Page 1

SIGMA SYSTEMS

MODELS C4 & CC-3

.5

PROGRAMMABLE TEMPERATURE CONTROLLER / INTERFACE

OPERATING & PROGRAMMING MANUAL

Firmware Version 7.5.2

Manual Revision 4

June 3, 1999

SIGMA SYSTEMS CORPORATION

1817 John Towers

San Diego, California 92116 USA

TEL: (619) 258-3700 WWW.SigmaSystems.Com FAX: (619/258-3712)

C4 Manual Rev 7.5.2

Page 2

Copyright 1997, 1998

Sigma Systems Corporation

1817 John Towers

El Cajon, California 92020 USA

All rights reserved

The manual may be reproduced, in whole, or in part, solely for the purposes of use

and training for the use, of Sigma Systems equipment, or as required to assist in the

sale of new Sigma Systems equipment. No modification of the content is permitted.

C4 Manual Rev 7.5.2

Page 3

TABLE OF CONTENTS

1. INTRODUCTION ................................................. 9

1.1 Models C4 & CC-3.5 Explained ................................. 9

1.2 General Description ........................................ 10

1.3 Custom Features / Interchangeability WARNING .................. 11

1.4 Release 7.5.2 Firmware ..................................... 11

1.5 C4 vs. CC-3 Differences (What’s New) ......................... 12

1.5.1 Hardware & Stability Improvements ..................... 12

1.5.2 Hardware Change (EEPROM replaces BBSRAM) .......... 12

1.5.3 Firmware Uploads ................................... 13

1.5.4 Forced Start from PROM Firmware ..................... 13

1.5.5 Front Panel Information Display at Startup ................ 13

1.5.6 Temperature Out of Range Shutdown ................... 13

1.5.7 Internal Error Shutdown Conditions ..................... 14

1.5.8 Fahrenheit Temperature Scale Supported ................ 14

1.5.9 Temperature Probe Correction (Calibration) ............... 14

1.5.10 “Bumpless” Temperature Control ...................... 14

1.5.11 Intelligent 2 Probe Control (Probe Averaging) ............ 15

1.5.12 Default Setup Parameters Restore..................... 16

1.5.13 Program Mode Step Insert & Delete .................... 16

1.5.14 Program Mode Any Step Points to Step 100 ............. 16

1.5.15 Program Mode Safer Program Clear ................... 16

1.5.16 Program Mode Run Time Program Pre-check ............ 16

1.5.17 Remote Mode EIA-232 Baud Rate Improvement .......... 16

1.5.18 Remote Mode EIA-232 Port Initialization ................ 17

1.5.19 Remote Mode Fault Tolerant Parser .............. 17

1.5.20 Remote Mode System Information Queries .............. 17

1.5.21 Remote Mode Operation Information Queries ............ 17

1.5.22 Remote Mode Setup Parameter Commands ............. 18

1.5.23 Remote Mode IEEE-488 (GPIB) Monitoring .............. 18

1.5.24 Setup Mode Easier Parameter Access .................. 18

2. PHYSICAL DESCRIPTION......................................... 19

2.1 Front Panel ............................................... 19

2.1.1 Digital LED Display.................................. 19

2.1.2 LED Indicators ..................................... 19

2.1.3 Mode Switch ....................................... 20

2.1.4 Keyboard ......................................... 21

2.2 Rear Panel Connections .................................... 22

3. GENERAL OPERATION & ERROR CONDITIONS ...................... 23

3.1 Startup Displays ........................................... 23

3.1.1 Model Number and Firmware Version Number Display ...... 23

3.1.2 Temperature Range Display ........................... 23

3.1.3 Serial Number Display................................ 24

C4 Manual Rev 7.5.2

3

Page 4

3.2 Updating Firmware .........................................24

3.2.1 Upgrading Firmware by PROM Replacement ..............25

3.2.2 Upgrading Firmware by Uploading through C4 Serial Port ....25

Making the physical connection for upload ................26

Running the upload software on the PC ..................26

Starting the upload on the C4 .......................... 27

3.3 Restoring Setup Parameters to Default Values....................27

3.4 Fahrenheit Operation .......................................28

3.5 System Operating (Temperature) Range ........................29

3.6 Probe Out of Range Shutdown ................................29

3.6.1 Effect of Probe Correction on Out of Range Shutdown .......30

3.6.2 Probe Out of Range Shutdown Reported in Error/Status String

.................................................30

3.6.3 Clearing a Probe Out of Range Shutdown ................30

3.7 Internal Error Shutdown Conditions ............................31

3.7.1 Watchdog Timer ....................................31

3.7.2 Memory signature checking ...........................31

3.7.3 Setup parameter integrity checking......................32

3.8 Software Probe Correction (Calibration) .........................32

3.9 Status and Error Reporting ...................................33

3.10 Fail-safe System .......................................... 34

4. INTELLIGENT 2 PROBE CONTROL..................................35

4.1 How Intelligent 2 Probe Control functions ........................36

4.2 Preparing for Intelligent 2 Probe Control ........................37

4.3 Using Intelligent 2 Probe Control ..............................38

5. LOCAL MODE ( Basic Operation ) ...................................39

5.1 Displaying Temperature .....................................39

5.2 Displaying and Changing the Setpoint ..........................40

5.3 Controlling to a Setpoint .....................................41

5.4 Compressor Control ........................................ 42

6. PROGRAM MODE ...............................................43

6.1 Description of a Program Step ................................43

6.1.1 Format of a Program Step.............................44

6.1.2 Maximizing Ramp Speed & Other Ramp Considerations .....45

6.2 Clearing Program Memory (Reinitializing program steps)............46

6.3 Displaying Program Steps.................................... 46

6.4 Entering or Changing a Program Step ..........................47

6.5 Insert Program Step ........................................ 47

6.6 Delete Program step........................................48

6.7 Running (Executing) a Program ...............................48

6.7.1 Program Run Time Information/Considerations ............49

6.7.2 Run Time Pre-read Errors .............................49

No Probe 2 Error ...................................50

4

C4 Manual Rev 7.5.2

Page 5

Invalid Loop Count Error ............................. 50

Setpoint Out of Range Error .......................... 50

6.8 Special Commands ........................................ 50

6.8.1 Controlled Program Looping ........................... 51

6.8.2 External Compressor On ............................. 52

6.8.3 External Compressor Off ............................. 52

6.8.4 Optional Aux/Power Control Port On .................... 52

6.8.5 Optional Aux/Power Control Port Off .................... 52

6.9 Common Programming Issues................................ 53

6.9.1 Step Numbering .................................... 53

6.9.2 Changing Substep Values ............................ 53

6.9.3 Control Ports....................................... 53

7. REMOTE MODE................................................. 55

7.1 EIA-232 Interface .......................................... 55

7.2 IEEE-488 Interface ......................................... 55

7.3 Command Summary (by functional group) ....................... 56

7.4 System Information Queries.................................. 57

7.4.1 QV Query Firmware Version........................... 57

7.4.2 QN Query Controller Serial Number ..................... 57

7.4.3 QR Query Controller Temperature Range ................ 58

7.4.4 QS Query Setpoint & Control Probe Number .............. 58

7.4.5 QF, QFA Query Setup Parameter Value ................ 59

7.5 Operation Information Queries & Commands .................... 61

7.5.1 RS, RSA Request Status Byte ......................... 61

