Page 1

OWNER’S MANUAL

Engine Drive Self-Priming Pump

NOTICE D’UTILISATION

Motopompe à amorçage

automatique

MANUAL DEL USUARIO

Bomba autocebante

accionada a motor

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867 /

1-800-546-7867

English . . . . . . . . . . . . . . . Pages 2-8

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867 /

1 (800) 546-7867

Français . . . . . . . . . . . . Pages 9-15

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867 /

1-800-546-7867

Español . . . . . . . . . . .Paginas 16-22

SIM753 (Rev. 10/2/08)

Model 4955

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

4584 0504

Page 2

IMPORTANT

For best possible performance and continuous, satisfactory operation, read these instructions before installing your new pump. Should service be required, this

manual can be a valuable guide, it should be kept near the

installation for ready reference.

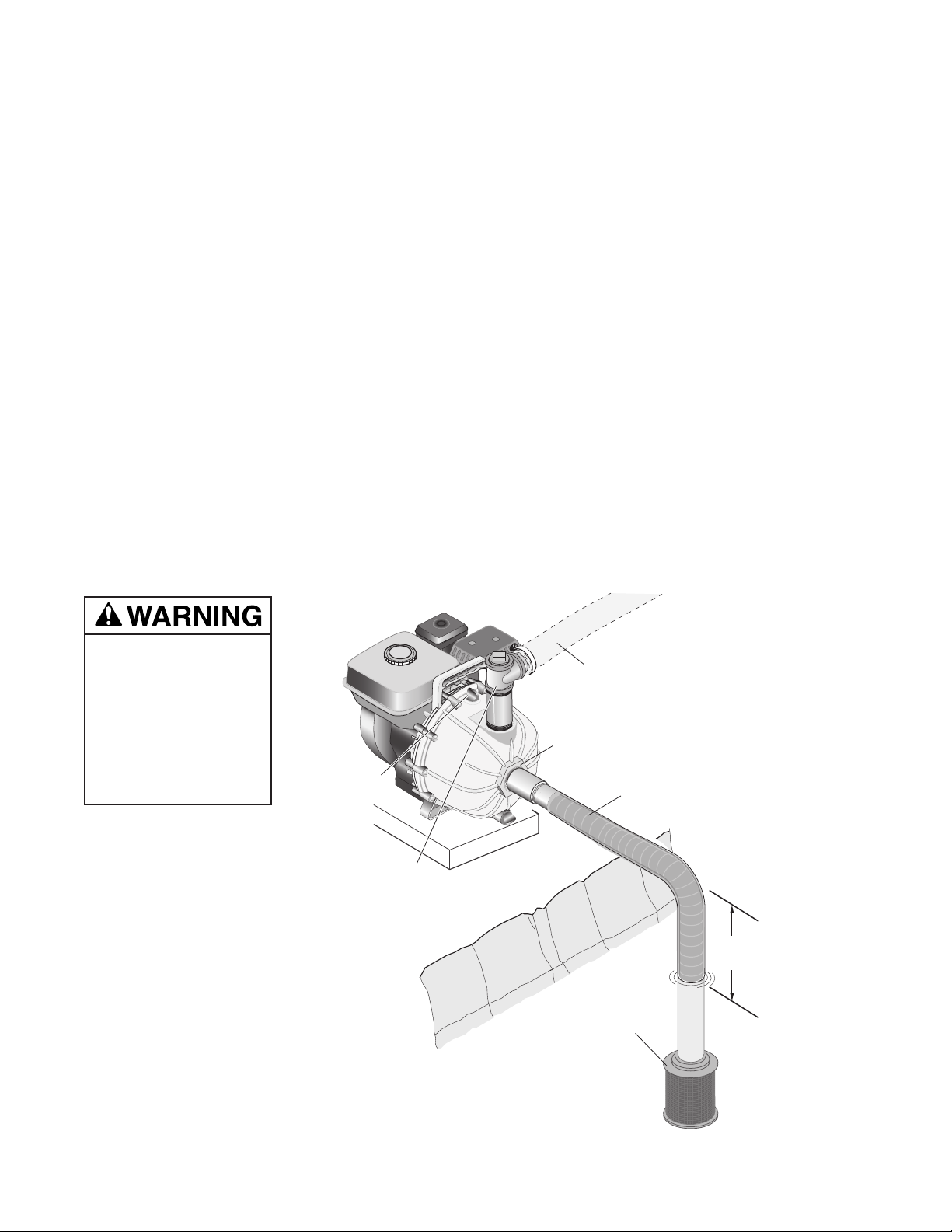

INSTALLATION

LOCATION

Place unit as close to water source as possible to minimize

suction lift, obtain the best pumping performance, and aid in

priming. A typical portable installation is shown in Figure 1.

For permanent installation, mount unit on a foundation that

will support the weight of pump and engine and also provide

stability while the pump is running. For most permanent

installations, it is advisable to bolt unit directly to foundation.

NOTICE: Settling and/or shifting during operation can cause

piping to place excessive strain on the pump and may damage pump case. Set pump on hard level surface.

SUCTION CONNECTION

Connect either rigid pipe or flexible suction hose to pump

suction as shown in Figure 1. If hose is selected, hose must

be rated to hold the suction pressure and prevent collapse

while the pump is running.

Make the suction line a continuous rise from the water

source to the pump. High spots can trap air and also make

priming difficult. Make sure all connections are tight and free

of air leaks.

NOTICE: Suction pipe or hose must be at least as large as the

pump suction inlet in order for the pump to operate properly.

Minimum depth for the suction inlet is determined by the

diameter of the suction line. See Figure 1.

NOTICE: Use a suction screen to keep debris out of pump.

DISCHARGE CONNECTIONS

Your pump is equipped with a single port discharge. Select

the appropriate size for the application. Install a “T” as

shown to allow priming the pump without disconnecting the

piping.

OPERATION

NOTICE: Do not start or run pump dry or damage to the

mechanical seal will result.

NOTICE: Add engine oil before startup. Refer to the

engine operation manual before startup.

PRIMING THE PUMP

A self priming pump only needs to be manually primed at the

first start-up. Once primed, under normal conditions the

pump will reprime automatically at each subsequent start-up.

If the pump is used in portable applications and the water has

been drained from the pump case, reprime before start-up

To prime, remove plug from top discharge outlet and fill

pump with water. Replace plug and start pump. The pump

will require a few minutes to evacuate air from the suction

line. After several minutes of operation, pump will be fully

primed and pumping water. Priming time will vary depending

on length and diameter of suction line.

2

Figure 1 – Typical Installation

Hazardous Suction.

Can trap persons

against suction inlet.

Always use strainer

on suction hose to

prevent entrapment.

Use pipe or reinforced hose to make

suction connection.

Hose must be strong enough to

not collapse during operation.

Suction screen area must be at least four

times suction pipe area.

All suction piping must slope up toward the

pump inlet.

Support the piping and fittings to reduce strain

on the pump case.

Priming Plug

Provide rigid

platform for pump.

Customer-supplied

Priming tee, plug

and nipple.

Discharge pipe not

smaller than the pump

discharge opening.

(2" x 25' Discharge hose

included in kit FP2731)

Pump Inlet

Suction hose

(2" x 15' Suction hose

included in kit FP2735).

Support pipe and

fittings.

Strainer or foot valve

(2" strainer included

in kit FP2735)

Depth of suction inlet at least

four (4) times the diameter of suction

pipe to avoid forming vortexes.

Example:

2" Pipe x 4 = 8" minimum depth.

25' Max

Page 3

RUNNING THE ENGINE

Refer to engine operation part of this manual for starting and

operating instructions.

Pump performance varies depending on engine R.P.M.

Refer to engine operation to adjust engine speed.

MAINTENANCE

PUMP LUBRICATION

Pump liquid end does not require any grease or oil for lubrication. The mechanical seal is lubricated by water when the

pump is operating.

3

CAUSE CORRECTIVE ACTION

1. ENGINE

A. Speed too low Refer to engine section

B. Rotating and/or reciprocating parts drag Refer to engine section

C. Speed too high Maximum engine speed not to exceed engine manufacturer’s recommendation.

D. Loose or broken parts Refer to engine section

2. PUMP

E. Not primed Reprime, inspect suction system for air leaks, and or clack assembly.

F. Pump takes too long to prime Check for air leaks or defective check valve.

G. Flow through pump completely Locate and remove obstruction. Attach strainer.

or partially blocked

H. Internal leakage Check clearances between face of vanes and case. Should not exceed 1/32".

I. Rotating parts drag Inspect. Repair.

J. Loose or broken parts Inspect. Repair.

3. SYSTEM

K. Pressure required by system at design Compare pump pressure and flow rate against pump performance chart.

flow rate exceeds pressure rating of pump Reduce system pressure requirement. Increase pressure capability of pump.

L. Obstruction in suction piping Locate and remove obstruction. Attach strainer.

M. Suction lift too high Check with gauge or measure vertical distance between water surface and

center line of pump, allowing for friction loss in suction pipe. Reduce rate of

flow to obtain desired lift. Refer to pump performance chart.

