Page 1

Ambassador 4700TEC Catalytic Wood

Heater Insert Manual

Installation & Operating Instructions

Please read this entire manual before installation. Save these instructions.

This manual describes the installation, operation and

maintenance of the SIERRA Ambassador Model Number

4700TEC catalytic wood heater.

Please read this entire manual before you install and use your

new room heater. Failure to follow instructions may result in

property damage, bodily injury, or even death.

Save these instructions for future reference.

SAFETY NOTICE

If this appliance is not properly installed, a house fire may

result. For your safety, follow the installation instructions.

Check with local building or fire officials about restrictions and

installation inspection requirements in your area.

It is best to have a professional install your Sierra Stove. If you

prefer to install it yourself (see Installation Instructions), be

GENERAL INFORMATION

W e wish to welcome you as a new owner of a SIERRA

Woodstove. You join many thousands of happy owners who

have been heating with SIERRA stoves since 1972. SIERRA

stoves have changed a great deal during that time, and all of

our knowledge and experience have culminated in this stove,

the SIERRA AMBASSADOR. Please read all of this manual

before using your stove, especially if you have owned another

woodstove in the past.

Failure to follow instructions may result in property damage,

bodily injury, or even death. We at SIERRA wish you many

happy years of warm th and com fort.

SAFETY NOTICE

<CAUTION: HOT WHILE IN OPERATION. KEEP

CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS.

<IF THIS HEATER IS NOT PROPERLY INSTALLED,

A HOUSE FIRE MAY RESULT.

<CONTACT LOCAL BUILDING OFFICIALS ABOUT

RESTRICTIO NS AND INSTALLATION INSPECTION

REQUIREM ENTS IN YOUR AREA.

<FAILURE TO COMPLY WITH OWNERS' MANUAL

INSTRUCTIONS WILL VOID YOUR WARRANTY!

NOT APPROVED FOR MOBILE HOMES

DO NOT USE CHEMICALS OR FLUIDS TO START

sure to obtain the proper permits. Have the local building

officials inspect the stove and chimney pipe for safety and

code compliance after the installation is

complete.

Your SIERRA insert generates a lot of heat, so treat it with

care. Read this manual thoroughly before installing and

operating your stove.

FAILURE TO FOLLOW INSTRUCTIONS M AY

RESULT IN PROPERTY DAMAGE, BODILY INJURY,

THIS STOVE CAN ONLY BE USED WITH A MASONRY

FIREPLACE. IT IS NOT APPROVED FOR OR SAFE TO

USE IN A FACTORY-BUILD “ZERO CLEARANCE”

FIREPLACE.

DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT

OR SYSTEM

YOUR SIERRA AMBASSADOR HAS BEEN TESTED BY

WARNOCK-HERSEY LABORATORIES TO ANSI/UL

STANDARD 737, ICBO NO. TL-116, NER-QA-219

OR “FRESHEN UP” THE FIRE!

DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS.

PLEASE LEAVE THIS MANUAL WITH THE OWNER !!

Listed by Warnock Hersey

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY

FLUE SERVING ANOTHER APPLIANCE.

Page 2

INSTALLATION INSTRUCTIONS

Catalytic Notice

This heater is certified to comply with July 1990 Particulate

Em issions Standards. Under specific test conditions, this

heater has been shown to deliver the heat at the following

rates:

4700TEC from 10,790 to 42,596 BTU/hr.

DO NOT OVERFIRE THIS HEATER. Attempts to achieve

heat output that exceeds the heater design can result in

permanent dam age to the heater and to the catalytic

combustor. Do not exceed surface temperatures of 800

degrees F. Do not burn with the ash pan open. Overfiring

can also void the manufacturer’s warranty.

The combustor supplied with this heater is a long life

combustor. Consult the catalytic combustor warranty also

supplied with this wood heater. Warranty claims should be

addressed to the combustor manufacturer. See combustor

warranty for address.

Catalytic Tampering

This wood heater contains a catalytic combustor, which

needs periodic inspection and replacement for proper

operation. It is against the law to operate this wood heater

in a m anner inconsistent with operating instructions in this

manual, of if the catalytic element is deactivated or

removed.

This heater is designed to burn natural wood only. Higher

efficiencies and lower emissions generally result when

burning air dried seasoned hardwoods, as com pared to

softwoods or to green or freshly cut hardwoods.

DO NOT BURN:

• treated woodcardboard

• coalsolvents

• garbagecolored paper

• trash

Burning treated wood, garbage, solvents, colored paper, or

trash may result in the release of toxic fumes and may

poison or render ineffective the catalytic combustor.

Burning coal, cardboard, or loose paper can produce soot,

large flakes of char or fly ash that can coat the

combustors, causing smoke spillage into the room, and

rendering the combustors ineffective.

Fuel Selection

A factory-build, prefabricated fireplace or chimney may

NOT be used for this SIERRA insert. This unit must be

connected to (1) a chimney complying with the

requirements for type HT chimneys in the standard for

chimneys, Factory-Built, Residential Type and Building

Heating Appliance, UL103, or (2) a code-approved

masonry chimney with a flue liner.

