Page 1

OWNER’S MANUAL

Submersible Utility Pumps

NOTICE D’UTILISATION

Pompe submersible

à usage général

MANUAL DEL USUARIO

Bomba sumergible

de uso general

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-468-7867

English . . . . . . . . . . . . . . . Pages 2-5

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (800) 468-7867

Français . . . . . . . . . . . . . Pages 6-9

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-800-468-7867

Español . . . . . . . . . . .Paginas 10-13

©2005 1000001370 (Rev. 6/23/05)

293 Wright St., Delavan, WI 53115

Phone:

1-800-468-7867

1-800-546-7867

Fax:

1-800-390-5351

Web Site:

http://www.simerpump.com

MOD. 2300, 2305, 2310, 2355

Page 2

Safety 2

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

READ AND FOLLOW

SAFETY INSTRUCTIONS!

Carefully read and follow all safety instructions in this

manual and on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

DESCRIPTION

These Submersible Utility Pumps are designed for draining water from basement floors, stock tanks, window

wells, boats, flat roofs and cisterns. The units are

equipped with a 3-prong grounding-type power cord. The

shaded-pole motors are oil filled and sealed for cooler

operation. The sleeve bearings on the motor shaft never

need lubrication. Automatic reset thermal protection.

NOTICE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will

void warranty.

SPECIFICATIONS

Power supply required...............................115V, 60 HZ.

Motor duty ....................................................continuous

Liquid Temp. Range .................. Less Than 120°F (50°C)

Individual Branch Circuit Required (min.).........15 Amps

Pump Discharge:...........................................1-1/4" NPT

Adapter:..............................................3/4" Garden Hose

Risk of fire or explosion. Do not use in

explosive atmospheres. Pump water only with this

pump.

PERFORMANCE

SIMER warrants to the original consumer purchaser (“Purchaser”) of its products that they are

free from defects in material or workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it shall be repaired or replaced at SIMER’s option, subject to

the terms and conditions set forth below. Your original receipt of purchase is required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Ninety (90) Day Warranty:

If within ninety (90) days from original consumer purchase any Drill Pump or MiniVac Pump

shall prove to be defective, it shall be replaced, subject to the terms set forth below.

Two (2) Year Warranty:

If within two (2) years from original consumer purchase, any 1/3 HP Submersible Sump Pump,

or Models 2330, 2300 or A5500, shall prove to be defective, it shall be repaired or replaced

at SIMER’s option, subject to the terms and conditions set forth below.

Three (3) Year Warranty:

If within three (3) years from original consumer purchase any 4” Submersible Well Pump, 1/2

HP Submersible Sump Pump, or Booster Pump Model 3075SS shall prove to be defective, it

shall be repaired or replaced at SIMER’s option, subject to the terms and conditions set forth

below.

Five (5) Year Warranty:

If within five (5) years from original consumer purchase any Pre-Charge water system tank

shall prove to be defective, it shall be repaired or replaced at SIMER’s option, subject to the

terms and conditions set forth below.

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by

this warranty. This warranty shall not apply to acts of God, nor shall it apply to products

which, in the sole judgement of SIMER, have been subject to negligence, abuse, accident,

misapplication, tampering, alteration; nor due to improper installation, operation, maintenance or storage; nor to other than normal application, use or service, including but not limited to, operational failures caused by corrosion, rust or other foreign materials in the system,

or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to

the Retail outlet or to SIMER as soon as possible after the discovery of any alleged defect.

SIMER will subsequently take corrective action as promptly as reasonably possible. No

requests for service under this warranty will be accepted if received more than 30 days after

the term of the warranty.

This warranty sets forth SIMER’s sole obligation and purchaser’s exclusive remedy for defective products.

SIMER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS

WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL

NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages

or limitations on how long an implied warranty lasts, so the above limitations or exclusions

may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Simer Limited Warranty

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Phone: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

EMail: info@simerwater.com • Web: http://www.simerwater.com

GPH (LPH) AT TOTAL FEET (M)

Model 0 5 10152025

No. (0) (1.5m) (3m) (4.6m) (6.1m) (7.6m)

CAPACITY GALLONS(L)/Hour

2300

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2305

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2310

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2355

2,160 1,740 1,620 1,260 720 60

(8,160) (6,600) (6,120) (4,790) (2,700) (240)

Page 3

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

General Information / Installation 3

ELECTRICAL & SWITCH

SPECIFICATIONS

GENERAL SAFETY INFORMATION

Electrically powered utility pumps normally give many

years of trouble-free service when correctly installed,

maintained, and used. See the “Troubleshooting Chart”

in this manual for information about common utility

pump problems and remedies. For more information,

see your retailer, or call Simer customer service at

1-800-468-7867 or 1-800-546-7867.

1. Know the pump application, limitations, and poten-

tial hazards.

2. Do not use in water where fish are present.

3. Disconnect the power before servicing.

4. Release all the pressure within the system before ser-

vicing any component.

5. Drain all the water from the system before servicing.

6. Secure the discharge line before starting the pump.

An unsecured discharge line will whip, possibly

causing personal injury and/or property damage.

7. Check hoses for a weak or worn condition before each

use, making certain that all connections are secure.

8. Periodically inspect the pump and the system com-

ponents. Keep free of debris and foreign objects.

Perform routine maintenance as required.

9. Provide a means of pressure relief for pumps whose

discharge line can be shut-off or obstructed.

10.Personal Safety:

a. Wear safety glasses at all times when working

with pumps.

b. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

c. Keep visitors at a safe distance from work area.

d. Make workshop child-proof – with padlocks, mas-

ter switches, and by removing starter keys.

11. When wiring an electrically driven pump, follow all

of the electrical and safety codes that apply.

12.This equipment is only for use on 115 volt (single

phase) and is equipped with an approved 3-conductor cord and 3-prong, grounding-type plug.

Hazardous voltage. Can shock, burn or

cause death. To reduce the risk of electric shock,

pull the plug before servicing. This pump has not

been investigated for use in swimming pool areas.

The pump is supplied with a grounding conductor

and grounding-type attachment plug. Be sure it is

connected only to a properly grounded groundingtype receptacle.

Where a 2-prong wall receptacle is encountered, it

must be replaced with properly grounded 3-prong

receptacle installed in accordance with the codes

and ordinances that apply.

Do not walk on wet area until all power has been

turned off. If the shut-off box is in the basement, call

the electric company or hydro authority to shutoff

the service to house, or call your local fire department for instructions. Failure to follow this warning

can result in a fatal electrical shock.

Do not lift the pump by the power cord.

13.All wiring should be performed by a qualified

electrician.

14.Make certain the power source conforms to the

requirements of your equipment.

