Page 1

EGL-12VX Oil-less Compressor

2018 USER MANUAL/Installation Instructions

1953 W. Gulf To Lake Hwy, Lecanto, FL 34461

Toll Free: 800-240-5677 FAX: 352-513-4801

Email Address:

SierraDentalProducts@Outlook.com

Website:

www.Dentalvacuums.com

Page 2

TABLE OF CONTENTS

Cover

Congratulations

Customer support

Warranty Policy

Safety

Safety Continued

System Layout

System Layout Cont.

Specifications

Installation

Installation Cont.

Start-up Procedure

Preventative Maintenance

Maintenance Cont.

Troubleshooting

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

On the Purchase of your Eagle 12 VX oil-less dental compressor. Our Eagle 12 VX

oil-less dental compressors provide clean dry air to each chair

flawlessly, requiring less maintenance than traditional compressors. Now that’s

peace of mind you can stand behind! We are certain you will love your new product!

If you are not satisfied 100% with this products please reach out and let us know,

we are successful because of your FEEDBACK!

800-240-5677

Email: sierradentalproducts@outlook.com

2

Page 3

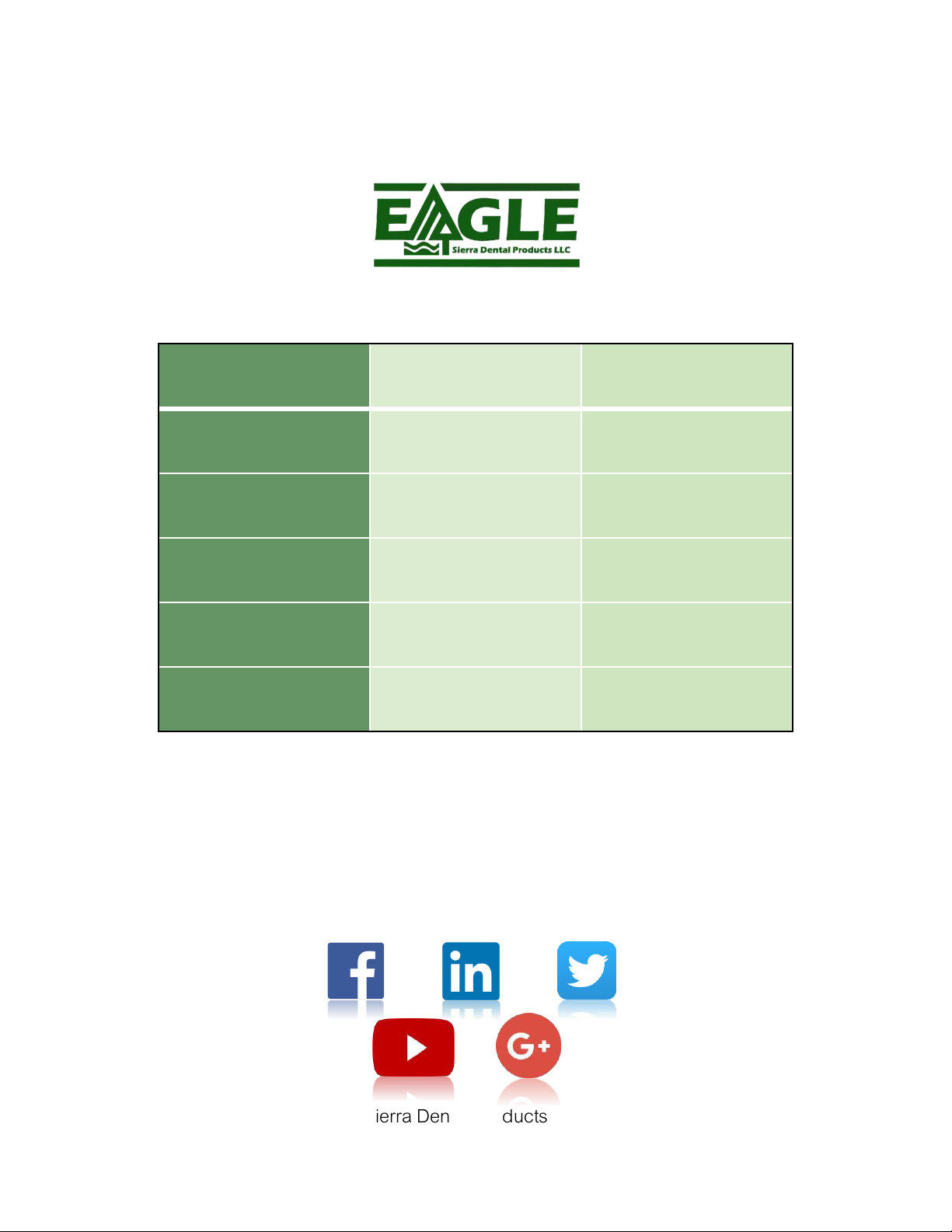

CUSTOMER SUPPORT

“We are happy to help you with any questions or concerns you

may have about your Eagle VX dental compressor”

Contact Us 24/7 We are here for you!

NAME

Karen Bennett

Chuck Bennett

David Rolerad

Matthew Ball

Toll Free

ROLE NUMBER

Owner

Owner/Engineer

Owner/Quality control

Operations Manager

24/7

(352) 527-1975

(352) 527-1975

(603) 493-3635

(352) 201-2770

(800) 240-5677

SierraDentalProducts@outlook.com

Look for us…

DentalVacuums.com

Sierra Dental Products LLC

1953 W. Gulf to Lake Hwy

Lecanto, FL 34461

on social media!

3

Page 4

WARRANTY POLICY

Sierra Dental Products Limited Warranty

Warranty for the EAGLE12 VX oil-less compressor is limited to the original

purchaser of the unit. Sierra Dental Products is only obligated under this warranty

to the repair or replacement of defective parts or materials. The defect(s) must be

reported to Sierra Dental Products within the valid warranty period.

Sierra Dental Products will examine the product to determine if the parts are

defective. Products that have been abused, neglected, or damaged by being

improperly installed/maintained are not covered by this warranty. We are not

responsible for work performed on the unit by any unauthorized service agents.

Warranty Period

Warranty is valid only with the return of the warranty card

purchase for a period of 3 years.

within 30 days of

Warranty Service and Return Policy

To obtain warranty service, product must be returned to Sierra Dental Products for

