Page 1

Users Manual

48Watt High Precision Temperature

Controlled Soldering Station

Product Code 868805

© December 2006

• This guarantee becomes effective at the date of retail purchase.

PLEASE KEEP YOUR RECEIPT.

• If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the fault.

You will receive a replacement or refund.

• If this product develops a fault within 3 years of purchase return it to;

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU

Include your original receipt, details of the fault, your name and address, place and

date of purchase. We do not refund carriage. All product should be in a suitably

clean and safe state for repair, and should be packaged carefully to prevent damage

or injury during transportation. We may reject unsuitable or unsafe deliveries.

• You must provide proof of purchase before any work can be carried out.

• All work will be carried out by Silverline Tools or its authorised repair agents.

• Any parts which are replaced will become the property of Silverline Tools.

• The repair or replacement of the product will not extend the period of guarantee.

• The repair or replacement of your product under guarantee provides benefits which

are additional to and do not affect your statutory rights as a consumer.

What is covered:

• The repair of the product, if found to be defective due to faulty materials or workmanship

within 3 years of purchase. If any part is no longer available or out of manufacture,

Silverline Tools will replace it with a functional replacement part.

• Use of the product in the UK.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

• Normal wear and tear eg blades, brushes, belts, bulbs, batteries etc.

• Accidental damage, faults caused by negligent use or care,

misuse, neglect, careless operation or handling of the product.

• Use of the product for anything other than normal domestic purposes.

• Change or modification of the product in any way.

• Use of parts and accessories which are not Silverline Tools genuine components.

• Faulty installation (except installed by Silverline Tools).

• Repairs or alterations carried out by parties other than

Silverline Tools or its authorised repair agents.

Silverline Tools 3 Year Guarantee

Thank you for choosing this product

Page 2

Product Familiarisation

High Precision Temperature Controlled

Soldering Iron Station

OPERATING INSTRUCTIONS

Introduction

• The electronic circuitry enables the user to change the tip

temperature from 302

°F (150°C) to 788°F (420°C) without the

need to change the tip or heating ele

ment.

• The temperature is maintained within +/- 10

°F of its preset

temperature. This is made possible by a unique temperature

sensor that is located near the tip. The sensor creates a rapid

response with very little temperature variation

.

• The tip of the unit is isolated from the AC line by a transformer.

• Low voltage (24Volts) is used to power the heating element.

• Total electronic switching prevents the voltage and current

sensitive components against transient spikes sometimes

caused by other units using mechanical switching circuits.

• This unit has a linear LCD readout which accurately indicates

the temperature of the t

ip.

Working temperature

• Soldering at the correct temperature is very important to ensure

perfect solder connection.

• If the temperature is too low the solder will not flow correctly

and will cause cold solder joints.

• If the temperature is to high, the flux will be burned and not

allow the solder t

oo flow.

• High temperatures can also cause damage to the printed circuit

board and other sensitive components.

• When the tip working temperature is set within the co

rrect

parameters suited to the particular solder being

used, a good joint is assured.

• The most common solder alloys used in the electronics

industry are 60% tin, 40% lead (60/40).

Introduction

Carefully read and understand this manual and any label attached

to the tool before use. Keep these instructions with the product for

future reference. Ensure all persons who use and service this

product are acquainted with this manual.

Electrical Safety Information

• The wires in this product are coloured:

Blue Neutral (N)

Brown Live (L)

Green & Yellow Earth (E)

• As the colours may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

• The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black, the

wire which is coloured brown must be connected to the terminal

which is marked L or coloured red.

• This appliance must be protected by a suitable fuse.

• To prevent fire or shock hazard, do not expose this product to

rain/water or moisture. There are no user serviceable parts inside

except those referred to in this manual. Always refer servicing to

qualified service personnel. Never remove any part of the casing

unless qualified to do so; this unit contains dangerous voltages.

• Use of a residual current device (RCD) will reduce the risk of

electric shock.

NEVER CONNECT THE BROWN OR BLUE WIRE TO THE

EARTH PIN OF THE 13 AMP PLUG. IF IN DOUBT CONSULT A

QUALIFIED ELECTRICIAN

General Safety Instructions

Even when used as prescribed it is not possible to eliminate all

residual risk factors. Use with caution.

Keep guards in position

• Always keep guards in position, in good working order, correctly

adjusted and aligned. Never attempt to use a power tool without

any guard supplied with it.

Remove adjusting keys

• Always check to see that keys and adjusting wrenches are

removed from power tool before turning on.

Clean work area

• Accidents occur where benches and work areas are cluttered

or dirty, floors must be kept clear, avoid working where the floor is

slippery.

Dangerous environment

• Do not use power tools in damp or wet conditions, or expose

them to rain. Provide adequate surrounding work space and keep

area well lit. Do not use power tools where there is a risk of

explosion or fire from combustible material, flammable liquids,

flammable gases or dust of an explosive nature. When using

power tools avoid contact with any earthed items such as pipes,

radiators, cookers, refrigerators, metal baths and taps.

Children & pets

• Children and pets should always be kept at a safe distance from

your workshop child-proof. Lock tool away where children can't get

access to them. Remove batteries from cordless tools.

