Page 1

RELIABLE SOLUTIONS

WL Trip Unit, MODBUS Communication

and Electronic Accessories Application

Guide

powerful ideas

WL Low Voltage Power

Circuit Breaker

ANSI / UL1066 & UL 489

Global network of innovation

Page 2

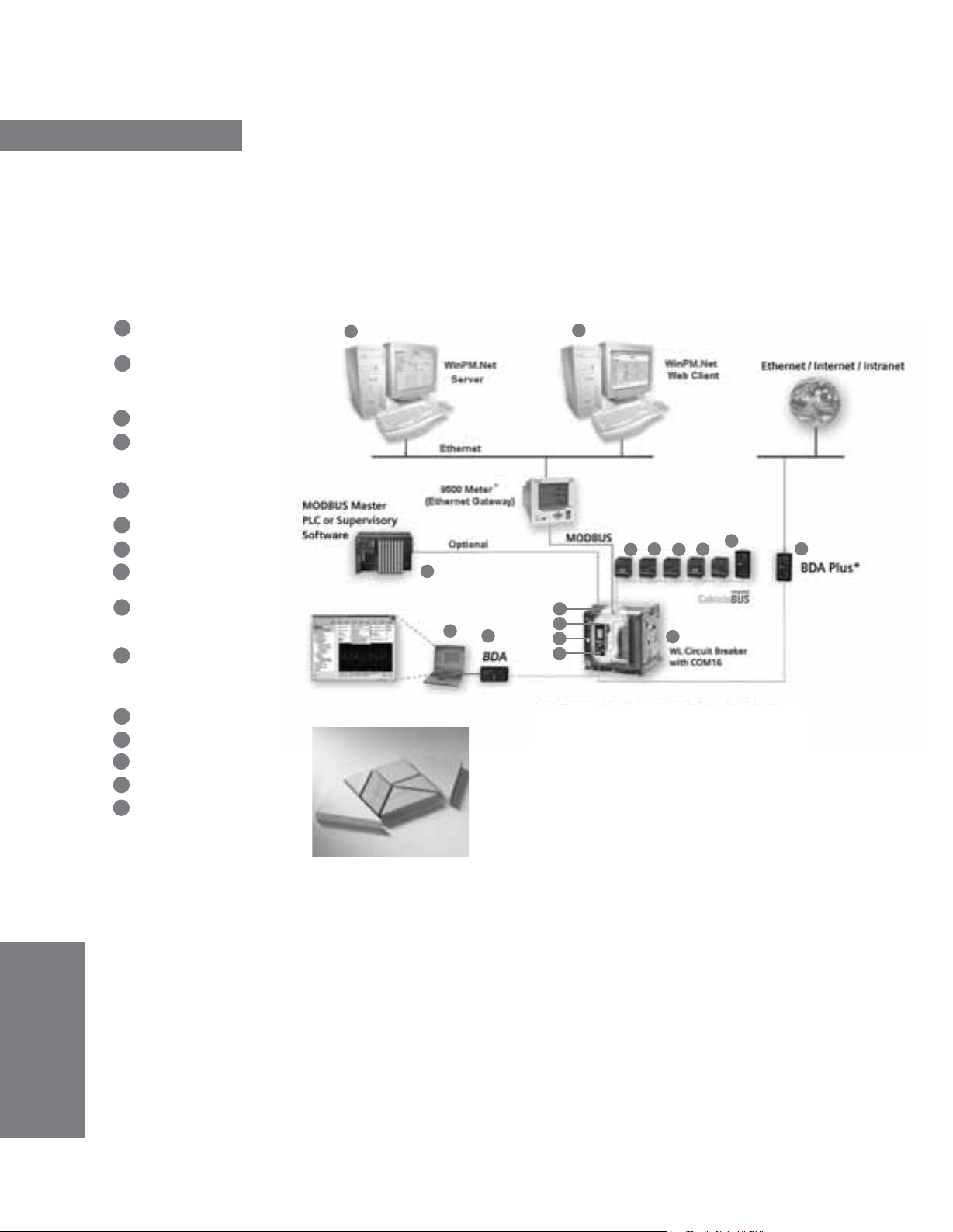

Communication-capable Circuit Breakers

WL Circuit Breaker

Connection Diagram

Technological Leader Among Circuit Breakers: WL Communication

1 Breaker Data Adapter

(BDA)

2 Browser-capable input

and output device

(e.g. notebook)