N. Discharge head too low Decrease rate of flow

O. Suction inlet not immersed deep enough Refer to “Installation”

P. Leaky suction line or connection admitting air Repair or replace suction line. Tighten connections.

PROBABLE CAUSE

SYMPTOM ENGINE PUMP SYSTEM

ABCDEFGH I JKLMNOP

No water delivered X X X X X X X

Not enough water delivered X X X X X X X

Not enough pressure X X X X X X

Engine heats excessively X X X X X X X

Abnormal noise and/or vibration X X X X X X X

Pump works for a while, then stops XXXXXX

Troubleshooting Guide

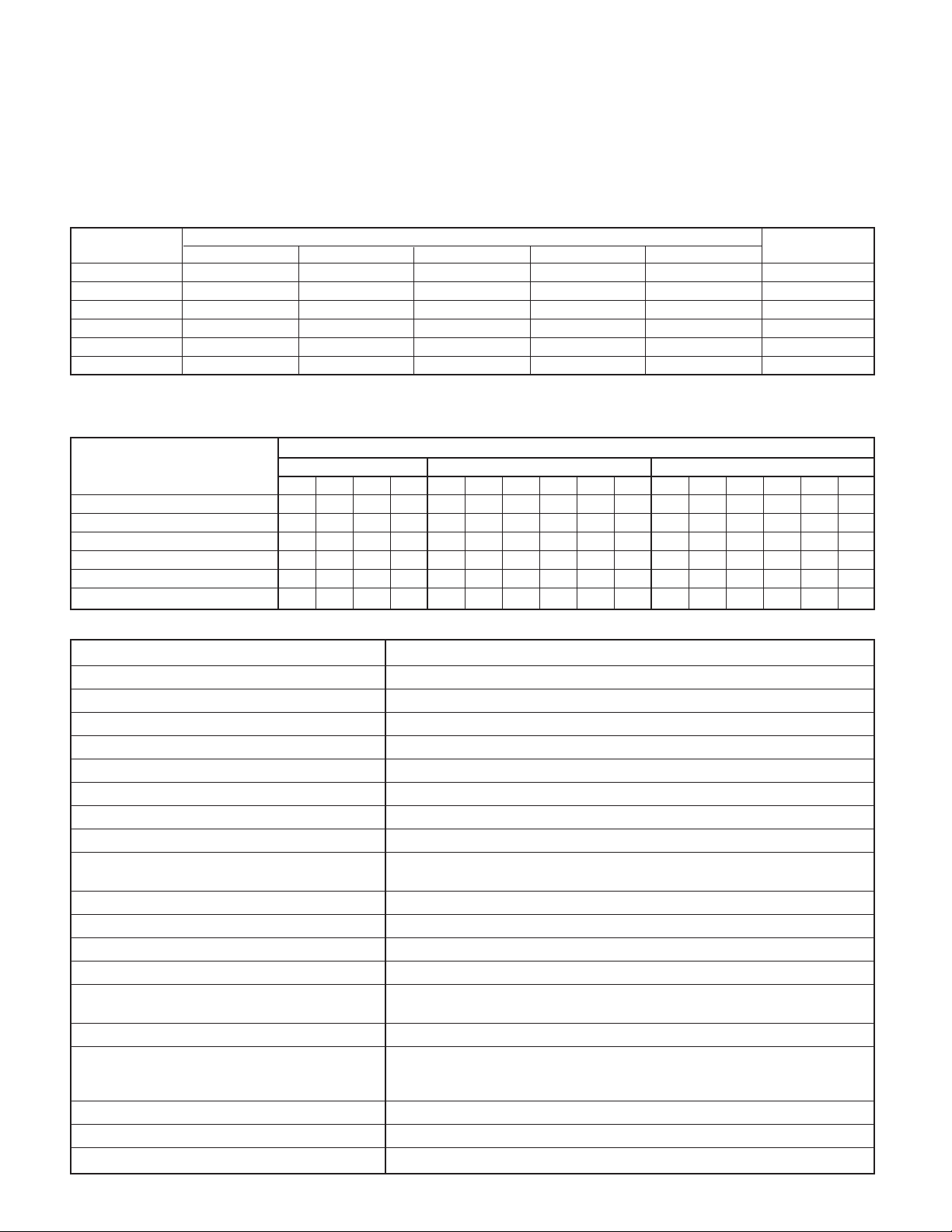

Depth Gallons per Minute at Discharge Pressure Maximum

to Water 15 PSI 25 PSI 35 PSI 45 PSI 50 PSI PSI

0 ft. 141 120 95 65 50 58

5 ft. 130 110 85 55 40 55

10 ft. 121 100 75 45 25 52

15 ft. 113 90 65 30 2 50

20 ft. 105 80 55 7 – 48

25 ft. 80 60 40 2 – 45

Performance Chart

Page 4

4

Pump Exploded View

• Not illustrated.

† Purchase locally.

* If needed, replace entire pump.

Item Description Qty. Part Number

1 Engine 1 *

2 Engine Mount Screws, 5/16-24 x .75 4 †

3 Seal Plate 1 M13906

4 O-Ring, Pump Body 1 M13910

5 Diffuser Gasket (O-Ring Segment) 1 M13918

6 Mechanical Seal 1 M13914

7 Impeller Kit (Includes Impeller Key) 1 M14457KIT

8 Impeller screw, 5/16-24 x 1.25 1 U30-986

9 Rubber Washer for Impeller Screw 1 M13913

10 Diffuser 1 M13907

11 Flapper Valve 1 M13909

12 Plug 2 M13911

12A O-Ring, Plug 2 M13912

13 Pump Housing 1 M13905

14 Screw, 1/4-20x2.5 hex Head Machine Screw 10 †

15 Nuts, 1/4-20 10 †

16 Lockwasher 10 †

• Screw, Diffuser, #6 x 1/2 Self-Tapping 2 †

• Screw, Diffuser, #10 x 1-1/2 Self-Tapping 1 †

1

3

4

5

7

2

10

15

16

9

12

12A

13

6

8

11

12A

12

14

Page 5

Engine Safety Precautions:

Fire and explosion hazard. Gasoline can

explode. Store gasoline away from the engine. Add gasoline

to the engine only when the engine is off.

Burn hazard. Hot surface.The engine gets

very hot during operation. Do not touch the engine surfaces.

Keep children away. Allow the engine to cool before moving

it indoors.

Deadly fumes. Carbon monoxide. Never run

the engine in an enclosed space. Only use outdoors with

plenty of ventilation.

Engine Operation

Before starting the engine:

Check and Fill Oil

The engine is shipped without oil. It must be filled before

starting the engine.

Fill oil by removing the fill cap / dipstick. Add oil until the

level reaches the bottom of the opening. Check the oil level

by pushing the cleaned dipstick into the oil fill opening. DO

NOT SCREW IT IN. Remove the dipstick and inspect it. Add

oil if needed. Reinstall the cap / dipstick.

Oil capacity is 0.63 quarts (0.6 liter). 10W-30 oil should be

used in normal conditions. Use 10W-40 oil if the engine is to

be run in temperatures over 90°F (32°C) .

Note that the engine has a low-oil monitoring system. If the

oil level drops too low, the system will automatically turn off

the engine.

Add Gasoline

Fill gas tank with clean fresh gasoline. This should be

unleaded fuel that has an octane rating of 86 or higher.

Do not fill the tank to overflowing. Clean up any spilled gasoline before starting the engine.

Open Fuel Valve

Move the fuel valve to the right to allow fuel to the engine.

Close Choke

When starting a cold engine, move the choke control to the

left (closed). As the engine warms up move it towards the

right (open). A warm engine should start with the choke

open.

Position Throttle

Move the throttle (speed control) slightly to the left.

Turn Engine Switch On

The engine switch controls the ignition. turn it to the ON

position to start the engine. The same control is used to stop

the engine.

Pull Starter

Pull the handle on the recoil starter. Adjust throttle to desired

speed. Move the choke to the right as engine warms.

Stopping the Engine

Stop the engine by turning the engine switch to OFF.

Turn the fuel control to OFF (left).

