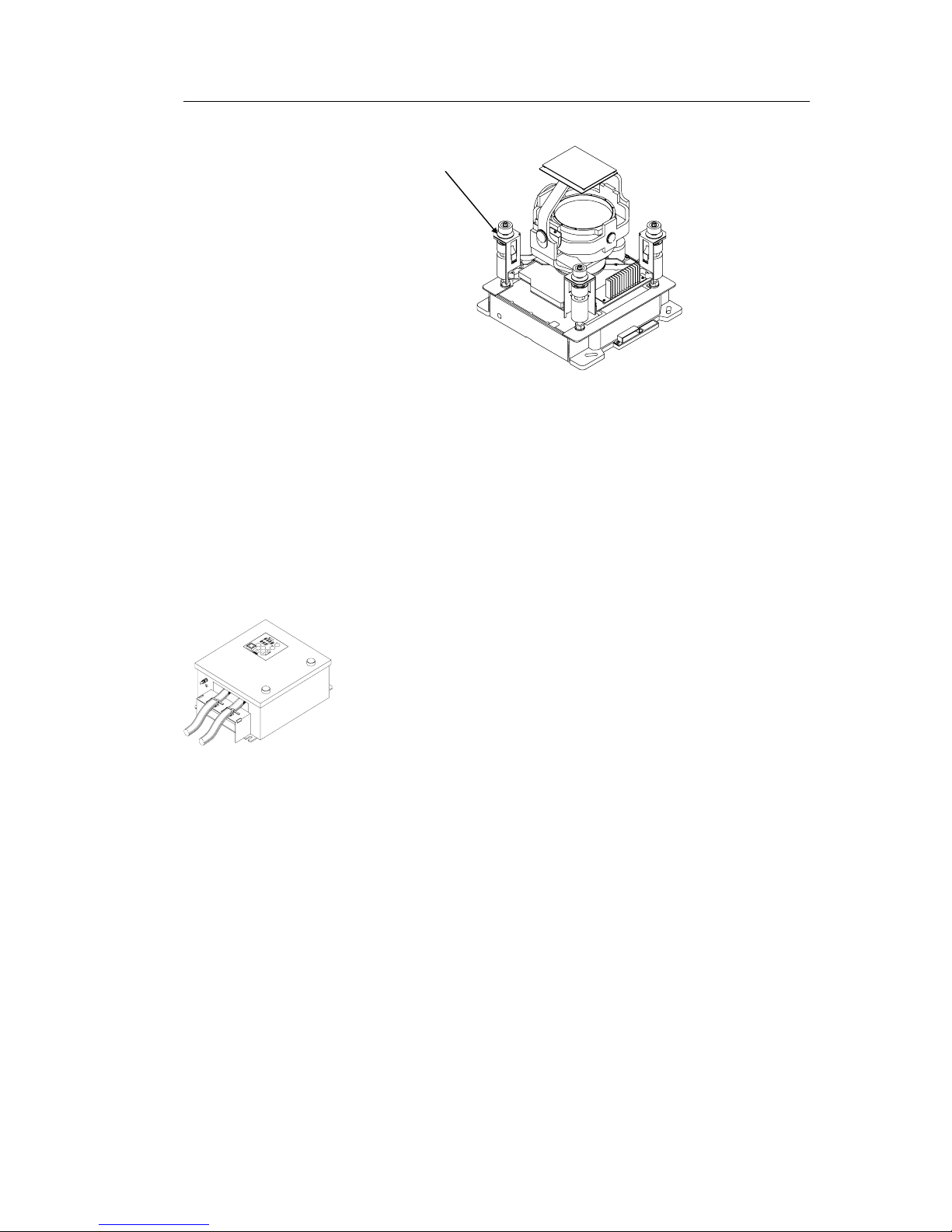

1.3 System components

A GC80/GC85 Expanded Gyro compass includes the following

units:

- Master Compass with Sensitive Element

- Expanded Control unit

Note! For details, refer TECHNICAL SPECIFICATION, page 63.

1.4 Bearing repeaters

GC80 and GC85 outputs step and serial signals used for

repeaters. Even when the gyro compass is supplied by the

emergency power supply, the connected repeaters will be driven

by the repeater backup function included in GC80/GC85.

If the serial output signal not is used for repeaters, the following

serial signal may be output:

- IEC61162-1 ed.2, close in comparison with NMEA0183

version 2.30 (4800 baud)

- IEC61162-2, based upon NMEA0183 version 2.30

(38400 baud, 9600 baud possible)

These signals may be set separately for each circuit.

For connection of repeaters, refer to wiring diagrams, page 74

onwards.

EXTERNAL HEADING SENSOR

GPS

SPEED

10 X NMEA

4 X 24V STEP

3 X ROT

110/220V AC POWER INPUT

MASTER

COMPASS

EXPANDED

CONTROL

UNIT

ALARM CONTACT

24V DC BACKUP SUPPLY

Page 13

USER INTERFACE

20221529 / C 5

2 USER INTERFACE

This section gives an overview of the GC80 Expanded

Control unit and the user interface.

Page 14

Simrad GC80/GC85 Expanded Gyro Compass

6 20221529 / C

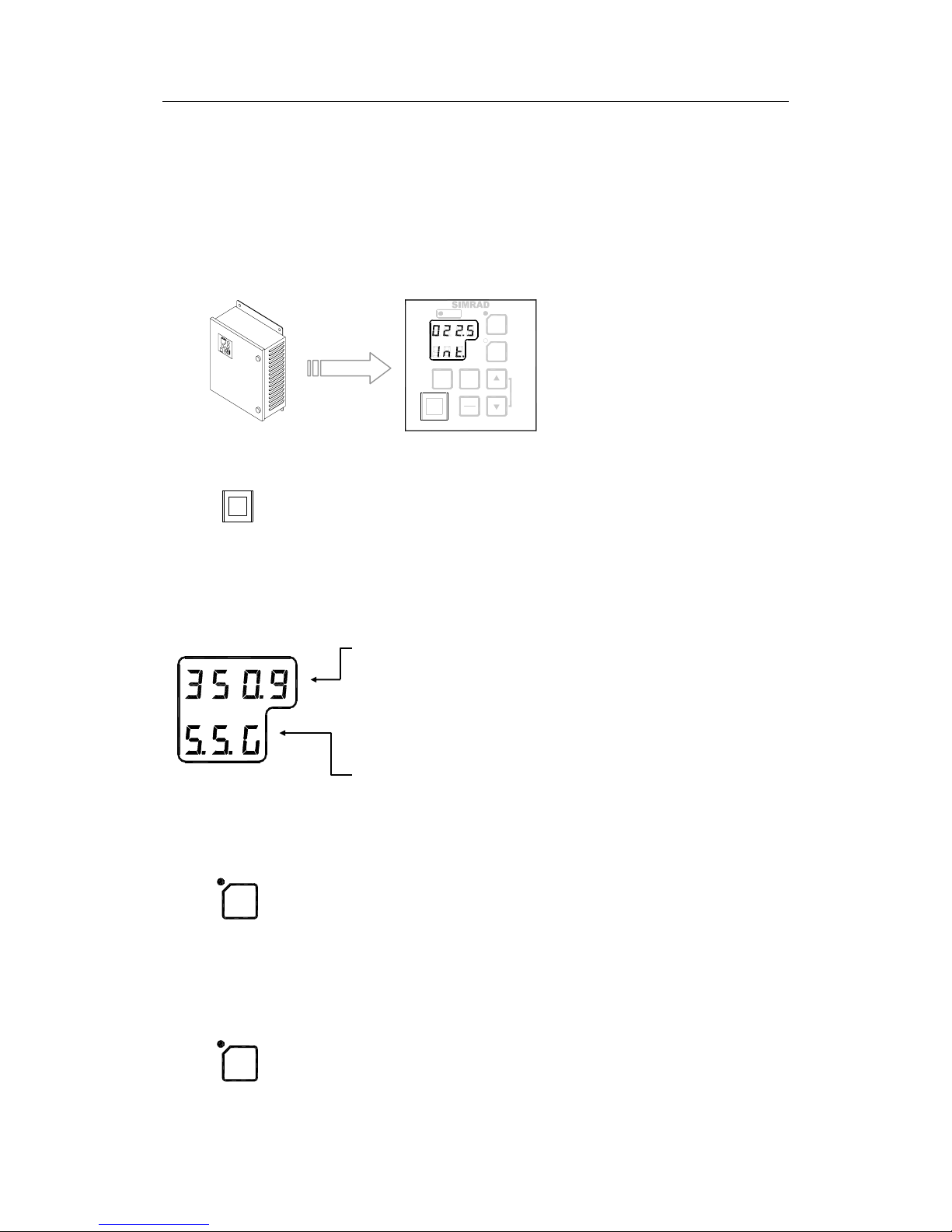

2.1 GC80 Expanded Control unit

The Control unit includes the control panel for the gyro

compass.

A flush mount kit (part number 27101757) may be ordered from

Simrad for remote installation of the control panel. Refer Flush

mounting the control panel, page 35.

^i^oj

dvol

buq

afpm pbq

afj

i^jm

qbpq

^`h

bkq

pfjo^a=d`UM

POWER Button

mltbo

Used for switching the gyro system ON. The button will be lit to

indicate that power is applied to the system. Refer System Start-

up and Shut-down, page 10.

Display

The LCD displays data in two rows: the Data indicator row and

the Mode indicator row.

- The Data indicator consists of four 7-segments red

LEDs. The indicator is used for displaying the vessel’s

bearing, latitude and speed. Refer Displaying present

settings, page 13.

The Data indicator is also used for displaying alarm

codes as described from page 18 onwards.

- The Mode indicator consists of three 7-segments green

LEDs. The Mode indicator displays codes used for

identifying input type for bearing, latitude and speed.

GYRO Button

dvol

Used for selecting the gyro compass as the active heading

reference system. The status lamp is lit to indicate that the gyro

system is active.

Refer Selecting active compass, page 12.

EXT Button

buq

Used for selecting the external heading system as the heading

reference. The status lamp will be lit to indicate that the external

heading reference system is active.

Refer Selecting active compass, page 12.

Page 15

USER INTERFACE

20221529 / C 7

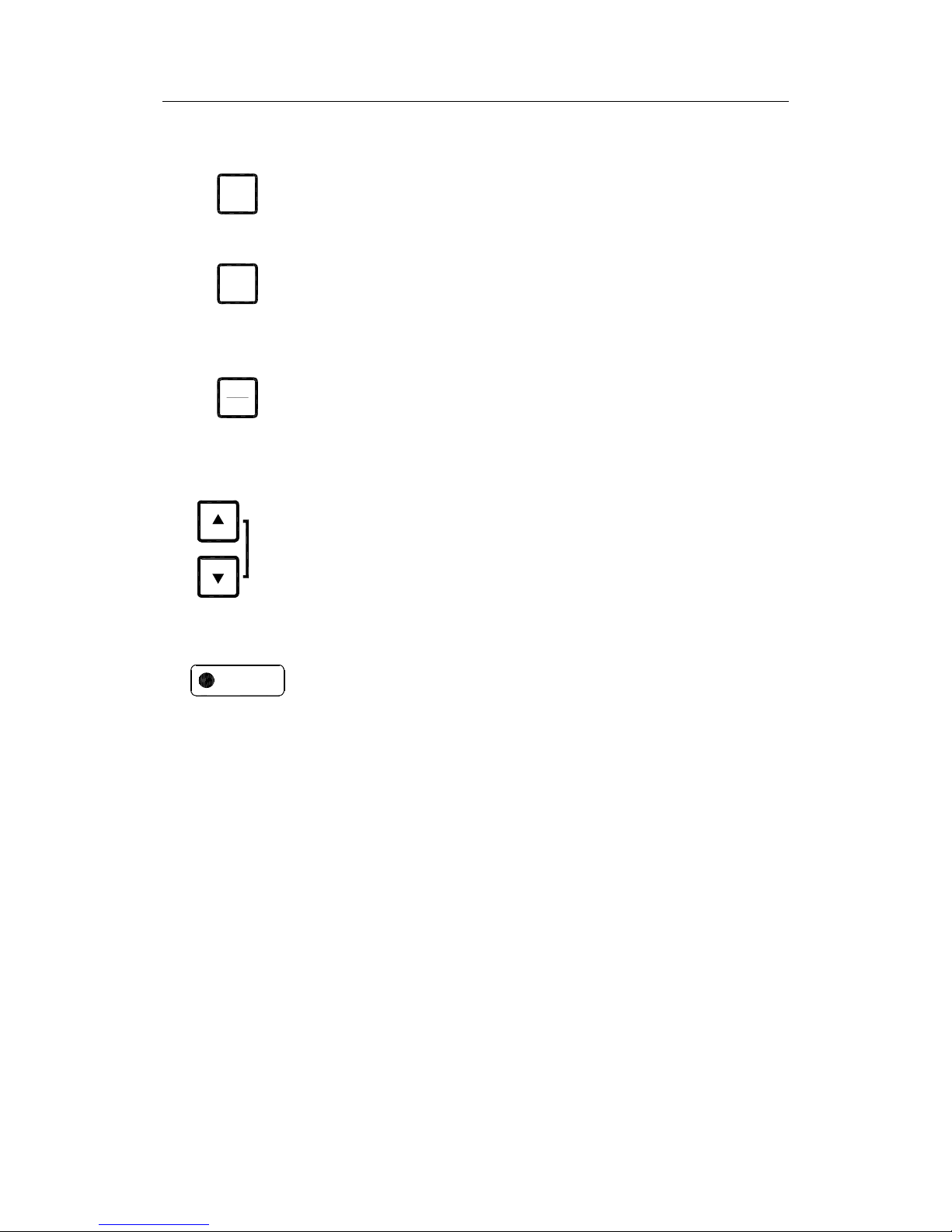

DISP Button

afpm

Used for displaying data on the LCD. Refer Displaying present

settings, page 13.

SET Button

pbq

Used for changing data and input systems. Refer System start-up

and software configuration, page 48 onwards.

ACK/ENT Button

^`h

bkq

Used for confirming a change in data and input systems. Refer

System start-up and software configuration, page 48 onwards.

The button is also used for acknowledging an alarm as described

in Acknowledging an alarm, page 20.

Arrow Buttons

afj

i^jm

qbpq

Used for increasing or decreasing a parameter value. Refer

System start-up and software configuration, page 48 onwards

Also used for lamp test and for setting the display illumination

as described in page 12.

Alarm Indicator

^i^oj

Used for indicating an alarm situation. Refer Alarm messages,

page 19.

Page 16

Simrad GC80/GC85 Expanded Gyro Compass

8 20221529 / C

THIS PAGE INTENTIONALLY LEFT

BLANK

Page 17

OPERATION

20221529 / C 9

3 OPERATION

This section describes the main operating procedure used

when operating the GC80/GC85 Expanded Gyro compass.

Page 18

Simrad GC80/GC85 Expanded Gyro Compass

10 20221529 / C

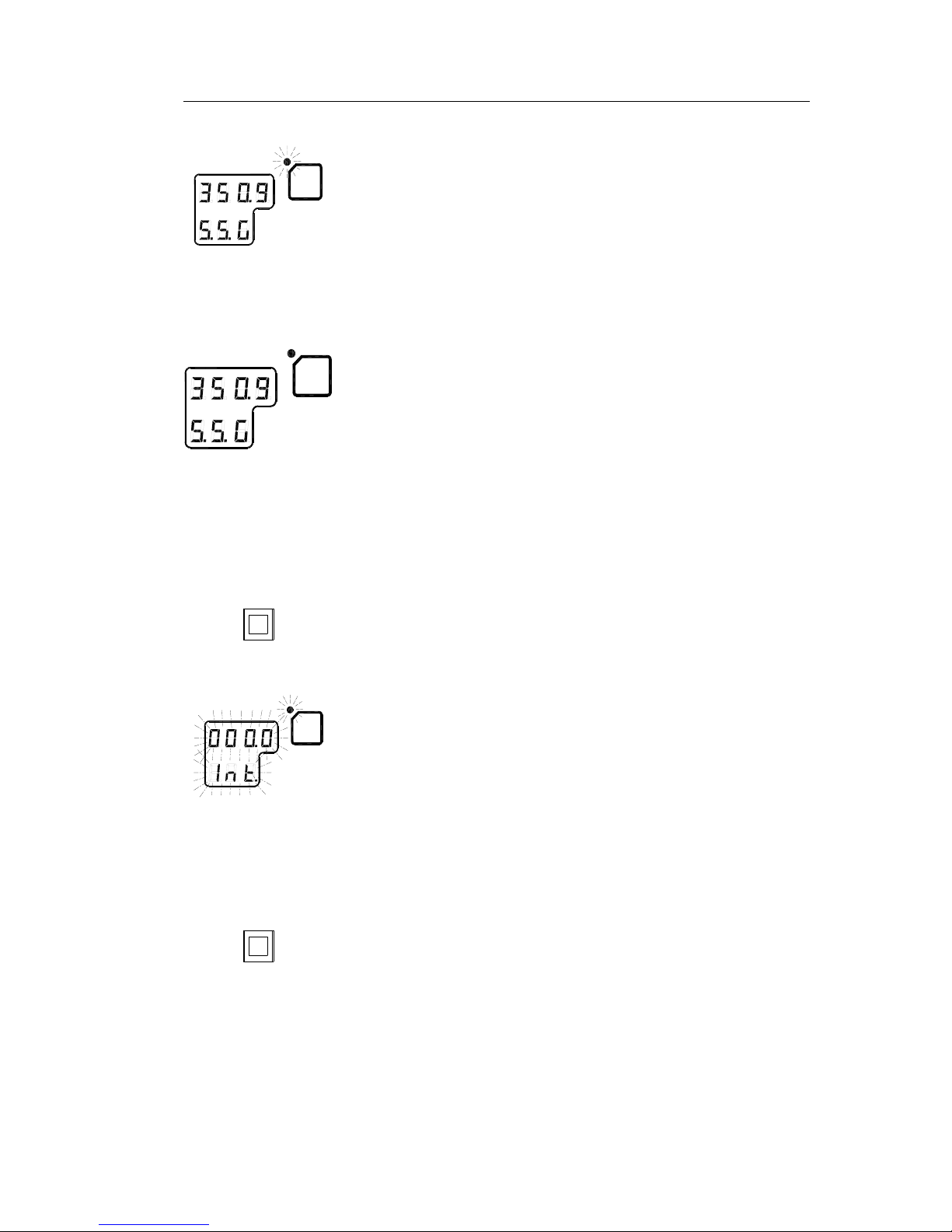

3.1 System Start-up and Shut-down

A GC80/GC85 Expanded gyro system is usually left with power

on. If the system has to be shut down and restarted, the

procedures in the following sections should be followed.

