Page 1

USER’S MANUAL

UM344-2

Issue 1

August 1995

XTC TRANSMITTERS

SERIES 344 TERMPERATURE TRANSMITTERS

USER’S MANUAL

Page 2

UM344-2 CONTENTS

TABLE OF CONTENTS

SECTION AND TITLE PAGE

1.0 INTRODUCTION................................................................................................................. 1-1

1.1 SECTION CONTENTS ......................................................................................................1-1

1.2 PRODUCT DESCRIPTION ...............................................................................................1-3

1.3 CONFIGURATION ........................................................................................................... 1-4

1.4 PRODUCT SUPPORT....................................................................................................... 1-4

2.0 XTC COMMUNICATOR .....................................................................................................2-1

2.1 DISPLAY.......................................................................................................................... 2-3

2.2 KEYPAD DESCRIP TION .................................................................................................2-3

2.2.1 Dedicated Keys ..........................................................................................................2-3

2.2.2 Function Keys ............................................................................................................ 2-5

2.3 LOOP CONNECTION....................................................................................................... 2-6

2.4 POWER .............................................................................................................................2-7

2.5 MXC SOFTWARE VERSION............................................................................................ 2-7

2.6 MXC MENU SCREENS AND PARAMETER MAP .......................................................... 2-7

3.0 INITIAL TRANSMITTER SET-UP..................................................................................... 3-1

3.1 COMMISSIONING TRANSMITTER ON THE BENCH OR IN THE FIELD ..................... 3-1

3.1.1 Test Equipment Needed.............................................................................................. 3-1

3.2 ESTABLISHING COMMUNICATION ..............................................................................3-3

3.3 TESTING THE TRANSMITTER, MXC, AND THE LOOP ................................................ 3-5

3.3.1 MXC Testing ............................................................................................................. 3-5

3.3.2 Transmitter Testing..................................................................................................... 3-6

3.3.3 Loop Testing.............................................................................................................. 3-7

3.4 REVIEW CONFIGURATION DATA ................................................................................ 3-7

3.5 CHECKING TRANSMITTER OUTPUT ............................................................................3-9

4.0 INSTALLATION................................................................................................................... 4-1

4.1 EQUIPMENT DELIVERY AND HANDLING................................................................... 4-1

4.1.1 Factory Shipment........................................................................................................ 4-1

4.1.2 Receipt of Shipment.................................................................................................... 4-1

4.1.3 Storage ...................................................................................................................... 4-1

4.2 ENVIRONMENTAL CONSIDERATIONS ........................................................................4-2

4.3 INSTALLATION CONSIDERATIONS............................................................................. 4-2

4.3.1 Mechanical ................................................................................................................4-2

4.3.2 Electrical.................................................................................................................... 4-3

4.3.3 Transmitter Operating Mode and Network Type ...........................................................4-3

4.3.3.1 Analog Mode .....................................................................................................4-4

4.3.3.2 Digital Mode ......................................................................................................4-4

4.3.4 Power Supply Requirements........................................................................................ 4-8

4.3.4.1 Point-To-Point Network..................................................................................... 4-9

4.3.4.2 Multi-Drop Network.......................................................................................... 4-9

4.3.5 Cable Capacitance and Maximum Length ..................................................................4-10

4.3.5.1 Cable Capacitance ........................................................................................... 4-10

4.3.5.2 Maximum Cable Length Calculation .................................................................. 4-10

September 1995

i

Page 3

CONTENTS UM344-2

SECTION AND TITLE PAGE

4.3.6 Network Junctions....................................................................................................4-11

4.3.7 Safety Barriers ......................................................................................................... 4-12

4.3.8 Connection of Miscellaneous Hardware.....................................................................4-12

4.3.9 Determine Sensor Cable Requirements......................................................................4-13

4.3.10 2-Wire RTD Accuracy Limitations ..........................................................................4-14

4.3.11 Shielding and Grounding ..........................................................................................4-15

4.4 MECHANICAL INSTALLATION .................................................................................. 4-16

4.4.1 Pipe Mounting..........................................................................................................4-16

4.4.2 Flat Surface Mounting...............................................................................................4-19

4.4.3 Direct Mounting to Process ....................................................................................... 4-20

4.4.4 Local Digital Display Installation, Repositioning and Removal ...................................... 4-23

4.4.5 Electrical Conduit and Cable Installation ..................................................................... 4-26

4.4.5.1 Conduit ...........................................................................................................4-26

4.4.5.2 Cables.............................................................................................................4-28

4.4.5.3 Access to Transmitter Terminal Compartment ................................................... 4-28

4.5 ELECTRICAL INSTALLATION.....................................................................................4-29

4.6 HAZARDOUS AREA INSTALLATION .........................................................................4-33

5.0 ON-LINE AND OFF-LINE OPERATION........................................................................... 5-1

5.1 ON-LINE OPERATION .................................................................................................... 5-1

5.1.1 Using the MXC for Configuration................................................................................ 5-1

5.1.1.1 Sensor Input Block............................................................................................. 5-3

5.1.1.2 Operator Display Block...................................................................................... 5-5

5.1.1.3 Transmitter ID Block .........................................................................................5-6

5.1.1.4 Output Block .....................................................................................................5-7

5.1.1.5 Alarm Block...................................................................................................... 5-7

5.1.1.6 Setpoint Track and Hold Block........................................................................... 5-8

5.1.1.7 A/M Transfer Block.......................................................................................... 5-8

5.1.1.8 Controller Block................................................................................................. 5-9

5.1.1.9 End or Review Configuration ..............................................................................5-9

5.1.2 Downloading A Configuration....................................................................................5-10

5.1.3 Local Transmitter Operation......................................................................................5-11

5.1.3.1 Display Functions ............................................................................................. 5-12

5.1.3.2 Local Pushbutton Input Ranging........................................................................5-13

5.1.3.3 Local Pushbutton Damping Adjustment.............................................................5-15

5.1.3.4 Local Pushbutton AUTO/MANUAL, SETPOINT and VALVE Adjustments .....5-16

5.1.4 Quick Access Key Operation .................................................................................... 5-19

5.2 OFF-LINE OPERATION.................................................................................................5-22

5.2.1 Using Off-Line Operations to Access an Archive.......................................................5-22

5.2.2 Using an Archive in On-Line Memory.......................................................................5-24

6.0 CALIBRATION AND MAINTENANCE............................................................................. 6-1

6.1 CALIBRATION................................................................................................................. 6-1

6.1.1 Equipment Required.................................................................................................... 6-2

6.1.2 Transmitter Analog Output Calibration......................................................................... 6-2

6.1.2.1 Transmitter Normally Configured for Analog Mode ..............................................6-2

6.1.2.2 Transmitter Normally Configured for Digital Mode ...............................................6-5

ii

September 1995

Page 4

UM344-2 CONTENTS

SECTION AND TITLE PAGE

6.1.3 RTD/OHM Type Input Calibration .............................................................................. 6-6

6.1.3.1 RTD/OHM Calibration Check ............................................................................6-6

6.1.3.2 Current Source Calibration ................................................................................. 6-7

6.1.4 Thermocouple/Millivolt Type Input Calibration.............................................................. 6-9

6.1.4.1 Thermocouple/Millivolt Calibration Check............................................................ 6-9

6.1.4.2 Narrow/Wide Millivolt Calibration.....................................................................6-11

6.2 PREVENTIVE MAINTENANCE ....................................................................................6-12

6.2.1 Tool and Equipment Requirements ............................................................................. 6-12

6.2.2 Transmitter Exterior Inspection..................................................................................6-13

6.2.3 Transmitter Exterior Cleaning....................................................................................6-13

6.2.4 Transmitter Enclosure Interior Inspection...................................................................6-13

6.2.5 Transmitter Calibration..............................................................................................6-14

6.3 TROUBLESHOOTING....................................................................................................6-14

6.3.1 Preliminary Troubleshooting ......................................................................................6-14

6.3.2 Troubleshooting........................................................................................................6-15

6.3.2.1 Diagnostic Messages .......................................................................................6-15

6.3.2.2 Possible Transmitter Output Problems...............................................................6-19

6.3.3 Diagnosing a Defective Digital (LCD) Meter .............................................................6-22

6.3.4 Enclosure Thread Lubrication .................................................................................... 6-23

6.4 NON-FIELD-REPLACEABLE ITEMS ............................................................................6-23

6.5 ASSEMBLY REMOVAL AND REPLACEMENT ...........................................................6-24

6.5.1 Electronics Module Removal and Replacement...........................................................6-24

6.6 MAINTENANCE RECORDS..........................................................................................6-25

6.7 RECOMMENDED SPARE AND REPLACEMENT PARTS ............................................ 6-25

6.8 SOFTWARE COMPATIBILITY ...................................................................................... 6-26

6.9 RETURN SHIPMENT .....................................................................................................6-26

7.0 CIRCUIT DESCRIPTION .....................................................................................................7-1

7.1 ELECTRONICS ASSEMBLY............................................................................................. 7-1

7.2 THEORY OF OPERATION................................................................................................ 7-3

7.2.1 Thermocouple/Millivolt Input ........................................................................................ 7-3

7.2.2 RTD/OHMS Input....................................................................................................... 7-3

7.2.3 Signal Conversion........................................................................................................ 7-4

7.2.4 Communication Format ................................................................................................7-4

8.0 MODEL DESIGNATION AND SPECIFICATIONS ...........................................................8-1

8.1 MODEL DESIGNATION................................................................................................... 8-1

8.2 ACCESSORIES ................................................................................................................. 8-2

8.3 SPECIFICATIONS............................................................................................................ 8-5

8.3.1 Mechanical ................................................................................................................8-5

8.3.2 Functional and Performance ........................................................................................8-5

8.3.3 Two-Wire Cable......................................................................................................... 8-7

8.3.4 Sensor Inputs ............................................................................................................. 8-8

8.3.5 Environmental ............................................................................................................8-8

8.3.6 Hazardous Area Classification..................................................................................... 8-9

8.3.6.1 CSA Hazardous Locations Precautions .............................................................8-11

September 1995

iii

Page 5

CONTENTS UM344-2

SECTION AND TITLE PAGE

9.0 GLOSSARY........................................................................................................................... 9-1

iv

September 1995

Page 6

UM344-2 CONTENTS

SECTION AND TITLE PAGE

A.0 APPENDIX A - FUNCTION BLOCK DESCRIPTIONS ...................................................A-1

B.0 APPENDIX B - HAZARDOUS AREA INSTALLATION .................................................. B-1

WARRANTY..............................................................................................................................W-1

PARTS LIST

LIST OF ILLUSTRATIONS

FIGURE AND TITLE PAGE

1-1 Basic Model 344....................................................................................................................... 1-2

1-2 Terminal Connections................................................................................................................ 1-3

2-1 Moore XTC Communicator (MXC)............................................................................................ 2-2

2-2 Major MXC Menu Screens ........................................................................................................2-2

