Page 1

C110 Flanged Fittings

2-64in C110 CAST IRON/DUCTILE IRON FLANGED FITTINGS

BASIC SPECIFICATIONS

MATERIAL: Ductile Iron ASTM A536 Grade 60-42-10, 65-45-12 or 70-50-05.

PRESSURE: 250 PSI Water Working Pressure for Cast Iron sizes 2” - 12”

250 PSI Water Working Pressure for Ductile Iron sizes 2” - 48”

150 PSI Water Working Pressure for Ductile Iron sizes 54” - 64”

150 PSI Water Working Pressure for Cast Iron sizes 14” - 54”

TESTING: In accordance with ANSI / AWWA C110 / A21.10 where applicable.

Other items are in accordance with manufacturer’s standards.

54” and above Flanged Fittings are manufactured as per AWWA C153/A21.53

LAYING LENGTH: In accordance with ANSI / AWWA C110 / A21.10 where applicable.

Other items are in accordance with manufacturer’s standards.

54” and above Flanged Fittings are manufactured as per AWWA C153/A21.53

CEMENT LINING: In accordance with ANSI / AWWA C104 / A21.4

COATING: Tar coated (bituminous) inside in accordance with ANSI / AWWA C104 / A21.04

Red Primer Outside.

For special conditions, other types of coatings and linings are available.

Please specify when ordering.

APPROVALS: 2”-16” Underwriters Laboratories listed and Factory Mutual Approved.

STANDARDS: ANSI / AWWA C110 / A21.10 Where applicable.

Other items are in accordance with manufacturer’s standards.

54” and above Flanged Fittings are manufactured as per AWWA C153/A21.53

Note: call for Cast Iron Fittings

®

Member

SIGMA Corporation

700 Goldman Drive

Cream Ridge, NJ 08514

800 999 2550 p

609 758 1163 f

www.sigmaco.com

crm-sales@sigmaco.com

®

®

Certified to

ANSI/NSF 61

Page 2

Flanged Fittings

INDEX

BENDS

90° Bends 3

45° Bends 3

22 1/2° Bends 3

11 1/4° Bends 4

90° Reducing Bends 4-5

90° Long Radius Bends 5

45° Long Radius Reducing Bends 5

90° Long Radius Reducing Bends 6

90° Long Radius Base Bends

90°Base Bends

Reducing Base Bends 7

90° Side Outlet Bend

TEES

Tees & Crosses 8

Reducing on Run Tees 8

Reducing Tees 9-10

Reducing Tees 11

Base Tees 12

Reducing Base Tees 12-13

7

7

8

CROSSES

Reducing Crosses 10-11

Reducing Cross 12

WYES

45° Lateral Wyes 13

45° Lateral Reducing Wyes 14-15

True Wyes 16

REDUCERS

Concentric Reducers 15

Eccentric Reducers 16

BLIND FLANGES - Solid and Tapped 17

Threaded Flanges 18

SLUDGE SHOES 18

FLARES

Straight Flare Pieces 18

90° Flare Bends 18

90° Flare Long Radius Bends 18

SIGMA Corporation www.sigmaco.com

2

Member

®

®

®

Certified to

ANSI/NSF 61

Page 3

T

BC

OD

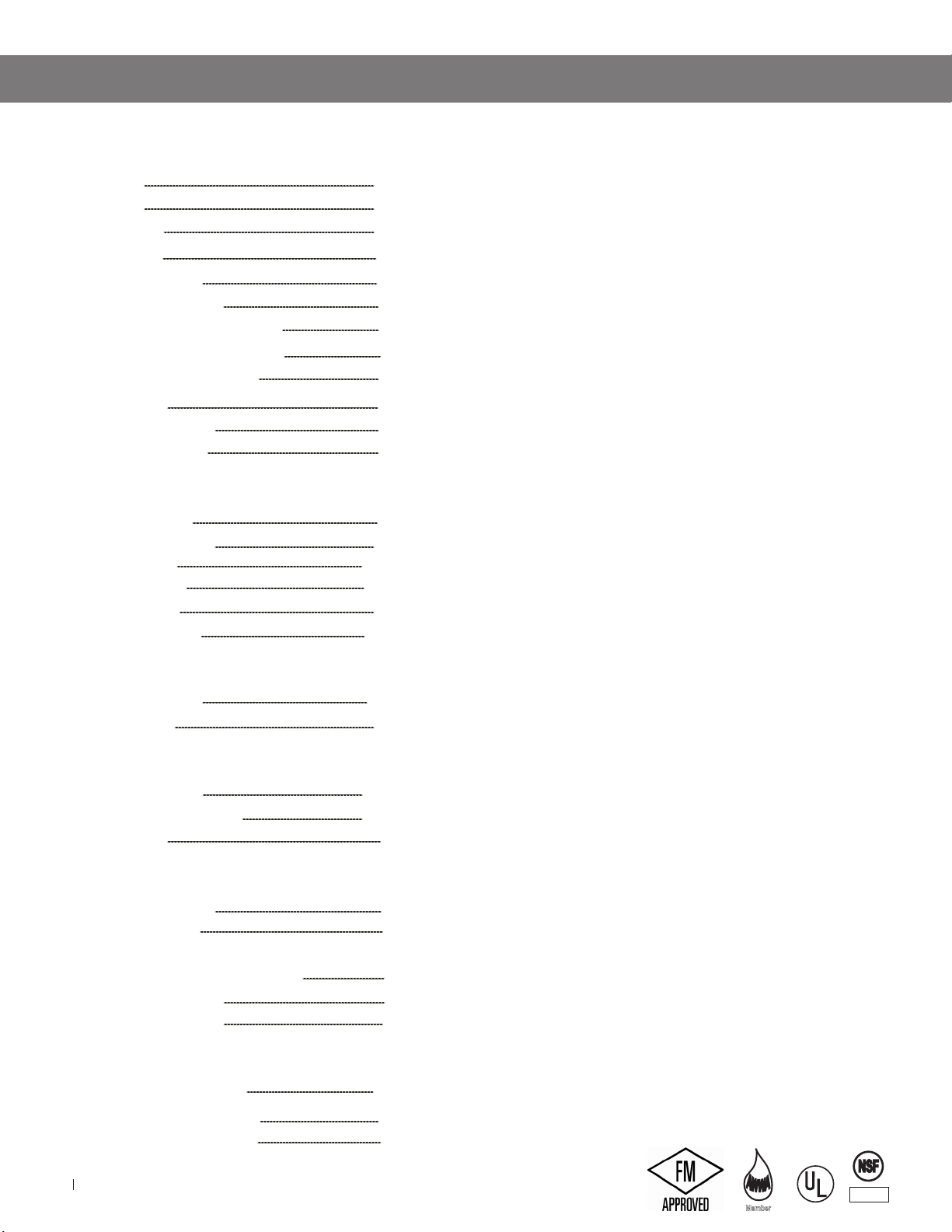

Size OD BC T Hole Dia. Bolt Size No. Bolts

2 6.00 4.75 0.62 0.75 5/8 x 2 1/2 4

3 7.50 6.00 0.75 0.75 5/8 x 2 1/2 4

4 9.00 7.50 0.94 0.75 5/8 x 3 8

5 10.00 8.50 0.94 0.88 3/4 x 3 8

6 11.00 9.50 1.00 0.88 3/4 x 3 1/2 8

8 13.50 11.75 1.12 0.88 3/4 x 3 1/2 8

10 16.00 14.25 1.19 1.00 7/8 x 4 12

12 19.00 17.00 1.25 1.00 7/8 x 4 12

14 21.00 18.75 1.38 1.12 1 x 4 1/2 12

16 23.50 21.25 1.44 1.12 1 x 4 1/2 16

18 25.00 22.75 1.56 1.25 1 1/8 x 5 16

20 27.50 25.00 1.69 1.25 1 1/8 x 5 20

24 32.00 29.50 1.88 1.37 1 1/4 x 5 1/2 20

30 38.75 36.00 2.12 1.37 1 1/4 x 6 1/2 28

36 46.00 42.75 2.38 1.62 1 1/2 x 7 32

42 53.00 49.50 2.62 1.62 1 1/2 x 7 1/2 36

48 59.50 56.00 2.75 1.62 1 1/2 x 8 44

54 66.25 62.75 3.00 2.00 1 3/4 x 8 1/2 44

60 73.00 69.25 3.12 2.00 1 3/4 x 9 52

64* 80.00 76.00 3.38 2.00 1 3/4 x 9 52

* Contact SIGMA for available ttings.