Your chim ney m ust be correctly sized. A chim ney that is

too small or too large in diameter, or too short, can cause

your stove to spill smoke when the door is opened.

Never place your stove closer to unprotected

combustible walls or furnishings than the recommended

clearance.

Never use gasoline, kerosene, lighter fluid, lantern fuel,

charcoal starter, or any such product to start or “freshen

up” a fire in the woodstove. Keep all such materials well

away from the stove while it is in use.

Before opening the door, open the prim ary air controls

and the bypass lever. After a m inute, open the door only

72 inches for 15-20 seconds to allow the smoke in the

firebox to be flushed up the chim ney.

In the event of a chimney fire: (1) stop loading fuel, (2)

close the stove doors, (3) shut off all air to the stove, (4)

alert everyone in the house, and (5) call the fire

department.

For further information on using your heater safely,

obtain the latest edition of the National Fir Protection

Association publication, “Using Coal and W ood Safely.”

Order No. HS-8-1974 from N.F.P.A., 470 Atlantic Ave.,

Boston, MA 02210

TABLE OF CONTENTS

I. BASIC FIREPLACE AND CHIMNEY

REQUIREMENTS

II. MINIMUM MASONRY FIREPLACE OPENING

AND MINIMUM CLEARANCES TO

COMBUSTIBLES

III FLOOR PROTECTION

Read This First

Your SIER RA insert generates a lot of heat, so treat it

with care. Read this manual thoroughly before installing

and operating your stove.

Your SIERRA AMBASSADOR has been tested by

Warnock-Hersey Laboratories to ANSI/UL Standard

737, ICBO NO. TL-116, NER-QA

Install and operate this SIERRA unit according to

instructions provided in this manual. Local building codes

may apply; therefore, contact your local building inspector

or fire marshal for necessary installation requirements and

permits which may go beyond these instructions.

Have any existing chimney inspected before attaching

the Ambassador to it. Some chimneys must be relined

or replaced before they are safe to use.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

IV. INSTALLATION INSTRUCTIONS

V. METHOD I

VI. METHOD II

VII. OTHER OPTIONS AND CONSIDERATIONS

VIII. SHROUD INSTALLATION

IX. LEVELING THE UNIT

X. FAN COVER REMOVAL

XI. ELECTRICAL

XII. OPERATING INSTRUCTIONS

XIII. COMBUSTOR LIFE AND REPLACEMENT

XIV. STOVE AND CHIMNEY MAINTENANCE

2

Page 3

General Information

The following items are shipped inside the Ambassador:

• This manual

• Sierra W arranty

• Combustor W arranty

• Ash Pan

1. Install Ash Pan — Your heater is now ready for

installation. Read instructions carefully.

I. BASIC FIREPLACE AND CHIMNEY

REQUIREMENTS

A Sierra woodstove may be installed using an all masonry

fireplace build in accordance with the Uniform Building

Code. The first step in this type of installation is to

determine the acceptability of the fireplace and chimney for

use with a woodstove. Both the construction and condition

of the fireplace are important considerations when

installing a wood stove. Do not install this stove in a poorly

constructed fireplace or chimney.

The following are general guidelines for a safe installation

and are based on recom mendations of the National Fire

Protection Association (NFPA). Contact your local building

code agency or fire safety inspector for specific details.

Local codes may vary by area.

8. This stove must be used alone in the chimney. Any

unused opening must be permanently sealed with

masonry by a skilled brick mason. A clip-in type flue

liner is not acceptable for this use because of the

possibility of it coming loose during a chimney fire and

possibly causing the fire to spread.

1. The chimney should have a fire clay liner in good

condition. Loose or cracked liner sections can be

hazardous. If the chimney does not have a liner, one

can be installed by a qualified professional. Some metal

liners area acceptable to use check with your stove

dealer or local building code agency for acceptability of

these liners.

2. No part of the chimney should have any leaks, missing

masonry, cracks, loose mortar or soft mortar.

3. There should be no mortar or parts of the chimney

blocking the chimney flue.

4. The fireplace and chim ney should be built on a solid

concrete footing supported by the ground and not

attached to the house. Older chimneys are sometimes

supported by the framework of the building itself. These

can be structurally unsound due to settling and shifting

of the building and possible cracking of the chimney

itself.

5. The chimney m ust have a good natural drat and should

be self-sta rting. A chim ney that has poor draft and is

subject to draft reversal should be repaired or replaced

before using.

6. The chimney should be the proper size. Some fireplace

chimneys are quite large and will cause poor stove

performance and excessive creosote. The rule of

thumb is that the chimney flue should be roughly no

more than three times the flue opening on the stove. A

6 inch stove flue will work in an 8 inch by 12 inch

fireplace flue. It may be necessary to install another

liner in an oversized chimney.. Use a 24 gauge flue, and

chimney connector. Use at least 3 screws.

