Page 1

C8051F96x/Si102x

UDP C8051F960/Si1020 MCU CARD WITH EMIF

U

SER’S GUIDE

1. Introduction

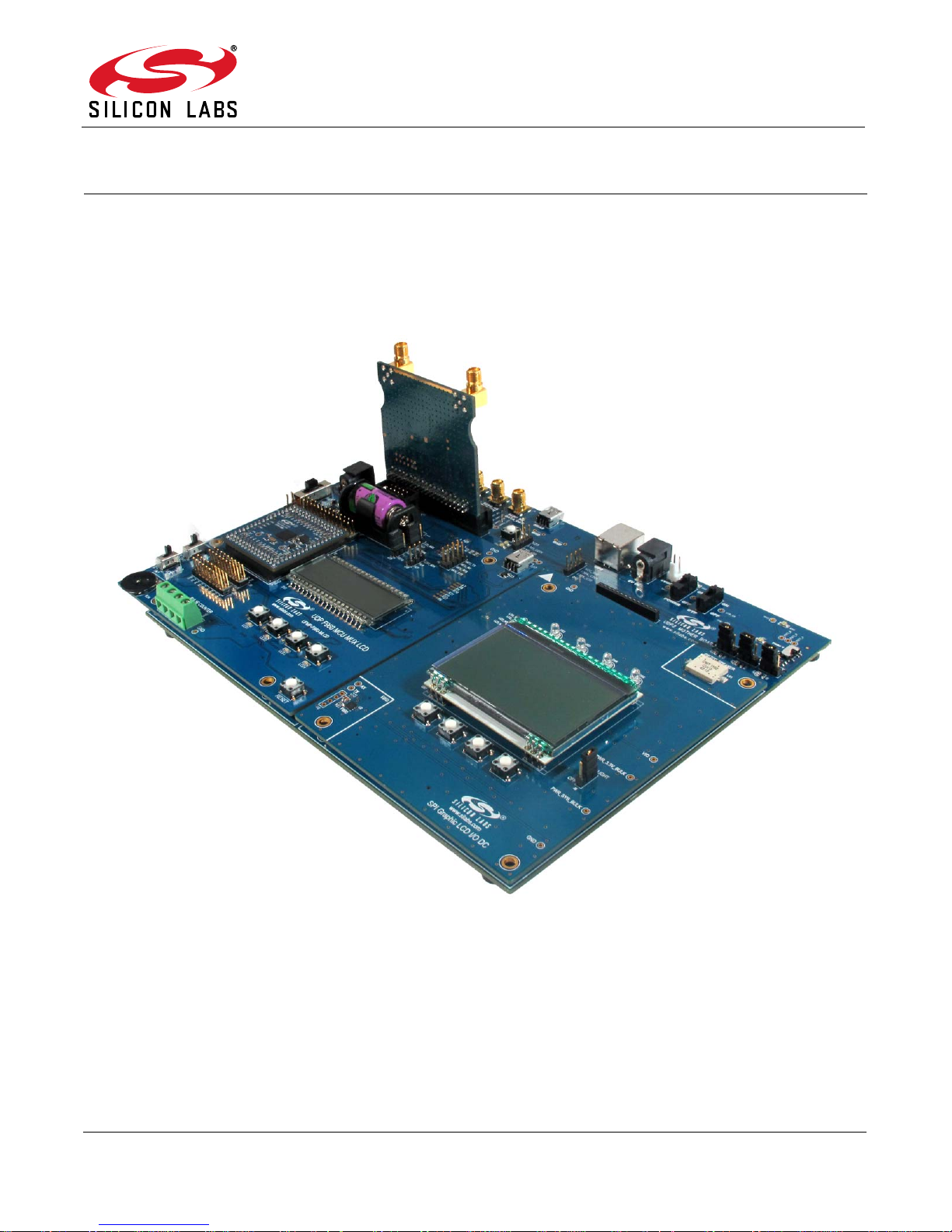

The Unified Development Platform (UDP) provides a development and demonstration platform for Silicon

Laboratories microcontrollers and the Silicon Laboratories software tools, including the Silicon Laboratories

Integrated Development Environment (IDE).

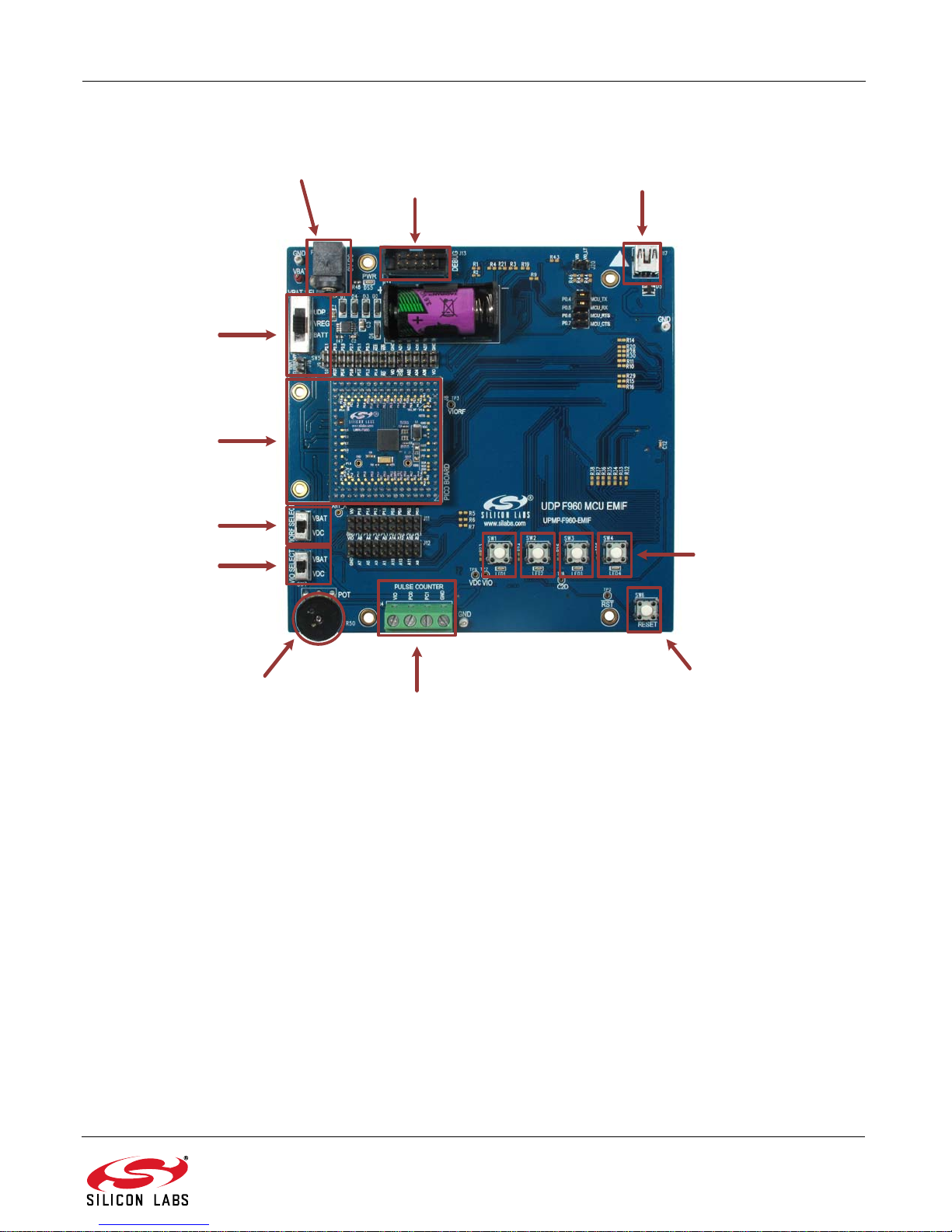

Figure 1. Unified Development Platform

Rev. 0.2 2/14 Copyright © 2014 by Silicon Laboratories C8051F96x

Page 2

C8051F96x/Si102x

2. Relevant Documents

This document provides a hardware overview for the Unified Development Platform (UDP) system UDP

C8051F960/Si1020 MCU Card with EMIF. Additional information on the UDP system can be found in the

documents listed in this section.

2.1. Motherboard User’s Guide

The UDP Motherboard User’s Guide contains information on the motherboard features and can be found at

www.silabs.com.

2.2. Card User’s Guides

The UDP MCU Card and Radio Card User’s Guides can be found at www.silabs.com.

2 Rev. 0.2

Page 3

C8051F96x/Si102x

USB Debug Adapter

USB

Connectivity

Power

Adapter (P1)

VBAT

Switch

VIORF

Switch

VIO

Switch

3. Hardware Setup

3.1. Using the MCU Card Alone

Refer to Figure 2 for a diagram of the hardware configuration when using the MCU card without a UDP

motherboard.

1. Connect the USB Debug Adapter to the 2x5 debug connector on the MCU card with the 10-pin ribbon

cable.

2. Connect one end of the USB cable to the USB connector on the USB Debug Adapter.

3. Connect the other end of the USB cable to a USB Port on the PC.

4. Move the SW5 VBAT switch to the middle VREG position.

5. Move the SW7 VIO switch to the upper VBAT position.

6. Move the SW12 VIORF switch to the upper VBAT position.

7. Connect the 9 V DC adapter to P1.

Notes:

Use the Reset button in the IDE to reset the target when connected using a USB Debug Adapter.

Remove power from the MCU card and the USB Debug Adapter before connecting or disconnecting the

ribbon cable from the MCU card. Connecting or disconnecting the cable when the devices have powe r can

damage the device and/or the USB Debug Adapter.

Figure 2. Hardware Setup Using the MCU Card Alone

Rev. 0.2 3

Page 4

C8051F96x/Si102x

USB Debug Adapter

Power

Adapter

(J20)

USB

Connector

(J16)

VBAT

Switch

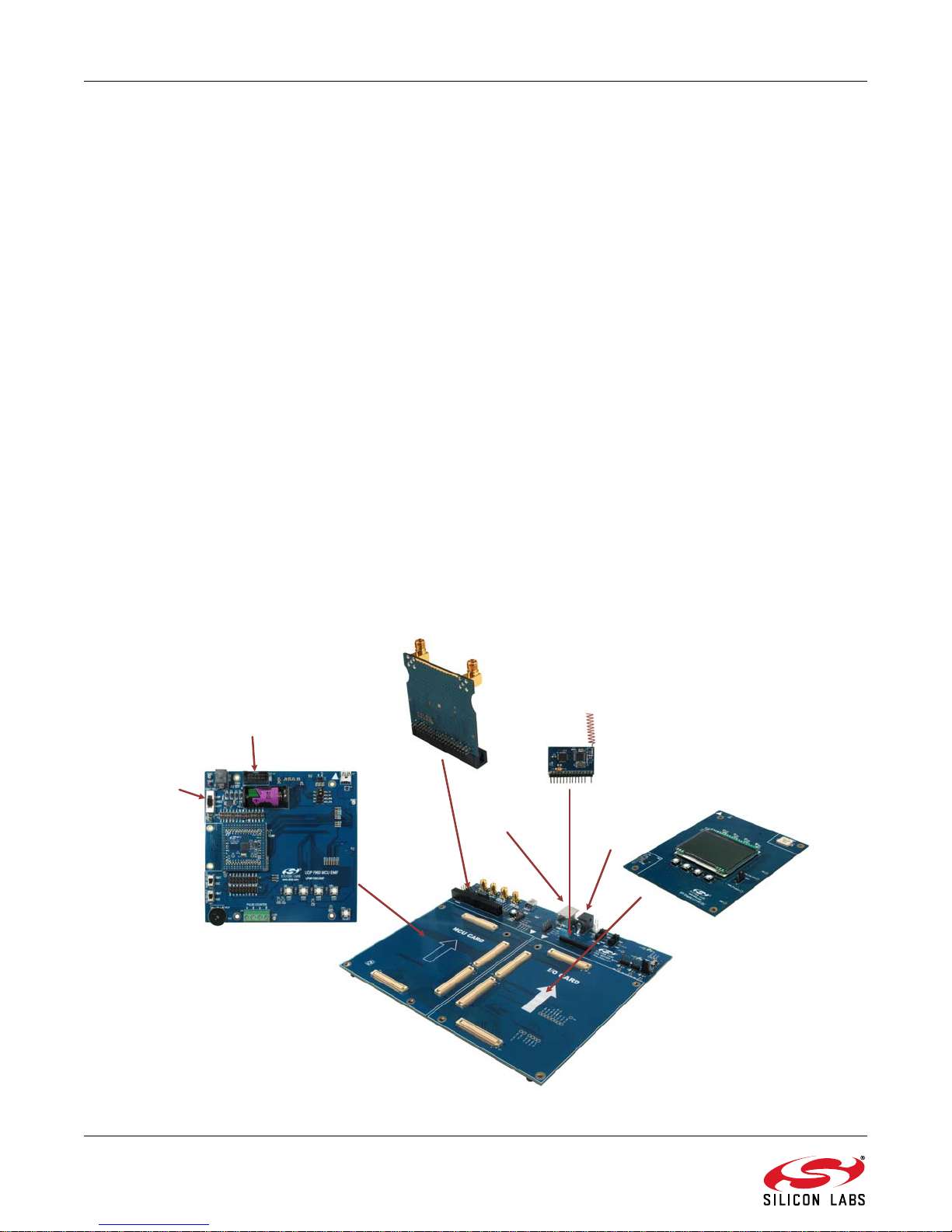

3.2. Using the MCU Card with the UDP Motherboard

Refer to Figure 3 for a diagram of the hardware configuration when using the MCU card with a UDP motherboard.

