Page 1

©2008 SIM838 (Rev. 10/14/08)

OWNER’S MANUAL

Battery Backup System

NOTICE D’UTILISATION

Système de secours à batterie

MANUAL DEL USUARIO

Sistema de batería de respaldo

A5000-04

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867 /

1-800-546-7867

English . . . . . . . . . . . . . . Pages 2-11

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867 /

1 (800) 546-7867

Français . . . . . . . . . . . Pages 12-21

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867 /

1-800-546-7867

Español . . . . . . . . . . .Paginas 22-31

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

5760 0108

Page 2

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

warns about hazards that will cause

serious personal injury, death or major property damage

if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which

are important but not related to hazards.

1. To avoid risk of serious bodily injury due to electrical

shock or burns and property damage due to flooding,

read the safety instructions carefully before installing

pump.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be

sure one hand is free when plugging in or unplugging

charger. If basement floor is wet, disconnect power to

basement before walking on floor.

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and property damage.

2. Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault

circuit interrupter (GFCI) is recommended for use on

any electrical appliance submerged in water.

3. Use this system only for backup sump pump duty in

a residential application. It is not designed as a

primary sump pump.

4. Do not lift pump by electrical cord.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

5. Pump clear water only with this pump.

6. Pump is permanently lubricated at the factory. Do

not try to lubricate it!

7. Keep battery charger and battery box off of the floor

and in a dry, cool, well ventilated area.

NOTICE: If a Carbon Monoxide (CO) sensor is

installed, it must be at least 15 feet away from

battery charger in order to avoid nuisance CO

alarms. Please refer to your CO detector’s installation

guidelines for more information.

8. To avoid danger of fire or explosion, keep sparks and

flame (pilot light) away from battery.

9. Maximum vertical pumping distance is 16 feet

(4.9M) for Model A5000-04.

10. Make sure sump is clear of debris. Debris can

damage the pump which can result in flooding.

GENERAL INFORMATION

The battery back-up sump system is not a substitute for

your primary sump pump. It is designed to temporarily

back up your primary sump pump during a power

outage or other problem which prevents normal operation of the primary pump. Do not use this system to

pump flammable liquids or chemicals. Pump clear water

only with this pump.

Keep the battery charger dry and protected from damage.

This system is designed to work with a deep cycle

marine battery, either a flooded lead-acid battery or a

sealed maintenance free lead-acid AGM battery. In an

emergency (such as an extended power outage) which

depletes the system deep cycle battery, your automobile

battery may be temporarily substituted. Be sure to

replace the system deep cycle battery as soon as

possible. Use of an automobile battery instead of a deep

cycle battery in this system will significantly reduce the

system’s total performance. Automobile batteries are not

designed for this type of application and will be quickly

ruined by the repeated charge/discharge cycling.

NOTICE: This system is not designed for applications

involving salt water or brine! Use with salt water or brine

will void warranty.

Page 3

Installation 3

BATTERY BACKUP SYSTEM (BBU)

INSTALLATION AND OPERATION

NOTICE:

• Install this system during a time when the primary

pump will not be needed. Gather all supplies before

starting. Read all warnings and installation steps

before you start.

• Be prepared for water to leak from the coupling or

piping when disassembling or cutting the discharge

pipe. Protect system components, tools and supplies

from getting wet. Dry any work areas that get wet.

BASIC TOOLS AND

MATERIALS NEEDED

Channel locks or large pliers

Tape measure

Socket wrench or 5/16” Nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Pencil

Teflon tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

100-120 Ampere-Hour Marine Deep Cycle Battery

(sold separately)

Required Battery Capacity:

Single Battery: 120 ampere-hour maximum.

Double Batteries: 100 ampere-hours per battery

(200 ampere-hours total)

Personal injury and flood hazard. Do not

turn the pump on until all the fittings are glued and the

glue has dried. Loose fittings can explode off of pipes

and cause personal injury and flooding.

RETAIN ORIGINAL RECEIPT FOR YOUR RECORDS.

LIMITED WARRANTY

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from defects in material and workmanship for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be repaired or replaced at

SIMER’s option, subject to the terms and conditions set forth below. The original purchase receipt and product warranty information label are

required to determine warranty eligibility. Eligibility is based on purchase date of original product – not the date of replacement under warranty. The

warranty is limited to repair or replacement of product only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service at 1-800-468-7867 /

1-800-546-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail outlet where it was

purchased immediately after the discovery of any alleged defect. SIMER will subsequently take corrective action as promptly as reasonably

possible. No requests for service will be accepted if received more than 30 days after the warranty expires.

SEWAGE PUMPS

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage pumps that have seen

service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, CM10, CMK, M40, M40P 90 days

2300, 2310, 2330, 2520ULST, 2955, 2956, 2957, 2960, A5500 2 Years

4” Submersible Well Pumps, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 Years

Pre-Charge Water System Tank, 3985, 3986 5 Years

3963, 3988, 3995, 3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not apply to the following:

(1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to negligence, abuse, accident, misapplication, tampering, or

alteration; (3) failures due to improper installation, operation, maintenance or storage; (4) atypical or unapproved application, use or service;

(5) failures caused by corrosion, rust or other foreign materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.THE FOREGOING

WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts, so

the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have other rights which vary

from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Web Site: http://www.simerpumps.com

Page 4

Installation 4

BBU INSTALLATION INSTRUCTIONS

Risk of electrical shock. At the circuit breaker

or fuse box, turn off the electrical power to the sump

pump before beginning this installation.

Setup

1. Locate the high water level in your sump pit (that is,

the water level at which the existing (primary) sump

pump starts - see Figure 1). Mark this point on the

discharge pipe with a pencil or marker.

2. Drain the sump pit as far as possible without running

the pump dry. Do this by:

A) PIGGYBACK SWITCH: Unplug the pump and switch

from the outlet, then unplug the pump from the

piggyback switch. Reset the circuit breaker or

reinstall the fuse and plug the pump directly into

the outlet. The pump will start. Drain the pit and

unplug the pump. OR

B) NO PIGGYBACK SWITCH: Reset the circuit breaker or

reinstall the fuse and use a non-conducting

broom handle or stick to raise the float switch;

the pump should start. Drain the pit and then

release the switch.

C) ALL INSTALLATIONS: When the pit has drained, turn

off (open) the circuit breaker or remove the fuse

again to avoid electrical shock while working on

the installation.

3. Support the discharge pipe so that it can’t collapse

when you take it apart or cut it.

4. If your discharge pipe has a hose coupling, disconnect the coupling. If not, cut the vertical discharge

pipe at any convenient spot above the floor level.

5. Lift the pump and attached pipe out of the sump pit.

Installation

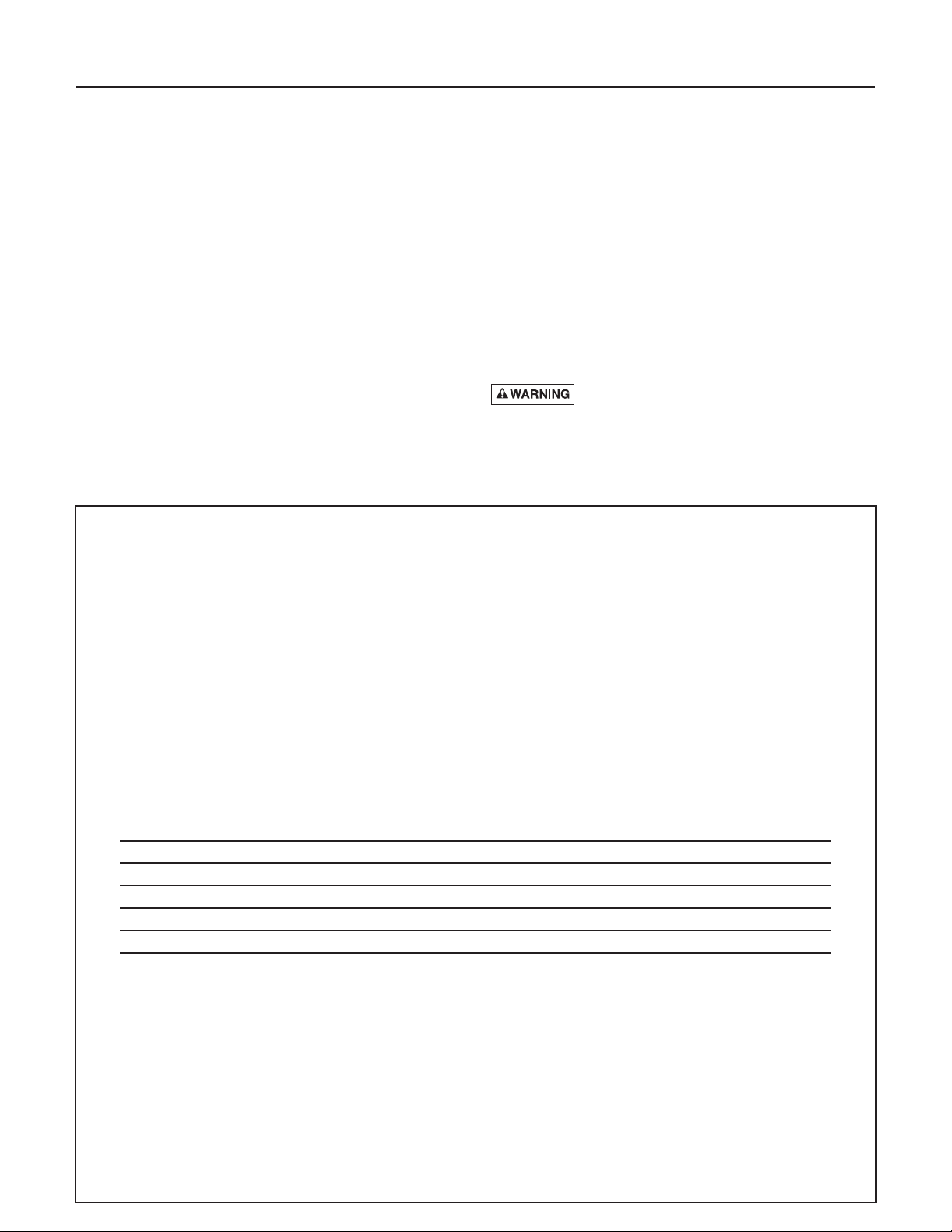

1. Study Figure 2 for suggested layouts.

The Easy-Install layout works better for deeper

sumps and allows a smaller diameter sump (diameter

13-1/2” or larger, depth more than 22”).

The Alternate layout works better for wider, shallower sump pits (diameter 18” or larger, depth 1822”). The Alternate layout will require that you

purchase (2) 1-1/4” x 90° elbows and (2) 1-1/4” x

close pipe nipples.

Other layouts may require more pipe fittings.

2. Find the high water level mark you made on the

discharge pipe in “Setup, Step 1”. Cut the pipe at this

point and set the cut-off piece aside for use later.

Clean up and debur the cut ends.

3. Wrap the threads of the Battery Back Up pump (BBU

pump) and the 1-1/4” x close nipple with 1-1/2 – 2

turns of teflon tape (see Figure 2). Leave the first

thread free of tape and wrap clockwise ( ).

4. Thread the tee, the close nipple, the 1-1/4” x 1-1/4”

check valve, and the BBU pump together. To get

them tight, hold the pump and insert a large screwdriver down through the tee and tighten the whole

assembly with the screwdriver. D

O NOT OVERTIGHTEN!

When the assembly is tight, the pump and tee should

align vertically (no twist – see Figure 2).

5. Glue the cut-off piece of pipe (which you set aside

in Step 2) into the top of the tee.

NOTE: If your discharge pipe is 1-1/4” inch, glue one

of the reducer bushings supplied with the system into

the tee, then glue the pipe into the bushing.

6. Look at your primary pump to determine if you have

a check valve in or near the pump discharge. If not,

install the auxiliary check valve in the bottom arm of

the tee and install the slip coupling on the check

valve (see Figure 2). For 1-1/4” discharge pipe, glue

the remaining reducer bushing into the slip coupling.

