Page 1

Ultrasonic Transducers

XPS10/15F

Operating Instructions 08/2013

Page 2

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as

that of others, and to protect the product and the connected equipment. These warning

notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with

this manual. Qualified personnel are only authorized to install and operate this equipment in

accordance with established safety practices and standards.

Unit Repair and Excluded Liability:

The user is responsible for all changes and repairs made to the device by the user or

the user’s agent.

All new components are to be provided by Siemens Milltronics Process Instruments.

Restrict repair to faulty components only.

Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens AG 2013. All Rights

Disclaimer of Liability

Reserved

This document is available in bound version

and in electronic version. We encourage users

to purchase authorized bound manuals, or to

view electronic versions as designed and

authored by Siemens Milltronics Process

Instruments. Siemens Milltronics Process

Instruments will not be responsible for the

contents of partial or whole reproductions of

either bound or electronic versions.

While we have verified the contents of

this manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents

of this manual are regularly reviewed

and corrections are included in

subsequent editions. We welcome all

suggestions for improvement.

Technical data subject to change.

MILLTRONICS® is a registered trademark of Siemens Milltronics Process Instruments.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens AG Industry Sector

Siemens Milltronics Process Instruments 76181 Karlsruhe

1954 Technology Drive, P.O. Box 4225 Deutschland

Peterborough, Ontario, Canada K9J 7B1

Email: techpubs.smpi@siemens.com

For a selection of Siemens Milltronics level measurement manuals, go to:

www.siemens.com/processautomation. Under Process Instrumentation, select Level

Measurement and then go to the manual archive listed under the product family.

For a selection of Siemens Milltronics weighing manuals, go to:

www.siemens.com/processautomation. Under Weighing Technology, select Continuous

Weighing Systems and then go to the manual archive listed under the product family.

© Siemens AG 2013

Page 3

Table of Contents

Table of Contents .................................................................................. i

About Siemens’ Transducers.............................................................. 1

Hazardous Area Applications...................................................1

Specifications ....................................................................................... 2

XPS 10 F Series Transducers.................................................. 2

XPS 15 F Series Transducers.................................................. 3

Outline and Dimensions ......................................................................4

XPS 10 F Series Transducers.................................................. 4

XPS 15 F Series Transducers.................................................. 5

Mounting ............................................................................................... 6

Recommendations...................................................................6

Solids Applications (XPS 10 F shown)..................................... 6

Liquid Applications...................................................................7

Interconnection .................................................................................... 8

Interconnection .................................................................................... 9

Recommendations...................................................................9

Applications........................................................................................ 11

Liquid Applications.................................................................11

Solids Applications................................................................. 16

Installation Diagram for the XPS 10 F............................................... 20

A5E32725813 XPS 10/15 F Series Transducer Page i

Page 4

Page ii XPS 10/15 F Series Transducer A5E32725813

Page 5

About Siemens’ Transducers

This product is intended for use in industrial areas. Operation of this

equipment in a residential area may cause interference to several

frequency based communications.