7.5.2 RE, REA Request Error Byte .......................... 61

7.5.3 QE, QEA Query Error/Status String..................... 62

7.5.4 QC Query Last Command ............................ 64

7.5.5 ES Enable SRQ (Status Request Mode) ................. 64

7.5.6 DS Disable the SRQ ................................ 64

7.5.7 PT Read Temperature ............................... 65

7.6 Setup Parameter Commands ................................. 66

7.6.1 SC Set Probe Correction ............................. 66

7.6.2 WP Set PID Constants .............................. 67

7.6.3 BF & BO Blower Off & Blower On Commands ............ 68

7.6.4 SL Set UUT Temperature Limits ....................... 69

7.6.5 SD Set UUT Temperature Differential Limits.............. 69

7.6.6 UP Write Current Parameters to NV Memory ............. 69

7.7 System Operation Commands ................................ 70

7.7.1 SI Select Immediate Mode............................ 70

7.7.2 SP Select Program Mode ............................ 70

7.7.3 PN Select Active (control) Probe ....................... 70

7.7.4 GT, GTF Go To Temperature ......................... 71

7.7.5 RA, RAF Ramp to Temperature ....................... 71

7.7.6 DL Delay (Dwell Interval) ............................. 72

7.7.7 CO & CF Turn the Refrigeration Port On................. 72

C4 Manual Rev 7.5.2

5

Page 6

7.7.8 TO & TF Turn Aux/Power Control Port On................ 72

7.7.9 QU Quit Controlling .................................73

7.8 Error and Status Reporting - Overview .......................... 74

7.8.1 Status Byte ........................................ 74

7.8.2 Error Byte .........................................75

7.8.3 Error/Status String...................................75

Error/Status String Bit Definitions ....................... 77

8. SETUP MODE...................................................79

8.1 Displaying the Field Values...................................81

8.2 Changing the Value of a Setup Field ............................82

8.3 Two Probe Mode ...........................................82

8.4 Auto-start Mode ........................................... 82

8.5 Blower Shut-off Mode .......................................83

8.6 Temperature Control Terms (PID) (Setup fields 0, 10, 11, 12) ........ 83

8.7 Software Probe Correction (Calibration) .........................83

Entering probe correction setup data ....................84

9. APPENDIX ......................................................87

9.1 Programming Examples & Notes ..............................87

9.1.1 Simple Local Program Example ........................ 87

9.1.2 Using shortcuts to shorten program entry time ............. 89

9.1.3 Local Program Example Using the Special Commands ...... 91

9.2 Keeping More than One Program in Memory ..................... 93

9.3 Sigma Systems C4 Programming Worksheet ..................... 95

9.4 Sample Command Structure for IEEE-488 GPIB Operation ..........96

9.5 Installation and Use of TTL Outputs and Input .................... 98

9.6 Field Calibration of Model C4 Controller .........................99

9.7 Troubleshooting ..........................................101

9.7.1 Servicing Considerations - Service WARNINGS...........101

9.7.2 Before you go any further..............................101

9.7.3 Diagnosing and Solving Hardware Problems .............101

9.7.4 Noise Immunity ....................................102

9.7.5 Diagnosing and Solving Local Mode Problems ............102

Controller starts immediately in Local Mode..............102

9.7.6 Diagnosing and Solving Program Mode Problems ......... 102

Hard Loops ....................................... 102

Explicit Program End ...............................103

Blowers Misbehaving ...............................103

Program hangs on Ramp as Quickly as Possible step ...... 103

9.7.7 Diagnosing and Solving Remote Mode Problems ..........103

EIA-232 Problems .................................104

GPIB IEEE-488 Problems ...........................104

9.7.8 Firmware Upload Problems ...........................104

Starting the C4 from PROM based firmware ............. 105

COM port issues...................................105

6

C4 Manual Rev 7.5.2

Page 7

9.8 Temperature Control (PID) Tuning & Problems.................. 105

Adjusting for changing needs ......................... 106

The Proportional Term .............................. 107

The Integral Term ................................. 107

The Differential Term............................... 108

9.9 Displayed Messages and Errors Table ......................... 109

9.10 Technical Support, Repairs & Returns ........................ 110

INDEX .......................................................... 111

C4 Manual Rev 7.5.2

7

Page 8

8

C4 Manual Rev 7.5.2

Page 9

1. INTRODUCTION

This manual describes the operating procedures for the Sigma Systems Models C4

& CC-3.5 Controllers, microprocessor based controllers and control communications

interfaces for the family of Sigma Systems temperature chambers and thermal

platforms.

1.1 Models C4 & CC-3.5 Explained

The models C4 & CC-3.5 controllers are successors to the model CC-3.

The model C4 is a completely redesigned controller that uses a

completely different and more modern set of internal components with

a new processor and completely new firmware. Model C4 controllers

are only available as new products from Sigma Systems.

The model CC-3.5 is a hybrid upgrade controller that uses only the

digital circuitry of the model C4. It is made by substituting the C4

digital p.c. board (known within Sigma Systems as the “CPU board”, or

the “A” board) for the CC-3's “A” board. The upgrade from CC-3 to

CC-3.5 also includes a few small modifications to other internal

components. The power supply, power switching, analog, and front

panel components of the CC-3 remain. Model CC-3.5 controllers are only

available as the product of upgrading a CC-3 controller.

From a functional perspective, models C4 & CC-3.5 are identical because all of the

functionality of the controllers is defined by the processor, bus interface components,

and firmware... all of which are integral with the C4 “A” board. The C4 analog and

front panel components that remain unique to the C4 (not included in the CC-3

upgrade from CC-3) provide slightly better accuracy and substantially better noise

and static immunity.

For the balance of this manual, the term C4 will mean to

include both the model C4 controller and the model CC-3

.5

controller. In the event that there is a difference between

the two models, that difference will be explicitly detailed.

C4 Manual Rev 7.5.2

.5

9

Page 10

1.2 General Description

Using the model C4, temperature control is available manually from the front

panel, by use of user entered programs, or via remote control via either a EIA-232

or IEEE-488 GPIB. The controller has a precision temperature reading capability

with a digital read-out. Two temperature probes can be connected to the

controller allowing either probe or both probes to be the control probe(s) while

either probe can be used to take measurements.

Two additional controlled device ports are available. They are intended for on/off

control of a refrigeration compressor and an external load such as a device under

test, or a main chamber or platform power relay. These ports normally are

supplied as TTL level (low voltage) ports but are optionally available with solid

state relays to control line voltage as in the case of units with mechanical

refrigeration. The compressor control port may be toggled from the front panel at

any time in the manual (LOCAL) mode. The compressor is designed to not cycle

on and off with the temperature control function.

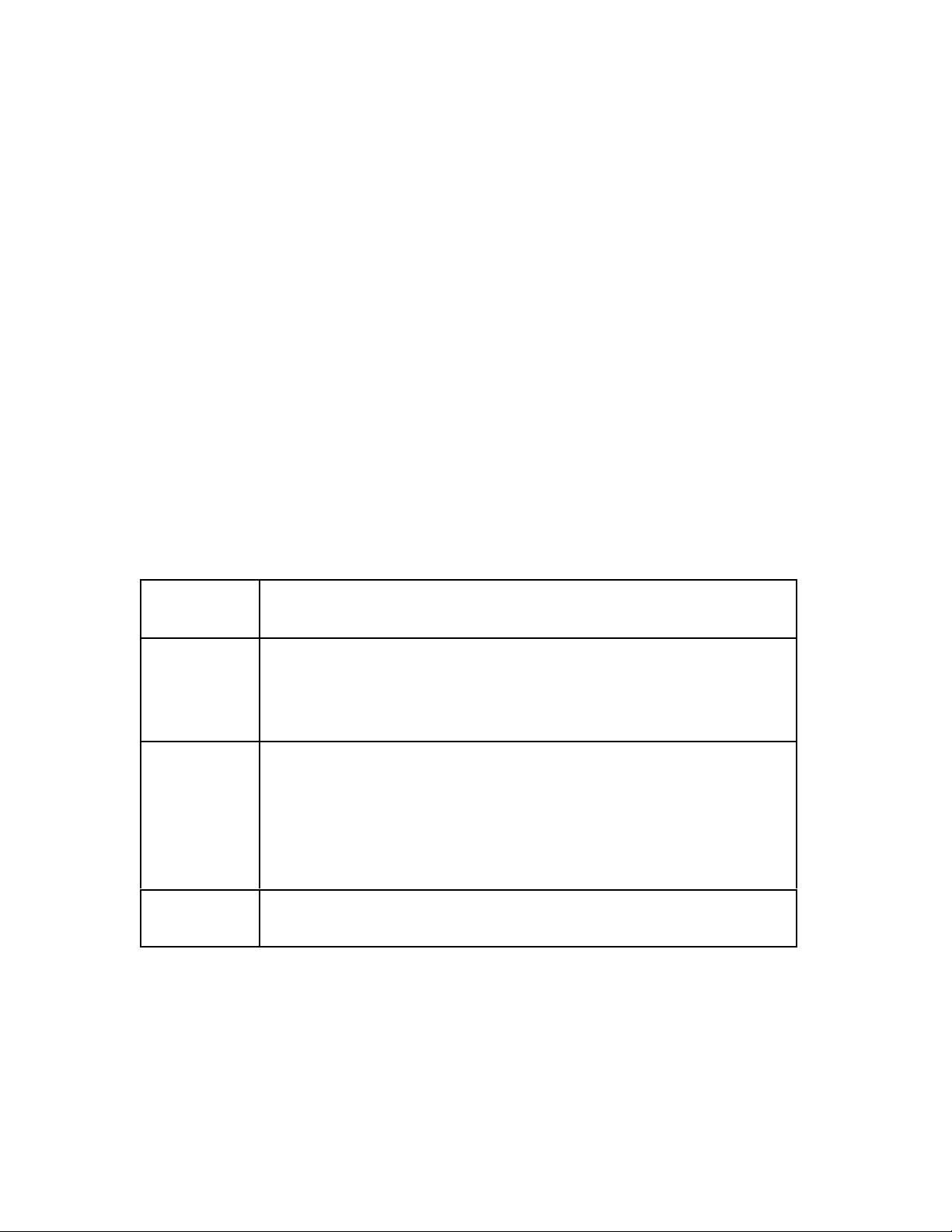

The controller operates in each of four modes:

Local

Mode

Program

Mode

Remote

Mode

Setup

Mode

Single Setpoint control from the front panel. Simple

Start/Stop functionality.

