Page 1

OWNER’S MANUAL

Pedestal Sump Pumps

Model 5020B-04

NOTICE D’UTILISATION

Pompes d’assèchement

sur pied

Modèle 5020B-04

MANUAL DEL USUARIO

Bombas de Pie para

Sumideros

Modelo 5020B-04

Installation/Operation/Parts

For further operating,

installation, or maintenance

assistance:

Call 1-800-468-7867

English ...................... Pages 2-6

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français ................. Pages 7-11

Instalación/Operación/Piezas

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español ...............Paginas 12-16

SIM722 (Rev. 3/17/09)

MOD. 5020B-04

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

Fax:

1-800-390-5351

E-Mail:

simer@simerpump.com

Web Site:

http://www.simerwater.com

Page 2

Warranty 2

RETAIN ORIGINAL RECEIPT FOR YOUR RECORDS.

LIMITED WARRANTY

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from

defects in material and workmanship for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall

be repaired or replaced at SIMER’s option, subject to the terms and conditions set forth below. The original purchase

receipt and product warranty information label are required to determine warranty eligibility. Eligibility is based on

purchase date of original product – not the date of replacement under warranty. The warranty is limited to repair or

replacement of product only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service

at 1-800-468-7867 / 1-800-546-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the

retail outlet where it was purchased immediately after the discovery of any alleged defect. SIMER will subsequently

take corrective action as promptly as reasonably possible. No requests for service will be accepted if received more

than 30 days after the warranty expires.

SEWAGE PUMPS

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage

pumps that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, CM10, CMK, M40, M40P 90 days

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 Years

4” Submersible Well Pumps, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 Years

Pre-Charge Water System Tank, 3985, 3986 5 Years

3963, 3988, 3995, 3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty

does not apply to the following: (1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to

negligence, abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation,

maintenance or storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or

other foreign materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long

an implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific

legal rights and You may also have other rights which vary from state to state.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

Web Site: http://www.simerpumps.com

Page 3

Safety 3

For parts or assistance, call Simer Customer Service at 1-800-468-7867

DESCRIPTION

This Pedestal Sump Pump is designed for home

sumps. Unit is equipped with a 3-prong groundingtype power cord. Sleeve bearings on motor shaft never

need lubrication. Automatic reset thermal protection.

NOTICE: This unit is not designed for applications

involving salt water or brine! Use with salt water or

brine will void warranty.

SPECIFICATIONS

Power supply required ........................115V, 60 HZ.

Horsepower ........................................................1/3

Motor duty .............................................Intermittent

Liquid Temp. Range ...............32°F to 70°F(0°-21°C)

Individual Branch Circuit

Required GFCI Class A...............................15 Amps

Motor full load (maximum) .......................3.5 Amps

Discharge:.............................................1-1/4" FNPT

PERFORMANCE

GENERAL SAFETY

Electrically powered sump pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. However, unusual circumstances (interruption of power to the pump, dirt/debris

in the sump, flooding that exceeds the pump’s capacity, electrical or mechanical failure in the pump, etc.)

may prevent your pump from functioning normally. To

prevent possible water damage due to flooding, consult your retailer about a secondary AC sump pump, a

DC backup sump pump, and/or a high water alarm.

See the “Troubleshooting Chart” in this manual for

information about common sump pump problems and

remedies. For more information, see your retailer or

call Simer customer service at 1-800-468-7867.

1. Know the pump application, limitations, and

potential hazards.

Do not use in explosive

atmospheres. Pump water

only with this pump. Failure to follow this warning can result in personal injury and/or property

damage.

2. Disconnect power before servicing.

3. Release all pressure within system before servicing any component.

4. Drain all water from system before servicing.

Risk of flooding. If a flexible discharge hose is used, pump may

move when motor starts. If it moves far enough so

that switch hits side of sump, switch may stick and

prevent pump from starting.Make sure pump is

secured so it cannot move around in sump.

5. Secure discharge line before starting pump. An

unsecured discharge line will whip, possibly

causing personal injury and/or property damage.

6. Check hoses for weak or worn condition before

each use, making certain all connections are

secure.

7. Inspect sump, pump and system components

monthly. Keep free of debris and foreign

objects. Perform routine maintenance as

required.

FIRE HAZARD - Do not store

or rest objects on or near

motor or switch linkage. Keep all flammable

objects or liquids away from motor.

8. Provide means of pressure relief for pumps

whose discharge line can be shut-off or

obstructed.

9. Personal Safety:

a. Wear safety glasses at all times when work-

ing with pumps.

b. Keep work area clean, uncluttered and

properly lighted – replace all unused tools

and equipment.

c. Keep visitors at a safe distance from work

area.

d. Make workshop child-proof – with pad-

locks, master switches, and by removing

starter keys.

10. When wiring an electrically driven pump, follow all electrical and safety codes, as well as

most recent National Electrical Code (NEC) and

Occupational Safety and Health Act (OSHA).

11. This equipment is only for use on 115 volt (single phase) and is equipped with an approved 3conductor cord and 3-prong, grounding-type

plug.

To reduce risk of electric

shock, be certain that it is

connected to properly grounded, groundingtype receptacle.

Never connect green (or

green and yellow) wire in

cord to a live terminal!

Where a 2-prong wall receptacle is encountered, it must be replaced with properly

grounded 3-prong receptacle installed in accordance with the National Electrical Code and

local codes and ordinances.

12. All wiring should be performed by a qualified

electrician.

13. Make certain that power source conforms to

requirements of your equipment.

14. Protect electrical cord from sharp objects, hot

surfaces, oil, and chemicals. Avoid kinking

cord. Replace or repair damaged or worn cords

immediately.

15. Do not touch an operating motor. Modern

motors are designed to operate at high temperatures.

16. Do not handle pump or pump motor with wet

hands or when standing on wet or damp surface, or in water.

If your basement has water or

moisture on floor, do not walk on

wet area until all power has been turned off. If

shut-off box is in basement, call electric company

to shut-off service to house, or call local fire

department for instructions. Remove pump and

repair or replace. Failure to follow this warning

can result in fatal electrical shock.

Do not use in hazardous or

explosive locations.

GPH (LPH) AT TOTAL FEET (M)

5 Ft. 10 Ft. 15 Ft. 20 Ft.

(1.52) (3.05) (4.57) (6.09)

3000 2460 1620 0

(11 355L) (9 312L) (6 131L) (0L)

Page 4

Installation / Operation 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867

INSTALLATION

1. This unit can be installed in sump pit with minimum diameter of 12"(30cm) and depth of 12"

(30cm). Sump pit may be constructed of tile,

concrete, steel or plastic. Check local codes for

approved materials.

2. Install pump on solid, level foundation, as near

as possible to center of sump pit. Do not hang

pump from discharge pipe or power cord.

Pump must be level (column

must be vertical) when oper-

ating. If motor is tilted, internal start/run switch

may overheat and damage motor.

3. Pump should not be installed on clay, earth or

sand surfaces. Clean sump pit of small stones

and gravel which could clog the pump. Keep

pump inlet screen clear.

4. Thread discharge pipe into pump body carefully to avoid stripping or crossing threads.

NOTICE: Do not use ordinary pipe joint compound on plastic pipe or pump. Pipe joint compound can attack plastics and damage pump.

5. To reduce motor noise and vibrations, a short

length of rubber hose (1-5/8"(41mm) I.D., e.g.

radiator hose) can be connected into discharge

line near pump using suitable clamps.

Risk of electric shock. Pump

is designed for 115V., 60 HZ

operation and requires an individual branch

circuit of 15 amperes capacity. It is supplied

with a 3-wire cord set with grounding-type

plug for use in a 3-wire, grounded outlet. Do

not cut off the round grounding prong. For

safety, outlet must always be electrically

grounded to a suitable electrical ground such

as a grounded water pipe or a properly

grounded metallic raceway or ground wire system.

