SIERRA VIDEO

Viper™ Component Series Routing Switcher

User’s Manual

VIPER™ SERIES ROUTING SWITCHER

User’s Manual

Sierra Video

P.O. Box 2462 Grass Valley, CA 95945

Tel: (530) 478-1000

Fax: (530) 478-1105

Email: info@sierravideo.com

Version 4.0

Publication Date: February 2012

The information contained in this manual is subject to change by Sierra Video

Table of

Contents

Introduction 1

Before You Begin 1

Regulatory Warnings & Safety Information 2

FCC Notice 3

Warning 3

Power Supply Cords 4

North American Power Supply Cords 4

International Power Supply Cords 4

EMC Regulatory Notices 4

Delivery Damage Inspection 4

Viper™ Wideband Routing Switcher 5

Introduction 5

Viper RGBHV Frame 6

Factors Affecting Quality of Results 8

Installation 9

Introduction 9

Rack Mounting 9

Multi-Frame Connections 10

Connecting To Video Devices 11

Sync 11

Connecting Peripherals 13

Master Frame Rear Panel 13

Slave Frame Rear Panel 14

Reference Sync 15

AC Power Connections 16

Control Processor DIP Switches 17

DIP Switch Settings Cont. 18

Ethernet Setup 19

GPI 28

Suggested GPI Circuitry 29

Software Upgrades 30

Mono Analog Audio 36

Balanced/Unbalanced Analog Audio

Connections 36

Stereo Analog Audio 36

Analog Audio Signal Path Overview 37

Input Buffers 37

Crosspoint/ Output Driver Modules 39

Module Layout 40

6464 Frame Analog Mono 40

6464 Frame Analog Stereo 40

128128 Frame Analog Mono 41

128128 Frame Analog Stereo 41

Front Door Fans 41

Operation 43

Introduction 43

Control System Overview 43

Serial Control Ports 44

Host Mode 44

Terminal Mode 44

Control Panels 45

Video Module Overview 47

Introduction 47

Module Layout 48

Input Module 49

Crosspoint Module 51

Output Module 52

Processor Module 53

Sync Modules 54

Power Supply Module 55

Specifications 57

Audio 31

Introduction 31

Control System Overview 31

Model 128128A 32

Model 6464A 33

Stereo Configurations 35

Connecting to Audio Devices 36

Contents - 1

Communication Protocol 61

Introduction 61

Generic Protocol 62

Commonly Used Switching Commands 82

Warranty 83

SIERRA VIDEO

Introduction

Before You Begin

There are several terms and acronyms that you should become familiar with before reading this

manual. They are shown below.

Term/Acronym Definition

Crosspoint The electronic switch that assigns one of the inputs on the

matrix crosspoint modules to an output.

Destination A device that receives signals from the output of the

switcher.

Output The signal that connects to the destination device.

Source The signal that is connected to the input of the routing

switcher.

Input Connected to the source that provides the signal to the

switcher.

Matrix An array of the switch modules that connects an input to an

output.

Protocol The command structure used to affect a switch or multiple

switches on the routing switcher or to control other

functions.

Routing Switcher Consists of one or more crosspoint modules that switch

together, or sometimes independently, to connect the

desired signals through the switcher.

Serial Port The 9-pin RS232 connector that allows you to control the

switcher using a standard personal computer or other

external device. Sends control protocol commands in

ASCII.

Chapter

1

1

SIERRA VIDEO

Regulator y Warnings & Safety Information

The information in the following section provides important warnings and safety guidelines for

both the operator and service personnel. Specific warnings and cautions may be found

throughout this manual. Please read and follow the important safety precautions noting especially

those instructions relating to risk of fire, electrical shock and injury to persons.

Any instructions in this manual that require opening the equipment cover or enclosure are

intended for use by qualified service personnel only. To reduce the risk of electrical shock, do not

perform any servicing other than what is contained in the operating instructions unless you are

qualified.

Warnings

Heed all warnings on the unit and in the operating instructions.

Disconnect AC power before installing or removing device or servicing unit.

Do not use this product in or near water.

This product is grounded through the grounding conductor of the power cord. To

avoid electrical shock, plug the power cord into a properly wired receptacle before

connecting inputs or outputs.

Route power cords and other cables so that they are not likely to be damaged, or

Dangerous voltages exist at several points in this product. To avoid personal injury,

To avoid fire hazard, use only the specified type, correct voltage, and current rating

Have qualified personnel perform safety checks after any comp leted service.

To reduce risk of electrical shock, be certain to plug each power supply cord into a

If equipped with redundant power, this unit has two power cords. To reduce the risk

Operate only with covers and enclosure panels in place – Do Not operate this

This is an FCC class A product. In a domestic environment, this product may cause

Cautions

Use the proper AC voltage to supply power to the switcher. When installing

To prevent damage to equipment when replacing fuses, locate and correct the trouble

create a hazard.

do not touch unsafe connections and components when th e power is on.

of fuse. Always refer fuse replacement to qualified service personnel.

separate branch circuit employing a separate service ground.

of electrical shock, disconnect both power cords before servicing.

product when covers or enclosure panels are removed.

radio interference, in which case the user may be required to take necessary

measures.

equipment, do not attach the power cord to building surfaces.

that caused the fuse to blow before applying power.

Use only the recommended interconnect cables to connect the switcher to other

frames.

Follow static precautions at all times when handling the equipment.

Power this product only as described in the installation section of this manual.

2

Cautions (continued)

Leave the sides, top, and bottom of the frame clear for air convection cooling and to

allow room for cabling. Slot and openings in the frame are provided for ventilation

and should not be blocked.

Only an authorized Sierra Video technician should service the switchers. Any user

who makes changes or modifications to the unit without the expressed approval of

Sierra Video will void the warranty.

If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than the room ambient

temperature. Therefore, consideration should be given to installing the equipment in

an environment compatible with the manufacturer’s maximum rated ambient

temperature (TMRA).

Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised.

Use a shielded data cable connection between the parallel data ports and peripherals

of this equipment.

Other connections between peripherals of this equipment may be made with low

voltage non-shielded computer data cables.

VIPER COMPONENT SERIES

Network connections may consist of non-shielded CAT 5 cable.

