Page 1

Siemens

Energy & Automation

USER'S MANUAL

UM353-1

Rev. 10

October 2001

Supersedes Rev. 9

s

2

42

453

.

TC2 0 5 3 . P

S P

PB1

PB2

M

LOOP

CLOSE

100

80

60

40

A

0

20

0

| ||

L

ACK

S

D

UNITS

100

|

OPEN

Moore 353

X03141S2

PROCESS AUTOMATION CONTROLLER

Page 2

Page 3

UM353-1 Contents

TABLE OF CONTENTS

SECTION AND TITLE PAGE

PREFACE........................................................................................................................................................... x

1.0 INTRODUCTION ....................................................................................................................................... 1-1

1.1 PRODUCT DESCRIPTION..................................................................................................................... 1-2

1.2 FUNCTION BLOCKS.............................................................................................................................1-4

1.2.1 LOOP Function Block Types.......................................................................................................... 1-4

1.2.2 Power Up Initialization ................................................................................................................... 1-6

1.2.3 Configuration ................................................................................................................................. 1-6

1.3 PRODUCT SUPPORT.............................................................................................................................1-6

1.4 EQUIPMENT DELIVERY AND HANDLING........................................................................................1-7

1.4.1 Factory Shipment ...........................................................................................................................1-7

1.4.2 Receipt of Shipment ....................................................................................................................... 1-7

1.4.3 Storage...........................................................................................................................................1-8

1.4.4 Typical Shipment Contents.............................................................................................................1-8

2.0 CONFIGURATION OVERVIEW..............................................................................................................2-1

2.1 STATION FUNCTION BLOCKS............................................................................................................ 2-1

2.2 STATION HARDWARE I/O BLOCKS...................................................................................................2-1

2.3 LOOP FUNCTION BLOCKS..................................................................................................................2-1

2.4 LIL GLOBAL DATA I/O FUNCTION BLOCKS .................................................................................... 2-2

2.5 ETHERNET DATA I/O FUNCTION BLOCKS....................................................................................... 2-3

2.6 LonWorks REMOTE I/O FUNCTION BLOCKS.....................................................................................2-3

2.7 CONFIGURATION PROCEDURE ......................................................................................................... 2-3

2.8 OPERATION DURING LOCAL ON-LINE CONFIGURATION.............................................................2-5

3.0 FUNCTION BLOCKS................................................................................................................................3-1

3.1 STATION FUNCTION BLOCKS............................................................................................................ 3-3

3.1.1 FCO LIB - Factory Configuration Library.......................................................................................3-3

3.1.2 SECUR - Security........................................................................................................................... 3-3

3.1.3 STATN - Station Parameters..........................................................................................................3-5

3.1.4 CLOCK - Real Time Clock (V2.0/2.2)............................................................................................ 3-7

3.1.5 ETHERNET - Ethernet Communication Network (V2.4)................................................................3-7

3.2 I/O AND LOOP FUNCTION BLOCKS ................................................................................................... 3-8

3.2.1 A/M - A/M Transfer....................................................................................................................... 3-8

3.2.2 ACS - ARCCOSINE..................................................................................................................... 3-10

3.2.3 ADD_ - Addition.......................................................................................................................... 3-10

3.2.4 AG3 - AGA 3 Orifice Metering of Natural Gas............................................................................3-11

3.2.5 AG7 - AGA 7 Measurement of Gas by Turbine Meters ................................................................ 3-13

3.2.6 AG8 - AGA 8 Compressibility Factors of Natural Gas................................................................ 3-14

3.2.7 AIE_ - Analog Input - Ethernet (V2.4)......................................................................................... 3-15

3.2.8 AIL_ - Analog Input - LIL............................................................................................................ 3-16

3.2.9 AIN_ - Analog Inputs................................................................................................................... 3-17

3.2.10 AINU_ - Analog Inputs, Universal .............................................................................................3-18

3.2.11 AIP_ - Analog Input lev_Percent............................................................................................... 3-20

3.2.12 ALARM - Alarm........................................................................................................................ 3-21

3.2.13 AND_ - AND Logic ................................................................................................................... 3-23

3.2.14 AOE_ - Analog Output- Ethernet (V2.4).................................................................................... 3-24

3.2.15 AOL_ - Analog Output - LIL...................................................................................................... 3-24

3.2.16 AOP_ - Analog Output lev_Percent............................................................................................ 3-25

October 2001 i

Page 4

Contents UM353-1

3.2.17 AOUT_ - Analog Outputs........................................................................................................... 3-26

3.2.18 ASN_ - ARCSINE ...................................................................................................................... 3-27

3.2.19 ATD_ - Analog Trend Display................................................................................................... 3-27

3.2.20 ATN_ - ARCTANGENT............................................................................................................ 3-28

3.2.21 BATOT - Batch Totalizer........................................................................................................... 3-29

3.2.22 BATSW - Batch Switch.............................................................................................................. 3-31

3.2.23 BIAS - Bias................................................................................................................................ 3-32

3.2.24 CIE_- Coil Inputs - Ethernet (V2.4)............................................................................................ 3-33

3.2.25 CHR_ - Characterizer................................................................................................................. 3-33

3.2.26 CMP_ - Comparator ................................................................................................................... 3-34

3.2.27 COS_ - COSINE ........................................................................................................................ 3-34

3.2.28 DAM_ - Deviation Amplifier...................................................................................................... 3-35

3.2.29 DID_ - Digital Input lev_Discrete............................................................................................... 3-36

3.2.30 DIE_ - Digital Input - Ethernet (V2.4)........................................................................................ 3-37

3.2.31 DIL_ - Discrete Input _ LIL........................................................................................................ 3-37

3.2.32 DIN_ - Digital Inputs ................................................................................................................. 3-38

3.2.33 DINU_- Digital Inputs, Universal............................................................................................... 3-39

3.2.34 DIS_ - Digital Input _ State ........................................................................................................ 3-40

3.2.35 DIV_ - Division .......................................................................................................................... 3-41

3.2.36 DNC_ - Divide by N Counter...................................................................................................... 3-41

3.2.37 DOD_ - Digital Output lev_Discrete........................................................................................... 3-42

3.2.38 DOE_ - Digital Output - Ethernet (V2.4).................................................................................... 3-43

3.2.39 DOL_ - Discrete Output - LIL .................................................................................................... 3-43

3.2.40 DOS__ - Digital Output State..................................................................................................... 3-44

3.2.41 DOUT_ - Digital Outputs........................................................................................................... 3-45

3.2.42 DTM_ - Dead Time Table.......................................................................................................... 3-46

3.2.43 DYT_ - Delay Timer .................................................................................................................. 3-47

3.2.44 E/I - External/Internal Transfer Switch....................................................................................... 3-48

3.2.45 ESL - Events Sequence Logger................................................................................................... 3-49

3.2.46 EXP_ - NATURAL EXPONENTIATION.................................................................................. 3-50

3.2.47 EXT_ - EXPONENTIATION ..................................................................................................... 3-50

3.2.48 FTG_ - Falling Edge Trigger...................................................................................................... 3-51

3.2.49 GB_ - Gain & Bias..................................................................................................................... 3-51

3.2.50 HLD_ - Hold ..............................................................................................................................3-51

3.2.51 ID - ID Controller ....................................................................................................................... 3-52

3.2.52 LL_ - Lead/Lag ..........................................................................................................................3-53

3.2.53 LMT_ - Limit............................................................................................................................. 3-53

3.2.54 LN_ - NATURAL LOGARITHM............................................................................................... 3-54

3.2.55 LOG_ - LOGARITHM BASE 10................................................................................................ 3-54

3.2.56 MTH_ - Math............................................................................................................................. 3-55

3.2.57 MUL_ - Multiplication ...............................................................................................................3-56

3.2.58 NND_ - NAND Logic................................................................................................................. 3-56

3.2.59 NOR_ - NOR Logic .................................................................................................................... 3-57

3.2.60 NOT_ - NOT Logic.................................................................................................................... 3-57

3.2.61 ODA - Operator Display for Analog indication & alarming (V2.2)............................................ 3-58

3.2.62 ODC - Operator Display for Controllers .....................................................................................3-60

3.2.63 ODD - Operator Display for Discrete indication & control (V2.2)............................................... 3-62

3.2.64 ODP - Operator Display for PushButtons (V2.2) ......................................................................... 3-64

3.2.65 ODS - Operator Display for Sequencer ....................................................................................... 3-66

3.2.66 ON/OFF - On/Off Controller ...................................................................................................... 3-68

3.2.67 OR_ - OR Logic ......................................................................................................................... 3-69

ii October 2001

Page 5

UM353-1 Contents

3.2.68 ORSL - Override Selector........................................................................................................... 3-69

3.2.69 OST_ - One Shot Timer ............................................................................................................. 3-70

3.2.70 PB1SW - PB1 Switch ................................................................................................................. 3-71

3.2.71 PB2SW - PB2 Switch ................................................................................................................. 3-72

3.2.72 PB3SW - PB3 Switch ................................................................................................................. 3-73

3.2.73 PCOM - Phase COMmunication................................................................................................. 3-74

3.2.74 PD - PD Controller..................................................................................................................... 3-76

3.2.75 PID - PID Controller .................................................................................................................. 3-78

3.2.76 PIDAG - PIDAG Controller .......................................................................................................3-80

3.2.77 PRSEQ - Program Sequencer ...................................................................................................... 3-82

3.2.78 QHD_ - Quickset Hold ............................................................................................................... 3-84

3.2.79 RATIO - Ratio............................................................................................................................ 3-85

3.2.80 RCT_ - Repeat Cycle Timer........................................................................................................ 3-86

3.2.81 RLM_ - Rate Limiter.................................................................................................................. 3-87

3.2.82 ROT_ - Retentive On Timer ....................................................................................................... 3-87

3.2.83 ROUT_ - Relay Outputs..............................................................................................................3-88

3.2.84 RSF_ - RS Flip-Flop................................................................................................................... 3-88

3.2.85 RTG_ - Rising Edge Trigger ...................................................................................................... 3-89

3.2.86 RTT_ - Real Time clock Trip (V2.0) ..........................................................................................3-89

3.2.87 SCL_ - Scaler............................................................................................................................. 3-90

3.2.88 SEL_ - Signal Selector ............................................................................................................... 3-90

3.2.89 SETPT - Setpoint ....................................................................................................................... 3-91

3.2.90 SIN_ - SINE............................................................................................................................... 3-92

3.2.91 SPLIM - Setpoint Limit.............................................................................................................. 3-93

3.2.92 SRF_ - SR Flip-Flop................................................................................................................... 3-94

3.2.93 SRT_ - Square Root .................................................................................................................... 3-94

3.2.94 SUB_ - Subtraction ..................................................................................................................... 3-95

3.2.95 TAN_ - TANGENT.................................................................................................................... 3-95

3.2.96 TH_ - Track & Hold................................................................................................................... 3-96

3.2.97 TOT_ - Totalizer (V2.3)............................................................................................................. 3-96

3.2.98 TSW_ - Transfer Switch............................................................................................................. 3-97

3.2.99 XOR_ - Exclusive OR Logic....................................................................................................... 3-97

4.0 FACTORY CONFIGURED OPTIONS .....................................................................................................4-1

4.1 FCO101 - Single Loop Controller w/ Tracking Setpoint...........................................................................4-2

4.2 FCO102 - Single Loop Controller w/ Fixed Setpoint ................................................................................ 4-3