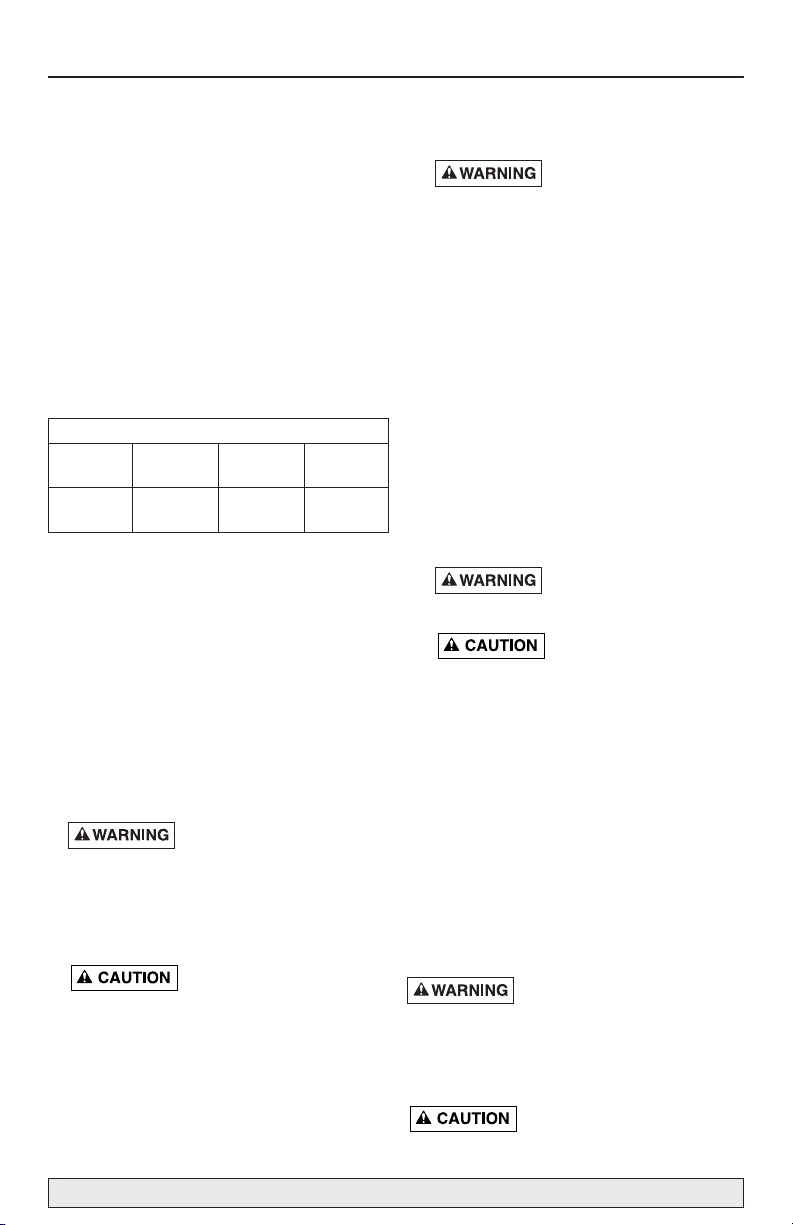

6. Locate Float Rod Guide (Key No. 6) about 6"

(16cm) below motor. Clamp guide to column

with screw provided.

Risk of flooding. Be sure that

guide is securely clamped so

that float rod is vertical and can move up and

down freely. If float is angled or binds, pump

may not start, allowing flooding to occur.

7. Screw float onto threaded end of rod. Threads

on rod will cut threads into corrosion resistant

float.

8. Insert plain end of float rod up through eye of

rod guide.

9. Slide one rod stop on float rod before passing

rod through eye of pump switch. Slide 2nd rod

stop on rod after passing through eye of switch.

Position 2nd rod stop flush with top of rod.

10. Position lower rod stop to within 8"(20cm) of

switch lever arm. With lower rod stop in this

position, pump will automatically cycle at

approximately 2-1/2"(6cm) off and 10-12"(2530cm) on. For faster cycling, move lower rod

stop closer to switch lever arm.

11. If pump discharge line is exposed to outside

subfreezing atmosphere, then portion of line

exposed must be installed so any water remaining in pipe will drain to outfall by gravity.

Failure to do this can cause water trapped in

discharge to freeze which could result in damage to pump.

12. Install an in-line check valve to prevent flow

backwards through pump after pump shuts off.

NOTICE: Simer check valves are equipped with

an air bleed hole to prevent airlocking the

pump. If using a check valve that is not a Simer

valve, drill a 1/8" (3.2mm) hole in discharge

pipe just above pump body but below the

check valve to prevent air locks.

13. After all piping and controls have been

installed, unit is ready for operation.

14. Run pump through one cycle to check float

switch operation.

The pump motor is equipped

with automatic resetting

thermal protector and may restart unexpectedly. Protector tripping is an indication of motor

overloading as a result of operating pump at

low heads (low discharge restriction), excessively high or low voltage, inadequate wiring,

incorrect motor connections, or a defective

motor.

Discharge

About 6"

About 8"

Check

Valv e

(Purchase

Separately)

Page 5

Troubleshooting

Operation 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867

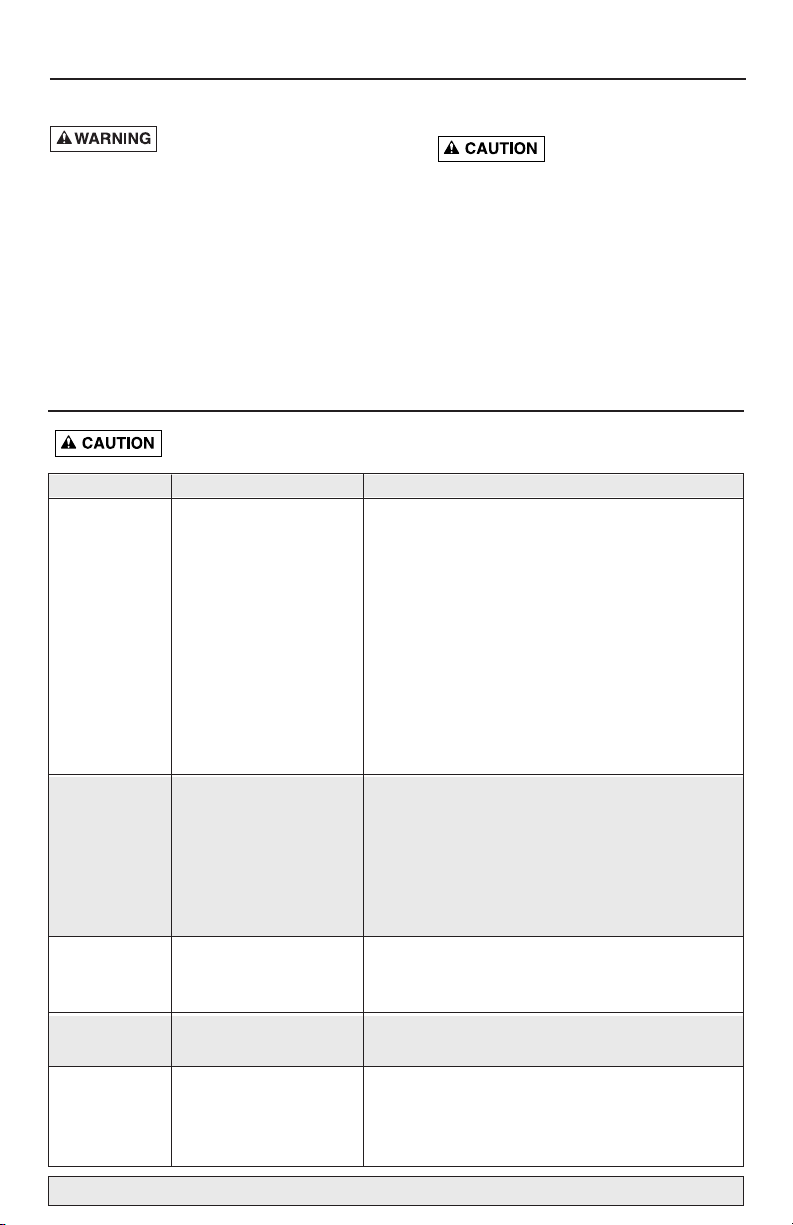

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not No electrical power Check fuse, circuit breaker, power cord and

startor run electrical outlet.