Do not cover chassis ventilation slots or block enclosure openings.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at the expense of the user.

The user may find the following publication prepared by the Federal Communications Commission

helpful:

“How to Identify and Resolve Radio-TV Interference Problems” (Stock number 004-00000345-4).

Available exclusively from the Superintendent of Documents, Government

Printing Office, Washington, DC 20402 (telephone 202 512-1800).

Warning

Changes or modifications not expressly approved by the party responsible for compliance to Part 15 of

the FCC Rules could void the user’s authority to operate the equipment.

3

SIERRA VIDEO

Power Supply Cords

Use only power cord(s) supplied with the unit.

If power cord(s) were not supplied with the unit, select as follows:

For units installed in the USA and Canada: select a flexible, three-conductor power cord

that is UL listed and CSA certified, with individual conductor wire size of #18 AWG, and a

maximum length of 4.5 meters. The power cord terminations should be NEMA Type 515P (three-prong earthing) at one end and IEC appliance inlet coupler at the other end.

Any of the following types of power cords are acceptable; SV, SVE, SVO, SVT, SVTO,

SVTOO, S, SE, SO, SOO, ST, STO, STOO, SJ, SJE, SJO, SJOO, SJT, SJTOO, SP-3,

G, W.

For units installed in all other countries; select only a flexible, three-conductor power

cord, approved by the cognizant safety organization of your country. The power cord

must be Type HAR (Harmonized), with individual conductor wire size of 0.75 mm². The

power cord terminations should be a suitably rated earthing-type plug at one end and IEC

appliance inlet coupler at the other end. Both of the power cord terminations must carry

the certification label (mark) of the cognizant safety organization of your country.

A non-shielded power cord may be used to connect AC power to every component and

peripheral of the system.

Connect an external 18 AWG wire from earth ground to the chassis of the system as

designated by the earth ground symbol.

North American Power Supply Cords

This equipment is supplied with North American power cords with molded grounded plug (NEMA15P) at one end and molded grounding connector (IEC 320-C13) at the other end. Conductors

are CEE color coded, light blue(neutral), brown(line), and green/yellow(ground). Operation of the

equipment at voltages exceeding 130VAC will require power supply cords that comply with NEMA

configurations.

International Power Supply Cords

If shipped outside North America, this equipment is supplied with molded ground connector (IEC

320-C13) at one end and stripped connectors (50/5mm) at the other end. Connections are CEE

color coded, light blue (neutral), brown(line), and green/yellow(ground). Other IEC 320-C13 type

power cords can be used if they comply with safety regulations of the country in which they are

installed.

EMC Regulatory Notices

Federal Communications Commission (FCC) Part 15 Information: This device complies with Part

15 of the FCC standard rules. Operation is subject to the following conditions:

This device may not cause harmful interference

This device must accept any interference received including interference that may cause

undesirable operations.

Delivery Damage Inspection

Carefully inspect the frame and exterior components to be sure that there has been no shipping

damage. Make sure all modules are seated correctly and have not detached during shipment.

4

Viper™ Wideband Routing Switcher

Introduction

500MHz RGBHV Routing Switcher up to 64x64

The new wideband video routing switcher from Sierra Video is top-of-the-line modular routing for

those applications requiring worry-free performance and mission critical reliability. The advanced

features and performance set it apart from the competition. These include:

Modular configurations expandable by 8 input and/or 8 output increments

Compact frame size – 10RU smaller than most competitive units (in RGBHV)

Hot-swappable video I/O boards, CPU boards, and power supplies

Optional redundant power supplies and control processors

Full range of Sierra control hardware and software components, including remote control

panels, IP and serial control. Supported by all major third party control systems.

Front-door access to hot-swappable video I/O boards allows for field service or matrix

reconfiguration. The power supplies are also hot-swappable, guarantee maximum in-service time

and minimal interruptions. IP (Ethernet) control via TCP/IP socket connection is standard in

every model.

VIPER COMPONENT SERIES

For applications requiring companion audio, the wideband routing switcher is compatible with our

time-tested Yosemite line of audio routing switchers. Sierra Video advanced SCP line of

programmable control panels manage the routing system along with our new TyLinx™ router

control software featuring the most intuitive router interface in the industry.

This manual covers only the Viper routing switcher. These robust routers offer RGB/HV compact

frames. Moreover, these durable frames can be populated from one to five video and pulse sync

channels. They have been engineered for high bandwidth with very low crosstalk. Many other

features include control via serial ports and optional processor and/or power redundancy. The

Viper™series can be configured to support composite, s-video, YC, YUV, RGBHV, analog HD.

5

SIERRA VIDEO

Viper RGBHV Frame

Frame Front Panels

6

Frame Rear Panels

VIPER COMPONENT SERIES

RED

GREEN

BLUE

H/HV SYNC

V SYNC

Note

The Viper models shown here and in the

subsequent sections are fully populated video

matrices. In some cases, the system may be

configured with fewer video channels and/or

frames. i.e. Viper models also offer redundant

power supplies. Consult the rear panel serial

number and model number to verify your order

and product.

The system you receive is customized for the size

& type requested at time of purchase from Sierra

Video.

7

SIERRA VIDEO

Factors Affecting Quality of Results

There are many factors affecting the quality of results when signals are transmitted from a source to a

destination.

Signal cables — Use only the best quality cables to avoid interference, degraded

signal quality and elevated noise levels.

Sockets and connectors of the sources and destinations — Use only the highest

quality, since "zero ohm" connection resistance is the target. Connectors should

also match the required impedance (75 ohm in video) to minimize return loss.

Amplifying circuitry — Must have quality performance when the desired end

result is high linearity, low distortion, and low noise.

Distance between sources and destinations — Plays a major role in the final

result. For long distances (over 15 meters) between sources and destinations,

special measures should be taken to avoid high frequency cable losses. These

measures include using higher quality cables and/or adding line cable equalizing

amplifiers.

Interference from neighboring electrical appliances — These can have an

adverse affect on signal quality. Balanced audio lines are less prone to

interference, but unbalanced audio should be installed away from any main

power lines, electric motors, transmitters, etc. even when the cables are shielded.