15. Protect the electrical cord from sharp objects, hot surfaces, oil, and chemicals. Avoid kinking the cord.

Replace or repair damaged or worn cords immediately.

16.Do not touch an operating motor. Modern motors

can operate at high temperatures.

17.Do not handle the pump or the pump motor, or

change fuses with wet hands or when standing on

wet or damp surface, or in water.

INSTALLATION

1. Set the pump on a hard surface in at least 2 inches

of water.

2. Connect the discharge line with the fittings provided.

3. The pump should not be installed on clay, dirt, mud

or sand surfaces. Although the pump will usually

pass small particles suspended in water, clean the

area to be pumped of small stones and gravel which

could clog the pump.

*NOTICE: Grass, mud, sand or pea gravel can clog the

pump and reduce it’s performance. Keep the pump inlet

screen clean.

4. To reduce motor noise and vibrations when using

rigid pipe, a short length of rubber hose (e.g. radiator

hose) can be connected into the discharge line near

the pump using suitable clamps.

5. Power Supply: These pumps are designed for 115 V.,

60 Hz., operation and requires a minimum 15 amp

individual branch circuit. Pump is supplied with a

3-wire cord with grounding-type plug.

Motor Individual

Model Motor Full Load Branch Circuit

No. HP Amps Req. (Amps)

2300 1/6 5.6 10

2305 1/6 6.0 10

2310 1/6 5.6 10

2355 3/10 10.0 15

Page 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Troubleshooting

Installation / Operation 4

Hazardous voltage. Can shock, burn or

cause death. Pump should always be electrically

grounded to a suitable electrical ground such as a

grounded water pipe or a properly grounded metallic

raceway, or ground wire system. Do not cut off round

ground pin.

6. If the pump discharge line is exposed to an outside

sub-freezing atmosphere, the portion of line exposed

must be installed so any water remaining in the pipe

will drain to the outfall by gravity. Failure to do this

can cause the water trapped in the discharge to

freeze which could result in damage to the pump.

7. Check the system operation by observing the pump

operation through one complete cycle.

Risk of flooding. Failure to make this

operational check may lead to improper operation,

premature failure, and flooding.

OPERATION

Hazardous voltage. Can shock, burn or

cause death. Do not handle a pump or pump motor with

wet hands or when standing on wet or damp surface, or

in water.

Before attempting to check why a unit has stopped operating, disconnect power from the unit.

1. The shaft seal depends on water for lubrication and

cooling. Do not operate the pump unless it is submerged in water as seal may be damaged if allowed

to run dry.

2. The pump will not remove all water. On a flat surface

Model Nos. 2300, C2300, 2305, 2310, C2310 and

2305G will pump down to within 1/8" of the pumping surface. Model No. 2355 will pump down to

within 5/8" of the pumping surface.

NOTICE: For continuous operation, the pump must

be submerged to prevent the motor from overheating.

A fully submerged pump is preferred for proper cooling when a pump runs continuously.

AIRLOCKS

When a pump airlocks, it runs but does not move any

water. An airlock will cause the pump to overheat and fail.

The -01 Series pumps have a built in anti-airlock hole. See

the exploded view on the repair parts page for the location

of the hole. Water leakage from the anti-airlock hole is

normal.

If you suspect an airlock, unplug the pump, clean out the

anti-airlock hole with a paper clip or a piece of wire, and

restart the pump.

Dewater flat roofs

Empty flooded rooms

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

Pump won’t start or run. Pump is not plugged in. Check and see if pump is plugged in to a proper outlet.

Blown fuse. If blown, replace with fuse of proper size or reset breaker.

Low line voltage. If voltage is under recommended minimum. Check size of

wiring from main switch on property. If OK, contact power

company or hydro authority.

Defective motor. Replace pump.

Pump operates but Restricted discharge Remove pump and clean pump and piping.

delivers little or no water. (obstacle or ice in piping).

Restricted intake. Remove the pump and clean out the intake screen.

Low line voltage. The voltage is under recommended minimum. Check size of

wiring from main switch on property. If OK, contact power

company or hydro authority.

Worn or plugged impeller. Replace pump.

The anti-airlock hole is plugged. Turn off the pump, clean out the anti-airlock hole, and

restart the pump.

