Page 1

7/2005 1

TP 300-7237-IR-HZ-N

Dealer Setup

& Adjustment Instructions

FastCut Hydro Drive Zero-Turn Riders & Mowers

TABLE OF CONTENTS:

SAFETY RULES .................................................................2

SETUP PROCEDURES

Quick Setup List ................................................................3

Uncrating............................................................................4

Battery Activation & Installation ......................................4

Rider Assembly .................................................................5

Seat and Safety Switch Assembly ...................................5

Install Ground Speed Control Levers...............................5

Check Fluid levels .............................................................5

Fill and Check Engine Oil.................................................6

Check Transmission Oil Level .........................................6

Reduce and Check Tire Pressure ....................................6

Torque Mower Blades .......................................................7

Lubrication .........................................................................7

Perform Safety Checks .....................................................8

Functional Tests...............................................................8

Mower Blade Stopping Check..........................................8

Seat Switch Connection...................................................8

Burnish PTO Clutch .........................................................8

Safety Interlock System ...................................................9

ADJUSTMENT PROCEDURES

Seat Adjustments ..............................................................9

Ground Speed Control Lever Adjustment.....................10

Operator Adjustment......................................................10

Speed Balancing Adjustment.........................................10

Return-To-Neutral & Neutral Adjustment .......................11

Parking Brake Adjustment..............................................12

PTO Clutch Adjustment ..................................................13

PTO Clutch Adjustment .................................................13

Blade Brake Check ........................................................13

Mower Deck Leveling ......................................................14

SERVICE PROCEDURES

Transmission Oil Filter Change .....................................15

Hydraulic Pump Drive Belt Replacement ......................16

Mower Belt Replacement ................................................17

ATTENTION SETUP PERSONNEL:

Sections and items denoted by the Setup symbol

provide the information necessary to fully assemble,

test, and prepare the units described above for

delivery to your customers.

Additional information concerning functional tests,

general adjustment procedures, and the location of

normal lubrication points are included in these

instructions.

The safety warnings provided in this guide and in

the operator's manual included with the unit contain

important information that must be obeyed when

assembling, setting-up, operating, servicing, transporting, or storing the unit.

These warnings are highlighted by the safety alert triangle symbol shown above, which signifies that an important safety message is being provided.

You must read, understand, and follow these warnings and

instructions, and use safe shop and work practices at all

times while working on or around this unit and all other

outdoor power equipment.

Mfg. No. Description

5900608 ZT18441KHC, 18HP Zero-Turn Rider with 44” Mower

5900609 ZT19441KWV, 19HP Zero-Turn Rider with 44” Mower

5900610 ZT20501BV, 20HP Zero-Turn Rider with 50” Mower

Form No. 5100277

Revision IR

This Dealer Setup Instruction covers the following products:

Page 2

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/20052

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of equipment, severe personal injury or death to you, yourself or bystanders, or damage to property or equipment. This mowing deck is capable of amputating hands and feet and throwing objects. The triangle in text signifies important cautions or warnings which must be followed.

IMPORTANT – Safe operation practices for riding mowers.

I. General operation

1. Read, understand, and follow all instructions in the manual and on

the unit before starting.

2. Only allow responsible adults, who are familiar with the instructions, to operate the unit.

3. Clear the area of objects such as rocks, toys, wire, etc., which

could be picked up and thrown by the blade(s).

4. Be sure the area is clear of other people before mowing. Stop the

unit if anyone enters the area.

5. Never carry passengers.

6. Do not mow in reverse unless absolutely necessary. Always look

down and behind before and while backing.

7. Be aware of the mower discharge direction and do not point it at

anyone. Do not operate the mower without either the entire grass

catcher or the guard in place.

8. Slow down before turning.

9. Never leave a running unit unattended. Always turn off blades, set

parking brake, stop engine, and remove keys before dismounting.

10. Turn off blades when not mowing.

11. Stop engine before removing grass catcher or unclogging chute.

12. Mow only in daylight or good artificial light.

13. Do not operate the unit while under the influence of alcohol or

drugs.

14. Watch for traffic when operating near or crossing roadways.

15. Use extra care when loading or unloading the unit into a trailer or

truck.

II. Slope operation

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. All slopes require

extra caution. If you cannot back up the slope or if you feel uneasy on

it, do not mow it.

DO

• See your authorized dealer for recommendations of wheel weights

or counterweights to improve stability.

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could overturn the

unit. Tall grass can hide obstacles.

• Use slow ground speed so that you will not have to stop or change

speeds while on the slope.

• Use extra care with grass catchers or other attachments. These

can change the stability of the unit.

• Keep all movement on the slopes slow and gradual. Do not make

sudden changes in speed or direction.

• Avoid starting or stopping on a slope. If tires lose traction, disengage the blade(s) and proceed slowly straight down the slope.

DO NOT

• Do not turn on slopes unless necessary, and then, turn slowly and

gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The unit

could suddenly turn over if a wheel is over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause sliding.

• Do not try to stabilize the unit by putting your foot on the ground.

• Do not use grass catcher on steep slopes.

III. Children

Tragic accidents can occur if the operator is not alert to the presence

of children. Children are often attracted to the unit and the mowing

activity. Never assume that children will remain where you last saw

them.

1. Keep children out of the mowing area and under the watchful care

of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and when backing, look behind and down for small children.

4. Never carry children. They may fall off and be seriously injured or

interfere with safe unit operation.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners, shrubs, trees, or

other objects that may obscure vision.

IV. Service

1. Use extra care in handling gasoline and other fuels. They are flammable and vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add fuel with the engine running.

Allow engine to cool before refueling. Do not smoke.

c) Never refuel the unit indoors.

d) Never store the unit or fuel container inside where there is an

open flame, such as a water heater.

d) Clean up oil and fuel spills immediately.

2. Never run a unit inside a closed area.

3. Keep nuts and bolts, especially blade attachment bolts, tight and

keep equipment in good condition.

4. Never tamper with safety devices. Check their proper operation

regularly.

5. Keep equipment free of grass, leaves, or other debris build-up.

6. Stop and inspect the equipment if you strike an object. Repair, if

necessary, before restarting.

7. Never make adjustments or repairs with the engine running.

8. Grass catcher components are subject to wear, damage, and deterioration, which could expose moving parts or allow objects to be

thrown. Frequently check components and replace, when necessary, with manufacturer’s recommended parts.

9. Mower blades are sharp and can cut. Wrap the blade(s) or wear

gloves, and use extra caution when servicing them.

10. Check brake operation frequently. Adjust and service as required.

11. Allow the unit to cool before storing.

WARNING – SLOPE OPERATION

Never operate on slopes greater than 17.6 percent (10°) which is a

rise of 3-1/2 feet (106 cm) vertically in 20 feet (607 cm) horizontally.