CAUTION!

Only an authorized Sierra Video technician can service the switchers. Any user who makes

changes or modifications to the unit without the expressed approval of the manufacturer will void

the warranty.

Use the proper AC voltage to supply power to the switcher.

Use only the recommended interconnect cables to connect the switcher to other frames

8

SIERRA VIDEO

Installation

Introduction

Installation procedures are similar for all frames covered within this manual. Exceptions, if any,

have been noted in each of the following paragraphs.

Rack Mounting

Chapter

2

Carefully inspect the frame to ensure that there has been no shipping damage. Make sure all

shipping material is removed from the router frame.

Each of the routing switchers described in this manual can be rack mounted in a standard 19"

(1RU) EIA rack assembly and includes rack "ears" at the ends of the front of the frames. None of

the switcher models require spacing above or below the unit for ventilation. To rack mount any of

the routing switchers, simply place the unit's rack ears against the rack rails of the rack, and

insert proper rack screws through each of the holes in the rack ears. Always rack mount the

routing switcher prior to plugging the unit into a power receptacle or attaching any cables.

Important; Rear mounting brackets must be installed prior to installation of the router into a

rack. The rear mounting brackets are contained in the accessory kit supplied with your router.

CAUTION!

The operating temperature range of the Viper series router is 0 to 40 °C. Do not exceed the maximum (40

°C) or minimum (0 °C) operating temperature.

Rear mounting brackets must be installed prior to installation of the router into a rack. The rear mounting

brackets are contained in the accessory kit supplied with your router.

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than the room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with the manufacturer’s maximum rated

ambient temperature (TMRA).

Installation of the equipment in a rack should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

9

SIERRA VIDEO

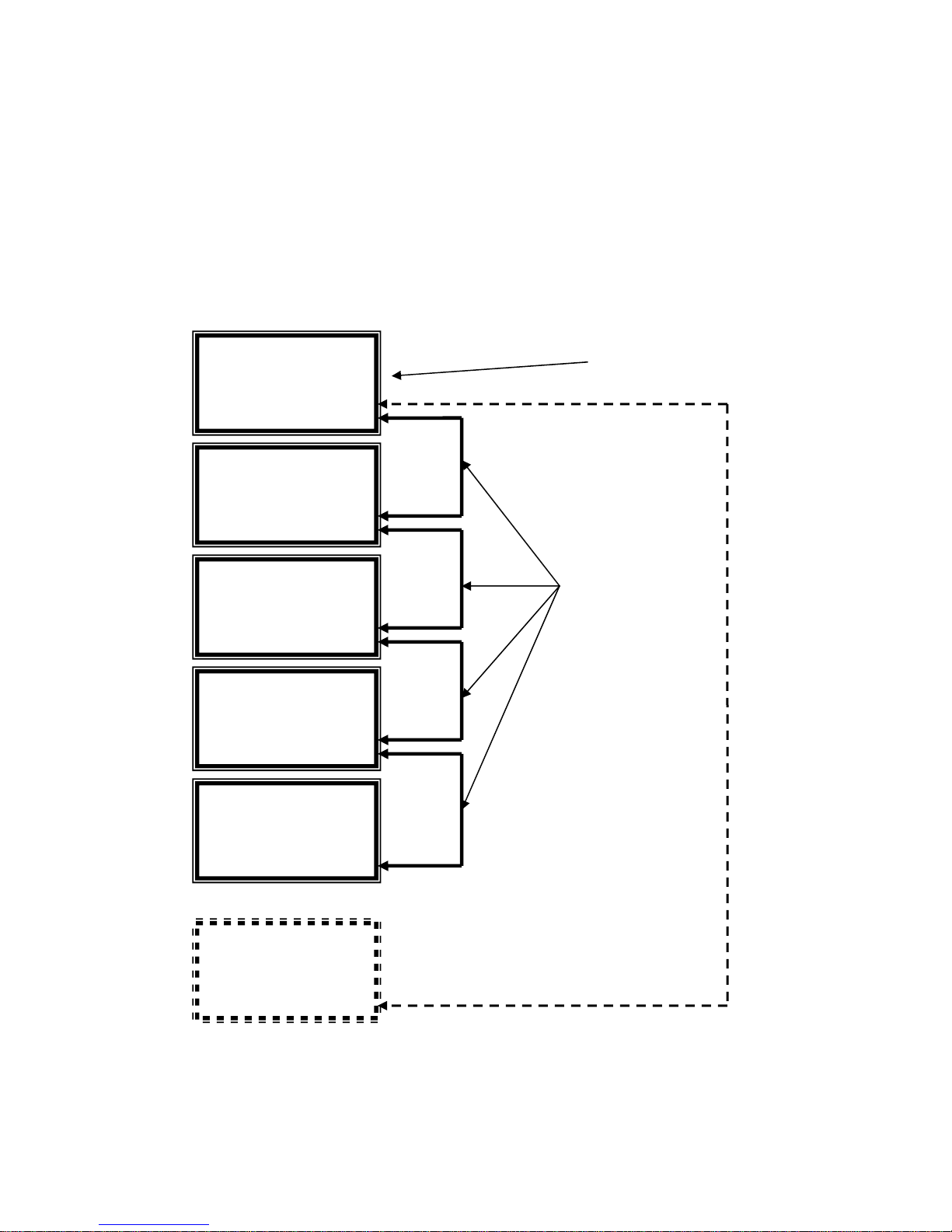

Multi-Frame Connections

The Viper RGBHV system consists of 5 individual frames connected together so that all 5 frames

operate as a single routing system. The “RED” frame contains the “Master” processor whereas

the other 4 frames each contain a “Slave” processor. The action of the slave frames are

controlled exclusively by the frame with the master processor. The frames are connected via a

“looping” 9-pin cable connected to the “multi-drop 1” port on each frame. The 25 pin J1 connector

is used when the audio option is ordered.

Control panels and serial control connect to the frame containing the master processor.

