Page 1

FS 70 OPERATOR MANUAL

974-24007001

Issue 3.0 January 2009

Page 2

Page 3

FS 70 Operators Manual 974-24007001/3.0

List of Contents Page 1

KONGSBERG MESOTECH LTD

Customer Products Warranty Policy

Effective January 1, 2009

Kongsberg Mesotech Ltd. Warrants each new product (equipment) to be free of

defects caused by faulty materials or poor workmanship for a period of twenty-four

(24) months for underwater and surface equipment from date of installation by an

authorized Kongsberg Group Company, Simrad Distributor, Dealer or Agency. The

warranty does not apply to defects caused by force majeure events or misuse

including water damage to the surface equipment, improper maintenance and

installation or including excessive wear and tear for which Kongsberg Mesotech Ltd.

is not responsible.

Underwater Equipment:

• Warranty for Underwater Equipment that is hull mounted, such as those

mentioned below, will be assessed on a case-by-case basis but shall generally

not be covered by the warranty:

• Hull Units, Sonar Dome Assemblies and Echo Sounder Transducers

• Transducer Units, Speed, Temperature and Depth Sensors

Note: Additional expenses connected with replacement of transducers, such as drydocking and diving, are not covered by this warranty.

Warranty on Parts or Equipment Replacement:

• It is at the sole discretion of Kongsberg Mesotech Ltd. to either repair or replace

any unit/part that fails within the limits of the Warranty Policy.

• The Warranty Policy is only valid on new equipment

• Replacement of parts, components, and/or PCB Boards during a warranty repair

does not extend the original warranty period.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 4

974-24007001/3.0 FS 70 Operators Manual

Page 2 List of Contents

Consumable Materials:

• Consumable materials, such as lamps, fuses, O-rings, gaskets and batteries, will

not be replaced free of charge.

Warranty Service:

• Warranty service is available worldwide through authorized Kongsberg Group

Companies, Simrad Distributors, Dealers or Agencies. When requesting warranty

service, you must supply the following information:

1. Proof of purchase.

2. Equipment part number and serial number.

3. Fault description and all relevant vessel information.

• Labour cost for the repair or replacement of any products/equipment and/or

module/parts is the responsibility of the servicing agent or dealer.

• All customs duties, brokerage charges ocal taxes, overtime, expenses for meals,

tools, launch services, ferries, lodgings, normal adjustments and routine

maintenance are not covered by this warranty policy.

DISCLAIMER

• Maximum liability shall not, in any case, exceed the contract price of the products

claimed to be defective.

• Consequential damages including, but not limited to, any loss of profit, property

damage or personal injury, are not covered by the warranty policy.

• This equipment is not certified or approved for navigation and/or safe-navigation

practices, and is not to be used for navigation purposes under any

circumstances.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 5

FS 70 Operators Manual 974-24007001/3.0

List of Contents Page 3

LIST OF CONTENTS

Part 1......................................................................................System Familiarization

Part 2.......................................................................................... Theory of Operation

Part 3...................................................................................FS 70 System Operation

Part 4..................................................... FS 70 Installation, System Set-Up and Test

Part 5....................................................................Troubleshooting and Maintenance

Part 6...................................................................................Drawings & Attachments

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 6

974-24007001/3.0 FS 70 Operators Manual

Page 4 List of Contents

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 7

FS 70 Operators Manual 974-24007001/3.0

List of Contents Page 5

MODIFICATION RECORD

FS 70 OPERATORS MANUAL

974-24007001

Issue: 3.0

January 2009

Issue No. Date Initial Comments

1.0 01.06 L.F First release

2.0 01.07 L.F Second release

______3.0_________01.09________ L.F________Third release_______________

To assist us in making improvements to the product and documentation,

Kongsberg Mesotech welcomes comments and constructive criticisms.

Please send all such comments, in writing or by E-mail, to:

Kongsberg Mesotech Ltd.

Documentation Department

1598 Kebet Way

Port Coquitlam, BC V3C 5M5

Canada

E-Mail: km.sales.vancouver@kongsberg.com

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 8

974-24007001/3.0 FS 70 Operators Manual

Page 6 List of Contents

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 9

FS 70 Operators Manual 974-24007001/3.0

System Familiarization Page 1.1

PART 1

SYSTEM FAMILIARIZATION

1. SYSTEM FAMILIARIZATION...........................................................................1.3

1.1 OVERVIEW ...............................................................................................1.3

1.1.1 Equipment Configuration .......................................................................1.3

1.1.2 System Configuration.............................................................................1.4

1.1.3 Display Monitor ......................................................................................1.4

1.1.4 Processor Unit .......................................................................................1.4

1.1.5 Power /TTM Interface Module................................................................1.5

1.1.6 Deployment Housing Unit ......................................................................1.5

1.1.7 Jointing Tool...........................................................................................1.6

1.1.8 Catch Sensors .......................................................................................1.6

1.1.9 PI Sensors Option..................................................................................1.6

1.1.10 Depth & Temperature NMEA Output..................................................1.6

1.1.11 Trawl Cable, Winch and Block ...........................................................1.6

1.1.12 19” Rack Cabinet 9U,.........................................................................1.7

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 10

974-24007001/3.0 FS 70 Operators Manual

Page 1.2 System Familiarization

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 11

FS 70 Operators Manual 974-24007001/3.0

System Familiarization Page 1.3

1. SYSTEM FAMILIARIZATION

1.1 OVERVIEW

The SIMRAD FS 70 Series is a third wire trawl monitoring system for pelagic and

bottom fishing trawlers. The system provides real time images from the trawl sonar

head and data from the sensors to the bridge, thus maximizing the quality of the

catch and reducing sea time.

The FS 70 vertical trawl sonar allows the operator to see the complete net opening

and operation by displaying individual fish targets in the vertical plane, the fish

school location, bottom/net location and net geometry. In addition to the vertical

monitoring, the FS 70 also allows the operator to measure the spread of the trawl

door, view and skim banks to avoid reefs and locate boulders on the ocean floor that

may damage the trawl net.

The 200kHz Echo Sounder capability ensures maximum control of the foot rope

during the tow. The active motion sensor for pitch and roll comes as a standard

feature.

The addition of the trawl system’s sensor module will allow the operator to monitor

trawl depth, water temperature and receive information from up to 6 catch receivers

indicating when the cod end fills up with fish.

The FS Trawl Sonar Series is a modular system. It is operated with ease through

direct access Mouse and Keyboard operated menus. The major benefit of the third

wire trawl sonar system is that it prevents the loss of communication with the trawl

as the vessel is changing course.

1.1.1 Equipment Configuration

A complete Trawl Monitoring System consists of:

• Simrad LCD or VGA display monitor. (optional)

• FS 70 Processing Server Industrial Unit.

• FS PWR/TTM Interface Module, 19” Rack Mounted 3U

• FS 70, Vertical Sonar Head 120kHz, or 330kHz, C/W 200kHz Sounder

• 40kHz or 70kHz Catch Sensors

• Integrated Pitch and Roll Motion Sensor

• FS 70 Deployment Housing and Installation materials

• Industrial 9U, 19” Rack Cabinet, c/w with fans and glass door, (optional)

• Industrial UPS 19” Rack mounted 2U, 120Vac or 230Vac, (optional)

Refer to Part 6 “Attachment” for full Configuration Overview

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 12

974-24007001/3.0 FS 70 Operators Manual

Page 1.4 System Familiarization

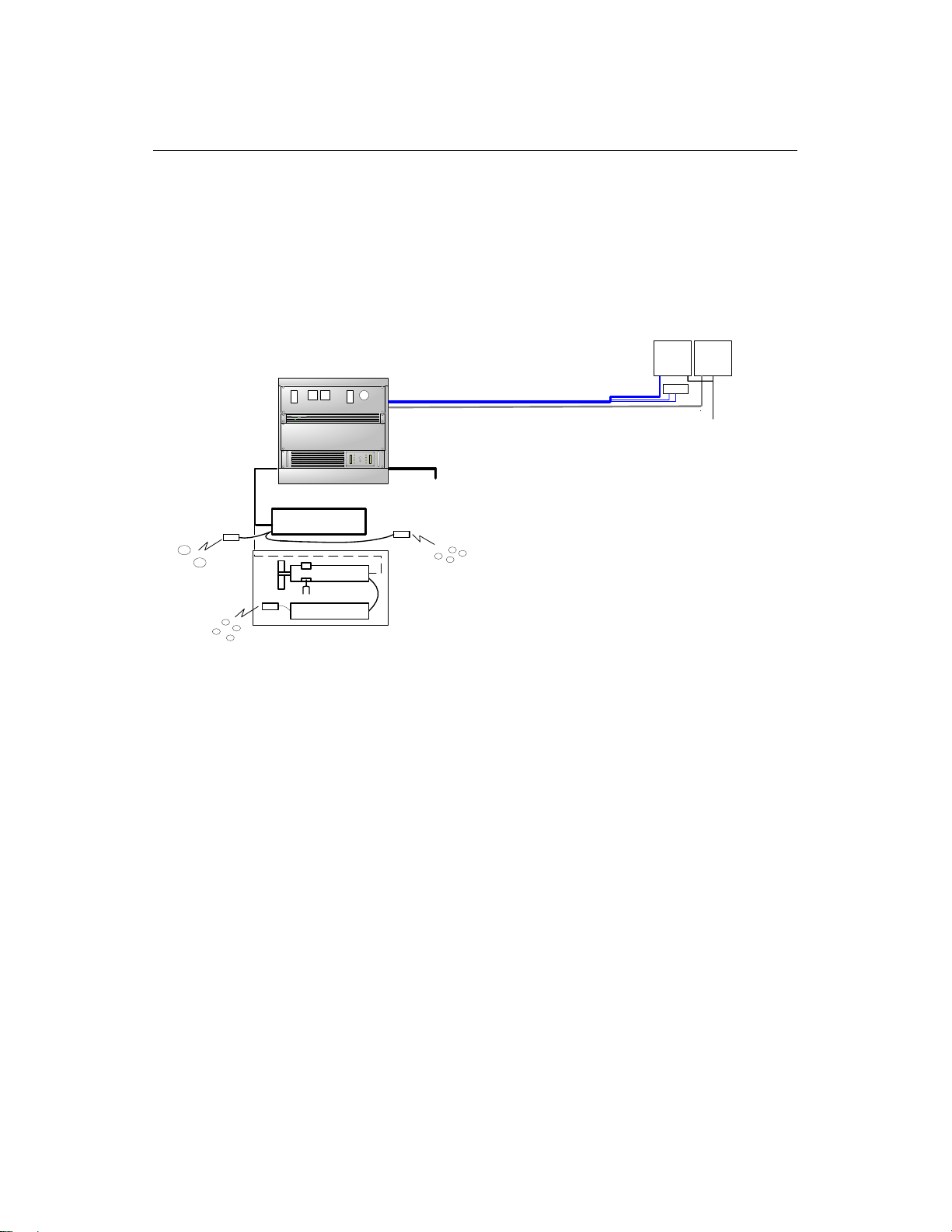

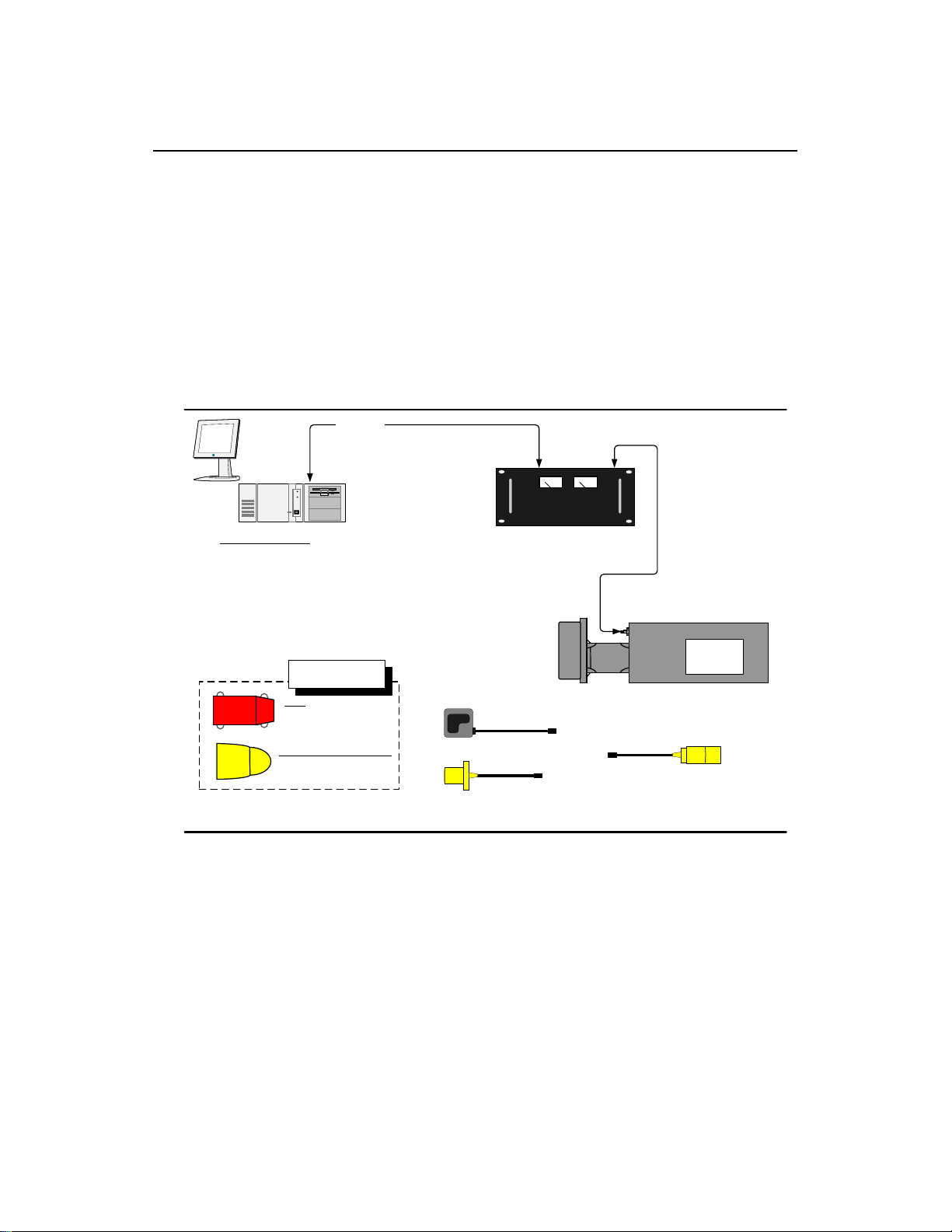

1.1.2 System Configuration

FS 70 TRAWL Monitoring

Integrated System Configuration

LCD

LCD

Monitor

KB & M

120 or 230 AC Power

Monitor

Input

1

PI Door Sensors

Door Spread

Hydrophone

2

Catch Sensors

1

2

70kHz Only

Rack Integrated System Cabinet

9 U

3 U

1 U

SIMRAD Power/TTM

30m.VGA Extender Cable c/w K & M,

30m.VGA Extender Cable

3 U

2 U

120 or 230 AC Power

Input

FS 70 Head Trawl unit

or

TS15 S Head

FS 3300 Sensor

3

4

Catch Hydrophone

2

1

3

PI Catch Sensors

40kHz or 70kHz

4

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

System Standard Equipments

3 U, 19" Rack Power/TTM c/w Front Test Cable Connection

1 U, 19" Rack Industrial Processing Unit

3 U, Expansion Space for Future Development

2 U, 19" Rack APC, 1500 UPS

Rack Cabinet Description

Cabinet, W 23.6", (600mm), D 23.6", (600mm) H 19.8", (502mm)

Dual 6" Ventilation Fan & Bracket

30m VGA Video Extender Cable c/w KB & Mouse

30m VGA Video extender Cable for Dual Monitor

Slide Rails

Glass Door

All Mounting Hardware Included

Refer to your price list for additional information

1.1.3 Display Monitor

The display monitor for the FS 70 can be a VGA ruggedized LCD monitor but any

commercially available VGA monitor may be used. This is in order to have the full

benefit of high resolution provided by the video Multi-Display adapter available with

the FS Processors.

1.1.4 Processor Unit

The FS 70 19” Rack mounted Industrial Processing unit is the control unit for the

system. The installed FS 70 system software provides a mechanism for the sonar

head detection, setup and operation. It is operated through the Main Control panel to

enable the Sonar selection, tilt, range, gain, cursor, and by moving the mouse

pointer over the toolbar will allow the operator to perform certain operations with a

simple Right or Left mouse click.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 13

FS 70 Operators Manual 974-24007001/3.0

System Familiarization Page 1.5

The sector heading and width are also controlled by a single mouse click used to set

the center of the area to be scanned and the width of the sector scan (up to 360°) in

the polar mode.