Start-Up

Caution Before the gyrocompass is turned into normal operation, it has

to be configured according to the description in System startup and software configuration, page 48 onwards.

mltbo

1 Turn ON the gyro system by pressing the POWER button

on the Control panel. The following start-up sequence will

be run:

Control unit type (GC80 Std, or GC85 HSc), SW version for

Control unit and for Master compass is displayed in rapid

succession. Examples of display text are shown below:

OR

GC80 CONTROL

UNIT

STD VERSION

GC80 CONTROL

UNIT

HIGH SPEED

VERSION

SW VERSION

CONTROL UNIT

SW. VERSION

MASTER COMPASS

dvol

2 If the rotor not was completely stopped when the POWER

button was pressed, a rotor break function will be activated

to stop the rotor.

Active rotor break is indicated with flashing display.

3 The sensitive element starts rising horizontally, and the

compass rotates 360° clockwise. The display shows

decreasing bearing as the compass is rotating.

dvol

4 When the rotation is stopped, start bearing is indicated

with flashing text in the display. The start bearing will be

the same as active bearing when the compass was turned

OFF.

Page 19

OPERATION

20221529 / C 11

dvol

5 The indicated start bearing is accepted by pressing the

ACK/ENT button, or increased/decreased by using the

arrow buttons and then pressing the ACK/ENT button. If

no action is taken within 3 minutes, the start-up process

will continue with the indicated start bearing.

The bearing indication stops flashing when the start

bearing is accepted, while the lamp remains flashing.

6 The rotor will now start rotating, and reaches pre-described

number of revolutions after maximum 30 minutes.

dvol

7 When the rotor has reached full speed, the compass starts

the north seeking rotation. The display will now change to

show the compass’ actual heading, and from now on

bearing output will be available.

The lamp beside the GYRO button change from flashing to

steady light.

The GC80/GC85 will be settled within 3 hours when started

with a deviation angle less than 5°. With a larger deviation

angle, the compass will be settled within 4 hours.

Turning the Gyro compass OFF

mltbo

1 Press the POWER button on the Control panel. The light in

the POWER button will be switched off.

dvol

2 Repress the POWER button to activate the rotor break

function. The light in the POWER button will be lit again.

Active rotor break is indicated by:

- flashing display as shown on the figure

- a soft clicking sound heard from the gyrocompass

The rotor break function will be active for maximum 4

minutes.

Caution It is very important that the rotor break is activated to stop the

rotor rotation. If not, the sensitive element may be damaged!

mltbo

3 Press the POWER button again to shut down the

gyrocompass when both the data and the dot in the display

change from flashing to steady light.

The light in the POWER button will now be turned OFF.

Page 20

Simrad GC80/GC85 Expanded Gyro Compass

12 20221529 / C

3.2 Selecting active compass

If an external heading sensor is connected to GC80/GC85, it is

possible to switch between gyro and external heading sensor as

active steering sensor.

The gyro system will normally be used with the gyro compass

selected as active compass. An external heading sensor should

only be used as active compass when the gyro compass not is

working properly.

dvol

buq

+

^`h

bkq

By pressing the GYRO or the EXT and the ACK/ENT buttons

simultaneously, the GC80/GC85 will toggle between using the

gyrocompass or an external sensor as active sensor.

When the active sensor is changed, an audible alarm will sound

three times.

Active compass is identified with light in the button’s indicator

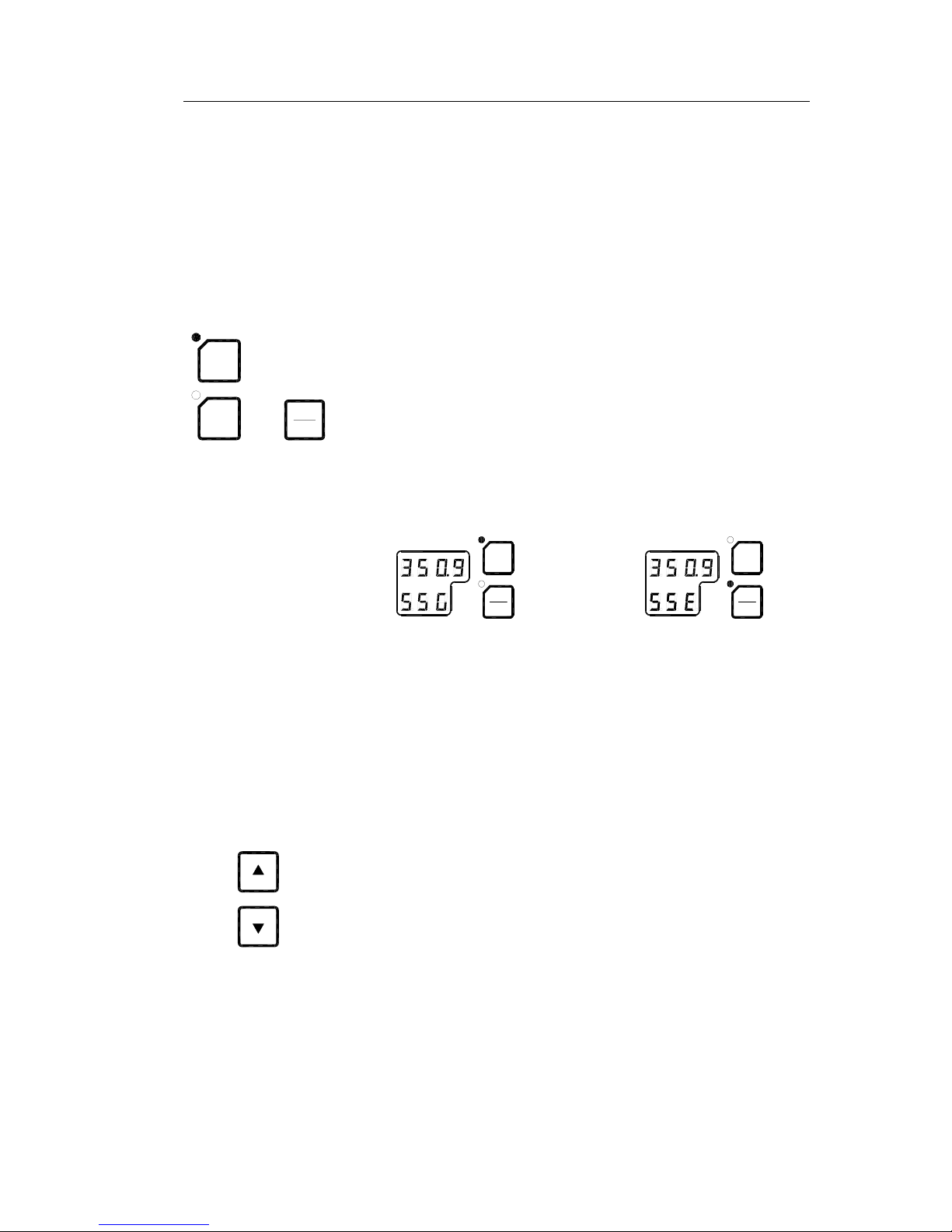

lamp, and with active compass type in the LCD as shown in the

figures below.

dvol

j^d

buq

dvol

j^d

buq

GYRO COMPASS SELECTED AS

ACTIVE STEERING SENSOR

EXTERNAL HEADING SENSOR

SELECTED AS

ACTIVE STEERING SENSOR

WARNING Changing active compass may result in large

change of true bearing. No changes should

therefore be made when the system is in

operation.

3.3 Adjusting dimming level

afj

The display illumination and the light intensity in the indicator

lamps can be increased or decreased in 5 steps by pressing the

arrow buttons.

When the illumination is set to lowest level, a faint light is still

present in the display, Alarm indicator, status lamp and Power

button.

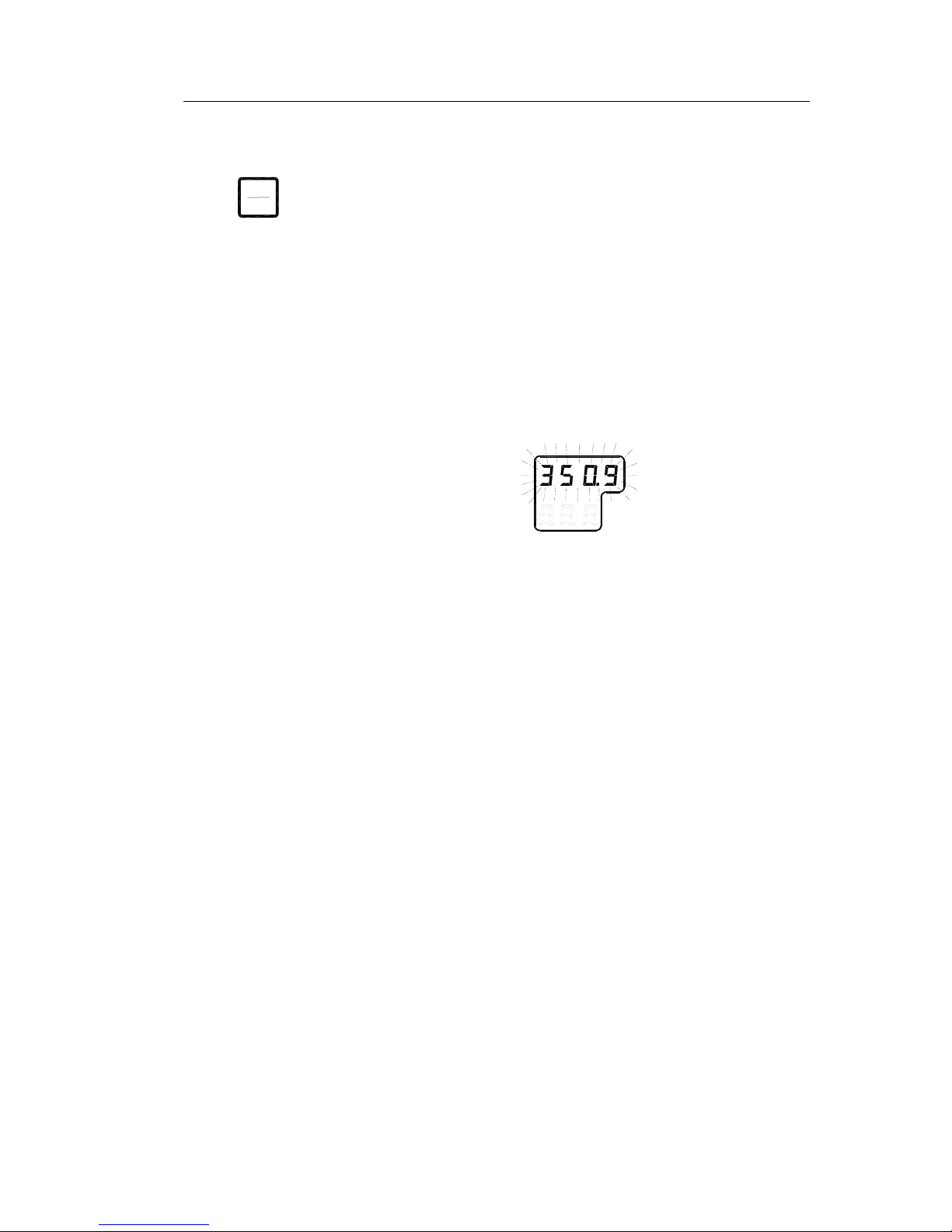

Panel lamps and display segments may be tested by pressing

both arrow buttons simultaneously. All lamps and display

segments will be lit, and a short audible alarm will be activated.

Page 21

OPERATION

20221529 / C 13

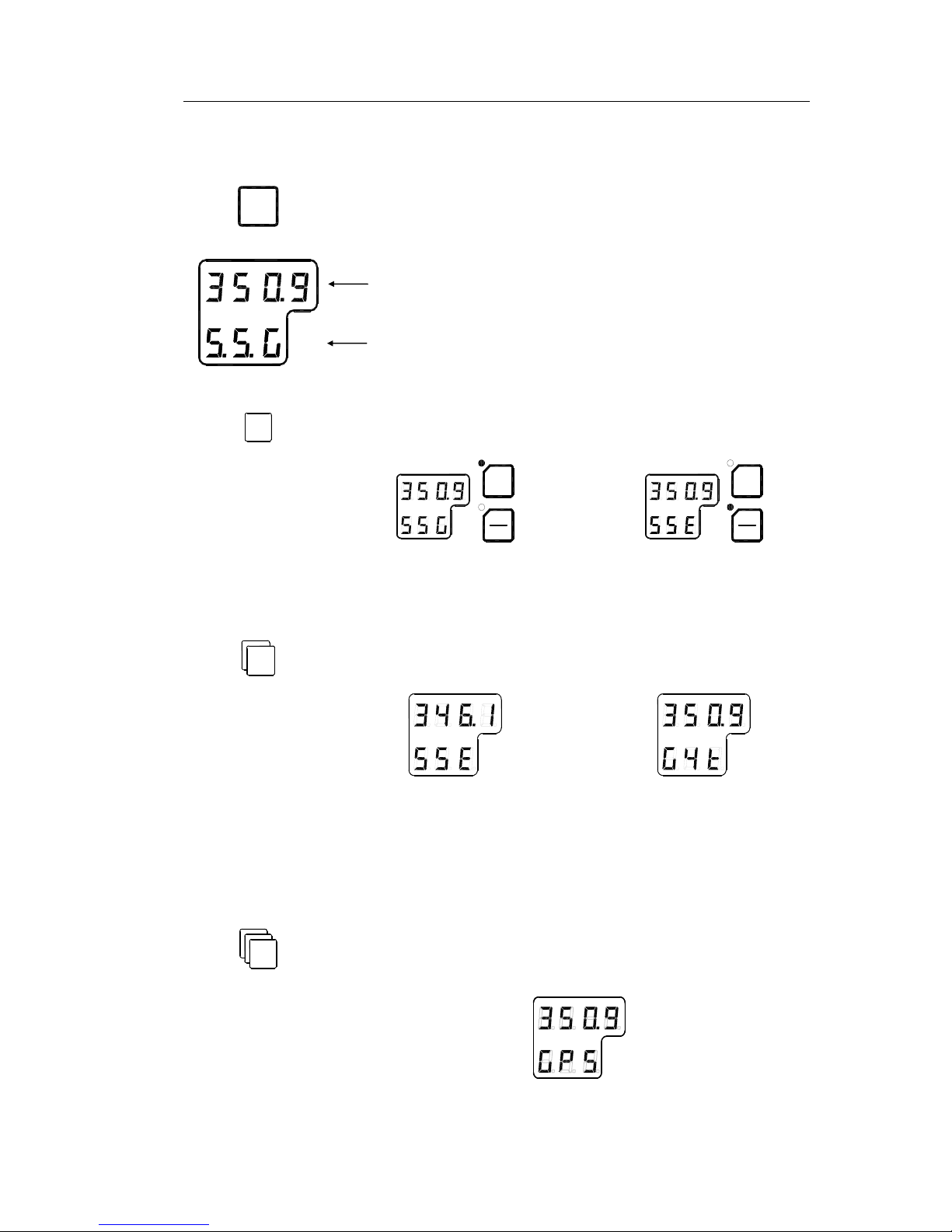

3.4 Displaying present settings

afpm

When pressing the DISP button on the GC80 Control unit, the

system will loop through a display sequence showing present

settings for the system.

