Page 1

Automation– and Drive Technology- SCE

Training document for the company-wide

automation solution

Totally Integrated Automation (T I A)

MODULE B4

Data blocks

T I A Training document Page 1 of 18 Module B4

Last revision: 02/2002 Data Blocks

Page 2

Automation– and Drive Technology- SCE

This document was provided by Siemens A&D SCE (automation and drive technology, Siemens A&D

Cooperates with Education) for training purposes. Siemens does not make any type of guarantee regarding its

contents.

The passing on or duplication of this document, including the use and report of its contents, is only permitted

within public and training facilities.

Exceptions require written permission by Siemens A&D SCE (Mr. Knust: E-Mail:

michael.knust@hvr.siemens.de). Offences are subject to possible payment for damages caused. All rights are

reserved for translation and any case of patenting or GM entry.

We thank the company Michael Dziallas Engineering and the instructors of vocational schools as well as further

persons for the support with the production of the document.

T I A Training document Page 2 of 18 Module B4

Last revision: 02/2002 Data Blocks

Page 3

Automation– and Drive Technology- SCE

PAGE:

1. Forward................................................................................................................. 4

2. Notes for Data Blocks.......................................................................................... 6

3. Generating Data Blocks ...................................................................................... 7

The following symbols stand for the specified modules:

Information

Programming

Example exercise

Notes

T I A Training document Page 3 of 18 Module B4

Last revision: 02/2002 Data Blocks

Page 4

Automation– and Drive Technology- SCE

1. FORWARD

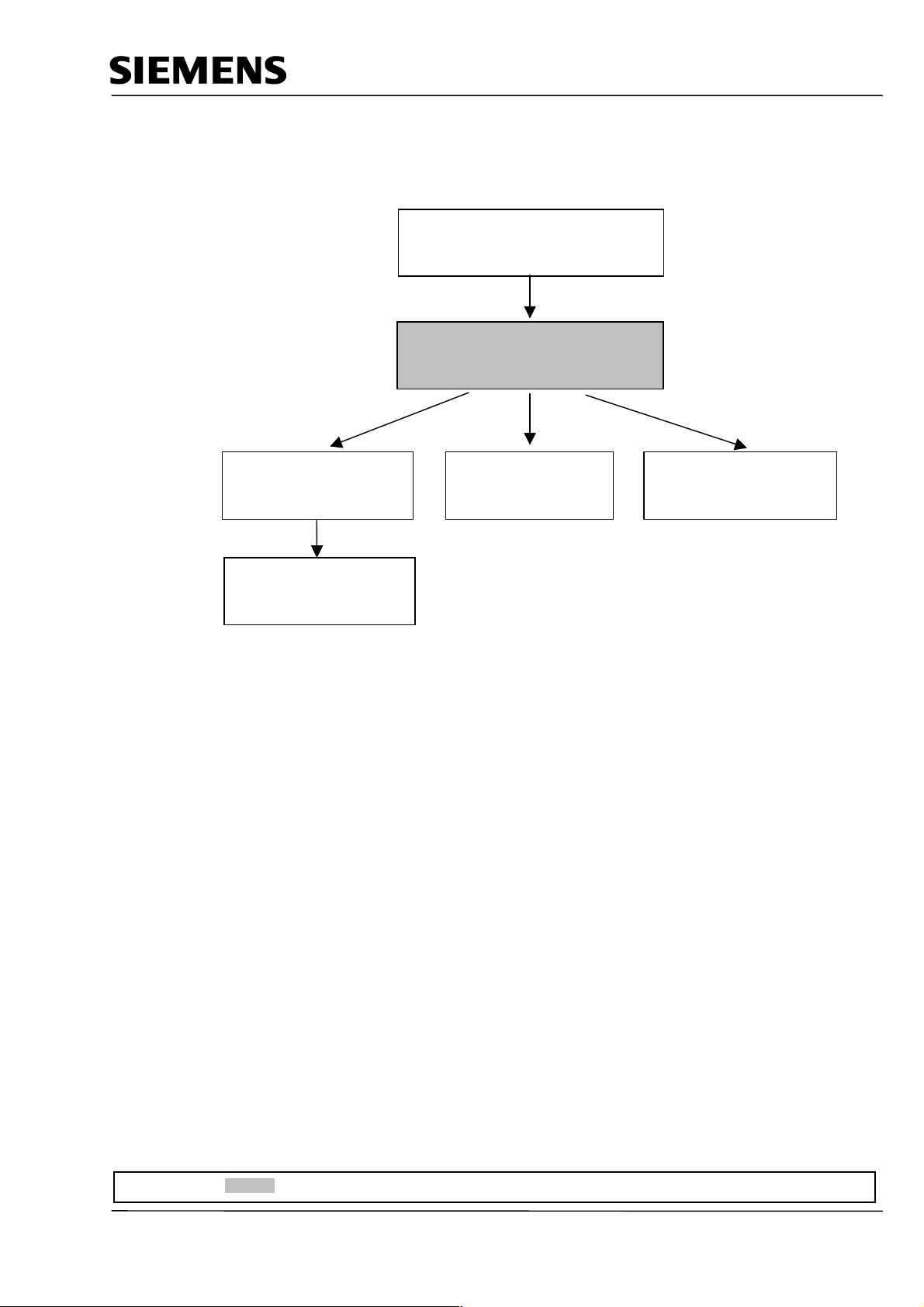

The module B4 is assigned content wise to Additional functions of STEP 7- Programming.

STEP 7- Programming

2 - 3 days A modules

Basics of

Additional functions of

STEP 7- Programming

2- 3 days B Modules

Industrial field bus

systems

2- 3 days D modules

Sequencer

programming

2- 3 days C modules

Process

visualization

2- 3 days F modules

IT- Communication

with SIMATIC S7

1- 2 days E modules

Learning goal:

In this module, the reader should learn how a data block can be used to save data.

· Generating data blocks

· Specifying a structure of a data block

· Access to a data element in a STEP 7- Program

Requirements:

For the successful use of this module, the following knowledge is assumed:

· Knowledge in the use of Windows 95/98/2000/ME/NT4.0

· Basics of PLC- Programming with STEP 7 (e.g. Module A3 - ‘Startup’

PLC programming with STEP 7)

· Basics to structured programming (e.g. Appendix I - Basics to PLC –Programming with

SIMATIC S7-300)

Forward Notes Generating data blocks

T I A Training document Page 4 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 5

Automation– and Drive Technology- SCE

Required hardware and software

1 PC, Operating system Windows 95/98/2000/ME/NT4.0 with

- Minimal: 133MHz and 64MB RAM, approx. 65 MB free hard disk space

- Optimal: 500MHz and 128MB RAM, approx. 65 MB free hard disk space

2 Software STEP 7 V 5.x

3 MPI- Interface for the PC (e.g. PC- Adapter)

4 PLC SIMATIC S7-300 with at least one digital in- and output module. The inputs must be lead

through a functional unit.

Example configuration:

- Power supply: PS 307 2A

- CPU: CPU 314

- Digital input: DI 16x DC24V

- Digital output: DO 16x DC24V / 0.5 A

1 PC

2 STEP 7

3 PC Adapter

4 SIMATIC S7-300

Forward Notes Generating data blocks

T I A Training document Page 5 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 6