NOTE: If the primary pump assembly already

includes a functioning check valve, do not use the

auxiliary check valve included in the BBU system.

You need one check valve between the primary

pump and the tee (to prevent backflow from either

pump into the sump pit), but two check valves will

restrict the pipe too much.

7. Trial Fit (NO GLUE YET): Place the primary pump

assembly back in the sump pit and add (dry) the

tee/check valve/BBU pump assembly to it. If necessary, also include the 1-1/2 x 1-1/4 reducer bushing

and the slip coupling and auxiliary check valve (see

“NOTE”, above).

8. Measure the assembly against the hanging upper

discharge pipe (where you cut it in Step 1 under

“Setup”). Mark the discharge pipe coming up from

the tee 1/4” below the point of overlap (that is, you

should have an air gap of 1/4” after you cut the

pipe). Don’t cut anything yet.

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Figure 1: Mark pipe at ‘start’ water level

Support the

Pipe before

cutting.

Mark pipe with

pencil here.

Sump Pit

‘Start’ water level

of Primary Pump

Check

Val ve

Page 5

Installation 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

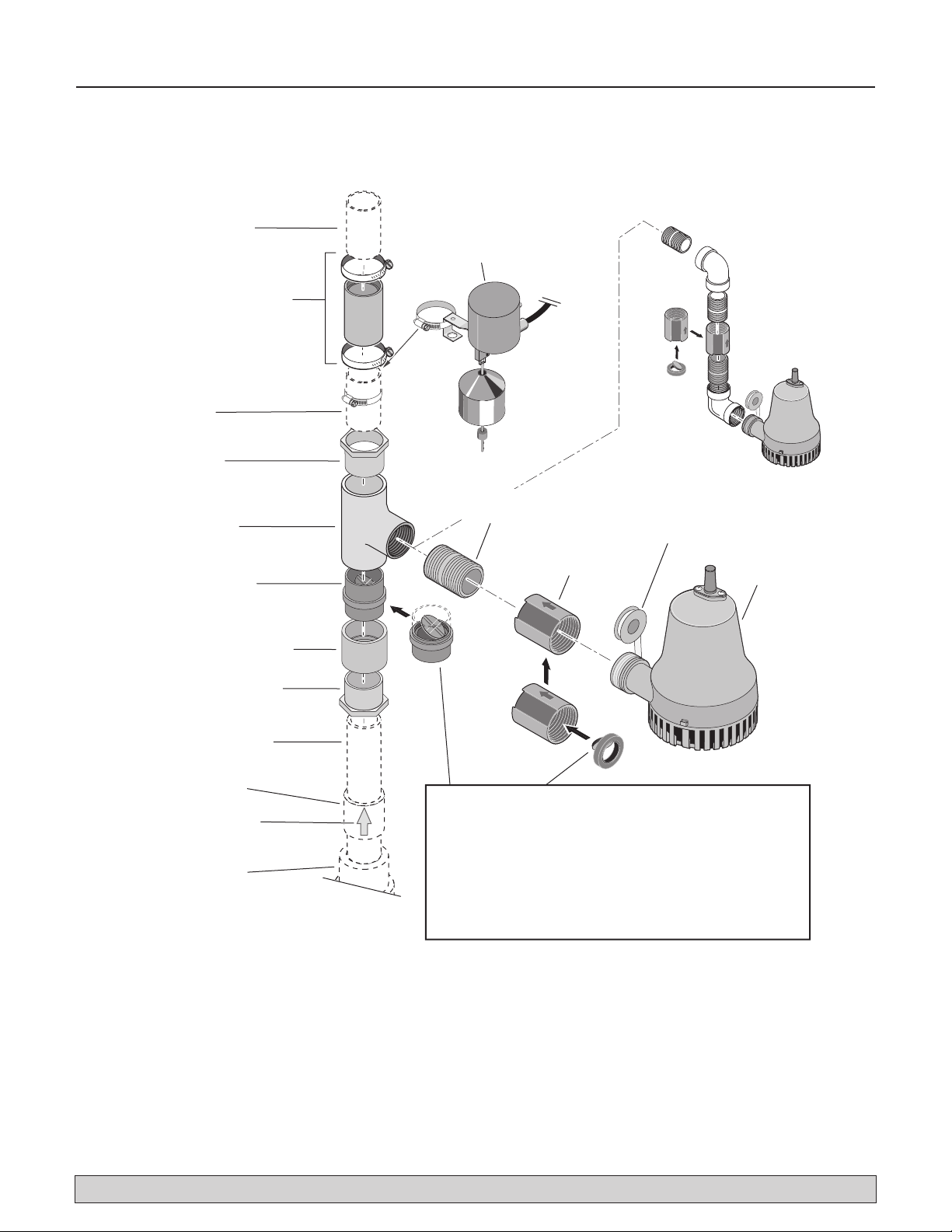

Figure 2: Typical Installation Layouts

“Easy Install” Layout

Upper Discharge pipe

Hose Coupling with Clamps*

Discharge pipe

cutoff piece

1-1/2"x1-1/4" Slip

Reducer bushing*

1-1/2"x 1-1/2" slip x

1-1/4" FNPT Tee*

Auxiliary Check Valve*

(

See Important Check Valve

Warranty Note, Below

†

)

Not to scale;

wiring omitted

for clarity.

Switch with Clamp*

1-1/4”x1-1/4”

Close Nipple*

1-1/4”x1-1/4”

Check Valve

Assembly*

Alternate Installation

for a Shallow Sump

##

Teflon tape all

threaded joints

Battery Back Up

Sump Pump*

1-1/2"x1-1/2" Slip Coupling*

1-1/2"x1-1/4" Slip Reducer

Bushing*

Primary Pump Discharge

Pipe (cut to fit)

Primary Sump Pump

Check Valve

Flow Arrow; Must point

AWAY from Pump being

Protected

Primary Sump Pump

Discharge Port

Notes:

* Supplied with the Battery Backup System.

†

Use if necessary to adapt a 1-1/4” discharge pipe to the 1-1/2” fittings supplied.

#

Use to adapt the auxiliary check valve to the discharge pipe.

##

Water level when the switch shuts off must be above the BBU pump intake.

†

#

IMPORTANT CHECK VALVE/WARRANTY NOTE:

Check Valve Flapper(s) must swing in direction shown.

Flow arrow(s) must point AWAY from pump being protected.

The 1-1/4” X 1-1/4” Check Valve Assembly must be installed

as shown or the warranty is void. Do not use a wrench (see

Installation Step 4, Page 4)! If the Primary Sump Pump

does not have a check valve installed as shown below the

Tee, the Auxiliary Check Valve must be installed as shown

or the warranty is void.

5763 0108

Page 6

Installation 6

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

9. Study the assembly in the pit for a moment and then

adjust it so that nothing interferes with the primary

pump or its switch. Mark the joints with a permanent

marker so that you can realign everything after you

pull it out of the pit for gluing (see Figure 3).

NOTE: Take your time with this - it takes care but

isn’t very difficult. Be sure you leave enough room

for the BBU pump’s vertical switch. Mark everything

that might move!

10. After you have marked everything, remove the

assembly from the pit.

11. Cut off the vertical discharge pipe at the cut point

you marked in Step 8. BE SURE YOU ARE CUTTING ON

THE RIGHT MARK

!

12. Recheck the alignment and glue up all the joints on

the primary pump assembly.

NOTE: You may need to support the assembly,

which won’t balance very well, in order to preserve

the alignment while gluing it. Check this before you

start gluing. Another pair of hands may help here!

13. After the glue has set, slide the hose coupling and its

clamps down over the assembled discharge pipe. If

the pipe is 1-1/4”, be sure to use the two reducing

inserts included with the coupling.

14. Hook the switch clamp over the switch bracket and

slide the assembly down over the hose coupling and

discharge pipe. Clamp the switch so that the water

level when the switch shuts off is above the BBU

pump’s intake.

15. Replace the assembly in the pit, slide the hose

coupling up over the air gap so that it joins the pipes,

and tighten the clamps enough to keep it there.

16. Check fit, alignment, etc. If everything looks good,

make sure that the BBU vertical switch is at the right

height and free of obstructions, then tighten the hose

clamps on the coupling.

17. Adjust the rod stop location on the BBU float rod to

give the desired switch travel. If necessary, nip off

the bottom of the float rod to provide clearance.