- The first row in the display will show the value

- The second row displays code used for identification

afpm

True output bearing from active compass

dvol

j^d

buq

dvol

j^d

buq

GYRO COMPASS SELECTED AS

ACTIVE STEERING SENSOR

EXTERNAL HEADING SENSOR

SELECTED AS

ACTIVE STEERING SENSOR

afpm

Bearing from passive sensor

EXTERNAL HEADING SENSOR

IS PASSIVE STEERING SENSOR

GYRO COMPASS IS

PASSIVE STEERING SENSOR

Note! This display is only available when an external sensor is

connected to the GC80/GC85.

afpm

Gyro compass bearing without correction, together with active

speed input system indication (GPS, Manual, Log or Serial

Log)

Page 22

Simrad GC80/GC85 Expanded Gyro Compass

14 20221529 / C

afpm

Latitude for the vessel’s current position. Value indicated as

North (n) or South (s) latitude

NORTH LATITUDE SOUTH LATITUDE

afpm

Vessel speed. GPS, Manual, Log or Serial Log may be selected

as speed input system

afpm

Rate of turn in °/min.

afpm

Error codes (up to 4), and error indication.

Page 23

OPERATION

20221529 / C 15

3.5 Confirming present settings

After the GC80/GC85 is configured according to the System

start-up and software configuration, described in page 48

onwards, it should not be necessary to adjust any settings when

operating the gyro compass.

However, if an error is reported in any of the input systems, it

may be necessary to switch to a different input system.

True bearing

Make sure that the gyro compass is selected as active compass.

Refer Selecting active compass, page 12.

dvol

Confirm that the gyro compass’s displayed true bearing is the

same as a known target or astronomical observation.

If there is any difference, adjust the bearing according to

Adjusting True heading, page 53.

Latitude

Press the DISP button until the vessel’s latitude is displayed.

The displayed latitude value is calculated based on the vessel’s

true bearing and the vessel’s actual speed. Refer setting the

latitude input system and speed input system, page 51 onwards.

- If GPS is selected as latitude input system, the latitude

obtained from the GPS is displayed on the LCD. Confirm

that the displayed latitude is the same as indicated on the

GPS indicator.

- If GYRO is selected as latitude input system and other

than MANUAL selected as the vessel’s speed input

system, the latitude will be automatically updated. In this

case, the indicated latitude should be confirmed every 4ht

hour when the vessel is in harbor. If there is any difference

between the displayed value and the vessel’s actual

latitude, the value should be adjusted according to Setting

the Latitude input system, page 51.

Note! When GYRO is selected as latitude input system and MANUAL

is selected as the speed input system, the indicated latitude value

will not be updated.

Page 24

Simrad GC80/GC85 Expanded Gyro Compass

16 20221529 / C

Speed

The GC80/GC85 gyro compass calculates bearing based on the

speed and latitude information that is input to the gyro system.

Any errors in speed input will therefore cause incorrect true

bearing from the gyro compass.

Press the DISP button until the vessel’s speed information is

displayed.

Confirm in 4 hours intervals that the displayed speed is the same

as the vessel’s actual speed.

Any discrepancy between displayed speed and actual speed is

corrected as described in Setting the Speed input system, page

52.

Speed error correction

Any gyro compass will generate a heading error caused by

vessel speed and the earth rotation. GC80/GC85 calculates this

error based on latitude and speed input information, and corrects

automatically the bearing signal output. If no speed information

is available, the gyro compass will output a heading error either

westwards or eastwards depending on the vessel’s course.

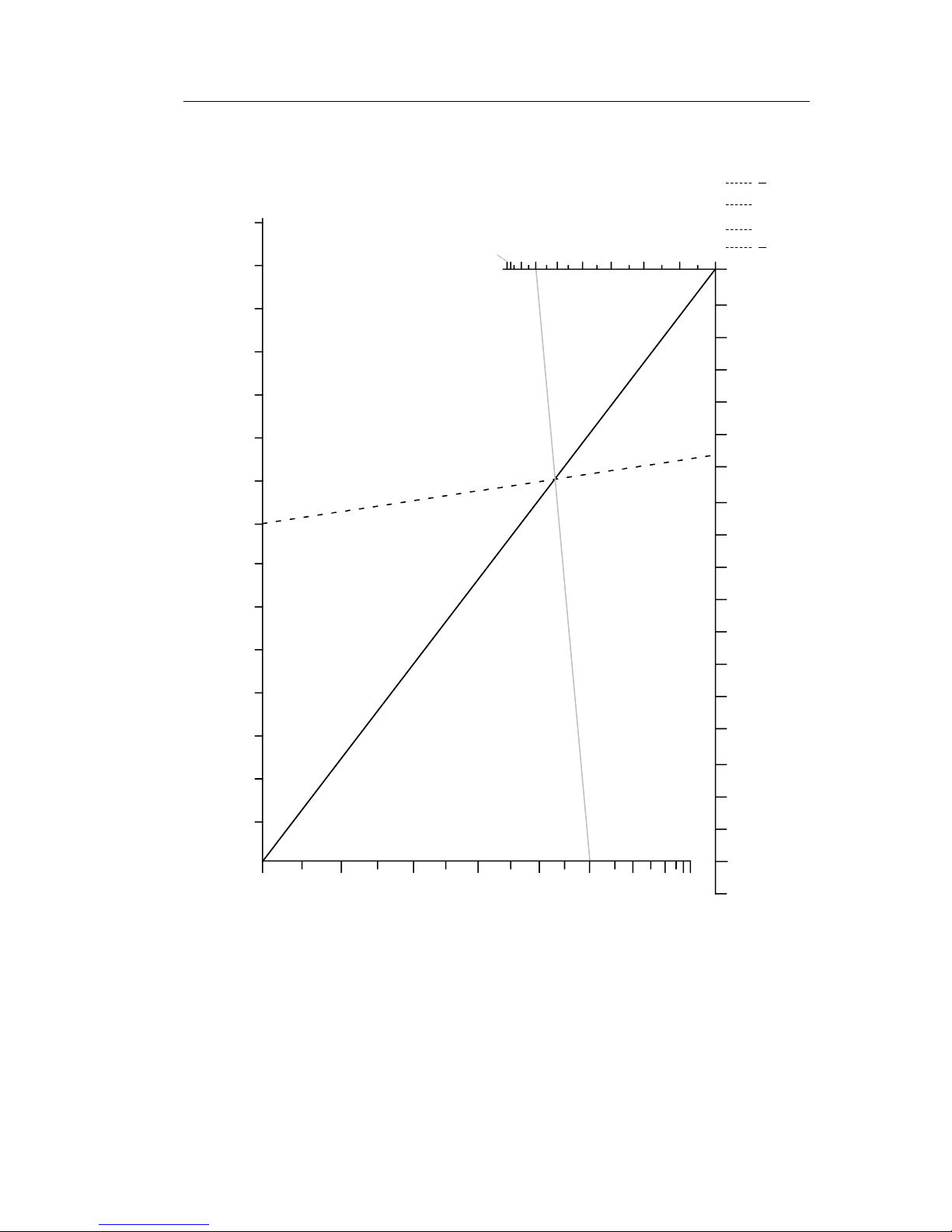

If speed information is unavailable, the figure on next page

could be used for manually calculating the heading error.

In this figure, the following values are used as example:

- Latitude: 40°

- Vessel speed: 16 knots

- Vessel heading: 30°

The heading error is found by:

1 Drawing a line between the latitude and the vessel heading

(shown with gray line on the figure)

2 Drawing a straight line (broken line in the figure) between

the vessel speed and the point where the latitude/heading

line intersects with the solid black line in the figure.

In the example above, the figure shows a speed error of appr.

1.1°, and the true bearing should then be 30°-1.1° = 28.9°.

Note! When the course is within 270° - 0° - 90°, true heading is found

by subtracting the speed error from the compass heading.

If the course is within 90° - 180° - 270°, true heading is found

by adding the speed error to compass heading.

Page 25

OPERATION

20221529 / C 17

VESSEL HEADING (degree)

VESSEL SPEED (knots)

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

90 80 70

60 50 40 30 20 10

3.8

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

0

90 - 90 - 270 - 270

80 - 100 - 260 - 280

0 - 180 - 190 - 0

70 - 110 - 250 - 290

60 - 120 - 240 - 300

50 - 130 - 230 - 310

40 - 140 - 220 - 320

30 - 150 - 210 - 330

20 - 160 - 200 - 340

10 - 170 - 190 - 350

(+)

(+)

( )

( )

SPEED ERROR (degrees)

LATITUDE (degrees)

Page 26

Simrad GC80/GC85 Expanded Gyro Compass

18 20221529 / C

3.6 Pendulum function

GC80/85 software includes a pendulum function that enables the

heading to be changed by 180°.

The heading change is activated by closing a potential free

contact connected between TB1, pin 71 and 72 on the GTERM

board in GC80/85 control unit.

Note! To identify the function, S2-4 on the SCC board has to be set to

ON. Refer DIP switch settings on SCC board, page 91 onwards.

When the switch is activated, the following actions are

performed:

- The compass heading and repeaters start to change

towards the new 180° shifted heading

- An acoustic alarm sounds 5 times

- The dots in the indicator field in the display starts flashing.

These will remain flashing for as long as the pendulum

function is active.

Normal compass operation is resumed by opening the closed

potential free contact. The function is indicated by the same

acoustic alarm, and the flashing dots returns to fixed illuminated

dots.

Page 27

OPERATION

20221529 / C 19

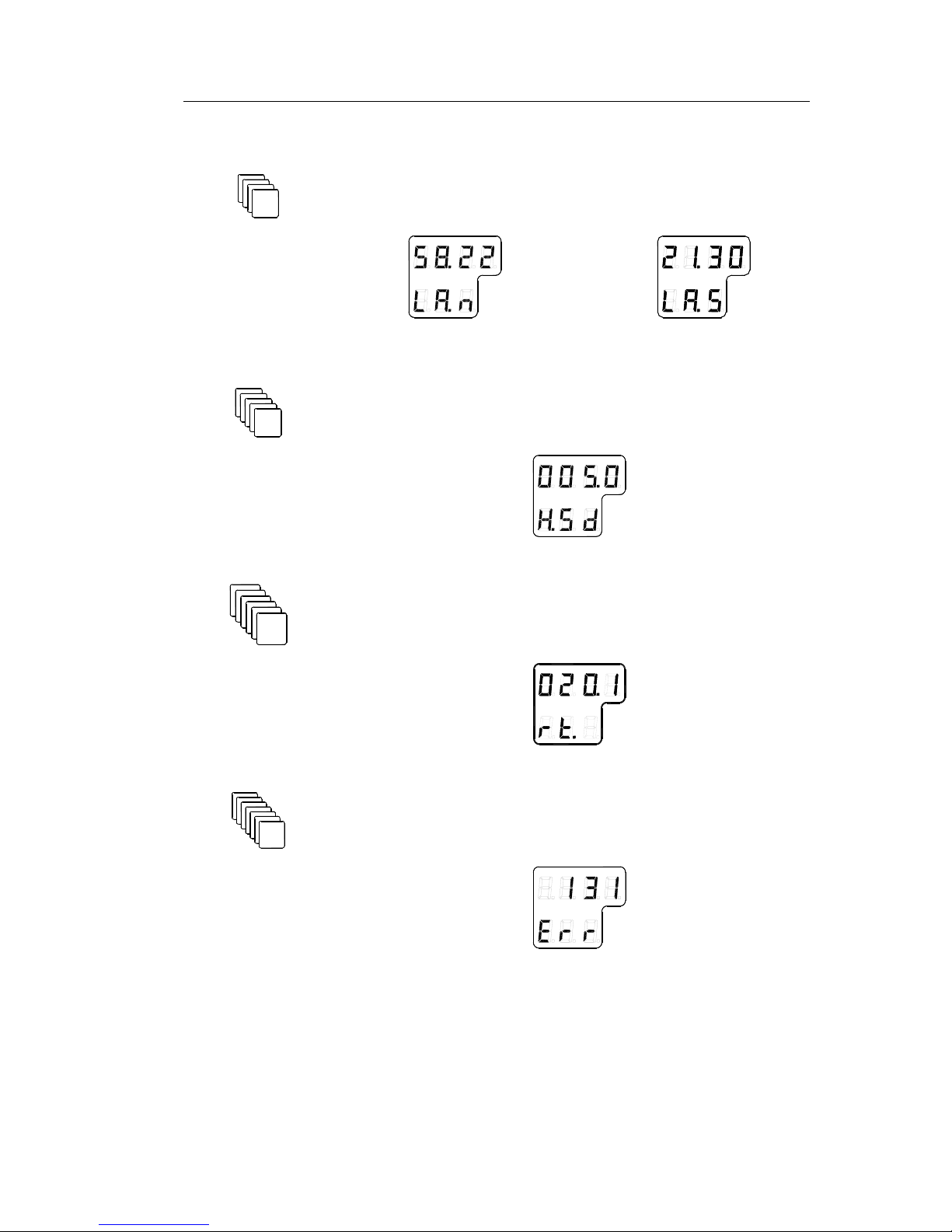

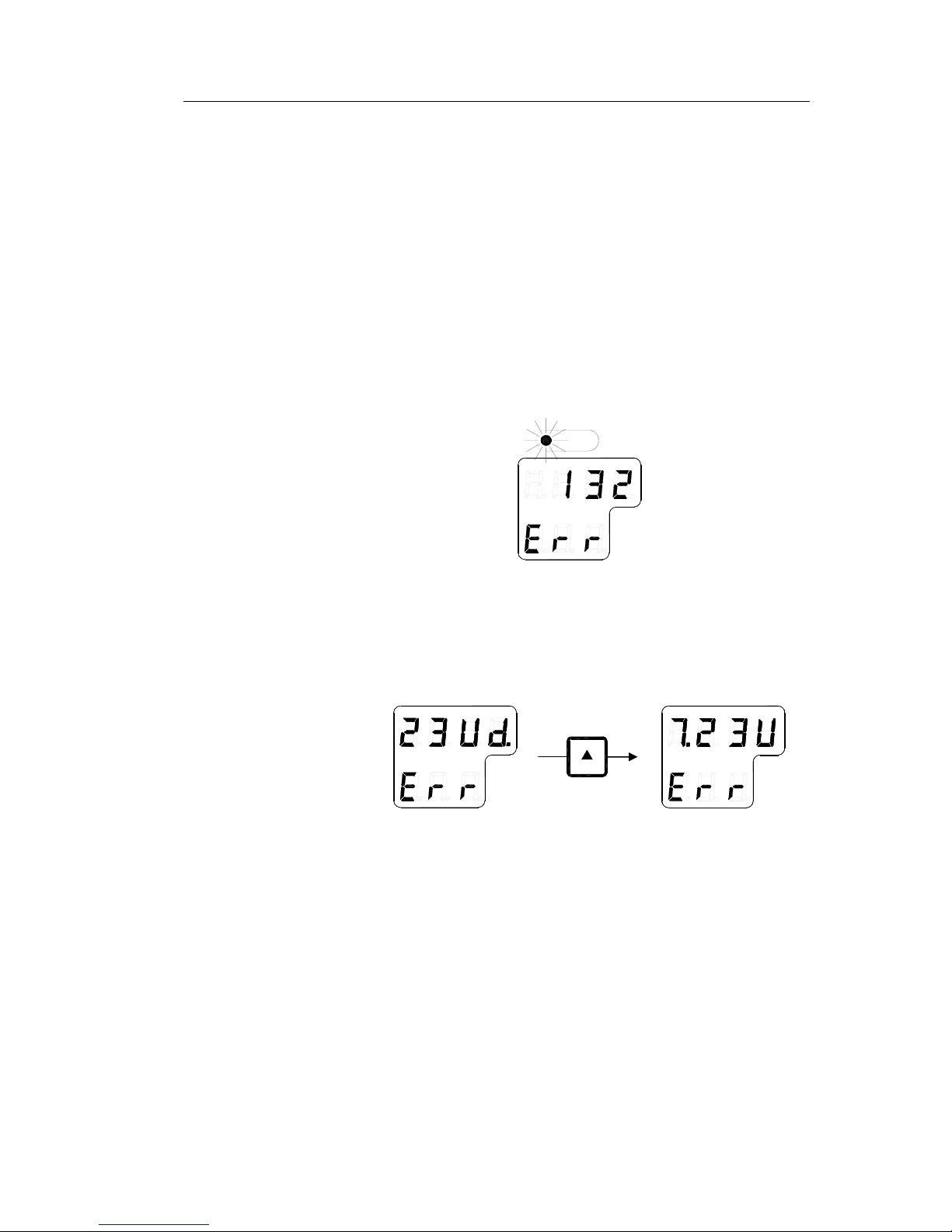

3.7 Alarm messages

The GC80/GC85 system will continually check for faults while

the system is running.