4.3 FCO103 - External Set Controller with Tracking Local Setpoint..............................................................4-4

4.4 FCO104 - External Set Controller with Non-Tracking Local Setpoint ...................................................... 4-6

4.5 FCO105 - Ratio Set Control w/ Operator Setpoint Limits.........................................................................4-8

4.6 FCO106 - Single Loop Controller w/ Operator Setpoint Limits .............................................................. 4-10

4.7 FCO107 - Dual Loop Controller ............................................................................................................ 4-11

4.8 FCO121 - Cascade Control.................................................................................................................... 4-13

4.9 FCO122 - Cascade Control w/ Operator Setpoint Limits........................................................................ 4-15

5.0 LONWORKS COMMUNICATIONS........................................................................................................5-1

6.0 NETWORK COMMUNICATIONS........................................................................................................... 6-1

6.1 MODBUS DATA MAPPING .................................................................................................................. 6-1

6.2 * Refer to the AIE function block in the Function Blocks section for details.LIL DATA MAPPING ........6-2

6.2 LIL DATA MAPPING ............................................................................................................................6-3

6.2.1 Station Data....................................................................................................................................6-3

6.2.2 Control Loop Data .......................................................................................................................... 6-5

October 2001 iii

Page 6

Contents UM353-1

6.2.3 Sequence Loop Data.......................................................................................................................6-6

6.2.4 Analog Indicator Loop Data ...........................................................................................................6-9

6.2.5 Discrete Indicator Loop Data........................................................................................................ 6-10

6.2.6 Pushbutton Loop Data ..................................................................................................................6-11

7.0 DATA MAPPING ....................................................................................................................................... 7-1

7.1 CONNECTING TO APACS 39ACM, MYCROADVANTAGE, ProcessSuite, i|ware PC.........................7-1

7.1.1 APACS...........................................................................................................................................7-1

7.1.2 MYCROADVANTAGE.................................................................................................................7-1

7.1.3 ProcessSuite ................................................................................................................................... 7-2

7.1.4 i|ware PC ........................................................................................................................................ 7-2

7.2 STATION DATA.................................................................................................................................... 7-3

7.2.1 Integer Data (16-bit Integer)...........................................................................................................7-3

7.2.2 Station String Data (8-bit ASCII Char - 2/Word)............................................................................ 7-5

7.2.3 Station Coil Data (1-bit)................................................................................................................. 7-5

7.2.4 Station Status Word (SSW).............................................................................................................7-5

7.3 LOOP DATA ..........................................................................................................................................7-6

7.3.1 Dynamic Loop Integer Data ............................................................................................................ 7-7

7.3.2 Variable Loop Integer Data.............................................................................................................7-8

7.3.3 Static Loop Integer Data............................................................................................................... 7-10

7.3.4 Dynamic Loop Floating Point Data (32-bit IEEE)......................................................................... 7-11

7.3.5 Variable Loop Floating Point Data (32-bit IEEE)..........................................................................7-12

7.3.6 Static Loop Floating Point Data (32-bit IEEE).............................................................................. 7-14

7.3.7 String Loop Data (8-bit ASCII Char - 2/Word)............................................................................. 7-16

7.3.8 Coil Loop Data (1-bit) .................................................................................................................. 7-19

7.3.9 PCOM Block Status...................................................................................................................... 7-31

7.3.10 Sequencer Loop I/O Coil Data (1-bit) .........................................................................................7-33

7.3.11 LonWorks Remote I/O (Models 352P, 353, 354N)...................................................................... 7-35

7.3.12 Trend Data (Loop Defined by MLTP)......................................................................................... 7-43

7.3.13 Configuration Data Sequencer Loop ........................................................................................... 7-46

7.3.14 LIL Alarm Type Word (ATW) ................................................................................................... 7-48

8.0 INSTALLATION........................................................................................................................................8-1

8.1 INSTALLATION CONSIDERATIONS ..................................................................................................8-1

8.2 ENVIRONMENTAL CONSIDERATIONS............................................................................................. 8-1

8.3 MECHANICAL INSTALLATION..........................................................................................................8-3

8.3.1 Removable Connectors and Covers................................................................................................. 8-3

8.3.2 Panel and Rack Mounting Guidelines............................................................................................. 8-5

8.3.3 Station Mounting............................................................................................................................8-7

8.4 ELECTRICAL INSTALLATION............................................................................................................8-8

8.4.1 Wiring Guidelines.......................................................................................................................... 8-8

8.4.2 Analog Signal Input Wiring (4-20 mA, 1-5 Vdc, and mV)........................................................... 8-13

8.4.3 Analog Output Wiring (4-20 mA, 1-5 Vdc) ..................................................................................8-15

8.4.4 Digital Input and Output Wiring...................................................................................................8-16

8.4.5 Thermocouple Input Wiring......................................................................................................... 8-18

8.4.6 RTD Input Wiring ........................................................................................................................ 8-19

8.4.7 Ohms and Slidewire Input Wiring................................................................................................ 8-20

8.4.8 Relay Output Wiring .................................................................................................................... 8-20

8.4.9 Local Instrument Link Wiring...................................................................................................... 8-20

8.4.10 LonWorks Wiring ......................................................................................................................8-22

8.4.11 Modbus Wiring .......................................................................................................................... 8-22

8.4.12 Ethernet Wiring .........................................................................................................................8-22

iv October 2001

Page 7

UM353-1 Contents

8.4.13 Wiring to a Model 363 VIEWPAC Recorder .............................................................................. 8-24

8.4.14 Power Wiring............................................................................................................................. 8-24

8.5 FACTORY CALIBRATION.................................................................................................................. 8-26

9.0 LOCAL FACEPLATE OPERATION........................................................................................................ 9-1

9.1 NORMAL OPERATION MODE............................................................................................................. 9-1

9.2 CONFIGURATION MODE..................................................................................................................... 9-3

9.3 AUTOTUNE PROCEDURE.................................................................................................................... 9-4

9.4 REMOVABLE CONFIGURATION BOARD ..........................................................................................9-7

9.5 REAL TIME CLOCK/CONFIGURATION BACKUP BOARD ............................................................... 9-7

10.0 CONTROLLER AND SYSTEM TEST.................................................................................................. 10-1

10.1 CONTROLLER CONFIGURATION AND TEST................................................................................ 10-1

10.1.1 Connections and Power .............................................................................................................. 10-1

10.1.2 Configuration............................................................................................................................. 10-2

10.1.3 Input/Output............................................................................................................................... 10-2

10.1.4 Auto/Manual.............................................................................................................................. 10-2

10.1.5 Modifying an FCO .....................................................................................................................10-2

10.1.6 Alarms....................................................................................................................................... 10-4

10.1.7 TAG........................................................................................................................................... 10-5

10.1.8 QUICK....................................................................................................................................... 10-5

10.1.9 TUNE......................................................................................................................................... 10-6

10.1.10 View mode............................................................................................................................... 10-7

10.2 SYSTEM CHECKOUT ....................................................................................................................... 10-7

11.0 MAINTENANCE.................................................................................................................................... 11-1

11.1 TOOLS AND TEST EQUIPMENT ..................................................................................................... 11-1

11.2 PREVENTIVE MAINTENANCE........................................................................................................ 11-2

11.2.1 Environmental Considerations....................................................................................................11-2

11.2.2 Visual Inspection ........................................................................................................................ 11-2

11.2.3 Cleaning.....................................................................................................................................11-2

11.2.4 Circuit Board Handling.............................................................................................................. 11-3

11.3 TROUBLESHOOTING .......................................................................................................................11-3

11.4 ERROR CODES.................................................................................................................................. 11-7

11.5 ASSEMBLY REPLACEMENT ......................................................................................................... 11-12

11.5.1 Fuse.......................................................................................................................................... 11-12

11.5.2 Display Assembly..................................................................................................................... 11-12

11.5.2.1 To Replace a Display Assembly....................................................................................... 11-12

11.5.2.2 To Replace the Bezel or Circuit Board............................................................................. 11-13

11.5.3 MPU Controller Board ............................................................................................................. 11-14

11.5.4 I/O Expander Board ................................................................................................................. 11-15

11.5.5 Accessory Boards ..................................................................................................................... 11-16

11.5.6 Ethernet Cable.......................................................................................................................... 11-20

12.0 CALIBRATION...................................................................................................................................... 12-1

12.1 ANALOG INPUT (AIN1-4)................................................................................................................. 12-2

12.2 ANALOG OUTPUT (AOUT1-3)......................................................................................................... 12-3

13.0 CIRCUIT DESCRIPTION...................................................................................................................... 13-1

13.1 OVERVIEW........................................................................................................................................ 13-1

13.2 MPU CONTROLLER BOARD............................................................................................................ 13-2

13.3 I/O EXPANDER BOARD.................................................................................................................... 13-2

13.4 LonWorks BOARD.............................................................................................................................. 13-3

13.5 LOCAL INSTRUMENT LINK (LIL) NETWORK BOARD................................................................. 13-3

October 2001 v

Page 8

Contents UM353-1

13.6 ETHERNET BOARD .......................................................................................................................... 13-3

14.0 MODEL DESIGNATION AND SPECIFICATIONS............................................................................. 14-1

14.1 MODEL DESIGNATION.................................................................................................................... 14-1

14.2 ACCESSORIES................................................................................................................................... 14-3

14.3 SERVICE PARTS KITS ...................................................................................................................... 14-4

14.4 MECHANICAL SPECIFICATIONS.................................................................................................... 14-6

14.5 POWER INPUT REQUIREMENTS ....................................................................................................14-6

14.6 MPU CONTROLLER BOARD SPECIFICATIONS............................................................................. 14-7

14.7 I/O EXPANDER BOARD SPECIFICATIONS ....................................................................................14-7

14.8 COMMUNICATION BOARDS......................................................................................................... 14-10

14.8.1 LonWorks Board...................................................................................................................... 14-10

14.8.2 LIL Network Board (Local Instrument Link)............................................................................ 14-10

14.8.3 Ethernet Board......................................................................................................................... 14-11

14.9 ENVIRONMENTAL SPECIFICATIONS.......................................................................................... 14-11

14.9.1 Standard Mounting................................................................................................................... 14-11

14.9.2 Enclosure Mounting................................................................................................................. 14-11

14.9.3 Electromagnetic Compatibility (EMC)...................................................................................... 14-11

14.10 AGENCY APPROVALS ................................................................................................................. 14-11

14.10.1 CSA Hazardous Locations Precautions................................................................................... 14-12

14.10.2 Special Conditions for Safe Use.............................................................................................. 14-13

15.0 ABBREVIATIONS AND ACRONYMS................................................................................................. 15-1

WARRANTY

SOFTWARE RELEASE MEMO

vi October 2001

Page 9

UM353-1 Contents

LIST OF ILLUSTRATIONS

FIGURE AND TITLE PAGE

1-1 Moore 353, Exploded View ......................................................................................................................1-2

1-2 Ethernet Architecture Example................................................................................................................. 1-4

2-1 Configuration Road Map ..........................................................................................................................2-6

3-1 PCOM Logic Diagram ............................................................................................................................ 3-75

8-1 Direct Entry Connectors, Cover Installation and Removal.........................................................................8-4

8-2 Side Entry Connectors, Removing a Connector......................................................................................... 8-5

8-3 Panel Cutout Dimensions..........................................................................................................................8-5