Automation– and Drive Technology- SCE

2. NOTES FOR DATA BLOCKS

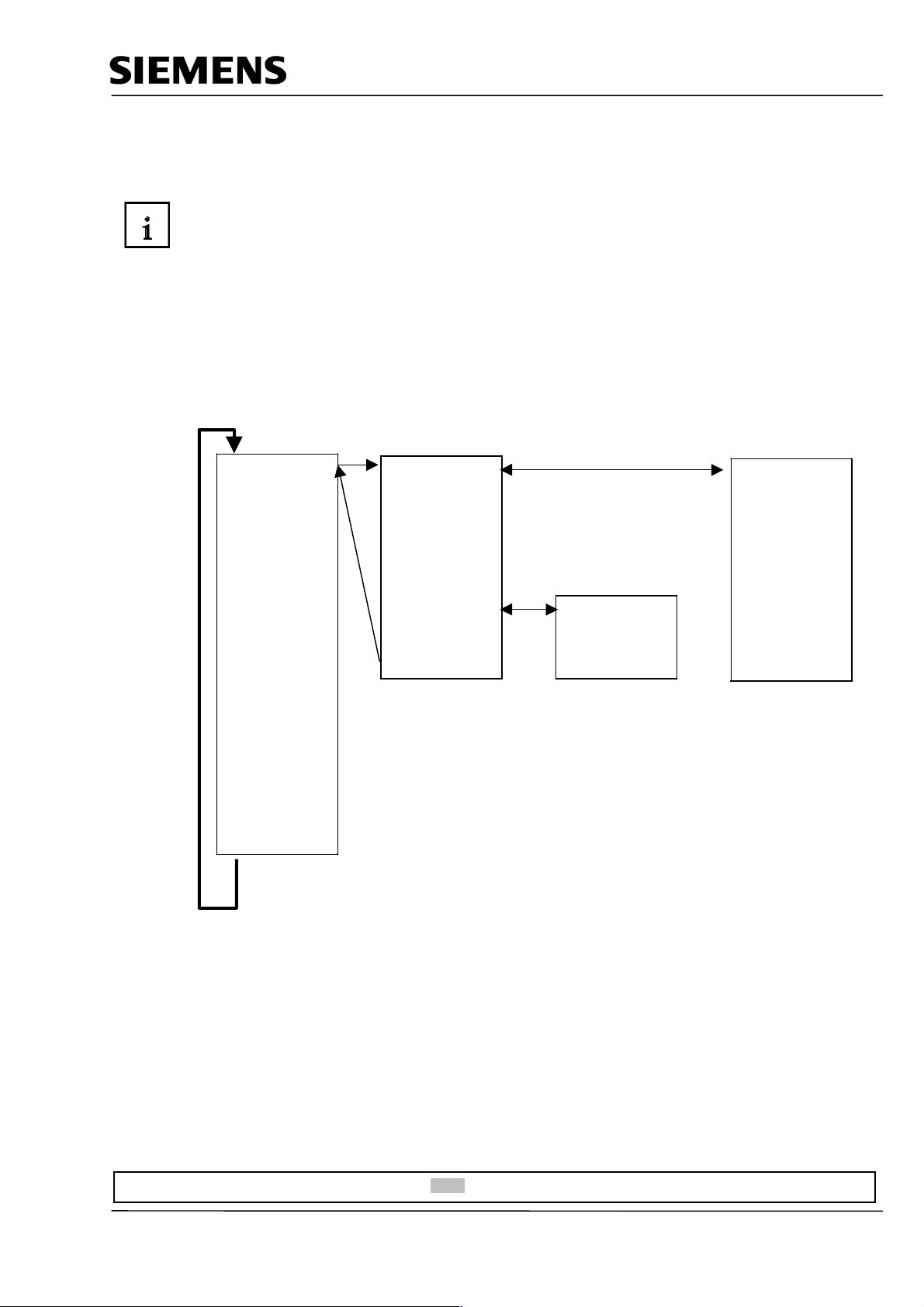

Data Blocks (DBs) can be used by your program to save data in the CPU. Your hard disk contains up

to 8 KBytes ( 8192 Bytes ) space.

There are two types of data blocks. Global DBs, where all OBs, FBs and FCs read all saved data or

can even write in the DB and local instance DBs, which are assigned a particular FB.

In the DBs, different data types (e.g. BOOL or WORD ) can be saved in arbitrary order.

This structuring of a DB follows through input in a table with the tool

LAD, STL,FBD - S7 Block Programming .

In the program structure from STEP 7, data blocks are found as follows:

OB 1

Call FB1, DB10

UC FC2

L DB11.DBW0

BE

DB 11DB 10FB 1

Global DB

For all

FBs

FCs

OBs

Instance DB

Local data only

FB1

OB = Organization Block

FB = Function Block

FC = Function

DB = Data Block

Forward Notes Generating data blocks

T I A Training document Page 6 of 18 Module B4

Last revision: 02/2002 Data block

Page 7

Automation– and Drive Technology- SCE

3. GENERATING DATA BLOCKS

Data blocks are generated and opened like program blocks in the tool LAD,STL,FBD: Program

blocks. They serve e.g. for the saving of data and system states.

In the following text, the generation of a simple example is described by the use of a global data

block:

Thereby values should be chosen with the switches 'S0' to 'S7' and displayed on an output module

‘Display‘. Thereby one has more switches by activation, where the representation of the value to

switch S7 has the highest priority and the representation of the value to switch S1 has the lowest.