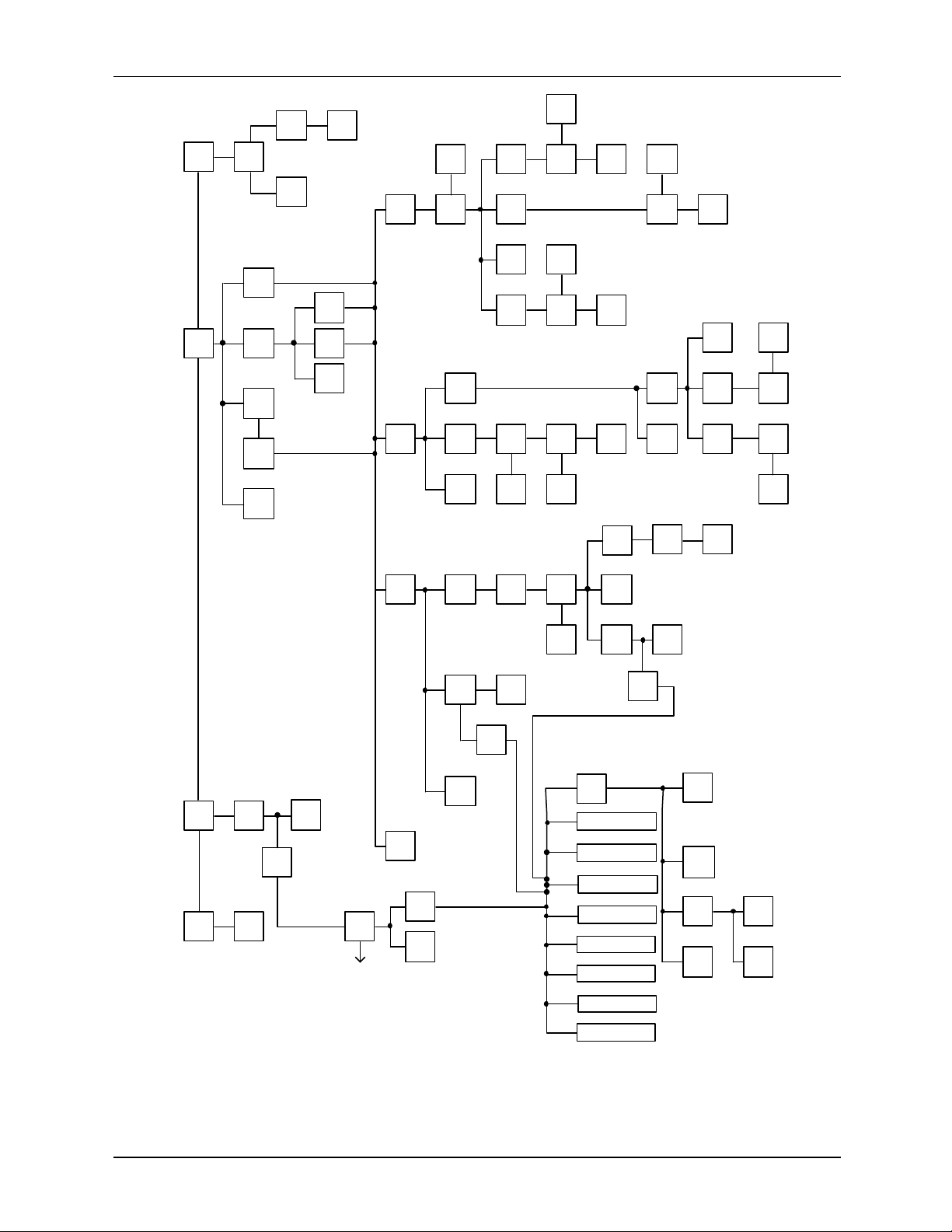

2-3 Parameter Map, MXC/Model 344.............................................................................................. 2-9

3-1 Bench Test Connections............................................................................................................ 3-2

3-2 Typical Field Test Connections ...................................................................................................3-2

4-1 Point-To-Point Network (Analog Mode) .....................................................................................4-5

4-2 Model 352 SLDC and Model 344 Connections (Analog Mode)..................................................... 4-6

4-3 Multi-Drop Network (Digital Mode)........................................................................................... 4-7

4-4 Supply Voltage versus Network Resistance................................................................................ 4-8

4-5 Dimensions, Mounting Bracket for Model 344 ........................................................................... 4-17

4-6 Model 344 Mounting Configurations with Supplied Bracket ........................................................ 4-18

4-7 Transmitte r -To-Process Mounting........................................................................................... 4-21

4-8 Sensor Assembly ....................................................................................................................4-22

4-9 Digital Meter Orientation and Mounting Hardware....................................................................4-24

4-10 Digital Meter Repositioning and Removal................................................................................4-25

4-11 Conduit Drain and Explosion Proof Installations.......................................................................4-27

4-12 Signal (Loop), Sensor, MXC and Test Terminals .....................................................................4-30

4-13 Model 344 Sensor Wiring ....................................................................................................... 4-31

5-1 Model 344 Digital Meter .......................................................................................................... 4-32

6-1 Bench Calibration Connections ...................................................................................................6-4

6-2 Field Calibration Connections ..................................................................................................... 6-4

6-3 RTD/Ohm Current Source Calibration Set Up............................................................................. 6-8

6-4 TC/mV Input Accuracy Check and Calibration Set Up................................................................ 6-9

7-1 Model 344 Electronics Module Block Diagram............................................................................ 7-2

8-1 Typical TC and RTD Thermowell Assemblies without Heads ...................................................... 8-3

8-2 Typical TC or RTD Thermowell Assembly with a Head.............................................................. 8-3

8-3 Model 344 Dimensions .............................................................................................................. 8-6

September 1995

v

Page 7

CONTENTS UM344-2

SECTION AND TITLE PAGE

LIST OF TABLES

4.1 Operating Mode and Network Type ........................................................................................... 4-3

4.2 Thermocouple and Extension Grade Wire Characteristics ..........................................................4-32

5.1 Output Display Code Choices...................................................................................................5-12

6.1 Self -Diagnostics Troubleshooting.............................................................................................. 6-16

6.2 Message - No Transmitter Found.............................................................................................6-17

6.3 Message - Communication Error ..............................................................................................6-18

6.4 Message - Field Device Malfunction.........................................................................................6-19

6.5 Symptom - Zero or Low Output ...............................................................................................6-19

6.6 Symptom - High Output...........................................................................................................6-20

6.7 Symptom - Output Current Fixed Below Scale at Approximately 3.84 mA ..................................6-21

6.8 Symptom - Output Current Fixed Above Scale at Approximately 21.8 mA ..................................6-11

6.9 Symptom - Erratic Output........................................................................................................6-11

8.1 Model 344T Model Designation ..................................................................................................8-1

8.2 General Accessories.................................................................................................................. 8-2

8.3 Thermal Sensors ....................................................................................................................... 8-2

8.4 Replacement Thermocouples and RTDs for 344T Temperature Elements .....................................8-4

8.5 Thermocouple Wire ...................................................................................................................8-4

8.6 Sensors: Type, Range, Span, and Accuracy................................................................................. 8-5

CHANGES FOR ISSUE 1, OCTOBER 1996

Section 8.3.2 At “Maximum Loop Voltage”, reference to Ex N use added.

Section 8.3.6 Ex N requirement added.

The cover date has been changed, however, page dates were not changed at this time. Change bars were

placed on revised pages in the outside margins.

XTC is a trademark of Moore Products Co.

HART is a registered trademark of the HART Communication Foundation.

All other trademarks are the property of their respective owners.

Moore Products Co. assumes no liability for errors or omissions in this document or for the application and use of information

included in this document. The information herein is subject to change without notice.

vi

September 1995

Page 8

Page 9

CONTENTS UM344-2

vi

September 1995

Page 10

1-1

UM344-2 INTRODUCTION

1.0 INTRODUCTION

This User’s Manual is for the XTC™ Model 344 Smart Temperature Transmitter. It covers both the

Transmitter-Controller and Transmitter only versions.

NOTE

Throughout this Manual the term Transmitter will include both versions

except when the Transmitter-Controller is specifically stated and when

discussing unique Transmitter-Controller features, such as the Controller

function block.

All information needed to bench test, install, configure, system test, and service a transmitter is included in

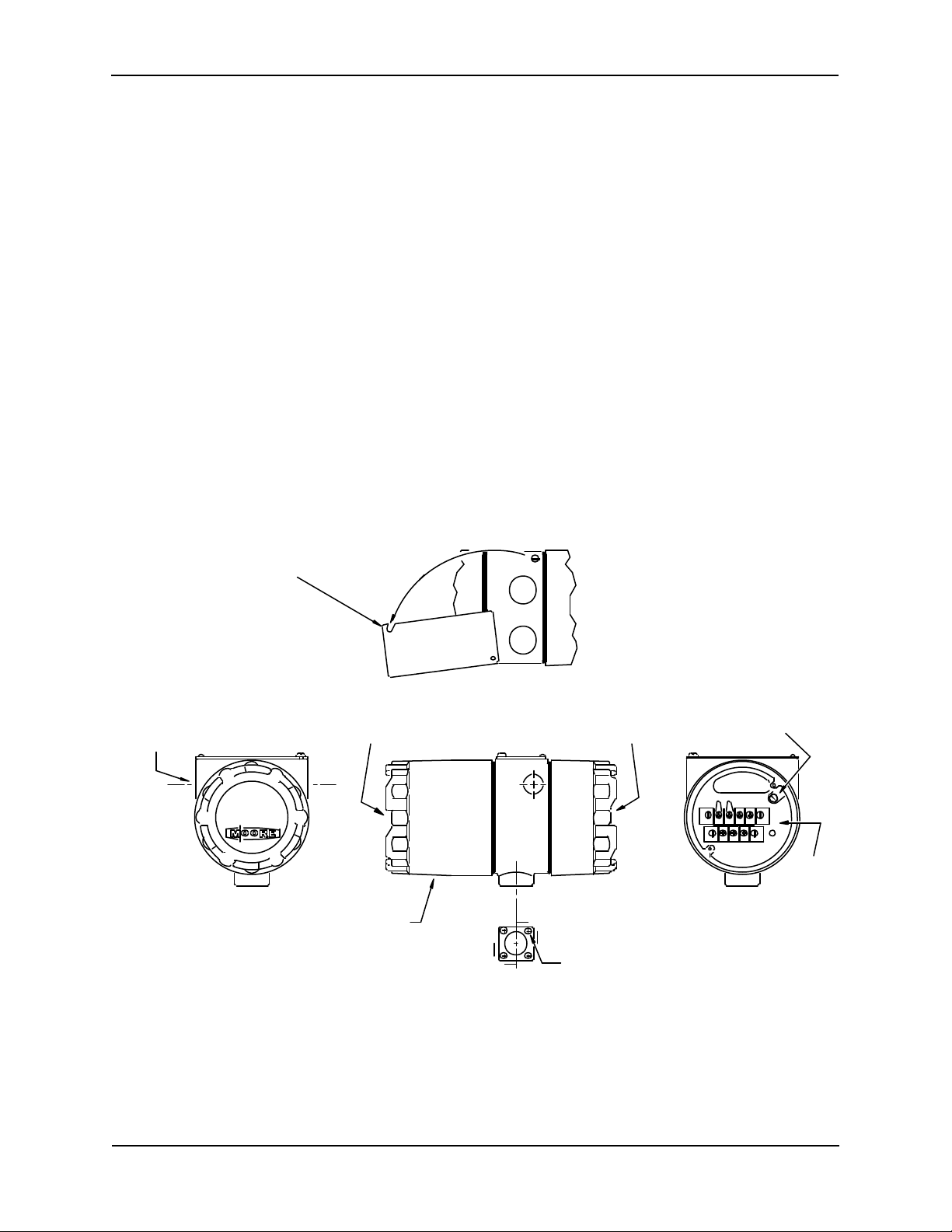

this User’s Manual. Figure 1-1 shows the basic Model 344. Figure 1-2 shows the two terminal strips for

loop, sensor, display, and test equipment connections .

IMPORTANT

Save this User's Manual for installing, configuring, operating and servicing

a Model 344 transmitter.

1.1 SECTION CONTENTS

Nine sections make up this Manual. A brief description of each section follows.

Section 1, INTRODUCTION, describes each section in this Manual and provides a brief description of

the Model 344 Smart Temperature Transmitter line.

Section 2, XTC COMMUNICATOR (MXC), describes use of the MXC to test, configure, and calibrate a

transmitter.

Section 3, INITIAL TRANSMITTER SETUP, provides procedures to perform a bench test of the

transmitter to ensure pr oper operation of all functions. Start-up configuration is described here. If desired,

go to Section 5 to perform a complete configuration.

