Page 1

OWNER’S MANUAL

Utility/Transfer Pump

NOTICE D’UTILISATION

Pompe à usage général et pour le

transfert

MANUAL DEL USUARIO

Bomba de transferencia / para uso

general

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . . Pages 2-7

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . . . Pages 9-15

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . . .Paginas 16-22

SIM819 (Rev. 5/12/08)

Model 4850C

293 Wright St., Delavan,WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

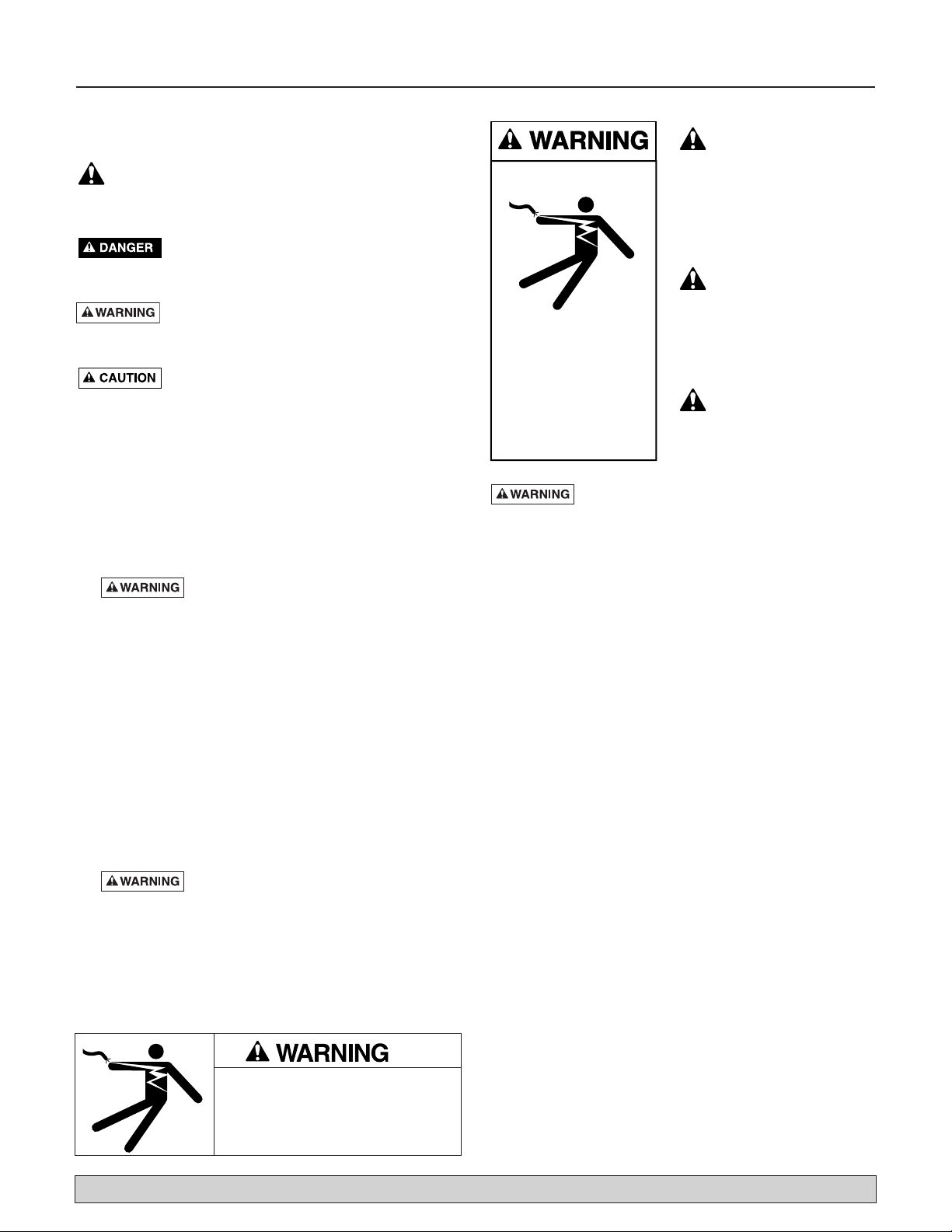

Risk of fatal electrical shock if pump

motor gets wet.

Keep motor dry.

Do not immerse pump or motor, or

run pump if motor is wet.

Risque d’électrocution si le moteur de la

pompe entre en contact avec de l’eau.

Maintenir le moteur à sec.

Ne pas immerger la pompe ou le moteur,

ou mettre en marche la pompe si le

moteur est mouillé.

AVERTISSEMENT

Peligro de descarga eléctrica fatal si se

moja el motor de la bomba.

Mantenga el motor seco.

No sumerja en agua la bomba o el motor

ni haga funcionar la bomba con el motor

mojado.

OUT

IN

ADVERTENCIA

Page 2

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

DANGER warns about hazards that will

cause serious personal injury, death or major property

damage if ignored.

WARNING warns about hazards that can

cause serious personal injury, death or major property

damage if ignored.

CAUTION warns about hazards that will or

can cause minor personal injury or property damage if

ignored.

The word NOTICE indicates special instructions which

are important but not related to hazards.

1. To avoid risk of serious bodily injury and property

damage, read safety instructions carefully before

installing pump.

2. Follow local and/or national plumbing and electrical

codes when installing pump.

3. To avoid fatal shocks, proceed as fol-

lows if pump needs servicing:

A. Disconnect power to pump outlet box before

pulling pump cord plug. After plug is pulled, let

pump cool for 20 minutes before attempting to

work on it.

B. Take extreme care when changing fuses. To re-

duce chance of fatal electrical shocks, DO NOT

stand in water or put your finger in the fuse socket.

C. Ground electrical outlet box.

D. Use only Ground Fault Circuit Interrupter (GFCI)

protected grounded outlet for cord plug.

4. Never run pump dry. To do so can damage internal

parts, overheat pump (which can cause burns to people

handling or servicing pump), and will void warranty!

5. Risk of fire or explosion from sparks

from motor brushes. Do not pump gasoline or any

other flammable liquids with pump. Do not use pump

in atmosphere that might contain flammable fumes or

vapors.

6. Do not pump chemicals or corrosive liquids with

pump.

If water is trapped in pump during operation, it may turn to steam, leading to explosion and

burns. Never run pump with outlet shut off or blocked.

NOTICE

Pump clean water only with pump. To avoid clogging

pump and damage to shaft seal, do not pump water containing solids, foreign material, sand, silt, or abrasives.

Always have suction strainer installed when pump is

operating. Failure to use strainer may cause pump failure

and void warranty.

Clean strainer and flush out pump after each use.

Make sure all hose and pipe connections in suction line

are tight. An air leak in suction line will prevent priming

and reduce performance.

To prevent damage to pump materials, do not use pipe

joint compounds on pump ports. Use only teflon tape or

Plasto-Joint-Stik* to seal threads.

Tighten all piping to pump hand tight +1-1/2 turns only.

Overtightening may break pump and will void warranty.

Maximum liquid temperature is 120˚F (48.8˚C).

*Lake Chemical Co., Chicago, Illinois

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Pump is supplied with

3-conductor grounding

type cord. Connect only to

properly grounded, GFCI

protected outlet. Do not lift

pump by electrical cord. Do

not use an extension cord.

Pump is non-sub-

mersible. Keep motor

dry at all times. Do not wash

motor. Do not immerse.

Pro-tect motor from wet

weather.

Unplug pump before

servicing.

Hazardous voltage.

Can shock, burn,

or cause death.

Ground pump before

connecting to

power supply.

Risk of fatal electrical shock if pump

motor gets wet.

Keep motor dry.

Do not immerse pump or motor, or run

pump if motor is wet.

Page 3

Table of Contents 3

Thank you for purchasing a top quality, factory tested pump.

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation .......................................................................................................4–6

Brush Changing Procedure...................................................................................7

Repair Parts .........................................................................................................8

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

ATTACH ORIGINAL RECEIPT HERE FOR WARRANTY CONSIDERATION.

SIMER warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it shall be repaired or

replaced at SIMER’s option, subject to the terms and conditions set forth below.Your original receipt of purchase is required to determine warranty

eligibility .

Exceptions to the Twelve (12) Month Warranty

Product/Model No. Warranty Period

M40P, M40, BW85P, CM10, CMK 90 days

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 Years

4" Submersible Well Pumps, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 Years

Pre-Charge Water System Tank, 3986, 3985, 2956 5 Years

3988, 3995, 3997, 3963 Lifetime

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty shall not apply to

acts of God, nor shall it apply to products which, in the sole judgement of SIMER, have been subject to negligence, abuse, accident, misapplication, tampering, alteration; nor due to improper installation, operation, maintenance or storage; nor to other than normal application, use

or service, including but not limited to, operational failures caused by corrosion, rust or other foreign materials in the system, or operation at

pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to SIMER as soon as possible after the discovery of any alleged defect.SIMER will subsequently take corrective action as promptly as reasonably possible.No

requests for service under this warranty will be accepted if received more than 30 days after the term of the warranty.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty

lasts, so the above limitations or exclusions may not apply to you.This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

SIMER • 293 Wright Street • Delavan,WI U.S.A. 53115

Phone: 1-800-468-7867/1-800-546-7867 • Fax: 1-800-390-5351

E-Mail: info@simerpumps.com • Web Site: http://www.simerpumps.com

Page 4

LOCATION OF UNIT

Locate pump as near as possible (vertically) to water

source, to keep suction lift (distance form water to pump)

as low as possible. Place pump on level support. Protect

against excess moisture and flooding.