Select slow ground speed before driving onto slope. In addition to

front and rear weights, use extra caution when operating on slopes

with rear-mounted grass catcher. Mow UP and DOWN the slope,

never across the face, use caution when changing directions and

DO NOT START OR STOP ON SLOPE.

SAFETY RULES

Page 3

FastCut Hydro Drive ZTR

7/2005 3

TP 300-7237-IR-HZ-N

Quick Setup List -

Page Setup Procedure Steps to Perform

4 Uncrating ❏ Remove crate & banding.

❏ Place transmissions in PUSH position & roll off skid.

4 Battery Activation & ❏ Charge the battery

(Note: proceed with other setup steps

Installation

while battery is charging).

❏ Test battery with hydrometer or load-tester.

❏ Install & secure battery.

5 Rider Assembly ❏ Install the seat and connect the seat switch

❏ Install ground speed control levers.

6 Check Fluid Levels ❏ Fill & check Engine oil level.

❏ Check transmission fluid level.

❏ Reduce & check tire pressures

(Front tires 40 psi, rear tires 15 psi).

7 Mower Assembly ❏ Torque mower blade bolts.

7 Lubrication ❏ Lubricate all grease & oil points.

8 SAFETY CHECKS ❏ Check for LOOSE HARDWARE.

❏ Check all OPERATOR CONTROLS.

❏ Test P

ARKING BRAKE.

❏ Perform MO

WER BLADE STOPPING CHECK.

(Blade must stop within 5 seconds!)

❏ Perform SAFETY INTERLOCK SYSTEM CHECK.

8 Burnish Electric Clutch ❏ Burnish electric clutch

(run for 15 seconds, repeat 10 times)

.

❏ Repeat MO

WER BLADE STOPPING CHECK.

(Blade must stop within 5 seconds!)

Page 4

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/20054

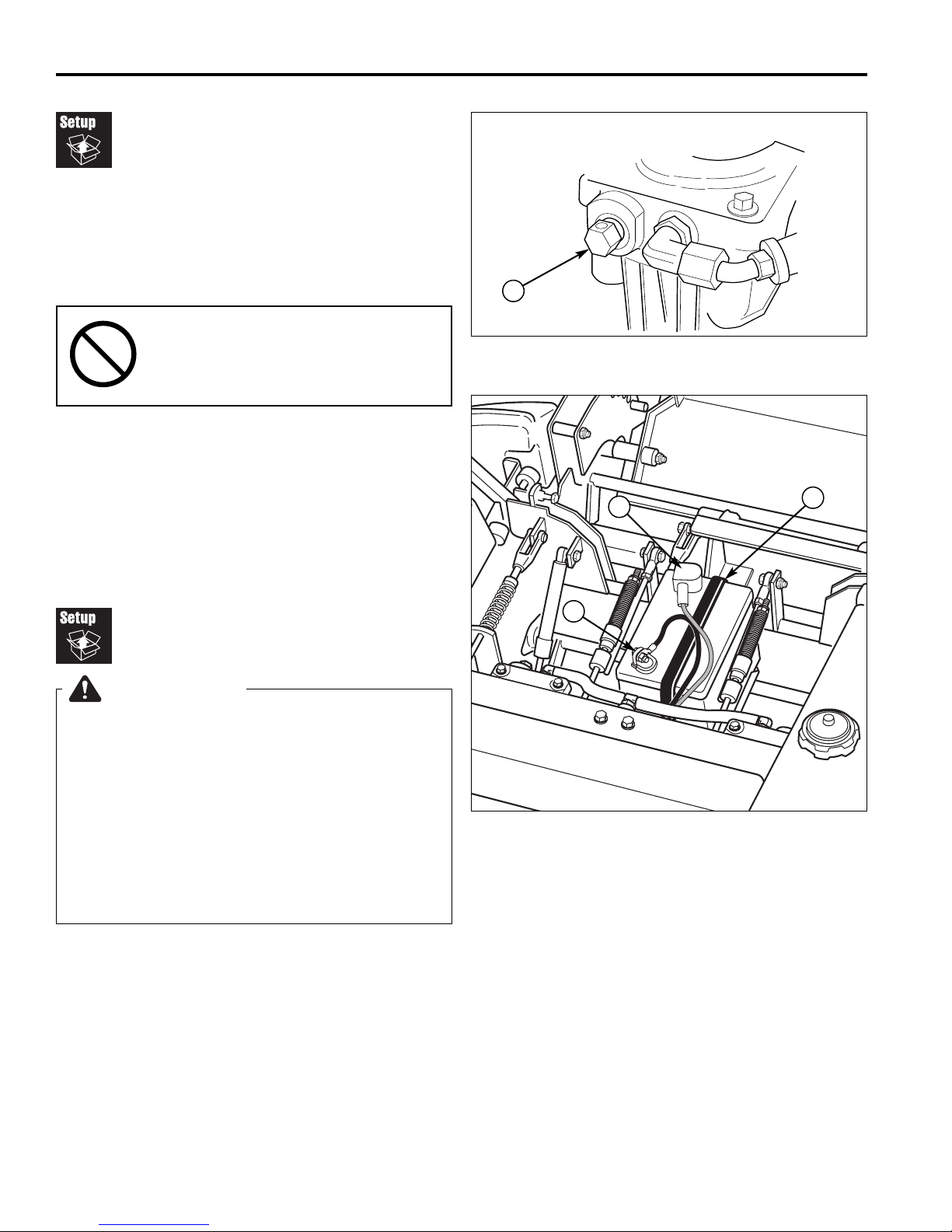

Uncrating

1. Using a reciprocating utility saw or equivalent, cut

crate away from bottom skid. Remove crate. Remove

shrink-wrap plastic.

2. Cut any banding securing the unit.

3. Release parking brake.

4. Place hydro release valves (A, Figure 1) in the PUSH

position by turning the valve counterclockwise one to

two turns.

5. Be sure there are no nails or sharp objects on the bottom of the skid to puncture the tires. Roll the rider forward off the skid.

6. Engage the hydro pumps by tightening the release

valves (A) to 80-120 in. lbs.

IMPORTANT NOTE

When cutting crate from bottom skid,

use caution around tires and mower

rollers.

Battery Activation &

Installation

Charge Battery

1. Tip the seat forward to access the battery.

2. To charge the battery, follow the instructions provided

by the battery charger manufacturer as well as all

warnings included in the safety rules section of this

document. Charge the battery until fully charged

(until the specific gravity of the electrolyte is 1.250 or

higher and the electrolyte temperature is at least 60°

F). Do not charge at a rate higher than 10 amps.

WARNING

BATTERY SAFETY RULES

• Battery acid causes severe burns. Avoid contact

with skin.

• Wear eye protection while handling the battery.

• To avoid an explosion, keep flames and sparks

away from battery, especially while charging.

• When installing battery cables, CONNECT THE

POSITIVE (+) CABLE FIRST and negative (-) cable

last. If not done in this order, the positive

terminal can be shorted to the frame by a tool.