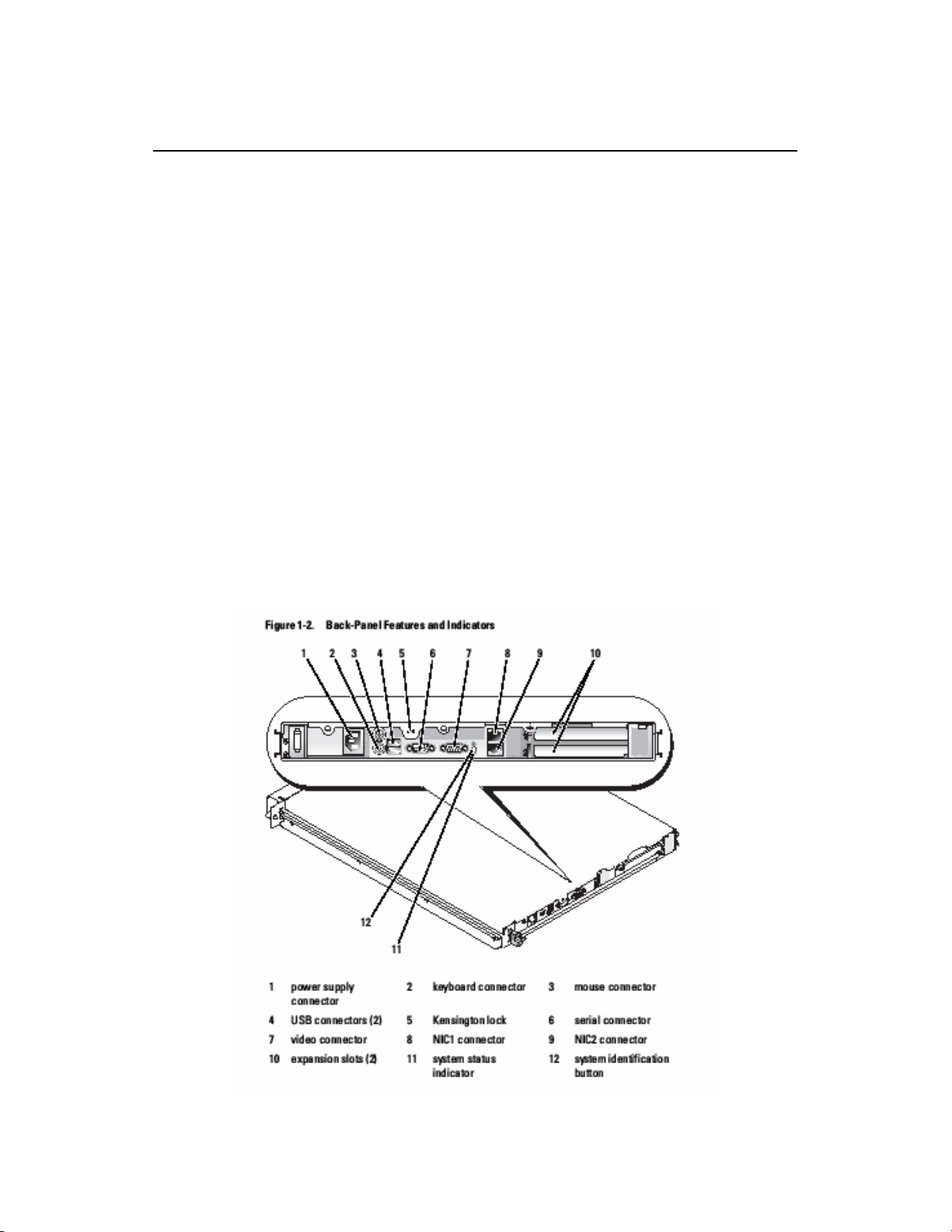

The rear panel of the Processing unit contains the connectors for AC power, Dual

Monitor port, one Serial port and several USB ports, Keyboard, Mouse, Printer, and

Network port. The Network port can be used to connect the remote workstation.

Note: A security key (or “dongle”) must be attached to a USB port to enable full

operation of the system.

1.1.5 Power /TTM Interface Module

The FS 19” Rack mounted Power/TTM interface Module unit provides the high

voltage required by the trawl sonar. The DC output voltage is combined with the

telemetry signals and supplied to the trawl sonar.

The power voltage supplied to the sonar head and current are monitored by voltage

and current meters. A selector switch located below the voltage meter can be used

to select the output voltage of the power supply required for the appropriate system

configuration. Also, a separate on/off switch is located in the front panel. Note: The

main on/off switch and fuse are located on the rear panel of the TTM Module.

The Power/TTM Interface provides translation between the Processing Unit Serial or

USB port and the sonar telemetry communication protocol.

A Test Cable connector and selection switch between the trawl cable and Test cable

are provided in the front panel, eliminating having to disconnect the 3

rd

wire cable

from the rear of the TTM.

1.1.6 Deployment Housing Unit

The trawl deployment housing unit is made from polyurethane and designed for the

harshest of environments yet it is easy to handle. The FS 70 trawl unit sits within the

deployment housing unit and contains the vertical sonar head, catch hydrophone

receiver, the optional forward hydrophone, the echo sounder 200kHz transducer and

depth and temperature sensors. The mounting kit supplied contains the strain relief

cable gland and other hardware used to attach the trawl cable to the trawl headrope.

The trawl cable is connected to the trawl sonar by a watertight connector and a

locking sleeve. Commands are sent down the cable from the processors to operate

the sonar. The sonar image and sensor data are sent up the cable to the processor

and displayed on the appropriate monitor.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 14

974-24007001/3.0 FS 70 Operators Manual

Page 1.6 System Familiarization

1.1.7 Jointing Tool

Jointing tools and materials are required for splicing the trawl cable and attaching the

trawl “2 pin pigtail” connector to the trawl sonar. We recommend using 3M 72-N1

jointing tool kits that can be purchase locally and especially designed for coaxial

cable with a breaking point of 1500kg. The jointing kit will allow you to make 1 cable

joint.

Note: Proper joining and crimping sleeve will be required based on the type of 3

rd

wire you are using.

1.1.8 Catch Sensors

The catch sensor “eggs” are wireless sensors mounted on the cod-end of the trawl

net to detect the stretch of the net as it fills up with the catch. When sufficient stretch

of the net occurs, the catch sensor sends an acoustic signal to the trawl sonar

through the catch receiver.

This information is then sent to the processor and displayed on the monitor.

The sensors are of a rugged construction in order to withstand the strain from

winches and the power block. The operator can use up to six sensors (with the

40kHz system) simultaneously. The catch sensors are equipped with rechargeable

batteries.

1.1.9 PI Sensors Option

The FS 70 provides full integration with the PI System, Door Spread, Bottom

Contact, Rip Sensor and Cod End Depth Sensor available from Simrad Horten AS.

1.1.10 Depth & Temperature NMEA Output

The FS 70 processing Unit can be configured to output NMEA 183 data information.

The integrated sensor module is included in the sonar head. The depth and

temperature outputs are transmitted to the processor and displayed on the monitor.

When interfaced to other Simrad echo sounders, the headrope depth information

appears on the sounder showing the location of the trawl in relation to the fish or

bottom returns.

1.1.11 Trawl Cable, Winch and Block

The trawl cable is chosen for maximum mechanical strength, durability and minimum

attenuation of the signals. Cables in common use are coaxial with breaking points of

1500kg and 6000kg.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 15

FS 70 Operators Manual 974-24007001/3.0

System Familiarization Page 1.7

Cable winches are delivered in different types and with different capacities; lowpressure hydraulic, high-pressure hydraulic and electrically driven. Choice of winch

is dependent on prevailing conditions; type and length of cable and available source

of power. Most types operate automatically - the cable is pulled out, kept tight during

towing, and hauled in together with the trawl. Control of the winch is done remotely

from the bridge.

Any commercially available pulley block may be used to properly align the cable onto

the winch. A snatch block has the advantage that it may be installed without having

to thread the cable through it. A unit with two movable steering arms (one on each

side of the pulley) is recommended to prevent the cable from coming off the pulley

and causing damage to the cable.

1.1.12 19” Rack Cabinet - 9U,

The Industrial Ventilated Rack Cabinet with a rugged black powder paint finish is an

ergonomic design with ventilated slots front and side. The pre-punched top allows

the installation of 2 fans. Cable accesses are available from the top or bottom.

The cabinet includes two pair of mounting rails, smoked glass door with full 180

degrees opening for easy access to the rack mounted equipment.

The overall dimensions are 19.8” (502mm) height, 23.6” (600mm) width, 24.0”

(600mm) depth.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 16

974-24007001/3.0 FS 70 Operators Manual

Page 1.8 System Familiarization

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 17

FS 70 Operators Manual 974-24007001/3.0

Theory of Operation Page 2.1

PART 2

THEORY OF OPERATION

2. THEORY OF OPERATION...............................................................................2.3

2.1 INTRODUCTION.......................................................................................2.3

2.1.1 Basic Principles......................................................................................2.3

2.1.2 Determining Target Position ..................................................................2.3

2.1.3 Forming an Image..................................................................................2.3

2.1.4 Key Feature Setting ...............................................................................2.4

2.1.4.1 AGC................................................................................................2.4

2.1.4.2 RCG................................................................................................2.4

2.1.4.3 RX Gain Response and Type.........................................................2.5

2.1.4.4 Pulse Length Control......................................................................2.5

2.1.4.5 Optimize Resolution........................................................................2.5

2.1.4.6 Maximize Range.............................................................................2.5

2.1.4.7 Peak Detection ...............................................................................2.6

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 18

974-24007001/3.0 FS 70 Operators Manual

Page 2.2 Theory of Operation

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 19

FS 70 Operators Manual 974-24007001/3.0

Theory of Operation Page 2.3

2. THEORY OF OPERATION

2.1 INTRODUCTION

This section explains the theory of operation of the Vertical and Sounder Scanning

Trawl Monitoring Sonar System.

2.1.1 Basic Principles

• Sound waves travel very efficiently through water.

• A sound pulse can be projected through water in a controlled direction with the

sonar transducer.

• An object in the path of the projected sound pulse will reflect some sound pulses

back toward the sonar transducer.

• The speed of the sound pulse projected through the water can be predicted for

given conditions.

2.1.2 Determining Target Position

The trawl scanning sonar processor measures the time from the start of the sound

pulse projected through water, to the reception of the sound pulse reflected back to

the sonar transducer. The measured time is then converted to distance by using the

value of sound speed through water.

Since the sound pulse is projected in a known direction, the bearing of the reflected

object is also known. This makes it possible to locate the object with respect to the

sonar transducer; the information will be used to plot the position of the reflected

target on a video graphic display monitor.

2.1.3 Forming an Image

The sound pulse projected will be attenuated as it travels through the water from the

transducer to the target and back. Much of this attenuation is a predictable function

of the total time or the distance the sound pulse traveled through water. Increasing

the receiving gain with time can compensate for this decrease in the signal level.

This is done automatically in the sonar with a Time Varying Gain (TVG) circuit.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 20

974-24007001/3.0 FS 70 Operators Manual

Page 2.4 Theory of Operation

After the TVG correction, the absolute levels of the received signals will be

determined by the acoustic response of the reflecting target.

The sonar processor system repeatedly measures the TVG corrected target levels

by digitizing a sequence of samples after each sound pulse transmission. Each

sample is then plotted on the video display at the appropriate position according to

its range and bearing. The level of the target strength sample determines the color

used to plot each sample.

The process can be repeated with the transducer pointed in different directions,

forming an image of a large area of the bottom, (or the trawl net geometry) and

displaying it on the video screen.

In simple words, the TVG function controls the gain of the receiver so that a school

with a given size and density is presented with approximately the same strength on

the display, inside the regulated TVG range.

2.1.4 Key Feature Setting

The following paragraph will explain some of the key features of the FS 70 System.

2.1.4.1 AGC

Automatic Gain Control (AGC)

The AGC “Automatic Gain Control” algorithm increases the gain during low acoustic

returns and reduces the gain during strong acoustic returns. The speed with which

the gain is adjusted is determined by the setting of the “RX Gain Response”

2.1.4.2 RCG

Reverberation Controlled Gain (RCG)

The RCG filter senses the noise level (reverberation, propeller noise, etc.), and

adjusts the gain of each of the received beams in order to eliminate noise on the

display. The strength of the filter can be selected in the menu. With maximum

strength selected, the RCG will effectively reduce the bottom in shallow water, while

variation on the bottom will be displayed.

Note that scattered fish can be perceived as reverberation. The RCG filter must be

used with care if scattered schools are to be detected.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 21

FS 70 Operators Manual 974-24007001/3.0

Theory of Operation Page 2.5

2.1.4.3 RX Gain Response and Type

The setting of the “RX Gain Response” determines the response of the filter

algorithm as selected by the “RX Gain Type”. For the AGC, this setting determines

the speed by which the gain is adjusted. For the RCG, this setting determines the

influence of the previous ping average over the current ping. If set to Slow, the

overall average is given by the sum of 20% current and 80% of previous average. In

Medium this ratio is 50% to 50%, and in Fast the ratio is 80% to 20%.

2.1.4.4 Pulse Length Control

The FS 70 Trawl Sonar Heads are capable of changing the acoustic pulse length

that is transmitted. The surface processing unit sets the pulse length based on the

operating range of the sonar head. It is generally better to use a longer pulse as the

operating range increases. However, the actual value can be optimized to enhance

the details in the sonar image (Optimize Resolution) or to increase the target visibility

at long distance away from the sonar head (Maximum Range). The system will

automatically set the pulse length to match the range, unless manually adjusted by

the operator.

2.1.4.5 Optimize Resolution

The pulse length selection can be optimized to enhance the detail of the targets. It

has been experimentally determined that the pulse length corresponding to 40% of

the sample period can increase the image resolution and details for targets that are

generally larger than a few samples. This pulse length increases linearly with

increasing operating range.

2.1.4.6 Maximize Range

The pulse length calculation can be optimized to increase the detection range of the

sonar head. Generally, the longer the pulse length, the more energy is transmitted

into the water which could then travel a longer distance and get reflected from the

targets that are further away from the sonar head. It has been determined that the

pulse length corresponding to 80% of the sample period can increase the detection

distance of the targets without a major drain on the sonar head power supply. This

pulse length increases linearly with increasing operating range.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 22

974-24007001/3.0 FS 70 Operators Manual

Page 2.6 Theory of Operation

2.1.4.7 Peak Detection

The Peak Detection feature is described as follows.

The older sonar heads were not capable of changing the acoustic pulse length. They

were generally operated at a pulse length of 100 Microseconds. This meant that at a

range greater than 50 meters, there would have been a good chance of not detecting

small targets. The reason for this is that the combination of small target size, short

pulse length and long sample period could result in the acoustic return from the

target falling between two samples and therefore not beings seen on the sonar

image.

To remedy this, it was decided to take additional samples and select the strongest

echo target for the sonar image display. This is generally referred to as Peak

Detection because we are detecting the peak value of signal in between two

samples. The user can select the number of additional samples that the system

takes in order to detect the peak value.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 23

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.1

PART 3

`FS 70 SYSTEM OPERATION

3. FS 70 SYSTEM OPERATION..........................................................................3.3

3.1 INTRODUCTION.......................................................................................3.3

3.2 CONTROL

3.2.1 Operating Control Panel Page ...............................................................3.5

3.2.2 Display Control Panel Page ...................................................................3.6

3.2.3 Setup Control Panel Page......................................................................3.7

3.2.4 Users Settings Control Panel Page........................................................3.8

3.2.5 Sensors Control Panel Page & Setup....................................................3.9

3.2.6 PI, 40kHz Channel Sensors Setup.......................................................3.10

3.2.7 PI, 40kHz Receiver Sensors Setup......................................................3.11

3.2.8 PI, 40kHz Sensors Activation Menu.....................................................3.12

3.2.9 PI, 70kHz Sensors Activation Menu.....................................................3.13

3.2.10 Advanced Panel Page......................................................................3.14

3.2.11 Advanced Operation TVG Mode ......................................................3.14

3.2.12 Display Rec Toolbar ......................................................................... 3.15

3.2.13 Record Selection..............................................................................3.15

3.3 DISPLAY

3.4 DEPTH

3.5 LANGUAGE.............................................................................................3.17

3.6 AUDIO

3.7 ACTIVATING

PANEL.....................................................................................3.4

TOOLS SELECTION.................................................................3.16

AND TEMPERATURE GRAPHS ................................................ 3.16

SET UP........................................................................................3.17

THE SONAR......................................................................3.18

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 24

974-24007001/3.0 FS 70 Operators Manual

Page 3.2 FS 70 System Operation

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 25

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.3

3. FS 70 SYSTEM OPERATION

3.1 INTRODUCTION

The FS 70 Sonar uses a control panel for the most frequently needed adjustments

and a software menu system for less frequently needed controls. This chapter

describes the menu system and explains the adjustments to the menu settings that

may be made to control the sonar operation

The menu system allows adjustments to several system parameters without

requiring a dedicated Control Panel for each item. Items that lead to dialog boxes

are shown in the “Advance Menu”. All other items are system parameters that may

be modified. As you move the pointer over the Control Panel, a simple help

message will pop up beside the pointer describing its function. To perform certain

operations, just left or right click the mouse over the desired item. Selected items