3 WL Circuit Breaker

4 COM16 MODBUS

module or COM 15

PROFIBUS module

5 Breaker Status Sensor

(BSS)

6 Electronic Trip Unit

Metering function PLUS

7

8 Zone Selective

Interlocking (ZSI) module

9 Digital output module

with relay or optocoupler

outputs

10

Digital output module

with relay or optocoupler

outputs, remotely

configurable

11 Analog output module

Digital input module

12

13

WinPM.Net on PC

14 PLC (e.g. SIMATIC S7)

15 BDA Plus

13

14

2

1

13

9

10

8

4

5

6

7

* The Siemens BDA Plus or meters, 9330, 9350, 95/9600

can be used as a gateway to enable Ethernet communication

to the WL Circuit Breaker.

The 9500 meter can also be used as a central display unit

for multiple WL breakers with metering capability.

3

12

11

15

Page 3

Communication-capable

Circuit Breaker

Introduction and Overview

WL Circuit Breaker

MODBUS Profile for WL Circuit Breaker

Breaker Data Adapter (BDA)

Breaker Data Adapter Plus (BDA Plus)

1

2

3

4

WL MODBUS Communication and Electronic Accessories • January 2005

Page 4

Communication-capable Circuit Breakers

WL Circuit Breaker

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger. This equipment contains hazardous

voltages. Death, serious personal injury or property damage can result if safety instructions are not followed.

Only qualified personnel should work on or around this equipment after becoming thoroughly familiar with

all warnings, safety notices, and maintenance procedures contained herein. The successful

and safe operation of this equipment is dependent upon proper handling, installation, operation and

maintenance.

Danger

For the purpose of this manual and product labels, DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

Warning

For the purpose of this manual and product labels, WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

Caution

For the purpose of this manual and product labels, CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

Attention

Draws your attention to particularly important information on the product, handling the product or to a

particular part of the documentation.

Qualified Personnel

For the purpose of this manual and product labels, a qualified person is one who is familiar with the

installation, construction and operation of the equipment, and the hazards involved. In addition, he or she

has the following qualifications:

(a) Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in

accordance with established safety practices.

(b) Is trained in the proper care and use of protective equipment, such as rubber gloves, hard hat, safety

glasses or face shield, flash clothing, etc., in accordance with established safety practices.

(c) Is trained in rendering first aid.

Correct Usage

Note the following:

Warning

This device and its components may only be used for the applications described in the catalog or

the technical descriptions, and only in connection with devices or components from other

manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed

correctly, and operated and maintained as recommended.

Registered Trademarks

WinPM.Net is a registered trademark of Siemens Energy & Automation. MODBUS® is a registered

trademark of MODICON. Some other designations used in these documents are also brands;

the owner's rights may be violated if they are used by third parties for their own purposes.

Excel and Explorer are registered trademarks of Microsoft Corporation. Java is a registered

trademark of Sun Microsystems. Netscape is a registered trademark of AOL Time Warner.

WL MODBUS Communication and Electronic Accessories • January 2005

Page 5

Introduction and

Overview

Content of the Manual

Overview of the Bus Systems

Communicating with the Circuit Breaker

1

WL MODBUS Communication and Electronic Accessories • January 2005

Page 6

Introduction and Overview

WL Circuit Breaker

General

This manual is aimed at those

who want to find out more

about the different applications

of communications-capable

circuit breakers in power

distribution systems.

It contains a detailed guide to

commissioning, operating,

diagnosing and maintaining the

new communications-capable

WL Circuit Breaker.

Content of the Manual

Chapter 1 contains a short

introduction to communications in

power distribution systems, and

provides an overview of the benefits

and applications of communicationscapable circuit breakers. The chapter

concludes with a short description of

the most important communication

bus systems.

Chapter 2 contains a general

description of the WL Circuit Breaker.

It includes information on

configuration data and provides

commissioning instructions.

Chapter 3 explains how the circuit

breakers are integrated in a power

management system and describes

the supported function codes,

register maps and exception codes.

WL is the first circuit breaker that

can be configured, diagnosed and

maintained remotely without the use

of field bus systems and higher-level

operator control and monitoring

systems. These procedures are carried

out using the breaker data adapter

(BDA), a state-of-the-art Internetcapable configuration device for

circuit breakers, which is described in

Chapter 4.