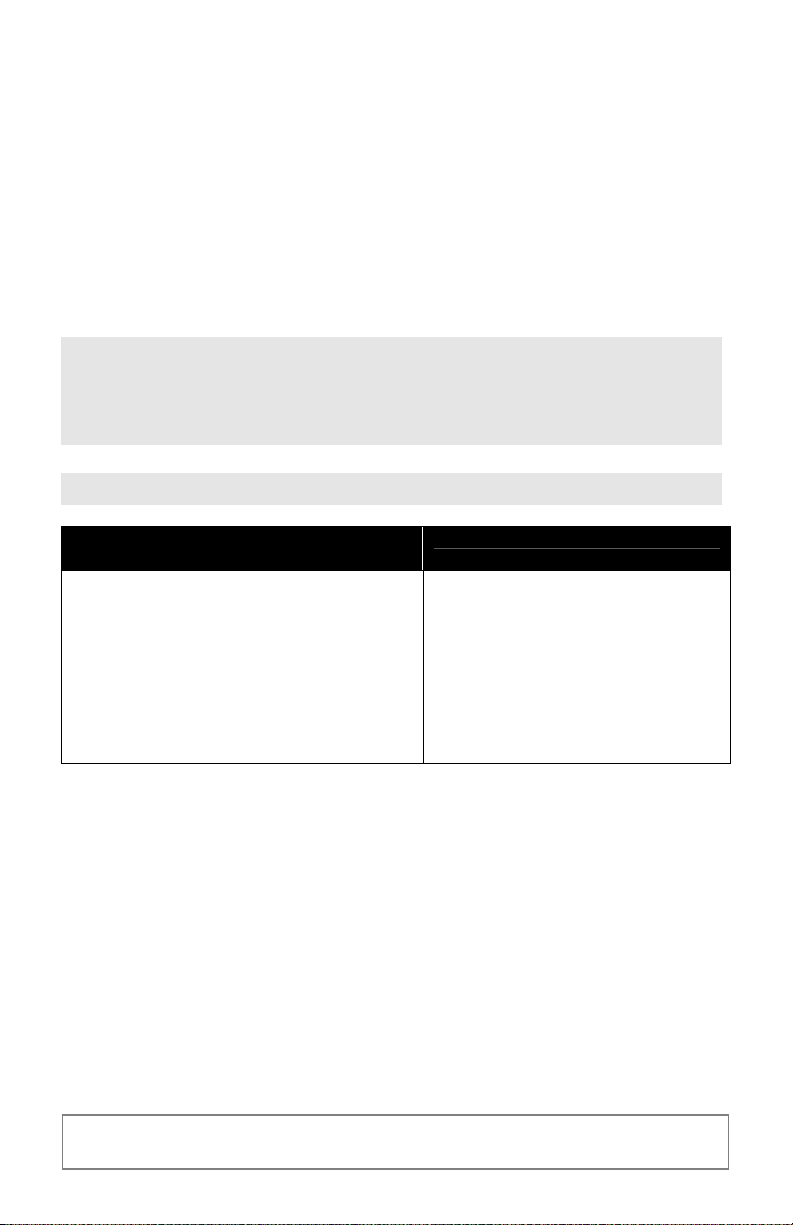

The Echomax XPS F series of

transducers operates in association with

Siemens ultrasonic level monitoring

hazardous seal

(XPS 10 F

series only)

products.

transducer

The transducer operates by converting

electrical pulses that are provided by the

transceiver into ultrasonic pulses. When

transmitted, these ultrasonic pulses

reflect from the material surface and echo

transducer

face

back to the transducer. The echo is

converted back to an electrical signal,

and is interpreted by the Siemens

-3db

boundary

tranceiver using our proven Sonic

Intelligence™ algorithms.

The effective acoustical energy is emitted

from the transducer face and radiated

outward, decreasing in amplitude at a

axis of

transmission,

perpendicular

to transducer

face

rate inversely proportional to the square

of the distance.

Maximum power is radiated axially

(perpendicular) from the transducer face in a line

referred to as the axis of transmission. Where power is reduced by half (– 3

dB), a conical boundary defining the sound beam, centered about the axis of

transmission, is established. The diametric measurement of the cone in

degrees defines the beam angle. Impedance matching techniques are used

to optimize the transfer of power from the transducer into air and vice versa.

About the…

The XPS F series transducers incorporate an integral temperature sensor

that reports the air temperature at the transducer to the transceiver. The

connection is transparent, in that both the ultrasonic and temperature

components of the transducer use the same leads.

Hazardous Area Applications

The Echomax XPS F series of transducers can be used in hazardous are as.

For the XPS 10 F series transducer, a hazardous seal must be used to suit

hazardous area classification. This seal is not supplied by Siemens.

The XPS 15 F comes equipped with a stainless steel coupling suitable for

use in hazardous locations.

A5E32725813 XPS 10/15 F Series Transducer Page 1

Page 6

Specifications

XPS 10 F Series Transducers

Measurement Range:

0.3 – 10m (1 – 33ft)

Frequency:

43kHz

Beam Angle:

12°

Environmental

Specifications

Construction

Supply Source

Weight2

Separation

location: indoor/outdoor

altitude: 2000m maxim um

ambient temperature: -20 to 95°C (-4 to 203°F)

pollution degre e: 4

exposure: Kynar

colour: slate gray

mounting: 1” NPT conduit connection

options: factory flange to suit ANSI standard

submergence shield, where flooding can occur

split flange for field mounting to suit ANSI

cable: 2-wire shielded / t wisted, 0.5 mm

®1

2

(20 AWG) PVC

jacket

Transducer sh all only be supplied by a Siemens certified controller.