are highlighted.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 26

974-24007001/3.0 FS 70 Operators Manual

Page 3.4 FS 70 System Operation

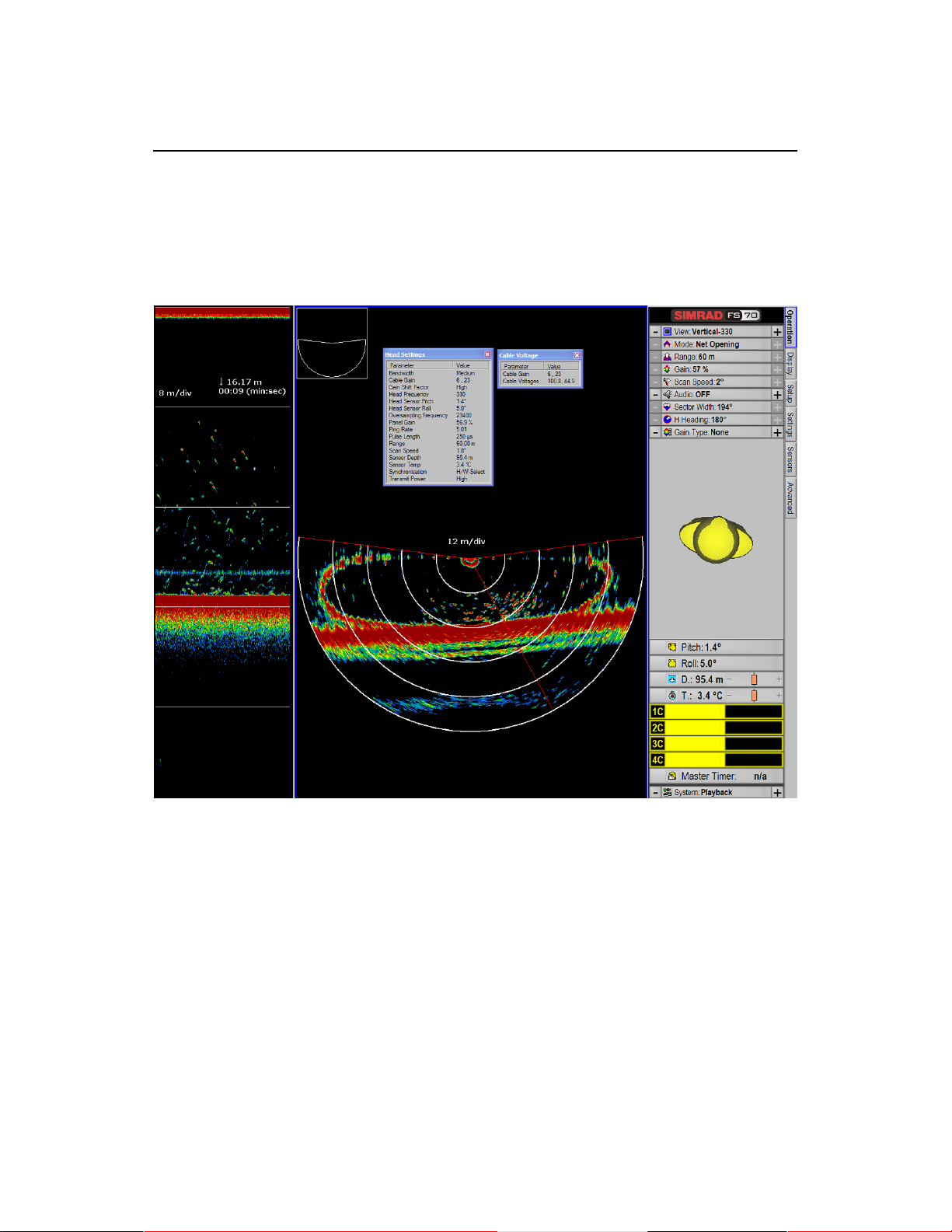

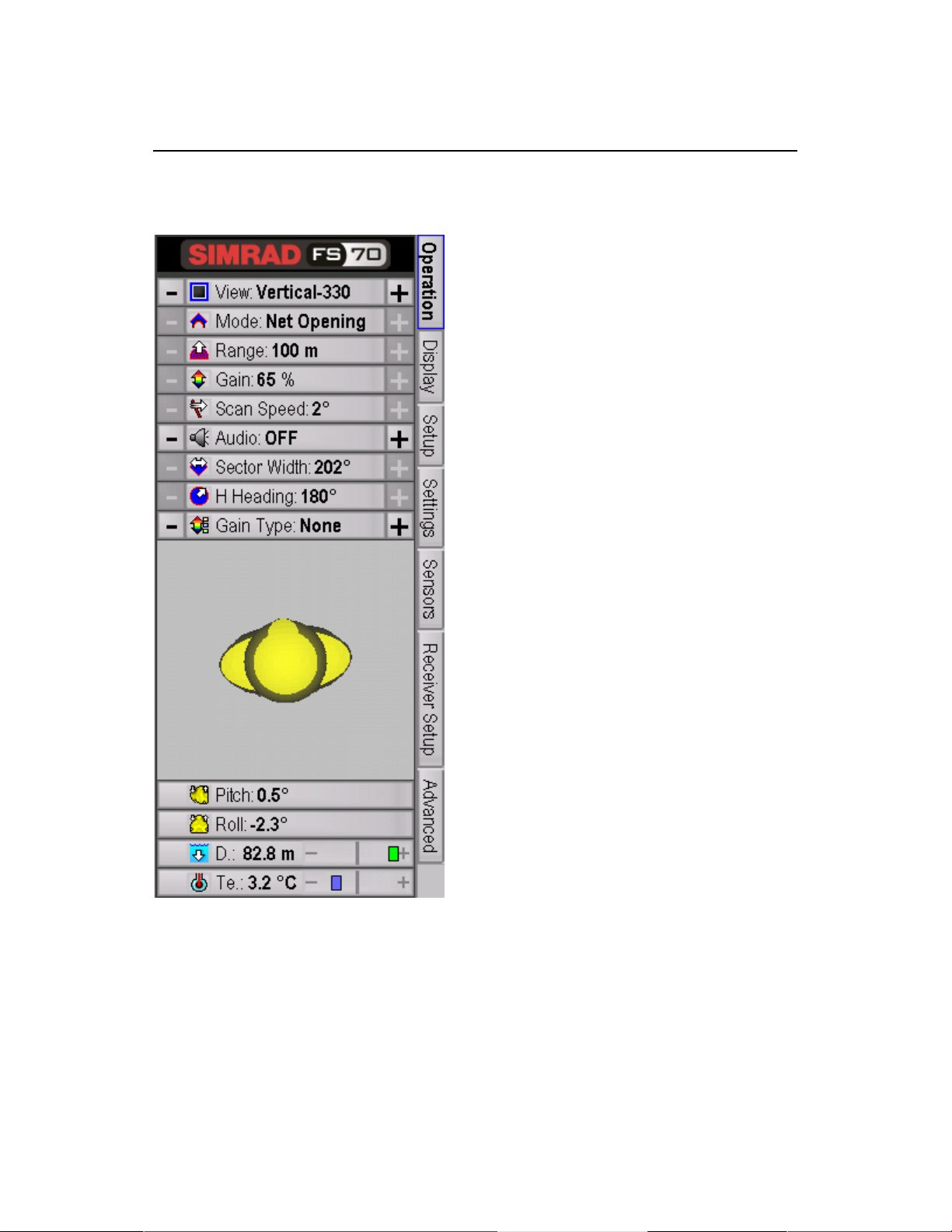

3.2 CONTROL PANEL

The Sonar Control Panel located above is divided into 7 Pages, Page 1 “Operation”,

Page 2 “Display”, Page 3 “Setup”, Page 4 “Settings”, Page 5 “Sensors Control”,

Page 6 & 9 “Sensors”, Page 4 & 8 “Receiver Setup” and Page 10 “Advanced”. Each

page allows you to change the system parameters. To change the value of a system

parameter, move the mouse up or down until the desired button is highlighted and

click the left mouse button or right mouse button to activate the new setting.

Note: The main control panel can be docked or auto-hidden.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 27

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.5

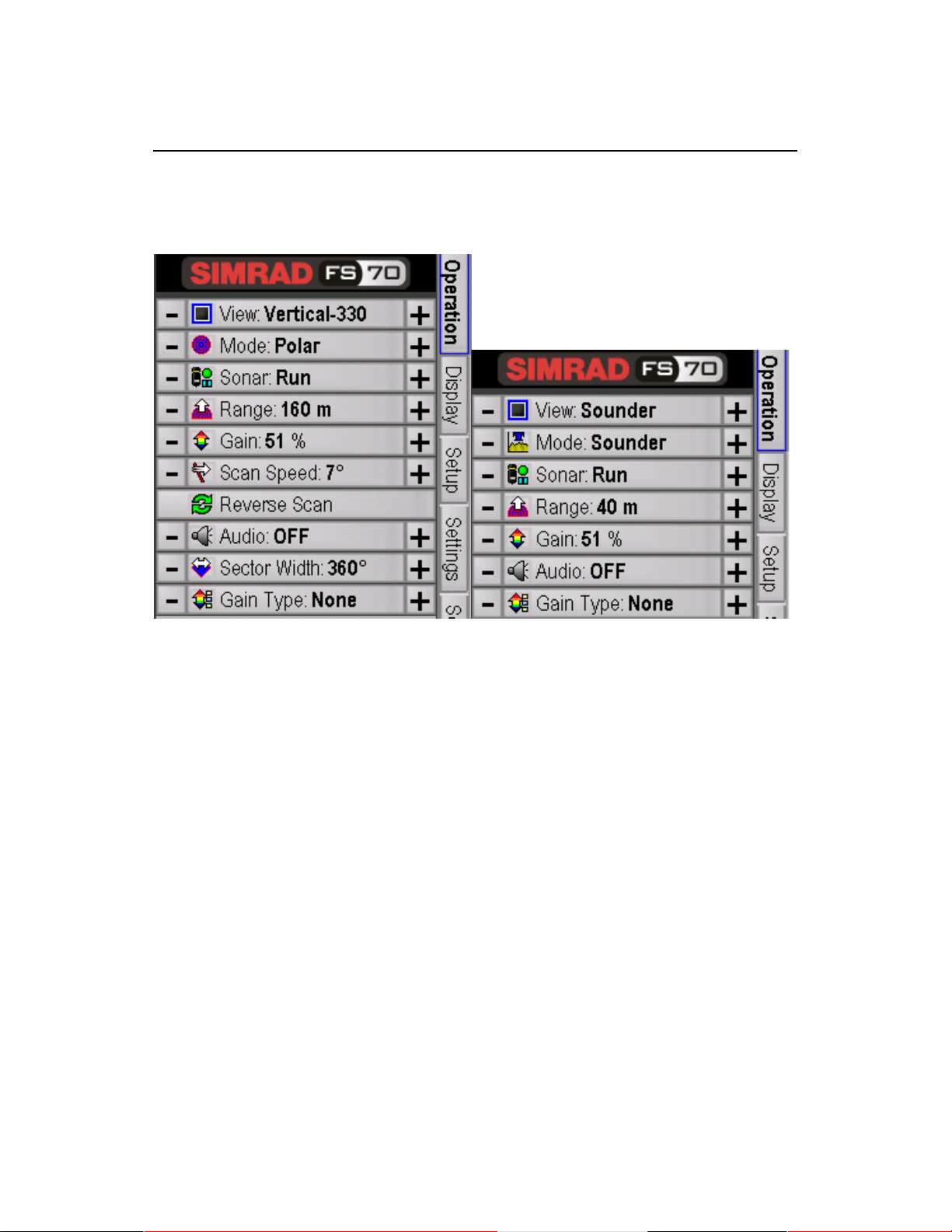

3.2.1 OPERATING CONTROL PANEL PAGE

The main “Operating” control panel allows you to select the sonar you want to

control; View Vertical or View Sounder as indicated above. Click on the appropriate

display window to activate the sonar you want to control, next position the mouse

cursor on the button you want to change, then, click the left mouse button or right

mouse button to change the settings.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 28

974-24007001/3.0 FS 70 Operators Manual

Page 3.6 FS 70 System Operation

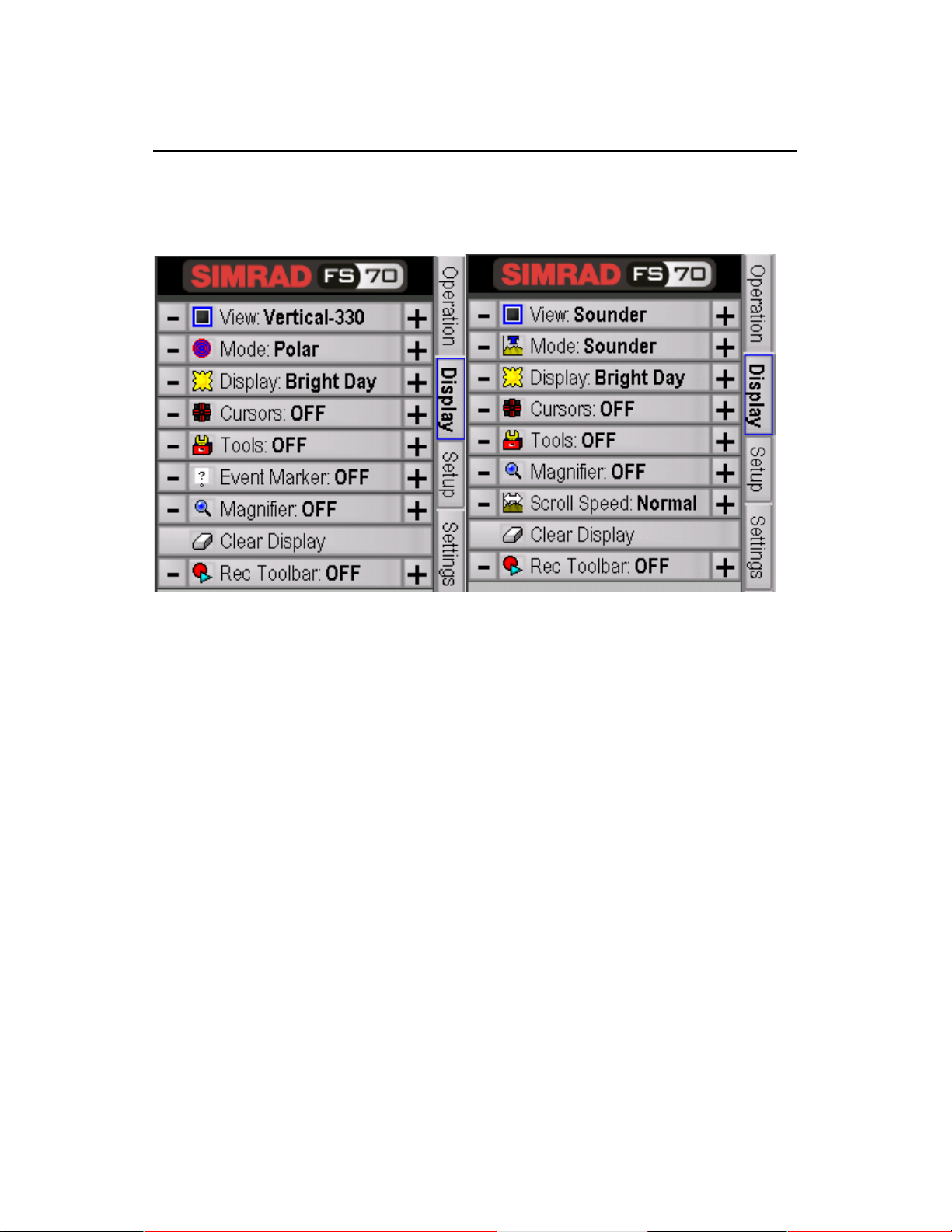

3.2.2 DISPLAY CONTROL PANEL PAGE

The main “Display” control panel allows you to select the sonar you want to control.