Programmed control using programs entered, stored, and

run from the front panel. 100 Temperature/Duration

Program steps available. Multiple programs may be stored

and called as needed.

Control via EIA-232 or IEEE-488 GPIB. The IEEE-488

interface implementation is a TALKER/LISTENER with

serial poll. Extended addressing and parallel poll

capabilities are not supported. The EIA-232 interface is

fully configurable for baud rate, data bits, stop bits and

parity.

Used to define and store operation and environment

variables that control how the C-4 behaves.

10

C4 Manual Rev 7.5.2

Page 11

1.3 Custom Features / Interchangeability WARNING

Each Sigma Systems C4 Controller has been custom configured for the chamber or

platform with which it was supplied or for which it was specified. Many units

include special wiring for custom control applications, precision fail-safe additions,

non-standard voltages, external unit power control, etc. Units that may appear

to be identical may be internally quite different. Do not interchange

controllers between controlled devices (chambers and/or platforms)

unless you are certain that the controllers have been identically

constructed.

Failure to heed this warning voids your warranty, may cause unpredictable

controlled device behavior that could cause damage to persons or property, pose a

risk of fire, or cause other problems. If you must move controllers between

controlled devices, please contact the Sigma technical support department for

assistance and advice.

1.4 Release 7.5.2 Firmware

This manual is specifically written to cover the features of Release 7.5.2 firmware

for the Sigma Systems Model C4 controller. The features of this release firmware

are largely backward compatible with all CC-3 and earlier CC-3.5 & C4 firmware.

This release fixes a number of bugs found in the CC-3.5 interim release versions

6.8.6, 6.9.0, and 7.0.0. It also adds a number of new features. See Section 1.5.

Note: This release implements probe temperature correction on a per

probe basis. Interim CC-3.5 releases implemented this feature on a global

basis.

Sigma highly recommends that all users update to the latest firmware release.

Contact Sigma Technical Support. See Section 9.10.

Note: This release is not available as an upload file for serial port firmware

updating of your controller. Due to non-backward compatible change in the way

some data is stored internally, this version must be installed using a PROM

obtained from Sigma Systems.

C4 Manual Rev 7.5.2

11

Page 12

1.5 C4 vs. CC-3 Differences (What’s New)

1.5.1 Hardware & Stability Improvements

The new C4 introduces a number of new improvements to make the controller

faster and more reliable than its predecessor.

The C4 has a completely new digital processing board. The new board has a much

faster processor, more memory, and a much faster IEEE-488 GPIB controller.

Interrupts have been completely restructured to improve stability. The multilayer

design is far more tolerant of both static and power line interference. There is

now a watchdog timer to detect system lockups in the event that something does

interfere with the system. The battery backed RAM has been replaced by an

EEPROM. The Vactrol type isolation device in the failsafe circuit has been

replaced. The C4 contains no components that have a time based failure mode.

The new firmware also monitors the state and integrity of internal memory.

Critical system information is stored in multiple places so that minor errors due to

uncontrollable transients or other causes can be repaired on the fly with no

disruption in process control. Likewise, both the front panel display and the GPIB

interface are monitored constantly to assure that their operation has not been

compromised by static discharge or line transient. In the event of a problem,

either device can be reset on the fly to allow operations to continue normally.

System integrity is further enhanced by a series of successive shutdown processes

that monitor the integrity of the data coming from the sensor probes. In the event

that any probe reports a temperature more than 20

/C beyond the limits set in the

controller, the controller will shut down all heating and cooling and display a

warning message. Likewise, in the event that a sensor probe reports an extreme

temperature, either hot or cold, the system will assume that a probe has become

compromised by an open or shorted circuit and stop applying heat and cooling,

shut down the system and display an appropriate warning message..

1.5.2 Hardware Change (EEPROM replaces BBSRAM)

All C4 controllers and CC-3.5 controllers converted after January 1998 have the

battery backed static RAM (BBSRAM) replaced with an EEPROM. This change

was implemented to reduce the possibility that the controller will require service.

Although changing the BBSRAM when the battery died (about every 5-12 years)

was a fairly simple matter, the necessity for doing so was found to be a nuisance

as was diagnosing the need for the change. The BBSRAM or EEPROM provides

the non volatile memory where the C4 stores both the setup parameter

information and the user programs.

12

C4 Manual Rev 7.5.2

Page 13

1.5.3 Firmware Uploads

When new firmware is available for your C4, you can easily upload it into the

controller using the controller’s serial port. The procedure requires only a diskette

bootable PC and a serial cable and takes only about ten minutes. Firmware

updates, when available, may be obtained on diskette for a fee from Sigma

Systems or for free by download from www.SigmaSystems.Com or

ftp.SigmaSystems.Com. See Section 3.2.2

1.5.4 Forced Start from PROM Firmware

The controller can be started from the original firmware version that is stored in

the PROM. Uploaded versions are stored in flash memory. If a firmware upload

session should go astray somehow, this feature allows the controller to still

operate. See Section 9.7.8.

1.5.5 Front Panel Information Display at Startup

The controller model is displayed at startup - See Section 3.1.1

The firmware version number is displayed at startup - See Section 3.1.1

The operating range may be displayed at startup - See Section 3.1.2

The controller serial number may be displayed - See Section 3.1.3

1.5.6 Temperature Out of Range Shutdown

The controller now stores the operational limits for itself, the controlled device

(Sigma chamber or platform), and the unit under test (UUT). The operating

temperature is checked against these limits, if it is too far outside these limits,.

the system is shutdown with an appropriate error message displayed. See

Section 3.5.

C4 Manual Rev 7.5.2

13

Page 14

1.5.7 Internal Error Shutdown Conditions

The C4 monitors system health by keeping track of three additional areas;

they are:

Processor health Tracked by watchdog timer

Memory condition Checked at startup

Setup parameter table Checked continuously as used

Some detected internal errors can be repaired on the fly. If this is possible, the C4

will recover from the error and you will not know the error existed. If, however,

the error is not repairable and the system must be shut down, an error message

will be displayed to help you understand what happened and how to prevent or

cope with it. See Section 3.7.

1.5.8 Fahrenheit Temperature Scale Supported

The controller will now operate in either Celsius /C or Fahrenheit /F mode. See

Section 3.4.

1.5.9 Temperature Probe Correction (Calibration)

The C4 will allow you to enter data via the Setup mode that will correct anomalies

in the temperature readings and control. Such adjustments are sometimes

necessary to optimize accuracy at a particular temperature, or to compensate for

differences between raw probe temperature data and actual temperatures. These

differences can be the result of probe placement, effects of the unit under test on

the temperature data, or other causes. See Section 3.8

1.5.10 “Bumpless” Temperature Control

(Not in this release. Available in next release, without charge. Check the

Sigma Systems FTP or WWW site for downloadable file.)

When the setpoint is changed, the PID control algorithm begins a new “search” for

the right amount of heat and/or cooling to maintain the new setpoint. Normally,

for each new setpoint, the PID routines begin the search anew... behaving as if the

controller was just turned on. The controller will quickly determine that heat or

cooling is called for, and while the chamber or platform advances toward the new

Setpoint, the PID routine adjusts for the response to heat and cool and

methodically settles the chamber or platform in on the new setpoint. For most

setpoint changes, where the new and old setpoints are quite different, this is a

fast, accurate and appropriate method of control.

14

C4 Manual Rev 7.5.2

Page 15

However, when the change in the Setpoint is very small, this “start from the

beginning” search routine can search over such a wide range that it will introduce

a “bump” in the platform or chamber temperature that can exceed the amount of

the Setpoint change. The C4 includes an intelligent PID routine that constrains

the search appropriately for the change in Setpoint and thus eliminates the “PID

bump”.

1.5.11 Intelligent 2 Probe Control (Probe Averaging)

(Not in this release. Available in next release, without charge. Check the

Sigma Systems FTP or WWW site for downloadable file.)

Intelligent 2 Probe Control allows the internal temperature of the unit under test

(UUT) to be used in the temperature control algorithm. Both the primary probe,

located in the chamber airstream or platform, and the secondary probe, typically

located inside the UUT, are used to provide a chamber or platform response that

can accelerate testing while respecting the absolute and relative limits of all the

affected components.

Common single probe control strives to maintain the Setpoint temperature in the

chamber airstream, or at the platform surface. If the UUT is massive, or is a poor

thermal conductor, the internal temperature of the UUT can lag the chamber or

platform temperature considerably. Conversely, using a second probe, buried

inside the UUT, to control the temperature may achieve better UUT interior

temperature control, but it will do so at the risk of extreme temperatures in the

chamber or on the platform. If not carefully monitored, second probe only control

can result substantial damage to the chamber or platform and UUT and risk

operator injury.