Roofs

.3

Basements

.3

3696 0500 NEW

Page 5

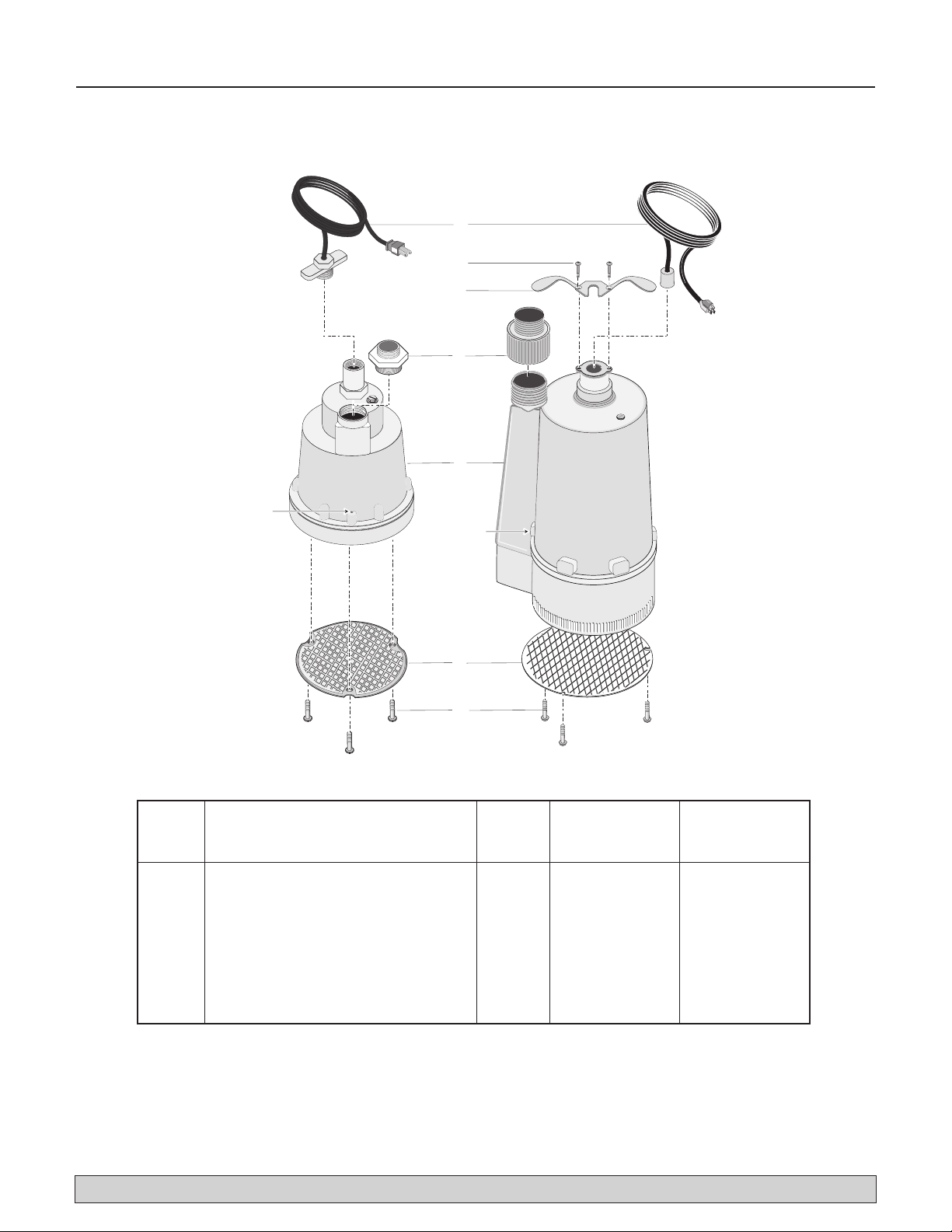

Repair Parts 5

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

2300-01 2305

2300-03 2305-03

Key Part Description Qty. 2310-01 2355

1 Power Cord (2310, C2310, 2305G) 1 PS117-136-TSU 2911-B

1 Power Cord (2300, C2300, 2305, 2355) 1 PS117-54-TSU 227-264-B-TSU

1 Power Cord (C2305, C2355) 1 – 227-228-TSU

2 Screw, Handle 2 – 670-646

3 Handle 1 – 383-147-B

4 Adapter 1 007-031 007-022

5 Cover, Motor Assembly 1 ** **

6 Inlet Screen 1 667-016 667-013

7 Screws, Screen 3 670-793 670-646

** If the motor fails, replace the entire pump.

Model Numbers

2300-01, 2300-03 and 2310-01

Model Numbers

2305, 2305-03 and 2355

Model Numbers

2300-01, C2300-01,

2310-01, and C2310-01

Anti-airlock

hole

1

2

3

4

5

Anti-airlock

hole

Model Numbers

2305, C2305, 2305G,

2355, and C2355

6

7

3993 0501

Page 6

Sécurite 6

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

LIRE TOUTES CES

INSTRUCTIONSET LES SUIVRE!

Lire attentivement toutes les consignes de sécurité contenues dans

cette Notice et collées sur la pompe.

Ce symbole indique qu’il faut être prudent. Lorsque ce sym-

bole apparaît sur la pompe ou dans cette Notice, rechercher

une des mises en garde qui suivent, car elles indiquent un potentiel

de blessures corporelles :

avertit d’un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants si on

l’ignore.

avertit d’un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels importants si on l’ignore.

avertit d’un danger qui causera ou qui risquera

de causer des blessures corporelles, la mort ou des dommages

matériels importants si on l’ignore.

Le mot NOTA indique des instructions spéciales et importantes

n’ayant aucun rapport avec les dangers.

Garder les autocollants de sécurité en bon état;

les remplacer s’ils manquent ou s’ils ont été endommagés.

DESCRIPTION

Ces pompes submersibles à usage général sont conçues pour vider

les réservoirs de stockage, les puits de lumière, les bateaux, les terrasses et les citernes. Elles sont équipées d’un cordon électrique

muni d’une fiche à 3 broches dont une de mise à la terre. Le

moteur étanche à bague de déphasage est rempli d’huile pour qu’il

chauffe moins pendant son fonctionnement. Les paliers à

coussinet-douille de l’arbre du moteur ne nécessitent aucune lubrification. Dispositif de protection thermique contre les surcharges à

réenclenchement automatique.

NOTA : Cette pompe n’est pas conçue pour pomper de l’eau salée

ni de la saumure! La garantie sera annulée si cette pompe est utilisée pour pomper de l’eau salée ou de la saumure.

CARACTÉRISTIQUES

Courant d’alimentation requis ...................................115 V, 60 Hz

Type de moteur ......................................................service continu

Température du liquide.........................inférieure à 120 °F (50 °C)

Circuit de dérivation individuel minimum....................15 ampères

Refoulement de pompe.............................................1 1/4 po NPT

Adaptateur............................................tuyau d’arrosage de 3/4 po

Risque d’incendie ou d’explosion. Ne pas utilis-

er dans une atmosphère explosive. Ne pomper que de l’eau.

RENDEMENT

Gal/h (L/h) À LA HAUTEUR TOTALE

DE REFOULEMENT EN PIEDS (m)

N° de 0 5 10152025

modèle

(0) (1,5m) (3m) (4,6m) (6,1m) (7,6m)

DÉBIT REFOULÉ EN GALLONS (L)/Hauteur

2300

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2305

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2310

1,260 1,140 1,120 840 480 –

(4,740) (4,320) (3,840) (3,180) (1,800) (–)

2355

2,160 1,740 1,620 1,260 720 60

(8,160) (6,600) (6,120) (4,740) (2,700) (240)

SIMER garantit à l’acheteur-utilisateur initial de ses produits (“Acheteur”) contre tout défaut

de fabrication et de matériaux.

Tout produit reconnu défectueux dans les douze (12) mois qui suivent la date d’achat d’origine

sera remplacé ou réparé à la discrétion de SIMER, selon les conditions stipulées ci-dessous. La

preuve d’achat est exigée pour déterminer l’admissibilité à la garantie.

Exceptions à la garantie de douze (12) mois

Garantie de quatre-vingt-dix (90) jours :

Si, dans les quatre-vingt-dix (90) jours à compter de la date d’achat par le consommateur d’origine, une pompe adaptable sur perceuse, une pompe d’amorçage ou une cartouche de filtre à

eau en ligne s’avérait être défectueuse, elle sera remplacée, conformément aux conditions stipulées ci-dessous.

Garantie de deux (2) ans :

Si, dans les deux (2) ans à compter de la date d’achat par le consommateur d’origine, une

pompe d’assèchement submersible de 1/3 ch ou modèle de FP2800DCC s’avérait être

défectueuse, elle sera réparée ou remplacée, au choix de SIMER, conformément aux termes et

conditions stipulés ci-dessous.

Garantie de trois (3) ans :

Si, dans les trois (3) ans à compter de la date d’achat par le consommateur d’origine, une pompe

de puits submersible de 4 pouces ou une pompe d’assèchement submersible de 1/2 ch s’avérait

être défectueuse, elle sera réparée ou remplacée, au choix de SIMER, conformément aux termes

et conditions stipulés ci-dessous.