Section 4, INSTALLATION, furnishes specific information for mechanical and electrical installation.

Section 5, ON-LINE AND OFF-LINE OPERATION, describes on-line and off-line configuration, and

the use of the transmitter’s zero and full-scale pushbuttons.

Section 6, CALIBRATION AND MAINTENANCE, provides calibration procedures for analog and

digital modes. It also furnishes preventive maintenance, troubleshooting, and assembly replacement

procedures. A spare and replacement parts list is provided at the back of this Manual.

Section 7, CIRCUIT DESCRIPTION, contains an assembly level circuit description to support transmitter

servicing.

September 1995

Page 11

1-2

INTRODUCTION UM344-2

4 Places

Section 8, MODEL DESIGNATION AND SPECIFICATIONS, furnishes tables describing transmitter

model numbers, and it contains mechanical, functional, performance, and environmental specifications.

Hazardous area certifications are also lis ted.

Before installing or servicing a transmitter, read the information on the nameplate and ensure that the

correct model is at hand and that the correct procedures are followed.

Section 9, GLOSSARY, contains definitions of various transmitter related terms.

APPENDIX A describes transmitter function blocks and the parameters available.

APPENDIX B contains hazardous area installation drawings and information needed for barrier selection.

WARRANTY contains the product warranty statements and information concerning servicing of the

product during the warranty period.

PARTS LIST shows an exploded view of the transmitter and a list of on-hand spare parts and field

replaceable parts.

Rotate Nameplate to Access Zero

and Full Scale Pushbuttons

Electrical Entrance

1/2 NPT or M20 X 1.5

Tapped Hole

2 Places

Z FS

Digital Meter Option Electrical Connections

Enclosure Cap

Quanitity 2

Mounting Hole

1/4-20 Thread

FIGURE 1-1 Basic Model 344

X02801S1

Ground Connection

TESTSIGNAL

+ -

321

Terminal

Strips

Shown with Enclosure

Cap Removed

September 1995

Page 12

1-3

UM344-2 INTRODUCTION

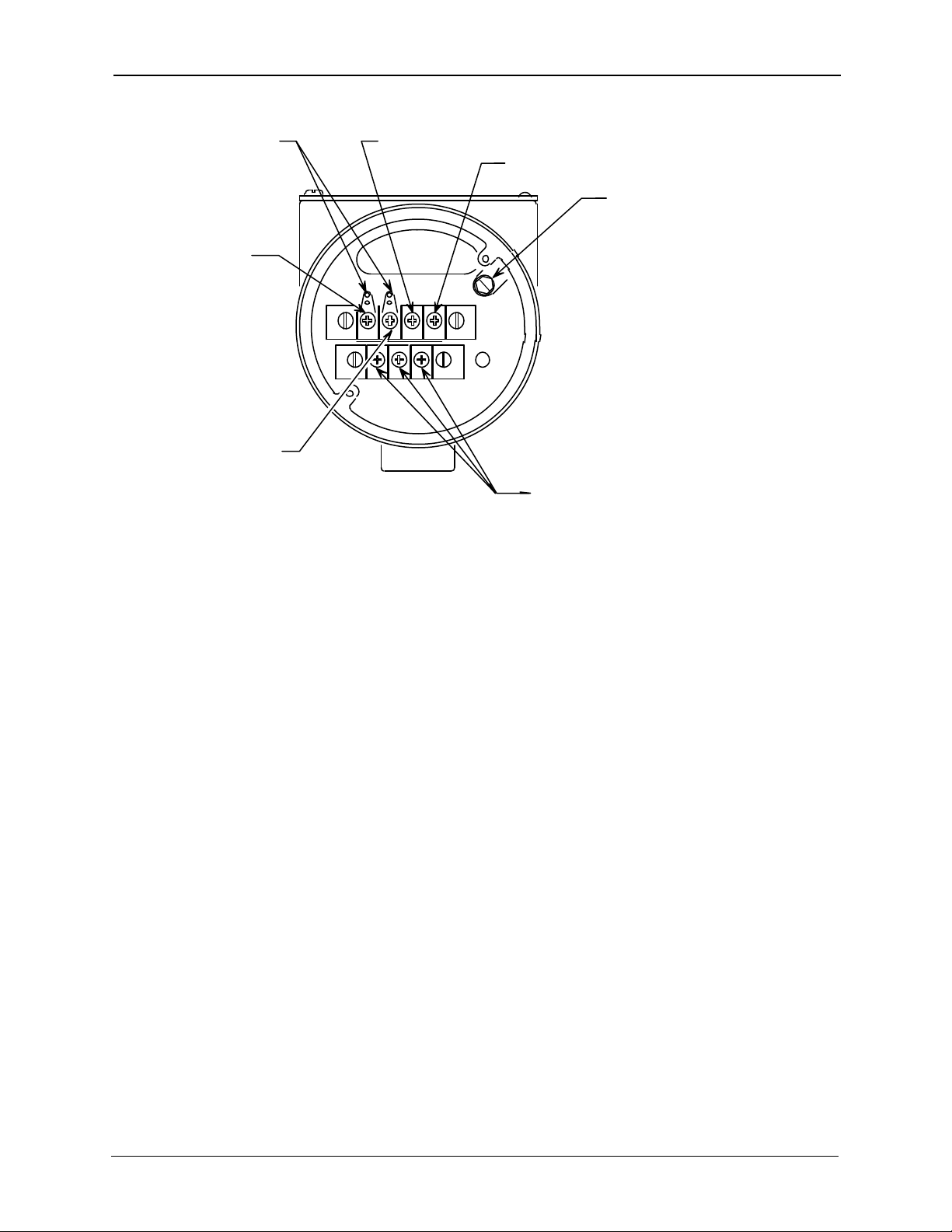

Ohms,or mV Input

MXC

Connections

Signal (+)

Terminal

Signal (-)

Terminal

Test (+)

Terminal

SIGNAL

+

TEST

Test (-)

Terminal

Ground

Screw

Notes:

-

Sensor Terminals for

Thermocouple, RTD,

1. Viewed with enclosure cap

removed.

2. MXC = Moore XTC

Communicator.

X02869S1

FIGURE 1-2 Terminal Connections

1.2 PRODUCT DESCRIPTION

The Model 344 Temperature Transmitter, shown in Figure 1-1, is a microprocessor -based measurement

and control device which combines accurate, reliable temperature measurement and a PID controller in

one unit. The Transmitter accepts an RTD, thermocouple, millivolt, slide wire or resistance sensor input.

It contains a custom ASIC (Application Specific Integrated Circuit) which contains standard temperature

calibration curves for J, K, E, T, R, S, B and N type thermocouples and US/DIN curves for 100, 200, and

500 ohm Platinum RTDs. The sensed signal is linearized and corrected for ambient temperature changes

by the microprocessor and then converted to an equivalent 4-20 mA or HART® (Highway Addressable

Remote Transducer) digital output signal.

The analog output signal, HART digital communications, and 24 Vdc power (typical) are carried on a

twisted-pair 2-wire cable. The HART digital communication signals are superimposed (AC coupled) onto

the 4-20 mA loop current allowing simultaneous communication with the Transmitter without

compromising loop integrity. A digital meter is available when local indication of transmitter output is

required. Loop wiring connections made to the electrical terminals shown in Figure 1-2.

A transmitter can be configured to operate in either an analog mode or a digital mode, for a Point-To-Point

or a Multi-Drop network respectively.

ANALOG MODE: A single transmitter is connected to a controller, recorder or other field device. A loop

known as a Point-To-Point Network interconnects the instruments. The transmitter's output is the process

variable and it is sent to a controller or recorder using a standard 4-20 mA analog current.

September 1995

Page 13

1-4

INTRODUCTION UM344-2

The HART protocol is used for communication between the transmitter and a Moore XTC Communicator

(MXC), a personal computer running MXTC Configuration Software or other remote device. A typical

communication can be to: transfer a new and edited configuration, remotely monitor the process variable,

or service a transmitter.

DIGITAL MODE: One to fifteen transmitters can be parallel connected to a Multi-Drop Network using

only twisted-pair cable. The HART protocol is employed to send all process variable information to a

HART-compatible controller, recorder, or other device.

A mounting bracket is included and permits either pipe mounting (2" pipe) or wall mounting. When

attached to a thermowell, the Transmitter can be mounted directly to a process vessel, chamber, or flow

pipe.

1.3 CONFIGURATION

A smart transmitter must be configured before being used on-line or off-line. Each transmitter is shipped

with either a default configuration or, if specified at time of order, a custom configuration defined by the

user. A default configuration may need to be edited by the user befor e the transmitter is used in a loop.

1.4 PRODUCT SUPPORT

Product support can be obtained from the Moore Products Co. Technical Information Center (TIC). TIC is

a customer service center that provides direct phone support on technical issues related to the functionality,

application, and integration of all products supplied by Moore Products Co.

To contact TIC for support, either call 215-646-7400, extension 4TIC (4842) or leave a message in the

bulletin board service (BBS) by calling 215-283-4958. The following information should be at hand when

contacting TIC for support:

• Caller ID number, or name and company name

When someone calls for support for the first time, a personal caller number is assigned. This number is

mailed in the form of a caller card. Having the number available when calling for support will allow the

TIC representative taking the call to use the central customer database to quickly identify the caller’s

location and past support needs.

• Product part number or model number and version

• If there is a problem with a product’s operation:

• Is the problem intermittent or constant?

• What steps were performed before the problem occurred?

• What steps have been performed since the problem occurred?

• What symptoms accompany the problem? Is an error message displayed?

• What is the installation environment? For example:

- type of plant and process, involved loop, control strategy, and related equipment.

- workstation or personal computer manufacturer and model, amount of memory, and

operating system.

For product support outside of North America, contact your nearest Moore Products Co. subsidiary.