Intelligent 2 Probe Control is designed to achieve the Setpoint temperature inside

the UUT (probe 2) either as quickly as possible, or at a controlled ramp rate, while

always respecting the limits of the controller, chamber or platform, and UUT. The

user may specify the absolute limits of the exterior of the UUT as well as limit

themal shock by specifying a dynamically changing “sliding scale” maximum

temperature differential for the UUT skin to core temperature. Intelligent 2

Probe Control will maximize speed in achieving internal UUT Setpoint

temperatures, while, at the same time, controlling the thermal stress on the UUT.

An in depth discussion of this feature can be found in Section 4.

1.5.12 Default Setup Parameters Restore

There is a procedure for erasing the current setup parameter table data and

restoring it basic default values. See Section 3.3

C4 Manual Rev 7.5.2

15

Page 16

1.5.13 Program Mode Step Insert & Delete

Program steps may now be deleted from or inserted into programs.

See Sections 6.5 & 6.6.

1.5.14 Program Mode Any Step Points to Step 100

Any program step may now point to step 100 (program end) as the next step to

execute.

1.5.15 Program Mode Safer Program Clear

Some deliberate delays have added to the key sequence to completely clear the

program memory to lessen the likelihood that all of program memory will be

erased by accident.

1.5.16 Program Mode Run Time Program Pre-check

When a program is run in Program Mode, the C4 pre-reads the program to look

for run-time errors that it can report to you before starting. By pre-checking your

program, errors are dealt with immediately rather than after the program has

partially completed. The following items are checked:

Calls for probe 2 when only one probe is defined for the system

Calls for setpoints that are not within the system operating range

Loop counter numbers not within the range of 1 to 999 integer

See Section 6.7.2 for a full explanation.

1.5.17 Remote Mode EIA-232 Baud Rate Improvement

EIA-232 communications are now supported at 19,200 and 38,400 bps.

See Section 8.

16

C4 Manual Rev 7.5.2

Page 17

1.5.18 Remote Mode EIA-232 Port Initialization

The CC-3 required that to use the EIA-232 port, the port had to be initialized by

switching the mode switch to SETUP before switching to REMOTE mode. The C4

eliminates this requirement. The EIA-232 port is initialized each time the remote

switch is switched to REMOTE mode.

1.5.19 Remote Mode Fault Tolerant Parser

The C4 uses a very fault tolerant parser. Command strings received over either

the EIA-232 or GPIB ports are converted to upper case, extra spaces and tabs are

removed, commas are converted to spaces and line terminators are corrected if

necessary. For this reason, programs that work properly with the C4 and not with

a CC-3, that use only CC-3 commands, probably have syntax errors that the C4

parser corrects. See Section 9.7.7

1.5.20 Remote Mode System Information Queries

QV Query Firmware Version ..................... See Section 7.4.1

QN Query Serial Number ........................ See Section 7.4.2

QR Query Temperature Range .................... See Section 7.4.3

QS Query Setpoint & Control Probe Number ........ See Section 7.4.4

QF Query Setup Parameter Data (Binary Query)..... See Section 7.4.5

QFA Query Setup Parameter Data (ASCII Query) ..... See Section 7.4.5

1.5.21 Remote Mode Operation Information Queries

RSA Request Status Byte (ASCII Query) ............. See Section 7.5.1

REA Request Error Byte (ASCII Query) ............. See Section 7.5.2

QE Query Error/Status String (Binary Query) ....... See Section 7.5.3

QEA Query Error/Status String (ASCII Query) ........ See Section 7.5.3

QC Query Last Command........................ See Section 7.5.4

C4 Manual Rev 7.5.2

17

Page 18

1.5.22 Remote Mode Setup Parameter Commands

SC Set Correction (Calibration) for Probe ........... See Section 7.6.1

WP Set PID Constants ........................... See Section 7.6.2

BF Turn Blowers Off ............................ See Section 7.6.3

BO Turn Blowers On ............................ See Section 7.6.3

SL Set UUT Temperature Limits .................. See Section 7.6.4

SD Set UUT Temperature Differential Limits........ See Section 7.6.5

UP Write SRAM Parameters to EEPROM ........... See Section 7.6.6

1.5.23 Remote Mode IEEE-488 (GPIB) Monitoring

The IEEE-488 bus controller is automatically reset if a problem is detected. No

message to the user is generated as no data is typically lost in the process.

1.5.24 Setup Mode Easier Parameter Access

Setup parameters may now be accessed directly by number rather than having to

scroll the entire list. If scrolling is used, there is now a backup key so the list can

be scrolled in either direction. Likewise, for parameters that are chosen from a

list, the list can be scrolled in either direction or the parameters can be keyed in

directly without scrolling the list. See Section 8.1.

18

C4 Manual Rev 7.5.2

Page 19

2. PHYSICAL DESCRIPTION

The SIGMA SYSTEMS Model C4 Controller fits into an area 3.5" x 5.5" x 9.5"

long. Connection to the chamber or platform is made through an umbilical cable

with a 12 pin connector that is standard for all SIGMA chambers and thermal

platforms. Controllers destined for use with SIGMA thermal platforms have an

additional 6 pin connector used for the sensor probe circuits. All C4 controllers

have a 3 pin “pigtail” connector at the back of the controller for control of

refrigeration via solid state relay. This feature was optional on CC-3 controllers

and is thus not a consistent feature of CC-3.5 controllers.

2.1 Front Panel

The front panel consists of four major parts: the LED digit display, the LED

indicators, the mode switch and the keypad. The numbers in circles on the front

panel guide the user through the steps for changing the temperature setting in

the LOCAL (manual) mode of operation. See Section 5.

2.1.1 Digital LED Display

The Digital LED Display is a 7 digit display arranged in the following

configuration:

***-****

The display is used for showing probe temperatures, setpoints, program steps,

fail-safe status and setup information.

2.1.2 LED Indicators

Below the Digital LED Display are four discrete LED Indicators. These indicators

are arranged in the following order:

REFERCOOL

HEAT

RUN

REFER indicator lights if power is applied to the refrigeration compressor

control port (not all units are equipped with compressors).

C4 Manual Rev 7.5.2

19

Page 20

COOL indicator lights when cooling is active, typically during the time the

cryogenic valve is open on cryogenically cooled units.

HEAT indicator is pulsed along with the on and off function of the heaters.

These indicators are active in all modes of operation.

RUN indicator shows whether the chamber temperature is being controlled.

2.1.3 Mode Switch

The Mode Switch is used to apply power to the chamber and to select the mode of

operation. It is a 5 position rotary switch arranged as follows:

The OFF position removes the power from heating and cooling and compressor

control circuits of both the controller and the chamber or thermal platform.

CAUTION: Placing the mode switch in the OFF position

does not remove all power from either the controller or the

chamber or thermal platform. Only the heating, cooling,

and compressor control circuits are turned off. Full line

voltage potential is still available in many places in both the

controller and the chamber or platform. See servicing

warnings and instructions in the appendix of this manual.

Moving the rotary switch changes the mode of operation of the chamber. The

different modes are described in detail in separate sections of this manual. When

the rotary mode switch is moved to a new position, other than OFF, the

temperature control loop, if running, is turned off, heating and cooling are

disabled but the chamber blowers will continue to run unless disabled via setup

20

C4 Manual Rev 7.5.2

Page 21

parameter F15. Likewise, at the end of a local or remotely controlled program,

chamber blowers will continue to run, but heating and cooling will be disabled.

Note that a chamber in this condition, with blowers running, will exhibit some

heating due to blower air friction. This effect is exaggerated in units equipped

with high velocity blowers. Moving the rotary switch between OFF and LOCAL

will maintain the last used setpoint for the next operation of the controller. See

6.3 for description of auto-start function.

2.1.4 Keyboard

The keyboard consists of 20 momentary contact keys. Certain keys are functional

only in some of the modes of operation. With some keys, such as the Display

Control, the function is different depending on the mode of operation. The

Keyboard is arranged in the following configuration:

123

456

789

.

CLEAR PROG Clear program from memory

START STOP Start/Stop temperature control

REFER Toggle refrigeration compressor on or off *

ENTER Enter/finalize current keyboard entry

ADV Advance to next program step

DISP TEMP Display temperature

CLEAR ENTRY Clear current keyboard/display entry

DISP CNTL Display control setpoint

0

+

-

CLEAR

PROG

REFER ENTER

ADV

CLEAR

ENTRY

START

STOP

DISP

TEMP

DISP

CNTL

* = LOCAL MODE ONLY.

