Siemens XPS10,XPS10F,XPS15F Operating Instructions Manual

Ultrasonic Transducers

XPS10/15F

Operating Instructions 08/2013

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as

that of others, and to protect the product and the connected equipment. These warning

notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with

this manual. Qualified personnel are only authorized to install and operate this equipment in

accordance with established safety practices and standards.

Unit Repair and Excluded Liability:

The user is responsible for all changes and repairs made to the device by the user or

the user’s agent.

All new components are to be provided by Siemens Milltronics Process Instruments.

Restrict repair to faulty components only.

Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens AG 2013. All Rights

Disclaimer of Liability

Reserved

This document is available in bound version

and in electronic version. We encourage users

to purchase authorized bound manuals, or to

view electronic versions as designed and

authored by Siemens Milltronics Process

Instruments. Siemens Milltronics Process

Instruments will not be responsible for the

contents of partial or whole reproductions of

either bound or electronic versions.

While we have verified the contents of

this manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents

of this manual are regularly reviewed

and corrections are included in

subsequent editions. We welcome all

suggestions for improvement.

Technical data subject to change.

MILLTRONICS® is a registered trademark of Siemens Milltronics Process Instruments.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens AG Industry Sector

Siemens Milltronics Process Instruments 76181 Karlsruhe

1954 Technology Drive, P.O. Box 4225 Deutschland

Peterborough, Ontario, Canada K9J 7B1

Email: techpubs.smpi@siemens.com

For a selection of Siemens Milltronics level measurement manuals, go to:

www.siemens.com/processautomation. Under Process Instrumentation, select Level

Measurement and then go to the manual archive listed under the product family.

For a selection of Siemens Milltronics weighing manuals, go to:

www.siemens.com/processautomation. Under Weighing Technology, select Continuous

Weighing Systems and then go to the manual archive listed under the product family.

© Siemens AG 2013

Table of Contents

Table of Contents .................................................................................. i

About Siemens’ Transducers.............................................................. 1

Hazardous Area Applications...................................................1

Specifications ....................................................................................... 2

XPS 10 F Series Transducers.................................................. 2

XPS 15 F Series Transducers.................................................. 3

Outline and Dimensions ......................................................................4

XPS 10 F Series Transducers.................................................. 4

XPS 15 F Series Transducers.................................................. 5

Mounting ............................................................................................... 6

Recommendations...................................................................6

Solids Applications (XPS 10 F shown)..................................... 6

Liquid Applications...................................................................7

Interconnection .................................................................................... 8

Interconnection .................................................................................... 9

Recommendations...................................................................9

Applications........................................................................................ 11

Liquid Applications.................................................................11

Solids Applications................................................................. 16

Installation Diagram for the XPS 10 F............................................... 20

A5E32725813 XPS 10/15 F Series Transducer Page i

Page ii XPS 10/15 F Series Transducer A5E32725813

About Siemens’ Transducers

This product is intended for use in industrial areas. Operation of this

equipment in a residential area may cause interference to several

frequency based communications.

