Page 1

Operation and Installation Instructions

MODEL ZS-30

Intrinsically Safe Module

Fire Safety

Operation

The SIEMENS System 3 Intrinsically Safe Zone Model

ZS-30, consisting of a Zone Module and a Diode

Shunt Barrier, is designed for use in System 3 low

voltage control panels. With detection devices located

in hazardous areas identified as Class I, II, and III,

Division 1, Groups A, B, C, D, E, F, and G, the intrinsically safe characteristic is achieved by using a diode

shunt barrier (P/N 515-180238) with the ZS-30. The

Diode Shunt Barrier, though physically a separate unit

of ZS-30, must always be used to achieve an intrinsically safe zone. The Diode Shunt Barrier limits the

energy to the detector circuit.

The following equipment is covered by this instruction

sheet.

Item Name and

Model Number Description

NON-HAZARDOUS LOCATION EQUIPMENT

Model ZS-30 Zone module (P/N 515-022079)

Model 515-180238 Diode shunt safety barrier

(P/N 515-180238)

HAZARDOUS LOCATION EQUIPMENT

Detector DI-3IS

Detector S121

Detector S122

Base DB-3 For use with DI-3IS

Cable 465-514391 Limited-energy shielded cable

(Optional)

Check that each device to be located in the intrinsically safe area has an FM intrinsically safe label. In

addition, direct shorting manual stations and/or

thermal detectors (devices not containing any energy

storing, or voltage producing, components) may be

connected in the detector loop without jeopardizing the

intrinsically safe characteristics of the system.

NEC Hazardous Location Classification

Class I: Class I locations are those in which flammable

gases or vapors are (or may be) present in the air in

quantities sufficient to produce explosive or ignitable

mixtures.

Class II: Class II locations are those that are hazardous

because of the presence of combustible dust.

Class Ill: Class Ill locations are those that are hazardous

because of the presence of easily ignitable fibers or

flyings, but in which such fibers or flyings are not likely

to be in suspension in the air in quantities sufficient to

produce ignitable mixtures.

Division 1: A Division 1 location is a location (a) in

which hazardous concentrations of flammable gases or

vapors exist continuously, intermittently, or periodically

under normal operating conditions; or (b) hazardous

concentrations of such gases or vapors may exist

frequently because of repair or maintenance operations

or because of leakage; or (c) breakdown or faulty

operation of equipment or processes that might release

hazardous concentrations of flammable gases or vapors

occur and might also cause simultaneous failure of

electric equipment.

Group A: Group A atmospheres contain acetylene.

Group B: Group B atmospheres contain such chemi-

cals as butadiene, hydrogen ethylene oxide

(or gases or vapors of equivalent hazard to

hydrogen, such as manufactured gas), or

propylene oxide.

Group C: Group C atmospheres contain such chemicals

as acetaldehyde, cyclopropane, diethyl

ether, ethylene, isoprene, or unsymmetrical

dimethyl hydrazine (UDMH).

Group D: Group D atmospheres contain such chemicals

as acetone, acrylonitrile, alcohols, ammonia,

Siemens Building Technologies, Inc.

8 Fernwood Road

Florham Park, New Jersey 07932

P/N 315-024056-17

Siemens Building Technologies, Ltd.

2 Kenview Boulevard

Brampton, Ontario L6T 5E4 CN

Page 2

benzine, benzol, butane, ethylene dichloride, gasoline, hexane, lacquer solvent

vapors, naphtha, natural gas, propane,

propylene, styrene, vinyl acetate, vinyl

chloride, or xylenes.

Group E: Atmospheres containing combustible metal

dusts regardless of resistivity, or other

combustible dusts of similarly hazardous

characteristics having resistivity of less than

105 ohm/centimeter.

Group F: Atmospheres containing carbon black,

charcoal, coal, or coke dusts which have

more than 8 percent total.

Group G: Atmospheres containing combustible dusts

having resistivity of 105 ohm/centimeter or

greater.

