Page 1

Instruction Manual SmartTrak® 50 Series

®

SmartTrak

Economical/OEM Digital Gas Mass Flow Control up to 200 slpm (nlpm)

50 Series

Instruction Manual

IM-50, Rev. I, June 2017

IM-50 1

Page 2

Instruction Manual SmartTrak® 50 Series

GLOBAL SUPPORT LOCATIONS: WE ARE HERE TO HELP!

CORPORATE HEADQUARTERS

5 Harris Court, Building L Monterey, CA 93940

Phone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

www.sierrainstruments.com

EUROPE HEADQUARTERS

Bijlmansweid 2 1934RE Egmond aan den Hoef

The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Second Floor Building 5, Senpu Industrial Park

25 Hangdu Road Hangtou Town

Pu Dong New District, Shanghai, P.R. China

Postal Code 201316

Phone: + 8621 5879 8521 Fax: +8621 5879 8586

IMPORTANT CUSTOMER NOTICE: OXYGEN SERVICE

Sierra Instruments, Inc. is not liable for any damage or personal injury, whatsoever, resulting from the use of Sierra

Instruments standard mass flow meters or controllers fo r oxygen gas. You are responsible for determi ni ng if this

mass flow meter or controller is appropriate for your oxygen application. You are responsible for cleaning the mass

flow meter or controller to the degree requir ed for your oxygen flow application.

© COPYRIGHT SIERRA INSTRUMENTS 2016

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

translated into any human or computer language, in any form or by any means, electronic, mechanical, manual, or

otherwise, or disclosed to third parties without the express written permission of Sierra Instruments. The information

contained in this manual is subject to change without notice.

TRADEMARKS

®

SmartTrak

listed in this manual are trademarks or trade names of their respective manufacturers.

50 Series is a Registered Trademark of Sierra Instruments, Inc. Other product and company names

IM-50 2

Page 3

Instruction Manual SmartTrak® 50 Series

Table of Contents

Chapter 1: Introduction .............................................................................................................................. 4

Chapter 2: Installation ................................................................................................................................. 9

Before You Begin Installation ..................................................................................................................... 9

Installing the Instrument—Plumbing ....................................................................................................... 10

Compression Fittings ..................................................................................................................... 10

VCO Fittings .................................................................................................................................. 11

VCR Fittings .................................................................................................................................. 11

1/4 Inch Female NPT .................................................................................................................... 11

Installing Your Instrument—Mechanical Mounting ................................................................................ 12

Installing Your Instrument—Electrical Connections .............................................................................. 12

Instrument Power: ..................................................................................................................................... 13

Chapter 3: Digital Operation .................................................................................................................... 15

Loading the SmartTrak® 50 Series Software ........................................................................................... 16

Connecting SmartTrak® 50 Series to Your Computer ............................................................................ 16

Chapter 4: Analog Operation ................................................................................................................... 26

Setpoint Adjustment .................................................................................................................................. 28

Zero Adjustment ........................................................................................................................................ 28

Over-Range Condition ............................................................................................................................... 29

Chapter 5: Technical Support & Service ................................................................................................ 30

Appendix A: Gas Tables & K-Factor Calculations .................................................................................. 33

Appendix B1: 50 Low Flow (to 50 slpm) Product Specifications .......................................................... 37

Appendix B2: 50 Medium Flow (to 200 slpm) Product Specifications ................................................. 40

Appendix C: Warranty Policy…………………………………………………………………………….………43

IM-50 3

Page 4

Instruction Manual SmartTrak® 50 Series

g

Chapter 1: Introduction

This instruction manual is your guide to the SmartTrak

®

50 Series. Visit the Sierra Instruments

website www.sierrainstruments.com/products/50series.html for more information about this

product.

Using This Manual

This manual is organized into five chapters:

Chapter 1: Introduction and Theory of Operation.

Chapter 2: Installation, Plumbing & Wiring instructions.

Chapter 3: Digital Operation

Chapter 4: Analog Operation

Chapter 5: Technical Support and Service.

There are also 4 Appendices:

Appendix A: Conversion Formula and Gas Tables.

Appendix B1: Low Flow Product Specifications

Appendix B2: Medium Flow Product Specifications

Appendix C: Warranty Policy

Throughout this manual, we use the word instrument as a generic term to represent the

SmartTrak® 50 Series mass flow meters and controllers.

Safety Information!

Caution and warning statements are used throughout this book to draw your attention to

important information.

WARNING!

CAUTION! OR IMPORTANT

NOTE

This statement appears with information that

is important to protect people and equipment

from damage. Pay very close attention to all

s that apply to your application.

warnin

IM-50 4

This statement appears with information that is

important for protecting your equipment and

performance. Read and follow all cautions that

apply to your application.

Page 5

Instruction Manual SmartTrak® 50 Series

Receipt of Your Instrument

When receiving the instrument, carefully check the outside packing carton for damage that may

have occurred during shipment. If the carton is damaged, notify the local carrier and submit a

report to the factory or distributor. Remove the packing slip and check that all ordered

components are present and match your specifications. Make sure any spare parts or accessories

are not discarded with the packing material. Do not return any equipment to the factory without

first contacting one of Sierra’s Technical Support Centers:

USA (Headquarters) Customer Service:

TOLL FREE: 800-866-0200

PHONE: +1-831-373-0200

FAX: +1-831-373-4402

EMAIL: service@sierrainstruments.com

European Customer Service:

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Customer Service:

PHONE: + 8621 5879 8521

FAX: +8621 5879 8586

EMAIL: www.sierra-asia.com

IM-50 5

Page 6

Instruction Manual SmartTrak® 50 Series

Definitions Used In This Manual

The following terms are used frequently in this manual. They are presented here with their

definitions for your information.

Setpoint—The command or control signal supplied to a flow controller is called the

setpoint. The controller will maintain the flow at this value.

Full scale—The highest flow that an instrument will measure within its specified

accuracy. It is often possible for an instrument to measure a flow beyond its full scale

(FS) value, but the accuracy of this measurement may be outside of published

specifications.

LFE—Laminar Flow Element (LFE) or bypass generates pressure drop forcing a small

fraction of the total flow to pass through the sensor capillary tube.