The example relates to the displayed addresses below:

Inputs:

- Switch S0 = I 0.0

- Switch S1 = I 0.1

- Switch S2 = I 0.2

- Switch S3 = I 0.3

- Switch S4 = I 0.4

- Switch S5 = I 0.5

- Switch S6 = I 0.6

- Switch S7 = I 0.7

Outputs:

- Display = QW4

Forward Notes Generating data blocks

T I A Training document Page 7 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 8

Automation– and Drive Technology- SCE

In order to generate this program example, the following steps must be followed (Thereby the

program is dispensed with the creation of the hardware configuration):

1. Call SIMATIC Manager with a double click ( ® SIMATIC Manager)

2. Create a new project ( ® File ® New)

Forward Notes Generating data blocks

T I A Training document Page 8 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 9

Automation– and Drive Technology- SCE

3. In the name path, create the project with the name Testproject_DB.

(® ’Testproject_DB’ ® OK)

4. Insert a new S7-Program ( ® Insert ® Program ® S7-Program).

Forward Notes Generating data blocks

T I A Training document Page 9 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 10

Automation– and Drive Technology- SCE

5. Highlight the folder Blocks. (® Blocks)

6. Insert Data Block ( ® Insert ® S7 Block ® Data Block).

Forward Notes Generating data blocks

T I A Training document Page 10 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 11

Automation– and Drive Technology- SCE

7. Enter the number DB10 for the data block and accept with OK (® DB10 ® OK).

8. Open the data block DB10 with a double click(® DB10).

Forward Notes Generating data blocks

T I A Training document Page 11 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 12

Automation– and Drive Technology- SCE

9. Acknowledge the type of data block. ( ® Data Block ® OK )

Note: Data blocks with an assigned FB are automatically displayed by the call of your

associated FB. It makes no sense to create this alone. Data blocks with assigned user

defined data types (UDT) are data blocks, whose structure was already assigned in this

UDT.

Forward Notes Generating data blocks

T I A Training document Page 12 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 13

Automation– and Drive Technology- SCE

10. The Data Block is generated with a symbol Name. The Type, an Initial value as well as a

Comment (optional) are entered.

The address is automatically generated and cannot be altered.

The data block can be saved

PLC must be on STOP! (® Name® Type ® Initial value ® Comment ®

and downloaded into the PLC . The mode switch on the

® )

The absolute address is created from

STEP 7, when the DB is compiled or

saved.

The address format is BYTE, BIT.

Over this address, the data elements can

also be accessed. (e.g. over downloadand compile operations or in logical

operations.).

Symbolic name

which is referenced

to the absolute

address.

Desired data

type (see below)

for your data

element.

Initial value , to which

the data type must be

compatible ( optional ).

Comment for

documentation

( optional ).

Note: If the data block is assigned as a local instance DB to a FB, the declarations table of the

FB declares the structure of the DB.

Forward Notes Generating data blocks

T I A Training document Page 13 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 14

Automation– and Drive Technology- SCE

Data in a data block must be determined through data types.

The following standard- data types are defined in the S7 below :

Type and

description

BOOL (Bit) 1 Boolean text TRUE/FALSE TRUE

BYTE (Byte) 8 Hexadecimal

WORD (Word) 16 Binary number 2#0 to 2#1111_1111_1111_1111 2#0001_0000_0000_0000

Hexadecimal

BCD C#0 to C#999 C#998

Decimal number

DWORD (Double

word)

Hexadecimal

Decimal number

INT (Integer) 16 Decimal number

DINT (Int,32 bit) 32 Decimal number

REAL (Floatingpoint number)

S5TIME

(Simatic-Time)

TIME

(IEC-Date)

DATE

(IEC-Date)

TIME_OF_DAY

(Time)

CHAR (Character) 8 ASCII-Characters ´A´, ´B´ etc. ´B´

Size

Format-Options Range and number notation

in Bits

number

number

unsigned

32 Binary number 2#0 to

number

unsigned

signed

signed

32 IEEE floating-point

number

16 S7-Time in steps of

10 ms

32 IEC-Time in steps

from 1ms, integer

signed

16 IEC-Date in steps

of 1 day

32 Time in steps of

1ms

Example

(lowest to highest values)

B#16#0 to B#16#FF B#16#10

W#16#0 to W#16#FFFF W#16#1000

B#(0,0) to B#(255,255) B#(10,20)

2#1111_1111_1111_1111_1111_1111

_1111_1111

DW#16#0000_0000 to

DW#16#FFFF_FFFF

B#(0,0,0,0) to B#(255,255,255,255) B#(1,14,100,120)