5

PUMP ENGINE OPERATION AND MAINTENANCE

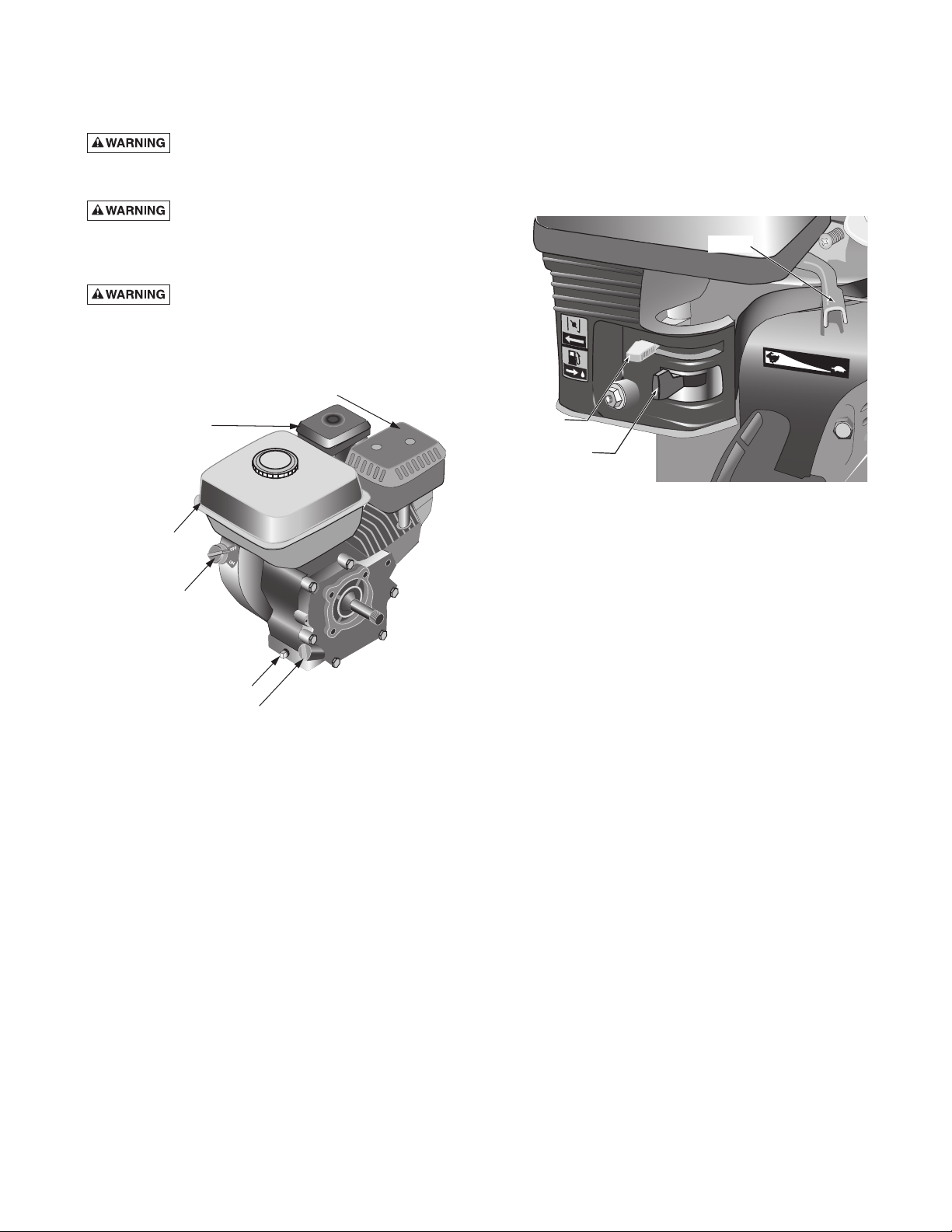

Muffler

Air Filter

Gas Tank

Engine On / Off Switch

Throttle

Engine Choke

Fuel Valve

Oil Drain Plug

Oil Fill and Dipstick

4646 0704

Page 6

Engine Maintenance

Air filter

The air filter should be checked every month for dust and

dirt accumulation. Every 6 months the filter element should

be removed and cleaned. Clean the foam element with

detergent and warm water. Squeeze out excess water and

let it dry. Before reinstalling the filter element, soak it with

engine oil, and squeeze out the excess. Reinstall the filter.

The engine will smoke upon startup if too much oil is left in

the filter element.

Oil level

The oil level should be checked before each use.

Oil Change

The oil should be changed in the first month, and then every

6 months (or 100 hours of operation). To drain the oil, run

the engine until warm. Turn off the engine, remove the oil

drain plug, and let the the oil drain into a pan. Reinstall the

plug and fill with oil.

NOTE: Dispose of used oil responsibly. DO NOT pour it

down drains, onto the ground or put it in the trash. Most

communities have collection points for used oil.

Spark Plug

The spark plug should be checked and cleaned every 6

months or 100 hours.

The sparkplug should be replaced if it is damaged, or excessively worn.

The sparkplug is type BPR6ES (NGK) or equivalent. The

plug gap should be 0.030 in. (0.75 mm)

Engine Troubleshooting

If the engine won’t start:

• Check that there is gas in the tank

• Make sure the fuel valve is ON and that the engine switch

is ON

• Make sure there is enough oil in the engine to reset the

low-oil sensor

• Check that fuel is getting to the carburetor*

• Check for spark at the sparkplug*

* These checks to be done by persons with small-engine

experience.

Extended storage

If the pump will be stored for more than a month or two, follow the steps below.

• Drain Gasoline

• Change oil

• Squirt oil (or a chemical made for storing engines) in the

spark plug hole.

• Rotate engine slowly until resistance is felt (this indicates

that both valves are closed).

• Install spark plug

• Cover engine

6

Page 7

7

1

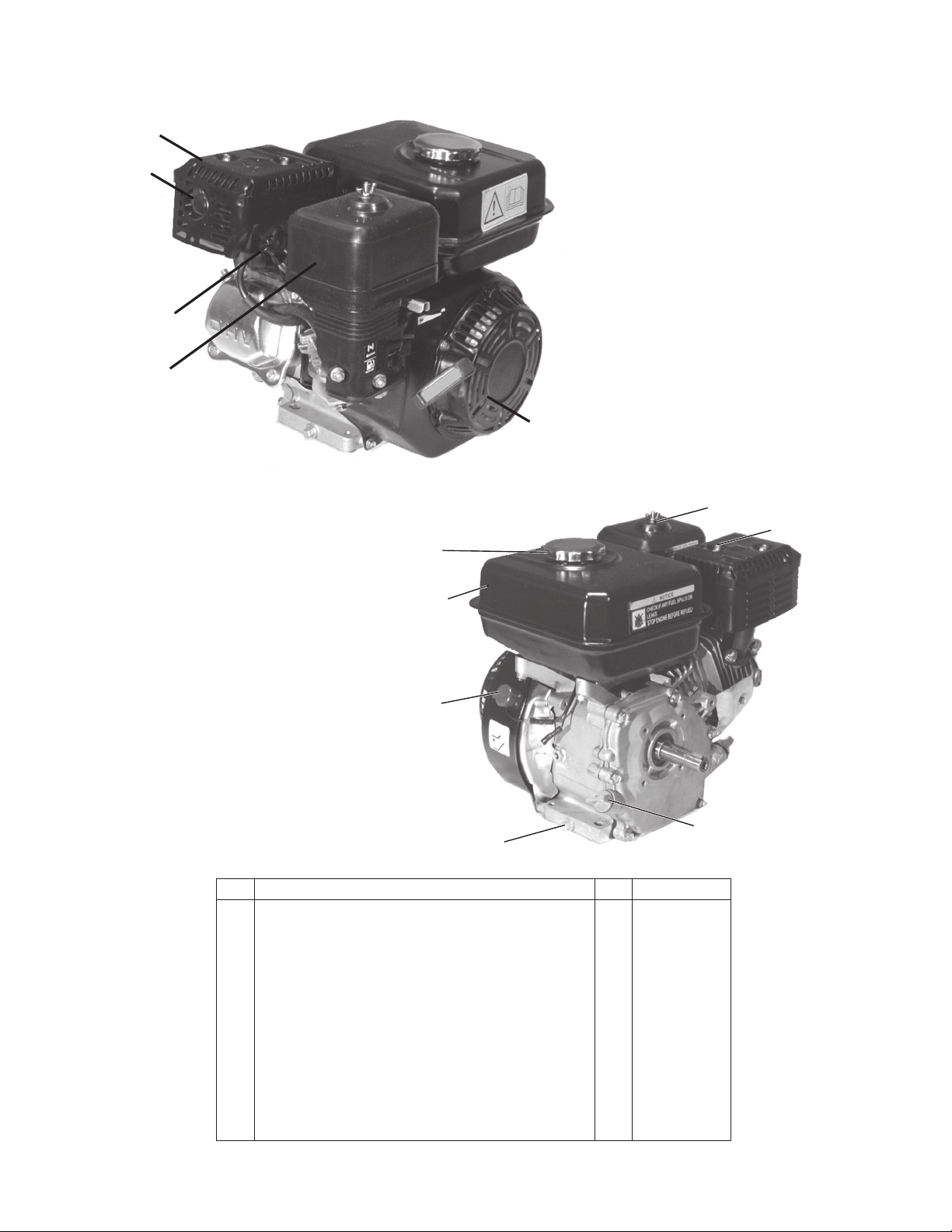

Engine Replacement Parts

Item Description Qty. Part Number

1 Muffler Cover 1 2545-0011

2 Muffler 1 2545-0010

3 Spark Plug (use NGK brand #BPR6ES) 1 *

4 Air Filter Cover 1 2545-0018

5 Air Filter Cartridge 1 2545-0001

6 Starter Assembly 1 2545-0005

(includes rope,handle and recoil assembly)

7 Wing-nut for Air Filter 1 2545-0019

8 Muffler Cover Mounting Hardware 2 2545-0020

9 Oil Fill Cap 1 2545-0003

10 Oil Drain Plug and Washer 1 2545-0021

11 On / Off Switch and Cover 1 2545-0004

12 Fuel Tank 1 2545-0009

13 Fuel Tank Cap 1 2545-0002

* Purchase locally.

2

4 & 5

3

6

7

8

13

12

11

9

10

Page 8

8

ENGINE

Refer to engine manufacturer’s operating manual for complete maintenance and warranty.

RETAIN ORIGINAL RECEIPT FOR YOUR RECORDS.

LIMITED WARRANTY

SIMER warrants to the original consumer purchaser (“Purchaser” or “You”) of its products that they are free from defects in

material and workmanship for a period of twelve (12) months from the date of the original consumer purchase.

If, within twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be

repaired or replaced at SIMER’s option, subject to the terms and conditions set forth below. The original purchase receipt

and product warranty information label are required to determine warranty eligibility. Eligibility is based on purchase date of

original product – not the date of replacement under warranty. The warranty is limited to repair or replacement of product

only – Purchaser pays all removal, installation, labor, shipping, and incidental charges.