IM-50 6

Page 7

Instruction Manual SmartTrak® 50 Series

Fig

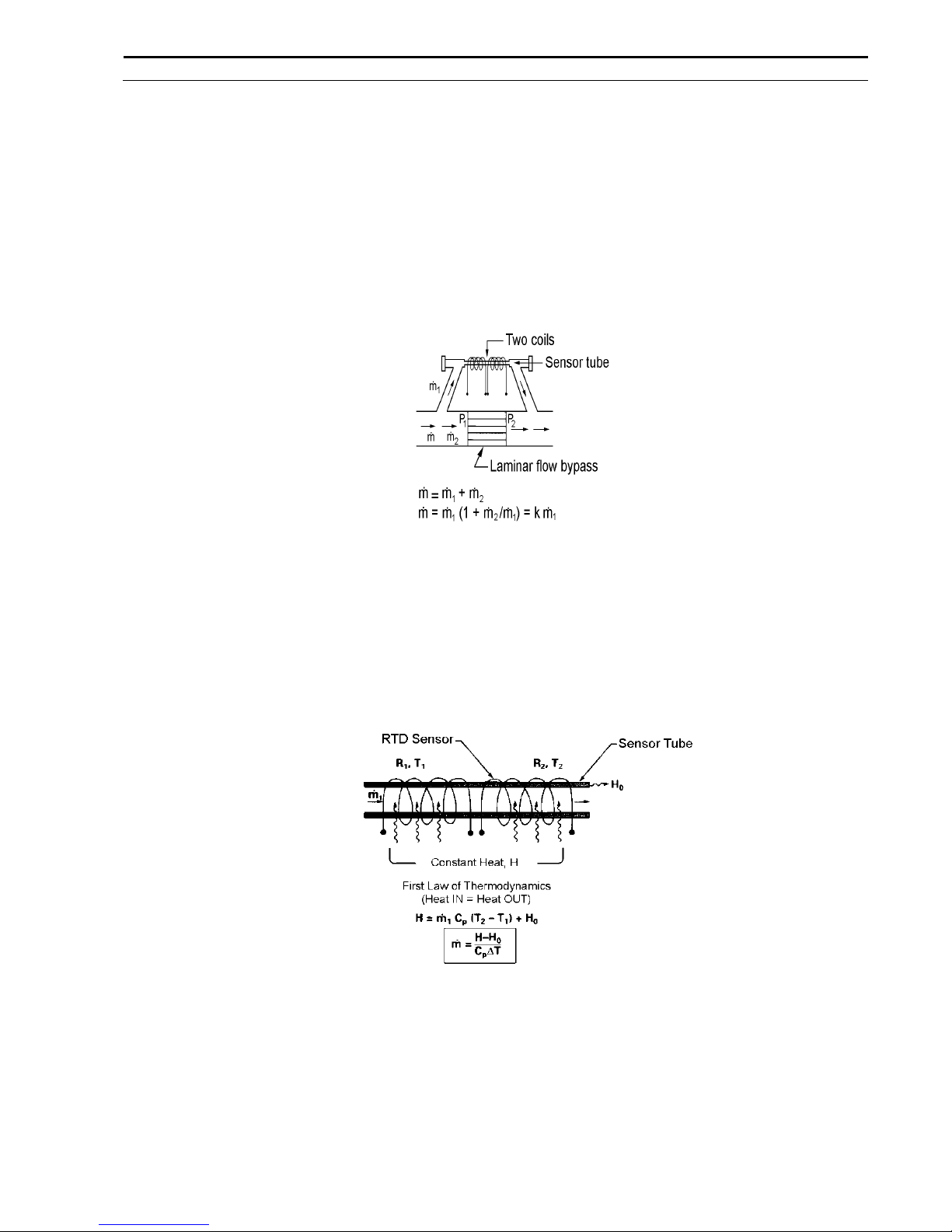

The SmartTrak® 50 Series Flow Sensing Principle

The operating principle of the SmartTrak® 50 Series instruments is based upon heat transfer and

the first law of thermodynamics. During operation process gas enters the instrument’s flow body

and divides into two flow paths, one through the sensor tube and the other through the laminar

flow bypass. The laminar flow bypass (often called LFE for “laminar flow element”) generates a

pressure drop, P1–P2, forcing a small fraction of the total flow to pass through the sensor tube

(m1).

ure 1-1. Flow Paths through the Instrument

Two resistance temperature detector (RTD) coils around the sensor tube direct a constant amount

of heat (H) into the gas stream. During operation, the gas mass flow carries heat from the

upstream coil to the downstream coil. The resulting temperature difference (∆T) is measured by

the SmartTrak® 50 Series microprocessor. From this, SmartTrak® 50 Series calculates the output

signal. Since the molecules of the gas carry away the heat, the output signal is linearly

proportional to gas mass flow.

Figure 1-2. Flow Measuring Principle

IM-50 7

Page 8

Instruction Manual SmartTrak® 50 Series

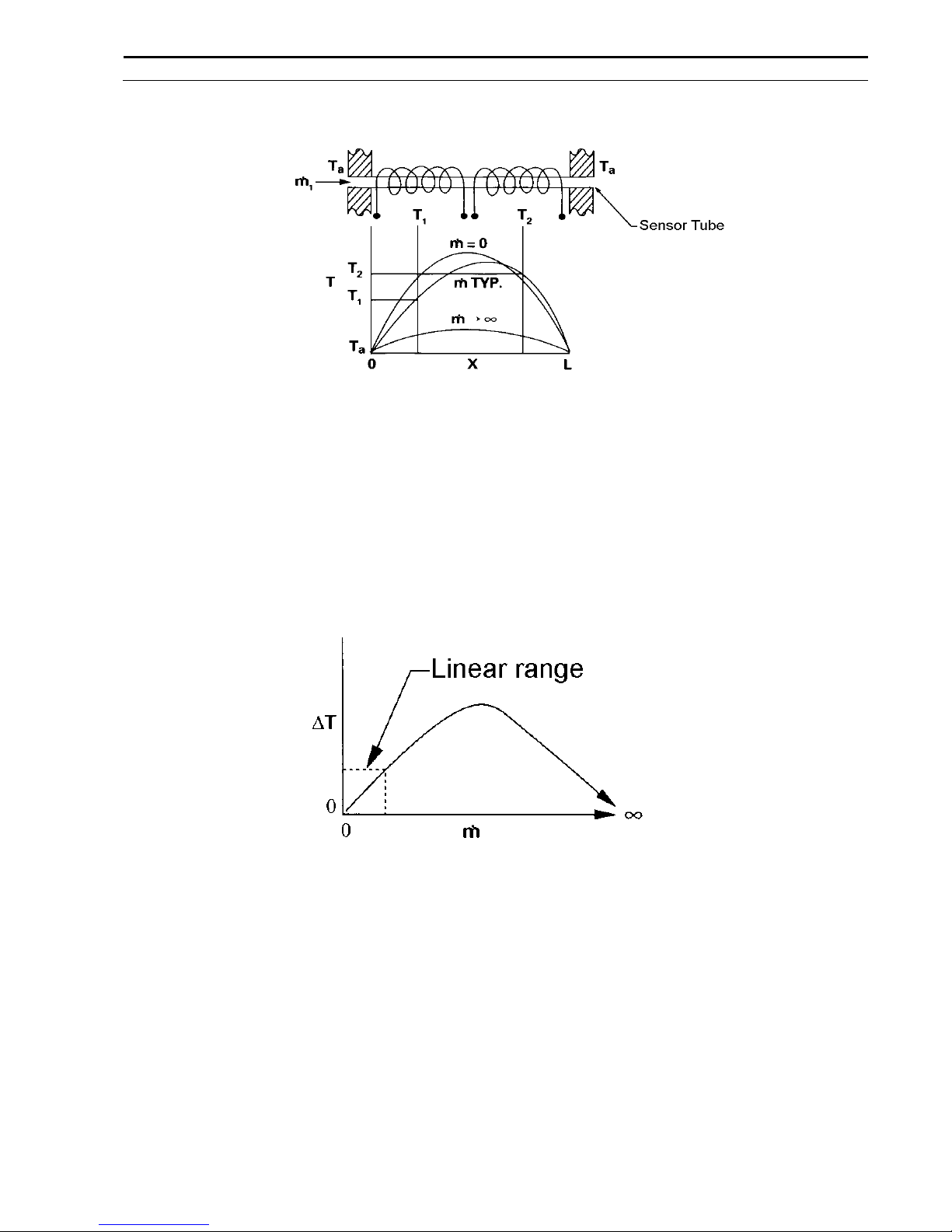

Fig

Figure 1-3. Sensor Temperature Distribution

Figures 1-2 and 1-3 show the mass flow through the sensor tube as inversely proportional to the

temperature difference of the coils. The coils are legs of a bridge circuit with an output voltage in

direct proportion to the difference in the coils’ resistance; the result is the temperature difference

(∆T). Two other parameters, heat input (H) and coefficient of specific heat (Cp) are both constant.

Through careful design and attention to these parameters, this output signal is made linear over the

transducer’s normal operating range (Figure 1-4). As a result, the measured flow through the

sensor tube is directly proportional to the gas flow in the main body.

In SmartTrak

®

50 Series mass flow controllers, the gas which flows through the monitoring

section is precisely regulated by the built-in electromagnetic valve. The normally closed valve is

similar to an on/off solenoid valve, except that the current to the valve coil, and hence the

magnetic field, is modulated so that the ferromagnetic valve armature, or valve plug, assumes the

exact height above the valve’s orifice required to maintain the valve’s command flow (set point).

The result is excellent resolution.

View an animated tutorial on the concepts discussed in this section at:

http://sierratechsupport.com/video/flow_control.html

IM-50 8

ure 1-4. Linear Range of the Transducer’s Output Signal

Page 9

Instruction Manual SmartTrak® 50 Series

Chapter 2: Installation

Before You Begin Installation

Before installing the instrument, ensure that the installation site conforms to the

specific operating parameters recorded on the instrument’s Data Label. The Data

Label is located on the back of the instrument electronics enclosure. This is

critical because each instrument is configured for a specific application range.

Please review the gas, the mounting orientation, the maximum flow range, the

Warning!

Injury can result if line

pressure exceeds the

maximum rating of

145 psig (10 barg).

inlet and outlet pressure and the operating temperature. The line pressure should

not exceed 145 psig (10 barg). The temperature should not exceed 122°F (50°C).