Garantie de cinq (5) ans :

Si, dans les cinq (5) ans à compter de la date d’achat par le consommateur d’origine, un réservoir de système d’eau préchargé s’avérait être défectueux, il sera réparé ou remplacé, au choix

de SIMER, conformément aux termes et conditions stipulés ci-dessous.

Conditions générales

L’Acheteur s’engage à payer tous les frais de main-d’œuvre et d’expédition nécessaires au

remplacement du produit couvert par la garantie. Cette garantie ne couvrira pas les cas de

force majeure, et ne s’appliquera pas aux produits qui, du seul avis de SIMER, ont fait l’objet

de négligence, d’utilisation abusive ou incorrecte, d’accident, de modification ou d’altération

; ni aux produits qui n’ont pas été installés, utilisés, entreposés ou entretenus correctement ;

ni à ceux qui n’ont pas été utilisés ou entretenus normalement, y compris, mais sans s’y limiter, aux produits ayant des pannes de fonctionnement causées par la corrosion, la rouille ou

autre corps étranger dans le système, ou à des produits ayant fonctionné à des pressions dépassant la limite maximale recommandée.

Les demandes de service en vertu de la présente garantie seront faites en retournant le produit

défectueux au détaillant ou à SIMER dès la découverte de tout défaut allégué. Simer prendra alors

les mesures correctives aussi rapidement qu’il est raisonnablement possible. Aucune demande de

service en vertu de la présente garantie ne sera acceptée si elle est reçue plus de 30 jours après

l’expiration de la dite garantie.

La présente garantie énonce la totalité des obligations de SIMER et le seul recours possible de

l’Acheteur dans le cas de produits défectueux.

SIMER NE SERA TENU RESPONSABLE D’AUCUN DOMMAGE INDIRECT, ACCIDENTEL OU

FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS, MAIS SANS S’Y LIMITER, LES

GARANTIES IMPLICITES AYANT TRAIT À LA COMMERCIABILITÉ ET À L’ADAPTATION À UN

USAGE PARTICULIER, NE DÉPASSERONT PAS LA DURÉE DES GARANTIES EXPRESSES APPLICABLES STIPULÉES DANS LES PRÉSENTES.

Certaines provinces n’autorisent pas d’exclure ou de limiter les dommages fortuits ou indirects ou

de limiter la durée d’une garantie implicite ; il se peut donc que les limitations ou exclusions cidessus ne s’appliquent pas à votre cas. La présente garantie vous donne des droits juridiques spécifiques et vous pouvez en avoir d’autres qui varient d’une province à l’autre.

Garantie limitée Simer

SIMER • 293 Wright Street • Delavan, WI U.S.A. 53115

Téléphone: 1-800-468-7867 / 1-800-546-7867 • Télécopieur: 1-800-390-5351

Courrier électronique: info@simerwater.com • Site Web: http://www.simerwater.com

ATTENTION

Page 7

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Consignes générales / Installation 7

CARACTÉRISTIQUES ÉLECTRIQUES

ET INTERRUPTEUR

CONSIGNES GÉNÉRALES DE

SÉCURITÉ

Normalement, les électropompes à usage général fournissent de

nombreuses années de service sans incident si elles sont bien

posées, entretenues et utilisées. Se reporter à «Tableau de

recherche des pannes» de cette Notice pour les problèmes

courants des pompes à usage général et comment y remédier.

Pour plus de renseignements, s’adresser au marchand ou appeler

le service à la clientèle Simer en composant le 1 800 468-7867

ou 1 800 546-7867.

1. Il faut connaître les utilisations de la pompe, ses limites et les

dangers potentiels que son utilisation représente.

2. Ne pas utiliser cette pompe dans une eau contenant des pois-

sons ou tout autre espèce vivante.

3. Couper le courant avant d’intervenir sur la pompe.

4. Dissiper toute la pression du circuit avant d’intervenir sur un

des éléments de la pompe.

5. Vidanger l’eau du circuit avant d’intervenir sur la pompe.

6. Bien immobiliser la canalisation de refoulement avant de

démarrer la pompe. Une canalisation de refoulement non

immobilisée risque de se déplacer comme un fouet et de

causer des blessures corporelles et/ou des dommages

matériels.

7. Avant chaque utilisation, s’assurer que les tuyaux souples ne

comportent pas de points faibles ni de parties usées et que

tous les raccords sont bien serrés.

8. Périodiquement, inspecter la pompe et tous les éléments de

l’ensemble. Procéder à un entretien périodique selon le

besoin.

9. Prévoir un moyen de dissiper la pression des pompes dont la

canalisation de refoulement risque d’être fermée ou obstruée.

10. Sécurité personnelle :

a. Lorsque l’on intervient sur une pompe, toujours porter des

lunettes de sécurité.

b. Toujours garder la zone de travail propre, dégagée et bien

éclairée - Enlever tous les outils et tout l’équipement

inutiles.

c. Les visiteurs doivent se tenir à une distance sécuritaire de

la zone de travail.

d. Poser des cadenas pour s’assurer que les enfants ne pour-

ront pas pénétrer dans l’atelier de travail. Poser aussi un

interrupteur général et enlever les clés des démarreurs.

11. Pour câbler une électropompe, observer tous les codes de

sécurité et de l’électricité en vigueur.

12. Cet équipement ne fonctionne que sur le courant alternatif

monophasé de 115 volts. Il est muni d’un cordon électrique

approuvé à 3 conducteurs et d’une fiche à 3 broches dont

une de mise à la terre.

Tension dangereuse. Risque de secousses

électriques, de brûlures, voire de mort. Avant d’intervenir sur

la pompe et pour minimiser les risques de secousses électriques, débrancher le cordon électrique de la pompe de la

prise de courant. Aucune étude n’a été faite pour savoir si

cette pompe pouvait être utilisée aux alentours des piscines.

Cette pompe est livrée avec un conducteur électrique dont un

de ses conducteurs et une broche de sa fiche servent à la mise

à la terre. Ne brancher cette fiche que dans une prise de

courant adéquatement mise à la terre.

Au cas où l’installation ne comporterait que des prises de

courant à 2 trous, remplacer la prise de courant dans laquelle

la fiche sera branchée par une prise de courant à 3 trous

adéquatement mise à la terre et posée conformément aux

codes et aux décrets en vigueur.

Ne pas marcher sur cette surface humide tant que toute l’alimentation en courant électrique n’aura pas été coupée. Si le

sectionneur principal se trouve au sous-sol, appeler la compagnie qui fournit l’électricité pour lui demander d’interrompre le service alimentant la maison ou appeler le service

d’incendie de la municipalité pour plus de renseignements.