Master Frame

“RED”

Level 1

Multi Drop 1

Slave Frame

“GREEN”

Level 2

Multi Drop 1

Multi Drop 2

Slave Frame

“BLUE”

Level 3

Multi Drop 1

Multi Drop 2

Slave Frame

“H/HV SYNC”

Level 4

Multi Drop 1

Multi Drop 2

Control Panels, RS-232/422 Serial

Control and Ethernet control Connect to

This Frame

J1

9 Pin Multi-Frame

Interconnect Cables

Slave Frame

“V SYNC”

Level 5

Multi Drop 1

Optional Audio

Frame(s)

10

J1

See the “Connecting Peripherals”

section of this manual for details.

Connecting To Video Devices

Video sources and output devices (such as monitors, or recorders) may be connected to the

routing switchers through the BNC type connectors located on the back of the unit. Keep in mind

that the output signal format will be that of the input signal format.

All signal connections that use more than one cable interconnecting between devices should be

of equal timing length (example: cables between a camera and the switcher should have the

same time delay).

The rear panel of the frame is laid out in the most logical fashion possible. The individual frames

are RED, GREEN, BLUE, H/HV SYNC, and V SYNC. The H/HV and V conventions, used for the

H and V sync channels, are arbitrary and these two channels are interchangeable. Each channel

can have only “H” or “V” signals – not both. All inputs are factory set for 75 ohm termination.

Unused outputs do not need to be terminated.

Sync

Horizontal (“H”) and Vertical (“V”) sync input termination is factory set to 75 ohms. Sync input

terminations can be changed to 510 ohms.

VIPER COMPONENT SERIES

To change sync input terminations;

1. Connect the COMM port from a computer to “CTRL 1” on the back of the “Master” frame.

2. Open HyperTerminal, Hyper Access or other similar terminal emulation program.

3. Set the program’s parameters to 115.2K baud, 8 Data bits, No parity, 1 stop bit, ANSI emulation.

4. Establish communication to the router’s processor by typing **!! on the keyboard. The terminal

program screen will answer **OK!! confirming communication.

Note:

To change sync input termination the “CTRL 1” port must be in the “Host” protocol mode. “CTRL 1” is

factory default to the “Host” mode. However, the CTRL 1 port can be changed to “terminal” via software or

DIP switch. To change the CTRL 1 port to “Host” mode type **HOST1!! (see the operation chapter section

of this manual).

11

SIERRA VIDEO

To set sync input terminations, type in the command(s) below for the type of change you want to

make;

Note:

Global change (all sync boards, all sync levels, all sync inputs) to input termination of 75 ohm;

**G XFER_ASCII,253,0,0,0F10FF52~!!

**G XFER_ASCII,253,0,0,0F10FF730401FF~!!

Global change to sync input termination of 510 ohm;

**G XFER_ASCII,253,0,0,0F10FF52~!!

**G XFER_ASCII,253,0,0,0F10FF73040100~!!

Per Board- Per Level All inputs, termination of 75 ohm;

**G XFER_ASCII,253,0,0,0F10FF52~!!

**G XFER_ASCII,253,0,0,(Level)10(Board Address)730401FF~!!

Per Board- Per Level, sync input termination to 510 ohm;

**G XFER_ASCII,253,0,0,0F10FF52~!!

**G XFER_ASCII,253,0,0,(Level)10(Board Address)73040100~!!

Board inputs are in groups of eight.

Level Numbers;

Level 1= 0

Level 2= 1

Level 3= 2

Level 4= 3

Level 5= 4

12

V

Connecting Peripherals

Control panels, sync inputs, and power are all connected to the rear of the “Master” frame. The

peripherals area may vary depending on the model size and type.