The minimum operating temperature is 32°F (0°C) and ambient temperature is 050°C. If your application exceeds any of these parameters, contact your Sierra

Sales Agent before installation. You may also contact one of Sierra’s Technical

Support Centers listed on Page 5 of this manual.

Installation Check List

1. Double-check to be sure that the O-ring material used in your instrument is

compatible with the gas to be measured. The O-ring material used in your

SmartTrak® 50 Series is Viton. See Appendix A for a table of elastomer

compatibility with a wide variety of gases.

2. Sierra strongly recommends you install an in-line filter upstream of the

instrument. Recommended filter size: 10 micron. A 10 micron filter will

eliminate the possibility of sensor tube clogs, maximizing the life of the unit and

accuracy of the calibration. A 10 micron filter is available from Sierra as an

accessory. See Appendix B or contact your local Sierra distributor.

3. Do not place the instrument in areas subject to sudden temperature changes,

excessive moisture or near equipment radiating significant amounts of heat.

Be sure to allow adequate space for cable connectors and wiring.

4. For controllers, use a properly sized pressure regulator. Make sure the

pressure regulator is not too small or too big. There can be no restrictions (such as

valves, tubing or pipe internal diameters, reducers, etc.) upstream or downstream

of the controller with a dimension that is less than the valve orifice diameter. To

determine orifice diameter, consult the factory for further information. If

restricted, controller will not reach full scale.

IM-50 9

Page 10

Instruction Manual SmartTrak® 50 Series

5. Output Signals: The 50 Series has RS-232 communications as the standard

configuration, with optional RS-485, 0-5 VDC or 4-20 mA. The output signals

specified at time of order will be indicated on the data label.

6. The instrument has specific power supply requirements. See the table later in

this chapter for a complete listing of power requirements.

Installing the Instrument—Plumbing

SmartTrak® 50 Series instruments are supplied with

compression, VCO®, VCR®, Festo®-type push-in or female

NPT process connections. To ensure a successful installation,

inlet and outlet tubing should be clean prior to plumbing the

instrument into the system. The shipping caps covering the

inlet/outlet fittings should not be removed until immediately

before installation.

Follow the installation instructions that are applicable to your instrument’s process

connection. Ensure that the tubing is free from burrs or sharp rims that may result from

cutting.

CAUTION!

Before use, all plumbing should be checked carefully for leaks, especially at

the connecting fittings. All instruments are leak-tested prior to shipping. It is not a

requirement to leak test your instrument. Do not use liquid leak detectors such as Snoop® to

search for leaks inside or outside the SmartTrak® 50 Series. Instead, monitor pressure

decay.

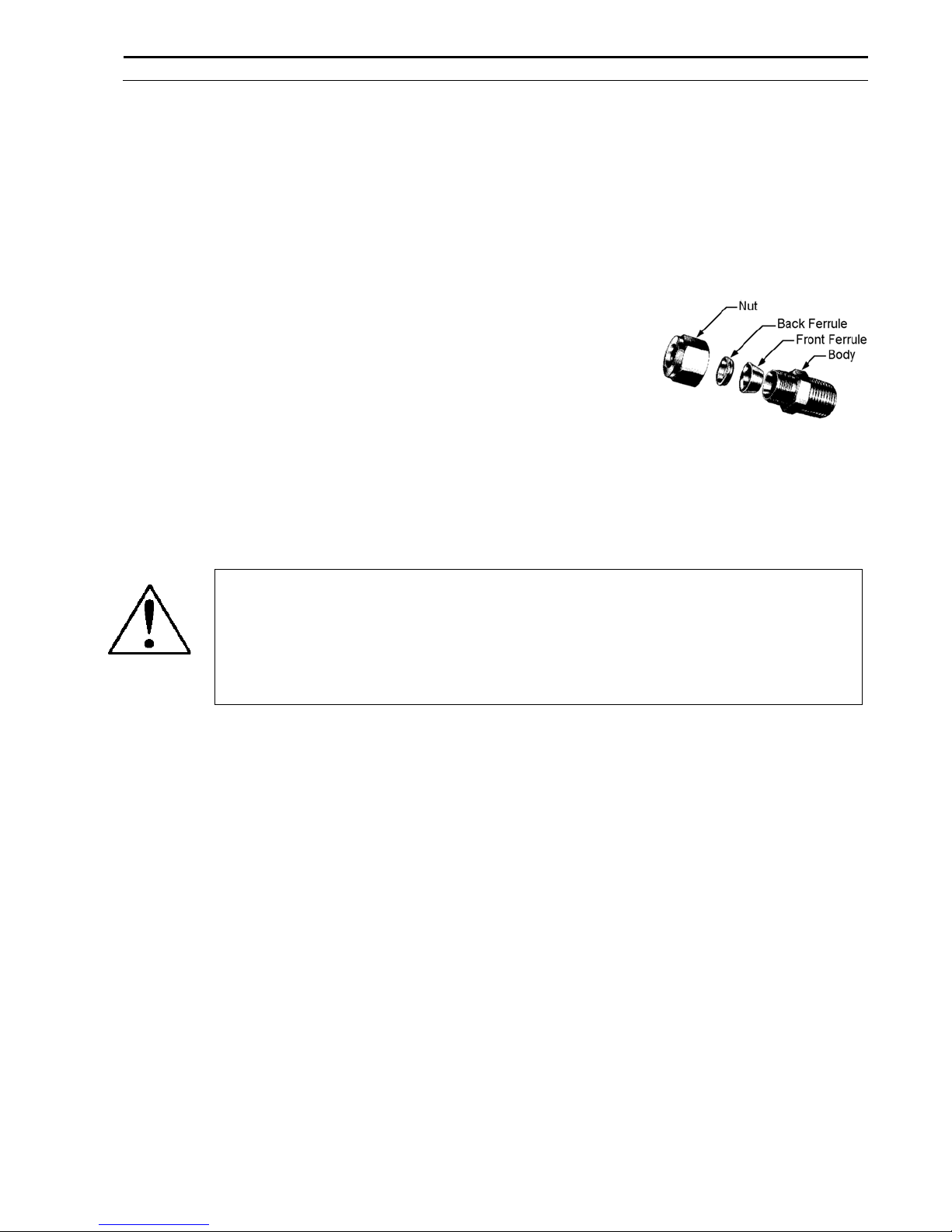

Compression Fittings

1. Position the instrument with the flow direction arrow pointing in the direction of

flow.

2. Verify the position of the front and back ferrule. Insert the tubing into the fitting.

Be sure that the tubing rests firmly on the shoulder of the fitting and that the nut is

finger-tight. Scribe the nut at the six o’clock position.

3. While holding the fitting body steady with a backup wrench, tighten the nut 1-1/4

turns, watching the scribe mark make one complete revolution and continue to the

nine o’clock position. For 1/8-inch fittings, tighten only 3/4 turns from fingertight. DO NOT OVER-TIGHTEN!

4. If you use flexible tubing (Example: Polyflow) use an “Insert” (see

www.swagelok.com)

5. Check the system’s entire flow path thoroughly for leaks. Do not use liquid leak

detectors on or near the unit. Exposing the instrument to leak detector fluid may

cause damage.

IM-50 10

Page 11

Instruction Manual SmartTrak® 50 Series

VCO Fittings

1. Position the instrument with the flow direction arrow pointing in the direction of

flow.

2. Tighten the nut finger-tight, and then 1/8 turn tighter with a wrench. Do not over-

tighten!

3. Check the system’s entire flow path thoroughly for leaks. Do not use liquid leak

detectors on or near the unit. Exposing the instrument to leak detector fluid may

cause damage.

VCR Fittings

1. Position the instrument with the flow direction arrow pointing the direction of

flow.

2. Install new gaskets that are compatible with the gas to be used.

3. Tighten the nut finger-tight, and then 1/8 turn tighter with a wrench. Do not over-

tighten!

4. Check the system’s entire flow path thoroughly for leaks. Do not use liquid leak

detectors on or near the unit. Exposing the instrument to leak detector fluid may

cause damage.

1/4 Inch Female NPT

1. Position the instrument with the flow direction arrow pointing the direction of

flow.

2. Apply high quality Teflon tape to the male NPT fitting. Alternatively, use a high

quality paste pipe thread sealant suitable for the application and gas, and apply

this compound to the inlet and outlet fittings. Avoid getting the tape or the thread

sealant onto the first two threads to keep it out of your process gas.