To change the value of the system parameter just left or right click the mouse over

the button you have selected, move the mouse up or down until the desired button is

highlighted and click the left mouse button or right mouse button to activate the new

setting.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 29

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.7

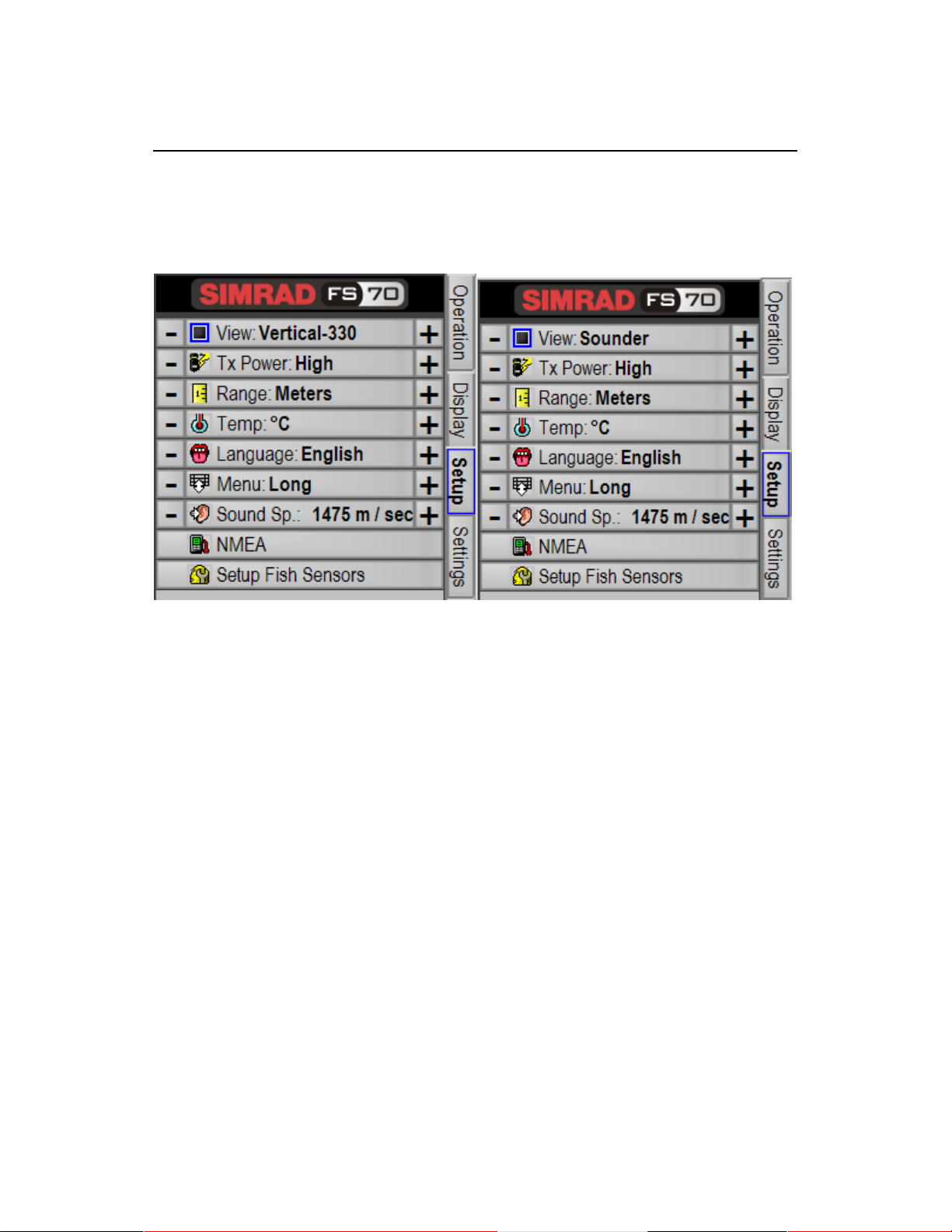

3.2.3 SETUP CONTROL PANEL PAGE

The main “Setup” control panel allows you to select the sonar you want to control. To

change the value of the system parameter just left or right click the mouse over the

button you have selected, move the mouse up or down until the desired button is

highlighted and click the left mouse button or right mouse button to activate the new

setting.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 30

974-24007001/3.0 FS 70 Operators Manual

Page 3.8 FS 70 System Operation

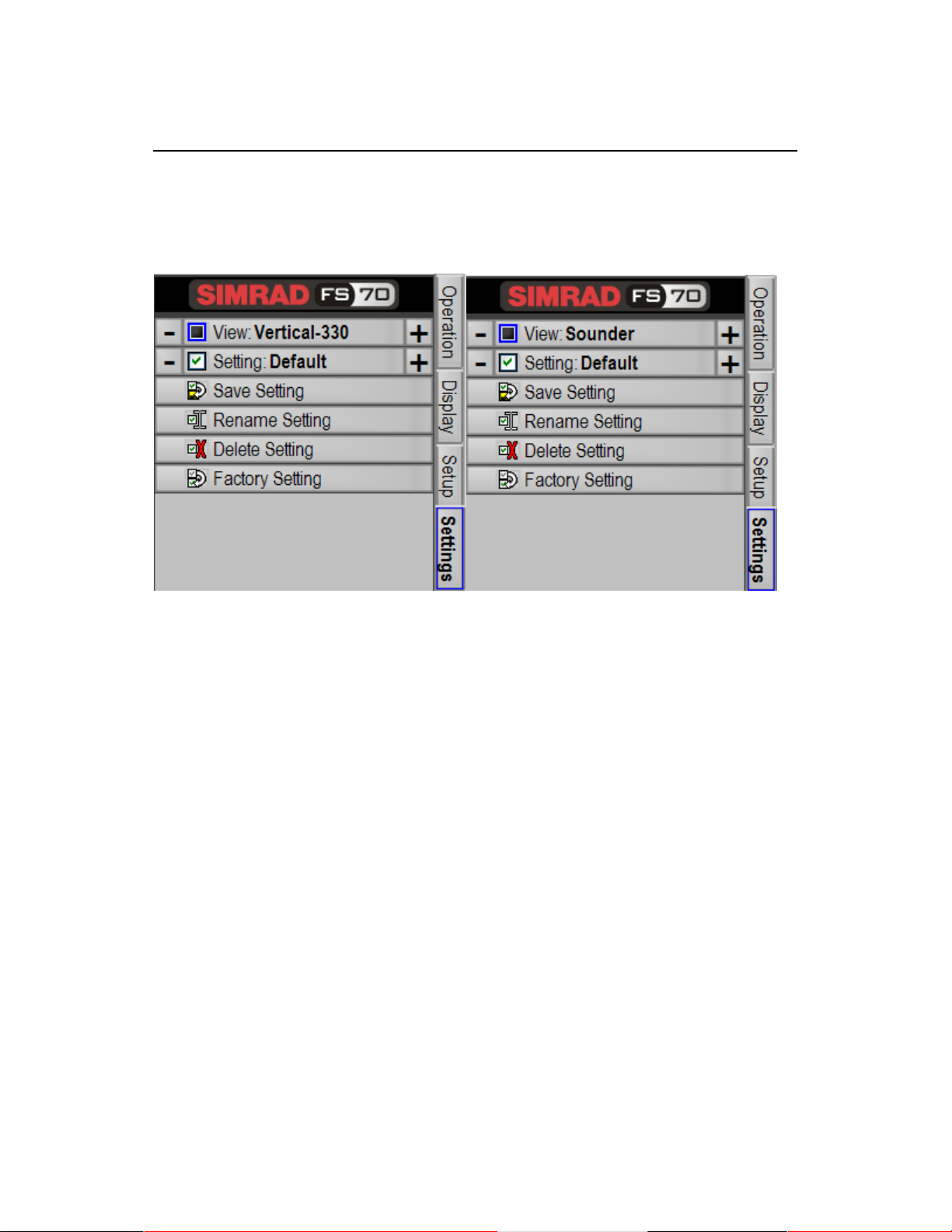

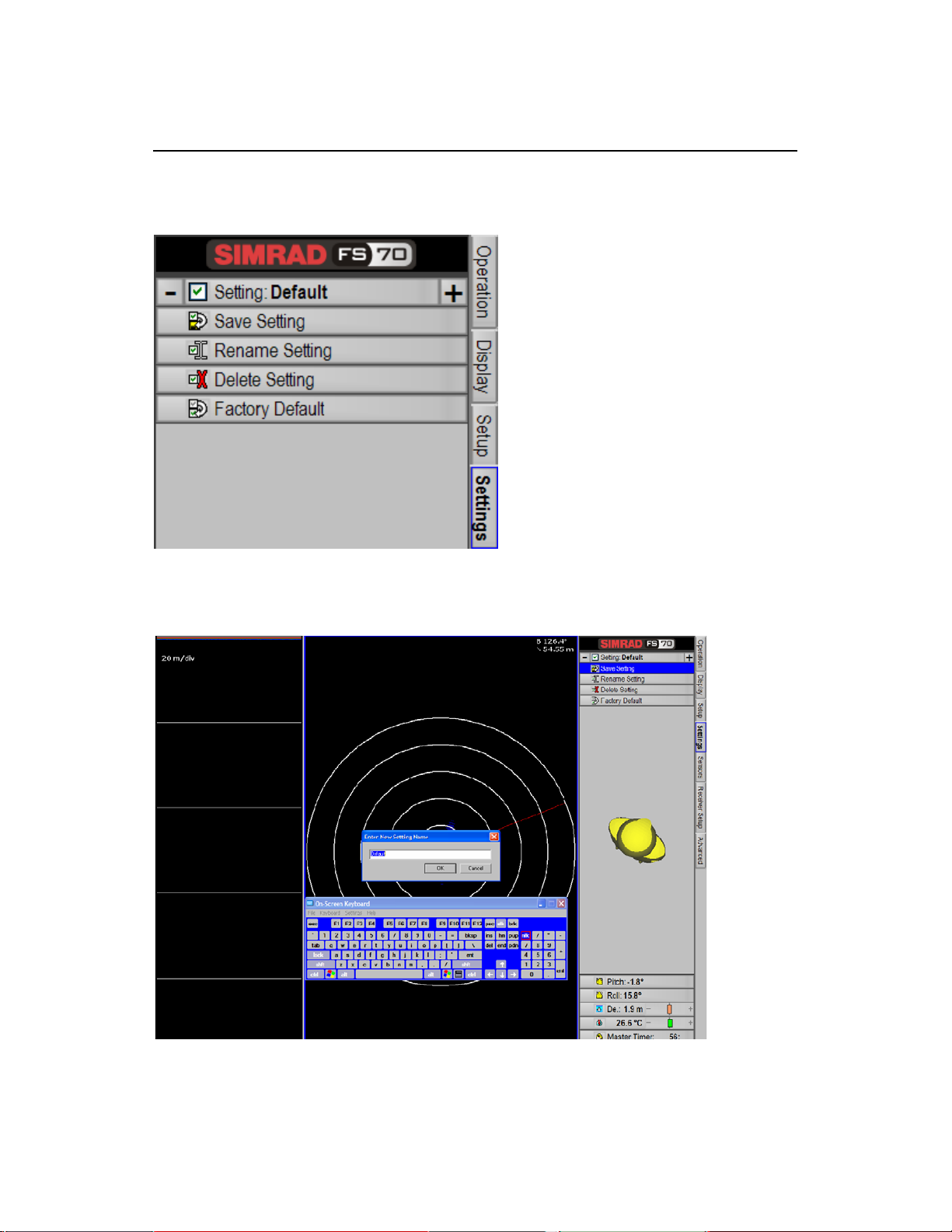

3.2.4 USERS SETTINGS CONTROL PANEL PAGE

The main “Users” control panel allows you to select the sonar you want to control. To

change the value of the system parameter, just left or right click the mouse over the

button you have selected, move the mouse up or down until the desired button is

highlighted and click the left mouse button or right mouse button to activate the new

setting.

Note: When you “Save Setting” you automatically save the setting for the vertical and

the sounder at the same time.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 31

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.9

3.2.5 SENSORS CONTROL PANEL PAGE & SETUP

The main “SENSORS” control panel allows you to select the sensors you want to

setup. To change the value of the system parameter just left or right click the mouse

over the button you have selected, move the mouse up or down until the desired

button is highlighted and click the left mouse button or right mouse button to activate

the new setting.

By placing the mouse cursor on the “Setup Fish Sensors” button and then left

clicking the mouse, the Fish Sensor Window will pop up as indicated on the following

page. Move the mouse cursor up or down to select the sensor you want to select

and then left click the mouse on the appropriate selection to activate the mode of

operation.

By placing the mouse cursor on the “Sensors Panel” button and then right clicking

the mouse a drop down menu will appear. Move the mouse cursor up or down to

select the location of the sensor panel you want to select. Next left click the mouse

on the appropriate button selection to activate the operation.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 32

974-24007001/3.0 FS 70 Operators Manual

Page 3.10 FS 70 System Operation

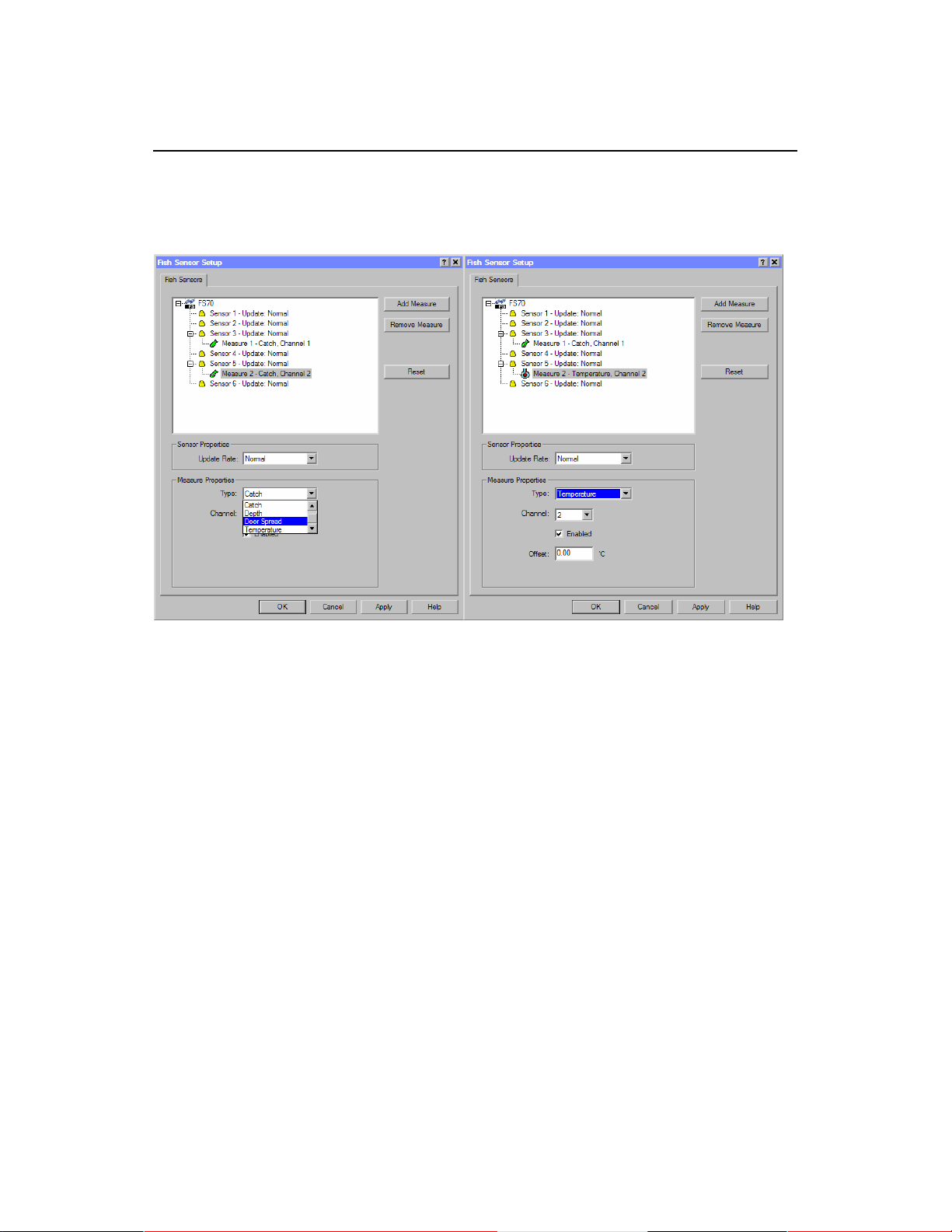

3.2.6 PI, 40KHZ CHANNEL SENSORS SETUP

The next step after the above operation, for example, will be to add a catch sensor.

Click on “sensor 5”; next select Door Spread or catch #2; next you would select the

channel of operation, in this case you would have selected #2.

If you are adding for example a temperature sensor you can setup an offset. see the

windows above for the example.

Note: For additional information on the Simrad PI 30 Setup, please refer to your PI

Instruction Manual.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 33

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.11

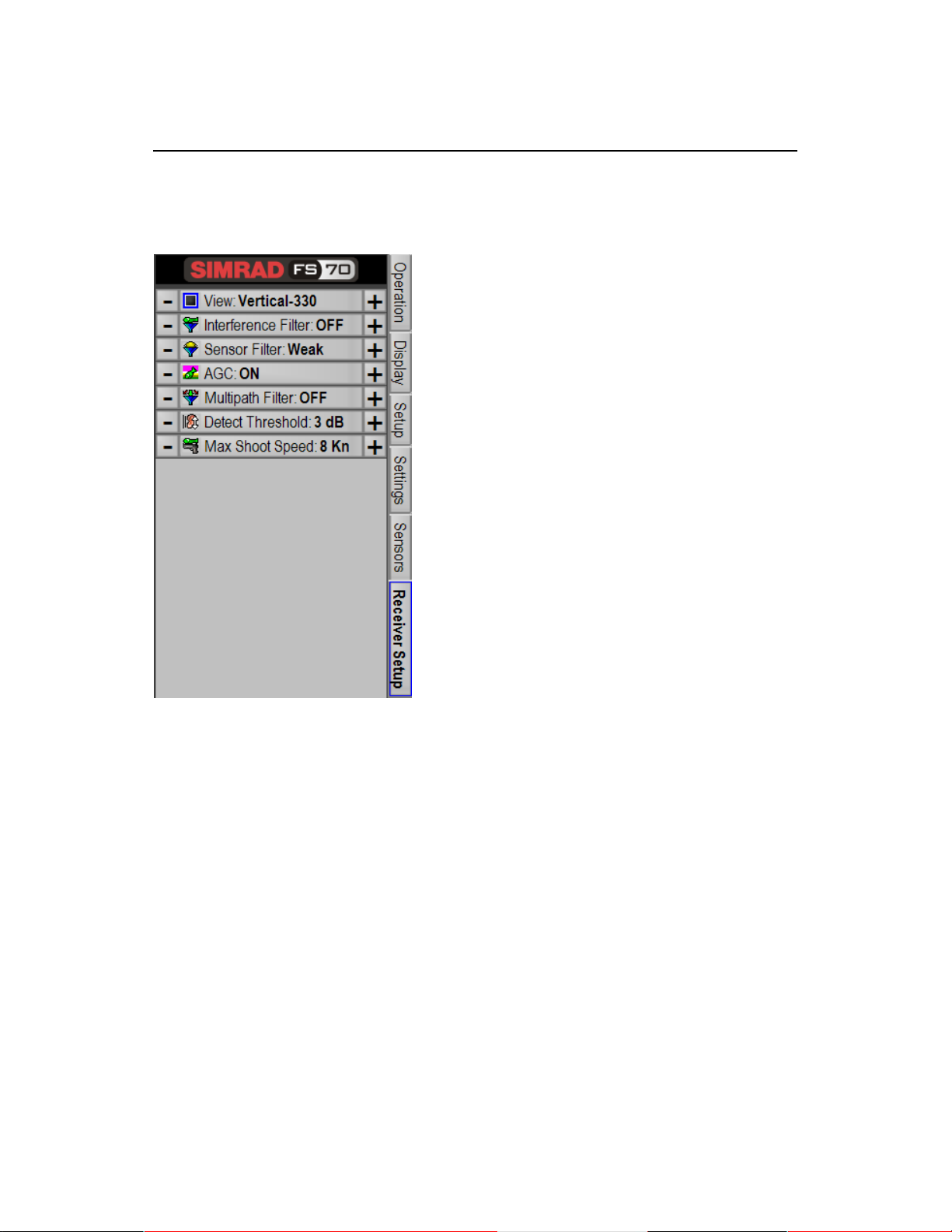

3.2.7 PI, 40KHZ RECEIVER SENSORS SETUP

The main “SENSORS RECEIVER SETUP” control panel allows you to select the

sensors you want to setup. To change the value of the system parameter just left or

right click the mouse over the button you have selected, move the mouse up or down

until the desired button is highlighted and click the left mouse button or right mouse

button to activate the new setting.