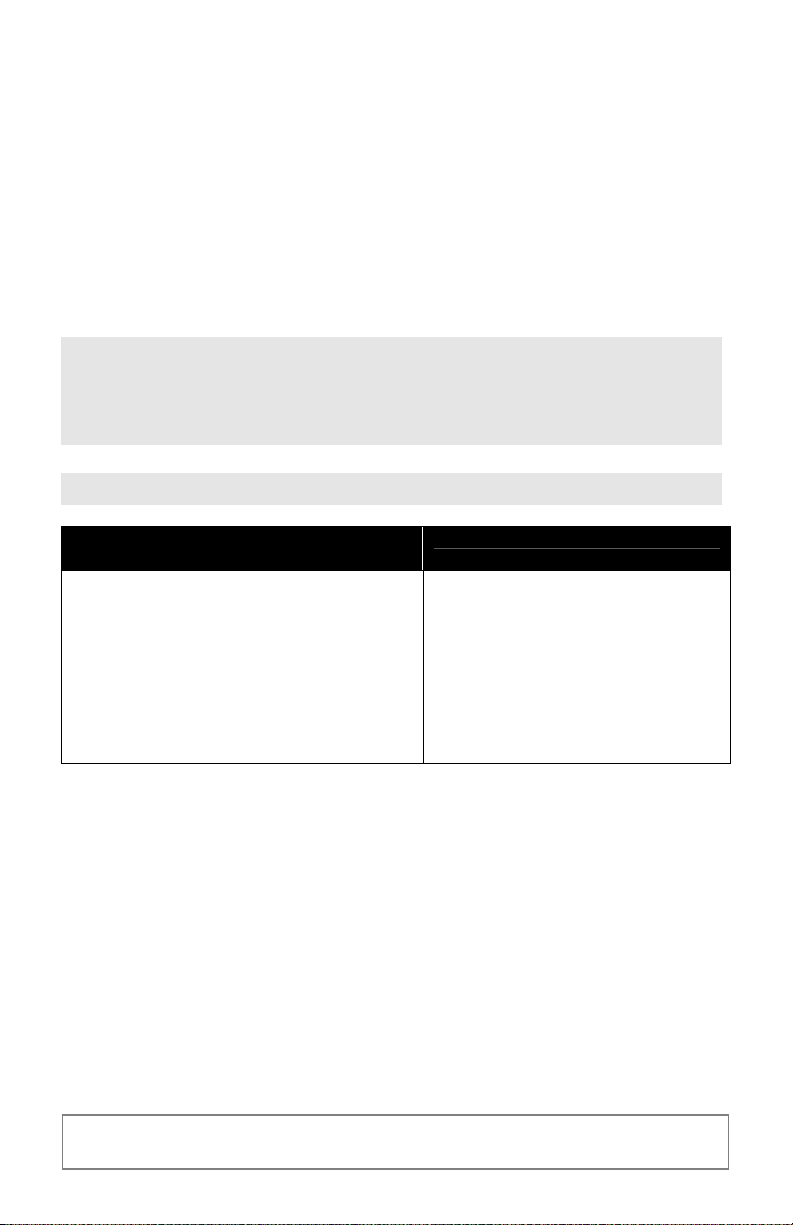

The Echomax XPS F series of

transducers operates in association with

Siemens ultrasonic level monitoring

hazardous seal

(XPS 10 F

series only)

products.

transducer

The transducer operates by converting

electrical pulses that are provided by the

transceiver into ultrasonic pulses. When

transmitted, these ultrasonic pulses

reflect from the material surface and echo

transducer

face

back to the transducer. The echo is

converted back to an electrical signal,

and is interpreted by the Siemens

-3db

boundary

tranceiver using our proven Sonic

Intelligence™ algorithms.

The effective acoustical energy is emitted

from the transducer face and radiated

outward, decreasing in amplitude at a

axis of

transmission,

perpendicular

to transducer

face

rate inversely proportional to the square

of the distance.

Maximum power is radiated axially

(perpendicular) from the transducer face in a line

referred to as the axis of transmission. Where power is reduced by half (– 3

dB), a conical boundary defining the sound beam, centered about the axis of

transmission, is established. The diametric measurement of the cone in

degrees defines the beam angle. Impedance matching techniques are used

to optimize the transfer of power from the transducer into air and vice versa.

About the…

The XPS F series transducers incorporate an integral temperature sensor

that reports the air temperature at the transducer to the transceiver. The

connection is transparent, in that both the ultrasonic and temperature

components of the transducer use the same leads.

Hazardous Area Applications

The Echomax XPS F series of transducers can be used in hazardous are as.

For the XPS 10 F series transducer, a hazardous seal must be used to suit

hazardous area classification. This seal is not supplied by Siemens.

The XPS 15 F comes equipped with a stainless steel coupling suitable for

use in hazardous locations.

A5E32725813 XPS 10/15 F Series Transducer Page 1

Specifications

XPS 10 F Series Transducers

Measurement Range:

0.3 – 10m (1 – 33ft)

Frequency:

43kHz

Beam Angle:

12°

Environmental

Specifications

Construction

Supply Source

Weight2

Separation

location: indoor/outdoor

altitude: 2000m maxim um

ambient temperature: -20 to 95°C (-4 to 203°F)

pollution degre e: 4

exposure: Kynar

colour: slate gray

mounting: 1” NPT conduit connection

options: factory flange to suit ANSI standard

submergence shield, where flooding can occur

split flange for field mounting to suit ANSI

cable: 2-wire shielded / t wisted, 0.5 mm

®1

2

(20 AWG) PVC

jacket

Transducer sh all only be supplied by a Siemens certified controller.