For parts or troubleshooting assistance, DO NOT return product to your retail store. Contact SIMER Customer Service at

1-800-468-7867 / 1-800-546-7867.

Claims made under this warranty shall be made by returning the product (except sewage pumps, see below) to the retail

outlet where it was purchased immediately after the discovery of any alleged defect. SIMER will subsequently take

corrective action as promptly as reasonably possible. No requests for service will be accepted if received more than

30 days after the warranty expires.

SEWAGE PUMPS

DO NOT return a sewage pump (that has been installed) to your retail store. Contact SIMER Customer Service. Sewage

pumps that have seen service and been removed carry a contamination hazard with them.

If your sewage pump has failed:

• Wear rubber gloves when handling the pump;

• For warranty purposes, return the pump’s cord tag and original receipt of purchase to the retail store;

• Dispose of the pump according to local disposal ordinances.

Exceptions to the Twelve (12) Month Limited Warranty

Product Warranty Period

BW85P, CM10, CMK, M40, M40P 90 days

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 Years

4” Submersible Well Pumps, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 Years

Pre-Charge Water System Tank, 3985, 3986 5 Years

3963, 3988, 3995, 3997 Lifetime

General Terms and Conditions

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does not

apply to the following: (1) acts of God; (2) products which, in SIMER’s sole judgement, have been subject to negligence,

abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation, maintenance or

storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or other foreign

materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE

DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal

rights and You may also have other rights which vary from state to state.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Web Site: http://www.simerpumps.com

Page 9

IMPORTANT

Pour obtenir le meilleur rendement possible et un fonctionnement permanent et satisfaisant, lire ces instructions avant

d'installer cette pompe neuve. Si un entretien s'impose, cette

Notice représente un guide précieux et elle doit être gardée près

de l'installation de façon à s'y reporter ultérieurement.

INSTALLATION

EMPLACEMENT

Placer la motopompe aussi près que possible d'une source d'eau

de façon à réduire la hauteur géométrique d'aspiration et obtenir

les meilleurs rendements de pompage et pour faciliter l'amorçage.

Une installation portative typique est illustrée à la figure 1.

Pour une installation permanente, monter la motopompe sur

une fondation qui pourra supporter le poids de la pompe et du

moteur et qui offrira également une surface stable pendant le

fonctionnement de la pompe. Dans le cas d'une installation permanente, il est conseillé de boulonner la motopompe directement sur les fondations.

NOTA : Tout déplacement de la motopompe pendant son fonctionnement risque d'exercer des contraintes excessives sur la

motopompe, ce qui risque d'endommager le corps de la pompe.

La pompe doit être placée sur une surface plane et dure.

RACCORDEMENT DE L'ASPIRATION

Raccorder soit un tuyau rigide, soit un tuyau souple sur l'aspiration de la pompe, comme il est illustré à la figure 1. Si l'on choisi

un tuyau souple, il devra être suffisamment solide pour supporter les pressions d'aspiration et ne pas s'affaisser pendant que la

pompe fonctionne.

La conduite d'aspiration montante devra être une conduite continue à

partir de la source d'eau jusqu'à la pompe. Les points hauts risquent

d'emprisonner l'air et de rendre l'amorçage difficile. S'assurer que

tous les raccords sont bien serrés et qu'ils ne fuient pas.

NOTA : Pour que la pompe puisse fonctionner correctement, le

diamètre du tuyau d'aspiration souple ou rigide doit être au

moins aussi large que l'admission de l'aspiration de la pompe.

La profondeur minimum de l'admission de l'aspiration est déterminée d'après le diamètre de la conduite d'aspiration. Voir la

figure 1.

NOTA : Poser une crépine en bas de la conduite d'aspiration

pour empêcher les débris de pénétrer dans la pompe.

RACCORDEMENTS DE REFOULEMENT

La pompe est équipée d’un seul orifice de refoulement. Choisir

la dimension appropriée en fonction de l’utilisation. Poser un

« té » comme il est illustré pour pouvoir amorcer la pompe sans

avoir à débrancher la tuyauterie.

FONCTIONNEMENT

NOTA : Ne pas démarrer la pompe à sec et ne pas la faire fonctionner à sec, sinon le joint mécanique sera endommagé.

NOTA : Mettre de l'huile dans le moteur avant de le démarrer.

Avant de démarrer le moteur, se reporter à sa Notice d’utilisation.

AMORÇAGE DE LA POMPE

Une pompe à amorçage automatique n'a besoin d'être

manuellement amorcée que lors de la première mise en service.

Une fois amorcée, et dans des conditions normales, la pompe

se réamorcera automatiquement à chaque démarrage. Si la

pompe est utilisée en tant que pompe portative et que l'eau a

été vidée du carter de la pompe, la pompe devra être réamorcée avant de la remettre en service.

Pour l’amorçage, déposer le bouchon de l’orifice de refoulement, puis remplir le corps de la pompe avec de l’eau. Reposer

ensuite le bouchon, puis démarrer le pompe. Il lui faudra

quelques minutes pour évacuer l’air de la conduite d’aspiration.

Après quelques minutes de fonctionnement, la pompe sera

complètement amorcer et débitera de l’eau. Le temps nécessaire pour qu’elle s’amorce dépendra de la longueur et du

diamètre de la conduite d’aspiration.

9

Figure 1 – Installation type

Français

Aspiration dangereuse.

Les personnes peuvent être

retenues contre l’entrée de

l’aspiration.

Toujours utiliser une crépine

ou un tuyau d’aspiration pour

éviter de se faire retenir par

l’aspiration.

Le diamètre du tuyau de refoulement ne doit

pas être plus petit que celui du refoulement

de la pompe. (Tuyau souple de refoulement

de 2 po x 7,62 mètres (25 pieds) inclus avec

la trousse FP2731).

Orifice d’aspiration

Tuyau souple d’aspiration. (Tuyau souple

d’aspiration de 2 po x 7,62 mètres (25 pieds)

inclus avec la trousse FP2735).

Supporter le tuyau

et les raccords.

Crépine ou clapet

de pied (Crépine de

2 po incluse avec la

trousse FP2735).

Té fournit par le

client. Bouchon et

raccord fileté.

Prévoir un socle rigide

pour supporter la pompe.

Bouchon

d’amorçage

7,62 mètres

(25 pieds)

maximum

Utiliser in tuyau rigide ou un tuyau souple renforcé pour le

branchement sur l’aspiration. Le tuyau souple doit être assez

rigide pour qu’il ne se déforme pas pendant le fonctionnement.

Le diamètre de la crépine d’aspiration doit être au moins quatre

fois celui du tuyau.

Toute la tuyauterie d’aspiration doit être inclinée vers l’aspiration

de la pompe.

Supporter la tuyauterie et les raccords afin de minimiser toute

contrainte sur le corps de la pompe.

Pour éviter la formation de tourbillons, la conduite d’aspiration

doit descendre à une profondeur d’au moins quatre (4) fois le

diamètre du tuyau d’aspiration.

Exemple :

Tuyau de 2 po x 4 = profondeur minimale de 20 cm (8 po).

AVERTISSEMENT

Use pipe or reinforced hose to make

suction connection.

Hose must be strong enough to

not collapse during operation.

Suction screen area must be at least four

times suction pipe area.

All suction piping must slope up toward the

pump inlet.

Support the piping and fittings to reduce strain

on the pump case.

Priming Plug

Provide rigid

platform for pump.

Customer-supplied

Priming tee, plug

and nipple.

Discharge pipe not

smaller than the pump

discharge opening.

(2" x 25' Discharge hose

included in kit FP2731)

Pump Inlet

Suction hose

(2" x 15' Suction hose

included in kit FP2735).

Support pipe and

fittings.

Strainer or foot valve

(2" strainer included

in kit FP2735)

Depth of suction inlet at least

four (4) times the diameter of suction

pipe to avoid forming vortexes.

Example:

2" Pipe x 4 = 8" minimum depth.

25' Max

Page 10

FONCTIONNEMENT DU MOTEUR

Pour les instructions de démarrage et de fonctionnement, se

reporter à la rubrique « Fonctionnement du moteur » de cette

Notice.

Les débits de la pompe varieront en fonction du régime du

moteur. Se reporte à la rubrique « Fonctionnement du moteur »

pour régler le régime du moteur.

ENTRETIEN

GRAISSAGE DE LA POMPE

La pompe ne nécessite aucune lubrification, par graisse ou par

huile. Le joint mécanique est lubrifié par l'eau pendant que la

pompe fonctionne.

10

CAUSE REMÈDE

1. MOTEUR

A. Régime trop lent Se reporter à la rubrique traitant du moteur.

B. Frottement des pièces rotatives et/ou à mouvement alternatif Se reporter à la rubrique traitant du moteur.

C. Régime trop élevé Le régime maximum du moteur ne doit pas dépasser le régime recommandé par le fabricant.

D. Pièces desserrées ou cassées Se reporter à la rubrique traitant du moteur.

2. POMPE

E. Ne s'amorce pas Réamorcer la pompe, inspecter le système d'aspiration à la recherche de fuites d'air et/ou

inspecter le clapet.

F. Prend trop de temps à s'amorcer Voir s'il n'y a pas de prise d'air du clapet antiretour ou s'il n'est pas défectueux.

G. Le débit de la pompe est partiellement Déterminer où se trouve l'obstruction et l'enlever. Poser une crépine.

ou complètement bouché

H. Fuite interne Vérifier le dégagement entre la surface des vannes et du carter. Le dégagement ne doit pas

dépasser 1/32 de pouce.