Note: For additional information on the Simrad PI Sensors Setup, please refer to

your PI Instruction Manual.

Note: The PI sensor setup menus are not available if you are using a 70kHz Catch

Sensors system.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 34

974-24007001/3.0 FS 70 Operators Manual

Page 3.12 FS 70 System Operation

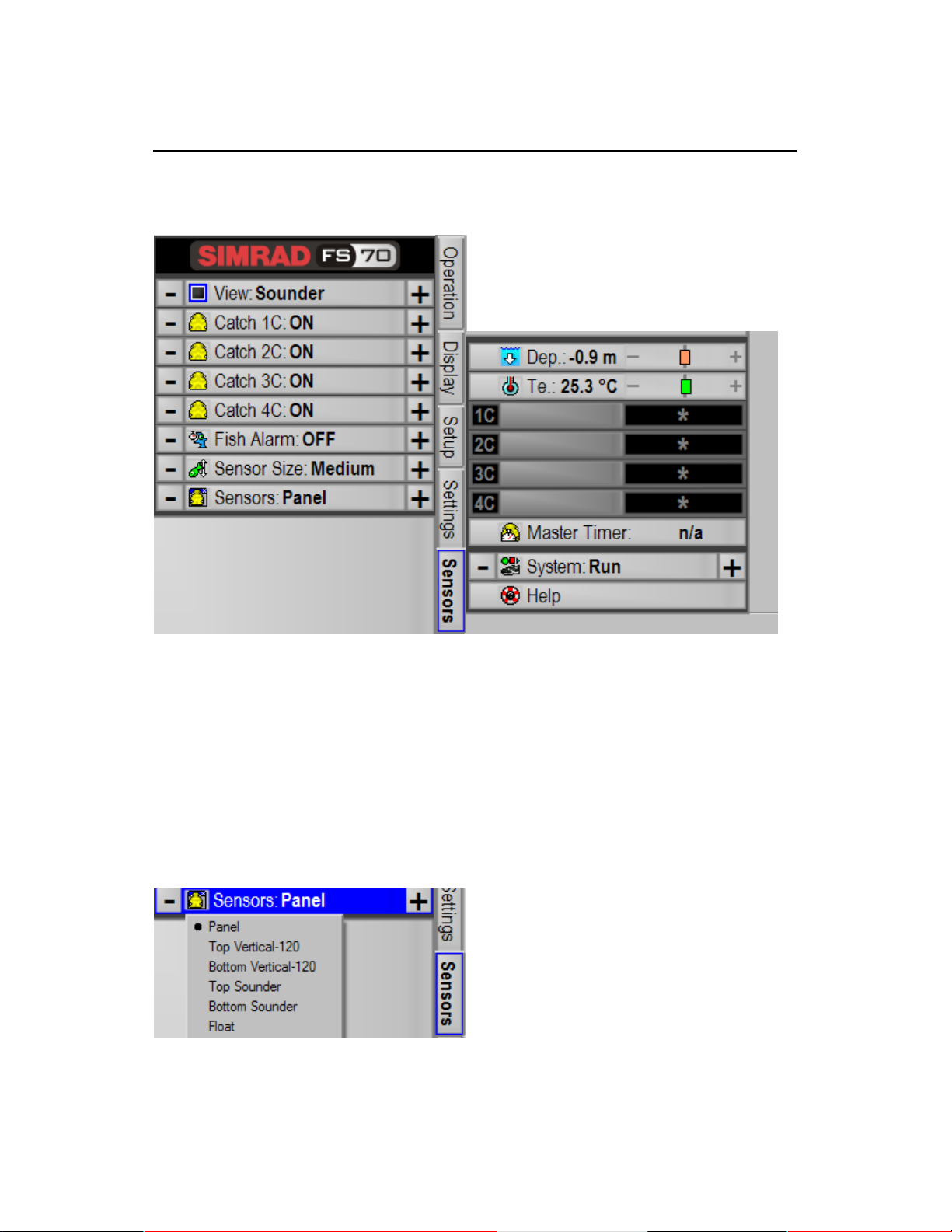

3.2.8 PI, 40KHZ SENSORS ACTIVATION MENU

The main “SENSORS ACTIVATION MENU” control panel allows you to select the

sensors you want to turn ON or OFF. To change the value of the system parameter

just left or right click the mouse over the button you have selected, move the mouse

up or down until the desired button is highlighted and click the left mouse button or

right mouse button to activate the new setting.

Note: The PI sensor setup menus are not available if you are using a 70kHz Catch

Sensors system. Refer to the following Windows for the 70kHz Catch Sensors

activation setup

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 35

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.13

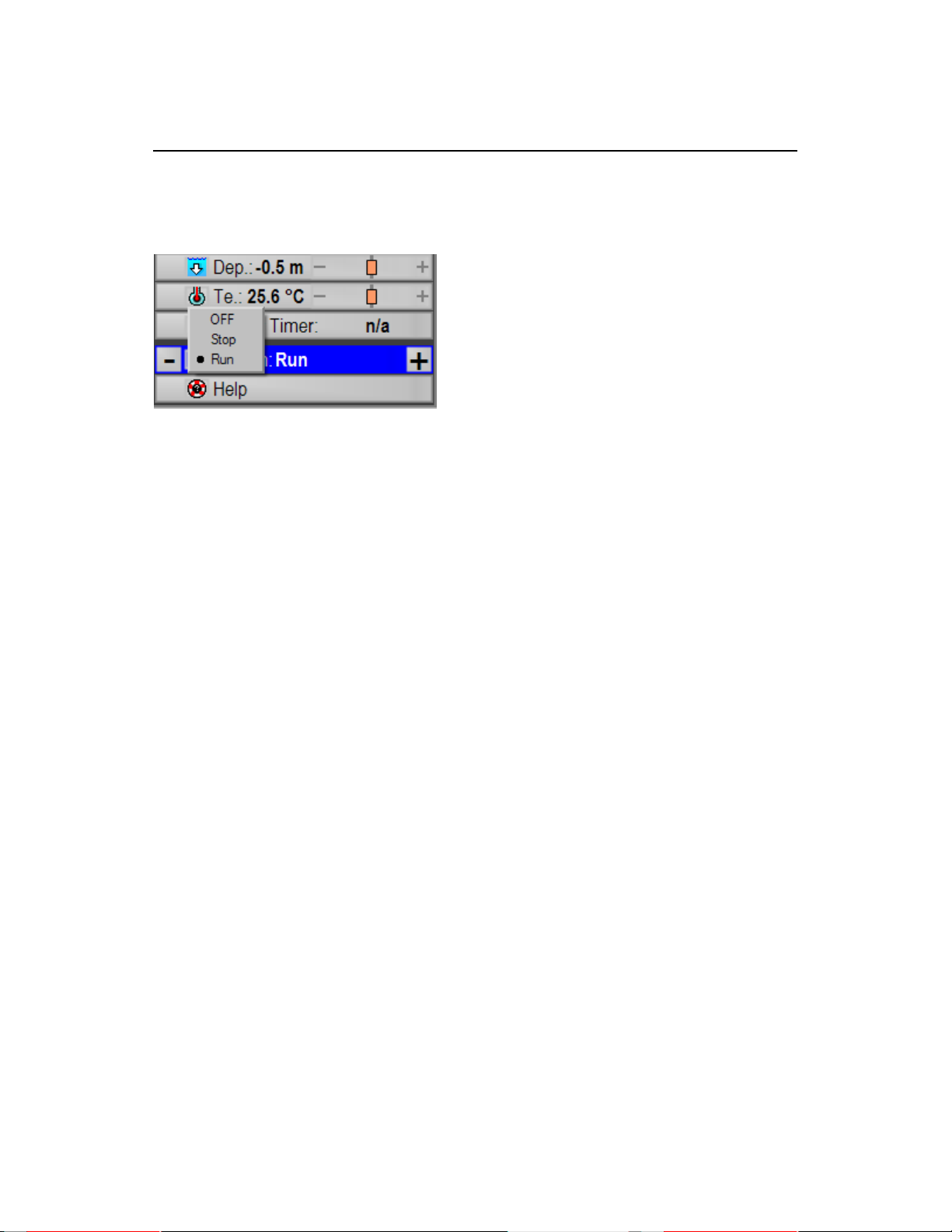

3.2.9 PI, 70KHZ SENSORS ACTIVATION MENU

The Catch Sensor windows will be displayed automatically when you left click on the

Catch Window button located on the Sensors Page. To activate or de-activate

individual Catch Sensors click on the appropriate button.

When you activate a Catch Sensor the sensor information is automatically displayed

in the Control Panel,

Note: Refer to the following windows. As indicated you may change the location of

the sensors panel.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 36

974-24007001/3.0 FS 70 Operators Manual

Page 3.14 FS 70 System Operation

3.2.10 ADVANCED PANEL PAGE

The main “Advanced” control panel allows you to select the sonar you want to

control. To change the value of the system parameter just left or right click the

mouse over the button you have selected, move the mouse up or down until the

desired button is highlighted and click the left mouse button or right mouse button to

activate the new setting.

3.2.11 ADVANCED OPERATION TVG MODE

Example of some of the controls located in the Advance panel

By placing the mouse cursor on the mode button and then right clicking the mouse a

drop down menu will appear. Move the mouse cursor up or down to select the TVG

mode of operation you want to select and then left click the mouse on the

appropriate TVG selection to activate the mode of operation.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 37

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.15

3.2.12 DISPLAY REC TOOLBAR

Place the mouse cursor on the Record “REC” Toolbar button, and then right click the

mouse to enable the Record Toolbar ON or OFF. The Toolbar will automatically popup on the left side of the screen. Move the mouse cursor up or down to select the

RECORD mode of operation you want then left click the mouse to activate the

recording.

3.2.13 RECORD SELECTION

When the RECORD mode is activated the following windows will appear. Click on

the “Select File” and type the name of the file you want to record. Next click OK.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 38

974-24007001/3.0 FS 70 Operators Manual

Page 3.16 FS 70 System Operation

3.3 DISPLAY Tools SELECTION

By placing the mouse cursor on the TOOLS button and then right clicking the mouse,

a drop down menu will appear. Move the mouse cursor up or down to select the

TOOL of operation you want to select. Next left click the mouse on the appropriate

TOOL selection to activate the operation.

3.4 DEPTH AND TEMPERATURE GRAPHS

To activate the Depth or the Temperature graphs you must right click the mouse on

the center of the sonar image. The following menu will pop-up. Move the mouse

pointer up or down and then left click the mouse button to display the appropriate

window

Note: Additional information from the above menu can also be displayed.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 39

FS 70 Operators Manual 974-24007001/3.0

FS 70 System Operation Page 3.17

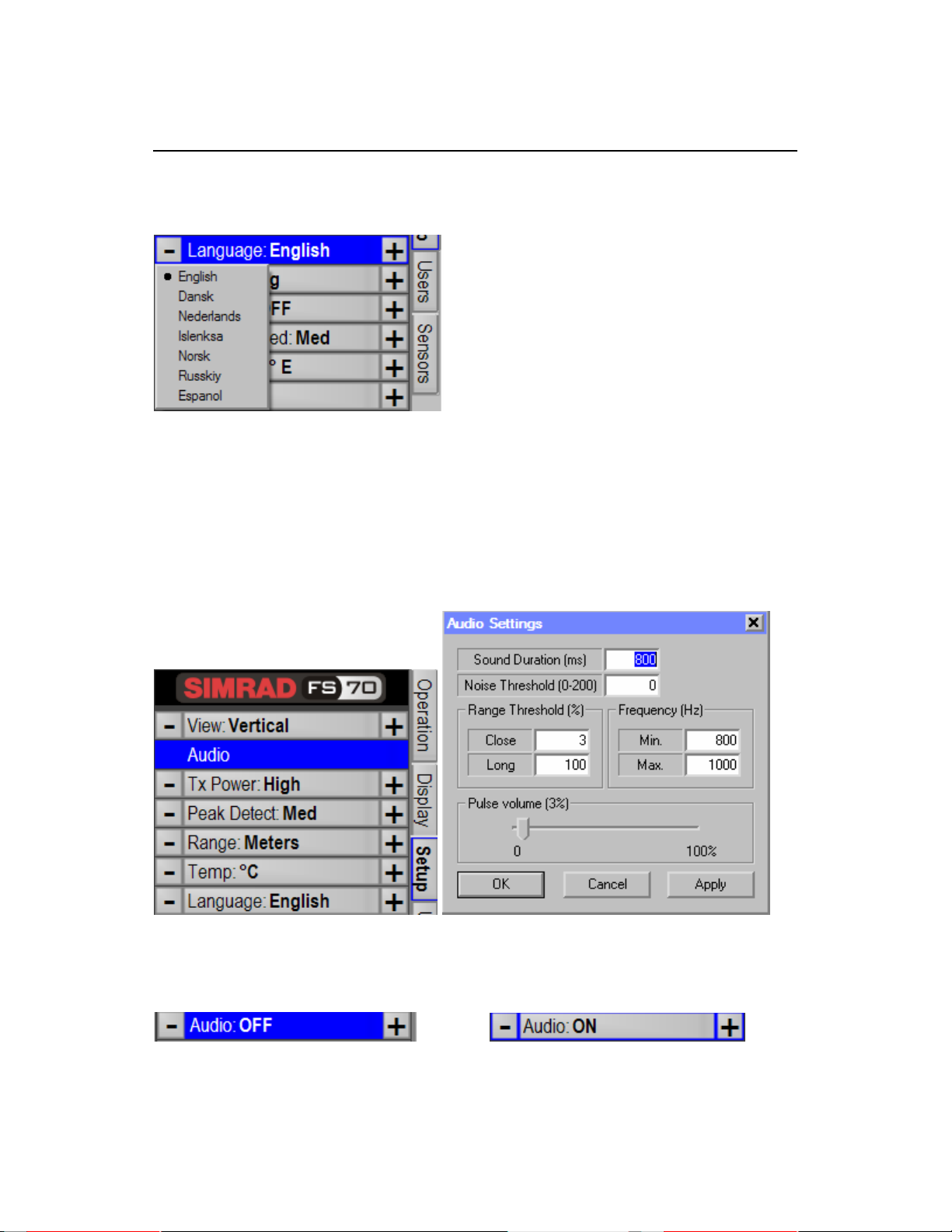

3.5 LANGUAGE

By placing the mouse cursor on the Language button and then right clicking the

mouse a drop down menu will appear. Move the mouse cursor up or down to select

the language of operation you want to select and then left click the mouse on the

appropriate selection to activate the language of operation.

3.6 AUDIO SET UP

Right Click on the “AUDIO” button located in the SETUP Page to open the Audio

Settings dialog window. After you have completed your changes. Click “Apply”. If

you are satisfied with your selection, Click “OK”

Next, go to the “Operation Page” to turn OFF or ON the Audio.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 40

974-24007001/3.0 FS 70 Operators Manual

Page 3.18 FS 70 System Operation

3.7 ACTIVATING THE SONAR

When you click on the Run button the system will initialize the serial port. and start

the calibration of each sonar head connected to the TTM module. When you click the

Stop button you will automatically disconnect the sonar heads from the system.