0.8kg (1.8lb)

365m (1200ft) from transducer

Approvals

FM Class 1 Div 1, Group A, B, C and D

FM Class 2 Div 1, Group E, F, and G

see nameplate or consult Siemens for other current approvals

1

Kynar® is registered trade mark of ELF Atochem.

2

approximate shipping weight of transducer with standard cable length

Page 2 XPS 10/15 F Series Transducer A5E32725813

XPS 15 F Series Transducers

Measurement Range:

0.45 – 15m (1.5 – 50ft)

Frequency:

43kHz

Beam Angle:

6°

Environmental

location: indoor/outdoor

altitude: 2000m maxim um

ambient temperature: -20 to 95°C (-4 to 203°F)

pollution degre e: 4

Specifications

Construction

jacket

®3

2

(20 AWG) PVC

exposure: Kynar

colour: slate gray

mounting: 1” NPT conduit connection

options: factory flange to suit ANSI standard

submergence shield, where flooding can occur

split flange for field mounting to suit ANSI

cable: 2-wire shielded / t wisted, 0.5 mm

Supply Source

Transducer sh all only be supplied by a Siemens certified controller.

Weight4

2.0 kg (4.4lb)

Separation

365m (1200ft) from transducer

Approvals

FM Class 1 Div 1, Group A, B, C and D

FM Class 2 Div 1, Group E, F, and G

see nameplate or consult Siemens for other current approvals

3

Kynar® is registered trade mark of ELF Atochem

4

approximate shipping weight of transducer with standard cable length

A5E32725813 XPS 10/15 F Series Transducer Page 3

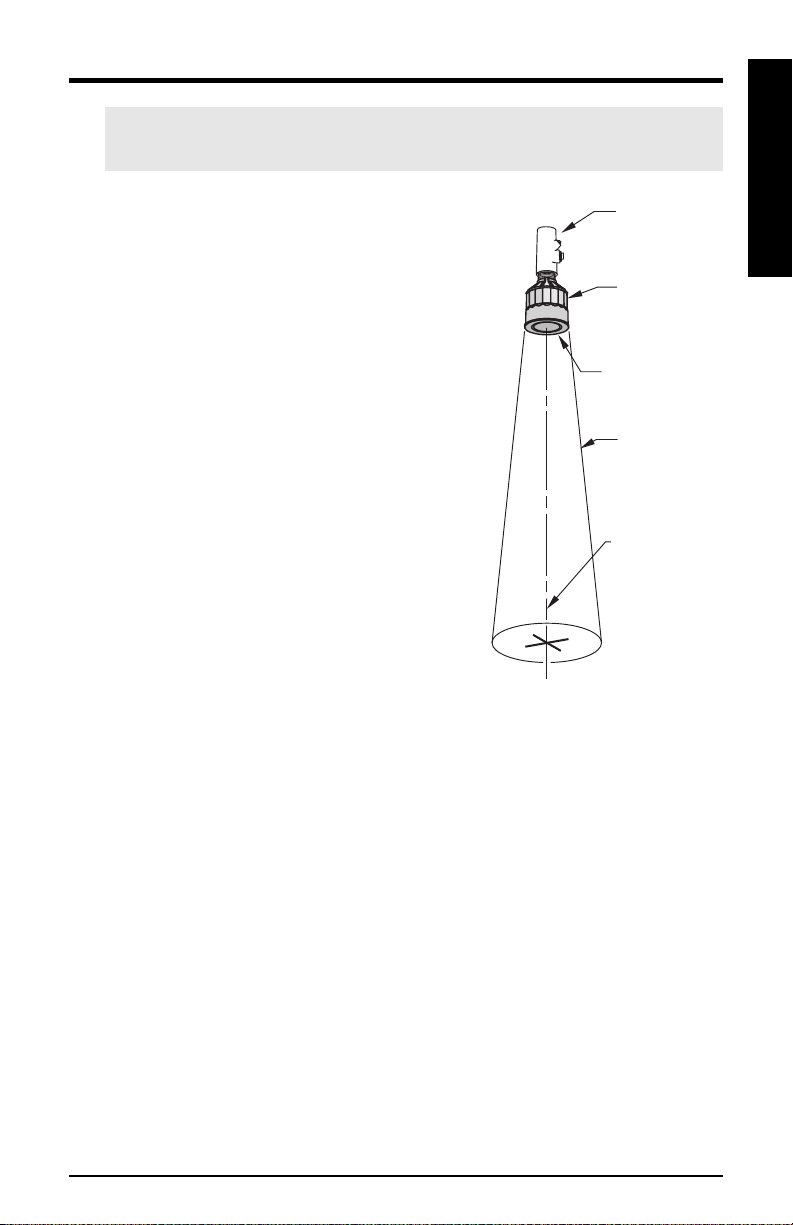

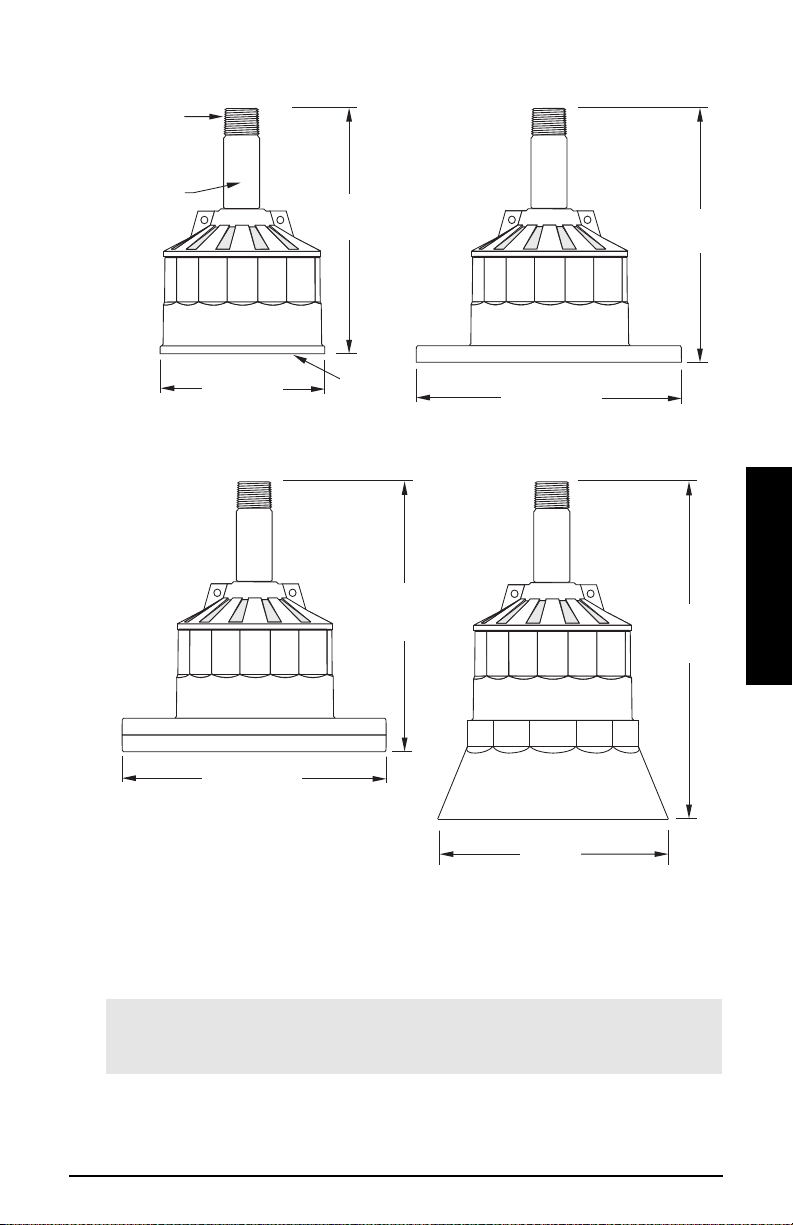

Outline and Dimensions

XPS 10 F Series Transducers

Standard Flange (optional)

Outline & Dimensions

122mm

(4.8”)

86mm

(3.4”)

radiating

face

to suit ANSI

standards

122mm

(4.8”)

Split Flange (optional) Submergence Shield (optional)

128mm

(5.0”)

to suit ANSI

standards

nominal

152mm

(6.0”)

124mm

(4.9”)

Refer to submergence shield instructions

(Siemens’ manual number

7ML19981EG01)

Note:

For the XPS 10 F series transducer, a hazardous seal must be used to

suit hazardous area classification. This seal is not supplied by Siemens.