examination at the purchaser’s expense. All returns must be authorized and a

return material authorization (RMA#) number must be obtained from Sierra Dental

Products. Returned units must be properly packaged for shipping. We are not

responsible for shipping damages or shipping charges. Sierra Dental Products

will, at their discretion, repair or replace defective parts.**PLEASE NOTE** there is

a 25% re-stocking fee on all returns.

4

Page 5

SAFETY

Use of the Eagle VX not in compliance with the

instructions specified in this manual may result in

permanent failure and voided warranty of the unit.

WARNING

To prevent fire or electrical shock, do

not expose this unit to rain or

moisture, excessive heat or improper ventilation.

ATTENTION USERS

Alerts users of important operating

and maintenance instructions. Read

carefully to avoid any problems

Warns users of a potentially hot

surface and a danger of burns

Warns users that uninsulated voltage

is present and can cause electric

shock

5

Page 6

SAFETY CONTINUED

1. IMPORTANT - This equipment:

a) Has hot, electrical, and moving parts;

b) May start or stop automatically, depending on the tank’s pressure or the tripping of electrical

protection elements;

c) May cause mechanical or electrical interferences in nearby equipment;

d) Must not be operated in places where non-authorized people, children, or animals may have

access;

e) Requires an authorized person to supervise its use and ensure proper maintenance;

f) Must be installed and operated in areas well ventilated and protected against humidity and

water;

g) Must be installed and operated in areas that do not exceed 104 degrees Fahrenheit

2. Never exceed the maximum pressure of 115 psi.

3. Before any maintenance, be sure the equipment is unplugged and not energized.

4. Never change the adjustment of the safety valve or pressure switch. They are factory regulated and any

adjustments out in the field could void your warranty. If any adjustments to the pressure switch is

needed, call your authorized dealer for Sierra Dental Products.

5. Never perform welding jobs or repairs on the air pressure tank because this can affect its resistance or

disguise more serious problems. If there is any leakage, crack, or corrosion, immediately stop operating

the equipment and contact your authorized dealer for Sierra Dental Products.

6. Air compression is a heat generating process. The pump unit and tubes are subject to high

temperatures. Therefore, one must be careful when handling them in order to avoid burns.