8-4 Moore 353 Dimensions, Direct Entry Connectors ..................................................................................... 8-6

8-5 Moore 353 Dimensions, Side Entry Connectors........................................................................................8-6

8-6 Case Mounting Clip.................................................................................................................................. 8-7

8-7 Rear Terminal Layout and Terminal Assignments, Direct Entry Connectors........................................... 8-10

8-8 Rear Terminal Layout and Terminal Assignments, Side Entry Connectors .............................................8-11

8-9 Analog Input AIN1, 2-Wire Transmitter ................................................................................................. 8-13

8-10 Analog Inputs ANI1, 2, and 3; 4-Wire Transmitters............................................................................... 8-14

8-11 Universal Analog Input AINU1 .............................................................................................................. 8-14

8-12 Analog Output AOUT1, Current Output................................................................................................. 8-15

8-13 Analog Output AOUT1, Voltage Output................................................................................................. 8-15

8-14 Digital Inputs DIN and DINU................................................................................................................. 8-16

8-15 Digital Output DOUT1, Resistive and Inductive Loads........................................................................... 8-17

8-16 Universal Analog Input AINU1, Thermocouple Input............................................................................. 8-18

8-17 Reference Junction Lead Forms .............................................................................................................. 8-18

8-18 Universal Analog Input AINU1; 2, 3, and 4-Wire RTD Inputs................................................................ 8-19

8-19 Universal Analog Input AINU1, Ohms Input.......................................................................................... 8-20

8-20 Universal Analog Input AINU1, Slidewire Input..................................................................................... 8-20

8-21 Universal Relay Outputs ROUT1 and 2, Resistive Load.......................................................................... 8-20

8-22 LIL Network Wiring............................................................................................................................... 8-21

8-23 LonWorks Network Wiring ....................................................................................................................8-22

8-24 Modbus Communications, Personal Computer to Moore 353 or Moore 354 ............................................8-23

8-25 Moore 353 to Model 363 VIEWPAC Analog Input Wiring ..................................................................... 8-24

8-26 Controller Power Wiring ........................................................................................................................8-24

8-27 Suggested Power Wiring......................................................................................................................... 8-25

8-28 Daisy Chained Power Wiring.................................................................................................................. 8-25

11-1 Moore 353 Exploded View .....................................................................................................................11-5

11-2 MPU Controller Board with RTC Jumper W8 ......................................................................................... 11-6

11-3 MPU Controller Board with RTC Jumper W7 ......................................................................................... 11-7

11-4 I/O Expander Board.............................................................................................................................. 11-15

11-5 Accessory Board Installation and Replacement..................................................................................... 11-16

11-6 LIL Network Board............................................................................................................................... 11-18

11-7 Ethernet Board ..................................................................................................................................... 11-18

11-8 LonWorks Board .................................................................................................................................. 11-19

11-9 Real Time Clock/Configuration Backup Board ..................................................................................... 11-19

13-1 Moore 353 Block Diagram...................................................................................................................... 13-1

October 2001 vii

Page 10

Contents UM353-1

LIST OF TABLES

TABLE AND TITLE PAGE

1.1 Contact Information.................................................................................................................................. 1-7

1.2 ISO/IEC Symbols ..................................................................................................................................... 1-8

3.1 Security Level vs. Accessible Operations................................................................................................... 3-4

3.2 Modbus Port Baud Rate Parameters.......................................................................................................... 3-6

3.3 Board Description and ID with Example Hardware and Software Revisions..............................................3-6

3.4 Input Types.............................................................................................................................................3-19

3.5 Calibration Input Values......................................................................................................................... 3-19

3.6 Sen Min/Max & Min/Max Scale Parameters ........................................................................................... 3-19

8.1 Rear Terminal Assignments...................................................................................................................... 6-8

8.2 Factory Calibration .................................................................................................................................6-26

9.1 Autotune Errors........................................................................................................................................ 9-6

9.2 Autotune Warnings................................................................................................................................... 9-6

11.1 RTC/CB and RCB Boards, Off-Line Error Codes.................................................................................... 11-9

11.2 On-Line Error and Status Codes........................................................................................................... 11-10

14.1 Moore 353 Model Designation................................................................................................................ 12-2

Changes for Revision 10, October 2001

Significant changes for Rev 10 are indicated by change bars in the outside page margins. Some of these changes

are listed below.

SECTION CHANGE

Cover Changed to Rev.10, October 2001.

1 Installation A table of MPU Controller board and I/O Expander board I/O has been added.

Figure 1-1 updated to show Ethernet cable and identify rear panel mounted

Ethernet connector.

3 Function Blocks AINU, BIAS, DNC, and SPLIM functions blocks updated.

4 Factory Configured Options FCO107 figure updated.

8 Installation Ethernet cable recommendations added in section 8.4.12 Ethernet Wiring.

11 Maintenance Figure 11-1, Section 11.5.3, and 11.5.5 updated. Section 11.5.6 added.

Ethernet board drawing added, as Figure 11-7.

14 Model Designation and

Specifications

SR353-8 Rev. 2 replaces Rev. 1.

CE approval for Case Option 4 added.

Note

At Rev. 9, the User’s Manual was reorganized to move the FCO and Network

Communications appendices into the body of the manual, as in the Procidia i|pac User’s

Manual. The Function Block section is now followed by the FCO section and the

Network Communications section is now followed by the Data Mapping section

(previously Appendix A Network Communications).

viii October 2001

Page 11

UM353-1 Contents

Procidia, i|pac, i|config, i|station, i|ware PC, APACS+, PAC 353, 352Plus, VIEWPAC, and XTC are trademarks of Siemens Energy & Automation,

Inc. Other trademarks are the property of their respective owners.

Siemens Energy & Automation, Inc. assumes no liability for errors or omissions in this document or for the application and use of information

included in this document. The information herein is subject to change without notice.

Procedures in this document have been reviewed for compliance with applicable approval agency requirements and are considered sound

practice. Neither Siemens Energy & Automation, Inc. nor these agencies are responsible for repairs made by the user

n

October 2001 ix

Page 12

Contents UM353-1

PREFACE

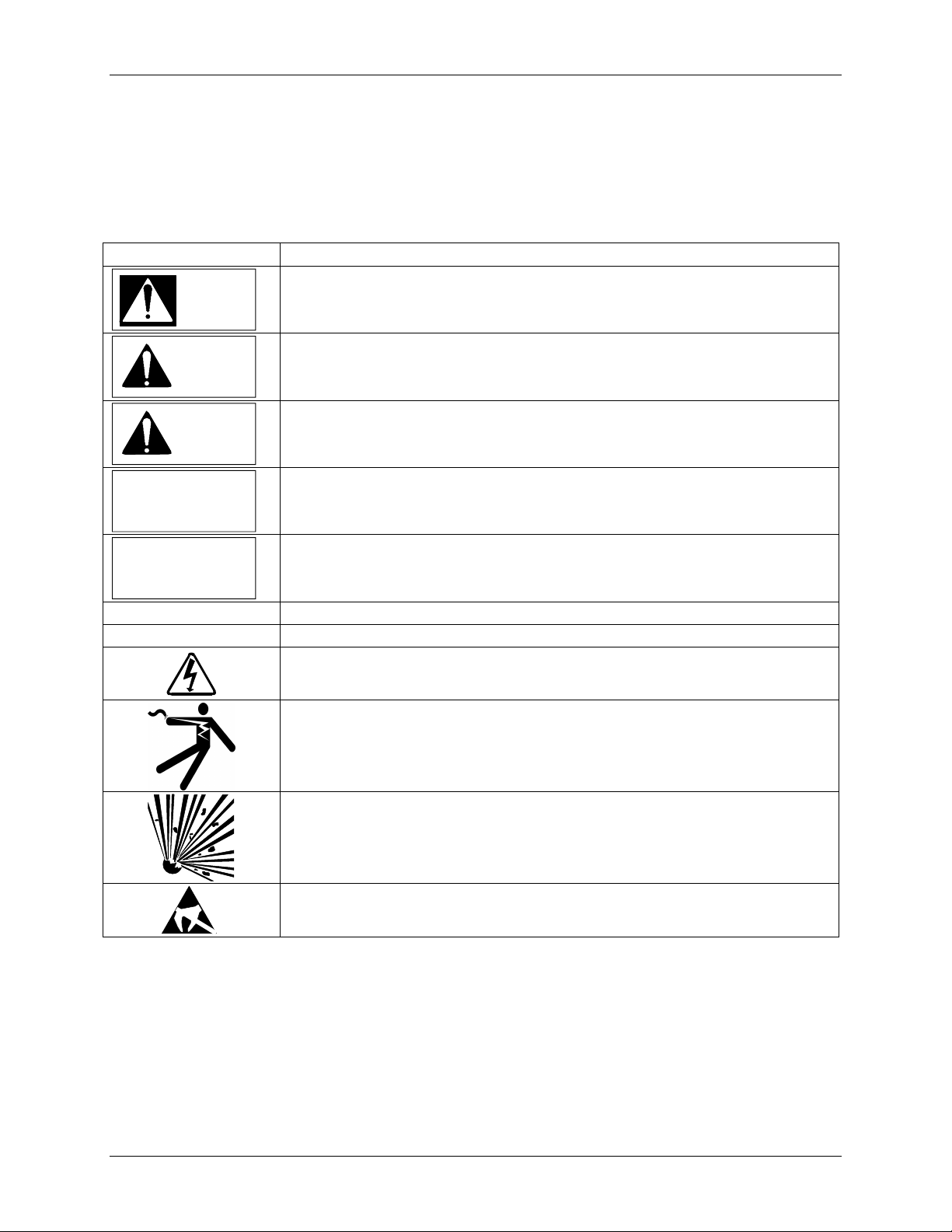

Conventions and Symbols

The following symbols may appear in this manual and may be applied to the equipment. The reader should become

familiar with the symbols and their meaning. Symbols are provided to quickly alert the user to safety related

situations, issues, and text.