Description

The heat and smoke actuated detectors are located

in a hazardous location. A Class B two wire detector

circuit extends back to the non-hazardous location

where connections are made to terminals 5 (output

ground) and 1 (output) of the Diode Shunt Barrier

located in the system control panel cabinet (or in a

separate enclosure). Under normal operating conditions voltage and current in the hazardous locations

are at levels known to be safe for intrinsically safe

electrical equipment operating in Group A atmospheres. However, should any combination of two

independent faults occur (plus field wiring failures)

within the system, the barrier will prevent the appearance of excessive voltage and currents in the hazardous location. The ZS-30 module is part of a low

voltage control panel and is connected to the barrier

and detector circuit. The module is mounted on a

System 3 panel along with the control unit. The

intrinsically safe module is interconnected to System 3

modules bus wire cable and draws its power from the

System 3 power supply through the control unit. The

module provides regulated voltage to the detectors in

the hazardous locations through the Diode Shunt

Barrier. It also detects and generates trouble and

alarm conditions. Alarm and trouble conditions are

indicated by red and yellow LEDs on the panel on the

intrinsically safe zone, and corresponding high-going

electronic signals are passed to the control unit. The

detector circuit consists of up to ten DI-3IS ionizationtype smoke detectors or up to five S121 or S122 flame

detectors, in addition to any number of mechanical

(non-energy storing) shorting devices. The detector

circuit is terminated by a 5.6K ohm end of line resistor.

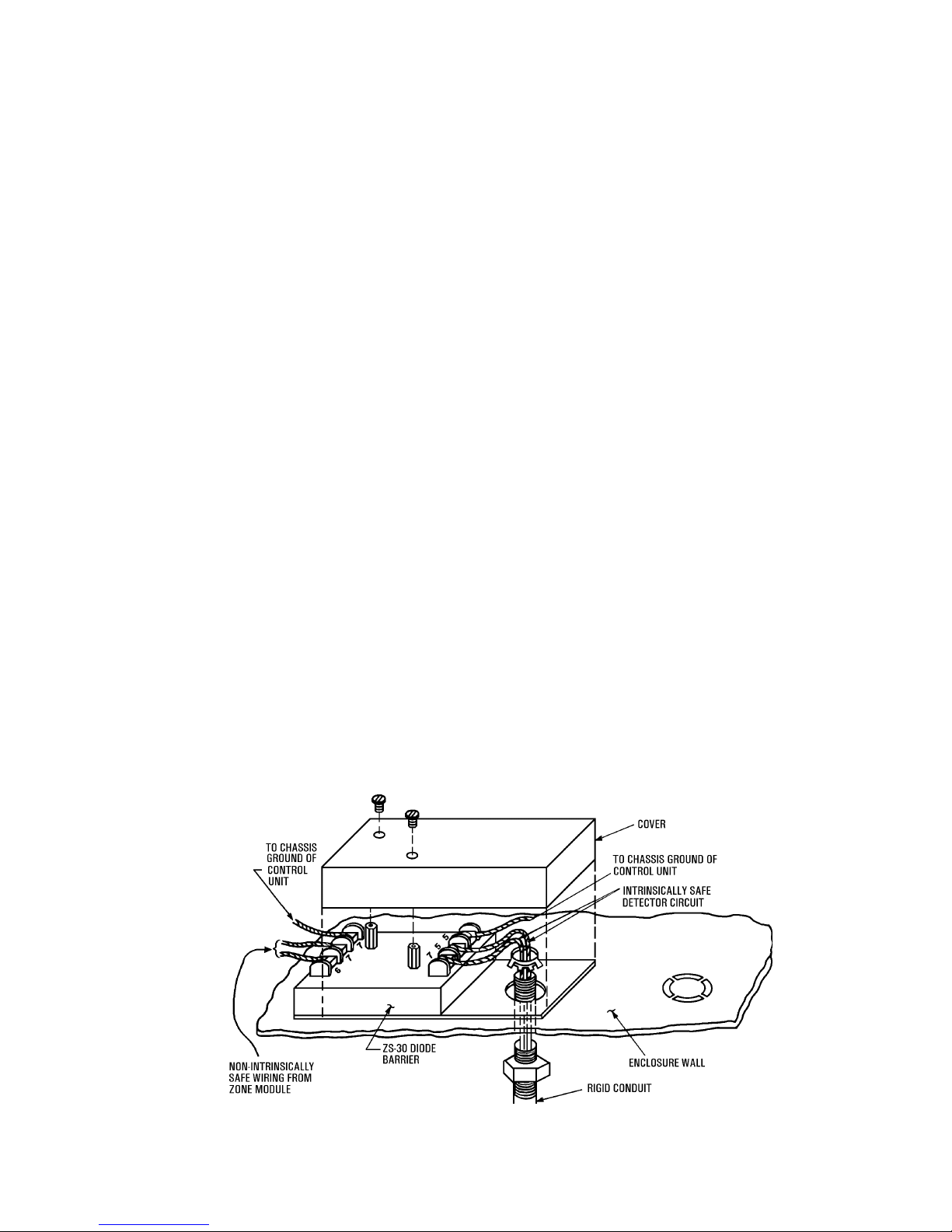

Installation

Refer to Figures 1-3 below when installing the ZS-30.