3. Tighten each fitting by hand. Then, tighten no more than one (1) turn. Do not

over-tighten.

4. Check the system’s entire flow path thoroughly for leaks. Do not use liquid leak

detectors on or near the unit. Exposing the instrument to leak detector fluid may

cause damage.

IM-50 11

Page 12

Instruction Manual SmartTrak® 50 Series

Installing Your Instrument—Mechanical Mounting

Mounting Your Instrument

The base plate or bottom of the instrument has four mounting holes. Two are SAE thread

and two are metric thread. For location and dimensions, please see Appendix B.

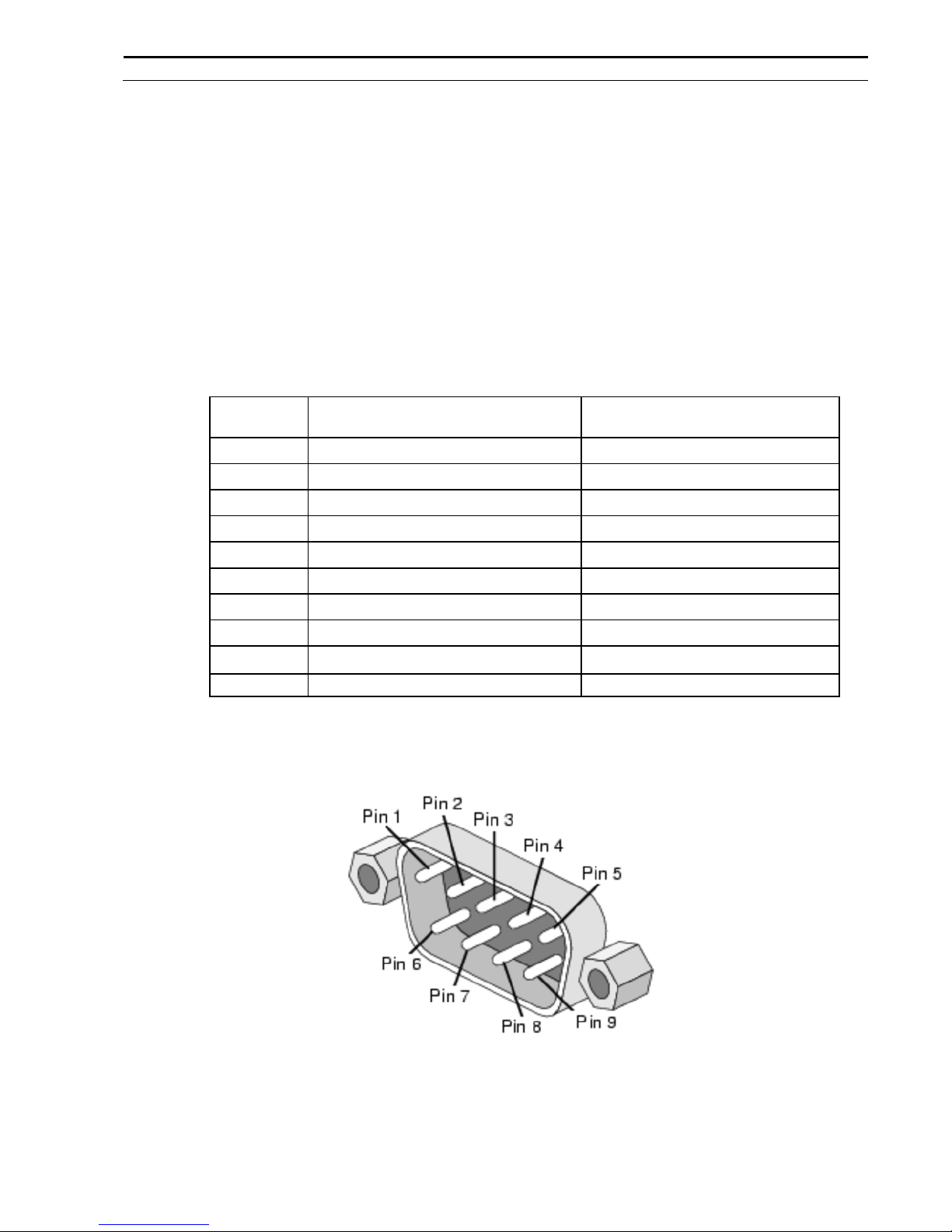

Installing Your Instrument—Electrical Connections

All electrical connections for your SmartTrak® 50 Series instrument can be made on

either side panel. See Figure 2-2 for the pinout

DB9 Pin-out locations on instrument. There are two DB9 connectors, one on each side of the enclosure.

50 Series

DB9 Description

1 4-20 mA / 0-5 VDC Output

2 4-20 mA / 0-5 VDC Output Return

3 4-20 mA / 0-5 VDC Setpoint in

4 4-20 mA / 0-5 VDC Setpoint Return

5 +24 VDC in/Power Input (+)

6 Power Return (-)/RS 232 Ground

7 N/C (RS-485 Bus Isolated Ground)

8 RS-232 Tx (RS-485 Bus B, +, D1)

9 RS-232 Rx (RS-485 Bus A, -, D0)

Shield/Case Earth Ground

Figure 2-2: SmartTrak® 50 Series Connections

Assure block off plate covers unused DB9...

Wire Color in Cable

White

Brown

Blue

Orange

Red

Green

Yellow

Purple

Gray

Shield/Drain Wire

IM-50 12

Page 13

Instruction Manual SmartTrak® 50 Series

Instrument Power:

The SmartTrak® 50 Series requires a 24 VDC power supply (meter can use

15 VDC). Connect power to the 9-pin connector on the side of the

instrument (pins 5 and 6). If you are supplying your own power source, it

must regulate 24 VDC, and supply at least 315 mA (445mA for RS-485

controller) (meter can use 15 VDC, 85 mA) (215mA for RS-485 Meter).

The instrument is polarity sensitive. If you reverse this wiring, the instrument will not be

damaged, but it will not function.

Instrument Grounding:

The SmartTrak® 50 Series has very high levels of RFI and EMI shielding built into the

metal electronics cover (meets or exceeds the CE Standard EN 61326-1; 2006). To

maintain the integrity of this CE rating, it is critical that a path be provided for any residual

internal noise to exit the instrument or it may register on the outputs. Grounding provides

this path.

To properly ground your instrument, secure the chassis to solid earth ground using the

mounting holes on the bottom of the flow body. If the instrument will be used without

permanent mounting (on a laboratory bench, for instance) then connect the shield wire (no

insulation) to earth ground in your facility. If you purchased a Sierra power supply, a

ground wire is provided for your convenience.

CAUTION! This instrument is not a loop-powered device! Do NOT apply power to the 4-

20 mA / 0-5 VDC output or setpoint connections.

Analog Signals:

Output Signal: Measure the current or voltage output signal, 4-20 mA / 0-5 VDC, across

pin 1 (positive) and 2 (negative). The minimum load is 50 Ohms, the maximum load is 500

Ohms.

Setpoint: To transmit an analog setpoint, supply the current signal across pins 3 (positive)

and 4 (negative).

For Digital Communication:

You can communicate with your instrument using the SmartTrak® 50 Series User Software

package and your PC running the Windows operating system. See the pinout on the previous

page regarding the necessary RS connections pending RS-232 vs. RS-485. After consulting the

pinout diagram, plug the DB9 connector into an appropriate serial port on your PC for RS-232.

For an RS-485 instrument you must go through an appropriate RS-232 or USB converter. If you

IM-50 13

Page 14

Instruction Manual SmartTrak® 50 Series

do not have a serial port, use a serial to USB convertor (available at most consumer electronics

stores or from Sierra).

To minimize the potential for RF interference, it is recommended to shield these wires. If you

are making your own cabling, Sierra recommends you use wire that comes shielded. Solder one

end of the shield wire/casing to the DB-9 connector at one end of the wire, so as to allow the

collected interference to dump to earth ground.

Digital RS-232 Communication Connections To DB9 PC Serial Port

50 Series DB9 Pin Connections PC Serial Port DB9 Pin Connections

RS-232 Transmit, Pin 8, Purple DB-9 Pin#2

RS-232 Receive, Pin 9, Gray DB-9 Pin#3

RS-232 Ground, Pin 6, Green DB-9 Pin#5

NOTE:

device or cable is connected. No damage will result, attempt communication after reversal.