Low line voltage If voltage wiring under recommended minimum,

check size of wiring from main source. If OK,

contact Electric Company or local Hydro authority.

Faulty automatic switch Operate switch manually and replace if inoperative.

Float or float rod stuck Check to see float is not rubbing sump wall or float

rod rubbing or stuck against sump cover.

Waterlogged float Replace float if filled with water.

Motor overload tripped If pump has been running and stops before sump

is emptied, automatic overload may have tripped.

Check inlet screen to be sure impeller is not

jammed. If so, free impeller of obstruction.

Electrical malfunction Check power cord, automatic switch and motor.

Replace faulty parts as needed.

Motor runs but Inlet clogged Check inlet and clean if needed.

pump will not

Discharge line plugged Clear discharge line and check valve for

pump

obstruction.

Low line voltage Refer to Corrective Action on low line voltage in

above section.

Pump airlocked Drill a 1/8” (3.2mm) hole in discharge pipe just

above pump body but below the check valve.

Broken impeller or shaft Replace impeller or shaft as needed.

Pump starts and Improper positioning of Lower float rod stop.

stops too often float rod stop

Faulty automatic switch Replace automatic switch.

Pump is noisy Improper installation Refer to No. 5 in Installation Instructions.

Noisy motor Replace pump.

Pump will not Debris around float or Remove debris from sump. Check to see float is

stop running float rod stuck not rubbing sump wall or float rod rubbing or stuck

against sump cover.

Faulty automatic switch Replace switch.

Motor defective Replace pump.

Unplug pump from power receptacle before working on pump.

OPERATION

Do not touch sump pump, pump

motor, water, or discharge piping

when pump is connected to electrical power.

Always disconnect pump cord (power) before

handling.

1. Plug this unit into a 115V outlet, on an individ-

ual branch circuit, with a Class A, 15 amp

GFCI (Ground Fault Circuit Interrupter).

Consult your local electrician for information

and availability.

2. Fill sump pit with water, pump will start auto-

matically when lower rod stop actuates switch

lever arm. When upper rod stop actuates

switch lever arm, pump will stop.

NOTICE: Do not allow pump to run dry.

Before attempting to service,

always disconnect power

from unit.

3. The motor is equipped with an automatic reset

thermal protector to protect unit from overheating. When motor has cooled sufficiently, switch

will reset automatically and restart motor.

Repeated tripping could be caused by low voltage, long extension cords, clogged impeller,

very low head or lift, etc. Cycling of protector

will cause eventual motor burnout.

Page 6

Repair Parts 6

For parts or assistance, call Simer Customer Service at 1-800-468-7867

1

2

3

4

5

6

7

8

9

10

11

12

Key Part No.

No. Description Used 5020B-04

1 Motor 1 *

2 Switch 1 †

3 Volute (Pump Body) 1 PS1-25P

4 Impeller 1 PS5-269P

5 Base Plate 1 PS4-17P

6 Screws (Base Plate) 8 U30-934ZP

7 Float Rod Guide 1 RP0005249

8 Screw (Guide Rod) 1 U30-929ZP

9 Screw (Base) 1 SC004-116

10 Float 1 FT0013-63

11 Float Rod 1 RP005168S

12 Float Stop 2 RP0005248

Model 5020B-04

* If motor fails, replace entire pump. † Select switch model number below.

Switch FP0020

Switch FP0018-7D

Page 7

Garantie 7

CONSERVER L’ORIGINAL DU REÇU POUR TOUTE RÉFÉRENCE ULTÉRIEURE.

GARANTIE LIMITÉE

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de

matériau et de fabrication. Cette garantie est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou

remplacé, à la discrétion de SIMER, conformément aux modalités et conditions exposées ci-dessous. Le reçu de

l’achat d’origine et l’étiquette d’information sur la garantie sont requis pour déterminer la recevabilité de la réclamation

au titre de la garantie. La recevabilité de la réclamation se base sur la date de l’achat d’origine du produit, et non sur la

date d’un éventuel remplacement sous garantie. La garantie est limitée à la réparation ou au remplacement du produit

uniquement. L’Acheteur assume les frais de retrait, d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la

clientèle de SIMER au 1-800-468-7867 / 1-800-546-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes

d’eaux d’égout, voir ci-dessous) au détaillant où il a été acheté, et ce, immédiatement après la découverte de la

défaillance supposée. SIMER prendra les mesures correctives nécessaires dans un délai rapide et raisonnable. Aucune

demande de réparation ne sera acceptée plus de 30 jours après l’expiration de la garantie.

POMPES D’EAUX D’ÉGOUT

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle

de SIMER. Les pompes d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porter des gants en caoutchouc pour manipuler la pompe.

• À des fins de garantie, retourner l’étiquette figurant sur le cordon de la pompe et l’original du reçu au détaillant.

• Mettre la pompe au rebut conformément à la réglementation locale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P, CM10, CMK, M40, M40P 90 jours

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 ans

Réservoir préchargé de système d’eau, 3985, 3986, 5 ans

3963, 3988, 3995, 3997 À vie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti

couvert par cette garantie. Cette garantie ne s’applique pas à ce qui suit : (1) Les catastrophes naturelles; (2) Les

produits qui, selon SIMER, ont fait l’objet d’une négligence, d’une utilisation abusive, d’un accident, d’une

mauvaise application ou d’une altération; (3) Les défaillances dues à une installation, une utilisation, un entretien ou

un entreposage inappropriés; (4) Une application, une utilisation ou une réparation atypique ou non approuvée;

(5) Les défaillances causées par la corrosion, la rouille ou d’autres matériaux étrangers au système, ou par une

utilisation à une pression supérieure au maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit

défectueux.

SIMER NE POURRA ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU

IMPLICITE, Y COMPRIS, MAIS SANS S’Y LIMITER, CELLE DE QUALITÉ MARCHANDE OU D’APTITUDE DU PRODUIT À

UN EMPLOI PARTICULIER. LES PRÉSENTES GARANTIES NE PEUVENT SE PROLONGER AU-DELÀ DE LA PÉRIODE DE

GARANTIE INDIQUÉE ICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations

relatives à la durée des garanties implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus

ne s’appliquent pas. Cette garantie procure des droits juridiques précis à l’Acheteur. Cependant, il est possible de

bénéficier d’autres droits, qui varient selon l’État.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 / 1 800 546-7867 • Télécopieur : 1 800 390-5351

Courriel : info@simerpumps.com • Site Web : http://www.simerpumps.com

Page 8

Sécurité 8

Pour les services des pièces ou d'assistance, appeler le service à la clientèle Simer en composant le 1 (800) 468-7867

DESCRIPTION

Cette pompe d’assèchement sur pied est conçue pour

les puisards d’habitation. Elle est équipée d’un cordon

électrique avec fiche de terre à 3 broches. Les

manchons de palier de l’arbre moteur sont lubrifiés à

vie. Le moteur est protégé par un interrupteur thermique à réenclenchement automatique.

