Page 1

SIERRA VIDEO SYSTEMS

Sequoia Family Routing Switchers

User’s Manual

Page 2

Page 3

SIERRA VIDEO SYSTEMS

SEQUOIA FAMILY ROUTING SWITCHERS

User’s Manual

Sierra Video Systems

P.O. Box 2462 Grass Valley, CA 95945

Tel: (530) 478-1000

Fax: (530) 478-1105

Email: info@sierravideo.com

Version 7

Publication Date: February 2012

The information contained in this manual is subject to change by Sierra Video System

Page 4

Page 5

SIERRA VIDEO SYSTEMS

Table of

Contents

Introduction 1

Before You Begin 1

Regulatory Warnings & Safety Information 2

Warnings 2

Cautions 2

Cautions (continued) 3

FCC Notice 3

Warning 3

Power Supply Cords 4

North American Power Supply Cords 4

International Power Supply Cords 4

EMC Regulatory Notices 4

Delivery Damage Inspection 5

Factors Affecting Quality of Results 5

Sequoia Family Overview 6

Introduction 6

Model Suffix Designations 6

Frame Configuration 7

Video Frame Types and Sizes 7

Sequoia Series System Components 7

Router Frame Front and rear Panel 8

Processor Frame Front Panel 9

Sequoia Series Processor Frame Rear

Panel 9

Sequoia Series Processor Frame Rear

Panel 48V version 9

Installation 11

Introduction 11

Rack Mounting 11

Connecting To Video Devices 12

Connecting Peripherals 12

Control System Connections 12

Serial Control Ports 12

Control Port 1 (by default the Terminal Port) 13

Control Port 2 (by default the Host Port) 13

Control Port 3 13

Control Panels 14

GPI I/O 14

Sync Input 15

AC Power Connections 15

Names 15

Control Processor DIP Switch Settings 16

Router Crosspoint Control 17

Theory of Operation 19

Control System Overview 19

Diagnostics 25

Analog Video Signal Path Overview 26

Digital Video Signal Path Overview 27

Operation 29

Introduction 29

Control via 9-pin Connectors 29

Host Mode 30

Terminal Mode 30

Power Up 30

Communication Protocol 31

Introduction 31

Generic Protocol 32

Troubleshooting 55

Introduction 55

Power and Indicators 55

Video Signal 56

Control 57

Switching Malfunctions 58

Specifications 59

Video Specifications 59

Control Port Specifications 60

Warranty 61

CONTENTS

Page 6

Page 7

SIERRA VIDEO SYSTEMS

Introduction

Before You Begin

There are several terms and acronyms that you should become familiar with before reading this

manual. They are shown below.

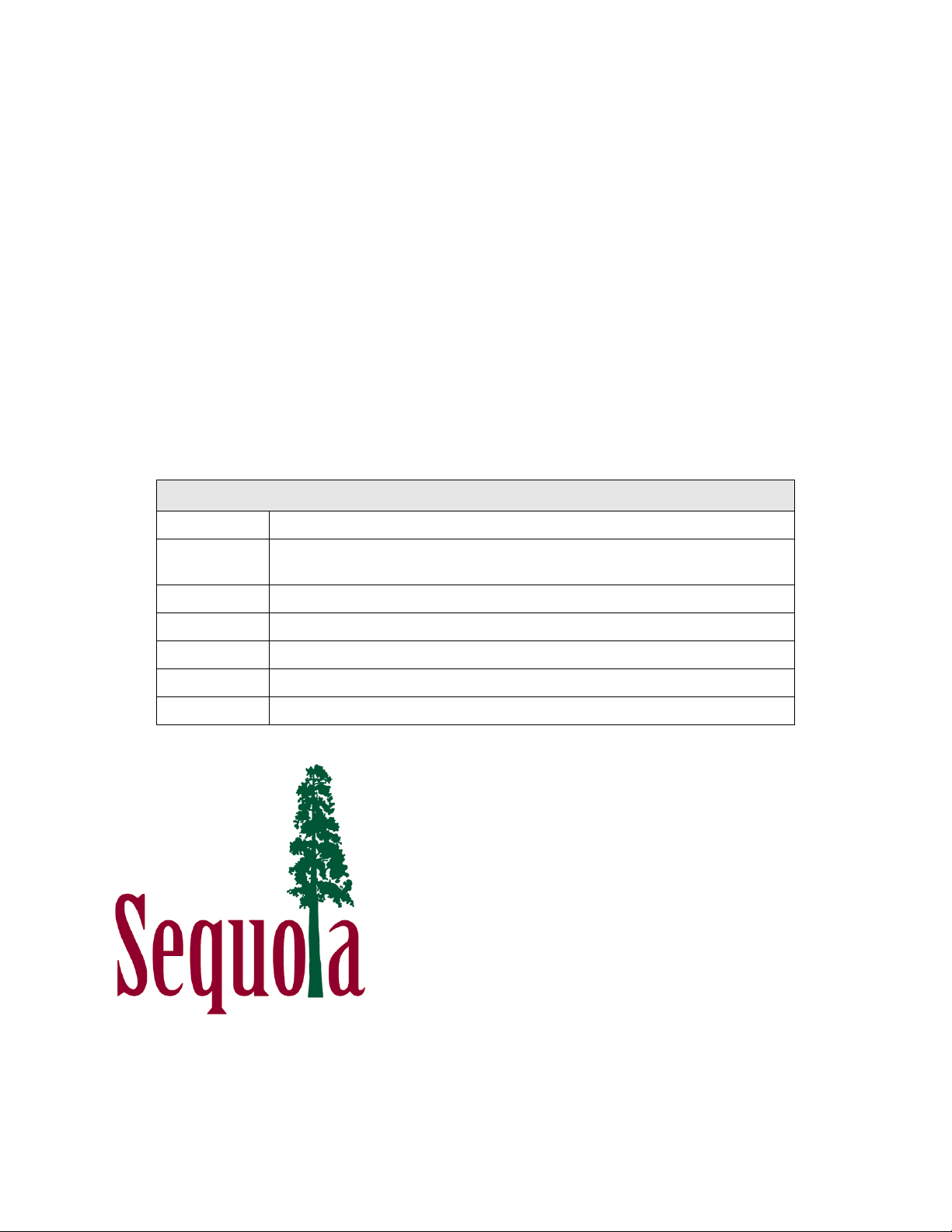

Chapter

1

Term/Acronym Definition

Crosspoint The electronic switch that assigns one of the inputs on the

matrix crosspoint modules to an output.

Destination The output of a routing switcher connected to a device that

receives signals from the output of the switcher.

Source The signal that is connected to the input of the routing

switcher.

Input Connected to the source that provides the signal to the

switcher.

Matrix The crosspoint array of the switcher module that selects

which input is selected to an output.

Output Connects the signal to the destination device.

Protocol The command structure used on a serial bus to affect a

switch or multiple switches on the routing switcher.

Routing Switcher Consists of one or more crosspoint modules that switch

together, or sometimes independently, to connect the

desired signals through the switcher.

Serial Port The 9-pin RS232 connector that allow you to control the

switcher using a standard personal computer or other

external device. Sends control protocol commands in

ASCII.

1

Page 8

SIERRA VIDEO SYSTEMS

Regulator y Warnings & Safety Information

The information in the following section provides important warnings and safety guidelines for

both the operator and service personnel. Specific warnings and cautions may be found

throughout this manual. Please read and follow the important safety precautions noting especially

those instructions relating to risk of fire, electrical shock and injury to persons.

Any instructions in this manual that require opening the equipment cover or enclosure are

intended for use by qualified service personnel only. To reduce the risk of electrical shock, do not

perform any servicing other than what is contained in the operating instructions unless you are

qualified.

Warnings

Heed all warnings on the unit and in the operating instructions.

Disconnect AC power before installing or removing device or servicing unit.

Do not use this product in or near water.

This product is grounded through the grounding conductor of the power cord. To avoid

electrical shock, plug the power cord into a properly wired receptacle before connecting

inputs or outputs.

Route power cords and other cables so that they are not likely to be damaged, or create a

hazard.

Dangerous voltages exist at several points in this product. To avoid personal injury, do

not touch unsafe connections and components when the power is on.

To avoid fire hazard, use only the specified type, correct voltage, and current rating of

fuse. Always refer fuse replacement to qualified service personnel.

Have qualified personnel perform safety checks after any completed service.

To reduce risk of electrical shock, be certain to plug each power supply cord into a

separate branch circuit employing a separate service ground.

If equipped with redundant power, this unit has two power cords. To reduce the risk of

electrical shock, disconnect both power cords before servicing.

Operate only with covers and enclosure panels in place – Do Not operate this product

when covers or enclosure panels are removed.

This is an FCC class A product. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take necessary measures.

Cautions

2

Use the proper AC voltage to supply power to the switcher. When installing equipment,

do not attach the power cord to building surfaces.

To prevent damage to equipment when replacing fuses, locate and correct trouble that

caused the fuse to blow before applying power.

Use only the recommended interconnect cables to connect the switcher to other frames.

Page 9

INTRODUCTION

Cautions (continued)

Follow static precautions at all times when handling the equipment.

Leave the side, top, and bottom of the frame clear for air convection cooling and to allow

room for cabling. Slot and openings in the frame are provided for ventilation and should

not be blocked.