Introduction

The demand for communicationscapable systems, data transparency

and flexibility in industrial

automation systems is growing all

the time. Bus systems and intelligent

switchgear are vital to ensure that

industrial power systems can meet

these demands, since industrial

production and building

management are now inconceivable

without communications technology.

The evermore-stringent requirements

placed on the electrical and

mechanical aspects of circuit

breakers, the growing need for

flexibility and efficiency, and

increasing cost pressure and

automation have contributed to the

recent major innovations in circuit

breaker technology. In power

distribution systems, the WL Circuit

Breaker uses industry-standard bus

systems to transmit key information

for warnings, commissioning and

load shedding to a central control

room. The wide range of applications

ensure that these circuit breakers are

more than just simple switching and

protective devices.

Point-to-point communication, as

well as data entry, transmission,

analysis and visualization are only

possible if the automation and lowvoltage switchgear technology

components can be easily integrated

in a communication solution to

leverage the full range of functions

available.

1/1

WL MODBUS Communication and Electronic Accessories • January 2005

Page 7

Introduction and Overview

WL Circuit Breaker

In this way, status information,

alarms, trip information and

setpoints (e.g. overcurrent, phase

unbalance, overvoltage) increase

transparency in power distribution

systems, enabling these situations

to be dealt with quickly. A

communication host can send

short text messages to the cell

phones of maintenance personnel.

Prompt analysis of this data enables

targeted intervention in the process

and helps reduce system down

time.

Information for preventive

maintenance (e.g. the number of

operating cycles or hours) enables

timely personnel and material

scheduling, which increases system

availability and helps prevent

sensitive system components from

being damaged.

Communication helps provide rapid

and targeted information on the

location and cause of power

failures. The cause of the fault can

be determined by recording the

phase currents (e.g. trip as a result

of a short-circuit of 2317 A in phase

L2 on 08/27/2002 at 14:27). This

information can be used to quickly

rectify the fault and reduces

downtime for quicker recovery.

Measuring and communicating

power, power factor and energy

allows an even greater number of

applications. The availibility of

power consumption data on a

targeted basis for business analysis

enables power profiles to be created

and costs to be clearly assigned. In

this way, energy costs can be

allocated and optimized by

balancing the peak loads.

WL Circuit Breakers—Modular and

Intelligent

Thousands of options with just a few

components: That's the WL. A new

generation of circuit breakers – from

200A to 5000A – with a modular

design to support every conceivable

application in power distribution

systems – cost effective and flexible,

its communication functionality

enables it to be integrated in

system solutions.

Cost Saving

Whatever the configuration, the WL

Circuit Breaker does the job where it

matters. Advantages include simple

retrofitting and a compact design

benefiting everyone who uses WL

Circuit Breakers, whether in

planning, business, or whether they

develop or operate switchgear

systems.

Easy Planning

The WL Circuit Breaker and EasyTCC

together provide a convenient

software package for coordinating

multiple circuit breakers.

System Solutions

By integrating WL Circuit Breakers in

a higher-level communication

system, they can be configured via

MODBUS, Ethernet or the Internet;

an integrated power management

system allows you to optimize

power distribution across the board.

Graphic

1-1

Graphic

1-2

Saving costs increases

productivity.

Simplified planning every

step of the way.

WL MODBUS Communication and Electronic Accessories • January 2005

System solutions - Supports

Graphic

energy management through

1-3

advanced metering and

communications.

1/2

Page 8

Introduction and Overview

WL Circuit Breaker

Communication Bus Systems

Communication bus systems

are used to connect distribution

devices with varying levels of

intelligence. With their

different structures and

mechanisms, certain bus

systems are designed for highly

specific applications, while

others are better suited for

more open applications. The

following section describes the

most important bus systems

used in automation and power

distribution systems.

MODBUS

MODBUS is an open, serial

communications protocol based on a

master-slave architecture. Since it is

very easy to implement on any kind

of serial interface, it can be used in a

wide range of applications. MODBUS

comprises a master and several

slaves, whereby communication is

controlled exclusively by the master.

MODBUS features two basic

communication mechanisms:

• Question/answer (polling): The

master sends an inquiry to a station

and waits for a response.

• Broadcast: The master sends a

command to all the network

stations, which execute the

command without confirmation.

The messages enable process data

(input/output data) to be written to

and read from the slaves either

individually or in groups.

The data can either be transmitted in

ASCII or as a package in RTU format.

MODBUS can be used over a wide

range of transmission media,

normally, on an RS 485 physical bus,

a twisted, shielded two-wire cable

with terminating resistors.