REMARQUE : Cette pompe n’est pas conçue pour

pomper de l’eau salée ni de la saumure! La garantie

sera annulée si cette pompe est utilisée pour pomper

de l’eau salée ou de la saumure.

CARACTÉRISTIQUES TECHNIQUES

Courant d’alimentation requis...................115 V, 60 Hz

Puissance nominale............................................1/3 Hp

Moteur ........................................................Intermittent

Gamme de températures

du liquide..........................de 0 à 21° C (de 32 à 70° F)

Circuit de dérivation individuel requis

Classe A - Disjoncteur de mise à la

terre défectueuse requis ....................................15 Amp

Charge complète du moteur (maximum)..........3,5 Amp

Refoulement ...........................................1-1/4 po FNPT

RENDEMENT

CONSIGNES GÉNÉRALES DE SÉCURITÉ

Si elle est bien installée, bien entretenue et bien utilisée,

une électropompe assure de nombreuses années de service sans entretien. Toutefois, toutes circonstances inhabituelles (interruption du courant alimentant la pompe,

saletés ou débris dans le puisard, débits de crue dépassant la capacité de la pompe, pannes électriques ou

mécaniques de la pompe, etc.) peuvent empêcher la

pompe de fonctionner normalement. Pour empêcher les

dégâts causés par l’eau suite à une inondation, s’adresser

au détaillant sur la possibilité de poser une deuxième

pompe de puisard fonctionnant sur le courant alternatif

ou une pompe de puisard de secours fonctionnant sur le

courant continu et/ou une alarme de niveau élevé d’eau.

Se reporter au «Tableau de recherche des pannes» de ce

Manuel pour plus de renseignements concernant les

problèmes courants des pompes de puisard et leurs

remèdes. Pour plus de renseignements, s’adresser au

marchand ou appeler le service à la clientèle Simer en

composant le 1 800 468-7867.

1. Il faut connaître les applications, les limitations et

les dangers de la pompe.

Ne pas utiliser cette pompe

dans des atmosphères

inflammables. Ne pomper que de l’eau avec cette

pompe. Le non-respect de cet avertissement peut

entraîner des blessures corporelles et des dommages matériels.

2. Couper le courant avant d’intervenir sur la pompe.

3. Dissiper toute la pression dans les tuyauteries avant

toute intervention sur les éléments de la pompe.

4. Vidanger l’eau des tuyauteries avant d’intervenir sur

la pompe.

Risque d’innondation. Si vous

utilisez un tuyau d’évacuation flexible, la pompe risque de se déplacer quand le moteur

se met en marche. Si à la suite de cela, l’interrupteur

vient heurter le côté du puisard, il se peut que l’interrupteur y adhère et empêche la mise en marche de la

pompe. Assurez-vous de bien caler la pompe, pour

qu’elle ne se déplace pas dans le puisard.

5. Caler la canalisation de refoulement avant de

démarrer la pompe. Une canalisation non calée

peut donner des coups de fouet qui risquent de

provoquer des blessures corporelles et des

dommages matériels.

6. Avant chaque utilisation, vérifier l’état des tuyaux

et s’assurer que tous les raccords sont bien serrés.

7. Inspecter tous les mois le puisard, la pompe et les

éléments du système. Éliminer tout débris et corps

étranger. Procéder à l’entretien de routine requis.

Danger d’incendie. Ne pas

placer d’objets sur ou à

côté du moteur ou du raccord de l’interrupteur.

Tenir le moteur à l’écart de tout objet ou liquide

inflammable.

8. Prévoir un moyen de réduire la pression sur les

pompes dont la canalisation de refoulement peut

être fermée ou bouchée.

9. Sécurité des personnes :

a. Toujours porter des lunettes de sécurité lorsque

l’on travaille sur une pompe.

b. Garder la zone de travail propre, dégagée et

bien éclairée ; ranger tous les outils et tout

l’équipement après utilisation.

c. Ne pas laisser les visiteurs s’approcher de la

zone de travail.

d. Prendre des mesures de sécurité dans l’atelier

pour protéger les enfants : poser des cadenas et

des interrupteurs généraux, et enlever les clés

de mise en marche.

10. Lors du câblage d’une pompe électrique, suivre

tous les codes électriques et les codes de sécurité

locaux.

11. Cette pompe ne peut être branchée que sur du

courant monophasé de 115 volts. Elle est équipée

d’un cordon d’alimentation à 3 conducteurs et

d’une fiche de terre à trois bornes.

Pour réduire les risques

d’électrocution, s’assurer

que la pompe est branchée sur une prise de terre

installée correctement.

Ne jamais brancher le fil vert

(ou vert et jaune) du cordon sur

une borne sous tension !

Si seule une prise de courant à 2 bornes est disponible, elle doit absolument être remplacée par une

prise à 3 broches correctement mise à la terre et

installée selon les codes et réglementations locaux.

12. Le câblage doit être installé par un électricien

qualifié.

13. S’assurer que le courant d’alimentation est conforme à celui sur lequel doit fonctionner la pompe.

14. Protéger les cordons électriques des objets tranchants, des surfaces chaudes, de l’huile et des produits chimiques. Éviter de tordre le cordon. Remplacer immédiatement tout cordon endommagé ou usé.

15. Ne pas toucher un moteur qui fonctionne. Les moteurs modernes sont conçus pour fonctionner à des

températures élevées.

16. Ne pas toucher à une pompe ni à un moteur de

pompe les mains humides, ou les pieds dans l’eau

ou sur une surface humide.

Si le sol de votre sous-sol

est hu mide ou mouillé,

coupez le courant avant de marcher dessus. Si le

coffret disjoncteur se trouve au sous-sol, appelez

la compagnie d’électricité qui coupera le courant,

ou appelez les pompiers qui vous donneront les

instructions à suivre. Déposez la pompe; réparezla ou remplacez-la. Le non-respect de cet avertissement peut entraîner la mort par électrocution.

Ne pas utiliser cette pompe

dans des endroits dangereux ou

des atmosphères inflammables.

L/H (GL/H) À UNE HAUTEUR DE (EN M/EN PI)

1,52 m 3,05 m 4,57 m 6,09 m

(5 pi) (10 pi) (15 pi) (20 pi)

11355 l 9312 l 6132 l

0

(3000 gl) (2460 gl) (1620 gl) (0 l)

Page 9

Installation / Fonctionnement 9

INSTALLATION

1. Cette pompe peut être installée dans un puisard de

vidange d’un diamètre et d’une profondeur de 30

cm (12 po) minimum. Le puisard peut être carrelé

ou revêtu de béton, d’acier ou de plastique. Voir

les codes locaux pour connaître les matériaux

autorisés.

2. Installer la pompe sur des fondations solides et à

niveau aussi près que possible du centre du

puisard. Ne pas suspendre la pompe au tuyau

de refoulement ou au câble électrique.

La pompe doit être à niveau

(la colonne doit être verticale).

Si le moteur est incliné, le commutateur interne

de marche-arrêt peut chauffer et l’endommager.

3. Ne pas installer la pompe sur des sols en argile, en

terre ou en sable. Nettoyer le puisard en enlevant

les cailloux et les graviers qui pourraient boucher

la pompe. Dégager la crépine d’aspiration de toute

obstruction.

4. Visser le tuyau de refoulement dans le corps de

la pompe en faisant bien attention de ne pas

arrancher les filets ni de les fausser.

REMARQUE : Ne pas utiliser de pâte à joint

ordinaire sur les tuyaux ou les raccords de la

pompe en plastique. La pâte à joint peut attaquer

le plastique et endommager la pompe.