I. Les pièces rotatives frottent Inspecter. Réparer.

J. Pièces desserrées ou cassées Inspecter. Réparer.

3. SYSTÈME

K. Les pressions requises par le système par rapport au débit Comparer les pressions de la pompe et les débits par rapport au tableau de rendement

de conception dépassent la pression nominale de la pompe de la pompe. Réduire la pression du système en conséquence. Augmenter la capacité de

la pression de la pompe.

L. Obstruction dans le tuyau d'aspiration Déterminer où se trouve l'obstruction; l'éliminer. Poser une crépine.

M.La hauteur géométrique d'aspiration est trop haute Vérifier avec un calibre ou mesurer la distance verticale qu'il y a entre la surface de l'eau

et la conduite centrale de la pompe en prenant en considération les pertes par friction dans

le tuyau d'aspiration. Réduire le débit de façon à obtenir la hauteur de refoulement désirée.

Se reporter au tableau de rendement de la pompe.

N. La hauteur de refoulement est trop basse Diminuer le débit.

O. L'admission de l'aspiration n'est pas suffisamment immergée Se reporter à «Installation».

P. La conduite d'aspiration fuit ou prise d'air des raccords Réparer la conduite d'aspiration ou la remplacer. Resserrer les raccords.

CAUSE PROBABLE

SYMPTÔME MOTEUR POMPE SYSTÈME

ABCDEFGH I JKLMNOP

Pas de débit d'eau

XXX XXX X

Débit d'eau insuffisant

X XX XXX X

Pression insuffisante

X XX XXX

Le moteur surchauffe excessivement

XX XXX X X

Bruits et/ou vibrations anormaux

XX X X XXX

La pompe fonctionne pendant

un moment, puis s'arrête

XXXXXX

Guide de recherche des pannes

Français

Profondeur Rendement en l/min aux pressions de refoulement Lb/po

2

de l’eau 103 kPa 172 kPa 241 kPa 310 kPa 345 kPa max.

0 m 534 454 360 246 189 400

1,5 m 492 416 322 208 151 379

3 m 458 379 284 170 95 359

4,6 m 428 341 246 114 8 345

6,1 m 397 303 208 26 – 331

7,6 m 303 227 151 8 – 310

Tableau de rendement

Page 11

11

Français

Vue éclatée de la pompe

• Pièces pas illustrées.

† À acheter localement.

* Au besoin, remplacer toute la pompe.

Réf. Désignation Qté Numéro de pièce

1 Moteur 1 *

2 Vis de fixation du moteur – 5/16-24 x 0,75 4 †

3 Plaque d’étanchéité 1 M13906

4 Joint torique, corps de la pompe 1 M13910

5 Joint du diffuseur (segment joint torique) 1 M13918

6 Joint mécanique 1 M13914

7 Trousse d’impulseur (comprend la clavette de l’impulseur) 1 M14457KIT

8 Vis de l’impulseur, 5/16-24 x 1,25 1 U30-986

9 Rondelle en caoutchouc pour la vis de l’impulseur 1 M13913

10 Diffuseur 1 M13907

11 Clapet à battant 1 M13909

12 Bouchon 2 M13911

12A Joint torique, bouchon 2 M13912

13 Corps de la pompe 1 M13905

14 Vis à métaux à tête hexagonale, 1/4-20x2,5 10 †

15 Écrous, 1/4-20 10 †

16 Rondelle-frein 10 †

• Vis autotaraudeuse, n° 6 x 1/2 2 †

• Vis autotaraudeuse, n° 10 x 1 1/2 1 †

1

3

4

5

7

2

10

15

16

9

6

8

11

12

12A

13

12A

12

14

Page 12

Consignes de sécurité concernant le moteur :

Risque d’incendie et d’explosion.

L’essence peut exploser. Stocker l’essence loin du moteur.

N’ajouter de l’essence dans le moteur que lorsqu’il est froid.

Risque de brûlures. Surface chaude.

Pendant qu’il fonctionne, le moteur devient très chaud. Ne

pas toucher ses surfaces. Ne pas permettre aux enfants de

s’en approcher. Avant de déplacer le moteur à l’intérieur, le

laisser refroidir.

Vapeurs nocives. Monoxyde de carbone.

Ne jamais faire fonctionner le moteur dans un espace clos.

Ne l’utiliser qu’à l’extérieur où l’aération sera bonne.

Fonctionnement du moteur

Avant de démarrer le moteur :

Le vérifier et faire le plein d’huile

Le moteur est expédié sans huile. Avant de le démarrer,

faire le plein de son carter d’huile.

Pour cela, déposer le bouchon ou la jauge d’huile, puis

ajouter de l’huile jusqu’à ce qu’elle arrive jusqu’à la partie

inférieure de l’ouverture. Vérifier le niveau en introduisant la

jauge d’huile propre dans le trou de remplissage d’huile. NE

PAS VISSER LA JAUGE. Ressortir la jauge et l’inspecter.

Faire le complément d’huile au besoin. Reposer le bouchon

ou la jauge d’huile.

Le carter inférieur contient 60 centilitres (0,63 pinte) d’huile.

Pour des conditions d’utilisation normales, utiliser de l’huile

10W-30. Utiliser de l’huile 10W40 si le moteur doit fonctionner par des températures supérieures à 32º C (90º F).

Le moteur est équipé d’un capteur de niveau d’huile. Si le

niveau de l’huile chute trop bas, le capteur arrêtera le

moteur.

Faire le plein d’essence

Faire le plein du réservoir avec de l’essence sans plomb

fraîche ayant un indice d’octane de 88 ou plus élevé.

Ne pas faire déborder le réservoir. Avant de démarrer le

moteur, essuyer l’essence renversée.

Ouvrir le robinet d’essence

Pour cela, le tourner à droite.

Fermer le volet de départ

Pour démarrer le moteur à froid, déplacer la commande du

volet de départ à gauche (position fermée). Au fur et à

mesure que le moteur se réchauffe, la déplacer à droite

(position ouverte). Lorsqu’il est chaud, le moteur doit démarrer sans l’aide du volet de départ.

Positionner l’accélérateur

Le déplacer légèrement à gauche (contrôle du régime).

Déplacer le contacteur du moteur sur marche

Ce contacteur contrôle l’allumage. Le déplacer sur la position « Contact établi » (ON) pour démarrer le moteur et sur

la position « Contact coupé » (OFF) pour l’arrêter.

Tirer sur le lanceur

À l’aide de sa poignée. Régler l’accélérateur au régime

désiré. Déplacer le volet de départ à droite au fur et à

mesure que le moteur se réchauffe.

Pour arrêter le moteur

Couper le contact (position OFF), puis fermer le robinet

d’essence en le tournant à gauche.

12

Français

FONCTIONNEMENT ET ENTRETIEN DU MOTEUR

Filtre à air

Silencieux

Réservoir

d’essence

Contacteur

marche-arrêt

Bouchon de vidange d’huile

Orifice de remplissage et jauge d’huile

Accélérateur

Volet de départ

du moteur

Robinet d’essence

Muffler

Air Filter

Gas Tank

Engine On / Off Switch

Throttle

Engine Choke

Fuel Valve

Oil Drain Plug

Oil Fill and Dipstick

4646 0704

Page 13

Entretien du moteur

Filtre à air

Le vérifier tous les mois à la recherche d’accumulation de

saleté et de poussière. La cartouche filtrante doit être

déposée et nettoyée tous les 6 mois avec du détergent et de

l’eau tiède. La serrer dans une main pour enlever l’excès

d’eau, puis la laisser sécher. Avant de la reposer, la tremper

dans de l’huile à moteur. La serrer dans une main pour

enlever l’excès d’huile. Reposer ensuite le filtre. Le moteur

dégagera de la fumée au démarrage si la cartouche filtrante

contient encore de l’huile.

Niveau d’huile

Le vérifier avant chaque utilisation du moteur.

Vidange d’huile

L’huile devra être vidangée après le premier mois de fonctionnement du moteur, puis tous les 6 mois (ou toutes les

100 heures de fonctionnement) par la suite. Avant de vidanger l’huile, laisser le moteur fonctionner jusqu’à ce qu’il soit

chaud. L’arrêter, puis enlever le bouchon de vidange et

laisser l’huile couler dans un bac. Reposer ensuite le bouchon de vidange et faire le plein d’huile du carter.

REMARQUE : Disposer de l’huile de façon responsable. Ne

pas la vider dans un égout, dans la terre et ne pas s’en

débarrasser dans un dépotoir. La plupart des municipalités

offrent des points de collecte des huiles usées.

Bougie

La vérifier et la nettoyer tous les 6 mois ou toutes les 100

heures de fonctionnement.

La remplacer si elle est endommagée ou extrêmement

usée.

Utiliser une bougie BPR6ES (NGK) ou une bougie équivalente. L’écartement de ses électrodes est de 0,75 mm

(0,0030 po).

Diagnostic du moteur

Si le moteur ne démarre pas :

• S’assurer qu’il y a de l’essence dans le réservoir

• S’assurer que le robinet d’essence est ouvert et que le

contact est établi (Sur ON)

• S’assurer qu’il y a suffisamment d’huile dans le carter

pour que le capteur de niveau d’huile se réenclenche

• S’assurer que l’essence parvient au carburateur*

• Vérifier l’écartement des électrodes de la bougie*

• Ces vérifications doivent être effectuées par des person-

nes spécialisées en petits moteurs.

