Page 1

C8051F930-DK

C8051F930 DEVELOPMENT KIT USER’S GUIDE

1. Relevant Devices

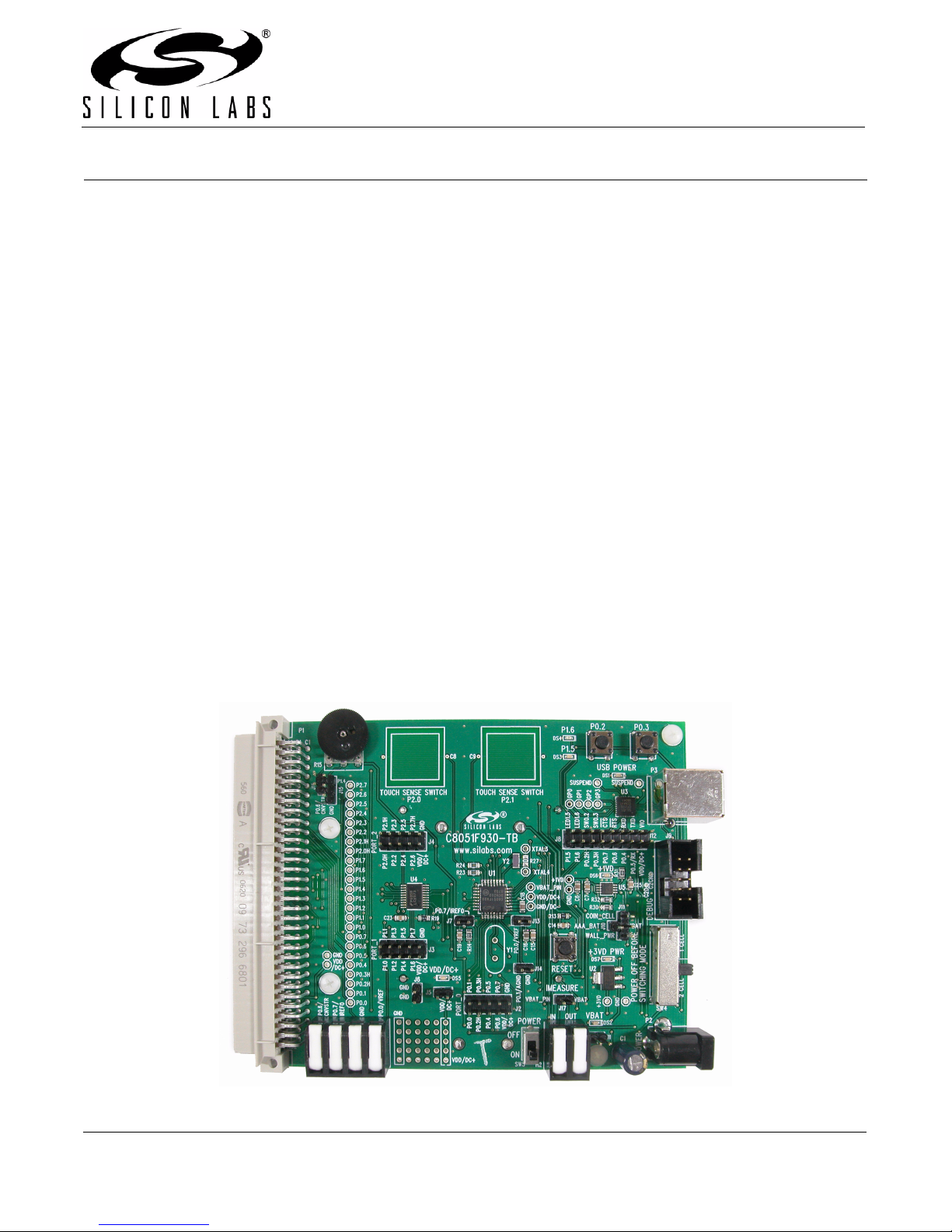

The C8051F930 Development Kit is intended as a development platform for the microcontrollers in the

C8051F93x-C8051F92x MCU family. The members of this MCU family are C8051F930, C8051F931, C8051F920,

and C8051F921.

Notes:

1. The target board included in this kit is provided with a pre-soldered C8051F930 MCU (LQFP32 package).

2. Code developed on the C8051F930 can be easily ported to the other members of this MCU family.

3. Refer to the C8051F93x-C8051F92x data sheet for the differences between the members of this MCU family.

2. Kit Contents

The C8051F930 Development Kit contains the following items:

C8051F930 Target Board

C8051Fxxx Development Kit Quick-Start Guide

Silicon Laboratories IDE and Product Information CD-ROM. CD content includes the following:

Silicon Laboratories Integrated Development Environment (IDE)

Keil 8051 Development Tools (macro assembler, linker, evaluation C compiler)

Source code examples and register definition files

Documentation

C8051F930 Development Kit User’s Guide (this document)

AC to DC Power Adapter

USB Debug Adapter (USB to Debug Interface)

2 USB Cables

2 AAA Batteries

Rev. 0.5 8/09 Copyright © 2009 by Silicon Laboratories C8051F930-DK

Figure 1. C8051F930 Target Board

Page 2

C8051F930-DK

3. Software Overview

All software required to develop firmware and communicate with the target microcontroller is included in the CDROM. The CD-ROM also includes other useful software.

Below is the software necessary for firmware development and communication with the target microcontroller:

Silicon Laboratories Integrated Development Environment (IDE)

Keil 8051 Development Tools (macro assembler, linker, evaluation C compiler)

Other useful software that is provided in the CD-ROM includes the following:

Configuration Wizard 2

Keil µVision Drivers

CP210x USB to UART Virtual COM Port (VCP) Drivers

3.1. Software Installation

The included CD-ROM contains the Silicon Laboratories Integrated Development Environment (IDE), Keil software

8051 tools and additional documentation. Insert the CD-ROM into your PC’s CD-ROM drive. An installer will

automatically launch, allowing you to install the IDE software or read documentation by clicking buttons on the

Installation Panel. If the installer does not automatically start when you insert the CD-ROM, run autorun.exe found

in the root directory of the CD-ROM. Refer to the ReleaseNotes.txt file on the CD-ROM for the latest information

regarding known problems and restrictions. After installing the software, see the following sections for information

regarding the software and running one of the demo applications.

3.2. CP210x USB to UART VCP Driver Installation

The C8051F930 Target Board includes a Silicon Laboratories CP2103 USB-to-UART Bridge Controller. Device

drivers for the CP2103 need to be installed before PC software such as HyperTerminal can communicate with the

target board over the USB connection. If the "Install CP210x Drivers" option was selected during installation, this

will launch a driver “unpacker” utility.

1. Follow the steps to copy the driver files to the desired location. The default directory is C:\SiLabs\MCU\CP210x.

2. The final window will give an option to install the driver on the target system. Select the “Launch the CP210x

VCP Driver Installer” option if you are ready to install the driver.

3. If selected, the driver installer will now launch, providing an option to specify the driver installation location. After

pressing the “Install” button, the installer will search your system for copies of previously installed CP210x

Virtual COM Port drivers. It will let you know when your system is up to date. The driver files included in this

installation have been certified by Microsoft.

4. If the “Launch the CP210x VCP Driver Installer” option was not selected in step 3, the installer can be found in

the location specified in step 2, by default C:\SiLabs\MCU\CP210x\Windows_2K_XP_S2K3_Vista. At this

location run CP210xVCPInstaller.exe.

5. To complete the installation process, connect the included USB cable between the host computer and the USB

connector (P3) on the C8051F930 Target Board. Windows will automatically finish the driver installation.

Information windows will pop up from the taskbar to show the installation progress.

6. If needed, the driver files can be uninstalled by selecting “Silicon Laboratories CP210x USB to UART Bridge

(Driver Removal)” option in the “Add or Remove Programs” window.

3.3. Silicon Laboratories IDE

The Silicon Laboratories IDE integrates a source-code editor, a source-level debugger, and an in-system Flash

programmer. See Section 5. "Using the Keil Software 8051 Tools with the Silicon Laboratories IDE‚" on page 9 for

detailed information on how to use the IDE. The Keil Evaluation Toolset includes a compiler, linker, and assembler

and easily integrates into the IDE. The use of third-party compilers and assemblers is also supported.

3.3.1. IDE System Requirements

The Silicon Laboratories IDE requirements:

Pentium-class host PC running Microsoft Windows 2000 or newer

One available USB port

64 MB RAM and 40 MB free HD space recommended

2 Rev. 0.5

Page 3

C8051F930-DK

3.3.2. 3rd Party Toolsets

The Silicon Laboratories IDE has native support for many 8051 compilers. The full list of natively supported tools is

as follows:

Keil

IAR

Raisonance

Tasking

Hi-Tech

SDCC

The demo applications for the C8051F930 target board are written to work with the Keil and SDCC toolsets.

3.4. Keil Evaluation Toolset

3.4.1. Keil Assembler and Linker

The Keil demonstration toolset assembler and linker place no restrictions on code size.

3.4.2. Keil Evaluation C51 C Compiler

The evaluation version of the C51 compiler is the same as the full version with the following limitations: (1)

Maximum 4 kB code generation, (2) There is no floating point library included. When installed from the CD-ROM,

the C51 compiler is initially limited to a code size of 2 kB, and programs start at code address 0x0800. Refer to

“AN104: Integrating Keil Tools into the Silicon Labs IDE" for instructions to change the limitation to 4 kB and have

the programs start at code address 0x0000.