7. Before connecting the compressor to a power supply, verify that all electrical fittings are tight.

8. Never use solvents to clean your compressor.

1. The use of solvents or paint accumulation may cause explosion risks and irreversible damage

to the product in general. Cleaning products and the environment may not contain solvents.

.

9. Do not remove the attached accessories when the compressor is pressurized. Do not clean or touch

the electric components without unplugging the compressor from the electrical power supply. Not

following the orientations may cause physical and material damage.

10. In case of any irregularities with the equipment, stop operating it immediately and contact your

authorized dealer for Sierra Dental Products.

6

Page 7

Inlet Filters (x4)

SYSTEM LAYOUT

Compressor heads

Pressure switch

On/off switches

Low voltage control box

Power cord

Desiccant dryer

Tank

Remote wires

Drain petcock

Air muffler & Auto purge

Purge silencer

½” Discharge connection

Purge shut off valve

7

Page 8

Fan shroud

Coalescing filter

SYSTEM LAYOUT

Handle

Pressure switch

Stainless steel braided

air hose

Rubber feet

ASME Safety valve

Pressure gauge

Tank inlet check valve

8

Page 9

SPECIFICATIONS

SITE REQUIREMENTS

Voltage 230 V AC

Circuit breaker rating 20 Amp

Minimum wire size 14 Gauge

Minimum trunk line size ½”

Max ambient temp.

Minimum ambient temp.

104° F

41° F

This equipment must be installed in a well ventilated mechanical room to

prevent over heating and failure not covered by the warranty.

Description Specification

Model # EGL-12VX

Max users 6

Air dryer Yes

Number of heads 2

Total horsepower 2

CFM 8.75

Tank gallons 27 g

Voltage 230 V AC

Amps 14

Decibels 74

Weight 201 lbs

Height 32”

Width 37”

Depth 24”

9

Page 10

INSTALLATION

1. Location: Install the compressor in a covered, well ventilated area, free of dust, gases,

toxic gases, humidity, or any other kind of pollutant. The maximum ambient

temperature recommended during operation is 104 degrees Fahrenheit.

a. IMPORTANT: Avoid installation in small places such as a storeroom or closet..

2. Position: Mount at least 32 inches (800mm) from any obstacle, to allow good ventilation

during operation and to make maintenance easier.

a. Compressor Installation: When connected to the air network,

connection must be joined by means of a hose or expansible gaskets

charges, thermal expansion, piping’s weight, mechanical and thermal shocks or

obstructions are not transmitted to the air tank. Physical damage to the

compressed air tank may occur if the above warnings are not followed.

3. Foundation/Floor: The compressor must be placed on a concrete base, which must be

able to bear the equipment’s weight. The equipment must be level. The compressor is

equipped with rubber feet (Assembled by installer)

4. Electric Connection:

a. Consult a specialized electrician to evaluate the electrical power supply and to

select the adequate protections and input devices, and to perform the

installation service.

the discharge

so that the

10

Page 11

INSTALLATION

5. The electrical input wires must be in accordance to the motor power, voltage and

distance from electrical energy source.

6. Before installing the product, verify that the product voltage is compatible to the local

electrical power supply (230 Volts plus or minus 10%) – Use of a Buck Booster may

be necessary if voltage is inadequate.

7. In order to avoid electrical shock, a grounding installation must be utilized.

8. For your safety, a circuit breaker/fuse must be installed.

9. Grounding Instructions: This product must be grounded in the event of an electrical

short circuit or insulation

providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire. Ensure that the product is properly installed and grounded in

accordance with all local codes and regulations.

10. WARNING

electric shock. If it is necessary to replace or repair both the cable and the connector,

do not connect or join the grounding wire to the neutral wire or any other. The green

wire, with or without yellow stripes, is only to the grounding function. In case of doubts

regarding the grounding information or whether the product is properly grounded,

make sure you contact a qualified electrician to verify the connections.

11. The thermal protector is located inside the electrical motor. This will shut the electric

: The incorrect installation of the grounding wire connector may result in an

failure, the grounding reduces the risk of electric shock by

motor off automatically.

-INSTALLATION EXPENSES ARE PURCHASER’S RESPONSIBILITY

11

Page 12

START-UP PROCEDURE

After installation is complete, perform the following start up procedure:

1. Completely open discharge connection (ball valve located on the handle)

2. Turn both of the compressor heads on. The compressor will automatically turn off when the

pressure gauge shows maximum pressure around 115 psig.