1. Connect the MCU card to the UDP motherboard slot.

2. (Optional) Connect the I/O card to the UDP motherboard slot.

3. (Optional) Connect a radio card to the radio card slot in the UDP motherboard.

4. (Optional) Connect an EZLink card to the EZLink card slot in the UDP motherboard.

5. Connect the USB Debug Adapter to the 2x5 debug connector on the MCU card with the 10-pin ribbon

cable.

6. Connect one end of the USB cable to the USB connector on the USB Debug Adapter.

7. Connect the other end of the USB cable to a USB Port on the PC.

8. Connect the ac/dc power adapter to power jack J20 on the UDP motherboard. The board can also be

powered from the J16 USB or J1 mini USB connectors.

9. Move the SW5 VBAT switch on the MCU card to the VREG position.

10. Move the SW7 VIO switch on the MCU card to the upper VBAT position.

11. Move the SW12 VIORF switch on the MCU card to the upper VBAT position.

12. Move the S3 power switch on the UDP motherboard to the ON position.

Notes:

Use the Reset button in the IDE to reset the target when connected using a USB Debug Adapter.

Remove power from the target boa rd and the USB De bug Adapter before connecting or disconnecting the

ribbon cable from the target board. Connecting or disconnecting the cable when the devices have power

can damage the device and/or the USB Debug Adapter.

Th e MCU card can be used alone without th e motherboard . However, the motherboard must be power ed if

an MCU card is connected.

Figure 3. Hardware Setup Using the Unified Development Platform

4 Rev. 0.2

Page 5

C8051F96x/Si102x

4. Software Setup

Simplicity Studio greatly reduces development time and complexity with Silicon Labs EFM32 and 8051 MCU

products by providing a high-powered IDE, tools for hardware configuration, and links to helpful resources, all in

one place.

Once Simplicity Studio is installed, the application itself can be used to install additional software and

documentation components to aid in the development and evaluation process.

The following Simplicity Studio components are required for the C8051F960 Development Kit:

8051 Products Part Support

Simplicity Developer Platform

Download and install Simplicity Studio from www.silabs.com/8bit-software or www.silabs.com/simplicity-studio.

Once installed, run Simplicity Studio by selecting St art

from the start menu or clicking the Simplicity Studio shortcut on the desktop. Follow the instructions to install the

software and click Simplicity IDE to launch the IDE.

The first time the project creation wizard runs, the Setup Environment wizard will guide the user through the

process of configuring the build tools and SDK selection.

In the Part Selection step of the wizard, select from the list of installed parts only the parts to use during

development. Choosing parts and families in this step affects the displayed or filtered parts in the later device

selection menus. Choose the C8051F96x family by checking the C8051F96x check box. Modify the part selection

at any time by accessing the Part Management dialog from the Window

Studio

Simplicity Studio can detect if certain toolchains are not activated. If the Licensing Helper is displayed after

completing the Setup Environment wizard, follow the instructions to activate the toolchain.

Part Management menu item.

Figure 4. Simplicity Studio

Silicon LabsSimplicity StudioSimplicity Studio

PreferencesSimplicity

Rev. 0.2 5

Page 6

C8051F96x/Si102x

4.1. Running Blinky

Each project has its own source files, target configuration, SDK configuration, and build configurations such as the

Debug and Release build configurations. The IDE can be used to manage multiple projects in a collection called a

workspace. Workspace settings are applied globally to all projects within the workspace. This can include settings

such as key bindings, window preferences, and code style and formatting options. Project actions, such as build

and debug are context sensitive. For example, the user must select a project in the Project Explorer view in order

to build that project.

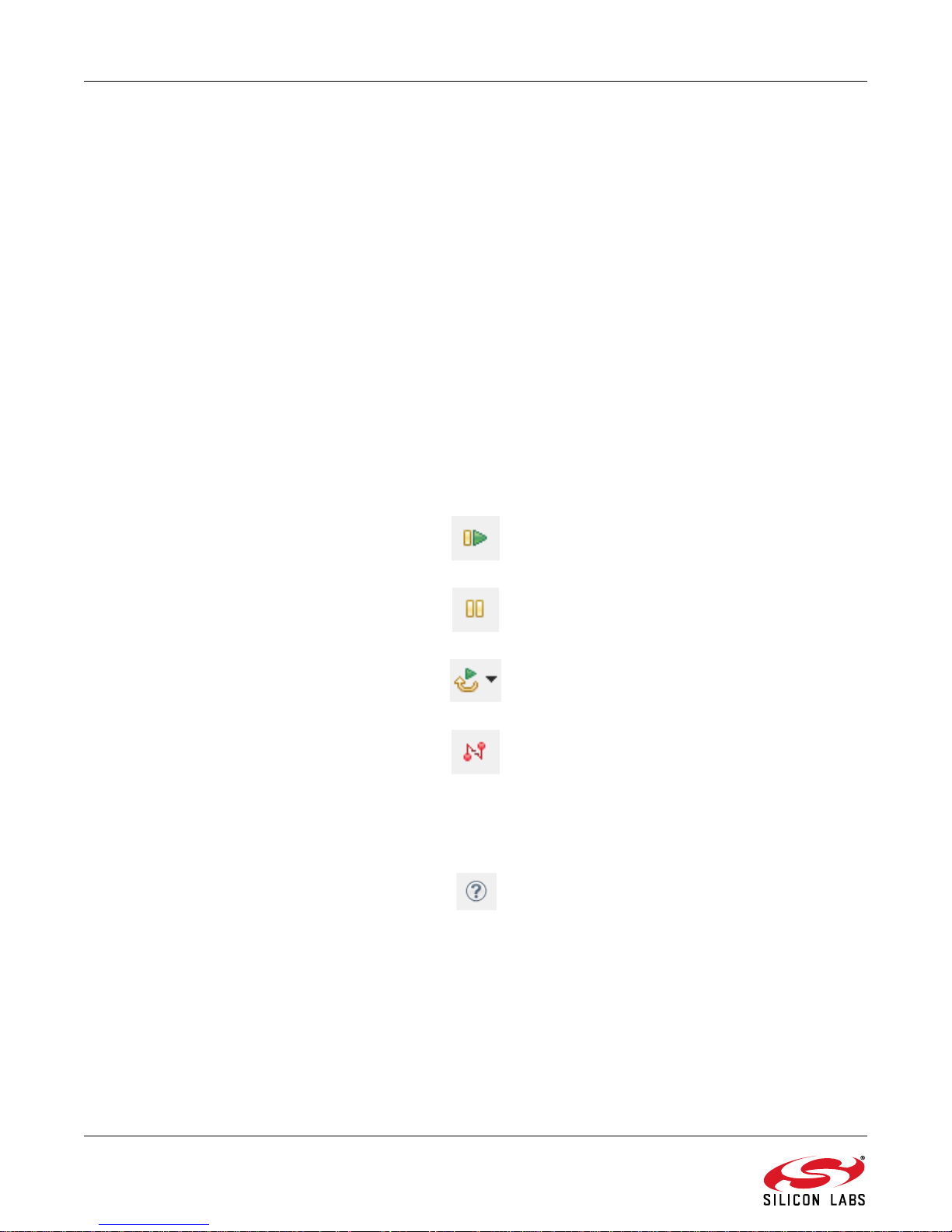

To create a project based on the Blinky example:

1. Click the Simplicity IDE tile from the Simplicity Studio home screen.

2. Click the Create new project link from the welcome screen or go to File

Project.

3. In the Kit drop-down, select C8051F960 Development Kit, in the Part drop-down, select C8051F960, and

in the SDK drop-down, select the desired SDK. Click Next.

4. Select Example and click Next.

5. Under C8051F960 Development Kit in the Blinky folder, select F96x Blinky and click Finish.

6. Click on the project in the Project Explorer and click Build, the hammer icon in the top bar. Alternatively,

go to Project

7. Click Debug to download the project to the hardware and start a debug session.

8. Press the Resume button to start the code running. The LED should blink.

Build Project.

NewSilicon Labs MCU

9. Press the Suspend button to stop the code.

10. Press the Reset the device button to reset the target MCU.

11. Press the Disconnect button to return to the development perspective.

4.2. Simplicity Studio Help

Simplicity Studio includes detailed help information and device documentation within the tool. The help contains

descriptions for each dialog window. To view the documentation for a dialog, click the question mark icon in the

window:

This will open a pane specific to the dialog with additional details.

The documentation within the tool can also be viewed by going to Help

Help Contents or HelpSearch.

6 Rev. 0.2

Page 7

C8051F96x/Si102x

4.3. Legacy 8-bit IDE

Note: Using the Simplicity Studio tools with the C8051F960 Development Kit is recommended. See section 4. "Software

Setup‚" on page 5 for more information.

Download the 8-bit software from the website (www.silabs.com/8bit-software) or use the provided installer on the

CD-ROM to install the software tools for the C8051F96x devices. After installation, examples can be found in

...\Examples\C8051F96x or ...\Examples\Si102x_3x in the installation directory. At a minimum, the C8051F960

DK requires:

Silicon Labs IDE—Software enabling initial evaluation, development, and debugging.

Configuration Wizard 2—Initialization code generation software for the C8051F96x devices.

Keil C51 Tools—Keil 8051 Compiler/Assembler/Linker toolchain.

CP210x Drivers—Virtual COM Port (VCP) drivers for th e CP210x COM interface. More information on this

installation process can be found in Section Figure 3.

Other software available includes:

Keil µVision Driver—Driver for the Keil µVision IDE that enables development and debugging on

C8051Fxxx MCUs.

Flash Programming Utilities and MCU Production Programmer—Programming utilities for the

production line. More information on the available programming options can be found on the website:

http://www.silabs.com/products/mcu/Pages/ProgrammingOptions.aspx.

ToolStick Development Tools—Software and examples for the ToolStick development platform. More

information on this platform can be found at www.silabs.com/toolstick.

Also available on the 8-bit software webpage is the Battery Life Estimator, which gives designers a quick and easy

way to understand the discharge characteristics of different system configurations to help optimize low-power

applications.

The development kit includes the latest version of the C51 Keil 8051 toolset. This toolset is initially limited to a code

size of 2 kB and programs start at code address 0x0800. After registration, the code size limit is removed entirely

and programs will start at code address 0x0000.

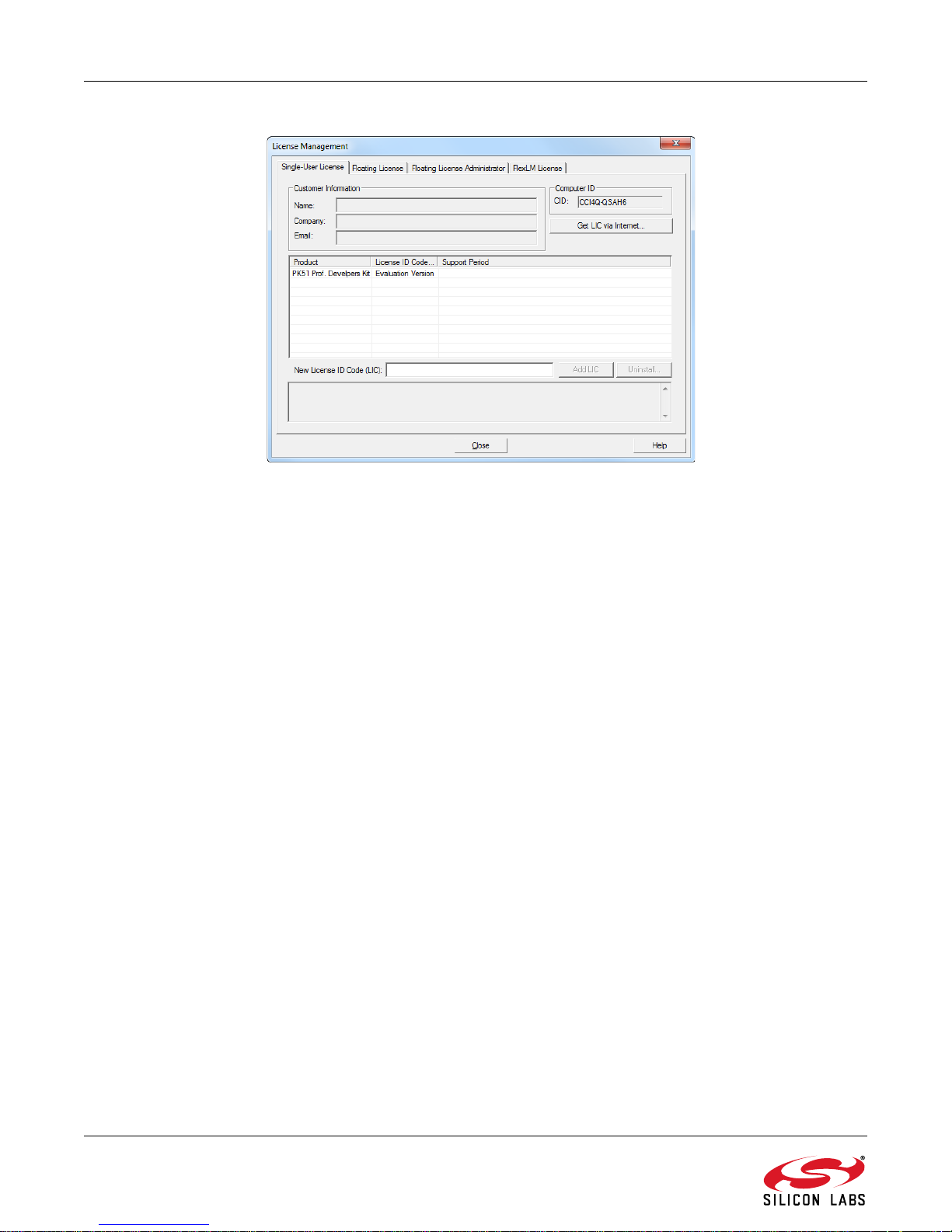

To register the Keil toolset:

1. Find the Product Serial Number printed on the CD-ROM. If you no longer have this serial number,

register on the Silicon Labs website (www.silabs.com/8bit-software) to obtain the serial number.

2. Open the Keil µVision4 IDE from the installation directory with administrative privileges.

3. Select File

License Management to open the License Management window.

Rev. 0.2 7

Page 8

C8051F96x/Si102x

Figure 5. Keil µVision4 IDE License Management Window

4. Click on the Get LIC via Internet... button to open the Obtaining a License IDE Code (LIC) window.

5. Press OK to open a browser window to the Keil website. If the window doesn’t open, navigate to

www.keil.com/license/install.htm.

6. Enter the Silicon Labs Product Serial Number printed on the CD-ROM, along with any additional required

information.

7. Once the form is complete, click the Submit button. An email will be sent to the provided email address

with the license activation code.

8. Copy the License ID Code (LIC) from the email.

9. Paste the LIC into the New License ID Code (LIC) text box at the bottom of the License Management

window in µVision4.

10. Press the Add LIC button. The window should now list the PK51 Prof. Developers Kit for Silabs as a

licensed product.

11. Click the Close button.

4.4. CP210x USB to UART VCP Driver Installation

The MCU Card includes a Silicon Labs CP210x USB-to-UART Bridge Controller. Device drivers for the CP210x

need to be installed before the PC software can communicate with the MCU through the UART interface. Use the

drivers included CD-ROM or download the latest drivers from the website (www.silabs.com/interface-software).

1. If using the CD-ROM, the CP210x Drivers option will launch the appropriate driver installer . If downloading

the driver package from the website, unzip the files to a location and run the appropriate installer for the

system (x86 or x64).

2. Accept the license agreement and follow the steps to install the driver on the system. The installer will let

you know when your system is up to date. The driver files included in this installation have been certified by

Microsoft.

3. To complete the installation process, connect the included USB cable between the host computer and the

COM PORT USB connector (J5) on the MCU Card. Windows will automatically finish the driver installation.

Information windows will pop up from the taskbar to show the installation progress.

4. If needed, the driver files can be uninstalled by selecting Windows Driver Package—Silicon

Laboratories... option in the Programs and Features window.

8 Rev. 0.2

Page 9

C8051F96x/Si102x

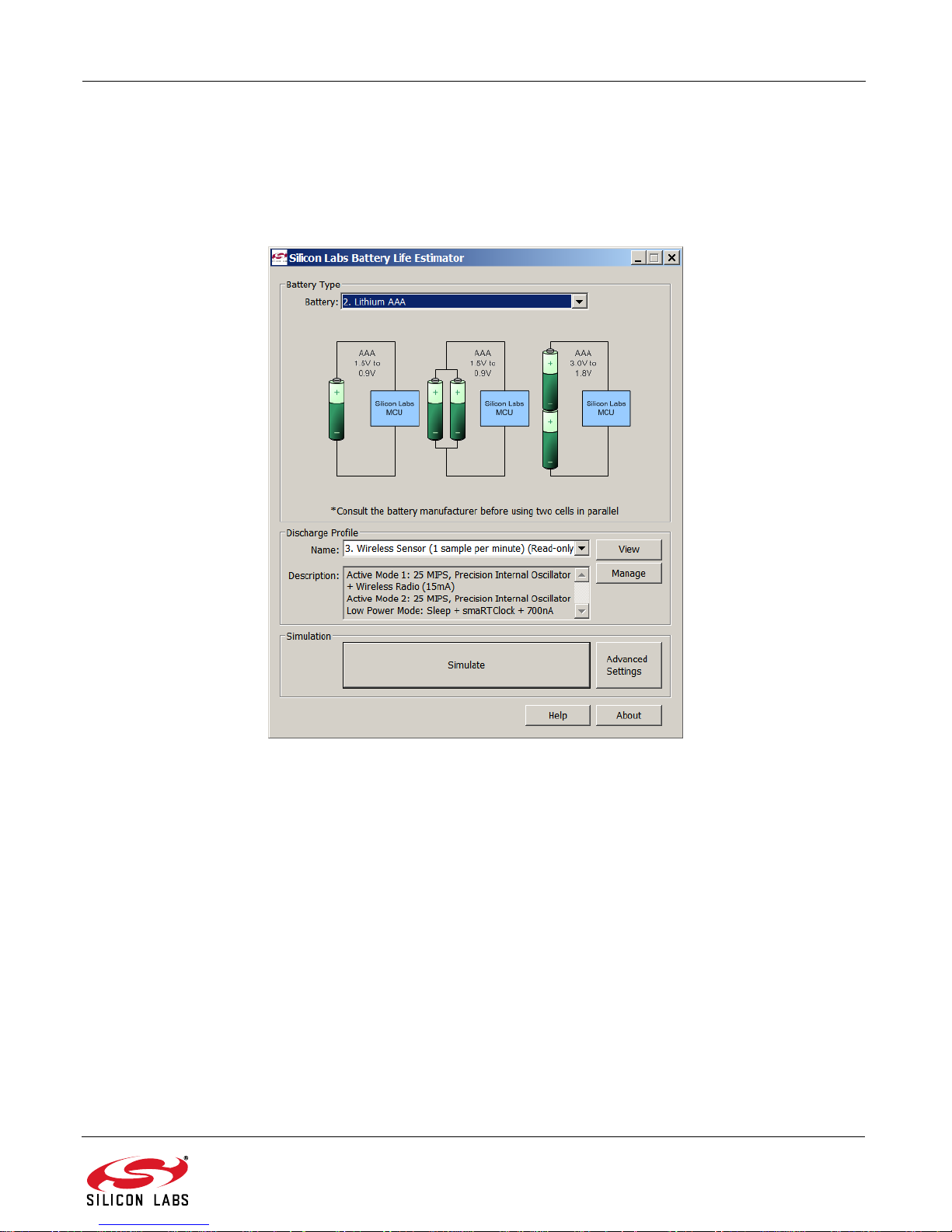

4.5. Silicon Labs Battery Life Estimator

The Battery Life Estimator is a system design tool for battery operated devices. It allows the user to select the type

of battery they are using in the system and enter the supply current profile of their application. Using this

information, it performs a simulation and provides an estimated system operating time. The Battery Life Estimator

is shown in Figure 6.

From Figure 6, the two inputs to the Battery Life Estimator are battery type and discharge profile. The utility

includes battery profiles for common battery types such as AAA, AA, A76 Button Cell, and CR2032 coin cell. The

discharge profile is application-specific and describes the supply current requirements of the system under various

supply voltages and battery configura tions. The discharge profile is independent of the selected power source.

Several read-only discharge profiles for common applications are included in the pulldown menu. The user may

also create a new profile for their own applications.

To create a new profile:

1. Select the profile that most closely matches the target application or choose the "Custom Profile".

2. Click Manage.

3. Click Duplicate.

4. Click Edit.

Profiles may be edited with the easy-to-use GUI (shown in Figure 7).

Figure 6. Battery Life Estimator Utility

Rev. 0.2 9

Page 10

C8051F96x/Si102x

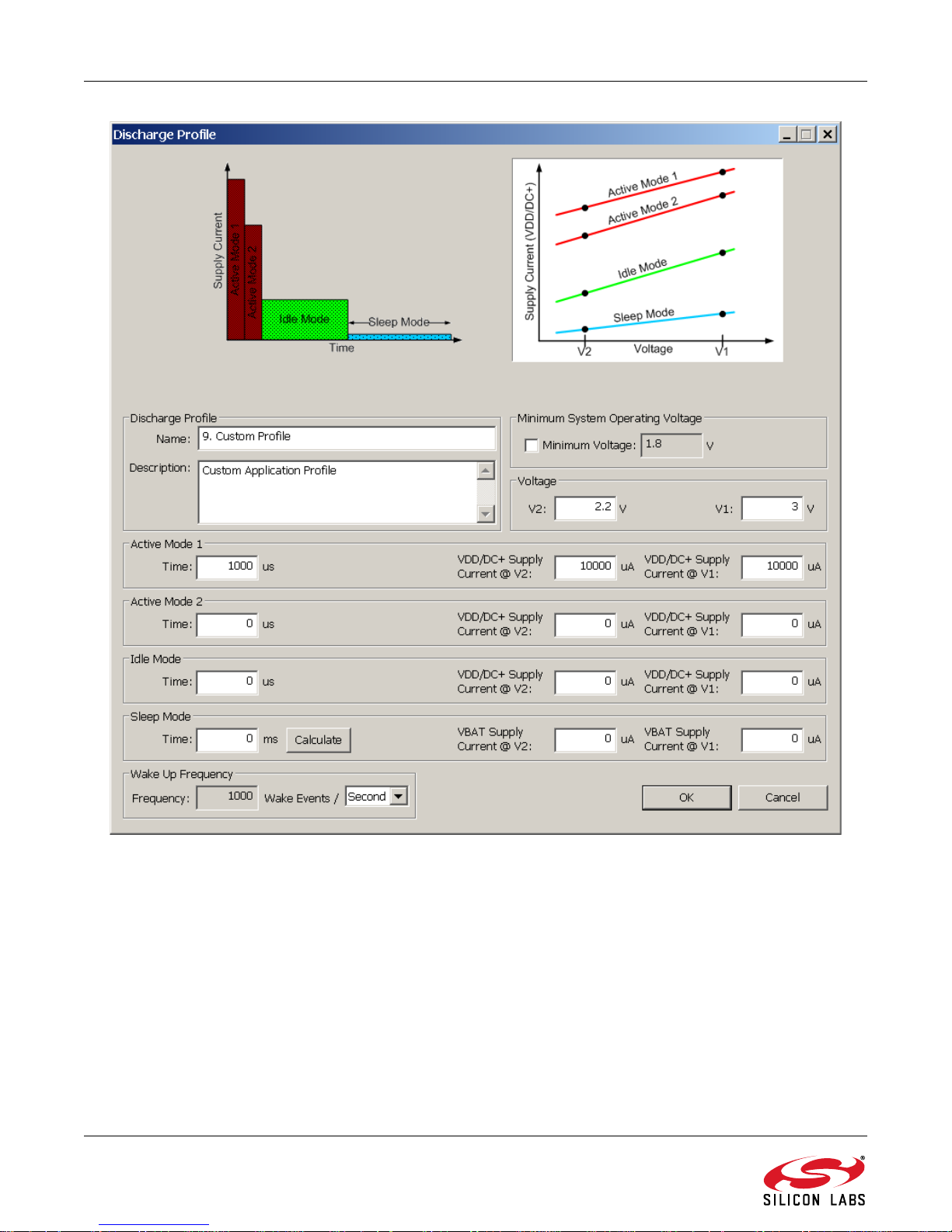

Figure 7. Battery Life Estimator Discharge Profile Editor

The Discharge Profile Editor allows the user to modify the profile name and description. The four text entry boxes

on the left hand side of the form allow the user to specify the a mount of time the system spends in each power

mode. On the right hand side, the user may specify the supply current of the system in each power mode.