Install Battery

1. Install the battery in the battery compartment and

secure using the rubber hold-down strap (C, Figure

2).

2. Connect the red positive battery cable (B) to the positive battery post.

3. Connect the black negative battery cable (A) to the

negative battery post using a capscrew, washer, lockwasher and nut.

Figure 2. Battery

A. Negative Cable

B. Positive Cable & Cover

C. Rubber Hold-Down Strap

A

C

B

Figure 1. Transmission Release Valves

A. Hydraulic Release Valve (On Each Pump)

A

Page 5

FastCut Hydro Drive ZTR

7/2005 5

TP 300-7237-IR-HZ-N

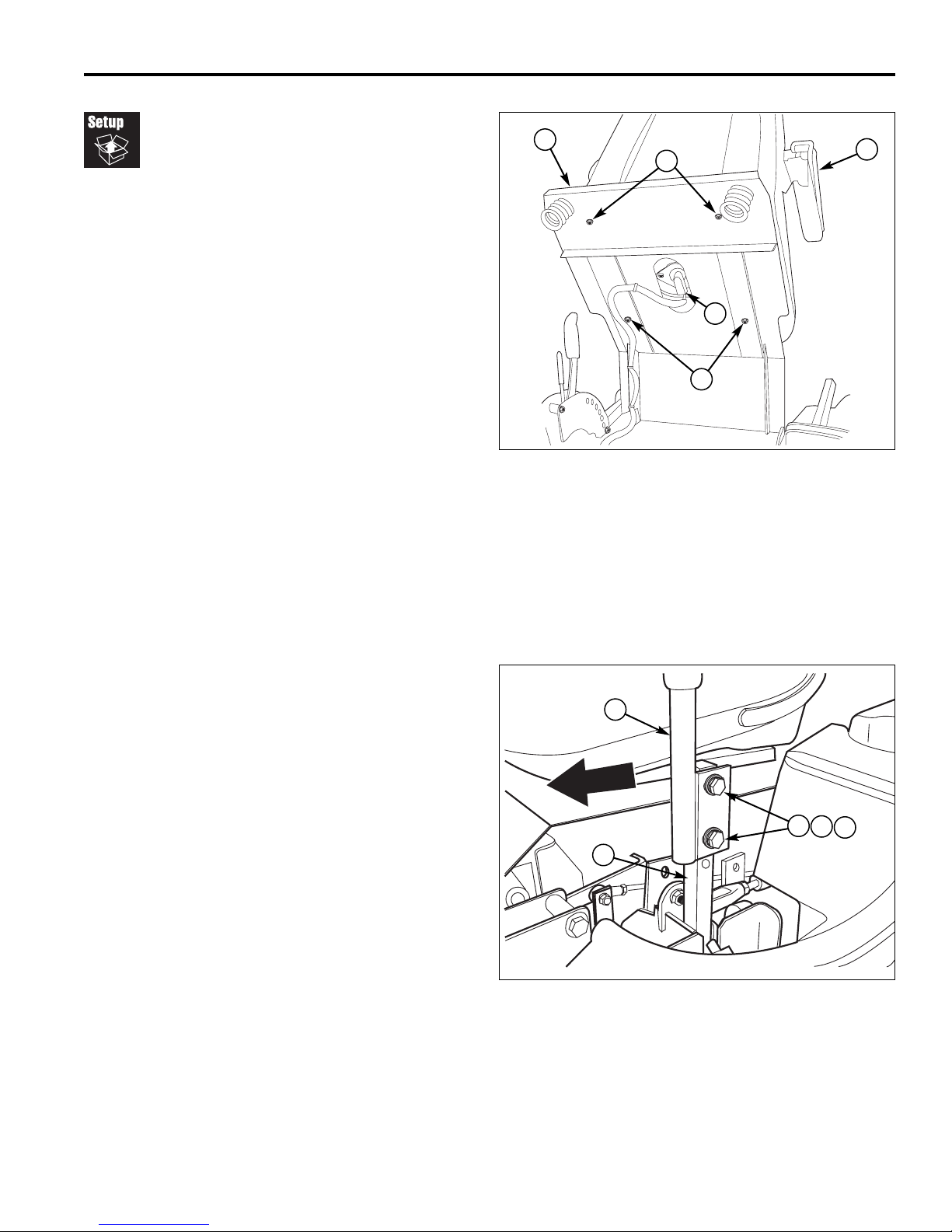

Rider

Assembly

Seat & Safety Switch Assembly

1. Mount the seat (A, Figure 3) to the seat plate (B)

using four 5/16-18 nylock flange nuts (C) and tighten

securely.

2. Connect the seat switch wire harness (D) to the seat

switch.

A

B

C

D

Figure 3. Seat Installation

A. Seat

B. Seat Plate

C. 5/16-18 Nylock Flange Nut (4)

D. Seat Switch Wire Harness

FRONTFRONTFRONT

A

B

C

D

E

Figure 4. Install Control Levers

A. 5/16-18 x 1” Bolts

B. 5/16 Lockwashers

C. 5/16 Washers

D. Control Lever

E. Control Lever Base

Install Ground Speed Control Levers

1. Mount the control levers (F, Figure 4) to the control

lever base (E) using four 5/16-18 x 1” bolts, lockwashers, and washers.

NOTE: The ground speed control levers and seat must

be adjusted to fit the operator. See SEAT ADJUSTMENTS and GROUND SPEED CONTROL LEVER

ADJUSTMENTS in the Adjustments section.