3. The compressor will automatically restart when the pressure gauge shows pressure around 85

psig.

Your EAGLE Compressor is ready to operate. Check if there is any leakage. You can do this by filling

the compressor up all the way (115psi) Do not use any compressed air. Wait about 15 minutes and

make sure the pressure has not dropper more than 5 psi. In case there is any loss, eliminate it before

proceeding.

12

Page 13

PREVENTATIVE MAINTENANCE

In order to guarantee the compressor’s perfect operation and to extend its life, please follow

these recommendations below:

1. Monthly

a. Check the operation of the pressure switch (85-115psi) by performing the start-

up procedure

b. Drain the condensed water from the tank, through drain petcock (The tank’s

pressure must not be greater than 10 psig)

c. Check for abnormal noise or vibration. If the problem persists after the following

corrective actions are taken, contact your local authorized dealer for Sierra

Dental Products

d. Check the intake filters. When an intake filters are clogged it is necessary that

they be replaced. Contact your local authorized dealer for Sierra Dental Products

for replacement filters – Do Not Wash the Filter Element

2. Quarterly

a. Change the intake filter elements & coalescing filter every three hundred (300)

hours or quarterly (whichever occurs first)

b. Clean the compressor’s external surface with neutral detergent and a wet cloth

3. Annually

a. Have the pressure switch, pressure gauge and ASME safety valve calibrated,

either by an official institution or according to the Local Technical Regulations.

This operation must be carried out by a device not coupled to the tank.

13

Page 14

PREVENTATIVE MAINTENANCE

Date of

Working

Ambient

Additional

Servicer

Signature

Services Provided

Service

Hours

Temp.

Remarks

14

Page 15

TROUBLESHOOTING

Check the installation and/or wait for the electric supply

Tank’s pressure goes up too fast or

High temperature of the compressor

Compressor operates uninterruptedly

PROBLEM PROBABLE CAUSE WHAT TO DO

Motor doesn’t start or doesn’t restart

Reduced air production (pressure

gauge keeps showing a lower

pressure than that of the job)

The compressor unit overheats

Voltage drop or electric supply is out

Damaged motor

Thermal protector went off

Tank is full of air

Check valve does not seal because of impurities

The demand is above the compressor’s capacity

Filter element is clogged Replace filter element(s)

Air leakage in the compressor Re-fasten bolts and/or fittings (See Table 3)

High ambient temperature (MAX 104 degrees

Fahrenheit)

Incorrect rotation direction (counter-clockwise)

Demand above compressor’s capacity

Filter element is clogged Replace filter element(s)

Contact your local authorized dealer for Sierra Dental

Motor will re-start as soon as temperature decreases. If

this continues to happen, contact your local authorized

dealer for Sierra Dental Products, LLC

Motor will re-start as soon as pressure in the tank

Contact your local authorized dealer for Sierra Dental

Evaluate the compressor’s capacity, if necessary to

Improve installation conditions (climate control,

Contact your local authorized dealer for Sierra Dental

Evaluate the compressor’s capacity, if necessary to

stabilization

Products, LLC

decreases to 85 psig

Products, LLC

verify

ventilation, etc…)

Products, LLC

verify

Premature wear of the compressor

unit internal components

Abnormal noise or vibrations

Motor overheats

many frequent starts (the normal

number of starts is roughly 6/hr)

unit

Insufficient pressure for the job

Operating in a non-adequate environment

Loose fastening elements Find and re-fasten them

Loose fan Re-fasten it

Compressor installed incorrectly

Damaged connecting rod(s) bearing and rings See Preventative Maintenance Section

Deficient or inadequate electric power supply

Water excess in the tank Drain the tank with the petcock

Too much dust on the pump Clean it externally

High ambient temperature (MAX 104 degrees

Fahrenheit)

Filter element is clogged Replace filter element(s)

The system’s demand is above compressor’s capacity Evaluate and verify the compressor’s stated capacity

Pressure regulator is not adjusted

Improve local conditions and/or contact your local

authorized dealer for Sierra Dental Products, LLC

Contact your local authorized dealer for Sierra Dental

Products, LLC

Consult a specialized electrician to check the power

supply

Improve installation conditions (climate control,

ventilation, etc.)

Contact your local authorized dealer for Sierra Dental

Products, LLC to adjust it

15

Loading...

Loading...