Only an authorized Sierra Video Systems technician should service the switchers. Any

user who makes changes or modifications to the unit without the expressed approval of

the Sierra Video Systems will void the warranty.

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of

the rack environment may be greater than the room ambient temperature. Therefore,

consideration should be given to installing the equipment in an environment compatible

with the manufacturer’s maximum rated a mbi e n t te mperature (TMRA).

Installation of the equipment in a rack should be such that the amount of air flow required

for safe operation of the equipment is not compromised.

Use a shielded data cable connection between the parallel data ports and peripherals of

this equipment.

Other connections between peripherals of this equipment may be made with low voltage

non-sheilded computer data cables.

Network connections may consist of non-sheilded CAT 5 cable.

Do not cover chassis ventilation slots or block enclosure openings.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at the expense of the user.

The user may find the following publication prepared by the Federal Communications Commission helpful:

“How to Identify and Resolve Radio-TV Interference Problems” (Stock number 004-000-00345-4).

Available exclusively from the Superintendent of Documents, Government Printing Office,

Washington, DC 20402 (telephone 202 512-1800).

Warning

Changes or modifications not expressly approved by the party responsible for compliance to Part 15 of

the FCC Rules could void the user’s authority to operate the equipment.

3

Page 10

SIERRA VIDEO SYSTEMS

Pow er Supply Cords

Use only power cord(s) supplied with the unit.

If power cord(s) were not supplied with the unit, select as follows:

For units installed in the USA and Canada: select a flexible, three-conductor power cord that is

UL listed and CSA certified, with individual conductor wire size of #18 AWG, and a maximum

length of 4.5 meters. The power cord terminations should be NEMA Type 5-15P (three-prong

earthing) at one end and IEC appliance inlet coupler at the other end. Any of the following types

of power cords are acceptable; SV, SVE, SVO, SVT, SVTO, SVTOO, S, SE, SO, SOO, ST, STO,

STOO, SJ, SJE, SJO, SJOO, SJT, SJTOO, SP-3, G, W.

For units installed in all other countries; select only a flexible, three-conductor po wer cord,

approved by the cognizant safety organization of your country. The power cord must be Type

HAR (Harmonized), with individual conductor wire size of 0.75 mm². The power cord terminations

should be a suitably rated earthing-type plug at one end and IEC appliance inlet coupler at the

other end. Both of the power cord terminations must carry the certification label (mark) of the

cognizant safety organization of your country.

A non-shielded power cord may be used to connect AC power to every component and peripheral

of the system.

Connect an external 16 AWG wire from earth ground to the chassis of the system as designated

by the earth ground symbol.

North American Power Supply Cords

This equipment is supplied with North American power cords with molded g rounded plug (NEMA15P) at one end and molded grounding connector (IEC 320-C13) at the other end. Conductors

are CEE color coded, light blue(neutral), brown(line), and green/yellow(ground). Operation of the

equipment at voltages exceeding 130VAC will require power supply cords that comply with NEMA

configurations.

International Power Supply Cords

If shipped outside North America, this equipment is supplied with molded ground conne ctor (IEC

320-C13) at one end and stripped connectors (50/5mm) at the other end. Conn ections are CEE

color coded, light blue (neutral), brown (line), and green/yellow (ground). Other IEC 320-C13 type

power cords can be used if they comply with safety regulations of the country in which they are

installed.

EMC Regulatory Notices

Federal Communications Commission (FCC) Part 15 Information: This device complies with Part

15 of the FCC standard rules. Operation is subject to the following conditions:

This device may not cause harmful interference.

This device must accept any interference received including interference that may cause

undesirable operations.

4

Page 11

INTRODUCTION

Delivery Damage Inspection

Carefully inspect the frame and exterior components to be sure that there has been no shipping

damage. Make sure all modules are seated correctly and have not detached during shipment.

Also, make sure the input buffer modules on the rear panel are secure.

Factors Affecting Quality of Results

There are many factors affecting the quality of results when signals are transmitted from a source

to a destination.

Signal cables — Use only the best quality cables to avoid interference, degraded signal

quality or elevated noise levels.

Sockets and connectors of the inputs and outputs — Use only the highest quality, since

"zero ohm" connection resistance is the target. Connectors should also match the routers

75 ohm impedance to minimize return loss.

Amplifying circuitry — Must have quality performance when the desired end result is

high linearity, low distortion, and low noise.

Distance between the router and devices connected to it — Plays a major role in the final

result. For long distances (over 15 meters) between sources and destinations, special

measures should be taken to avoid high frequency cable losses. These measures include

using higher quality cables and/or adding line cable equalizing amplifiers.

Interference from neighboring electrical appliances — These can have an adverse affect

on signal quality. Balanced signals are less prone to interference, but and signal wire

should be installed away from any power lines, electric motors, transmitters, etc. to

minimize the possibility of electro-magnetic interference.

CAUTION!

Only an authorized Sierra Video Systems technician can service the switchers. Any user who

makes changes or modifications to the unit without the expressed approval of the manufacturer

will void the warranty

Use the proper AC voltage to supply power to the switcher.

Use only the recommended interconnect cables to connect the switcher to other frames.

5

Page 12

SIERRA VIDEO SYSTEMS

Sequoia Family Overview

Introduction

The Sequoia Family of routers provides a high-end multi format solution for every routing

requirement. Broadcast, Post Production, Government and large-scale presentat ion customers

can take advantage of Sequoia’s ability to mix signal formats within the same frame. With 16

levels of control standard, the system controller can provide any Sierra Video System router with

complete control. Using our SCP series of programmable remote control panels along with GRIP

router setup software, engineers will have complete control of the entire routing system.

The Sequoia Family router frames have a variety of sub-assemblies and interconnecting PC

boards based on the signal format and module types present in a particular frame.

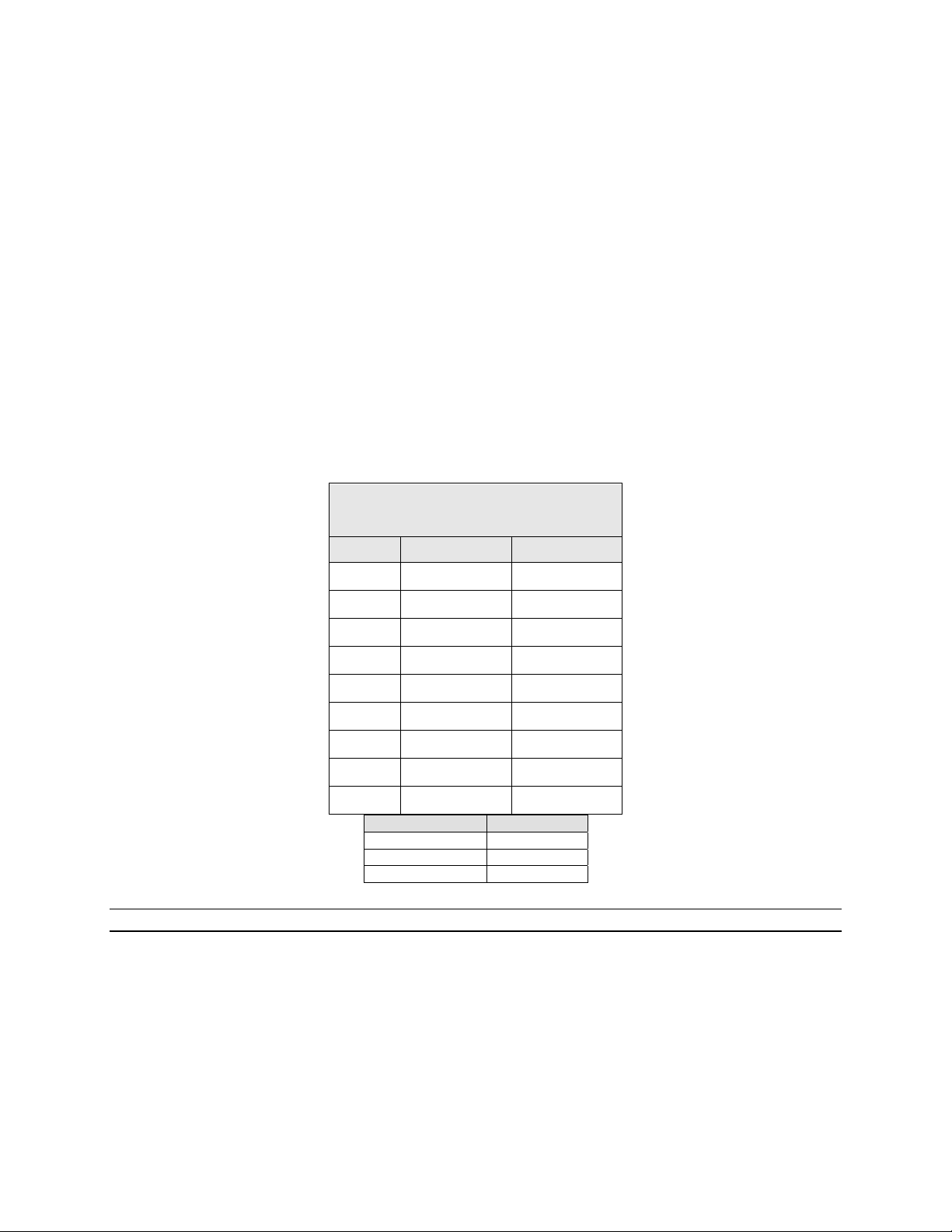

Model Suffix Designations

Model Suffix Designations

V Analog video (40 to 60 MHz bandwidth depending on specific model)

W

D SMPTE 259M-A through E serial digital video

A Analog audio

E AES/EBU Digital audio

M RS422 machine control

3216 Matrix size – in this example the router has 32 in puts and 16 outputs

Wide bandwidth analog video (120 to 250 MHZ depending on specific

model)

6

Page 13

INTRODUCTION

Frame Configuration

Each frame can be configured in a wide variety of sizes. The building-block modules are

incremental, based on:

Frame size

Different crosspoint modules

Input and Output buffer modules

Flexibility in frame size, combined with an incremental module building block design, allows for a

large array of configurations that will match your requirements.