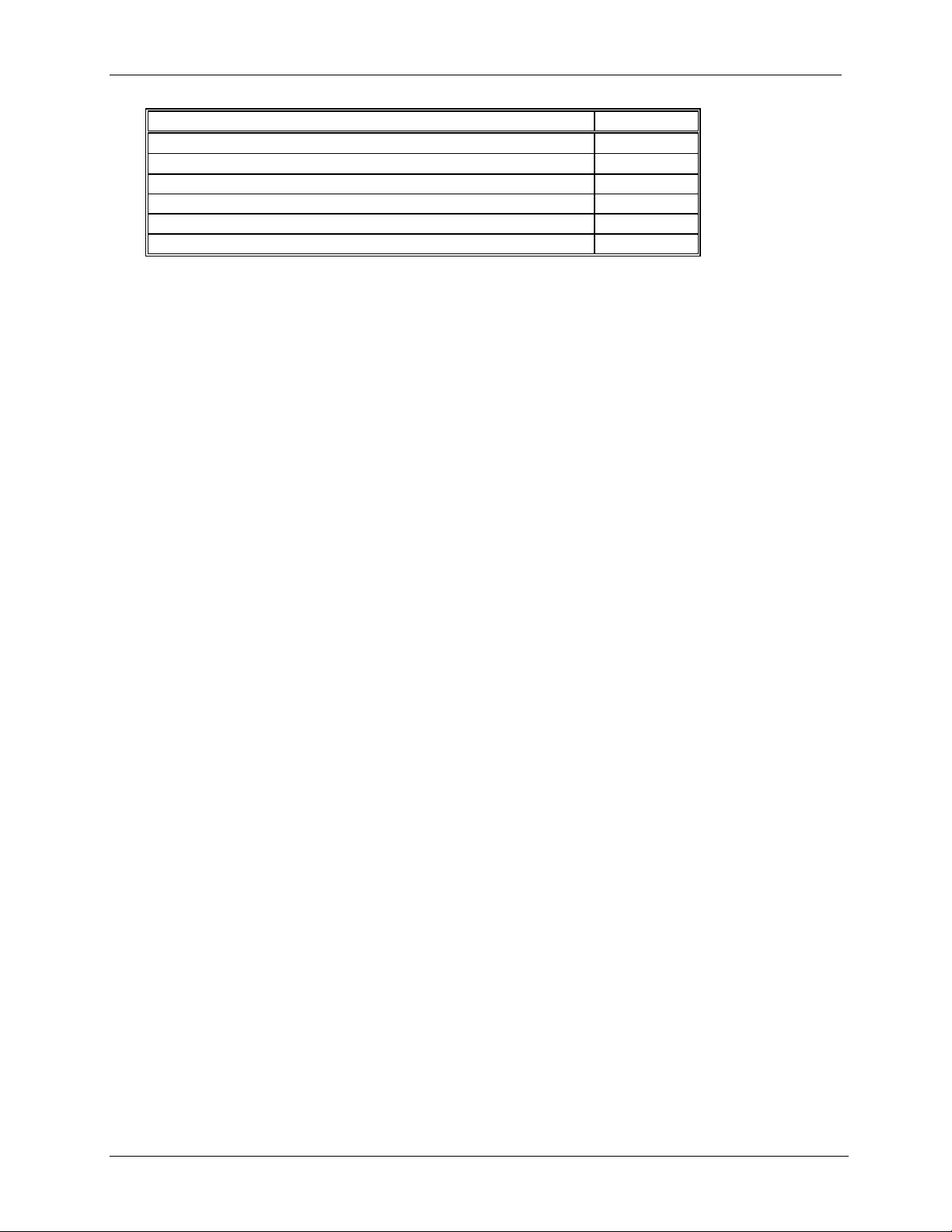

Symbol Meaning

Indicates an immediate hazardous situation which, if not avoided, will result in death

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Important Identifies an action that should be taken to avoid an undesirable result or state.

Note Identifies additional information that should be read.

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

Indicates a potential situation which, if not avoided, may result in an undesirable

result or state.

Electrical shock hazard. The included Warning text states that the danger of

electrical shock is present.

Electrical shock hazard. Indicated that the danger of electrical shock is present.

Explosion hazard. Indicates that the danger of an explosion hazard exists.

Electrostatic discharge. The presence of this symbol indicates that electrostatic

discharge can damage the electronic assembly.

Conventions and Usage Notes:

• In this User’s Manual, a Moore 353 can be referred to using the term Moore 353, Model 353, or simply 353.

The terms controller and station are also used to prevent repetition.

• Several chapters of this manual are also used in manuals for sister controllers and may contain references to

those controllers.

• This manual describes the functionality provided by the current MPU Controller board firmware version.

Where necessary a firmware version is identified by a phrase such as “in version x.x and higher” or simply

x October 2001

Page 13

UM353-1 Contents

• Part numbers are for items ordered from the Process Industries Division of Siemens Energy & Automation,

except as noted.

• Date format is Month-Day-Year, except as noted.

• Time format is 12 hour (a.m./p.m.), except as noted.

Qualified Persons

The described equipment should be installed, configured, operated, and serviced only by qualified persons

thoroughly familiar with this publication. A copy of this publication is shipped with the equipment. The current

version, in Portable Document Format (PDF), is available at www.sea.siemens.com/ai/.

For the purpose of this publication and product labels, a qualified person is one who is familiar with the

installation, construction, and operation of the equipment, and the involved hazardous. In addition, he or she has

the following qualifications:

• Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in accordance

with established safety practices.

• Is trained in the proper care and use of protective equipment such as rubber gloves, hard hat, safety glasses or

face shields, flash clothing, etc., in accordance with established safety practices.

• Is trained in rendering first aid.

Scope

This publication does not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met in connection with installation, operation, or maintenance. Should further information be

desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to one of the support groups listed in the Product Support section of this manual.

The contents of this manual shall not become part of or modify any prior or existing agreement, commitment or

relationship. The sales contract contains the entire obligation of Siemens. The warranty contained in the contract

between the parties is the sole warranty of Siemens. Any statements continued herein do not create new warranties

or modify the existing warranty.

General Warnings and Cautions

WARNING

This equipment contains hazardous voltages, and it has been certified for use in the hazardous locations specified

on the product nameplate and in the Model Designation and Specifications section. Death, serious personal injury,

or property damage can result if safety instructions are not followed. Only qualified personnel should work on or

around this equipment after becoming thoroughly familiar with all warning, safety notices, and maintenance

procedures contained herein. The successful and safe operation of this equipment is dependent upon proper

handling, installation, operation, and maintenance.

The perfect and safe operation of the equipment is conditional upon proper transport, proper storage, installation

and assembly, as well as, on careful operation and commissioning.

The equipment may be used only for the purposes specified in this publication.

October 2001 xi

Page 14

Contents UM353-1

CAUTION

Electrostatic discharge can damage or cause the failure of semiconductor devices such as integrated

circuits and transistors. The symbol at right may appear on a circuit board or other electronic assembly

to indicate that special handling precautions are needed.

COIL INPUTS 16 CHAN - ETHERNET

CIE_

C0 Output C0

COIL INPUTS

16-CHAN ETHERNET

CF Output CF

Ethernet Network

QS Output QS

P A R E S

(H)

I D

IP ADdRESs

S

T A RFCL

T

STARTing CoiL

CLNO O

NO. OF COILs (H) ................ 1 - 16 (1)

. nnn.nnn.nnn.nnn (192.168.0.0)

(H)

.. 0000 - 65535

(Rev. 2)

(0)

• A properly grounded conductive wrist strap must be worn whenever an electronics module or circuit board is

handled or touched. A service kit with a wrist strap and static dissipative mat is available from Siemens

(PN15545-110). Equivalent kits are available from both mail order and local electronic supply companies.

• Electronic assemblies must be stored in anti-static protective bags when not installed in equipment.

n

xii October 2001

Page 15

UM353-1 Introduction

1.0 INTRODUCTION

This User’s Manual contains configuration, installation and service information

for the Moore 353 Process Automation Controller. It is divided into fifteen

sections.

• Section 1, Introduction, has general information about the organization of this

manual, the controller, product support, and the contents of a typical

shipment.

• Section 2, Configuration Overview, contains a list of the functions blocks

available for use in configuring the controller and a procedure for

MG00189b

configuration. Function block availability depends on controller model and

MPU Controller board firmware version.

• Section 3, Function Blocks, contains a detailed description of each function block.

• Section 4, Factory Configured Options, provides a graphical presentation of the function blocks used in FCOs

and a listing of changes made to default function block parameters.

• Section 5, LonWorks Communications, provides an overview of LonWorks® communication.

• Section 6, Network Communications, furnishes overviews of Modbus, LIL, and Ethernet communication data.

• Section 7, Data Mapping, contains network data details for Modbus, Local Instrument Link (LIL), and

Ethernet.

• Section 8, Installation, contains drawings and steps detailing mechanical and electrical installation. Electrical

connections to the controller are identified and numerous wiring diagrams are included.

• Section 9, Local Faceplate Operation, describes and illustrates the Display Assembly’s operator controls and

displays. Use of these for on-line operation, for configurations and for autotuning is described.

• Section 10, Controller and System Test, has procedures for testing the controller and the installation.

• Section 11, Maintenance, lists the tools and test equipment to service a controller. It also has preventive

maintenance and servicing procedures, including error codes. Assembly replacement steps are included as are

detailed jumper selection criteria and jumper setting steps.

• Section 12, Calibration, provides step-by-step procedures for calibration of analog input and output circuits.

• Section 13, Circuit Description, furnishes a block diagram level description of the controller’s circuits.

• Section 14, Model Designation and Specifications, shows controller model numbers; a list of accessories;

mechanical, electrical, and environmental specifications; and a list of current agency approvals.

• Section 15, Abbreviations and Acronyms, is a convenient reference for new users that explains many

abbreviations and acronyms appearing in this manual.

IMPORTANT

Save this User’s Manual. It should be available to those installing, configuring,

operating, and servicing the controller.