VIPER COMPONENT SERIES

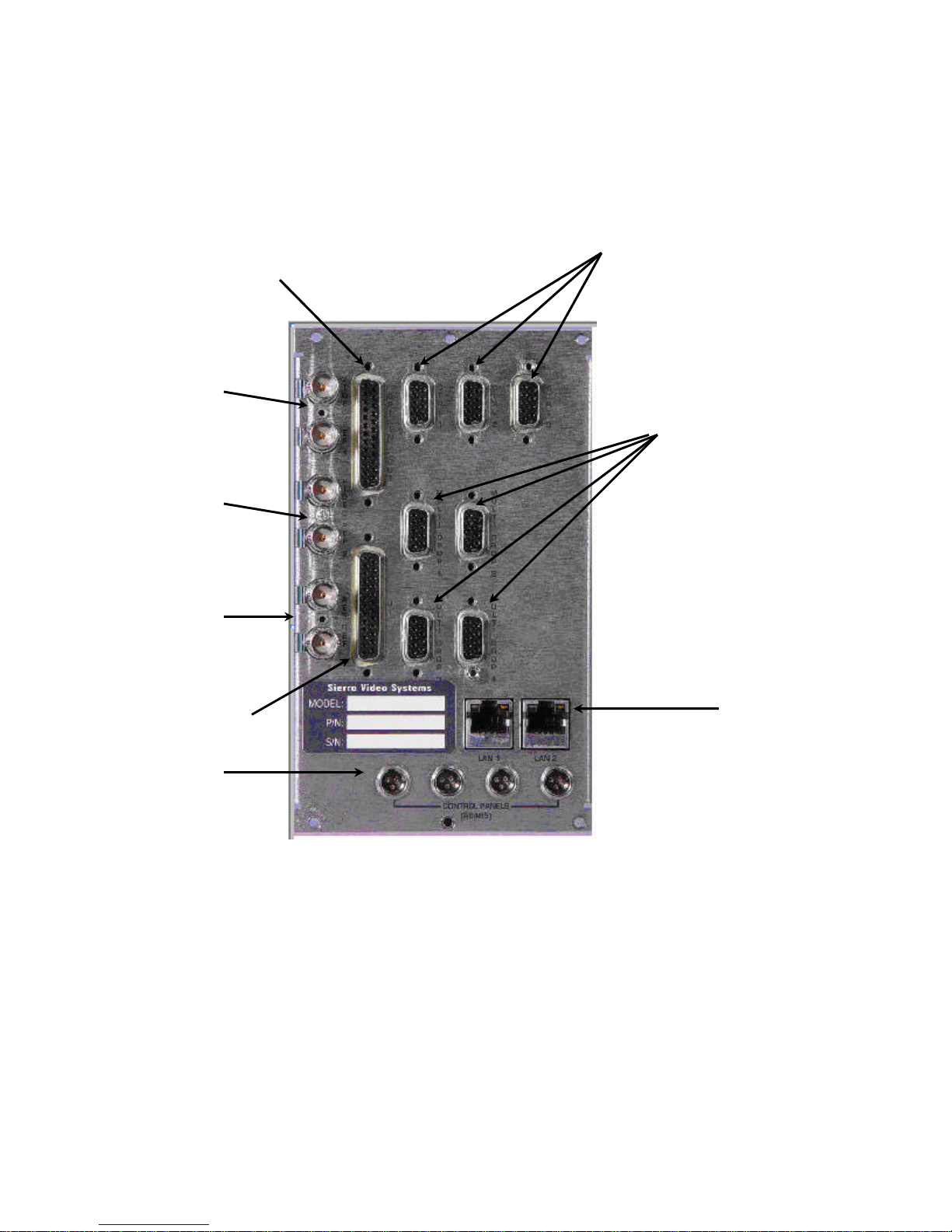

Master Frame Rear Panel

ideo Sync

Referencing

Inputs

(Looping)

Not Used

Not Used

GPI/0

RS-232 and RS-422

control connectors

Multi-Frame Inter

Connect

J1 Connector

Control Panel

Connectors

Ethernet

Connectors

13

SIERRA VIDEO

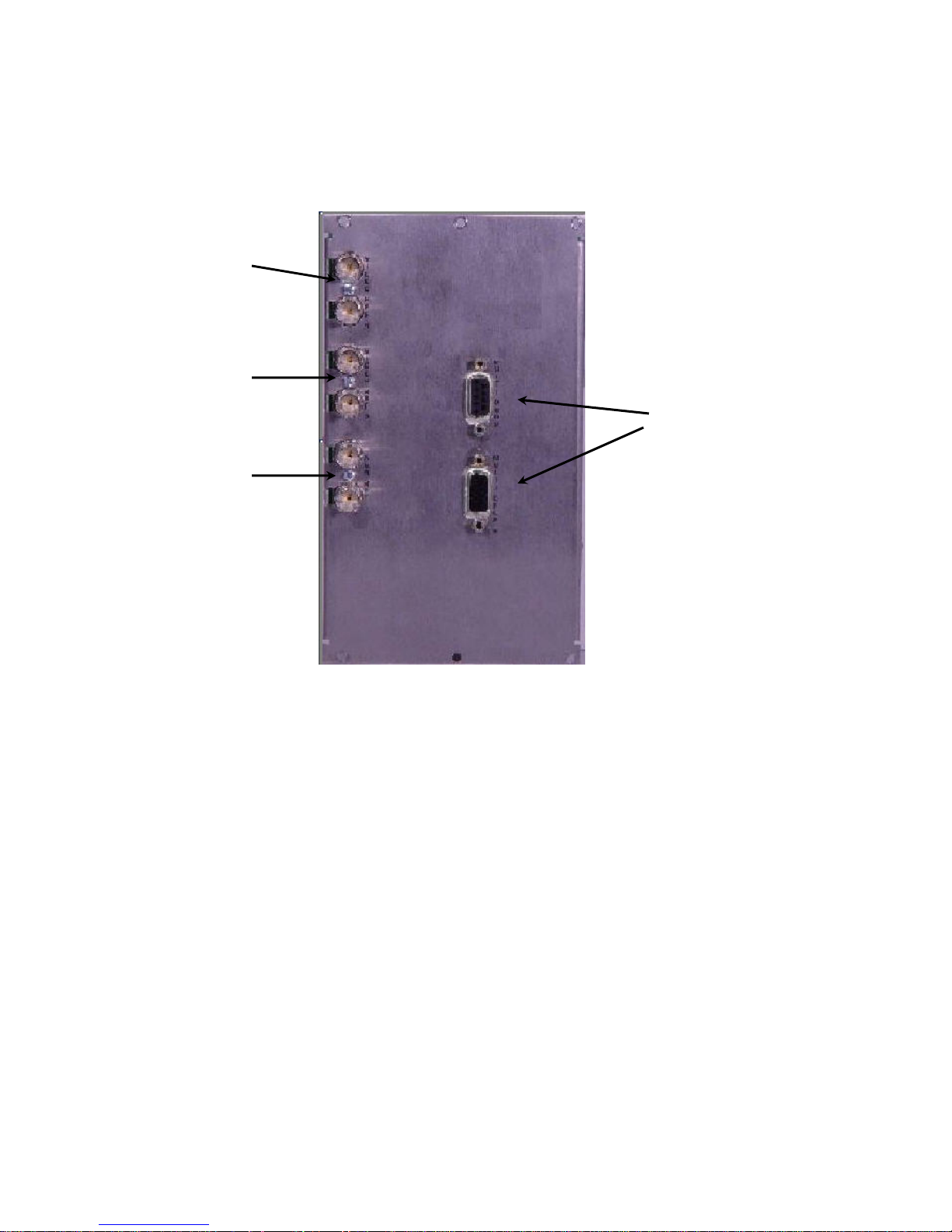

V

Slave Frame Rear Panel

Reference sync need not be connected unless the “Slave” frame contains a different signal type

than the “Master” frame, i.e. the master frame has video (which requires video sync) and the

slave frame has AES audio (which requires AES sync).

ideo Sync

Referencing

Inputs

Looping

Not Used

Not Used

Multi-Frame

Inter- Connect

14

VIPER COMPONENT SERIES

Reference Sync

There are three “looped” sets of BNC connectors labeled "VIDEO REF 1", “VIDEO REF 2””.

These are "looping" inputs for sync referencing. Connect either composite sync or video with sync

to either set of BNCs. If desired, use the second BNC in the set to loop the signal to another

device. If the loop is not used, terminate the second BNC with 75 ohms.

The set of sync connectors labeled “VIDEO REF 2” is for future use and are not

connected.

If no sync is available, the routing switcher will switch at a random point rather than during the

vertical interval of the reference signal.

Note:

Reference sync need only be connected to the “Master” frame. The “Master” frame is the frame where the

processor is installed, typically the “RED” frame.