C4 Manual Rev 7.5.2

21

Page 22

2.2 Rear Panel Connections

At the rear panel of the controller, a cable is provided to connect to the power,

cooling solenoid, mechanical refrigeration and heaters of the chamber. In

addition, a six lug screw terminal block (J1) is provided for eyelet terminal

connection of the temperature probes and for connection of one additional optional

device such as the Sigma PFS-2 Precision Fail Safe.

J1 TOP

Probe 1 (Black lead)

ì

Probe 2 (Black lead)

í

Chassis Ground (Probe shield)

î

(Chamber or platform ground, etc.)

Probe 1 & 2 return (Red or White lead)

ï

Auxiliary device ground

ð

12 VDC for Fail-Safe

ñ

Please observe all standard anti-static procedures when making connections to

these points!

There is also an IEEE-488 (GPIB) connector, series 57 (metric threads), and an

EIA-232 connector, female DB-25, for the remote modes of operation. Two TTL

outputs and one TTL input are also available on J6. (See Section 9.5)

22

C4 Manual Rev 7.5.2

Page 23

3. GENERAL OPERATION & ERROR CONDITIONS

3.1 Startup Displays

3.1.1 Model Number and Firmware Version Number Display

The C4 identifies itself upon power up. It will display the model number for 1

second, then the firmware version number for 2½ seconds as follows:

c3-5 rel 7.5.2

c4 rel 7.5.2

3.1.2 Temperature Range Display

Each C4 controller is set at the factory for use with a specific device (chamber or

platform). Because the controlled device was made to specific thermal limit

specifications, and because constraining the operating range of the controller

improves it’s accuracy, the controller to be used with each device is set to operate

only within the range appropriate for that device. The setting of an operating

range involves a number of internal adjustments and calibrations and the loading

of specific control tables for that range. This setting can only be changed by

Sigma Systems service personnel. We recommend that each controller be kept

with the device for which it was originally configured.

However, if you find that it is necessary to move a controller to another device, it

is important that you check to be sure that the controller that is moved is

configured to operate in the appropriate range for the device it is to control. As of

November, 1998, controllers are supplied for five ranges as follows:

/C to 200/C -148/F to 392/F -100/C to 300/C -148/F to 572/F

-100

-100

/C to 350/C -148/F to 662/F -175/C to 400/C -283/F to 752/F

-195/C to 300/C -319/F to 572/F

To check the internal range setting of your C4 controller, turn the mode switch

from OFF to any other position. During the 2½ seconds that the firmware release

number is shown on the display, rapidly press <DISP/TEMP> three times. The

internal range setting will be displayed for 5 seconds following the version display.

An example:

200 - 100c 392 - 148f

(Celsius mode) (Fahrenheit mode)

C4 Manual Rev 7.5.2

23

Page 24

3.1.3 Serial Number Display

The controller serial number can be displayed at startup by pressing

<DISP/CTRL> while the model number (

number will be displayed in the format:

c3-5 or c4) is displayed. The serial

4-0 3276

The first digit (either a 3 or 4) indicates whether the controller is a CC-3

and the 5 digits to the right of the dash is the sequential part of the number.

There is no significance to the leftmost of the 5 sequential digits being separated

from the other 4 digits. The separation is a limitation of the display. When

recording or reporting serial numbers, please always use the 7 digit string,

including the leftmost digit and the dash in this format: 4-03276.

When the serial number is displayed, the controller is not controlling. The

number will remain on the display until the controller is turned off.

3.2 Updating Firmware

There are two methods of updating the firmware in the C4.

.5

or C4,

1. Physically replace the EEPROM that contains the firmware.

(There is usually a charge for firmware EEPROMs)

.

2. Use a PC to upload the firmware through the C4 serial port.

(Firmware and upload software are free from Sigma

System’s internet sites, www.SigmaSystems.com or

ftp.SigmaSystems.com)

Note: All firmware updates are available on EEPROM chips for physical

installation. Not all updates are available as downloads from the Sigma Systems

web site. The reason for this is that some firmware updates make changes in the

basic data structures inside the C4. Because firmware loaded into the C4 through

the serial port is stored separately, and in addition to, the EEPROM firmware,

and because the C4 can be started from either resident version, the two versions

must use compatible data structures. Thus, versions that will modify the data

structures in the C4 may only be installed by changing the firmware EEPROM.

24

C4 Manual Rev 7.5.2

Page 25

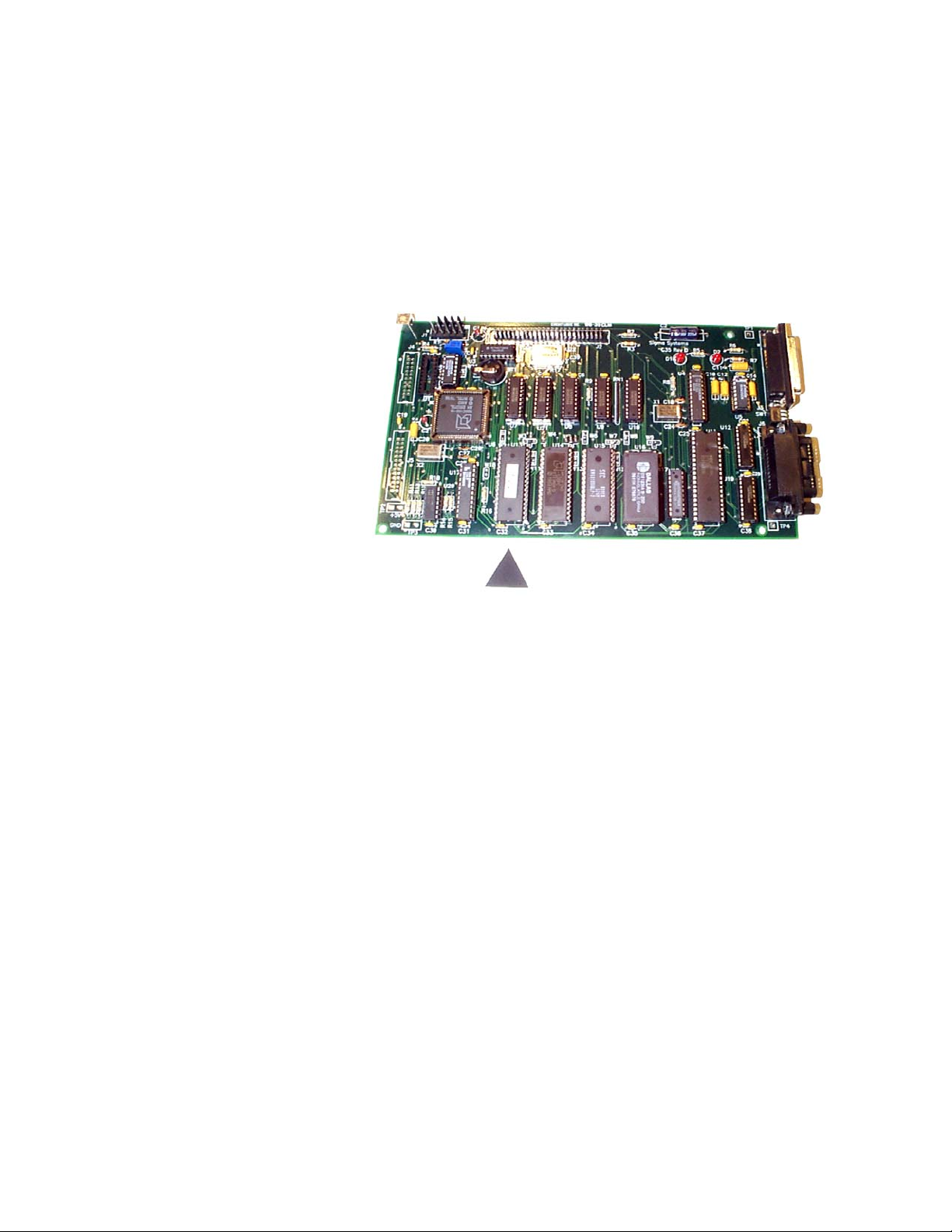

3.2.1 Upgrading Firmware by PROM Replacement

Before starting, be certain that you have a properly grounded antistatic

surface and a grounding strap to prevent damaging the C4 components

during disassembly and reassembly.

Remove the C4 from its cabinet or rack, then remove the EEPROM chip that

contains the firmware and replace it with a new one containing the updated

firmware. Firmware

EEPROMs are available

from Sigma Systems.

There is a charge for

firmware EEPROMs.

The firmware EEPROM

is located on the digital or

“A” board, the same board

that has the EIA-232 and

GPIB connectors on the

end. The location of the

firmware EEPROM is

shown by the triangle

pointer. The EEPROM

socket is labeled U13. Make certain that the end of the EEPROM with the notch

or notch mark is toward the inside, or center, of the board.