Use the correct power tool

• Don't force, or attempt to use a power tool for a purpose it was

not designed for. Do not use a small tool to do the job of a heavy

duty tool.

Wear correct clothing and footwear.

• Don't wear loose clothing, neckties or jewellery or other items

which may get caught in moving parts. Wear non-slip footwear,

cover or tie back long hair. Use safety footwear if necessary.

Protect your head

• Wear safety goggles at all times, every day glasses are not

sufficient for eye protection, as lenses are not impact resistant

and could shatter. Use an approved face or dust mask when

operation creates dust. Ensure dust extraction equipment is

functioning and correctly used. Hearing protection should be used

if the sound intensity level for the operator could exceed 85dB(A).

Use a hard hat where there is a risk of falling objects or striking

your head on low level obstructions.

Protect yourself from vibration.

• Hand held power tools may produce vibration. Vibration can

cause disease. Gloves to keep the operator warm and dry and

therefore maintain good blood circulation in the fingers may help.

This tool has not been designed for extended or industrial

operation.

Secure work

• Always secure work. Where practical use a clamp or vice, it will

allow you to use both hands to operate your power tool.

Keep your balance

• Don't over reach, keep proper footing at all times to ensure

correct balance.

Maintain your power tool

• Keep your power tool in good working order, keep tools sharp and

clean for best and safest performance. Ensure ventilation holes

are kept clean and unrestricted at all times.

Always disconnect.

• Before changing tools, always ensure they are disconnected from

the power source.

Accessories

• The use of any attachment or accessory other than those

mentioned in this manual could result in damage or injury. The

use of improper accessories could be dangerous.

Never stand on your power tool

• Standing on your power tool or its stand could cause serious

injury if the tool is tipped or if the cutting tool is accidentally

contacted. Do not store materials above or near the tool so that it

is necessary to stand on the tool or its stand to reach them.

Switch off before connecting.

• Ensure the power tool is switched

off before connecting to the

power source. If the power tool stops unexpectedly turn the power

switch to off.

Do not abuse the power cord.

• Be sure your cable/extension cable is properly wired and in good

condition. Always replace a damaged cable/extension cable or

have it repaired by a qualified person before using it. Never yank

or pull the cable to disconnect it from the power socket. Never

carry your power tool by it’s cable. Keep the cable away from

damp, heat, oil, solvents, and sharp edges.

Check for damaged or missing parts

.

• Before each use check if any part of the power tool is damaged or

missing, check carefully that it will operate properly and perform

its intended function. Check alignment of moving parts for binding.

Any guard or other part that is damaged should be correctly

repaired or replaced. Do not use if the power switch does not turn

the power on and off. Check any other condition that may affect

the safety of the power tool. DO NOT USE IF DEFECTIVE.

Direction of feed

• Feed work into a blade or cutter against the direction of rotation of

the blade or cutter only.

Don’t leave the tool running unattended

• Always wait until your power tool has come to a complete stop

before leaving it and then disconnect from power source.

FUSE

BROWN

(Live)

BLUE

(Neutral)

E

L

N

FUSE

GREEN/YELLOW

OR GREEN

FUSE

BROWN

(Live)

BLUE

(Neutral)