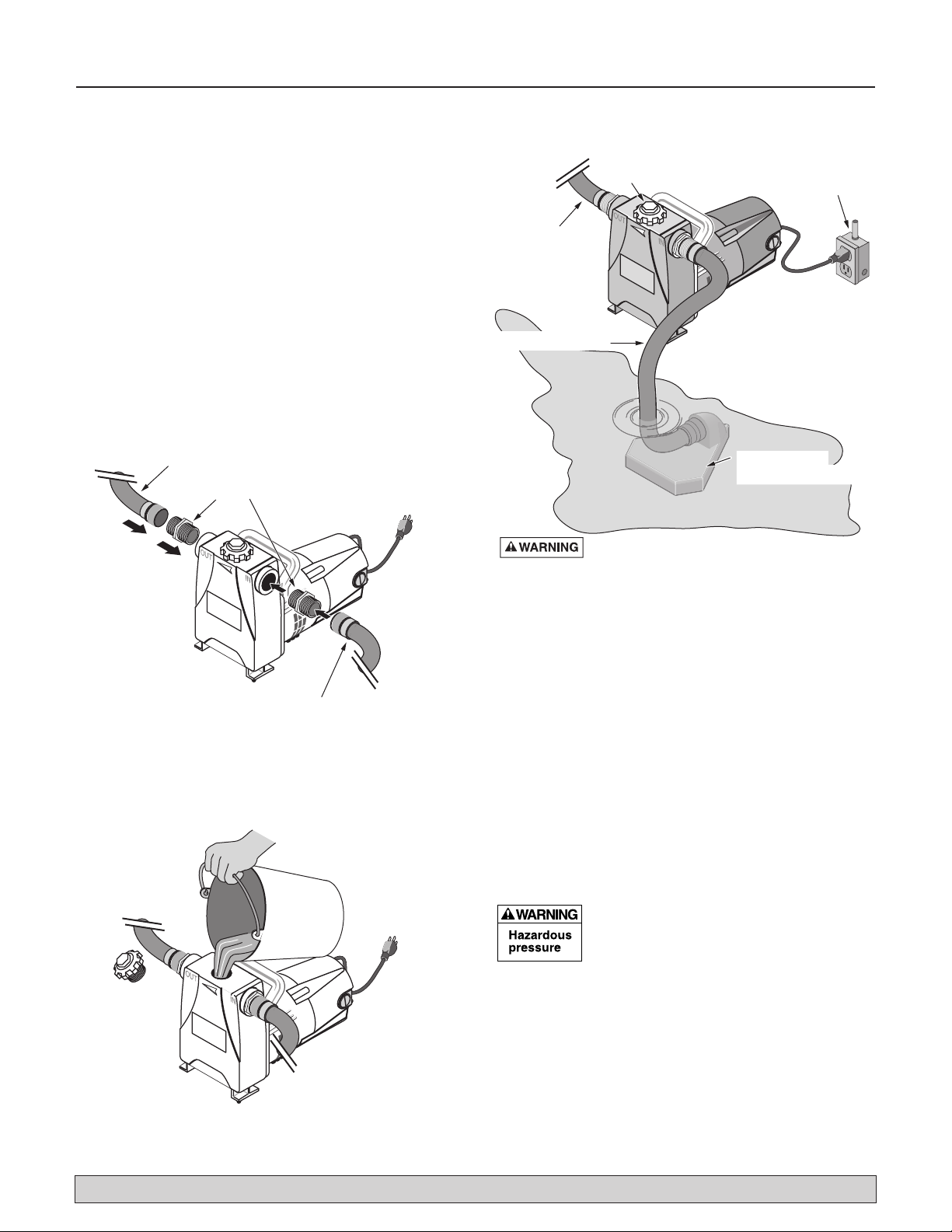

PIPING

Both suction and discharge ports are tapped for 3/4"

pipe. If using hoses, use hose to pipe thread adapter. To

prevent suction line collapse, use pipe or reinforced hose

only for suction line. Install strainer or puddle gulper on

end of suction line. Inspect and clean strainer frequently

(Fig. 1). Plastic pipe can be used for all installations.

PRIMING/OPERATION

NOTICE: Do not run pump dry. Running pump without

water can damage impeller and may damage seal, causing leaking or flooding, and will void warranty.

All suction connections must be airtight. Make sure

suction lift is not more than 25' (7.6M). Fill pump body

through priming port before starting pump. Start pump;

it should pump water in under 10 minutes (depending

on length of suction hose and height of pump above

water).

ELECTRICAL

Risk of dangerous or fatal electric shock.

Unplug pump before servicing it. Do not

handle pump or attempt to work on pump

with wet hands or while standing on wet or damp floor.

Plug pump into 115 Volt, 60 Cycle outlet only. Pump is

equipped with 3-wire, grounded, cord and plug. Do not

modify or remove plug. Plug in to properly grounded,

grounding type outlet only. Make sure pump circuit

meets National Electrical Code. To avoid dangerous electrical shock hazard, keep cord dry at all times.

Installation 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

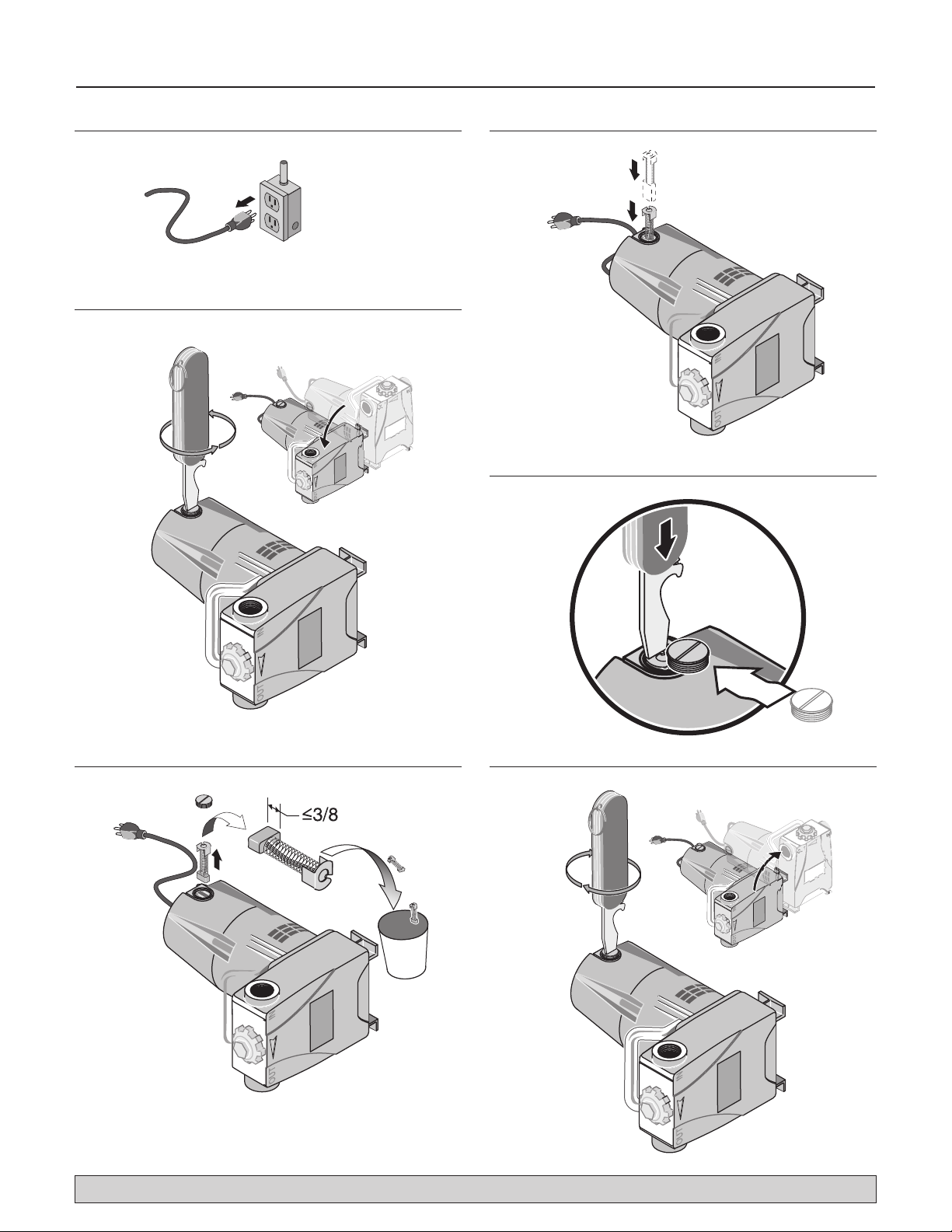

Figure 2: Remove the priming plug and fill the pump

body with water.The pump must be full of water before

you start it!

Figure 3:Typical Installation. Be sure to connect the

pump to a grounded outlet. Do not immerse the pump

and motor!

Figure 1: Install the adapters and connect the inlet and

discharge hoses.

Discharge hose or

plastic pipe

1" NPT to

Hose Adapter

OUT

IN

Operate pump on

Priming

Plug

OUT

3/4" Discharge

Hose or Plastic

Pipe

3/4" Suction Hose

Electrical shock hazard. Pump and motor

are not submersible. Keep them dry!

IN

115 volt curent only!

115 Volt grounded

outlet box.

NOTICE:

Pump suction port must

be 25' (7.6M) or less

above water level.

Max. water temp. is

104° F (40°C).

Puddle Scoop

(Clean Frequently)

Reinforced Inlet Hose

or Plastic Pipe

OUT

IN

Page 5

Installation 5

NOTICE: Pump motor is equipped with carbon brushes

with a normal operating life of about 300 hours. One

extra set of brushes is included. Replacement brushes are

available from your dealer. Motor brushes not included

in warranty.

Fire hazard. Incorrectly mounted brushes

may cause fire. Be sure curve on end of brush matches

curve on commutator.

LUBRICATION

Motor is lubricated at factory for life of bearings. Pump

seal is water cooled and self lubricating.

PUMP SERVICE

Motor has auto-reset thermal overload. If motor overheats, overload will cut off power to prevent damage

and will reset after motor cools. If overload trips repeatedly, check pump for cause (low voltage, clogged

impeller, etc.).