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

®

®

Certified to

ANSI/NSF 61

®

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

SIGMA Corporation www.sigmaco.com

Weights in pounds

3

Page 4

Flanged Fittings

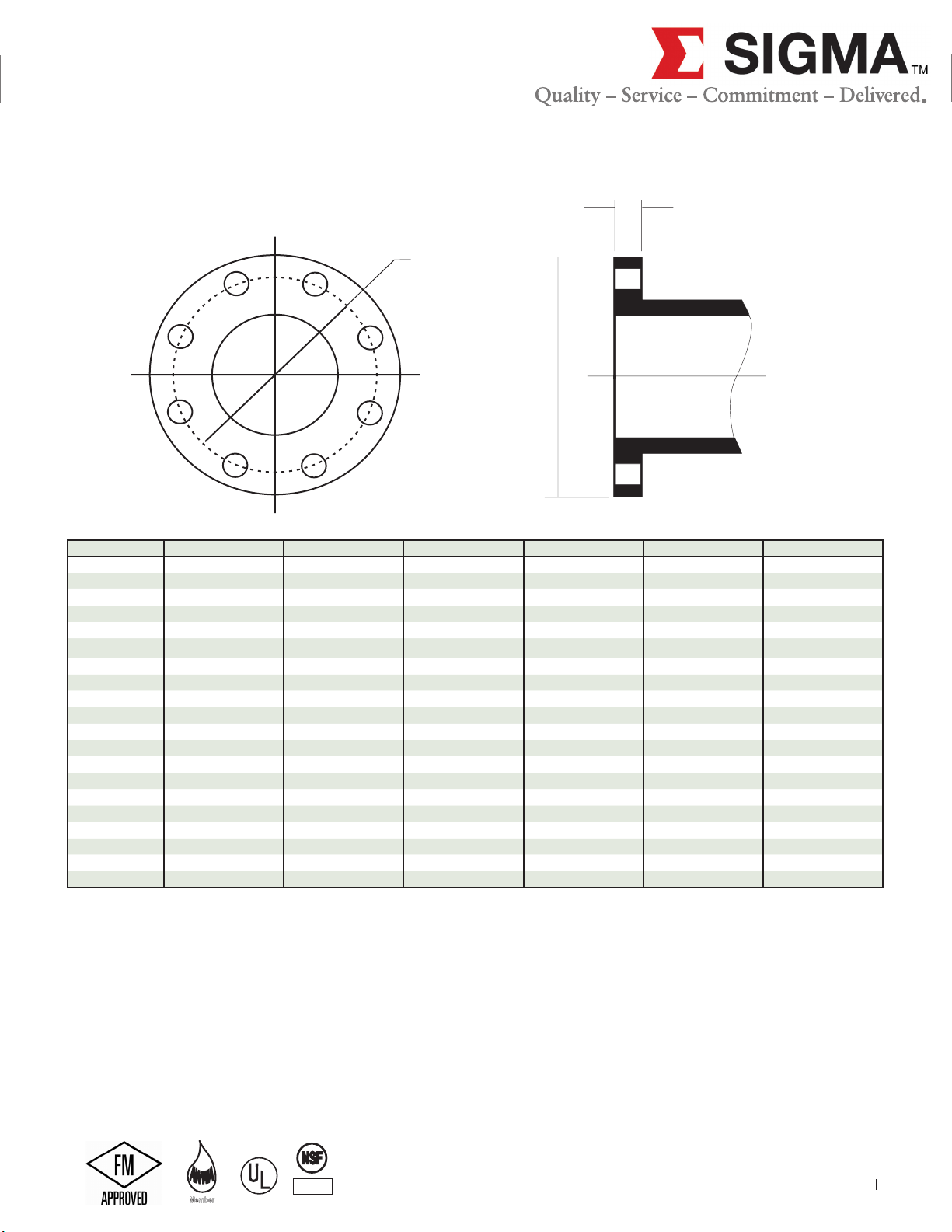

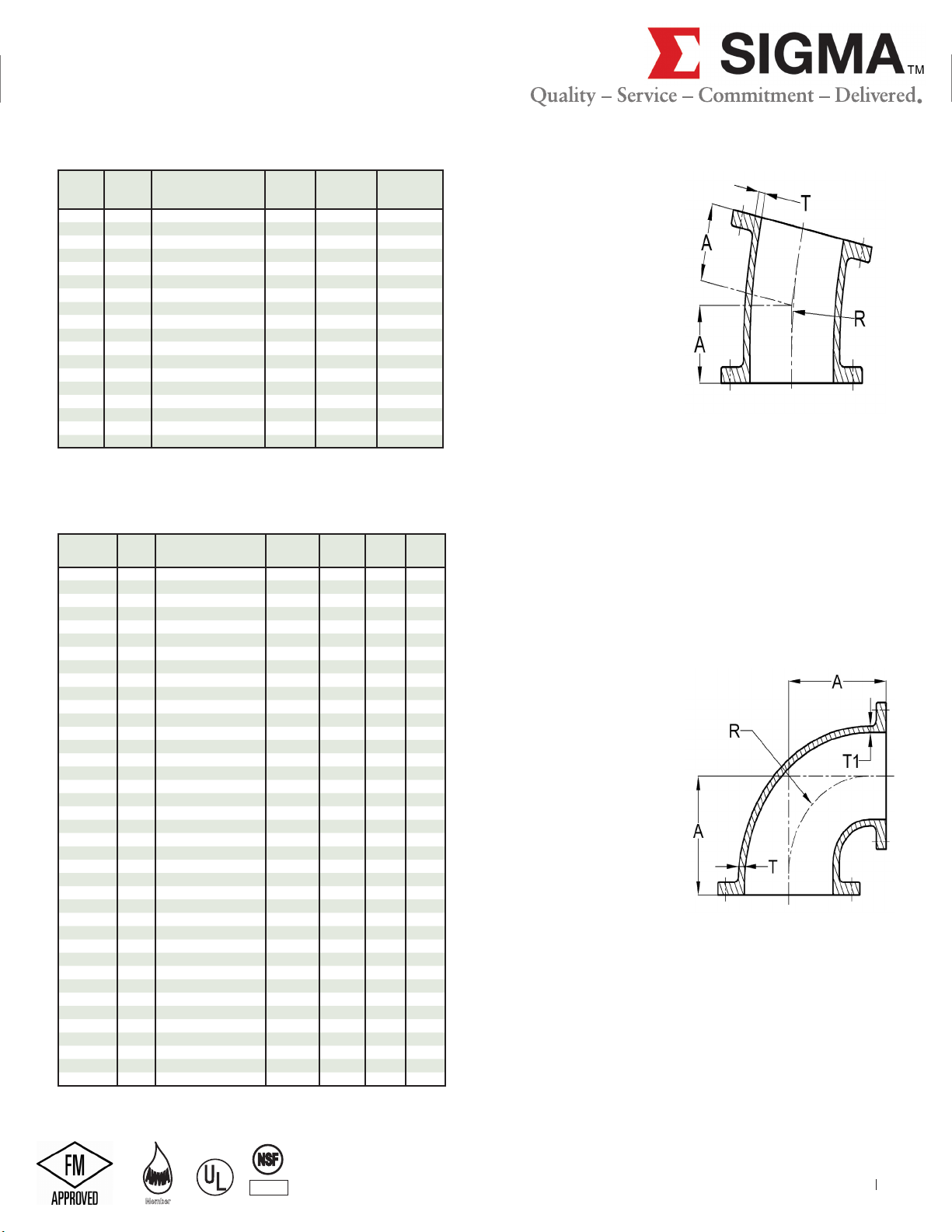

BENDS, 1/4 90°

Size Wt.

2 16 DFB290 4.50 3.00 0.31

2.5 DFB2.590 5.00 3.50 0.31

3 25 DFB390 5.50 4.00 0.48

4 45 DFB490 6.50 4.50 0.52

5 52 DFB590 7.50 5.50 0.52

6 65 DFB690 8.00 6.00 0.55

8 105 DFB890 9.00 7.00 0.60

10 165 DFB1090 11.00 9.00 0.68

12 235 DFB1290 12.00 10.00 0.75

14 290 DFB1490 14.00 11.50 0.66

16 370 DFB1690 15.00 12.50 0.70

18 450 DFB1890 16.50 14.00 0.75

20 580 DFB2090 18.00 15.50 0.80

24 900 DFB2490 22.00 18.50 0.89

30 1,430 DFB3090 25.00 21.50 1.03

36 2,135 DFB3690 28.00 24.50 1.15

42 3,055 DFB4290 31.00 27.50 1.28

48 4,095 DFB4890 34.00 30.50 1.42

54 6,695 DFB5490 37.00 33.50 1.62

60 DFB6090 43.00 36.50 0.94

BENDS, 1/8 45°

Size Wt.

2 12 DFB245 2.50 2.41 0.31

2.5 DFB2545 3.00 3.62 0.48

3 20 DFB345 3.00 3.62 0.48

4 40 DFB445 4.00 4.81 0.52

5 45 DFB545 4.50 6.04 0.52

6 55 DFB645 5.00 7.25 0.55

8 90 DFB845 5.50 8.44 0.60

10 130 DFB1045 6.50 10.88 0.68

12 195 DFB1245 7.50 13.25 0.75

14 220 DFB1445 7.50 12.06 0.66

16 280 DFB1645 8.00 13.25 0.70

18 325 DFB1845 8.50 14.50 0.75

20 430 DFB2045 9.50 16.88 0.80

24 630 DFB2445 11.00 18.12 0.89

30 1,120 DFB3045 15.00 27.75 1.03

36 1,755 DFB3645 18.00 35.00 1.15

42 2,600 DFB4245 21.00 42.25 1.28

48 3,580 DFB4845 24.00 49.50 1.42

54 5,755 DFB5445 27.00 55.68 1.62

DUCTILE IRON

Item No.

DUCTILE IRON

Item No.

A R T

A R T

FLXFL Bend 90°

FLXFL Bend 45°

BENDS, 1/16 22-1/2°

Size Wt.

2 12 DFB222 2.50 6.04 0.31

3 20 DFB322 3.00 7.56 0.48

4 40 DFB422 4.00 10.06 0.52

5 45 DFB522 4.50 10.86 0.52

6 55 DFB622 5.00 15.06 0.55

8 90 DFB822 5.50 17.62 0.60

10 135 DFB1022 6.50 22.62 0.68

12 205 DFB1222 7.50 27.62 0.75

14 225 DFB1422 7.50 25.12 0.66

16 285 DFB1622 8.00 27.62 0.70

18 335 DFB1822 8.50 30.19 0.75

20 435 DFB2022 9.50 35.19 0.80

24 640 DFB2422 11.00 37.69 0.89

30 1,135 DFB3022 15.00 57.81 1.03

36 1,790 DFB3622 18.00 72.88 1.15

42 2,665 DFB4222 21.00 88.00 1.28

48 3,665 DFB4822 24.00 103.06 1.42

54 DFB5422 14.00 50.00 0.90

60 DFB6022 14.00 48.50 0.94

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

4

DUCTILE IRON

Item No.

A R T

FLXFL Bend 22-1/2°

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 5

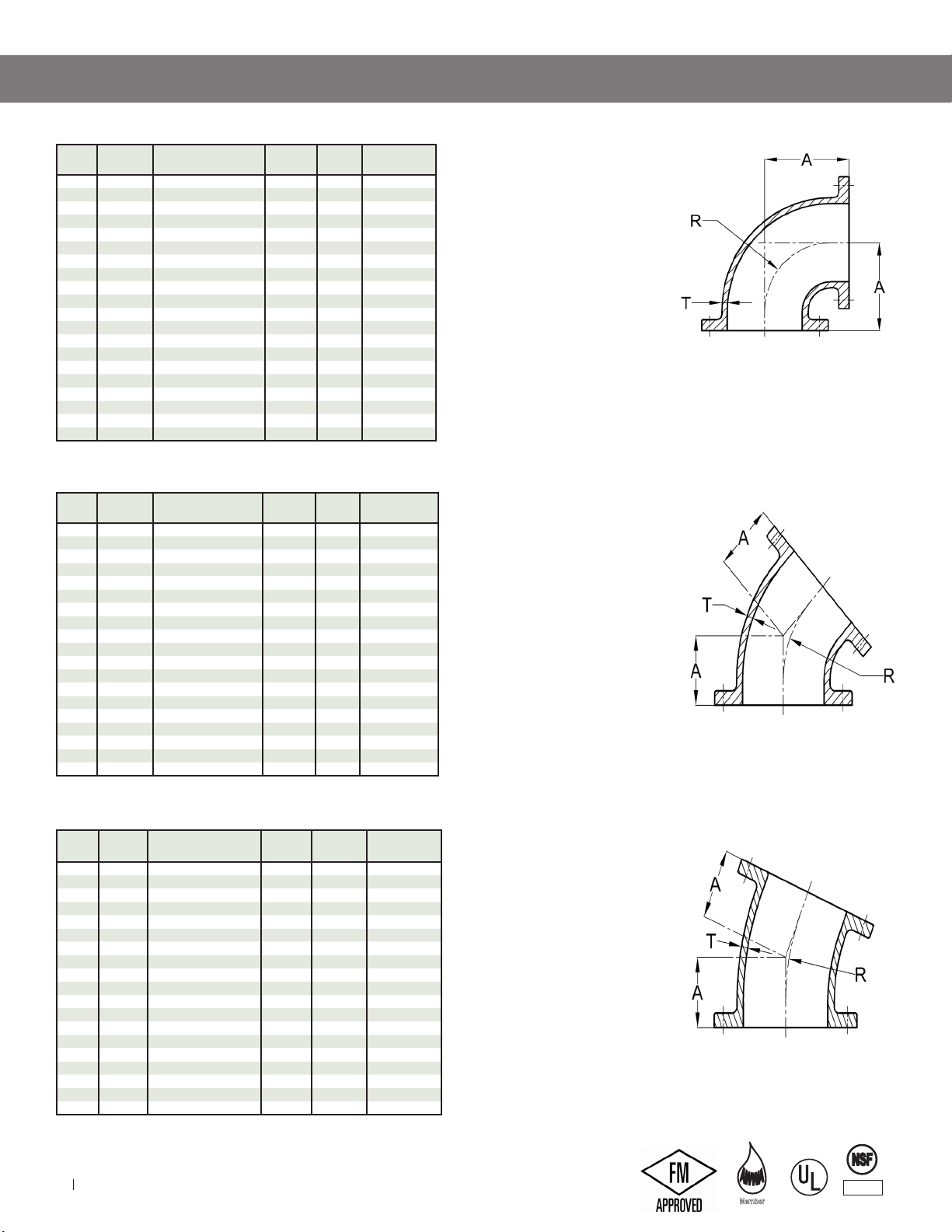

BENDS, 1/32 11-1/4°

Size Wt.

DUCTILE IRON

Item No.

A R T

2 12 DFB211 2.5 12.69 0.31

3 20 DFB311 3.0 15.25 0.48

4 40 DFB411 4.0 20.31 0.52

5 45 DFB511 4.5 22.85 0.52

6 55 DFB611 5.0 30.5 0.55

8 90 DFB811 5.5 35.5 0.60

10 135 DFB1011 6.5 45.69 0.68

12 205 DFB1211 7.5 55.81 0.75

14 225 DFB1411 7.5 50.75 0.66

16 285 DFB1611 8.0 55.81 0.70

18 335 DFB1811 8.5 60.9 0.75

20 435 DFB2011 9.5 71.06 0.80

24 645 DFB2411 11.0 76.12 0.89

30 1,150 DFB3011 15.0 116.75 1.03

36 1,805 DFB3611 18.0 147.25 1.15

42 2,680 DFB4211 21.0 177.69 1.28

48 3,695 DFB4811 24.0 208.12 1.42

60 DFB6011 10.5 62.41 0.94

REDUCING 90° BENDS

Size Wt.

3 x 2 22 DFB32 5.60 4.00 0.48 0.31

3 x 2.5 DFB325 5.50 4.00 0.48 0.31

4 x 2 DFB42 6.50 4.50 0.52 0.31

4 x 3 29 DFB43 6.50 4.50 0.52 0.48

6 x 3 56 DFB63 8.00 6.00 0.55 0.48

6 x 4 55 DFB64 8.00 6.00 0.55 0.52

6 x 5 65 DFB65 8.00 6.00 0.55 0.52

8 x 4 75 DFB84 9.00 7.00 0.60 0.52

8 x 5 80 DFB85 9.00 7.00 0.60 0.52

8 x 6 85 DFB86 9.00 7.00 0.60 0.55

10 x 4 130 DFB104 11.00 9.00 0.68 0.52

10 x 6 135 DFB106 11.00 9.00 0.68 0.55

10 x 8 150 DFB108 11.00 9.00 0.68 0.60

12 x 4 140 DFB124 12.00 10.00 0.75 0.52

12 x 6 160 DFB126 12.00 10.00 0.75 0.55

12 x 8 180 DFB128 12.00 10.00 0.75 0.60

12 x 10 200 DFB1210 12.00 10.00 0.75 0.68

14 x 6 144 DFB146 14.00 11.50 0.66 0.55

14 x 8 215 DFB148 14.00 11.50 0.66 0.60

14 x 10 240 DFB1410 14.00 11.50 0.66 0.68

14 x 12 270 DFB1412 14.00 11.50 0.66 0.75

16 x 6 220 DFB166 15.00 12.50 0.70 0.55

16 x 8 240 DFB168 15.00 12.50 0.70 0.60

16 x 10 280 DFB1610 15.00 12.50 0.70 0.68

16 x 12 310 DFB1612 15.00 12.50 0.70 0.75

16 x 14 335 DFB1614 15.00 12.50 0.70 0.66

18 x 6 260 DFB186 16.50 14.00 0.75 0.55

18 x 8 330 DFB188 16.50 14.00 0.75 0.60

18 x 10 330 DFB1810 16.50 14.00 0.75 0.68

18 x 12 350 DFB1812 16.50 14.00 0.75 0.75

18 x 14 385 DFB1814 16.50 14.00 0.75 0.66

18 x 16 420 DFB1816 16.50 14.00 0.75 0.70

20 x 6 320 DFB206 18.00 15.50 0.80 0.55

20 x 8 345 DFB208 18.00 15.50 0.80 0.60

20 x 10 445 DFB2010 18.00 15.50 0.80 0.68

20 x 12 415 DFB2012 18.00 15.50 0.80 0.75

20 x 14 455 DFB2014 18.00 15.50 0.80 0.66

20 x 16 495 DFB2016 18.00 15.50 0.80 0.70

20 x 18 525 DFB2018 18.00 15.50 0.80 0.75

DUCTILE IRON

Item No.