C

Page 6

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/20056

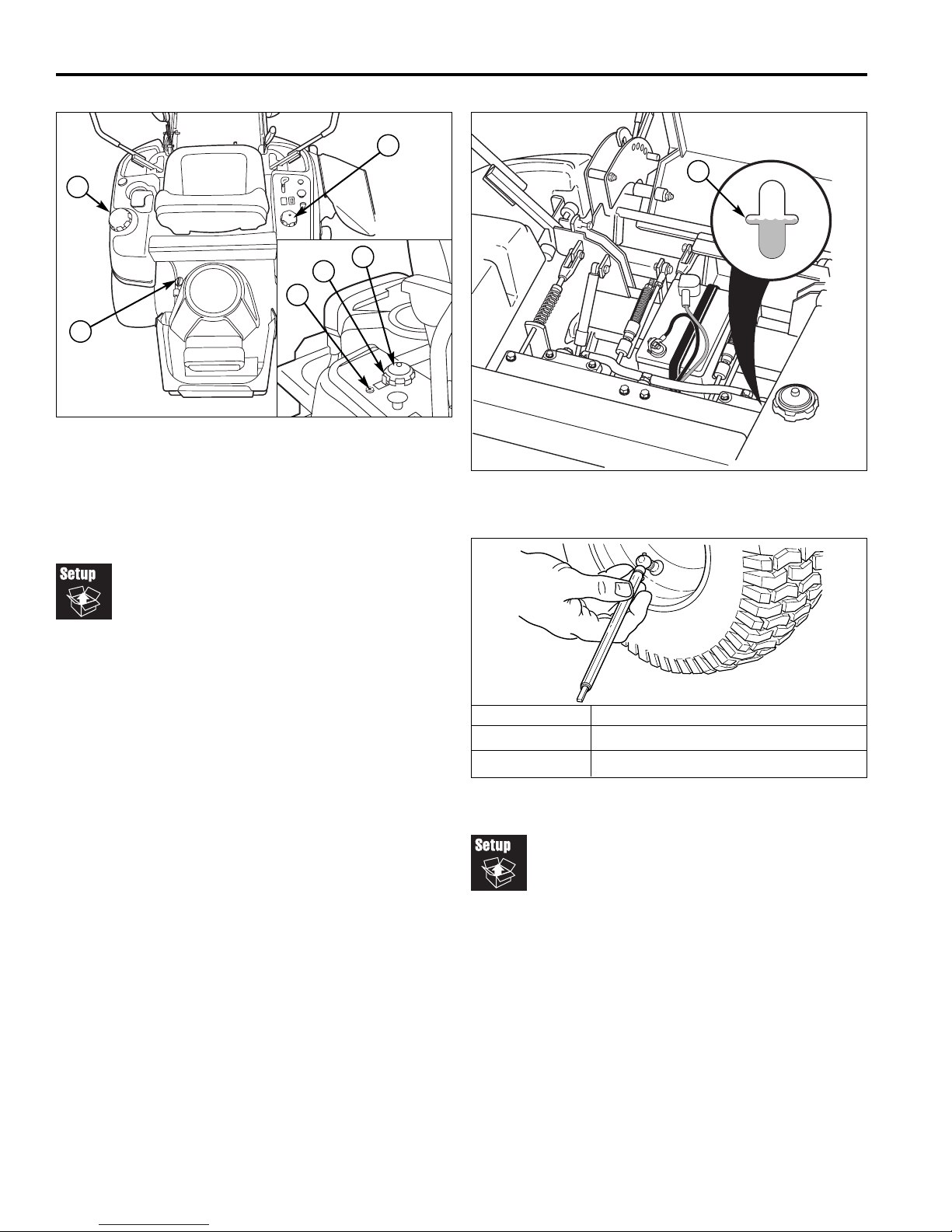

Figure 7. Tire Pressures

Check

Fluid Levels

Fill & Check Engine Oil

1. Use the dipstick (C, Figure 5) to check the engine oil

level. If necessary add engine oil. Check engine

manufacturer’s owner’s manual for oil recommendations.

Check /Fill Transmission Oil

Oil Type: Mobil 1™, 15W-50 synthetic oil or Castrol

Syntec™ 5W-50 oil.

1. Check the oil level when the unit is cold. The inspection port is located on the inside of the right tank

cover. The oil level should be within 1/2” (1.3 cm) of

the horizontal level mark (A, Figure 6). If the oil is

below this level, proceed to step 2.

2. Before removing the reservoir cap, make sure the

area around the reservoir cap and fill neck of the

reservoir is free of dust, dirt, or other debris. Loosen

the locking capscrew (E, Figure 5) securing the locking tab (D), slide the lock tab back, and remove the

cap (B).

3. Add either Mobil 1™, 15W-50 synthetic oil or Castrol

Syntec™ 5W-50 oil. DO NOT use conventional oils.

4. Reinstall the reservoir cap, move the locking tab

between two notches, and tighten the locking capscrew. The locking tab is installed as a reminder to

the customer to not put fuel in this reservoir.

Tire Pressure

Front 40 psi (2,76 bar)

Rear 15 psi (1,03 bar)

Figure 5. Check Fluid Levels

A. Fuel Tank Cap

B. Transmission Oil Cap

C. Engine Oil Dip Stick

D. Locking Tab

E. Locking Screw

B

A

C

D

E

B

A

Figure 6. Transmission Oil Fill Level

A. Fill Level Mark

Reduce & Check Tire

Pressures

The tires are over-inflated for shipping purposes. Inflate

to the pressures shown. Note that these pressures may

differ slightly from the “Max Inflation” stamped on the

side-wall of the tires. The pressures shown provide proper traction, improve cut quality, and extend tire life.

Page 7

FastCut Hydro Drive ZTR

7/2005 7

TP 300-7237-IR-HZ-N

Torque Mower Blades

1. Check that blades are installed with the tabs pointing

up toward deck as shown in Figure 8. Secure with a

capscrew, spring washer and spline/hex washer (be

certain the spline/hex washer is aligned with the

shaft). Use a wooden block to prevent blade rotation

and torque capscrews to 45-55 ft.lbs. (61-75 N.m.).

WARNING

For your personal safety, blade mounting

capscrews must each be installed with a hex

washer and spring washer, then securely

tightened. Torque blade mounting capscrew to

45 - 55 ft. lbs. (61 - 75 N.m.)

A

D

C

B

Figure 8. Blade Installation

A. 4x4 Wood Block

B. Hex Washer

C. Spring Washer

D. Blade Capscrew

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts and pulleys. Remember to wipe fittings and surfaces clean both before and after lubrication.

Use grease fittings when present. Disassemble parts to

apply grease to moving parts when grease fittings are

not installed. Not all greases are compatible. Use automotive-type lithium grease.

Lubrication

Lubricate the unit at the following lubrication points

shown in Figure 9.

Grease:

• front caster wheel axles

• front caster yokes

• mower deck idler arm

• mower deck arbors

Figure 9. Lubrication

Lube Idler

Arm Pivot

Oil:

• control handle pivots

• discharge chute hinge

Page 8

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/20058

Perform

Safety Checks

Functional Tests

1. Check for loose bolts, screws, nuts, etc.

2. Start the engine and check all controls for proper

operation: ground speed control levers, parking brake

lever, throttle and choke cables, electric PTO clutch,

attachment lift, etc.

3. Stop the engine and check for fluid leaks: oil, gasoline, or transmission oil.

4. If any control fails to operate properly during testing or

seems to be out of adjustment, check and readjust it

according to the following Adjustments section.

4. Turn the key to OFF to end the demonstration.

Mower Blade Stopping Check

Mower blades and mower drive belt should come to a

complete stop within five seconds after the electric clutch

switch is turned off.

With the tractor in neutral, the electric clutch switch disengaged, and an operator in the seat, start the tractor

engine. Run the engine at full throttle. Engage the electric

PTO clutch switch and wait several seconds. Disengage

electric clutch switch and check the time it takes for the

mower drive belt to stop. If the mower drive belt does not

stop within five seconds, adjust the PTO clutch according

to the instructions in the Electric Clutch Adjustment section.

Seat Switch Connection

Check that the seat switch wire harness (D, Figure 2) is

connected to the seat switch.