7. The chimney should extend at least 3 feet above the

roof and at least 2 feet above any point on the roof

within 10 feet.

Your local building code agency or fire safety inspector can

refer you to a qualified professional who can inspect the

chimney for you.

3

Page 4

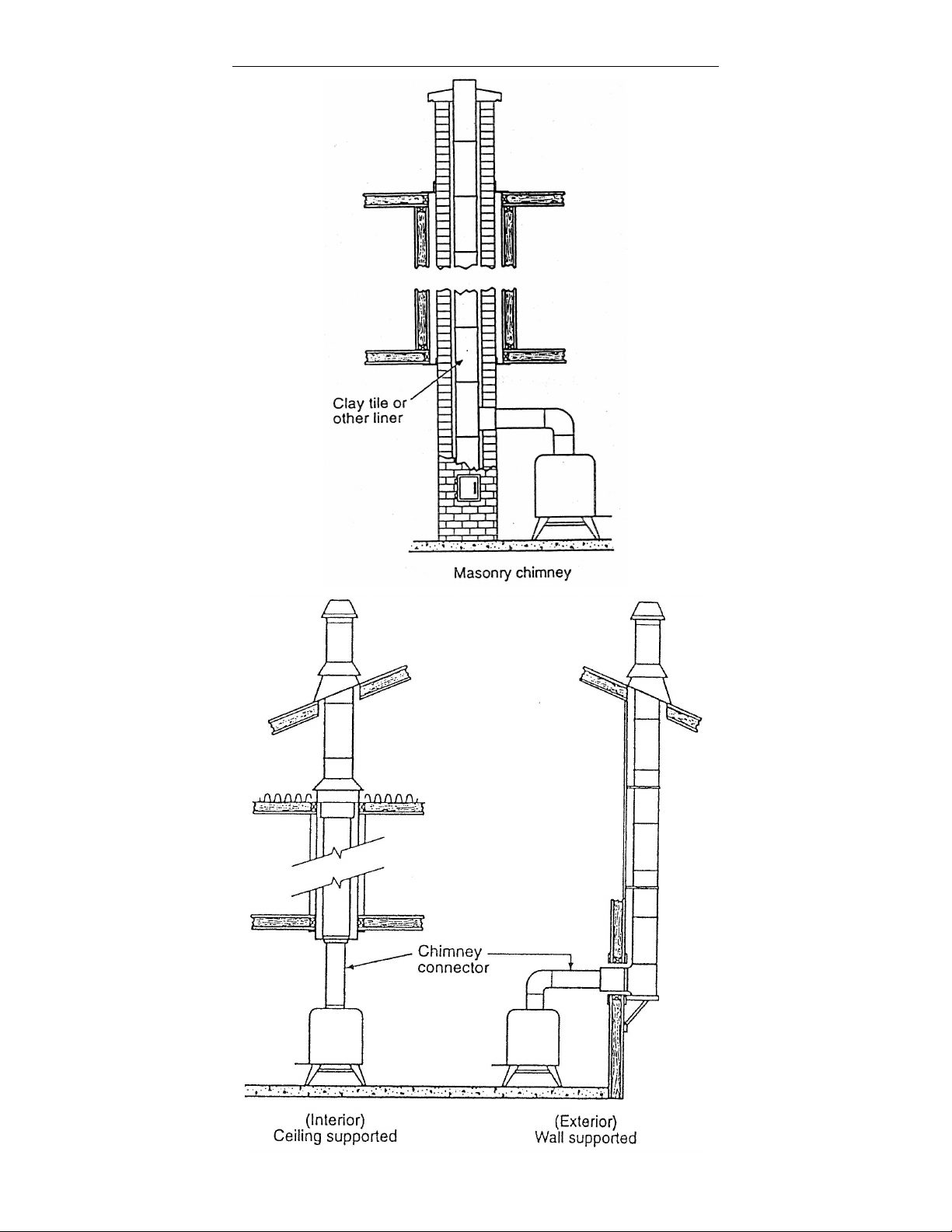

Typical Factory Built or Masonry Chimney Installations

4

Page 5

CHIMNEY CONNECTOR SYSTEMS AND CLEARANCES

FROM COMBUSTIBLE WALLS FOR RESIDENTIAL

HEATING APPLIANCES

A. Minimum 3.5 inch thick brick masonry all fram ed into

combustible wall with a minimum of 12 inch brick

separation from clay liner to combustibles. The fireclay

liner shall run from the outer surface of brick wall to, but

not beyond, the inner surface of chimney flue liner and

shall be firmly cemented in place.

B. Solid-insulated, listed factory-build chimney length of the

same inside diameter as the chimney connector and

having 1 inch or more of insulation with a minimum 9

inch air space between the outer wall of the chimney

length and combustibles.