Remisage prolongé

Si la pompe doit être remisée pendant plus d’un mois ou

deux, procéder comme suit :

• Vider le réservoir d’essence

• Changer l’huile

• Verser quelques gouttes d’huile (ou un produit chimique

prévu pour le remisage des moteurs) dans le trou de la

bougie.

• Tourner lentement le moteur jusqu’à ce que l’on ressente

une résistance (ce qui indique que les soupapes sont fermées)

• Reposer la bougie

• Couvrir le moteur

13

Français

Page 14

14

Français

Pièces de rechange pour le moteur

Réf. Désignation Qté Numéro de pièce

1 Couvercle du silencieux 1 2545-0011

2 Silencieux 1 2545-0010

3 Bougie (Utiliser une bougie de marque NGK, n° BPR6ES) 1 *

4 Couvercle du filtre à air 1 2545-0018

5 Cartouche filtrante du filtre à air 1 2545-0001

6 Lanceur (Comprend la corde, 1 2545-0005

la poignée et le dispositif de rappel)

7 Écrou à oreilles du filtre à air 1 2545-0019

8 Fixations du couvercle du silencieux 2 2545-0020

9 Bouchon de remplissage d’huile 1 2545-0003

10 Bouchon de viande d’huile et rondelle 1 2545-0021

11 Contacteur marche-arrêt et couvercle 1 2545-0004

12 Réservoir d’essence 1 2545-0009

13 Bouchon du réservoir d’essence 1 2545-0002

* À acheter localement.

1

2

4 & 5

3

6

7

13

12

11

9

10

8

Page 15

15

Français

MOTEUR

Se reporter à la Notice d’utilisation du fabricant du moteur

pour plus de renseignements concernant l’entretien et la garantie.

CONSERVER L’ORIGINAL DU REÇU POUR TOUTE RÉFÉRENCE ULTÉRIEURE.

GARANTIE LIMITÉE

SIMER garantit à l’acheteur/au consommateur d’origine (l’Acheteur) que ses produits sont exempts de tout vice de matériau et de

fabrication. Cette garantie est valable pendant douze (12) mois à partir de la date d’achat d’origine.

Si, dans les douze (12) mois suivant la date d’achat d’origine, un produit se révèle défectueux, il sera réparé ou remplacé, à la discrétion de SIMER, conformément aux modalités et conditions exposées ci-dessous. Le reçu de l’achat d’origine et l’étiquette

d’information sur la garantie sont requis pour déterminer la recevabilité de la réclamation au titre de la garantie. La recevabilité de

la réclamation se base sur la date de l’achat d’origine du produit, et non sur la date d’un éventuel remplacement sous garantie.

La garantie est limitée à la réparation ou au remplacement du produit uniquement. L’Acheteur assume les frais de retrait,

d’installation, de transport et tous les frais accessoires.

Pour obtenir des pièces ou de l’aide technique, NE PAS retourner le produit au détaillant. Contacter le service à la clientèle de

SIMER au 1-800-468-7867 / 1-800-546-7867.

Les réclamations au titre de cette garantie doivent être effectuées en retournant le produit (à l’exception des pompes d’eaux

d’égout, voir ci-dessous) au détaillant où il a été acheté, et ce, immédiatement après la découverte de la défaillance supposée.

SIMER prendra les mesures correctives nécessaires dans un délai rapide et raisonnable. Aucune demande de réparation ne sera

acceptée plus de 30 jours après l’expiration de la garantie.

POMPES D’EAUX D’ÉGOUT

NE PAS RETOURNER une pompe d’eaux d’égout (qui a été installée) au détaillant. Communiquer avec le service à la clientèle de

SIMER. Les pompes d’eaux d’égout qui ont été utilisées, puis retirées présentent un risque de contamination.

En cas de défaillance de la pompe d’eaux d’égout :

• Porter des gants en caoutchouc pour manipuler la pompe.

• À des fins de garantie, retourner l’étiquette figurant sur le cordon de la pompe et l’original du reçu au détaillant.

• Mettre la pompe au rebut conformément à la réglementation locale.

Exceptions à la garantie limitée de douze (12) mois

Produit Période de garantie

BW85P, CM10, CMK, M40, M40P 90 jours

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 ans

Réservoir préchargé de système d’eau, 3985, 3986 5 ans

3963, 3988, 3995, 3997 À vie

Modalités et conditions générales

L’Acheteur doit payer tous les frais de main d’œuvre et de transport nécessaires au remplacement du produit garanti couvert par

cette garantie. Cette garantie ne s’applique pas à ce qui suit : (1) Les catastrophes naturelles; (2) Les produits qui, selon SIMER,

ont fait l’objet d’une négligence, d’une utilisation abusive, d’un accident, d’une mauvaise application ou d’une altération; (3) Les

défaillances dues à une installation, une utilisation, un entretien ou un entreposage inappropriés; (4) Une application, une

utilisation ou une réparation atypique ou non approuvée; (5) Les défaillances causées par la corrosion, la rouille ou d’autres matériaux étrangers au système, ou par une utilisation à une pression supérieure au maximum recommandé.

Cette garantie établit la responsabilité unique de SIMER et le recours exclusif de l’Acheteur en cas de produit défectueux.

SIMER NE POURRA ÊTRE TENUE RESPONSABLE DE TOUT DOMMAGE INDIRECT OU CONSÉCUTIF QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET REMPLACENT TOUTE AUTRE GARANTIE EXPRESSE OU

IMPLICITE, Y COMPRIS, MAIS SANS S’Y LIMITER, CELLE DE QUALITÉ MARCHANDE OU D’APTITUDE DU PRODUIT À UN

EMPLOI PARTICULIER. LES PRÉSENTES GARANTIES NE PEUVENT SE PROLONGER AU-DELÀ DE LA PÉRIODE DE

GARANTIE INDIQUÉE ICI.

Certains États ne permettent pas l’exclusion ou la limitation des dommages indirects ou consécutifs, ni les limitations relatives

à la durée des garanties implicites. Par conséquent, il se peut que les limitations ou les exclusions ci-dessus ne s’appliquent pas.

Cette garantie procure des droits juridiques précis à l’Acheteur. Cependant, il est possible de bénéficier d’autres droits, qui varient

selon l’État.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone : 1 800 468-7867 / 1 800 546-7867 • Télécopieur : 1 800 390-5351

Courriel : info@simerpumps.com • Site Web : http://www.simerpumps.com

Page 16

IMPORTANTE

Para el mejor rendimiento y operación continua y satisfactoria posibles, lea estas instrucciones antes de instalar su

nueva bomba. Si requiriese servicio, este manual puede ser

una guía valiosa y debe ser guardado cerca de la instalación

para inmediata referencia.

INSTALACION

UBICACION

Coloque la unidad tan cerca de la fuente de agua como sea

posible para disminuir al mínimo la altura de succión, obtener el

mejor rendimiento de bombeo y ayudar al cebado. En la Figura

1 se muestra una instalación portátil típica.

Para una instalación permanente, monte la unidad sobre una

base que soporte el peso de la bomba y el motor y que proporcione además estabilidad mientras la bomba está en operación.

Para instalaciones más permanentes, es aconsejable fijar directamente la unidad a la cimentación con pernos.

AVISO: El asentamiento y/o movimiento durante la operación

puede causar que la tubería aplique demasiado esfuerzo a la

bomba y puede dañar la caja de la misma. Coloque la bomba

en una superficie firme bien nivelada.

CONEXION DE SUCCION

Conecte ya sea tubería rígida o manguera flexible de succión a

la succión de la bomba como se muestra en la Figura 1. Si se

usa manguera, ésta debe ser capaz de soportar la succión e

impedir su colapso mientras la bomba está operando.

Haga que la línea de succión esté en una pendiente continua a

partir desde la fuente de agua hasta la bomba. Los puntos altos

pueden atrapar aire y también hacer más difícil el cebado.

Asegúrese que todas las conexiones estén ajustadas y libres de

fugas de aire.

AVISO: La tubería o manguera de succión por lo menos debe

ser del tamaño de la entrada de succión de la bomba para que

ésta funcione correctamente.

La profundidad mínima de la entrada de succión está determinada por el diámetro de la línea de succión. Ver Figura 1.

AVISO: Use un cedazo de succión para impedir la entrada a la

bomba de materias extrañas.

CONEXIONES DE DESCARGA

Su bomba viene equipada con una sola abertura de descarga.

Seleccione el tamaño adecuado para el uso. Instale un tubo en

“T” según se ilustra para permitir la cebadura de la bomba sin

desconectar la tubería.

OPERACION

AVISO: No arranque u opere la bomba en seco porque, de hacerlo, ocurrirán daños al sello mecánico.

AVISO: Añada aceite al motor antes de arrancarlo. Consulte

el manual de operación del motor antes de encenderlo.

CEBADO DE LA BOMBA

Una bomba autocebante sólo necesita ser cebada manualmente

la primera vez que se arranca. Una vez que ha sido cebada,

bajo condiciones normales, la bomba volverá a cebarse

automáticamente en cada arranque subsecuente. Si la bomba

se usa en aplicaciones portátiles y el agua ha sido drenada de la

caja de la bomba, debe volverla a cebar antes de arrancarla.