Rev. 0.5 3

Page 4

C8051F930-DK

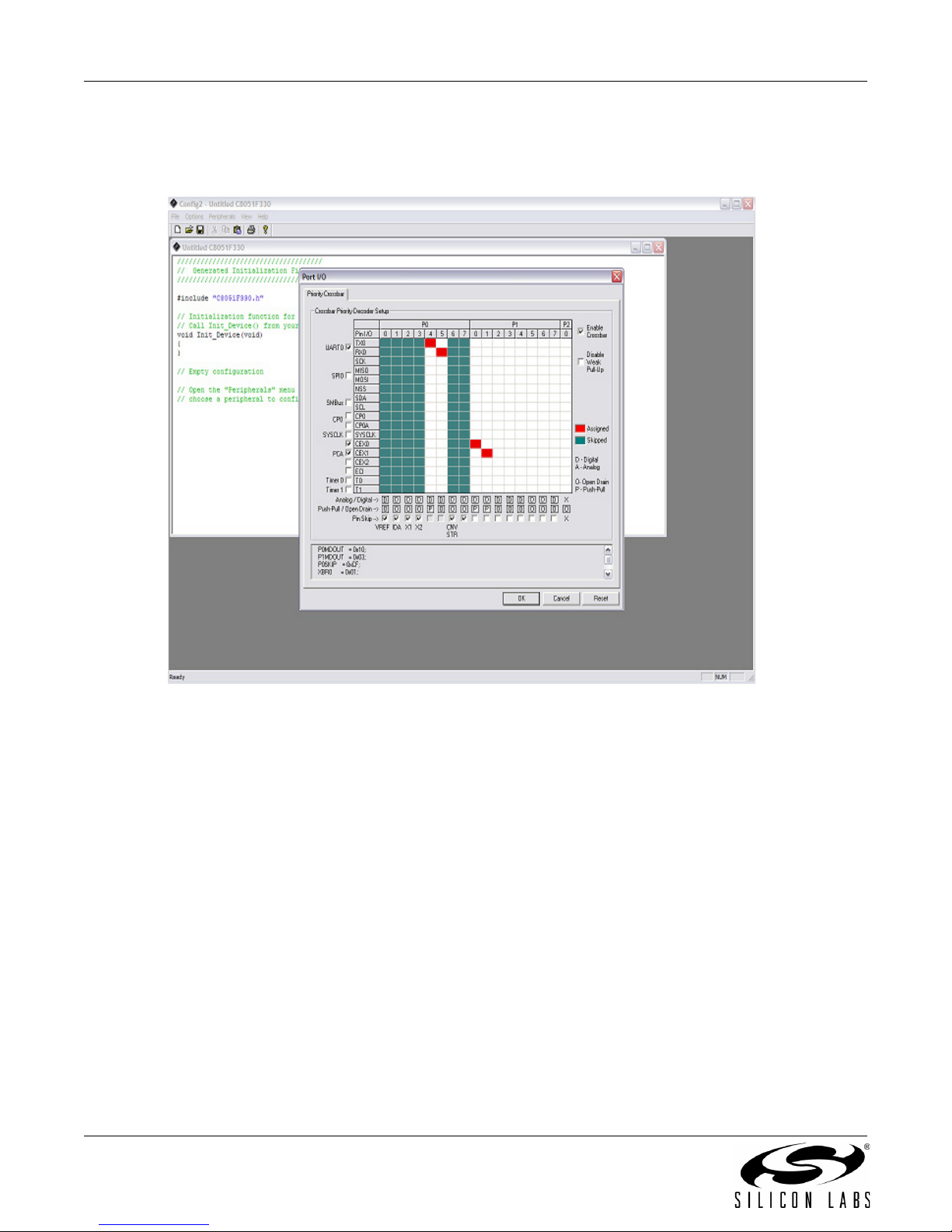

3.5. Configuration Wizard 2

The Configuration Wizard 2 is a code generation tool for all of the Silicon Laboratories devices. Code is generated

through the use of dialog boxes for each of the device's peripherals.

Figure 2. Configuration Wizard 2 Utility

The Configuration Wizard utility helps accelerate development by automatically generating initialization source

code to configure and enable the on-chip resources needed by most design projects. In just a few steps, the wizard

creates complete startup code for a specific Silicon Laboratories MCU. The program is configurable to provide the

output in C or assembly language. For more information, refer to the Configuration Wizard documentation.

Documentation and software is available on the kit CD and from the downloads webpage: www.silabs.com/

mcudownloads.