BBU WIRING AND SETUP

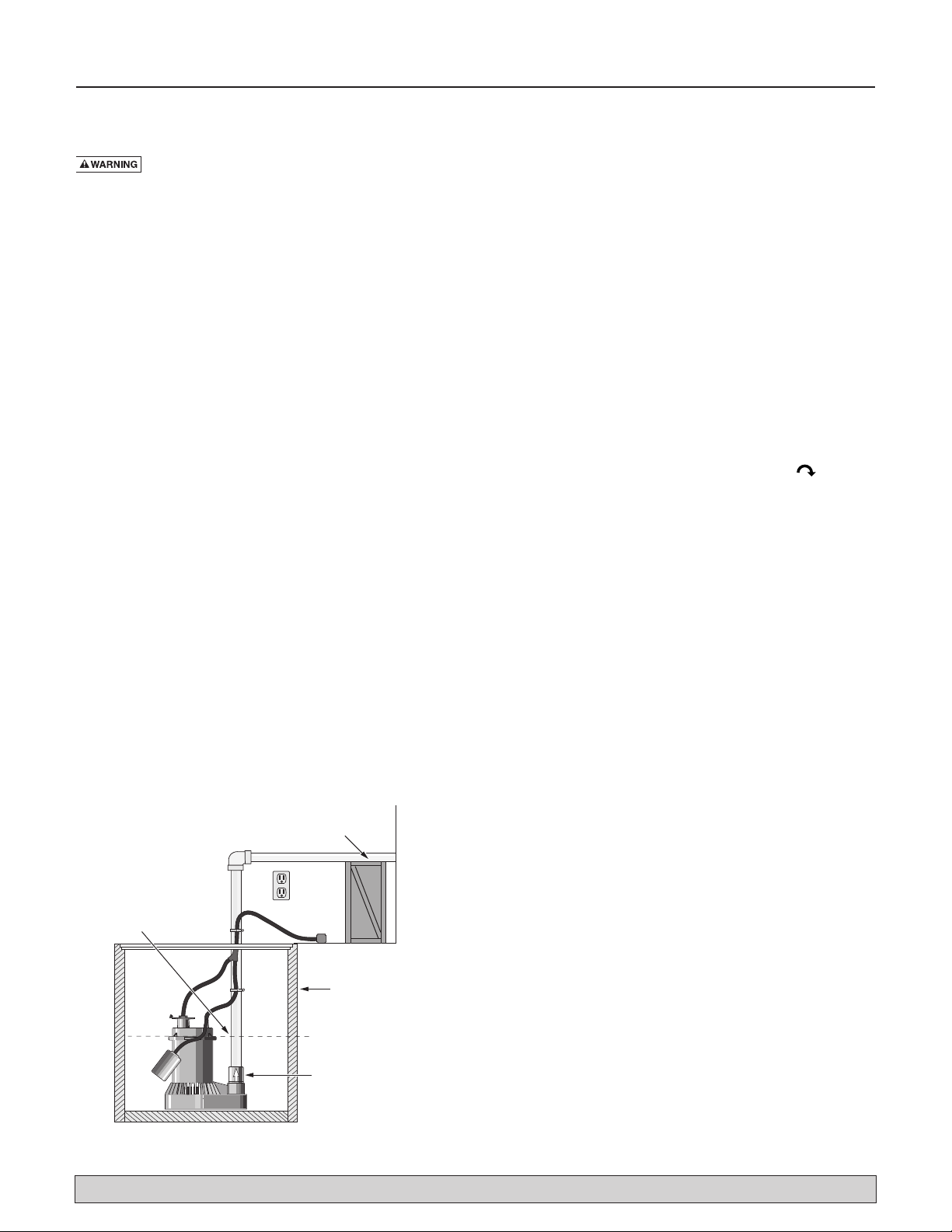

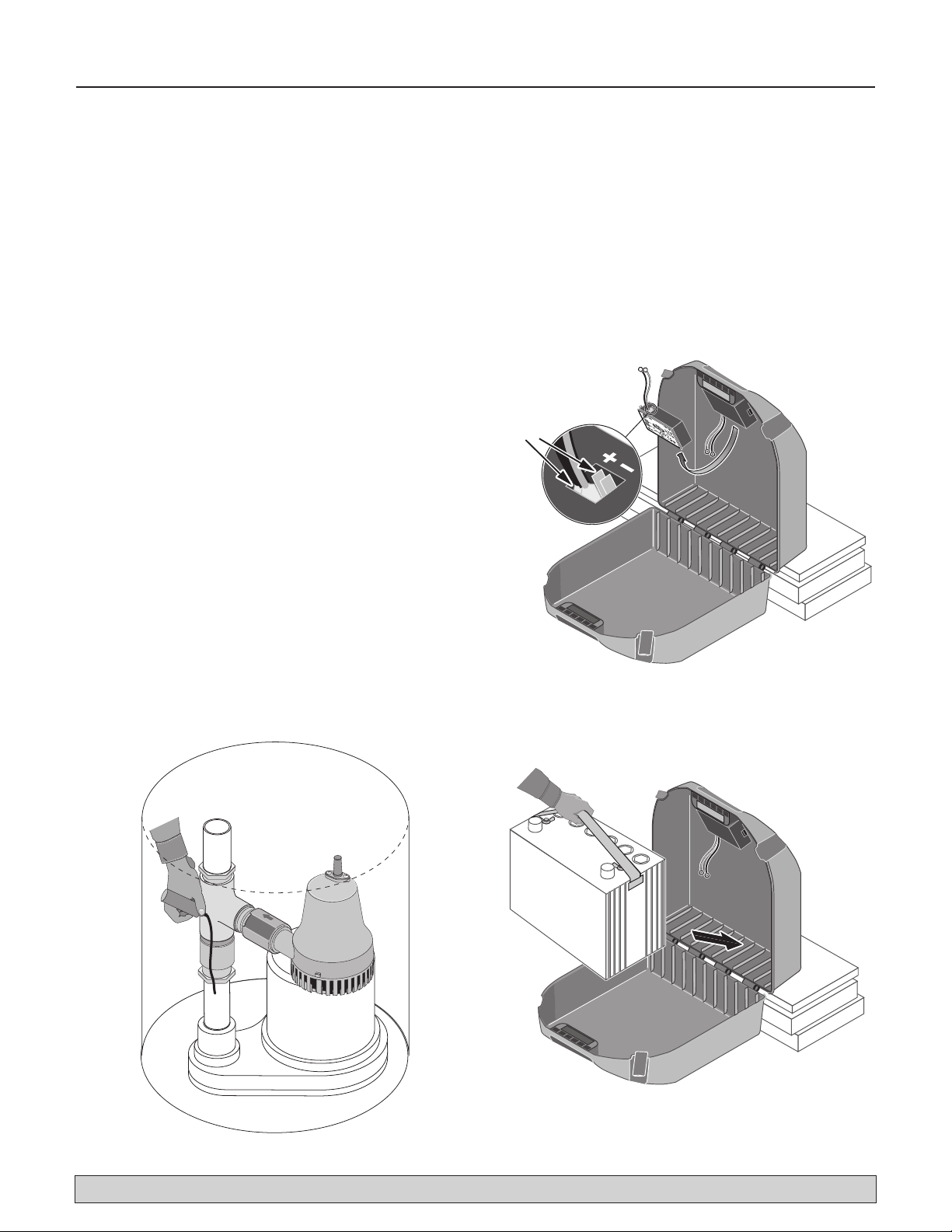

See Figures 4, 5, and 6 for battery installation and

connection information.

Figure 3: Mark joints for gluing

Figure 4: The battery input is inside the battery case.

Support the case when opening it. The support must be

at least 4” thick.

Figure 5: Install the battery in the case. Have someone

support the case while you do this. Once the battery is in

the case, connect the leads from the charger/controller:

+(Red) to +(Red), and –(Black) to –(Black).

Battery

Inputs

5768 0108

Page 7

Installation 7

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

1. The pump leads are polarity sensitive; connect the

positive pump lead to the terminal labeled ‘Pump +’

and the negative pump lead to the terminal labeled

‘Pump –’.

NOTE: If the leads are reversed, the pump will run

backward and not pump water.

2. The vertical float switch leads are not polarity sensitive; connect the float switch leads to the ‘Float

Switch’ tabs on the Charger/Controller. If you are

using two batteries, use the second set of terminals

and connect the second battery in the same manner.

Connect the

positive

(+) battery lead (red) to the

positive Charger/Controller terminal (red). Connect

the

negative

(–) battery lead (black) to the negative

terminal (black) on the Charger/Controller.

3. Test the float switch and the pump by lifting and

holding the float rod. The ‘Pump Status’ LED will

light continuously and the buzzer will beep steadily.

The pump should start after 3 seconds. If the pump

does not run, check all the connections and remake

them as necessary.

4. With the pump operating, press the ‘Silence Alarm’

button; hold for one second; release. The ‘Silenced

Alarm’ LED should illuminate and the buzzer should

stop sounding. To reset the buzzer (make it sound)

and extinguish the ‘Silenced Alarm’ LED, press the

‘Silence Alarm’ button again for one second.

5A. To stop the pump, lower the float switch; after 3

seconds the pump should stop, the ‘Pump Status’

LED should flash, and the buzzer should beep.

5B. Depress the ‘System Test’ button; hold it for one second;

release. The ‘Pump Status’ LED should stop flashing.

NOTE: During normal operation, the flashing ‘Pump

Status’ LED indicates that the pump has run in your

absence. See Table II, “Operating Code Displays”,

Page 9.

6. Press and hold ‘System Test’ button. All LEDs will

light up, pump will run and buzzer will sound.

Release the button and LEDs should go off, pump

should stop, buzzer should stop.

7. The ‘Battery Status’ LED indicates the battery

capacity when the A.C. power is off.

A. Continuously ‘ON” - the battery voltage is above

10.9 Volts Direct Current (10.9VDC) and

capacity is above 20%.

B. Slow Beep/Slow LED Flash - the battery’s

capacity is between 0 and 20%.

C. Fast Beep/Fast LED Flash - the battery is severely

discharged. The battery will continue to charge

(as long as the 115V AC power to the charger is

on) at the rate of .5 AH until the battery’s charge

is above 20%.

When the first warning occurs (slow beep/slow

flash), you will have approximately 2 hours (or less)

of pump operation left. The actual time of operation

will depend on the condition of the battery and may

be as little as 15 minutes.

8. Connect the Power Supply cable (supplied) to the

Charger/Controller’s Power Input jack.

LED Display and Control Buttons

(Tables II, III, IV, and V)

NOTE: When the unit is first plugged in, or when it first

receives power from the battery, the Battery Status LED

will flash for 3 seconds.

NOTE: To activate any Control Button, depress and hold

it for 1 second.

Possible Remedies

1. Wrong Battery Voltage

Reconnect charger to a 12 volt battery.

2. Reversed Battery Connections

Check all connections. The negative (black) on the

battery must connect to the negative (black) on the

charger, and the positive on the battery must connect

to the positive on the charger. Reversing the battery

connections will cause the ‘System Alert’ and

‘Silenced Audible Alarm’ LEDs to flash.

3. Thermal Runaway Condition

“Thermal Runaway” is the technical term for the

condition of the battery when some (or all) of the

cells have deteriorated to the point that they won’t

take a charge. In this case, replace the battery.

4. Charge Time Monitor – 1 and 2

Battery took too long to complete its charge. The

‘Charge Time Monitor’ will shut down the charger

after 84 hours of continuous charging.

Possible causes are:

A) Pump ran for a long period of time during

charging, or

B) Battery is too large for the charger (including

several batteries connected in a parallel circuit).

Apply the formula in Table I to determine whether

or not your battery is too large for the charger. If the

calculated charging time is more than 84 hours, use

a smaller battery (or group of batteries).

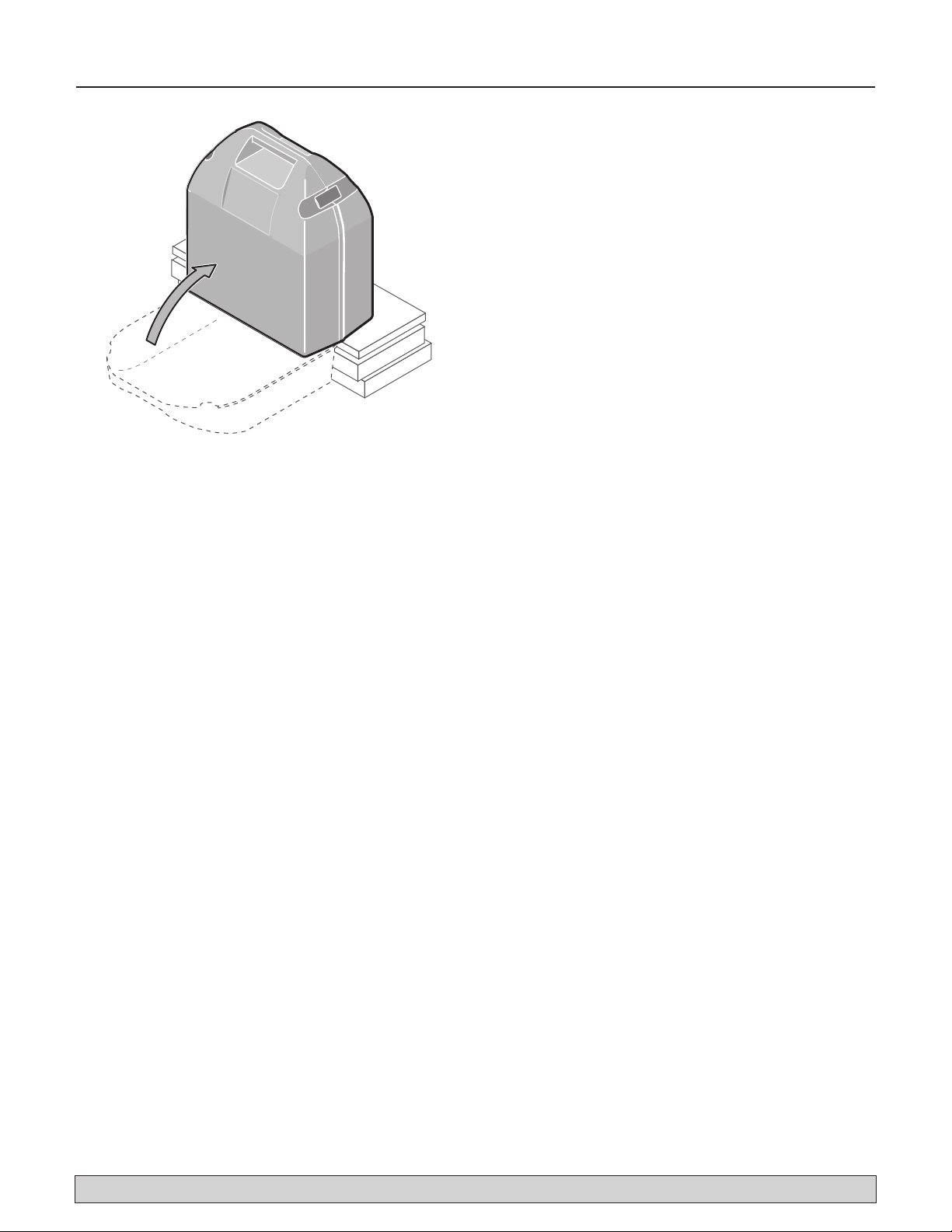

Figure 6: Close and latch the case while holding it in

position.