Burnish PTO Clutch

1. Select a safe area to operate the mower deck. With

the drive in neutral, the PTO switch disengaged, and

an operator in the seat, start the tractor engine. Run

the engine at full throttle.

2. Engage the PTO switch and run the deck for fifteen

seconds. Disengage the PTO switch and wait for the

mower drive belt to stop.

3. Repeat step 2 above ten times, and then re-check the

mower blade stopping time. (Stopping time must be

five seconds or less.)

WARNING

Disengage the PTO, stop the engine, set the

parking brake, and wait for moving parts to stop

before leaving operator's position for any reason.

If the unit does not pass the test, do not operate

it. Under no circumstance should you attempt to

defeat the purpose of the safety system.

Page 9

Seat Adjustments

The seat and ground speed control levers should be

adjusted so that operator’s elbows are supported by the

arm rests when his/her hands are on the controls, and

the ground speed control levers can be moved through

their full range of motion without contacting the operator’s

legs.

Seat Position Adjustment

The seat can be adjusted forward and back. Move the

adjustment lever (A, Figure 10) towards the left hand side

of the machine, slide the seat to the desired position, and

release the lever.

FastCut Hydro Drive ZTR

7/2005 9

TP 300-7237-IR-HZ-N

SAFETY INTERLOCK

SYSTEM

This unit is equipped with safety interlock switches.

These safety systems are present for your safety, do

not attempt to bypass safety switches, and never tamper with safety devices. Check their operation regularly.

Operational SAFETY Checks

TEST 1 — ENGINE SHOULD NOT CRANK IF:

• PTO switch is engaged, OR

• Parking brake is not engaged, OR

• Motion control handles are not in their NEUTRAL

positions.

TEST 2 — ENGINE SHOULD CRANK IF:

• PTO switch is NOT engaged, AND

• Parking brake is engaged, AND

• Motion control handles are locked in their NEUTRAL positions.

TEST 3 — ENGINE SHOULD SHUT OFF IF:

• Operator rises off seat with PTO engaged, OR

• Operator rises off seat with parking brake disengaged, OR

• Operator moves motion control handles out of their

neutral positions before disengaging parking brake.

TEST 4 — BLADE BRAKE CHECK

The mower blades and mower drive belt should come

to a complete stop within five seconds after the electric

PTO switch is turned off (or operator rises off seat). If

mower drive belt does not stop within five seconds, see

your dealer.

NOTE: Once the engine has stopped, the PTO switch

must be turned off, parking brake must be engaged,

and the ground speed control handles must be locked

in their NEUTRAL positions in order to start the engine.

WARNING

If the unit does not pass a safety test, do not

operate it. Under no circumstance should you

attempt to defeat the purpose of the safety

interlock system.

Adjustment

Procedures

Figure 10. Seat Adjustment

A. Adjustment Lever

A

Page 10

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/200510

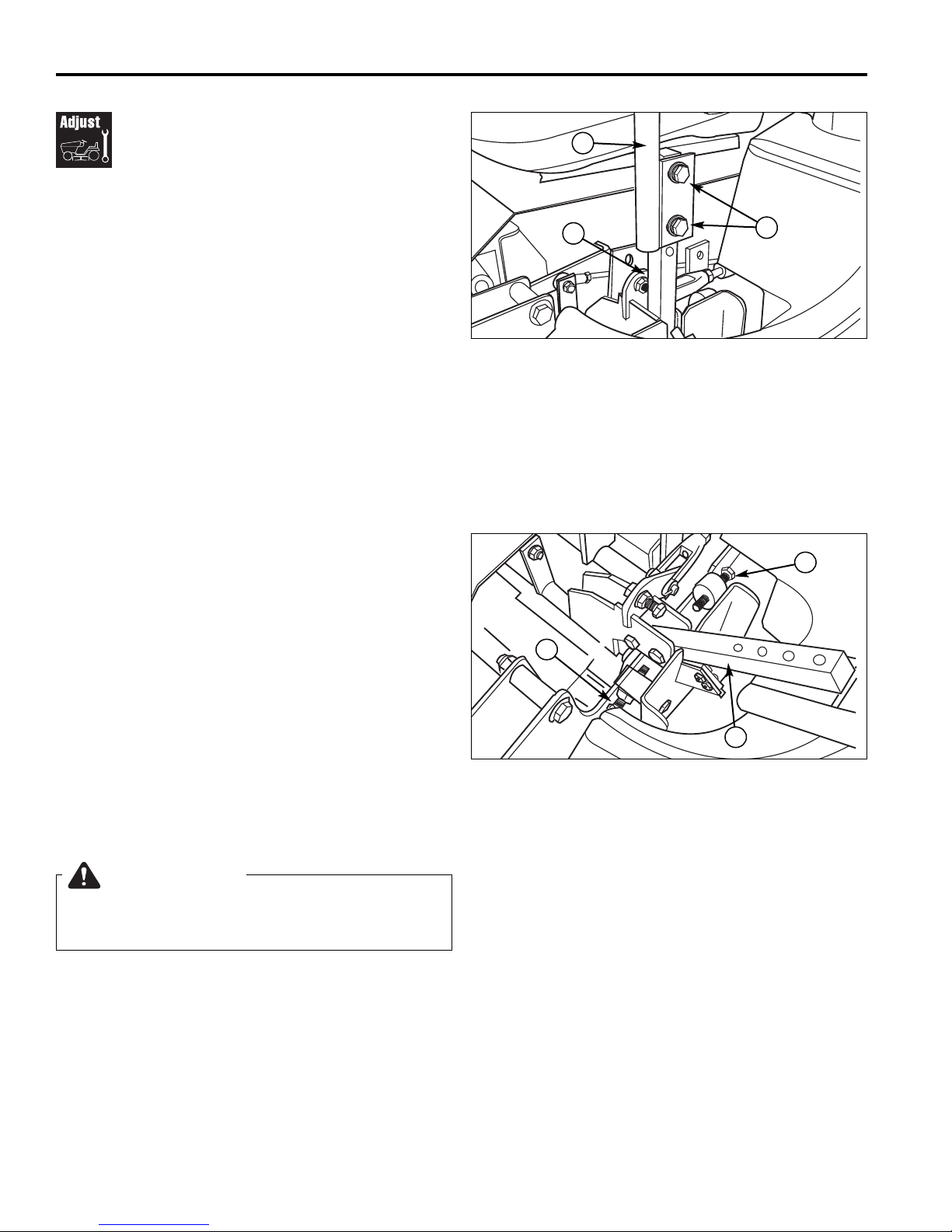

Ground Speed Control

Lever Adjustment

Operator Adjustment

The control levers can be adjusted in three ways. The

alignment of the control levers, the placement of the

levers (how close the ends are to one another) and the

height of the levers can be adjusted.

To Adjust the Handle Alignment: Loosen the mount

bolts (A, Figure 11) and pivot the lever(s) (C) to align

with each other.