D. Solid insulated, listed factory-build chim ney length with

an inside diameter 2 inch larger than the chimney

connector and having 1 inch or more of insulation,

serving as a pass-thru for a single wall sheet steel

chimney connector of minimum 24 gauge thickness,

with a m inimum 2 inch air space between the outer wall

of chimney section and combustibles. Minimum length

of chimney section shall be 12 inch chimney section

spaced 1 inch away from connector using sheet steel

support plates on both ends of chimney section.

Opening shall be covered, and chimney section

supported on both sides with sheet steel supports

securely fastened to wall surfaces of minimum 24 gauge

thickness. Fasteners used to secure chimney section

shall not penetrate chimney flue liner.

II. MINIMUM MASONRY FIREPLACE OPENING AND

MINIMUM CLEARANCES TO COMBUSTIBLES

C. Sheet steel chimney connector, minimum 24 gauge

thickness, with a ventilated thimble, minimum 24 gauge

in thickness, having two 1 inch air channels, separated

from combustibles by a minimum of 6 inch of glass fiber

insulation. Opening shall be covered, and thim ble

supported with a sheet steel support, minimum 24

gauge in thickness.

III. FLOOR PROTECTION

In accordance with NFPA 211 guidelines, any com bustible

floor in front of your 4700TEC must be protected with a

non-combustible floor protector equivalent to one layer of

3/8" asbestos millboard.

NOTE: ASBESTOS CANNOT BE USED

Reference to asbestos is used as a standard only, 3/8"

asbestos millboard has a “K” factor of .84. The newer

substitute CERAFORM BOARD has a “K” factor of .21.

Contact your local dealer for off the shelf approved floor

protectors.

5

Page 6

The k, C or R factor that correlates with the floor protector

material used during the test if the room heater is not

provided with a floor protector. The units of measure for k,

C and R factors shall use the sam e applicable units.

Directions and exam ples on how to use alternate materials

and how to calculate equivalent thickness shall be shown.

An easy means of determining if a proposed alternate floor

protector meets requirements listed in the appliance

manual is to follow this procedure:

1. Convent specifications to R-value

a. R-value is given - no conversion is needed.

b. K-factor is given with a required thickness (T) in

inches: R=1/k+T

c. C-factor is given: R=1/C

2. Determine the R-value of the proposed alternate floor

protector.

a. Use the formula in step 1 to convert values not

expressed as “R”.

b. For m ultiple layers, add R-values of each layer to

determine the overall R-value.

3. If the overall R-value of the system is greater than the Rvalue of the specified floor protector, the alternate is

acceptable.

EXAMPLE:

The specified floor protector should be 3/4 inch thick

material with a k-factor of .84.

The proposed alternate is 4" brick with a C-factor of 1.25

over 1/8" mineral board with a k-factor of .29.

Step 1: Use formula above to convert specification to

R-value. R=1/kT = 1/0.84 x .75 = .893

Step 2: Calculate R of proposed system.

4" brick of C - 1.25, therefore

R brick = 1/C = 1/1.25 = 0.80

1/8" mineral board of k+ 0.29, therefore

R min.bd. = 1/0.29 x 0.125 = 0.431

Total R = R brick + R brick + R m ineral Board

= 0.8 + 0.431 = 1.231

Step 3: Compare the proposed system R of 1.231 to

specified R of 0.893. Since proposed system R

is greater than required, this is acceptable.

Definitions:

If your chimney is lined and clean, it must still be measured

to insure that the lliner is not oversized.

For best performance and efficiency, we highly

recommend the following minimums:

Chimney Size: 6" x 6" or 36 sq. in.

Chimney Height: 15 feet and at least 2 feet above the

highest point of your roof.

Draft: .06 w.c.

Measure your fireplace. Your fireplace must be: 29 ½"

wide, 22 ½" high, 15" deep.

Your lintel must be 8" or less. Your hearth must be 9" or

more. You m ust be able to provide 16" of non-com bustible

hearth extension in front of this 9 ½".

Clean out your fireplace and remove screen and glass

doors if present.

Remem ber to have your chimney inspected for leaks and

blockage before you install your stove.

Draft Requirements

Draft is the force which moves air from the appliance up

through the chimney. The amount of draft in your chimney

depends on the size, height and general condition of your

chimney, local geography, nearby obstructions, and other

factors. Inadequate draft will cause the appliance to leak

smoke into the room when starting a fire or adding fuel to

the existing fire. Too much draft m ay cause the stove to

burn too hot and damage the unit.

Minim um Chim ney Requirem ents

Size – 6x6 Height – 15 ft. Draft – .06WC

NOTE: Nine out of ten times, dirty glass, lack of “heating”,

or failure to continue burning after the doors are shut is

evidence of inadequate draft.