September 1995

Page 14

UM344-2 XTC COMMUNICATOR

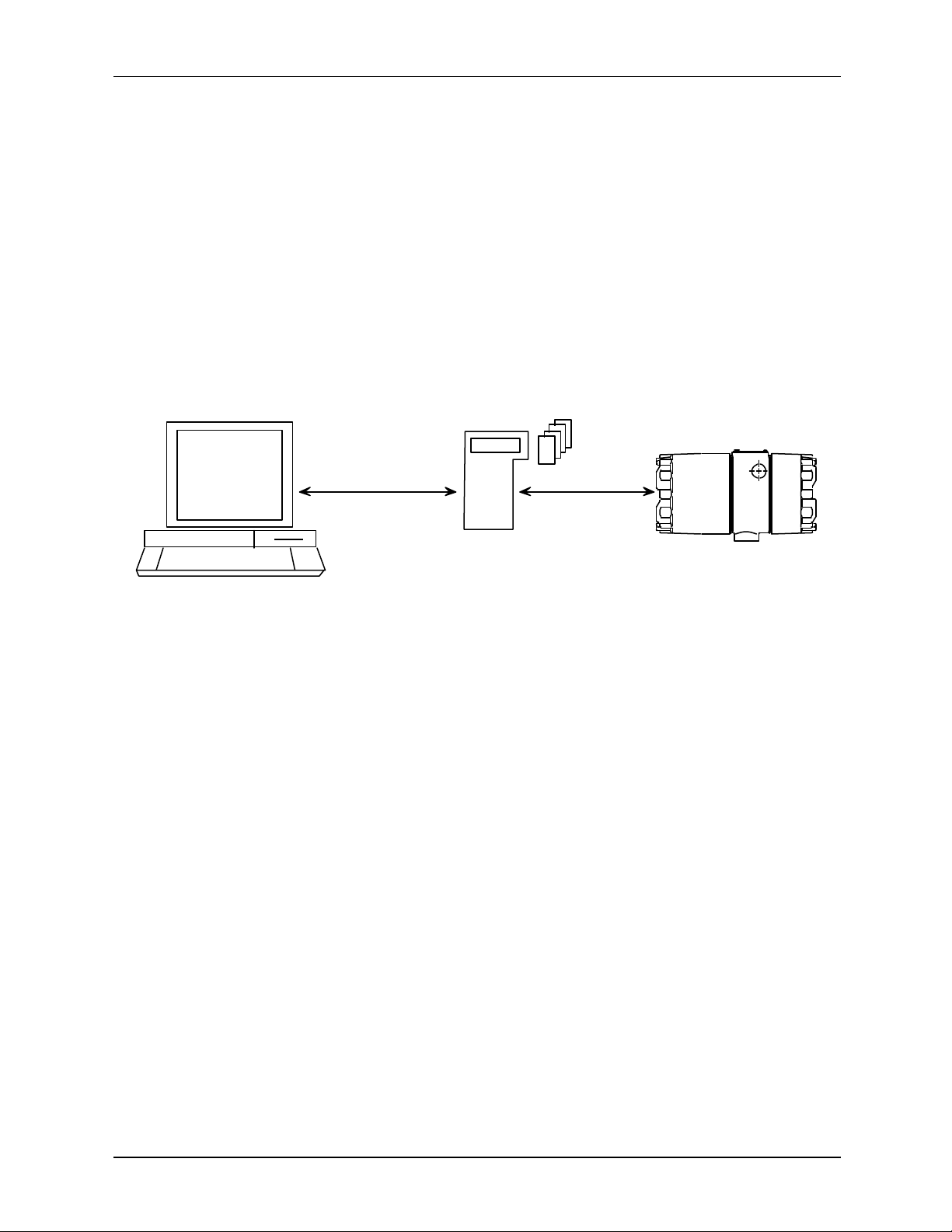

Personal Computer

2.0 XTC COMMUNICATOR

The Moore XTC Communicator (MXC) is a HART protocol-based, hand-held instrument capable of

communicating with HART conformant instruments from Moore Products Co. and from other

manufacturers. It provides full access to on-line and off-line configuration data and to monitoring of

process variables. An MXC is shown in Figure 2-1.

When used with HART-conformant field instruments, the MXC can:

• Store up to 100 instrument configurations in its non-volatile memory.

• Download a stored configuration from the MXC to an on-line instrument (e.g., a transmitter).

• Upload a configuration from an on-line instrument to the MXC

• Store configurations created at and downloaded from a personal computer running Moore XTC

Configuration Software.

• Communicat e with a field instrument from any point in the loop.*

Stored

Configurations

(Archives)

X02856S0

Configuration Transfer

MXC

Moore XTC

Communicator

Configuration Transfer

Model 344

Temperature Transmitter

The MXC and the field instruments with which it communicates use the HART protocol for remote

communications. HART uses Frequency Shift Keying (Bell 202 standard) to superimpose digital signaling

on the standard 4-20 mA analog signal. Since there is no net energy change, the analog signal will not be

disturbed and loop integrity is maintained.

An MXC can be used on-line and off-line. On-line, it can display process data from a field instrument or

transfer a configuration between the MXC and a field instrument. Off-line, it is used to create a

configuration or to edit a configuration stored in the MXC. Off-line, an MXC can communicate with a

personal computer to transfer configurations between the MXC and personal computer.

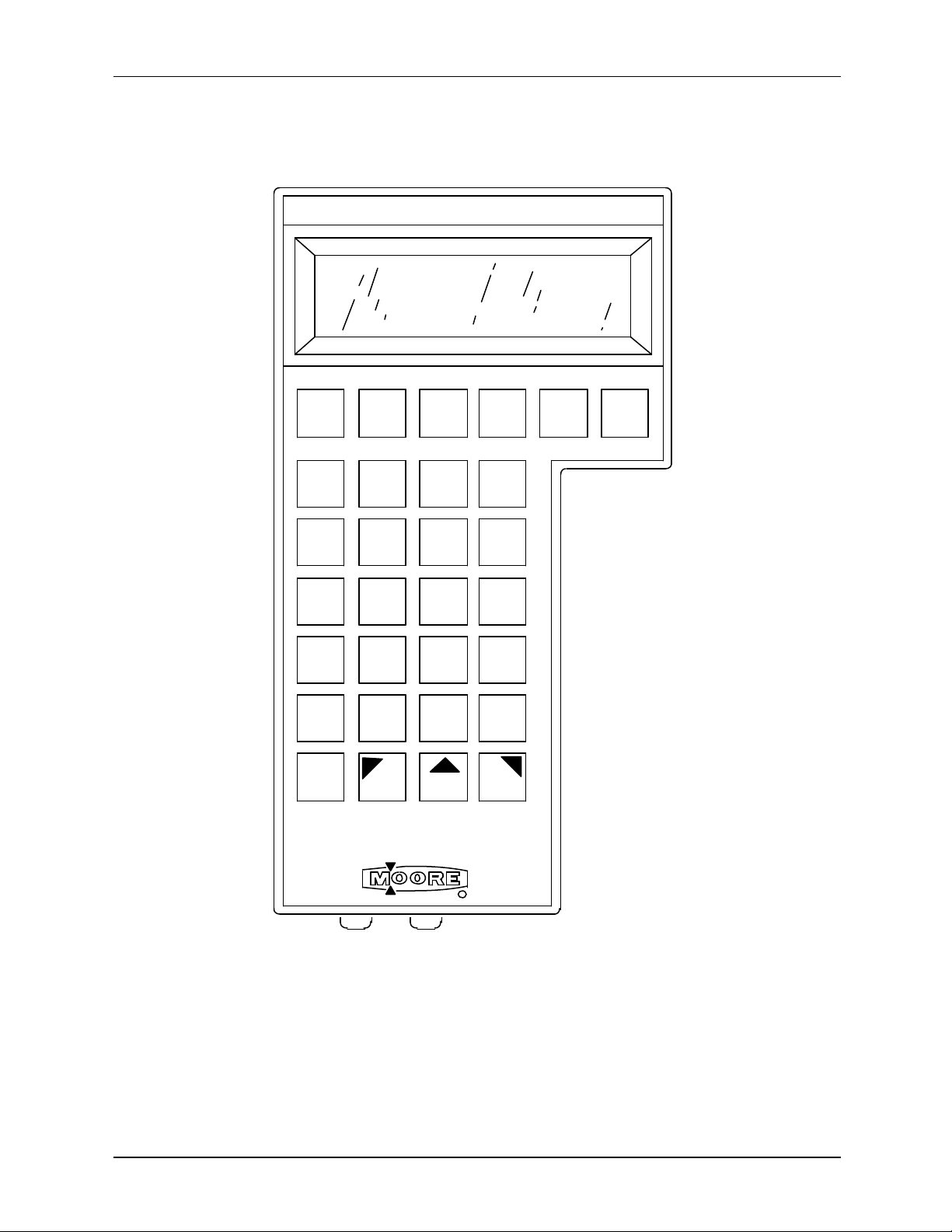

In the following sections, MXC hardware and software will be described. Included in this description will

be the display, keypad, wiring, and power requirements. In addition, at the end of this section, major MXC

menu screens are shown in Figure 2-2 and Model 344 parameters accessible through the MXC are

shown.

* Between the sense resistor and instrument in a non-hazardous area installation. Between the sense resistor and a barrier

in a hazardous area installation.

September 1995

Page 15

XTC COMMUNICATOR UM344-2

2-2

MOORE XTC COMMUNICATOR

ON F1

TRANS.

VAR'S

CHANGE

SP

CHANGE

VALVE

A/M

TUNE

BACK

LIGHT SHIFT SHIFT SHIFT

TREND ZOOM

A B C

1

J K L

4

S T U V W X Y Z #

7

@ % &

__

F2 F3

STATUS

D E F G H I

2 3

M N O P Q R

5

8 9

SPACE0+ / *

F4

OFF

6

.

X02665O0

Figure 2-1 Moore XTC Communicator (MXC)

September 1995

Page 16

UM344-2 XTC COMMUNICATOR

2.1 DISPLAY

The MXC has a 5 by 8 dot matrix Liquid Crystal Display (LCD) with

four lines of twenty characters each to show configuration

parameters, operating status , on-line variables, and trends. The LCD

has a back light that can be turned on for viewing in dimly lighted

SELECT BLOCK TO EDIT

- SENSOR INPUT SELPREV NEXT END ECT

areas.

All MXC screens have a similar layout. As shown here, most configuration screens use the top two lines

to describe the current screen, and the lower two lines to show the selections available from this screen.

Selections are entered by pressing keys on the MXC keypad. Some on-line variable and trend screens are

slightly different from that shown here, but they will always have a selection to access the next screen.

A blinking infinity symbol (∞) at the lower right corner of the screen indicates that the MXC is

communicating with a field instrument or a personal computer. No keyboard keys should be pressed until

the symbol is cleared upon completion of the communication.

2.2 KEYPAD DESCRIPTION

The thirty-key keypad is shown in Figure 2-1. It contains dedicated keys, alphanumeric keys with shift

keys, and function keys. These keys are color coded as follows:

Ÿ Red - dedicated ON key

Ÿ Black - dedicated OFF key

Ÿ Gray - function keys and dedicated keys (for controller block, on-line monitoring, and MXC functions)

Ÿ White - dedicated alphanumeric, symbol, and shift keys

A dedicated key performs a given function no matter what screen is showing. A function key is

dependent upon the action being performed and the MXC's firmware; available selections are shown on

the screen's bottom two lines.

2.2.1 Dedicated Keys

ON - This key powers up the MXC and initiates the MXC self -test. Press and hold the key until the

Moore logo appears and then release it. If the MXC fails self -test, a warning message will be displayed.

The MXC will now show the options available: communicate with a field instrument or personal computer

or do off-line configuration. These topics are discussed further in Section 5.

To conserve battery power, the MXC will shut off after 10 minutes if no keypad key is pressed. This

auto-shut-off is disabled when the MXC is on-line (e.g., displaying a process variable).

OFF - This key powers down the MXC. It may be used at any time. During configuration, however,

care should be taken so important information is not discarded. When the MXC is in certain modes and

communicating with a field instrument or personal computer, it will query the user as to whether or not it

should be turned off in this mode.

September 1995

Page 17

XTC COMMUNICATOR UM344-2

2-4

BACK LIGHT - This key turns on the LCD back light for easier viewing of the display in a dimly lighted

area. The back light is activated by pressing the key and is deactivated by again pressing the key.

NOTE

The back light consumes significant power. To extend battery life, use

the back light only when needed.

TRANS. VAR'S. - The Transmitter Variables key is a quick access key that is pressed to display a

screen showing the transmitter's on-line parameters: measured variable (MV), current output (I), process

variable (PV) and their respective units. Exit this screen by again pressing the TRANS. VAR'S. key or

by pressing the F4 key, for END. If the transmitter is conf igured as a transmitter-controller you will be

prompted to choose either transmitter variables or controller variables. Controller variables include process

variable, setpoint and valve.

TREND - The TREND key is another quick access key that is pressed to trend a variable and show up to

thirteen samples. Any one of the following variables can be trended: the measured variable (MV), the

current output (I), or the process variable (PV). The trend sampling rate can be set to 1-300 seconds

between samples. Exit this screen by again pressing the TREND key or by pressing the F4 key, for END.

ZOOM - The ZOOM key is a quick access key that allows a closer examination of a variable chosen in

the Trend screen. This key functions only when a Trend screen is displayed.

ZOOM magnifies a range of values equal to 10% of the span. The midscale value is user selected.

For example, when viewing a range of 0-100% in the Trend screen, the value of 50% is chosen to zoom

on. The Trend screen now shows a range of 45-55%. Exiting the Zoom screen again displays the Trend

screen. Exit the Trend screen to return to the Main Menu.

STATUS - The STATUS key is a quick access key that is pressed to display the Status screen. This

screen will show the instrument tag name, model number, software revision number, serial number, and

functional statuses such as fixed current mode and error conditions. Exit the Status Screen by again

pressing the Status key or by pressing the F4 key.