Transmit and Receive may need to be reversed, depending in which type of

IM-50 14

Page 15

The Smart-Trak

50 Series is not a

loop-powered

device. Do not

apply power to the

4-20 mA outputs.

Instruction Manual SmartTrak® 50 Series

Chapter 3: Digital Operation

Mass Flow Meter

After your instrument is installed and the system has undergone a complete leak check as

discussed in detail in Chapter 2, follow these steps:

1. Power Up Your Instrument: Apply power to your instrument. See Chapter 2, Figure

®

Mass Flow Controller

2-2: SmartTrak® 50 Series Connections. After a few seconds of warm up, the display

(optional) will turn on.

2. Open the gas supply: SmartTrak® 50 Series MFM is now ready to monitor the gas

mass flow rate. Let the instrument warm up for at least 15 minutes for optimal

performance accuracy.

Your SmartTrak® 50 Series Mass Flow Meter is now ready for use!

After your instrument is installed and the system has undergone a complete leak check as

discussed in detail in Chapter 2, follow these steps:

1. The valve will remain closed until power is supplied and a setpoint is given. The

unit was shipped to you without a setpoint. However, we recommend that you

confirm this yourself, for safety sake. See Chapter 2 for wiring instructions.

CAUTION! Remember that the valve in the SmartTrak

®

50 Series is NOT a guaranteed

positive shut-off device. For dangerous applications, Sierra recommends use of an external

shut-off safety valve. DO NOT LEAVE A SETPOINT APPLIED FOR AN EXTENDED PERIOD

OF TIME TO A CONTROLLER WHEN THE GAS SUPPLY IS SHUT OFF OR BLOCKED.

Damage may result and the instrument will become hot to the touch.

WARNING! If you do not know the setpoint or the valve state of the Mass Flow Controller

before it was shut down, you must assume that the valve will open when power is applied.

TAKE NECESSARY PRECAUTIONS.

2. Power Up Your Instrument: Apply power to your instrument using Sierra’s power

supply or your own input power source. See Chapter 2, Figure 2-2: After a few

seconds of warm up the display (Optional) will turn on.

3. Open the gas supply: SmartTrak® 50 Series MFC is now ready to monitor and

control the gas mass flow rate. Let the instrument warm up for at least 15 minutes for

optimal performance accuracy.

Your SmartTrak® 50 Series Mass Flow Controller is now ready for use!

IM-50 15

Page 16

Instruction Manual SmartTrak® 50 Series

Loading the SmartTrak® 50 Series Software

If you are using your SmartTrak® 50 Series instrument or your computer for the first

time, it is necessary to install the SmartTrak® 50 Series Software into your computer. If

this software is already installed, skip this section.

Each SmartTrak® 50 Series order is shipped with a CD-ROM containing the SmartTrak®

50 Series Software. Locate this disk. At this point, EXIT OUT OF ANY OPEN

APPLICATIONS BEING RUN ON YOUR COMPUTER.

PROCEDURE:

1. Insert the SmartTrak® 50 Series Software CD into your CD-ROM

2. Open “My Computer” on your desktop

3. Open the CD Named: “SmartTrak® 50 Series” on your D-drive

4. Run “setup.exe”

5. Follow the instructions on screen

CAUTION! It is recommended that you do not change the default installation directory

for this software. The default directory is: Program Files. Changing the installation directory

may lead to malfunctions in the software.

Connecting SmartTrak® 50 Series to Your Computer

We suggest you use the Sierra Instruments RS-232 communication cable (part number

C9RS232). This pre-manufactured cable has the correct DB9 connection to mate with all

computer DB9 serial ports, and a DB9 to connect to the instrument.

1. Plug the DB9 connector into an appropriate serial port on your computer (if

you do not have a serial port, use an off-the-shelf USB-to-serial converter

available from most consumer electronics stores or from Sierra).

2. Note the serial port channel number. You can look this up in the ‘System

Properties’ window of your PC. This can be accomplished by right-clicking

on ‘My Computer,’ left-click ‘Properties,’ or in the ‘Control Panel’ under

‘System.’

3. Under the ‘Hardware’ tab, click the button ‘Device Manager.’ Once ‘Device

Manager’ is open, expand the collapsible menu item ‘Ports.’ All available

ports on your computer should be listed. Find which one is the native serial

port on your computer (generally COM1 or COM2), or the USB/serial

converter COM port.

NOTE: If you cannot find the USB/serial converter you installed listed, or it has a yellow

exclamation mark on it, you may have incorrectly installed the driver software. Please refer to the

manufacturer’s instructions on driver installation before proceeding.

IM-50 16

Page 17

Instruction Manual SmartTrak® 50 Series

If you plan to control more than one SmartTrak® 50 Series from your

computer…

If you wish to operate more than one 50 Series at a time, you will need a dedicated COM

port for each, be it native serial or a USB/serial converter. After looking up and recording

which ports are which in ‘Device Manager’ (see last paragraph for review), open up an

instance of the user software for each unit (Example: If you have 5 units, you need to

have 5 instances of the program running at once). Setup communications for each

instance to match the communication type (RS-232 vs. RS-485) for each unit, the port it

is on, and the device address (if necessary).

Once communications are established for each unit individually, you can switch between

instances with mouse clicks to take readings and change settings on multiple units using a

single PC.

NOTE: Computers have limited capacity and computational ability, as well as streaming

speeds; the more instances you run, the slower the response. Please remain patient with

the system, or consider upgrading your PC to handle the load.

If connecting your computer to the SmartTrak® 50 Series creates any confusion, please

contact Sierra Instruments or your IT person for assistance.

Running the SmartTrak® 50 Series User Software

1. Locate the program named “50 Series User Software” and open it.

WINDOWS XP WINDOWS 7

IM-50 17

Page 18

Instruction Manual SmartTrak® 50 Series

You will see the following main screen:

NOTE: Hovering the mouse pointer over any of the input fields and buttons will give you a

description of its purpose.

2. Select ComPort in the menu to set up the ComPort. (See below)

IM-50 18

Page 19

Instruction Manual SmartTrak® 50 Series

3. Select the ComPort pull down menu shown

As shown above, use the pull-down menu to choose the port number that corresponds to the

serial port channel your 50 Series is connected to. Depending on whether the unit is RS-232 or

RS-485, you’ll need to select the proper “ASCII Commands” setting to match as shown above

right.

If your unit is RS-485, you’ll want to match the Device Address, Baud Rate and Parity to that of

your instrument (default settings are shown below). Once you have established communication,

you can change the Device Address, Baud Rate, and Parity to set up the instrument for use on

your RS-485 Bus system.

IM-50 19

Page 20

Instruction Manual SmartTrak® 50 Series

4. Close the window using the X button in the upper right corner of the dialog box. The

communications are set up, and the unit should be communicating with the computer, as evident

by the changing numbers right of the COM1: port in the picture below. If the numbers are not

changing, click ‘Get Parameters.’

RESET NOTE: If you are not able to establish communication with your instrument be sure you have the proper

ComPort selected to match your PC port then hit the “Reset Host Port To Default” button in the Port Dialog Box and

power down your instrument. Next, power up the instrument again and hold the zero pushbutton (located inside your

instruments side plate behind the silver socket head cap screw) for a minimum of one second after powering up your

instrument. This will reset both the host software and your instrument to the default settings. Click on the ‘Get

Parameters’ button and communication should be established.

IM-50 20

Page 21

Instruction Manual SmartTrak® 50 Series

Important Features of the SmartTrak® 50 Series User Software

You can learn more about your unit, including the Serial Number, Firmware Version,

etc., by clicking on the ‘Info’ button.

The final window below will provide control of the system. Click the ‘Adjustments’

button.

IM-50 21

Page 22

Instruction Manual SmartTrak® 50 Series

Hovering the mouse pointer over the input fields and buttons listed above will give you a

description of its purpose. For your reference, this is shown below.

IM-50 22

Page 23

Instruction Manual SmartTrak® 50 Series

Change the value in any input field by selecting the data and inputting a desired value.

Below left, for example, we have selected Setpoint. Below right, we have entered 1.234

IM-50 23

Page 24

Instruction Manual SmartTrak® 50 Series

Select ‘Enter’ on your computer keyboard to confirm. The value will change from RED

to BLACK.