Video Frame Types and Sizes

The Sequoia Series is built on a universal 7 RU frame, which can accommodate multiple signal

types (if needed) in the same frame.

32 x 32 Analog or Digital Video or through 128 x 128 Analog Video 7 RU

256 x 256 Analog or Digital Video 18 RU

512 x 512 Analog or Digital Video 10 - 7 RU frames

Sequoia Series System Components

This User’s Manual provides installation and operation information for the Sequoia Series Matrix

Switcher. Front and Rear panel illustrations are provided in the following subsections. Take time

to familiarize yourself with the location of your switcher model features.

7

Page 14

SIERRA VIDEO SYSTEMS

Router F rame Front and rear Panel

Note

The Sequoia models shown here and in the

subsequent sections are not fully populated video

matrices. In some cases, these frames may be

configured with fewer or more inputs and/or

outputs. Sequoia models also offer redundant

power supplies and redundant processors.

Consult the rear panel serial number and model

number to verify your order and product.

The system you receive is customized for the size

& type requested at time of purchase from Sierra

Video Systems.

8

Page 15

INTRODUCTION

Processor Frame Front Panel

Sequoia Series Processor Frame Rear Panel

Sequoia Series Processor Frame Rear Panel 48V version

9

Page 16

Page 17

SIERRA VIDEO SYSTEMS

Installation

Introduction

Installation procedures are similar for all four frames covered under this manual. Exceptions, if

any, have been noted in each of the following paragraphs.

Chapter

2

Rack Mounting

Carefully inspect the frame to ensure that there has been no shipping damage. Make sure all

shipping material is removed from the router frame.

Each of the routing switchers described in this manual can be rack mounted in a standard 19"

(RU) EIA rack assembly and includes rack "ears" at the ends of the front of the frames. None of

the switcher models require spacing above or below the unit for ventilation. If ample space exists,

a 1RU spacing gap is recommended.

To rack mount any of the routing switchers, simply place the unit's rack ears against the rack rails

of the rack, and insert proper rack screws through each of the holes in the rack ears. Always rack

mount the routing switcher prior to plugging the unit into a power receptacle or attaching any

cables.

CAUTION!

The operating temperature range of the SVS Sequoia series router is 0 to 40 °C. Do not exceed the

maximum (40 °C) or minimum (0 °C) operating temperature.

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than the room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with the manufacturer’s maximum rated

ambient temperature (TMRA).

Installation of the equipment in a rack should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

11

Page 18

SIERRA VIDEO SYSTEMS

(

V

r

Connecting To Video Devices

Video input and output devices (such as monitors or recorders) may be connected to the routing

switchers through the BNC type connectors located on the back of the unit. Keep in mind that the

output signal format will be the same as the input signal.

All signal connections that use more than one cable interconnecting between devices should be

of equal timing length (example: cables between a camera and the switcher should have the

same time delay).

Unused outputs do not need to be terminated.

Connecting Peripherals

Control panels, sync inputs, and power are all connected to the rear of the processor frame. The

peripherals area may vary depending on the model size and type.

AC Power

Connection

And Fuse

Control Panel

Connectors

Looped)

Referencing

Inputs (Looped)

Control System Connections

Connectors associated with the system's internal control computer are located on the rea r of the

Processor frame.

ideo Sync

Multi-frame

interconnect

Future Use

GPI I/O Connecto

Future Use

RS-232/422 Serial

Control Connectors

The following section only pertains to the 1 RU Control Processor frame.

Serial Control Ports

The internal control computer has three serial control ports. Each has a separate purpose.

12

Page 19

INSTALLATION

Control Port 1 (by default the Terminal Port)

This port can be either RS-232 or RS-422 using a 9 pin D connection. RS-232 op eration requires

the router to be configured as a DCE (Pin 2 TX, Pin 3 Rx, Pin 1, 9 GND) device with a PC being a

DTE device.

Control Port 2 (by default the Host Port)

This ports can be either RS-232 or RS-422 using a 9 pin D connection. RS-232 operation

requires the router to be configured as a DCE (Pin 2 TX, Pin 3 Rx, Pin 1, 9 GND) device with a

PC being a DTE device.

Control Port 3

This port can be either RS-422 or RS-485 using a 9 pin D connection.

Connections to the 9-pin are shown in the table below. “Transmit” and “Receive” are names used

by the Sierra Video Systems router. For connection to an external PC or other controlling device

use the opposite names.

Host & Terminal Port

Installation

Pin RS-232 RS-422

1 Ground Ground

2 Transmit Transmit (-)

3 Receive Receive (+)

4 Not used Not used

5 Not used Not used

6 Not used Not used

7 Not used Transmit (+)

8 Not Used Receive (-)

9 Ground Ground

PC RTR

2 RX 2 TX

3 TX 3 RX

5 GND 1 , 9 GND

NOTE:

To convert the 9-pin connector to an RS422 serial port, move the jumpers on JP-3 (for port 1) or JP-4 (for

port 2) as indicated by the silk screen on the control processor board.

13

Page 20

SIERRA VIDEO SYSTEMS

A

Control Panels

There are four male 3-pin connectors labeled "CTL PNL RS-485" (for Control Panel) on the back

of the processor frame. Each Sierra Video Systems control panel has two connectors. The

connectors are in parallel for daisy chaining multiple control panels.

If you make your own interconnect cables, Pin 2 is ground. Pin 1 and Pin 3 connect pin for pin.

The maximum control panel cable length is 5,000 feet (1,524 m) when operated at 31.25K baud.

See the Control Panel manual for detailed information about control panels.

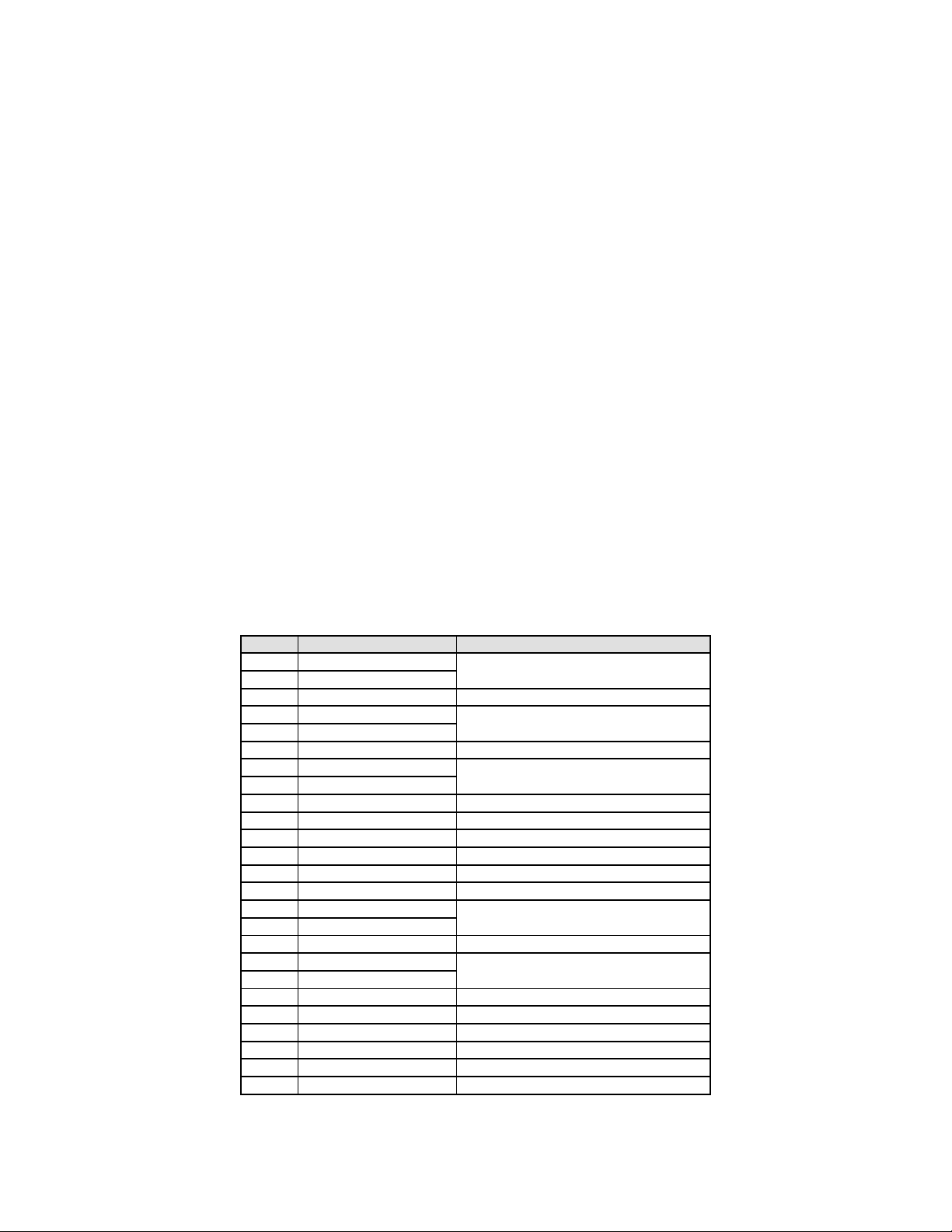

GPI I/O

The 25 pin D connector on the rear of the Sequoia CPU frame provides relay contacts under

software control that can be used to indicate a failure of router frame power supplies and fans.