Note that it is possible to remove and replace the firmware EEPROM without

disassembling the C4. If you lay the controller upside down, and look at the

digital board from the bottom, the firmware EEPROM is the first large chip from

the front of the controller. You will not be able to see the U13 label, but you can

see the C32 label on the small capacitor located next to the firmware EEPROM

socket. Using a small flat bladed screwdriver or chip removal tool, carefully pry

the old EEPROM from it’s socket. Try to keep the chip as flat as possible while

removing it to prevent damage to the pins or socket. When replacing, keep the

replacement EEPROM flat to the socket, make sure all pins are started in their

respective receivers in the socket, then press the chip firmly into place.

3.2.2 Upgrading Firmware by Uploading through C4 Serial Port

Note: CC-3.5 controllers with version 7.0.0 firmware or earlier have battery

backed RAMS for non volatile storage. These units MUST have the BBRAM

replaced with an EEPROM before newer firmware is installed.

C4 Manual Rev 7.5.2

25

Page 26

Use a DOS bootable diskette and a PC type computer to load the new firmware

through the C4's serial port. You can obtain the required diskette from Sigma

Systems for a fee, or you can provide your own DOS bootable diskette and obtain

the necessary files for the upload process from the Sigma Systems site on the

Internet. The Internet address for this site is:

www.SigmaSystems.com

The download file, SSUPxxxx.EXE, may contain specific instructions that replace

the instructions in the next paragraph. After downloading the file, copy it to an

otherwise empty DOS bootable diskette and run SSUPxxxx.EXE. This file is a

self extracting ZIP archive that will install all the files you need onto the diskette.

Check for the presence of a README.TXT file on the diskette for instructions that

supplement or supercede these instructions.

Making the physical connection for upload

To upload firmware to your C4, you will need to connect the C4 to a DOS bootable

PC compatible computer using a straight-through, or modem type serial cable.

The C4 is configured as DCE (Data Communications Equipment). Therefore, do

NOT use a “null modem” type serial cable that has pins 2 & 3 crossed. Connect

the cable to either COM1 or COM2 on the PC and to the female DB25 connector

on the back of the C4.

Running the upload software on the PC

After you run the SSUPxxxx.EXE file on your DOS bootable diskette you are

ready to run the software. Place the floppy in the “A” drive of the PC and turn on

or reset the PC to allow it to boot from the floppy. Follow the instructions on the

screen. Note that the menu will allow you to do successive uploads without

restarting and will allow you to change serial ports as you do so. Users who will

be uploading to a number of controllers in one session will find that this feature

saves some time.

If the uploads are being done on a bench (as opposed to leaving the controller in

it’s chamber or platform housing), be certain to follow all precautions about

removing all power before removing the controller and about taking care to use

proper anti-static procedures when handling the controller. Be certain that the

bench has a properly grounded anti-static surface.

If you are going to upload firmware into many controllers successively in a bench

environment, you can use a PC with two serial ports (COM1 and COM2) and two

serial cables. You can then have the upload program alternate serial ports for the

26

C4 Manual Rev 7.5.2

Page 27

uploads so that you can upload to one controller while connecting and

disconnecting the other.

Starting the upload on the C4

When the PC is ready, turn the C4 controller on. During the 1 second display of

the model number, rapidly press <CLEAR/PROG> three times. The display will

read:

rs load

The firmware upload should begin immediately. The PC will indicate when the

load is complete.

If you have difficulties, see the trouble shooting information in Section 9.7.8.

3.3 Restoring Setup Parameters to Default Values

Note: The default values are very generic. They are not the values that were

likely in the controller when it was shipped from the factory. After completing

this procedure, please check each value to make certain that it is appropriate.

To restore the default values to the setup parameter table, turn the controller off,

then back on. During the 1 second in which the controller model is displayed,

press <CLEAR/ENTRY> very quickly 3 times. The display should then read

su res

Press <ENTER> to confirm that you want restore the default values. (Any other

key will abort the process). The display should then read

ee busy and then su done

Turn the controller off, then on again to resume operation with the new values.

The first time the controller is turned back on after restoring the default setup

parameters, the display will show

turned to SETUP. (You may see an ee busy display and model number

and/or firmware version number at this time.) The controller forces you to SETUP

mode before it will function as a reminder that the default values have been

loaded and that the parameters needed for your operation have not yet been set.

all res . The mode switch must then be

C4 Manual Rev 7.5.2

27

Page 28

When you have set the necessary parameters for your needs, you are ready to go

to LOCAL, PROGRAM, or REMOTE mode.

28

C4 Manual Rev 7.5.2

Page 29

3.4 Fahrenheit Operation

The C4 can use either Celsius or Fahrenheit temperature scales. Celsius is the

default mode. When the controller is operating in Celsius mode it’s behavior is

identical to the model CC-3 controller. When the controller is operating in

Fahrenheit mode, both the displays and the bus communications are different.

These differences are intentional and designed to prevent errors that might arise

from a user using setpoints in one scale while the controller is operating in the

other scale. Note, however, that there is no difference in the Program mode

programming operation of the C4 when operating in either Fahrenheit or Celsius

mode. It is incumbent upon the user to notice the differences in the temperature

displays and program accordingly.

To change the temperature scale, use SETUP mode (See Section 8) to access setup

parameter F16. Select either of these field values:

0 Celsius

1 Fahrenheit

When in Fahrenheit mode, temperature displays have an “F” following the probe

identifier on the left side of the display. Example:

p1f 102.4

Likewise, temperature inquires over the bus (PT command - See Section 7.5.7)

will return a string with an “F” as the third byte in the string. The string will

therefore be 1 byte longer than the string returned in Celsius mode. This

difference was intentional as it requires a modification of the parsing routine that

will assure that Celsius and Fahrenheit data are recognized properly. Thus, if the

current probe 1 temperature is 86.7/F, the result of a Fahrenheit mode get

temperature query for probe 1 (query command = PT1) would be

T1F 86.7<CR><LF>

If the temperature at probe 1 was 55.4/C, the same command in Celsius mode

would return

T1 55.4<CR><LF>

During Remote mode operation, the C4 may be queried to determine the current

temperature scale by using the QS, Query Setpoint, command. See Section 7.4.4.

C4 Manual Rev 7.5.2

29

Page 30

3.5 System Operating (Temperature) Range

The C4 controller operates within the limits of the system devices. There are 3

pairs (low-high) of temperature limits that constrain the range of operations.

1. The range of the C4 as it is set at the factory

2 The range of the controlled device (chamber or platform) as

described by setup parameters F25 & F26.

3 The range of the UUT (unit under test) as described by

setup parameters F27 & F28.

Each of these ranges is characterized by a low limit and a high limit. The highest

of the 3 low limits is the low temperature System Operation Limit. The lowest

of the 3 high limits is the high temperature System Operation Limit. In other

words, the controller will respect the most restrictive limits that are described by

the combination of the 3 ranges listed above.

The low and high temperature System Operating Limits define the System

Operating Range. The controller will not accept setpoints outside the System

Operating Range and will report error conditions and stop controlling if the

controlling probe(s) report a temperature too far outside that range.

Note: Probe 1 is always in the chamber airstream or platform and is always

monitored for conformance with the System Operating Range. Probe 2 is

monitored for conformance only if it is being used for control.

3.6 Probe Out of Range Shutdown

When the C4 is actively controlling the temperature of a chamber or platform, it

frequently checks to be certain that the control temperature, as reported by any

active control probe, is within the System Operating Range.

In the event that the temperature reported by the active control probe is more

than 20/C, and less than 50/C, outside the controller’s System Operating Range,

then the controller will presume that a “run away” condition exists. The controller

will turn off all heating and cooling and stop controlling. Blowers will be left in

the condition determined by setup parameter F15 (Blower shut-off mode). The

controller display will show

p1 lo p1 hi

30

C4 Manual Rev 7.5.2

Page 31

“LO” indicates that the reported temperature was 20-50/C below the System

Operating Range. “HI” indicates that the reported temperature was 20-50

above the System Operating Range. The number following the p is the number of

the probe that reported the excessive temperature.

In the event that the control temperature reported by the active control probe is

more than 50/C beyond the System Operating Range, the controller will presume

that the operation of the probe has been compromised by an open or shorted

circuit. The controller will turn off all heating and cooling and stop controlling.

Blowers will be left in the condition determined by setup parameter F15 (Blower

shut-off mode). The controller display will show

/C

p1 err p1 -err

The minus sign in the display indicates that the reported temperature was below

the System Operating Range and the absence of the minus sign indicates that it

was above the System Operating Range.

Note that because the C4 will report a hi or lo condition and stop controlling

for an error of 20-50/C, the only events that will typically trigger an err or -

err

open circuit (err) or short (-err ).