4 Rev. 0.5

Page 5

C8051F930-DK

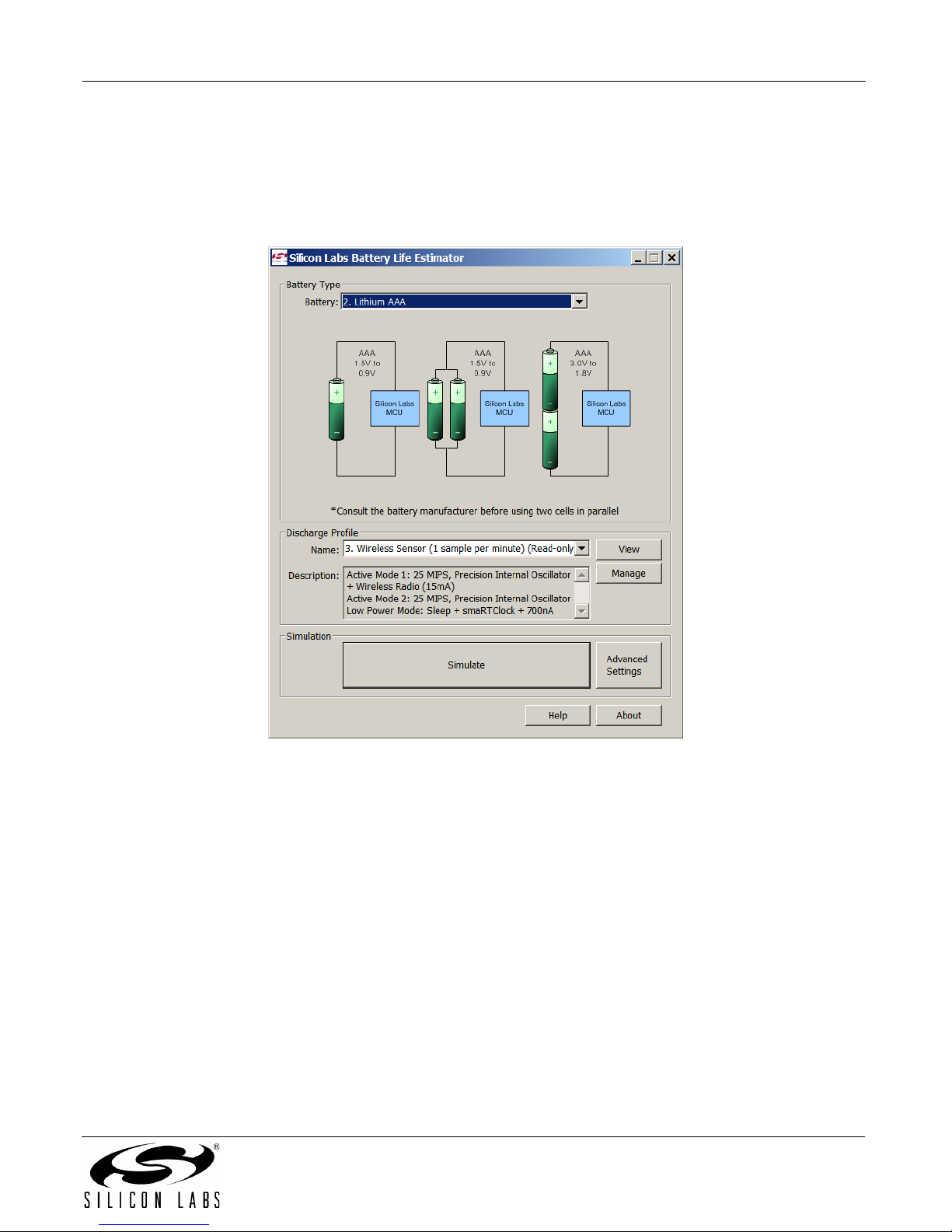

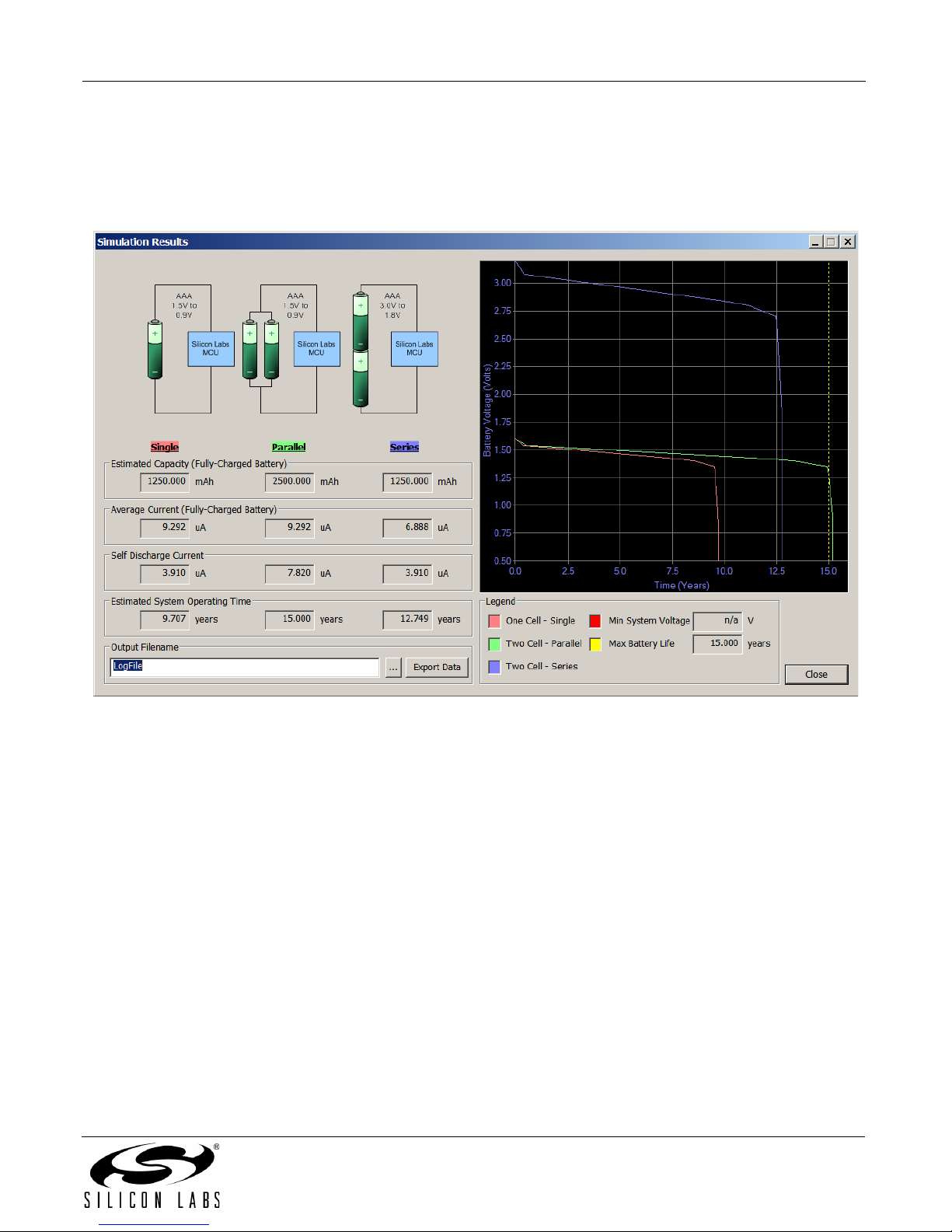

3.6. Silicon Labs Battery Life Estimator

The Battery Life Estimator is a system design tool for battery operated devices. It allows the user to select the type

of battery they are using in the system and enter the supply current profile of their application. Using this

information, it performs a simulation and provides an estimated system operating time. The Battery Life Estimator

is shown in Figure 3.

From Figure 3, the two inputs to the Battery Life Estimator are battery type and discharge profile. The utility

includes battery profiles for common battery types such as AAA, AA, A76 Button Cell, and CR2032 coin cell. The

discharge profile is application-specific and describes the supply current requirements of the system under various

supply voltages and battery configurations. The discharge profile is independent of the selected power source.

Several read-only discharge profiles for common applications are included in the pulldown menu. The user may

also create a new profile for their own applications.

To create a new profile:

1. Select the profile that most closely matches the target application or choose the "Custom Profile".

2. Click Manage

3. Click Duplicate

4. Click Edit

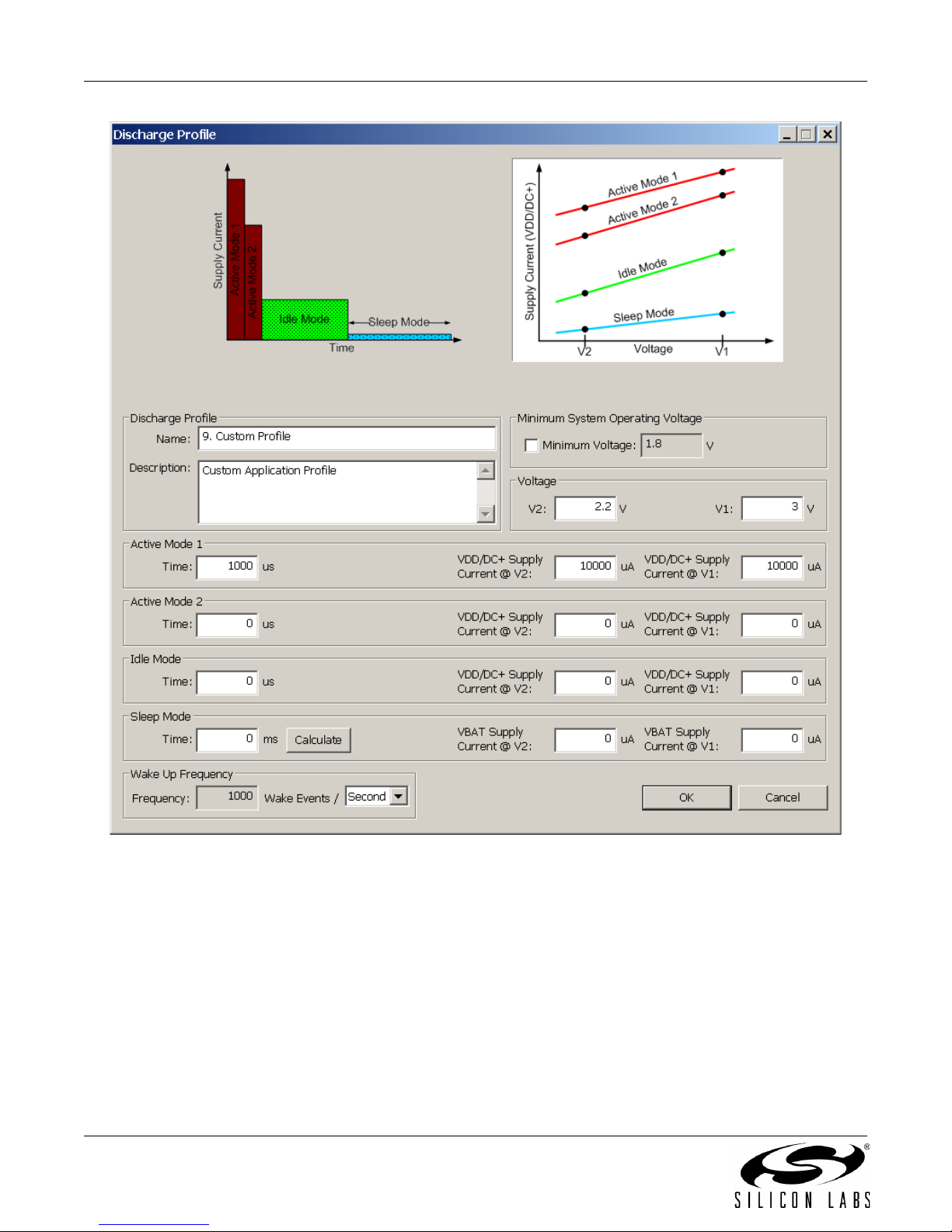

Profiles may be edited with the easy-to-use GUI (shown in Figure 4).

Figure 3. Battery Life Estimator Utility

Rev. 0.5 5

Page 6

C8051F930-DK

Figure 4. Battery Life Estimator Discharge Profile Editor

The Discharge Profile Editor allows the user to modify the profile name and description. The four text entry boxes

on the left hand side of the form allow the user to specify the amount of time the system spends in each power

mode. On the right hand side, the user may specify the supply current of the system in each power mode.

Since supply current is typically dependent on supply voltage, the discharge profile editor provides two columns for

supply current. The V2 and V1 voltages at the top of the two columns specify the voltages at which the current

measurements were taken. The Battery Life Estimator creates a linear approximation based on the input data and

is able to feed the simulation engine with an approximate supply current demand for every input voltage.

The minimum system operating voltage input field allows the system operating time to stop increasing when the

simulated battery voltage drops below a certain threshold. This is primarily to allow operating time estimates for

systems that cannot operate down to 1.8 V, which is the voltage of two fully drained single-cell batteries placed in

series.

6 Rev. 0.5

Page 7

C8051F930-DK

The wakeup frequency box calculates the period of a single iteration through the four power modes and displays

the system wake up frequency. This is typically the "sample rate" in low power analog sensors.

Once the battery type and discharge profile is specified, the user can click the "Simulate" button to start a new

simulation. The simulation engine calculates the estimated battery life when using one single-cell battery, two

single-cell batteries in series, and two single-cell batteries in parallel. Figure 5 shows the simulation output window.

Figure 5. Battery Life Estimator Utility Simulation Results Form

The primary outputs of the Battery Life Estimator are an estimated system operating time and a simulated graph of

battery voltage vs. time. Additional outputs include estimated battery capacity, average current, self-discharge

current, and the ability to export graph data to a comma delimited text file for plotting in an external graphing

application.