Note: If you only want to “PAUSE” the sonar image, just right click the mouse on the

Sonar “Run/PAUSE” Button located on the Operation Page. Left click the mouse to

“RUN” the system.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 41

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.1

PART 4

FS 70 INSTALLATION,

SYSTEM SET-UP AND TEST

4. FS 70 INSTALLATION, SYSTEM SET-UP AND TEST...................................4.3

4.1 INSTALLATION PROCEDURE.....................................................................4.3

4.2 SURFACE UNIT ELECTRONICS INSTALLATION.......................................4.3

4.2.1 Mounting of Units ...................................................................................4.3

4.2.2 Power Considerations............................................................................ 4.4

4.2.3 Connecting a Display Unit...................................................................... 4.4

4.2.4 Connecting the TTM Module..................................................................4.5

4.2.5 Selecting AC Input Supply Voltage ........................................................4.5

4.2.6 Connecting the Processing Unit............................................................. 4.6

4.2.7 Connecting an Echo Sounder ................................................................ 4.7

4.2.8 FS 70 Heading Sensor Installation Procedure.......................................4.7

4.2.9 Selecting the Trawl Output Voltage........................................................4.8

4.2.10 Connection to Cable Winch/Slip-Rings............................................... 4.9

4.3 ASSEMBLING OF TRAWL UNIT..................................................................4.9

4.3.1 FS 70 Configuration ............................................................................... 4.9

4.4 SYSTEM SET-UP AND TESTING USING TEST CABLE...........................4.10

4.4.1 Start Up................................................................................................ 4.10

4.4.2 Power-Up Configuration.......................................................................4.10

4.4.3 FS 70 Start-up Procedure ....................................................................4.11

4.4.4 FS 70 RUN UP Procedure ...................................................................4.14

4.4.5 Advanced Menu Display Settings ........................................................4.15

4.4.6 Control Setting ..................................................................................... 4.15

4.4.7 Head Sensors Setting .......................................................................... 4.17

4.4.8 FS 70 Head Setting.............................................................................. 4.18

4.4.9 Transmit Setting................................................................................... 4.19

4.4.10 TVG Page Setting............................................................................. 4.20

4.4.11 Info....................................................................................................4.21

4.4.12 Sensors Page................................................................................... 4.22

4.4.13 Auxiliary Transducer (Net Sounder) ................................................. 4.23

4.5 SAVE USER SETTING ...............................................................................4.24

4.5.1 Add User Setting..................................................................................4.25

4.5.2 Final System Test ................................................................................ 4.26

4.5.3 Completing the Trawl Unit Assembly ...................................................4.26

4.5.4 Mounting CATCH SENSORS ..............................................................4.27

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 42

974-24007001/3.0 FS 70 Operators Manual

Page 4.2 FS 70 Installation, System Set-Up and Test

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 43

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.3

4. FS 70 INSTALLATION, SYSTEM SET-UP AND TEST

4.1 INSTALLATION PROCEDURE

The installation of the FS 70 Trawl Monitoring System involves the following steps:

• Deciding on the locations in the wheel house for the surface units.

• Mounting the surface units and making the connections between the FS 70

Processor, the display unit, the FS Power Supply/TTM interface unit, and other

optional equipment being installed.

• Assembling the trawl unit.

• Running up the system on the test cable to verify proper installation, configuring

the control unit, and performing initial system tests.

• Installing the cable winch, snatch block and trawl cable, and connecting the

winch slip-rings to the control unit.

• Mounting the trawl unit to the headrope and completing the final system test.

• Mounting the catch sensors to the cod-end of the trawl and other PI sensors.

4.2 SURFACE UNIT ELECTRONICS INSTALLATION

4.2.1 Mounting of Units

If you have selected the FS Integrated Rack Mounted System, you can install the

cabinet up to 30 meters from the monitors. With a KVM extender option you can

install the cabinet up to 150 meters away from the monitors. If not, you will have to

follow the procedure indicated below.

The display unit should be located in the wheel house in a place that provides a good

view of the screen and avoids direct sunlight if possible. Depending on the monitor

that was selected the unit may be mounted on top or recessed into the bridge console.

Simrad supplied display units include the necessary mounting brackets.

If you have not selected the Rack Mounted System, the FS 70 Processing unit should

be mounted in close vicinity to the operator's position in the wheel house and near the

display unit. The unit may be mounted on top of the bridge console or recessed into a

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 44

974-24007001/3.0 FS 70 Operators Manual

Page 4.4 FS 70 Installation, System Set-Up and Test

cabinet. Note: You must have access to the ON/OFF switch and provide proper

ventilation to avoid overheating.

The Power Supply/TTM interface module supplied with the system may be mounted on

top of the bridge console or recessed and flush mounted into the bridge console.

Sufficient space should be left around the control unit for proper ventilation.

Optional equipment for interface to the control unit may be mounted in any convenient

location provided the user supplied interconnect cables are of sufficient length and the

required power is available.

Note:

The Processing Unit and the Power/TTM must be connected to a dedicated UPS.

4.2.2 Power Considerations

The display unit, generally, will require 120 VAC or 230 VAC. Depending on the

capabilities of the unit chosen, it may automatically detect the supply voltage or the

unit may have to be ordered for the correct voltage.

The FS 70 Processor will operate from either 120 VAC or 230 VAC. Voltage selection

must be selected, a voltage input selector switch is located at the rear of the unit. Note:

Some of the processors are equipped with auto detection voltage input. Failure to

select the proper Input voltage will damage the internal power supply.

The FS Power Supply/TTM module can be operated with either 120 VAC or 230 VAC.

Selection of the supply voltage is done by moving the voltage selector card located in

the power entry module at the rear panel. Details on selecting the proper voltage are

indicated on the voltage card. You must position the “indicator pin” location to the

desired voltage. The safety fuses must also be changed to the proper rating.

4.2.3 Connecting a Display Unit

Either an LCD VGA monitor or a Simrad LCD monitor may be connected to the FS

70 Processor. Depending on which type of monitor is used, the video output type

must be set accordingly.

An industry standard VGA monitor will connect directly to the miniature DB-15

connector located on the rear panel of the control unit.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 45

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.5

The FS 70 Processor Unit has a Dual NVIDIA Quadro Video interface card installed as

standard equipment. You must set up your display software as per your requirement. If

you have only one monitor, simply plug your monitor cable into the monitor connector

marked “Connector 1” on the adapter card. If you are using two monitors, you must

connect the 2

nd

monitor to the “Connector 2” on the adapter card.

Note!

The FS 70 Processor must be is turned “OFF” prior to connecting the video

monitors

A User Guide manual is provided with the system including a Recovery CD-ROM. With

this CD you can recover your system as delivered and run the diagnostics.

Note:

The Dual NVIDIA software is installed at the factory, you only have to set up your

monitor configuration as per Window’s XP or Window’s Server.

4.2.4 Connecting the TTM Module

The TTM interface module comes with the long line power supply incorporated in

one unit, thus making the installation easier.

The Front Panel comes with an ON/Off switch, trawl DC output voltage meter,

amperage meter and a four position trawl voltage rotary selection switch. The

possible selections are; “OFF”, “TEST”, “120VDC and 200VDC”. A “TEST/TRAWL”

selector switch and test cable connector is also provided in the front panel.

The Rear Panel of the TTM module comes with the AC 110/230 power input, master

ON/OFF switch and fuse located in the AC power entry module, an RS232 serial port

“A”, “B” and “C” including the 3

rd

wire trawl cable connector.

4.2.5 Selecting AC Input Supply Voltage

You must select and position the line voltage card located inside the power entry

module to the desired position.

To change the input line voltage, use a small blade screwdriver and pop the cover.

Pull the voltage selector card straight out from the housing, and place the indicator

pin to the selected voltage. Reinsert the card, reinstall the cover and verify that the

indicator shows the desired voltage. You must insure that the proper fuse rating is

installed, 2 Amp for 230Vac and 4 Amp for 110Vac. Spare fuses are supplied with

the TTM module.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 46

974-24007001/3.0 FS 70 Operators Manual

Page 4.6 FS 70 Installation, System Set-Up and Test

4.2.6 Connecting the Processing Unit

The FS 70 Processor unit comes with the FS 70 Trawl Sonar System operating

software installed by the factory.

Note!

All Device drivers and utilities are preloaded on your system and

provided on a Driver, Utilities and documentation CD-ROM. This

CD-ROM also includes tips for re-installing the operating system.

If you have not selected the Rack Integrated Mounted System, mount the FS

Processing unit with easily accessible power outlet and enough space for the display,

keyboard, mouse, TTM module, and any other accessories. The connectors are

shaped to go in one way only.

For additional information, please refer to the User’s Guide supplied with the system.

Before applying the power to the processing unit, if required

ensure that the proper AC input voltage has been selected.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 47

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.7

Connect the serial RS 232 Port “A” from the Power Supply/TTM module using the

RS232/USB dual channels telemetry converter part number 901-80010000 supplied

with the TTM module or connect the 2 meter RS232 crossover cable also supplied with

the system. (Note: The preference would be the USB converter). Connect the 2 meter

USB adaptor supplied cable to the RS232/USB telemetry converter and to a USB port

located at the rear of the processing unit.

Connecting the Dongle

Connect the security key “USB Dongle” to a USB port located at the rear of the

processing Unit.

Connecting a GPS

If you have to connect the GPS NMEA 183 output to the serial port at the rear of the

processing Unit. The Interconnect cable is not supplied.

The pin connections for your DGPS input/output PC/RS232 are as follows:

Pin number “2” 232 Rx, Pin number “3” 232 Tx, and Pin number “5” GND.

Note: If you require additional USB ports at the rear of the Processing Unit, you may

buy a USB HUB Locally.

4.2.7 Connecting an Echo Sounder

The FS 70 Processor Unit may be connected to an echo sounder for display of the

trawl unit depth on the sounder. This is made via the RS232 serial port on the rear

panel of the Processing Unit or an RS232/USB converter. The processor will output

the Temperature and the Depth from the trawl integrated sensor module in a NMEA

0183 format.

If port “B” is not available you will have to install an additional serial card or install an

RS232/USB external converter. The recommended type of serial card to install and

the installation procedure are provided in the Processing Unit Owner’s Manual

available on request.

4.2.8 FS 70 Heading Sensor Installation Procedure

If you need to connect a heading sensor output to the serial port at the rear of the

processing unit, you will have to install an additional serial card in the Processing Unit

or install an RS232/USB converter. The recommended type of serial card to install and

the installation procedure are provided in the Processing Unit Owner’s Manual

available on request.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 48

974-24007001/3.0 FS 70 Operators Manual

Page 4.8 FS 70 Installation, System Set-Up and Test

The pin connections for your heading sensor input/output PC/RS232 are as follows:

Pin number “2” 232 Rx, Pin number “3” 232 Tx, and Pin number “5” GND.

Your FS 70 Processing Unit comes equipped with a Network LAN interface adapter.

The LAN adapter provides two (2) ports. Both ports support 10Mbit/s and 100Mbit/s

operations and automatically detect which network type is being used. The RJ-45

plugs into your FS 70 workstation. LAN cables are not supplied with the system.

For additional information, please refer to the User’s Guide supplied with the system.

Warning!

Before applying the power to the processing unit, ensure that the

proper AC input voltage has been selected.

4.2.9 Selecting the Trawl Output Voltage

You must select the proper trawl voltage in accordance with the under water trawl

unit system you are using,

A- In the “OFF” position, no voltage is applied to the trawl cable.

B- In the “TEST” position, 60 VDC will be provided to the trawl cable. Note: The

“TEST” position is provided for the old FS 3300, 1000 meter sonar head. You

must connect the test cable supplied with the system to the front panel

connector of the TTM marked “TEST CABLE” and position the Trawl/Test

switch located on the front panel of the TTM module to “TEST”.

C- In the 120VDC position, 120 VDC will be provided to the trawl cable. The

120VDC is provided to run all FS3300, 1800 meter sonar head. The same

procedure should be used to test an FS3300 1800 meter head as indicated in

paragraph “B”

D- In the 200VDC position, 200VDC will be provided to the trawl cable. The

200VDC is provided to run all TS10, TS15, TS15S and the FS70 sonar

heads.

Note: To Test a TS10, TS15, TS15S and FS70 sonar head. Position the trawl

voltage switch to 120VDC, connect the test cable supplied with the system to

the front panel connector of the TTM marked “TEST CABLE”, and position

the Trawl/Test switch located on the front panel of the TTM module to

“TEST”.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 49

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.9

4.2.10 Connection to Cable Winch/Slip-Rings

The connection between the FS TTM Interface unit and the cable winch/slip-rings

should be made with an 18 GA., or heavier, shielded twisted pair cable. The

connection to the control unit is made using the 3-pin MS connector supplied in the

TTM module accessory kit. To minimize noise interference on the cable, the shield

of the cable should be attached to the connector.

Note!

The shield of the cable between the FS TTM module and the slip-

rings should be connected at the TTM module, but NOT at the

slip-rings.

4.3 ASSEMBLING OF TRAWL UNIT

Assembling the trawl unit for the first time should be conducted in the wheel house

where the surface unit electronics have been mounted. This will facilitate testing the

trawl unit using the test cable.

Note!

WARNING

Make sure you have selected the trawl voltage for the appropriate sonar head

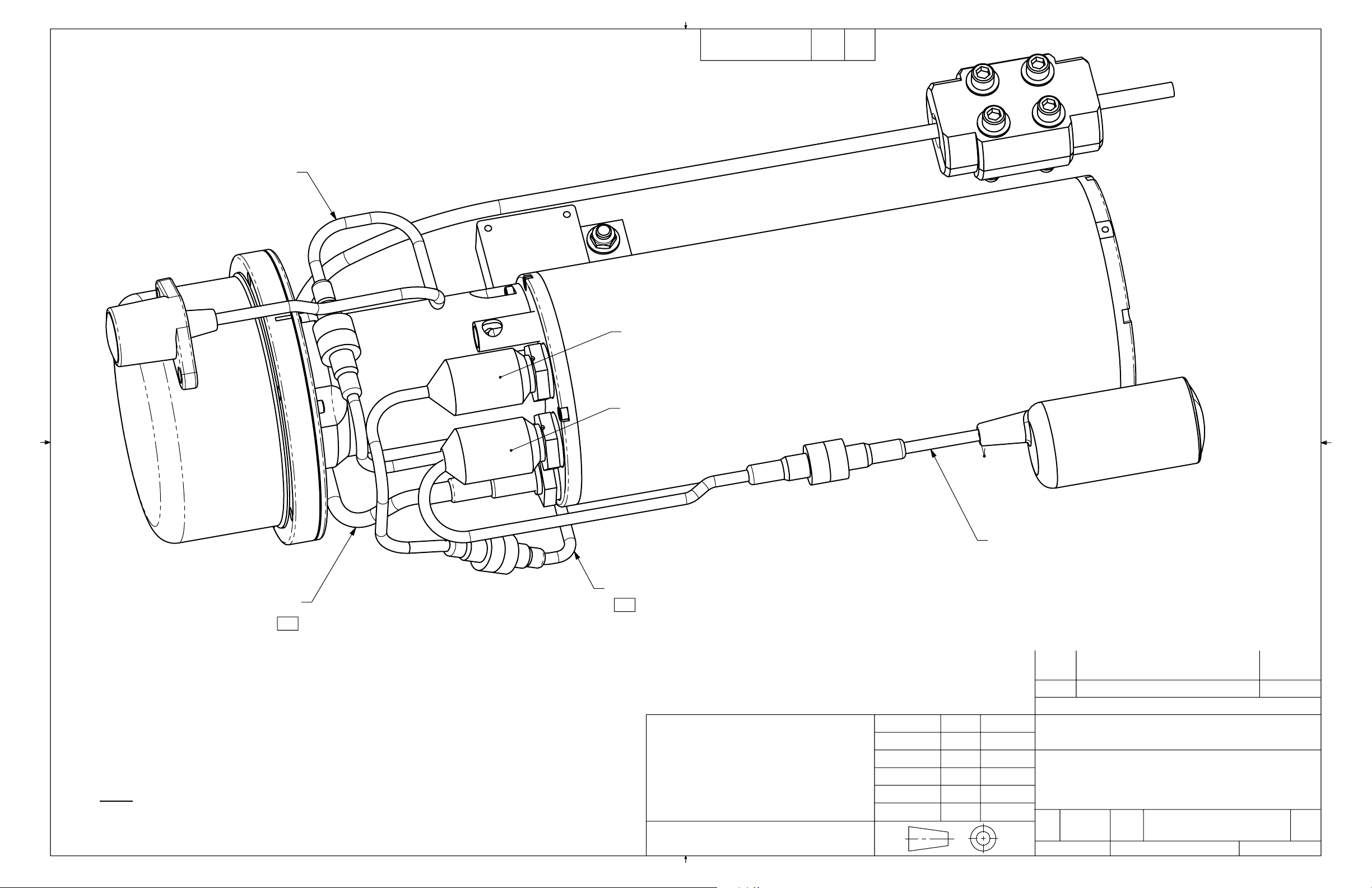

4.3.1 FS 70 Configuration

The FS 70 trawl configurations all consist of an FS 70, 120kHz or 330kHz vertical

sonar head with a 200kHz echo sounder, an FS 70 sensor module is integrated in

the trawl sonar head. The FS 70 polyurethane housing includes mounting and

assembling hardware and a strain relief. The trawl unit also contains a catch receiver

unit and the echo sounder transducer. Assembly of the unit involves correctly

locating the sonar head, attaching the strain relief to the trawl cable, proper routing

and connection of the cable to the sonar head and bolting the polyurethane housing

together. This section describes the connection and location of the sonar head, the

sensor module and catch receive transducer. Final assembly is illustrated in Part 6

“Drawings”.