This document describes that functionality.

The female 25 pin D connector on the rear of the Sequoia CPU frame provides access to 5 relay

contact sets. Two of these contact sets are used to indicate failures in the router frames. Pins 8

and 7 will be connected to each other when any of the four router frame power supplies fail. A

light on the failed power supply will also extinguish to indicate the module to be replaced. Pins 1

and 2 will be connected to each other when any of the four router frame fans fail. A light on the

failed power supply module (which carries the failed fan) will also extinguish to indicate the

module to be replaced.

All relay contacts are floating relative to any ground in the router or CPU frame. No relay contact

should be more than 1500VRMS from CPU frame ground. Relay contact ratings are 0.5A @

125VAC, 2A @ 30VDC.

Pin # Connection

1 GPI-4 out N/O *Factory Configurable

2 GPI-4 out Common

3 GPI-3 out N/C Failure- Fan Power Supply # 2

4 GPI-2 out N/O Failure- Fan Power Supply # 1

5 GPI-2 out Common

6 GPI-1 out N/C Not Used

7 GPI-0 out N/O Failure- Power Supply # 1

8 GPI-0 out Common

9 GPI-4 in *Factory Configurable

10 GPI-3 in *Factory Configurable

11 GPI-2 in *Factory Configurable

12 GPI-1 in *Factory Configurable

13 GPI-0 in Close All GPI- out Contacts

14 GPI-4 out N/C *Factory Configurable

15 GPI-3 out N/O Failure- Fan Power Supply # 2

16 GPI-3 out Common

17 GPI-2 out N/C Failure- Fan Power Supply # 1

18 GPI-1 out N/O Failure- Power Supply # 2

19 GPI-1 out Common

20 GPI-0 out N/C Failure- Power Supply # 1

21 GND Ground Connection for GPI in

22 GND Ground Connection for GPI in

23 GND Ground Connection for GPI in

24 GND Ground Connection for GPI in

25 GND Ground Connection for GPI in

larm Description

* Contact the Sierra Video Systems factory for custom GPI configurations.

14

Page 21

INSTALLATION

Sync Input

The “BNC” sync input is used to generate accurate vertical interval switching. If no sync is

available, the router will switch at a random point rather than in the vertical interval. There are

three BNC connectors labeled Ref 1, Ref 2, Ref 3. These are "looping" inputs. Connect either

composite sync or video with sync to any of the reference inputs. If desired, use the second BNC

to "loop" the signal to another device. If you do not use a loop through connection to another

device, the second BNC must be terminated with a 75-ohm terminator.

AC Po wer Connections

The power supply units for the Sequoia video frames are plug-in sub-assemblie s. If you only

ordered one power supply with your initial system then the second power supply slot is occupied

by a fan assembly with no power supply on it. You can add a redundant power supply to your

system a\t any time in the future. When redundant supplies are used, the two AC power cords

should be connected to separate AC fuse or circuit breaker lines to maximize the benefits of the

redundancy.

Warning!

Turn on power to the frame ONLY AFTER all video and control connections have been completed.

Names

Source, Destination, and level names can be applied using two methods. Names can be ap plied

using the GRIP program (See the GRIP manual for details on naming), or names can be applied

using the serial port (See the Generic Protocol section of this manual).

15

Page 22

SIERRA VIDEO SYSTEMS

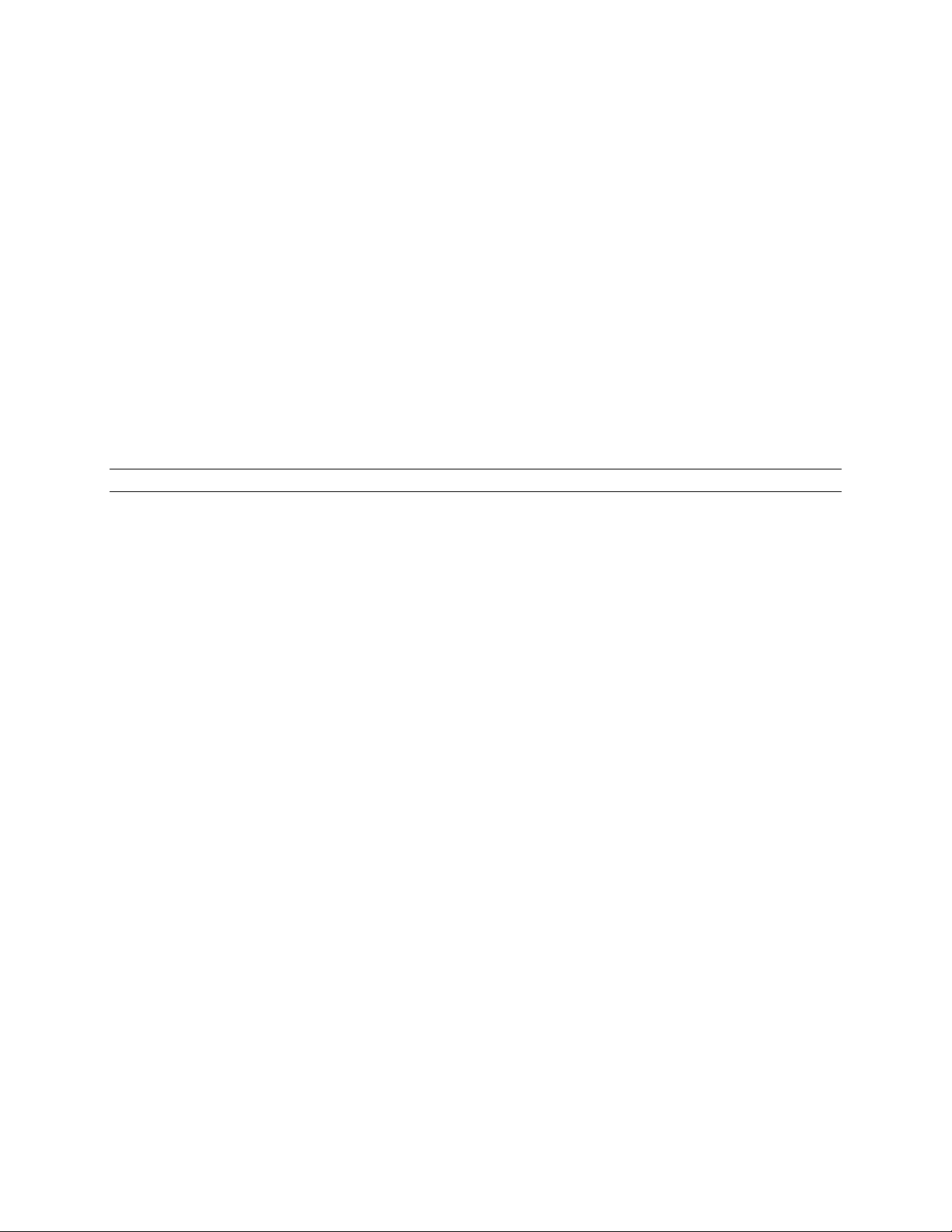

Control Processor DIP Switch Settings

Your switcher has been configured at the factory for the settings you are most likely to need.

However, if you want to configure the switcher differently, you can do so by setting the switches

located on the processor board (behind the front panel). Dip Switches and their action are given

in the table that follows;

DIP switch settings for software versions 11.30 or older

Important!

In a redundant processor system all DIP switches except S1-1 must be set identically on both processors

or the processor will flash it’s “I am sick” LED.

16

Page 23

INSTALLATION

DIP switch settings for software versions 11.35 or newer

Router Crosspoint Control

When multiple frames, audio and/or video, are combined into the same control system, all of the

frames must be installed so that the high-speed control interconnect system is limited in length.

The total length should not exceed 25 feet (7.6 m). The entire system will only use one 505150-

controller module. The "master" frame is whichever frame contains the 505150-control.