Rev. 0.5 7

Page 8

C8051F930-DK

PC

USB

Cable

AC/DC

Adapter

Target Board

P0.2 P0.3

J3

J4

J2

`

P3

CP

2103

U3

P2

DEBUG

J9

USB POWER

RESET

P1.6

P1.5

POWER OFF BEFORE

SW4

SWITCHING MODE

2 CELL

1 CELL

J17

IMEASURE

H2

SILICON LABS

www.silabs.com

H1

J6

VDD/DC+

J5

J7 J13

F930

U1

J14

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

TOUCH SENSE SWITCH

P2.0

TOUCH SENSE SWITCH

P2.1

J15

J16

R15

J12J8

+3VD

+1VD

VBAT

J1

SW5

ON

OFF

Silicon Laboratories

USB DEBUG ADAPTER

Run

Stop Power

USB Debug

Adapter

3.7. Keil µVision2 and µVision3 Silicon Laboratories Drivers

As an alternative to the Silicon Laboratories IDE, the µVision debug driver allows the Keil µVision2 and µVision3

IDEs to communicate with Silicon Laboratories’ on-chip debug logic. In-system Flash memory programming

integrated into the driver allows for rapid updating of target code. The µVision2 and µVision3 IDEs can be used to

start and stop program execution, set breakpoints, check variables, inspect and modify memory contents, and

single-step through programs running on the actual target hardware. For more information, refer to the µVision

driver documentation. The documentation and software are available on the kit CD and from the downloads

webpage: www.silabs.com/mcudownloads.

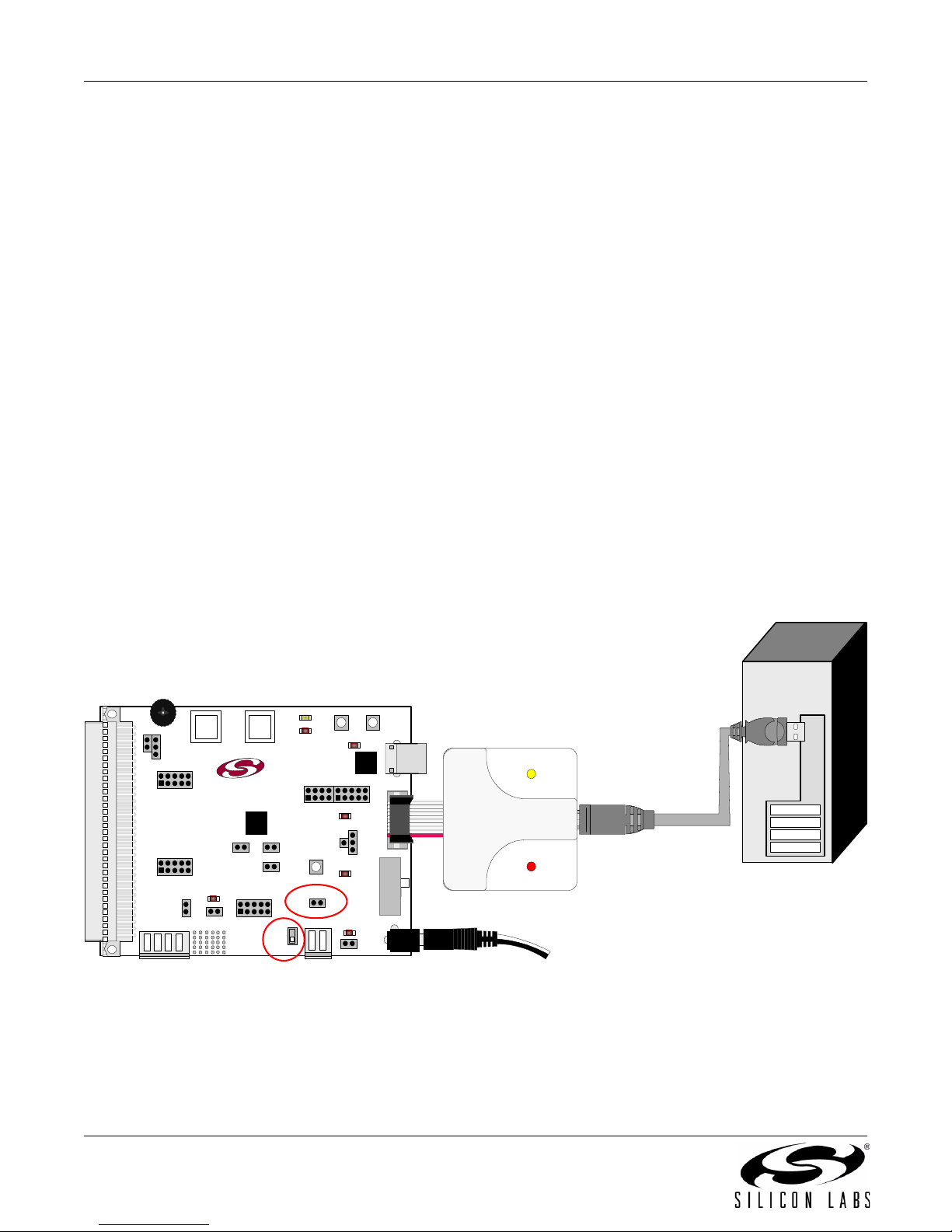

4. Hardware Setup using a USB Debug Adapter

The target board is connected to a PC running the Silicon Laboratories IDE via the USB Debug Adapter as shown

in Figure 6.

1. Connect the USB Debug Adapter to the DEBUG connector on the target board with the 10-pin ribbon cable.

2. Connect one end of the USB cable to the USB connector on the USB Debug Adapter.

3. Verify that a shorting block is installed on J17 and that SW5 is in the ON position.

4. Connect the other end of the USB cable to a USB Port on the PC.

5. Connect the ac/dc power adapter to power jack P1 on the target board (Optional).

Notes:

Use the Reset button in the IDE to reset the target when connected using a USB Debug Adapter.

Remove power from the target board and the USB Debug Adapter before connecting or disconnecting the

ribbon cable from the target board. Connecting or disconnecting the cable when the devices have power can

damage the device and/or the USB Debug Adapter.

8 Rev. 0.5

Figure 6. Hardware Setup using a USB Debug Adapter

Page 9

C8051F930-DK

5. Using the Keil Software 8051 Tools with the Silicon Laboratories IDE

To perform source-level debugging with the IDE, configure the Keil 8051 tools to generate an absolute object file in

the OMF-51 format with object extensions and debug records enabled. Build the OMF-51 absolute object file by

calling the Keil 8051 tools at the command line (e.g., batch file or make file) or by using the project manager built

into the IDE. The default configuration when using the Silicon Laboratories IDE project manager enables object

extension and debug record generation.

the “SiLabs\MCU\Documentation\ApplicationNotes” directory on the CD-ROM for additional information on using the

Keil 8051 tools with the Silicon Laboratories IDE.

To build an absolute object file using the Silicon Laboratories IDE project manager, you must first create a project.

A project consists of a set of files, IDE configuration, debug views, and a target build configuration (list of files and

tool configurations used as input to the assembler, compiler, and linker when building an output object file).

The following sections illustrate the steps necessary to manually create a project with one or more source files,

build a program, and download it to the target in preparation for debugging. (The IDE will automatically create a

single-file project using the currently open and active source file if you select Build/Make Project before a project is

defined.)

5.1. Creating a New Project

1. Select Project

2. Select File

recognized extension, such as .c, .h, or .asm, to enable color syntax highlighting.

3. Right-click on “New Project” in the Project Window. Select Add files to project. Select files in the file browser

and click Open. Continue adding files until all project files have been added.

4. For each of the files in the Project Window that you want assembled, compiled and linked into the target build,

right-click on the file name and select Add file to build. Each file will be assembled or compiled as appropriate

(based on file extension) and linked into the build of the absolute object file.

5. If a project contains a large number of files, the “Group” feature of the IDE can be used to organize. Right-click

on “New Project” in the Project Window. Select Add Groups to project. Add pre-defined groups or add

customized groups. Right-click on the group name and choose Add file to group. Select files to be added.

Continue adding files until all project files have been added.

New Project to open a new project and reset all configuration settings to default.

New File to open an editor window. Create your source file(s) and save the file(s) with a

Refer to

"AN104: Integrating Keil 8051 Tools into the Silicon Labs IDE"

in

Rev. 0.5 9

Page 10

C8051F930-DK

5.2. Building and Downloading the Program for Debugging

1. Once all source files have been added to the target build, build the project by clicking on the Build/Make Project

button in the toolbar or selecting Project

Note: After the project has been built the first time, the Build/Make Project command will only build the files that

have been changed since the previous build. To rebuild all files and project dependencies, click on the Rebuild

All button in the toolbar or select Project

2. Before connecting to the target device, several connection options may need to be set. Open the Connection

Options window by selecting Options

adapter in the “Serial Adapter” section. Next, the correct “Debug Interface” must be selected. C8051F93xC8051F92x family devices use the Silicon Labs 2-wire (C2) debug interface. Once all the selections are made,

click the OK button to close the window.

3. Click the Connect button in the toolbar or select Debug

4. Download the project to the target by clicking the Download Code button in the toolbar.

Note: To enable automatic downloading if the program build is successful select Enable automatic connect/

download after build in the Project

the IDE will not attempt the download.

5. Save the project when finished with the debug session to preserve the current target build configuration, editor

settings and the location of all open debug views. To save the project, select Project

the menu. Create a new name for the project and click on Save.

Build/Make Project from the menu.

Rebuild All from the menu.

Connection Options... in the IDE menu. First, select the appropriate

Connect from the menu to connect to the device.