5. Pour réduire les bruits et vibrations du moteur, un

bout de tuyau en caoutchouc (D.I. de 41 mm

(1-5/8 po), par exemple une durit) peut être relié

à l’aide de colliers appropriés au circuit de

refoulement qui se trouve près de la pompe.

Risques d’électrocution.

La pompe ne doit être branchée que sur un circuit de dérivation individuel

requis 15 ampères, 115 volts et 60 Hz mis à la

terre. Elle est livrée avec un cordon électrique à 3

fils avec fiche de terre pour usage sur une prise de

courant à 3 fils avec borne de terre. Ne pas cou-

per la borne de terre. Par mesure de sécurité, la

prise de courant doit toujours être mise à la terre

sur un support électrique qui convient tel qu’une

canalisation d’eau mise à la terre ou bien un guide-fils ou un système de fils à la terre correctement mis à la terre.

6. Placer le guide de tige du flotteur (n° réf. 6) à

environ 16 cm (6 po) au-dessous du moteur.

Attacher le guide sur la colonne avec la vis

fournie.

Risques de débordement.

Le guide doit être

correctement fixé pour que la tige du flotteur soit

en position verticale et puisse monter et descendre

librement. Si le flotteur est incliné ou bloqué, la

pompe risque de ne pas démarrer, ce qui peut

provoquer un débordement.

7. Viser le flotteur sur l’extrémité filetée de la tige. Le

filetage de la tige taraudera un trou dans le flotteur

résistant à la corrosion.

8. Insérer l’extrémité sans filetage de la tige du

flotteur dans l’œillet du guide de tige.

9. Glisser un dispositif d’arrêt sur la tige du flotteur

avant d’insérer la tige dans l’œillet de

l’interrupteur de la pompe. Glisser un second

dispositif d’arrêt sur la tige à sa sortie de l’œillet de

l’interrupteur. Placer le second dispositif d’arrêt à

fleur de l’extrémité supérieure de la tige.

10. Placer le dispositif d’arrêt inférieur à environ 20

cm (8 po) du levier de l’interrupteur. Lorsque le

dispositif d’arrêt inférieur se trouve dans cette

position, le cycle de la pompe se règle

automatiquement à 6 cm (2-1/2 po) pour l’arrêt et

à 25 cm (10-12 po) pour la marche. Pour un cycle

plus rapide, placer le dispositif d’arrêt inférieur

plus près du levier de l’interrupteur.

11. Si une partie de la canalisation de refoulement

de la pompe est soumise à des températures

extérieures inférieures à zéro, l’installer de façon

à ce qu’elle se vidange par gravité. Sinon l’eau

restant dans la canalisation risque de geler et

d’endommager la pompe.

12. Installer un clapet de retenue en ligne pour éviter

le reflux du liquide dans la pompe après l’arrêt de

cette dernière.

NOTA : Les clapets anti-retour Simer sont munis

d’un trou de purge d’air pour empêcher la

formation de bouchons d’air dans la pompe. Si

l’on utilise un clapet anti-retour autre qu’un clapet

Simer, percer un trou de 3,2 mm (1/8 de pouce)

dans le tuyau de refoulement, just au-dessus de

corps de la pompe, mais plus bas que le clapet

anti-retour, pour empêcher la formation de

bouchons d’air.

13. Après l’installation de toutes les canalisations et

commandes, l’appareil est prêt à être mis en

service.

14. Faire faire un cycle complet à la pompe pour

vérifier le bon fonctionnement de l’interrupteur

du flotteur.

Le moteur de la pompe est

équipé d’un dispositif de

protection thermique à réenclenchement automatique

et peut redémarrer de façon inattendue. Le déclenchement de ce dispositif de protection est une indication

de la surcharge du moteur provoquée par le fonctionnement de la pompe à une hauteur de refoulement

trop faible, avec un voltage trop élevé ou trop bas,

avec un câblage défectueux, de mauvaises connexions

sur le moteur, ou bien avec un moteur défectueux.

Pour les services des pièces ou d'assistance, appeler le service à la clientèle Simer en composant le 1 (800) 468-7867

Discharge

About 6"

About 8"

Check

Valv e

(Purchase

Separately)

Environ

8 pouces

Environ

6 pouces

Refoulement

Clapet antiretour

(À acheter

séparément)

Page 10

Pour les services des pièces ou d'assistance, appeler le service à la clientèle Simer en composant le 1 (800) 468-7867

Fonctionnement 10

Diagnostic des pannes

SYMPTÔME CAUSE(S) PROBABLE(S) MESURE CORRECTIVE

Le moteur Panne d'électricité Vérifier fusible, disjoncteur, cordon électrique

ne démarre et prise électrique.

pas ou ne

Basse tension de la ligne Si le voltage est au-dessous du minimum

tourne pas

recommandé, vérifier la force du câblage depuis sa

source. S’il n’y a pas de problème, contacter la

Compagnie d’électricité ou les services

hydro-électriques locaux.

Interrupteur automatique Faire fonctionner l’interrupteur manuellement et le

défectueux remplacer si nécessaire.

Flotteur ou tige de Vérifier si le flotteur frotte contre la paroi du puisard,

flotteur bloquée ou si la tige du flotteur frotte ou est bloquée contre

le couvercle du puisard.

Flotteur noyé Remplacer le flotteur s’il est plein d’eau.

Interrupteur de surcharge Si la pompe s’arrête en plein fonctionnement avant

déclenché que le puisard ne soit vide, l’interrupteur

automatique de surcharge s’est peut-être déclenché.

Vérifier le filtre de la crépine pour voir si la roue

motrice n’est pas bloquée. La dégager de toute

obstruction si nécessaire.

Mauvais fonctionnement Vérifier cordon électrique, interrupteur automatique

électrique et moteur. Remplacer les pièces défectueuses si nécessaire.

Le moteur Crépine bouchée Vérifier la crépine et la nettoyer si nécessaire.

tourne mais

Canalisation de Nettoyer la canalisation de refoulement et vérifier si

la pompe refoulement bouchée la valve est bloquée.

pompe pas

Basse tension de la ligne Se reporter à la mesure corrective indiquée pour la

basse tension de ligne dans la section ci-dessus.

Bouchon d’air dans Percer un trou de 3,2 mm (1/8 de pouce) dans le

la pompe tuyau de refoulement, juste au-dessus du corps de

la pompe, mais plus bas que le clapet anti-retour.

Impulseur ou arbre cassé Remplacer l’impulseur ou l’arbre, selon le besoin.

La pompe Mauvaise position de Baisser l’arrêt de la tige du flotteur.

démarre et l'arrêt de la tige du

s'arrête trop flotteur

souvent

Interrupteur automatique Remplacer l’interrupteur automatique.

défectueux

La pompe Mauvaise installation Se reporter au N° 5 des instructions d’installation.

fait du bruit Moteur bruyant Remplacer la pompe.

La pompe Débris autour du flotteur Retirer les débris du puisard. Vérifier si le flotteur frotte

tourne sans ou tige du flotteur contre la paroi du puisard ou si la tige du flotteur frotte

s'arrêter bloquée ou est bloquée contre le couvercle du puisard.

Interrupteur automatique Remplacer l’interrupteur.

défectueux

Moteur défectueux Remplacer la pompe.

Débrancher la pompe avant de travailler sur la pompe.

FONCTIONNEMENT

Ne pas toucher la pompe, le

moteur de la pompe, l’eau ou

la canalisation de refoulement quand la pompe est

branchée sur le courant électrique. Toujours

débrancher le cordon d’alimentation (électrique)

de la pompe avant de la manier.

1. Brancher cette pompe dans la prise du courant

d’un circuit de dérivation individuel protégé par

un disjoncteur de fuite à la terre de 15 ampères,

classe A. Consultez un électricien local pour tout

renseignement.