On risque d’être mortellement électrocuté si on ne respecte

pas cet avertissement.

Ne jamais lever la pompe par son cordon électrique.

13. Tout le câblage doit être exécuté par un électricien qualifié.

14. S’assurer que le courant d’alimentation est conforme aux caractéristiques de l’équipement.

15. Protéger le cordon électrique contre les objets tranchants, les

surfaces chaudes, l’huile et les produits chimiques. Éviter de

faire des noeuds avec le cordon. Remplacer immédiatement le

cordon électrique s’il est endommagé ou usé.

16. Ne pas toucher le moteur de la pompe pendant qu’il fonctionne. Les moteurs peuvent fonctionner par les températures

élevées.

17. Ne pas manipuler la pompe ni le moteur de la pompe ni remplacer un fusible lorsqu’on a les mains humides ou lorsqu’on

se tient debout sur une surface mouillée, humide ou dans

l’eau.

INSTALLATION

1. Poser la pompe sur une surface dure et dans au moins 2

pouces d’eau.

2. Brancher la conduite de refoulement avec les raccords fournis.

3. Il ne faut pas poser la pompe sur une surface en argile, en

terre ou sablonneuse. Bien que la pompe puisse habituellement pomper les petites particules en suspension dans l’eau,

débarrasser la zone à pomper des petites pierres et des petits

graviers qui risqueraient de boucher la pompe.

*NOTA : L’herbe, la boue, le sable et les petits gravillons peuvent

boucher la pompe et réduire son débit. Garder l’orifice d’aspiration de la pompe propre.

4. Pour minimiser le bruit du moteur et les vibrations au cas où

on utiliserait un tuyau rigide, un petit morceau de tuyau en

caoutchouc, (une durite de radiateur, par exemple) peut être

posé sur la conduite de refoulement à l’aide de colliers, près

de la pompe.

5. Courant électrique : Ces pompes sont conçues pour fonctionner sur le courant électrique de 115 V, 60 Hz. Elles doivent

être branchées sur un circuit de dérivation individuel d’au

moins 15 ampères. Chaque pompe est livrée avec un cordon

électrique à 3 conducteurs avec broche de mise à la terre.

Circuit de

Pleine dérivation

Puissance charge individuel

N° de du moteur du moteur minimum

modèle (ch) (en ampères) (en ampères)

2300 1/6 5,6 10

2305 1/6 6,0 10

2310 1/6 5,6 10

2355 3/10 10,0 15

Page 8

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

Recherche des pannes

Installation / Fonctionnement 8

Tension dangereuse. Risque de secousses

électriques, de brûlures, voire de mort. La pompe doit tou-

jours être électriquement raccordée à la terre, sur un tuyau

d’eau mis à la terre, une canalisation adéquatement mise à la

terre ou un circuit électrique adéquatement mis à la terre. Ne

jamais couper la broche ronde de mise à la terre de la fiche.

6. Si la conduite de refoulement de la pompe est exposée aux températures de congélation extérieures, la partie exposée au gel

doit être installée de façon que l’eau restant dans le tuyau puisse

se vidanger en retombant par gravité. Si l’on ne respecte pas

cette recommandation, l’eau emprisonnée dans la conduite de

refoulement peut geler et la pompe risque d’être endommagée.

7. Vérifier le fonctionnement du système en observant la pompe

qui effectue un cycle complet.

Risque d’inondation. Ne pas procéder à cette

vérification de fonctionnement risque de causer un mauvais fonctionnement, une panne prématurée, voire une inondation.

FONCTIONNEMENT

Tension dangereuse. Risque de secousses électriques, de brûlures, voire de mort. Ne pas manipuler une pompe

ni un moteur de pompe si on a les mains humides ou si on se tient

sur une surface mouillée ou humide ou dans l’eau.

Couper le courant alimentant la pompe avant d’intervenir sur la

pompe.

1. Le joint de l’arbre est lubrifié et refroidi par l’eau. Ne pas faire

fonctionner la pompe si elle n’est pas dans l’eau. Le joint sera

endommagé si la pompe fonctionne à sec.

2. La pompe n’enlèvera pas toute l’eau. Lorsqu’elles sont posées

sur une surface plane, les pompes 2300, C2300, 2305, 2310,

C2310 et 2305G pomperont jusqu’à 1/8 de pouce de la surface de pompage. Le modèle no 2355 pompera jusqu’à 5/8 de

pouce de la surface de pompage.

NOTA : En fonctionnement continu, et pour que le moteur

ne surchauffe pas, la pompe doit toujours être immergée.

Si la pompe fonctionne en continu et pour qu’elle refroidisse

adéquatement, il est préférable qu’elle soit entièrement

submergée.

BOUCHON D'AIR

Si un bouchon d’air se forme dans la pompe, elle fonctionnera mais

ne débitera pas d’eau. Un bouchon d’air causera la surchauffe de la

pompe, puis sa panne. La pompe de série «-01» est équipé d’un bouchon d’air, (voir la Page 9). Fuite de la bouchon d’air est normale.

Si l’on soupçonne un bouchon d’air, débrancher la pompe, nettoyer le trou antibouchon d’air avec un trombone ou un morceau de

fil de fer, puis redémarrer la pompe.

SYMPTÔMES CAUSES POSSIBLES REMÈDES

La pompe ne démarre pas La pompe n’est pas branchée. S’assurer que la pompe est branchée dans une prise de

ou ne fonctionne pas. courant électrique adéquate.

Fusible sauté. Le remplacer par un fusible de calibre adéquat ou bien

réarmer le disjoncteur.

Tension de ligne basse. Si la tension est inférieure à la tension minimum

recommandée, vérifier le calibre des conducteurs côté

sectionneur principal de la propriété. Si le calibre des

conducteurs est bon, s’adresser à la compagnie d’électricité.

Moteur défectueux. Remplacer la pompe.

La pompe fonctionne mais ne Le refoulement est obstrué Déposer la pompe et la nettoyer ainsi que les tuyauteries.

débite pas d’eau ou débite (obstruction ou glace dans

très peu d’eau. la tuyauterie).

L’aspiration est obstruée. Déposer la pompe et nettoyer son aspiration.

Tension de ligne basse. Si la tension est inférieure à la tension minimum

recommandée, vérifier le calibre des conducteurs côté

sectionneur principal de la propriété. Si le calibre des

conducteurs est bon, s’adresser à la compagnie d’électricité.

Des pièces de l’impulseur sont Remplacer la pompe.

usées ou bien l’impulseur est

bouché.

Bouchon d'air. Arrêter la pompe pendant quelques secondes, nettoyer

le trou antibouchon d’air, puis redémarrer la pompe.