Target Build Configuration dialog. If errors occur during the build process,

Save Project As... from

10 Rev. 0.5

Page 11

C8051F930-DK

6. Example Source Code

Example source code and register definition files are provided in the “SiLabs\MCU\Examples\C8051F93x_92x\”

default directory during IDE installation. These files may be used as a template for code development. Example

applications include a blinking LED example which configures the green LED on the target board to blink at a fixed

rate.

6.1. Register Definition Files

Register definition files C8051F930.inc and C8051F930_defs.h define all SFR registers and bit-addressable

control/status bits. A macro definition header file compiler_defs.h is also included, and is required to be able to use

the C8051F930_defs.h header file with various tool chains. These files are installed into the

“SiLabs\MCU\Examples\C8051F93x_92x\Header_Files\” directory during IDE installation by default. The register

and bit names are identical to those used in the C8051F93x-C8051F92x data sheet. These register definition files

are also installed in the default search path used by the Keil Software 8051 tools. Therefore, when using the Keil

8051 tools included with the development kit (A51, C51), it is not necessary to copy a register definition file to each

project’s file directory.

6.2. Blinking LED Example

The example source files F93x_Blinky.asm and F93x_Blinky.c installed in the default directory

“SiLabs\MCU\Examples\C8051F93x_92x\Blinky” show examples of several basic C8051F930 functions. These

include disabling the watchdog timer (WDT), configuring the Port I/O crossbar, configuring a timer for an interrupt

routine, initializing the system clock, and configuring a GPIO port pin. When compiled/assembled and linked this

program flashes the green LED on the C8051F930 Target Board about five times a second using the interrupt

handler with a C8051F930 timer.

6.3. Touch Sensitive Switch Example

The example source file F93x_CapTouchSense_Switch.c demonstrates the configuration and usage of the touch

sensitive (contactless) switches located on P2.0 and P2.1. Refer to the source file for step-by-step instructions to

build and test this example. This is installed in the “SiLabs\MCU\Examples\C8051F93x_92x\

CapTouchSense_Switch” directory by default.

Rev. 0.5 11

Page 12

C8051F930-DK

P0.2 P0.3

Pin 1

Pin 2

J3

J4

J2

`

P3

CP

2103

U3

P2

DEBUG

J9

USB POWER

RESET

P1.6

P1.5

POWER OFF BEFORE

SW4

SWITCHING MODE

2 CELL

1 CELL

J17

IMEASURE

H2

SILICON LABS

www.silabs.com

H1

Pin 1

J6

VDD/DC+

J5

J7 J13

F930

U1

J14

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

TOUCH SENSE SWITCH

P2.0

TOUCH SENSE SWITCH

P2.1

P1.4

J15

GND

J16

R15

J12J8

+3VD

+1VD

VBAT

J1

SW5

ON

OFF

P1

SW2 SW3

PORT2

PORT1

SW1

PORT0

7. Target Board

The C8051F930 Development Kit includes a target board with a C8051F930 device pre-installed for evaluation and

preliminary software development. Numerous input/output (I/O) connections are provided to facilitate prototyping

using the target board. Refer to Figure 7 for the locations of the various I/O connectors. Figure 9 on page 14 shows

the factory default shorting block positions.

P1 Expansion connector (96-pin)

P2 Power connector (accepts input from 7 to 15 VDC unregulated power adapter)

P3 USB connector (connects to PC for serial communication)

J1 Enable/Disable VBAT Power LED

J2, J3, J4 Port I/O headers (provide access to Port I/O pins)

J5 Enable/Disable VDD/DC+ Power LED

J6 Provides an easily accessible ground clip

J7 Connects pin P0.7 (IREF0 Output) to resistor R14 and capacitor C19

J8 Connects P0.2 and P0.3 to switches and P1.5 and P1.6 to LEDs

J9 DEBUG connector for Debug Adapter interface

J10, J11 Selects the power supply source (Wall Power, AAA Battery, or Coin Cell)

J12 Connects Port I/O to UART0 interface

J13 Connects external VREF capacitor to the P0.0/VREF

J14 Connects the PCB ground plane to P0.1/AGND

J15 Connects negative potentiometer (R14) terminal to pin P1.4 or to GND

J16 Connects the potentiometer (R14) wiper to P0.6/CNVSTR

J17 Creates an open in the power supply path to allow supply current measurement

H1 Analog I/O terminal block

H2 Provides terminal block access to the input and output nodes of J17

SW4 Switches the device between One-Cell (0.9–1.8 V supply) or Two-Cell (1.8–3.6 V) mode

SW5 Turns power to the MCU on or off

12 Rev. 0.5

Figure 7. C8051F930 Target Board

Page 13

The following items are located on the bottom side of the board. See Figure 8.

NEG

POS

NEG

POS

BT4

BT2 BT1

BT3

(CR2032)

(A76 or 357)

(AAA)(AAA)

Note: BT2 is

only used in

two-cell mode.

BT1 Battery Holder for 1.5 V AAA. Use for one-cell or two-cell mode.

BT2 Battery Holder for 1.5 V AAA. Use for two-cell mode only.

BT3 Battery Holder for 3 V Coin Cell (CR2032).

BT4 Battery Holder for 1.5 V Button Cell (A76 or 357).

C8051F930-DK

Figure 8. Bottom of C8051F930 Target Board

Rev. 0.5 13

Page 14

C8051F930-DK

P0.2 P0.3

Pin 1

Pin 2

J3

J4

J2

`

P3

CP

2103

U3

P2

DEBUG

J9

USB POWER

RESET

P1.6

P1.5

POWER OFF BEFORE

SW4

SWITCHING MODE

2 CELL

1 CELL

J17

IMEASURE

H2

SILICON LABS

www.silabs.com

H1

Pin 1

J6

VDD/DC+

J5

J7 J13

F930

U1

J14

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

TOUCH SENSE SWITCH

P2.0

TOUCH SENSE SWITCH

P2.1

P1.4

J15

GND

J16

R15

J12J8

+3VD

+1VD

VBAT

J1

SW5

ON

OFF

P1

SW2 SW3

PORT2

PORT1

SW1

PORT0

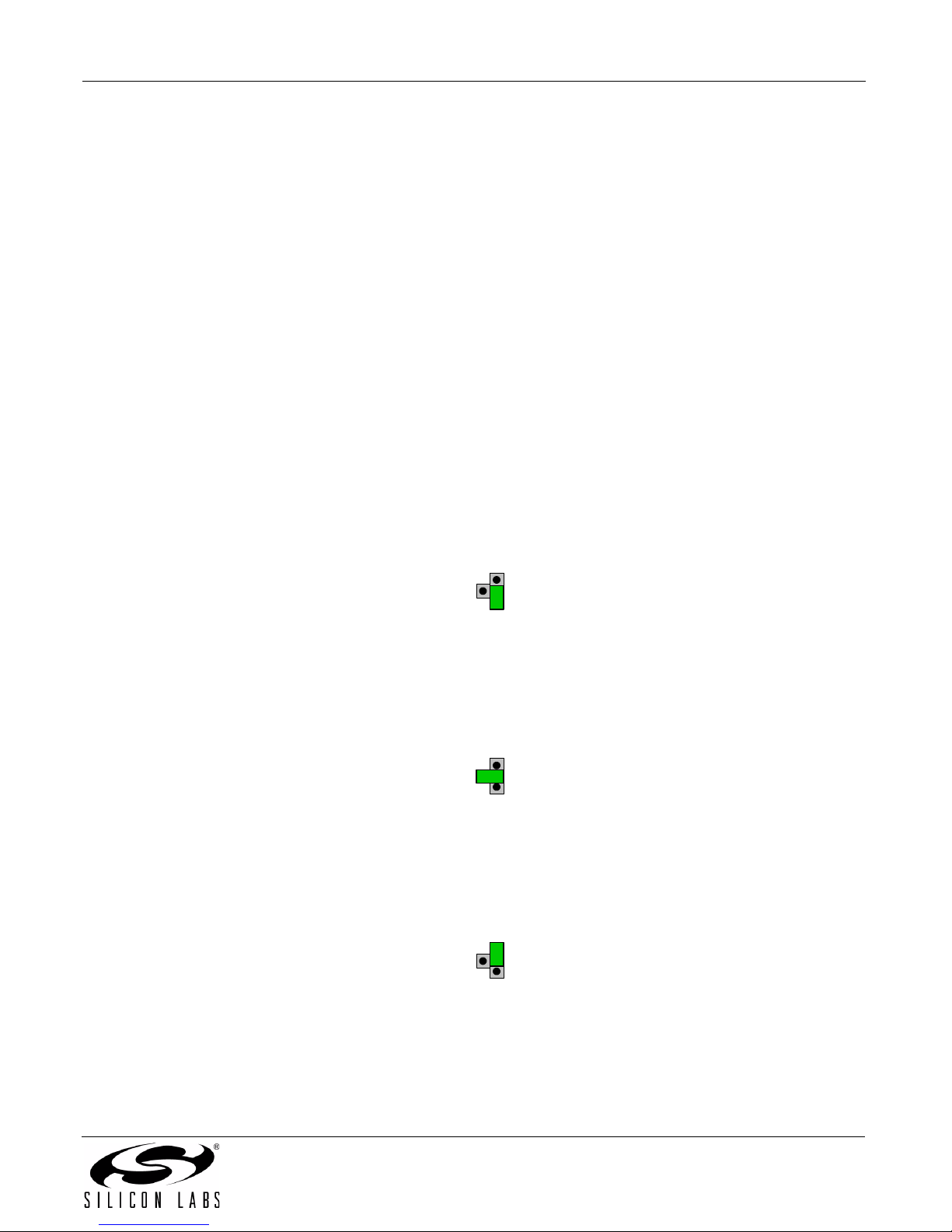

7.1. Target Board Shorting Blocks: Factory Defaults

The C8051F930 target board comes from the factory with pre-installed shorting blocks on many headers. Figure 9

shows the positions of the factory default shorting blocks.