IM-50 24

Page 25

Instruction Manual SmartTrak® 50 Series

Using the 50 Series Software

A. Software Window

Across the upper half of the 50 Series User Software window, you will see three yellow

boxes. These are titled:

Flow

Setpoint (flow controllers only, meters will have numbers grayed out)

Full Scale

These boxes display the current operating conditions of your 50 Series instrument. The

features of these boxes are described below.

Flow

The box displays the mass flow rate, the engineering units, and the gas type listed.

Setpoint

The Setpoint box displays the current setpoint given to the flow controller in the

‘Adjustments’ window, the engineering units, the source of the setpoint signal, the dac values

for the valve (for Sierra troubleshooting only).

Full Scale

The box displays the full scale flow rate, the engineering units, the Com Port selected, and

communications count.

IM-50 25

Page 26

Instruction Manual SmartTrak® 50 Series

Chapter 4: Analog Operation

Your SmartTrak® 50 Series instrument has an optional analog mode

This chapter will discuss Analog Operation. The analog output option is a 4-20 mA or 0- 5

VDC output signal corresponding to 0% to 100% of the mass flow full scale range.

For mass flow controllers, one analog setpoint signal and one analog output signal of either 420 mA or 0-5 VDC may be chosen to set the mass flow rate to any desired value within the

range of the device, or to read mass flow value as an outputted analog value. This input signal

must be a direct linear representation of 0% to 100% of the desired gas mass flow full scale

value. Your unit was programmed for either 4-20 mA or 0-5 VDC, not both; please refer to

the data label or calibration certificate for this information

2-2.

Analog Operation, Mass Flow Meter

After your instrument is installed and the system has undergone a complete leak check as

discussed in detail in Chapter 2, you are ready to supply power.

Power Your Instrument: Provide adequate power per Figure 2-2. Apply power using

Sierra’s power supply or your own power source. Hook up the analog output per Figure 2-2

if desired, or use the RS communications or display (optional) to read mass flow value. Let

the instrument warm up for at least 15 minutes for optimal performance.

Analog Operation, Mass Flow Controller

After your instrument is installed and the system has undergone a complete leak check as

discussed in detail in Chapter 2, follow these steps:

1. The valve will remain closed until power is supplied. See Chapter 2 for wiring

instructions. Remember that the valve in the SmartTrak® 50 Series is not a positive

shut-off device. When power is applied, the flow control valve will operate per any

instructions it receives. When the SmartTrak® 50 Series is delivered, the valve will

be closed. However, upon subsequent power-ups, the valve will return to the state it

was in the last time the instrument was operated.

CAUTION! If you do not know the value of the setpoint or the valve state given to the

SmartTrak® 50 Series when it was last operated, you must assume that the valve will open

when power is applied. TAKE NECESSARY PRECAUTIONS. You may use the SmartTrak

50 Series Software to check the setpoint or the valve state currently on your instrument. See

Chapter 4 or Chapter 5 for information on Setpoint and Valve State.

2. Power Your Instrument: Provide adequate power per Figure 2-2. Apply power

using Sierra’s power supply or your own power source. Let the instrument warm

up for at least 15 minutes for optimal performance.

IM-50 26

®

Page 27

Instruction Manual SmartTrak® 50 Series

3. Adjust the controller setpoint to the desired flow rate by supplying an

appropriate signal (mA, voltage or digital). The effective control range of the unit

is 5% to 100% of the calibrated full scale flow range. Automatic shut-off occurs at

4.9% of the factory full scale calibrated range unless specifically modified at time of

order. (This 5-100% flow is taken directly from the functional specs and the data

sheet) SmartTrak® 50 Series will immediately begin accurately monitoring and

controlling the gas mass flow rate. Let the instrument warm up for at least 15

minutes for optimal performance.

IM-50 27

Page 28

Instruction Manual SmartTrak® 50 Series

50 Series Features

Setpoint Adjustment

The setpoint (command) input signal you supply to the 50 Series must be a direct linear

representation of 0% to 100% of the mass flow full scale value. Apply the setpoint signal

per Chapter 2. A setpoint value of 0 VDC or 4 mA will regulate the flow to 0% and a

setpoint value of 5 VDC or 20 mA will adjust the flow to 100% of the instrument’s full

scale range.

When the setpoint (command) signal is applied, the flow controller will reach the setpoint

value within two seconds to within ±2% of the selected flow rate.

CAUTION! DO NOT LEAVE A SETPOINT APPLIED FOR AN EXTENDED

PERIOD OF TIME TO A CONTROLLER WHEN THE GAS SUPPLY IS

SHUT OFF OR BLOCKED.

Damage may result and the instrument will become hot to the touch.

Zero Adjustment

Remove the silver

screw to expose

the zero

adjustment port

If you believe your instrument requires a zero adjustment, allow the instrument to warm

up for at least 15 minutes at your operating conditions (Orientation, Temperature, and

Pressure), be sure there is ZERO flow through the instrument. Remove the silver screw

to expose the zero adjustment port to expose the zero adjustment button. Using a small

screwdriver or ball point pen, press the zero button, momentarily. The display should

flash and then read zero. If the display “freezes” at another value, or if computer

communication is lost, remove power and allow the device to re-initialize.

IM-50 28

Page 29

Instruction Manual SmartTrak® 50 Series

CAUTION! Note: Zero-button needs only a light touch to activate. Pay attention for a

physical click feeling and/ or a very quiet, but audible *click* noise. DO NOT push hard!

There is no reason to hold the button down, either. If you push too hard the plastic button

may become stuck under the edge of the metal shroud that holds it. If this happens you

can use the same device you use to reset to ‘unstick’ the button, CAREFULLY. Returns for

this issue will NOT be covered by warranty, as it is considered device abuse.

Over-Range Condition

If the mass flow rate exceeds the full scale range listed on the SmartTrak® 50 Series data

label the output signal will measure above full-scale. However, the device has not been

calibrated for flows in excess of the calibrated full scale value and the value will be both

non-linear and inaccurate if an over-range condition exists. Please be aware that the

analog outputs can exceed full scale by as much as 20%, or more.

Once the over-range condition has been removed, it may take up to 30 seconds for the 50

Series to recover and resume normal operation. An over-range condition will not harm

the instrument.

IMPORTANT NOTES ABOUT PURGING

Purging Non-Reactive Gases:

Purge your 50 Series with clean, dry nitrogen for a minimum of two hours. To purge an

MFC apply a full scale setpoint.

Purging Reactive Gases:

One of the following methods may be used:

Cycle purge. This is done by alternately evacuating and purging the instrument for 2

to 4 hours with clean, dry nitrogen.

Purge the instrument with clean, dry nitrogen for 18 to 24 hours.

Evacuate the instrument for 18 to 24 hours.

IM-50 29

Page 30

Instruction Manual SmartTrak® 50 Series

Important Safety Notes About Purging

WARNING! When toxic or corrosive gases are used, purge unit thoroughly with inert

dry gas before disconnecting from the gas line to prevent personnel from being injured

when coming in contact with the instrument. Above discusses how to purge your

instrument. Always neutralize any toxic gas trapped inside the instrument before removing

it from the gas line. If an instrument used with a toxic or corrosive gas is returned to the

factory a Material Safety Data Sheet (MSDS) must be enclosed & attached to the outside

of the box to alert Sierra personnel of the potential hazard. Also make sure the inlet &

outlet are securely sealed.

Chapter 5: Technical Support & Service

Technical Support

If you encounter any problem with your instrument, review the configuration information

for each step of the installation, operation, and set up procedures as explained in this

manual. Verify that your settings and adjustments are consistent with factory

recommendations.

If the problem persists, Sierra is eager to help you. You may contact us at any of the

following Technical Support Centers listed below. It may also help to call your Sierra

Sales Agent, who is also well trained in the operation of the product.

IMPORTANT: When contacting Technical Support, make sure you have

included the following information:

The flow range, serial number, Sierra order number and model number (all

marked on the instrument data label).

The problem you are encountering and any corrective action taken.

Application information (gas, pressure, temperature, pipe and fitting configuration).