0.8kg (1.8lb)

365m (1200ft) from transducer

Approvals

FM Class 1 Div 1, Group A, B, C and D

FM Class 2 Div 1, Group E, F, and G

see nameplate or consult Siemens for other current approvals

1

Kynar® is registered trade mark of ELF Atochem.

2

approximate shipping weight of transducer with standard cable length

Page 2 XPS 10/15 F Series Transducer A5E32725813

Page 7

XPS 15 F Series Transducers

Measurement Range:

0.45 – 15m (1.5 – 50ft)

Frequency:

43kHz

Beam Angle:

6°

Environmental

location: indoor/outdoor

altitude: 2000m maxim um

ambient temperature: -20 to 95°C (-4 to 203°F)

pollution degre e: 4

Specifications

Construction

jacket

®3

2

(20 AWG) PVC

exposure: Kynar

colour: slate gray

mounting: 1” NPT conduit connection

options: factory flange to suit ANSI standard

submergence shield, where flooding can occur

split flange for field mounting to suit ANSI

cable: 2-wire shielded / t wisted, 0.5 mm

Supply Source

Transducer sh all only be supplied by a Siemens certified controller.

Weight4

2.0 kg (4.4lb)

Separation

365m (1200ft) from transducer

Approvals

FM Class 1 Div 1, Group A, B, C and D

FM Class 2 Div 1, Group E, F, and G

see nameplate or consult Siemens for other current approvals

3

Kynar® is registered trade mark of ELF Atochem

4

approximate shipping weight of transducer with standard cable length

A5E32725813 XPS 10/15 F Series Transducer Page 3

Page 8

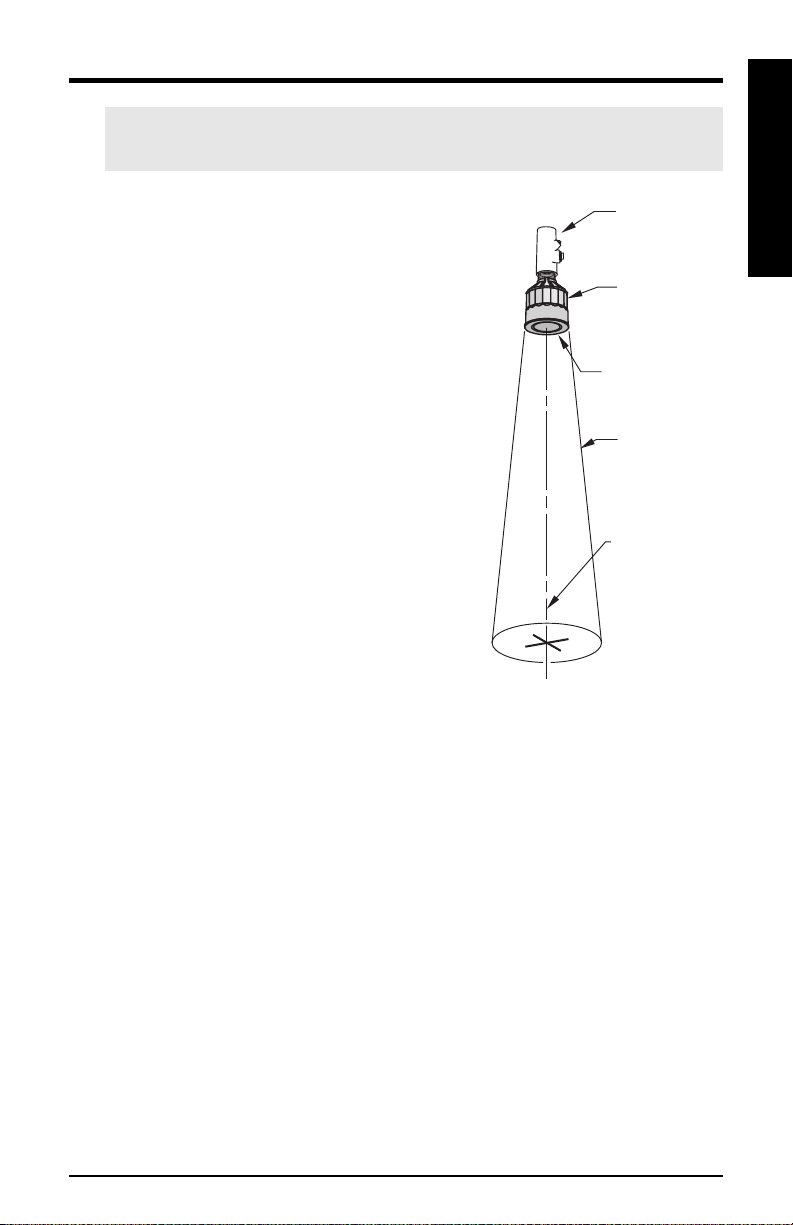

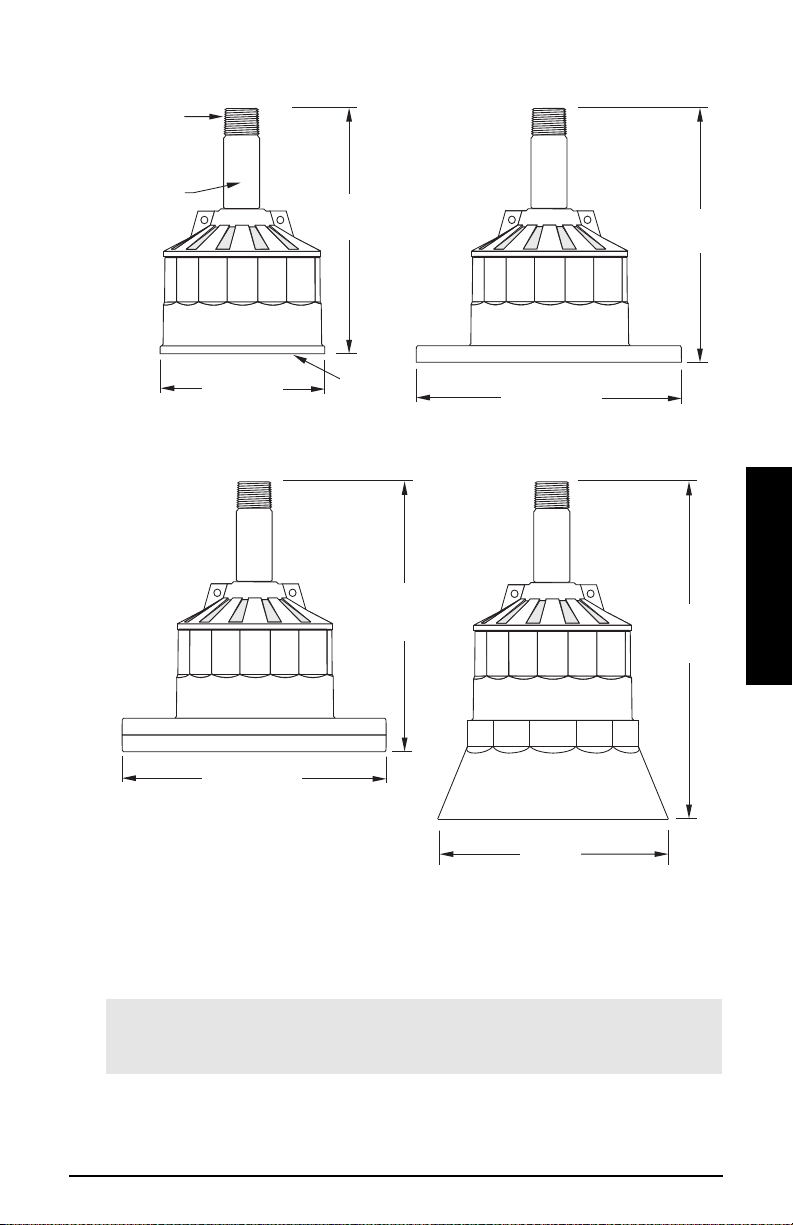

Outline and Dimensions

XPS 10 F Series Transducers

Standard Flange (optional)