V. METHOD I

Method I – This installation uses a direct connection (

direct connect adapter kit) or a section of flexible or rigid

pipe. This connects the stove flue outlet to the first section

of tile liner at the bottom of the chimney. The width of the

damper opening or the throat of the chimney will determine

which type of pipe, rigid, round flexible, or oval flexible,

should be used. Some openings are large enough (6

inches or more) to allow the use of the standard connector

pipe. If the dam per or throat area is narrow, oval flexible

pipe or sheet metal adapter must be used

IV. INSTALLATION INSTRUCTIONS

Your Sierra 4700TEC must be direct connected using

Method I or Method II

Chimney Sizing – Have your chimney cleaned and

inspected by a certified chimney sweep. Chimney MUST

have some type of lining. If your chimney is not lined, you

MUST have your chimney relined.

Relining can be done by either of two methods. Some

dealers reline with a poured masonry mix. Others use

stainless steep pipe wrapped with ceram ic insulation. Both

systems produce excellent results when installed by

competent professionals.

Installation – Method

1. Re move the existing dam per in the fireplace or lock it in

the open position.

2. Determine the type of pipe required for your installation.

3. Cut the pipe to the proper length. 22 inches (approx.

height of flue collar) above the bottom of the fireplace to

at least half way into the first chimney liner.

4. Slide the pipe up through the damper area into the first

chimney liner

5. Measure from the bottom of the fireplace 22 inches.

This should be the bottom of the pipe.

6. Completely pack the damper area or bottom of the first

chimney liner with ceramic wool or other non-

combustible material in a way which no air can go up the

chimney except through the pipe. This is very important,

as it directly affects the chimney draft.

7. Slide the 4700 into the fireplace until the shroud flanges

are approximately 2 inches in front of the face of the

fireplace.

6

Page 7

8. Install the pipe into the flue collar, making sure the pipe

is seated all the way down in the collar.

NOTE: YOU MAY NEED TO REACH UP THROUGH

THE BYPASS MECHANISM TO INSURE PROPER

SEATING.

Be extremely careful to make this connection air tight

with furnace cement, high temperature silicon, or other

high tem perature sealant.

9. Install the shroud and brass trim .

10. Gently slide the 4700TEC the rest of the way into

the fireplace.

11. Level the unit.

12. Double check the seal of the connecting pipe by

reaching through the by-pass opening.

Method I and II – The flue collar of the 4700TEC is an

industry standard 8 inch oval. Most 8 inch oval pipe will fit

into it nicely. Depending on the location, angle, etc., of the

throat or dam per of the fireplace, it may be necessary to

use an adapter. These adapters will allow the pipe to be

connected to the unit at many different angles and be

bolted to the unit in place of being cemented.

VIII. SHROUD INSTALLATION

1. Install the left side by sliding the shroud over the bracket

on the unit and between the front of the side and the

cleat. Align the bottom of the side with the bottom of the

stove.

2. Install right side in the same manner.

3. Install top in the same manner aligning the top shroud

bracket on the stove and tops of both sides.

4. Using a rubber hammer, continue to slide both sides

equal and top on to the brackets until com pletely

seated and each side is straight with the ends on the

top.

5. Install brass trim .

VI. METHO D II

The Method II installation is similar to Method I except that

the connector pipe extends the full length of the chimney

and terminates at the top of the chim ney. Either rigid

round sections or a continuous length of flexible pipe may

be used. This pipe must be constructed of stainless steel

6" diameter minimum. All joints must be secured by at

least 1/8" self-threading sheet m etal screws. Because this

method is usually more difficult and involved, we

recommend that you have a qualified professional installer

do the job for you.

VII. OTHER OPTIONS AND CONSIDERATIONS.

Method I - Depending on the size, shape, or location of the

throat of your fireplace, the ceramic wool installation

cannot be used or will not be acceptable. For those

installations, you m ay need a sheet metal adapter kit.

These kits consist of a piece of sheet metal cut to size to

totally block off the upper portion of the fireplace with a

hole for the pipe to pass through. Consult your local dealer

for more details.

Figure 5

IX. LEVELING THE UNIT

The Sierra 4700TEC is equipped with three leveling bolts,

one behind the ash pan and one on each side behind the

fan covers. The unit should be leveled for proper door

operation and to insure the shroud is aligned with the face

of the fireplace.

----Access the back leveling bolt by removing the ash pan

and ash grate.

----Access the front leveling bolts by removing the fan

covers.

X. FAN COVER REMO VAL

The fan covers of the 4700TEC are held in place with two

spring clips (l each side). The clips have small dimples on

their outer surface that hold them behind the metal body of

the unit. (See Figure 6)

7

Page 8

Figure 6

REMOVAL:

1. Gently pull the edge of the fan cover away from the body

of the unit approx. 1/8"

2. Locate the center of the spring clip.

3. Using a flat screw driver, compress the spring clip.

4. Pull the fan cover out of its opening.

Thermostat – Automatically turns the blowers on when

the unit reaches normal operating temperature and off

when the unit cools below normal operating

temperature.

Automatic/Manual Switch – Allows manual operation of

the blowers before and after thermostat is activated.