Since supply current is typically dependent on supply voltage, the discharge profile ed itor provides two columns for

supply current. The V2 and V1 voltages at the top of the two column s specify the voltages at which the current

measurements were taken. The Battery Life Estimator creates a linear approximation based on the input data and

is able to feed the simulation engine with an approximate supply current demand for every input voltage.

The minimum system operating voltage input field allows the system operating time to stop increasing when the

simulated battery voltage drops below a certain threshold. This is primarily to allow operating time estimates for

systems that cannot operate down to 1. 8 V, which is the voltage of two fully drained single-cell batteries plac ed in

series.

10 Rev. 0.2

Page 11

C8051F96x/Si102x

The wakeup frequency box calculates the period of a single iteration through the four power modes and displays

the system wake up frequency. This is typically the "sample rate" in low power analog sensors.

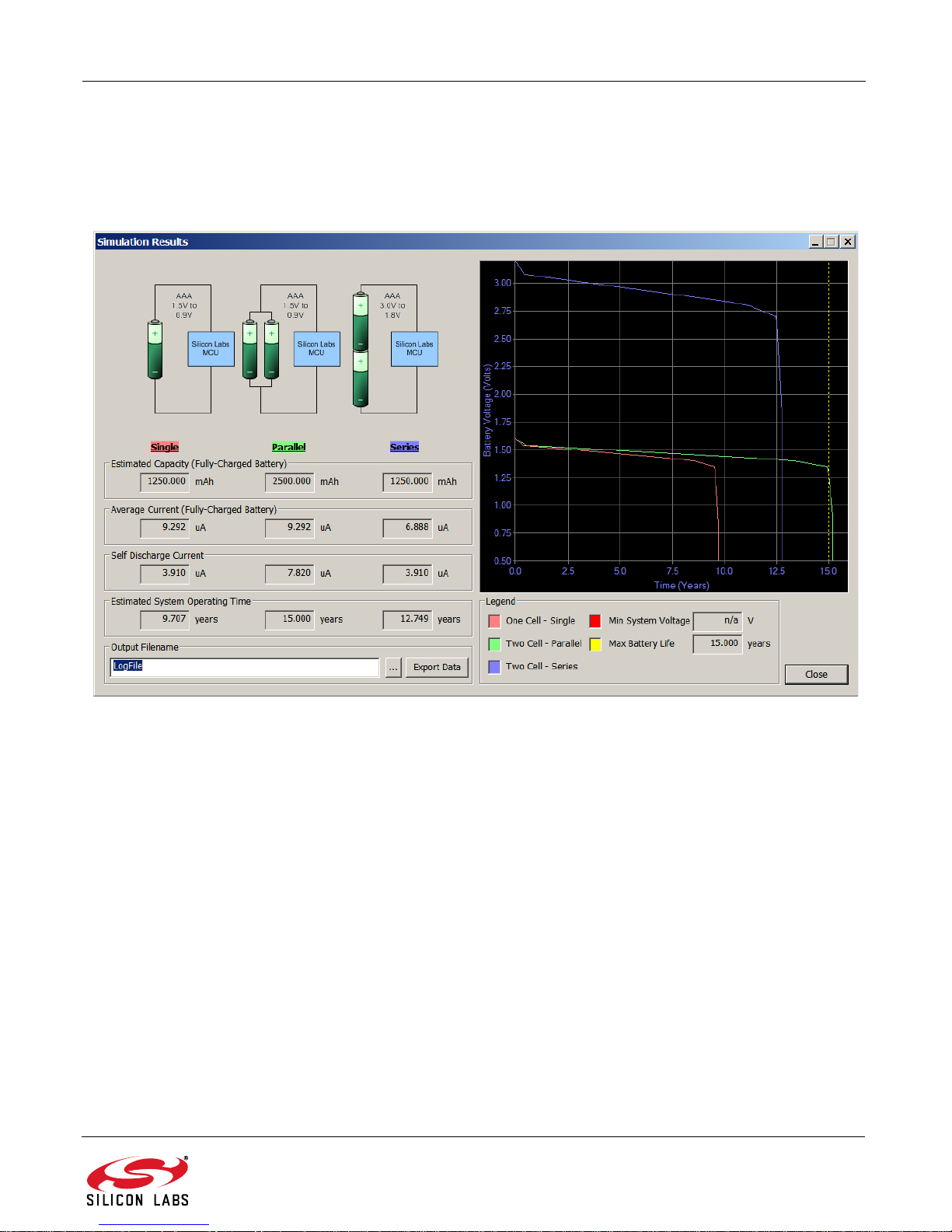

Once the battery type and discharge profile is specified, the user can click the "Simulate" button to start a new

simulation. The simulation engine calculates the estimated battery life when using one single-cell battery, two

single-cell batteries in series, and two single-cell batteries in parallel. Figure 8 shows the simulation output window.

Figure 8. Battery Life Estimator Utility Simulation Results Form

The primary outputs of the Battery Life Estimator are an e stimate d system ope ratin g time and a sim ulated gr aph of

battery voltage vs. time. Additional outputs include estimated battery capacity, average current, self-discharge

current, and the ability to export graph data to a comma delimited text file for plotting in an external graphing

application.

Rev. 0.2 11

Page 12

C8051F96x/Si102x

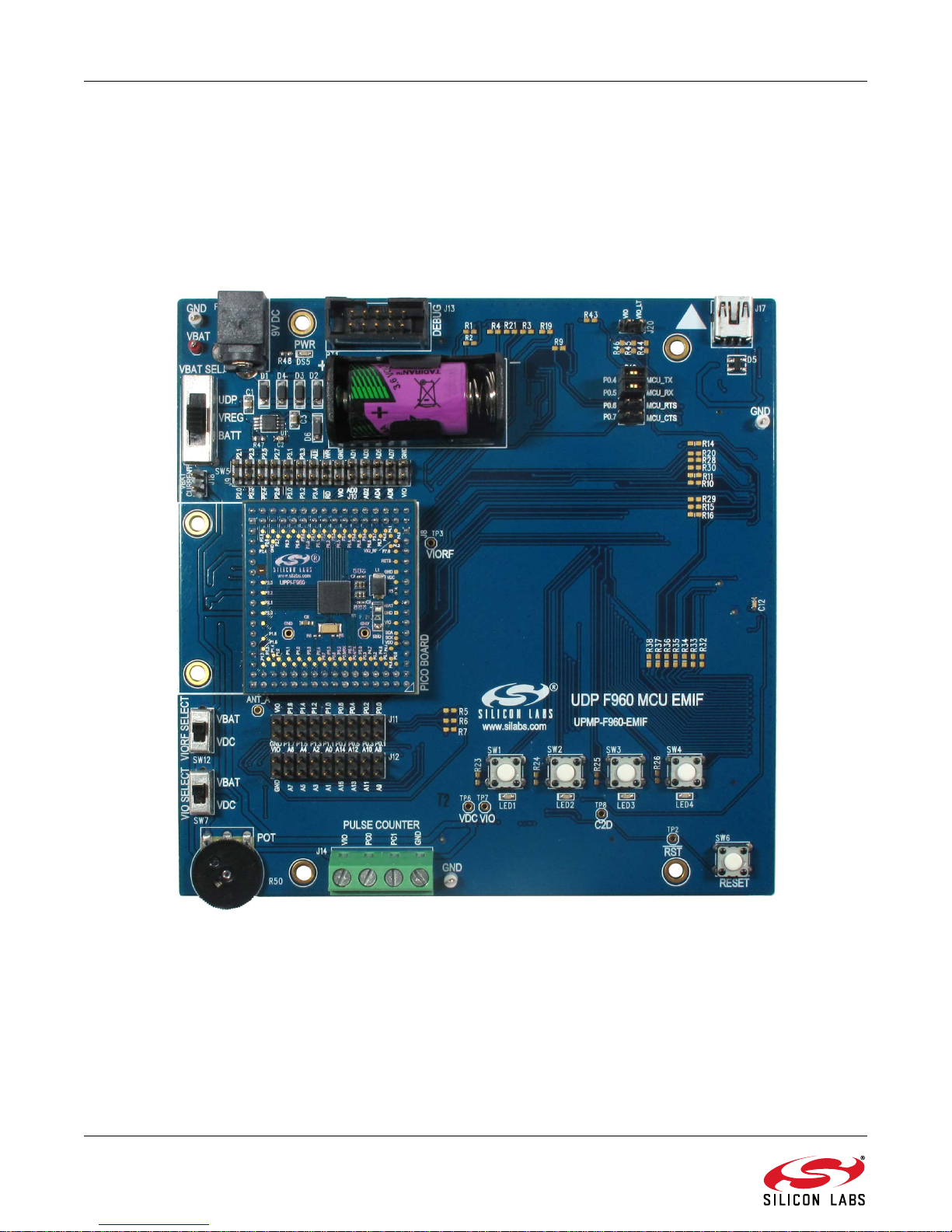

5. UDP C8051F960/Si1020 MCU Card with EMIF Overview

The C8051F96x MCU card enables application development on the C8051F960 MCU. The card connects to the

MCU Card expansion slot on the UDP motherboard and provides complete access to the MCU resources. Each

expansion board has a unique ID that can be read out of an EEPROM or MCU on the board, which enables

software tools to recognize the connected hardw are and automatically select the appropriate firmware image. The

target MCU card can also be detached from the UDP and used alone as a development or demonstration tool.

Figure 9 shows the C8051F96x MCU card.

Figure 10 highlights some of the features of the UDP C8051F960/Si1020 MCU Card with EMIF.

12 Rev. 0.2

Figure 9. C8051F96x UDP MCU Card

Page 13

C8051F96x/Si102x

Debug Connector

9 V Wall Adapter

Connector

VIO Switch

VIORF Switch

VBAT Switch

UPPI Pico Board

Connector

Potentiometer

Pulse Counter

Terminals

Reset Push-Button

Push-Button Switches

and LEDs

Mini-B USB

Connector

5.1. UPPI Pico Board Connector (J5, J6, J7, J8)

The UPPI Pico Board connector accommodates a variety of C8051F96x and Si102x/3x UPPI Pico Boards. The

C8051F960 MCU and Si1020 Wireless MCU UPPI Pico Boards share a common form factor. This enables the

MCU card to support a wide variety of wired and wireless applications.

The supported UPPI Pico Boards include:

The Si1020/30 UPPI Pico Boards include an EZRadioPRO

include an RF transceiver; instead, these boards support most Silicon Labs 40-pin radio test cards when used with

the Unified Development Platform Motherboard.

Figure 10. UDP C8051F960/Si1020 MCU Card with EMIF

UPPI-F960

UPPI-Si1020GMxxxTR

®

transceiver. The C8051F960 UPPI Pico Boards do not

Rev. 0.2 13

Page 14

C8051F96x/Si102x

5.2. Push-Button Switches and LEDs (SW1–SW4, LED1–LED4)

The UDP C8051F960/Si1020 MCU Card with EMIF has four push-button switches. The four switches connect to

P3.0 through P3.3. The switches are normally open and pull the pin voltage to ground when pressed.

Port pins P3.0 through P3.3 also connect to four LEDs: LED1 through LED4. The LEDs connect to VIO through a

current limiting resistor.

This multiplexing arrangement reduces the number of port pins used from eight to four. Firmware may easily use

either the LED or the switch for each port pin. When using both the LED and the switch on the same port pin,

firmware must momentarily toggle off the LED by writing a 1 to the pin’s port latch to read the push-button switch

status.

5.3. VBAT Selection Switch (SW5)

The UDP C8051F960/Si1020 MCU Card with EMIF has many power options. The VBAT selector switch (SW5)

selects the power source for the main C8051F960/Si1020 VBAT supply pin.

The center VREG position selects the output of the on-board 3.3 V re gulator (U1). This is the pr imary supp ly option

for development. The on-board regulator has multiple 5 V and 9 V power sources connected via Schottky diodes to

the regulator input. The highest voltage power source will supply power to the regulator.

The power sources for the on-board regulator (U1) are as follows:

9 V DC Wall Adapter power receptacle (P1).

Mini-B USB receptacle (J17).

10-pin Debug connector (J13).

UDP motherboard +5 V (when connected).

The BATT position selects the ultra long life 3.6 V lithium thionyl chloride battery (BT1). This batter y is a typical

power source for metering applications. The o n-boa rd r egu lator should be used primaril y for de velopment becau se

the battery has a limited peak current capacity.

The UDP position on the VBA T selector selects the UDP motherbo ard progra mmable supply (PWR_VDD_OUT) as

the power source for the UPPI Pic o Board. Use this position when using the programmable power supply under

software control.

The UDP motherboard can also provide power to the on-board regulator. The VREG position will always work with

the motherboard, while the UDP switch position requires some motherboard configuration. The UDP motherboard

User’s Guide contains additional information.

The VBAT voltage and ground are available on test points in the top-left corner of the MCU card. Use these test

points to power the board from an external lab power supply. When using a lab supply, the VBAT selector switch

should be in the BATT position with the battery removed.