CHANGE SP, CHANGE VALVE, A/M, and TUNE Keys - These are dedicated keys that are

reserved for use with XTC Model 340 and 344 Transmitter-Controllers. These keys are inactive when

communicating with an instrument that does not have a controller function block.

CHANGE SETPOINT - Press the CHANGE SP key to view and change the value of the online setpoint of the controller in either automatic or manual mode. If the controller is in MANUAL with

tracking setpoint, then the setpoint cannot be changed. The SP is displayed in the same units as the

transmitter dis play configured in the operator’s display function block. Press the “CHANGE SP” key

again, or F3, to exit this mode.

CHANGE VALVE - This key allows you to view and change the position of the valve. If the

controller is in AUTO, the valve cannot be changed. Press the “CHANGE VALVE” key again, or

F3, to exit this mode.

September 1995

Page 18

UM344-2 XTC COMMUNICATOR

AUTO/MANUAL - The A/M key toggles the controller between automatic and manual control.

Press the “MANUAL”, key F1, or “AUTO”, key F2 to change state. Press “A/M” key again, or F4,

to exit this mode.

TUNE - This key allows tuning of the controller. The first screen displays the controller action,

DIRECT or REVERSE. The controller action may be viewed from the TUNE key, but it must be

changed in the configuration mode. Press F4 to continue.

The Proportional Gain (PG), Time Integral (TI) and Time Derivative (TD) can be changed from this

screen. Press F1, F2 or F3 to display the current value and edit the parameter. Press “CONT”, key

F4 to continue.

The Derivative Gain (DG) and Manual Reset (MR) can be changed from this screen. Press F1 or F2

to display the current value and edit the parameter. Press F4 to go to the previous screen. Press the

“TUNE” key again, or F3, to exit this mode.

ALPHANUMERIC Keys - Twelve white keys with alphanumeric characters and symbols are located

toward the center of the keypad area. Pressing a 1-9, 0, -, or . key will display that character on the

screen. These keys also have alphabetic characters and symbols that require the use of a SHIFT key.

These numbers, letters and symbols are typically used in writing a range, damping value, tagname,

message, or descriptor.

SHIFT Keys - Three shift keys are located below the alphanumeric keys. They are used to access a

letter or symbol located in the upper left, center, or right portion of an alphanumeric key. To select an

alphabetic character or upper symbol, press the proper SHIFT key (left, center, or right arrow) and then

press the desired alphanumeric or symbol key.

2.2.2 Function Keys

F1, F2, F3, and F4 - The function keys are the gray keys located just below the MXC display. The

function or action performed by each key is shown on the bottom two lines of the display, immediately

above each key. For example, when the MXC is first turned on and the Main Menu screen appears, the

following selections are aligned with the function keys: F1 - FIND

XMTR, F2 - ARCH FUNC, F3 - TEST MXC, and F4 - END. To

make a selection, press the corresponding Function key and the next

screen will appear. These keys are used extensively when

configuring or monitoring a field instrument.

SELECT FUNCTION

FIND ARCH TEST

XMTR FUNC MXC END

September 1995

Page 19

XTC COMMUNICATOR UM344-2

2-6

2. Connect the MXC only in a non-hazardous area.

2.3 LOOP CONNECTION

The MXC is quickly connected into a transmitter loop. A 40" (1m) cable with a dual banana plug on one

end and two mini-grabber clips on the other is provided. The dual banana plug is inserted into the bottom

of the MXC. The mini-grabber clips are connected to the Model 344's signal terminals or to the loop's

current sense resistor, usually at a receiving instrume nt such as a Model 352 Single -Loop Digital Controller

(see notes below). This is a non-polar connection. The MXC can now communicate with the transmitter

from the control room or a field location. The diagram below shows a basic loop with the MXC connected

at various locations.

NOTE

The HART protocol requires a network (loop) resistance between

250Ω and 1100Ω to support communications. See Section 4.3.5 to

determine resistance value.

IMPORTANT

In a hazardous area installation, connect the MXC on the safe side

of the barrier, between the current sense resistor and the barrier.

Current Sense

Resistor, 250 to

1100 Ohms

Controller,

Recorder,

Indicator,

or other

Device

Notes:

1. Connect an MXC to any of the locations shown.

+

_

MXC

MXC

X02849S1

MXC

Signal Test

_

+

+

Model 344

Terminals

_

September 1995

Page 20

UM344-2 XTC COMMUNICATOR

2.4 POWER

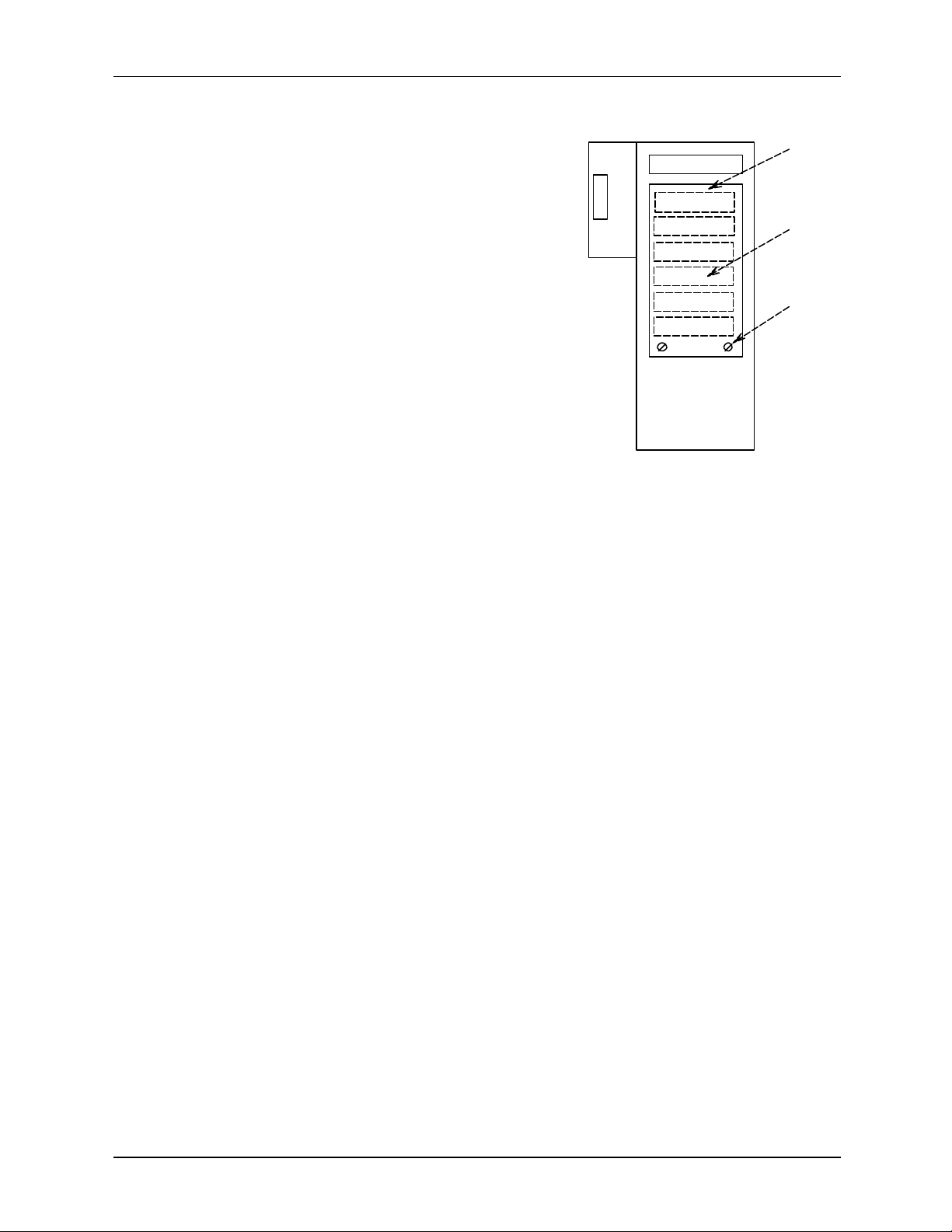

Six "AA" alkaline batteries are supplied with the MXC. Remove

the rear cover to access the battery compartment, as shown in the

figure. Typical operating time of the MXC with new batteries and

the back light off is approximately 80 hours; with new batteries and

the back light on, approximately 30 hours.

A Low Battery indicator (LB) is displayed in the lower right corner

of the LCD when about one -half of the battery charge is spent.

Fresh batteries should then be available for installation.

++

+

+

+

+

+

Battery

Access

Cover

Batteries

Captive

Screw

NOTE

If the MXC fails due to low batteries, data in the On-Line

Memory section of the MXC will be lost. The MXC

should not be used to troubleshoot critical loops while the

low battery indicator is showing.

The MXC will automatically conserve battery life when in the configuration mode. After approximately

ten minutes with no keys on the keypad being pressed, the MXC will shut itself off. This will not occur

while the MXC is monitoring variables from a field instrument.

2.5 MXC SOFTWARE VERSION

To read an MXC's software version, perform the following steps.

1. Press and hold the MXC's ON key until the MOORE logo appears on the display.

2. Watch the MXC display. The MXC's software version will be momentarily displayed.

3. Press the OFF key or continue on to configure or monitor a transmitter.

2.6 MXC MENU SCREENS AND PARAMETER MAP

Major MXC menu screens are shown in Figure 2-2. The screen's name appears in the left column.

These screens are shown in block form in Figure 2-3.

Figure 2-3 is a Parameter Map which shows general configuration and calibration flow. Detailed

configuration procedures are given in Section 5 of this Manual. Calibration is described in Section 6.

September 1995

Page 21

XTC COMMUNICATOR UM344-2

2-8

OVRD

QUIT SAVE VIEW LOAD

Main Menu

On-Line Menu

On-Line Configuration Menu

Calibrate/Test Menu

Function Block Menu

Configuration Complete Menu

Loop Override Menu

MXC screens X02781S0

SELECT FUNCTION

FIND ARCH TEST

XMTR FUNC MXC END

Dev ID: 210300003C

Tag: TTC-101 ADD: 00

LOOP CAL/ CON -

TEST FIG

CONFIGURATION MODE

END

EDIT EDIT

ARCH CONF END

CALIBRATE / TEST

CAL TEST END

SELECT BLOCK TO EDIT

- SENSOR INPUT SELPREV NEXT END ECT

CONFIGURATION

COMPLETE

RE- DOWN

LOOP OVERRIDE - CHOOSE

CURRENT OUTPUT LEVEL

4 MA 20 MA OTHR END

FIGURE 2-2 Major MXC Menu Screens

September 1995

Page 22

UM344-2 XTC COMMUNICATOR

MAIN MENU

TEST

MXC

MXC SELF TEST MENU

TEST

KEYS

TEST

SCRN

END

END

ON-LINE

MENU

LOOP

OVRD

PROCEED

LOOP

OVERRIDE

MENU

20mA

4mA

ABORT

ENTER

END

ABORTABORT

ENTER

END

ANA-

LOG

FIND

XMTR

DIGI

-TAL

SRCH

TAG

ENTER

TAG

END

NOTE:

This Map is intended to show

general configuration and

calibration flow. Every key

and screen is not shown.