To Adjust the Handle Placement: Loosen the jam nuts

and adjust the placement bolt (B, Figure 11) in or out to

properly adjust the lever end spacing.

To Adjust the Handle Height: Remove the mounting

hardware and reposition the handle either up or down

from its original position. You will need to readjust the

handle alignment as described above.

Speed Balancing Adjustment

If the rider veers to the right or left when the ground

speed control levers are in the maximum forward or

reverse position, the top speed of each of these levers

can be balanced by turning the adjustment bolt(s) (A,

Figure 12). Only adjust the speed of the wheel that is

traveling faster.

TO REDUCE THE SPEED OF THE FASTER WHEEL

1. Loosen the securing nut.

2. Turn the top speed adjustment bolt COUNTERCLOCKWISE to reduce the speed.

3. Retighten the securing nut when adjustment is complete.

WARNING

DO NOT adjust the rider for a faster overall speed

forward or reverse than it was designed for.

Figure 11. Control Lever Adjustment

A. Alignment Hardware

B. Placement Hardware

C. Ground Speed Control Lever

Figure 12. Top Speed Adjustment

A. Forward Top Speed Adjustment Bolt

B. Control Lever Base

C. Reverse Top Speed Adjustment Bolt

B

C

A

A

B

C

Page 11

FastCut Hydro Drive ZTR

7/2005 11

TP 300-7237-IR-HZ-N

Figure 14. Neutral Adjustment

A. Control Rod Spring

B. Rod End

Return-To-Neutral &

Neutral Adjustment

RETURN-TO-NEUTRAL ADJUSTMENT

To determine if it is necessary to adjust the neutral

return, perform the following steps.

1. Disengage the PTO, engage the parking brake and

turn off the engine.

2. Move the ground speed control levers into the operating position, pull levers rearward and release.

3. Move the ground speed control levers out towards

the neutral position. If the levers do not align with the

notches in the neutral lock plate, it is necessary to

adjust the neutral return rod (C, Figure 13).

TO ADJUST:

1. Loosen the jam nut (B) locked against the clevis (A).

2. Turn the neutral return rod (C) to adjust handle position.

4. Pull lever rearward and release to check position

again. Adjust as necessary to align levers with

notches.

It is important to note that after every adjustment of the

neutral return rod, the lever must be pulled rearward and

released to properly check the neutral position.

5. Once the lever alignment has been adjusted, lock

jam nut against the clevis.

NEUTRAL ADJUSTMENT

If the tractor creeps while the ground speed control

levers are locked in neutral, then it may be necessary to

adjust the linkage rods.

Perform this adjustment on a hard level surface such as

a concrete floor.

IMPORTANT NOTE: This adjustment should be performed with the engine OFF. Perform the adjustment,

then start the engine to check the adjustment. If further

adjustment is required, stop the engine before adjusting

the linkage.

1. Determine which wheel is creeping. The left side

hydro pump and control linkage control the left wheel,

the right linkage controls the right wheel.

2. Disengage the PTO, engage the parking brake, turn

the engine off, remove the key, and wait for all moving parts to stop.

3. Check the control rod spring (A, Figure 14) length.

The compressed spring length should be 2-3/16”

(5,56cm)

4. Disconnect the rod end (B) and loosen the jam nut.

Turn the rod end one to two turns to lengthen or

shorten the control rod, then retighten the jam nut,

and reconnect the rod end.

B

A

5. Start the unit and check for transmission creep.

Repeat steps 2-4 if necessary.

Figure 13. Return-To-Neutral Adjustment

A. Clevis

B. Jam Nut

C. Neutral Return Rod

A

B

C

Page 12

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/200512

2"

(5 cm)

3/16"

(5 mm)

Figure 15. Parking Brake Adjustment

A. Brake Spring

B. Set Collar

C. Locknut

Parking Brake

Adjustment

1. Disengage the PTO, stop the engine, block the front

wheels, remove the ignition key, and engage the

parking brake. For easier access to the brake adjustment linkage, the rear wheels may be removed.

2. Check the brake spring (A, Figure 15) length (both

wheels). With the brake engaged the compressed

spring length should be 2” (5 cm). If not, adjust the

locknut (C) to achieve the compressed spring length

of 2” (5 cm).

3. After achieving the correct spring compression, check

the set collar gap (B). With the parking brake

engaged, the set collar gap should be 3/16" (5 mm).

If not, loosen the set collar screw and move the collar

to the correct position.