Para cebar, saque el tapón de la salida superior de descarga y

llene la bomba de agua. Vuelva a colocar el tapón y encienda la

bomba. La bomba necesitará unos minutos para evacuar el aire

de la línea de aspiración. Después de unos minutos de funcionamiento, la bomba estará completamente cebada y

bombeará el agua. El tiempo de cebadura depende del largo y

del diámetro de la tubería de aspiración.

16

Figura 1 - Instalación típica

Español

Aspiración peligrosa.

Personas pueden quedar

atrapadas contra la

entrada de aspiración.

Siempre se debe usar un

tamiz en la manguera de

aspiración para evitar que

alguien quede atrapado.

Tubería de descarga no menor que

la abertura de descarga de la bomba

(manguera de descarga de 2" x 25

pies incluida en el kit FP2731).

Admisión de la bomba

Manguera de aspiración (manguera

de aspiración de 2" x 15 pies incluida

en el kit FP2735).

Cesta de aspiración o válvula

de pie (cesta de aspiración de

2" incluida en el kit FP2735)

Use un tubo o una manguera reforzada para hacer la

conexión de aspiración. La manguera debe ser lo suficientemente fuerte para no desplomarse durante la operación.

La malla de aspiración debe ser al menos cuatro veces

más grande que el área de la tubería de aspiración.

Toda la tubería de aspiración debe ascender en pendiente

hacia la admisión de la bomba.

Apoye bien la tubería y los accesorios para reducir el

esfuerzo sobre la caja de la bomba.

Tubo en T de cebadura, tapón y entrerrosca

suministrados por el cliente.

Apoye bien la tubería

y los accesorios.

Proporcione una plataforma

rígida para la bomba.

Tapón de

cebadura

La admisión de aspiración debe tener al menos una

profundidad cuatro (4) veces mayor que el diámetro de

la tubería de aspiración para prevenir la formación de

torbellinos.

Ejemplo: tubería de 2" x 4 = profundidad mínima de 8"

ADVERTENCIA

Use pipe or reinforced hose to make

suction connection.

Hose must be strong enough to

not collapse during operation.

Suction screen area must be at least four

times suction pipe area.

All suction piping must slope up toward the

pump inlet.

Support the piping and fittings to reduce strain

on the pump case.

Priming Plug

Provide rigid

platform for pump.

Customer-supplied

Priming tee, plug

and nipple.

Discharge pipe not

smaller than the pump

discharge opening.

(2" x 25' Discharge hose

included in kit FP2731)

Pump Inlet

Suction hose

(2" x 15' Suction hose

included in kit FP2735).

Support pipe and

fittings.

Depth of suction inlet at least

four (4) times the diameter of suction

pipe to avoid forming vortexes.

Example:

2" Pipe x 4 = 8" minimum depth.

Strainer or foot valve

(2" strainer included

in kit FP2735)

25' Max

Page 17

OPERACION DEL MOTOR

Consulte la sección de operación del motor en este manual

para obtener las instrucciones de encendido y operación.

El desempeño de la bomba varía según las rpm del motor.

Consulte la sección de operación del motor para ajustar su

velocidad.

MANTENIMIENTO

LUBRICACION DE LA BOMBA

El extremo líquido de la bomba no requiere grasa ni aceite para

su lubricación. El sello mecánico es lubricado por agua al operar la bomba.

17

CAUSA ACCION CORRECTORA

1. MOTOR

A. Velocidad muy baja Consulte la sección del motor.

B. Las partes rotatorias y/o reciprocantes se mueven muy lentamente Consulte la sección del motor.

C. Velocidad demasiado alta La velocidad máxima del motor no debe exceder la recomendada por el fabricante

del motor.

D. Elementos sueltos o rotos Consulte la sección del motor.

2. BOMBA

E. No está cebada Vuelva a cebar, inspeccione el sistema de succión para determinar si hay fugas

de aire y/o el cabezal de la bomba.

F. La bomba toma mucho tiempo para cebar Compruebe si hay fugas de aire o si la válvula de retención está defectuosa

G. El flujo a través de la bomba está total o parcialmente Ubique y retire la obstrucción. Instale un cedazo

bloqueado

H. Fugas internas Compruebe la luz libre entre las aletas del impulsor y la caja. No debe exceder de 1/32"

I. Las partes rotatorias se mueven muy lentamente Inspeccione. Repare

J. Elementos sueltos o rotos Inspeccione. Repare

3. SISTEMA

K. La presión requerida por el sistema para el flujo de Compare la presión y flujo de la bomba contra la tabla de rendimiento de la misma.

diseño excede la presión nominal de la bomba Reduzca los requisitos de presión del sistema. Incremente la capacidad

de presión de la bomba.

L. Obstrucción en la tubería de succión Ubique y retire la obstrucción. Instale un cedazo

M.La altura de succión es demasiado alta Compruebe con un manómetro o mida la distancia vertical entre la superficie del agua

y el centro de la bomba, considerando las piezas de fricción en la tubería de succión.

Reduzca el flujo para obtener la succión deseada. Consulte la tabla de rendimiento

de la bomba.

N. La presión de descarga es demasiado baja Disminuya el flujo.

O. La entrada de succión no está suficientemente sumergida

en el agua Consulte "Instalación"

P. La tubería de succión tiene fugas o conexiones que admiten aire Repare o reemplace la tubería de succión. Ajuste las conexiones.

CAUSA PROBABLE

SINTOMA MOTOR BOMBA SISTEMA

ABCDEFGH I JKLMNOP

No se entrega agua X X X X X X X

No se entrega suficiente agua X X X X X X X

No hay suficiente presión X X X X X X

El motor se calienta excesivamente X X X X X X X

Ruidos y/o vibraciones anormales X X X X X X X

La bomba trabaja por un momento,

luego se detiene

XXXXXX

Guía para detección y solución de problemas

Español

Profundidad Rendimiento en litros por min. a las Presiones de Descarga Lbs/pulg.

2

del agua 103 kPa 172 kPa 241 kPa 310 kPa 345 kPa max.

0 m 534 454 360 246 189 400

1,5 m 492 416 322 208 151 379

3 m 458 379 284 170 95 359

4,6 m 428 341 246 114 8 345

6,1 m 397 303 208 26 – 331

7,6 m 303 227 151 8 – 310

Funcionamiento

Page 18

18

Español

Vista Despiezada de la Bomba

• No se ilustra.

† Adquirir localmente.

* De ser necesario, reemplace toda la bomba.

Artículo Descripción Cantidad Número de pieza

1 Motor 1 *

2 Tornillos de montaje del motor, 5/16-24 x 0.75 4 †

3 Placa de sello 1 M13906

4 Aro tórico, unidad de la bomba 1 M13910

5 Empaquetadura del Difusor (Segmento del aro tórico) 1 M13918

6 Sello mecánico 1 M13914

7 Juego de impulsor (incluye la llave del impulsor) 1 M14457KIT

8 Tornillo del impulsor, 5/16-24 x 1.25 1 U30-986

9 Arandela de caucho para el tornillo del impulsor 1 M13913

10 Difusor 1 M13907

11 Válvula de chapaleta 1 M13909

12 Tapón 2 M13911

12A Aro tórico, Tapón 2 M13912

13 Caja de la bomba 1 M13905

14 Tornillo, Tornillo para metales con cabeza hexagonal, 1/4-20 x 2.5 10 †

15 Tuercas, 1/4-20 10 †

16 Arandela de presión 10 †

• Tornillo, Difusor, #6 x 1/2 autorroscante 2 †

• Tornillo, Difusor, #10 x 1-1/2 autorroscante 1 †

1

3

4

5

7

2

10

15

16

9

12

12A

6

8

11

14

13

12A

12

Page 19

Español

19

Precauciones de seguridad del motor:

Peligro de incendio y explosión. La gasolina

puede explotar. Guarde la gasolina lejos del motor. Agregue

gasolina al motor sólo cuando esté apagado.

Peligro de quemadura. Superficie caliente. El

motor se calienta mucho durante el funcionamiento. No toque

las superficies del motor. Mantenga a los niños alejados.

Permita que el motor se enfríe antes de moverlo al interior.

Gases fatales. Monóxido de carbono. Nunca

haga marchar un motor en un lugar encerrado. Use sólo en

exteriores con mucha ventilación.

Operación del motor

Antes de encender el motor:

Inspeccione y llene de aceite

El motor se despacha sin aceite. Se debe llenar antes de

encenderlo.

Llene de aceite, sacando la tapa de llenado / varilla medidora.

Agregue aceite hasta que el nivel llegue al fondo de la abertura.

Verifique el nivel del aceite, empujando la varilla medidora

limpia dentro de la abertura de llenado de aceite. NO LA

ATORNILLE. Saque la varilla medidora y verifique. De ser

necesario, agregue aceite. Vuelva a colocar la tapa / varilla

medidora.

La capacidad de aceite es de 0.63 cuartos (0.6 litro). Se debe

usar aceite 10W-30 en condiciones normales Si el motor marchará a temperaturas superiores a los 90˚ F (32˚ C), use aceite

10W-40.

Observe que el motor tiene un sistema de monitoreo del nivel

de aceite. Si el nivel del aceite desciende demasiado, el sistema apagará el motor automáticamente.

Agregue gasolina

Llene el tanque con gasolina fresca y limpia. Es necesario que

sea combustible sin plomo con un octanaje de 86 o mayor.

No llene el tanque hasta que se desborde. Limpie toda gasolina

que se haya derramado antes de encender el motor.