3.6.1 Effect of Probe Correction on Out of Range Shutdown

Any adjustments to the probe readings made by the Software Probe Correction

feature (See Section 3.8) will not affect system over/under temperature shutdown

operations. The raw (uncorrected) probe readings for the current active control

probe(s) are used for the system health monitoring.

3.6.2 Probe Out of Range Shutdown Reported in Error/Status String

Any Probe Out of Range Shutdown will set a bit in Byte 03 of the Error/Status

String. See Section 7.8.3 for specific bit assignments.

3.6.3 Clearing a Probe Out of Range Shutdown

condition is a instantaneous failure of the sensing circuit, most likely an

C4 Manual Rev 7.5.2

31

Page 32

The Probe Out of Range Shutdown condition can be cleared by pressing

<START/STOP> in Local or Program mode, by rotation the mode switch on the

front panel to a different position, or by issuing a Device Clear in Remote mode.

3.7 Internal Error Shutdown Conditions

The C4 monitors system health by keeping track of four internal areas; they are:

Processor health Tracked by watchdog timer

Memory condition Checked at startup

Setup parameter integrity Checked continuously

IEEE-488 bus integrity Checked continuously

The first three items, above, are discussed in sub sections below. The IEEE-488

bus controller is automatically reset if a problem is detected. No message to the

user is generated as no data is typically lost in the process.

3.7.1 Watchdog Timer

Should the system become locked due to corruption that causes the processor to

continuously malfunction, an independent watchdog timer will cause a full system

reset. After a watchdog reset, the display will show

res err

When this occurs, the mode switch must be turned to the OFF position, then back

to the desired mode to clear the reset message and continue operation. Internal

memory will be the same as it was when the shutdown condition occurred.

3.7.2 Memory signature checking

Each time the C4 is powered up, the system checks a series of memory signature

bytes to test the integrity of system memory. If the signature bytes are not

correct, the system assumes that memory has been compromised. If this should

occur (a normal event any time a memory chip is replaced) all of system memory

is reinitialized. All program steps for Program mode are reset to their default

values, and all setup parameters are reset to their default values. The display

will show

32

all res

C4 Manual Rev 7.5.2

Page 33

The mode switch must be subsequently turned to the SETUP position to clear the

display and resume normal operations. Be sure you remember to restore any

setup parameters that have been changed by the system reset.

3.7.3 Setup parameter integrity checking

Each time the system must rely on a system setup parameter the condition of the

setup parameter table is checked against a replica that the system stores in

another place in memory. If there is any difference between the two copies of the

parameter table, the system will try to determine which table is correct and

restore the incorrect copy. If restoration is not possible, the system will turn off

all heating and cooling, reinitialize the setup parameters to their defaults, and

display

su err

The mode switch must be subsequently turned to the SETUP position to clear the

display and resume normal operations. Be sure you remember to restore any

setup parameters that have been changed by the system reset

3.8 Software Probe Correction (Calibration)

The C4 will allow you to enter data via Setup or Remote mode that will correct

any anomalies in the temperature readings and control at two points. Such

adjustments are sometimes necessary to optimize accuracy at a particular

temperature, or to compensate for differences between raw probe temperature

data and actual temperatures.

Note: The purpose of Software Probe Correction is to allow precise calibration at

two points near the critical points of the user’s testing scheme. It does not replace

the hardware calibration process, nor should it. A number of system health

checks as well as process limits are based upon the raw, or uncorrected,

temperatures reported by the probes. It is important to optimize the hardware

level calibration before using this software calibration method.

Software probe correction is achieved by entering four temperatures, U1, C1, U2,

& C2, for each probe into the setup parameter table. U1 & U2 are the

uncorrected, or displayed, temperatures at two points. C1 & C2 are the corrected,

or actual, temperature at those same two points. Thus to make a correction using

ice water (0/C) and boiling water (100/C) when the display shows 2.3/C for the ice

water and 99/C for the boiling water, the user would enter the following:

C4 Manual Rev 7.5.2

33

Page 34

U1 2.3

C1 0

U2 99

C2 100

The C4 will then calculate a new slope and offset for the entire probe curve. All

temperatures reported by the corrected probe will be adjusted by applying this

new slope and offset to the raw temperature data reported by the probe.

Note: Software probe correction is done separately for each probe. The following

table shows the U1, C1, U2, C2 setup parameter assignments:

Probe 1 Probe 2

U1 F17 F21

C1 F18 F22

U2 F19 F23

C2 F20 F24

Entering these parameters via Setup mode is discussed in Section 8.7

Changing these parameters “on the fly” in Remote mode is discussed in Section

7.6.1

3.9 Status and Error Reporting

There are three sources for error and status information:

The Status Byte CC-3 compatible

The Error Byte CC-3 compatible

The Error/Status String

(64 bytes) CC-3.5 & C4 only

The Status Byte and Error Byte are bit mapped single bytes of data. The Error

Byte and the EIA-232 version of the Status Byte are replicated in the Error/Status

string. Maintaining the separate Error Byte allows CC-3 programs to run

properly on the C4. Their interaction with the SRQ error system is important for

all controllers. Here’s how it works:

When an error occurs, the appropriate bit is set in the Error Byte. Setting a bit in

the Error Byte, in turn, sets the error bit in the Status Byte. Setting the error bit

in the Status Byte sets the SRQ. The SRQ will also be set if either Interval

Complete or Setpoint Reached in the Status Byte are set.

34

C4 Manual Rev 7.5.2

Page 35

Some errors, especially those unique to the C4, are only defined in the

Error/Status String. In the event of one of these errors, bit 1 of the Error Byte

(this bit was not used by the CC-3) is set to indicate an extended error. The

Status Byte and SRQ are thus set as well.

The Error/Status String is a bit mapped 64 byte string (512 bits) that contains

both “event triggered” and “status monitoring” information. A complete

description of the Error/Status String and it’s behavior can be found in Section

7.8.3.

3.10 Fail-safe System

The C4 is designed to sense the loss of control circuit power due to opening of a

safety limit switch such as those supplied with all Sigma chambers and thermal

platforms. If the controller is in the RUN mode and the fail-safe is tripped, the

controller will stop controlling and display

display. It will also report the fail-safe tripped condition over the computer bus

interface if in use. In order to re- establish normal operation, the failsafe system

on Sigma chambers and thermal platforms requires that power be cycled off then

on in addition to the out of range temperature condition subsiding. Use the rotary

Mode Switch on the controller front panel. Turn the switch to OFF to clear the

fail-safe condition.

If the controller is to be used independently of a Sigma Systems temperature

chamber or thermal platform, connect pins 10 & 11 of the 12-pin power plug to pin

3 for 120 volt operation. In the case of 208-240 volt operation connect pins 10 &

11 to pin 6 through a 56kS ½ watt resistor. Opening this connection will cause

the above described failsafe condition.

fl safe on the digital LED

C4 Manual Rev 7.5.2

35

Page 36

36

C4 Manual Rev 7.5.2

Page 37

4. INTELLIGENT 2 PROBE CONTROL

(Probe Averaging)

(Not in this release. Available in next release, without charge. Contact Sigma

Systems to receive a revised firmware EEPROM.)

Intelligent 2 Probe Control allows the internal temperature of the UUT (Unit

Under Test) to be used in the temperature control algorithm. Both the primary

probe, located in the chamber airstream or in the platform, and the secondary

probe, typically located inside the UUT, are used to provide a chamber or platform

response that can accelerate testing while respecting the absolute and relative

limits of all the affected components.

Common single probe control strives to maintain the setpoint temperature in

either the chamber airstream, or at the platform surface. If the UUT is massive,

or is a poor thermal conductor, the internal temperature of the UUT can lag the

chamber or platform temperature considerably. If, as a result of measuring the

chamber air stream or platform temperature only, the test is terminated too

quickly, the UUT may not have actually achieved the desired setpoint test

temperature. Conversely, using a second probe, buried inside the UUT, to control

the temperature may achieve better UUT interior temperature control, but it will

do so at the risk of extreme temperatures in the chamber or on the platform and

thus at the UUT surface as well.

Intelligent 2 Probe Control is designed to achieve the setpoint temperature inside

the UUT (probe 2) either as quickly as possible, or at a controlled ramp rate, while

always respecting the limits of the controller, chamber or platform, and UUT. The

user may specify the absolute limits of the UUT as well as limit thermal shock by

specifying a proportionally applied maximum temperature differential for the

UUT skin to core temperature. Intelligent 2 Probe Control will maximize speed in

achieving internal UUT setpoint temperatures, while, at the same time,

controlling the thermal stress on the UUT.

Note: For the balance of this section, the description of Intelligent 2 Probe Control will

be related to operation of temperature chamber. All of this information applies to

thermal platforms as well, but they are not mentioned further to make the text easier to

read.