17

Page 24

Page 25

SIERRA VIDEO SYSTEMS

Theory of

Operation

Control System Overview

Chapter

3

A high quality routing switcher system requires that a high performance switching system be

combined with a flexible, reliable and easy-to-use control system. The control system used with

Sequoia routing switchers builds upon the proven capabilities of the time-tested Tahoe control

system. There are well over 10,000 Sierra Video Systems Tahoe Series routing switchers in

service throughout the world today. The Sequoia control system is completely compatible with all

Tahoe Series products. Therefore all control panels that work on a Tahoe Series routin g switcher

will work with a Sequoia Series router.

The easy to use SVS serial protocol is used for control of the router by external devices. In

applications where automation or third party control systems are used, this protocol provides

complete control and configuration remotely. The control system protocol is compatible with all

Tahoe and Shasta family products and is supported by multiple control and automation

companies (see Chapter on Communication Protocol).

A wide variety of control panels are available, operating on the standard Sierra Video Systems

RS-485 control panel network using a simple twisted pair of wires. Control panels can be located

up to 5,000 feet (1,500 m) away from the frame. Each system has a capacity of up to 100 panels.

Non-vola tile RAM

The control processor board contains non-volatile memories, which are used to store the

crosspoint matrix state, salvo presets, input/output/level names, control panel configuration, and

other non-volatile information. Any information stored in the non-volatile RAM remains valid when

the switcher is powered down. This allows the switcher to return the router to its previous state

when power is restored. When power is applied to the router the non-volatile RAM data is

checked for validity and then all crosspoints are set to the values they last had when the

processor was previously running.

Although it is not recommended

re-initialization is forced, there is the possibility that all existing customization and configuration

data will be lost, and it can be a lengthy procedure to restore the data. However, in some cases it

19

, it is possible to force re---initialization of the non-volatile RAM. If

Page 26

SIERRA VIDEO SYSTEMS

makes sense to reinitialize the non-volatile RAM. To accomplish a re-initialization, turn on DIP

switch S1-8, power up the router, power it down, and turn off S1-8. If for any reason a customer

decides to do this, it is highly recommended that they record as much of their router setup data as

possible, using the terminal port to access the data.

LED Definitions

The LEDS on the edge of the processor board have the following meanings (LEDa is at the top

and LEDf is at the bottom):

LEDa (Blue) ON if this processor is in control of the router, OFF if it is in standby mode.

LEDb (Yellow) flashing if master and standby processors are syncing up, OFF if they are synced.

LEDc (Green) ON if this processor thinks it is operating properly.

LEDd (Red) flashing if this processor thinks there is a system error.

Note:

LEDe and LEDf are always OFF.

On the Control Processor board, along the top of the board and behind the edge mounted LEDs

are three additional status LEDs. The LED closest to the front of the board is used to indicate

condition of the external sync. When there is no external sync connected or detected by the

router the front LED is flashed at about 3 times per second. If the router is locked to an external

sync this LED becomes the MSB of the idle counter. The other two LEDs behind the sync

detection LED are the next two MSBs of the idle counter.

Redundant Processor Capability

The Sequoia router family supports the use of redundant processors. A router with this option has

two control processors. At any given time, one of them is the master and the other is the standby

processor. The master processor is the one that controls the system. The standby processor

simply monitors the activity of the master processor, keeping track of the same router status

information as the master, and takes over the job of master if it detects that the master processor

has failed.

The two processors always monitor each other and present status information on the processor

LEDS to indicate the processor health. See above LED Definitions for a brief description of these

LEDS. Further information is given below. To enable redundant processors, DIP switch S1-2

must be ON. If it is off, the processor will ignore the presence of another processor and will start

up as master processor and control the system (and will not flash the LED that indicates that the

other processor has a problem).

Note:

All DIP switches except S1-1 must be set identically on both processors, or the slave processor will flash

its “I am sick” LEDd. (See DIP Switch Settings in Installation section)

20

Page 27

THEORY OF OPERATION

Preferred Master Switch

A requirement of both processors in a two processor (redundant) system is that they are set so

that one is the preferred master processor and the other is the preferred standby processo r. This

setting determines which processor will become the master processor when both processors are

powered on at the same time. The setting is made with DIP switch S1-1.

It is essential that S1-1 be set differently on the two processors. Furthermore, it is recommended

that the processor in the uppermost or leftmost slot be the one with S1-1 on (default Master), and

the processor in the lowermost or rightmost slot be the one with S1-1 off (default Slave).

Summarizing:

Processor Slot Recommended S1-1 Setting;

Top or Left ON (default Master)

Bottom or Right OFF (default Slave).

Note:

If S1-1 is set to the same setting on both processors, the router will not function properly.

It is important to know that the setting of S1-1 only determines which processor is the master and

which is the standby immediately following power-up. Later on, the standby processor may have

taken over as master processor, in which case the setting of S1-1 will no longer indicate which

processor is the master.

The current master processor turns on its LEDa, and the standby processor turns it off. So, only

one of the two LEDa’s should be lit at one time, expect during the Boot process

Always look for the processor with LEDa on, and know that it is the current master processor in

control of the router.

Processor Synchronization

The usual state of affairs regarding the redundant processors is that both processors always

power up at the same time, and continue to operate until powered down. In that situation, the

standby processor always is up-to-date with regard to any router configuration information that

the master processor has received. (crosspoints, salvos, panel settings, input/output/level names,

etc.) If the standby processor has to take over as master, it has all the information it needs to do

so.

This usual state of affairs may not always be the case, however. If one processor is removed

from the router for some time, it will no longer have the same router configuration information as

the processor that is running in the frame as master. When this happens, it is important that the

two processors “resynchronize” their configuration information as soon as the processor is put

back in the router. Resynchronization involves the transfer of a considerable amount of

configuration information from the current master processor to the standby processor. If the

standby processor becomes master before the synchronization proce ss is finished, the router

may be running with outdated configuration information.

During the synchronization process, the Yellow LEDs are flashed. When it stops flashing,

synchronization is complete. Complete synchronization may take up to ten minutes. The

synchronization process is always done at power-up.

21

Page 28

SIERRA VIDEO SYSTEMS

When it is necessary to remove a processor from the router, the master processor should not be

removed while the synchronization is in process, i.e. while Yellow LEDs are flashing. If it is

removed, the standby processor will take over with possibly out-of-date configuration information.

If the user knows that the two processors actually are in sync, this doesn’t matter and the master

processor can be pulled at any time. It can also be pulled if it doesn’t matter that the configuration

information changes when he does so.

The standby processor can be pulled at any time, even during synchronization, with no negative

impact on operation. When it is reinserted, the synchronization process will be restarted.

When the router is powered on with two processors that were not synced to one another, the

processor with the most recent configuration information should be the one with switch S1-1 on

(making it the Preferred Master). If the processor with the older configuration data were the one

with S1-1 on, it would become master processor and would send its older data to the standby

processor, wiping out its newer data.

For example, suppose the master processor is removed from the router for an extended period of

time. Later, it is reinserted. If it is inserted hot, without powering down the frame, then it will

become the standby processor and the master will synchronize it with the latest data. On the

other hand, if it is inserted with the frame powered down, with the S1-1 on and the processor that

has been running the frame has S1-1 off, then when the frame is powered on the processor that

has not been in the system for a long time becomes the master, and will operate the router with

obsolete configuration data. Furthermore, the other processor’s newer configuration data is wiped

out as it becomes synchronized with the other processor.

CAUTION!

Whenever it is necessary to remove a processor from the router, the master processor should not be removed while

synchronization is in process, i.e. while Yellow LEDs are flashing.

Synchronizing Host and Terminal Protocols

All three external serial ports can run either host or terminal protocol. If both processors are

powered on at the same time, they should both stay in sync with one another, and the ports on

the two processors should be running the same protocols. If the standby processor is inserted

after the master has been running for a while, the synchronization process described above

causes the standby processor to switch to running the same protocol as the master processor.

However, the standby processor may not be in sync with the master processor within that

protocol.

For example, suppose the master processor is running host protocol on the host port, and a

partial command has been sent to the port. Then, the standby processor starts up, and after that,

the rest of the command is sent to the host port.

The standby processor never sees the first part of the command, so it will ignore the whole

command. This situation is unlikely to cause problems, because usually host commands are sent

quickly, and any commands that the slave processor misses will have been sent before the

synchronization process even started. By the time the synchronization process finishes, the two

processors have their data in sync, and both are processing complete host commands.

The same situation could happen when terminal protocol is in effect, but in that case it has more

potential to cause problems. The user often stays in a submenu for a long time, when terminal

protocol is in effect, and the standby processor starts up in the main terminal menu, therefore

rendering it unable to sync itself to a submenu. To try to prevent out-of-sync problems from

occurring, every time the standby processor comes on line, the master processor’ s terminal

22

Page 29

THEORY OF OPERATION

protocol displays a message to the user that a standby processor is now available, and asks him

to press the “Control/C key combination”. After Control/C is pressed, the router configuration

screen is displayed. This serves to synchronize both processors to the same terminal screen.

Processor Health Monitoring and LEDS

Each processor monitors its own health, as well as that of the other processor, and displays a

healthy/sick indication on the processor edge LEDS. Two LEDS indicate the health of the

processor on which the LEDS are located, and two indicate the health of the other processor.

LEDc and LEDd indicate the health of the processor on which those

LEDS are located. Both processors continually monitor the following expected conditions within

themselves:

Presence of vertical sync interrupt.

Regular operation of the crosspoint control software.