October 2001 1-1

Page 16

Introduction UM353-1

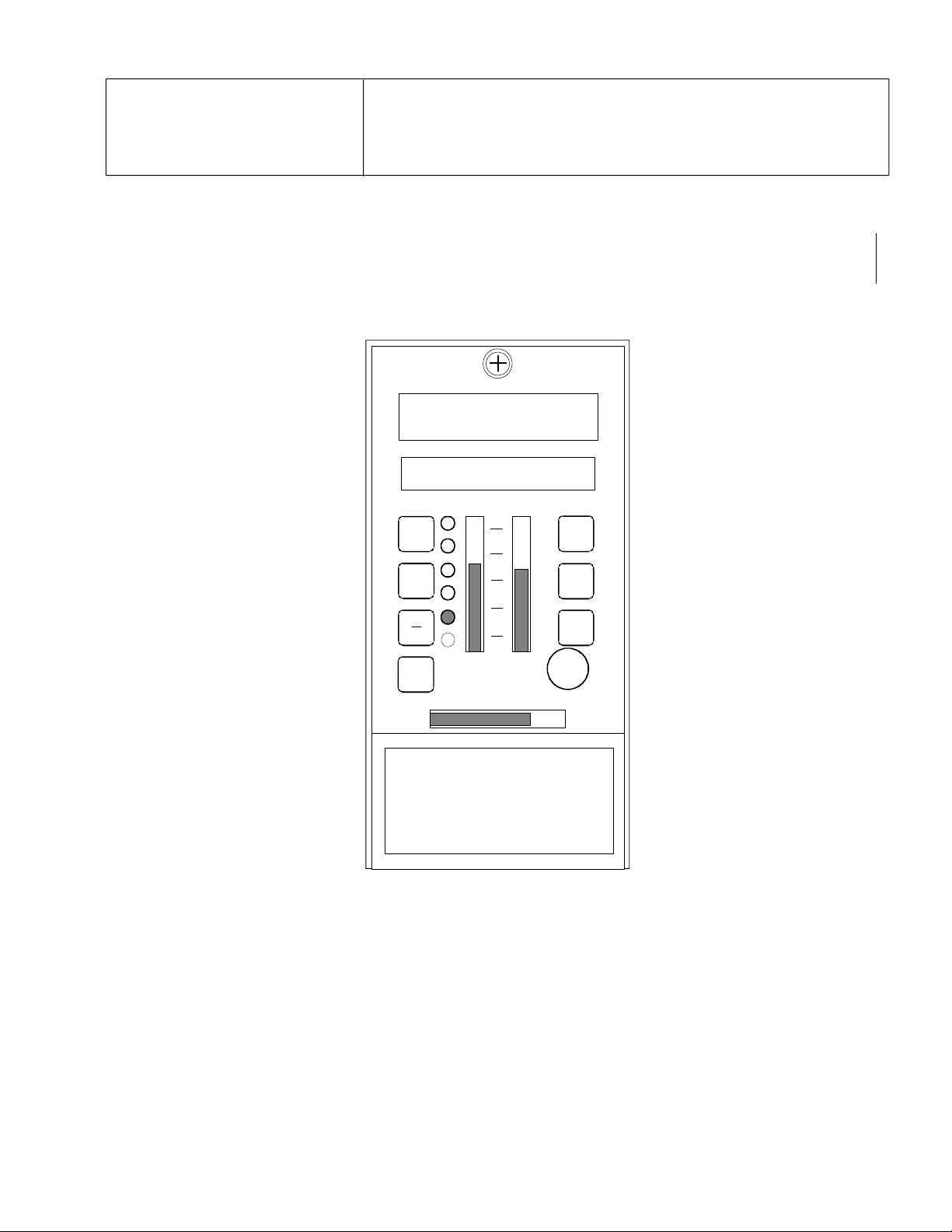

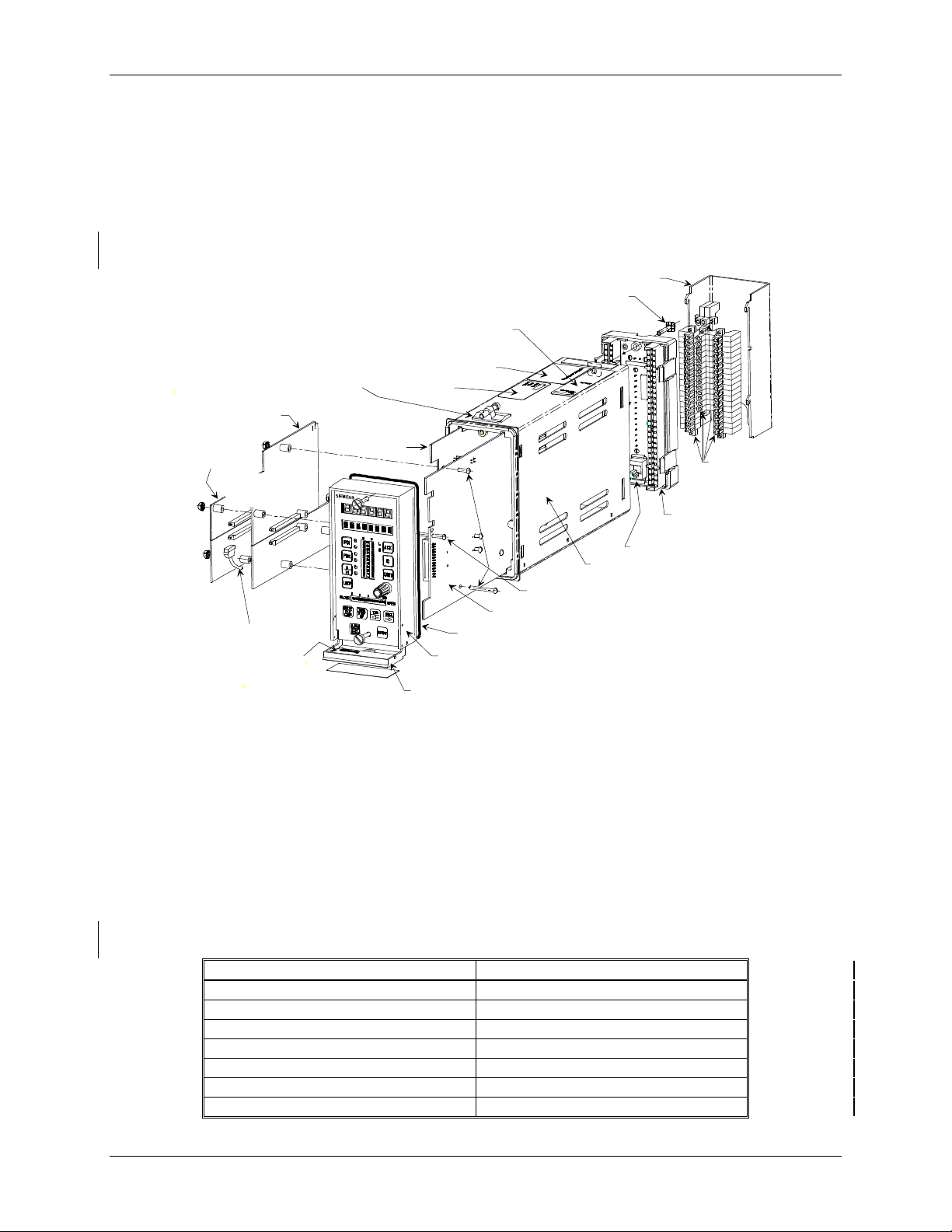

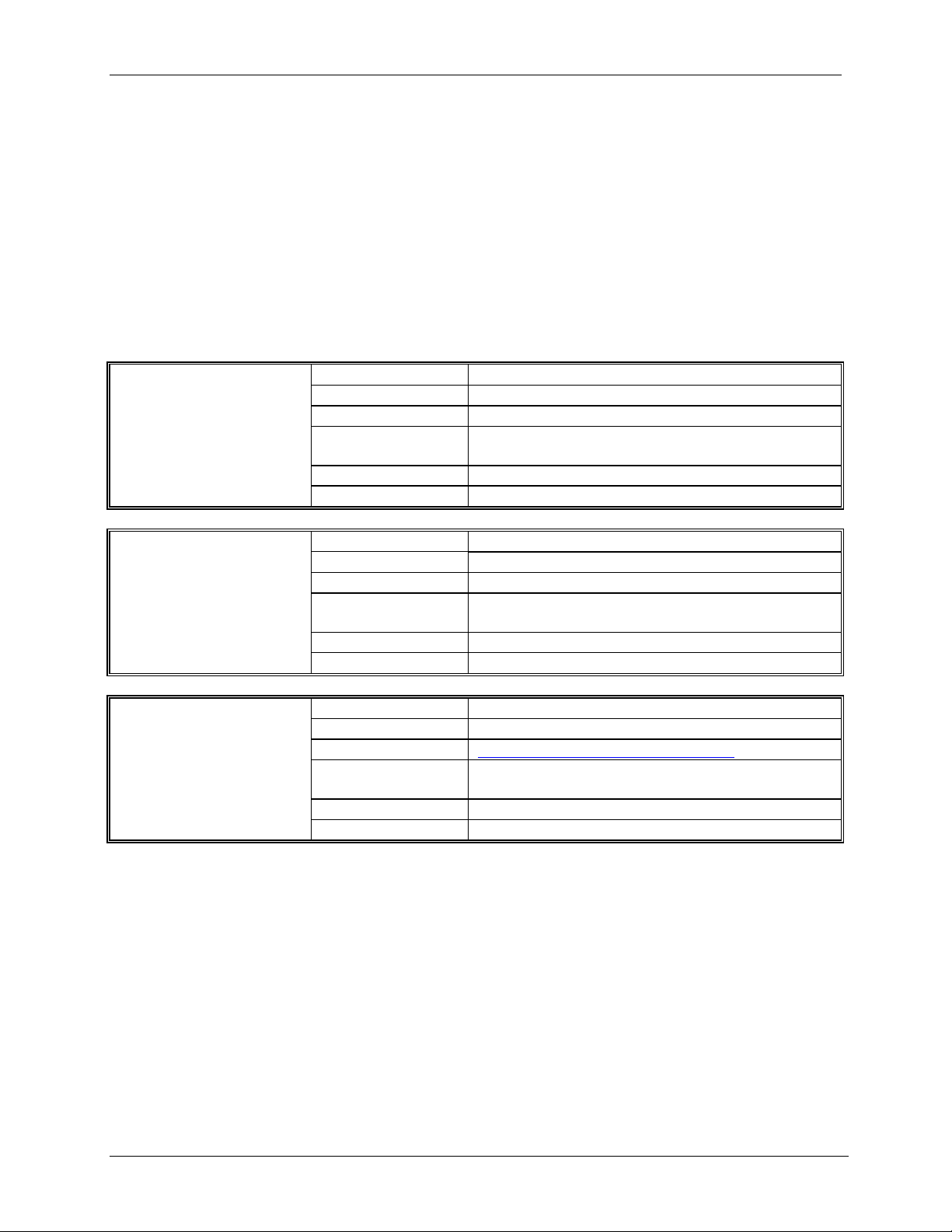

1.1 PRODUCT DESCRIPTION

The Moore 353 offers the control system designer the ultimate in flexibility and capability for the implementation

of continuous solutions and batch solutions. An exploded view of the controller appears in Figure 1-1.

At the heart of the Moore 353 is a powerful MPU Controller board that uses the latest in microprocessor

technology. It includes on-board I/O and reusable function blocks, and it is capable of solving a vast array of

control implementations including single loop, cascade, and dual loop. Available MPU board I/O is listed below.

Voltage Input, Approvals, and

Warning Label*

Warning and I/O

Capacity Label*

Nameplate*

I/O Expander

Board

MPU Controller Board

O-Ring, Display Assembly

Display Assembly with Operator Faceplate

Communication Port on Underside

Flip-Down Door with Loop ID Card

LIL or Ethernet

Network Board

RTC/CB or

RCB Board

Accessory or

Option Boards

Future

Use

Ethernet

Cable

Warning Label

Mounting Clip,

Top and Bottom*

LonWorks

Board

FIGURE 1-1 Moore 353, Exploded View

Modbus communication is standard and a port (RS485, half-duplex) at the rear terminals provides for network

connection of up to 32 controllers (e.g. Models 352P, 353, 354, 354N, and Procidia™ i|pac™) to an operator

workstation, Human/Machine Interface (HMI), or DCS, enabling integration of controllers into a plant-wide

system. A popular HMI is the Procidia i|station™ running i|ware PC™ operator interface software. A

communication port (RS232) on the underside of the Display Assembly is available for configuration and/or

debugging when using i|config™, the optional PC-based Graphical Configuration Utility.

An optional I/O Expander Board can be added to the base Moore 353. It includes direct thermocouple, RTD, and

frequency inputs and additional I/O for direct process measurement of temperature and frequency variables,

improving accuracy and control. Available Expander board I/O is listed below.