Outline & Dimensions

122mm

(4.8”)

86mm

(3.4”)

radiating

face

to suit ANSI

standards

122mm

(4.8”)

Split Flange (optional) Submergence Shield (optional)

128mm

(5.0”)

to suit ANSI

standards

nominal

152mm

(6.0”)

124mm

(4.9”)

Refer to submergence shield instructions

(Siemens’ manual number

7ML19981EG01)

Note:

For the XPS 10 F series transducer, a hazardous seal must be used to

suit hazardous area classification. This seal is not supplied by Siemens.

For more information, refer to page 20.

Page 4 XPS 10/15 F Series Transducer A5E32725813

Page 9

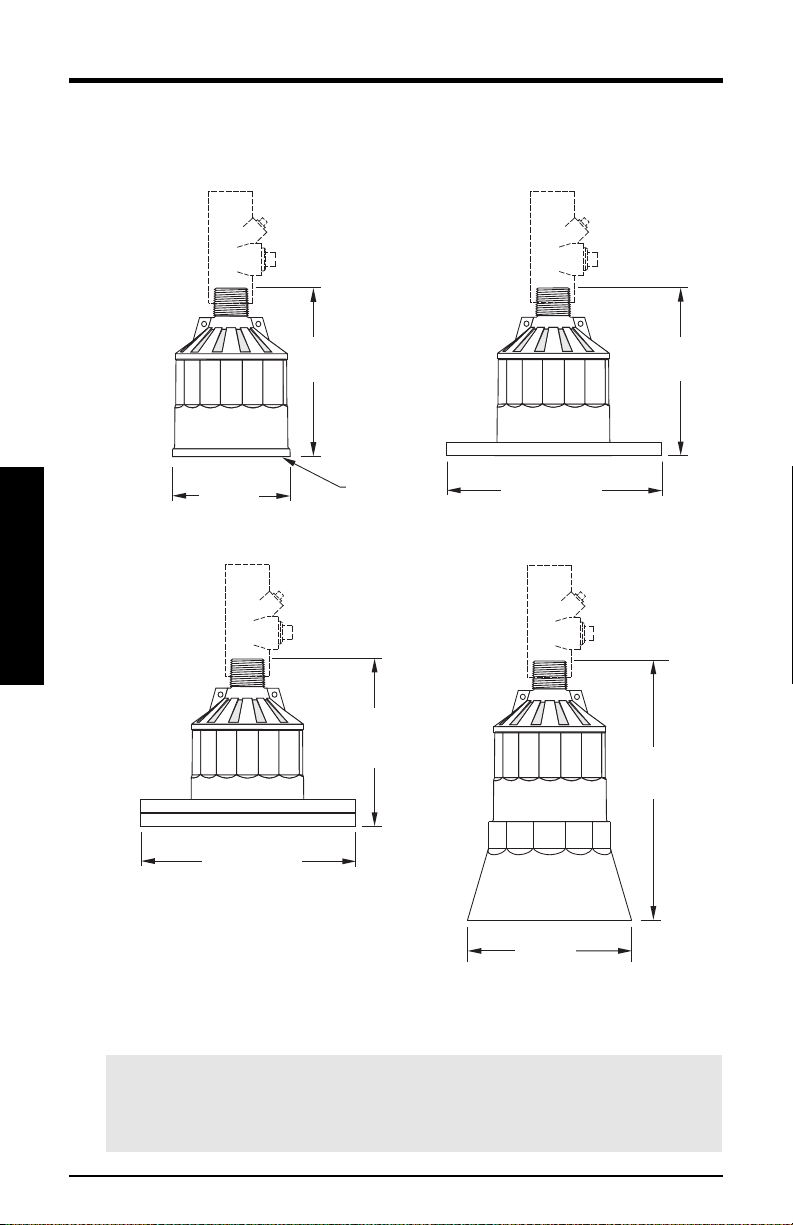

XPS 15 F Series Transducers

Standard Flange (optional)

1” NPT

304

stainless

steel

120mm

(4.7”)

185mm

(7.3”)

radiating

face

to suit ANSI

standards

185mm

Split Flange (optional) Submergence Shield (optional)

191mm

(7.5”)

nominal

253mm

(10.0”)

(7.3”)

Outline & Dimensions

to suit ANSI

standards

158mm

(6.2”)

Refer to submergence shield instructions

(Siemens’ manual number

7ML19981EG01)

Note:

The XPS 15 F comes equipped with a stainless steel coupling suitable for

use in hazardous locations.