Figure 9. C8051F930 Target Board Shorting Blocks: Factory Defaults

14 Rev. 0.5

Page 15

C8051F930-DK

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

J11

J10

VBAT

WALL_PWR

AAA_BAT

COIN_CELL

7.2. Target Board Power Options and Current Measurement

The C8051F930 Target Board supports three power options, selectable by the three-way header (J10/J11). The

power options vary based on the configuration (one-cell or two-cell mode) selected by SW4. Power to the MCU

may be switched on/off using the power switch (SW5). Important Note: The power switch (SW5) must be in the

OFF position prior to switching between one-cell and two-cell mode using SW4. The power options are

described in the paragraphs below.

7.2.1. Wall Power

When the J10/J11 three-way header is set to WALL_PWR, the C8051F930 Target Board may be powered from the

following power sources:

9 VDC power using the ac to dc power adapter (P2)

5 VDC USB VBUS power from PC via the USB Debug Adapter (J9)

5 VDC USB VBUS power from PC via the CP2103 USB connector (P3)

All the three power sources are ORed together using reverse-biased diodes (D1, D2, D3), eliminating the need for

headers to choose between the sources. The target board will operate as long as any one of the power sources is

present. The ORed power is regulated to a 3.3 V dc voltage using a LDO regulator (U2). The output of the regulator

powers the +3 VD net on the target board.

If SW4 is configured to select two-cell mode, the VBAT supply net on the target board is powered directly from the

+3 VD net. If SW4 is configured to select one-cell mode, the VBAT supply net is powered directly from the +1 VD.

This power supply net takes +3 VD and passes it through a 1.65 V LDO. The LDO’s output voltage is variable and

can be set by changing the value of resistor R32.

7.2.2. AAA Battery

When the J10/J11 three-way header is set to AAA_BAT, the C8051F930 Target Board may be powered from a

single AAA battery inserted in BT1 or from the series combination of the AAA batteries inserted in BT1 and BT2. A

single battery is selected when SW4 is configured to one-cell mode. The two AAA batteries configured in series to

provide a voltage of ~3 V are selected when SW4 is configured to two-cell mode.

7.2.3. Coin Cell Battery

When the J10/J11 three-way header is set to COIN_CELL, the C8051F930 Target Board may be powered from a

single 1.5 V Alkaline (A76) or Silver Oxide (357) button cell inserted in BT4 or from a single 3 V Lithium (CR2032)

coin cell inserted in BT3. The button cell (BT4) is selected when SW4 is configured to one-cell mode, and the coin

cell (BT3) is selected when SW4 is configured to two-cell mode.

7.2.4. Measuring Current

The header (J17) and terminal block (H2) provide a way to measure the total supply current flowing from the power

supply source to the MCU. The measured current does not include any current from the VBAT LED (DS2), the

address latch (U4) or the quiescent current from the power supply; however, it does include the current used by

any LEDs powered from the VDD/DC+ supply net or sourced through a GPIO pin. See the target board schematic

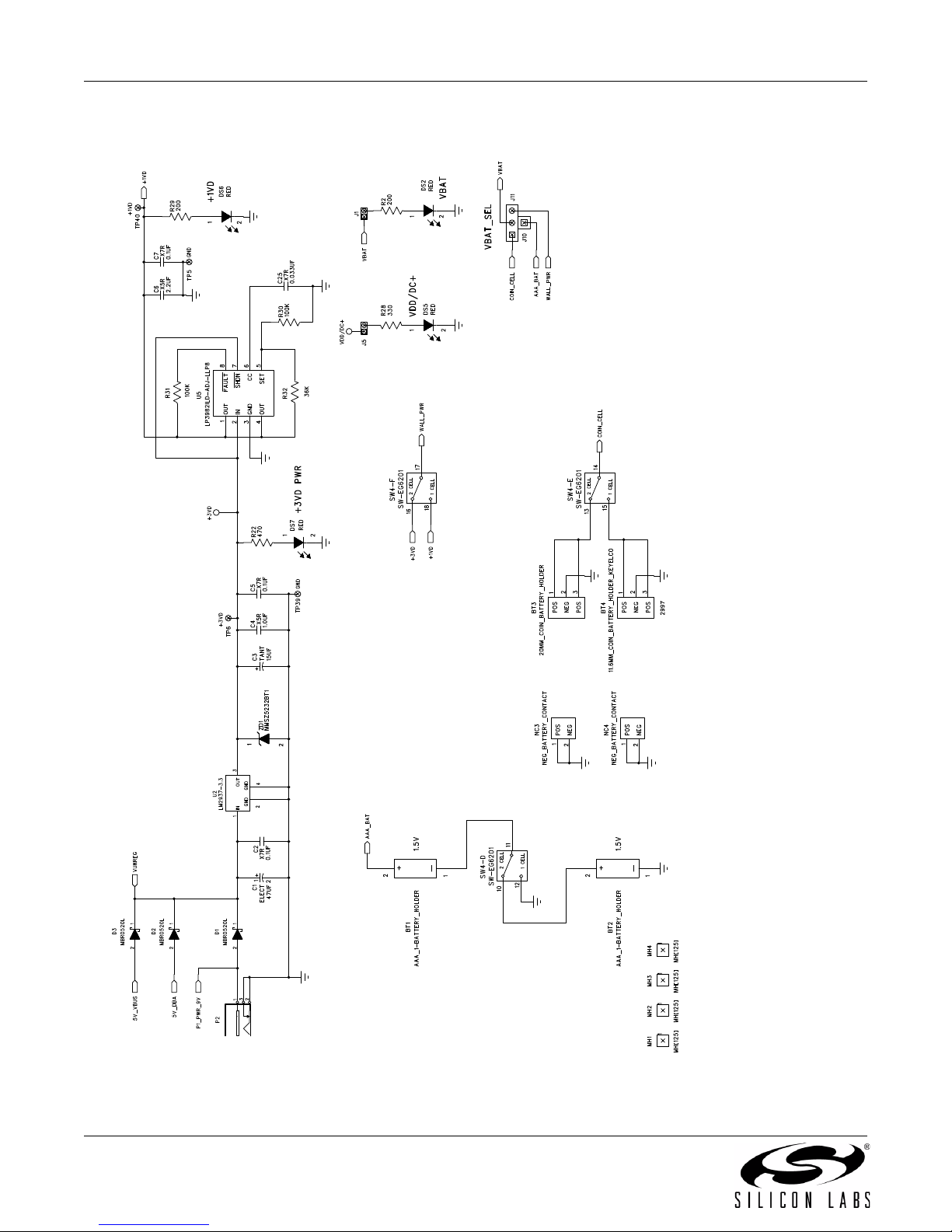

in Figure 10 through Figure 12 for additional information.

Rev. 0.5 15

Page 16

C8051F930-DK

7.3. System Clock Sources

7.3.1. Internal Oscillators

The C8051F930 device installed on the target board features a factory calibrated programmable high-frequency

internal oscillator (24.5 MHz base frequency, ±2%) and a low power internal oscillator (20 MHz ±10%). After each

reset, the low power oscillator divided by 8 results in a default system clock frequency of 2.5 MHz (±10%). The

selected system clock and the system clock divider may be configured by software for operation at other

frequencies. For low-frequency operation, the C8051F930 features a smaRTClock real time clock. A 32.768 kHz

Watch crystal (Y2) is included on the target board. If you wish to operate the C8051F930 device at a frequency not

available with the internal oscillators, an external crystal may be used. Refer to the C8051F93x-C8051F92x data

sheet for more information on configuring the system clock source.

7.3.2. External Oscillator Options

The target board is designed to facilitate the installation of an external crystal (Y1). Install a 10 M resistor at R9

and install capacitors at C20 and C21 using values appropriate for the crystal you select. If you wish to operate the

external oscillator in capacitor or RC mode, options to install a capacitor or an RC network are also available on the

target board. Populate C21 for capacitor mode, and populate R16 and C21 for RC mode. Refer to the C8051F93xC8051F92x data sheet for more information on the use of external oscillators.

7.4. Port I/O Headers (J2, J3, J4, J6)

Access to all Port I/O on the C8051F930 is provided through the headers J2, J3, and J4. The header J6 provides

access to the ground plane for easy clipping of oscilloscope probes.

16 Rev. 0.5

Page 17

C8051F930-DK

7.5. Switches and LEDs

Three push-button switches are provided on the target board. Switch SW1 is connected to the reset pin of the

C8051F930. Pressing SW1 puts the device into its hardware-reset state. Switches SW2 and SW3 are connected to

the C8051F930’s general purpose I/O (GPIO) pins through headers. Pressing SW2 or SW3 generates a logic low

signal on the port pin. Remove the shorting block from the header (J8) to disconnect the switches from the port

pins. The port pin signal is also routed to pins on the J2 and P1 I/O connectors. See Table 1 for the port pins and

headers corresponding to each switch.

Two touch sensitive (contactless) switches are provided on the target board. The operation of these switches

require appropriate firmware running on the C8051F930 MCU that can sense the state of the switch. See Section

6.3. "Touch Sensitive Switch Example‚" on page 11 for details about example source code.