5.4. Debug Header (J13)

The standard 10-pin debug header supports the Silicon Labs USB Debug Adapter. This connector provides a C2

debug connection to C8051F960/Si1020 on the UPPI Pico Board. The USB Debug Adapter supports two types of

debug connections: C2 and JTAG. When using this MCU card with the Silicon Labs IDE, select C2 in the

connection options dialog before connecting.

The USB Debug Adapter also provides a 5 V power source that can power the regulator. When powering the MCU

from the debug connector, the VBAT switch must be in the VREG position. Additionally, select the Power Target

after Disconnect check box in the Silicon Labs IDE connections options dialog to ensure the MCU always has

power.

5.5. Reset Button (SW6)

The reset push-button switch is in the lower-right corner. Pushing this button will always reset the MCU. Note that

pushing this button while the IDE is connected to the MCU will result in the IDE disconnecting from the target.

14 Rev. 0.2

Page 15

C8051F96x/Si102x

5.6. Pin Power Supply Select Switches

The C8051F960/Si1020 MCU has two VIO pins: VIO and VIORF. These VIO pins set the logic level and drive

voltage for the MCU port pins. The VIORF pin sets the level for the port pins n ormally supporting r adio functiona lity:

P1.5 through P2.3. The Si1020 P2.0-2.3 pins are connected internally to the EZRadioPRO. The VIO pin sets the

level for all other port pins.

5.6.1. VIORF Select Switch (SW12)

When using the dc-dc buck con verter to pow er the radio, set the VIOR F selector switc h to the VDC po sition. This

connects the output of the buck converter to the VIORF pin. When using the Si1020, this switch also selects the

power source for the radio. In this position, firmwar e controls the voltage on the VDC pin. The C8051F960/Si1020

buck converter also has a bypass switch that can power the radio from the full supply voltage. The dc-dc buck

converter and bypass switch are off by default after an MCU reset, so the VDC pin voltage is floating until firmware

turns on the bypass switch or configures the dc-dc converter.

When the VIORF selector switch is set to the VBAT position, the VIORF pin connects via hardware to the VBAT

pin. In this position, the dc-dc buck converter cannot power the radio.

The VBAT position powers the VIORF pin without any firmware. This position is more convenient for simple code

examples. Use this position for the code ex am p les pr ovided unless otherwise indicated.

5.6.2. VIO Select Switch (SW7)

The VIO selector switch provides the same functionality as the VIORF switch for the main VIO pin. Normally this

switch should be in the VBAT position, which will set the drive and input levels of the pins to VBAT.

Setting the switch to the VDC position connects the VIO pin to the output of the buck converter. In this position, the

battery powers the MCU, and all of the I/O port s oper ate at a lo wer vo lt age set by the buck conve rter. This option is

best if most of the I/O pins connect to a low voltage radio or other low-volt age periphe rals. Most applications should

use the VBAT position.

The C2 connection requires a VIO power source and VDC is not powered by default, so the VBAT position must be

used for initial development.

5.7. UART VCP Connection Options

The MCU card features a USB virtual COM port (VCP) UART connection via the mini-B USB connector (J17). The

VCP connection uses the CP2102 USB-to-UART bridge chip.

The UART pins on the target MCU either connect to the CP2102 USB-to-UART bridge chip or to the UDP

motherboard. The MCU card has level translators with enables that normally route the UART connections to the

on-board USB-to-UART bridge chip. However, the UDP motherboard can drive the enable pins to route the UART

connections to the UDP motherboard instead of the on-board USB-to-UART bridge chip. There are two enable

signals: one with a default pull-down (UART_VCP_EN) and one with a default pull-up (UART_SYS_EN).

When using the UART with either the on-board USB-to-UART bridge or the UDP motherboard, install shorting

blocks on header P12 to connect P0.4 to MCU_TX and P0.5 to MCU_RX.

If desired, install shorting blocks for hardware handshaking on P0.6 and P0.7 on the P12 header. Hardware

handshaking is not required for most applications. Firmware must implement hardware handshaking on the target

MCU using P0.6 and P0.7. These pins also connect to the 40-pin radio card I2C signals by default. If necessary,

disconnect these signals by cutting the traces on R9 and R10.

The MCU card includes provisions to facilitate ultra-low power measurements. The UART pins of the target MCU

are completely disconnected from the USB-to-UART bridge by removing all the shorting blocks on P12. The VIO

supply powers the level translator. To remove the level-shifter current from the ultra-low power measurement, cut

the trace on the bottom of the board between the two pins of header J20. This will completely disconnect the level

translators from VIO. After cutting this trace, a shorting block is required on J20 to use the USB-to-UART bridge or

UDP UART connection.

Rev. 0.2 15

Page 16

C8051F96x/Si102x

5.8. Potentiometer (R50)

The potentiometer is available on P1.4. To facilitate a low-power potentiometer, P2.7 connects to bottom of the

potentiometer as a potentiometer enable (POT_EN). Drive P2.7 low to enable the potentiometer. Alternatively,

install a 0 resistor for R51 to continuously enable the potentiometer.

5.9. Pulse Counter Terminals (J14)

The MCU card includes a 4-position screw terminal connection. These field-wiring terminals will accept large wire

for a commercial water or gas meter. The PC0 and PC1 signals connect to P1.0 and P1.1 on the target MCU.

These are dedicated pins for th e C8051F960/Si1020 low-power pulse counter. The VIO and ground connections

are also available for Form C meters. Refer to the C8051F960 dat a sheet for addition al infor mation abou t the pulse

counter.

5.10. Port Pin Headers (J9-J12)

All of the MCU port pins are available on the 0.100 inch headers on either side of the UPPI Pico Board.

Pins P1.2 and P1.3 are normally used for the RTC and are not connected by default to the P1.2 an d P1 .3 he ad ers.

To use P1.2 and P1.3 for other purposes, remove the RTC crystal on the UPPI Pico Board and populate the two

small adjacent resistors with 0 resistors.

When using the Si1020 UPPI Pico Board, the SPI1 pins are connected internally and do not connect to the header

pins.

16 Rev. 0.2

Page 17

C8051F96x/Si102x

5.11. C8051F96x Board Default and Optional Connections

The C8051F96x MCU card has many default and optional connections for use with different radios and the UDP

motherboard. The default connections have shorting jumpers consisting of a 603 resistor footprint with a trace

between the pads. To disconnect a default connection, cut the trace between the pads. To reconnect, install a 0

603 resistor or connect the two pads with solder. The optional connections are non-populated (no-pop) resistor

footprints. To connect, install a 0 603 resistor or connect the two pads with solder.

When using the Si1020 UPPI Pico Board, some of the MCU port pins connect to EZRadioP RO port pins by default.

Note that plugging the UPPI Pico Board into the MCU card will connect some pins together.

Table 1 shows a summary of the default and optional connections for each pin.

Table 1. MCU Pin Functions

MCU Pin

P0.0 SPI_LCD_SCK EBID_SCK

P0.1

P0.2

P0.3

P0.4/TX TX

P0.5/RX RX

P0.6 CTS EZR_I2C_SDA

P0.7 RTS EZR_I2C_SCL GPIO2

P1.0 PC0

P1.1 PC1

P1.2 XTAL3

P1.3 XTAL4

P1.4 POT EZR_ARSSI

P1.5 GPIO_1

P1.6

P1.7 EZRP_SDN

P2.0/SCK1 EZRP_SCK

P2.1/MISO1 EZRP_MISO

P2.2/MOSI1 EZRP_MOSI

P2.3/NSS1 EZRP_NSS

P2.4 PIEZO

P2.5 GPIO_0 EZRP_TX_DATA_IN/

P2.6 SPI_LCD_A0

P2.7 POT_EN

P3.0 SW1/LED1

P3.1 SW2/LED2

MCU Card Function UDP Motherboard Signal

Default Optional Default Optional

SPI_LCD_MISO EBID_MISO

SPI_LCD_MOSI EBID_MOSI

VREF SPI_LCD_NSS

EZRP_RX_DOUT/

EZRP_GPI0_1

EZRP_NIRQ

EZRP_GPIO_0

EZR_FFIT

Rev. 0.2 17

Page 18

C8051F96x/Si102x

Table 1. MCU Pin Functions (Continued)

MCU Pin

P3.2 SW3/LED3

P3.3 SW4/LED4

P3.4 RF_EBIF_NSS

P4.6 ANT_A EZR_CLKIN/

P4.7 GPIO2 EZRP_RX_CLKOUT/

5.11.1. P0.0 through P0.3

Pins P0.0 through P0.3 connect to the UDP SPI_LCD signals (SPI_LCD_SCK, SPI_LCD_MISO, SPI_LCD_MOSI,

SPI_LCD_NSS) by default. These signals support th e optional Graphical LCD display I/O card when used with the

UDB motherboard. To disconnect these default connections, cut the traces on R1 through R4. Optionally, these

signals can also connect to the EBID SPI on the 40-pin radio card. R8 provides an option to use P0.0 as a voltage

reference.

5.11.2. P0.6

Pin P0.6 connects to EZRP_I2C_SDA b y default. This si gnal supports I2C radios and EZRadio transceivers using

the 40-pin radio connector on the UDP motherboard.

5.11.3. P0.7

Pin P0.7 connects to EZRP_I2C_SCL by default. This signal supports I2C radios using the 40-pin radio connector

on the UDP motherboard. The MCU card provides optional conne ctions to co nnect P0.7 to EZ RP_RX_CL KOUT or

use P0.7 as the IREF current reference pin.

MCU Card Function UDP Motherboard Signal

Default Optional Default Optional

EZRP2_GPIO3

EZRP_GPIO2

5.11.4. P1.4

Pin P1.4 normally connects to the potentiometer. Optionally, P1.4 can connect to EZR_ARSSI. This signal supports

an analog RSSI measurement using an EZRadio 40-pin test card.

5.11.5. P1.5

Pin P1.5 connects to GPIO_1 via R15 and R29 by default. To disconnect this signal, cut the trace on R15. This

signal supports the clear-to-send (CTS) signal for EZRadioPRO.

5.11.6. P1.6

Pin P1.6 normally connects to nIRQ us ing R17. Cut the tr ace on R17 to disconnect these signals. Note that P1.7

also connects to nIRQ on the UPPI Pico Board, so a trace on the UPPI Pico Board must also be cut.

5.11.7. P1.7

Pin P1.7 connects to SDN via R18. To disconnect these signals, cut the trace on R18. P1.7 also connects to SDN

on the UPPI Pico Board, so it is necessary to also cut a trace on the UPPI Pico Board.

5.11.8. P2.4

P2.4 normally connects to the PIEZO signal. This signal drives a piezo transducer on the graphical LCD I/O card.

5.11.9. P2.5

Pin P2.5 connects to the GPIO_0 via R20 and R28 b y default. Cut the trace on R20 to disconnect these signals.

This signal supports direct mode communication with the Si1020 EZRadio.

5.11.10. P3.6

P3.6 normally connects to SPI_LCD_A0. This signal supports the Graphical LCD display I/O card.

18 Rev. 0.2

Page 19

C8051F96x/Si102x

5.11.11. EZRadio GPIO Signals

When using a Si1020 UPPI Pico Board, the four EZRadioPRO GPIO signals connect to the SMA connectors on

the motherboard.

GPIO_0 connects to EZRP_TX_DATA_IN via R20. This signal supports direct mode TX input data from an external

source using the SMA connector.

GPIO_1 connects to EZRP_RX_DOUT via R21. This signal supports direct mode RX data out of the SMA

connector. Normally, the RX data out is used with the RX clock out.

GPIO_2 connects to EZRP_RX_CLK_OUT via R22. This signal supports direct mode RX data out of the SMA

connector.

ANT_A connects to EZR_CLK_IN using R23. This provides a connection to the forth SM A co nnector. Cut the trace

on R23 when using an external 10 MHz clock with EZRadio.

5.11.12. EMIF Connections

Some of the EMIF lines also connect to the 40-pin rad io card connector. EMIF_A15/- connects to GPIO_2, and

EMIF_A14/- connects to GPIO_3. Disconnect these signals when using the EMIF in 16-bit address nonmultiplexed mode.

Table 2 describes the C8051F96x MCU card’s EMIF connections.