A5E32725813 XPS 10/15 F Series Transducer Page 5

Page 10

Mounting

Recommendations

Special handling precautions must be taken to protect the face of the

transducer from any damage.

Mount the transducer so that it is above the maximum material level by at

least the blanking value (0.3m for XPS 10 F and 0.45m for XPS 15 F). Refer

to the associated transceiver manual for instructions on setting the blanking

value.

On liquid applications, the transducer must be mounted so that the axis of

transmission is perpendicular to the liquid surface.

On solids applications, a Siemens Easy Aimer should be used to facilitate

aiming of the transducer.

Do not over-tighten mounting. Hand tightening of the mounting hardware is

sufficient.

Secure installation by connecting a safety chain from the transducer to a

structural member.

Consider the optional temperature sensor when mounting the transducer.

Solids Applications (XPS 10 F shown)

Easy Aimer

(typical model)

Mounting

safety chain

transducer

Note:

For the XPS 10 F series transducer, a hazardous seal must be used

to suit hazardous area classification. This seal is not supplied by

Siemens. For more information, refer to page 20.

Page 6 XPS 10/15 F Series Transducer A5E32725813

Page 11

Liquid Applications

Notes:

In, the examples that follow, an XPS 10 F Series transducer is shown

using a hazardous seal. This seal is not supplied by Siemens.

An XPS 15 F transducer can also be used in these applications, but,

because it comes equipped with a stainless steel coupling, no

hazardous seal is required.

Flexible Conduit

safety

chain

(XPS 10 F shown) Bracket (XPS 10 F shown)

flexible

conduit

steel

channel

hazardous seal

(XPS 10 F only)

transducer

Flexible conduit transducer should not be

subjected to wind, vibration or jarring.

Submersible (XPS 10 F shown)

rigid metal

conduit

safety

chain

hazardous seal

(XPS 10 F only)

submergence

shield

Submersible transducer, used in

applications where flooding is possible.

A5E32725813 XPS 10/15 F Series Transducer Page 7

Mounting

Page 12

Blind Flange (XPS 10 F shown)

Flange, gasket, hazardous seal and hardware supplied by customer.

Refer to page 13

nipple welded

to bind flange

hazardous seal

(XPS 10 F only)

Flanged (XPS 10 F shown)

Mounting

Flange, gasket, and hardware supplied by customer.

Refer to page 13

Note: Tighten the flange bolts evenly in order to ensure a good seal between

the mating flanges.

Caution: Over-tightening can cause performance degradation.

hazardous seal

(XPS 10 F only)

factory flanged

transducer

bolt

gasket

customer flanged,

flat face only

nut

Page 8 XPS 10/15 F Series Transducer A5E32725813

Page 13

Interconnection

Note:

Installation should only be performed by qualified personnel and in

accordance with local governing regulations.

Recommendations

When using an XPS 15 F transducer, configure the electronic transceiver for

an XCT-12. These two transducers use the same settings.

Do not route cable openly.

For optimum isolation against electrical noise, run cable separately in a

grounded metal conduit.

Seal all thread connections to prevent ingress of moisture.

Do not run cable near high voltage or current runs, contactors and SCR

control drives.

Note:

In the interconnection examples that follow:

an XPS 10 F Series transducer is shown. An XPS 15 F transducer can

also be used, but no hazardous seal is required.

assume that the transducer is located in a Hazardous location (Class I,

Div. 1, Group A,B,C,D or Class II, Div. 1, Group E,F,G.) and the

transceiver in a Non-Hazardous (Safe) Location.