For more information, refer to page 20.

Page 4 XPS 10/15 F Series Transducer A5E32725813

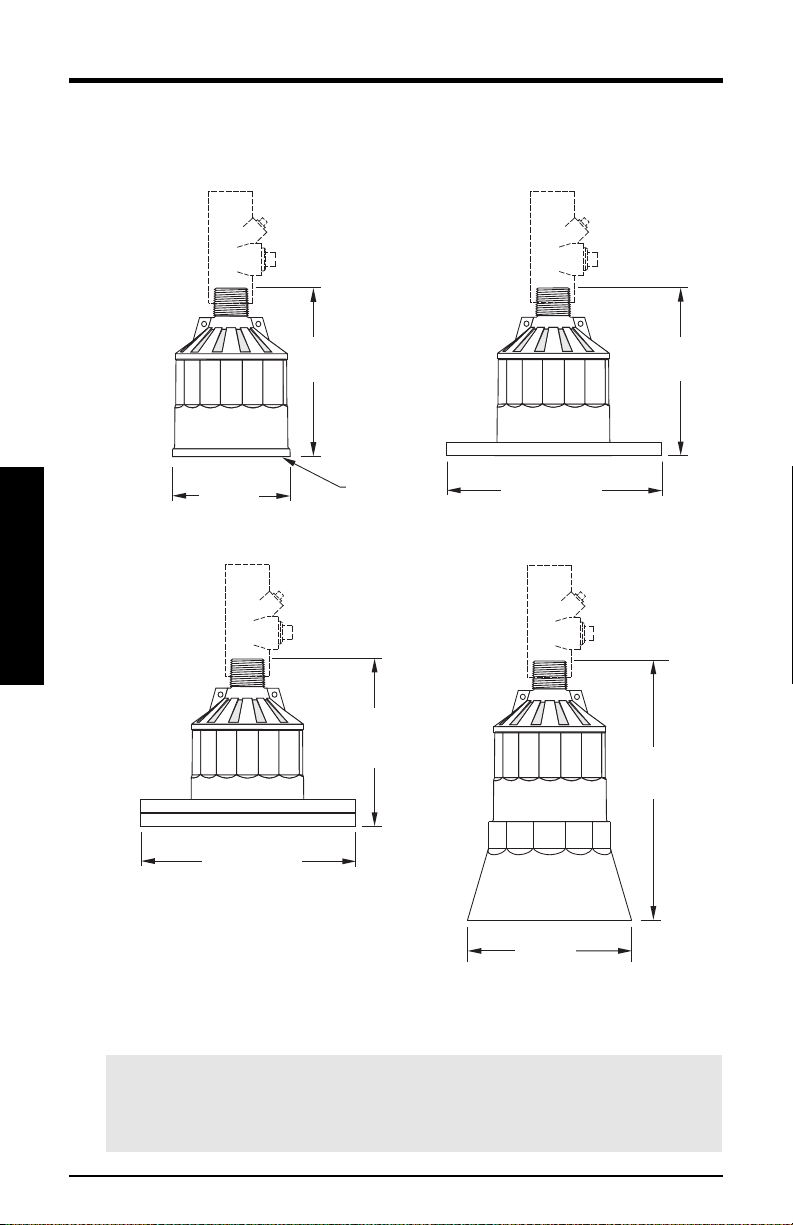

XPS 15 F Series Transducers

Standard Flange (optional)

1” NPT

304

stainless

steel

120mm

(4.7”)

185mm

(7.3”)

radiating

face

to suit ANSI

standards

185mm

Split Flange (optional) Submergence Shield (optional)

191mm

(7.5”)

nominal

253mm

(10.0”)

(7.3”)

Outline & Dimensions

to suit ANSI

standards

158mm

(6.2”)

Refer to submergence shield instructions

(Siemens’ manual number

7ML19981EG01)

Note:

The XPS 15 F comes equipped with a stainless steel coupling suitable for

use in hazardous locations.

A5E32725813 XPS 10/15 F Series Transducer Page 5

Loading...

Loading...