A

C

B

Page 13

FastCut Hydro Drive ZTR

7/2005 13

TP 300-7237-IR-HZ-N

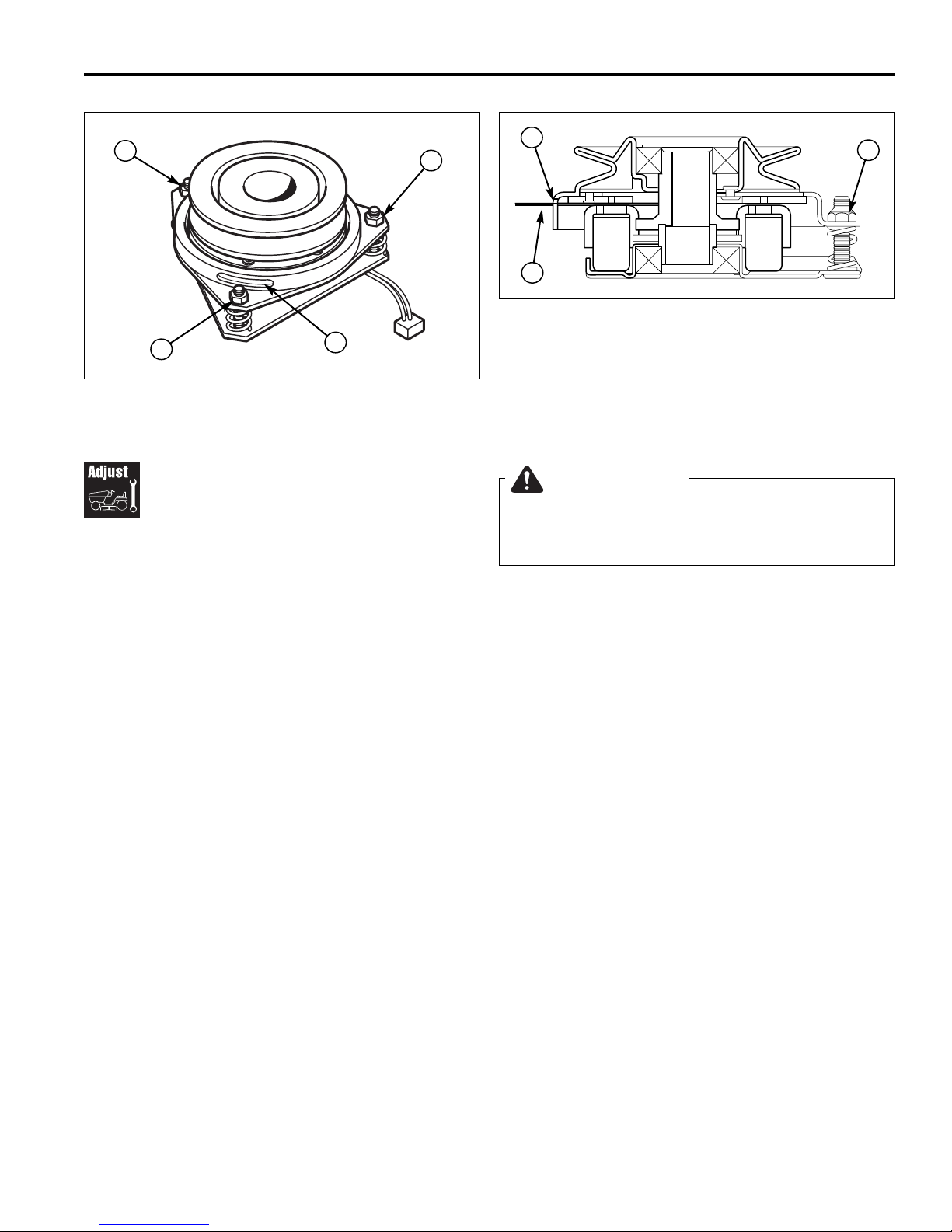

WARNING

To avoid serious injury, perform adjustments only

with engine stopped, key removed and rider on

level ground.

B

A

C

A

B

B

B

Figure 16. PTO Clutch Adjustment

A. Adjustment Window (Qty. 3, one shown)

B. Adjustment Nut

Figure 17. Adjust PTO Clutch

A. Window

B. Adjustment Nut

C. .016”-.018” (0,40-0,45mm) Feeler Gauge

PTO Clutch Adjustment

Check the PTO clutch adjustment after the initial 25 hour

break-in period and then after every 250 hours of operation. Also perform the following procedure if the clutch is

slipping or will not engage, or if a new clutch has been

installed.

1. Remove key from ignition switch and disconnect

spark plug wires to prevent the possibility of accidental starting while the PTO is being adjusted.

2. See Figure 16. Note the position of the 3 adjustment

windows (A) in the side of the brake plate and the

nylock adjustment nuts (B).

3. Insert a .016”-.018” (0,40-0,45mm) feeler gauge (C)

through each window, positioning the gauge between

the rotor face and the armature face as shown in

Figure 17.

4. Alternately tighten the adjustment nuts (B, Figure 16)

until the rotor face and armature face just contacts

the gauge.

5. Check the windows for an equal amount of tension

when the gauge is inserted and removed, and make

any necessary adjustments by tightening or loosening the adjustment nuts.

NOTE: The actual air gap between the rotor and armature may vary even after performing the adjustment procedure. This is due to dimensional variations on component parts, and is an acceptable condition.

6. Check the mower blade stopping time. The mower

blades and mower drive belt should come to a complete stop within five seconds after the electric PTO

switch is turned off.

Blade Brake Check

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned off.

1. With parking brake engaged, PTO disengaged and

an operator in the seat, start the engine.

2. Have an assistant observe the mower drive belt

through the opening between the frame and top of

mower deck. Engage the PTO and wait several seconds. Disengage the PTO and check the amount of

time it takes for the mower drive belt to stop.

3. If the mower drive belt does not stop within five seconds, perform the PTO Clutch Adjustment. If the belt

still does not stop within 5 seconds, replace the

clutch.

Page 14

Mower Deck Leveling

Perform these adjustments on a flat level surface.

SIDE-TO-SIDE LEVELING

1. With the mower installed, place the rider on a

smooth, level surface such as a concrete floor. Turn

the front wheels so they are straight.

2. Check for bent blades and replace if necessary.

3. Place the mower cutting height pin in the 4th hole

from the bottom (see insert, Figure 20). Arrange the

outside mower blades so that they are pointing from

side-to-side (Figure 18).

4. Measure the distance between the outside tips of

each blade and the ground (Figures 18 & 19). If there

is more than 1/8” (3mm) difference between the measurements on each side, proceed to step 5. If the difference is 1/8” (3mm) or less, proceed to step 6.

5. Use the rear leveling links (B, Figure 20) to adjust the

side-to-side leveling of the deck. Repeat step 4 if

necessary.

FRONT-TO-BACK LEVELING

6. Arrange the blades so they face front-to-back (Figure

21).

7. Measure the distance from the ground to the front tip

of the center blade, and from the ground to rear tips

of left-hand and right-hand blades (Figures 19 & 21).

The front tip of the center blade should be 1/4" (6mm)

higher than rear tips of left-hand and right-hand

blades. If not, proceed with steps 8 - 11.

8. Check the length of the hanging rods. The rear (D,

Figure 20) should be 15” (38,1cm) and is not adjusted. To adjust the pitch of the mower deck, adjust the

front leveling nuts only.

9. Loosen the front lock nuts (E, Figure 20).

10. Turn the leveling nuts (A, Figure 20) counterclockwise to lower the front of mower deck. Turn the

nuts clockwise to raise the front of the mower. Make

adjustments in small increments, trying to keep tension on both leveling nuts.

11. Tighten the front lock nuts (E).

12. Re-check the blade measurement then repeat steps

7-11 as necessary.

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/200514

Figure 21. Orient Blades Front-to-Back

Figure 18. Orient Blades Side-to-Side

Figure 19. Measure Blade Tips to Ground

A. Mower Deck C. Level Ground

B. Blade Tip

A

B

C

Figure 20. Mower Leveling

A. Front Leveling Nuts

B. Rear Leveling Rods

C. 4th Cutting Height Hole

D. Rear Hanger Rods

E. Front Lock Nuts

B

D

C

A

E

Page 15

FastCut Hydro Drive ZTR

7/2005 15

TP 300-7237-IR-HZ-N

Service Procedures

Transmission Oil Filter

Change

Change Interval: Every 250 Hours

Filter Part Number: 1719168

1. Locate the transmission oil filter (C, Figure 24) at the

rear of the battery compartment under the seat.

2. Lubricate the new filter base with a few drops of transmission oil. Fill the filter half full of oil.

3. Clean the area around the filter base and remove the

filter. Do NOT drain the hydraulic system oil.

4. Thread the new filter onto the filter base until the gasket makes contact, then tighten 3/4 of a turn more.

NOTE: The oil will drain from the reservoir tank if the new

filter is not quickly reinstalled.

5. Run the unit for several minutes and check the transmission oil level (D).

IMPORTANT NOTE: Use caution after changing the filter; air in the hydraulic system may affect the responsiveness of the control levers. Repeat step 5 until the air is

out of the system.