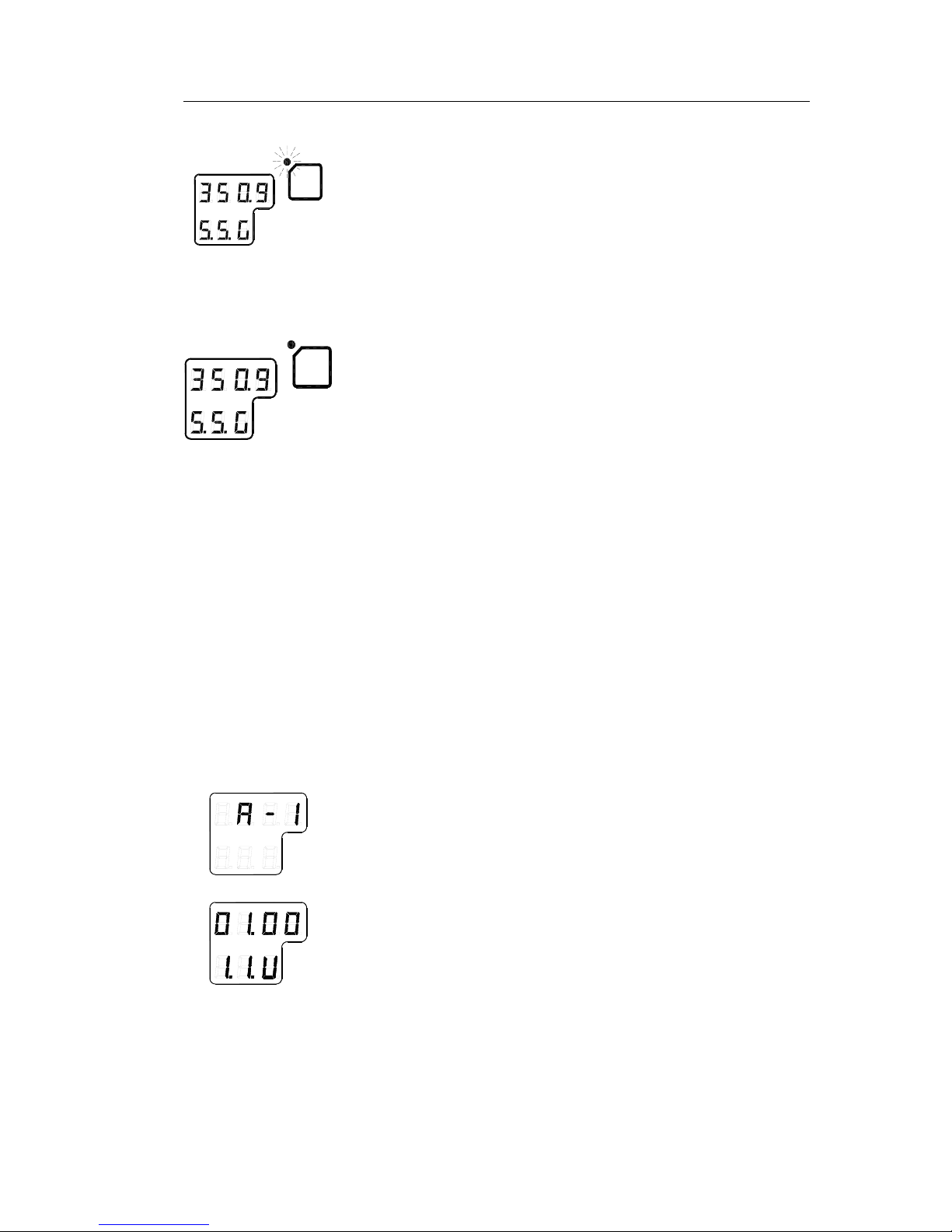

If a fault occurs, an alarm code will be displayed in the LCD, the

Alarm lamp will be flashing, and an audible alarm will be

activated.

Up to 4 alarm codes may be displayed in the LCD to indicate

that several alarm situations are present. The last activated alarm

will be displayed on the right side of the display. The figure

shows that alarm with code 1, 3 and 2 were generated in that

order.

^i^oj

If more than 4 alarms are active, this will be indicated with a dot

behind the last number as shown on the figure below. Further

alarm codes may then be displayed by pressing the “arrow up”

button.

The example shows that alarm code 2, 3, U, d and 7 were

activated.

Caution When an alarm is generated, bearing information from the

GC80/GC85 may not be present or may have large error. Any

equipment using bearing information from the gyro compass

should therefore immediately be operated according to the

equipment’s emergency operating procedure.

Page 28

Simrad GC80/GC85 Expanded Gyro Compass

20 20221529 / C

Acknowledging an alarm

^`h

bkq

An alarm is acknowledged by pressing the ACK/ENT button on

the control panel, or on an external acknowledge button is this is

installed.

- The audible alarm will be silenced

- If the alarm situation has disappeared, the alarm lamp will

be switched off, and the alarm code will be removed from

the LCD

- If the alarm situation continues, the alarm lamp will switch

from flashing to steady light. The LCD will return to show

true bearing with flashing numbers to indicate that the

bearing may have large errors

An alarm code for an active error may be recalled by pressing

the DISP button until the alarm display is shown. It is possible

to recall any alarm code in the LCD for as long as the alarm

situation is present.

The Complete alarm code list section, page 109, has a complete

list of alarm codes.

Buzzer silence only

By installing an external acknowledging switch, it is possible to

silence the buzzer while the alarm code remains in the display.

Install the switch to the control unit according to the Wiring

diagram on page 74 onwards.

Note! Could only be used if no pendulum switch is installed!

Page 29

MAINTENANCE

20221529 / C 21

4 MAINTENANCE

This section holds descriptions for maintenance procedures

that should be performed by the system operator.

The section also includes a detailed description for how to

replace the sensitive element and the fuses.

Page 30

Simrad GC80/GC85 Expanded Gyro Compass

22 20221529 / C

4.1 General

All units in the GC80 system are designed for optimum safety

and reliability. However, a limited amount of preventive

maintenance should be performed to verify safe operation and

durability.

If any strange motion, smell, sound or heat is generated from

any unit, a Simrad dealer shall be contacted.

4.2 Precautions

Touching internal parts may cause electric chock if power is

connected to the system, even if the POWER button is turned

OFF. Do not touch any terminal board or power supply unit

when maintaining and checking the system. If necessary,

disconnect the power cable from the Control unit.

Electrostatic charges may damage components on the circuit

boards inside the units. Always wear a correctly connected

earthing strap when opening the units.

4.3 Cleaning the operator panels and the cabinet

surface

Use a vacuum cleaner with a soft brush to avoid damage to the

buttons and the panel. If required, clean the buttons and panel

with a non-abrasive cloth moistened with mild soap solution.

4.4 Checking the connectors

The connectors should be checked by visual inspection only.

Push the connector plugs into the connector. If the connector

plugs are equipped with a lock, ensure that this is in correct

position.

4.5 Checking mechanical installation

Vibration and chock may cause mechanical parts to loosen. All

fastening screws should therefore regularly be checked and

eventually tightened.

Page 31

MAINTENANCE

20221529 / C 23

4.6 Preventive maintenance intervals

Local evaluations should be made to determine site-specific

maintenance intervals.

ACTION INTERVAL RECOMMENDED

Confirm that the value of each

repeater synchronizes with the

displayed true bearing on the

Operator panel.

Daily

Confirm that the displayed

latitude and speed is according to

the vessel’s actual latitude and

speed.

Daily

Check connectors Every six month

Tighten fastening screws Every six month

Clean panels and cabinet Once a year or as required

4.7 Replacing the Sensitive element

Caution The Sensitive element should only be replaced by authorized

Simrad personnel.

Note! A special tool (Simrad part no. 44174449) is required when

installing the Sensitive element. This tool is delivered together

with the gyro, and the sensitive element should not be installed

without using this tool.

Mechanical installation

Caution Use extreme caution when handling the Sensitive element! Do

not tilt the element. It is filled with oil and the top is open.

1 Ensure that the power is disconnected from the Control

unit.

2 Remove the four screws securing the compass case, and

lift the case carefully upwards and away.

3 Loosen the screw on the plug-holder on the Sensitive

element, and disconnect the plug.

Page 32

Simrad GC80/GC85 Expanded Gyro Compass

24 20221529 / C

4 Remove the four screws securing the Sensitive element.

Tilt the Horizontal ring to the side where the plug is

located, and carefully remove the element from the

compass.

5 Place the defective Sensitive element in its original

package, and put the rubber tube on top of the element.

6 Re-install the plug-holder on the defective Sensitive

element.

7 Lift the new element carefully from its package, and

remove the rubber tube on top of the element.

Note! The package and the rubber tube should be kept for re-use if the

Sensitive element has to be sent to factory for service!

Page 33

MAINTENANCE

20221529 / C 25

8 Tilt the Horizontal ring to the side where the plug is

located, and carefully put the sensitive element into the

ring.

- The socket on the Sensitive element should be located

right above the plug attached to the Horizontal ring.

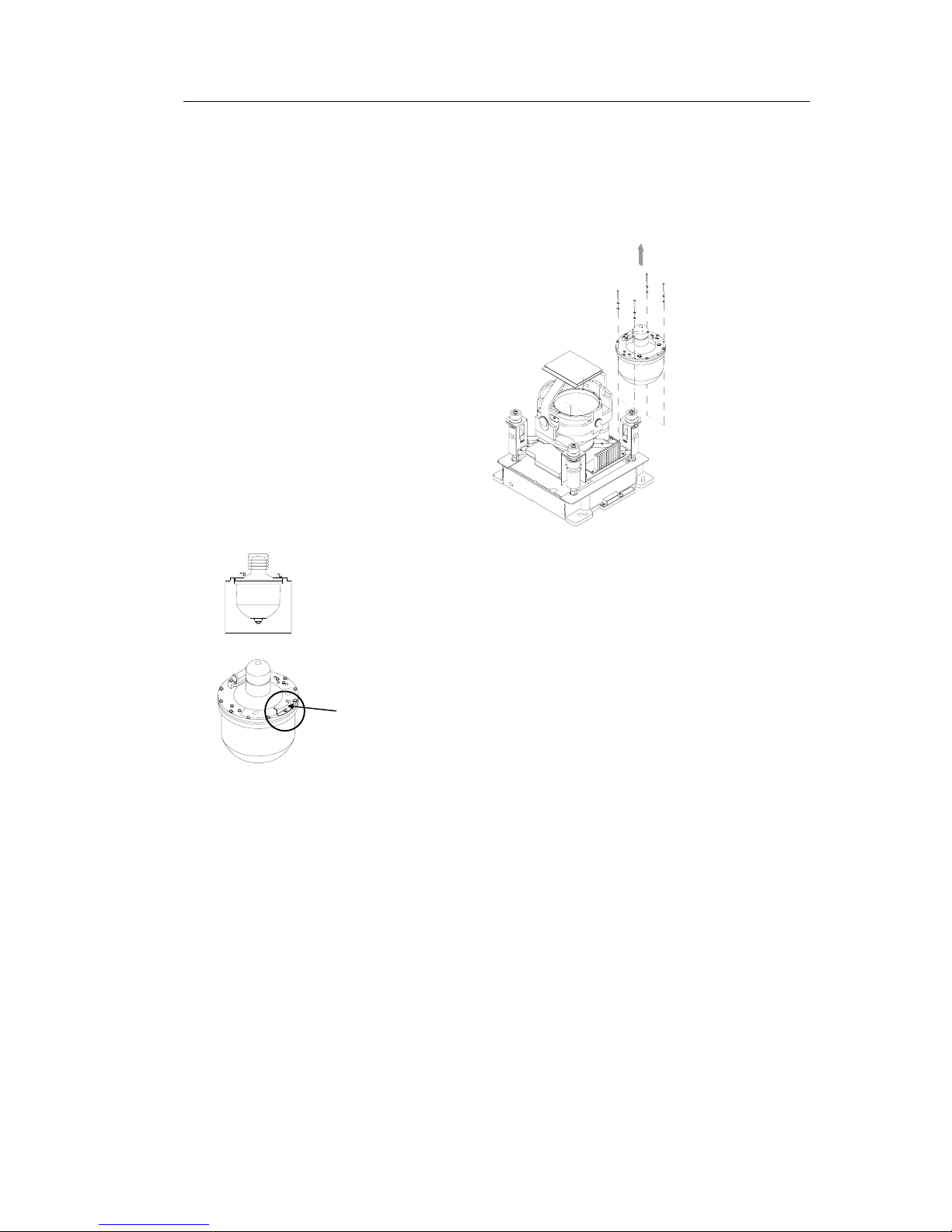

9 Position the Sensitive element on the Horizontal ring by

putting the assembly jigs into the holes as indicated on the

figure below. Observe the rings on the jigs to ensure

proper positioning. Insert and fasten the two screws in the

other holes.

ASSEMBLY JIG

WITH 1 CIRCLE

ASSEMBLY JIG

WITH 2 CIRCLES

Page 34

Simrad GC80/GC85 Expanded Gyro Compass

26 20221529 / C

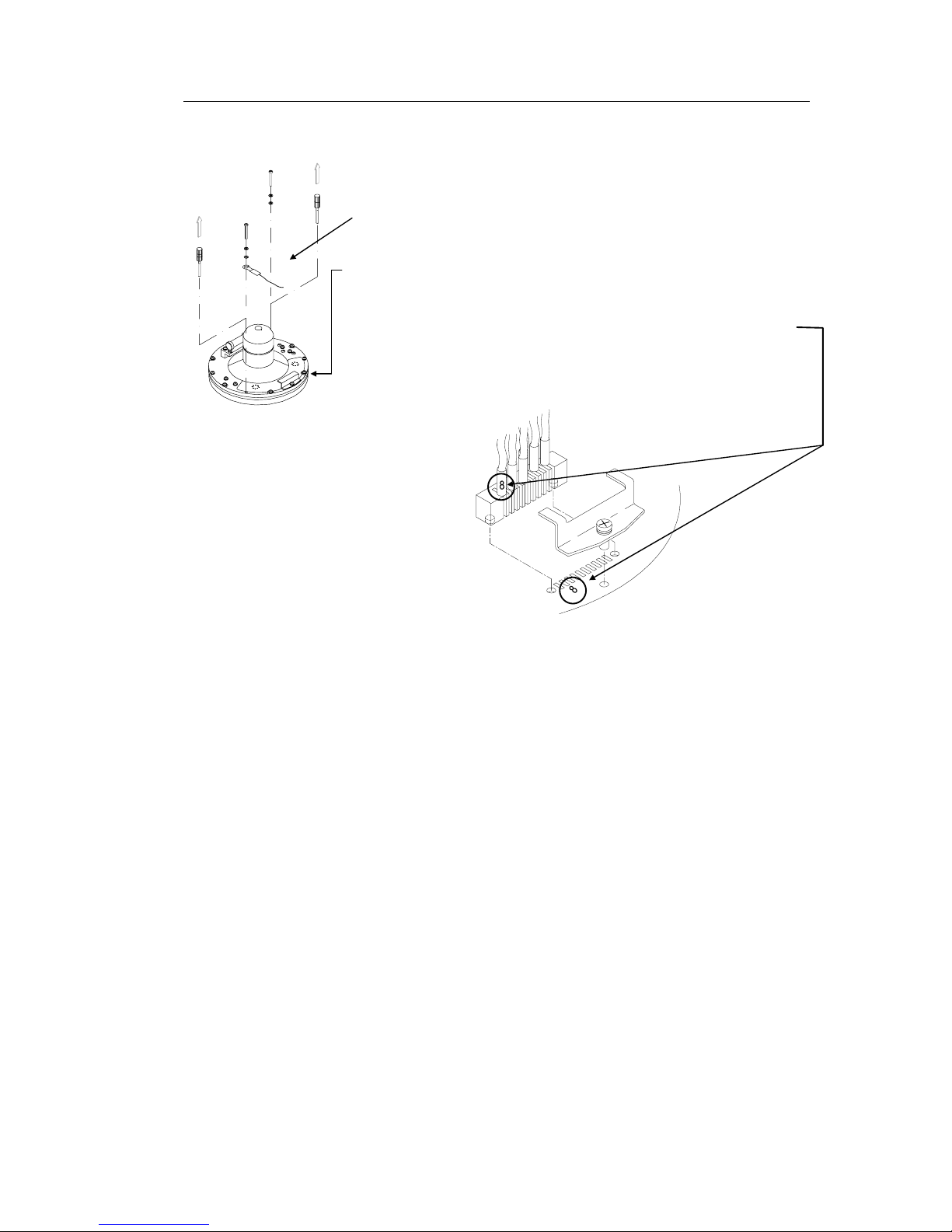

10 Replace the assembly jigs with the two remaining screws

after placing the ground wire as shown on the figure.