Roofs

3696 0500 NEW

.3

Basements

.3

Asséchage

des toits-terrasses

Vidage des

pièces inondées

Page 9

Pièces de rechange 9

Pour obtenir des pièces ou de l’aide, appeler le Service à la clientèle Simer en composant le 1 800 468-7867/1 800 546-7867

2300-01 2305

2300-03 2305-03

Réf. Désignation Qté 2310-01 2355

1 Cordon électrique (2310, C2310, 2305G) 1 PS117-136-TSU 2911-B

1 Cordon électrique (2300, C2300, 2305, 2355) 1 PS117-54-TSU 227-264-B-TSU

1 Cordon électrique (C2305, C2355) 1 – 227-228-TSU

2 Vis de la poignée 2 – 670-646

3 Poignée 1 – 383-147-B

4 Adaptateur 1 007-031 007-022

5 Couvercle du moteur 1 ** **

6 Crépine d’aspiration 1 667-016 667-013

7 Vis de la crépine 3 670-793 670-646

** Si le moteur tombe en panne, remplacer toute la pompe.

Numéros de modèle

2300-01, 2300-03 et 2310-01

Numéros de modèle

2305, 2305-03 et 2355

Anti-bouchon

d’air

Anti-bouchon

d’air

Anti-airlock

hole

Model Numbers

2300-01, C2300-01,

2310-01, and C2310-01

1

2

3

4

5

Anti-airlock

hole

Model Numbers

2305, C2305, 2305G,

2355, and C2355

6

7

3993 0501

Page 10

Seguridad 10

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

¡LEA Y OBSERVE LAS INSTRUCCIONES

DE SEGURIDAD!

Lea con atención y siga todas las instrucciones de seguridad que

aparecen en este manual y en la bomba.

Este es un símbolo de alerta de seguridad. Cuando vea este

símbolo en su bomba o en este manual, busque una de las

siguientes palabras de señal y esté alerta a las posibilidades de

lesiones personales:

advierte sobre peligros que, si se ignoran, oca-

sionarán lesiones personales graves, muerte o daños materiales

considerables.

advierte sobre peligros que, si se ignoran, pueden

ocasionar lesiones personales graves, muerte o daños materiales

considerables.

advierte sobre peligros que, si se ignoran,

ocasionarán o pueden ocasionar lesiones personales o daños materiales de menor envergadura.

La etiqueta AVISO indica instrucciones especiales que son importantes pero no están relacionadas con peligros.

Mantenga las etiquetas de seguridad en buen estado.

Cambie toda etiqueta dañada y vuelva a colocar aquellas que

estén ausentes.

DESCRIPCIÓN

Estas Bombas Sumergibles de Uso General han sido diseñadas para

drenar el agua de los pisos de sótanos, tanques de almacenamiento, pozos de luz, embarcaciones, techos planos y cisternas. Las

unidades vienen equipadas con un cordón eléctrico de 3 clavijas

de tipo conexión a tierra. Los motores con polos de color están

llenos de aceite y vienen sellados para una operación más fría.

Los cojinetes de manguito en el eje del motor nunca necesitan

lubricación. Protección automática de reposición térmica.

AVISO: Esta unidad no ha sido diseñada para uso con agua salada

o salubre. El uso con agua salada o salubre anulará la garantía.

ESPECIFICACIONES

Suministro de corriente requerido...............................115V, 60 Hz

Servicio del motor............................................................continuo

Gama de temp. del líquido .....................Menos de 120° F (50° C)

Requisito (mínimo) del ramal individual .....................15 amperios

Descarga de la bomba .............................................NPT de 1-1/4"

Adaptador ...........................................Manguera de jardín de 3/4"

Riesgo de incendio o explosión. No la use en

atmósferas explosivas. Bombee solamente agua con esta bomba.

RENDIMIENTO

Simer garantiza al comprador consumidor original (“Comprador”) de sus productos, que éstos se

encuentran libres de defectos de material o mano de obra

.

Si dentro de los doce (12) meses de la fecha original de la compra cualquiera de los productos

demostrara estar defectuoso, el mismo será reparado o reemplazado, a opción de Simer con sujeción a los términos y condiciones expuestos a continuación. Se requiere su recibo original de

compra para determinar si se encuentra bajo garantía.

Excepciones a la Garantía por Doce (12) Meses

Garantía de noventa (90) días

Si se comprueba que una Bomba de Perforación, una Bomba de Émbolo Buzo o un Cartucho

de Filtro de Agua en línea, tienen defectos, dentro de los noventa (90) días a partir de la compra del consumidor original, éstos serán reemplazados, sujeto a las condiciones indicadas a

continuación.

Garantía de dos (2) años

Si se comprueba que una Bomba Sumergible de Sumidero de 1/3 CV o Modelo FP2800DCC

tiene defectos, dentro de los dos (2) años a partir de la compra del consumidor original, ésta

será reparada o reemplazada, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Garantía de tres (3) años

Si se comprueba que una Bomba Sumergible de Pozo de 4”, o una Bomba Sumergible de

Sumidero de 1/2 CV tienen defectos, dentro de los tres (3) años a partir de la compra del consumidor original, éstas serán reparadas o reemplazadas, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Garantía de cinco (5) años

Si se comprueba que un tanque precargado del sistema de agua tiene defectos, dentro de los

cinco (5) años a partir de la compra del consumidor original, éste será reparado o reemplazado, a opción de SIMER, sujeto a los términos y a las condiciones indicadas a continuación.

Términos y Condiciones Generales

El comprador debe pagar todos los gastos de mano de obra y transporte necesarios para reemplazar el producto cubierto por esta garantía. Esta garantía no se aplicará a hechos de fuerza mayor, ni se aplicará a los productos que, a juicio exclusivo de Simer, hayan sido objeto

de negligencia, abuso, accidente, aplicaciones contraindicadas, manejo indebido, alteraciones; ni debido a instalación, funcionamiento, mantenimiento o almacenaje incorrectos; ni a

ninguna otra cosa que no sea su aplicación, uso o servicio normales, incluyendo, pero no limitado a, fallas operacionales causadas por corrosión, oxidación u otros elementos extraños

en el sistema, o funcionamiento a presión por encima del máximo recomendado.

Los pedidos de servicio bajo los términos de esta garantía serán efectuados mediante la devolución del producto defectuoso al Vendedor o a Simer, tan pronto como sea posible, después de localizado cualquier supuesto defecto. Simer tomará luego acción correctiva, tan

pronto como sea razonablemente posible. Ningún pedido de servicio bajo esta garantía será

aceptado si se recibe más de 30 días después del término de la garantía.

Esta garantía establece la obligación única de Simer y el remedio exclusivo del comprador en

el caso de productos defectuosos.