A locating block located at the end of the housing or a guide bracket is used to prevent

the sonar head from rotating. Only one guide block is required and it can be placed

into the positioning hole of the bottom half of the trawl unit housing. As shown in the

assembly drawing in Chapter 6,

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 50

974-24007001/3.0 FS 70 Operators Manual

Page 4.10 FS 70 Installation, System Set-Up and Test

Note!

Incorrect placement of the sonar head, may result in movement

of the sonar head that could damage the transducer and/or drive

shaft and result in water damage to the entire unit.

Note!

Dow Corning #55 grease must be applied to all mating surfaces

of underwater connectors to insure proper sealing. Sufficient

grease should be applied so that excess squeezes out with any

air when the connectors are mated. RTV or any other sealant

must NOT be used, and when tightening the locking sleeves, do

NOT use a wrench or pliers! See chapter 5, "Troubleshooting and

Maintenance", for proper connector maintenance.

4.4 SYSTEM SET-UP AND TESTING USING TEST CABLE

Initial power-up, set-up and test of the system should be made with the trawl unit in

the wheel house connected to the PWR/TTM module using the supplied test cable.

The 3-pin MS connector of the test cable is attached to the connector labeled “TEST

CABLE” located on the front panel of the PWR/TTM unit. The other end of the test

cable is plugged into the 2-pin connector on the sonar head of the trawl unit.

4.4.1 Start Up

1. Check that the system has been properly installed and that all connections have

been made to the PWR/TTM and the Processing Unit.

2. First turn on the PWR/TTM interface module. The voltmeter should display

approximately 120 volts if on “120VDC” setting, 200 volts if on the “200VDC”

setting and approximately 60 volts if on “TEST” setting. The current meter

should read approximately 0.15 – 0.7 amps if everything is okay.

3. Next turn on the display monitor, and then turn on the processing unit. The

system will start up automatically.

4.4.2 Power-Up Configuration

For the system to operate properly the trawl unit configuration must be selected

correctly. In addition, modification of these power-up configuration parameters is

done in a special mode selected after power-up of the Processor unit.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 51

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.11

The following sections describe the process of configuring these parameters. These

steps must be followed only when the system is powered-up for the first time or when

you have to replace the Processing unit or the TTM Module assembly.

4.4.3 FS 70 Start-up Procedure

For the purpose of demonstrating the Start-up Procedure in this chapter, we are

using the recommended Processing Unit that has 2 Com Ports, Com 1 and Com 3.

The Com 1 and COM 3 Ports from the Processing Unit are not connected to the FS

TTM module RS 232 port “A”. No communication will be made from the Com 1 or

Com 3 to the TTM module. We will be using an RS232/USB telemetry converter

“KML-USB1” connected to the “A” port of the TTM module

We will be using an FS 70, 120kHz/40kHz Catch Trawl Sonar Head with the 200kHz

net sounder option with the integrated sensor module.

Configuring the System for the first time, or if you have replaced the Processing Unit

or the TTM Module, you will select and “Click” on “Setup Page” and then the

following window will pop up.

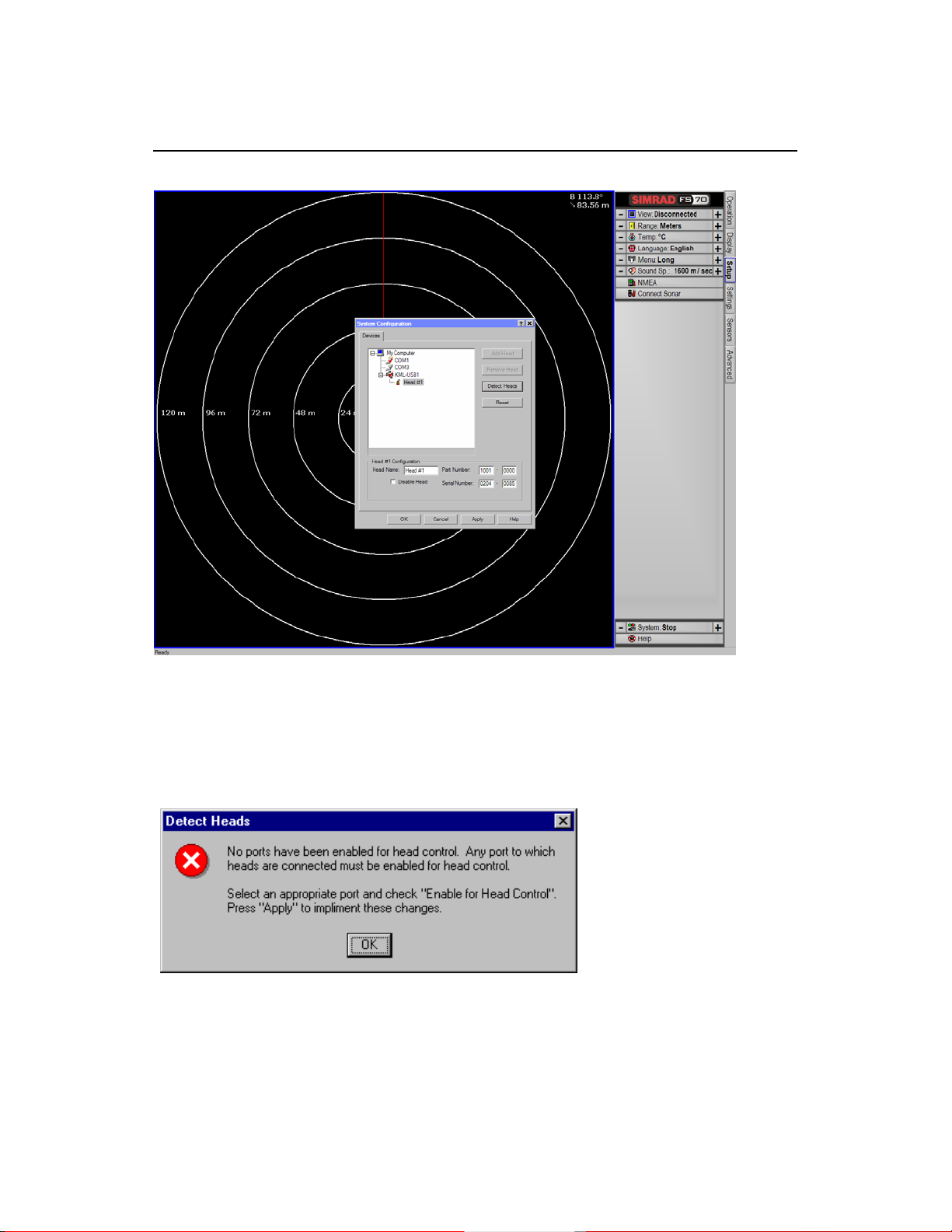

Next: Select “Connect Sonar” menu and “Click”. The following “System

Configuration” window will pop up, next “Click” on “Detect Heads”.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 52

974-24007001/3.0 FS 70 Operators Manual

Page 4.12 FS 70 Installation, System Set-Up and Test

After the “Detect Heads” the above Window will pops up, note that no Com ports

have not been enabled yet (and red check mark beside Com port). And If you “Click”

on “Detect Heads” from this position, the following warning window will pop up.

This warning window indicates that “No Ports have been enabled”; just “Click” “OK”.

The “System Configuration” window will reappear. Use the mouse to highlight KMLUSB 1. Use the mouse to “Enable for Head Control” (Left button click, check mark in

box to enable).

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 53

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.13

“Click” on “Apply”. The following window will appear, overlaying the above window,

asking you to reboot the computer. Just “Click” “OK” and do not “Reboot the

computer now”; “Click” “OK” in the “System Configuration” window.

From the Operating Panel, position the mouse to highlight “System Stop” located at

the bottom of the panel, next, left Click on “Stop” and a “Off, Stop, Run and playback

window will pop up. To start the System, position the mouse on the “Run” bottom

and Click.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 54

974-24007001/3.0 FS 70 Operators Manual

Page 4.14 FS 70 Installation, System Set-Up and Test

4.4.4 FS 70 RUN UP Procedure

After you Click on the “Run” Icon, the system will automatically detect and setup the

sonar heads attached to the trawl cable. This operation will take approx. 40 sec.

After the system Run Up is completed the best way to setup your windows is to Click

on the separation window line and drag “Tile Windows”. By clicking on the individual

window, you can rearrange, change the size, as you prefer, etc.

The first step after a successful power up is to configure the system for the desired

“User Setting” operating mode and set-up, if not already done; you will automatically

select “Default”. Clicking on “Default” or clicking on specific types of fishery does

this. Refer to the following window. From this point on we will be using all Factory

Default setting

By clicking on the “Vertical Window” of the Sounder Window you will have control

over the selected Sonar. The sonar you have selected will be highlighted by a blue

bar across the top..

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 55

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.15

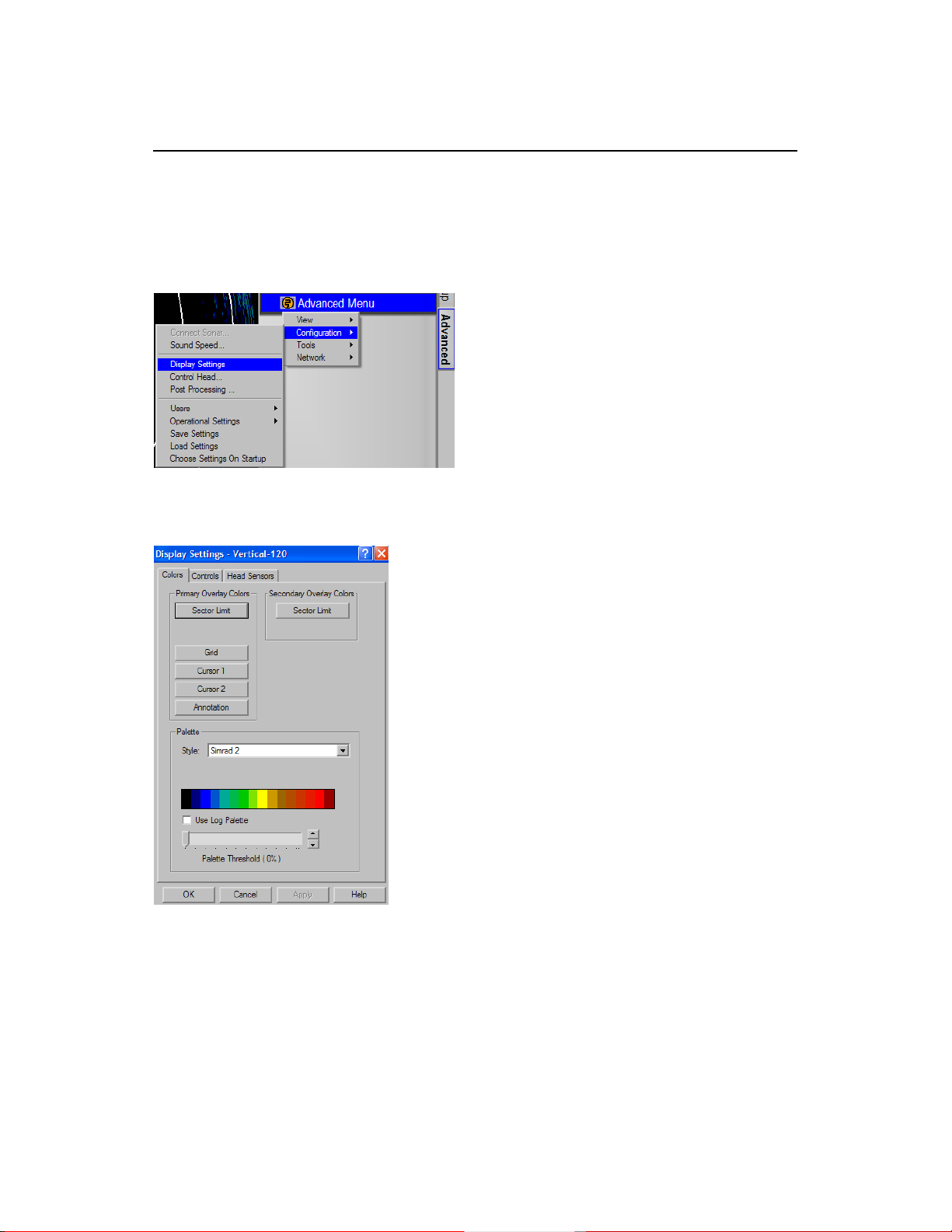

4.4.5 Advanced Menu Display Settings

Position the cursor on the “Display Settings” Icon, and Click. The window below will

pop up.

By selecting the appropriate “Key”, you will be able to setup your Colors, Controls

Setting and the Head Sensors.

By clicking on the appropriate “key” you will be able to change the color i.e. Overlay

colors, Palette styles and threshold, etc.

The same operation will apply to the FS Sounder window.

4.4.6 Control Setting

By selecting and clicking on the “Control” key on the above window, the following

window will pop up.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 56

974-24007001/3.0 FS 70 Operators Manual

Page 4.16 FS 70 Installation, System Set-Up and Test

By clicking on the appropriate key, you will be able to setup your control setting, i.e.

Gain Control, RX Gain, Scan Marker, etc.

Note: The “Timer Control” will be turned “ON” automatically when you Click on Timer

located on the “Menu Control Panel”.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 57

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.17

4.4.7 Head Sensors Setting

By selecting and clicking on the “Head Sensors” key on the following window will pop

up.

By clicking on the appropriate key, The Depth and Temperature range can also be

changed.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 58

974-24007001/3.0 FS 70 Operators Manual

Page 4.18 FS 70 Installation, System Set-Up and Test

4.4.8 FS 70 Head Setting

Position the cursor on the “Control Head” Icon, and CLICK. The window below will

pop up.

By clicking on the appropriate “KEY”, you will be able to setup your Scan option. You

also have full control of the Scan mode via the operator control panel.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 59

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.19

4.4.9 Transmit Setting

By selecting and clicking on the “Transmit” key on the above window, the following

window will pop up.

By clicking on the appropriate key, you will be able to setup your Transmitter

configuration in order to optimize fish detection.

The same operation will apply to the FS Sounder Window.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 60

974-24007001/3.0 FS 70 Operators Manual

Page 4.20 FS 70 Installation, System Set-Up and Test

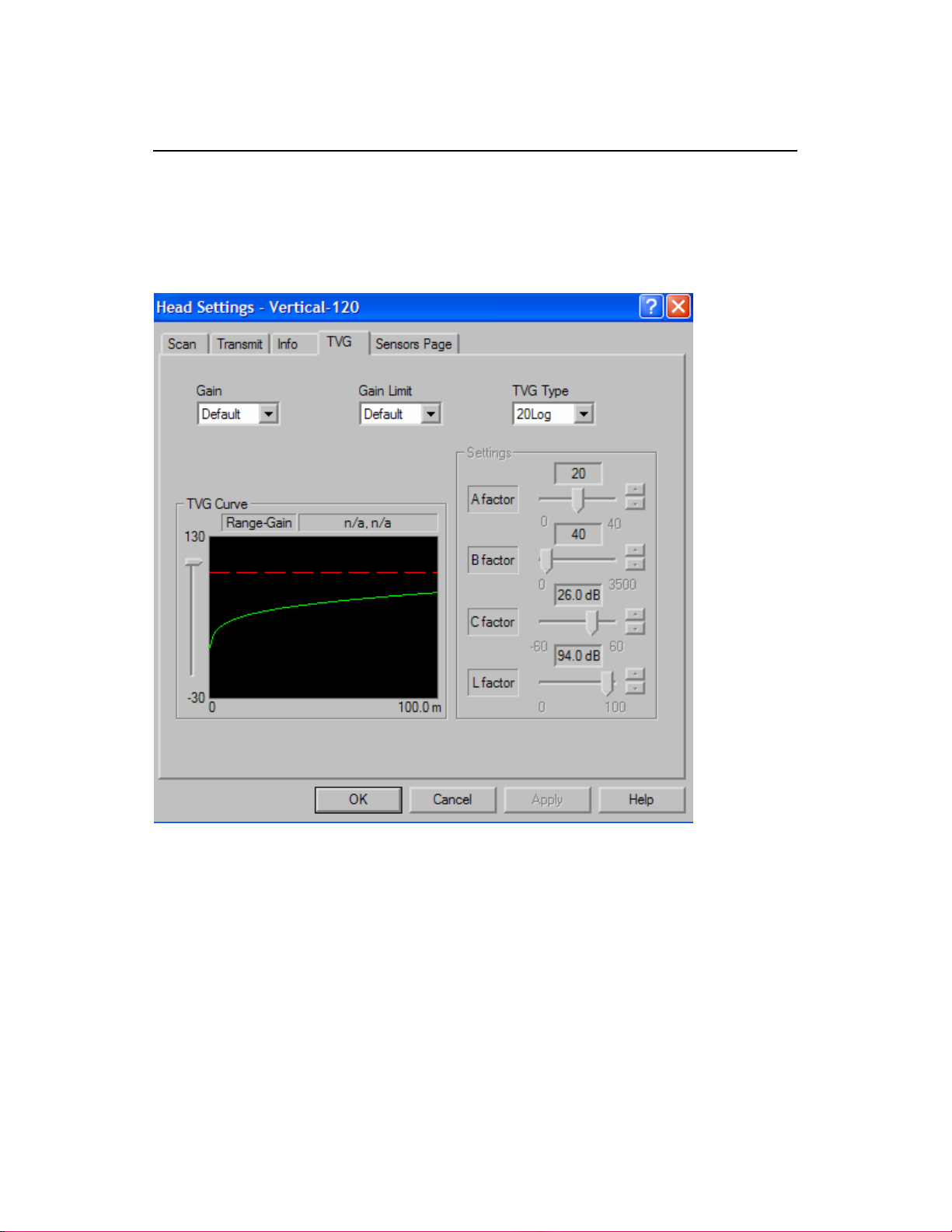

4.4.10 TVG Page Setting

By selecting and clicking on the “TVG Page” key on the above window, the following

window will pop up.