11 Loosen the screw on the plug-holder on the Sensitive

element, and lift the holder 2-3 mm upwards.

12 Connect the plug to the connectors on the Sensitive

element’s pcb according to the labelling on the pcb and on

the wires. Make sure that the pin guides on the plug are

properly entered, and that the wires are not twisted.

13 Firmly tighten the screw on the holder.

Page 35

MAINTENANCE

20221529 / C 27

Verifying the element’s tilt angle

1 Tilt the Sensitive element by hand towards the level tool

on the Horizontal ring and keep it tilted for approximately

1 minute. Remove the pressure and observe that the tilt

angle remains at:

- GC80: 15° to 19°

- GC85: 18° to 22°

The tilt angle is indicated on the figures below.

1

5

°

1

9

°

Max and min tilt angle for GC80 std system

1

8

°

2

2

°

Max and min tilt angle for GC85 High Speed system

Note! The tilt angle shown above is correct for cold condition. The

angle may change when the element has reached normal

operational temperature!

Page 36

Simrad GC80/GC85 Expanded Gyro Compass

28 20221529 / C

2 If the tilt angle is incorrect, weight disks must be adjusted

by moving weights from one side to the other. After

adjustments, wait for 2 minutes before the tilt angle

verification is repeated.

Caution The sensitive element must have equal number of weight disks

on both weight points on the tilting side (north and south

side)!

3 Carefully rotate the Horizontal ring at least one complete

rotation. Verify that all movable parts will rotate without

making any contact with mechanical or electrical

components.

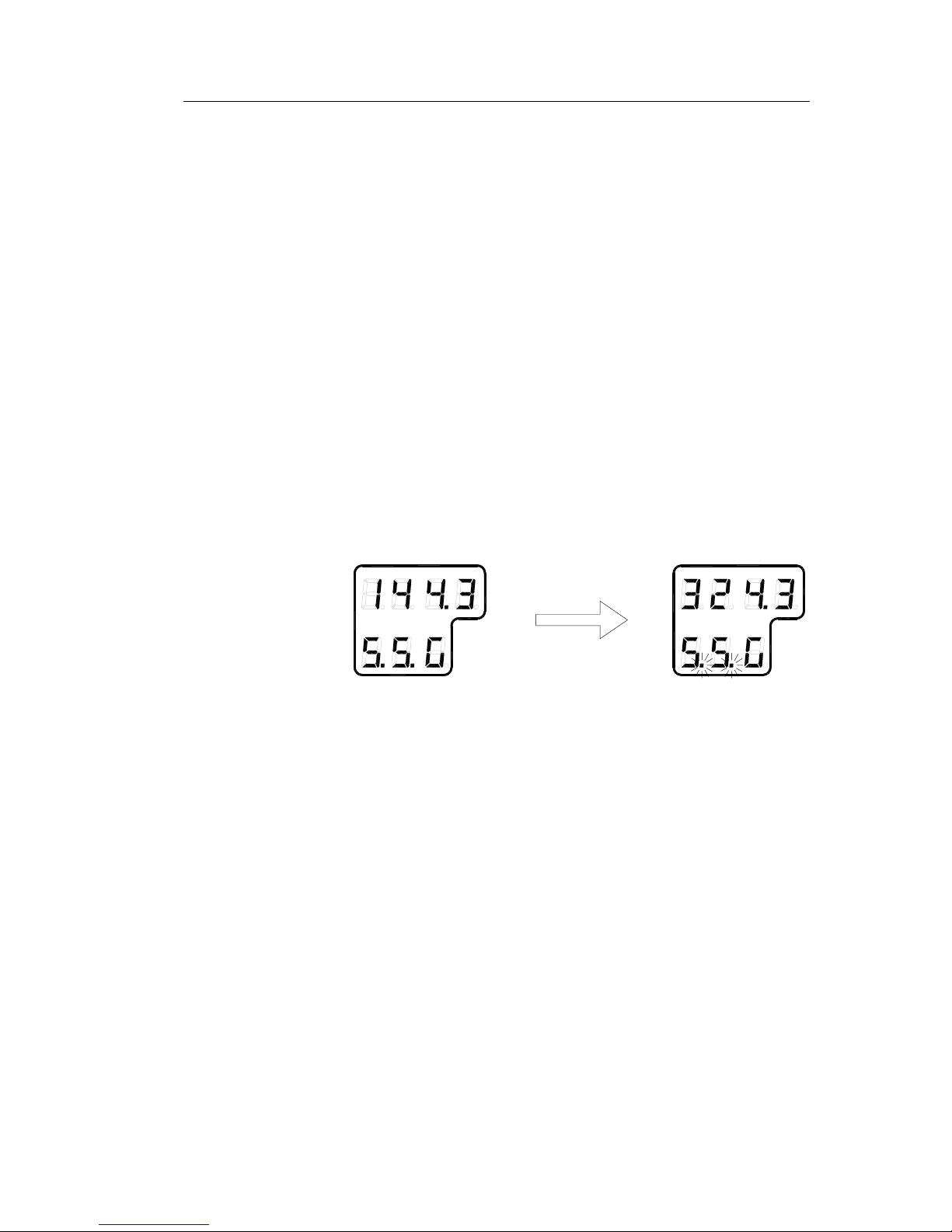

Parameter updates

When a sensitive element is replaced, parameters for the new

element have to be loaded into the GC80 Control unit before the

gyro compass is started. This is done from the Extension menu

as described below.

1 Enter the Extension menu by pressing and holding the SET

button and the ACK/ENT buttons simultaneously for at

least 3 seconds.

Main category A-1 will be displayed.

2 Press the SET button to enter the sub-category loop. Sub-

category 1.1.U and its parameter values will be displayed.

3 Use the arrow buttons to increase or decrease the

parameter value until the value is according to the labelling

for the new sensitive element.

4 Confirm the entry by pressing the ACK/ENT button. The

display will return to sub-category 1.1.U, and the data will

be transferred to the gyro immediately.

5 Press the DISP button again to select sub-category 1.6.t,

and use the arrow buttons to increase or decrease the

parameter value until the value corresponds with the

parameter for the new sensitive element. Confirm the entry

by pressing the

ACK/ENT button.

Page 37

MAINTENANCE

20221529 / C 29

6 Exit the sub-category by pressing the SET button, and then

exit the Extension main category by pressing and holding

the SET and ACK/ENT buttons simultaneously for at least

3 seconds.

For more information about the Extension menu, see

ADVANCED SETTINGS, page 55 onwards.

Balancing the Horizontal ring

After the Sensitive element has been replaced, the gyro compass

should be started as described on page 10.

When the compass has been running continuously for at least 2

hours, the horizontal ring should be adjusted.

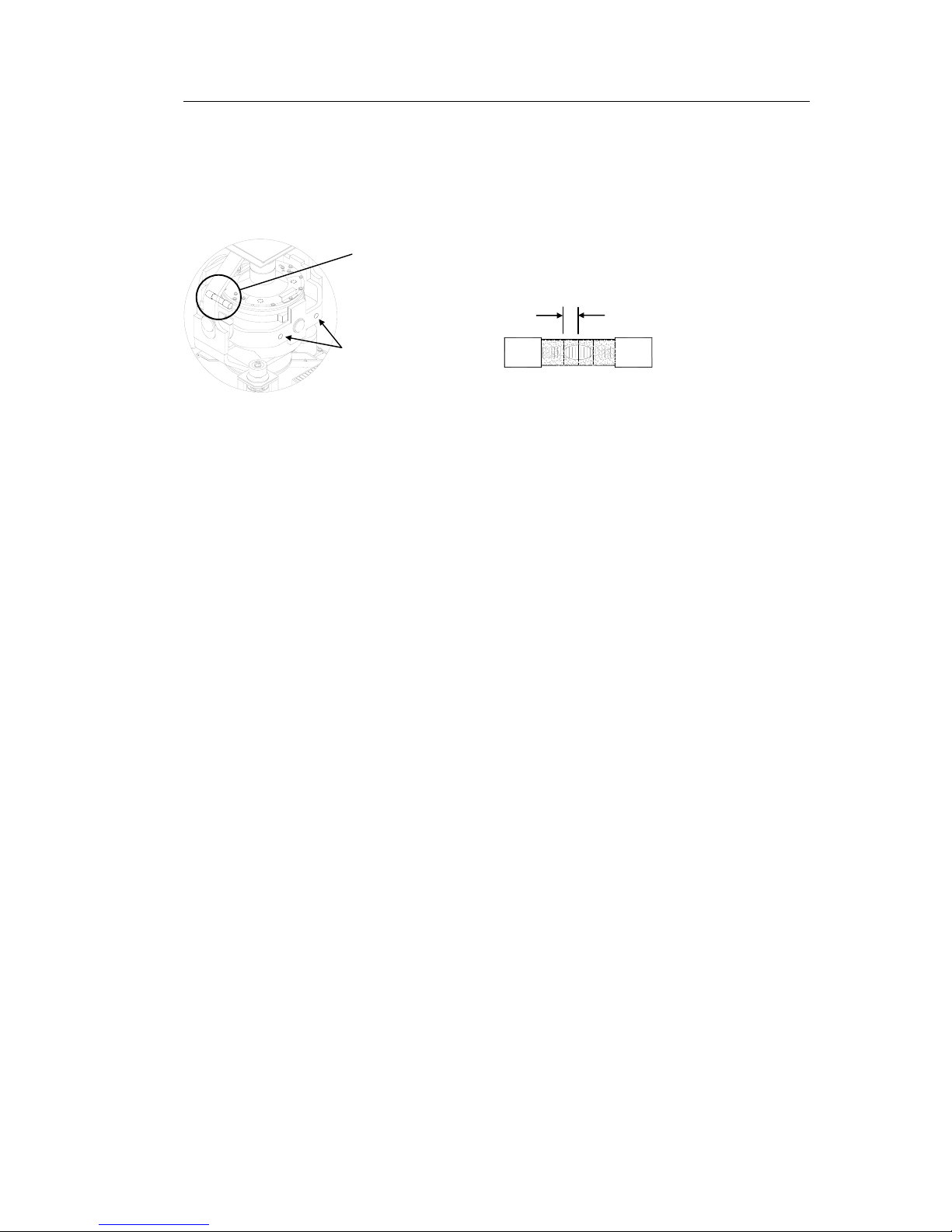

1 Locate the reference level tool on the horizontal ring, and

check that the level bubble is within +/-10 minutes from

the center. Each division equals 2 minutes.

2 If the level bubble not is within this limit, add or remove

weights from the horizontal ring until it is level.

Note! It is important that the total number of weights on the horizontal

ring are as few as possible.

3 Let the compass run for at least 20 minutes before the

level is rechecked and eventually confirmed.

WARNING If the horizontal ring is tilted more than +/-

10’, a bearing error will be generated!

10 minutes

Page 38

Simrad GC80/GC85 Expanded Gyro Compass

30 20221529 / C

4.8 Replacing the Fuses

WARNING Before a fuse is replaced, ensure that both

the main power and the emergency power is

disconnected from the unit.

Use the procedures described in the following pages when

replacing the fuses.

Master Compass

Fuse F1 is located inside the fuse holder in the front of the

Master compass.

1 Open the fuse holder by pressing and turning the fuse

holder edge counter-clockwise with a screw driver.

2 Replace fuse F1, and close the holder by turning it

clockwise.

F1 (12A)