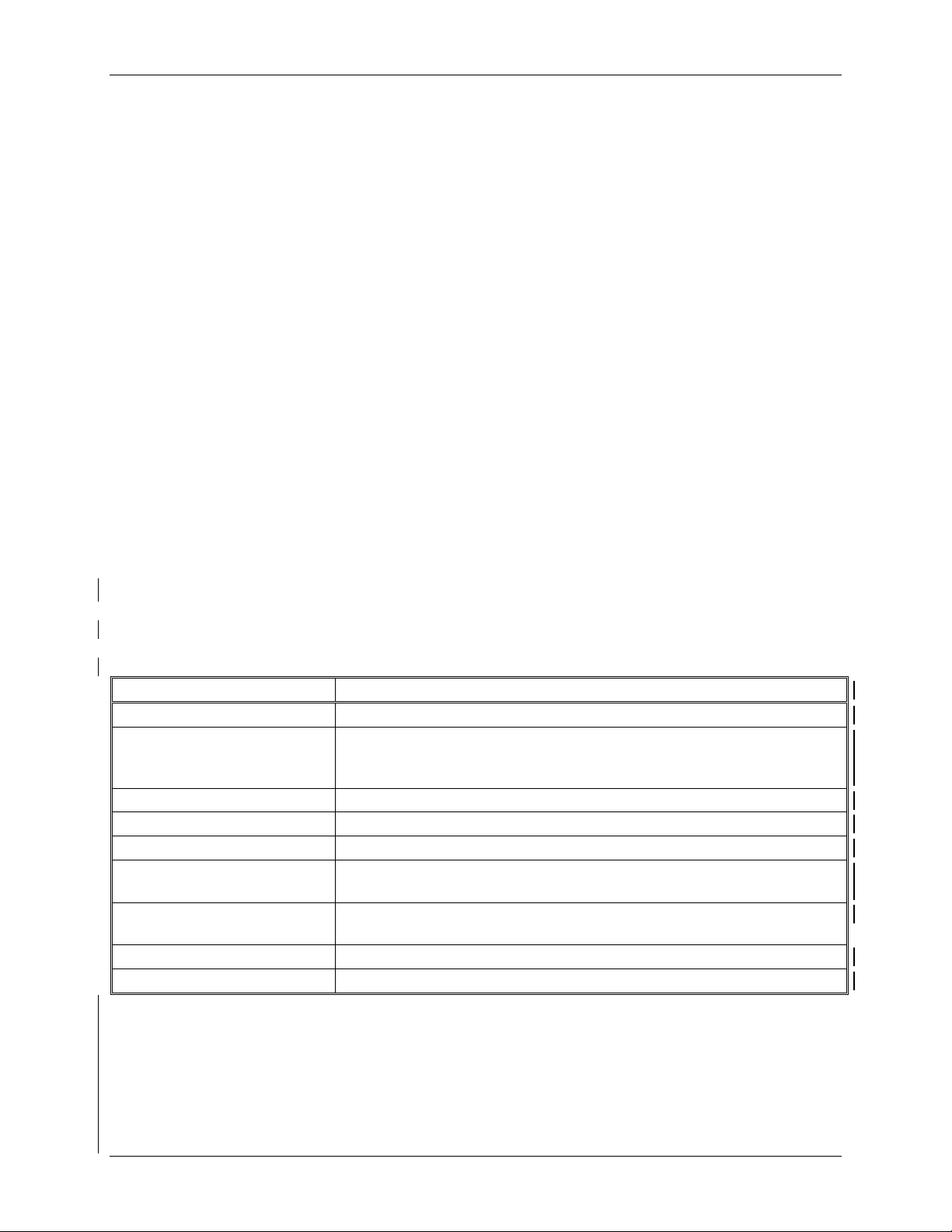

I/O on MPU Controller Board I/O on Expander Board

Analog Inputs 1, 2, and 3 Analog Input 4

Analog Outputs 1 and 2 Analog Output 3

Digital Inputs 1 and 2 Digital Inputs 3 and 4

Digital Outputs 1 and 2 ---

--- Analog Inputs Universal 1 and 2

--- Digital Inputs Universal 1 and 2

--- Relay Outputs 1 and 2

Connector Cover*

Ground Screw*

Removable

Portions of

Connectors*

Connector Socket

Assembly*

RJ-45 Ethernet Connector*

Case with Flange*

Mounting Kit, Accessory Boards

MG00392b

* = Case Assembly

1-2

October 2001

Page 17

UM353-1 Introduction

When even more I/O is needed for multiple-loop applications, advanced control, or batch sequencing, a remote I/O

option board that uses the popular LonWorks protocol can be installed. This LonWorks board provides

connectivity via a high-speed digital fieldbus to a large selection of standard I/O products: analog inputs and

outputs and digital inputs and outputs using relay or solid state technology.

Although the Moore 353 can be connected to and operated entirely from a central operator workstation, such as

i|station, a controller faceplate is included. This local operator interface is for applications where loops need

individual attention during startup, troubleshooting, maintenance, or emergency conditions. The convenient

faceplate layout and sophisticated software allow process and configuration changes to be made quickly and easily.

The controller can be completely configured from the operator faceplate or, as mentioned above, configured

remotely using i|config™, the optional PC-based Graphical Configuration Utility. An optional Real Time

Clock/Configuration Board (RTC/CB) is available to quickly transfer a configuration from one controller to

another when downloading a configuration over a network is not available. The RTC/CB also provides a real time

clock function.

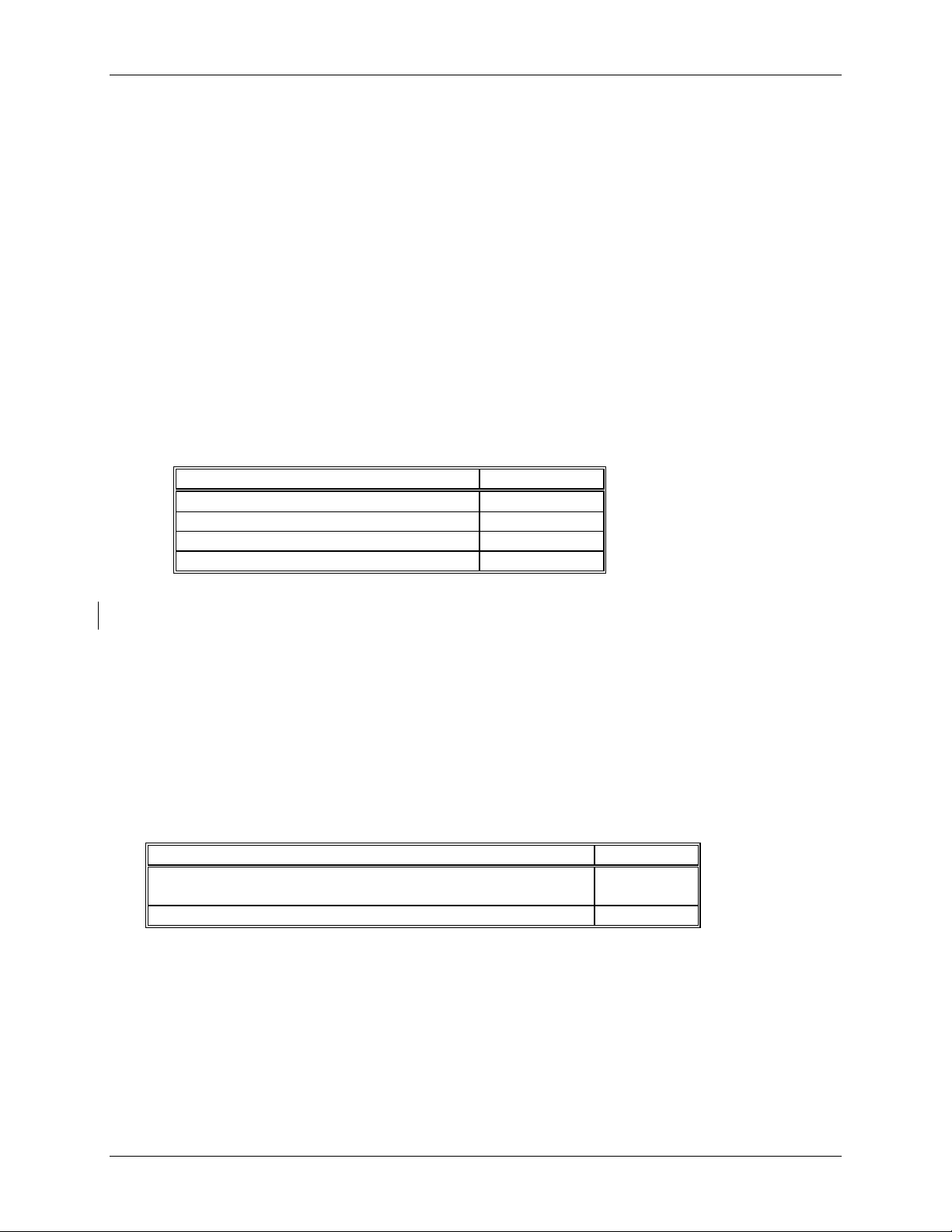

Network communication options are listed in the following table.

Protocol (Select One) Available Connection Option Board Needed

Modbus Standard Rear Terminals, NCA and NCB None

Local Instrument Link Optional Rear Terminals, NCA and NCB LIL Communication

Ethernet Optional Rear Panel, RJ -45 (requires case option 4) Ethernet Communications

Modbus communication is standard. An optional Local Instrument Link (LIL) network board is available in place

of the Modbus communication to provide higher speed networking and peer-to-peer communication between

controllers. This provides connectivity with an array of network-enabled products, including those listed below.

Current Controller Models Previous Controller Models

Procidia i|pac Internet Control System

Moore 352P Single-Loop Digital Controller

Moore 354/354N Universal Controllers

Model 352 Single-Loop Digital Controller

Model 351 Triple-Loop Digital Controller

Model 382 Logic and Sequence Controller

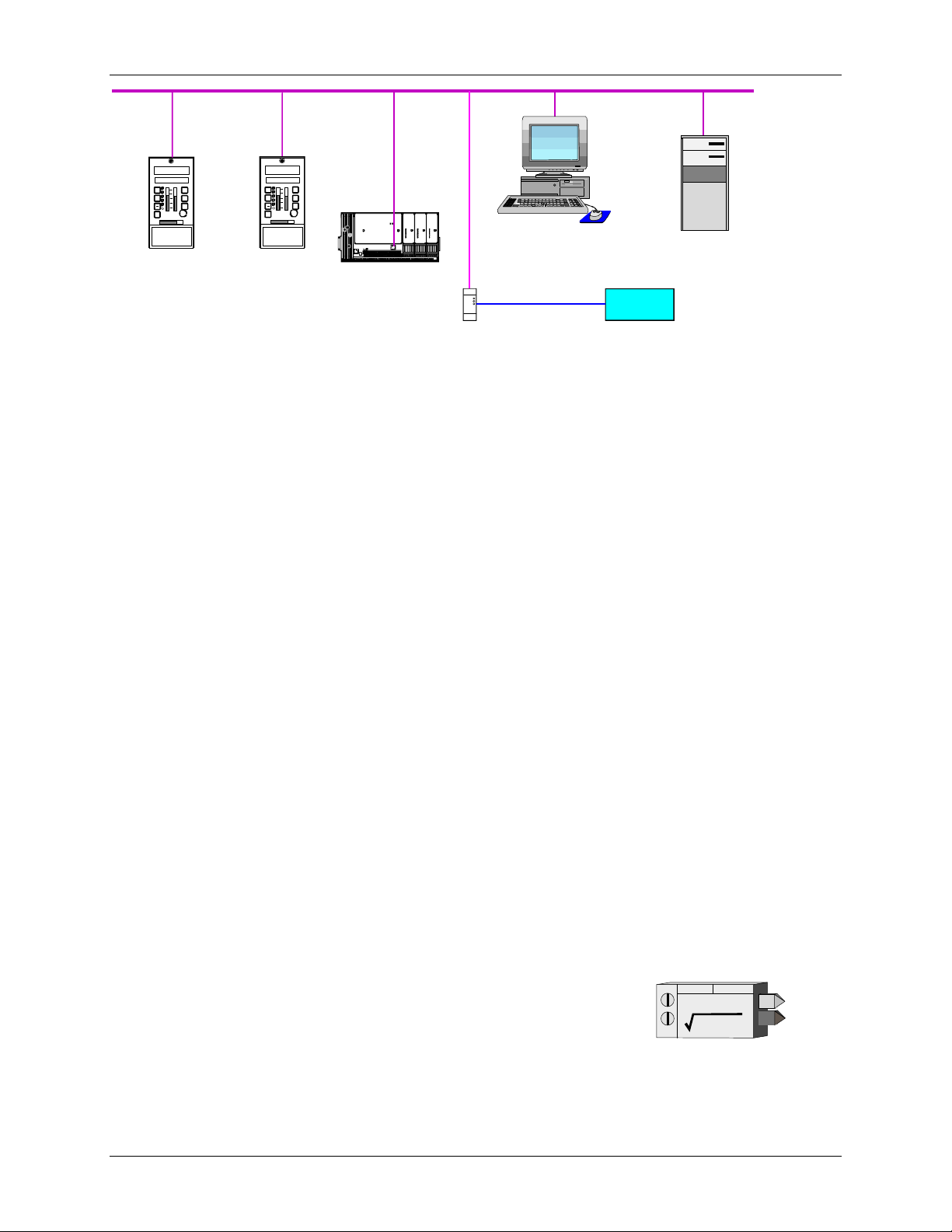

An optional Ethernet board is available in place of Modbus and LIL communication. This option enables peer-topeer communication between Moore 353 controllers, Procidia i|pac controllers, and many other devices that feature

Ethernet (embedded Modbus RTU protocol). Ethernet communications requires an Ethernet board and controller

firmware V2.4 or higher.