Direct Connection (XPS 10 F shown)

Hazardous Location

(Class I, Div. 1, Group

A,B,C,D or Class II, Div.

1, Group E,F,G)

metal conduit

Note:

When connecting to SITRANS LUT400, SITRANS LUC500,

MultiRanger 100/200, or HydroRanger 200, the white,

black, and shield wires are all connected separately. DO

NOT tie the white and shield wires together.

A5E32725813 XPS 10/15 F Series Transducer Page 9

Non-Hazardous Location

(Safe)

blk

wht

drain / shield

interconnection

Page 14

2-Wire Extension (XPS 10 F shown)

Hazardous Location

(Class I, Div. 1, Group

A,B,C,D or Class II, Div.

1, Group E,F,G)

metal conduit

Non-Hazardous Location

Note:

When connecting to SITRANS LUT400, SITRANS

LUC500, MultiRanger 100/200, or HydroRanger 200, the

white, black, and shield wires are all connected

separately. DO NOT tie the white and shield wires

together.

Coaxial Cable (XPS 10 F shown)

Hazardous Location

(Class I, Div. 1, Group

A,B,C,D or Class II, Div.

1, Group E,F,G)

Non-Hazardous Location

(Safe)

junction box

drain / shield

blk

wht

extend cable using 18 AWG

shielded / twisted pair

(Safe)

Interconnection

Page 10 XPS 10/15 F Series Transducer A5E32725813

metal conduit

extend cable using RG – 62 A/U

coax for optimum noise immunity

Note:

When connecting to SITRANS LUT400, SITRANS

LUC500, MultiRanger 100/200, or HydroRanger 200, do

NOT use coaxial cable.

Page 15

Applications

r

Notes:

The transducer is to be used only in the manner outlined in this

instruction manual.

Normally, the transducer requires no cleaning or maintenance.

However, if performance changes are observed, immediately shut

down the level measurement system and perform a thorough

inspection, especially on the transducer.

An XPS 10 F Series transducer is shown in these examples. An XPS

15 F transducer can also be used, but no hazardous seal is required.

Liquid Applications

Stilling Well / OCM

blind flange

air vent

TS-3 *

Applications

transduce

standpipe

bracing

standpipe inlet

primary element

stilling well inlet

Refer to page 13.

A5E32725813 XPS 10/15 F Series Transducer Page 11

stilling well

Page 16

Submergence

Applications

* the use of a TS-3 temperature sensor provides better temperature tracking in

applications where the temperature can change quickly.

In applications where flooding is possible, the transducer can be fitted with a

submergence shield*. The shield acts as a bell to create an air pocket in

front of the transducer face. The associated transceiver* interprets this as a

flooding condition, and reacts accordingly.

Note:

Refer to transceiver manual for programming requirements.

hazardous seal

(XPS 10 F only)

transducer

submergence shield*

(Refer to Siemens

instruction manual

7ML19981EG01 for

assembly details)

air pocket

* on applicable models

Page 12 XPS 10/15 F Series Transducer A5E32725813

Page 17

Standpipes

In many applications, access must be made via a standpipe. In such cases,

Siemens can provide factory bonded flanged transducers or a split flange kit

that will readily mate to the flanged standpipe. Another option is to hang the

transducer from a blind flange.

The standpipe length should be as short and the diameter as large as

possible. As a rule of thumb, the -3 dB cone of the sound beam should not

intersect the standpipe wall in applications opening into a vessel or larger

area. Otherwise, additional blanking will be required to compensate for the

interference zone created by the opening.

Note: When using a stilling well, make sure there is no build-up, welds,

couplings, or other debris on the inside of the well wall. This can affect

reliability of measurement.

flanged

transducer

Applications

no

vessel

vessel

no

intersection

no additional blanking required no additional blanking required

transducer

can read

level inside

or below

standpipe

no additional blanking required near blanking extension of 150 mm (6”)

nipple

welded into

blind flange

transducer

standpipe

end cut on a

45° angle

typically

vessel

past end of standpipe may be required.

nipple

welded into

blind flange

transducer

sound beam

intersects

reflection at

interference

zone created

by opening

A5E32725813 XPS 10/15 F Series Transducer Page 13

Page 18

Volume

‘Alternate’

‘Preferred’

‘Bad’

Maintain full level

for full calibration.