Abra la válvula de combustible

Mueva la válvula de combustible a la derecha para permitir que

el combustible llegue al motor.

Cierre el estrangulador

Cuando encienda un motor frío, mueva el control del estrangulador hacia la izquierda (cerrado). A medida que el motor se

caliente, mueva el estrangulador hacia la derecha (abierto). Un

motor caliente se debe encender con el estrangulador abierto.

Coloque el regulador en posición

Mueva al regulador (control de velocidad) ligeramente hacia la

izquierda.

Coloque el interruptor del motor en la posición de

encendido

El interruptor del motor controla el encendido. Muévalo a la

posición ON para encender el motor. El mismo control se usa

para detener el motor.

Jale del estárter

Jale del mango en el estárter de retroceso. Ajuste el regulador a

la velocidad deseada. Mueva el estrangulador hacia la derecha

a medida que el motor se caliente.

Parada del motor

Detenga el motor, colocando el interruptor del motor en la posición OFF.

Coloque el control de combustible en la posición apagada

“OFF” (izquierda).

OPERACIÓN Y MANTENIMIENTO DEL MOTOR DE LA BOMBA

Filtro de aire

Amortiguador

Tanque de gas

Interruptor de

encendido/apagado

del motor

Tapón de drenaje de aceite

Llenado y varilla medidora de aceite

Regulador

Estrangulador

del motor

Válvula de

combustible

Muffler

Air Filter

Gas Tank

Engine On / Off Switch

Throttle

Engine Choke

Fuel Valve

Oil Drain Plug

Oil Fill and Dipstick

4646 0704

Page 20

Mantenimiento del motor

Filtro de aire

Es necesario inspeccionar el filtro de aire todos los meses para

verificar que no se haya acumulado polvo y suciedad. El elemento del filtro se debe sacar cada 6 meses para limpiarlo.

Limpie el elemento de espuma con agua tibia y detergente.

Escurra el exceso de agua y deje que se seque. Antes de

volver a colocar el elemento del filtro, póngalo en remojo en

aceite de motor y escurra el exceso. Vuelva a colocar el filtro.

El motor emitirá humo cuando se encienda si se ha dejado

demasiado aceite en el elemento del filtro.

Nivel del aceite

Es necesario inspeccionar el nivel del aceite antes de cada uso.

Cambio de aceite

Se debe cambiar el aceite durante el primer mes, y luego cada

6 meses (o 100 horas de funcionamiento). Para drenar el

aceite, deje marchar el motor hasta que se caliente. Apáguelo,

saque el tapón de drenaje de aceite y drene el aceite en una

bandeja. Vuelva a colocar el tapón y llene de aceite.

NOTA: Elimine el aceite usado en forma responsable. NO lo

vierta por el desagüe, en el suelo ni en la basura. La mayoría

de las comunidades tienen lugares de recolección para aceite

usado.

Bujías

Es necesario chequear y limpiar las bujías cada 6 meses o

cada 100 horas. Si la bujía está averiada o demasiado gastada,

se deberá reemplazar.

Use bujía tipo BPR6ES (NGK) o equivalente. El intervalo de la

bujía debe ser 0.030 in. (0.75 mm)

Localización de fallas del motor

Si el motor no arranca:

• Verifique que haya gasolina en el tanque

• Verifique que la válvula de combustible esté en la posición

ON y que el interruptor del motor esté en la posición ON

• Verifique que haya suficiente aceite en el motor para reposicionar el detector de nivel bajo de aceite

• Verifique que el combustible llegue al carburador*

• Verifique que haya una chispa en la bujía*

• Estas verificaciones deben ser realizadas por personas con

experiencia en motores pequeños.

Almacenamiento prolongado

Si la bomba estará almacenada por más de uno o dos meses,

siga las siguientes instrucciones.

• Drene la gasolina

• Cambie el aceite

• Agregue un chorro de aceite (o una sustancia química para

guardar motores) en el orificio de la bujía.

• Haga girar el motor lentamente hasta que se sienta resistencia (eso indica que ambas válvulas están cerradas).

• nstale la bujía

• Cubra el motor

20

Español

Page 21

21

Español

Piezas de repuesto del motor

1

• Adquirir localmente.

Artículo Descripción Cantidad Número de pieza

1

Cubierta del amortiguador 1 2545-0011

2

Amortiguador 4 2545-0010

3 Bujía (use marca NGK #BPR6ES) 1*

4

Cubierta del filtro de aire 1 2545-0018

5

Cartucho del filtro de aire 1 2545-0001

6

Unidad del estárter

(incluye cuerda, mango y unidad de retroceso)

1 2545-0005

7 Tuerca de mariposa para el filtro de aire 1 2545-0019

8

Tuercas de montaje para la cubierta del amortiguador 1 2545-0020

9 Tapa de llenado de aceite 1 2545-0003

10 Tapón de drenaje de aceite y arandela 1 2545-0021

11 Interruptor de encendido / apagado y cubierta 1 2545-0004

12 Tanque de combustible 2 2545-0009

13

Tapa del tanque de combustible 1 2545-0002

2

4 & 5

3

6

7

13

12

11

9

10

8

Page 22

22

MOTOR:

Consulte el manual de operación del fabricante del motor

para obtener información completa sobre su mantenimiento y garantía.

Español

GUARDE EL RECIBO ORIGINAL PARA CULAQUIER REFERENCIA POSTERIOR.

GARANTÍA LIMITADA

SIMER le garantiza al comprador consumidor original (el “Comprador” o “Usted”) de sus productos, que éstos estarán libres de

defectos en materiales y en mano de obra por un período de doce (12) meses, a partir de la fecha de la compra original del

consumidor.

Si dentro de los doce (12) meses a partir de la fecha de la compra inicial del consumidor, se comprueba que cualquiera de esos

productos es defectuoso, éste será reparado o reemplazado, a la discreción de SIMER, sujeto a los términos y a las condiciones

indicadas a continuación. Se necesitará su recibo de compra original y la etiqueta de información sobre la garantía del producto,

para determinar la admisibilidad de la garantía. La admisibilidad se basa en la fecha de compra del producto original - no en la

fecha de reemplazo bajo la garantía. La garantía está limitada a la reparación o el reemplazo del producto solamente - El comprador

pagará todos los costos de remoción, instalación, mano de obra y envío necesarios, así como todo costo adicional asociado.

Si necesita piezas o resolución de problemas, NO regrese el producto a la tienda minorista. Llame el Servicio a la Clientela de

SIMER al 1-800-468-7867 / 1-800-546-7867.

Las reclamaciones bajo esta garantía se deberán realizar mediante la devolución del producto (excepto en el caso de las bombas

cloacales, ver a continuación) a la tienda minorista en donde se haya adquirido, inmediatamente después de haber descubierto un

supuesto defecto. SIMER entonces tomará la medida correctiva tan pronto como sea razonablemente posible. No se

aceptarán solicitudes de servicio, si se reciben más de 30 días después del vencimiento de esta garantía.

BOMBAS CLOACALES

NO devuelva una bomba cloacal (que se haya instalado) a su tienda minorista. Comuníquese con el Departamento de Atención al

Cliente de SIMER. Las bombas cloacales que hayan estado en servicio y se hayan removido pueden representar un peligro de

contaminación.

Si su bomba cloacal ha fallado:

• Use guantes de caucho cuando manipule la bomba;

• Para los fines de la garantía, devuelva la etiqueta del cordón de la bomba y el recibo de compra original a la tienda minorista;

• Descarte la bomba cumpliendo con todas las normas locales que correspondan para su eliminación.

Excepciones para la Garantía Limitada de Doce (12) Meses

Producto Período de garantía

BW85P, CM10, CMK, M40, M40P 90 días

2300, 2310, 2330, 2520ULST, 2943, 2955, 2956, 2957, 2960, 5023SS, A5500 2 años

Bombas de pozo sumergibles de 4”, 2945, 2958, 2975PC, 2985, 3075SS, 3983, 3984 3 años

Tanque precargado del sistema de agua, 3985, 3986 5 años

3963, 3988, 3995, 3997 De por vida

Términos y condiciones generales

Usted deberá pagar por todos los gastos de mano de obra y de envío necesarios para reemplazar el producto cubierto por esta

garantía. Esta garantía no se aplicará en las siguientes situaciones: (1) caso de fuerza mayor (2) productos que, a sólo juicio de

SIMER hayan sido sometidos a negligencia, abuso, accidente, mala aplicación, manejo indebido o alteraciones; (3) fallas debido a

instalación, operación, mantenimiento o almacenamiento inadecuados; (4) aplicaciones, usos o servicios que no sean normales o

aprobados; (5) fallas provocadas por corrosión, herrumbre u otros materiales extraños en el sistema, o una operación a presiones

que excedan los máximos recomendados.

Esta garantía establece la única obligación de SIMER y el recurso exclusivo del Comprador con respecto a los productos defectuosos.

SIMER NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA,

INCLUYENDO PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN FIN

ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN PROVISTA EN LA

PRESENTE.

Algunos Estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de tiempo sobre

garantías implícitas, de modo que es posible que las limitaciones o exclusiones que preceden no correspondan en su caso. Esta

garantía le otorga derechos legales específicos y es posible que Usted también tenga otros derechos que pueden variar de un

Estado al otro.

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Sitio Web: http://www.simerpumps.com

Page 23

23

Page 24

Loading...

Loading...