2. Remplir d’eau le puisard ; la pompe démarre

automatiquement quand le dispositif d’arrêt

inférieur actionne le levier de l’interrupteur.

Elle s’arrête quand le dispositif d’arrêt supérieur

actionne le levier de l’interrupteur.

REMARQUE : Veiller à ce que la pompe ne

s’assèche pas.

Avant d’entreprendre tout

entretien, toujours débrancher

la pompe.

3. Le moteur est équipé d’un dispositif de protection

thermique à réenclenchement automatique qui

protège l’appareil de la surchauffe. Après un

refroidissement suffisant du moteur, l’interrupteur

s’enclenche automatiquement et redémarre le

moteur. Le déclenchement répété de ce dispositif

peut être causé par une basse tension, des

rallonges longues, une turbine obstruée, une hauteur d’élévation ou de refoulement très faible, etc...

Le réenclenchement répété du dispositif de protection risque de faire griller le moteur.

Page 11

Pièces de rechange 11

Pour les services des pièces ou d'assistance, appeler le service à la clientèle Simer en composant le 1 (800) 468-7867

1

2

3

4

5

6

7

8

9

10

11

12

Réf. Désignation des pièces Qté 5020B-04

1 Moteur 1 *

2 Interrupteur 1 †

3 Volute (Corps de la pompe) 1 PS1-25P

4 Impulseur 1 PS5-269P

5 Plaque du socle 1 PS4-17P

6 Vis (De la plaque du socle) 8 U30-934ZP

7 Guide de la tige du flotteur 1 RP0005249

8 Vis (Du guide de la tige) 1 U30-929ZP

9 Vis (Du socle) 1 SC004-116

10 Flotteur 1 FT0013-63

11 Tige du flotteur 1 RP005168S

12 Butée du flotteur 2 RP0005248

Modèle 5020B-04

* Si le moteur tombe en panne, remplacer la pompe.

† Choisir le modèle d’interrupteur en se reportant ci-dessous.

Interrupteur FP0020

Interrupteur FP0018-7D

Page 12

Garantía 12

GUARDE EL RECIBO ORIGINAL PARA CULAQUIER REFERENCIA POSTERIOR.

GARANTÍA LIMITADA

SIMER le garantiza al comprador consumidor original (el “Comprador” o “Usted”) de sus productos, que éstos

estarán libres de defectos en materiales y en mano de obra por un período de doce (12) meses, a partir de la fecha de

la compra original del consumidor.

Si dentro de los doce (12) meses a partir de la fecha de la compra inicial del consumidor, se comprueba que

cualquiera de esos productos es defectuoso, éste será reparado o reemplazado, a la discreción de SIMER, sujeto a los

términos y a las condiciones indicadas a continuación. Se necesitará su recibo de compra original y la etiqueta de

información sobre la garantía del producto, para determinar la admisibilidad de la garantía. La admisibilidad se basa

en la fecha de compra del producto original - no en la fecha de reemplazo bajo la garantía. La garantía está limitada a la

reparación o el reemplazo del producto solamente - El comprador pagará todos los costos de remoción, instalación,

mano de obra y envío necesarios, así como todo costo adicional asociado.

Si necesita piezas o resolución de problemas, NO regrese el producto a la tienda minorista. Llame el Servicio a la

Clientela de SIMER al 1-800-468-7867 / 1-800-546-7867.

Las reclamaciones bajo esta garantía se deberán realizar mediante la devolución del producto (excepto en el caso de

las bombas cloacales, ver a continuación) a la tienda minorista en donde se haya adquirido, inmediatamente después

de haber descubierto un supuesto defecto. SIMER entonces tomará la medida correctiva tan pronto como sea

razonablemente posible. No se aceptarán solicitudes de servicio, si se reciben más de 30 días después del vencimiento

de esta garantía.

BOMBAS CLOACALES

NO devuelva una bomba cloacal (que se haya instalado) a su tienda minorista. Comuníquese con el Departamento

de Atención al Cliente de SIMER. Las bombas cloacales que hayan estado en servicio y se hayan removido pueden

representar un peligro de contaminación.

Si su bomba cloacal ha fallado:

• Use guantes de caucho cuando manipule la bomba;

• Para los fines de la garantía, devuelva la etiqueta del cordón de la bomba y el recibo de compra original a la tienda

minorista;

• Descarte la bomba cumpliendo con todas las normas locales que correspondan para su eliminación.

Excepciones para la Garantía Limitada de Doce (12) Meses

Producto Período de garantía

BW85P, CM10, CMK, M40, M40P 90 días

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 años

Bombas de pozo sumergibles de 4”, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 años

Tanque precargado del sistema de agua, 3985, 3986 5 años

3963, 3988, 3995, 3997 De por vida

Términos y condiciones generales

Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto

por esta garantía. Esta garantía no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos

que, a sólo juicio de SIMER hayan sido sometidos a negligencia, abuso, accidente, mala aplicación, manejo

indebido o alteraciones; (3) fallas debido a instalación, operación, mantenimiento o almacenamiento inadecuados;

(4) aplicaciones, usos o servicios que no sean normales o aprobados; (5) fallas provocadas por corrosión, herrumbre

u otros materiales extraños en el sistema, o una operación a presiones que excedan los máximos recomendados.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del Comprador con respecto a los

productos defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA EXPLÍCITA O

IMPLÍCITA, INCLUYENDO PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E

IDONEIDAD PARA UN FIN ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO SE EXTENDERÁN MÁS ALLÁ DE LA

DURACIÓN PROVISTA EN LA PRESENTE.

Algunos Estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de

tiempo sobre garantías implícitas, de modo que es posible que las limitaciones o exclusiones que preceden no

correspondan en su caso. Esta garantía le otorga derechos legales específicos y es posible que Usted también tenga

otros derechos que pueden variar de un Estado al otro.

SIMER • 293 Wright St., Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Sitio Web: http://www.simerpumps.com

Page 13

Para refacciones o asistencia, llame a Simer Servicios al Cliente al: 1 800 468-7867

Seguridad 13

DESCRIPCIÓN

Esta Bomba de Pie para Sumideros está diseñada para sumideros domésticos. La unidad está equipada con un cable de

alimentación de tres púas con contacto a tierra. Los cojinetes de manga del eje del motor nunca requieren lubricación. Protección térmica de restablecimiento automático.

NOTA: Esta unidad no ha sido diseñada para uso con

agua salada o salubre. El uso con agua salada o salubre anulará la garantía.

ESPECIFICACIONES

Energía eléctrica necesaria .........................115V, 60 Hz

Caballos de fuerza ....................................................1/3

Funcionamiento del motor .........................Intermitente

Margen de temperatura del líquido32 a 70 °F (0–21 °C)

Requiere un ramal individual GFCI Clase A .....15 amps

Carga Completa del motor (máxima) ..............3,5 amps

Descarga: ...................................................1-1/4" FNPT

RENDIMIENTO

INFORMACIONES GENERALES

SOBRE SEGURIDAD

Las bombas de sumidero eléctricas por lo regular duran

muchos años sin sufrir problemas de servicio, cuando

son instaladas, mantenidas y usadas correctamente. Sin

embargo, las situaciones inusuales (interrupción del

suministro eléctrico que va a la bomba, tierra o

suciedad en el sumidero, inundación superior a la

capacidad de la bomba, fallas eléctricas y mecánicas,

etc.), pueden evitar que su bomba funcione como

acostumbra. Para evitar posibles daños ocasionados

por inundación de agua, consulte a su representante

de ventas sobre la instalación de una bomba de

sumidero con CA secundaria, una bomba de sumidero

de respaldo con CD, y/o una alarma de alto nivel de

agua. Consulte la “Tabla de solución de problemas”

contenida en este manual para información sobre

problemas comunes de la bomba de sumidero y

soluciones. Para mayor información, acuda con su

representante de ventas o llame al centro de servicio a

clientes Simer al 1-800-468-7867.