Page 8

Installation 8

Excessive Battery Drain

Pump may have run for a very long time, discharging the

battery. In this case:

A) If 115VAC power is OFF, the charger shuts down

until the power comes back on, but the pump

will run as long as the battery charge lasts. You

may need to replace the battery afterwards.

B) If 115VAC power is ON, the charger/controller

continues to try to charge the battery at a

charging rate of .5 AH until the battery charge is

more than 20%, at which point the charger will

resume charging at a rate of 2 AH.

C) If the pump is running and the AC power is on,

you may need to stop the pump to allow the

battery to charge.

Pre-Qualification Test – 1 and 2

Charger is charging at a very low level to try to bring a

dead battery back to life. If the battery is taking too long,

try resetting the charger once or twice (push the ‘System

Test’ and ‘Silence Alarm’ buttons to reset the charger).

Special Features:

• The charger is equipped with reverse battery, short

circuit, and “run-away charge” protection.

BATTERY REQUIREMENTS

Hazardous electrical current. Can cause

severe burns and start a fire if the battery terminals are short

circuited. Install the battery in the battery case (See Key No.

12, Page 11). To prevent accidental shorting across battery

terminals, close and latch the battery case securely. Do not

leave the battery uncovered. Do not allow children to play

around the battery backup system installation.

Your backup sump pump depends on the battery used

with it for power. The better the battery, the better the

performance of the pump. We recommend the use of a

size 27M Marine Deep Cycle Battery. It will perform as

indicated in Table VI, on Page 10, and will stand up well

to long periods of little or no use.

This system is designed to work with a deep cycle

marine battery, either a flooded lead-acid battery or a

sealed maintenance free lead-acid AGM battery. Use of a

standard automobile battery with this charger is not

recommended. An automobile battery may require

charging after only 1–2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size 13" long, 7" wide and 10" high [330.2mm x

177.8mm x 254mm] including terminals) and supply

enough voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. An acid-filled standard

lead-acid battery contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

NOTICE: To protect the battery case from chipping and

gouging, do not let the battery sit on a concrete floor.

Install the battery on a shelf or protective pad (plywood,

2x4s, etc.). Always install the battery in a dry location

that is protected from flooding.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of the battery.

TROUBLESHOOTING

Pump won’t run.

1. Check all the wiring connections.

2. Check for a low or defective battery.

3. Check that the automatic switch is free to move up

and down.

4. Press the circuit breaker reset button on the control

panel.

Motor hums but pump won’t run:

1. Check for low or defective battery.

Pump runs but pumps very little or no water:

1. Make sure a check valve is installed and functioning

between the primary pump discharge and the Battery

Backup tee.

2. Check for an obstruction in the discharge pipe.

3. The discharge pipe length and/or height exceeds the

capacity of the pump. See Table VI, Page 10, for

pump capacity.

4. Check for a low or defective battery.

5. The Positive (+) and negative (–) pump wires are

reversed. Disconnect them and reconnect correctly.

Pump cycles too frequently:

The check valve located between the discharge of

the primary pump and the Battery Backup tee is not

installed or is not working properly. Install the auxiliary check valve (see Pages 4 and 5) or replace the

existing check valve as required.

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

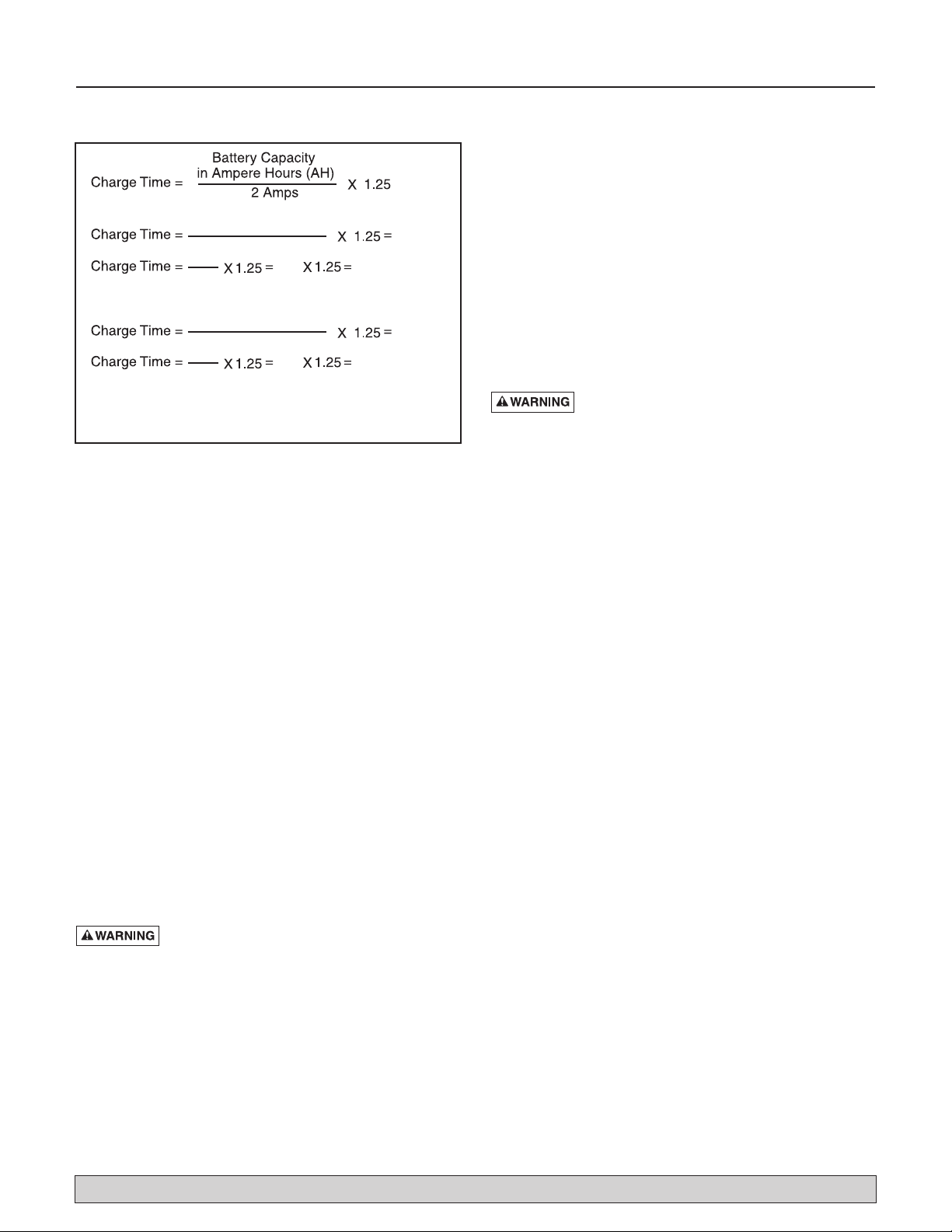

TABLE I – Battery Capacity Calculation

Example 1:

Less than 84 hours to charge; OK to use.

Example 2:

Capacity too large – use a battery of 130A-H or less.

NOTE: A 100AH battery in good condition should charge

in approximately 62 hours.

130 Ampere Hours

2 Amperes

130H

2

160 Ampere Hours

2 Amperes

160H

2

65H

80H

81.25 Hrs

100Hrs

5764 0108

Page 9

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Installation 9

A

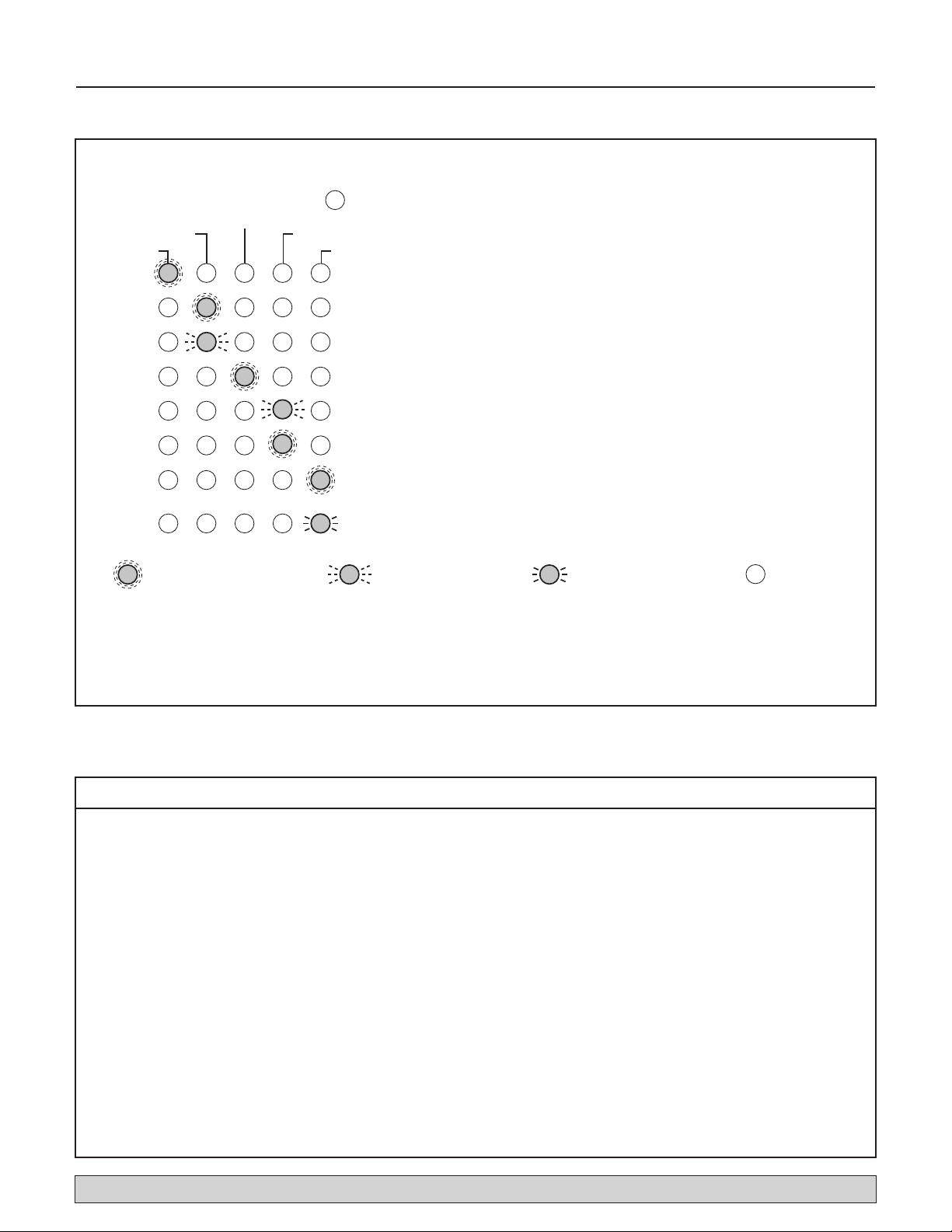

TABLE II – Operating Code Displays (LEDs Lighted Continuously or Flashing)

Control LED: Continuous Illumination Indicates Normal Operation:

AC Power AC power is present.

Pump Status

The float switch has been activated. The LED remains on (flashing) after the pump

has stopped. Depress the‘System Test’ button to reset it.

Silenced Audible Alarm Audible Alarm has been silenced. Press and release the ‘Silence Alarm’ button to

reset (activate) the audible alarm and turn OFF the LED.

Charging

Indicates that the battery is charging – see Table II, above.

Battery Status A. Continuous ‘ON” - the battery voltage is above 10.9 Volts DC and capacity is

above 20%.

B. Slow Beep/Slow LED Flash - the battery’s capacity is below 20%, and voltage

is between 8.2VDC and 10.9VDC.