Hazardous voltage. Can shock, burn, or

cause death. Disconnect motor from electrical power

before servicing pump.

Always replace

both

brushes - to avoid fire hazard,

never replace just one.

Seal Changing Procedure

Hazardous voltage. Unplug pump before

continuing.

1. Unplug the pump from the outlet and remove all

piping or hoses from the pump.

2. To avoid breaking the brushes when you remove or

replace the motor shaft, remove the motor brushes

(see “Brush Changing Procedure”, Page 7, Steps 1

and 2). Put the brushes where they will not get lost

or damaged while you proceed.

3. Remove 4 screws from the back of the pump body

(Key No. 1, Page 8) and remove the pump body

from the motor. Remove the old Square-cut O-Ring

(Key No. 4C) from the assembly.

4. Unscrew the impeller (Key No. 4A) from the motor

shaft and discard it.

5. Pull the seal plate (Key No. 5) from the motor shaft.

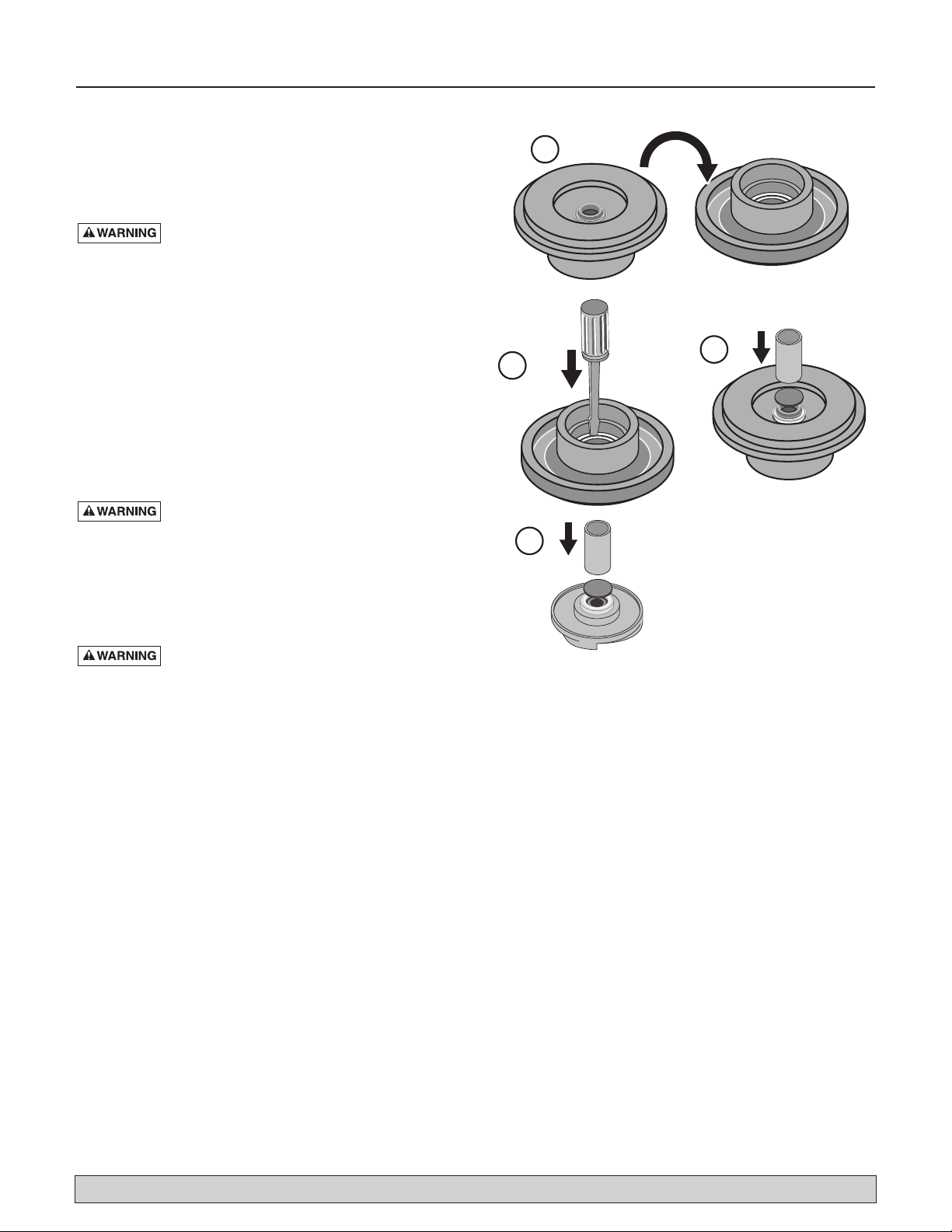

6. Turn the seal plate face down (See Figure 4A) and

use a screwdriver or small tube to push the stationary seal half out of the seal plate (Figure 4B).

7. Place a cardboard washer over the seal face to protect it and use a tube to push the stationary seal half

into the seal plate until it seats (Figure 4C). Be sure

you don’t scratch or mar the polished face of the

seal. Also, keep your hands away from the seal face

to keep dirt and grease off of it.

8. Use the cardboard washer and tube to push the

rotating half of the seal into the new impeller, polished face out (Figure 4D). Be sure you don’t scratch

or mar the polished face of the seal. Also, keep your

hands away from the seal face to keep dirt and

grease off of it.

9. CAREFULLY slide the seal plate back onto the motor

shaft, making sure that you don’t chip or scratch the

seal face in the process.

10. Thread the new impeller onto the motor shaft,

making sure that you don’t chip or scratch the seal

face in the process.

11. Reinstall the motor shaft in the motor.

12. Install the new square-cut O-ring on the seal plate.

13. Bring the impeller/motor assembly up to the pump

body and insert the impeller and seal plate into the

pump body.

14. Install the 4 body screws (be sure to reinstall the

handle on the upper screws) and tighten them

securely.

15. Replace the motor brushes (see “Brush Changing

Procedure”, Page 7, Steps 4, 5, and 6).

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Figure 4: Seal Changing Procedure

A

C

B

D

5678 0807

Page 6

Installation 6

Cord Replacement

Hazardous voltage. Unplug pump before

working on or servicing pump. Don’t attempt to modify

the cord or plug; these instructions are ONLY for

replacement of cord.

1. Unplug the pump.

2. Unscrew the two screws holding the cord plate to

the back of the motor. Pull the cord gently out of the

motor cavity.

3. Cut the existing wires on the motor side of the

crimps, as close to the connectors as possible (in

other words, leave yourself as much wire in the

motor as possible).

4. Strip all the wires back about 5/8” from the wire

ends.

NOTE: Make connections with wire nuts designed

for connecting 2 #16 AWG wires (see the wire nut

package).

5. Connect the green (ground) wire from the cord to the

green (ground) wire from the motor. Connect the

black (hot) wire from the cord to either black wire

from the motor. Connect the white (neutral) wire

from the cord to the remaining black wire from the

motor.

6. After you have made the connections, check all connections carefully to be sure that no bare copper

shows. If you see any bare wire, disconnect the wire

nut and remake that connection.

7. Once you are sure that there is no exposed wire,

carefully stuff the wire and wire nuts back into the

cavity in the motor.

8. Hold the cord plate up against the motor and reinstall the screws. Tighten thoroughly but do not overtighten!

9. Once assembly is complete, SET THE PUMP DOWN

(that is, don’t touch it) and plug it in (very briefly, to

avoid damaging the shaft seal) to make sure that

everything is correctly connected and nothing is

shorted.