-32768 to 32767 1

L#-2147483648 to L#2147483647 L#1

Upper limit: +/-3.402823e+38

Lower limit: +/-1.175495e-38

S5T#0H_0M_0S_10MS to

S5T#2H_46M_30S_0MS and

S5T#0H_0M_0S_0MS

-T#24D_20H_31M_23S_648MS to

T#24D_20H_31M_23S_647MS

D#1990-1-1 to D#2168-12-31 DATE#1994-3-15

TOD#0:0:0.0 to TOD#23:59:59.999 TIME_OF_DAY#1:10:3.3

2#1000_0001_0001_1000_1

011_1011_0111_1111

DW#16#00A2_1234

1.234567e+13

S5T#0H_1M_0S_0MS

S5TIME#1H_1M_0S_0MS

T#0D_1H_1M_0S_0MS

TIME#0D_1H_1M_0S_0MS

Forward Notes Generating data blocks

T I A Training document Page 14 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 15

Automation– and Drive Technology- SCE

11. Values should be modified in a data block. It is not adequate to modify them in the field Initial

value . This is only possible, when one switches to the Data View under View ( ® View ® Data

View).

12. Now a new value can be entered in the field Actual value and saved onto the hard drive with

as well as downloaded into the CPU with ( ® Actual value ® ® ).

Forward Notes Generating data blocks

T I A Training document Page 15 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 16

Automation– and Drive Technology- SCE

13. In order to generate the program with the accessible data elements, the OB1 must be opened

through a double click in SIMATIC Manager ( ® SIMATIC Manager ® OB1).

14. Then accept the setting with OK (® OK ).

Forward Notes Generating data blocks

T I A Training document Page 16 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 17

Automation– and Drive Technology- SCE

There are three possibilities to access the data:

1. Direct address access:

One can access one data element in a data block with the following instructions:

Example:

L DB 20. DBB2 Load data byte 2 from DB20 into ACCU 1

L DB 22. DBW4 Load data word 4 from DB22 into ACCU 1

A DB 2. DBX5.6 Carry out an AND- logical operation with data bit 5.6 from DB2.

2. Access to the data elements in the already opened data blocks:

In order to be able to access a data element over several data elements, the DB must first be opened

with the instructions OPN DB or OPN DI. Then several data bits (DBX/DIX),data bytes (DBB/DIB),

data words (DBW/DIW) or data double words (DBD/DID) can be processed in digital or binary

operations.

In doing so, one especially uses OPN DI for the opening of instance DBs. It can also be used for

global DBs, when 2 DBs remain open at the same time.

Example:

OPN DB 20 Opening of DB20

OPN DI 22 Opening of DB22

L DBW 0 Download data word 0 from DB20 into AKKU 1

T MW 1 Transfer the contents from ACCU 1 to memory bit 1

A DIX 0.0 AND- Operation from data bit 0.0 to DB22 with

A I 1.0 input bit 1.0

= Q 4.0 Assignment of the result to output bit 4.0

3. Access to data out of local instance DBs by call with the function block:

Data can be transferred by the call of the corresponding instance data block with the instruction CALL

FB1, DB19. The assignment of the variables that would be defined in the declarations table of the FB

and whose value stands in the DB, take place directly in the absolute address (e.g. IW0, M 10.0 or

QW4) with the CALL instruction.

Example:

CALL FB1, DB19

COUNT:= IW 0 The variable COUNT is assigned to IW 0 as an absolute address.

OUT:= Q 4.0 The variable OUT is assigned to Q4.0 as an absolute address.

Note: The format of the variables and the assigned absolute address must be equal.

Forward Notes Generating data blocks

T I A Training document Page 17 of 18 Module B4

Last revision: 02/2002 Data blocks

Page 18

Automation– and Drive Technology- SCE

15. With LAD, STL, FBD: Program blocks, you now have an editor that give you the possibility to

generate your STEP 7-Program.

The schema for the selection of the data element through the button is shown for the first three

inputs as specified below.

If the organization block OB1 is not generated for all switches S0 to S7, it should be saved

and downloaded into the PLC

. The mode switch of the CPU must be on STOP! ( ® ®

)

16. Through the switching of the key switch to RUN, the program is started.

If only one of buttons S0 to S7 is activated through inching, the display of the value in the data

block that is assigned takes place on the output module with the address QW4.

Forward Notes Generating data blocks

T I A Training document Page 18 of 18 Module B4

Last revision: 02/2002 Data blocks

Loading...

Loading...