C. Fast Beep/Fast LED Flash - the battery has been discharged to less than

8.2VDC.

System Alert Flashing (in unison with the buzzer) indicates that the charger has entered ‘Failure

Mode’. Press the ‘System Test’ and ‘Silence Alarm’ buttons to reset it.

NOTE: If the source of the failure is not corrected, the charger will reenter ‘Failure

Mode’. See Table IV for error code information.

TABLE III – LED Function Displays (LEDs Lighted Continuously)

LED Operating Code Display

System Alert

Pump status

C power

Silenced audible alarm

= =

LED is ON Continuously

NOTE: All of the situations listed above indicate normal system operation; no action is required.

However, if the BBU pump is running or has run, check the primary pump and actively monitor the

charger status for battery life. Always reset the charger after the pump runs.

During normal system operation, the ‘System Alert’ LED does not light up. The “AC Power” LED

is lighted as long as the system is plugged in to an operating AC power circuit.

Charging

Battery status

Indicates 115V AC Power is connected

Indicates Pump is running (continuous LED)

Indicates Fast flashing LED: Pump has run

Indicates Audible alarm is switched off

Indicates Fast flashing LED: Battery pre-qualification test is running

Indicates Battery is charging normally

Indicates Continuous LED: battery charge is above 20%,

system is maintaining charge

Indicates Slow flashing LED: battery charge is below 20%

=

LED is Flashing (Fast)

System Operating Condition

=

LED is Flashing (Slow)

LED is OFF

Page 10

Installation 10

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

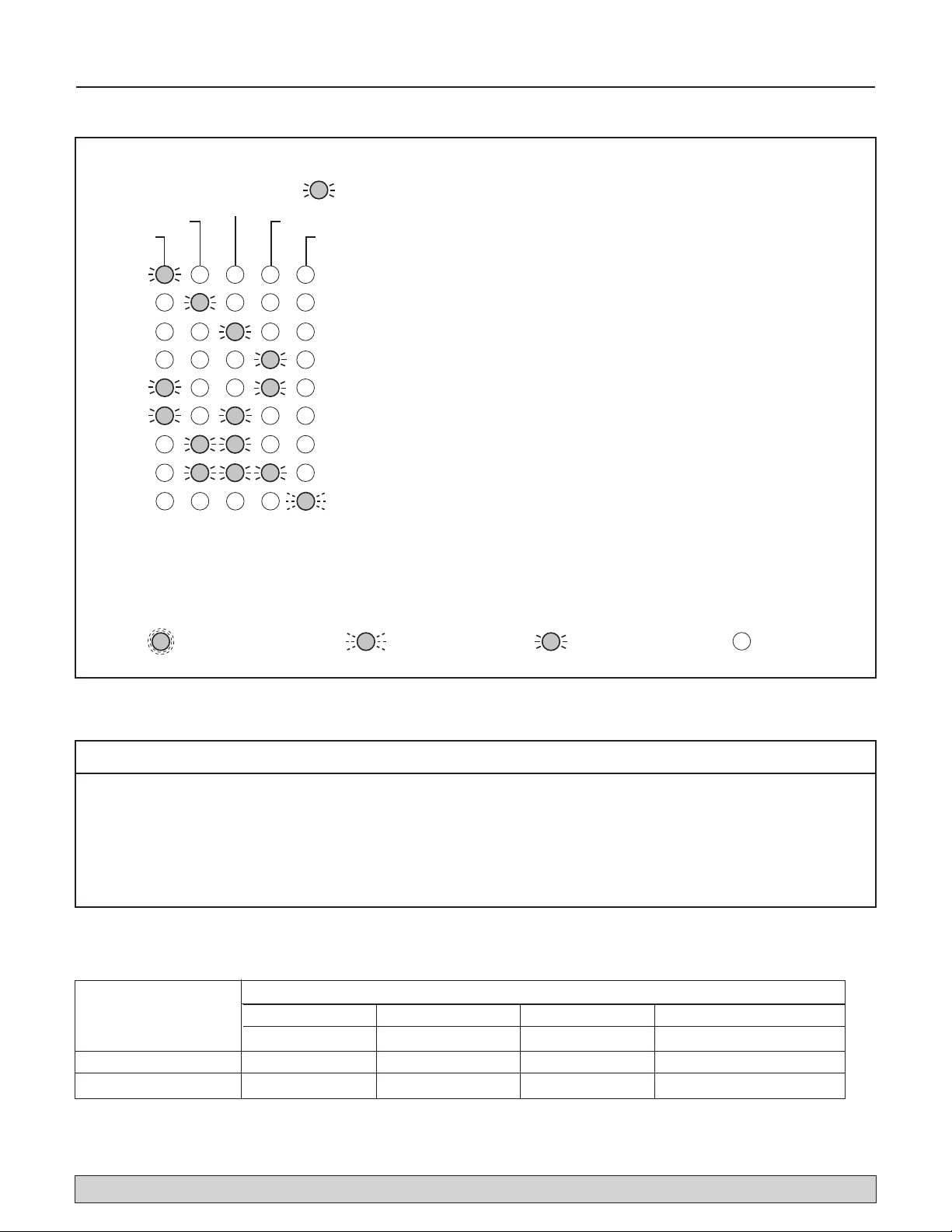

TABLE IV – Error Code Displays (LEDs Flashing)

VERTICAL PUMPING DISTANCE - MODEL A5000-04

8 FEET (2.4 M) 10 FEET (3.0 M) 12 FEET (3.7 M) 16 FEET (4.9 M)

Gallons Per Hour 1,440 1,200 840 No Flow at this Height

Aproximate Hrs Available 10 11.5 13 –

Total Gallons Pumped 8,500 7,000 5,000 –

TABLE VI – Capacity Ratings with a 100 A-H Deep Cycle Marine Battery

* These flow rates were obtained with a constant 12.7 VDC battery source. The actual GPH will vary due to a reduction in

output voltage from the battery as it discharges.

Control Button: Result of Pushing Button:

System Test Pump starts and all LEDs light up.

Will reset the ‘Pump Status’ LED.

When pushed with the ‘Silence Alarm’ button, the Charger/Controller

microprocessor resets and error code resets.

Silence Alarm Toggle; Prevents the audible alarm sounding. Press and release to reset.

Flood Light Toggles the flood light on the Charger/Controller on and off.

TABLE V – Control Button Functions

Pump status

AC power

LED Error Code Display

System Alert

Silenced audible alarm

Error Condition and Corrective Action

NOTE: When the ‘System Alert’ LED is flashing,

look for one of the following error conditions.

Charging

Battery status

Condition Action

= Excessive battery drain; Stop pump, allow battery to charge (AC must be on)

= Battery will not take a charge***; Replace battery with a new 12V lead-acid battery

= Reversed battery connections; Connect + to + and – to –.*

= Wrong battery voltage; Replace battery with a new 12V lead-acid battery

= Failed pre-qualification test – 1**; Replace battery with a new 12V lead-acid battery

= Failed pre-qualification test – 2**; Replace battery with a new 12V lead-acid battery

= Charge time monitor – 1; Check battery for damage to cells; replace battery

= Charge time monitor – 2; Check battery for damage to cells; replace battery

= Battery Charge is Below 20%; Pump will shut down, battery is not charging. Replace

battery.

* NOTE: If your AC power is off and the unit is dead (no LEDs lighted, no audible alarm, pump isn’t running),

check for reversed battery connections to the charger/controller.

** Charger was charging at a very low level to try to bring a dead battery back to life, but the battery took too long

to charge. Try resetting the charger once or twice (push the ‘System Test’ and ‘Silence Alarm’ buttons at the same

time to reset the charger).

*** Thermal Runaway condition

= =

LED is ON Continuously

=

LED is Flashing (Fast)

=

LED is Flashing (Slow)

LED is OFF

5766 0108

Page 11

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Repair Parts 11

Key No. Part Description Part Number

1 Hardware Replacement Kit (Includes Key Nos. 1A through 1G) PS198-270

1A Rubber Hose Coupling with Inserts (2) and Clamps (2) U74-68

1B 1-1/2 x 1-1/4 PVC Slip Reducer Bushing (2) *

1C PVC Tee 1-1/2 x 1-1/2 Slip x 1-1/4 FNPT *

1D Auxiliary Check Valve *

1E 1-1/2 x 1-1/2 PVC Slip Coupling *

1F PVC Pipe Nipple, 1-1/4 NPT x Close *

1G

Check Valve Assembly, 1-1/4 FNPT x 1-1/4 FNPT

*

2 DC Backup Pump **

3 Vertical Float Switch Package PS198-269REP

4 Charger PS217-1512

5 Battery Case (Complete) PS17-1512

6 AC Adaptor PS17-1530

• Electrical Replacement Kit (Includes Area Light LED and PS1513REP

Battery Leads)

* Included in Hardware Replacement Kit, Key No. 1.

** If pump fails, replace entire system.

NOTE: Key No. 1G Check Valve Assembly must be correctly installed or warranty is void. If

primary sump pump has no check valve installed below the Battery Backup Tee, Key No. 1D

Auxiliary Check Valve must be correctly installed or warranty is void.

4

1A

1

1B

1C

1D

1E

1F

1G

3

2

5

6

5767 0108

1B

Page 12

Sécurité 12

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

LIRE ET OBSERVER

LES INSTRUCTIONS DE SÉCURITÉ!

Voici le symbole indiquant qu'il faut être prudent.

Lorsque ce symbole apparaît sur la pompe ou dans

la présente Notice, chercher une des mises en garde

suivantes et rester aux aguets pour éviter des blessures

corporelles :

avertit d'un danger qui causera des

blessures corporelles, la mort ou des dommages

matériels importants si on l'ignore.

avertit d'un danger qui risque de causer

corporelles, la mort ou des dommages matériels importants si on l'ignore.

avertit d'un danger qui causera ou qui

risquera de causer des blessures corporelles, la mort ou

des dommages matériels importants si on l'ignore.

Le mot REMARQUE indique des instructions spéciales et

importantes n'ayant aucun rapport avec les dangers.

1. Pour éviter tout risque de blessures corporelles ou de

brûlures graves par choc électrique et des dommages

matériels importants causés par une inondation, lire

attentivement ces consignes de sécurité avant de

procéder à l’installation de la pompe.

L’acide des batteries est corrosif. Ne pas

en renverser sur la peau, les vêtements ou le chargeur.

Porter des lunettes de sécurité à coques et se protéger la

tête lorsqu’on intervient sur une batterie. Ne brancher et

ne débrancher les bornes de sortie en courant continu

qu’après avoir débranché le chargeur de la prise de

courant alternatif. Ne jamais permettre aux bornes du

courant continu de se toucher.

Tension dangereuse. Risque de secousses

électriques graves, voire mortelles. Ne pas brancher ni

débrancher le chargeur de la batterie si on se tient sur un

sol humide ou dans l’eau. S’assurer d’avoir une main

libre lorsque l’on branche et débranche le chargeur.

Couper le courant alimentant le sous-sol si on doit

marcher sur son sol humide.

Risque d’inondation. Ne pas laisser la

pompe fonctionner à sec, sinon ses joints seront endom-

magés, ce qui risque de causer des fuites et des

dommages matériels.

2. Pour installer ce système, respecter tous les Codes de

la plomberie de la municipalité et du gouvernement

fédéral. Il est recommandé d’utiliser un disjoncteur

de fuite à la terre pour protéger tous les appareils

électriques immergés dans l’eau.

3. N’utiliser ce système qu’en tant que pompe de

puisard de secours dans une résidence. Il n’est pas

conçu pour être utilisé en tant que pompe de puisard

primaire.

4. Ne pas lever la pompe par son cordon électrique.

Risque de secousses électriques. Ne pas

lever la pompe par son cordon électrique. Ne la lever

que par le tuyau de refoulement, son anneau de levage

ou sa poignée. Lever la pompe par son cordon endommagera le cordon.