IM-50 30

Page 31

Instruction Manual SmartTrak® 50 Series

Customer Service and Support Information

Email Technical Support: service@sierrainstruments.com

Email Sales: sales@sierrainstruments.com

FACTORY USA

TOLL FREE: 800-866-0200

PHONE: +1-831-373-0200

FAX: +1-831-373-4402

EMAIL: service@sierrainstruments.com

European Sales & Service Center:

PHONE: +31 72 5071400

FAX: +31 72 5071401

EMAIL: service@sierra-instruments.nl

Asia Sales & Service Center:

PHONE: + 8221 5879 8521

FAX: +8621 5879 8586

EMAIL: www.sierra-asia.com

Returning Equipment to the Factory

Factory Calibration—All Models

Sierra Instruments maintains a fully-equipped calibration laboratory. All measuring

and test equipment used in the calibration of Sierra transducers are traceable to NIST

Standards. Sierra is ISO-9001 registered and conforms to the requirements of

ANSI/NCSL-Z540 and ISO/IEC Guide 25.

Instructions for Returning Your Instrument for Service

The following information will help you return your instrument to Sierra Instruments'

Factory Service Center and will ensure that your order is processed promptly. Prices

may vary depending on the flow range, type of gas and operating pressure of your unit.

To request detailed pricing, contact your local Sierra Instruments distributor or contact

one of our offices directly.

Please follow these easy steps to return your instrument for factory service:

1. To obtain a Return Materials Authorization (RMA) number from the Sierra

Instruments to http://www.sierrainstruments.com/rma/new.php to create a

Sierra Account.

2. Once you have created an account, click on the Submit New RMA tab and fill in

the RMA form and follow the instructions. You will receive an email

confirmation once you have submitted your RMA.

IM-50 31

Page 32

Instruction Manual SmartTrak® 50 Series

3. Print a copy of the RMA (that now includes RMA #) and send a copy of the

RMA form along with your meter back to the factory.

If you require service beyond calibration, but do not know which service(s) will be

required, describe the symptoms as accurately as possible on the RMA form.

Pack your instrument carefully. Use the original packaging and foam or bubble wrap

(packing peanuts NOT recommended) and include a copy of the RMA form

(complete with Sierra supplied RMA number) with the unit(s).

Ship the unit(s) to the following address:

Sierra Instruments, Inc.

Attention: Factory Service Center

5 Harris Court, Building L

Monterey, CA 93940 USA

RE: RMA# (your number

)

RE: RMA# (your number)

IM-50 32

Page 33

Instruction Manual SmartTrak® 50 Series

Appendix A: Gas Tables & K-Factor Calculations

K-Factor Calculations-Using SmartTrak

If you will be using SmartTrak® 50 Series with a gas other than as calibrated, you may

use the tables below. They provide K-factors and thermodynamic properties of gases

commonly used with mass flow meters and controllers. This is particularly useful if the

actual gas is not a common gas or if it is toxic, flammable, corrosive, etc. The tables can

also be used to interpret the reading of a flow meter or flow controller that has been

calibrated with a gas other than the actual gas.

Before applying the tables, set the instrument for Air. Then, the following fundamental

relationship may be used:

Q

Where:

Q = The volumetric flow rate of the gas referenced to normal

conditions of 0°C and 760 mm Hg (sccm or slm),

K = The K-factor from the following tables, referenced to Air

( ) 1 = Refers to the “actual” gas, and

( ) N = Refers to the “reference” gas, Air in this case.

= K1/KN

1/QN

®

50 Series with Other Gases

IM-50 33

Page 34

Instruction Manual SmartTrak® 50 Series

r

(

r

r

(

(

(

(

(

r

(

(

Gas Tables and K-factors

Actual Gas

Acetylene C2H2 .581 .4036 1.079 1.162

1.000 .240 1.200 1.293

Ai

Allene

Propadiene) C

Ammonia NH

Argon Ar 1.398 .1244 1.655 1.782

Arsine AsH

Boron Trichloride BCl3 .411 .1279 4.852 5.227 800 Series Recommended

Boron Trifluoride BF3 .511 .1778 2.808 3.025 KR

Boron Tribromide B

Bromine B

Bromine Pentafluoride BrF5 .261 .1369 7.244 7.803 KR

Bromine Trifluoride BrF

Bromotrifloromethane

Freon-13 B1)

1,3-Butadiene C4H6 .321 .3514 2.240 2.413

Butane C

1-Butane C4H8 .301 .3648 2.324 2.503 NEO KR

2-Butane C

2-Butane C

Carbon Dioxide CO2 .737 .2016 1.835 1.964

Carbon Disulfide CS

Carbon Monoxide CO 1.002 .2488 1.160 1.250

Carbon Tetrachloride CCl4 .311 .1655 6.368 6.860 KR

Carbon Tetrafluoride

Freon-14)

Carbonyl Fluoride COF

Carbonyl Sulfide COS .661 .1651 2.488 2.680

Chlorine CL

Chlorine Trifluoride CIF3 .401 .1650 3.829 4.125 KR

Chlorodifluoromethane

Freon-22)

Chloroform CHCI

Chloropentafluoroethane

Freon-115)

Chlorotrifluromethane

Freon-13)

Cyanogen C2N2 .611 .2613 2.156 2.322 KR

Cyanogen Chloride CICN .611 .1739 2.545 2.742

Cychlopropane C3H5 .461 .3177 1.742 1.877 KR

Deuterium D

Diborane B

Dibromodifluoromethane CB

Dibromethane .471 .075 7.204 7.76 KR

Dichlorodifluoromethane

Freon-12)

Dichlorofluoromethane

Freon-21)

Chemical

Symbol

3H4

3

3

.381 .0647 10.378 11.18 KR

3

.812 .0539 6.619 7.130

2

3

CBrF

4H10

CIS .325 .336 2.324 2.503 NEO KR

4H8

TRANS .292 .374 2.324 2.503

4H8

2

CF

4

2

CHClF

CIF5 .241 .164 6.398 6.892 KR

C

2

CCIF

1.002 .1722 1.670 1.799

2

2H6

2F2

CCI

2F2

CHCl

2

K-factor

Relative

to Air

Cp

(Cal/g)

Density

(g/l) @

70°F

Density

(g/l) @

0°C

Elastomers*

O-ring Valve

Seat

.431 .352 1.659 1.787 KR

.732 .492 .706 .760 NEO KR/NEO

.671 .1167 3.229 3.478 KR

.381 .1161 5.670 6.108 KR

.371 .1113 6.168 6.644

3

.261 .4007 2.407 2.593 NEO KR

.601 .1428 3.153 3.397

.421 .1654 3.645 3.926 KR

.541 .1710 2.734 2.945

2

.862 .114 2.936 3.163 800 Series Recommended

.461 .1544 3.581 3.858 KR

2

.391 .1309 4.944 5.326 KR

3

.381 .153 4.326 4.660 KR

3

.441 .508 1.147 1.235 KR

.190 .15 8.691 9.362 KR

.351 .1432 5.008 5.395 KR

F .421 .140 4.597 4.952 KR

If no O-ring material is specified then O-ring to be used is Viton. NEO is neoprene or equivalent. KR is DuPont Kalrez or

equivalent. Valve Seat applies only to controllers.

IM-50 34

Page 35

Instruction Manual SmartTrak® 50 Series

(

(

(

y

y

r

y

Actual Gas Chemical

Symbol

Dichloromethylsilane (CH

Dichlorosilane SiH

Dichlorotetrafluoroethane

3) 2

C

2Cl2F4

SiCl

2Cl2

(Freon-114)

1,1-Difluoroethylene

C

2H2F2

Freon-1132A)

Dimethylamine

Dimethyl Ether

CH

CH

3) 2

3) 2

2,2-Dimethylpropane C3H12 .220 .3914 2.988 3.219 KR

Ethane C

Ethanol C

2H6

O .391 .3395 1.908 2.055 KR

2H6

EthylAcetylene C4H6 .321 .3513 2.240 2.413 KR

Ethyl Chloride C

CI .391 .244 2.673 2.879 KR

2H5

Ethylene C2H4 .601 .358 1.161 1.251

Ethylene Oxide C2H4O .521 .268 1.824 1.965 KR

Fluorine F

.982 .1873 1.574 1.695 800 Series Recommended

2

Fluoroform (Freon-23) CHF3 .501 .176 2.903 3.127 KR

Freon-11 CCI3F .331 .1357 5.690 6.129 KR

Freon-12 CCI

2F2

Freon-13 CCIF3 .381 .153 4.326 4.660 KR

Freon-13 B1 CFrF3 .371 .1113 6.168 6.644 KR

Freon-14 CF

4

Freon-21 CHCI2F .421 .140 4.597 4.952 KR

Freon-22 CHCIF2 .461 .1544 3.581 3.858 KR

Freon-113

Freon-114 C

CCI2FCCIF

2Cl2F4

Freon-115 C2ClF5 .241 .164 6398 6.892 KR

Freon-C318 C

4F6

Germane GeH4 .571 .1404 3.173 3.418

Germanium Tetrachloride GeCL4 .271 .1071 8.879 9.565 KR

Helium He 1.399 1.241 .164 .1786

Hexafluoroethane

C

2F6

(Freon-116)