Above this level

erroneous readings

Applications

will result as level

has entered

blanking zone.

(shaded area)

Empty level for

‘alternate locations.

Below this level,

echo would reflect

away from the

transducer.

may require target to

obtain empty reading

rise

discharge

beam

angle

tank

manufacturer’s

full level

span:

corresponds to tank

manufacturer’s

empty level.

tank

manufacturer’s

empty level

1. Beam should not detect bin bottom. If this occurs, use range extension

parameters (on transceivers where available) to omit false echoes. A 6° beam

angle (XPS 15 F) represents a rise:run of about 20:1 (10:1 for the 12° beam

angle of the XPS 10 F). In most tanks, the transducer should be centered as

much as possible (without interference from inlet) for optimum reading range.

2. Sound beam must be perpendicular to liquid surface. If standpipe is used,

refer to page 13.

3. Echo has missed improperly levelled transducer.

4. When performing an empty or full calibration, the tank must contain its

normal vapour and be at its normal temperature.

5. When used in hazardous areas, the XPS 10 F series transducer (shown)

must use a hazardous seal. This seal is not supplied by Siemens. The XPS

15 F Series transducer comes equipped with a stainless steel coupling

suitable for use in hazardous locations.

Page 14 XPS 10/15 F Series Transducer A5E32725813

Page 19

Water / Wastewater

Differential Level

Pump Control

Applications

Sewage Lift

A5E32725813 XPS 10/15 F Series Transducer Page 15

Page 20

Solids Applications

r

Typical

1. Transducer angled to avoid seams in bin wall and aimed at discharge in

2. Avoid intersecting bin wall seams, structural members and wall irregularities.

Applications

3. Transducer too close to material inlet. Falling material will intersect sound

order to read bin when empty.

1

bin wall seams

2

filling profile

emptying profile

beam and cause erroneous readings or loss of echo.

Easy Aime

3

Page 16 XPS 10/15 F Series Transducer A5E32725813

Page 21

4. On fluid like solids, aim transducer perpendicular to material surface.

r

minimal angle

of repose

4

Applications

discharge

5. On dual discharge bins, aim each transducer at the discharge point.

transduce

5

A5E32725813 XPS 10/15 F Series Transducer Page 17

Page 22

Special

r

1. Transducer should be kept away from infeed.

2. Where agitators are in use, use the Agitator Discrimination parameter on

Applications

3. Transducer should be aimed away from wall projections.

4. When used in hazardous areas, the XPS 10 F series transducer (shown)

Storage Bin with Agitator

transceivers where available.

must use a hazardous seal. This seal is not supplied by Siemens. The XPS

15 F Series transducer comes equipped with a stainless steel coupling

suitable for use in hazardous locations.

infeed

agitato

Page 18 XPS 10/15 F Series Transducer A5E32725813

Page 23

Dryer - Wood Chips

r

1. Transducer should be mounted perpendicular to slope of wood chips.

2. When used in hazardous areas, the XPS 10 F series transducer (shown)

must use a hazardous seal. This seal is not supplied by Siemens. The XPS

15 F Series transducer comes equipped with a stainless steel coupling

suitable for use in hazardous locations.

infeed

drag conveyo

Applications

typical low

level

typical high

level

A5E32725813 XPS 10/15 F Series Transducer Page 19

Page 24

Installation Diagram for the XPS 10 F

Installation Diagram

Page 20 XPS 10/15 F Series Transducer A5E32725813

Page 25

Notes

Page 26

Notes

Page 27

Page 28

www.siemens.com/processautomation

For more information

www.siemens.com/level

www.siemens.com/continuous-weighing

Siemens AG

Industry Sector

1954 Technology Drive

P.O. Box 4225

Peterborough, ON

Canada K9J 7B1

email: techpubs.smpi@siemens.com

www.siemens.com/processautomation

Subject to change without prior notice

A5E32725813 Rev. AA

© Siemens AG 2013

*A5E32725813*

Printed in Canada

Loading...

Loading...