NOTE: On low burns (less than .8 Kg/hr.) and medium

burns (.80 to 1.25 Kg/hr.) the room air fan should be

operated on the lowest setting. On high burns (1.90 Kg/hr.

or greater) and m edium high burns (1.25 to 1.90 Kg/hr.)

the blower fans must be operating to avoid excessive heat

build up and possible damage to the fan blades and

electrical components.

Wiring Information

INSTALLATION:

1. Make sure the spring clips are installed in the edge of

the fan cover properly.

2. Center the fan cover over the opening.

3. W ith a flat screw driver, compress the spring while

pushing the fan cover into place.

4. Repeat for the other edge.

XI. ELECTRICAL

Your Sierra 4700TEC is equipped with a 6 ft. power cord,

on/off variable speed control, thermostat and

automatic/manual switch.

On/Off Variable Speed Control

–extreme left –off

–right past click –high

–continuing to the right –high to low

Figure 8

8

Page 9

XII. OPERATING INSTRUCTIONS

For the first few days, the stove will give off an odor and a

small amount of smoke. This happens when the high

temperature paint is bonding to the metal. This is normal

and will stop when the paint is cured, and will reoccur every

time you repaint or touch up your stove.

1. Starting a fire. Crumble three or four full sheets of

newspaper and place them on the flow of your SIERRA

stove.

2. Crisscross two layers of dry kindling on the paper. Add

a few large splits of dry wood on top of the kindling.

3. Make sure the primary air controls are fully open. Also

be sure that the bypass lever is open.

4. Light the paper under the kindling with a match or

lighter. Do not use gasoline, lighter fluid, charcoal

starter, kerosene, or any other such fuel to start a fire in

a woodstove.

5. At higher altitudes, or when starting a fire on a very cold

chimney, it may be necessary to leave the door cracked

open for a few m inutes, no longer than 5 minutes, to

encourage a hot fire.

prevent flashbacks which occur when a very smoky fire

suddenly is given a lot of oxygen.

Every stove chim ney com bination functions a little

differently. Be patient, and expect the stove to be

different in January when it is very cold outside, than it

was in September when the weather was warmer. Once

a chimney is warmed up, its draft is a function of how

muchwarmer it is than the air around it. On m ild fall

evenings, a stove can appear to be finicky and difficult.

However, the very next night, in the midst of a fall storm,

it might act like acompletely different stove.

9. As you burn your stove and wood is consumed, ashes

will fall through the grate and into the ash pan. Also, as

you rearrange your ashes you should work them toward

the ash pan. W hen the ash pan becom es full (this

should be checked daily), pull the ash pan 3/4 of the way

out of the stove. Remove the ashes with a shovel and

place them in a metal container with a tight-fitting lid.

Assum e that there are still hot coals mixed in the. There

usually are for as long as three days.

DO NOT PLACE ASHES WITH THE GARBAGE OR

NEAR ANYTHING COMBUSTIBLE.

THE BEST IDEA IS TO LEAVE THEM OUTSIDE, THREE

FEET AWAY FROM THE HOUSE IN A METAL

CONTAINER FOR THREE DAYS.

NEVER LEAVE YOUR STOVE UNATTENDED WHEN

THE DOOR IS UNLATCHED.

6. W hen the kindling has been consumed and larger splits

are burning well, load the stove to the level you desire,

using well-seasoned, dry wood.

(Wet wood does not heat well.)

DO NOT BURN CO AL IN TH IS UNIT !

Close the doors and continue to burn the stove on high

and with the bypass open until the wood becom es fully

involved. It is not necessary to use additional grates or

irons to support the fuel.

7. Once your chimney and stove are warmed up and

drawing well, close the air inlets to the desired heat

output. Close the bypass before slowing down the air.

Reload when convenient, but always while you still have

a good bed of glowing embers. Always open the bypass

3 minutes before opening the door to reload. Never

close the bypass imm ediately after adding fresh wood to

the fire.

Ashes should be placed in a metal container with a tight

fitting lid. The closed container of ashes should be placed

on a non-combustible floor or on the ground, well away

from all combustible materials, ending final disposal. If the

ashes are disposed of by burial in soil orotherwise locally

dispersed, they should be retained in the closed container

until all cinders have thoroughly cooled. Ash removal doors

must be closed when in operation.

DEFINITION AND PURPO SE OF A CATALYT IC

COMBUSTOR

Catalytic combusto rs for woodstoves (cats ) are sim ilar in

principle to catalytic converters on autom obiles. T he big

difference is that the heat generated by your woodstove

combustor is put to use heating your home instead of

being dum ped out the tailpipe of your car. Catalytic

combustors cause wood smoke to burn at very low

temperatures, releasing energy that would otherwise be

lost in the form of smoke.

As smoke passes through the combustor, a rare metal

coating on the ceramic base of the combustor changes fuel

molecules in the smoke so that they burn at 500 to 600

degrees Fahrenheit, instead of the more normal 1000 to 1200

degrees Fahrenheit. In addition to making stoves burn

cleaner, combustors improve their heating efficiency. On the

average, you will receive 30 to 50% more heat from each

piece of wood, up to 90% less creosote and because the cat

burns most of the smoke, 90% less air pollution than you

would from burning a com parable stove. Of course, results

may be higher or lower depending on the operation, chimney

draft, and combustor age.