10. The pump is ready for operation.

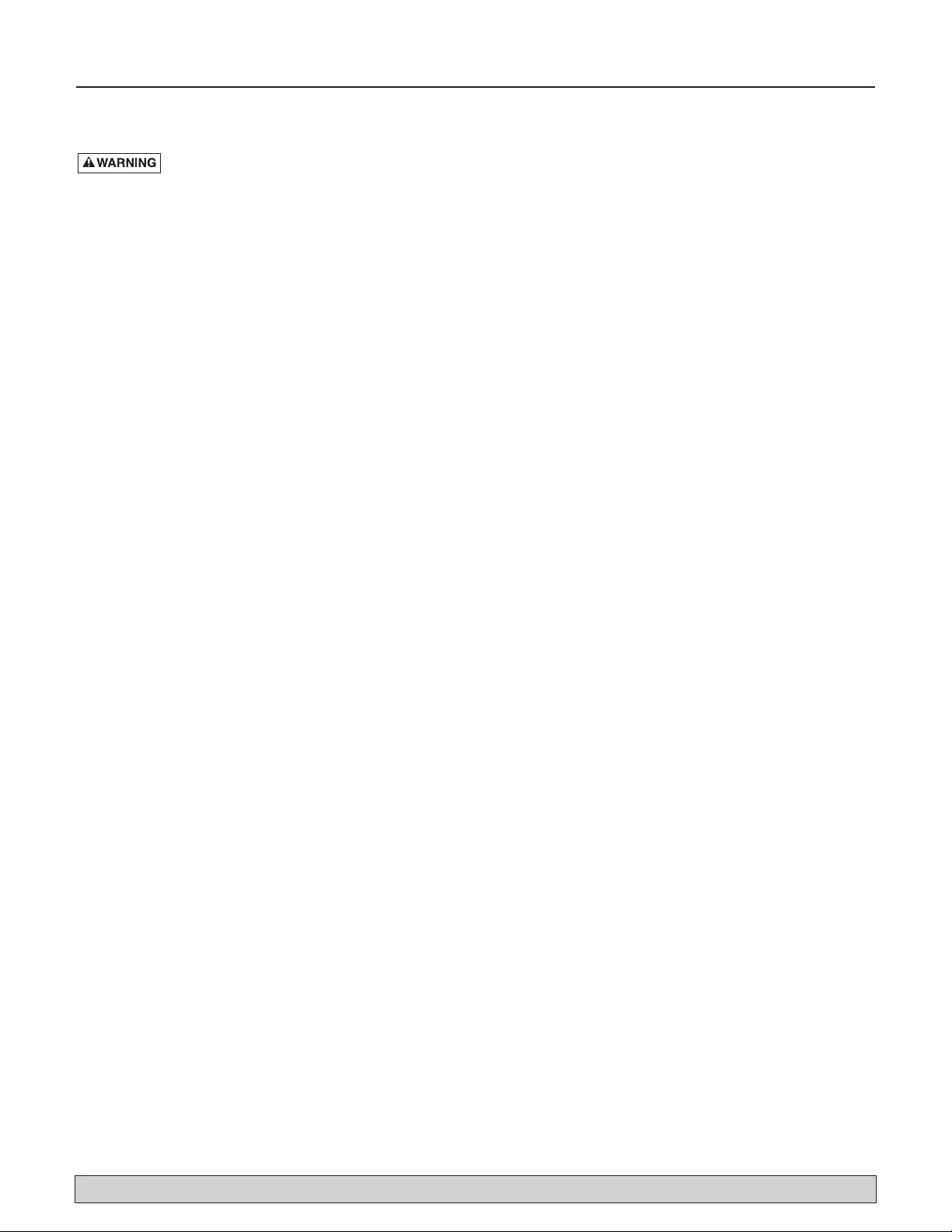

Motor Brush Replacement (See Brush Changing

Procedure, page 7:

Replace brushes when they wear down to 3/8" (9.5mm)

length.

1. Unplug pump from power outlet.

2. Unscrew brush caps and remove brushes.

NOTICE: Pull brushes straight out of holders, being

careful not to stretch springs. If reusing same brushes,

mark brush and brush cap for replacement to original

position.

3. Install new brushes and brush caps.

NOTICE: When reinstalling same brushes that were

removed, replace on same side of motor they were on

originally. Match curve on ends of brushes to curve

on commutator.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Page 7

Brush Changing Procedure 7

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Step 1

Step 2

Step 6Step 3

Step 4

Step 5

B

5602 0407

N

OUT

A

IN

T

UT

OUT

5606 0407

IN

OUT

IN

OUT

5604 0407

"

5605 0407

5607 0407

B

A

IN

OUT

IN

UT

OUT

5604 0407

Page 8

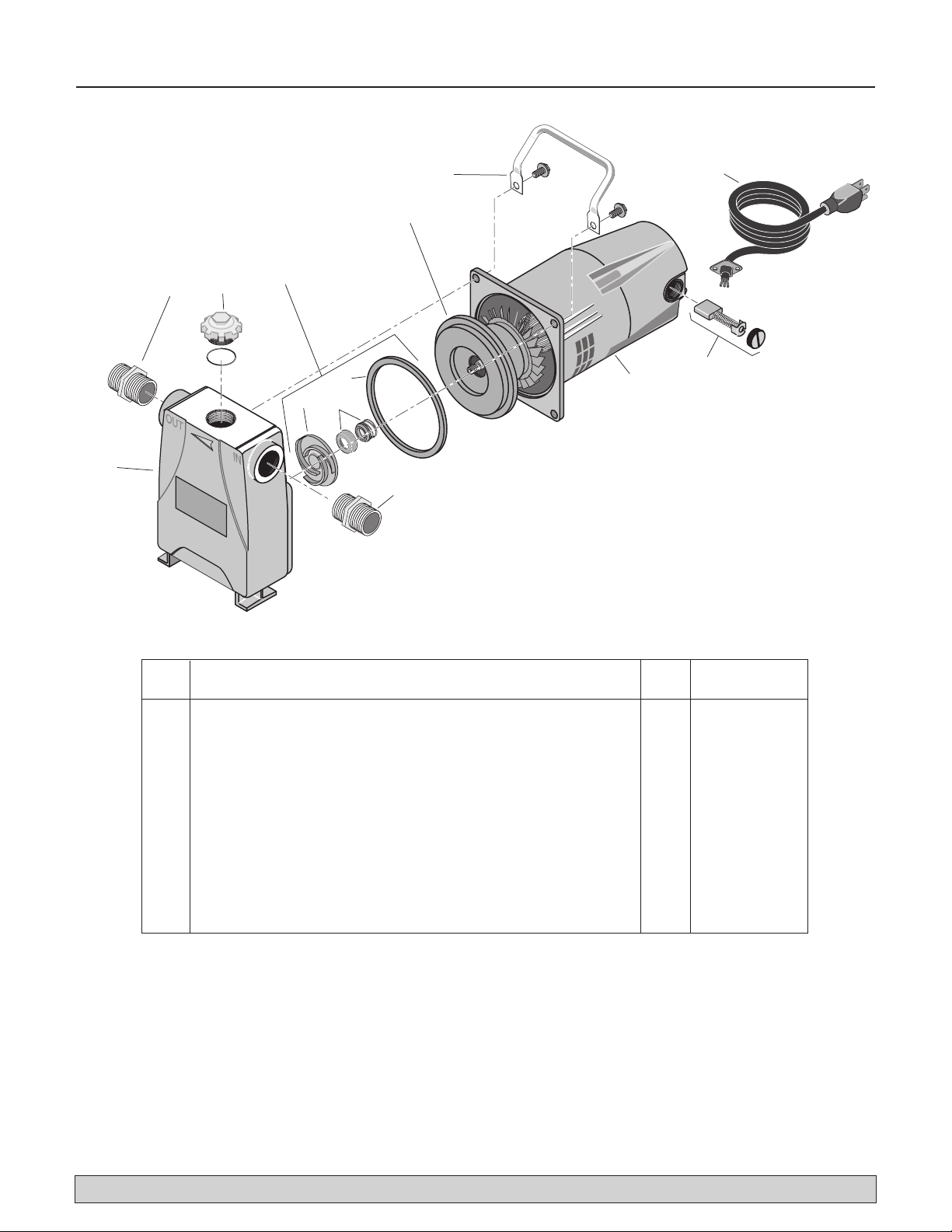

Repair Parts 8

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Key

No. Part Description Qty. Part Number

1 Pump Body 1 *

2 3/4” NPT x 3/4” Garden Hose Adapter 2 †

3 Fill Plug 1 **

4 Overhaul Kit (Includes 4A, 4B, 4C) 1 FPPKG 225-P2

4A Impeller 1 ***

4B Shaft Seal 1 ***

4C Square Cut O-Ring 1 ***

5 Seal Plate 1 ***

6 Handle With Hardware 1 C54-30

7 Power Cord 1 PS17-1507

8 Brush Kit (Includes 1 Pair of Brushes with springs and Retainer Caps) 1 FPPKG 226-P2

9 Motor 1 *

* If Pump Body or Motor fail, replace entire pump.

** NOTE: Fill Plug threads do not match inlet or discharge threads; Fill Plug is not interchangeable with Garden Hose

Adapter (Key No. 2).

*** Not available separately.

† Purchase locally.

Repair Parts — Model 4850C

6

7

5

2

3

4

8

OUT

4C

4A

4B

IN

9

5676 0807

1

2

Page 9

Sécurité 9

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Lire soigneusement et respecter toute les consignes de sécurité

figurant dans ce manuel ou sur la pompe.

Voici le symbole de sécurité. La présence de ce symbole

sur la pompe ou dans ce manuel signale l’une des men-

tions suivantes qui avertissent du risque de blessures!

DANGER avertit des dangers qui entraîneront

des blessures graves, voire mortelles, ou d’importants dommages matériels si l’on ne respecte pas les consignes.

AVERTISSEMENT avertit des dangers

qui peuvent provoquer des blessures graves, voire mortelles, ou

d’importants dommages matériels si l’on ne respecte pas les

consignes.

ATTENTION avertit des dangers qui

entraîneront ou peuvent entraîner des blessures moins graves ou

de petits dommages matériels si l’on ne respecte pas les consignes.

La mention AVIS indique des instructions spéciales et importantes, mais qui ne se rapportent pas à des dangers.

1. Lire avec soin ces régles et instructions avant le montage.

La non- observation de celles-ci risque de provoquer des

blessures graves et/ou des dommages matériels.

2. Suivre le code local en matière de plomberie et d’électricité

avant d’effectuer le montage.

3. Pour éviter tout risque d’électro-

cution, suivre la procédure suivante si la pompe a besoin

d’être réparée.

A. Couper l’alimentation en courant électrique de la boîte

de sortie avant de débrancher la prise de la pompe.

Une fois la prise débranchée, laisser la pompe refroidir

pendant 20 minutes avant d’essayer de la réparer.

B. Faire extrêmement attention en changeant les fusibles.

Pour réduire les risques d’électrocution, NE PAS avoir

les pieds en contact avec de l’eau ou mettre le doigt

dans la douille du fusible.

C. Mettre à la masse la boîte de sortie de courant.

D. N’utiliser qu’un interrupteur à la masse pour circuits

de faille (GFCI) et une sortie à la masse pour la prise.

4. Ne jamais faire fonctionner la pompe à sec car cela peut

endommager les pièces intérieures et provoquer une surchauffe de la pompe (qui peut brûler la personne la faisant

fonctionner ou la réparant). Cela annulerait également l’application de la garantie.

5. Risque de feu ou d’explosion à

partir d’étincelles émises par les brosses du moteur. Ne pas

pomper de l’essence ou tout autre liquide inflammable

avec cette pompe, ni l’utiliser dans un environnement pouvant contenir des vapeurs ou gaz inflammables.

6. Ne pas pomper de produits chimiques ou corrosifs avec

cette pompe.

Si de l’eau est retenue dans la pompe

pendant le fonctionnement, de la vapeur peut se créer causant

une explosion et des brûlures. Ne jamais faire fonctionner la

pompe avec la decharge en courant fermée ou bloquée.