Five power LEDs are provided on the target board to serve as indicators. Each of the two regulators has a red LED

used to indicate the presence of power at the output of the regulator. A red USB Power LED turns on when a USB

cable is plugged into the USB connector P3. One power LED is also added to each of the two primary supply nets

powering the MCU (VDD/DC+ and VBAT). The LEDs connected to the supply nets may be disabled by removing

the shorting blocks from J1 and J5.

Two LEDs are connected to GPIO pins P1.5 and P1.6 for use by application software. See Table 1 for the port pins

and headers corresponding to each LED.

A potentiometer (R15) is also provided on the target board for generating analog signals. Place a shorting block on

J16 to connect the wiper to P0.6/CNVSTR. The header J15 allows the negative terminal of the potentiometer to be

tied to GND or to P1.4. When tied to GND, the potentiometer is always enabled and will draw a measurable

amount of supply current. When tied to P1.4, it only draws current when P1.4 is driving a logic 0 and draws no

current when P1.4 is driving a logic 1.

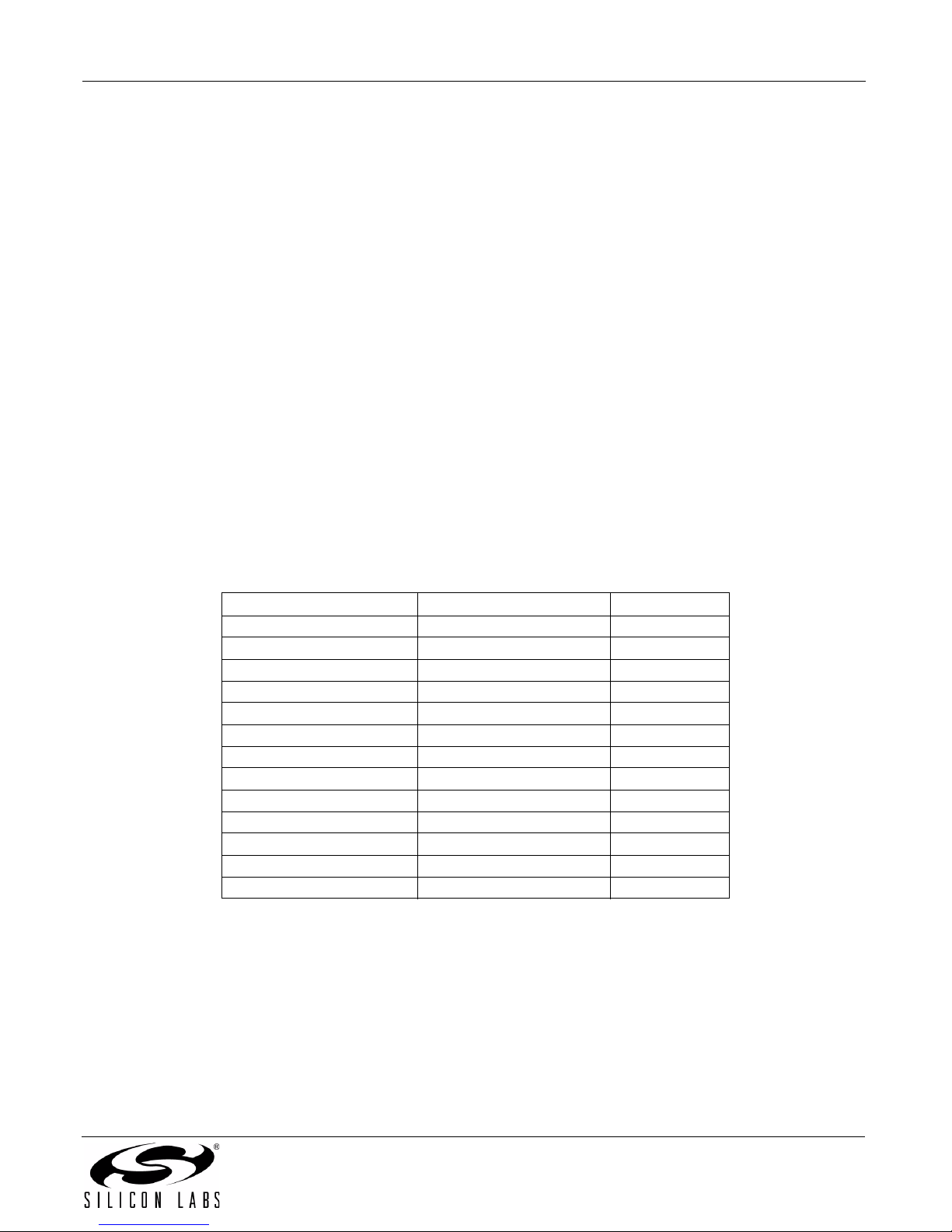

Table 1. Target Board I/O Descriptions

Description I/O Header(s)

SW1 Reset none

SW2 P0.2 J8[5–6]

SW3 P0.3 J8[7–8]

P2.0 (Touch Sense Switch) P2.0 none

P2.1 (Touch Sense Switch) P2.1 none

Red LED (P1.5) P1.5 J8[1–2]

Yellow LED (P1.6) P1.6 J8[3–4]

Red LED (VDD/DC+) VDD/DC+ Supply Net J5

Red LED (VBAT) VBAT Supply Net J1

Red LED (USB Power) USB VBUS none

Red LED (+1 VD Power) +1 VD Regulator Output none

Red LED (+3 VD Power) +3 VD Regulator Output none

Potentiometer (R15) P0.6/P1.4 J15, J16

Rev. 0.5 17

Page 18

C8051F930-DK

7.6. Expansion I/O Connector (P1)

The 96-pin Expansion I/O connector P1 provides access to all signal pins of the C8051F930 device (except the C2

debug interface signals). In addition, power supply and ground pins are included. A small through-hole prototyping

area is also provided. See Table 2 for a list of pin descriptions for P1.

Table 2. P1 Pin Descriptions

Row A

Pin #

1+3VD 1 GND 1 nc

2nc 2nc 2nc

3nc 3nc 3nc

4nc 4nc 4nc

5nc 5nc 5nc

6nc 6nc 6nc

7nc 7nc 7nc

8nc 8nc 8nc

9nc 9nc 9nc

10 nc 10

11

12 P0.2H 12

13 P1.7/AD7 13 P1.6/AD6 13 P1.5/AD5

14 P1.4/AD4 14 P1.3/AD3 14 P1.2/AD2

15 P1.1/AD1 15 P1.0/AD0 15 A7-Latch

16 A6-Latch 16 A5-Latch 16 A4-Latch

17 A3-Latch 17 A2-Latch 17 A1-Latch

18 A0-Latch 18 P2.3/A11 18 nc

19 nc 19 nc 19 P2.3/A11

20 P2.2/A10 20 P2.1/A9 20 P2.0/A8

21 /WR

22 P2.3/A11 22 P2.2/A10 22 P2.1/A9

23 P2.0/A8 23 ALE 23 nc

24 nc 24 nc 24 nc

25 nc 25 GND 25 nc

26 GND 26 nc 26 nc

27 nc 27 nc 27 nc

28 nc 28 VDD/DC+ 28 VBAT

29 nc 29 nc 29 nc

30 nc 30 nc 30 nc

31 nc 31 nc 31 nc

32 nc 32 GND 32 nc

Description

P0.5/RX

Row B

Pin #

11

21 /RD 21 P0.2H

Description

P0.7/IREF0

P0.4/TX

P0.1/AGND

Row C

Pin #

10

11 P0.3H

12

Description

P0.6/CNVSTR

P0.0/VREF

18 Rev. 0.5

Page 19

C8051F930-DK

7.7. Target Board DEBUG Interface (J9)

The

DEBUG

Serial Adapter or the USB Debug Adapter to the target board for in-circuit debugging and Flash programming.

Table 3 shows the

7.8. Serial Interface (J12)

A USB-to-UART bridge circuit (U3) and USB connector (P3) are provided on the target board to facilitate serial

connections to UART0 of the C8051F930. The Silicon Labs CP2103 (U3) USB-to-UART bridge provides data

connectivity between the C8051F930 and the PC via a USB port. The VIO power supply and TX, RX, RTS and

CTS signals of UART0 may be connected to the CP2103 by installing shorting blocks on header J12. The shorting

block positions for connecting each of these signals to the CP2103 are listed in Table 4. To use this interface, the

USB-to-UART device drivers should be installed as described in Section 3.2. "CP210x USB to UART VCP Driver

Installation‚" on page 2.

connector J9 provides access to the

DEBUG

pin definitions.

Table 3. DEBUG Connector Pin Descriptions

Pin # Description

1 +3VD (+3.3VDC)

2, 3, 9 GND (Ground)

4 P2.7/C2D

5RST

6P2.7

7RST

8 Not Connected

10 USB Power (+5 VDC from J9)

DEBUG

(C2) pins of the C8051F930. It is used to connect the

(Reset)

/C2CK

Table 4. Serial Interface Header (J12) Description

Header Pins UART0 Pin Description

J12[9–10] CP2103_VIO (VDD/DC+)

J12[7–8] TX_MCU (P0.5)

J12[5–6] RX_MCU (P0.4)

J12[3–4] RTS (P0.6)

J12[1–2] CTS (P0.7)

7.9. Analog I/O (H1)

Several of the C8051F930 target device’s port pins are connected to the H1 terminal block. Refer to Table 5 for the

H1 terminal block connections.