1. Infórmese acerca de las aplicaciones, limitaciones

y peligros potenciales de la bomba.

No utilice la bomba en

atmósferas explosivas. Utilice

esta bomba para bombear agua solamente. Ignorar esta advertencia puede ocasionar daños personales y/o materiales.

2. Desconecte la bomba antes de hacer reparaciones

o realizar tareas de mantenimiento.

3. Libere la presión existente dentro del sistema

antes de efectuar el mantenimiento de cualquier

componente.

4. Drene toda el agua del sistema antes de efectuar

tareas de mantenimiento.

Peligro de inundación. Si se utiliza

una manguera de descarga flexible,

puede que la bomba se mueva al encenderse el

motor. Si al moverse la bomba ésta causa que el

interruptor roce un lado del sumidero, puede que

el interruptor se atasque impidiendo que la bomba

funcione. Cerciórese de que la bomba esté bien

asegurada para que no choque contra el sumidero.

5. Asegure la tubería de descarga antes de poner en

funcionamiento la bomba. Si la tubería de descar-

ga está suelta puede “latiguear”, ocasionando posibles daños personales y/o materiales.

6. Inspeccione las mangueras antes de usar la bomba, para asegurarse de que están en buen estado, y

verifique que las conexiones estén firmes.

7. Inspeccione mensualmente el sumidero, la bomba

y los componentes del sistema. Manténgalos libres

de residuos y objetos extraños. Realice el

mantenimiento periódico que sea necesario.

Peligro de Incendio – No

guarde ni coloque objetos

sobre o cerca del motor o interruptor de enlace.

Mantenga todo objeto o líquido inflamable lejos

del motor.

8. Proporcione medios alternativos para liberar la

presión de las bombas cuya tubería de descarga

puede taparse u obstruirse.

9. Seguridad personal:

a. Use gafas protectoras en todo momento cuando

trabaje con las bombas.

b. Mantenga el área de trabajo limpia, ordenada y

bien iluminada – retire del lugar las herramientas y equipos que no se usen.

c. Mantenga a los visitantes alejados del área de

trabajo.

d. Haga que su taller sea a prueba de niños – con

candados, llaves maestras y retirando siempre

las llaves de encendido.

10. Cuando haga el cableado de una bomba eléctrica,

observe todos los códigos locales de electricidad y

seguridad.

11. Este equipo es para ser usado únicamente con 115

voltios

(monofásico) y está equipado con un cable

aprobado de tres conductores y enchufe de tres

púas con contacto a tierra.

Para reducir los riesgos de

choque eléctrico asegúrese

de que la bomba esté conectada a una toma

correctamente conectada a tierra.

¡Nunca conecte cables verdes (o

verdes y amarillos) a un terminal

con corriente!

Donde haya una toma de pared para enchufes de

dos púas, deberá ser reemplazada por una toma

para enchufes de tres púas correctamente

conectada a tierra, de acuerdo con los códigos y

las ordenanzas locales.

12. Todas las tareas de cableado deben ser efectuadas

por electricistas calificados.

13. Asegúrese de que la fuente de energía concuerda

con los requerimientos de su equipo.

14. Proteja el cable eléctrico de objetos afilados,

superficies calientes, aceites y productos químicos.

Evite enredar el cable. Reemplace o repare

inmediatamente los cables dañados o gastados.

15. No toque un motor en funcionamiento. Los

motores modernos están diseñados para funcionar

a altas temperaturas.

16. No toque la bomba o el motor de la bomba con

las manos mojadas o mientras esté parado sobre

superficies húmedas o mojadas, o en el agua.

Si su sótano tiene agua o

humedad en el piso, no

camine sobre la superficie húmeda hasta que se

hayadesconectado la electricidad. Si la caja

eléctrica está en el sótano, llame a la compañía

eléctrica para que corte la electricidad de la

casa, o llame al departamento de bomberos para

solicitar instrucciones. Retire la bomba y repárela

o reemplácela. Ignorar estas instrucciones puede

originar choques eléctricos fatales.

No use la bomba en lugares

peligrosos o explosivos.

GPH (Galones Por Hora) (LPH - Litros Por Hora)

POR TOTAL DE PIES (M)

5 pies 10 pies 15 pies 20 pies

(1,52 m) (3,05 m) (4,57 m) (6,09 m)

3000 2460 1620

0

(11355 l) (9312 l) (6131 l) (0 l)

Page 14

Para refacciones o asistencia, llame a Simer Servicios al Cliente al: 1 800 468-7867

Instalación / Funcionamiento 14

INSTALACIÓN

1. Esta unidad puede instalarse en un pozo de

sumidero de un mínimo de 12" (30 cm) de

diámetro y 12" (30 cm) de profundidad. El pozo

de sumidero puede estar construido de azulejos,

concreto, acero o plástico. Verifique los códigos

locales para

establecer cuáles son los materiales aprobados.

2. Instale la bomba sobre una base sólida y nivelada,

tan cerca como sea posible del centro del

sumidero. No cuelgue la bomba de la tubería

de descarga o del cable de alimentación.

La bomba debe estar nivelada (la

columna debe estar vertical)

mientras funciona. Si el motor está inclinado, el

interruptor interno de arranque/funcionamiento

puede recalentarse y dañar al motor.

3. La bomba no debe ser instalada sobre superficies

de arcilla, tierra o arena. Limpie el sumidero de

piedras pequeñas o gravilla que puedan tapar la

bomba. Mantenga limpia la rejilla de entrada de la

bomba.

4. Atornille la tubería de descarga en el cuerpo de la

bomba, evitando cuidadosamente de raspar o

torcer las roscas.

NOTA: No utilice compuestos ordinarios para

conexiones de tubos sobre el tubo plástico o la

bomba. Los compuestos para conexiones de tubos

pueden dañar tanto el plástico como la bomba.

5. Para reducir el ruido y las vibraciones del motor

puede conectarse una manguera de caucho corta

(1-5/8" [41 mm] de diámetro interno, p. ej.

manguera de radiador) a la tubería de descarga

cerca de la bomba, empleando grapas adecuadas.

Peligro de choque eléctrico.

La bomba está diseñada para

funcionar con 115V, 60 Hz y requiere un ramal

individual de 15 amperios de capacidad. Viene

equipada con un cordón de tres cables y enchufe

de tres púas para uso en tomas con contacto a

tierra para enchufes de tres púas. No corte la púa

de contacto a tierra. Para mayor seguridad, la

toma eléctrica siempre debe estar conectada

a tierra a un medio conveniente para la

electricidad, tal como una tubería de agua

enterrada, o un canal metálico de cables de

conducción o un sistema de conexión a tierra.

6. Ubique la Guía de la Varilla de Flotación (No. 6),

a unas 6" (16 cm) por debajo del motor. Instale la

guia en la columna con el tornillo provisto.

Peligro de inundación.

Asegúrese de que la guía

esté sujetada firmemente para que la varilla de

flotación quede en posición vertical y pueda

moverse de arriba abajo libremente. Si el flotador

está inclinado o se dobla, la bomba puede no

arrancar y provocar inundaciones.

7. Enrosque el flotador al extremo con rosca de la

varilla. La rosca de la varilla cortará la rosca en el

flotador anticorrosivo.

8. Inserte el otro extremo de la varilla (sin rosca) en

el ojo de la guía de la varilla.