E

L

N

FUSE

Double Insulated

Earthed

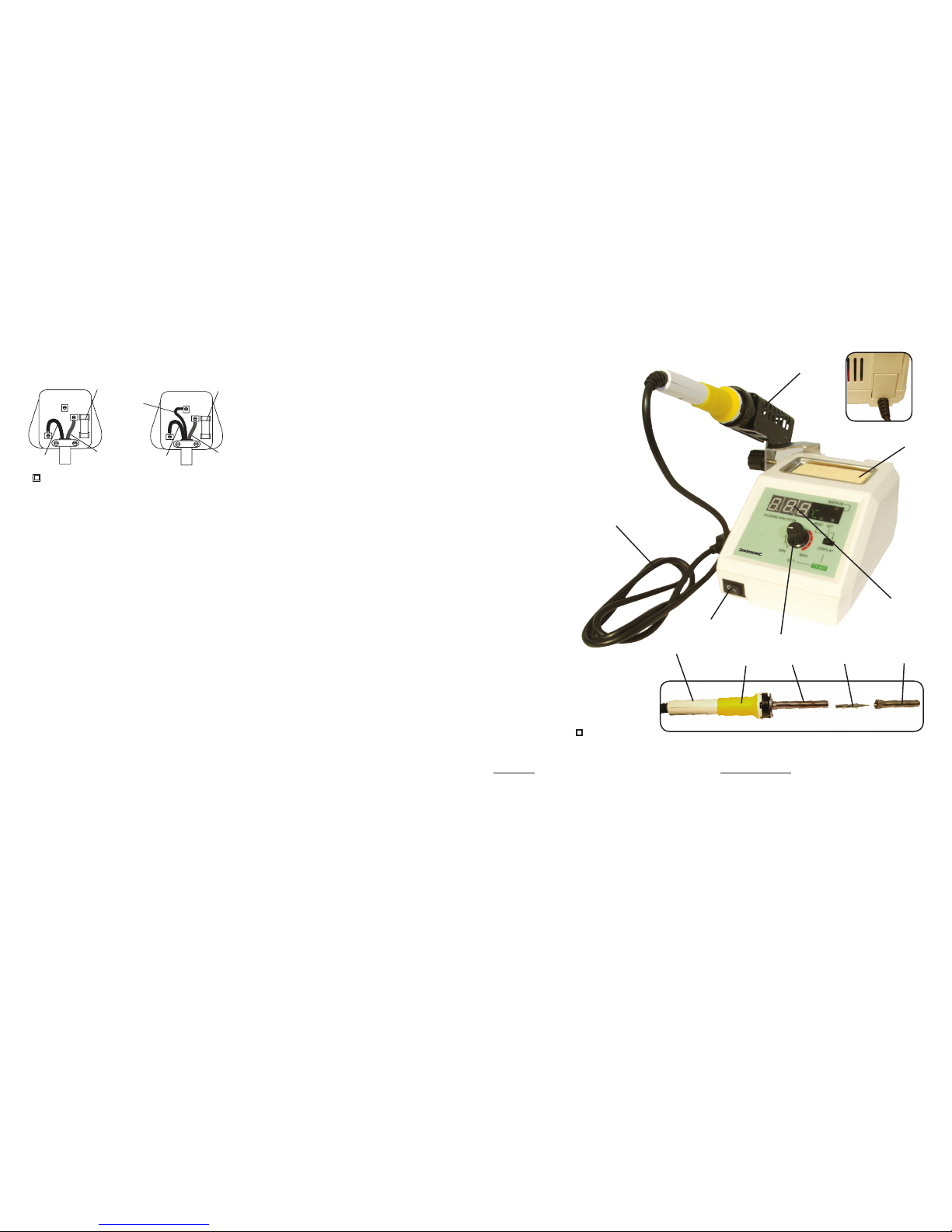

1. Fuse holder (rear)

Use 1A MGP fuse only

2. Temperature display

3. Heat resistant silicone cable

4. Handle

5. Collar

6. Magnet

7. Soldering iron tip

8. Knurled nut barrel assembly

9. Power switch

10. Temperature adjustment

11. Tip cleaning sponge

12. Iron holder

SPECIFICATION:

Input v

oltage: 230V

Frequency:

50Hz

Heater operating voltage:

24V

Wattage:

48W

Unit fuse rating

1A

Temperature range

: 150°C-420°C

(302°F-788°F)

Double insulated

:

2.

3.

9.

10.

11.

12.

1.

4.

8.

7.

6.

5.

Fig 1.

Fig 2.

Page 3

Common working tip temperature of 60/40 solder

(This may vary from manufacturer to manufacturer)

Melting point: 419

°F (215°C)

Normal operation: 518

°F - 572°F

(270°C - 300°C)

Production line operation: 608

°F - 716°F

(320

°C - 380°C)

De-soldering operation for

small joint: 599

°F (315°C)

De-soldering operation f

or

larger joint: 752

°F (400°C)

Care of the tip

The tip supplied is iron plated copper. If used properly , it will give

many hours of use.

• Always keep tips tinned before switching off or storing for

any period of time

.

• Wipe only BEFORE use.

• Do not keep the iron set at high temperature for a long period

of time as this will break down the surface of the tip.

• NEVER clean the tip with coarse abrasive materials or files.

• If an oxide film does form it can be cleaned by lightly rubbi

ng

with 600-800 grit emery cloth, isopropyl alcohol or equivalent and

then immediately reheat and re-tin the tip to prevent oxidation

of the wettable surface.

• Remove the tip and clean after every 24 hours of use, or at least

once a week, and remove any loose build up in the barrel.

• Do not use fluxes containing chloride or acid.

• Use only rosin or activated resin fluxes.

• Do no use any compound or anti-seize materials on the

wettable surface.

MAINTENANCE

• The soldering iron must be placed on its stand when not in

use.

• If the supply cord is damaged, it must be replaced by a

qualified person.

Tip replacement and dressing

NOTE: Tip replacement or cleaning should be done only when the

iron is at room temper

ature.

• The tip can be changed or replaced simply by unscrewing the

knurled nut barrel assembly.

(Fig 2.(8)

NOTE: The station must be switched off and disconnected from the

power su

pply, and allowed to cool before and during this process as

damage may result if the unit is left on without the tip inserted.

• After removing the tip blow out any oxide dust that may have

formed in the tip retaining area of the barrel.

NOTE: Use suitable eye protection.

• Replace the tip and screw the retaining knurled nut

barrel assembly, using only hand pressure to tighten.

• Pliers should only be used to tighten the nut if loosening

should occur when the iron is hot to avoid personal injury.

• Care should be taken to not over tighten as this will

damage the element.

General cleaning

• The outer casing of the iron and station may be cleaned with a

damp cloth using small amounts of liquid detergent.

• NEVER immerse the unit in liquid or allow any liquid to enter

the case of the station.

• NEVER use solvent to clean the case.

Loading...

Loading...