5. Ne pomper que de l’eau claire avec cette pompe.

6. La pompe a été lubrifiée en permanence à l’usine.

Ne pas la lubrifier!

7. Le chargeur et le coffret de la batterie ne doivent pas

reposer sur le sol. Ils doivent être installés dans un

endroit sec, frais et bien aéré.

REMARQUE : Si un détecteur de monoxyde de

carbone (CO) est utilisé, il doit être installé à au

moins 5 mètres (15 pieds) du chargeur de la batterie

pour empêcher son déclenchement intempestif. Pour

de plus amples renseignements, se reporter aux

instructions d’installation de ce détecteur.

8. Pour empêcher tout risque d’incendie ou d’explosion, ne pas approcher d’étincelle ni de flamme nue

(veilleuse) de la batterie.

9. La distance verticale maximale de refoulement de

cette pompe est de 4,90 mètres (16 pieds).

10. S’assurer que le puisard ne contient pas de débris

qui risqueraient d’endommager la pompe et causer

une inondation.

RENSEIGNEMENTS GÉNÉRAUX

Le système de puisard de secours à batterie n’est pas

prévu pour être utilisé en tant que pompe de puisard

primaire. Il est conçu pour être utilisé comme système de

secours temporaire pour la pompe primaire d’un puisard

en cas de panne de courant ou de tout autre problème

pouvant empêcher le fonctionnement normal de la

pompe primaire. Ne pas pomper de liquides inflammables ni de produits chimiques avec ce système. Ne

pomper que de l’eau claire.

Garder le chargeur de la batterie sec et protégé contre

les dommages.

Ce système est prévu pour fonctionner avec une batteriemarine au plomb à décharge poussée ouverte ou sans

entretien AGM (à fine feuille de fibre de Boron-Silicate).

En cas d’urgence (panne de courant prolongée qui

risquerait de décharger complètement la batterie à

décharge poussée du système, par exemple), une batterie

d’automobile pourra être utilisée temporairement. La

batterie d’automobile devra toutefois être remplacée

aussitôt que possible par la batterie à décharge poussée

du système. L’utilisation, avec ce système, d’une batterie

autre qu’une batterie à décharge poussée diminuera

considérablement le rendement de ce système. Les

batteries d’automobile ne sont pas conçues pour ce type

d’utilisation et elles seront rapidement détruites par les

cycles répétés de charge et de décharge. REMARQUE :

Ce système n’est pas conçu pour pomper de l’eau salée ni

de la saumure! Cette pratique annulera la garantie.

Page 13

Installation 13

INSTALLATION ET FONCTIONNEMENT

DU SYSTÈME DE SECOURS À BATTERIE

REMARQUE :

• Installer ce système lorsque le fonctionnement de la

pompe primaire n’est pas requis. Préparer tout ce dont

on aura besoin et lire tous les avertissements et toutes

les instructions d’installation avant de commencer.

• Se préparer à récupérer l’eau qui coulera des tuyauteries ou des raccords lorsqu’on démontera ou coupera

le tuyau de refoulement. Protéger de l’eau les

composants du système, les outils et les fournitures.

Sécher toutes les zones de travail mouillées.

OUTILS ET FOURNITURES DE BASE

DONT ON AURA BESOIN

Pince à prise multiple ou grande pince

Ruban à mesurer

Clé à douille ou tourne-écrou de 5/16 de pouce

Pince coupante de côté

Scie à métaux (pour couper le tuyau en plastique)

Pince moyenne

Crayon

Ruban pour raccords filetés

Colle pour plastique (collage par solvant)

Nettoyant de tuyaux en plastique

Chiffon

Batterie-marine à décharge poussée d’une capacité de 100

à 120 ampères/heure (vendue séparément)

Capacité requise des batteries :

Une seule batterie : 120 ampères/heure maximum.

Deux batteries : 100 ampères/heure par batterie

(200 ampères/heure au total)

Risque de blessures et d’inondation. Ne

pas démarrer la pompe tant que tous les raccords n’auront

pas été collés et tant que la colle n’aura pas séché. Des

raccords mal collés risquent d’exploser et de causer des

blessures corporelles et une inondation.

CONSERVER L’ORIGINAL DU REÇU POUR TOUTE RÉFÉRENCE ULTÉRIEURE.

GARANTIE LIMITÉE

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de matériau et de fabrication. Cette garantie

est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou remplacé, à la discrétion de SIMER,

conformément aux modalités et conditions exposées ci-dessous. Le reçu de l’achat d’origine et l’étiquette d’information sur la garantie sont requis pour

déterminer la recevabilité de la réclamation au titre de la garantie. La recevabilité de la réclamation se base sur la date de l’achat d’origine du produit, et non

sur la date d’un éventuel remplacement sous garantie. La garantie est limitée à la réparation ou au remplacement du produit uniquement. L’Acheteur assume

les frais de retrait, d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la clientèle de SIMER au 1-800-468-7867 /

1-800-546-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes d’eaux d’égout, voir ci-dessous) au

détaillant où il a été acheté, et ce, immédiatement après la découverte de la défaillance supposée. SIMER prendra les mesures correctives nécessaires dans

un délai rapide et raisonnable. Aucune demande de réparation ne sera acceptée plus de 30 jours après l’expiration de la garantie.

POMPES D’EAUX D’ÉGOUT

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle de SIMER. Les pompes

d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porter des gants en caoutchouc pour manipuler la pompe.

• À des fins de garantie, retourner l’étiquette figurant sur le cordon de la pompe et l’original du reçu au détaillant.

• Mettre la pompe au rebut conformément à la réglementation locale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P, CM10, CMK, M40, M40P 90 jours

2300, 2310, 2330, 2520ULST, 2955, 2956, 2957, 2960, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 ans

Réservoir préchargé de système d’eau, 3985, 3986 5 ans

3963, 3988, 3995, 3997 À vie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti couvert par cette garantie. Cette garantie

ne s’applique pas à ce qui suit : (1) Les catastrophes naturelles; (2) Les produits qui, selon SIMER, ont fait l’objet d’une négligence, d’une utilisation abusive,

d’un accident, d’une mauvaise application ou d’une altération; (3) Les défaillances dues à une installation, une utilisation, un entretien ou un entreposage

inappropriés; (4) Une application, une utilisation ou une réparation atypique ou non approuvée; (5) Les défaillances causées par la corrosion, la rouille ou

d’autres matériaux étrangers au système, ou par une utilisation à une pression supérieure au maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit défectueux.

SIMER NE POURRA ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE, Y COMPRIS, MAIS SANS

S’Y LIMITER, CELLE DE QUALITÉ MARCHANDE OU D’APTITUDE DU PRODUIT À UN EMPLOI PARTICULIER. LES PRÉSENTES GARANTIES NE

PEUVENT SE PROLONGER AU-DELÀ DE LA PÉRIODE DE GARANTIE INDIQUÉE ICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations relatives à la durée des garanties

implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus ne s’appliquent pas. Cette garantie procure des droits juridiques précis à

l’Acheteur. Cependant, il est possible de bénéficier d’autres droits, qui varient selon l’État.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 / 1 800 546-7867 • Télécopieur : 1 800 390-5351

Courriel : info@simerpumps.com • Site Web : http://www.simerpumps.com

Page 14

Installation 14

INSTRUCTIONS D’INSTALLATION DU

SYSTÈME DE SECOURS À BATTERIE

Risque de secousses électriques. Avec le

disjoncteur ou en enlevant le fusible, couper le courant

alimentant la pompe avant de procéder à cette installation.

Montage

1. Repérer le niveau le plus haut auquel l’eau monte dans

le puisard (c’est-à-dire le niveau auquel la pompe existante (primaire) démarre – voir la Figure 1). Avec un

crayon ou un marqueur, repérer ce niveau sur le tuyau

de refoulement.

2. Vider le puisard autant que possible sans faire démarrer

la pompe. Pour cela :

A) P

RISE MULTIPLE DE L’INTERRUPTEUR À FLOTTEUR :

Débrancher l’ensemble fiche de la pompe et prise

de l’interrupteur à flotteur de la prise de courant,

puis débrancher la fiche de la pompe de la prise

multiple de l’interrupteur à flotteur. Réarmer le

disjoncteur ou reposer le fusible, puis rebrancher la

pompe directement dans la prise de courant. Elle

démarrera. Vider le puisard, puis débrancher la

pompe, OU

B) F

ICHE SIMPLE DE L’INTERRUPTEUR À FLOTTEUR : Réarmer le

disjoncteur ou reposer le fusible, puis à l’aide d’un

manche à balai en bois ou d’un morceau de bois

non conducteur, lever l’interrupteur à flotteur. La

pompe démarrera. Vider le puisard, puis relâcher

l’interrupteur.

C) T

OUTES LES INSTALLATIONS: Dès que le puisard est

vide, désarmer le disjoncteur ou déposer le fusible

pour ne pas subir de secousses électriques pendant

qu’on intervient sur l’installation.

3. Soutenir le tuyau de refoulement pour qu’il ne tombe pas

lorsqu’on le débranchera ou lorsqu’on le coupera.

4. Si un raccord en caoutchouc est utilisé sur le tuyau de

refoulement, le débrancher. Sinon, couper le tuyau de

refoulement vertical à une hauteur pratique, au-dessus

du niveau du sol.

5. Sortir du puisard la pompe et le morceau de tuyau de

refoulement qui y est toujours branché.

Installation

1. Étudier la Figure 2 pour les montages suggérés.

Le montage « Facile » est préférable pour les pompes

profondes et les puisards de petit diamètre (13 1/2

pouces et d’une profondeur supérieure à 22 pouces).

Le montage « Alternatif » est préférable pour les puisards de plus grand diamètre et moins profonds (18

pouces et plus d’une profondeur de 18 à 22 pouces).

Pour le montage alternatif, il faudra acheter (2) coudes

à 90 ° x 1 1/4 de pouce et (2) mamelons courts de 1

1/4 pouce. Pour tout autre montage, plus de raccords

de tuyau seront requis.

2. Repérer où le repère du niveau supérieur d’eau a été

fait sur le tuyau de refoulement, lors de l’opération 1

sous « Montage ». Couper le tuyau à cet endroit, puis

mettre le morceau de tuyau coupé de côté. Il sera

utilisé plus tard. Enlever toutes les bavures des

extrémités coupées.

3. Envelopper les filets de la pompe du système de secours

à batterie et le mamelon court de 1 1/4 de pouce de

1 1/2 à 2 tours de ruban pour raccords filetés (voir la

figure 2). Ne pas mettre de ruban sur le premier filet.

Enveloppez les filets en tournant le ruban à droite ().

4. Ensemble, visser le té, le mamelon court, le clapet antiretour de 1 1/4 x 1 1/4 pouce et la pompe du système

de secours à batterie. Pour bien les serrer, immobiliser

la pompe et introduire un grand tournevis dans le té,

puis serrer l’ensemble avec le tournevis. N

E PAS SERRER

EXAGÉRÉMENT

! Lorsque l’ensemble est bien serré, la

pompe et le té doivent s’aligner verticalement (pas de

travers – voir la figure 2).

5. Coller le morceau de tuyau coupé (que l’on a mis de côté

lors de l’opération 2) dans la partie supérieure du té.

REMARQUE : Si le diamètre du tuyau de refoulement

est de 1 1/4 pouce, coller une des bagues de réduction

fournies avec le système dans le té, puis coller le tuyau

dans la bague.

6. Examiner la pompe primaire pour déterminer si un

clapet antiretour est posé dans ou près du tuyau de

refoulement. Sinon, poser le clapet antiretour auxiliaire

dans le bras inférieur du té, puis poser le raccord lisse

sur le clapet antiretour (voir la figure 2). Dans le cas

d’un tuyau de refoulement de 1 1/4 pouce, coller

l’autre bague de réduction dans le raccord lisse.