Simer NO SERÁ RESPONSABLE POR NINGÚN DAÑO CONSECUENTE, INCIDENTAL O

CONTINGENTE DE NINGUNA NATURALEZA.

LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y REEMPLAZAN CUALESQUIERA OTRAS

GARANTÍAS EXPRESAS. LAS GARANTÍASIMPLÍCITAS, INCLUYENDO, PERO NO LIMITADAS A, LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD Y APTITUD PARA UN

PROPÓSITO EN PARTICULAR, NO DEBERÁN EXCEDER EL PERÍODO DE DURACIÓN DE

LAS GARANTÍAS EXPRESAS APLICABLES AQUÍ PROVISTAS.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes

ni las limitaciones respecto a la duración de garantías implícitas; de modo que las limitaciones o exclusiones precedentes pueden no aplicarse en su caso. Esta garantía le concede derechos legales específicos. Usted puede tener, además, otros derechos que varían de un estado a otro.

Garantía limitada de Simer

SIMER • 293 Wright St. • Delavan, WI U.S.A. 53115

Teléfono: 1-800-468-7867 / 1-800-546-7867 • Fax: 1-800-390-5351

e-Mail (correo electrónico): info@simerwater.com • Dirección web: http://www.simerwater.com

GPH (LPH) A ALTURA TOTAL EN PIES (M)

Modelo

0 5 10152025

No.

(0) (1,5m) (3m) (4,6m) (6,1m) (7,6m)

CAPACIDAD EN GALONES(LITROS)/Hora

2300

1,260 1,140 1,020 840 480 –

(4,740) (4,320) (3,840) (3,180) (1800) (–)

2305

1,260 1,140 1,020 840 480 –

(4,740) (4,320) (3,840) (3,180) (1800) (–)

2310

1,260 1,140 1,020 840 480 –

(4,740) (4,320) (3,840) (3,180) (1800) (–)

2355

2,160 1,740 27 1,260 720 60

(8,160) (6,600) (102) (4,740) (2,700) (240)

PELIGRO

PRECAUCIÓN

Page 11

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Información general / Instalación 11

ESPECIFICACIONES ELÉCTRICAS

Y DE CONMUTACIÓN

INFORMACIÓN GENERAL SOBRE LA

SEGURIDAD

Las bombas de uso general con accionamiento eléctrico, generalmente brindan muchos años de servicio sin problemas cuando se

las instala, mantiene y emplea correctamente. Consulte la “Tabla

de localización de fallas” en este manual para obtener información sobre los problemas comunes con bombas de uso general y

sus soluciones. Para mayor información, consulte con su representante de ventas o llame al departamento de servicio al cliente,

marcando 1-800-468-7867 o 1-800-546-7867.

1. Infórmese sobre la aplicación, limitaciones y posibles peligros

de la bomba.

2. No la use en agua con peces.

3 Desconecte la energía eléctrica antes de efectuar repara-

ciones.

4. Descargue toda la presión dentro del sistema antes de reparar

cualquier componente.

5. Drene toda el agua del sistema antes de efectuar reparaciones.

6. Asegure bien la tubería de descarga antes de poner en marcha

la bomba. Una tubería de descarga que no esté firme puede

saltar repentinamente y provocar lesiones personales y/o

daños materiales.

7. Antes de cada uso, verifique si las mangueras están débiles o

gastadas, asegurándose de que todas las conexiones estén

firmes.

8. Inspeccione periódicamente la bomba y los componentes del

sistema. Manténgalos limpios de escombros y objetos foráneos. Realice el mantenimiento de rutina según sea necesario.

9. Provea un medio de descarga de presión para aquellas bom-

bas cuya tubería de descarga se pueda bloquear o pueda

quedar obstruida.

10. Seguridad Personal:

a. Use gafas protectoras en todo momento cuando trabaje con

la bomba.

b. Mantenga la zona de trabajo limpia, despejada y debida-

mente iluminada - guarde toda herramienta y equipo que

no se use.

c. Mantenga a los visitantes a una distancia segura de la zona

de trabajo.

d. Asegúrese de que su taller sea a prueba de niños - con

candados, conmutadores maestros y sacando las llaves del

arrancador.

11. Cuando realice el cableado de una bomba de accionamiento

eléctrico, observe todos los códigos eléctricos y de seguridad

que correspondan.

12. Esta máquina se debe usar solamente con corriente de 115

voltios (monofásica) y viene equipada con un cordón aprobado de 3 conductores y 3 clavijas con conexión a tierra.

Tensión peligrosa. Puede provocar choques,

quemaduras o muerte. Para reducir el riesgo de choque eléc-

trico, desenchufe la bomba antes de repararla. No se ha investigado aún la posibilidad de usar esta bomba en albercas. La

bomba viene con un conductor de puesta a tierra y un

enchufe de tipo con conexión a tierra. Asegúrese de que se

conecte solamente a un tomacorriente puesto a tierra, de tipo

con conexión a tierra.

Si el tomacorriente mural es del tipo para 2 clavijas, éste debe

ser reemplazado por un tomacorriente de 3 clavijas debidamente puesto a tierra e instalado conforme con los códigos y

reglamentos que correspondan.

No camine en un lugar mojado hasta que no haya desactivado toda fuente de corriente eléctrica. Si la llave de paso está

en el sótano, llame a la compañía de electricidad o de energía

para cortar el servicio a su casa, o llame al departamento de

bomberos de su localidad para solicitar instrucciones. El

incumplimiento de esta advertencia puede resultar en un

choque eléctrico mortal.

No levante la bomba por medio del cordón eléctrico.

13. Todo el cableado debe ser efectuado por un electricista

certificado.

14. Asegúrese de que la fuente de alimentación cumpla con los

requisitos de su equipo.

15. Proteja el cordón eléctrico contra objetos afilados, superficies

calientes, aceite y sustancias químicas. Evite que se enrede.

Reemplace o repare inmediatamente un cordón que esté

dañado o gastado.

16. No toque un motor cuando esté funcionando. Los motores

pueden funcionar a temperaturas altas.

17. No maneje la bomba, el motor de la bomba, ni cambie los

fusibles, con las manos mojadas o cuando esté parado en

suelo húmedo o mojado, o en el agua.

INSTALACIÓN

1. Coloque la bomba sobre una superficie dura dentro de 2 pulgadas de agua como mínimo.

2. Conecte la línea de descarga a los accesorios suministrados.

3. La bomba no se debe instalar sobre superficies de arcilla,

polvo, lodo o arena. Aunque la bomba generalmente pasará

partículas pequeñas suspendidas en el agua, es importante

que se limpie la zona de bombeo de piedras pequeñas y

grava que puedan obstruir la bomba.