9. Coloque un tope en la varilla de flotación antes de

pasar la varilla a través del ojo del interruptor de

la bomba. Coloque un segundo tope en la varilla

después de pasarla a través del ojo del interruptor.

Sitúe el segundo tope al mismo nivel que el

extremo de la varilla.

10. Ubique el tope inferior de la varilla a unas 8" (20

cm) del brazo de la palanca del interruptor. Con

el tope inferior de la varilla en esta posición,

la bomba tendrá ciclos automáticos de

aproximadamente 2-1/2" (6 cm) afuera y 10-12"

(25-30 cm) adentro. Para un ciclo más rápido,

sitúe el tope inferior de la varilla más cerca del

brazo de la palanca del interruptor.

11. Si la tubería de descarga está expuesta a una

atmósfera externa de temperaturas inferiores al

punto de congelamiento, parte de la tubería

expuesta debe instalarse de manera tal que el

agua que permanezca adentro drene a una boca

de descarga mediante gravedad. Ignorar esta

indicación puede ocasionar el congelamiento del

agua atrapada en la tubería de descarga, lo cual

puede a su vez dañar la bomba.

12. Instale una válvula de control interna para impedir

el retroceso de líquidos en dirección a la bomba,

una vez que la misma se apaga.

NOTA: Las válvulas de retención SIMER están

provistas de un agujero de purga del aire para

evitar que se formen burbujas de aire en la bomba.

Si utiliza una válvula de retención que no sea

Simer, taladre un agujero de 3,2 mm (1/8”) en la

tubería de descarga, justo arriba del cuerpo de la

bomba, pero debajo de la válvula de retención a

fin de evitar la formación de burbujas de aire.

13. Una vez instaladas todas las tuberías y controles,

la unidad está lista para funcionar.

14. Haga funcionar la bomba durante un ciclo para

verificar el funcionamiento del interruptor flotador.

El motor de la bomba está

equipado con un protector

térmico automático de restablecimiento y puede

volver a arrancar inesperadamente. Si el protector

salta es una indicación de que el motor está

sobrecargado porque la bomba está funcionando con

baja caída (restricción de baja descarga), voltaje

excesivamente alto o bajo, cableado eléctrico

inadecuado, conexiones del motor incorrectas o

de que el motor es defectuoso.

Discharge

About 6"

About 8"

Check

Valv e

(Purchase

Separately)

Alrededor

de 8"

Alrededor

de 6"

Descarga

Válvula de

retención

(adquirir por

separado)

Page 15

Para refacciones o asistencia, llame a Simer Servicios al Cliente al: 1 800 468-7867

Funcionamiento 15

Solución de problemas

SÍNTÔMA CAUSA(S) PROBABLE(S) ACCIÓN CORRECTIVA

El motor No hay electricidad Inspeccione el fusible, el interruptor de circuito, el

no arranca cable de alimentación y la toma eléctrica.

ni funciona Bajo voltaje en la línea Si el voltaje del cableado eléctrico está por debajo

del mínimo recomendado, verifique el tamaño de

los cables desde la fuente de alimentación. Si el

cableado está bien, comuníquese con la compañía

eléctrica o la autoridad de recursos hidrológicos.

Interruptor automático Accione el interruptor manualmente y reemplácelo

defectuoso si no funciona.

Flotador o varilla del Asegúrese de que el flotador no roce contra la pared

flotador atascados del sumidero y que la varilla del flotador no roce o

esté atascada contra la tapa del sumidero.

Flotador anegado Reemplace el flotador si está saturado de agua.

Saltó la protección de Si la bomba ha estado funcionando y se para antes

sobrecarga de vaciar al sumidero, el protector de sobrecarga

puede haber saltado. Inspeccione la rejilla de

entrada para asegurarse de que el impulsor no está

atascado. Si lo estuviera, libere el impulsor de obstrucciones.

Defecto eléctrico Inspeccione el cable de alimentación, el interruptor

automático y el motor. Reemplace las partes

defectuosas según sea necesario.

El motor Entrada tapada Inspeccione la entrada y límpiela si fuera necesario.

funciona pero Tubería de descarga Limpie la tubería de descarga e inspeccione la válvu

la bomba tapada la de control para ver si hay obstrucciones.

no bombea Bajo voltaje en la línea Refiérase a la acción correctora referente a bajo

voltaje en la línea en la sección anterior.

Burbajas de aire en Taladre un agujero de 3,2 mm (1/8”) en la tubería de

la bomba descarga, justo arriba del cerpo de la bomba, pero

debajo de la válvula de retención.

Impulsor o eje quebrado Reemplace el impulsor o el eje según sea necesario.

La bomba Ubicación incorrecta del Ubique más abajo el tope inferior de la varilla

arranca y se tope de la varilla de del flotador.

para demasiado flotación

a menudo Interruptor automático Reemplace el interruptor automático.

defectuoso

La bomba es Instalación incorrecta Refiérase al No. 5 en las instrucciones de

muy ruidosa instalación.

Motor ruidoso Reemplace la bomba.

La bomba Residuos alrededor del Retire los residuos del sumidero. Verifique que el

no deja flotador o varilla del flotador no roce la pared del sumidero ni que la

de funcionar flotador atascada varilla del flotador roce o esté atascada en la tapa

del sumidero.

Interruptor automático Reemplace el interruptor.

defectuoso

Motor defectuoso Reemplace la bomba.

Desconecte la bomba de la fuente de alimentación eléctrica antes de efectuar

cualquier trabajo en la misma.

FUNCIONAMIENTO

No toque la bomba, el motor de la

bomba, la tubería de agua o de descarga cuando la bomba está conectada a la fuente de

energía eléctrica. Siempre desconecte el cable de la

bomba (alimentación) antes de tocarla.

1. Enchufe esta unidad en un tomacorriente de 115

voltios, en un ramal individual, con un disyuntor de

escape a tierra Clase A de 15 amperios.

Consulte a su electricista local para mayor información y disponibilidad.

2. Llene el sumidero con agua. La bomba arrancará

automáticamente cuando el tope inferior de la

varilla active el brazo de la palanca del interruptor.

Cuando el tope superior de la varilla active el

brazo de la palanca del interruptor, la bomba

dejará de funcionar.

NOTA: No permita que la bomba funcione sin agua.

Antes de intentar reparar la

bomba, desconéctela siempre

de la fuente de energía.

3. El motor está equipado con un protector térmico

automático de restablecimiento para proteger la

unidad de recalentamientos. Cuando el motor se

haya enfriado lo suficiente, el interruptor se

reactivará automáticamente y el motor volverá a

arrancar. Si el interruptor salta repetidamente

puede deberse a bajo voltaje, cables de extensión

muy largos, impulsor tapado, una caída muy baja

o carga baja, etc. La desconexión del protector

causará el quemado del motor.

Page 16

Para refacciones o asistencia, llame a Simer Servicios al Cliente al: 1 800 468-7867

Refacciones 16

1

2

3

4

5

6

7

8

9

10

11

12

No. Descripción Cant. 5020B-04

1 Motor 1 *

2 Interruptor 1 †

3 Voluta (Cuerpo de la bomba) 1 PS1-25P

4 Impulsor 1 PS5-269P

5 Placa de base 1 PS4-17P

6 Tornillos (Placa de base) 8 U30-934ZP

7 Guía de la varilla de flotación 1 RP0005249

8 Tornillo (Varilla de flotación) 1 U30-929ZP

9 Tornillo (Base) 1 SC004-116

10 Flotador 1 FT0013-63

11 Varilla de flotación 1 RP005168S

12 Tope del flotador 2 RP0005248

Modelo 5020B-04

* Si el motor falla, reemplace la bomba.

† Seleccione el número del modelo del interruptor a continuación.

Interruptor FP0020

Interruptor FP0018-7D

Loading...

Loading...