Table 2. MCU EMIF Connections

EMIF Configurations

MCU Pin

Non-Multiplexed Multiplexed

MCU Card Signal

Name

UDP Motherboard

Signal Name

16-bit 8-bit 16-bit 8-bit

P3.5 ALE ALE EMIF_ALE EMIF_ALE

P3.6 /RD /RD /RD /RD EMIF_RD EMIF_OEB

P3.7 /WR /WR /WR /WR EMIF_WR EMIF_WRB

P4.0 A8

P4.1 A9

P4.2 A10

P4.3 A11

P4.4 A12

P4.5 A13

P4.6 A14

P4.7 A15

P5.0 A0 A0 A8

P5.1 A1 A1 A9

P5.2 A2 A2 A10

P5.3 A3 A3 A11

P5.4 A4 A4 A12

P5.5 A5 A5 A13

P5.6 A6 A6 A14

P5.7 A7 A7 A15

P6.0 D0 D0 AD0 AD0 EMIF_D0/AD0 EMIF_A0

P6.1 D1 D1 AD1 AD1 EMIF_D1/AD1 EMIF_A1

P6.2 D2 D2 AD2 AD2 EMIF_D2/AD1 EMIF_A2

EMIF_A8/- EMIF_A16

EMIF_A9/- EMIF_A17

EMIF_A10/- EMIF_A18

EMIF_A11/- EMIF_A19

EMIF_A12/- EMIF_A20

EMIF_A13/- EMIF_A21

EMIF_A14/- EMIF_A22

EMIF_A15/- EMIF_A23

EMIF_A0/A8/- EMIF_A8

EMIF_A1/A9/- EMIF_A9

EMIF_A2/A10/- EMIF_A10

EMIF_A3/A11/- EMIF_A11

EMIF_A4/A12/- EMIF_A12

EMIF_A5/A13/- EMIF_A13

EMIF_A6/A14/- EMIF_A14

EMIF_A7/A15/- EMIF_A15

Rev. 0.2 19

Page 20

C8051F96x/Si102x

Table 2. MCU EMIF Connections (Continued)

EMIF Configurations

MCU Pin

Non-Multiplexed Multiplexed

MCU Card Signal

Name

UDP Motherboard

Signal Name

16-bit 8-bit 16-bit 8-bit

P6.3 D3 D3 AD3 AD3 EMIF_D3/AD3 EMIF_A3

P6.4 D4 D4 AD4 AD4 EMIF_D4/AD4 EMIF_A4

P6.5 D5 D5 AD5 AD5 EMIF_D5/AD5 EMIF_A5

P6.6 D6 D6 AD6 AD6 EMIF_D6/AD6 EMIF_A6

P6.7 D7 D7 AD7 AD7 EMIF_D7/AD7 EMIF_A7

20 Rev. 0.2

Page 21

C8051F96x/Si102x

6. Using the C8051F96x with the UDP Motherboard

6.1. VBAT Selector Switch

When used with the UDP motherboard, the motherboard can power the C8051F96x MCU card. With the VBAT

selector switch in the VREG position, the motherboard powers the regulator on the card. With the VBAT selector

switch in the UDP position, the UDP motherboard powers VBAT directly. This position supports software control of

the variable voltage power supply and current measurements.

The S1 switch on the UDP motherboard select s between th e fixed o r programmable volt age. The varia ble supply is

controlled by the C8051F384 board control MCU through the U1 digital potentiometer. Use the fixed supply when

the variable supply is not under software control.

6.2. MCU Card Header Connections

The C8051F96x MCU card has four connectors with 100 pins each. These 400 pins are directly tied to th e UDP

motherboard and I/O cards. These signals are named and designed to support a wide variety of features and

applications, and the UDP C8051F960/Si1020 MCU Card with EMIF card implements a subset of these

connections.

The MCU cards and I/O cards are designed so that a maximum number of functions are shared between each

card. This allows a particular type of I/O card to be shared amongst all MCU cards that connect to the same

signals.

The MCU card slot includes the following components:

J1 MCU card connector H1

J2 MCU card connector H2

J3 MCU card connector H3

J4 MCU card connector H4

The C8051F96x MCU card implements the signals described in Table 4, Table 5, Table 6, and Table 7 in the

Appendix.

Rev. 0.2 21

Page 22

C8051F96x/Si102x

6.3. Shorting Blocks: Factory Defaults

The UDP C8051F960/Si1020 MCU Card with EMIF comes from the factory with pre-installed shorting blocks on

several headers. Figure 11 shows the positions of the factory default shorting blocks.

Figure 11. Shorting Blocks: Factory Defaults

Shorting blocks are installed on P2 to connect P0.4 to MCU_TX and P0.5 to MCU_RX.

22 Rev. 0.2

Page 23

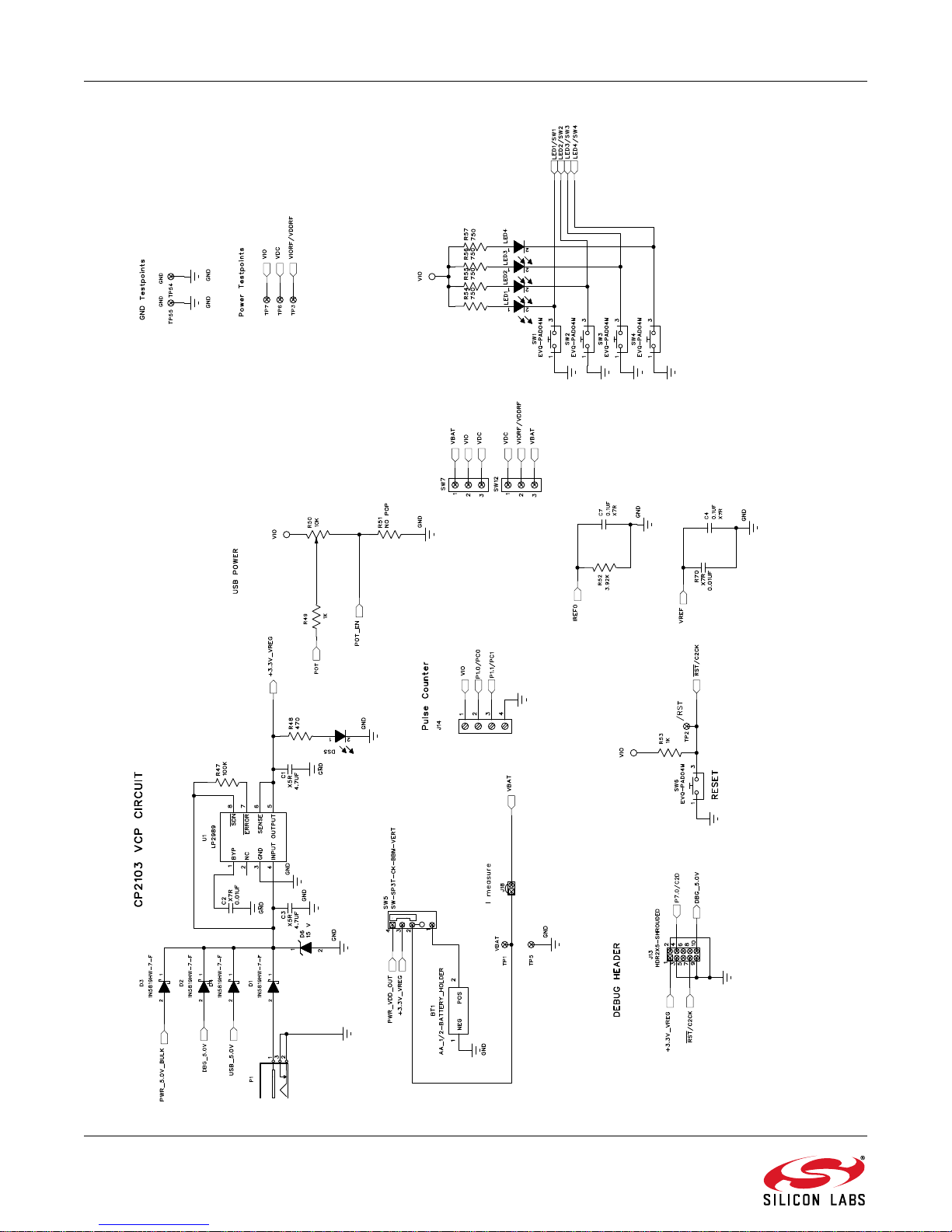

7. Schematics

C8051F96x/Si102x

Figure 12. C8051F96x UDP MCU Card Schematic (1 of 6)

Rev. 0.2 23

Page 24

C8051F96x/Si102x

24 Rev. 0.2

Figure 13. C8051F96x UDP MCU Card Schematic (2 of 6)

Page 25

C8051F96x/Si102x

Figure 14. C8051F96x UDP MCU Card Schematic (3 of 6)

Rev. 0.2 25

Page 26

C8051F96x/Si102x

26 Rev. 0.2

Figure 15. C8051F96x UDP MCU Card Schematic (4 of 6)

Page 27

C8051F96x/Si102x

Figure 16. C8051F96x UDP MCU Card Schematic (5 of 6)

Rev. 0.2 27

Page 28

C8051F96x/Si102x

28 Rev. 0.2

Figure 17. C8051F96x UDP MCU Card Schematic (6 of 6)