A R T T1

FLXFL Bend 11-1/4°

Reducing Bend 90°

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

®

®

Certified to

ANSI/NSF 61

®

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

5

Page 6

Flanged Fittings

REDUCING 90° BENDS (continued)

Size Wt.

24 x 6 480 DFB246 22.00 18.50 0.89 0.55

24 x 8 505 DFB248 22.00 18.50 0.89 0.60

24 x 10 545 DFB2410 22.00 18.50 0.89 0.68

24 x 12 575 DFB2412 22.00 18.50 0.89 0.75

24x 14 635 DFB2414 22.00 18.50 0.89 0.66

24 x 16 685 DFB2416 22.00 18.50 0.89 0.70

24 x 18 675 DFB2418 22.00 18.50 0.89 0.75

24 x 20 740 DFB2420 22.00 18.50 0.89 0.80

30 x 12 840 DFB3012 25.00 21.50 1.03 0.75

30 x 14 1,090 DFB3014 25.00 21.50 1.03 0.66

30 x 16 900 DFB3016 25.00 21.50 1.03 0.70

30 x 18 980 DFB3018 25.00 21.50 1.03 0.75

30 x 20 1,070 DFB3020 25.00 21.50 1.03 0.80

30 x 24 1,205 DFB3024 25.00 21.50 1.03 0.89

36 x 12 1,195 DFB3612 28.00 24.50 1.15 0.75

36 x 14 1,215 DFB3614 28.00 24.50 1.15 0.66

36 x 16 1,255 DFB3616 28.00 24.50 1.15 0.70

36 x 18 1,295 DFB3618 28.00 24.50 1.15 0.75

36 x 20 1,360 DFB3620 28.00 24.50 1.15 0.80

36 x 24 1,520 DFB3624 28.00 24.50 1.15 0.89

36 x 30 1,785 DFB3630 28.00 24.50 1.15 1.03

42 x 12 1,655 DFB4212 31.00 27.50 1.28 0.75

42 x 14 1,675 DFB4214 31.00 27.50 1.28 0.66

42 x 16 1,715 DFB4216 31.00 27.50 1.28 0.70

42 x 18 1,755 DFB4218 31.00 27.50 1.28 0.75

42 x 20 1,895 DFB4220 31.00 27.50 1.28 0.80

42 x 24 1,980 DFB4224 31.00 27.50 1.28 0.89

42 x 30 2,345 DFB4230 31.00 27.50 1.28 1.03

42 x 36 3,390 DFB4236 31.00 27.50 1.28 1.15

48 x 12 2,175 DFB4812 34.00 30.50 1.42 0.75

48 x 14 2,195 DFB4814 34.00 30.50 1.42 0.66

48 x 16 2,235 DFB4816 34.00 30.50 1.42 0.70

48 x 18 2,275 DFB4818 34.00 30.50 1.42 0.75

48 x 20 2,340 DFB4820 34.00 30.50 1.42 0.80

48 x 24 3,240 DFB4824 34.00 30.50 1.42 0.89

48 x 30 3,600 DFB4830 34.00 30.50 1.42 1.03

48 x 36 3,255 DFB4836 34.00 30.50 1.42 1.15

48 x 42 4,685 DFB4842 34.00 30.50 1.42 1.28

54 x 48 DFB5448 39.00 33.50 0.90 0.94

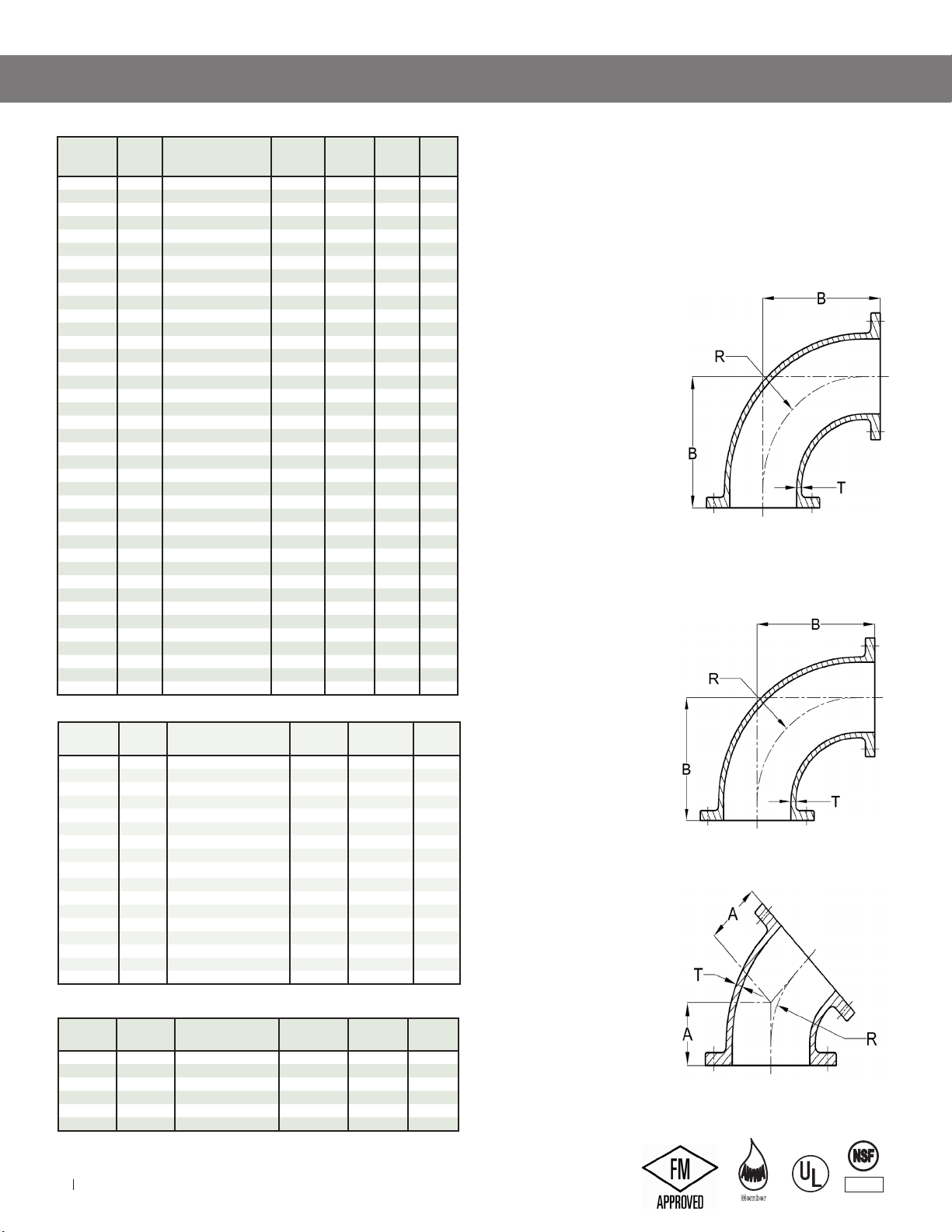

LONG RADIUS BENDS 90°

Size Wt.

2 20 DFL290 6.50 0.31

3 30 DFL390 7.75 0.48

4 50 DFL490 9.00 7.00 0.52

5 65 DFL590 10.25 0.52

6 80 DFL690 11.50 9.50 0.55

8 140 DFL890 14.00 12.00 0.60

10 215 DFL1090 16.50 14.50 0.68

12 325 DFL1290 19.00 17.00 0.75

14 385 DFL1490 21.50 19.00 0.66

16 505 DFL1690 24.00 21.50 0.70

18 630 DFL1890 26.50 24.00 0.75

20 810 DFL2090 29.00 26.50 0.80

24 1,240 DFL2490 34.00 30.50 0.89

30 2,105 DFL3090 41.50 38.00 1.03

36 3,285 DFL3690 49.00 45.50 1.15

42 4,865 DFL4290 56.50 53.00 1.28

48 6,790 DFL4890 64.00 60.50 1.42

DUCTILE IRON

Item No.

DUCTILE IRON

Item No.