AVIS

N’utiliser la pompe que pour pomper de l’eau propre. Pour

éviter qu’elle ne s’obstrue et que le joint de l’arbre soit endommagé, ne pas pomper d’eau contenant des corps solides, des

matériaux étrangers, du sable, du limon ou des particules abrasives. Toujours s’assurer qu’une crépine d’aspiration est montée

lorsque la pompe est en marche. Manquer à cette régle peut

provoquer un mauvais fonctionnement et annuler la garantie.

Nettoyer la crépine et rincer la pompe après chaque utilisation.

Veiller à ce que tous les raccords du conduit plastique ou tuyau

flexible de la ligne d’aspiration sont étanches. Une fuite d’air

dans la ligne d’aspiration empêchera l’amorce et réduira la

performance.

Pour éviter tout dommage aux pièces de la pompe, ne pas utiliser de compound de raccords sur les orifices. Utiliser uniquement du ruban téflon ou *Plasto-Joint-Stik pour sceller les filets.

Serrer manuellement tous les raccords à la pompe de 1,5 tour

seulement. Exercer un excès de serrage casserait la pompe et

annulerait la garantie.

La température maximale du liquide doit être de 48,8 °C (120 °F).

*Lake Chemical Co., Chicago, Illinois, États-Unis

La pompe est fournie avec un

câble à masse à 3 conducteurs. Ne relier qu’à une sortie électrique correctement mise à la masse

et protégée par un interrupteur à la

masse pour circuits à faille. Ne pas

lever la pompe à l’aide du câble

électrique. Ne pas utiliser de

rallonge.

La pompe n’est pas sub-

mersible. Toujours maintenir

le moteur à sec. Ne pas le laver. Ne

pas l’immerger. Le maintenir à l’abri

des intempéries.

Débrancher la pompe avant

de passer à l’entretien.

AVERTISSEMENT

Tension dangereuse.

Peut provoquer des électro-

cutions, des brûlures et la

mort.

Mettre la pompe à la masse

avant de brancher à l’alimentation en courant.

Risque d’électrocution si le moteur de la

pompe entre en contact avec de l’eau.

Maintenir le moteur à sec.

Ne pas immerger la pompe ou le moteur, ou

mettre en marche la pompe si le moteur est

mouillé.

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Page 10

Table des matières 10

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Merci d'avoir acheté une pompe de qualité supérieure mise à l'essai à l'usine.

Page

Sécurité................................................................................................................9

Garantie.............................................................................................................10

Installation....................................................................................................11–13

Remplacement des balais...................................................................................14

Pièces de rechange ............................................................................................15

ATTACHER LE REÇU D'ORIGINE ICI À DES FINS DE GARANTIE

SIMER garantit à l’acheteur-utilisateur initial de ses produits (“Acheteur”) contre tout défaut de fabrication et de matériaux.

Tout produit reconnu défectueux dans les douze (12) mois qui suivent la date d’achat d’origine sera remplacé ou réparé à la discrétion de

SIMER, selon les conditions stipulées ci-dessous. La preuve d’achat est exigée pour déterminer l’admissibilité à la garantie.

Exceptions à la garantie de douze (12) mois

Produits/Node modèle Période de garantie

M40P, M40, BW85P, CM10, CMK 90 jours

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 ans

Pompe pour puits submersibles de 4 pouces, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 ans

Réservoir préchargé de système d’eau, 3986, 3985, 2956 5 ans

3988, 3995, 3997, 3963 À vie

Conditions générales

L’Acheteur s’engage à payer tous les frais de main-d’œuvre et d’expédition nécessaires au remplacement du produit couvert par la garantie. Cette garantie ne couvrira pas les cas de force majeure, et ne s’appliquera pas aux produits qui, du seul avis de SIMER, ont fait l’objet de négligence, d’utilisation abusive ou incorrecte, d’accident, de modification ou d’altération ; ni aux produits qui n’ont pas été installés,

utilisés, entreposés ou entretenus correctement ; ni à ceux qui n’ont pas été utilisés ou entretenus normalement, y compris, mais sans s’y

limiter, aux produits ayant des pannes de fonctionnement causées par la corrosion, la rouille ou autre corps étranger dans le système, ou

à des produits ayant fonctionné à des pressions dépassant la limite maximale recommandée.

Les demandes de service en vertu de la présente garantie seront faites en retournant le produit défectueux au détaillant ou à SIMER dès la découverte de tout défaut allégué.SIMER prendra alors les mesures correctives aussi rapidement qu’il est raisonnablement possible.Aucune demande de service en vertu de la présente garantie ne sera acceptée si elle est reçue plus de 30 jours après l’expiration de la dite garantie.

La présente garantie énonce la totalité des obligations de SIMER et le seul recours possble de l’Acheteur dans le cas de produits défectueux.

SIMER NE SERA TENU RESPONSABLE D’AUCUN DOMMAGE INDIRECT, ACCIDENTEL OU FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE.LES GARANTIES

IMPLICITES, Y COMPRIS, MAIS SANS S’Y LIMITER, LES GARANTIES IMPLICITES AYANT TRAIT À LA COMMERCIABILITÉ ET À

L’AD APTATION À UN USA GE PARTICULIER, NE DÉPASSERONT PAS LA DURÉE DES GARANTIES EXPRESSES APPLICABLES STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter les dommages fortuits ou indirects ou de limiter la durée d’une garantie implicite ; il se peut donc que les limitations ou exclusions ci-dessus ne s’appliquent pas à votre cas. La présente garantie vous donne des droits

juridiques spécifiques et vous pouvez en avoir d’autres qui varient d’une province à l’autre.

SIMER • 293 Wright Street • Delavan,WI U.S.A. 53115

Téléphone: 1-800-468-7867/1-800-546-7867 • Télécopieur: 1-800-390-5351

Courrier électronique: info@simerpumps.com • Site Web: http://www.simerpumps.com

Page 11

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Installation 11

EMPLACEMENT DE L’UNITÉ

Situer la pompe aussi près que possible (verticalement) de la

source hydrique pour maintenir la hauteur d’aspiration (distance entre l’eau et la pompe) aussi basse que possible. Placer

la pompe sur un support équilibré. La protéger contre l’humidité et les inondations.

TUYAUTERIE

Les orifices de déversement et d’aspiration sont taraudés pour

recevoir des conduits de 1,90cm (3/4”). Si des tuyaux flexibles

sont utilisés, opter pour un adaptateur fileté. Pour éviter tout

effondrement, n’utiliser qu’un conduit plastique ou un tuyau

renforcé pour la voie d’aspiration. Monter une crépine au bout

de la voie d’aspiration. Inspecter et nettoyer la crépine

régulièrement (voir schéma 1). Des conduits en plastique peuvent étre utilisés pour tous les montages.

AMORCE/FONCTIONNEMENT

AVIS: Ne pas faire fonctionner la pompe à sec. Faire fonction-

ner la pompe sans eau peut endommager la roue hélice ainsi

que le joint, causant des fuites ou des inondations, et entraînera l’annulation de la garantie.

Tous les raccords de la voie d’aspiration doivent être étanches.

Veiller à ce que la hauteur d’aspiration n’excède pas 7,6m

(25'). Remplir le corps de la pompe par l’orifice d'amorcage

avant de mettre en marche. Mettre en marche; l’eau devrait

commencer à àtre pompée dans les 10 minutes (selon la

longueur du tuyau d’aspiration et la hauteur de la pompe audessus du niveau d’eau).

DONNÉES ÉLECTRIQUES

Risque d’électrocution dangereuse, voire

mortelle. Débrancher la pompe avant de

passer à l’entretien. Ne pas manipuler la

pompe, ou y travailler, avec les mains mouillées, en ayant les

pieds en contact avec de l’eau ou en se tenant sur un sol

mouillé.

Ne brancher la pompe que sur une sortie de 115 volts, 60

cycles. Cette pompe est équipée d’un câble et d’une prise à 3

fils métalliques et à masse. Ne pas modifier, ni ôter, la prise.

Ne brancher qu’à une sortie correctement mise à masse. Veiller

à ce que le circuit de la pompe réponde bien au code électrique du pays. Pour éviter tout risque d’électrocution, toujours

maintenir le câble à sec.

Figure 2: Déposer le bouchon de remplissage, puis remplir d’eau le corps de la pompe. Avant de démarrer la

pompe, son corps doit être plein d’eau.

Figure 3: Installation type. S’assurer de brancher la

pompe dans une prise de courant mise à la terre. Ne

pas immerger la pompe ni le moteur!

Figure 1: Poser les adaptateurs, puis brancher les tuyaux

d’arrivée et de refoulement.

Tuyau de refoulement souple

ou en plastique rigide

1 po NPT vers adaptateurs

de tuyau souple

Tuyau souple renforcé ou

en plastique rigide

Bouchon de

remplissage

Ne faire fonctionner la

pompe que sur le courant

de 115 volts!

Boîte de prise de courant

de 115 volts mise à la terre.

Tuyau de refoulement souple ou

en plastique

rigide de 3/4 de

pouce

Tuyau d’aspiration

de 3/4 de pouce

AVIS : L’or ifice d’aspiration doit être à moins de

7,60 m (25 pieds) sous le

niveau de l’eau. La température maximale de

l’eau doit être de 40 °C

(104 °F).

Puddle Scoop (Nettoyer

fréquemment)

Risques de secousses électriques. La

pompe et le moteur ne sont pas submersibles. Les garder au sec!

OUT

IN

AVERTISSEMENT

OUT

IN

OUT

IN

AVERTISSEMENT

Tension

dangereuse

Page 12

Installation 12

AVIS: Le moteur de la pompe est équipé de brosses en carbone

d’une durée de vie normale d’environ 300 heures. Un jeu supplémentaire est inclus et des brosses de rechange sont

disponibles auprès de votre détaillant. Ces piéces ne sont pas

couvertes par la garantie.