SHORT

ADDR

POLL

END

CALIBRATE/TEST

MENU

CAL/

TEST

CONF

CAL

TEST

END

ON-LINE

CONFIGURATION

MENU

EDIT

ARCH

EDIT

CONF

END

OTHER

PROCEED

ABORT ABORT

ENTER

ARCH#

QUIT

QUIT

ENTER

mA

SELF

TEST

CONT

ABORT

END

END

PRO-

CEED

DOWN

LOAD

END

EDIT

ARCH

CONT

ABORT

DOWN

LOAD

QUIT

CONT CONT

TRIM

DAC

ZERO

ABORT

ABORT

CONT

ABORT

ARCH

FUNC

END

X02882S1

September 1995

ENTER

ARCH#

RE-

START

EXIST

NOT

EXIST

TEMPERATURE TRANSMITTER

SELECT

TYPE

END

EDIT

ARCH

END

CONT

END

FUNCTION BLOCK

MENU

END

SENSOR INPUT

OUTPUT

OPERATOR DISPLAY

TRANSMITTER ID

ALARM

SP TRACK & HOLD

A/M TRANSFER

CONTROLLER

FIGURE 2-3 Parameter Map, MXC/Model 344

CONFIGURATION

COMPLETE MENU

SAVE

REVIEW

DOWN

LOAD

QUIT

DOWN

LOAD

ABORT

Page 23

XTC COMMUNICATOR UM344-2

2-10

September 1995

Page 24

UM344-2 INITIAL TRANSMITTER SET-UP

3-1

3.0 INITIAL TRANSMITTER SET-UP

Before operating a Model 344 on-line, the instrument should be commissioned using the MXC and set-up

either at the bench or in the field. Commissioning consists of checking that the transmitter and the loop

are operational and that all configuration information is correct. This section contains step-by-step

procedures describing commissioning of the transmitter. For an in -depth discussion of transmitter

configuration, refer to Section 5.1 On-Line Operation.

3.1 COMMISSIONING TRANSMITTER ON THE BENCH OR IN THE FIELD

A Model 344 can be commissioned either before or after installation into the loop. Commissioning on the

bench before installation is suggested. A complete transmitter functional test can be performed and

configuration procedures can be practiced. If commissioning after installation, install the transmitter as

described in Section 4 and then return to this section. Configuration data for the transmitter will be

needed.

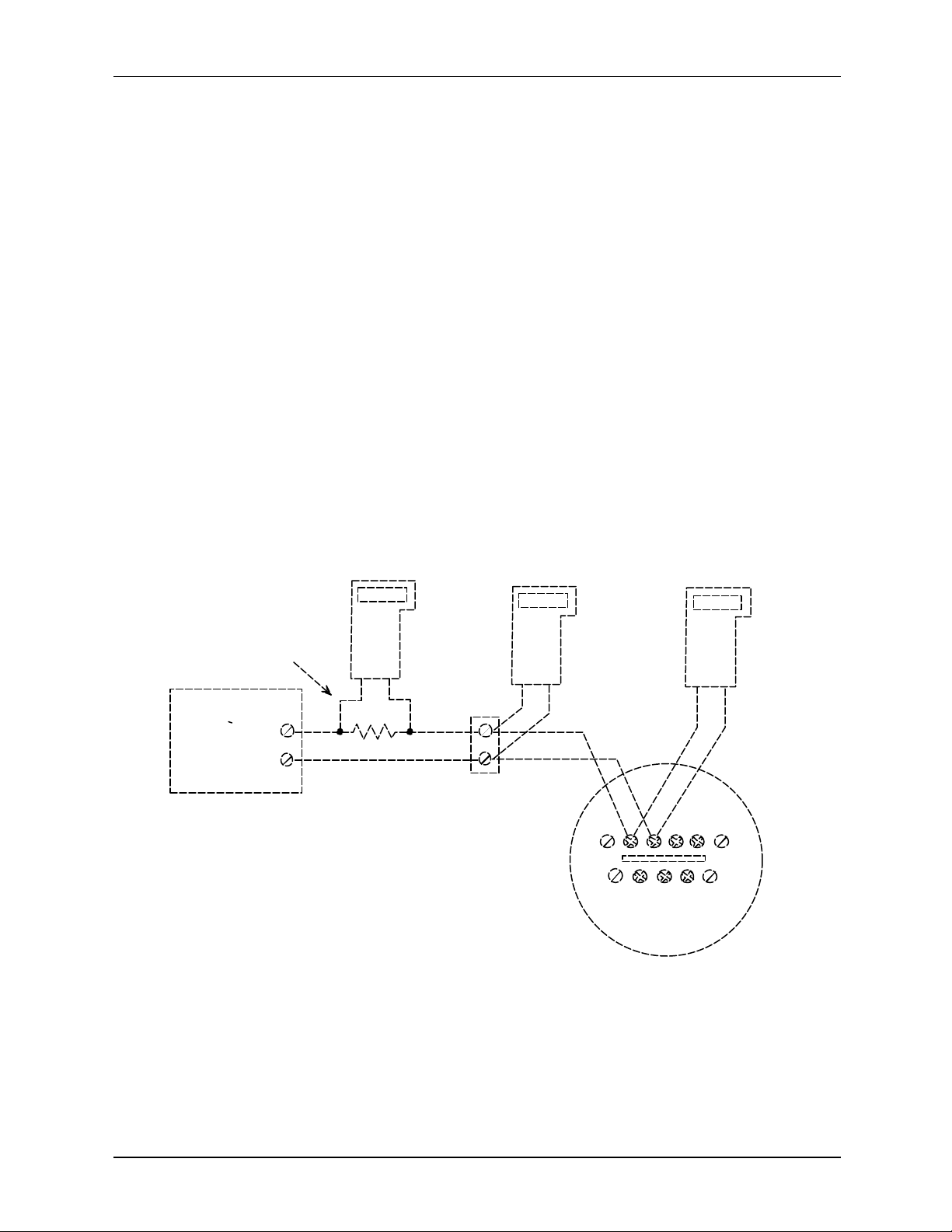

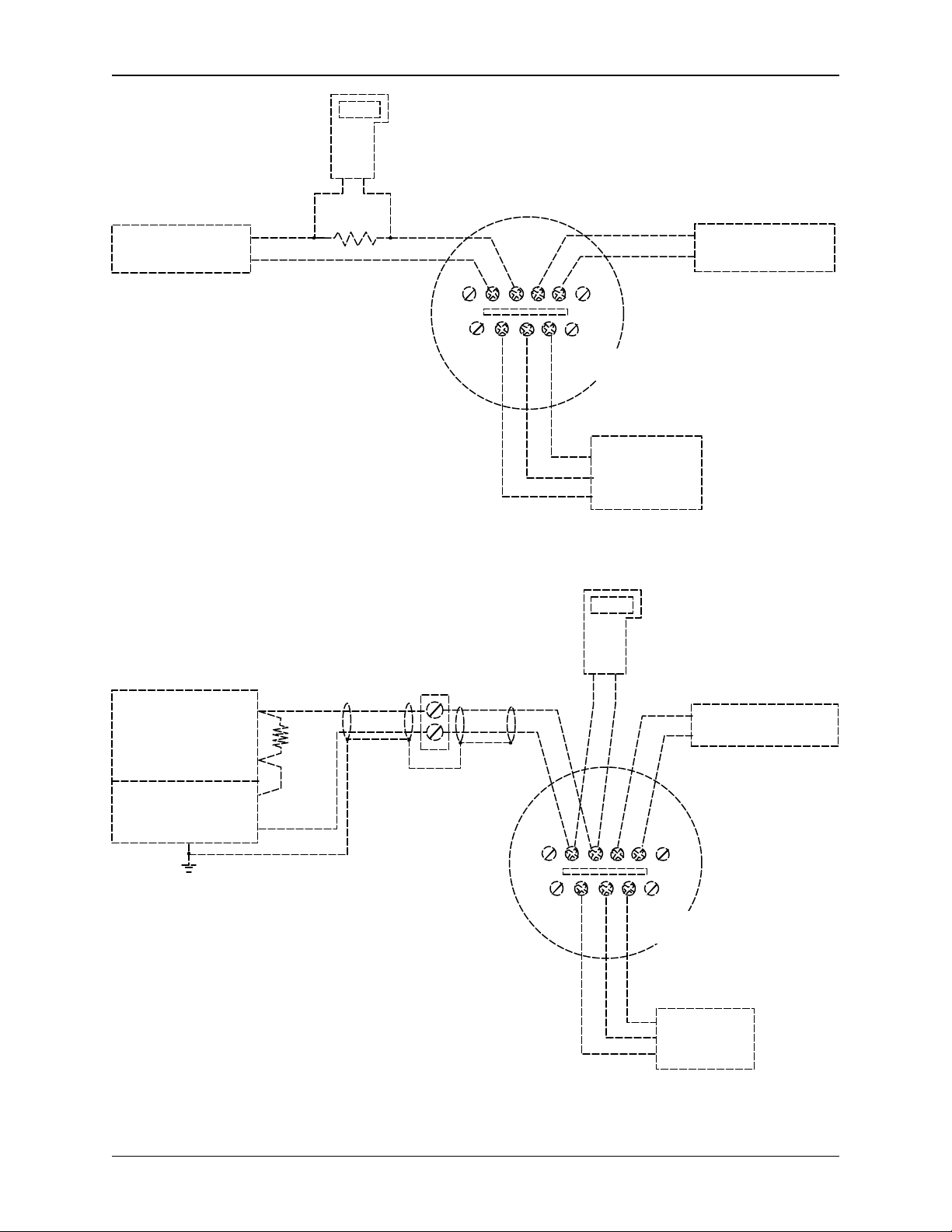

To commission the transmitter on the bench, make the connections shown in Figure 3-1. To commission

the transmitter in the field, make the connections shown in Figure 3-2 or those shown in Section 4.3.3,

Figure 4-1, 4-2, or 4-3. Connect the MXC in the loop either across the current sense resistor or, often

more conveniently, across the two signal terminals of the Model 344 (non-hazardous area only).

3.1.1 Test Equipment Needed

TEST EQUIPMENT DESCRIPTION (see Specifications, Section 8.3.2)

Power Supply 12 to 42 Vdc, see Section 4.3.4

Multimeter:

Current

Voltage

Current Sense Resistor

Accuracy of at least .05% to check calibration

Range: 4 to 20 mA to measure loop current

Range: 10-40 Vdc to measure power supply and loop voltage

250 to 1100Ω to support HART digital communications

Configuration Device Moore XTC Communicator (MXC)

User Configuration Configuration data for transmitter under test

NOTE

Test equipment should be 2 to 10 times more accurate than the desired

transmitter accuracy.

September 1995

Page 25

INITIAL TRANSMITTER SET-UP UM344-2

3-2

MXC

250

Bench Power

Supply (DC)

X02807S1

_

+

Signal Test

_

+

+

_

Model 344

Terminals

Resistance

Decade

Box

+

_

Digital

Milliammeter

FIGURE 3-1 Bench Test Connections

Controller,

Recorder,

Indicator, or

other 1-5 Vdc

Device

System

Power

Supply

X02808S1

Circuit

Junction

+

250

_

_

+

MXC

Signal

_

+

Test

_

+

Model 344

Terminals

+

_

Sensor

Wires

Digital

Milliammeter

FIGURE 3-2 Typical Field Test Connections

September 1995

Page 26

UM344-2 INITIAL TRANSMITTER SET-UP

3-3

3.2 ESTABLISHING

COMMUNICATION

SELECT FUNCTION

FIND ARCH TEST

XMTR FUNC MXC END

SEARCH FOR WHAT TYPE

OF TRANSMITTER?

ANA- DIG- SRCH

LOG ITAL TAG END

ENTER TAG TO SEARCH

WITH:

EN < > QUIT TER

1. Connect the transmitter as shown in either Figure 3-1

or 3-2.

2. Apply power to the loop.

3. Press and momentarily hold the MXC's ON key.

The first screen that will appear after the initial

power up screens is the Main Menu, shown

adjacent. Press FIND XMTR (F1) to have the

MXC initially establish communication with the

Model 344.

4. From the next screen, select either Analog, Digital,

or Search Tag to begin communication with the

transmitter. Read the following and then press one

of the four following keys (F1, F2, F3, or END).