A R T T1

B R T

Reducing Bend 90°

Long Radius Bend 90°

LONG RADIUS REDUCING BEND 45°

Size Wt. Item No. A R T

3 DFL345 5.25 7.85 0.48

4 DFL445 6.50 9.66 0.52

6 DFL645 8.50 13.28 0.55

8 DFL845 10.50 18.11 0.60

10 DFL1045 12.00 21.73 0.68

12 DFL1245 14.50 27.76 0.75

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

6

Long Radius Reducing Bend 45°

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 7

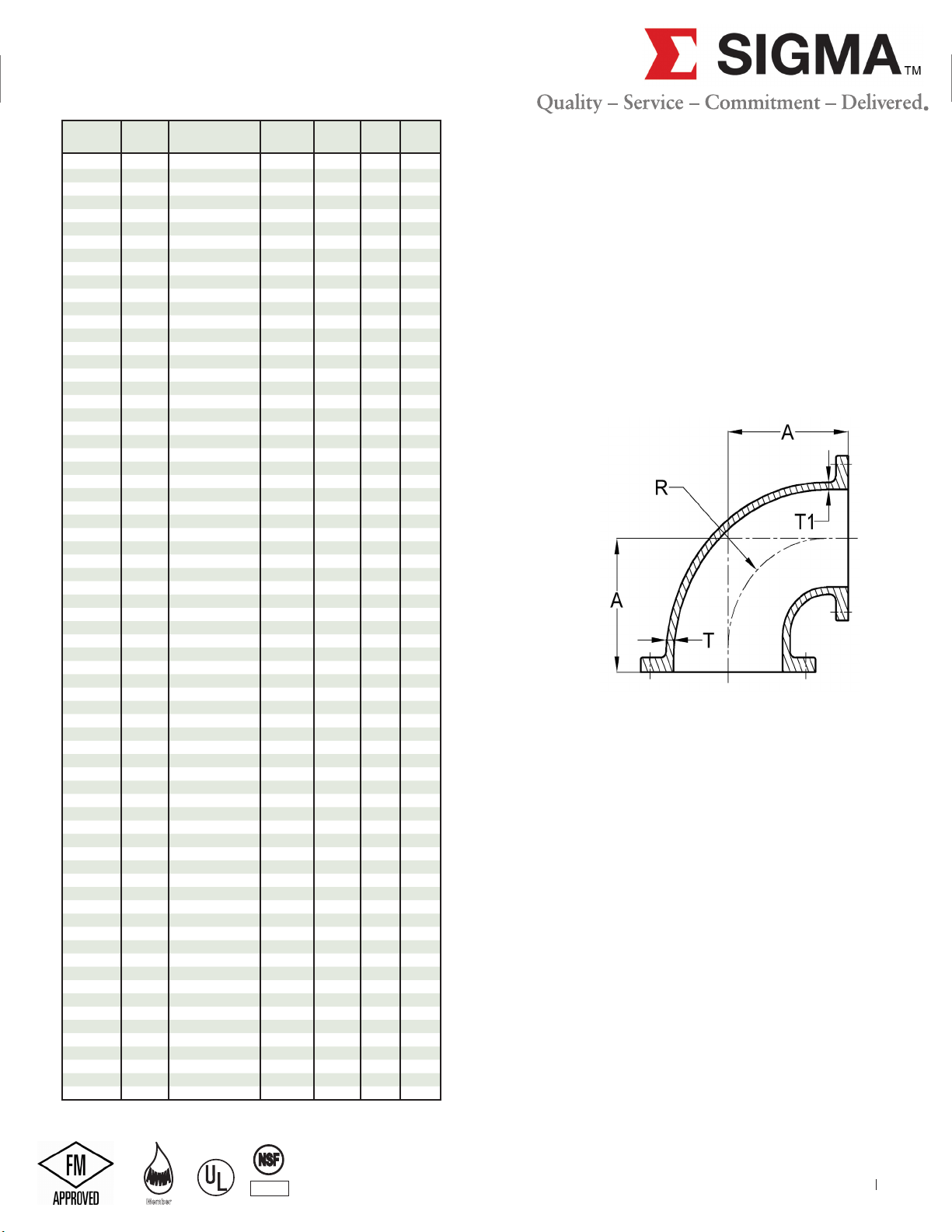

LONG RADIUS REDUCING BEND 90°

Size Wt. Item No. A R T T1

4 x 3 DFL43 9.00 7.00 0.52 0.48

6 x 3 DFL63 11.50 9.50 0.55 0.48

6 x 4 DFL64 11.50 9.50 0.55 0.52

8 x 4 DFL84 14.00 12.00 0.60 0.52

8 x 6 DFL86 14.00 12.00 0.60 0.55

10 x 4 DFL104 16.50 14.50 0.68 0.52

10 x 6 DFL106 16.50 14.50 0.68 0.55

10 x 8 DFL108 16.50 14.50 0.68 0.60

12 x 6 DFL126 19.00 17.00 0.75 0.55

12 x 8 DFL128 19.00 17.00 0.75 0.60

12 x 10 DFL1210 19.00 17.00 0.75 0.68

14 x 6 DFLI46 21.50 19.00 0.66 0.55

14 x 8 DFL148 21.50 19.00 0.66 0.60

14 x 10 DFL1410 21.50 19.00 0.66 0.68

14 x 12 DFL1412 21.50 19.00 0.66 0.75

16 x 6 DFL166 24.00 21.50 0.70 0.55

16 x 8 DFL168 24.00 21.50 0.70 0.60

16 x 10 DFL1610 24.00 21.50 0.70 0.68

16 x 12 DFL1612 24.00 21.50 0.70 0.75

16 x 14 DFL1614 24.00 21.50 0.70 0.66

18 x 6 DFL186 26.50 24.00 0.75 0.55

18 x 8 DFL188 26.50 24.00 0.75 0.60

18 x 10 DFL1810 26.50 24.00 0.75 0.68

18 x 12 DFL1812 26.50 24.00 0.75 0.75

18 x 14 DFL1814 26.50 24.00 0.75 0.66

18 x 16 DFL1816 26.50 24.00 0.75 0.70

20 x 6 DFL206 29.00 26.50 0.80 0.55

20 x 8 DFL208 29.00 26.50 0.80 0.60

20 x 10 DFL2010 29.00 26.50 0.80 0.68

20 x 12 DFL2012 29.00 26.50 0.80 0.75

20 x 14 DFL2014 29.00 26.50 0.80 0.66

20 x 16 DFL2016 29.00 26.50 0.80 0.70

20 x 18 DFL2018 29.00 26.50 0.80 0.75

24 x 6 DFL246 34.00 30.50 0.89 0.55

24 x 8 DFL248 34.00 30.50 0.89 0.60

24 x 10 DFL2410 34.00 30.50 0.89 0.68

24 x 12 DFL2412 34.00 30.50 0.89 0.75

24x 14 DFL2414 34.00 30.50 0.89 0.66

24 x 16 DFL2416 34.00 30.50 0.89 0.70

24 x 18 DFL2418 34.00 30.50 0.89 0.75

24 x 20 DFL2420 34.00 30.50 0.89 0.80

30 x 12 DFL3012 41.50 38.00 1.03 0.75

30 x 14 DFL3014 41.50 38.00 1.03 0.66

30 x 16 DFL3016 41.50 38.00 1.03 0.70

30 x 18 DFL3018 41.50 38.00 1.03 0.75

30 x 20 DFL3020 41.50 38.00 1.03 0.80

30 x 24 DFL3024 41.50 38.00 1.03 0.89

36 x 12 DFL3612 49.00 45.50 1.15 0.75

36 x 14 DFL3614 49.00 45.50 1.15 0.66

36 x 16 DFL3616 49.00 45.50 1.15 0.70

36 x 18 DFL3618 49.00 45.50 1.15 0.75

36 x 20 DFL3620 49.00 45.50 1.15 0.80

36 x 24 DFL3624 49.00 45.50 1.15 0.89

36 x 30 DFL3630 49.00 45.50 1.15 1.03

42 x 12 DFL4212 56.50 53.00 1.28 0.75

42 x 14 DFL4214 56.50 53.00 1.28 0.66

42 x 16 DFL4216 56.50 53.00 1.28 0.70

42 x 18 DFL4218 56.50 53.00 1.28 0.75

42 x 20 DFL4220 56.50 53.00 1.28 0.80

42 x 24 DFL4224 56.50 53.00 1.28 0.89

42 x 30 DFL4230 56.50 53.00 1.28 1.03

42 x 36 DFL4236 56.50 53.00 1.28 1.15

48 x 12 DFL4812 64.00 60.50 1.42 0.75

48 x 14 DFL4814 64.00 60.50 1.42 0.66

48 x 16 DFL4816 64.00 60.50 1.42 0.70

48 x 18 DFL4818 64.00 60.50 1.42 0.75

48 x 20 DFL4820 64.00 60.50 1.42 0.80

48 x 24 DFL4824 64.00 60.50 1.42 0.89

48 x 30 DFL4830 64.00 60.50 1.42 1.03

48 x 36 DFL4836 64.00 60.50 1.42 1.15

48 x 42 DFL4842 64.00 60.50 1.42 1.28

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

®

®

Member

Certified to

ANSI/NSF 61

®

Long Radius Reducing Bend 90°

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

SIGMA Corporation www.sigmaco.com

Dimensions in inches

Weights in pounds

7

Page 8

Flanged Fittings

LONG RADIUS BASE BEND 90°

Size Wt. Item No. R S T U

12 420 DFN1290 11.25 11.00 1.00 1.00

20 985 DFN2090 16.00 13.50 1.12 1.12

24 1,430 DFN2490 18.50 13.50 1.12 1.12

24 X 16 DFN2416 18.50 13.50 1.12 1.12

24 x 20 DFN2420 18.50 13.50 1.12 1.12

36 x 30 DFN3630 26.00 19.00 1.25 1.15

48 x 42 DFN4842 34.00 25.00 1.56 1.42

BASE BENDS 90°

DUCTILE IRON

SIZE

Item No.

Base Bend Base Only

3 DFD390 35 10 4.88 5.00 0.56 0.50

4 DFD490 55 10 5.50 6.00 0.62 0.50

6 DFD690 85 20 7.00 7.00 0.69 0.62

8 DFD890 145 40 8.38 9.00 0.94 0.88

10 DFD1090 210 45 9.75 9.00 0.94 0.88

12 DFD1290 300 65 11.25 11.00 1.00 1.00

14 DFD1490 360 70 12.50 11.00 1.00 1.00

16 DFD1690 445 75 13.75 11.00 1.00 1.00

18 DFD1890 565 11 5 15.00 13.50 1.12 1.12

20 DFD2090 700 120 16.00 13.50 1.12 1.12

24 DFD2490 1,030 130 18.50 13.50 1.12 1.12

30 DFD3090 1,625 190 23.00 16.00 1.19 1.15

36 DFD3690 2,385 250 26.00 19.00 1.25 1.15

42 DFD4290 3,465 410 30.00 23.50 1.44 1.28

48 DFD4890 4,610 515 34.00 25.00 1.56 1.42

60 DFD6090 42.00 32.00 1.88 1.75

Weight

R S T U

REDUCING BASE BENDS

Size Item No. Wt. R S T U

8 x 6 DFD86 120 8.38 9.00 0.94 0.88

10 x 8 DFD108 195 9.75 9.00 0.94 0.88

12 x 10 DFD1210 285 11.25 11.00 1.00 1.00

14 x 12 DFD1412 390 12.50 11.00 1.00 1.00

16 x 10 DFD1610 355 13.75 11.00 1.00 1.00

16 x 12 DFD1612 385 13.75 11.00 1.00 1.00

16 X 14 DFD1614 13.75 11.00 1.00 1.00

20 x 18 DFD2018 515 16.00 13.50 1.12 1.12

24 x 16 DFD2416 680 16.00 13.50 1.12 1.12

24 x 18 DFD2418 720 16.00 13.50 1.12 1.12

30 x 14 DFD3014 1,280 23.00 16.00 1.19 1.15

30 x 24 DFD3024 1,294 18.50 13.50 1.12 1.12

36 x 24 DFD3624 1,585 18.50 13.50 1.12 1.12

Long Radius Base Bend 90°

Base Bend 90°

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

8

Reducing Base Bend

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 9

SIDE OUTLET 90° BEND

Size Wt. Item No. A R T

3 DFO390 5.50 4.00 0.48

4 DFO490 6.50 4.50 0.52

6 DFO690 8.00 6.00 0.55

8 DFO890 9.00 7.00 0.60

10 DFO1090 11.00 9.00 0.68

12 DFO1290 12.00 10.00 0.75

14 DFO1490 14.00 11.50 0.66

16 DFO1690 15.00 12.50 0.70

18 DFO1890 16.50 14.00 0.75

20 DFO2090 18.00 15.50 0.80

24 DFO2490 22.00 18.50 0.89

DFO

DFT

DFC

TEES & CROSSES

TEES

Size

DUCTILE IRON

Wt. H J T

Item No.

2 DFT22 20 4.50 4.50 0.31 DFC22 30

3 DFT33 40 5.50 5.50 0.48 DFC33 50

4 DFT44 65 6.50 6.50 0.52 DFC44 80

5 DFT55 85 7.50 7.50 0.52 DFC55 105

6 DFT66 95 8.00 8.00 0.55 DFC66 120

8 DFT88 155 9.00 9.00 0.60 DFC88 195

10 DFT1010 270 11.00 11.00 0.80 DFC1010 330

12 DFT1212 385 12.00 12.00 0.87 DFC1212 460

14 DFT1414 435 14.00 14.00 0.66 DFC1414 530

16 DFT1616 550 15.00 15.00 0.70 DFC1616 665

18 DFT1818 665 16.50 16.50 0.75 DFC1818 795

20 DFT2020 855 18.00 18.00 0.80 DFC2020 1,015

24 DFT2424 1,330 22.00 22.00 0.89 DFC2424 1,570

30 DFT3030 2,150 25.00 25.00 1.03 DFC3030 2,500

36 DFT3636 3,160 28.00 28.00 1.15 DFC3636 3,620

42 DFT4242 4,470 31.00 31.00 1.28 DFC4242 5,065

48 DFT4848 5,900 34.00 34.00 1.42 DFC4848 6,570

54 DFT5454 8,900 37.00 37.00 1.62 DFC5454

60 DFT6060 43.00 43.00 1.10

CROSSES

DUCTILE IRON

Item No.

BULLHEAD TEES

Size

4 x 4 x 6 DBT446 90 8.00 8.00 .52 .55

6 x 6 x 8 DBT668 140 9.00 9.00 .55 .60

8 x 8 x 10 DBT810 260 11.00 11.00 .60 .67

10 x 10 x 12 DBT101012 355 12.00 12.00 .80 .87

14 x 14 x 20 DBT141420

20 x 20 x 30 DBT202030 1737 25.00 25.00 1.03 0.80

24 x 24 x 30 DBT242430 25.00 25.00 1.03 0.89

24 x 24 x 36 DBT242436

30 x 30 x 42 DBT303042 3588 31.00 31.00 1.28 1.03

30 x 30 x 36 DBT303036

42 x 42 x 60 DBT424260 44.50 43,00 1.10 0.88

DUCTILE

IRON

Wt. H J T T1

Wt.

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

®

®

Member

Certified to

ANSI/NSF 61

®

DBT

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

SIGMA Corporation www.sigmaco.com

Dimensions in inches

Weights in pounds

9

Page 10

Flanged Fittings

REDUCING TEES

Size Wt.

DUCTILE IRON

Item No.