Table 5. H1 Terminal Block Pin Descriptions

Pin # Description

1 P0.6/CNVSTR

2P0.7/IREF0

3 GND (Ground)

4 P0.0/V

(Voltage Reference)

REF

Rev. 0.5 19

Page 20

C8051F930-DK

7.10. IREF Connector (J7)

The C8051F930 Target Board also features a current-to-voltage 1 k load resistor that may be connected to the

current reference (IREF0) output that can be enabled on port pin (P0.7). Install a shorting block on J7 to connect

port pin P0.7 of the target device to the load resistor. If enabled by software, the IREF0 signal is then routed to the

J2[8] and H1[2] connectors.

7.11. VREF and AGND Connector (J13, J14)

The C8051F930 Target Board also features 4.7 µF capacitor in parallel with a 0.1 µF that can be connected to

P0.0/VREF when using the Precision Voltage Reference. The capacitors are connected to P0.0/VREF when a

shorting block is installed on J13. Using the Precision Voltage Reference is optional since 'F93x-'F92x devices

have an on-chip High-Speed Voltage Reference.

The shorting block J14 allows P0.1/AGND to be connected to ground. This provides a noise-free ground reference

to the analog-to-digital Converter. The use of this dedicated analog ground is optional.

7.12. C2 Pin Sharing

On the C8051F930, the debug pins C2CK and C2D are shared with the pins RST and P2.7, respectively. The

target board includes the resistors necessary to enable pin sharing which allow the RST

normally while simultaneously debugging the device. See Application Note “AN124: Pin Sharing Techniques for the

C2 Interface” at www.silabs.com for more information regarding pin sharing.

and P2.7 pins to be used

20 Rev. 0.5

Page 21

C8051F930-DK

8. Frequently Asked Questions

1. Should power be turned off when switching between one-cell and two-cell mode?

Yes, power must be turned off by placing SW5 in the OFF position when switching between one-cell and twocell mode. Switching between modes while power is on may result in increased power consumption and

possible damage to low voltage transistors.

2. I have placed the MCU in Sleep Mode. Why is the supply current greater than 1 µA?

This can be caused by a number of factors. Check the following:

a. Verify that the USB Debug Adapter is not connected to the device. When connected, it can draw

approximately 2–5 µA from the VDD/DC+ supply net.

b. Verify that the P1.5 and P1.6 LEDs are turned off in software (P1.5 and P1.6 set to logic HIGH).

Alternatively, the P1.5 and P1.6 LEDs can be disabled by removing the corresponding shorting blocks

from J8.

c. Verify that the VDD/DC+ Power LED is disabled (remove shorting block from J5).

d. Verify that the shorting block on J15 does not connect the potentiometer negative terminal to GND, since

this would result in continuous current of ~ 300 µA. The shorting block may be removed, or configured to

enable the potentiometer when P1.4 is set to logic LOW. When the potentiometer enable is under

software control, be sure to set P1.4 to logic HIGH prior to placing the device in Sleep Mode.

e. Verify that J7, J13, and J14 do not have shorting blocks installed.

3. I have been measuring the sleep mode current using the “µA” setting on my multimeter. Why am I no

longer able to connect to the IDE?

When most multimeters are placed in “µA” mode, a large resistance is placed in series with the power supply.

This “current limiting” resistor prevents the MCU from starting up. To measure current during startup, make sure

that the multimeter is configured to its “mA” setting.

Alternatively, a shorting block can be placed on J17 to ensure that the multimeter does not limit current during

startup.

4. Where can I find a schematic of the C8051F930 Target Board?

A target board schematic can be found in the C8051F930-DK User’s Guide which is available on the

Development Tools CD and is installed in the following folder (by default):

C:\SiLabs\MCU\Documentation\UsersGuides

5. Which power LED should I use to determine if the MCU is powered?

The VDD/DC+ LED (DS5) should be used to determine if the MCU is powered. If you have applied power to the

board, but the VDD/DC+ LED is not turning on, check the following:

a. Verify that the correct power source (J10, J11) is selected.

b. Verify that J17 has a shorting block.

c. Verify that SW5 is in the ON position.

d. Verify that J5 has a shorting block installed.

Rev. 0.5 21

Page 22

C8051F930-DK

6. What can I do to reduce active supply current?

Below are some suggestions for reducing the active supply current:

a. Clear all wake-up sources in the PCU0CF register. This will allow the low power oscillator to be disabled

when it is not being used as the system clock. This optimization can reduce the supply current by up to

30 µA.

b. When operating at system clock frequencies above 10 MHz, minimize supply current by setting the

BYPASS bit (FLSCL.6) to 1. If the system clock needs to decrease below 10 MHz, clear the BYPASS bit

to 0.

c. If the precision oscillator is not being used, turn off the precision oscillator bias by setting the OSCBIAS

bit (REG0CN.4) to 0.

7. Why does P0.7/IREF0 have a voltage of 200 mV when IREF0CN is set to 0x00?

When IREF0CN is set to 0x00, the current reference is completely turned off. When a shorting block is installed

on J7, the voltage at P0.7/IREF0 should be 0 V unless one of the following conditions is present:

a. The P0.7/IREF0 pin is not configured for analog I/O (weak pull-up enabled).

b. The P0.7/IREF0 pin is being used as CTS

(a shorting block is installed on J12).

8. I have configured a Port pin as an analog input. Why is it still shorted to ground?

On C8051F93x-C8051F92x devices, configuring a Port pin to analog mode (using PnMDIN) disables the digital

input path and the weak pull-up. It does not explicitly disable the output drivers.

Software can ensure that the output drivers are disabled by configuring the Port pin to open-drain output mode

(using PnMDOUT) and writing 1 to the port latch.

9. Why does power consumption increase when an analog signal (hovering around mid-supply) is

connected to a digital input?

This phenomenon is called the “crowbar” effect and is present in all CMOS circuitry. If the input of a CMOS

structure is not a strong 1 or 0, then both the PMOS and NMOS devices are partially turned on causing current

flow from VDD to GND.

To prevent the “crowbar” effect, ensure that pins with analog voltage levels are configured for analog I/O.

10.Why does the dc/dc converter stop regulating when the load current exceeds 10 mA?

The default register settings for the dc/dc converter are optimized for low power applications requiring less than

10 mA of supply current. If the application requires additional supply current, the default values may be

overridden to provide up to 65 mW of output power.

To configure the dc/dc converter to high power mode, perform the following steps prior to enabling any high

power device:

a. Set DC0CN = 0x01. This selects the high-current switches.

b. Set DC0CF = 0x04. This sets the peak inductor current limit to 500 mA.

22 Rev. 0.5

Page 23

C8051F930-DK

11. When the missing clock detector is enabled, why does the MCU reset if I switch from the default system

clock (Low Power Oscillator divided by 8) to smaRTClock divided by 1?

Background:

—The missing clock detector will trigger a reset if the system clock period exceeds 100 µs.

—Switchover between clock sources occurs in 1 clock cycle of the slowest clock.

—Changing the clock divide value requires up to 128 cycles of the undivided clock source.

Since the clock source change occurs in a single cycle and the clock divide change can take up to 128

cycles, the system clock will be set to the new clock source divided by the old divide value for a brief period

of time. In this example, the actual system clock will be 4.096 kHz for up to 128 cycles of the undivided clock

source. This causes the missing clock detector to time out and reset the MCU.

The proper way of changing the system clock when both the clock source and the clock divide value are

being changed is as follows:

If switching from a fast “undivided” clock to a slower “undivided” clock:

a. Change the clock divide value.

b. Poll for CLKRDY >

c. Change the clock source.

If switching from a fast “undivided” clock to a slower “undivided” clock:

1.

d. Change the clock source.

e. Change the clock divide value.

f. Poll for CLKRDY >

12.Why is the MCU pre-maturely released from reset when using a wall supply with a slow rise time?

The maximum VDD Ramp Time is specified at 3 ms. If the power supply ramp takes longer than 3 ms to reach

0.9 V, then the device may be released from reset before the supply has reached the minimum operating

voltage. The slow ramp time (>3 ms) can occur when using a bench power supply that does not have an output

enable switch.

1.

Rev. 0.5 23

Page 24

C8051F930-DK

9. Schematics

24 Rev. 0.5

Figure 10. C8051F930 Target Board Schematic (Page 1 of 3)

Page 25

C8051F930-DK

Figure 11. C8051F930 Target Board Schematic (Page 2 of 3)

Rev. 0.5 25

Page 26

C8051F930-DK

26 Rev. 0.5

Figure 12. C8051F930 Target Board Schematic (Page 3 of 3)

Page 27

NOTES:

C8051F930-DK

Rev. 0.5 27

Page 28

C8051F930-DK

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silicon Laboratories assumes no responsibility for errors and omissions, and disclaims responsibility for any consequences resulting from

the use of information included herein. Additionally, Silicon Laboratories assumes no responsibility for the functioning of undescribed features

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Silicon Laboratories assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Silicon Laboratories product could create a situation where personal injury or death may occur. Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

CONTACT INFORMATION

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

Please visit the Silicon Labs Technical Support web page:

https://www.silabs.com/support/pages/contacttechnicalsupport.aspx

and register to submit a technical support request.

Silicon Laboratories and Silicon Labs are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

28 Rev. 0.5

Loading...

Loading...