15

SIERRA VIDEO

AC Power Connections

Viper series routing switchers offer redundant power supplies but must be specified prior to order.

The power supplies are universal AC inputs. Voltage selection is not necessary because the

power supply senses the correct AC input automatically.

The rear of the frame has two AC connectors labeled Primary and Redundant regardless of if

redundant power supplies are installed. For non-redundant power systems only the AC connector

“primary” is connected.

There are 4 “health monitoring” LEDs on each power supply. The LEDs indicate fan and power

status.

If redundant power supplies are ordered, the frame will contain two complete power supplies with

health monitoring LEDs. If a power supply should fail the other power supply will automatically

take over.

If a non-redundant power supply system is ordered, the redundant power supply slot will contain

a power supply frame with only the fan and health monitoring LEDs. This is referred to as a “fan

sled”. The “Module power” LED will not be lit on the fan sled. The redundant power AC

connection need not be connected for units with non-redundant power supplies. The fan sled will

operate from the primary power supply.

The “Fault” LED (red) turns on if there is a fan failure.

16

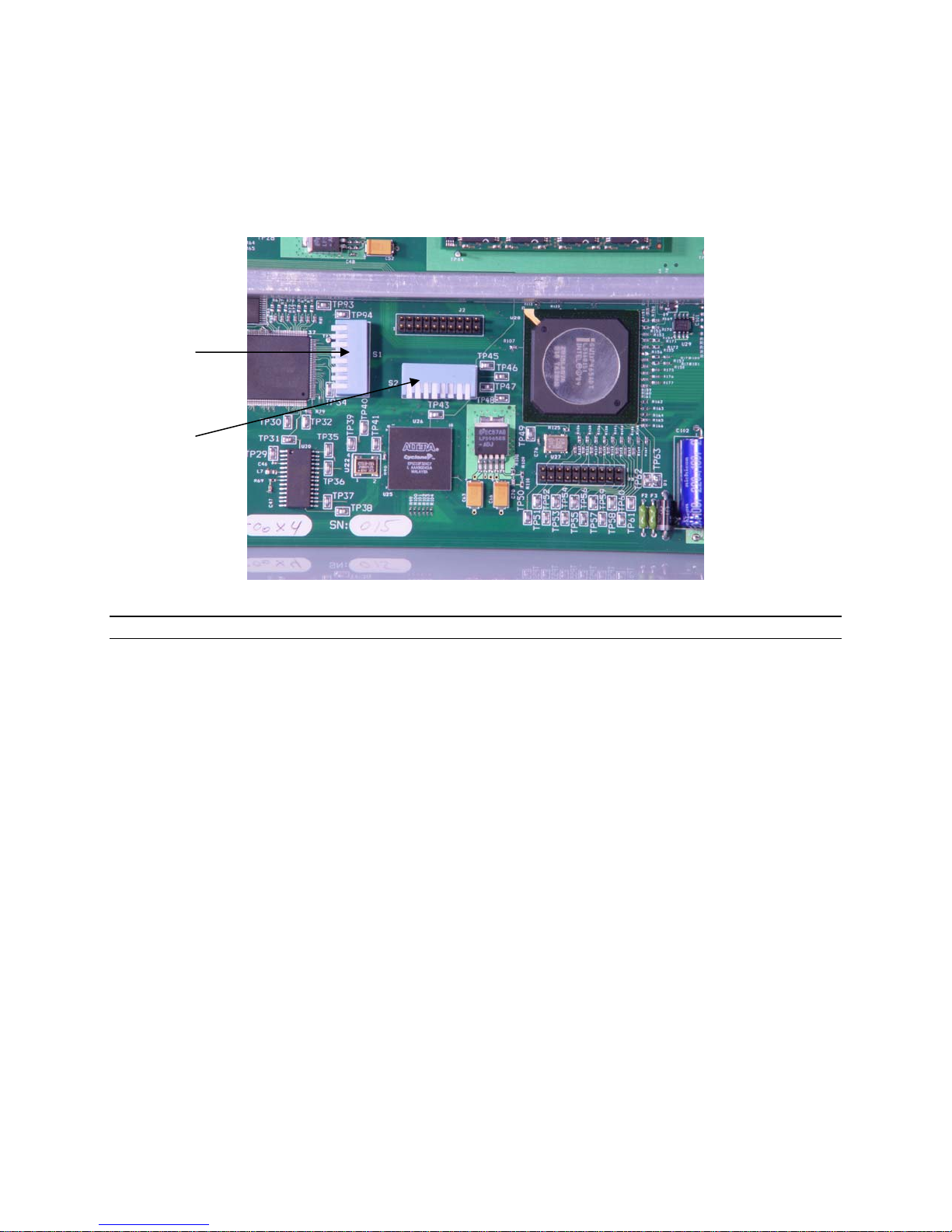

Control Processor DIP Switches

Your switcher has been configured at the factory for the settings you are most likely to need.

However, if you want to configure the switcher differently, you can do so by setting the switches

located on the processor board. DIP Switches and their action are given in the table that follows.

DIP Switches are shown in their factory default settings.

S1

S2

VIPER COMPONENT SERIES

Note:

Changing any DIP Switch causes an automatic reset after a few seconds.

Switch position down = ON.

17

SIERRA VIDEO

DIP Switch Settings Cont.