H J T T1

2 1/2 x 2 1/2 29 DFT2525 5.50 5.50 0.48 0.48

3 x 2 35 DFT32 5.50 6.50 0.48 0.31

4 x 2 50 DFT42 6.50 6.50 0.52 0.31

4 x 2 ½ 55 DFT425 6.50 6.50 0.52 0.31

4 x 3 60 DFT43 6.50 6.50 0.52 0.48

6 x 2 85 DFT62 8.00 8.00 0.55 0.31

6 x 3 85 DFT63 8.00 8.00 0.55 0.48

6 x 4 90 DFT64 8.00 8.00 0.55 0.52

8 x 2 9.00 9.00 0.60 0.31

8 x 3 DFT83 9.00 9.00 0.60 0.48

8 x 4 140 DFT84 9.00 9.00 0.60 0.52

8 x 6 145 DFT86 9.00 9.00 0.60 0.55

10 x 3 DFT103 11.00 11.00 0.68 0.48

10 x 4 205 DFT104 11.00 11.00 0.68 0.52

10 x 6 215 DFT106 11.00 11.00 0.68 0.55

10 x 8 225 DFT108 11.00 11.00 0.68 0.60

12 x 4 290 DFT124 12.00 12.00 0.75 0.52

12 x 6 295 DFT126 12.00 12.00 0.75 0.55

12 x 8 310 DFT128 12.00 12.00 0.75 0.60

12 x 10 360 DFT1210 12.00 12.00 0.87 0.80

14 x 4 DFT144 14.00 14.00 0.66 0.52

14 x 6 375 DFT146 14.00 14.00 0.66 0.55

14 x 8 390 DFT148 14.00 14.00 0.66 0.60

14 x 10 400 DFT1410 14.00 14.00 0.66 0.68

14 x 12 425 DFT1412 14.00 14.00 0.66 0.75

16 x 4 DFT164 15.00 15.00 0.70 0.52

16 x 6 465 DFT166 15.00 15.00 0.70 0.55

16 x 8 475 DFT168 15.00 15.00 0.70 0.60

16 x 10 495 DFT1610 15.00 15.00 0.70 0.68

16 x 12 520 DFT1 612 15.00 15.00 0.70 0.75

16 x 14 530 DFT1614 15.00 15.00 0.70 0.66

18 x 6 480 DFT1 86 13.00 15.50 0.75 0.55

18 x 8 495 DFT188 13.00 15.50 0.75 0.60

18 x 10 510 DFT1810 13.00 15.50 0.75 0.68

18 x 12 535 DFT1812 13.00 15.50 0.75 0.75

18 x 14 630 DFT1814 16.50 16.50 0.75 0.66

18 x 16 650 DFT1816 16.50 16.50 0.75 0.70

20 x 4 DFT204 14.00 17.00 0.80 0.52

20 x 6 610 DFT206 14.00 17.00 0.80 0.55

20 x 8 620 DFT208 14.00 17.00 0.80 0.60

20 x 10 635 DFT2010 14.00 17.00 0.80 0.68

20 x 12 660 DFT2012 14.00 17.00 0.80 0.75

20 x 14 665 DFT2014 14.00 17.00 0.80 0.66

20 x 16 810 DFT2016 18.00 18.00 0.80 0.70

20 x 18 820 DFT2018 18.00 18.00 0.80 0.75

24 X 4 DFT244 15.00 19.00 0.89 0.52

24 x 6 845 DFT246 15.00 19.00 0.89 0.55

24 x 8 860 DFT248 15.00 19.00 0.89 0.60

24 x 10 880 DFT2410 15.00 19.00 0.89 0.68

24 x 12 890 DFT2412 15.00 19.00 0.89 0.75

24 x 14 900 DFT2414 15.00 19.00 0.89 0.66

24 x 16 915 DFT2416 15.00 19.00 0.89 0.70

24 x 18 1,220 DFT2418 22.00 22.00 0.89 0.75

24 x 20 1,255 DFT2420 22.00 22.00 0.89 0.80

30 x 12 1,490 DFT3012 18.00 23.00 1.03 0.75

30 x 14 1,490 DFT3014 18.00 23.00 1.03 0.66

30 x 16 1,505 DFT3016 18.00 23.00 1.03 0.70

30 x 18 1,515 DFT3018 18.00 23.00 1.03 0.75

30 x 20 1,540 DFT3020 18.00 23.00 1.03 0.80

30 x 24 2,025 DFT3024 25.00 25.00 1.03 0.89

36 x 6 DFT366 20.00 26.00 1.15 0.55

36 x 8 DFT368 20.00 26.00 1.15 0.60

36 x 12 2,170 DFT3612 20.00 26.00 1.15 0.75

36 x 14 2,175 DFT3614 20.00 26.00 1.15 0.66

36 x 16 2,185 DFT3616 20.00 26.00 1.15 0.70

36 x 18 2,190 DFT3618 20.00 26.00 1.15 0.75

36 x 20 2,210 DFT3620 20.00 26.00 1.15 0.80

36 x 24 2,255 DFT3624 20.00 26.00 1.15 0.89

36 x 30 3,000 DFT3630 28.00 28.00 1.15 1.03

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

10

DFT

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 11

REDUCING TEES (continued)

Size Wt.

42 x 10 DFT4210 23.00 30.00 1.28 0.68

42 x 12 3,165 DFT4212 23.00 30.00 1.28 0.75

42 x 14 3,170 DFT4214 23.00 30.00 1.28 0.66

42 x 16 3,180 DFT4216 23.00 30.00 1.28 0.70

42 x 18 3,185 DFT4218 23.00 30.00 1.28 0.75

42 x 20 3,205 DFT4220 23.00 30.00 1.28 0.80

42 x 24 3,245 DFT4224 23.00 30.00 1.28 0.89

42 x 30 4,125 DFT4230 31.00 31.00 1.28 1.03

42 x 36 5,360 DFT4236 31.00 31.00 1.78 1.58

48 x 12 4,315 DFT4812 26.00 34.00 1.42 0.75

48 x 14 4,315 DFT4814 26.00 34.00 1.42 0.66

48 x 16 4,330 DFT4816 26.00 34.00 1.42 0.70

48 x 18 4,330 DFT4818 26.00 34.00 1.42 0.75

48 x 20 4,350 DFT4820 26.00 34.00 1.42 0.80

48 x 24 4,385 DFT4824 26.00 34.00 1.42 0.89

48 x 30 4,455 DFT4830 26.00 34.00 1.42 1.03

48 x 36 5,555 DFT4836 34.00 34.00 1.42 1.15

48 x 42 7,195 DFT4842 34.00 34.00 1.96 1.78

54 x 16 DFT5416 25.00 37.00 1.05 0.50

54 x 24 3,794 DFT5424 26.00 39.00 1.05 0.61

54 x 30 DFT5430 31.00 37.00 1.05 0.72

54 x 36 4,695 DFT5436 31.00 37.00 1.05 0.77

60 x 30 DFT6030 33.00 42.00 1.10 0.72

60 x 36 6,015 DFT6036 33.00 42.00 1.10 0.77

64 x 24 DFT6424 28.00 44.00 1.16 0.61

64 x 36 DFT6436 32.00 44.00 1.16 0.77

60 x 54 6,754 DFT6054 43.00 43.00 1.10 1.05

DUCTILE IRON

Item No.

H J T T1

DFT

REDUCING CROSSES

Size Wt.

3 x 2 45 DFC32 5.50 6.50 0.48 0.31

4 x 2 60 DFC42 6.50 6.50 0.52 0.31

4 x 2 ½ 65 DFC425 6.50 6.50 0.52 0.31

4 x 3 70 DFC43 6.50 6.50 0.52 0.48

6 x 2 90 DFC62 8.00 8.00 0.55 0.31

6 x 3 95 DFC63 8.00 8.00 0.55 0.48

6 x 4 11 0 DFC64 8.00 8.00 0.55 0.52

8 x 4 155 DFC84 9.00 9.00 0.60 0.52

8 x 6 165 DFC86 9.00 9.00 0.60 0.55

10 x 4 220 DFC104 11.00 11.00 0.68 0.52

10 x 6 240 DFC106 11.00 11.00 0.68 0.55

10 x 8 265 DFC108 11.00 11.00 0.68 0.60

12 x 4 310 DFC124 12.00 12.00 0.75 0.52

12 x 6 320 DFC126 12.00 12.00 0.75 0.55

12 x 8 345 DFC128 12.00 12.00 0.75 0.60

12 x 10 415 DFC1210 12.00 12.00 0.87 0.80

14 x 6 400 DFC146 14.00 14.00 0.66 0.55

14 x 8 425 DFC148 14.00 14.00 0.66 0.60

14 x 10 460 DFC1410 14.00 14.00 0.66 0.68

14 x 12 505 DFC1412 14.00 14.00 0.66 0.75

16 x 6 490 DFC166 15.00 15.00 0.70 0.55

16 x 8 520 DFC168 15.00 15.00 0.70 0.60

16 x 10 555 DFC1610 15.00 15.00 0.70 0.68

16 x 12 605 DFC1612 15.00 15.00 0.70 0.75

16 x 14 620 DFC1614 15.00 15.00 0.70 0.66

18 x 6 505 DFC186 13.00 15.50 0.75 0.55

18 x 8 535 DFC188 13.00 15.50 0.75 0.60

18 x 10 560 DFC1810 13.00 15.50 0.75 0.68

18 x 12 610 DFC1812 13.00 15.50 0.75 0.75

18 x 14 720 DFC1814 16.50 16.50 0.75 0.66

18 x 16 765 DFC1816 16.50 16.50 0.75 0.70

20 x 6 635 DFC206 14.00 17.00 0.80 0.55

20 x 8 665 DFC208 14.00 17.00 0.80 0.60

20 x 10 685 DFC2010 14.00 17.00 0.80 0.68

DUCTILE IRON

Item No.

H J T T1

DFC

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

®

®

Certified to

ANSI/NSF 61

®

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

SIGMA Corporation www.sigmaco.com

Dimensions in inches

Weights in pounds

11

Page 12

Flanged Fittings

REDUCING CROSSES (continuted)

Size Wt.

20 x 12 735 DFC2014 14.00 17.00 0.80 0.75

20 x 14 745 DFC2016 14.00 17.00 0.80 0.66

20 x 16 915 DFC2018 18.00 18.00 0.80 0.70

20 x 18 945 DFC246 18.00 18.00 0.80 0.75

24 x 6 875 DFC248 15.00 19.00 0.89 0.55

24 x 8 895 DFC2410 15.00 19.00 0.89 0.60

24 x 10 930 DFC2412 15.00 19.00 0.89 0.68

24 x 12 960 DFC2414 15.00 19.00 0.89 0.75

24 x 14 975 DFC2416 15.00 19.00 0.89 0.66

24 x 16 1,010 DFC2418 15.00 19.00 0.89 0.70

24 x 18 1,365 DFC2420 22.00 22.00 0.89 0.75

24 x 20 1,430 DFC3012 22.00 22.00 0.89 0.80

30 x 12 1,565 DFC3014 18.00 23.00 1.03 0.75

30 x 14 1,570 DFC3016 18.00 23.00 1.03 0.66

30 x 16 1,605 DFC3018 18.00 23.00 1.03 0.70

30 x 18 1,615 DFC3020 18.00 23.00 1.03 0.75

30 x 20 1,670 DFC3024 18.00 23.00 1.03 0.80

30 x 24 2,245 DFC3612 25.00 25.00 1.03 0.89

36 x 12 2,240 DFC3614 20.00 26.00 1.15 0.75

36 x 14 2,240 DFC3616 20.00 26.00 1.15 0.66

36 x 16 2,270 DFC3618 20.00 26.00 1.15 0.70

36 x 18 2,280 DFC3620 20.00 26.00 1.15 0.75

36 x 20 2,325 DFC3624 20.00 26.00 1.15 0.80

36 x 24 2,405 DFC3630 20.00 26.00 1.15 0.89

36 x 30 3,300 DFC4212 28.00 28.00 1.15 1.03

42 x 12 3,240 DFC4214 23.00 30.00 1.28 0.75

42 x 14 3,240 DFC4216 23.00 30.00 1.28 0.66

42 x 16 3,270 DFC4218 23.00 30.00 1.28 0.70

42 x 18 3,275 DFC4220 23.00 30.00 1.28 0.75

42 x 20 3,320 DFC4224 23.00 30.00 1.28 0.80

42 x 24 3,395 DFC4230 23.00 30.00 1.28 0.89

42 x 30 4,375 DFC4236 31.00 31.00 1.28 1.03

42 x 36 5,720 DFC4812 31.00 31.00 1.78 1.58

48 x 12 4,390 DFC4814 26.00 34.00 1.42 0.75

48 x 14 4,385 DFC4816 26.00 34.00 1.42 0.66

48 x 16 4,415 DFC4818 26.00 34.00 1.42 0.70

48 x 18 4,420 DFC4820 26.00 34.00 1.42 0.75

48 x 20 4,460 DFC4824 26.00 34.00 1.42 0.80

48 x 24 4,535 DFC4830 26.00 34.00 1.42 0.89

48 x 30 4,670 DFC4836 26.00 34.00 1.42 1.03

48 x 36 5,880 DFC4842 34.00 34.00 1.42 1.15

48 x 42 7,630 DFC6048 34.00 34.00 1.96 1.78

60 x 48 43.00 43.00 1.10 0.94

DUCTILE IRON

Item No.

H J T T1

DFC

REDUCING TEES

Size Wt.

6 x 4 x 4 85 DRT644 8.00 8.00 0.55 0.52

6 x 4 x 6 90 DRT646 8.00 8.00 0.55 0.52

8 x 6 x 4 125 DRT864 9.00 9.00 0.60 0.55

8 x 6 x 6 135 DRT866 9.00 9.00 0.60 0.55

8 x 6 x 8 145 DRT868 9.00 9.00 0.60 0.65

10 x 8 x 10 DRT10810 11.00 11.00 0.68 0.60

12 x 8 x 12 DRT12812 12.00 12.00 0.75 0.60

14 x 8 x 14 DRT14814 14.00 14.00 0.66 0.60

16 x 12 x 12 DRT161212 15.00 15.00 0.70 0.75

18 x 12 x 18 DRT181218 16.50 16.50 0.75 0.75

24 x 16 x 16 DRT241616 17.00 19.00 0.89 0.70

24 x 20 x 20 DRT242020 22.00 22.00 0.89 0.80

24 x 20 x 24 DRT242024 22.00 22.00 0.89 0.80

30 x 20 x 20 DRT302020 25.00 23.00 1.03 0.80

30 x 20 x 24 DRT302024 25.00 25.00 1.03 0.80

30 x 20 x 30 DRT302030 25.00 25.00 1.03 0.80

30 x 24 x 30 DRT302430 25.00 25.00 1.03 0.89

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

12

DUCTILE IRON

Item No.

H J T T1

DRT

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 13

REDUCING CROSS

Size Wt. Item No. H J T T1

20x20x20x12 DFC20202012 18.00 18.00 0.80 0.75

30x30x30x24 DFC30303024 25.00 25.00 1.03 0.89

36x36x36x24 DFC36363624 28.00 28.00 1.15 0.89

36x36x36x42 DFC36363642 31.00 31.00 1.78 1.58

36x36x36x48 DFC36363648 34.00 34.00 1.42 1.15

BASE TEES

DUCTILE IRON

Size

Item No.