AVISO: Césped, lodo, arena o gravilla pueden obstruir la bomba y

reducir su rendimiento. Mantenga limpia la malla de admisión de

la bomba.

4. Para reducir el ruido y las vibraciones del motor, cuando se

use una tubería rígida, se puede conectar una manguera corta

de caucho (por ej. manguera de radiador) en la línea de

descarga, cerca de la bomba, usando abrazaderas adecuadas.

5. Suministro de energía: Estas bombas han sido diseñadas para

funcionar con una corriente de 115 V, 60 Hz, y requieren un

ramal individual con un mínimo de 15 amperios. La bomba

viene equipada con un cordón trifilar con enchufe de tipo

conexión a tierra.

Requisito

Carga del ramal

Modelo CV Completa del individual

No. del motor Motor en Amps. (Amps.)

2300 1/6 5,6 10

2305 1/6 6,0 10

2310 1/6 5,6 10

2355 3/10 10,0 15

Page 12

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

Localización de fallas

Instalación / Operación 12

Tensión peligrosa. Puede provocar choques,

quemaduras o muerte. La bomba siempre debe estar puesta a

tierra por medio de una conexión eléctrica a tierra adecuada

como una tubería de agua puesta a tierra, una canalización

metálica debidamente puesta a tierra, o un sistema de cableado a tierra. No corte la clavija redonda de conexión a tierra.

6. Si la línea de descarga de la bomba está expuesta a la intemperie

con temperaturas heladas, la porción de la línea que quede

expuesta, deberá ser instalada de manera que el agua que permanezca en la tubería se desagüe hacia la salida por gravedad.

Si se ignora esta precaución, existe el riesgo de que el agua que

quede atrapada en la descarga se congele y dañe la bomba.

7. Inspeccione la operación del sistema observando el funcionamiento de la bomba durante un ciclo completo.

Riesgo de inundación. Si no se realiza esta

verificación de la operación, existe el riesgo de un funcionamiento inadecuado, una falla prematura e inundaciones.

OPERACIÓN

Tensión peligrosa. Puede provocar choques, que-

maduras o muerte. No maneje la bomba ni el motor de la bomba

con las manos mojadas o cuando esté parado sobre una superficie

mojada o húmeda, o en agua.

Antes de tratar de verificar la razón por la que una unidad dejó de

funcionar, desconecte la corriente desde la misma.

1. El sello del eje depende del agua para su lubricación y su

enfriamiento. No opere la bomba a menos que se encuentre

sumergida dentro del agua, ya que el sello se perjudicará si

marcha en seco.

2. La bomba no eliminará toda el agua. Sobre una superficie

plana, los Modelos Números 2300, C2300, 2305, 2310,

C2310 y 2305G bombearán y reducirán el agua hasta un nivel

de 1/8 pulgada de la superficie de bombeo. El Modelo No.

2355 bombeará y reducirá el agua hasta un nivel de 5/8 pulgada de la superficie de bombeo.

AVISO: Para una operación continua, la bomba debe estar

sumergida para evitar que el motor se recaliente. Se prefiere

una bomba totalmente sumergida para obtener un enfriamiento

adecuado cuando funcione continuamente.

BOLSAS DE AIRE (“AIRLOCK”)

Cuando el flujo de la bomba disminuye o se para debido a bolsas de

aire, la bomba marcha pero no mueve agua. Una bolsa de aire

puede hacer que la bomba se recaliente y falle. Esta bomba de serie

-01 posee un orificio “anti-airlock” para eliminar las bolsas de aire,

(ver la pagina 13). Fugas del orificio “anti-airlock” está normal.

Si usted sospecha que hay una bolsa de aire, desenchufe la

bomba, limpie el orificio “anti-airlock” con un clip de papel o un

trozo de alambre y vuelva a activarla.

SÍNTOMA CAUSA(S) PROBABLE(S) ACCIÓN CORRECCTIVA

La bomba no arranca o La bomba no está enchufada. Verifique que la bomba esté enchufada en un

no marcha. tomacorriente adecuado.

Fusible quemado. Si está quemado, reemplace por un fusible del tamaño

adecuado o reposicione el disyuntor.

Baja tensión de línea. La tensión se encuentra por debajo del mínimo

recomendado. Verifique el tamaño de los cables desde el

conmutador principal en la propiedad. Si es el correcto,

comuníquese con la empresa de energía o de suministro de

corriente eléctrica.

Motor defectuoso. Reemplace la bomba.

La bomba funciona pero Descarga limitada Saque la bomba y limpie la bomba y la tubería.

entrega poco o nada de (obstáculo o hielo en la tuberia).

agua.

Admisión restringida. Saque la bomba y limpie el accesorio de admisión.

Baja tensión de línea. La tensión se encuentra por debajo del mínimo

recomendado. Verifique el tamaño de los cables desde el

conmutador principal en la propiedad. Si es el correcto,

comuníquese con la empresa de energía o de suministro de

corriente eléctrica.

Piezas gastadas o impulsor Reemplace la bomba.

tapado.

Bolsa de aire (disminución Apague la bomba por unos segundos, limpie el orificio

de flujo). “anti-airlock” y luego vuelva a activarla.

Roofs

3696 0500 NEW

.3

Basements

.3

Desaguar

techos planos

Vaciar habitaciones

inundaras

Page 13

Piezas para reparaciones 13

Si necesita repuestos o asistencia llame al Servicio al Cliente de Simer, 1-800-468-7867/1-800-546-7867

2300-01 2305

2300-03 2305-03

Clave Descripción de la pieza Cantidad 2310-01 2355

1 Cordón eléctrico (2310, C2310, 2305G) 1 PS117-136-TSU 2911-B

1 Cordón eléctrico (2300, C2300, 2305, 2355) 1 PS117-54-TSU 227-264-B-TSU

1 Cordón eléctrico (C2305, C2355) 1 – 227-228-TSU

2 Tornillo, mango 2 – 670-646

3 Mango 1 – 383-147-B

4 Adaptador 1 007-031 007-022

5 Cubierta, unidad del motor 1 ** **

6 Malla de admisión 1 667-016 667-013

7 Tornillos, malla 3 670-793 670-646

** Si falla el motor, reemplace la bomba completa.

Modelos números

2300-01, 2300-03 y 2310-01

Modelos números

2305, 2305-03 y 2355

Orificio

“anti-airlock”

Orificio

“anti-airlock”

Anti-airlock

hole

Model Numbers

2300-01, C2300-01,

2310-01, and C2310-01

1

2

3

4

5

Anti-airlock

hole

Model Numbers

2305, C2305, 2305G,

2355, and C2355

6

7

3993 0501

Page 14

14

Page 15

15

Loading...

Loading...