ANALOG (F1) - Press to search for an analog

mode transmitter. Analog mode is used when there

is one transmitter in the loop and it has an address of

zero. If all Point-to-Point Network connections are

correct, when the MXC finds a transmitter with an

address of “0”, the MXC will display the ID and

TAG. Go to Step 6.

If a problem exists in the Transmitter or Network

Wiring, the MXC will show “NO TRANSMITTER

FOUND”. Go to Section 6.3 Troubleshooting to

confirm and resolve wiring problems.

DIGITAL (F2) - Press to search for a digital (multi -

drop) mode transmitter. Digital mode allows up to 15

transmitters to be connected to the loop. Each

transmitter in a loop is assigned a unique address

between 1 and 15. Go to Step 5.

SRCH TAG (F3) - Press to search for a specific

transmitter. Search can be used when the

transmitter is in either Analog or Digital mode. Type

the tagname (8 character alphanumeric string) of the

transmitter that is to be configured or interrogated

and press ENTER (F4). To edit the tagname, use

the arrow keys to select any character that needs to

be changed. Go to Step 6.

If a problem exists in a transmitter or loop wiring the

MXC will show “NO TRANSMITTER FOUND”.

END - Press to return to the previous screen.

September 1995

Page 27

INITIAL TRANSMITTER SET-UP UM344-2

3-4

SHORT OR LONG FORM

ADDRESS?

SHRT LONG

ADDR ADDR POLL END

ENTER TRANSMITTER

ADDRESS (1-15)

EN < END TER

ENTER TRANSMITTER

ADDRESS:

EN < END TER

SEARCHING FOR

TRANSMITTER

PLEASE WAIT

XMTR ID: 210100044F

TAG: MPCO 340 ADD: 01

LAST NEXT SELXMTR XMTR END ECT

NOTE

Analog and Digital modes are

discussed in detail in Section 4.

5. The MXC will next prompt for a digital method of

searching. Press one of the following keys.

SHRT ADDR (F1) - Press and then enter the short

address (1-15) stored during configuration.

IMPORTANT

The factory default setting for the short

address is 0, analog mode.

LONG ADDRESS (F2) - Press and then enter the

long address stored in memory at the factory. (The

long address, the Dev. ID shown in the On-Line

Menu and the XMTR. ID shown by polling are the

same.) This address can not be altered.

POLL (F3) - Press to instruct the MXC to look for

any live addresses on the multi-drop network (1-15).

While the MXC is searching for one or more

transmitters, it will display SEARCHING. The MXC

will then display the long and short addresses of all

live transmitters on the network; select one by

pressing the SELECT (F4) key.

To view each of the live transmitters, press the

LAST XMTR and NEXT XMTR keys to scroll

forward and backward. Each screen will show the

transmitter ID number (i.e. device ID or long

address in hexadecimal), tagname, and short address.

Check IDs against user documentation to confirm

that all transmitters are present

If a problem exists in a transmitter or its wiring it will

be excluded from the poll. If a major fault exists in

the network wiring, the MXC will display the

warning message “NO TRANSMITTER FOUND”.

Go to section 6.3 Troubleshooting to confirm and

resolve wiring problems.

6. Communication has now been established between

the transmitter and MXC and the transmitter's

configuration has been uploaded to the MXC's OnLine Memory.

September 1995

Page 28

UM344-2 INITIAL TRANSMITTER SET-UP

3-5

OVRD

The next screen to appear is used to save the

WOULD YOU LIKE TO

SAVE TRANSMITTER

DATA IN

ARCHIVES NO YES

configuration to an archive. If the configuration is to

be edited, press YES (F4) to save the configuration

in case a mistake is made. The next screen will

prompt for an archive number (0-99). The archive

number chosen will be the location where the MXC

ENTER ARCHIVE NUMBER

(0-99):

EN < > END TER

stores the transmitter's configuration data. Archiving

will be discussed in more detail in the Off-Line

portion of section 5.

The MXC can now be used to calibrate or configure the

transmitter, monitor loop parameters, or test loop

Dev ID: 210300003C

Tag: TTC-101 ADD: 00

LOOP CAL/ CON -

TEST FIG

END

functionality. Section 5 of this Manual describes

configuring and monitoring of the transmitter, and

calibration is described in Section 6. The screen

selections to choose the options of configuration,

calibration, and loop checkout are found on the On-Line

menu screen.

3.3 TESTING THE

TRANSMITTER, MXC, AND THE

LOOP

The test routines available through the MXC are used to

verify that the Transmitter, the MXC , and the loop are all

working properly. Whenever a problem with any of the

instruments or the loop is suspected, test the equipment

to make sure there are no component failures. The test

functions can be accessed in two locations in the MXC,

and these are described below.

3.3.1 MXC Testing

SELECT FUNCTION

FIND ARCH TEST

XMTR FUNC MXC END

MXC SELF TEST

PRESS ANY KEY TO

CONFIRM CONTACT

_ _ _ _ _ _ _ _ _ _ END

TEST

1. Press and momentarily hold the MXC's ON key.

The Main Menu will appear.

TEST TEST

KEYS SCRN END

2. Press TEST MXC (F3) to display the MXC Self

Test screen.

3. Press one of the following keys.

TEST KEYS - Press to test MXC keys. At the next

screen, press any key on the keyboard and the

September 1995

Page 29

INITIAL TRANSMITTER SET-UP UM344-2

3-6

screen will display a character

associated with that key. The

screen will show up to 10 characters

before erasing the oldest.

September 1995

Page 30

UM344-2 INITIAL TRANSMITTER SET-UP

3-7

MXC SCREEN TEST

ABOUT TO BEGIN

MXC SCREEN TEST

COMPLETED

3.3.2 Transmitter Testing

CALIBRATE / TEST

CAL TEST END

TEST - PERFORMS

DIAGNOSTIC TEST ON

TRANS- A- PROMITTER BORT CEED

WARNING! SELF TEST

MAY BUMP TRANSMITTER

OUTPUT A BORT CONT

TRANSMITTER PASSED

TRANSMITTER SELFTEST

CONT

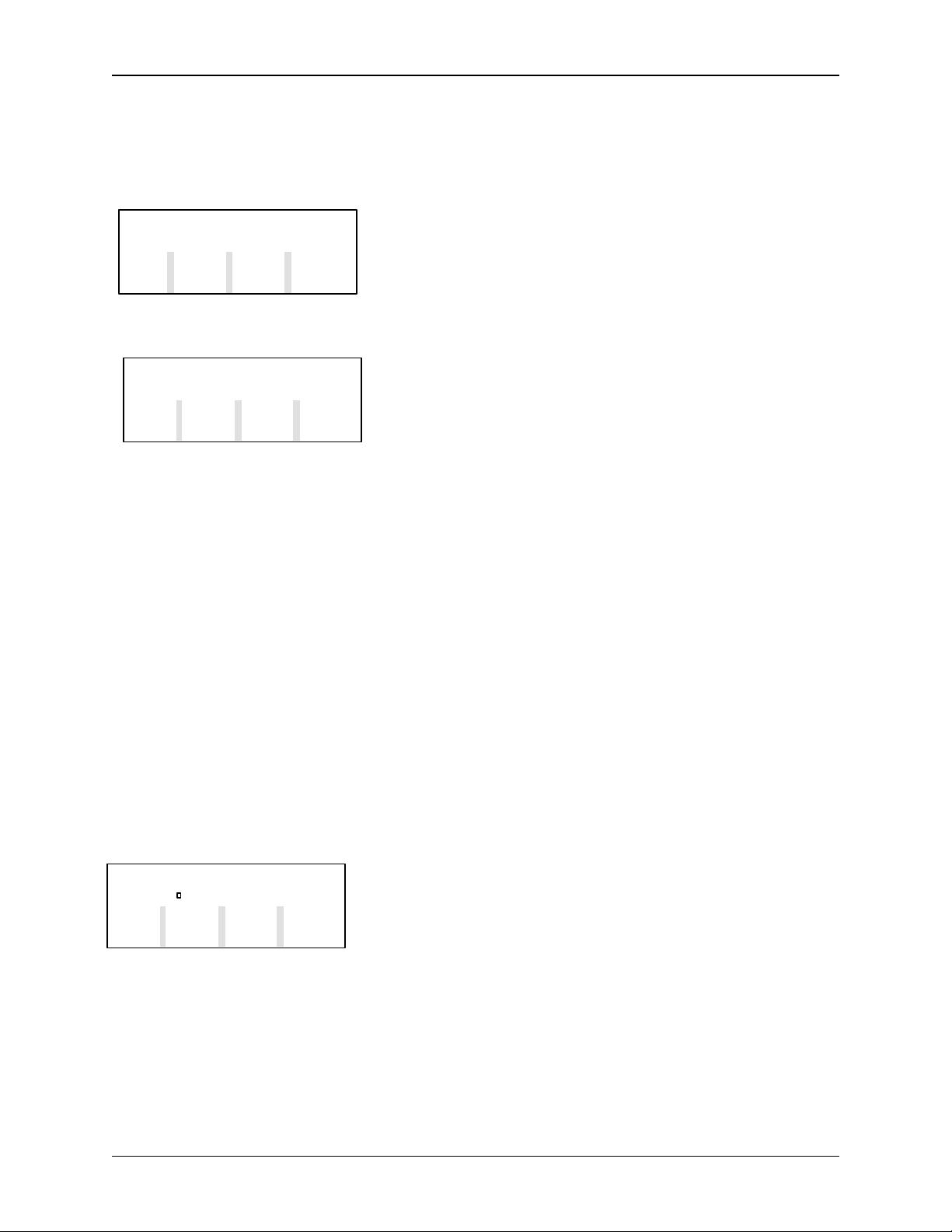

TEST SCRN - Press to test all screen segments.

When this key is pressed, the MXC displays the

"Begin" message to the left, then lights all the

segments, turns them all off, displays the

"Completed" message, and the n returns to the

original test screen.

END - Press to exit the test mode and return to the

Main Menu screen.

Although the Transmitter continuously performs an online self test, a more extensive self test can be performed

after communication with the MXC has been established.

1. At the On-Line Menu, press CAL/TEST (F2) to

display the Calibrate and Test selections.

2. At the Calibrate/Test Menu, press TEST. A Test

caution screen will appear. Press one of the

following:

ABORT - Press to return to the Calibrate/Test

Menu.

PROCEED - Press to continue the self test. A

warning screen will be displayed then a message

states that the test is occurring. After the test, the

MXC will show whether or not the transmitter has

passed or failed the self test.

If the MXC indicates that the Transmitter has:

Passed - Press CONT then END.

Failed - Check installation wiring thoroughly. Go to

Section 6 for troubleshooting suggestions.

3. When the MXC displays the Transmitter’s ID (OnLine Menu), press the STATUS Key to check for

Transmitter errors. If an error is present, the

ERROR Key (F2) will be displayed. Press

ERRORS (F2) to check for ROM, RAM, EEPROM,

TIMER and SENSOR errors. Refer to Section 6.3

Troubleshooting to confirm and resolve the error.

4. If the alarm function is enabled, press ALARM (F1)

to check the ALARM OUT OF SERVICE status.

September 1995

Page 31

INITIAL TRANSMITTER SET-UP UM344-2

3-8

OVRD

3.3.3 Loop Testing

Testing the loop involves making sure that the

Transmitter is sending out the proper current signal and

that the other elements in the loop are receiving this

signal. The Loop Override mode is used to test the loop.

LOOP OVERRIDE SETS

TRANSMITTER OUTPUT

TO ENTERED VALUE END CONT

1. At the On-Line Menu, press LOOP OVRD. The

adjacent screen will be displayed. Press CONT and

then PROCEED.