Page 39

MAINTENANCE

20221529 / C 31

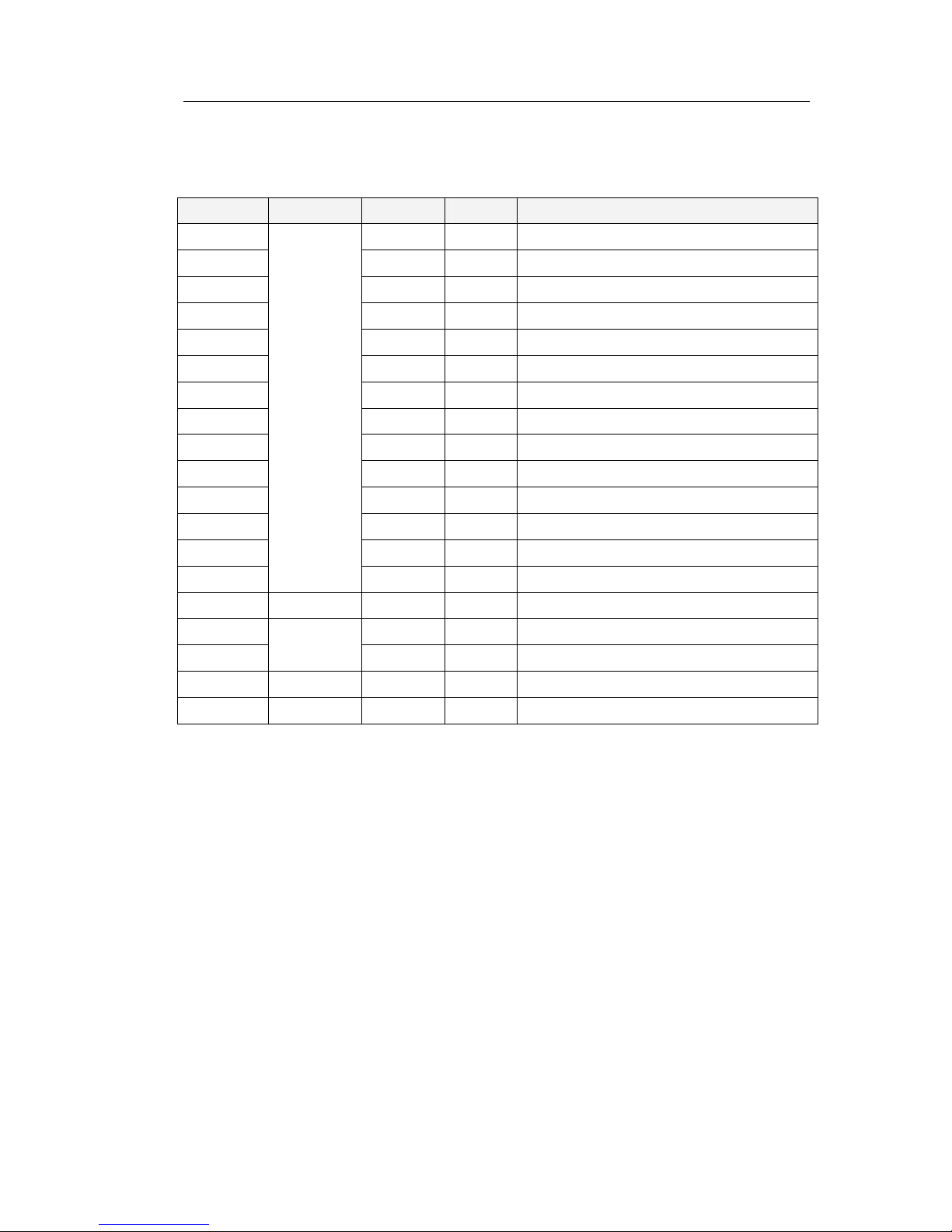

Expanded Control unit

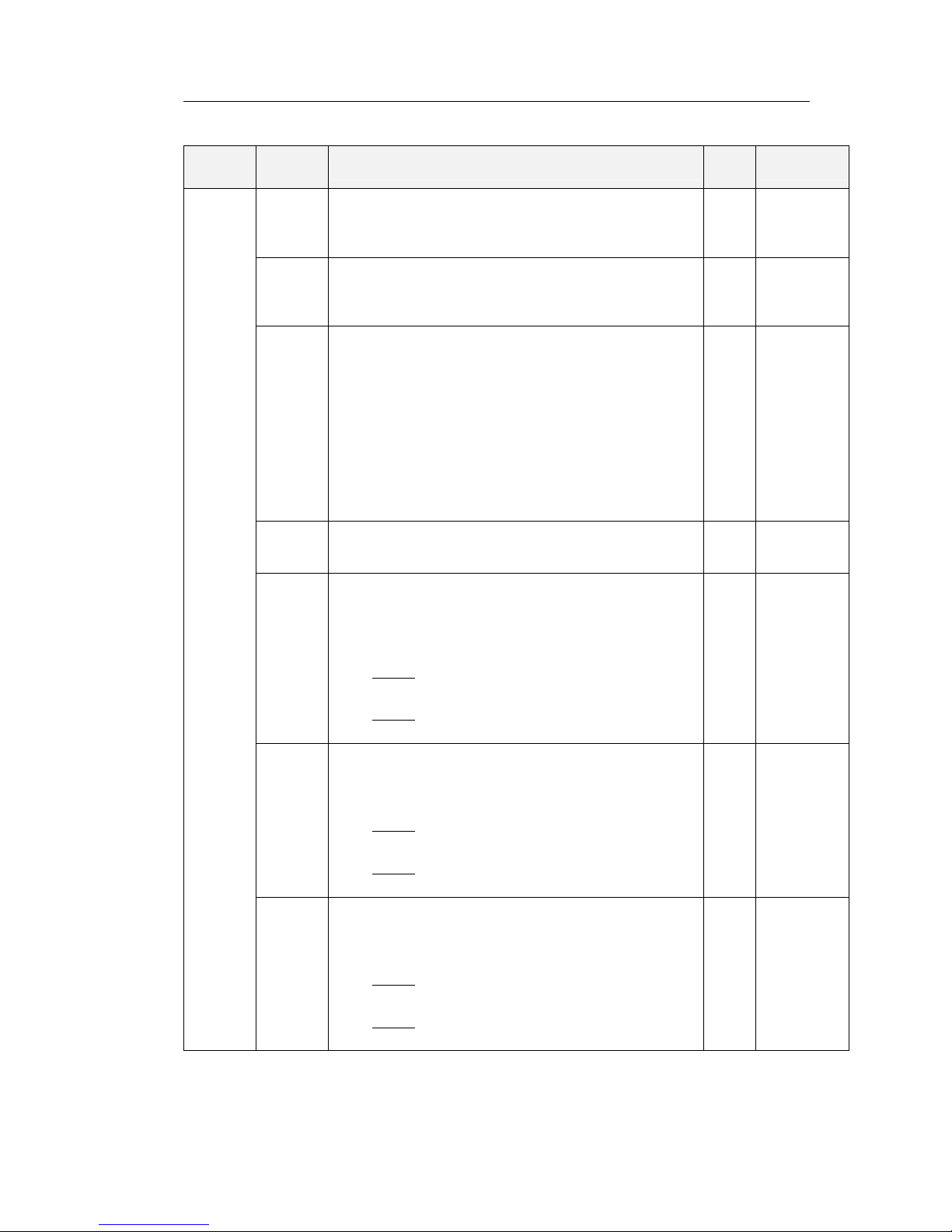

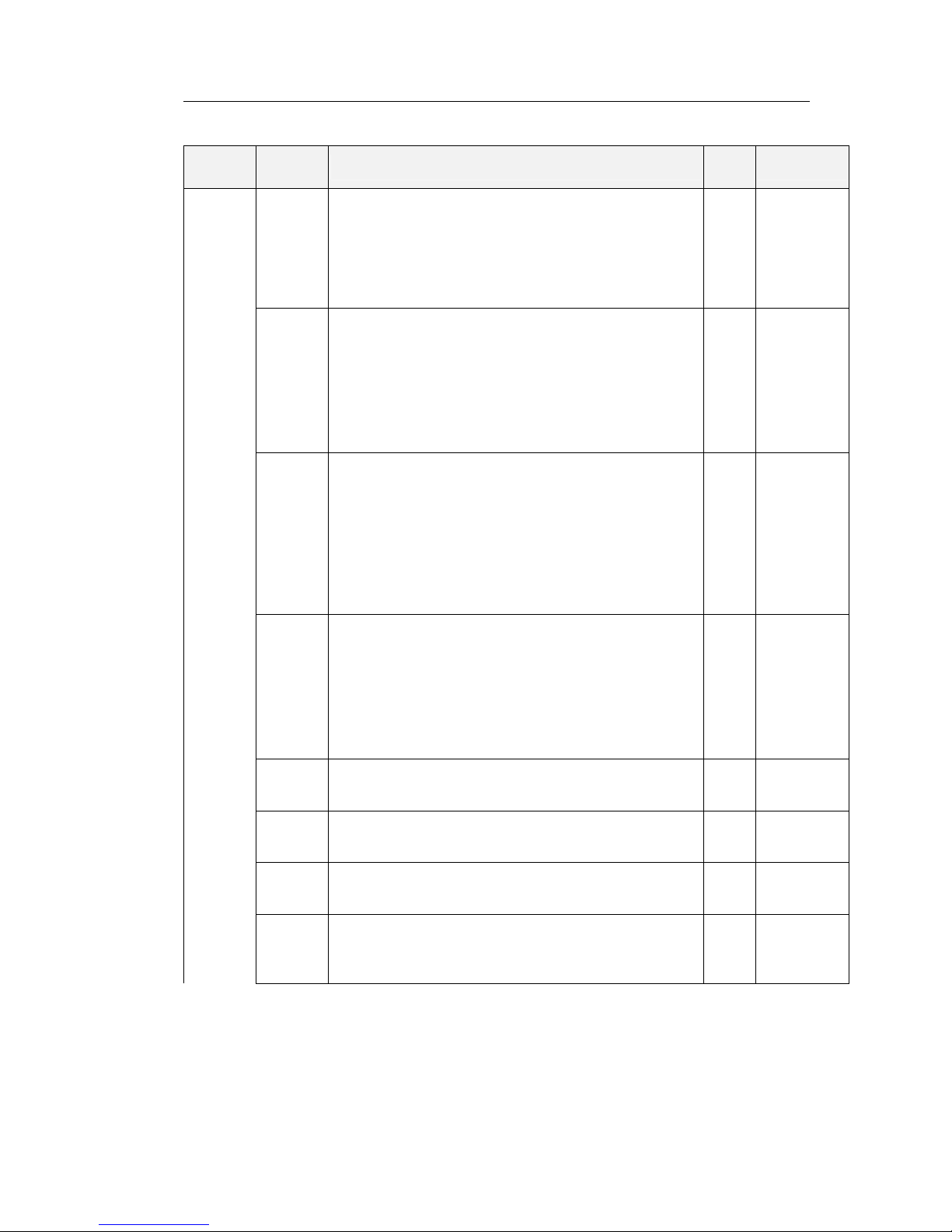

FUSE NO CAPACITY TB-NO SIGNAL DESCRIPTION

F1 TB2-5 1R24+ Power supply for ch.1 serial repeater

F2 TB2-10 2R24+ Power supply for ch.2 serial repeater

F3 TB2-15 3R24+ Power supply for ch.3 serial repeater

F4 TB2-20 4R24+ Power supply for ch.4 serial repeater

F5 TB2-29 5R24+ Power supply for ch.5 serial repeater

F6 TB2-34 6R24+ Power supply for ch.6 serial repeater

F7 TB2-39 7R24+ Power supply for ch.7 serial repeater

F8 TB2-44 8R24+ Power supply for ch.8 serial repeater

F9 TB1-31 9R24+ Power supply for ch.9 serial repeater

F10 TB1-36 10R24+ Power supply for ch.10 serial repeater

F11 TB2-61 Power supply for ch.1 step motor repeater

F12 TB2-66 Power supply for ch.2 step motor repeater

F13 TB2-71 Power supply for ch.3 step motor repeater

F14

1A

TB2-24 Power supply for ch.4 step motor repeater

F15 15A J9, 1-6 Repeater power supply

F16 J4, 23-27 Power supply for SCC and SIFC boards

F17

3.15A

J9, 15-16 Power supply for HDM part

F101 6.3A TB101 Main power supply

F102 20A TB101 Emergency power supply

Page 40

Simrad GC80/GC85 Expanded Gyro Compass

32 20221529 / C

F15

F16

F11

F10

F2

F1

F5

F6

F7

F9

F3

F12

F8

F4

F13

F14

F17

WARNING Make sure that the main power switch SW1 is

turned OFF before any fuses are replaced!

Note! The fuses in the Expanded Control unit are open glass type and

may be damaged if handles with force.

1 Pull the broken fuse up from the holder.

2 Re-install a new fuse by carefully pushing it into the

holder. When correctly located, it should be fixed 1-2mm

above and parallel with the mounting level.

SW1

MAIN

POWER

SWITCH

F101

F102

F3, F4, F8,

F13, F14

F17

F15

F1 - F2, F5 - F7,

F9 - F11

F16

Page 41

INSTALLATION

20221529 / C 33

5 INSTALLATION

This section is a reference guide for correctly installing and

configuring the GC80/85 Gyro Compasses.

Page 42

Simrad GC80/GC85 Expanded Gyro Compass

34 20221529 / C

5.1 Unpacking and handling

A GC80/85 Gyro compass consist of the following units:

- Master compass

- Sensitive element

- Control unit

- Spare part kit

- Mounting jigs

- Documentation

The sensitive element is shipped from the factory packed

separately in foaming phenylethene to protect it from shock and

vibration. The final assembly of the sensitive element into the

Master compass have to be done when the Master compass is

mounted onboard the vessel. Refer page 43.

Note! It is recommended to keep the packing material for the Sensitive

element. This original packing should be used if the element is

sent to the factory for service or repair.

Care should be taken when unpacking and handling the

equipment. A visual inspection should be made to see that the

equipment has not been damaged during shipment and that all

components and parts are present.

5.2 Mechanical installation

The units included in the GC80/GC85 system should be

mounted with special regard to the units’ environmental

protection, temperature range and cable length. Refer Technical

specifications, page 63 onwards.

Note! A special tool (Simrad part no. 44174449) is required when

installing the Sensitive element. This tool is delivered together

with the gyro, and the sensitive element should not be installed

without using this tool.

Page 43

INSTALLATION

20221529 / C 35

Control unit

The Control unit is bulkhead mounted by using 4 bolts as shown

in the illustration.

Flush mounting the control panel

The control panel may be removed from the Control unit and

mounted in a remote location by using the optional flush

mounting kit (part number 27101757).

The flush mounting kit includes:

- 1 flush mounting panel

- 4 corners

- 4 mounting screws

- 1 blind cover

In addition to this kit, an optional control panel cable must be

ordered. The cable is available in three different lengths:

- 5m (part no. 44170736)

- 10m (part no. 44170744)

- 15m (part no. 44170751)

Use the following procedure when remotely mounting the

control panel:

1 Open the control unit, and remove the wiring strips

holding the control panel’s cable.

2 Disconnect the cable’s grounding wires (labelled FG)

from the control panel and from the PWB SCC board in

the Control unit.

CONTROL

PANEL

GC80/85

REMOTE PANEL

Page 44

Simrad GC80/GC85 Expanded Gyro Compass

36 20221529 / C

3 Disconnect the plugs and remove the control panel’s

cable.

4 Loosen the 4 nuts holding the control panel, and remove

the panel. These nuts are to be re-used when fastening the

control panel to the flush mounting panel.

5 Insert the control panel in the flush-mounting kit from the

front side as shown on the figure. Fasten the panel with the

4 nuts.

6 Insert the plug on the optional control panel cable, and

connect the grounding wire.

7 Mount the cover on the back side.

8 Fasten the cable to the cover by a wire strip.

9 Slide the control panel cable through the cable inlet, insert

the plug in PWB SCC board and connect the grounding

wire. Secure the cable to the control unit by a wire strip.

10 Insert the blind cover in the Control unit by using the 4

bolts included in the kit.

Page 45

INSTALLATION

20221529 / C 37

Master compass

Select a mounting location where the deck is horizontally, flat

and with little vibration, and where the pitch/roll motion is as

small as possible.

It is also important to select a mounting location with sufficient

space for installation and service. Refer dimensional drawing,

page 72.

1 Locate the compass on or parallel to the vessel’s

horizontal centerline, with the bow indication on the top of

the case pointing towards the vessel’s bow.

2 Use the datum line in the front and back to of the compass

to line up the unit.

- It is possible to compensate for a small mounting offset

by using the heading offset feature as described in

Adjusting True heading, page 53.

3 Remove the four screws holding the compass case, and lift

the case carefully upwards and away.

4 Remove the cable inlet cover.

5 Fasten the compass to the deck with four bolts. The bolts

should be located in the center of the trails for later to be

able to adjust the compass direction when the heading is

tuned in. Refer Adjusting True heading, page 53.

6 Remove strips and foam rubber from the chock absorbers,

together with all strips used for securing moving parts

during transportation.

Page 46

Simrad GC80/GC85 Expanded Gyro Compass

38 20221529 / C

Note! The foam rubber should be kept for re-use if the Master compass

has to be sent to factory for service!

5.3 Cabling

Note! No cables are included when the gyro system is delivered from

factory.

The wiring diagram on page 74 onwards includes cable

specification for all cables that is to be used.

Connect power and signal cables according to the wiring

diagram on page 74 onwards.

To avoid that vibration should cause the cables to loose

connection, the cables could be fastened to the fixing device by

using wire straps as illustrated on the figure.

Page 47

INSTALLATION

20221529 / C 39

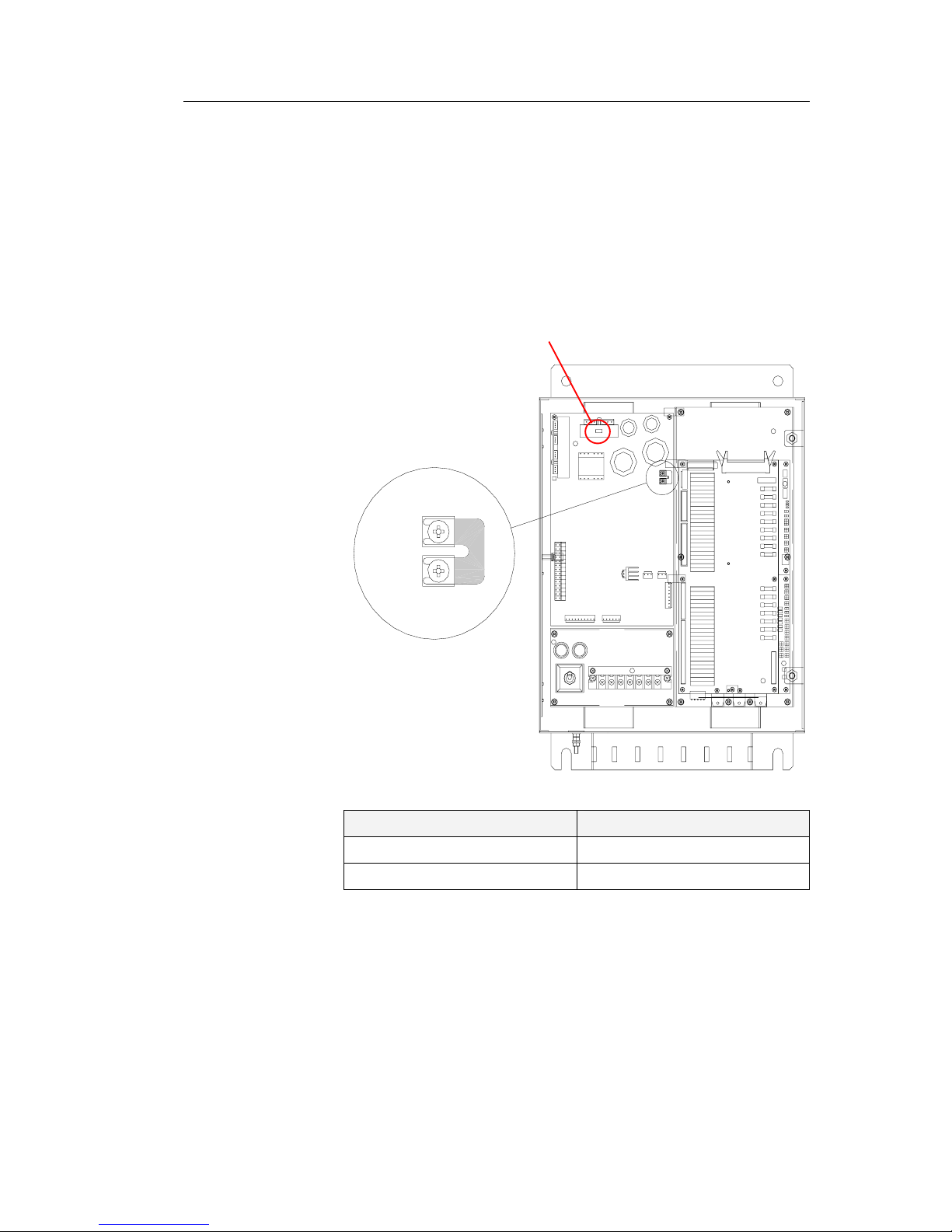

Power supply

GC80/GC85 is to be supplied with 110 or 220V AC.

When delivered from factory, the system is set up for 220V AC.

If the system is to be supplied with 110V AC, a strap on the

GPOWER board has to be added according to the figure and the

table below.

Note! Replace the 220V AC label with a 110V AC indication if the

compass is set up for 110V AC power supply!

TB3

TB4

TB4

TB3

TB3 – TB4 VOLTAGE

Open 220V AC (default)

Short 100/110/115V AC

Page 48

Simrad GC80/GC85 Expanded Gyro Compass

40 20221529 / C

5.4 Grounding the units

All units in the GC80/GC85 system should have a proper

ground connection from the unit’s ground terminal.

The wires should be as short as possible and have a cross section

of at least 16mm2 (gauge).