Page 29

C8051F96x/Si102x

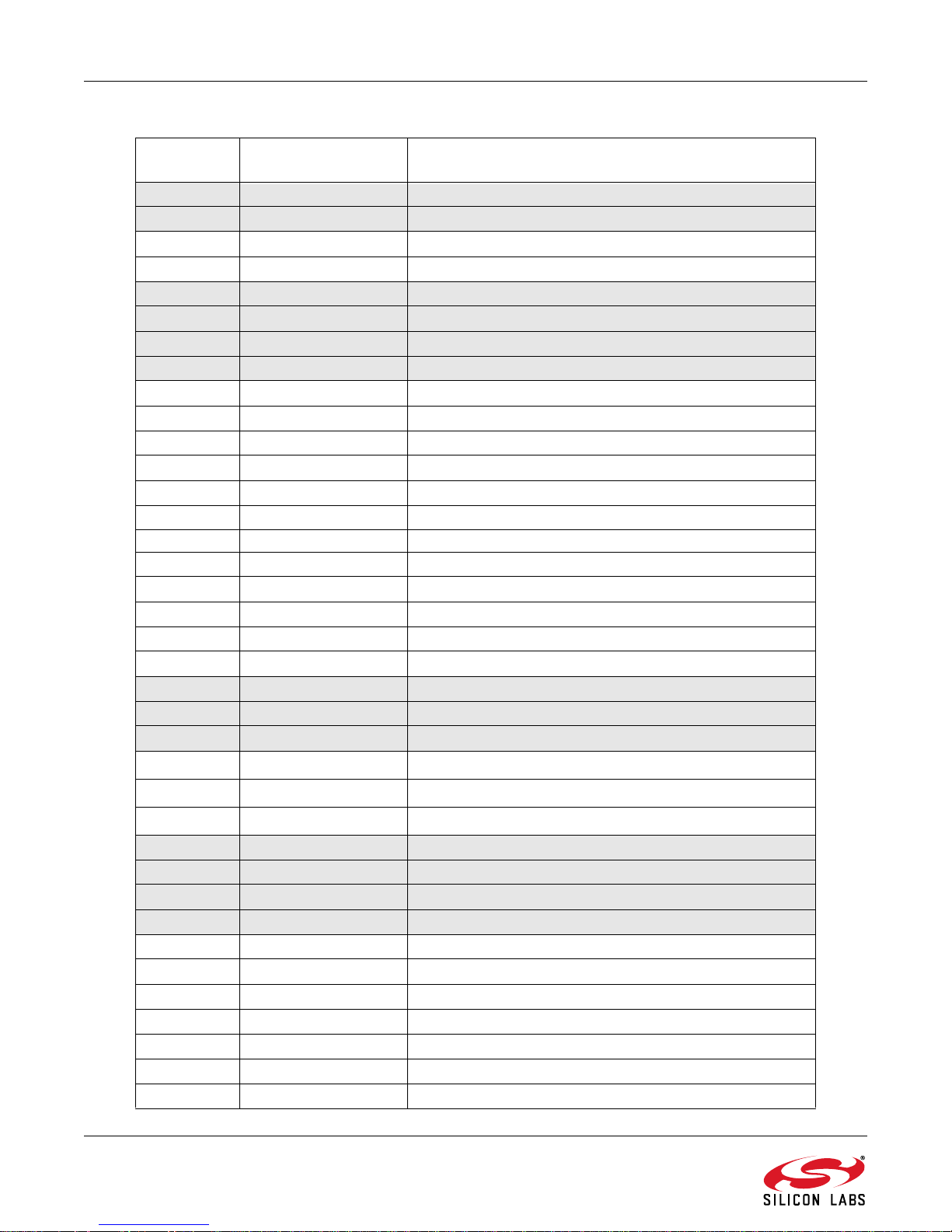

8. Bill of Materials

Table 3. UDP C8051F960/Si1020 MCU Card with EMIF Bill of Materials

Reference Part Number Source Description

U2 24AA64T-I/MNY Microchip Technology 64KBIT I2C SERIAL FLASH, 400kHZ, 8-

TDFN

U4-5 SN74AVC4T245PWR Texas Instruments Quad Dual-Supply Level Shifter, TSSOP

BT1 12BH1/2AA-2P-GR Eagle Plastic Devices HOLDER BATTERY, 1/2 CELL AA, PCB

MNT OR EQ, RoHS

C2, C12,

R70

C4-8, C10-

11, C13

C14 GRM188R71A105KA61D Murata Electronics

C15 GRM188R71A105KA61D Murata Electronics

C1, C3, C9 EMK212BJ475KG-T Taiyo Yuden CAP, 4.7UF, X5R, CERAMIC, 0805, 16V,

P1 RAPC722X Switchcraft Inc CONN, POWERJACK MINI.08" RA PC

J1-4 FX8-100P-SV1(91) Hirose Electric Co Ltd CONN, HDR, 100POS, .6MM, GOLD, SMD,

U63 CP2102 Silicon Labs SINGLE-CHIP USB TO UART BRIDGE,

D1-4 1N5819HW-7-F Diodes Inc DIODE SCHOTTKY, 40V, 1A, SOD123,

D6 MMSZ5245B-7-F Diodes Inc DIODE, ZENER, 15V, 500MW, SMT,

D5 SP0503BAHTG Littelfuse Inc TVS AVAL DIODE ARRAY, 3 CH, SOT143,

J7-8 25631401RP2 Norcomp Inc. 14POS, 2MM VERT SGL ROW

J18, J20 PBC02SAAN Sullins Connector

P12 PBC04DAAN Sullins Connector

J10 PBC05DAAN Sullins Connector

J9, J11-12 PBC09DAAN Sullins Connector

J5-6 A3C-32DA-2DSC(71) Hirose Electric Co Ltd HEADER RECEPTACLE, 32 POS, 2MM,

J13 N2510-6002-RB 3M HEADER, SHROUDED, 2X5, OR EQ,

L1 NLV25T-R68J-PF TDK INDUCTOR, POWER, 0.68UH, 1008 SMD,

06035C103KAT2A AVX Corporation CAP, 0.01UF (10000PF), X7R, CERAMIC,

0603, 50V, ±10%, OR EQ, RoHS

C0603C104J3RACTU Kemet CAP, 0.1UF, X7R, CERAMIC, 0603, 25V,

±5%, OR EQ, RoHS

CAP CERAMIC, 1.0UF, X5R, 0603, 10V,

North America

CAP CERAMIC, 1.0UF, X5R, 0603, 10V,

North America

STAKE HEADER, 1X2, 0.1"CTR, GOLD,

Solutions

STAKE HEADER, 2X4, 0.1"CTR, OR EQ,

Solutions

STAKE HEADER, 2X5, 0.1"CTR, GOLD,

Solutions

STAKE HEADER, 2X9, 0.1' CTR GOLD,

Solutions

±10%, RoHS

±10%, RoHS, NOPOP

±10%, OR EQ, RoHS

MNT, RoHS

RoHS

QFN28, RoHS

RoHS

SOD123, RoHS

RoHS

RECEPTACLE

OR EQ, RoHS, NOPOP

RoHS

OR EQ, RoHS

OR EQ, RoHS

DUAL ROW

RoHS

RoHS, NOPOP

Rev. 0.2 29

Page 30

C8051F96x/Si102x

Table 3. UDP C8051F960/Si1020 MCU Card with EMIF Bill of Materials (Continued)

Reference Part Number Source Description

DS5, LED1-4 SML-LX0603IW-TR Lumex

Opto/Components Inc

U1 LP2989AIMM-3.3/NOPB National

Semiconductor

R50 RV100F-30-4K1B-B10K-

B301

R47 ERJ-3GEYJ104V Panasonic - ECG RES, 100K, SMT, 0603, 1/10W, ±5%, OR

R41-42 ERJ-3EKF1002V Panasonic - ECG RES, EQ. 10.0K OHM, SMT, 0603, 1/10W,

R49, R53 ERJ-3EKF1001V Panasonic - ECG RES, 1K OHM, SMT, 0603, 1/10W, ±1%,

R52 ERJ-3EKF3921V Panasonic - ECG RES, 3.92K OHM, SMT, 0603, 1/10W, ±1%,

R40 ERJ-3EKF4751V Panasonic - ECG RES, 4.75K OHM , SMT, 0603, 1/10W,

R48 MCR03EZPJ471 Rohm Semiconductor RES, 470 OHM, SMT, 0603, 1/10W, ±5%,

R54-57 ERJ-3EKF7500V Panasonic - ECG RES, 750 OHM, SMT, 0603, 1/10W, ±1%,

R5-8, R11-

12, R14,

R16, R34-38,

R51

R1-4, R9-10,

R13, R15,

R17-33, R39,

R43-46

SW7, SW12 OS102011MS2QN1 C&K Components SWITCH, SPDT, 12VDC, OR EQ, RoHS

SW1-4, SW6 EVQ-PAD04M Panasonic - ECG SWITCH, LIGHT TOUCH, 130GF, 6MM SQ,

SW5 OS103012MU1QP1 C&K Components SWITCH SLIDE SP3T COMPACT PIN,

J14 1729144 Phoenix Contact CONN TERM BLOCK, 5.08MM CTRS PCB,

J17 54819-0519 Molex Inc CONN, USB MINI RECEPT, 5POS RT

Alpha (T aiwan) POT , 10K, THUMBWHEEL LINEAR, 0.03W,

LED, RED DIFF, 635NM, SMT0603, OR

EQ, RoHS

LDO REG, 500MA, ADJ, MSOP, RoHS

±20%, OR EQ, RoHS

EQ, RoHS

±1%, OR EQ, RoHS

OR EQ, RoHS

OR EQ, RoHS

±1%, OR EQ, RoHS

OR EQ, RoHS

OR EQ, RoHS

RES, SMT, 0603, OR EQ, RoHS, NOPOP

0603 SHORT, NOPOP

RoHS

PCB MNT, OR EQ, RoHS

4 POS, RoHS

ANG, TYPE B OR EQ, RoHS

30 Rev. 0.2

Page 31

C8051F96x/Si102x

APPENDIX—MCU CARD HEADER PIN DESCRIPTIONS

Table 4. UDP C8051F960/Si1020 MCU Card with EMIF H1 Pin Descriptions (J1)

MCU Card

Pin

1GND

2 USART_TX_A

3 USART_RX_A

4 USART_RTS_A

5 USART_CTS_A

6 USART_UCLK_A

7 CAN_TX_B

8 CAN_RX_B

9 SPI_SCK_A Graphical LCD I/O Card SPI clock

10 SPI_MISO_A Graphical LCD I/O Card SPI master-in, slave-out

11 SPI_MOSI_A Graphical LCD I/O Card SPI master-out, slave-in

12 SPI_NSS0_A Graphical LCD I/O Card SPI slave select

13 SPI_NSS1_A Graphical LCD I/O Card A0 address signal

14 SPI_NSS2_A

15 SPI_NSS3_A

16 USART_TX_B

17 USART_RX_B

18 USART_RTS_B

19 USART_CTS_B

20 USART_UCLK_B

21 EPCA_ECI_A

22 EPCA_CH0_A

23 EPCA_CH1_A

24 EPCA_CH2_A

25 EPCA_CH3_A

26 EPCA_CH4_A

27

28

29

30

31

32

33

34

35

36

Signal Name Usage

EPCA_CH5_A

LIN_TX_A

LIN_RX_A

PCA_ECI_A

PCA_CH0_A Graphical LCD I/O Card Piezo

PCA_CH1_A

PCA_ECI_B

PCA_CH0_B

PCA_CH1_B

I2SOUT_DFS_A

Rev. 0.2 31

Page 32

C8051F96x/Si102x

Table 4. UDP C8051F960/Si1020 MCU Card with EMIF H1 Pin Descriptions (J1) (Continued)

MCU Card

Pin

37

38

39

40

41

42

43

44

45

46

47

48

49

50 GND

51 UART_RX_SYS System UART receive

52 UART_RTS_SYS System UART hardware handshaking

53 UART_CTS_SYS System UART hardware handshaking

54 SPI_SCK_EZR EZRadioPRO SPI clock (P2.0)

55 SPI_MISO_EZR EZRadioPRO SPI master-in, slave-out (P2.1)

56 SPI_MOSI_EZR EZRadioPRO SPI master-out, slave-in (P2.2)

57 SPI_NSS0_EZR

58 SPI_NSS1_EZR

59 SPI_NSS2_EZR

60

61

62

63 I2SIN_DFS_A

64 I2SIN_CLK_A

65 I2SIN_DOUT_A

66 CLKOUT0

67 GPIO00 LED1/SW1

68 GPIO01 LED2/SW2

69 GPIO02 LED3/SW3

70 GPIO03 LED4/SW4

71 GPIO04 LED1/SW1

72 GPIO05 LED2/SW2

73 GPIO06 LED3/SW3

Signal Name Usage

I2SOUT_CLK_A

I2SOUT_DOUT_A

I2C_SDA_EZR EZRadioI2C data

I2C_SCL_EZR EZRadio I2C clock

TIMER_CT_A

TIMER_EX_A

TIMER_CT_B

TIMER_EX_B

UART_TX_A UART A transmit

UART_RX_A UART A receive

UART_RTS_A

UART_CTS_A

UART_TX_SYS System UART transmit

SPI_NSS3_EZR

I2C_SDA_B EZRadioPRO I2C data

I2C_SCL_B EZRadioPRO I2C clock

UART A hardware handshaking

UART A hardware handshaking

EZRadioPRO SPI slave select (P2.3)

32 Rev. 0.2

Page 33

C8051F96x/Si102x

Table 4. UDP C8051F960/Si1020 MCU Card with EMIF H1 Pin Descriptions (J1) (Continued)

MCU Card

Pin

74 GPIO07 LED4/SW4

75 GPIO08 Graphical LCD I/O Card Backlight

76 GPIO09

77 GPIO10

78 GPIO11

79 GPIO12

80 GPIO13

81

82 GPIO15

83 PORT_MATCH0

84 PORT_MATCH1

85

86

87

88 EXT_INT1

89 EXT_ADC_TRIG0

90 EXT_ADC_TRIG1

91 EXT_DAC_TRIG0

92 EXT_DAC_TRIG1

93 EXT_DMA_TRIG0

94 EXT_DMA_TRIG1

95 CAN_TX_A

96 CAN_RX_A

97 LIN_TX_B

98 LIN_RX_B

99 LPTIMER_IN_A

100 LPTIMER_OUT_A

Signal Name Usage

GPIO14

WAKEUP0

WAKEUP1

EXT_INT0

Rev. 0.2 33

Page 34

C8051F96x/Si102x

Table 5. UDP C8051F960/Si1020 MCU Card with EMIF H2 Pin Descriptions (J2)

MCU Card

Pin

1GND

2 UDPBUS_SDA_A Electronic Board ID I2C data

3 UDPBUS_SCL_A Electronic Board ID I2C clock

4 EPCA_ECI_MOTOR

5 EPCA_CH0_MOTOR

6 EPCA_CH1_MOTOR

7 EPCA_CH2_MOTOR

8 EPCA_CH3_MOTOR

9 EPCA_CH4_MOTOR

10 EPCA_CH5_MOTOR

11 HVGPIO0

12 HVGPIO1

13 HVGPIO2

14 HVGPIO3

15 HVGPIO4

16 HVGPIO5

17 HVGPIO6

18 HVGPIO7

19 EMIF_A23 EMIF A15/- (non-mux/mux)

20 EMIF_A22 EMIF A14/21 EMIF_A21 EMIF A13/-)

22 EMIF_A20 EMIF A12/23 EMIF_A19 EMIF A11/24 EMIF_A18 EMIF A10/25 EMIF_A17 EMIF A9/26 EMIF_A16

27

28

29

30

31

32

33

34

35

36

37

Signal Name Description

EMIF A8/-

EMIF_A15

EMIF_A14

EMIF_A13

EMIF_A12

EMIF_A11

EMIF_A10

EMIF_A9

EMIF_A8

EMIF_A7

EMIF_A6

EMIF_A5

EMIF A7/A15/- (non-mux/16-bit mux/8-bit mux)

EMIF A6/A14/EMIF A5/A13/-

EMIF A4A12/-

EMIF A3/A11/-

EMIF A2/A10/-

EMIF A1/A9/EMIF A0/A8/-

EMIF D7/AD7 (non-mux/mux)

EMIF D6/AD6

EMIF D5/AD5

34 Rev. 0.2

Page 35

C8051F96x/Si102x

Table 5. UDP C8051F960/Si1020 MCU Card with EMIF H2 Pin Descriptions (J2)

MCU Card

Pin

38

39

40

41

42

43

44

45

46

47

48

49

50 GND

51 LCD_SEG00_A

52 LCD_SEG01_A

53 LCD_SEG02_A

54 LCD_SEG03_A

55 LCD_SEG04_A

56 LCD_SEG05_A

57 LCD_SEG06_A

58 LCD_SEG07_A

59 LCD_SEG08_A

60

61

62

63 LCD_SEG12_A

64 LCD_SEG13_A

65 LCD_SEG14_A

66 LCD_SEG15_A

67 LCD_SEG16_A

68 LCD_SEG17_A

69 LCD_SEG18_A

70 LCD_SEG19_A

71 LCD_SEG20_A

72 LCD_SEG21_A

73 LCD_SEG22_A

74 LCD_SEG23_A

Signal Name Description

EMIF_A4

EMIF_A3

EMIF_A2

EMIF_A1

EMIF_A0

EMIF_WRB EMIF write signal (active low)