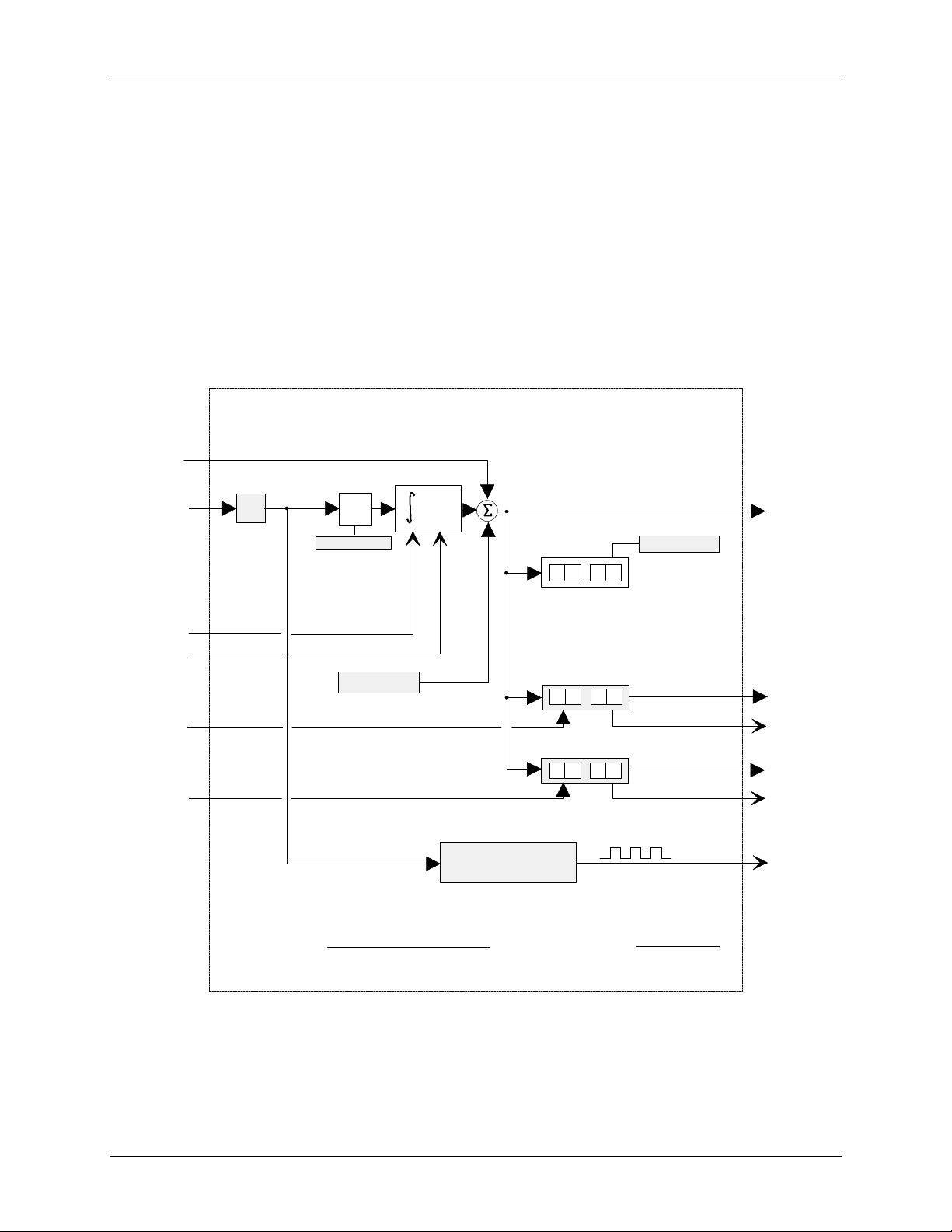

The Ethernet board supports uploading and downloading of controller configurations over the Ethernet LAN. For

example, if i|config Graphical Configuration Utility software is loaded on the local client shown in Figure 1-2,

controller configurations can be developed on the client, or uploaded from the controller for editing, and then

downloaded to the controller. Data can also be acquired from remote servers for the purpose of archiving and/or

data mining. The Ethernet-Modbus Bridge in Figure 1-2 accepts an Ethernet data command from the controller

and outputs an equivalent Modbus command to a Modbus device at address 1. The returning Modbus data is

embedded by the bridge in an Ethernet packet to be sent to the requesting controller.

Regardless of the selected communication option, the RS232 port on the underside of the Display Assembly will

communicate using Modbus. Controller hardware architecture is designed to accommodate other emerging fieldbus

technologies. This includes field communications that require lower power for intrinsic safety and higher speed for

interplant networking.

For small retrofit applications, the Moore 353 with operator faceplate is a replacement for a simple stand-alone

single-loop controller. It is easily upgraded with additional I/O and communication options for advanced control

strategies and plant networking.

October 2001 1-3

Page 18

Introduction UM353-1

Ethernet

s

4 2.453

2

TC2 0 5 3 . P

S P

100

L

PB1

ACK

S

80

60

D

PB2

40

A

20

UNITS

M

0

LOOP

100

0

| ||

|

CLOSE

OPEN

Moore 353

X03141S2

Multiple Moore 353 and Procidia i|pac Nodes,

each with an Ethernet Network Board.

s

4 2.453

2

TC 20 5 3 . P

S P

100

PB1

80

60

PB2

40

A

20

M

0

LOOP

0

| ||

CLOSE OPEN

Moore 353

L

ACK

S

D

UNITS

100

|

P3

X03141S2

P4

P1

13 5 7 9 111315 1 3 57 9111315 1 3 5 7 9111315

Local Client

Internal Web Server

Intranet

Modbus

Ethernet-Modbus

Bridge

Foreign Device with

Modbus Communications

MG00388a

FIGURE 1-2 Ethernet Architecture Example

Often in this publication, reference is made to the labels on the controller to ensure that the controller being

installed has the correct power input, I/O, communication options, and approvals. This is particularly important

when non-incendive requirements are present or a critical process is involved where a custom configuration or

calibration has been created. Label locations are shown in Figure 1-1 and typical labels are shown in Section 14

Model Designation and Specifications.

1.2 FUNCTION BLOCKS

Controller software is built on proven function block designs from previous LIL products and from Siemens

APACS® products that support the IEC1131 standard. In many cases, the controller has been enhanced with

features only now possible with state of the art technology.

Function blocks are selected for use within a LOOP. Multiple loops can be configured, and each loop can be

associated with an operator faceplate. Certain blocks are used once within each loop (e.g. controller, setpoint,

auto/manual), others can be used as many times as needed. Some notable features include Auto Tuning within the

PID function blocks, an expandable Sequencer that allows configuration of up to 250 steps, and up to 256 discrete

inputs and outputs. In addition, the Graphical Configuration Utility can be used to design the logic in a ladder

diagram. Combining these features with continuous control loops within the same controller offers a wellintegrated solution for small batch operations.

Several function blocks are available at the station level for configuration of STATION level parameters, such as

the station address and station tag name. Function blocks include the CLOCK block (when the RTC/CB option

board has been included), and the ETHERNET block (when the Ethernet board has been installed and the

controller contains firmware V2.4 or higher) to configure parameters such as the IP address. All other function

blocks are used for configuration within an individual LOOP. Control implementations are configured in the

Moore 353 by first creating a loop, then entering a unique loop tag name and selecting function blocks for use

within that loop. A number of loops can be configured in the Moore 353 and a number of function block types are

available as described in the sections that follow.