MASTER COMPASS

EXPANDED CONTROL UNIT

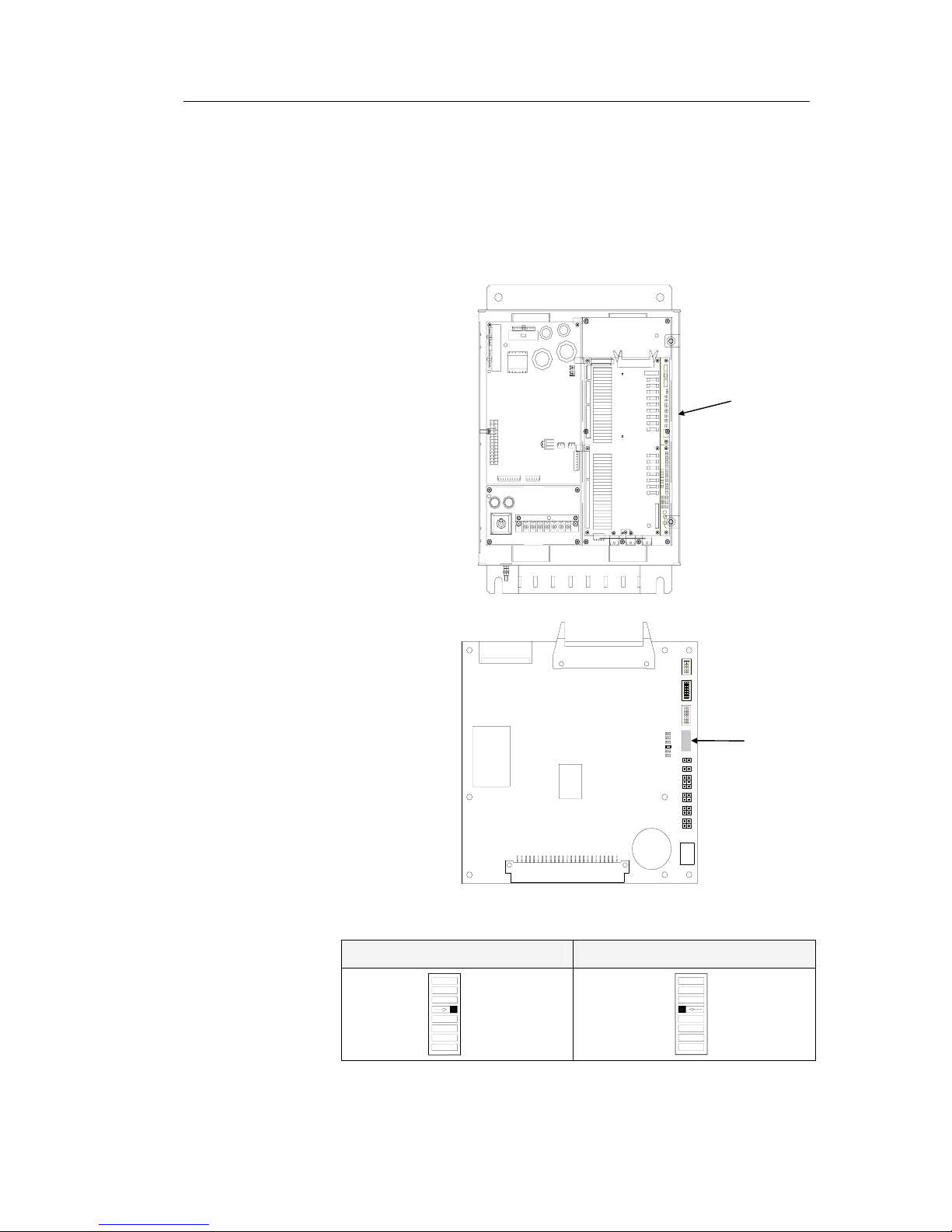

5.5 Dip-switch settings

GC80 and GC85 gyro systems include several dip switches.

With the exception of two switches on the SCC board in the

Control unit, no switches have to be set when installing the

system. These two switches are used to configure the Control

unit to match type of gyro system (GC80 or GC85), and to

activate an external heading sensor.

Note! These dip switch settings are read when the system is started.

Any changes when the system is running will therefore not take

affect before the system is restarted.

For a complete list of dip switch settings, refer to DIP SWITCH

SETTINGS, page 87.

Page 49

INSTALLATION

20221529 / C 41

Configuring the Control unit

When the gyro system is shipped from factory, all dip switches

in the Control unit are set as for a standard GC80 system.

Before the system is started, dip switch no.2 on S1 on the SCC

board has to be changed to identify the system as a GC85

system.

The SCC board is located underneath the GTERM board.

J1

J4

J3

J2

6

1ON

8

1ON

SW4

8

1ON

SW3

SW2

SW1

ON81

DS1

DS2

DS3

DS4

DS5

DS6

12

12

12

56

12

34

132

4

132

4

J5

J6

J7

J8

J9

J10

U1

U52

BT1

SCC board

GC80 system GC85 system

OFF

S1

1

8

S1

8

1

ON

SCC

BOARD

SW1

Page 50

Simrad GC80/GC85 Expanded Gyro Compass

42 20221529 / C

External heading sensor

If an external heading sensor is connected to the GC80/GC85,

dip switch no.5 on S1 on the SCC board has to be set to activate

the external heading sensor.

J1

J4

J3

J2

6

1ON

8

1ON

SW4

8

1ON

SW3

SW2

SW1

ON81

DS1

DS2

DS3

DS4

DS5

DS6

12

12

12

56

12

34

132

4

132

4

J5

J6

J7

J8

J9

J10

U1

U52

BT1

SCC board

No external sensor Active external sensor

OFF

8

1

S1

ON

S1

1

8

SCC

BOARD

SW1

Page 51

INSTALLATION

20221529 / C 43

Pendulum function

If an external switch is connected to GC80/85 to operate the

pendulum function, dip switch no.4 on S2 on the SSC board has

to be set to activate the pendulum function.

SCC board

U52

J3

U1

J1

21

BT1

J2

J10

4

J9

J8

2

2

4

4

3

1

1

3

3

DS2

DS6

DS5

DS4

DS3

DS1

SW1

J6

J7

2

6

2

J5

ON

2

1

5

1

1

1

SW2

SW3

ON

ON

8

1

8

1

8

J4

SW4

ON 1

6

Pendulum function disabled Pendulum switch enabled

OFF

S2

1

8

ON

S2

8

1

SCC

BOARD

SW2

Page 52

Simrad GC80/GC85 Expanded Gyro Compass

44 20221529 / C

5.6 Installing the Sensitive element

The Sensitive element is shipped from the factory packed

separately, and the element has to be installed in the Master

compass according to the description below.

Note! A special tool (Simrad part no. 44174449) is required when

installing the Sensitive element. This tool is delivered together

with the gyro, and the sensitive element should not be installed

without using this tool.

Caution Use extreme caution when handling the Sensitive element! Do

not tilt the element. It is filled with oil and the top is open.

1 Make sure that the master compass is installed and cables

connect according to the description on page 37 onwards.

2 Remove the four screws on the Horizontal ring.

3 Lift the sensitive element carefully from its package, and

remove the rubber tube on top of the element.

Note! The package and the rubber tube should be kept for re-use if the

Sensitive element has to be sent to factory for service!

4 Tilt the Horizontal ring to the side where the plug is

located, and carefully put the sensitive element into the

ring.

- The socket on the Sensitive element should be located

right above the plug attached to the Horizontal ring.

5 Position the Sensitive element on the Horizontal ring by

putting the assembly jigs into the holes as indicated on the

figure below. Observe the labelling and the diameter on

the jigs. Fasten two screws in the other two holes.

Page 53

INSTALLATION

20221529 / C 45

6 Replace the assembly jigs with the two remaining screws.

Locate the ground wire on one of the screws as shown on

the figure.

7 Loosen the screw on the plug-holder on the Sensitive

element, and lift the holder 2-3 mm upwards.

8 Connect the plug to the connectors on the Sensitive

element’s pcb according to the labelling on the pcb and on

the wires. Make sure that the pin guides on the plug are

properly entered, and that the wires not are twisted.

9 Firmly tighten the screw on the holder.

ASSEMBLY JIG

WITH 1 CIRCLE

ASSEMBLY JIG

WITH 2 CIRCLES

Page 54

Simrad GC80/GC85 Expanded Gyro Compass

46 20221529 / C

Verifying the element’s tilt angle

1 Tilt the Sensitive element by hand towards the level tool

on the Horizontal ring and keep it tilted for approximately

1 minute. Remove the pressure and observe that the tilt

angle remains at:

- GC80: 15° to 19°

- GC85: 18° to 22°

The tilt angle is indicated on the figures below.

1

5

°

1

9

°

Max and min tilt angle for GC80 std system

1

8

°

2

2

°

Max and min tilt angle for GC85 High Speed system

Note! The tilt angle shown above is correct for cold condition. The

angle may change when the element has reached normal

operational temperature!

Page 55

INSTALLATION

20221529 / C 47

2 If the tilt angle is incorrect, weight disks must be adjusted

by moving weights from one side to the other. After

adjustments, wait for 2 minutes before the tilt angle

verification is repeated.

Caution The sensitive element must have equal number of weight disks

on both weight points on the tilting side (north and south

side)!

3 Carefully rotate the Horizontal ring at least one complete

rotation. Verify that all movable parts will rotate without

making any contact with mechanical or electrical

components.

4 Lift the lid from the damper oil case, and fill the container

with the supplied damper oil. The oil has high viscosity,

and care should be taken when pouring the damper oil into

the container to avoid spill. Reinstall the lid on the damper

oil case.

Any oil spilled on the outside should be wiped up.

Page 56

Simrad GC80/GC85 Expanded Gyro Compass

48 20221529 / C

5.7 System start-up and software configuration

When all GC80 units are installed and the cables connected

according to the procedures described in previous chapters, the

system is ready for the first time start-up procedure.

System Start-up

mltbo

1 Turn ON the gyro system by pressing the POWER button

on the Control panel. The following start-up sequence will

be run:

- Control unit type (GC80 Std, or GC80 HSc), SW version

for Control unit and for Master compass is displayed in

rapid succession. Examples of display text are shown

below:

OR

GC80 CONTROL

UNIT

STD VERSION

GC80 CONTROL

UNIT

HIGH SPEED

VERSION

SW VERSION

CONTROL UNIT

SW. VERSION

MASTER COMPASS

dvol

2 The sensitive element starts rising horizontally, and the

compass rotates 360° clockwise. The display shows

decreasing bearing as the compass is rotating.

3 If the gyro has been turned ON and OFF again, but rotor

still rotation when the

POWER button was pressed for new

start, a rotor break function will be activated to stop the

rotor completely.

- Active rotor break is indicated with flashing display.

dvol

4 When the rotation is stopped, start bearing is indicated

with flashing text in the display. The start bearing will be

the same as active bearing when the compass was turned

OFF.

Page 57

INSTALLATION

20221529 / C 49

dvol

5 The indicated start bearing is accepted by pressing the

ACK/ENT button, or increased/decreased by using the

arrow buttons and then pressing the ACK/ENT button. If

no action is taken within 3 minutes, the start-up process

will continue with the indicated start bearing.

The bearing indication stops flashing when the start

bearing is accepted, while the lamp remains flashing.

The rotor starts rotating, and reaches pre-described number

of revolutions after maximum 30 minutes.

dvol

6 When the rotor has reached full speed, the compass starts

the north seeking rotation. The display will now change to

show the compass’ actual heading, and from now on

bearing output will be available.

The lamp beside the GYRO button change from flashing to

steady light.

The GC80/GC85 will be settled within 3 hours when started

with a deviation angle less than 5°. With a larger deviation

angle, the compass will be settled within 4 hours.

Configuring the gyro system

Each Sensitive element is tuned to its Master compass before it

is shipped from the factory. This tuning is reflected in a set of

parameters specific for this gyro compass. These parameters are

included in the sensitive element’s package, and they have to be

entered into the Control unit as part of the gyro compass’

installation procedure.

The parameters are loaded into the Control unit from the

Extension menu as described below.

1 Enter the Extension menu by pressing and holding the SET

button and the ACK/ENT buttons simultaneously for at

least 3 seconds.

Main category A-1 will be displayed.

2 Press the SET button to enter the sub-category loop. Sub-

category 1.1.U and its parameter values will be displayed.

3 Use the arrow buttons to increase or decrease the

parameter value until the value is according to the labelling

for the sensitive element.

4 Confirm the entry by pressing the ACK/ENT button. The

display will return to sub-category 1.1.U, and the data will

be transferred to the gyro immediately.

Page 58

Simrad GC80/GC85 Expanded Gyro Compass

50 20221529 / C

5 Press the DISP button again to select sub-category 1.2.F,

and use the arrow buttons to increase or decrease the

parameter value until the value corresponds with the

parameter for the new sensitive element. Confirm the entry

by pressing the ACK/ENT button.

6 Repeat step 5 for sub-category 1.3.S, 1.4.u, 1.5.L and

1.6.t.

7 Press the SET button again to return to main category A1,

and then press the DISP button to go to A2 main category.

8 Press the

SET button, and enter values for 2.1.o and 2.3.h

as described above.

While still in A2 main category, enter values for 2.5.y (Year),

2.6.N (Month and Day), 2.7.t (Hour and Minute) and 2.8.d (total

days of operation. This value should be reset after installation).

Note! All time parameters should be in CET (Central European Time)

or local time.

9 Press the SET button again to return to main category A2,

and then press the DISP button until main category A7 is

displayed.

10 Press the

SET button, and enter the value for 7.3.u as

described above.

11 Exit the sub-category by pressing the

SET button, and then

exit the Extension main category by pressing and holding

the SET and ACK/ENT buttons simultaneously for at least

3 seconds.

For more information about the Extension menu, see

ADVANCED SETTINGS, page 55 onwards.

Page 59

INSTALLATION

20221529 / C 51

Setting the Latitude input system

The latitude input system may be changed during the settling

process of the start-up procedure from item 7 onwards.

1 Press the DISP button until the display shows latitude

value.

2 Press SET button once, and the upper line in the display

starts flashing.

3 Use the arrow buttons for selecting Gyro or GPS as the

latitude input system, and confirm the entry with the

ACK/ENT button.

4 The display will change to flashing number.

5 Press the arrow buttons for increasing/decreasing the

latitude value, and confirm the entry with the ACK/ENT

button.

- This entered latitude value will now be used, together

with speed and bearing information, for calculating the

vessel’s current latitude.

6 The display will return to show latitude value without

flashing.

Page 60

Simrad GC80/GC85 Expanded Gyro Compass

52 20221529 / C

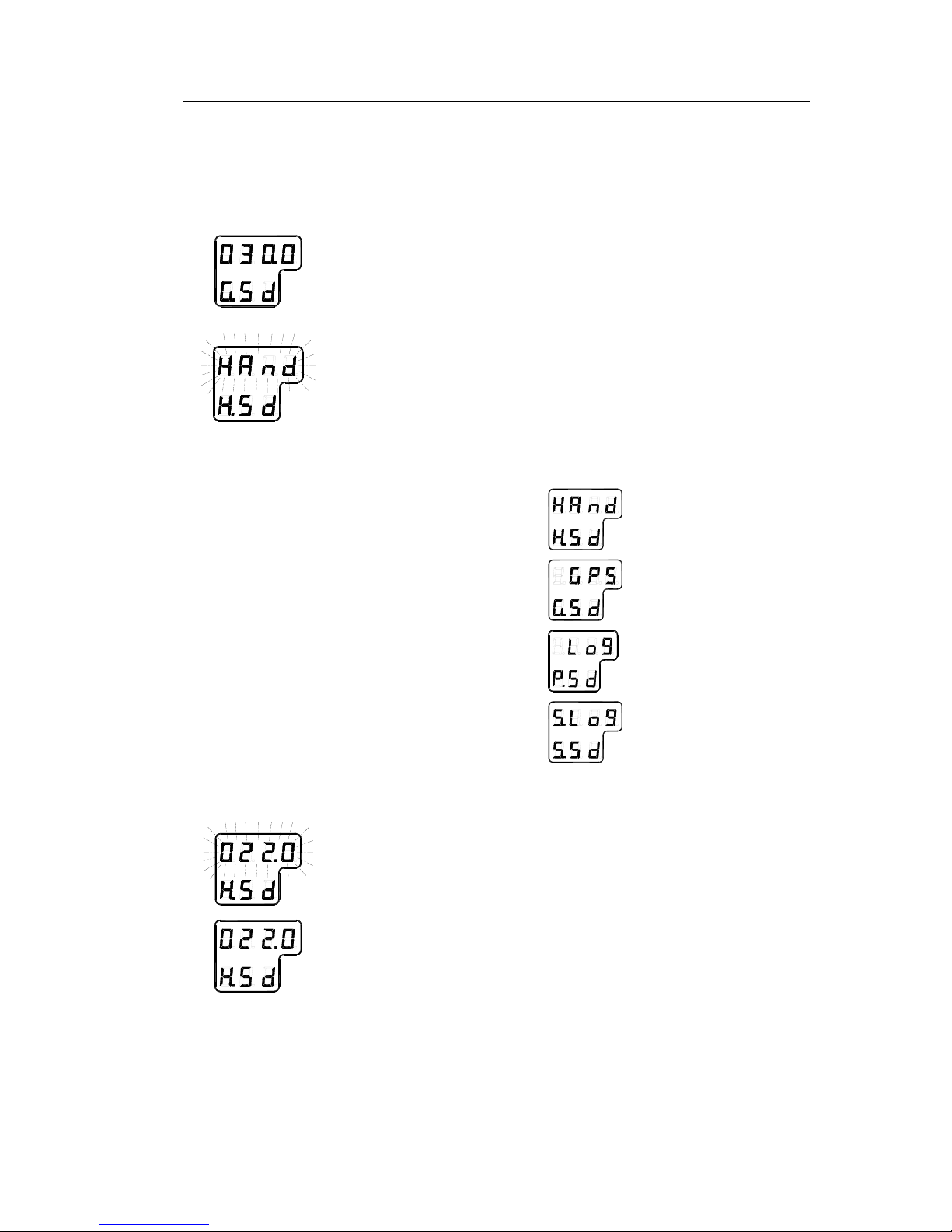

Setting the Speed input system

The latitude input system may be changed during the settling

process of the start-up procedure from item 7 onwards.