2. Choose either 4 mA or 20 mA from the menu, or

WARNING! SELF TEST

MAY BUMP TRANSMITTER

OUTPUT A BORT CONT

choose OTHR to enter another value. After a value

is entered, the Transmitter will output the value

chosen. Read the analog current value on a:

Ÿ Recorder or control station in the loop

Ÿ Milliammeter connected in series in the loop

LOOP OVERRIDE - CHOOSE

CURRENT OUTPUT LEVEL

4 MA 20 MA OTHR END

Ÿ Milliammeter connected to the TEST terminals

(Figures 3-1 and 3-2)

Ÿ Analog Voltage may be read on a voltmeter

connected across the sense resistor.

NOTE

This is intended as a functional test. To

check calibration accuracy a DMM of at

least .05% accuracy must be used.

If the transmitter is not working properly, try to

recalibrate it (see Section 6.1).

3.4 REVIEW CONFIGURATION

DATA

Dev ID: 210300003C

Tag: TTC-101 ADD: 00

LOOP CAL/ CON -

TEST FIG

END

Before placing the Transmitter on-line, check that the

proper configuration information has been stored.

1. Establish communication between the Transmitter

and MXC.

2. Using the MXC screens, compare the uploaded

configuration with user's configuration

documentation.

September 1995

Page 32

UM344-2 INITIAL TRANSMITTER SET-UP

3-9

1) At the On-Line Menu, press CONFIG to access

the function blocks. Continue through the menu

sequence until reaching the Function Block

Menu.

2) Check the information in the eight function

blocks listed below. Edit values as needed while

reviewing.

3. Archive the revised configuration in the MXC

4. Download the configuration to the Transmitter.

TRANSMITTER FUNCTION BLOCKS*

SENSOR INPUT

Input Type

Measured Variable Units

Range Lo & Hi

Damping

Burnout Direction

OPERATOR DISPLAY

Process Variable Units

Range Lo & Hi

Auto Rerange

Local Display Code

TRANSMITTER ID

Tag

Descriptor

Message

Date

Device Serial Number

Short Address

OUTPUT

Failsafe Level

ALARM

Alarm 1 Enable/Disable

Alarm 1 SP

Alarm 1 Type

Alarm 2 Enable/Disable

Alarm 2 SP

Alarm 2 Type

Self Clearing NaKS

Alarms Out of Service

September 1995

Page 33

INITIAL TRANSMITTER SET-UP UM344-2

3-10

SP TRACK & HOLD

Tracking Setpoint

PUSP

A/M TRANSFER

Power-Up Mode

Automatic Only

Power-Up Valve

CONTROLLER BLOCK

Controller ON/OFF

Controller Type

Action

Prop. Gain

Time-Integral

Time-Derivative

Derivative Gain

Manual Reset

Manual Reset Track

* For more detailed information on these function

blocks, refer to Section 5 and Appendix A.

3.5 CHECKING TRANSMITTER

OUTPUT

At this point, check to be sure that the transmitter is

reading the proper sensor input in the proper units.

1. Set the sensor input to the transmitter to a known

value either by adjusting the process variable to a

field mounted transmitter or the simulated input to a

bench test transmitter.

VIEW WHICH VARIBLES

2. With the On-Line Menu displayed, press the gray

TRANS.VAR’s key on the MXC keypad to display

XMTR CONT

END

the VIEW WHICH VARIABLES screen.

3. Press one of the following keys depending upon

controller activation:

P: 63.301%

S: 50.000%

V: 10.000%

END

Controller Block ON: Press CONT (F2) to display

the controller variables.

P - Process

S - Setpoint

V - Valve

M: 76.534 deg F

I: 4.8377 mA

P: 76.534 deg F

END

Controller Block OFF: Press XMTR (F1) to display

the process variables.

M - Measured Variable

I - Current (mA)

September 1995

Page 34

UM344-2 INITIAL TRANSMITTER SET-UP

3-11

P - Process Variable

4. Check these Transmitter Variables to ensure the

readings are correct.

5. Press END (F4) to return to the main menu.

September 1995

Page 35

UM344-2 INSTALLATION

4-1

4.0 INSTALLATION

This Section describes installation of a Model 344 Temperature Transmitter. Topics include: receipt of

shipment, installation considerations, and mechanical and electrical installation.

IMPORTANT

The installation must conform to the National Electrical Code and all

other applicable construction and electrical codes.

Refer to the installation drawings in Appendix B when locating a

Transmitter in a hazardous area.

4.1 EQUIPMENT DELIVERY AND HANDLING

4.1.1 Factory Shipment

Prior to shipment, a Transmitter is fully tested and inspected to ensure proper operation. It is then

packaged for shipment. Most accessories are shipped separately.

4.1.2 Receipt of Shipment

Each carton should be inspected at the time of delivery for possible external damage. Any visible damage

should be immediately recorded on the carrier's copy of the delivery slip.

Each carton should be carefully unpacked and its contents checked against the enclosed packing list. At

the same time, each item should be inspected for any hidden damage that may or may not have been

accompanied by exterior carton damage.

If it is found that some items have been damaged or are missing, notify Moore Products Co. immediately

and provide full details. In addition, damages must be reported to the carrier with a request for their onsite inspection of the damaged item and its shipping carton.

4.1.3 Storage

If a Transmitter is to be stored for a period prior to installation, review the environmental specifications in

Section 8.3.5.

September 1995

Page 36

INSTALLATION UM344-2

4-2

4.2 ENVIRONMENTAL CONSIDERATIONS

Many industrial processes create severe environmental conditions. The conditions at each transmitter

location must be within the specifications stated in Section 8.3.5.

The Transmitter is designed to perform in harsh conditions, however, it is prudent to locate a Transmitter

to minimize the effects of heat, vibration, shock, and electrical interference.

CAUTION

Exceeding the specified operating temperature limits can adversely affect

performance and may cause damage.

4.3 INSTALLATION CONSIDERATIONS

Sections 4.3.1 and 4.3.2 outline basic considerations needed to achieve a successful mechanical/electrical

installation. The remaining sections then provide detailed pre-installation information.

4.3.1 Mechanical

• Select the sensor input: thermocouple, millivolt, RTD, or resistance. Refer to Section 8.2 for sensor

accessories.

• Determine if an optional digital meter for local monitoring of transmitter output is required. Refer to

Section 8.1 for model designation or 8.2 for accessory part numbers.

• Determine physical mounting of Transmitter. Consider:

• Using supplied bracket for pipe or wall mounting. Refer to Sections 4.4.1 and 4.4.2.

• Transmitter-to-process mounting. Refer to Section 4.4.3.

• Clearance for installation and maintenance and for reading the optional digital meter. Refer to

Figure 8-3.

• Need to rotate optional digital meter for viewing ease. Refer to Section 4.4.4.

Refer to Figure 8-3 for transmitter dimensions and the figures in Section 4.4 for typical mechanical

installations. Refer to Section 8.3 for mechanical and environmental specifications.

Ÿ Determine if an explosion-proof or intrinsically safe installation is required. Refer to Transmitter

nameplate for electrical classifications and Sections 8.1, 8.3, and 4.6.

An intrinsically safe installation requires user-supplied intrinsic safety barriers that must be installed in

accordance with barrier manufacturer's instructions for the specific barriers used.

Transmitter certification is based on the "Entity" concept in which the user selects barriers that permit

the system to meet the entity parameters.

September 1995

Page 37

UM344-2 INSTALLATION

4-3

Ÿ Determine conduit routing. Refer to Section 4.4.5.

Ÿ Prepare installation site drawings showing the following:

Ÿ Location of the Master Device (e.g. MXC or controller)

Ÿ Location and identification of each Transmitter

Ÿ Routing plan of signal cable(s)

Ÿ Location of any signal cable junctions for connecting the MXC

4.3.2 Electrical

Ÿ Determine Transmitter operating mode (analog or digital) and type of Network needed; refer to

Section 4.3.3.

Ÿ Determine minimum power supply requirements. Refer to Section 4.3.4.

Ÿ Select twinaxial cable type and determine maximum cable length. Refer to Section 4.3.5.

Ÿ Determine the need for network junctions. Refer to Section 4.3.6.

Ÿ Intrinsically Safe installations will need barriers. Refer to Section 4.3.7.

Ÿ Consider the effect of connecting additional equipment (e.g., recorder, loop powered display) to the

network. Refer to Section 4.3.8.

• Select sensor cable type. Refer to Section 4.3.9.

• Consider the accuracy limitation of a 2-wire RTD. Refer to Section 4.3.10.

• Read Section 4.3.11 for grounding and shielding recommendations.

4.3.3 Transmitter Operating Mode and Network Type

A Transmitter will output either an analog current or an equivalent digital signal, depending upon the

selected operating mode. The operating mode also determines the type of Network (Point-To-Point or

Multi -Drop) to be installed, as shown in Table 4.1 and the following subsections. Select the operating

mode during Transmitter configuration as described in the following subsections and Section 5.

TABLE 4.1 Operating Mode and Network

OPERATING MODE NETWORK TYPE NETWORK FIGURE(S)

Analog Point-To-Point 4-1 and 4-2

Digital Multi-Drop 4-3

September 1995

Page 38

INSTALLATION UM344-2

4-4

4.3.3.1 Analog Mode

Ÿ The Transmitter outputs a 4-20 mA signal for input to devices such as controllers and recorders.

Ÿ Analog operation employs a Point-To-Point Network comprising a Transmitter, Primary/Secondary

Master, and other non-signaling devices. Transmitter short address is 0 (zero).

Ÿ Use the optional Digital Meter for local indication of transmitter output.

Ÿ The Transmitter is factory configured for analog mode unless otherwise ordered.

Ÿ Use an MXC for configuration, diagnostics, and reporting the current process variable.

4.3.3.2 Digital Mode

Ÿ The number of Allowable Network Elements is:

Primary and Secondary Masters - 1 each

Transmitters - 1 to 15

Ÿ The process variable is transmitted digitally. The analog output of each transmitter is "parked" at 4

mA.

Ÿ The HART communication source can be a Primary or Secondary Master. A Primary Master can be

used for data acquisition, maintenance, or control purposes. A Se condary Master, the MXC for

example, may be used for configuration, diagnostics, and reporting current process variable.

Ÿ Use the optional Digital Meter for local indication of transmitter output.

Ÿ Place the transmitter in the digital mode by assigning it a SHORT ADDRESS from 1 to 15 when

configuring the TRANSMITTER ID BLOCK with the MXC (see Section 5).

September 1995

Page 39

UM344-2 INSTALLATION

4-5

Network for Non-Hazardous Locations

250

See

Note 2

Controller,

Recorder, or Other

1-5 Vdc Device;

See Note 1

System Power

Supply

See

Note 3

MXC

+

_

+

_

250

See

Note 2

See Note 4

Non-Hazardous

Location

Network

Junction

See Note 5

Hazardous

Location

See

Note 3

See Note 6

Signal Test

MXC

_

+

+

Model 344

Terminals

See Note 6

_

Controller,

Recorder, or

Other 1-5 Vdc

Device; Note 1

System Power

Supply

See Note 4

Network for Hazardous Locations

Notes:

1. The System Power Supply is shown separate from the host input device. In practice, it may be part

of the host input device. The host input device can be either a HART or non-HART signaling device,

a Primary Master or a Secondary Master.

2. Network resistance equals the sum of the barrier resistances and the current sense resistor.

Minimum value 250 Ohms; maximum value 1100 Ohms.

3. Connect the MXC (a Secondary Master) to the loop only in the non-hazardous location. The MXC

is a non-polar device.

4. Interconnect all cable shields and ground only at the power source.

+

See Note 5

_

+

_

Supply and

Return Barriers

Shown Above

Signal Test

_ _

+

+

Model 344

Terminals

5. For access to Model 344 terminals, remove shorter end cap.

6. Maximum loop cable length calculated by formula in Section 4.3.5.

X02866S1

September 1995

Page 40

INSTALLATION UM344-2

4-6

6. Maximum loop cable length calculated by formula in Section 4.3.5.

FIGURE 4-1 Point-To-Point Network (Analog Mode)

See