Hexane C6H14 .180 .3968 3.569 3.845 KR

Hydrogen H

1.001 3.419 .083 .0899

2

Hydrogen Bromide HBr 1.002 .0861 3.351 3.610 KR

Hydrogen Chloride HCl 1.002 .1912 1.510 1.627 800 Series Recommended

drogen Cyanide HCN 1.072 .3171 1.120 1.206 KR

H

Hydrogen Fluoride HF 1.002 .3479 .829 .893 800 Series Recommended

H

drogen Iodide HI 1.002 .0545 5.298 5.707 KR

Hydrogen Selenide H

Se .792 .1025 3.354 3.613 KR

2

Hydrogen Sulfide H2S .802 .2397 1.411 1.520 NEO KR

Iodine Pentafluoride IF

.251 .1108 9.190 9.90 KR

5

Isobutane CH(CH3)3 .271 .3872 3.335 2.593 KR

Isobutylene C4H8 .291 .3701 2.324 2.503 KR

Krypton K

1.456 .0593 3.471 3.739

Methane CH4 .754 .5328 .665 .715

Methanol CH3OH .581 .3274 1.327 1.429

Meth

l Acetylene C3H4 .431 .3547 1.659 1.787 KR

Methyl Bromide CH

Br .581 .1106 3.932 4.236

3

Methyl Chloride CH3Cl .193 2.253 2.092 KR

Methyl Fluoride CH

F .681 .3221 1.409 1.518 KR

3

If no O-ring material is specified then O-ring to be used is Viton. NEO is neoprene or equivalent. KR is DuPont Kalrez or

equivalent. Valve Seat applies only to controllers.

K-factor

Relative

Air

.251 .1882 5.345 5.758 KR

2

Cp

(Cal/g)

Density

(g/l) @

70°F

Density

(g/l) @

0°C

Elastomers*

O-ring Valve

Seat

.401 .150 4.183 4.506 KR

.220 .1604 7.079 7.626 KR

.185 .224 2.652 2.857 KR

NH .371 .366 1.867 2.011 KR

O .391 .3414 1.908 2.055 KR

.501 .4097 1.246 1.342

.351 .1432 5.008 5.395 KR

.421 .1654 3.645 3.926

.200 .161 7.761 8.360 KR

2

.220 .160 7.079 7.626 KR

.170 .185 7.795 8.397 KR

.241 .1834 5.716 6.157 KR

IM-50 35

Page 36

Instruction Manual SmartTrak® 50 Series

y

(

)

g

y

(

y

Actual Gas

Methyl Mercaptan CH3SH .521 .2459 1.992 2.146 KR

Meth

l Trichlorosilane

Molybdenum Hexafluoride MoF

Monoethylamine C2H5NH2 .351 .387 1.867 2.011 KR

Monomethylamine CH3NH2 .511 .4343 1.287 1.386 KR

Neon NE 1.463 .245 .836 .900

Nitric Oxide NO .992 .2328 1.243 1.339

Nitrogen N2 1.002 .2485 1.161 1.25

Nitro

en Dioxide NO2 .742 .1933 1.905 2.052 800 Series Recommended

Nitrogen Trifluoride NF

Nitrosyl Chloride NOCl .611 .1632 2.711 2.920 KR

Nitrous Oxide N

Octafluorocyclobutane

(Freon-C318)

Oxygen Difluoride OF2 .631 .1917 2.234 2.406

Oxygen O2 .998 .2193 1.326 1.427

Ozone O3 .447 .3 1.990 2.144

Pentaborane B

Pentane C

Perchloryl Fluoride CIO3F .391 .1514 4.243 4.571 KR

Perfluoropropane C

Phosgene COCl2 .441 .1394 4.101 4.418 KR

Phosphine PH3 .762 .2374 1.408 1.517 KR

Phosphorous Ox

chloride POCl3 .361 .1324 6.352 6.843 KR

Phosphorous

Pentafluoride

Phosphorous Trichloride PCl5 .301 .1250 5.688 6.127 KR

Propane C

Propylene C3H6 .411 .3541 1.742 1.877

Silane SiH4 .601 .3189 1.330 1.433 KR

Silicon Tetrachloride SiCl

Silicon Tetrafluoride SiF4 .351 .1691 4.310 4.643 KR

Sulfur Hexafluoride SF6 .261 .1592 6.049 6.516 KR

Sulfuryl Fluoride SO

Teos .090 800 Series Recommended

Tetrafluorahydrazine N

Trichlorofluormethane

(Freon-11)

Trichlorisilane SiHCl3 .331 .1380 5.610 6.043 KR

1,1,2-Trichloro-1,2,2

Trifluorethane

Freon-113)

Trisobutyl Aluminum (C4H9)Al .061 .508 8.214 8.848 KR

Titanium Tetrachloride TiCl4 .271 .120 7.858 8.465 KR

Trichloro Ethylene C2HCl3 .321 .163 5.523 5.95 KR

Trimethylamine (CH

Tungsten Hexasfuoride WF6 .251 .0810 12.328 13.28 800 Series Recommended

Uranium Hexafluoride UF6 .200 .0888 14.574 15.70 KR

Vin

l Bromide CH2CHBr .461 .1241 4.430 4.772 KR

Vinyl Chloride CH

Xenon Xe 1.443 .0378 5.438 5.858

If no O-ring material is specified then O-ring to be used is Viton. NEO is neoprene or equivalent. KR is DuPont

Kalrez or equivalent. Valve Seat applies only to controllers.

Chemical

Symbol

CH

SiCl3 .251 .164 6.191 6.669 KR

3

3

O .716 .2088 1.836 1.964

2

K-factor

Relative

Air

.210 .1373 8.695 9.366 KR

6

Cp

(Cal/g)

Density

(g/l) @

70°F

Density

(g/l) @

0°C

Elastomers*

O-ring Valve

Seat

.481 .1797 2.941 3.168 KR

C4F6 .170 .185 7.795 8.397 KR

.261 .38 2.614 2.816 KR

5H9

.210 .398 2.988 3.219 KR

5HI2

.174 .197 7.787 8.388 KR

3F8

PH

.301 .1610 5.217 5.620 KR

5

.335 .3885 1.826 1.967

3H8

.281 .1270 7.037 7.580 KR

4

.391 .1543 4.235 4.562 KR

2F2

.321 .182 4.307 4.64 KR

2F4

CCl3F .331 .1357 5.690 6.129 KR

CCl2FCClF

.200 .161 7.761 8.360 KR

2

N .281 .3710 2.450 2.639 KR

3)3

CHCl .481 .12054 2.588 2.788 KR

2

IM-50 36

Page 37

Instruction Manual SmartTrak® 50 Series

Appendix B1: 50 Low Flow (to 50 slpm) Product

Specifications

IM-50 37

Page 38

Instruction Manual SmartTrak® 50 Series

IM-50 38

Page 39

Instruction Manual SmartTrak® 50 Series

IM-50 39

Page 40

Appendix B2: 50 Medium Flow (to 200 slpm) Product

Specifications

IM-50 40

Page 41

IM-50 41

Page 42

IM-50 42

Page 43

Appendix C: Warranty Policy

LIMITED WARRANTY POLICY- REGISTER ONLINE

All Sierra products are warranted to be free from defects in material and workmanship and will

be repaired or replaced at no charge to Buyer, provided return or rejection of product is made

within a reasonable period but no longer than one (1) year for calibration and non-calibration

defects, from date of delivery. To assure warranty service, customers must register their products

online on Sierra’s website. Online registration of all of your Sierra products is required for our

warranty process. Register now at www.sierrainstruments.com/register. Learn more about

Sierra’s warranty policy at www.sierrainstruments.com/warranty.

IM-50 43

Loading...

Loading...