3 DFV33 45 5 4.88 5.00 0.56 0.50 5/8

4 DFV44 75 10 5.50 6.00 0.62 0.50 3/4

6 DFV66 110 15 7.00 7.00 0.69 0.62 3/4

8 DFV88 185 30 8.38 9.00 0.94 0.88 3/4

10 DFV1010 300 30 9.75 9.00 0.94 0.88 3/4

12 DFV1212 430 45 11.25 11.00 1.00 1.00 7/8

14 DFV1414 485 50 12.50 11.00 1.00 1.00 7/8

16 DFV1616 600 50 13.75 11.00 1.00 1.00 7/8

18 DFV1818 740 75 15.00 13.50 1.12 1.12 7/8

20 DFV2020 930 75 16.00 13.50 1.12 1.12 7/8

24 DFV2424 1,410 80 18.50 13.50 1.12 1.12 7/8

30 DFV3030 2,270 120 23.00 16.00 1.19 1.15 1

36 DFV3636 3,320 160 26.00 19.00 1.25 1.15 1

42 DFV4242 5,850 270 30.00 23.50 1.44 1.28 1 1/8

48 DFV4848 7,720 335 34.00 25.00 1.56 1.42 1 1/4

WEIGHT

Base

Tee

Base

Only

R S T U

Base - Bolt Hole

REDUCING BASE TEES

Size Wt. Item No. R S T U

4 x 3 70 DFV43 5.50 6.00 0.62 0.50

6 x 3 100 DFV63 7.00 7.00 0.69 0.62

6 x 4 105 DFV64 7.00 7.00 0.69 0.62

8 x 4 170 DFV84 8.38 9.00 0.94 0.88

8 x 6 187 DFV86 8.38 9.00 0.94 0.88

10 x 4 235 DFV104 9.75 9.00 0.94 0.88

10 x 6 245 DFV106 9.75 9.00 0.94 0.88

10 x 8 330 DFV108 9.75 9.00 0.94 0.88

12 x 4 335 DFV124 11.25 11.00 1.00 1.00

12 x 6 340 DFV126 11.25 11.00 1.00 1.00

12 x 8 355 DFV128 11.25 11.00 1.00 1.00

12 x 10 405 DFV1210 11.25 11.00 1.00 1.00

14 x 6 425 DFV146 12.50 11.00 1.00 1.00

14 x 8 440 DFV148 12.50 11.00 1.00 1.00

14 x 10 450 DFV1410 12.50 11.00 1.00 1.00

14 x 12 475 DFV1412 12.50 11.00 1.00 1.00

16 x 6 515 DFV166 13.75 11.00 1.00 1.00

16 x 8 525 DFV168 13.75 11.00 1.00 1.00

16 x 10 545 DFV1610 13.75 11.00 1.00 1.00

16 x 12 570 DFV1612 13.75 11.00 1.00 1.00

16 x 14 580 DFV1614 13.75 11.00 1.00 1.00

18 x 6 555 DFV186 15.00 13.50 1.12 1.12

18 x 8 570 DFV188 15.00 13.50 1.12 1.12

18 x 10 585 DFV1810 15.00 13.50 1.12 1.12

18 x 12 640 DFV1812 15.00 13.50 1.12 1.12

18 x 14 705 DFV1814 15.00 13.50 1.12 1.12

18 x 16 725 DFV1816 15.00 13.50 1.12 1.12

20 x 6 685 DFV206 16.00 13.50 1.12 1.12

20 x 8 695 DFV208 16.00 13.50 1.12 1.12

20 x 10 710 DFV2010 16.00 13.50 1.12 1.12

20 x 12 681 DFV2012 16.00 13.50 1.12 1.12

DFC

Diam.

DFV

DFV

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

®

®

Certified to

ANSI/NSF 61

®

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

13

Page 14

Flanged Fittings

REDUCING BASE TEES (continued)

Size Wt. Item No. R S T U

20 x 14 740 DFV2014 16.00 13.50 1.12 1.12

20 x 16 885 DFV2016 16.00 13.50 1.12 1.12

20 x 18 895 DFV2018 16.00 13.50 1.12 1.12

24 x 6 925 DFV246 18.50 13.50 1.12 1.12

24 x 8 940 DFV248 18.50 13.50 1.12 1.12

24 x 10 960 DFV2410 18.50 13.50 1.12 1.12

24 x 12 970 DFV2412 18.50 13.50 1.12 1.12

24 x 14 980 DFV2414 18.50 13.50 1.12 1.12

24 x 16 993 DFV2416 18.50 13.50 1.12 1.12

24 x 18 1,300 DFV2418 18.50 13.50 1.12 1.12

24 x 20 1,335 DFV2420 18.50 13.50 1.12 1.12

30 x 6 1,344 DFV306 23.00 16.00 1.19 1.15

30 x 8 1,344 DFV308 23.00 16.00 1.19 1.15

30 x 12 1,610 DFV3012 23.00 16.00 1.19 1.15

30 x 14 1,610 DFV3014 23.00 16.00 1.19 1.15

30 x 16 1,622 DFV3016 23.00 16.00 1.19 1.15

30 x 18 1,635 DFV3018 23.00 16.00 1.19 1.15

30 x 20 1,660 DFV3020 23.00 16.00 1.19 1.15

30 x 24 2,145 DFV3024 23.00 16.00 1.19 1.15

36 x 12 2,027 DFV3612 26.00 19.00 1.25 1.15

36 x 14 2,335 DFV3614 26.00 19.00 1.25 1.15

36 x 16 2,345 DFV3616 26.00 19.00 1.25 1.15

36 x 18 2,350 DFV3618 26.00 19.00 1.25 1.15

36 x 20 2,370 DFV3620 26.00 19.00 1.25 1.15

36 x 24 2,415 DFV3624 26.00 19.00 1.25 1.15

36 x 30 3,160 DFV3630 26.00 19.00 1.25 1.15

42 x 12 3,435 DFV4212 30.00 23.50 1.44 1.28

42 x 14 3,440 DFV4214 30.00 23.50 1.44 1.28

42 x 16 3,450 DFV4216 30.00 23.50 1.44 1.28

42 x 18 3,455 DFV4218 30.00 23.50 1.44 1.28

42 x 20 3,475 DFV4220 30.00 23.50 1.44 1.28

42 x 24 3,515 DFV4224 30.00 23.50 1.44 1.28

42 x 30 4,395 DFV4230 30.00 23.50 1.44 1.28

42 x 36 4,630 DFV4236 30.00 23.50 1.44 1.28

48 x 12 4,650 DFV4812 34.00 25.00 1.56 1.42

48 x 14 4,650 DFV4814 34.00 25.00 1.56 1.42

48 x 16 4,665 DFV4816 34.00 25.00 1.56 1.42

48 x 18 4,665 DFV4818 34.00 25.00 1.56 1.42

48 x 20 4,685 DFV4820 34.00 25.00 1.56 1.42

48 x 24 4,720 DFV4824 34.00 25.00 1.56 1.42

48 x 30 4,970 DFV4830 34.00 25.00 1.56 1.42

48 x 36 5,890 DFV4836 34.00 25.00 1.56 1.42

48 x 42 6,055 DFV4842 34.00 25.00 1.56 1.42

DFV

45° LATERAL WYES

Size Wt.

3 45 DFY33 10.00 3.00 10.00 0.48

4 75 DFY44 12.00 3.00 12.00 0.52

6 120 DFY66 14.50 3.50 14.50 0.55

8 200 DFY88 17.50 4.50 17.50 0.60

10 335 DFY1010 20.50 5.00 20.50 0.68

12 515 DFY1212 24.50 5.50 24.50 0.75

14 605 DFY1414 27.00 6.00 27.00 0.66

16 805 DFY1616 30.00 6.50 30.00 0.70

18 980 DFY1818 32.00 7.00 32.00 0.75

20 1,265 DFY2020 35.00 8.00 35.00 0.80

24 1,905 DFY2424 40.50 9.00 40.50 0.89

30 3,225 DFY3030 52.50 18.30 52.50 1.03

36 5,740 DFY3636 60.00 19.50 60.00 1.15

42 9,170 DFY4242 71.00 15.00 71.00 1.28

48 12,100 DFY4848 77.00 16.00 77.00 1.42

60 DFY6060 100.00 25.00 100.00 1.10

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

14

DUCTILE IRON

Item No.

A B C T

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

DFY

Manufactured in accordance with AWWA/ANSI C110/A21.10.

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 15

45° LATERAL REDUCING WYES

Size Wt.

4 x 3 65 DFY43 12.00 3.00 12.00 0.52 0.48

6 x 3 100 DFY63 14.50 3.50 14.50 0.55 0.48

6 x 4 115 DFY64 14.50 3.50 14.50 0.55 0.52

8 x 4 180 DFY84 17.50 4.50 17.50 0.60 0.52

8 x 6 190 DFY86 17.50 4.50 17.50 0.60 0.55

10 x 4 260 DFY104 20.50 5.00 20.50 0.68 0.52

10 x 6 270 DFY106 20.50 5.00 20.50 0.68 0.55

10 x 8 295 DFYI08 20.50 5.00 20.50 0.68 0.60

12 x 4 380 DFY124 24.50 5.50 24.50 0.75 0.52

12 x 6 395 DFY126 24.50 5.50 24.50 0.75 0.55

12 x 8 420 DFY128 24.50 5.50 24.50 0.75 0.60

12 x 10 455 DFY1210 24.50 5.50 24.50 0.75 0.68

14 x 4 505 DFY144 27.00 6.00 27.00 0.66 0.52

14 x 6 520 DFY146 27.00 6.00 27.00 0.66 0.55

14 x 8 545 DFY148 27.00 6.00 27.00 0.66 0.60

14 x 10 580 DFY1410 27.00 6.00 27.00 0.66 0.68

14 x 12 620 DFY1412 27.00 6.00 27.00 0.66 0.75

16 x 4 665 DFY164 27.00 6.00 27.00 0.70 0.52

16 x 6 680 DFY166 30.00 6.50 30.00 0.70 0.55

16 x 8 710 DFY168 30.00 6.50 30.00 0.70 0.60

16 x 10 740 DFY1610 30.00 6.50 30.00 0.70 0.68

16 x 12 785 DFY1612 30.00 6.50 30.00 0.70 0.75

16 x 14 830 DFY1614 30.00 6.50 30.00 0.70 0.66

18 x 4 275 DFY184 25.00 1.00 27.50 0.75 0.52

18 x 6 450 DFY1 86 25.00 1.00 27.50 0.75 0.55

18 x 8 625 DFY188 25.00 1.00 27.50 0.75 0.60

18 x 10 885 DFY1810 32.00 7.00 32.00 0.75 0.68

18 x 12 930 DFY1812 32.00 7.00 32.00 0.75 0.75

18 x 14 975 DFY1814 32.00 7.00 32.00 0.75 0.66

18 x 16 1,025 DFY1816 32.00 7.00 32.00 0.75 0.70

20 x 4 710 DFY204 27.00 1.00 29.50 0.80 0.52

20 x 6 720 DFY206 24.00 1.00 29.50 0.80 0.55

20 x 8 740 DFY208 29.00 1.00 29.50 0.80 0.60

20 x 10 805 DFY2010 27.00 1.00 29.50 0.80 0.68

20 x 12 1,110 DFY2012 35.00 8.00 35.00 0.80 0.75

20 x 14 1,215 DFY2014 35.00 8.00 35.00 0.80 0.66

20 x 16 1,270 DFY2016 35.00 8.00 35.00 0.80 0.70

20 x 18 1,315 DFY2018 35.00 8.00 35.00 0.80 0.75

24 x 4 790 DFY244 31.50 0.50 34.50 0.89 0.52

24 x 6 1,060 DFY246 31.50 0.50 34.50 0.89 0.55

24 x 8 1,080 DFY248 31.50 0.50 34.50 0.89 0.60

24 x 10 1,105 DFY2410 31.50 0.50 34.50 0.89 0.68

24 x 12 1,200 DFY2412 31.50 0.50 34.50 0.89 0.75

24 x 14 1,750 DFY2414 40.50 9.00 40.50 0.89 0.66

24 x 16 1,805 DFY2416 40.50 9.00 40.50 0.89 0.70

24 x 18 1,855 DPY2418 40.50 9.00 40.50 0.89 0.75

24 x 20 1,930 DFY2420 40.50 9.00 40.50 0.89 0.80

30 x 12 2,795 DFY3012 49.00 10.00 49.00 1.03 0.75

30 x 14 2,850 DFY3014 49.00 10.00 49.00 1.03 0.66

30 x 16 2,905 DFY3016 49.00 10.00 49.00 1.03 0.70

30 x 18 2,960 DFY3018 49.00 10.00 49.00 1.03 0.75

30 x 20 3,040 DFY3020 49.00 10.00 49.00 1.03 0.80

30 x 24 3,205 DFY3024 49.00 10.00 49.00 1.03 0.89

36 x 12 4,490 DFY3612 60.00 19.50 60.00 1.15 0.75

36 x 14 4,545 DFY3614 60.00 19.50 60.00 1.15 0.66

36 x 16 4,455 DFY3616 54.00 15.30 54.00 1.15 0.70

36 x 18 4,505 DFY3618 54.00 15.30 54.00 1.15 0.75

36 x 20 4,575 DFY3620 54.00 15.30 54.00 1.15 0.80

36 x 24 4,725 DFY3624 54.00 15.30 54.00 1.15 0.89

36 x 30 5,200 DFY3630 56.00 15.30 56.00 1.15 1.03

42 x 12 5,725 DFY4212 68.50 21.00 68.50 1.28 0.75

42 x 14 5,800 DFY4214 68.50 21.00 68.50 1.28 0.66

42 x 16 5,850 DFY4216 68.50 21.00 68.50 1.28 0.70

42 x 18 6,000 DFY4218 68.50 21.00 68.50 1.28 0.75

42 x 20 6,110 DFY4220 60.00 12.00 60.00 1.28 0.80

42 x 24 6,255 DFY4224 60.00 12.00 60.00 1.28 0.89

42 x 30 6,855 DFY4230 63.00 12.00 63.00 1.28 1.03

42 x 36 7,650 DFY4236 66.00 12.00 66.00 1.28 1.15

48 x 12 7,200 DFY4812 77.00 22.50 77.00 1.42 0.75

DUCTILE IRON

Item No.