Figure 9

8. When opening the door to reload or to poke the fire,

open the bypass first. Crack the door and hesitate just a

few seconds before swinging it open. All this is to

OPERATION

Achieving catalytic light off. During each burning cycle, the

temperature within the stove should be raised high enough

to cause the catalyst to become active or “light off.” The

most convenient w ay to do this is during fuel loading while

warming up the wood and the chimney. With a new

combustor, smoke temperatures between 500 and 600

degrees (F) will begin catalytic burning. (Since the

com bustors sit right above a roaring fire, this is not hard to

9

Page 10

achieve if you follow the instructions in Starting a Fire and

Operating Your Stove.) As a combustor ages, its catalytic

activity decreases, so an older cat (beyond three years old)

needs m ore heata during the start-up. 700 degrees will

generally be sufficient for light off even on an old

combustor.

Your SIERRA Ambassador Insert has an option from your

dealer, a catalytic indicator which will take the guesswork

out of knowing when you have light-off.

W henever the stove is being loaded,

KEEP THE BYPASS OPEN.

Once or twice a season, remove the mixer plates and

lightly brush the face of the com bustors to rem ove any fly

ash which may have been sucked in by the chim ney draft.

Remember, the combustors and mixers can stay hot for a

long time after the last fire. Always use gloves. NEVER

remove the combustors to clean them. You will break the

seal around the combustor which will allow smoke leakage

and reduce the efficiency of the catalyst.

MAINTAINING CATALYTIC CONDITIONS:

During the start-up of a cold stove, a medium to high air

setting must be m aintained for amout 20 minutes to ensure

that the stove, catalyst, fuel, and chimney are all at proper

operating temperatures. Even though it is possible to have

smoke temperatures reach 600 degrees within two or three

minutes after a fire is started, the combustor and the

chimney are not yet warm enough.

At the end of the burn cycle, it’s possible that the amount of

burning charcoal might not provide sufficient temperatures

for the catalyst. During the refueling, we recommend that

the stove be fired hard for at least 10 minutes to ensure the

catalyst and chimney are properly warmed up. If you have

an extra long or large diamenter chimney, or if it is very

cold outside, run the stove on high for a longer period.

BURN UNTREATED WOOD ONLY, OTHER MATERIALS

SUCH AS WOOD PRESERVATIVES, METAL FOILS,

COAL, PLASTIC, GARBAGE, SULPHUR OR OIL MAY

DAMAGE THE CATALYST.

WARNING – OPERATE ONLY WITH DOORS FULLY

OPEN OR FULLY CLOSED. IF DOORS ARE LEFT

PARTLY OPEN, GAS AND FLAME MAY BE DRAWN

OUT OF THE OPENING CREATING RISKS FROM BOTH

FIRE AND SMOKE.

XIII. COMBUSTOR LIFE AND REPLACEMENT

SIERRA uses only “12,000 hour long-life combustors.” The

com bustor will still be functioning at 70% of its

effectiveness after 12,000 hours of use. Depending on the

frequency of stove use, it will last for four to twelve years

before needing replacem ent. If you find your com bustor is

not igniting, finish the burn cycle you have begun. You may

order replacement catalytic combustors from your SIERRA

dealer.

CATALYTIC WARRANTY

10

Page 11

Refer to the catalytic combustor manufacturer’s warranty

card which is packaged with the combustor.

REMOVAL FOR INSPECTION OR REPLACEMENT OF

CATALYTIC COMBUSTORS

1. Combustor assembly is accessed through stove door

opening. Using 3/8" socket, remove the two nuts (one on

each side) that holds heat shield and mixer plates.

Remove assembly through stove door. (See figure 10)

2. After removing mixer plate, use an extended socket to

loosen nuts on catalytic assembly base (one on either

side). Remove nuts and slide catalytic base assembly out

through front of unit and through stove door opening.

3. Catalytic combustors can no be inspected. If combustors

are rem oved from the holders, check condition of inter rim

gasket m aterial around the combusto rs and replace if

necessary.

4. To reassemble, ensure combustors are properly seated

in combustor holder and that the inter rim gasket is in good

condition. To complete assembly, reverse steps 1 and 2.

TO INSPECT OR REPLACE BYPASS DAMPER GASKET

For top efficiency and low emissions the bypass must be

sealed. Bypass gasket may be checked by putting a light

inside of stove (inside of fire box), looking in through flue

opening on top of stove, check for light leakage.

Should gasket need replacing, it can be accessed through

stove door. Lift old gasket up out of channel, clean

channel, re-glue, and press new gasket into place.

This is done with damper in open position.

TO REPLACE DAMPER ROD (See Fig. 12)

Reaching in through stove door, use a 5/16" open end

wrench to loosen lock nut at end of rod (against yoke).