Regular polling of control panels.

If any of the above cease to occur, or if a processor fails one of its startup diagnostics, it

considers itself “sick”, and it flashes its LEDd to tell the user that it has a problem. Otherwise, is

turns on LEDc to indicate that it thinks everything is okay with itself. Any time a processor is

flashing LEDd, it indicates the processor has something wrong with it. Use the terminal protocol

“D” (DIAG) screen to make sure the processor didn’t fail its startup diagnostics.

It is possible for a processor to flash LEDd briefly and then stop, if it should detect absence of any

of the above-listed activity. If this happened, it would indicate a software failure. LEDe and LEDf

indicate the health of the opposite processor. Besides monitoring their own health, both

processors continually report to and monitor the other processor. If the other processor stops

reporting that it is okay, LEDf is flashed to tell the user that the other processor is not working

properly. Otherwise, LEDe is turned on to indicate that the other processor appears to be working

properly.

Takeover by Standby Processor

As noted above, both processors monitor the health of the other processor. If the standby

processor detects that the master processor is sick, or if it detects that the other processor is not

acting as master for some reason, the standby processor will attempt to take over control of the

system as the new master processor.

Furthermore, if the master processor has determined that it is “sick” (see description of LEDd

above) or if any of the following behavior occurs in the master processor, it will shut itself down

and allow the standby processor to take over:

Unexpected processor interrupts;

Processor data bus errors.

Software integrity check failures.

Manual takeover initiation by the user via a host protocol command or terminal port “T” screen

command.

23

Page 30

SIERRA VIDEO SYSTEMS

If the standby processor has determined that it is “sick” (it is flashing its LEDd), it will refuse to

take on the job of master processor, even if the other processor is not present. A processor can

only be master processor when it thinks itself is okay.

Therefore, the master processor will never flash LEDd. If the master processor thinks it is sick, it

will relinquish control to the standby processor. The standby processor will normally never flash

LEDf, but will instead take over as master processor if it detects that the master processor is

having problems. However, if the standby processor also thinks that it is sick, it will flash both

LEDd and LEDf, and will not take over as master processor. If both processors are sick, they can

both remain in a standby state, in which case the router will be inoperative.

When the standby processor takes over, all control outputs (in particular, crosspoint control and

serial port transmit data) are switched over to the new processor. The crosspoint data is then

sent to the crosspoint matrices to make sure that the actual crosspoint state matches the new

master processor state.

Normally, this will cause no change in the crosspoint state. However, if the new master had not

yet completed synchronization with the old master before it took over control, it is possible that

some crosspoints will change state. The new master processor also sends the state of all

crosspoints to all control panels but not to ports running host protocol. Every port that is running

host protocol will receive a “G REDUNDANT_PROCESSOR” command, with the <new_master>

argument set to 1. Host application software, upon receiving such a command, should assume

that any data it has cached from the previous master may be invalid. This includes crosspoint

data, panel configuration data, and any other data. It should request the data again from the new

master processor.

At takeover, if synchronization had not been completed, the new master also resets all control

panels, because that is the only way it can find out what types of control panels are present.

Finally, the new master begins normal operation.

With this activity taking place at takeover, users may notice a period of a few seconds during

which control panels and host and terminal commands have a delayed response.

At takeover the master processor’s terminal protocol displays a message to the user to indicate

that a new master processor is in control, and is pressed, the router configuration screen is

displayed. This serves as a clear notification to the user that a takeover has occurred.

Periodic Testing of the Standby Processor

Although the LEDS indicate whether or not a processor has detected a problem with itself, it is

still possible that the processor can be unhealthy without it being detected. For example, a

processor might have a burned out control line for controlling the crosspoints, and it has no way

to detect this situation.

Unless the customer takes steps to perio dically test the standby processor, he can never be sure

that it is fully functional and ready to take over if the master processor goes down.

The only way to reliably test the standby processor is to force it to become the master processor.

This can be done with a host protocol command, or simply by using the terminal interface and the

“T” screen described above. As mentioned earlier, a switch from one processor to the other can

cause a temporary (several seconds) slowdown in router response. Therefore, switching sho uld

be done at a time when it will not inconvenience users. It is not necessary to switch back again

after making sure the router continues to function properly with the other processor.

Instead, you can simply switch processors every so often, say once a month. Half the time, the

preferred master is in control, and half the time the preferred standby processor is in control.

24

Page 31

THEORY OF OPERATION

Diagnostics

When the switcher is powered up or resets for any reason, it performs a series of self-tests,

signaling progress using the LEDS as follows:

All LEDS are flashed quickly for about one second, immediately after startup (after initializing the

processor registers). This indicates that the processor is up and running and that the LEDS work.

The LEDs with then go through a diagnostics sequence which lasts about ½ second, then turns

the LEDs off. Then the LEDS will begin normal operation as described above.

Synchronization with House reference

There are three sets of looping reference BNC connectors. If there is nothing connected to any of

these BNC, the “not locked” LED will blink at a rate of 3 times/second and the router will operate

completely normally. If it is desirable for the router to switch during the video vertical interval,

then the control system should be locked to an external signal. The external reference can be

any valid NTSC/PAL composite video signal (although black is recommended). Any of the

reference loop through BNCs can be used, however only connect one reference signal to the

router. When the router is locked to an external reference, the “not locked” LED will become a

software idle counter and blink about once every 8 seconds.

When the router control system is locked to a reference crosspoints will be swit ched at a field

boundary of the video. In addition, deterministic control is possible using the Host serial port.

The delay between receiving a command and performing a crosspoint switch can be set to

practically any number of frames so that the control system can be tailored to the requirements of

any automation or external control system.

Five Port Controller System

The Sequoia Series control system has a total of 5 serial control ports.

One of these ports is dedicated to the RS485 based control panel system. A network of up to 100

Sierra Video Systems control panels can be linked via shielded twisted-pair audi o or data cable.

A variety of control panel types are available, including a push-button keypad or "shot" panel.

The Control Panel ports are marked “CTL PNL (RS-485)”.

Multi-Drop Ports 1, 2, 3 and 4 are used to control the crosspoint hardware. The Sequoia control

system uses hi speed serial communications and these ports are use d to connect all of the

frames within a single system to the CPU. It is not important which Multi-Drop port is used as

long as there is a connection between each and every frame in the system and one of the four

Multi-Drop ports on the CPU.

Port 1 and Port 2 can be used as either RS232 or RS422 host control ports using a variety of

popular data rates. Either port can be used as a simple terminal control port or as a Host control

port using the Sierra Video Systems serial control protocol.

Port 3 can be used as either RS485 or RS422 host control ports using a variety of popular data

rates. This port can be used as a simple terminal control port, a Host control port, or as an extra

control panel network allowing more that 100 control panels.

The ports can be connector to a wide variety of external devices. The most common is a PC,

which is why we also supply the Sierra Video Systems Windows 95/98/NT program, known as

GRIP (Graphical Router Interface Program) with each router. When software control systems

grow and needs increase, such as tielining and network capability, Sierra offers I ntellipath

software to fill these needs.

25

Page 32

SIERRA VIDEO SYSTEMS

Crosspoint Control De-Scrambling

The interconnection between input buffer to crosspoint modules and crosspoint modules to output

drives is determined for optimal signal performance. This interconnection results in a "scram bled"

sequence of connections to the inputs and outputs of each crosspoint and output module. Thi s is

handled by using de-scrambling look-up table that is part of the control interface in the Sequoia

processors. The de-scrambling results in the control processor addressing the switching

hardware in correct manor. This is a very important concept to understand in the maintenance

and trouble-shooting of the internal control system.

A configuration file is loaded into the Sequoia processor by the factory before shipment, and is

also provided on an accompanying CD. If the processors lose this information, it can be reloaded

using GRIP software or generic terminal software running on an IBM compatible PC.

The de-scrambling process is different for each and every Sequoia router configuration. As part of

the circuit description and schematic diagrams for the crosspoint modules, Sierra Video Systems

include the de-scrambling lists for each module.

Analog Video Signal Path Overview

The Sequoia Series analog video routers are based on a conventional “two stage” cro s spoint

matrix design. The signal path consists of three elements or modules:

32 Input module

128 x 64 crosspoint module

4X1X32 Output module

Each input buffer assembly consists of a PCB which is installed and removed from the front of the

router frame. Rear panel BNC connectors pass through intermediate connectors to 32 buffers

which individually isolate incoming video signals, providing correct terminations to external

sources and providing 50 Ohm source impedance signals for crosspoint assemblies. One or two

50 Ohm impedance coaxial ribbon cables connect the 32 outputs of each input buffer assembly to

one or two 128X64 crosspoint assemblies.

128X64 crosspoint assemblies accept up to (4) 32 signal ribbon cables from input boards, or up

to 128 signals from a crosspoint backplane bus, which can be driven by a crosspoint board to

which input cables have been attached. One or two 32 signal coaxial ribbon cables leave each

crosspoint assembly and connect to output assemblies.

4X1X32 output assemblies consist of (32) 4X1 switchers and output buffers which pass through

intermediate connectors to reach rear panel BNC connectors. 1 to (4) 32 signal coaxial ribbon

cables arrive at each output board from up to (4) 128X64 crosspoint assemblies. This allows each

output to connect to 4X128 or 512 inputs in the three board system.