1 Press the DISP button until the display shows speed value

and speed input system.

2 Press SET button once, and the upper line in the display

starts flashing.

3 Use the arrow buttons for toggling between available

speed input systems:

Manual

GPS

LOG (pulse)

LOG (serial)

4 Select active speed input system, and confirm the selection

by pressing the

ACK/ENT button.

5 If Manual input system is selected, the display will change

to show flashing numerical values.

6 Use the arrow buttons for entering the speed value, and

confirm the input by the ACK/ENT button.

7 The display will return to shown speed value and speed

input system without flashing.

Page 61

INSTALLATION

20221529 / C 53

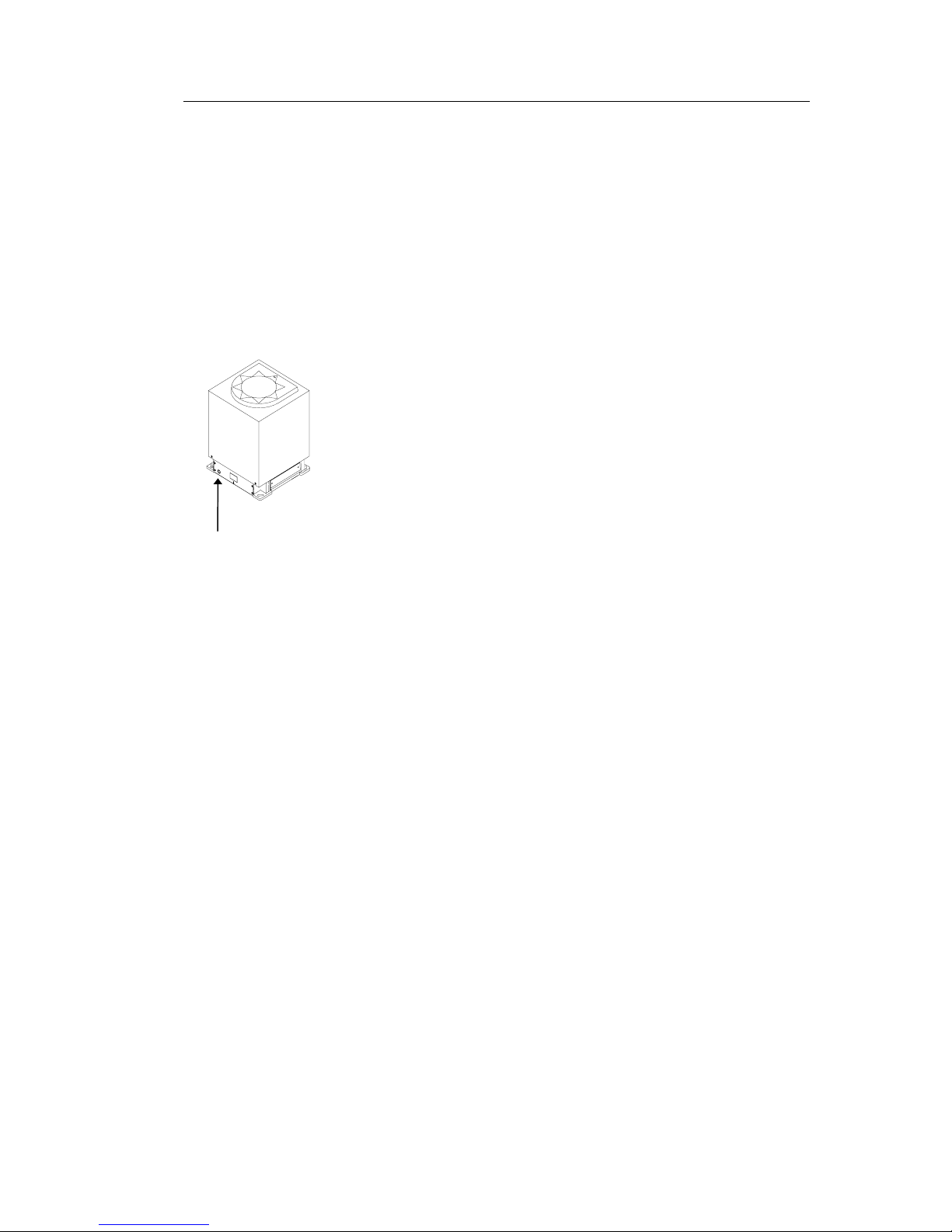

5.8 Balancing the Horizontal ring

After the compass has been running continuously for at least 2

hours, the horizontal ring should be adjusted.

1 Locate the reference level tool on the horizontal ring, and

check that the level bubble is within +/-10 minutes from

the center. Each division equals 2 minutes.

2 If the level bubble not is within this limit, add or remove

weights from the horizontal ring until it is levelled.

Note! It is important that the total number of weights on the horizontal

ring are as few as possible.

3 Let the compass run for at least 20 minutes before the

level is rechecked and eventually confirmed.

Caution If the horizontal ring is tilted more than +/-10’, a bearing error

will be generated.

Adjusting True heading

After the GC80/85 is settled, the gyrocompass has to be

calibrated against an external reference, e.g.:

- a known target

- astronomical observation

- the heading of the pier or quay the vessel is moored to

- two fixed points on the chart that the vessel is sailing

between

The observation period for the heading difference should be as

long as possible.

If there is any difference between the gyro bearing and the

confirmed external reference that not can be corrected by

adjusting the mechanical location of the master compass, an

offset value may be inserted in the GC80. This value is entered

by using the Extension menu as follows:

1 Activate the Extension menu by pressing and holding the

SET button and the ACK/ENT buttons simultaneously for

at least 3 seconds.

- Main category A-1 will be displayed.

10 minutes

Page 62

Simrad GC80/GC85 Expanded Gyro Compass

54 20221529 / C

2 Press the DISP button once to display main category A-2.

3 Press the SET button to enter the sub-category 2.1.o.

4 Use the arrow buttons to increase or decrease the offset

parameter value.

Note! To correct for +1.5°, press the Arrow Up button until the

display shows 1.5°.

To correct for -1.5°, press the Arrow Down button until the

display shows 358.5°!

5 Confirm the new value by pressing the ACK/ENT button,

or reject the changes by pressing the SET button. The

display will return to sub-category 2.1.o.

6 Exit the Extension menu by pressing and holding the

SET

and

ACK/ENT buttons simultaneously for at least 3

seconds.

For further information about the Extension menu, refer Using

the Extension menu, page 56 onwards.

Page 63

ADVANCED SETTINGS

20221529 / C 55

6 ADVANCED SETTINGS

This section gives an overview of the Extension menu, how

to enter the menu and how to change parameter values.

Page 64

Simrad GC80/GC85 Expanded Gyro Compass

56 20221529 / C

6.1 General

The Extension menu holds internal parameters and

communication parameters required to achieve the best possible

heading accuracy on the GC80/GC85 Gyro compass.

The Extension menu is grouped in 8 main categories, named A1 through A-8. Each of these main categories has again several

sub-categories where parameter values may be set.

All values in the Extension menu are stored in the nonvolatile

memory of the compass.

6.2 Using the Extension menu

Caution The Extension menu should not be entered by unauthorized

personnel. Incorrect parameters may result in irregular

operation of the GC80/GC85 gyro compass!

The extension menu can be entered when any display is shown

in the LCD.

1 Activate the menu by pressing and holding the SET button

and the ACK/ENT buttons simultaneously for at least 3

seconds.

- Main category A-1 will be displayed.

2 Page through the main categories to the selected category

by pressing the DISP button. Pressing the DISP and

ACK/ENT buttons simultaneously will display the main

category loop in reversed order.

3 Press the SET button to enter the sub-category loop, and

use the DISP button to select sub-category that holds the

parameter to be changed.

4 Use the arrow buttons to increase or decrease the

parameter value.

5 Confirm the new value by pressing the ACK/ENT button,

or reject the changes by pressing the SET button. The

display will return to selected sub-category.

6 Exit the Extension menu by pressing and holding the SET

and ACK/ENT buttons simultaneously for at least 3

seconds.

Page 65

ADVANCED SETTINGS

20221529 / C 57

afpm

afpm

^`h

bkq

pbqpbq

^`h

bkq

afpm

afpm

^`h

bkq

pbq

^`h

bkq

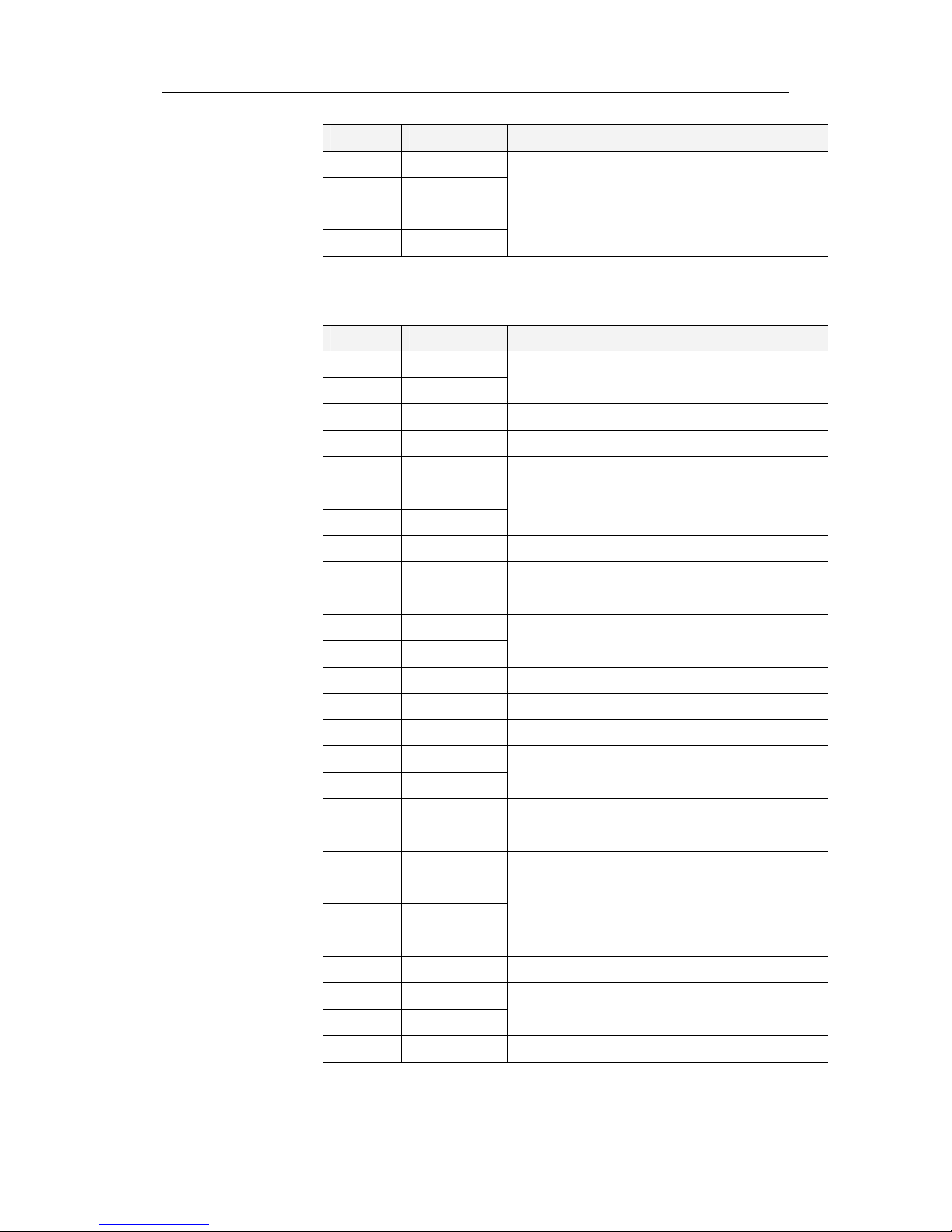

6.3 The Extension menu overview

Main

Category

Sub

Category

Parameter/description

Default

value

Range

A-1

1.1.U Damping gain

Determines the damping (damping operation in northseeking motion = half cycle attenuation) and actually

represents a coefficient (ratio) to the standard value

stored in the software.

1.00 0.00 – 2.00

1.2.F Bearing servo gain

Determines the gain of the bearing servo loop where phi

Φ signal (deviation signal around rotor’s vertical axis)

is calculated, drives the azimuth step motor and has the

sensitive element follow to the gyro-sphere vertical axis

(around azimuth axis) rotation. Presents a coefficient

(ratio) to the standard value stored in software.

1.00 0.00 – 2.00

1.3.S Horizontal servo gain

Determines the gain of the horizontal servo loop where

theta θ signal (rotor tilting angle signal) is calculated,

drives the horizontal DST and has the sensitive element

follow to the gyro sphere tilting angle (rotor tilting

angle). Present a coefficient (ration) to the standard

value stored in software.

1.00 0.00 – 2.00

1.4.u Leveling servo gain

Leveling motion (sensitive element erection motion)

calculates X signal (equivalent inclination angle) which

is output from the sensitive element and relative

inclination angle signal from HRZC board, controls to

have the sensitive element keep horizontal. The value

determines this control loop gain. Presents a coefficient

(ratio) to the standard value stored in the software.

1.00 0.00 – 2.00

CHANGE /

CLEAR

PARAMETER

VALUE

NEXT MAIN

CATEGORY

NEXT SUB

CATEGORY

MAIN

MENU

Page 66

Simrad GC80/GC85 Expanded Gyro Compass

58 20221529 / C

Main

Category

Sub

Category

Parameter/description

Default

value

Range

A-1 cont.

1.5.L (φ) Phi offset (°)

Offset value (°) around the vertical axis of gyro sphere

(rotor axis) and the sensitive element.

0.00 -3.00 – 3.00

1.6.t (θ) Theta offset (°)

Offset value (°) around the horizontal axis of gyro

sphere (rotor axis) and the sensitive element.

0.00 -3.00 – 3.00

1.7.G X signal pickup gain (v/°)

Distance of the sensitive element share and the rotor

axis direction. Inclination angle around horizontal axis

is obtained equivalently by monitoring this signal. For

example, when north side of the rotor axis rises, the

sensitive element follows to rise its north side, then

gyro sphere suspended by the suspension wire moves to

south side. X signal represents this amount of

movement (v/°).

This parameter is only used for GC85.

2.32 0.00 – 5.00

1.8.c Ks/H

Suspension wire twist torque. Fixed value.

1.477 1.000 – 2.000

1.9.r Maximum rate of turn (°/sec)

Maximum rate of turn in the turn rates which the

b

earing servo system followed up to this moment

(°/sec).

NOTE:

The maximum is measured after 3 hours from

system start.

NOTE:

Reset this data certainly after completion of

installation!

0.00 -

1.A.F Maximum deviation of bearing servo (°)

Maximum deviation value in the bearing servo loop that

occurred up to this moment (°).

NOTE:

The maximum is measured after 3 hours from

system start.

NOTE:

Reset this data certainly after completion of

installation!

0.00 -

1.b.S Maximum deviation of horizontal servo (°)

Maximum deviation value in the horizontal servo loop

that occurred up to this moment (°).

NOTE:

The maximum is measured after 3 hours from

system start.

NOTE:

Reset this data certainly after completion of

installation!

0.00 -

Page 67

ADVANCED SETTINGS

20221529 / C 59

Main

Category

Sub

Category

Parameter/description

Default

value

Range

A-2

2.1.o Bearing offset A (°)

Offset value included in the “master bearing” and used