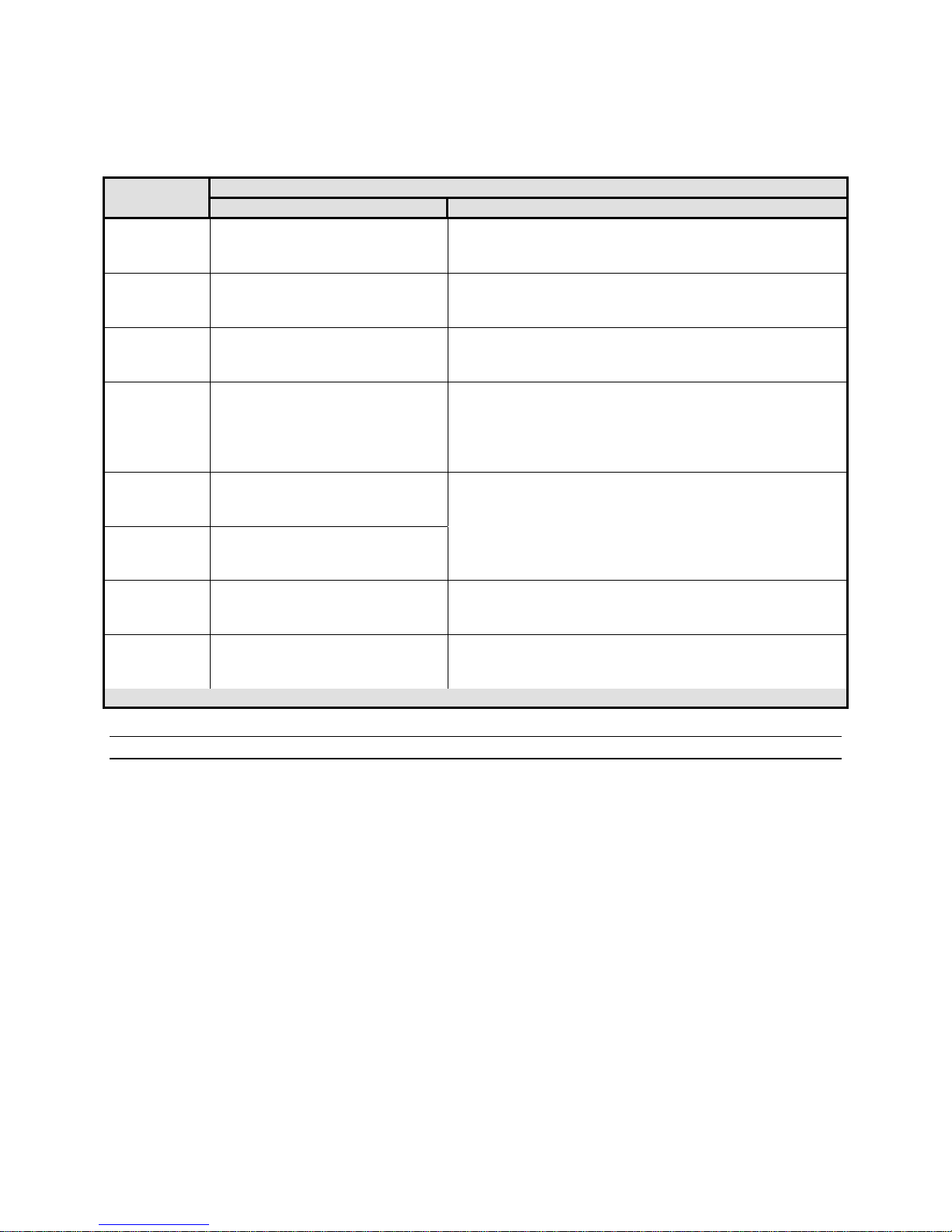

DIP Switch

1

2

3

4

5

6

7

8

S1 S2

Debug Messages

ON= Debug Messages

*OFF= Normal Operation

Bootloader Menu

ON= Menu Enable

*OFF= Menu Disable

Router Application Startup

ON= Application Disable

*OFF= Application Enable

Debug Server

ON= Server Enable

*OFF= Server Disable

Debug Break

ON= Break

*OFF= No Break

Unused- Set to OFF

Redundant Processor Enable

ON= Redundant Processors

OFF= Only One Processor

Preferred CPU Select

ON= Master CPU

OFF= Standby CPU

* = Factory Default Settings

Action

Force Crosspoint Initialization

ON= Set X-points to 1-1, 2-2, 3-3, etc.

*OFF= Last X-point Remembered

Initialize Non-Volatile Memory

ON= Clear All Settings

*OFF= Normal Operation

Port 1 Protocol

ON= Terminal Protocol- XOn/ XOff Enabled

*OFF= Port Can be Changed by Software

Port 1 Type

If S2-3 is ON;

ON= RS-422

*OFF= RS-232

If S2-3 is OFF Settings Can be Changed by Software

Port 1 Baud Rate

If S2-3 is ON;

1.2K Baud 5 = OFF, 6 = OFF

9.6K Baud 5 = OFF, 6 = ON

38.4K Baud 5 = ON, 6 = OFF

*115.2K Baud 5 = ON, 6 = ON

Unused

Unused

Note:

To manually set Port 1 to RS-422, turn S2-3 ON and S2-4 ON.

(Baud Rate is now set by S2-5 and S2-6)

18

VIPER COMPONENT SERIES

Ethernet Setup

There are two Ethernet connectors on the “Master” frame labeled “LAN 1” and “LAN 2”. For

single processor systems only “LAN 1” is active.

Ethernet connections are made to the connector labeled LAN 1.

Default IP settings;

IP Address- 192.168.1.200

***If there are redundant processors, the redundant processor IP

address will be 192.168.1.201 (LAN 2 connection)

Subnet mask- 255.255.255.0

Gateway IP Address- 0.0.0.0

Telnet Port- 10001

To set IP parameters using the Ethernet port;

1. Connect the Ethernet cable to “LAN 1” on the back of the “Master” frame.

2. Open the command prompt on a PC. In Windows XP Pro, you can access the Command Prompt

by clicking on the “Start” menu “Programs”, “Accessories”, “Command Prompt”.

3. Verify communications to the router by “Pinging” the router. You can do this by typing in the ping

command in the Command Prompt window as follows;

“ping 192.168.1.200” followed by a carriage return.

4. Once communications have been established you can Telnet into the router. You can do this by

typing in the telnet command in the Command Prompt window as follows;

“telnet 192.168.1.200” followed by a carriage return.

5. To login to the router, type “svsadmin” at the login prompt followed by a carriage return. Then

enter the password “TED” the password is case sensitive and must be typed in uppercase

characters.

6. To view the current network parameters you need to type in the following command;

“SvsBootApp Params” followed by a carriage return.

7. To change the IP address the command is as follows;

“SvsBootApp SetParam IP xxx.xxx.x.xxx

Where the “x” is the IP address you want to assign to the router.