REMARQUE : Si la pompe primaire est déjà dotée d’un

clapet antiretour qui fonctionne, ne pas utiliser le clapet

antiretour auxiliaire livré avec le système de secours à

batterie. Un seul clapet antiretour est requis entre la

pompe primaire et le té (pour que le liquide de l’une ou

de l’autre des deux pompes ne retourne dans le

puisard). Deux clapets antiretour limiteront beaucoup

trop le débit dans le tuyau.

7. Ajustement d’essai (N

E PAS COLLER POUR LE MOMENT):

Remettre la pompe primaire assemblée dans le puisard,

puis y ajouter, sans les coller, l’ensemble té, clapet antiretour pompe du système de secours à batterie. Au

besoin, inclure également la bague de réduction de 1

1/2 x 1 1/4 pouce et le clapet antiretour auxiliaire (voir

la « REMARQUE » ci-dessus).

8. Mesurer l’ensemble par rapport au tuyau de refoulement

supérieur (là où on l’a coupé lors de l’opération 1 sous «

Montage »). Sous le point de chevauchement (c’est-àdire que l’on devra avoir un espace de 1/4 de pouce

après que l’on aura coupé le tuyau), faire un repère sur

le tuyau de refoulement venant du té de 1 1/4 de pouce.

Ne procéder à aucune coupe pour le moment.

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

pp

Figure 1 : Repérer le tuyau au niveau d’eau de

« démarrage »

Soutenir le tuyau de refoulement

avant de le couper.

Avec un crayon,

faire un repère

sur le tuyau.

Puisard

Niveau d’eau de

« démarrage » de la

pompe primaire

Clapet antiretour

Mark pipe with

pencil here.

Pipe before

cutting.

Sump Pit

‘Start’ water level

of Primary Pump

Check

Val ve

Page 15

Installation 15

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

Figure 2 : Montages types d’une installation

Montage « Facile »

Pas à l’échelle : pour

des raisons de clarté, le

câblage n’est pas illustré.

Tuyau de refoulement

supérieur

Raccord en caoutchouc

avec colliers*

Interrupteur avec collier*##

Installation alternative dans

un puisard peu profond

Morceau du tuyau de

refoulement coupé

Bague de réduction lisse

de 1 1/2 x 1 1/4 pouce*†

1 1/2 x 1 1/2 pouce lisse x té

femelle fileté de 1 1/4 pouce*

Raccord lisse 1 1/2 x 1 1/2 pouce*#

Bague de réduction lisse

de 1 1/2 x 1 1/4 pouce*†

Tuyau de refoulement de la pompe

primaire (à couper pour qu’il soit ajusté)

Clapet antiretour de la pompe

primaire du puisard

Flèche indiquant le débit : Doit

être orientée À L’OPPOSÉ de

la pompe qui est protégée

Orifice du refoulement de la

pompe primaire du puisard

Remarque :

* Livrés avec le système de secours à batterie.

† À utiliser si on doit adapter un tuyau de refoulement de 1 1/4 pouce sur les raccords de 1 1/2 pouce fournis.

# À utiliser pour poser le clapet antiretour auxiliaire sur le tuyau de refoulement.

## Lorsque l’interrupteur s’arrête, le niveau de l’eau doit arriver au-dessus de l’aspiration de la pompe de secours à batterie.

REMARQUE IMPORTANTE SUR LE CLAPET

ANTIRETOUR ET LA GARANTIE :

Le(s) battant(s) du clapet antiretour doit s’ouvrir dans le sens

indiqué. La flèche indiquant le débit doit être orientée À

L’OPPOSÉ de la pompe qui est protégée.

L’ensemble clapet antiretour 1 1/4 pouce x 1 1/4 pouce doit

être installé tel qu’illustré, sinon la garantie sera nulle et non

avenue. Ne pas utiliser une clé (voir l’étape 4 de l’Installation

à la page 14)! S’il n’y a pas de clapet antiretour installé sur la

pompe primaire du puisard tel qu’indiqué en dessous du té,

le clapet antiretour auxiliaire doit être installé tel qu’illustré,

sinon la garantie sera nulle et non avenue.

Mamelon court de 1 1/4 de

pouce x 1 1/4 de pouce*

Clapet antiretour de

1 1/4 pouce x 1 1/4

de pouce*

Ruban pour raccords

filetés sur tous les filets

Pompe de puisard

de secours à

batterie*

Clapet antiretour auxiliaire*

(Voir la Remarque importante

sur le clapet antiretour et

la garantie, ci-dessous)

“Easy Install” Layout

Upper Discharge pipe

Hose Coupling with Clamps*

Discharge pipe

cutoff piece

1-1/2"x1-1/4" Slip

Reducer bushing*

1-1/2"x 1-1/2" slip x

1-1/4" FNPT Tee*

Auxiliary Check Valve*

(

See Important Check Valve

Warranty Note, Below

†

)

Not to scale;

wiring omitted

for clarity.

Switch with Clamp*

1-1/4”x1-1/4”

Close Nipple*

##

1-1/4”x1-1/4”

Check Valve

Assembly*

Alternate Installation

for a Shallow Sump

Teflon tape all

threaded joints

Battery Back Up

Sump Pump*

1-1/2"x1-1/2" Slip Coupling*

1-1/2"x1-1/4" Slip Reducer

Bushing*

Primary Pump Discharge

Pipe (cut to fit)

Primary Sump Pump

Check Valve

Flow Arrow; Must point

AWAY from Pump being

Protected

Primary Sump Pump

Discharge Port

†

#

IMPORTANT CHECK VALVE/WARRANTY NOTE:

Check Valve Flapper(s) must swing in direction shown.

Flow arrow(s) must point AWAY from pump being protected.

The 1-1/4” X 1-1/4” Check Valve Assembly must be installed

as shown or the warranty is void. Do not use a wrench (see

Installation Step 4, Page 4)! If the Primary Sump Pump

does not have a check valve installed as shown below the

Tee, the Auxiliary Check Valve must be installed as shown

or the warranty is void.

Page 16

Installation 16

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

9. Étudier l’ensemble dans le puisard, puis l’ajuster de

façon que rien ne gêne le fonctionnement de la pompe

primaire ni celui de son interrupteur. Repérer les

raccordements avec un marqueur permanent de façon à

pouvoir réaligner l’ensemble après l’avoir sorti du

puisard pour le coller (voir Figure 3).

REMARQUE : Prendre son temps pour procéder à cette

opération – elle demande de la prudence, mais elle

n’est pas difficile à effectuer. S’assurer de laisser suffisamment de place pour l’interrupteur vertical de la

pompe du système de secours à batterie. Repérer tout

ce qui risque de bouger!

10. Après avoir tout repéré, sortir l’ensemble du puisard.

11. Couper le tuyau de refoulement vertical au point de

coupe repéré lors de l’opération 8. S’ASSURER DE

COUPER SUR LE BON REPÈRÈ!

12. Revérifier l’alignement, puis coller tous les raccords sur

la pompe primaire.

REMARQUE : Il faudra peut-être soutenir l’ensemble

(car il ne restera pas bien en équilibre) de façon à

pouvoir conserver l’alignement pendant l’opération de

collage. Procéder à cette vérification avant de procéder

au collage. L’aide d’une autre personne sera peut-être

utile pour cela!

13. Après avoir collé l’ensemble, glisser le raccord en

caoutchouc et ses colliers par-dessus le tuyau de

refoulement assemblé. Si le diamètre du tuyau est de 1

1/4 de pouce, ne pas oublier d’utiliser les deux bagues

de réduction livrées avec le raccord en caoutchouc.

14. Accrocher le collier de l’interrupteur par-dessus le

support de l’interrupteur, puis glisser l’ensemble pardessus le raccord en caoutchouc et le tuyau de refoulement. Serrer le collier du flotteur de façon que le

niveau d’eau, lorsque l’interrupteur s’arrêtera, soit plus

haut que l’aspiration de la pompe de secours à batterie.

15. Remettre l’ensemble dans le puisard, glisser le raccord

en tuyau souple par-dessus l’espace de façon qu’il

raccorde les deux tuyaux, puis serrer tout juste assez ses

colliers pour qu’ils restent en place.

16. Vérifier l’ajustement, l’alignement, etc. Si tout est beau,

s’assurer que l’interrupteur vertical du système de

secours à batterie est réglé à la bonne hauteur et que

rien ne gêne son fonctionnement. Bien serrer ensuite

les colliers du tuyau en caoutchouc.

17. Régler la butée de la tige du flotteur du système de

secours à batterie de façon que l’interrupteur fonctionne sur la course désirée. Au besoin, pour obtenir

suffisamment de dégagement, enlever la partie

inférieure de la tige.

CÂBLAGE ET MONTAGE DU SYSTÈME

DE SECOURS À BATTERIE

Pour l’installation de la batterie et les informations

concernant les branchements, se reporter aux figures 4,

5 et 6.

Figure 3 : Repérer les raccords pour les coller

Figure 4 : Les entrées de la batterie sont à l’intérieur du

coffret de la batterie. Soutenir le couvercle du coffret

lorsqu’on l’ouvre. Le support doit avoir au moins 4

pouces d’épaisseur.

Figure 5 : Mettre la batterie dans son coffret. Demander à

une autre personne de tenir le coffret pendant cette

opération. Lorsque la batterie sera dans son coffret,

brancher les fils du chargeur et du panneau de contrôle :

+ (Rouge) sur + (Rouge, et - (Noir) sur - (Noir).

Entrées de

la batterie

Battery

Inputs

5768 0108

Page 17

Installation 17

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

1. Les fils de la pompe sont sensibles à la polarité;

brancher le fil positif de la pompe sur la borne repérée

« Pompe + » et le fil négatif de la pompe sur la borne

repérée « Pump - ».

REMARQUE : Si les fils sont inversés, la pompe

tournera à l’envers et ne pompera pas d’eau.

2. Les fils de l’interrupteur du flotteur vertical ne sont pas

sensibles à la polarité; les brancher sur les pattes

repérées « Float Switch » du chargeur et du panneau

de contrôle. Si deux batteries sont utilisées, utiliser le

deuxième jeu de bornes et brancher la batterie

secondaire de la même façon.

Brancher le fil (rouge)

positif

(+) de la batterie sur la borne

(rouge) positive du chargeur et du panneau de contrôle.

Brancher le fil (noir)

négatif

(-) de la batterie sur la borne

(noir) positive du chargeur et du panneau de contrôle.

3. Vérifier le fonctionnement de l’interrupteur à flotteur et

de la pompe en levant la tige du flotteur et en la tenant

levée. La DEL « Pump Status » (état de la pompe)

restera allumée et l’avertisseur retentira. La pompe doit

démarrer dans les trois secondes qui suivent. Sinon,

vérifier tous les branchements et, au besoin, les refaire.

4. Pendant que la pompe fonctionne, appuyer sur la

touche « Silence Alarm » (arrêt de l’alarme); la tenir

appuyée pendant une seconde, puis la relâcher. La DEL

« Silence Alarm » (arrêt de l’alarme) doit s’allumer et

l’avertisseur doit cesser de retentir. Pour réenclencher

l’avertisseur (pour qu’il sonne à nouveau) et pour

éteindre la DEL « Silence Alarm » (arrêt de l’alarme),

appuyer de nouveau pendant une seconde sur la

touche « Silence Alarm » (arrêt de l’alarme).

5A. Pour arrêter la pompe, abaisser l’interrupteur à flotteur;

après trois secondes, la pompe doit s’arrêter, la DEL «

Pump Status » (état de la pompe) doit clignoter et

l’avertisseur doit retentir.

5B. Appuyer sur la touche « System Test » (contrôle du

système) et la tenir appuyée pendant une seconde avant

de la relâcher. La DEL « Pump Status » (état de la pompe)

doit cesser de clignoter.

REMARQUE : En fonctionnement normal, la DEL clignotante « Pump Status » (état de la pompe) indique que la

pompe a fonctionné pendant qu’on était absent. Voir le

tableau II « Codes de fonctionnement » à la page 19.