The Diode Barrier may be located in the main control

panel or in a separate enclosure; but, in either case,

care must be exercised in installation.

System 3 chassis ground must be removed. Each

duplicate (redundant) grounding conductor should be

connected to the grounding connections on the barrier

device and run directly to the ground electrode not

via other paths leading to that electrode.

Each ground wire must be 14 or 18 AWG wire and

should not exceed an impedance of 1 ohm. All ground

wires should be connected separately to the same

ground location. Wiring connected to the barrier output

Figure 1

Field Assembly of Diode Barrier

2

Page 3

(terminals 1 and 5) must be grouped with intrinsically

safe circuits and must not run in conduits and wireways containing non-intrinsically safe circuits.

Wiring from the control unit enclosure or separate

diode barrier enclosure to the intrinsically safe zone

must be rigid conduit, and the conduit should be sealed

off from the hazardous area at the barrier wall by using

standard EY conduit seals to isolate the hazardous

atmosphere from the control equipment. Chico X fiber

and Chico A sealing compound must be used to make

the seal. Wiring in the hazardous area may be either

limited energy shielded cable (Siemens Building

Technologies, Inc. P/N 465-514391) or any type of

general purpose wire. The diode barrier may be

located either in the control unit enclosure or in its own

enclosure. Proper assembly and conduit are essential;

follow Figure 1.

Non-energy storing devices such as a manual station

may be connected in the detector loop without jeopar-

dizing the intrinsically safe characteristics of the

system. Such devices must be connected in parallel

with the barrier output, must not contain any energy

storing component(s), and must be operationally

approved by Factory Mutual for the intended purpose.

Maximum detector loop resistance must not exceed

50 ohms, exclusive of the 5.6K ohm end of line resistor.

The maximum inductance and capacitance for cables

or wires connected to the barrier output should not

exceed the following values for each group.

Maximum Maximum Capacitance

Inductance Excluding Detector

in mH Capacitance in µF

Group A 20 .1

Group B 20 .1

Group C,E,F 80 .3

Group D,G 150 .8

Note: FM Control Document there are to be no changes to this document without prior Factory Mutual approval.

Figure 2

Barrier Label

3

Page 4

NOTES:

1. TROUBLE AND ALARM OUTPUT:

OPEN CIRCUIT VOLTAGE 22 VDC

SHORT CIRCUIT CURRENT 30 mA

2. WHEN ZS-30 IS USED, SYSTEM CHASSIS GROUND CONNECTION MUST BE

REMOVED AND TERMINALS 5 AND 7 OF DIODE SHUNT BARRIER MUST BE

INDEPENDENTLY CONNECTED TO CHASSIS GROUND.

3. MAXIMUM LOOP RESISTANCE MUST NOT EXCEED 50 OHMS.

4. A MAXIMUM OF TEN DI-3IS IONIZATION DETECTORS OR UP TO

FIVE S121 OR S122 FLAME DETECTORS CAN BE USED IN ADDITION TO

MECHANICAL (NON-ENERGY STORING) SHORTING DEVICES.

5. MAXIMUM SAFE SYSTEM VOLTAGE IS 250 VAC.

P/N 315-024056-17

6. REFER TO TEXT FOR LIMITATIONS AND DEFINITION OF THE HAZARDOUS

AREA.

7. ONLY MECHANICAL (NON-ENERGY STORING) SHORTING DEVICES SUCH AS

THE MS-51 MANUAL STATION MAY BE USED.

8. WARNING: DO NOT MAKE ANY CONNECTION TO TERMINAL 6 OF THE DI-3IS

BASE. SUCH A CONNECTION WOULD VOID USE IN AN INTRINSICALLY SAFE

APPLICATION.

9. IN ADDITION, S121 AND S122 ARE ALSO APPROVED FOR USE IN CLASS II

AND CLASS III, GROUPS E, F, AND G.

Figure 3

Wiring Diagram

ZS-30 Intrinsically Safe Zone

Loading...

Loading...