A B C T T1

DFY

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

®

®

Certified to

ANSI/NSF 61

®

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

15

Page 16

Flanged Fittings

45° LATERAL REDUCING WYES (continued)

Size Wt.

48 x 14 7,275 DFY4814 77.00 22.50 77.00 1.42 0.66

48 x 16 7,400 DFY4816 77.00 22.60 77.00 1.42 0.70

48 x 18 7,620 DFY4818 65.00 9.00 65.00 1.42 0.75

48 x 20 7,685 DFY4820 65.00 9.00 65.00 1.42 0.80

48 x 24 6,840 DFY4824 58.00 5.00 64.00 1.42 0.89

48 x 30 8,015 DFY4830 63.00 9.00 68.00 1.42 1.03

48 x 36 8,970 DFY4836 69.00 7.00 72.00 1.42 1.15

48 x 42 11,010 DFY4842 77.00 12.00 77.00 1.42 1.28

54 x 36 DFY5436 78.00 12.00 78.00 1.05 0.77

54 x 42 DFY5442 80.00 12.00 80.00 0.90 0.82

60 x 36 DFY6036 80.00 12.00 80.00 0.94 0.66

64 x 36 DFY6436 100.00 10.00 105.00 1.16 0.77

DUCTILE IRON

Item No.

A B C T T1

DFY

CONCENTRIC REDUCERS

Size Wt.

2 1/2 x 2 DFR252 6.00 0.48 0.31

3 x 2 16 DFR32 6.00 0.48 0.31

3 x 2 1/2 21 DFR325 6.00 0.48 0.31

4 x 2 25 DFR42 7.00 0.52 0.31

4 x 2 1/2 28 DFR425 7.00 0.52 0.31

4 x 3 30 DFR43 7.00 0.52 0.48

6 x 2 35 DFR62 9.00 0.55 0.31

6 x 2 1/2 38 DFR625 9.00 0.55 0.31

6 x 3 40 DFR63 9.00 0.55 0.48

6 x 4 45 DFR64 9.00 0.55 0.52

6 x 5 51 DFR65 9.00 0.55 0.52

8 x 4 65 DFR84 11.00 0.60 0.52

8 x 5 70 DFR85 11.00 0.60 0.52

8 x 6 75 DFR86 11.00 0.60 0.55

10 x 4 85 DFR104 12.00 0.68 0.52

10 x 6 90 DFR106 12.00 0.68 0.55

10 x 8 110 DFR108 12.00 0.68 0.60

12 x 4 120 DFR124 14.00 0.75 0.52

12 x 6 130 DFR126 14.00 0.75 0.55

12 x 8 145 DFR128 14.00 0.75 0.60

12 x 10 170 DFR1210 14.00 0.75 0.68

14 x 6 155 DFR146 16.00 0.66 0.55

14 x8 175 DFR148 16.00 0.66 0.60

14 x 10 190 DFR1410 16.00 0.66 0.68

14 x 12 220 DFR1412 16.00 0.66 0.75

16x6 190 DFR166 18.00 0.70 0.55

16 x 8 210 DFR168 18.00 0.70 0.60

16 x 10 235 DFR1610 18.00 0.70 0.68

16 x 12 265 DFR1612 18.00 0.70 0.75

16 x 14 280 DFR1614 18.00 0.70 0.66

18 x 6 DFR186 19.00 0.75 0.55

18 x 8 240 DFR188 19.00 0.75 0.60

18 x 10 265 DFR1810 19.00 0.75 0.68

18 x 12 295 DFR1812 19.00 0.75 0.75

18 x 14 310 DFRI814 19.00 0.75 0.66

18 x 16 340 DFR1816 19.00 0.75 0.70

20 x 6 DFR206 20.00 0.80 0.55

20 x 8 DFR208 20.00 0.80 0.60

20 x 10 310 DFR2010 20.00 0.80 0.68

20 x 12 345 DFR2012 20.00 0.80 0.75

20 x 14 355 DFR2014 20.00 0.80 0.66

20 x 16 390 DFR2016 20.00 0.80 0.70

20 x 18 410 DFR2018 20.00 0.80 0.75

24 x 6 DFR246 24.00 0.89 0.55

24 x 10 DFR2410 24.00 0.89 0.68

24 x 12 480 DFR2412 24.00 0.89 0.75

24 x 14 490 DFR2414 24.00 0.89 0.66

24 x 16 525 DFR2416 24.00 0.89 0.70

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

16

DUCTILE IRON

Item No.

L T T1

Size Wt.

DUCTILE IRON

Item No.

L T T1

24 x 18 550 DFR2418 24.00 0.89 0.75

24 x 20 590 DFR2420 24.00 0.89 0.80

30 x 6 DFR306 30.00 1.03 0.55

30 x 16 DFR3016 30.00 1.03 0.70

30 x 18 810 DFR3018 30.00 1.03 0.75

30 x 20 870 DFR3020 30.00 1.03 0.80

30 x 24 970 DFR3024 30.00 1.03 0.89

36 x 14 DFR3614 36.00 1.15 0.66

36 x 16 DFR3616 36.00 1.15 0.70

36 x 18 DFR3618 36.00 1.15 0.75

36 x 20 1,230 DFR3620 36.00 1.15 0.80

36 x 24 1,345 DFR3624 36.00 1.15 0.89

36 x 30 1,555 DFR3630 36.00 1.15 1.03

42 x 24 1,820 DFR4224 42.00 1.28 0.89

42 x 30 2,060 DFR4230 42.00 1.28 1.03

42 x 36 2,345 DFR4236 42.00 1.28 1.15

48 x 14 DFR4814 48.00 1.42 0.66

48 x 24 DFR4824 48.00 1.42 0.89

48 x 30 2,625 DFR4830 48.00 1.42 1.03

48 x 36 2,950 DFR4836 48.00 1.42 1.15

48 x 42 3,320 DFR4842 48.00 1.42 1.28

54 x 36 DFR5436 28.00 0.90 0.66

54 x 48 5,330 DFR5448 64.00 1.62 1.42

60 x 36 DFR6036 32.00 0.94 0.66

60 x 48 DFR6048 32.00 0.94 0.80

60 x 54 DFR6054 15.00 0.94 0.90

72 x 36 DFR7236 40.00 1.40 1.15

72 x 48 DFR7248 40.00 1.40 1.40

72 x 54 DFR7254 40.00 1.40 0.90

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

DFR

Member

®

®

®

Certified to

ANSI/NSF 61

Page 17

ECCENTRIC REDUCERS

Size Wt.

3 x 2 16 DFE32 6.00 0.48 0.31

3 x 2 1/2 21 DFE325 6.00 0.48 0.31

4 x 2 25 DFE42 7.00 0.52 0.31

4 x 2 1/2 28 DFE425 7.00 0.52 0.31

4 x 3 30 DFE43 7.00 0.52 0.48

6 x 2 35 DFE62 9.00 0.55 0.31

6 x 2 1/2 38 DFE625 9.00 0.55 0.31

6 x 3 40 DFE63 9.00 0.55 0.48

6 x 4 45 DFE64 9.00 0.55 0.52

6 x5 51 DFE65 9.00 0.55 0.52

8 x 4 65 DFE84 11.00 0.60 0.52

8 x 5 70 DFE85 11.00 0.60 0.52

8 x 6 75 DFE86 11.00 0.60 0.55

10 x 4 85 DFE104 12.00 0.68 0.52

10 x 6 90 DFE106 12.00 0.68 0.55

10 x 8 110 DFE108 12.00 0.68 0.60

12 x 4 120 DFE124 14.00 0.75 0.52

12 x 6 130 DFE126 14.00 0.75 0.55

12 x 8 145 DFE128 14.00 0.75 0.60

12 x 10 170 DFE1210 14.00 0.75 0.68

14 x 6 155 DFE146 16.00 0.66 0.55

14 x 8 175 DFE148 16.00 0.66 0.60

14 x 10 190 DFE1410 16.00 0.66 0.68

14 x 12 220 DFE1412 16.00 0.66 0.75

16 x 6 190 DFE166 18.00 0.70 0.55

16 x 8 210 DFE168 18.00 0.70 0.60

16 x 10 235 DFE1610 18.00 0.70 0.68

16 x 12 265 DFE1612 18.00 0.70 0.75

16 x 14 280 DFE1614 18.00 0.70 0.66

18 x 6 DFE186 19.00 0.75 0.55

18 x 8 240 DFE188 19.00 0.75 0.60

18 x 10 265 DFE1810 19.00 0.75 0.68

18 x 12 295 DFE1812 19.00 0.75 0.75

18 x 14 310 DFE1814 19.00 0.75 0.66

18 x 16 340 DFE1816 19.00 0.75 0.70

20 X 6 DFE206 20.00 0.75 0.55

20 X 8 DFE208 20.00 0.75 0.60

20 x 10 310 DFE2010 20.00 0.80 0.68

20 x 12 345 DFE2012 20.00 0.80 0.75

20 x 14 355 DFE2014 20.00 0.80 0.66

DUCTILE IRON

Item No.

L T T1

TRUE WYES

Size Wt.

3x3 30 DFW33 5.50 3.00 0.48 0.48

4x4 55 DFW44 6.50 3.00 0.52 0.52

6x4 60 DFW64 6.50 3.50 0.55 0.52

6x6 85 DFW66 8.00 3.50 0.55 0.55

8x6 100 DFW86 8.00 4.50 0.60 0.55

8x8 140 DFW88 9.00 4.50 0.60 0.60

10 x 8 155 DFW108 9.00 5.00 0.68 0.60

10 x 10 185 DFW1010 11.00 5.00 0.68 0.68

12 x 8 210 DFW128 9.00 5.50 0.75 0.60

12 x 10 DFW1210 12.00 5.50 0.75 0.68

12 x 12 300 DFW1212 12.00 5.50 0.75 0.75

14 x 14 435 DFW1414 14.00 6.00 0.66 0.66

16 x 16 580 DFW1616 15.00 6.50 0.70 0.70

18 x 18 680 DFW1818 16.50 7.00 0.75 0.75

20 x 20 960 DFW2020 18.00 8.00 0.80 0.80

24 x 24 1,370 DFW2424 22.00 9.00 0.89 0.89

30 x 18 1,185 DFW3018 25.00 10.00 1.03 0.75

30 x 20 1,210 DFW3020 25.00 10.00 1.03 0.80

30 x 24 1,585 DFW3024 25.00 10.00 1.03 0.89

30 x 30 2,630 DFW3030 25.00 10.00 1.03 1.03

36 x 24 2,080 DFW3624 28.00 12.00 1.15 0.89

36 x 30 2,655 DFW3630 28.00 15.00 1.15 1.03

36 x 36 3,470 DFW3636 28.00 15.00 1.15 1.15

42 x 30 3,410 DFW4230 31.00 11.75 1.28 1.03

42 x 36 4,205 DFW4236 31.00 19.00 1.28 1.15

42 x 42 5,235 DFW4242 31.00 21.00 1.28 1.28

48 x 36 4,415 DFW4836 28.00 14.00 1.42 1.15

Manufactured in accordance with AWWA/ANSI C110/A21.10.

48 x 48 6,565 DFW4848 34.00 18.00 1.42 1.42

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Member

DUCTILE IRON

®

®

Item No.

®

Certified to

ANSI/NSF 61

A B T T1

Size Wt.

DUCTILE IRON

Item No.