EMIF_OEB EMIF Read (active low)

EMIF_ALE EMIF address latch enable

EMIF_CS0B

EMIF_BE1B

EMIF_CS1B

EMIF_BE0B

LCD_SEG09_A

LCD_SEG10_A

LCD_SEG11_A

EMIF D4/AD4

EMIF D3/AD3

EMIF D2/AD2

EMIF D1/AD1

EMIF D0/AD0

Rev. 0.2 35

Page 36

C8051F96x/Si102x

Table 5. UDP C8051F960/Si1020 MCU Card with EMIF H2 Pin Descriptions (J2)

MCU Card

Pin

75 LCD_SEG24_A

76 LCD_SEG25_A

77 LCD_SEG26_A

78 LCD_SEG27_A

79 LCD_SEG28_A

80 LCD_SEG29_A

81

82 LCD_SEG31_A

83 LCD_SEG32_A

84 LCD_SEG33_A

85

86

87

88 LCD_SEG37_A

89 LCD_SEG38_A

90 LCD_SEG39_A

91 LCD_COM0_A

92 LCD_COM1_A

93 LCD_COM2_A

94 LCD_COM3_A

95 LCD_COM4_A

96 LCD_COM5_A

97 LCD_COM6_A

98 LCD_COM7_A

99 CMOSCLK_XTAL1_A

100 CMOSCLK_XTAL2_A

Signal Name Description

LCD_SEG30_A

LCD_SEG34_A

LCD_SEG35_A

LCD_SEG36_A

36 Rev. 0.2

Page 37

C8051F96x/Si102x

Table 6. UDP C8051F960/Si1020 MCU Card with EMIF H3 Pin Descriptions (J3)

MCU Card

Pin

1GND

2 PWR_VDD_IN

3 PWR_VDD_IN

4 PWR_VDD_OUT Programmable Supply from UDP to VBAT

5 PWR_VDD_OUT

6 PWR_RADIO_IN VDC Output of DCDC to power 40-pin radio car d

7PWR_RADIO_IN

8 PWR_RADIO_OUT Power input for the radio card

9 PWR_RADIO_OUT Power input for the radio card

10 PWR_IO_IN VIO (controlled by VIO select)

11 PWR_IO_IN

12 PWR_IO_OUT

13 PWR_IO_OUT

14 PWR_IO_BUS VIO (controlled by VIO select)

15 PWR_IO_B US

16 PWR_AUX_BUS

17 PWR_AUX_BUS

18 PWR_HV1_BUS

19 PWR_HV1_BUS

20 PWR_HV2_BUS

21 PWR_HV2_BUS

22 PWR_VPP_BULK

23 PWR_VPP_BULK

24 PWR_5.0_BULK 5.0 V power from the UDP motherboard

25 PWR_5.0_BULK

26

27 PWR_5.0_BULK

28

29

30

31

32

33

34

35

36

37

Description Description

(VBAT Select set to UDP)

(Powers MCU Card regulator)

PWR_5.0_BULK

VCC_3.3V

VCC_3.3V

VCC_3.3V

VCC_3.3V

PWR_SYS_BULK 3.3 V power supply for EBID EEPROM

PWR_SYS_BULK

GND

EBID_SCK RF EBID SPI clock

EBID_MOSI RF EBID SPI master-out, slave in

EBID_MISO RF EBID SPI master-in, slave-out

Rev. 0.2 37

Page 38

C8051F96x/Si102x

Table 6. UDP C8051F960/Si1020 MCU Card with EMIF H3 Pin Descriptions (J3)

MCU Card

Pin

38

39

40

41

42

43

44

45

46

47

48

49

50 GND

51 JTAG_TDO_A

52 JTAG_TDI_A

53 VCP_EN Active-low enable for MCU Card VCP Bridge (default)

54 UART_SYS_EN Active-low enable for MCU to UDP UART path

55 H3_55

56 H3_56

57 H3_57

58 H3_58

59 H3_59

60

61

62

63 H3_63

64 H3_64

65 H3_65

66 H3_66

67 H3_67

68 H3_68

69 H3_69

70 H3_70

71 H3_71

72 H3_72

73 H3_73

74 H3_74

Description Description

EBID_NSS RF EBID SPI slave select

C2_CLK_A Reset/C2 interface clock

C2_DAT_A P7.0/C2 interface data

C2_CLK_B

C2_DAT_B

C2_CLK_C

C2_DAT_C

C2_CLK_D

C2_DAT_D

C2_CLK_E

C2_DAT_E

nc

H3_60

H3_61

H3_62

38 Rev. 0.2

Page 39

C8051F96x/Si102x

Table 6. UDP C8051F960/Si1020 MCU Card with EMIF H3 Pin Descriptions (J3)

MCU Card

Pin

75 H3_75

76 H3_76

77 H3_77

78 H3_78

79 H3_79

80 H3_80

81

82 H3_82

83 H3_83

84 H3_84

85

86

87

88 H3_88

89 H3_89

90 H3_90

91 H3_91

92 H3_92

93 H3_93

94 H3_94

95 H3_95

96 H3_96

97 H3_97

98 H3_98

99 H3_99

100 H3_100

Description Description

H3_81

H3_85

H3_86

H3_87

Rev. 0.2 39

Page 40

C8051F96x/Si102x

Table 7. UDP C8051F960/Si1020 MCU Card with EMIF H4 Pin Descriptions (J4)

MCU Card

Pin

1GND

2 C2D_TX00_A Capacitive Sensing output 0

3 C2D_TX01_A Capacitive Sensing output 1

4 C2D_TX02_A Capacitive Sensing output 2

5 C2D_TX03_A Capacitive Sensing output 3

6 C2D_TX04_A Capacitive Sensing output 4

7 C2D_TX05_A Capacitive Sensing output 5

8 C2D_TX06_A Capacitive Sensing output 6

9 C2D_TX07_A Capacitive Sensing output 7

10 C2D_TX08_A

11 C2D_TX09_A

12 C2D_TX10_A

13 C2D_TX11_A

14 C2D_TX12_A

15 C2D_TX13_A

16 C2D_TX14_A

17 C2D_TX15_A

18 C2D_RX00_A Capacitive Sensing input 0

19 C2D_RX01_A Capacitive Sensing input 1

20 C2D_RX02_A Capacitive Sensing input 2

21 C2D_RX03_A Capacitive Sensing input 3

22 C2D_RX04_A Capacitive Sensing input 4

23 C2D_RX05_A Capacitive Sensing input 5

24 C2D_RX06_A Capacitive Sensing input 6

25 C2D_RX07_A Capacitive Sensing input 7

26 C2D_RX08_A Capacitive Sensing input 8

27

28

29

30

31

32

33

34

35

36

37

Description Description

Capacitive Sensing output 8

Capacitive Sensing output 9

Capacitive Sensing output 10

Capacitive Sensing output 11

Capacitive Sensing output 12

Capacitive Sensing output 13

Capacitive Sensing output 14

Capacitive Sensing output 15

C2D_RX09_A Capacitive Sensing input 9

C2D_RX10_A Capacitive Sensing input 10

C2D_RX11_A Capacitive Sensing input 11

C2D_RX12_A Capacitive Sensing input 12

C2D_RX13_A Capacitive Sensing input 13

C2D_RX14_A Capacitive Sensing input 14

C2D_RX15_A Capacitive Sensing input 15

GND

ADC_VREF ADC voltage reference

ADC_VREFGND ADC VREF ground

ADC_IN0

40 Rev. 0.2

Page 41

C8051F96x/Si102x

Table 7. UDP C8051F960/Si1020 MCU Card with EMIF H4 Pin Descriptions (J4) (Continued)

MCU Card

Pin

38

39

40

41

42

43

44

45

46

47

48

49

50 IDAC_B IDAC B output

51 CP_OUT_A Comparator A synchronous output

52 CP_OUTA_A Comparator A asynchronous output

53 CP_POS_A Comparator A positive input

54 CP_NEG_A Comparator A negative input

55 CP_POS_B Comparator B positive input

56 CP_NEG_B Comparator B negative input

57 GND

58 HVDA_INP_A High Voltage Differential Amplifier A positive input

59 HVDA_INN_A High Voltage Differential Amplifier A negative input

60

61

62

63 I2V_INP_A Current-to-Voltage converter A input 0

64 I2V_INN_A Current-to-Voltage converter A input 1

65 EXTREG_SP_A External Voltage Regulator SP input

66 EXTREG_SN_A External Voltage Regulator SN input

67 EXTREG_OUT_A External Voltage Regulator OUT output

68 EXTREG_BD_A External Voltage Regulator base drive output

69 GND

70 EZRP_CLK_IN Radio card clock input (SMA connector)

71 GND

72 EZRP_TX_DATA_IN Radio card transmit data input (SMA connector)

73 EZRO_RX_CLK_OUT Radio card receive clock output (SMA connector)

74 EZRP_RX_DATA_OUT Radio card receive data output (SMA connector)

Description Description

ADC_IN1

ADC_IN2

ADC_IN3

GND

DAC_VREF DAC voltage reference

DAC_VREFGND DAC voltage reference ground

DAC_OUT0

DAC_OUT1

DAC_OUT2

DAC_OUT3

GND

IDAC_A IDAC A output

HVDA_INP_B

HVDA_INN_B

GND

High Voltage Differential Amplifier B positive input

High Voltage Differential Amplifier B negative input

Rev. 0.2 41

Page 42

C8051F96x/Si102x

Table 7. UDP C8051F960/Si1020 MCU Card with EMIF H4 Pin Descriptions (J4) (Continued)

MCU Card

Pin

75 GND

76 EZRP_SDN Radio card peripheral shutdown

77 EZRP_NIRQ Radio card peripheral interrupt status

78 EZR_NFFS

79 EZR_SI100X_TX Radio card Si100x transmit

80 EZR_DTO

81

82 EZR_SI100X_RX Radio card Si100x receive

83 EZR_RESET Radio card reset

84 EZR_ARSSI

85

86

87

88 EZR_GPIO2

89 EZR_GPIO3

90 EZR_GPIO4

91 H4_91 General purpose signal

92 ITM_DAT0

93 ITM_DAT1

94 ITM_DAT2

95 ITM_DAT3

96 ITM_CLK

97 H4_97 General purpose signal

98 H4_98 General purpose signal

99 H4_99 General purpose signal

100 GND

Description Description

EZR_FFIT

EZR_VDI

EZR_GPIO0 Radio card general purpose I/O 0

EZR_GPIO1 Radio card general purpose I/O 1

Radio card general purpose I/O 2

Radio card general purpose I/O 3

Radio card general purpose I/O 4

42 Rev. 0.2

Page 43

Simplicity Studio

One-click access to MCU and

wireless tools, documentation,

software, source code libraries &

more. Available for Windows,

Mac and Linux!

IoT Portfolio

www.silabs.com/IoT

Disclaimer

Silicon Laboratories intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules available for system and software implementers

using or intending to use the Silicon Laboratories products. Characterization data, available modules and peripherals, memory sizes and memory addresses refer to each specific

device, and "Typical" parameters provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon Laboratories

reserves the right to make changes without further notice and limitation to product information, specifications, and descriptions herein, and does not give warranties as to the accuracy

or completeness of the included information. Silicon Laboratories shall have no liability for the consequences of use of the information supplied herein. This document does not imply

or express copyright licenses granted hereunder to design or fabricate any integrated circuits. The products must not be used within any Life Support System without the specific

written consent of Silicon Laboratories. A "Life Support System" is any product or system intended to support or sustain life and/or health, which, if it fails, can be reasonably expected

to result in significant personal injury or death. Silicon Laboratories products are generally not intended for military applications. Silicon Laboratories products shall under no

circumstances be used in weapons of mass destruction including (but not limited to) nuclear, biological or chemical weapons, or missiles capable of delivering such weapons.

Trademark Information

Silicon Laboratories Inc., Silicon Laboratories, Silicon Labs, SiLabs and the Silicon Labs logo, CMEMS®, EFM, EFM32, EFR, Energy Micro, Energy Micro logo and combinations

thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZMac®, EZRadio®, EZRadioPRO®, DSPLL®, ISOmodem ®, Precision32®, ProSLIC®, SiPHY®,

USBXpress® and others are trademarks or registered trademarks of Silicon Laboratories Inc. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or registered trademarks of

ARM Holdings. Keil is a registered trademark of ARM Limited. All other products or brand names mentioned herein are trademarks of their respective holders.

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

SW/HW

www.silabs.com/simplicity

Quality

www.silabs.com/quality

Support and Community

community.silabs.com

http://www.silabs.com

Loading...

Loading...