8. To set the Subnet Mask the command is as follows;

“SvsBootApp SetParam SUBNET xxx.xxx.xxx.x

Where the “x” is the Subnet address you wish to assign to the router

9. Once the IP address and Subnet mask have been set you can close the telnet connection to the

router by typing “exit” at the \> prompt then restart the router by power cycling the “Master” frame.

10. Once the system has restarted you can verify that your settings are correct by pinging the IP

address you just assigned the router i.e.

“ping (your new IP address) followed by a carriage return.

Note:

192.168.1.200 is the factory default IP address. 192.168.1.201 is the address of the redundant processor

(if installed)

19

SIERRA VIDEO

To set IP parameters using the serial port;

1. Connect the COMM port from a computer to “CTRL 2” on the back of the “Master” frame.

2. Open HyperTerminal, Hyper Access or other similar terminal emulation program.

3. Set the program’s parameters to 115.2K baud, 8 Data bits, No parity, 1 stop bit, ANSI emulation.

4. Establish communication to the router’s processor by pressing the “Esc” button on the keyboard.

The terminal program screen will re-write confirming communication.

5. Turn the power off to the “Master” frame, leaving the terminal program running.

6. Remove the CPU board and set DIP switches S1-1 and S1-2, on the processor module, to on.

7. Replace the CPU board.

8. Turn power to the “Master” frame on.

9. The processor will begin to boot.

10. Within the first 4 seconds of boot-up when the processor is turned on, press the keyboard

spacebar. This will interrupt the booting of the unit and enter the configuration menu.

11. Press “0” and enter the IP information, then press ENTER.

12. Turn the “Master” frame off, remove the CPU and set the DIP switches S-1 and S1-2 back to the

off position.

13. Replace the board and power the frame up.

Note:

The Ethernet port accepts HOST protocol commands to switch the router. See the

section of this manual on Protocol for information on Host protocol commands.

*If your server is capable of IP reservations by the MAC address you can enable the DHCP option. It is

advisable to contact the Factory for further information regarding this feature.

Commands:

“SvsBootApp SetParam DHCP 0 “ DHCP disabled

“SvsBootApp SetParam DHCP 1” DHCP enabled

20

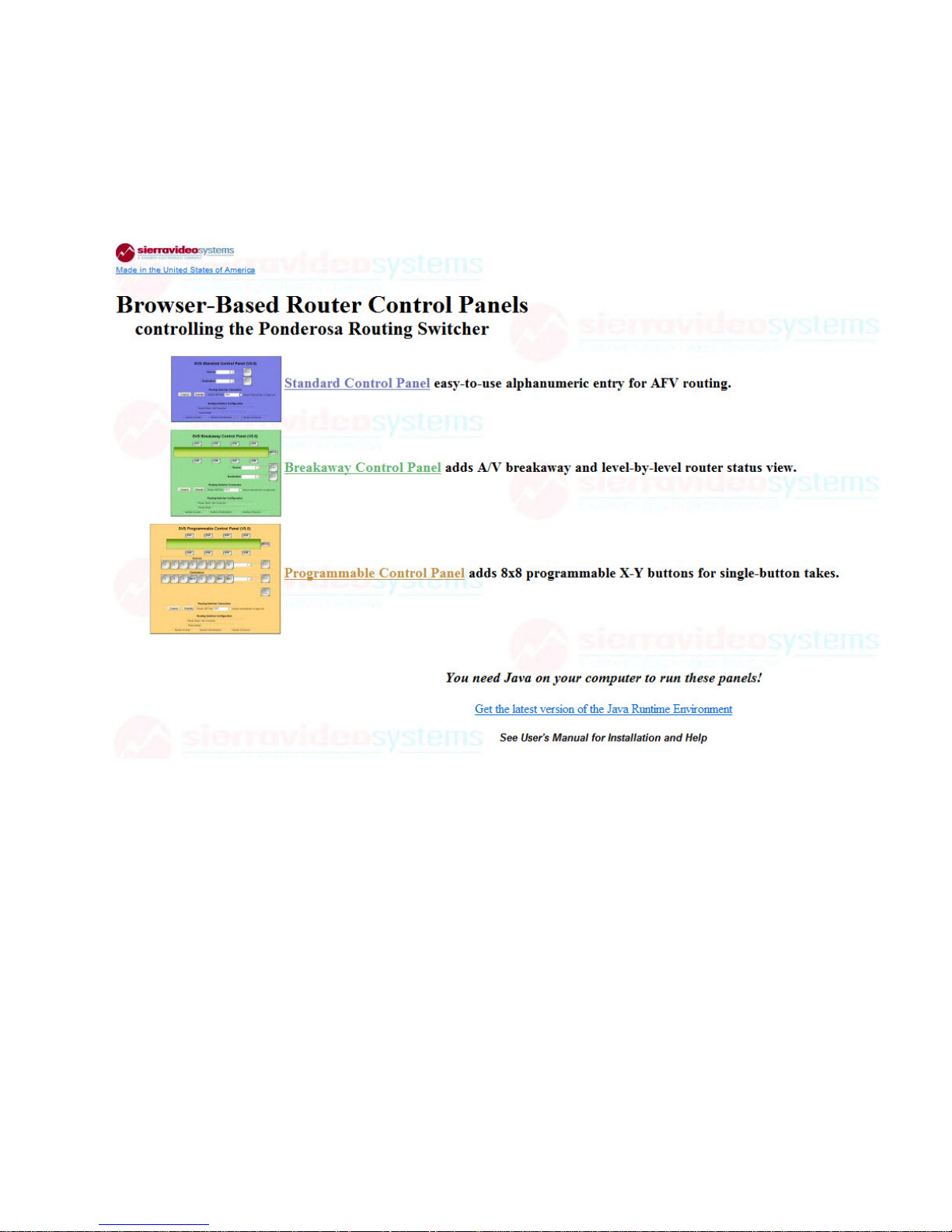

V18 and newer software

Software version 18 and newer contains web pages for switching the router. Once your PC and

the routing switcher are on the same Ethernet network, open your internet browser and type in

the default address of the routing switcher in the address line of the internet browser (factory

default 192.168.1.200). The following will display allowing switching of the router;

VIPER COMPONENT SERIES

You are provided with 3 different options to switch the router;

21