Risque de feu. Des brosses incor-

rectement installées peuvent provoquer un feu. S’assurer que

la courbe de l’extrémité de la brosse correspond à la courbe du

commutateur.

GRAISSAGE

Le moteur est graissé à l’usine pour toute la durée de vie des

roulements. Le joint de la pompe est refroidi par eau et à graissage automatique.

ENTRETIEN DE LA POMPE

Le moteur dispose d’une surcharge thermique de remise en

marche automatique. Si le moteur surchauffe, la surcharge

coupe l’alimentation électrique pour éviter tout dommage et se

remet en marche automatiquement après que le moteur ait

refroidi. Si la surcharge se déclenche à maintes reprises, en

rechercher la cause en inspectant la pompe (faible tension,

roue à hélice obstruée, etc...)

Tension dangereuse. Peut provoquer

des électrocutions, des brûlures et la mort. Débrancher le moteur

de l’alimentation en courant avant de passer à l’entretien.

Pour éviter tout danger, toujours remplacer les deux brosses à

la fois.

Remplacement du joint

Tension dangereuse. Débrancher

la pompe avant de procéder à ce qui suit.

1. Débrancher la pompe de la prise de courant, puis

tous les tuyaux souples ou rigides de la pompe.

2. Pour ne pas briser les balais lorsque l’on déposera

l’arbre du moteur, les déposer du moteur. (Voir «

Remplacement des balais », page 7, opérations 1. et

2.). Mettre les balais dans un endroit où ils ne risqueront pas d’être perdus ou endommagés.

3. Déposer les quatre (4) vis à l’arrière du corps de la

pompe (Réf. 1, page 8), puis séparer le corps de la

pompe du moteur. Déposer le joint torique à taille

carrée (Réf. 4C) de l’ensemble.

4. Dévisser l’impulseur (Réf. 4A) de l’arbre du moteur,

puis le jeter.

5. Sortir la plaque d’étanchéité (Réf. 5) de l’arbre du

moteur.

6. Tourner la plaque d’étanchéité à l’envers (voir la

Figure 4A) puis, à l’aide d’un tournevis ou d’un petit

tube, pousser sur la moitié du joint fixe pour la sortir

de la plaque d’étanchéité. (Figure 4B).

7. Poser une rondelle en carton sur le joint pour le protéger, puis, à l’aide d’un tube, pousser la moitié du

joint fixe dans la plaque d’étanchéité jusqu’à ce

qu’elle repose bien. (Figure 4C). Faire bien attention

de ne pas rayer ni endommager la surface polie du

joint. Ne pas non plus toucher la surface du joint

avec les mains afin de ne pas y déposer de la saleté

ni de la graisse.

8. En se servant de la rondelle en carton et d’un tube,

pousser la moitié rotative du joint dans l’impulseur

neuf, sa surface polie étant orientée vers l’extérieur.

(Figure 4D). Faire bien attention de ne pas rayer ni

endommager la surface polie du joint. Ne pas non

plus toucher la surface du joint avec les mains afin

de ne pas y déposer de la saleté ni de la graisse.

9. PRUDEMMENT, glisser la plaque d’étanchéité sur

l’arbre du moteur en faisant bien attention de ne pas

entailler ni rayer sa surface d’étanchéité.

10. Visser l’impulseur neuf sur l’arbre du moteur en

faisant bien attention de ne pas rayer ni endommager sa surface d’étanchéité.

11. Reposer l’arbre du moteur dans le moteur.

12. Poser le joint torique à taille carrée neuf sur la

plaque d’étanchéité.

13. Apporter l’ensemble impulseur et moteur jusqu’au

corps de la pompe, puis introduire l’impulseur et la

plaque d’étanchéité dans le corps de la pompe.

14. Visser les quatre (4) vis dans le corps de la pompe

(ne pas oublier de reposer la poignée sur les vis du

haut). Bien serrer les vis.

15. Reposer les balais du moteur. (Voir « Remplacement

des balais », page 7, opérations 4., 5. et 6.).

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Figure 4: Remplacement du joint

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

A

C

B

D

5678 0807

Page 13

Installation 13

Remplacement du cordon électrique

Tension dangereuse. Avant d’intervenir sur la pompe ou de l’entretenir, débrancher son

cordon électrique de la prise de courant. Ne pas modifi-

er le cordon électrique ni sa fiche. Les instructions qui

suivent NE CONCERNENT que le remplacement du cordon électrique.

1. Débrancher la pompe de la prise de courant.

2. Dévisser les deux (2) vis de fixation de la plaque du

cordon électrique à l’arrière du moteur. Sortir

prudemment le cordon électrique de la cavité du

moteur.

3. Couper les fils existants côté moteur des sertissures,

aussi près que possible des connecteurs (autrement

dit, laisser le plus possible de longueur de fils dans le

moteur).

4. Dénuder l’extrémité de tous les fils sur 5/8ede

pouce.

REMARQUE : Rebrancher les fils avec des serre-fils

spécifiés pour 2 fils de calibre 16 AWG. (Se reporter

au sachet des serre-fils).

5. Brancher le fil vert (de terre) du cordon électrique

avec le fil vert (de terre) du moteur. Brancher le fil

noir (sous tension) du cordon électrique avec n’importe quel fil noir du moteur. Brancher le fil blanc

(neutre) du cordon électrique avec l’autre fil noir du

moteur.

6. Après avoir effectué les connexions, les vérifier attentivement pour s’assurer qu’aucun fil de cuivre nu

n’est exposé. Si un fil nu est exposé, déposer le serrefil et refaire la connexion.

7. Dès qu’on est sûr qu’aucun fil nu n’est exposé,

pousser prudemment les fils et les serre-fils dans la

cavité du moteur.

8. Immobiliser la plaque du cordon électrique contre le

moteur, puis reposer les vis. Bien les serrer, mais pas

exagérément!

9. Lorsque le remontage est terminé, POSER LA POMPE

À TERRE (c’est-à-dire qu’il ne faut pas la toucher),

puis brancher son cordon électrique dans la prise de

courant (très brièvement pour ne pas endommager le

joint de l’arbre) afin de s’assurer que tout fonctionne

correctement et qu’il n’y a pas de court-circuit.

10. La pompe est maintenant prête à fonctionner.

Remplacement des balais du moteur (voir page 7 «

Comment procéder pour remplacer les balais »):

Remplacer les balais lorsque leur longueur n’est plus que de 9,5

mm (3/8

e

de pouce).

1. Débrancher la pompe de la prise de courant.

2. Dévisser les bouchons des porte-balais, puis déposer les

balais.

REMARQUE : Sortir bien droit les balais de leur porte-balai

en faisant bien attention de ne pas étirer le ressort. Si les

mêmes balais sont reposés, les repérer, ainsi que leur bouchon, afin de les reposer dans leur positon d’origine.

3. Poser les ensembles balais, porte-balais et bouchons neufs

en place.

REMARQUE : Si on réutilise les mêmes balais, reposer

chaque balai sur le même côté du moteur qu’à l’origine en

faisant correspondre sa courbe avec celle du collecteur.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

AVERTISSEMENT

Page 14

Comment procéder pour remplacer les balais 14

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Étape 1

Étape 2

Étape 6Étape 3

Étape 4

Étape 5

B

5602 0407

N

OUT

A

IN

T

UT

OUT

5606 0407

IN

OUT

IN

OUT

5604 0407

"

5605 0407

5607 0407

B

A

IN

OUT

IN

UT

OUT

5604 0407

Page 15

Pièces de rechange 15

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Numéros

Réf. Désignation des pièces Qté de pièce

1 Corps de la pompe 1 *

2 Adaptateur de tuyau d’arrosage de 3/4 de pouce NPT x 3/4 de pouce 2 †

3 Bouchon de remplissage 1 **

4 Trousse de réparation (comprend Réf. 4A, 4B et 4C) 1 FPPKG 225-P2

4A Impulseur 1 ***

4B Joint d’arbre 1 ***

4C Joint torique à taille carrée 1 ***

5 Plaque d’étanchéité 1 ***

6 Poignée et fixations 1 C54-30

7 Cordon électrique 1 PS17-1507

8 Trousse de balais (comprend 1 paire de balais, les ressorts et 1 FPPKG 226-P2

les bouchons)

9 Moteur 1 *

* Si le corps de la pompe ou si le moteur tombe en panne, remplacer la pompe au complet.

** REMARQUE : Le filetage du bouchon de remplissage n’est pas le même que celui des orifices d’arrivée et de refoule-

ment. Le bouchon de remplissage n’est pas interchangeable avec l’adaptateur du tuyau d’arrosage (Réf. 2).

*** Ces pièces ne sont pas vendues séparément.

† À acheter localement.

Pièces de rechange — Modèle 4850C

6

7

5

2

3

4

8

OUT

4C

4A

4B

IN

9

5676 0807

1

2

Page 16

Lea y siga cuidadosamente todas las instrucciones de seguridad

en este manual o en la bomba.

Este es el símbolo de alerta de seguridad. Cuando vea

este símbolo en la bomba o en este manual, fíjese en una

de las siguientes palabras indicadoras y esté alerta a posibles

lesiones personales.

Este símbolo advierte sobre peligros que

causarán lesiones personales graves, la muerte o daños materiales importantes en caso de no respetarse.

Este símbolo advierte sobre peligros que

pueden causar lesiones personales graves, la muerte o daños

materiales importantes en caso de no respetarse.

Este símbolo advierte sobre peligros que

causarán o pueden causar lesiones personales menores o daños

materiales importantes en caso de no respetarse.

La palabra AVISO indica instrucciones especiales importantes

que no están relacionadas con peligros.

1. A fin de evitar riesgos de lesiones graves y daños materiales

importantes, lea detenidamente las instrucciones de seguridad antes de instalar la bomba.

2. Respete los códigos eléctricos y de plomería locales y

nacionales al instalar la bomba.