L T T1

20 x 16 390 DFE2016 20.00 0.80 0.70

20 x 18 410 DFE2018 20.00 0.80 0.75

24 x 8 DFE248 24.00 0.89 0.60

24 x 12 480 DFE2412 24.00 0.89 0.75

24 x 14 490 DFE2414 24.00 0.89 0.66

24 x 16 525 DFE2416 24.00 0.89 0.70

24 x 18 550 DFE2418 24.00 0.89 0.75

24 x 20 590 DFE2420 24.00 0.89 0.80

30 x 10 DFE3010 30.00 1.03 0.68

30 x 12 DFE3012 30.00 1.03 0.75

30 x 16 DFE3616 30.00 1.03 0.70

30 x 18 810 DFE3018 30.00 1.03 0.75

30 x 20 870 DFE3020 30.00 1.03 0.80

30 x 24 970 DFE3024 30.00 1.03 0.89

36 x 10 DFE3610 36.00 1.15 0.68

36 x 16 DFE3616 36.00 1.15 0.70

36 x 20 1,230 DFE3620 36.00 1.15 0.80

36 x 24 1,345 DFE3624 36.00 1.15 0.89

36 x 30 1,555 DFE3630 36.00 1.15 1.03

42 x 24 1,820 DFE4224 42.00 1.28 0.89

42 x 30 2,060 DFE4230 42.00 1.28 1.03

42 x 36 2,345 DFE4236 42.00 1.28 1.15

48 x 30 2,625 DFE4830 48.00 1.42 1.03

48 x 36 2,950 DFE4836 48.00 1.42 1.15

48 x 42 3,320 DFE4842 48.00 1.42 1.28

54 x 24 DFE5424 32.00 0.90 0.61

54 x 30 DFE5430 32.00 0.90 0.61

54 x 36 DFE5436 28.00 0.90 0.66

54 x 42 DFE5442 25.00 0.90 0.76

54 x 48 DFE5448 18.00 0.90 0.80

60 x 36 DFE6036 32.00 1.50 1.15

60 x 48 DFE6048 20.00 0.94 0.80

DFE

DFW

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in

SIGMA Corporation www.sigmaco.com

Dimensions in inches

Weights in pounds

17

Page 18

Flanged Fittings

BLIND FLANGES

Size Weight

2 BDF2 6.00 0.62 0.31

2.5 BDF25 7.00 0.69 0.48

3 9 BDF3 DTF3 7.50 0.75 0.69

4 14 BDF4 DTF4 9.00 0.94 0.88

6 24 BDF6 DTF6 11.00 1.00 0.94

8 38 BDF8 DTF8 13.50 1.12 1.06

10 59 BDF10 DTF10 16.00 1.19 1.12

12 76 BDF12 DTF12 19.00 1.25 0.81

14 110 BDF14 DTF14 21.00 1.38 0.88

16 145 BDF16 DTF16 23.50 1.44 1.00

18 185 BDF18 DTF18 25.00 1.56 1.06

20 217 BDF20 DTF20 27.50 1.69 1.12

24 370 BDF24 DTF24 32.00 1.88 1.25

30 500 BDF30 DTF30 38.75 2.12 1.44

36 790 BDF36 DTF36 46.00 2.38 1.62

42 1,175 BDF42 DTF42 53.00 2.62 1.81

48 1,585 BDF48 DTF48 59.50 2.75 2.00

54 2,600 BDF54 DTF54 66.25 3.00 2.25

60 BDF60 73.00 3.12 2.50

64 BDF64 80.00 3.38 2.56

72 BDF72 86.50 3.50 2.56

96 BDF96 113.25 4.25 3.20

DUCTILE IRON

Solid Tapped

O Q V

BDF

DTF

SLUDGE SHOES

Size Weight Item No.

A

Bolt Circle

3 25 CFS3 5.75 7/8 12.00

4 35 CFS4 6 7/8 12.00

6 45 CFS6 8 7/8 12.00

8 65 CFS8 10 7/8 12.00

10 85 CFS10 12.25 1.00 12.00

12 120 CFS12 14.5 1.00 12.00

Bolt Hole

Diameter

B

THREADED FLANGES

Size Wt. Item No. C E A Item No. Wt. C E A

3 7 DF3 1.935 0.75 4.50 DF3-S 7.00 1.63 0.75 4.50

4 12 DF4 2.065 0.94 5.32 DF4-S 12.00 1.69 0.94 5.32

6 16.5 DF6 2.255 1.00 7.56 DF6-S 16.50 1.94 1.00 7.56

8 25 DF8 2.435 1.12 9.73 DF8-S 25.00 2.25 1.12 9.73

10 35 DF10 2.625 1.19 12.06 DF10-S 35.00 2.38 1.19 12.06

12 55 DF12 2.875 1.25 14.16 DF12-S 55.00 2.50 1.25 14.16

14 63 DF14 3.065 1.38 16.25 DF14-S 63.00 2.63 1.38 21.00

16 81 DF16 3.255 1.44 18.44 DF16-S 81.00 2.63 1.44 23.50

18 89 DF18 3.505 1.56 20.53 DF18-S 89.00 3.50 1.56 25.00

20 109 DF20 3.685 1.69 22.63 DF20-S 109.00 3.69 1.69 27.50

24 154 DF24 4.125 1.88 26.82 DF24-S 154.00 4.12 1.88 32.00

30 215 DF30 4.69 2.12 32.75 DF30-S 237.00 4.69 2.12 38.75

36 324 DF36 5.31 2.38 39.12 DF36-S 350.00 5.31 2.38 46.00

42 534 DF42 5.94 2.63 45.31 DF42-S 493.00 5.94 2.62 53.00

48 650 DF48 6.57 2.75 51.75 DF48-S 610.00 6.57 2.75 59.50

54 762 DF54 7.19 3.00 58.75 DF54-S 726.00 7.19 3.00 66.25

60 1,055 DF60 7.19 3.12 63.76 DF60-S 7.19 3.12 73.00

64 1,200 DF64 7.19 3.38 70.32 DF64-S

DFS

Note: Cast Iron ttings available upon request

Dimensions in inches

Weights in Pounds, Less Accessories / Dimensions in inches

Weights in pounds

SIGMA Corporation www.sigmaco.com

18

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

Manufactured in accordance with AWWA/ANSI C110/A21.10.

eral guidance of AWWA/ANSI C153/A21.53

®

®

Member

Certified to

ANSI/NSF 61

®

Page 19

STRAIGHT FLARE PIECES

Size Wt

3 20 DFA3 0.48 7.50 8.00 6.00

4 30 DFA4 0.52 9.00 8.00 6.00

6 40 DFA6 0.55 11.00 8.00 6.00

8 70 DFA8 0.60 13.50 10.00 8.00

10 95 DFA10 0.68 16.00 10.00 10.00

12 155 DFA12 0.75 19.00 12.00 12.00

14 165 DFA14 0.66 21.00 12.00 14.00

16 240 DFA16 0.70 23.50 14.00 16.00

18 275 DFA18 0.75 25.00 14.00 18.00

20 355 DFA20 0.80 27.50 13.00 20.00

24 480 DFA24 0.89 32.00 16.00 24.00

30 1,100 DFA30 1.03 38.75 15.00 30.00

36 1,460 DFA36 1.15 46.00 14.00 36.00

42 1,750 DFA42 1.28 53.00 12.00 42.00

48 2,375 DFA48 1.42 59.50 18.00 48.00

DUCTILE IRON

Item No.

T C L R

90 DEGREE FLARE BENDS

Size Wt

3 30 DFF390 0.48 7.50 5.50 11.00

4 45 DFF490 0.52 9.00 6.50 12.00

6 75 DFF690 0.55 11.00 8.00 12.00

8 120 DFF890 0.60 13.50 9.00 14.00

10 195 DFF1090 0.68 16.00 11.00 17.00

12 275 DFF1290 0.75 19.00 12.00 18.00

14 310 DFF1490 0.66 21.00 14.00 21.50

16 395 DFF1690 0.70 23.50 15.00 23.00

18 495 DFF1890 0.75 25.00 16.50 25.00

20 630 DFF2090 0.80 27.50 18.00 27.00

24 995 DFF2490 0.89 32.00 22.00 32.50

30 1,970 DFF3090 1.03 38.75 25.00 36.00

36 2,730 DFF3690 1.15 46.00 28.00 38.00

42 3,200 DFF4290 1.28 53.00 31.00 35.00

48 5,235 DFF4890 1.42 59.50 34.00 46.00

54 DFF5490 0.90 66.25 39.00 47.50

60 DFF6090 0.94 73.00 43.00 54.00

DUCTILE IRON

Item No.

T C A B

DFA

DFF

90 DEGREE FLARE LONG RADIUS BENDS

Size Wt

4 50 DFG490 0.52 9.00 9.00 14.50

6 90 DFG690 0.55 11.00 11.50 15.50

8 155 DFG890 0.60 13.50 14.00 19.00

10 250 DFG1090 0.68 16.00 16.50 22.50

12 375 DFG1290 0.75 19.00 19.00 25.00

14 400 DFG1490 0.66 21.00 21.50 29.00

16 530 DFG1690 0.70 23.50 24.00 32.00

18 675 DFG1890 0.75 25.00 26.50 35.00

20 865 DFG2090 0.80 27.50 29.00 38.00

24 1,335 DFG2490 0.89 32.00 34.00 44.50

30 2,190 DFG3090 1.03 38.75 41.50 48.50

36 3,465 DFG3690 1.15 46.00 49.00 56.00

42 5,150 DFG4290 1.28 53.00 56.50 63.50

48 6,725 DFG4890 1.42 59.50 64.00 71.00

Manufactured in accordance with AWWA/ANSI C110/A21.10.

54” ttings are manufactured in accordance with manufacturer’s standards in gen-

eral guidance of AWWA/ANSI C153/A21.53

Weights in Pounds, Less Accessories / Dimensions in inches

Flanges are drilled and faced in accordance with ANSI B16.1 CLASS 125

DUCTILE IRON

Item No.

®

®

Member

T C A B

®

Certified to

ANSI/NSF 61

DFG

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in

SIGMA Corporation www.sigmaco.com

Dimensions in inches

Weights in pounds

19

Page 20

Flanged Fittings

Note: Cast Iron ttings available upon request

Weights in Pounds, Less Accessories / Dimensions in inches

SIGMA Corporation www.sigmaco.com

20

Member

®

®

®

Certified to

ANSI/NSF 61

Page 21

DESIGNATION OF OUTLETS

Member

®

®

®

Certified to

ANSI/NSF 61

SIGMA Corporation www.sigmaco.com

21

Page 22

Flanged Fittings

C110 Flanged Fittings Non-Standard Items:

•

Item # Description

•

DFB105 C110 DI 10" X 5" FLG X FLG 5-5/8 DEGREE BEND

•

DFB2430 C110 DI 24" X 30" FLG X FLG 30 DEGREE BEND

•

DFB2460 C110 DI 24" X 24" FLG X FLG 60 DEGREE BEND

•

DFB4180 C110 DI 4" X 4" FLG X FLG 180 DEGREE RETURN BEND

•

DFB54 C110 DI 5" X 4" FLG X FLG REDUCING BEND

•

DFB6180 C110 DI 6" X 6" FLG X FLG 180 DEGREE RETURN BEND

•

DFB8180 C110 DI 8" X 8" FLG X FLG 180 DEGREE RETURN BEND

•

DFB83 C110 DI 8" X 3" FLG X FLG REDUCING BEND

•

DFC3610 C110 DI 36" X 10" FLG X FLG CROSS

•

DFC8886 C110 DI 8" X 8" X 8" X 6" FLG X FLG X FLG X FLG CR

•

DFL124 C110 DI 12" X 4" FLG X FLG REDUCING LR BEND

•

DFL1445 C110 DI 14" FLG x FLG 45 DEGREE LR BEND

•

DFL1645 C110 DI 16" FLG x FLG 45 DEGREE LR BEND

•

DFL1845 C110 DI 18" FLG x FLG 45 DEGREE LR BEND

•

DFL2045 C110 DI 20" FLG x FLG 45 DEGREE LR BEND

•

DFL2445 C110 DI 24" FLG x FLG 45 DEGREE LR BEND

•

DFL311 C110 DI 3” FLG x FLG 11-1/4 DEGREE LR BEND

•

DFL54 C110 DI 5" X 4" FLG X FLG REDUCING LR BEND

•

DFL65 C110 DI 6" X 5" FLG X FLG REDUCING LR BEND

•

DFL85 C110 DI 8" X 5" FLG X FLG REDUCING LR BEND

•

DFT2525 C110 DI 25" X 25" FLG X FLG TEE

•

DFT3010 C110 DI 30" X 10" FLG X FLG TEE

•

DFT306 C110 DI 30" X 6" FLG X FLG TEE

•

DFT308 C110 DI 30" X 8" FLG X FLG TEE

•

DFT343 C110 DI 3" X 4" X 3" FLG X FLG X FLG TEE

•

DFT3610 C110 DI 36" X 10" FLG X FLG TEE

•

DFT52 C110 DI 5" X 2" FLG X FLG TEE

•

DFT53 C110 DI 5" X 3" FLG X FLG TEE

•

DFT54 C110 DI 5" X 4" FLG X FLG TEE

•

DFT544 C110 DI 5" X 4" X 4" FLG X FLG X FLG TEE

•

DFT643 C110 DI 6" X 4" X 3" FLG X FLG X FLG TEE

•

DFT644 C110 DI 6" X 4" X 4" FLG X FLG X FLG TEE

•

DFT646 C110 DI 6" X 4" X 6" FLG X FLG X FLG TEE

•

DFT65 C110 DI 6" X 5" FLG X FLG TEE

•

DFT85 C110 DI 8" X 5" FLG X FLG TEE

•

DFD128 C110 DI 12" X 8" FLG X FLG 90 DEGREE BASE BEND

•

DFD1816 C110 DI 18" X 16" FLG X FLG 90 DEGREE BASE BEND

•

DFD2012 C110 DI 20" X 12" FLG X FLG 90 DEGREE BASE BEND

•

DFD2016 C110 DI 20" X 16" FLG X FLG 90 DEGREE BASE BEND

•

DFD2412 C110 DI 24" X 12" FLG X FLG 90 DEGREE BASE BEND

•

DFD2416 C110 DI 24" X 16" FLG X FLG 90 DEGREE BASE BEND

•

DFD2418 C110 DI 24" X 18" FLG X FLG 90 DEGREE BASE BEND

•

DFD3018 C110 DI 30" X 18" FLG X FLG 90 DEGREE BASE BEND

•

DFD3020 C110 DI 30" X 20" FLG X FLG 90 DEGREE BASE BEND

Note: Contact SIGMA for more information on non-standard ttings

®

SIGMA Corporation www.sigmaco.com

22

Member

®

®

Certified to

ANSI/NSF 61

Loading...

Loading...