Do not allow dirt, water, or other debris to

enter the expansion chamber or

transmission. Even a small amount of dirt

can damage the transmission

Figure 23. Maintenance

A. Fuel Tank Cap

B. Transmission Oil Cap

C. Fuel Filter

D. Locking Tab

E. Locking Screw

B

A

C

D

E

B

Figure 24. Battery Compartment

A. Positive (+) Cable & Terminal

B. Negative (-) Cable & Terminal

C. Transmission Filter

D. Transmission Fill Level Mark

C

B

A

D

Page 16

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/200516

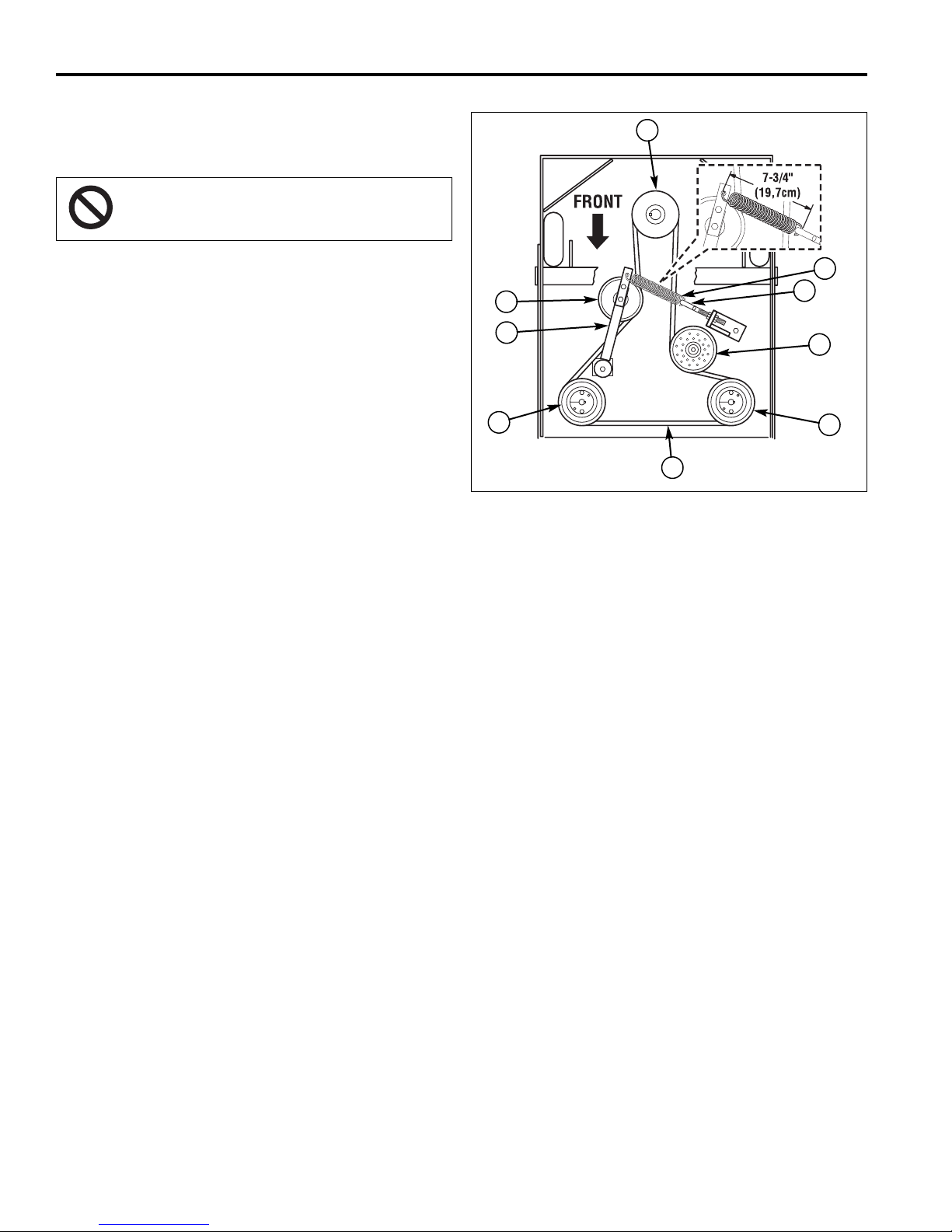

Hydraulic Pump Drive Belt

Replacement

1. Park the rider on a smooth, level surface such as a

concrete floor. Disengage the PTO, engage the parking brake, turn off the engine, and remove the ignition

key.

2. Remove the PTO drive belt (see MOWER BELT

REPLACEMENT for removal instructions).

3. Loosen the nut towards the front of the machine on

the spring anchor hook (H, Figure 25) to release the

majority of the belt tension. Use caution and remove

the nut to completely release the tension.

4. Remove the old belt and replace it with the new one.

Make sure the V-side of the belt runs in the grooves

of the crankshaft pulley and pump pulleys (B & C).

5. Reinstall the anchor hook (H) into the anchor tab and

loosely fasten the nut. Adjust the spring until a measurement of 7-3/4” (19,7cm) is achieved from the outside of the spring hooks. Tighten nut.

6. Reinstall the PTO drive belt.

To avoid damaging belts, DO NOT

PRY BELTS OVER PULLEYS.

Figure 25. Hydraulic Pump Drive Belt Replacement

(Shown from Below)

A. Pump Drive Belt

B. Crankshaft Pulley

C. Pump Pulley

D. Idler Pulley (stationary)

E. Idler Pulley

F. Idler Arm

G. Spring

H. Spring Anchor Hook

B

E

F

A

C

C

H

D

G

Page 17

FastCut Hydro Drive ZTR

7/2005 17

TP 300-7237-IR-HZ-N

Mower Belt Replacement

1. Park the rider on a smooth, level surface such as a

concrete floor. Disengage the PTO, engage the

parking brake, turn off the engine, and remove the

ignition key.

2. Raise the mower deck to transport position. Pull the

lever (A, Figure 27) towards the rear of the machine

to release tension on the mower belt. Secure the

lever in the guard notch (B).

3. Remove the old drive belt and install the new one as

shown in Figure 26. Note that the back of the drive

belt must ride against the back-side idler pulleys (B).

Use the belt tension lever (A, Figure 27) to release

tension on the idler pulley for installation.

To avoid damaging belts, DO NOT

PRY BELTS OVER PULLEYS.

Figure 26. Mower Belt Routing

A. Arbor Pulleys

B. Back-Side Idler Pulleys

C. PTO Pulley

D. Belt Tension Release Lever

A

A

A

C

D

B

Figure 27. Release Belt Tension

A. Belt Tension Release Lever

B. Guard Notch

A

B

Page 18

FastCut Hydro Drive ZTR

TP 300-7237-IR-HZ-N

7/200518

Notes

Page 19

FastCut Hydro Drive ZTR

7/2005 19

TP 300-7237-IR-HZ-N

Notes

Page 20

© 2003 Simplicity Manufacturing, Inc. All Rights Reserved

PRODUCTS, INC.

McDonough, GA., 30253

www.snapper.com

Loading...

Loading...