C4 Manual Rev 7.5.2

37

Page 38

4.1 How Intelligent 2 Probe Control functions

Intelligent 2 Probe Control takes advantage of the fact that increasing the

temperature differential between two objects increases the rate of heat transfer

between them. For instance, if a thick and heavy object is to be heated from 0/ to

100/, and the object is placed in a temperature chamber with a 100/ internal air

stream temperature, the temperature of the object will rise quickly at first

because of the large differential between the temperature of the chamber air

stream and the object.

However, as the object continues to absorb heat, the differential decreases and the

rate of heat transfer decreases. The closer the object’s temperature approaches

the air stream temperature, the more slowly the object absorbs heat. To maintain

the thermal transfer efficiency that existed early in the warming process (when

the differential was, for example, 80/), the air stream would have to continually

get warmer as the object heated. When the object was 20/, the air would have to

be 100/, when the object was 50/, the air would have to be 130/, when the object

was 80/, the air would have to be 160/, etc. Heating efficiency can be substantially

improved by this method.

However, because our object is thick and heavy, there likely is a large

temperature differential between the surface temperature of the object and the

core temperature that we are measuring. Even though the object’s core is only 80/

at some point in this process, the surface temperature, exposed to 160/ air, may

well be much higher. In fact, if the object is a poor thermal conductor, the surface

temperature may approach the air temperature... in this example, 160/.

While we would like to have our object’s core temperature increase as quickly as

possible, inducing a surface temperature that is 60/ over the setpoint may be more

than the object can tolerate. If we knew, however, that the object’s surface could

tolerate 130

/, then we could use an air stream temperature of 130/ - but no more -

to speed the transfer of heat into the object.

When the object’s core temperature started to approach the setpoint, we could

reduce the amount of over heating of the air and object surface. The closer the

core temperature got to the setpoint, the less overheating would be applied.

Eventually, just as the core temperature reached the setpoint, the amount of

overheating would be zero. The ramp rate of the core of the object would have

been maximized without exposing any of the object to temperatures exceeding it’s

tolerance.

There is one more consideration. You may want to achieve an object core

temperature as quickly as possible to improve production testing efficiency, but

you may want to not apply thermal differentials that will “shock” the object you

are testing. In fact, the object may have more tolerance for differentials when hot

38

C4 Manual Rev 7.5.2

Page 39

than cold, or visa versa. To properly protect your object you need to be able to

constrain the air temperature in the chamber (and thus the surface temperature

of the object) such that the difference between surface temperature and the core

temperature does not exceed some difference the object can tolerate. It would be

useful to be able to specify such a differential tolerance for both the high and low

thermal limits of the object.

4.2 Preparing for Intelligent 2 Probe Control

The Sigma Systems C4 controller, using Intelligent 2 Probe Control, provides

temperature control based upon all of the factors discussed above. The process is

very simple. You will first need to set all the limits that the C4 will need. Then,

you use the normal commands or operations, in Local mode, Program mode, or

Remote mode, to go to temperatures, ramp to temperatures, hold temperatures,

etc.

The limits for the UUT temperature extremes are set in Setup parameter fields

F27 (lower limit) and F28 (upper limit). These values can be set in Setup mode as

described in Section 8, or by using the SL (Set UUT Temperature Limits)

command from Remote mode as described in Section 7.6.4.

The UUT temperature differential limits are set in Setup parameter fields F29

(lower differential limit) and F30 (upper differential limit). These values can be

set in Setup mode as described in Section 8, or by using the SD (Set UUT

Temperature Differential Limits) command from Remote mode as described in

Section 7.6.5.

Note that the low limit you set is the allowable differential between the air stream

temperature (platform surface temperature) as measured by probe 1 and the UUT

core temperature as measured by probe 2 at the UUT low temperature limit as

described by Setup parameter F27. Likewise, the high limit you set is the

allowable differential between the air stream temperature (platform surface

temperature) as measured by probe 1 and the UUT core temperature as measured

by probe 2 at the UUT high temperature limit as described by Setup parameter

F28. For example:

If the lower UUT limit (F27) is set to -100

limit (F29) is set to 60

/, and the setpoint is set to -80/ while the UUT is

/ and the the lower differential

considerably warmer than that, then the controller will try to take the

temperature of the chamber down below the setpoint (max -100

the down ramp. However, because the differential limit is 60

/) to speed

/, the

controller will be constrained to keep the amount of thermal lead (difference

between probe 1 in the air stream and probe 2 in the UUT core), to 60

/. The

C4 Manual Rev 7.5.2

39

Page 40

air stream temperature, based upon this 60/ limit, would not be allowed to

drop to -100

/ until the UUT core temperature had reached -40/

The same rules hold true for the high end of the UUT range except that the high

differential limit (F30) is applied at the high limit of the UUT range (F28).

For UUT core temperatures between those limits, a proportional differential limit

is calculated by the C4 based upon the limits specified at the extremes. For

Example:

If the lower UUT limit (F27) is set to -100

/ and the the lower differential

limit (F29) is set to 60/, and the upper UUT limit (F28) is set to 200/, and

the upper differential limit (F30) 20

temperature of -25

/ would be 50/.

/, the differential limit calculated for a

Important: Intelligent 2 Probe Control, like normal control using probe 1 or

probe 2, is constrained by the limits of the controller range and the

chamber/platform operating temperature limits (F25 & F26). If a probe correction

has been implemented for either or both probes (F17 - F24), those adjustments

will be used as well. It is imcumbent upon the user to be certain that they are

aware of these settings and their potential for interaction.

4.3 Using Intelligent 2 Probe Control

Once all of the necessary settings have been made and verified, using Intelligent 2

Probe Control is very easy. To use Intelligent 2 Probe Control, set the probe

number to zero (0). Intelligent 2 Probe Control will be used in any mode, Local,

Program, or Remote, if the probe number = 0.

40

C4 Manual Rev 7.5.2

Page 41

5. LOCAL MODE ( Basic Operation )

The C4 Local mode of operation provides simple control of the chamber or

platform through the front panel controls. In this mode, a single setpoint is

entered from the front panel and the controller will attempt to have the chamber

or platform reach and hold that temperature. In local mode the compressor of

mechanically refrigerated units can be turned on or off using the <REFER> button

on the front panel.

The controller can be set to automatically start controlling at the last used

temperature upon startup by setting the controller to the AutoStart mode. See

AutoStart mode description, Section 8.4.

The circled numbers on the front panel guide the user through the sequence for

the basic operation of changing the setpoint. The reasoning for each keystroke is

as follows:

1. Display control setpoint temperature.

2. Clear the existing setpoint value.

3. Key-in control probe number (only if 2 probes defined in setup parameter

F1) & new setpoint.

4. Commit new setpoint entry.

5. Display current chamber temperature.

If controller RUN LED is not ON press <START/STOP> to begin controlling

at set temperature.

5.1 Displaying Temperature

The temperature may be displayed at any time by pressing the <DISP/TEMP> key.

The format of the display is

Pn TT.T Example:

PnF-TTT.T Example:

p1 - 102.6 (Celsius)

p1f- 102.6 (Fahrenheit)

where n indicates from which probe the reading originates and the -TTT.T

indicates the numeric temperature. In single probe mode, n is always 1. In two

C4 Manual Rev 7.5.2

41

Page 42

probe mode, n can be 1 or 2 as the temperature display toggles between probe 1

and probe 2 with each press of the Display Temperature <DISP/TEMP> key. If

Intelligent 2 Probe Control is implemented (probe number set to 0), the display

will rotate from probe 1 to probe 2 to probe 0 (average), then back to probe 1, etc.

with each press of <DISP/TEMP>. The temperature is displayed to the nearest

tenth of a degree C. although internal temperature values are kept at a much

higher precision. The value is rounded so that a display of 30.2 means a

temperature between 30.15 and 30.24. Fahrenheit values display an F after the

probe number.

5.2 Displaying and Changing the Setpoint

The setpoint may be displayed by pressing the Display Control key <DISP/CNTL>.

The format of the display is

Sn TT.T Example:

SnF-TTT.T Example: s1f- 102.6 (Fahrenheit)

where n is the probe used for control. Upon entering the LOCAL mode from the

PROGRAM REMOTE or SETUP mode, the control probe defaults to 1 and the

setpoint is erased. If the setpoint has been erased, the “no setpoint” message

displays in lieu of the setpoint temperature. Example:

s1 - 102.6 (Celsius)

s1 nsp s1f nsp

To change either the setpoint temperature or the control probe (of a 2 probe

configuration only), use the following procedure:

1. First display the setpoint using <DISP/CNTL>.

2. Press <CLEAR/ENTRY> to clear the current value from the display. If

single probe mode is in effect,

display indicating the control probe must be 1. If two probe mode is in

effect, the probe number is also cleared.

s1 or s1f will appear at the left of the

42