6. Appuyer sur la touche « System Test » (contrôle du

système) et la tenir appuyée. Toutes les DEL doivent

s’allumer, la pompe doit fonctionner et l’avertisseur doit

retentir. Relâcher cette touche et les DEL doivent

s’étendre, la pompe doit s’arrêter de fonctionner et

l’avertisseur doit cesser de retentir.

7. La DEL « Battery Status » (état de la batterie) indique

la capacité de la batterie pendant que le courant alternatif ne l’alimente pas.

A. La DEL reste allumée – la tension de la batterie est

supérieure à 10,9 volts en courant continu et sa

capacité est supérieure à 20 %.

B. Avertisseur retentissant/DEL clignotant lentement – la

capacité de la batterie se situe entre 0 et 20 %.

C. Avertisseur retentissant rapidement/DEL clignotant

rapidement – la batterie est complètement

déchargée. La batterie continuera d’être chargée

(aussi longtemps que le courant alternatif de 115

volts alimentera le chargeur) à une capacité de 0,5

A/h, et ceci jusqu’à ce que la charge de la batterie

soit supérieure à 20 %.

Après le premier avertissement (avertisseur retentissant

lentement/DEL clignotant lentement), la pompe devrait

pouvoir fonctionner pendant encore un maximum

approximatif de deux heures. La durée pendant laquelle

la pompe fonctionnera dépendra de l’état de la batterie.

Il se peut qu’elle ne fonctionne que pendant 15 minutes.

8. Brancher le câble d’alimentation en courant (fourni)

dans le connecteur femelle d’arrivée de courant du

chargeur et du panneau de contrôle.

DEL affichées et touches de commande

(Tableau II, III, IV et V)

REMARQUE : Lorsque l’on branche ce système pour la

première fois, ou lorsqu’il est alimenté pour la première fois

par la batterie, la DEL d’état de la batterie clignotera

pendant trois secondes.

REMARQUE : Pour actionner n’importe quelle touche de

contrôle, appuyer dessus et la tenir appuyée pendant une

seconde.

Remèdes possibles

1. La tension de la batterie n’est pas bonne

Brancher le chargeur sur une batterie de 12 volts.

2. Branchements de la batterie inversés

Vérifier tous les branchements. Le fil négatif (noir) de la

batterie doit être branché sur le négatif (noir) du

chargeur et le positif de la batterie doit être branché sur

le positif du chargeur. Les DEL « System Alert » (alerte

du système) et « Silenced Audible Alarm » (alarme

sonore rendue silencieuse) clignoteront.

3. Claquage thermique

« Claquage thermique » est le terme technique qui

désigne l’état d’une batterie lorsque certains de ses

éléments, voire tous, sont détériorés au point qu’ils ne

retiennent plus la charge. Dans ce cas, la batterie doit

être remplacée.

4. Indicateur du temps de charge – 1 et 2

Il a fallu beaucoup trop de temps pour charger complètement la batterie. Le témoin « Charge Time Monitor »

(indicateur du temps de charge) arrêtera le fonctionnement du chargeur après 84 heures de charge continue.

Causes possibles :

A) La pompe a fonctionné longtemps pendant le

processus de charge, ou

B) la batterie est trop grosse pour le chargeur (y

compris plusieurs batteries branchées en parallèle).

Utiliser la formule indiquée dans le tableau I pour

déterminer si la batterie est trop grosse pour le

chargeur. Si le temps de charge calculé est supérieur à

84 heures, utiliser une batterie plus petite (ou un

groupe de batteries plus petit).

Figure 6 : Fermer le couvercle du coffret et le verrouiller.

Page 18

Installation 18

Décharge excessive de la batterie

La pompe a peut-être fonctionné pendant trop longtemps et

la batterie s’est déchargée. Dans ce cas :

A) Si le courant alternatif de 115 volts est COUPÉ, le

chargeur ne fonctionnera pas tant que le courant ne

sera pas rétabli. Toutefois, la pompe continuera de

fonctionner tant que la batterie sera chargée. Dans ce

cas, la batterie devra être remplacée.

B) Si le courant alternatif de 115 volts est ÉTABLI, le

chargeur et le panneau de contrôle essayent de charger

la batterie à une capacité de 0,5 A/h jusqu’à ce que la

charge de la batterie soit supérieure à 20 %. À ce point,

le chargeur chargera la batterie à une capacité de 2 A/h.

C) Si la pompe fonctionne et que le chargeur est alimenté

en courant alternatif, il faudra peut-être arrêter la

pompe pour permettre que la batterie se charge.

Contrôle de préqualification – 1 et 2

Le chargeur ne charge pas suffisamment une batterie complètement déchargée. S’il faut trop de temps pour charger la

batterie, essayer de réenclencher le chargeur (appuyer sur les

touches « System Test » [contrôle du système] et « Silence

Alarm » [arrêt de l’alarme] pour réenclencher le chargeur).

Caractéristiques spéciales :

• Le chargeur est équipé d’une protection contre une

inversion de branchement de la batterie, un courtcircuit et une charge « de claquage thermique ».

CRITÈRES DE LA BATTERIE

Courant électrique dangereux pouvant

causer de graves blessures et provoquer un incendie si les

bornes de la batterie sont court-circuitées. Installer la

batterie dans son coffret (Réf. 12, page 21). Pour empêcher

tout court-circuit accidentel entre les bornes de la batterie,

immobiliser en toute sécurité le couvercle du coffret de la

batterie. Ne pas laisser une batterie découverte et ne pas

permettre aux enfants de jouer autour de l’installation d’un

système de secours à batterie.

La pompe de puisard de secours dépend de la batterie pour

être alimentée en courant. La qualité de la batterie déter-

minera le rendement de la pompe. Nous recommandons

d’utiliser une batterie-marine à décharge poussée du groupe

27M. Son rendement correspondra à ceux indiqués dans le

tableau VI à la page 20, et elle durera longtemps, qu’elle

soit utilisée au minimum ou pas du tout.

Ce système est prévu pour fonctionner avec une batteriemarine au plomb à décharge poussée ouverte ou sans entretien AGM (à fine feuille de fibre de Boron-Silicate). Il n’est

pas recommandé d’utiliser une batterie d’automobile standard avec ce chargeur. Une batterie d’automobile devra

peut-être être rechargée après seulement une ou deux

heures d’utilisation continue et les cycles répétés de charge

et de décharge risquent de causer la panne prématurée de

ses plaques.

N’utiliser que la batterie recommandée ou une batterie du

même type et de la même dimension pour qu’elle rentre

dans le coffret de la batterie (dimensions maximales (y

compris les bornes) : 320,7 mm x 177,8 mm x 238 mm

[12 5/8 x 7 x 9 3/8 pouces]) et dont la tension sera suffisante pour un rendement maximal.

ENTRETIEN DE LA BATTERIE

Risque de brûlures. Une batterie pleine

contient de l’acide sulfurique. Éviter tout contact avec la

peau, les yeux et les vêtements.

REMARQUE : Pour protéger le coffret de la batterie contre

les coups et les entailles, ne pas la laisser reposer sur un sol

en béton. Poser la batterie sur une étagère ou un support de

protection (contreplaqué, 2x4, etc.). Toujours installer la

batterie dans un endroit sec, protégé des inondations.

Suivre les recommandations du fabricant de la batterie pour

l’entretenir. L’utiliser en toute sécurité.

RECHERCHE DES PANNES

La pompe ne démarre pas :

1. Vérifier les branchements des fils.

2. S’assurer que la batterie n’est pas défectueuse ou

déchargée.

3. S’assurer que son interrupteur se déplace librement à la

verticale.

4. Appuyer sur le bouton de réarmement du disjoncteur

du tableau électrique.

Le moteur murmure et la pompe ne fonctionne pas :

1. S’assurer que la batterie n’est pas défectueuse ou

déchargée.

La pompe fonctionne, mais ne débite pas ou débite très peu :

1. S’assurer qu’un clapet antiretour est posé entre le tuyau

de refoulement de la pompe primaire et le té de la

pompe secondaire et qu’il fonctionne adéquatement.

2. S’assurer que le tuyau de refoulement n’est pas obstrué.

3. La longueur du tuyau ou la hauteur de refoulement dépasse

les capacités de la pompe. Pour connaître les capacités de

la pompe, se reporter au tableau VI à la page 20.

4. S’assurer que la batterie n’est pas défectueuse ou déchargée.

5. Le branchement des fils positif (+) et négatif (-) est

inversé. Les débrancher et les brancher correctement.

La pompe fonctionne trop fréquemment :

Il n’y a pas de clapet antiretour posé entre le refoulement de la pompe primaire et le té de la pompe de

secours ou bien il ne fonctionne pas adéquatement.

Selon le besoin, poser le clapet antiretour auxiliaire

(voir pages 14 et 15) ou bien remplacer le clapet antiretour existant défectueux.

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

TABLEAU 1 – Calcul de la capacité de la

batterie

Capacité de la batterie

Temps de charge =

Exemple 1 :

Temps de charge =

Temps de charge =

Moins de 84 heures pour charger la batterie; on peut l’utiliser.

Exemple 2 :

Temps de charge =

Temps de charge =

La capacité est trop grande – utiliser une batterie de

130 A/h maximum.

REMARQUE : Il faut approximativement 62 heures pour

charger une batterie de 100 A/h en bon état.

en ampères heure (A/h)

2 ampères

130 ampères heure

2 ampères

130h

1,25 = 65 h 1,25 = 81,25 heures

2

160 ampères heure

2 ampères

160h

1,25 = 80 h 1,25 = 100 heures

2

1,25

1,25

1,25

Page 19

Installation 19

Pour le service des pièces ou de l’assistance, appeler le Service à la clientèle Simer en composant le 1 800 468-7867 / 1 800 546-7867

TABLEAU II – Codes de fonctionnement (Les DEL restent allumées ou clignotent)

DEL de contrôle : Toujours allumée, elle indique un fonctionnement normal :

Courant alternatif Le courant alternatif est présent.

État de la pompe L’interrupteur à flotteur a été actionné. La DEL reste allumée (clignote) après que la

pompe s’arrête. Appuyer sur la touche « System Test » (contrôle du système) pour

l’éteindre.

Alarme sonore rendue L’alarme sonore a été rendue silencieuse. Appuyer sur la touche « Silence Alarm »

silencieuse (arrêt de l’alarme) puis la relâcher pour réactiver l’alarme sonore et ÉTEINDRE la DEL.

Charge Indique que le chargeur charge la batterie — voir le tableau II ci-dessus.

État de la batterie A. Toujours « ALLUMÉE » — la tension de la batterie est supérieure à 10,9 volts en

c.c. et sa capacité est supérieure à 20 %.

B. L’avertisseur retentit lentement/la DEL clignote lentement — la capacité de la

batterie est inférieure à 20 %, sa charge se situe entre 8,2 et 10,9 volts en c.c.

C. L’avertisseur retentit rapidement/la DEL clignote rapidement — la charge de la

batterie est inférieure à 8,2 volts en c.c.

Alerte du système Clignotement (en même temps que l’avertisseur sonore retentira) indique que le

chargeur est entré dans le « mode panne ». Appuyer sur les touches « System Test »

(contrôle du système) et « Silence Alarm » (arrêt de l’alarme) pour réarmer.

REMARQUE : Si la source de la panne n’est pas corrigée, le chargeur repassera en «

mode panne ». Voir le tableau IV pour tout renseignement concernant les codes

d’erreurs.

TABLEAU III – DEL des fonctions (les DEL restent allumées)

DEL des codes de fonctionnement

System Alert (Alerte du système)

Silenced audible alarm (Alarme sonore rendue silencieuse)

Pump status (État de la pompe)

AC power

(Courant alternatif)

= =

La DEL reste ALLUMÉE

Charging (Charge)

Battery status (État de la batterie)