By clicking on the appropriate key you will be able to set up your TVG setting. You

also have the option of customizing your TVG setting for a specific fishery.

The same operation will apply to the FS Sounder Window.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 61

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.21

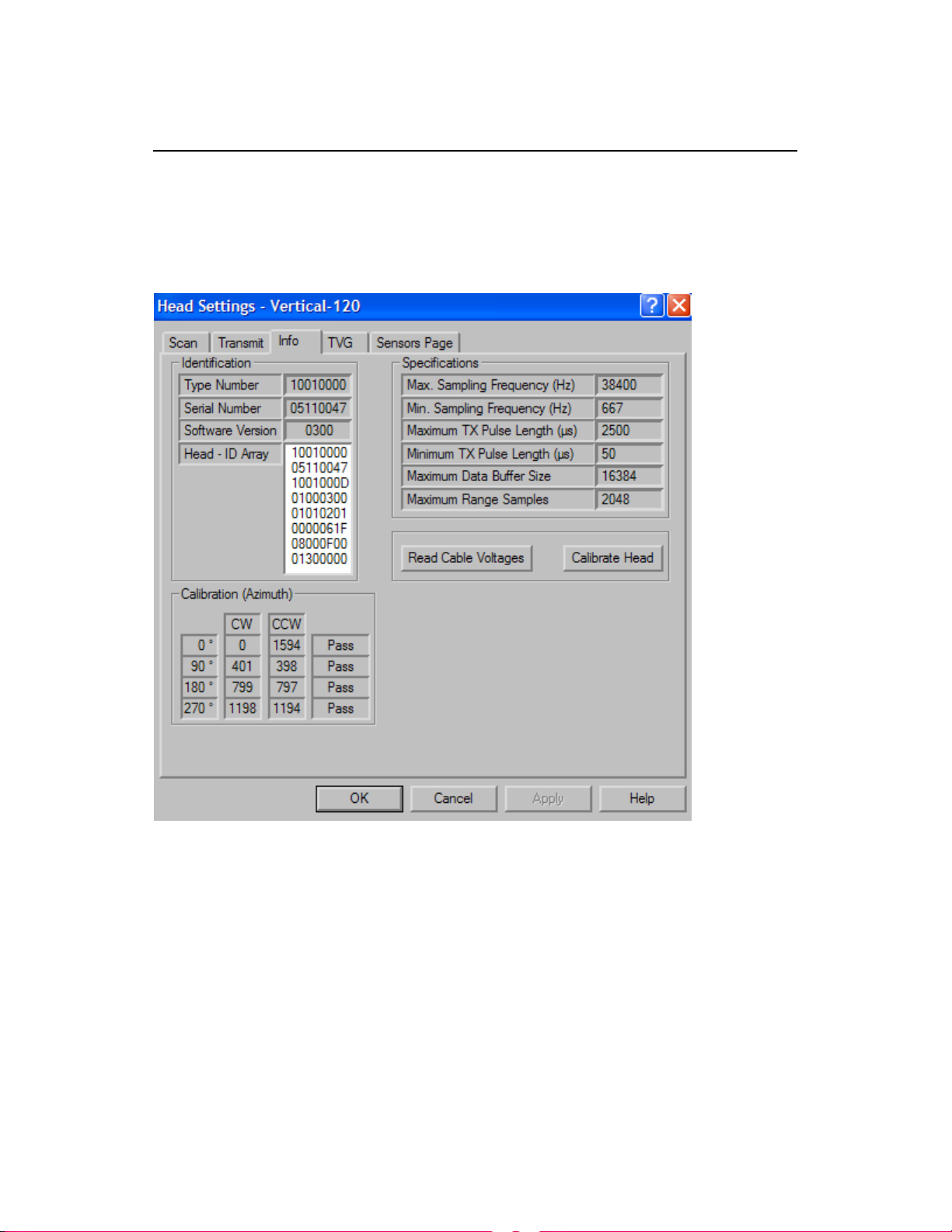

4.4.11 Info

By selecting and clicking on the “INFO” key on the above window, the following

window will pop up.

This INFO page will provide you with all the relevant information on the sonar head

attached to the system.

The same information will apply to the FS Sounder Window.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 62

974-24007001/3.0 FS 70 Operators Manual

Page 4.22 FS 70 Installation, System Set-Up and Test

4.4.12 Sensors Page

By selecting and clicking on the “sensors Page” key on the above window, the

following window will pop up.

This Sensors Page will provide you with all the relevant information on the sonar

head attached to the system.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 63

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.23

4.4.13 Auxiliary Transducer (Net Sounder)

By Clicking on the “Auxiliary Transducer” key on the above window, the following

window will pop up.

By Clicking on the appropriate key, you will be able to control the FS Sounder option.

Note: The Auxiliary Transducer window is only applicable to the FS Sounder.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 64

974-24007001/3.0 FS 70 Operators Manual

Page 4.24 FS 70 Installation, System Set-Up and Test

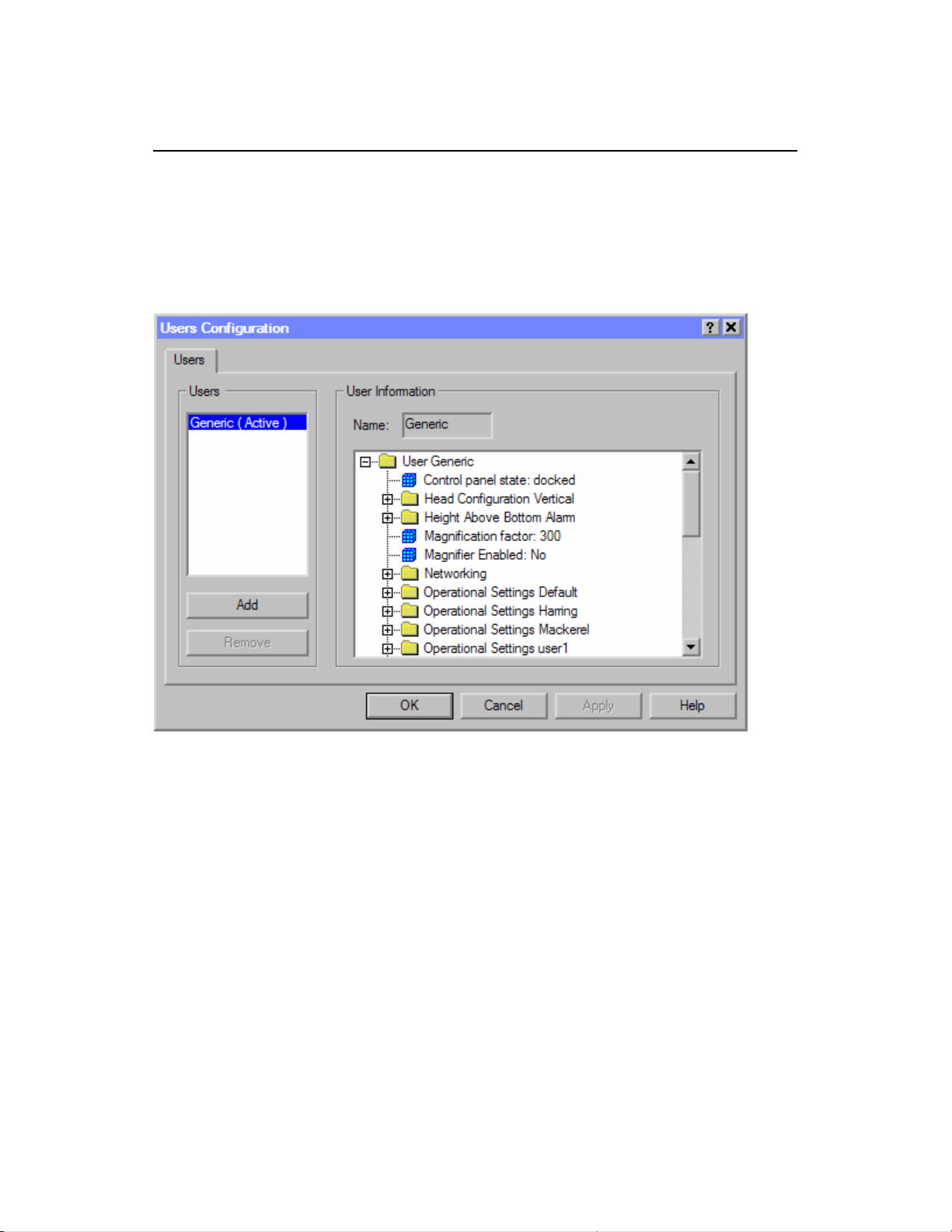

4.5 SAVE USER SETTING

After you have completed your system configuration, you should “SAVE” your

setting. Go to the User Menu and “Click” on “Save Setting”. The following window will

pop up.

Type the name of the “New Setting Name” by using the pop up keyboard, next Click

“OK”

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 65

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.25

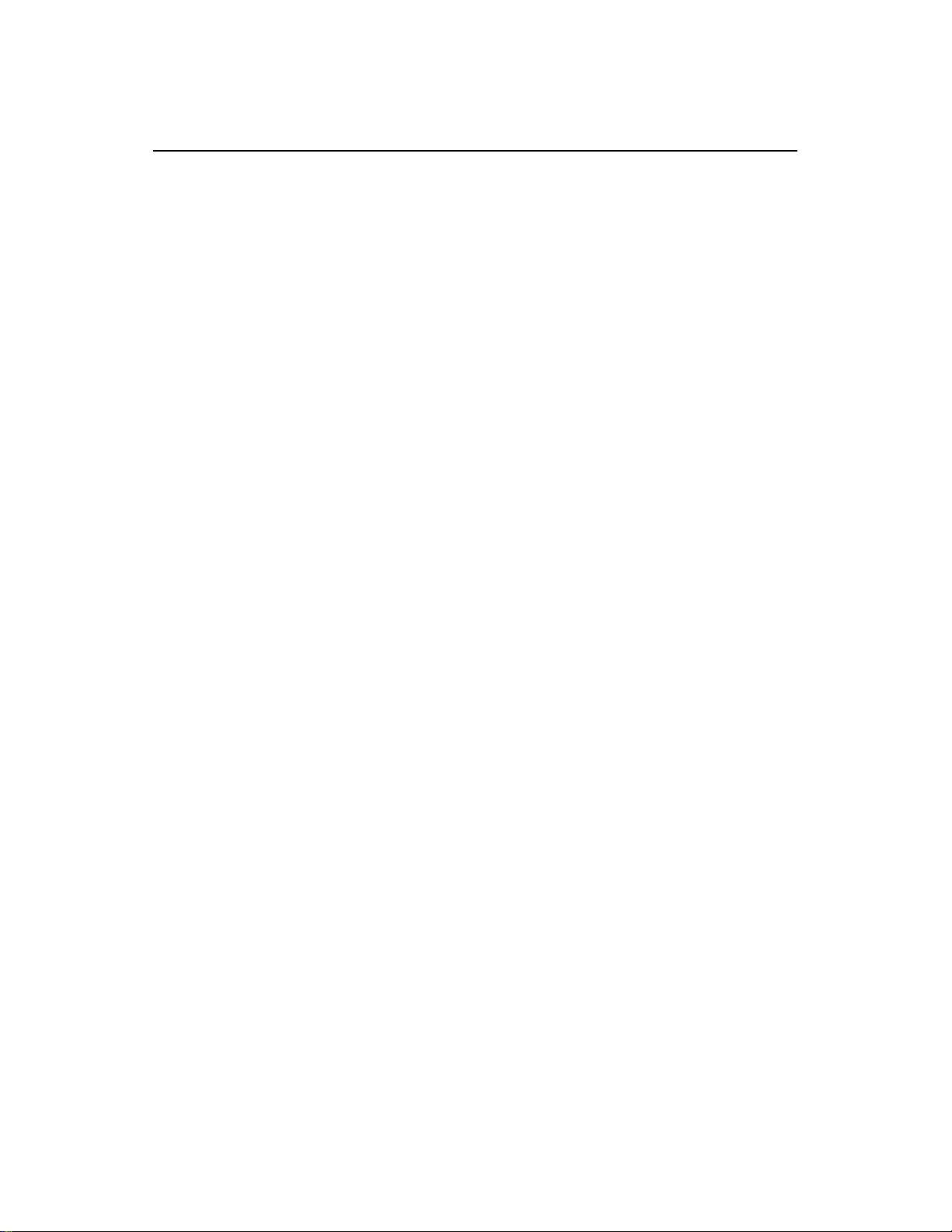

4.5.1 Add User Setting

After you have completed your system configuration you should save your setting,

Go to the Header Menu and Click on “Configuration”. Next Click on “USERS”, then

Click on “DEFINE”. The following window will pop up.

If you want to Add a User, the next step is to click “Add” then type your name in the

User 1 window. Next Click on “Apply” then “OK”.

The next time you start up the system, the “Select User” window will pop up

automatically. You must then select the type of Fishery or User setting you want and

“CLICK”. The system will start up with your personal setting.

When you Exit the system, the system will request if you want to save your setting.

Just click “YES” or “NO”

Note: After the Service Engineer has completed the initial Setup and Sea trial, we

recommend that all the settings are saved in the “GENERIC” setting or in a specific

file created as a reference in case a problem occurs.

Do not change the “GENERIC” setting. If you have a problem, just go

back and select the “GENERIC” setting, or to your specific file.

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 66

974-24007001/3.0 FS 70 Operators Manual

Page 4.26 FS 70 Installation, System Set-Up and Test

4.5.2 Final System Test

After preparing the trawl cable and before the final trawl unit assembly a system test

should be conducted to insure correct operation of the FS 70 Trawl Monitoring

System over the trawl cable.

As before, the start- up procedures should be followed to power up the system. Once

the FS 70 has been turned on, the power supply voltage and current meters should be

examined. Expected values are 0.2 – 0.5 (output voltage selection switch should be

set to 200VDC. If the voltage and current values differ significantly from these values,

it indicates a problem with the trawl cable or its connections.

If there are any errors during the calibration a status report page will appear containing

the results that the control unit obtained from the tests performed. Again, any errors

will be due to the trawl cable or its connections. Check the connections again and

ensure that the signal polarity at the trawl unit is correct. A DC voltmeter can be used

to check that the positive voltage is on the small pin of the pigtail when the

FS PWR/TTM unit is powered up.

If all is okay then the sonar head will begin scanning and the sonar image display will

appear.

4.5.3 Completing the Trawl Unit Assembly

First, the plastic cable strain relief supplied with the trawl unit must be bolted to the

trawl cable. The location should be at or very near the pigtail splice, but NOT on the

pigtail itself. You must slide the rubber hose on the trawl cable, if used, down so that

approximately 3-4 cm (1-2") of the hose is clamped inside the strain relief.

Next, the trawl cable is connected to the sonar head. Liberal amounts of Dow Corning

#55 grease are applied to the connector surfaces before mating so that a water tight

seal is obtained. The locking sleeve is then hand-tightened.

Note!

Dow Corning #55 grease must be applied to all mating surfaces of

underwater connectors to insure proper sealing. Sufficient grease

should be applied so that excess squeezes out with any air when the

connectors are mated. RTV or any other sealant must NOT be used,

and when tightening the locking sleeves do NOT use a wrench or

pliers! See chapter 5, "Troubleshooting and Maintenance", for proper

connector maintenance.

The plastic strain relief attached to the trawl cable is now placed in the trawl unit

housing containing the electronics and the excess cable is routed in the housing as

shown in Chapter 6 “Drawings”. Care must be taken to insure that all cables within the

Kongsberg Mesotech Ltd.

Port Coquitlam, BC - Canada

Page 67

FS 70 Operators Manual 974-24007001/3.0

FS 70 Installation, System Set-Up and Test Page 4.27

trawl unit housing are properly placed to avoid being pinched and possibly damaged.

The top half of the trawl unit housing is then placed on top and the two halves are

secured together with the bolts supplied. Finally, the dome is secured over the Vertical

Sonar Head transducer with four additional bolts.

The fully assembled trawl unit is now ready for mounting to the trawl headrope in the

chosen manner.

4.5.4 Mounting CATCH SENSORS

Proper mounting of the catch sensors on the cod-end is shown in drawing # 830056482 (see chapter 6, “Drawings”).

The fill of the cod-end and the sensitivity of the sensors is dependent upon the

number of mesh knots between the catch sensor and the rubber straps. Make sure