After backing lock nut away from yoke, rod may be

unscrewed by turning counter clockwise from front of

stove. After rod is loose from yoke, remove lock nut from

rod and pull rod out.

Insert new rod through opening in front of stove, screw lock

nut onto rod, align with weld nut in yoke and turn clockwise

to tighten. When tight, run lock nut against yoke and

tighten securely.

XIV. STOVE AND CHIMNEY MAINTENANCE

CHIMNEY AND CREOSOTE

Creosote is one of the facts of life for wood burners. When

wood is burned slowly, it produces tar and oth er organic

vapor which combines with expelled moisture (even “dry”

wood contains approximately 20% moisture) to form

creosote. The creosote vapors condense in the relatively cool

chimney connectors and flue of a slow-burning fire. As a

result, creosote residue accumulates on the flue lining. Large

amounts of this tough, gummy, tar-like substance can pile up

quickly and virtually choke a stove pipe. W hen ignited, this

creosote makes an extremely hot and dangerous fire.

Be sure to examine the chimney connector pipe and the

chimney above it every few weeks so you can determine

the rate of creosote build up. Any excessive build up of

creosote (more than 1/4") will then be apparent and must

be removed for continued safe operation.

The chimney must be inspected from the top of the

chimney. For a thorough cleaning and inspection, your

SIERRA woodstove should be removed from the hearth.

If creosote has accumulated, it should be removed to

reduce the risk of a chimney fire. Creosote formations can

be chipped away from flue openings with a sturdy metal

blade such as a heavy duty scraper. C AUTIO N : The acid

content can cause burns to skin and eyes, so wear

protective glasses and gloves. T he chim ney itself is

normally cleaned from the roof. Most stove dealers carry

stiff metal brushes in sized and shapes to fit standard flue

liners. These are usually attached to rods which can be

extended for the length of the chimney. It is recommended

that you call a professional chimney cleaner to do the job

for you.

If any deterioration or damaged areas are found during

routine cleaning and inspection, consult a skilled chimney

sweep or brick mason for advice. Any repairs needed

should be com pleted before operating unit.

11

Page 12

STOVE MAINTENANCE

CARE AND CLEANING OF WOODSTOVE GLASS

At the end of each season, thoroughly clean the inside of

the firebox area including the area under the grate and ash

drawer. Vacuum all air passageways and the fan cover

screens. Check the door and window gaskets and replace

if necessary. Replace any broken bricks on the firebox

bottom. The external surface may be lightly sanded and

repainted with SIERRA high temperature stove paint,

available from your local dealer, whenever necessary.

(Make sure stove is cool.)

CLEANING THE GLASS

Your SIERRA woodstove is designed so that the glass

stays clean from normal usage. The hotter the fire and the

closer the fire is to the glass, the cleaner the glass will stay.

If your glass does become dirty, you can clean it with a

damp cloth, after the stove has cooled down. For

particularly hard to remove buildup you may use a razor

blade. Be very careful not to scratch the glass.

The glass may becom e dirty on ;your 4700 during the startup period. If this occurs, simply open the bypass

damper:then, after a minute or so, slowly open the loading

door. Gently scrape the glass clean of build-up and reclose

the door. At this point the glass will stay clean if a high

temperature level is maintained.

Inspect the glass regularly for cracks or breaks. If you find

a crack or break, replace your glass im m ediately, as air

can enter the firebox through the crack and you will not be

able to control your fire. See your SIERRA dealer for

replacement glass.

The window glass on your SIERRA woodstove is designed

for high temperature performance and will withstand

normal woodstove temperatures. However, like most glass,

it will break if struck with sufficient force. So be careful

when loading wood. You may break your glass by jamming

a lot of wood against it, or by attem pting to push a log into

the fire with the stove door. Never load your SIERRA stove

with materials which could ignite explosively; even sm all

explosions in a small airtight stove may blow out the glass.

Always use the fiberglass window gasket supplied with the

replacement glass.

Replace the door gaskets on your SIERRA stove every two

to three seasons. Replace the window gaskets only if you

need to replace the glass. See your SIERRA dealer for

SIERRA replacement parts.

BLOWER MAINTENANCE

Regularly check the fan covers for dust buildup and

remove any present. Also be sure to check the power cord

for any signs of wear or damage. Have the cord replaced

by a qualified electrician if necessary.

By following the manufacturer’s recommendations your

Sierra Stove will give you years of service

CONSUMER PROTECTION WARRANTY

Your Sierra Stove has a Lim ited Five-Year W arranty.

Please read it carefully, fill out the short registration form

and return it, within 30 days of purchase, to

Sierra Products, Inc., 5061 Brooks St. Ste. B

Montclair, CA 91763.

Sierra Products, Inc.

5061 Brooks St., Ste B

Montclair, CA 91763

(909) 399-3355

12

Page 13

Sierra Ambassador Model 4700TEC Parts List

13

P/N 140820 4700TEC MANUAL r1

Loading...

Loading...