3. Para evitar descargas eléctricas

fatales, haga lo siguiente en caso de que sea necesario

efectuar operaciones de servicio en la bomba:

A. Desconecte la corriente de la caja de distribución de

la bomba antes de desenchufar el cordón de la

bomba. Después de desenchufarla, déjela enfriar

durante 20 minutos antes de tratar de trabajar en la

misma.

B. Tenga mucho cuidado al cambiar fusibles. Para

reducir la posibilidad de descargas eléctricas fatales,

NO SE QUEDE PARADO en lugares mojados ni meta

los dedos en el receptáculo de los fusibles.

C. Conecte a tierra la caja de distribución eléctrica.

D. Para el cordón de alimentación use solamente una toma

de corriente conectada a tierra protegida por un interruptor accionado por corrientes de pérdida a tierra.

4. No haga funcionar nunca la bomba en seco. Esto puede

ocasionar daños en las piezas internas y recalentar la

bomba (que puede causar quemaduras a las personas que

manipulen o efectúen operaciones de servicio en la

bomba), además de anular la garantía.

5. Peligro de incendio o explosión

debido a chispas producidas por las escobillas del motor.

No bombee gasolina ni ningún otro líquido inflamable. No

use la bomba en una atmósfera que pueda contener humos

o vapores inflamables.

6. No bombee productos químicos o líquidos corrosivos.

Si queda atrapada agua en la bomba

durante la operación, puede convertirse en vapor, produciendo

una explosión y quemaduras. No haga funcionar nunca la

bomba con la salida cerrada o bloqueada.

AVISO

Utilice la bomba con agua limpia solamente. Para evitar que se

obstruya la bomba y se dañe el sello del eje, no bombee agua

que contenga sólidos, partículas extrañas, arena, limo o materiales abrasivos. Tenga instalado siempre el filtro de succión

cuando la bomba esté operando. Si no se usa el filtro se puede

producir la falla de la bomba además de anular la garantía.

Limpie el filtro y lave por dentro la bomba con agua abundante

después de usarla.

Cerciórese de que todas las mangueras y conexiones de la

tubería de succión estén bien apretadas. Si entra aire en la línea

de succión la bomba no se cebará y disminuirá su rendimiento.

Para impedir que se dañen los materiales de la bomba no use

compuestos para juntas de tuberías en los orificios de la bomba.

Use solamente cinta de teflón o Plasto-Joint-Stik* para sellar las

roscas.

Apriete todas las tuberías en la bomba con la mano + 1 1/2

vueltas solamente. Si aprieta demasiado las tuberías se puede

romper la bomba y se anulará la garantía.

La temperatura máxima del líquido es de 120°F (48.8°C).

*Lake Chemical Co., Chicago, Illinois

Seguridad 16

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

ADVERTENCIA

Voltaje peligroso.

Puede producir

descargaseléctricas, quemaduras o causar la muerte

Conecte la bomba a tierra

antes de conectarla aa fuente

de alimentación.

La bomba tiene un

cordón de puesta a tierra

de 3 conductores. Conecte

solamente a una toma de corriente conectada a tierra protegida por un interruptor accionado por corrientes de pérdida a

tierra. No levante la bomba por

el cordón eléctrico. No use un

cordón de alargue.

La bomba no es sumergi-

ble. Mantenga el motor

seco en todo momento. No

lave el motor. No lo sumerja.

Proteja el motor contra la

intemperie.

Desenchufe la bomba antes

de efectuar el servicio.

Peligro de descarga eléctrica fatal si se moja el

motor de la bomba.

Mantenga el motor seco.

No sumerja en agua la bomba o el motor ni

haga funcionar la bomba con el motor mojado.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 17

Indice de Contenido 17

Gracias por adquirir una bomba de calidad superior que ya ha sido probada en la fábrica.

Página

Seguridad General .............................................................................................16

Garantía.............................................................................................................17

Instalación ..................................................................................................18–20

Procedimiento para cambiar las escobillas ........................................................21

Refacciones........................................................................................................22

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

ADHÍERA AQUÍ EL RECIBO ORIGINAL PARA VALIDACION DE GARANTÍA

SIMER garantiza al comprador consumidor original (“Comprador”) de sus productos, que éstos se encuentran libres de defectos de material o mano de

obra

.

Si dentro de los doce (12) meses de la fecha original de la compra cualquiera de los productos demostrara estar defectuoso, el mismo será reparado

o reemplazado, a opción de

SIMER

con sujeción a los términos y condiciones expuestos a continuación.Se requiere su recibo original de compra para

determinar si se encuentra bajo garantía.

Excepciones a la Garantía por Doce (12) Meses

Producto/Modelo No. Período de garantía

M40P, M40, BW85P, CM10, CMK 90 días

2330, 2300, 2310, 2955, 2956, 2957, 2960, A5500 2 años

Bombas de pozo sumergibles de 4”, 3984, 3983, 2975PC, 2958, 2985, 3075SS 3 años

Tanque precargado del sistema de agua, 3986, 3985, 2956 5 años

3988, 3995, 3997, 3963 De por vida

Términos y Condiciones Generales

El comprador debe pagar todos los gastos de mano de obra y transporte necesarios para reemplazar el producto cubierto por esta garantía. Esta

garantía no se aplicará a hechos de fuerza mayor, ni se aplicará a los productos que, a juicio exclusivo de

SIMER

, hayan sido objeto de negligencia, abuso, accidente, aplicaciones contraindicadas, manejo indebido, alteraciones; ni debido a instalación, funcionamiento, mantenimiento o almacenaje incorrectos; ni a ninguna otra cosa que no sea su aplicación, uso o servicio normales, incluyendo, pero no limitado a, fallas operacionales

causadas por corrosión, oxidación u otros elementos extraños en el sistema, o funcionamiento a presión por encima del máximo recomendado.

Los pedidos de servicio bajo los términos de esta garantía serán efectuados mediante la devolución del producto defectuoso al V endedor o a

SIMER

,

tan pronto como sea pos ble, después de localizado cualquier supuesto defecto.

SIMER

tomará luego acción correctiva, tan pronto como sea razo-

nablemente posible.Ningún pedido de servicio bajo esta garantía será aceptado si se recibe más de 30 días después del tér mino de la garantía.

Esta garantía establece la obligación única de

SIMER

y el remedio exclusivo del comprador en el caso de productos defectuosos.

SIMER

NO SERÁ RESPONSABLE POR NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE DE NINGUNA NATURALEZA.

LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y REEMPLAZAN CUALESQUIERA OTRAS GARANTÍAS EXPRESAS. LAS GARANTÍAS

IMPLÍCITAS, INCLUYENDO, PERO NO LIMITADAS A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD Y APTITUD PARA UN PROPÓSITO

EN PARTICULAR, NO DEBERÁN EXCEDER EL PERÍODO DE DURACIÓN DE LAS GARANTÍAS EXPRESAS APLICABLES AQUÍ PROVISTAS.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes ni las limitaciones respecto a la duración de garantías implícitas; de modo que las limitaciones o exclusiones precedentes pueden no aplicarse en su caso.Esta garantía le concede derechos legales

específicos. Usted puede tener, además, otros derechos que varían de un estado a otro.

SIMER • 293 Wright Street • Delavan,WI U.S.A. 53115

Teléfono:1-800-468-7867/1-800-546-7867 • Fax:1-800-390-5351

e-Mail (correo electrónico): info@simerpumps.com • Dirección web: http://www.simerpumps.com

Page 18

Instalación 18

UBICACIÓN DE LA UNIDAD

Coloque la bomba lo más cerca posible (verticalmente) de la

fuente de agua, de modo que la altura de succión (distancia del

agua a la bomba) sea lo más baja posible. Mantenga la bomba

nivelada y protéjala contra los excesos de humedad y las inundaciones.

TUBERÍAS

Tanto el orificio de succión como el de descarga están roscados

para conectar tuberías de 3/4”. Si se usan mangueras, use un

adaptador de rosca de manguera a tubería. Para impedir que

colapse la línea de succión, use tubería o manguera reforzada

para la línea de succión solamente. Instale el filtro o Puddle

Gulper (placa colectora) en un extremo de la línea de succión.

Inspeccione y limpie el filtro frecuentemente (Figura 1). Se

pueden usar tuberías de plástico para todas las instalaciones.

CEBADO Y OPERACIÓN

AVISO: No haga funcionar la bomba en seco. Si se hace fun-

cionar la bomba sin agua se puede dañar el rodete y el sello,

produciéndose fugas e inundaciones, además de anularse la

garantía.

Todas las conexiones de succión deben ser herméticas.

Cerciórese de que la altura de succión no sea mayor que 7,6 m

(25 pies). Llene el cuerpo de la bomba por el orificio de cebado antes de arrancar la bomba. Arranque la bomba; debe

empezar a bombear agua en menos de 10 minutos (dependiendo de la longitud de la manguera de succión y de la altura de

la bomba por encima del nivel de agua).

SISTEMA ELÉCTRICO

Riesgo de descarga eléctrica peligrosa o

mortal. Desenchufe la bomba antes de efectuar el servicio de la misma. No toque la

bomba ni intente trabajar en la misma con

las manos mojadas o estando parado sobre un suelo mojado.

Enchufe la bomba solamente en una toma de corriente de 115

voltios y 60 ciclos. La bomba está equipada con un cordón de

3 conductores conectado a tierra y un enchufe. No modifique

ni quite el enchufe. Enchufe el cordón en una toma de corriente conectada a tierra de forma adecuada. Cerciórese de que

el circuito de la bomba satisfaga el Código Eléctrico Nacional.

Mantenga el cordón seco en todo momento a fin de evitar

descargas eléctricas peligrosas.

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Figura 2: Saque el tapón de cebadura y llene la unidad

de la bomba con agua. ¡La bomba debe estar llena de

agua antes de encenderla!