For a 128 x 128 system, there will be 4 input cards, 2 crosspoint cards, and 4 output cards. For a

256 x 256 frame there will be 8 input cards, 8 crosspoint cards, and 8 output cards. In a 512X512

router, there will be 16 input cards, 32 crosspoint cards, and 16 output cards.

26

Page 33

THEORY OF OPERATION

Digital Video Signal Path Overview

The Sequoia Series digital video routers are based on a conventional "one stage" (for compact

routers up to 128X128 in size) or “two stage” (for expandable routers up to 512X512 in size)

crosspoint matrix design.

32 Input module

128 x 64 crosspoint/output module

4X1X32 Output module

Each input buffer assembly consists of a PCB which is installed and removed from the front of the

router frame. Rear panel BNC connectors pass through intermediate connectors to 32 IC's which

adaptively equalize incoming video signals, providing correct terminations to external sources and

providing 50 Ohm source impedance signals for crosspoint assemblies. One or two 50 Ohm

impedance coaxial ribbon cables connect the 32 outputs of each input buffer assembly to one or

two crosspoint or crosspoint/output assemblies.

128X64 crosspoint assemblies accept up to (4) 32 signal ribbon cables from input boards, or up

to 128 signals from a crosspoint backplane bus, which can be driven by a crosspoint board to

which input cables have been attached. One or two 32 signal coaxial ribbon cables leave each

crosspoint assembly and connect to output assemblies.

4X1X32 output assemblies consist of (32) 4X1 switchers, reclockers, and output buffers. 1 to (4)

32 signal coaxial ribbon cables arrive at each output board from up to (4) 128X64 crosspoint

assemblies. This allows each output to connect to 4X128 or 512 inputs in the three board system.

For a 128 x 128 compact system, there will be 4 input cards and 4 crosspoint/output cards. For a

256 x 256 frame there will be 8 input cards, 8 crosspoint cards, and 8 output cards. In a 512X512

router, there will be 16 input cards, 32 crosspoint cards, and 16 output cards.

27

Page 34

Page 35

SIERRA VIDEO SYSTEMS

Operation

Introduction

The purpose of a routing switcher is to switch any of the inputs (source) to any of the outputs

(destination). Any input can be connected to any or all outputs but each output can only be

connected to a single input. Control remains the most important component of your new system.

The standard local control panel empowers full control of the routing switcher while allowing

external RS-232 control via the serial port.

Chapter

4

Control via 9-pin Connectors

The 9-pin connectors allow you to control the routing switcher via an external computer. The

serial ports can be changed internally for RS422 configuration (RS232 is factory default

configuration). To change to RS-422 see the “Installation” section of this manual.

Connections to the 9-pin are shown in the table below. “Transmit” and “Receive” are names used

by the Sierra Video Systems router. For connection to an external PC or other controlling device

use the opposite names.

Host & Terminal Port

Pin RS-232 RS-422

1 Ground Ground

2 Transmit Transmit (-)

3 Receive Receive (+)

4 Not used Not used

5 Not used Not used

6 Not used Not used

7 Not used Transmit (+)

8 Not Used Receive (-)

9 Ground Ground

Installation

29

Page 36

SIERRA VIDEO SYSTEMS

Connection to PC;

Host Mode

Sequoia series routing switchers have several 9-pin RS-232 connectors that allow you to control

the switcher using a standard personal computer or other external devices (such as Creston or

AMX). Most external controllers use “HOST” protocol commands to switch the router.

Some of the serial connectors are shipped in the “Host” mode but can be changed to the

“Terminal” mode by the following procedure:

Connect a terminal to the serial port and send the following command:

**HOST0!!

The port now uses the terminal protocol.

PC RTR

2 RX 2 TX

3 TX 3 RX

5 GND 1 , 9 GND

To restore back to the Host port, send the following command:

**HOST1!!

T erminal Mode

The 9-pin connector labeled RS232/422 Control can be used for simple terminal control, (V=T100

emulation capability). The terminal performs the following functions:

Serves as an overall system controller

Sets up the personality of the entire system (size, level control, change names,

mapping, etc.)

These setups are stored in non-volatile memory so that a terminal is not required unless it is

necessary to change a setup.

Power Up

Once all signal and control connections have been made, turn on the power swit ch. AC to the

router is indicated by a illuminated power switch button. If you have power up problems ensure

that the AC fuse on the back of the switcher is seated properly.

On power up, the controller will restore the routing switcher to the last state it was in before the

power was turned off including all configuration settings as well as crosspoint switcher statu s.

30

Page 37

SIERRA VIDEO SYSTEMS

Communication

Protocol

Introduction

Chapter

5

The protocol uses the 7-bit ASCII character set, usually sent over an RS232-C or RS422 serial

link — 115.2K Baud is recommended with 8 data bits and no parity. The protocol is compact, with

few characters required to cause switch changes to occur. It is also human -readable and thus

easy to understand and use. Several different crosspoint switch request commands are defined,

so that the one that is most compact for any given switcher and application can be chosen.

The protocol is useful with both very small and very large routing switchers. The sizes of the

numbers representing inputs, outputs, and levels are not fixed, but can be as large or small as

necessary. Special provisions allow numbers to be packed one after another with no intervening

delimiter character, in order to make the protocol compact, as long as each number is the larg est

size necessary for that particular switcher.

All input, output, and level numbers begin at number 1, not 0.

Note:

When writing commands for a “third party” controller, pay careful attention to the levels of control.

31

Page 38

SIERRA VIDEO SYSTEMS

Generic Protocol

Commands are sent to a routing switcher in a group called a command string. A command string

can contain zero or more commands, limited only by the size of the receive buffer of the router,

whose size depends on the particular router model.

A command string consists of a leader string of asterisk characters, zero, or more commands,

and a trailer string of exclamation marks. Larger routers require two leader (**) and trailer (!!)

characters, while small routers require only one, in order to make the protocol compact for those

routers. The remainder of this document gives examples using doubled characters. Note that two

leader/trailer characters may be sent to small routers even when only one is required, and they

will still work fine.

If a leader character (**) is encountered within the command string being processed by a router,

the command string up to that point is discarded and a new command string is expected. This

ensures that a router will always act on a complete command string sent to it, even if the previous

one was never completely received.

When a command string is received, it is not acted upon (but rather, is merely buffered up) until

the final trailer character (!) character of the command string is received. At that time, the routing

switcher begins to execute the commands within the string.

The protocol uses only 7-bit ASCII characters. The 8th bit of received characters is treated as if it

is 0. Within the command string, certain ASCII characters may be present and are ignored: any

ASCII character whose code is less than the SPACE character (includes all control characters

and the SPACE character) and the DEL (ASCII 7F) character. Alphabetic characters within the

command string may be in either upper-case or lower-case letters. The router always sends

upper case characters, except for character strings such as input, output, and level names, which

may have lower case characters in them.

When sending commands to the router, SPACE characters are optional, but if used may only

appear before and after each individual command and NOT embedded within a n individual

command. Within command strings sent from the router, a single SPACE character appears

before and after each individual command. SPACES may also appear in character strings, such

as input, output, and level names.

Certain commands (R, Q, L, and G) have character strings that appear as arguments. The first

three, “R”, “Q”, and “L”, have character strings only in commands sent from the router, and these

character strings are always terminated with a ~ (tilde) character. No special character marks the

start of these strings, they simply begin at the appropriate point within the command. The “G”

command, on the other hand, uses the ~ (tilde) character to mark both the start and end of a

character string argument.

Just before the router begins executing a command string, it sends a leader (**) to the host (the

same number as are required in commands from the host). As it executes the commands, some

of them may generate additional output back to the host. These command response characters

are always preceded and followed by a space character, making the response string ea sily

human-readable.

32

Page 39

GENERIC PROTOCOL

After the command string has been executed, the routing switcher returns the string " OK " (with

a single space character before and after the word "OK"), followed by the trailer (!!) and a CR

(carriage return, ASCII 0D) character, to the host. This indicates that the command has executed

successfully. If an error occurs within any command of a command string, the remainder of the

command string is ignored and the router returns the string " ERROR ", followed by an optional

descriptive string followed by a string of trailer characters and a CR character, to the host. An

error can be caused by an unknown command name or bad arguments to a command.

The simplest possible command string would be:**!! which consists of the leader and trailer

characters but no commands between them. This command string would generate the response:

** OK !!<CR>

This can be useful for verifying that the serial link to the router is operational. In routers requiring

only one leader/trailer character, the simplest command string would be: *! which would generate

the response:

* OK !<CR>

(To determine whether a particular router uses one or two leader/trailer characters, send it "!!**"

and check the response to see which of the above two responses it is. It won’t hurt to always use

two even if only one is required.)

The simplest error response is one with no optional descriptive string. For example, this

command string:

** XXX !! might generate this response from the router:

** ERROR Syntax: No Number:XX !!

The descriptive string always ends with a colon and up to three characters from the com mand

string that caused the error. Generally, the error can be assumed to have occurred just before

these characters.

Leader and Trailer

The simplest possible command string would be “**!!” which consists of the leader and trailer

characters but no command between them. This command string would gene rate the response

“**OK!!” followed by “CR”. This can be useful for verifying that the serial link to the switcher is

operational.