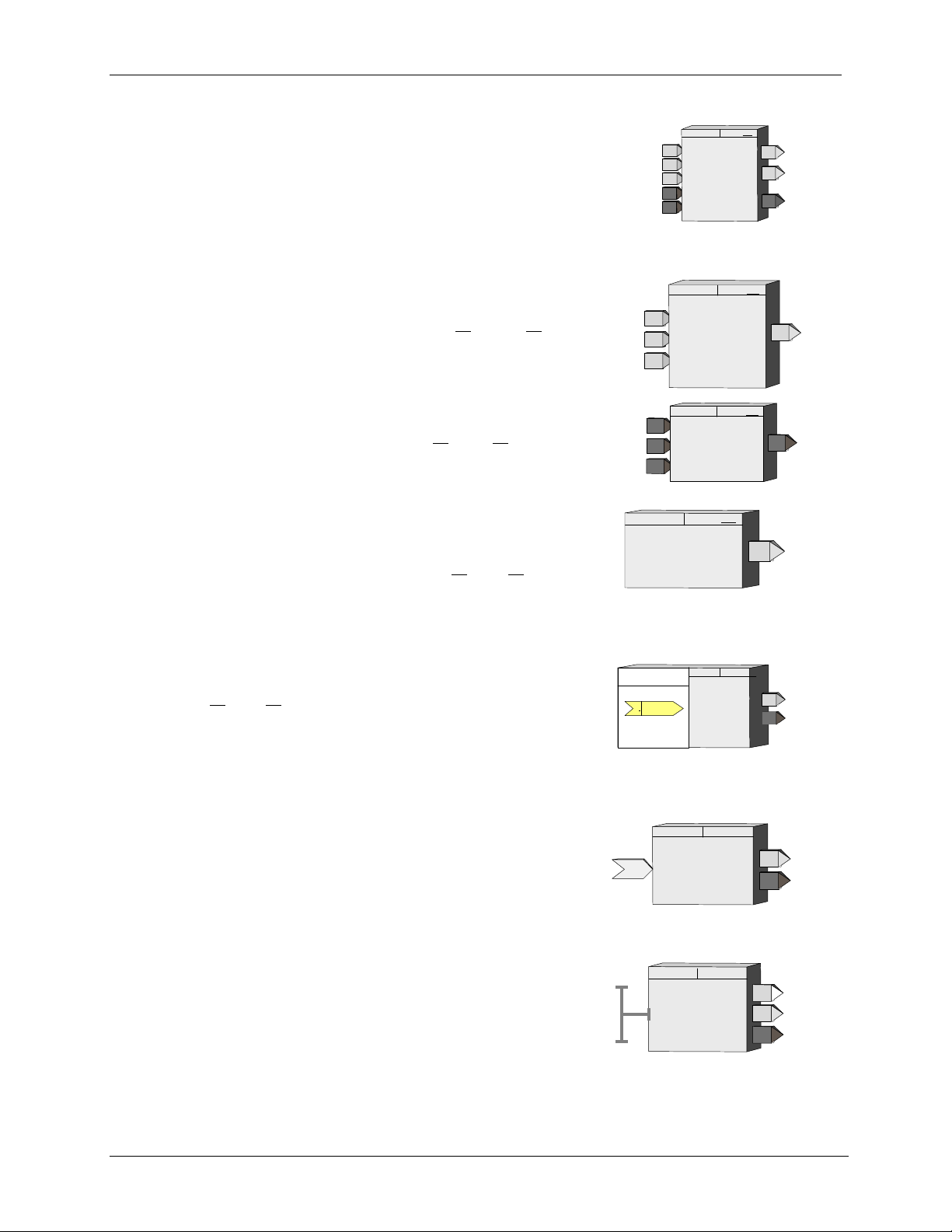

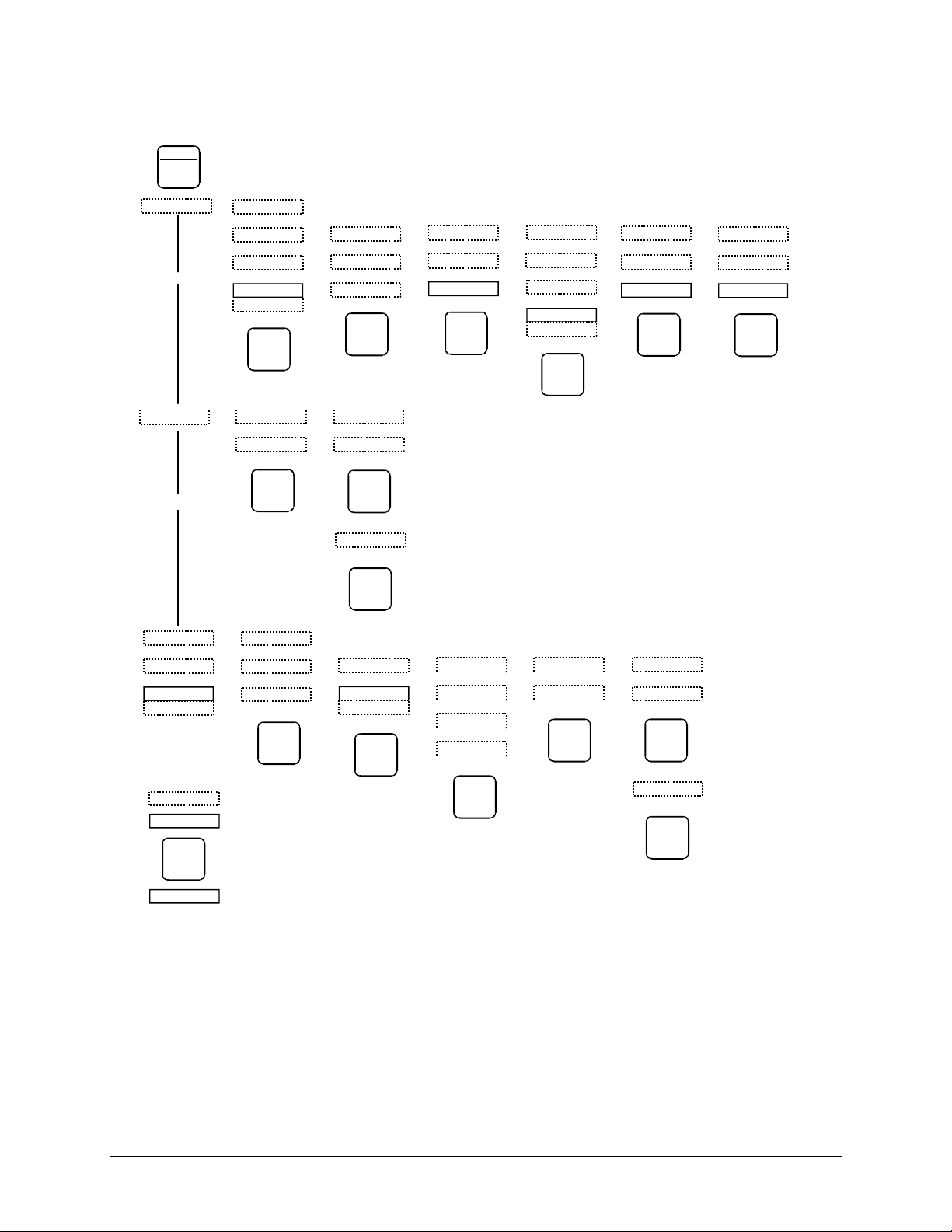

1.2.1 LOOP Function Block Types

Local I/O Function Blocks are provided on both the MPU Controller Board

and the I/O Expander Board. These blocks can be used in any LOOP, but as

fixed resources are expendable. When used within a loop, the unique block

AIN_+

AIN_c

name becomes <loop>.<block> (e.g. TC2053.AIN1 for Analog Input 1 used in

loop TC2053).

1-4

October 2001

AIN_

ANALOG INPUT

EXTRACTOR

QS

utput

O

O1

1

uality Status

Q

Page 19

UM353-1 Introduction

Fixed Loop Function Blocks can be selected for use within each configured LOOP and include those blocks which

define the major functions of a loop. The operator display function block (e.g.

ODC Operator Display for Controllers) defines the loop type, the function of

the local faceplate as well as the processing of commands coming from a

remote workstation. A single controller function block can be selected from

one of five available choices (ID, ON_OFF, PD, PIDAG, & PID) within each

loop. When used within a loop the unique block name becomes

Process

Setpoint

Feedback

Auto

P

S

F

A

IInitialize

ESN = 000

PID

PID

CONTROLLER

O1 Output

Absolute Error

AE

AT Warning

AW

<loop>.<block> (e.g. TC2053.PID for the PID controller used in loop

TC2053).

Arithmetic Function Blocks are also designated as LOOP function blocks

and can be used as many times as needed in each loop. Each use of a block

is automatically assigned a unique name (i.e. MATH01, MATH02) within

each loop so that the unique block name becomes <loop>.<block> (e.g.

TC2053.MATH01).

Input

Input

Input

A

B

C

A

B

C

MTH_ ESN = 000

MATH

ADD, SUB, MUL, DIV

O1 O

utput

Logic Function Blocks are also designated as LOOP function blocks and

can be used as many times as needed in each loop. Each use of a block is

automatically assigned a unique name (i.e. AND01, AND02) within each

loop so that the unique block name becomes <loop>.<block> (e.g.

TC2053.AND01).

Input

Input

Input

A

B B

C

AND_

A

C

AND

ESN =

000

utput

O1

O

General Purpose Function Blocks are also designated as LOOP function

blocks and include blocks that do not fall into the arithmetic or logic

categories. These can be used as many times as needed and each use will

HLD_

HOLD

ESN =

000

O1

Output 1

automatically be assigned a unique name (e.g. HLD01, HLD02) within each

loop so that the unique block name becomes <loop>.<block> (e.g.

TC2053.HLD01).

Remote I/O Bus Function Blocks can be used as needed in each LOOP to provide a method for sending and

receiving both analog and discrete data to and from remote devices over the

remote I/O digital bus. Each use will automatically be assigned a unique

name (e.g. AIP01, AOP01) within the station so that the unique block name

becomes <loop>.<block> (e.g. TC2053.AIP01 for Analog Input-lev_Percent

LONWorks

nviAIPnn1

nv *

SNVT_lev_percent

Network

AIP

ANALOG INPUT

LEV_PERCENT

O1

QS

Output 1

Quality Status

used in loop TC2053). The second AIP block used within the station will be

assigned AIP02 even if in a different loop so that the remote I/O blocks have

unique names within the station. This will enable unique names for station variables on the LON network.

LIL Global Function Blocks are used as needed within a LOOP when the LIL option board is installed to enable

global data communication over the LIL. They will automatically be

assigned a unique name (e.g. AIL01, DIL01) within each loop when it is

configured so that the unique block name becomes <loop>.<block> (e.g.

TC2053.AIL01). Input and output data blocks are available as needed and

ANALOG INPUT - LIL

LIL

GLOBAL

DATA

AIL_

O1

QS

Output

Output

O1

QS

will be assigned unique names as used (e.g. AIL01, AIL02 for Analog InputLIL blocks).

Ethernet Function Blocks (V2.4) are used as needed within a LOOP when

the Ethernet option board is installed They will automatically be assigned a

unique name (e.g. AIE01, DIE01) within each loop when it is configured so

that the unique block name becomes <loop>.<block> (e.g. TC2053.AIE01).

AIE_

ANALOG INPUT

ETHERNET

OR

O1

QS

Output

Output

Output

OR

O1

QS

1

1

October 2001 1-5

Page 20

Introduction UM353-1

1.2.2 Power Up Initialization

The Moore 353 will retain, in the station NVRAM, calculated block values (e.g. outputs, elapsed time, last

input/output logic states), including the time since power was lost. Three power up modes (hot, warm, and cold)

are utilized in the Moore 353 that affect the initialization of function blocks. These modes are configured by two

power up timers (warm and cold), included in STATION parameters. The station will initialize a hot start when

power up occurs prior to the expiration of the warm timer. A cold start will occur when power up occurs after the

expiration of the cold timer and a warm start will take place when the station powers up after the expiration of the

warm timer but prior to the expiration of the cold timer.

Hot Start1 - All function block execution continues from the last state prior to power fail.

Warm Start1 - Function blocks that have a power up in a last state feature, either by design or by configuration

selection, will power up as defined in the individual block descriptions. All other function blocks will initialize at

cold start conditions.

Cold Start1 - All function block outputs will initialize at 0 unless otherwise stated in individual block descriptions.

1.2.3 Configuration

The Moore 353 can be configured either locally or remotely. First, the local faceplate includes buttons located

behind a flip-down door for complete configuration including the addition/deletion of loops and function blocks

and the editing of function block parameters. Section 2 Configuration Overview includes a road map for stepping

through configuration. Certain block parameters (e.g. gains, constants) can be edited while on-line but design

changes (e.g. block interconnections, block additions) will put the station in “configuration hold” which will hold

outputs at the current value until the Exit button is pressed. This will enable bumpless changes to be made while

on-line.

The second method is to use the Graphical Configuration program. A

configuration can be downloaded to a controller either via the port on the local

faceplate or over a network (either Modbus, Ethernet, or LIL). During a

download, all outputs will be held and the controller will retain all the

intermediate calculations of all the blocks it had been running prior to the

download. After the download, all function block parameters with the same tag

name as those held will be used to initialize the downloaded function block

parameters, thus providing a bumpless download under these conditions. If a

loop tag name is changed, the tag names of all function blocks within that loop

will change and will, therefore, require re-initialization of all of these blocks.

However, the loop tag can be changed from the local faceplate without causing

re-initialization, providing a bumpless tag change.

Optional PC-Based

Graphical Configuration Software

X03145S0

1.3 PRODUCT SUPPORT

Product support can be obtained from a customer service center (i.e. Technical Support Group in North America or

a Technical Information Center (TIC) in Asia or Europe). Each region has a customer service center that provides

direct telephone support on technical issues related to the functionality, application, and integration of all products