Figura 1: Instale los adaptadores y conecte las

mangueras de admisión y de descarga.

Figura 3: Instalación típica.Verifique que haya conectado

la bomba a un tomacorriente con puesta a tierra. ¡No

sumerja la bomba ni el motor!

Manguera de descarga o

tubería de plástico

Adaptador de 1" NPT a la

manguera

Manguera de admisión reforzada

o tubería de plástico

Tapón de

cebadura

¡Sólo opere la bomba

con una corriente de

115 voltios!

Caja de salida con conexión

a tierra de 115 voltios.

Manguera o

tubería de plástico

de descarga

de 3/4"

Manguera de

aspiración de 3/4"

AVISO:La toma de

aspiración de la bomba

debe estar a 25 pies

(7.6 m) de largo o menos

sobre el nivel del agua. La

temperatura máxima del

agua es de 104°F (40°C)

“Puddle Scoop”

(Limpiar con frecuencia)

Peligro de choque eléctrico. La bomba y

el motor no son sumergibles. ¡Manténgalos secos!

OUT

IN

ADVERTENCIA

OUT

IN

OUT

IN

ADVERTENCIA

Voltaje

peligroso

Page 19

Instalación 19

AVISO: El motor de la bomba está equipado con escobillas de

carbón con una duración de operación de aproximadamente

300 horas. Se incluye un conjunto de escobillas adicional. Las

escobillas de repuesto las puede obtener en su distribuidor.

Las escobillas del motor no están incluidas en la garantía.

Peligro de incendio. Las escobillas mal

colocadas pueden provocar incendios. Cerciórese de que la

curva del extremo de las escobillas corresponda a la curva del

conmutador.

LUBRICACIÓN

El motor se lubrica en fábrica para la duración total de los

cojinetes. El sello de la bomba está enfriado por agua y se

lubrica por sí solo.

SERVICIO DE LA BOMBA

El motor tiene una sobrecarga térmica de reposición automática. Si se recalienta el motor, la sobrecarga cortará la corriente

para impedir daños y reconectará el circuito después de enfriarse el motor. Si la sobrecarga se desconecta de forma repetida, examine la bomba para averiguar la causa (bajo voltaje,

rodete atascado, etc.).

Voltaje peligroso. Puede producir

descargas eléctricas, quemaduras o causar la muerte.

Desconecte la corriente eléctrica del motor antes de efectuar

el servicio de la bomba.

Reemplace siempre ambas escobillas para evitar peligros de

incendio. No reemplace nunca una sola escobilla.

Procedimiento para cambiar la junta

Tensión peligrosa. Desenchufe la

bomba antes de continuar.

1. Desenchufe la bomba del tomacorriente y saque todos

los tubos o mangueras de la bomba.

2. Para evitar romper las escobillas cuando saque o cambie el eje del motor, saque las escobillas del motor

(consulte el "Procedimiento para cambiar las escobillas

" en la página 21, pasos 1 y 2). Coloque las escobillas

en donde no se puedan perder o dañar mientras usted

continua.

3. Saque los 4 tornillos de la parte posterior de la unidad

de la bomba (Referencia No. 1, Página 22) y retire la

unidad de la bomba del motor. Saque el aro tórico de

corte recto usado (Referencia No. 4C) de la unidad.

4. Destornille el impulsor (Referencia No. 4A) del eje del

motor y descártelo.

5 . Saque la placa de estanqueidad (Referencia No. 5) del

eje del motor.

6. Coloque la placa de estanqueidad boca abajo (consulte

la Figura 4A) y use un destornillador o un tubo

pequeño para empujar la mitad fija de la junta y sacarla de la placa de estanqueidad (Figura 4B).

7. Coloque una arandela de cartón sobre la cara de la

junta para protegerla y use un tubo para empujar la

mitad fija de la junta dentro de la placa de estanqueidad hasta que quede asentada (Figura 4C). Asegúrese

de no rayar ni estropear la cara pulida de la junta.

Además, mantenga las manos alejadas de la cara de la

junta para impedir que se ensucie o se engrase.

8. Use la arandela de cartón y el tubo para empujar la

mitad giratoria de la junta en el nuevo impulsor, con la

cara pulida hacia afuera (Figura 4D). Asegúrese de no

rayar ni estropear la cara pulida de la junta. Además,

mantenga las manos alejadas de la cara de la junta

para impedir que se ensucie o se engrase.

9. Deslice CUIDADOSAMENTE la placa de estanqueidad

nuevamente sobre el eje del motor, asegurándose de

no cascar ni rayar la cara de la junta en el proceso.

10. Enrosque el nuevo impulsor en el eje del motor, asegurándose de no cascar ni rayar la cara de la junta en

el proceso.

11. Vuelva a instalar el eje del motor en el motor.

12. Instale el nuevo aro tórico de corte recto en la placa de

estanqueidad.

13. Traiga la unidad del impulsor/motor hacia la unidad de

la bomba e introduzca el impulsor y la placa de

estanqueidad en la unidad de la bomba.

14. Instale los 4 tornillos en la unidad (asegúrese de volver

a instalar la manija en los tornillos superiores) y

apriételos firmemente.

15. Vuelva a colocar las escobillas del motor (consulte el

“Procedimiento para cambiar las escobillas”, en la

Página 21, Pasos 4, 5, y 6).

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Figura 4: Procedimiento para cambiar la junta

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

A

C

B

D

5678 0807

Page 20

Instalación 20

Reemplazo del cordón

Tensión peligrosa. Desenchufe la

bomba antes de trabajar o de repararla. No trate de

modificar el cordón o el enchufe: estas instrucciones son

SOLO para cambiar el cordón.

1. Desenchufe la bomba.

2. Destornille los dos tornillos que sujetan la placa del

cordón a la parte posterior del motor. Jale suavemente del cordón para sacarlo de la cavidad del

motor.

3. Corte los cables presentes del lado del motor de los

pliegues, tan cerca de los conectores como sea posible (es decir, deje todo el cable que pueda en el

motor)

4. Pele todos los cables hasta unos 5/8” del extremo de

los mismos.

NOTE: Haga las conexiones con conectores de

cables diseñados para conectar cables 2 #16 AWG

(consulte el paquete de las tuercas de cables).

5. Conecte el cable verde (a tierra) desde el motor.

Conecte el cable negro (caliente) desde el cordón a

cualquiera de los cables negros del motor. Conecte

el cable blanco (neutro) del cordón al cable negro

restante del motor.

6. Después de haber hecho las conexiones, verifíquelas

cuidadosamente para asegurarse de que no hayan

hilos de cobre desnudos. Si ve un hilo desnudo,

desconecte el conector del cable y vuelva a hacer la

conexión.

7. Cuando esté seguro de que no haya hilos expuestos,

cuidadosamente introduzca los cables y los conectores del cable nuevamente en la cavidad del motor.

8. Sostenga la placa del cordón contra el motor y vuelva a instalar los tornillos. Apriételos firmemente,

¡pero no demasiado!

9. Cuando haya terminado de ensamblarla, DEJE LA

BOMBA EN POSICIÓN (es decir, no la toque) y

enchúfela (muy brevemente, para evitar dañar la

junta del eje) para verificar que todo esté debidamente conectado y no haya cortocircuitos.

10. La bomba está lista para funcionar.

Reemplazo de las escobillas del motor (Consulte el

Procedimiento para cambiar las escobillas, página 21:

Reemplace las escobillas cuando se hayan desgastado

hasta medir 9,5 mm (3/8”) de largo.

1. Desenchufe la bomba de la toma de corriente.

2. Desatornille las tapas de las escobillas y saque las

escobillas.

AVISO: Saque las escobillas de los portaescobillas

tirando recto de las mismas y teniendo cuidado de

no estirar los muelles. Si se vuelven a usar las

mismas escobillas, marque la escobilla y su tapa

correspondiente para poder volver a colocarlas en la

posición original.

3. Instale nuevas escobillas y tapas de escobillas.

AVISO: Al volver a instalar las mismas escobillas que

se desmontaron, colóquelas en el mismo lado del

motor en que estaban originalmente. Haga corresponder la curva de los extremos de las escobillas

con la curva del conmutador.

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

ADVERTENCIA

Page 21

Procedimiento para cambiar las escobillas 21

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Paso 1

Paso 2

Paso 6Paso 3

Paso 4

Paso 5

B

5602 0407

N

OUT

A

IN

T

UT

OUT

5606 0407

IN

OUT

IN

OUT

5604 0407

"

5605 0407

5607 0407

B

A

IN

OUT

IN

UT

OUT

5604 0407

Page 22

Refacciones 22

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Ref. Número

No. Descripción de la pieza Cantidad de pieza

1 Unidad de la bomba 1 *

2 Adaptador para manguera de jardín de 3/4” NPT x 3/4” 2 †

3 Tapón de llenado 1 **

4 Juego de revisión (Incluye 4A, 4B, 4C) 1 FPPKG 225-P2

4A Impulsor 1 ***

4B Junta del eje 1 ***

4C Aro tórico de corte recto 1 ***

5 Placa de estanqueidad 1 ***

6 Mango con accesorios de ferretería 1 C54-30

7 Cordón eléctrico 1 PS17-1507

8 Juego de escobillas (Incluye 1 par de escobillas con resortes y

casquetes de retención) 1 FPPKG 226-P2

9 Motor 1 *

* Si la Unidad de la bomba o el motor fallan, reemplace toda la bomba.

** NOTA: Las roscas del tapón de llenado no concuerdan con las roscas de admisión o de descarga; el tapón de llenado no se puede

intercambiar con el adaptador para manguera de jardín (Referencia No. 2).

*** No disponible por separado.

† Adquirir localmente.

Piezas de repuesto — Modelo 4850C

6

7

5

2

3

4

8

OUT

4C

4A

4B

IN

9

5676 0807

1

2

Page 23

23

Page 24

Loading...

Loading...