The following is the set of commands available for sending to the router, a subset of which may

be implemented in any given routing switcher.

33

Page 40

SIERRA VIDEO SYSTEMS

Syntax Example Description

R R Router Reset

I I Capabilities Inquiry

Q Q Model Name and Software Version

L L Matrix Size and Level Names Inquiry

O O5 Output Status inquiry

N N5 Input Status inquiry

S S Status inquiry

C C Clear matrix

K K9999 Set Password to Change Protected

M M139 Set Remote Address

U {0 1} U0 Update request on/off

Inquiry

Settings

V out,in,in… V3,1,2,2 Connect levels

W lvl,in,in… W1,4,19 Connect outputs

X out,in,lvl X12,9,2 Connect crosspoint

Y out,in Y1,7 Connect AFV

Z in in… Z13,12,8 Connect AFV

D numsyncs D300 Delay vertical sync intervals

T {A-Z} TB Trigger a Salvo Connect sequence

P {A-Z} PBY1,7~ Preset a Salvo connect sequence

B B21 Output Lock inquiry or change

F F5 Field Delay for crosspoint output

HOST HOST0 Select Host or Terminal Protocol

G G1,10~

The command "G" is used to query

or modify a router configuration

parameter or parameters.

34

Page 41

GENERIC PROTOCOL

“R”: Router R eset

Use this command to force the routing switcher to reset, by sending it the command "RESET". If

an administrator password has been set (using the “G ADMIN_PASSWORD” command

described later in this document), then the password must be sent in a “K” message prior to

sending this command, else this command will generate an error. For example, the command:

**RESET!!

would initiate a reset (if the password has been entered, if required), and when the router finished

the reset operation, something like this would be received, just as if the router had powered up:

** RESET Tahoe Vx.xx (C) 2000~ !!<CR>

“I”: Capabilities Inquiry

The command "I" requests that command capability information be returned to the host. The

information is sent as a string of characters. The first characters are a space followed by "I", the

next characters are the letters of the commands that are implemented and available in this router,

and the last character is "~" (tilde). Do not count on the characters being in any specific order.

Search all characters for a particular one.

All routing switchers implement the I, L, S, and X commands. The Q command will

eventually be added to all.

For example, the command: **I!!

might return the following string:

** ILSX~ OK !!<CR>

indicating that the router supports the I, L, S, and X commands from the host.

“Q”: Model Name and Software V ersion Inquiry

The command "Q" requests that the router model name and software version number string be

returned to the host. The information is sent as a string of characters. The first characters are a

space followed by "Q", the next characters are the router model name, terminated by a "~" (tilde).

Following this are the characters of the software version number string, again terminated by a "~"

(tilde).

For example, the command:

**Q!!

might return the following string:

** QSmall~V2.1~ OK !!<CR>

indicating that the router model name is "Small" and the software version number is "V2.1".

35

Page 42

SIERRA VIDEO SYSTEMS

“L ”: Matrix Size and Le v el Names Inquiry

The command "L" requests that matrix size (Nout, Nlvl, Nin) and level name information (lvl1, lvl2,

etc.) be returned to the host. The information is sent as a string of characters. The first characters

are a space followed by "L", some optional values described below, then the number of outputs

(Nout), a comma, the number of levels (Nlvl), a comma, the number of inputs (Nin), a comma,

and then the level names, each terminated by a "~" (tilde), and the last followed by two tildes.

For example, the command:

**L!!

might return the following string:

** L64,3,32,VIDEO~AudioL~AudioR~~ OK !!<CR>

indicating that the router has 64 outputs, 3 levels, and 32 inputs, and the levels are named

"VIDEO", "AudioL", and "AudioR".

“O”: Output Status Inquiry

The command "O" requests that matrix status information for a single output be returned to the

host. The status information is sent as a “Y” command or a “V” command or as a sequen ce of L

“X” commands, where L=number of levels.

For example, the command:

**O5!!

to a 3-level router might have the following three commands as its response:

** X65,23,1 X5,-,2 X5,0,3 !!

Note the dash, indicating that on level 2, output 65 is not connected to an input. Also note the 0,

indicating that the connection on level 3 is either unknown or that output 65 doesn’t exist or isn’t

mapped on level 3.

Or, a 3-level router might have the following single command as its response:

** V65,23,-,0 !!

which has the same information as the three X commands in the previous example.

If the router has only one level, or if all levels are connected the same, the router might instead

use the Y command. For example:

** Y65,23 !!

36

Page 43

GENERIC PROTOCOL

“N”: Input Status Inquiry

The command "N" requests that matrix status information for a single input be returned to the

host. This command is only useful on those router levels that allow an input to be connected to at

most one output. The status information is sent as a “Y” command or a sequence of L “X”

commands, where L=number of levels that allow an input to be connected to at most one output

(each such level generates a single “X” command of status). Thus, a 6-level router with three

single-output-per input levels would generate 3 “X” commands of status command output. A

router that has all of its levels as single-output-per-input may return a single “Y” command instead

of individual “X” commands if all of the levels are connected to the same output. The “X” and “Y”

commands are formatted exactly as with the "O" command.

For example, the command:

**N4!!

to a router might have the following three commands as its response:

** X12,4,2 X-,4,3 X0,4,4 !!

giving the status of levels 2, 3, and 4 (level 1 presumably not being a single-output-per-input

level). Note that on level 3 the ë-ë (dash) indicates that the input is disconnected, and on level 4

the 0 indicates that the connection to the input is either unknown or that input does not exist or is

not available on that level.

If the router has only one level, or if all levels are connected the same, it might instead use the Y

command. For example:

** Y12,4 !!

“S”: Status Inquiry

Use command S to request that status information be returned to the host. The status information

is sent as a string of L x O substrings, where L = number of levels and O = number of outputs.

Each level/output combination generates a single substring of status. Thus, a 21-level 16 output

router would generate 2x16 = 32 substrings of status command output. The length of each

substring depends on the size of the particular switcher involved. Larger switchers use bigger

numbers for inputs, outputs, and levels.

The first substring of status is for level 1 output 2, etc.; however, each substring contains the level

and output numbers, so the sequence in which the data is sent is not important). The first

characters of each substring are a space followed by “X”, then the output number, a comma

character, the input number connected to the output (or 0 if no connection exists), another

comma, and finally the level number at which the input-output pair is connected. For example, the

command:

**S!!

might have the following two substrings at the beginning of its response:

**x01, 12, 1 x02, 02, 1!!

37

Page 44

SIERRA VIDEO SYSTEMS

This indicates that output 1 is connected to input 12 on level 1, and that output 2 is connected to

input 2 on level 1.

The number of digits used for each number is generally the maximum number of digits ever

required for that particular switcher. Thus, a switcher with between 10 and 99 inp uts would use

two digits for the input number, and a switcher with less than 10 levels would use one digit for the

level number.

“C”: Clear Matrix

Use command C to request that the switcher matrix be cleared so that all outputs are

disconnected from inputs (in switchers where this is possible) or else all outputs at all levels have

input 1 as their source. This command can take several seconds to execute (depending on the

size of the switcher matrix). In order to help ensure that this command isn’t accidentally executed,

it requires four additional characters following the “C” character, to spell out the word “CLEAR” in

full. For example, the command:

**CLEAR!!

would clear the matrix and when finished — the following response would be generated:

**OK!!<CR>

“K”: Set Passw ord

The command "K" is followed by a password, which may be 0 to cancel the previous password,

thus causing no password to be specified, or, it may be a value between 1 and 9999 to supply a

password, which remains in effect until another password (or password 0) is supplied in another

“K” command. The password is stored by the router under the remote address specified using an

“M” command, or under the control portís remote address if an “M” command wa s not specified

before the “K” command in the same command string as the “K” command. The password that is

set remains in effect until another “K” command is received from the same remote address.

It would be used to establish a password for a remote address, to be used for such things as

locking and unlocking outputs and modifying the router configuration. When the router receives a

protected command (one which requires use of a password) from a remote a ddress, it compares

the current password for that remote address with the password required to execute the protected

command. Protected commands consist of many of the “G” commands that change router

configuration, as well as take and salvo trigger commands when the output to be taken is locked.

In the former case, the administrator password is the one that must be sent in the “K” command

to permit the router configuration to be changed, while in the latter case the password that was

used to lock the output is the one that must be sent in the “K” command to permit the take to

occur.

Refer to the “B” command and the “G ADMIN_PASSWORD” command (in a separate document)

for more information.

For example, the command:

** M197 K1777 !!

38

Page 45

GENERIC PROTOCOL

requests that password 1777 be stored as the current password for remote address 197. The

command:

** M197 Y7,9 !!

requests that output 7 be connected to input 9, using the password stored for remote address 197

as the output lockout override password. The take will succeed if output 9 is either not locked or

is locked with password 1777. Otherwise, the take will fail.

“M”: Set Remote Address

The command "M" is followed by a remote address value, and it sets the remote address to be

used by all remaining commands in the current command string. This command is supported on

larger routers. It would be used when a client/server software system on a router control p ort

permits multiple remote users to send commands to the router through that control port. In such a

system, the server software that talks to the control port can insert an “M” command at the