The MODBUS protocol was originally

developed for networking control

systems, and is often used for

connecting input/output modules to

a central PLC. Due to the low

transmission rate of 38.4 kBaud

max., MODBUS is particularly

recommended for applications with a

low number of stations or low

response time requirements.

1/3

WL MODBUS Communication and Electronic Accessories • January 2005

Page 9

Introduction and Overview

WL Circuit Breaker

Communication Structure of the

WL Circuit Breakers

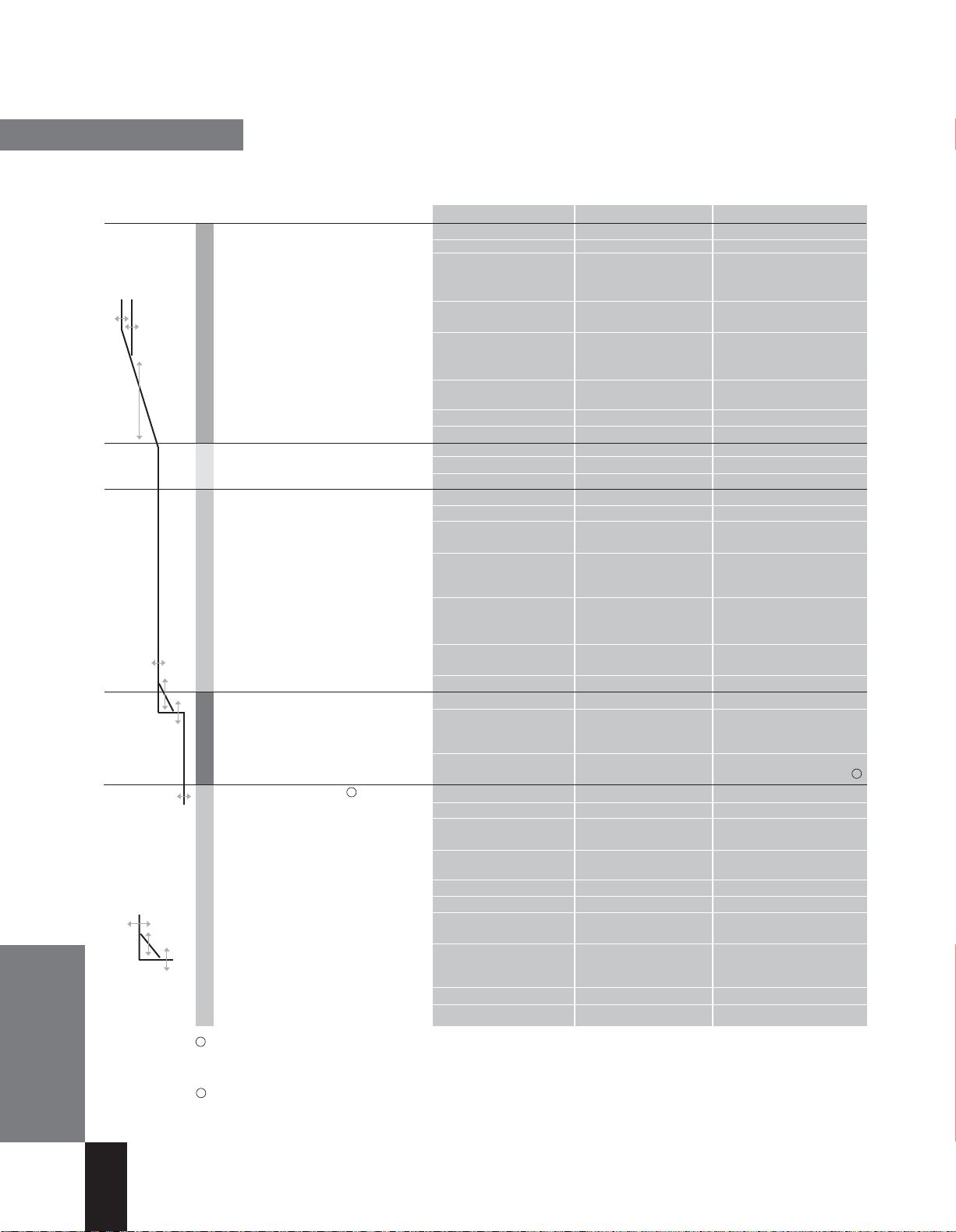

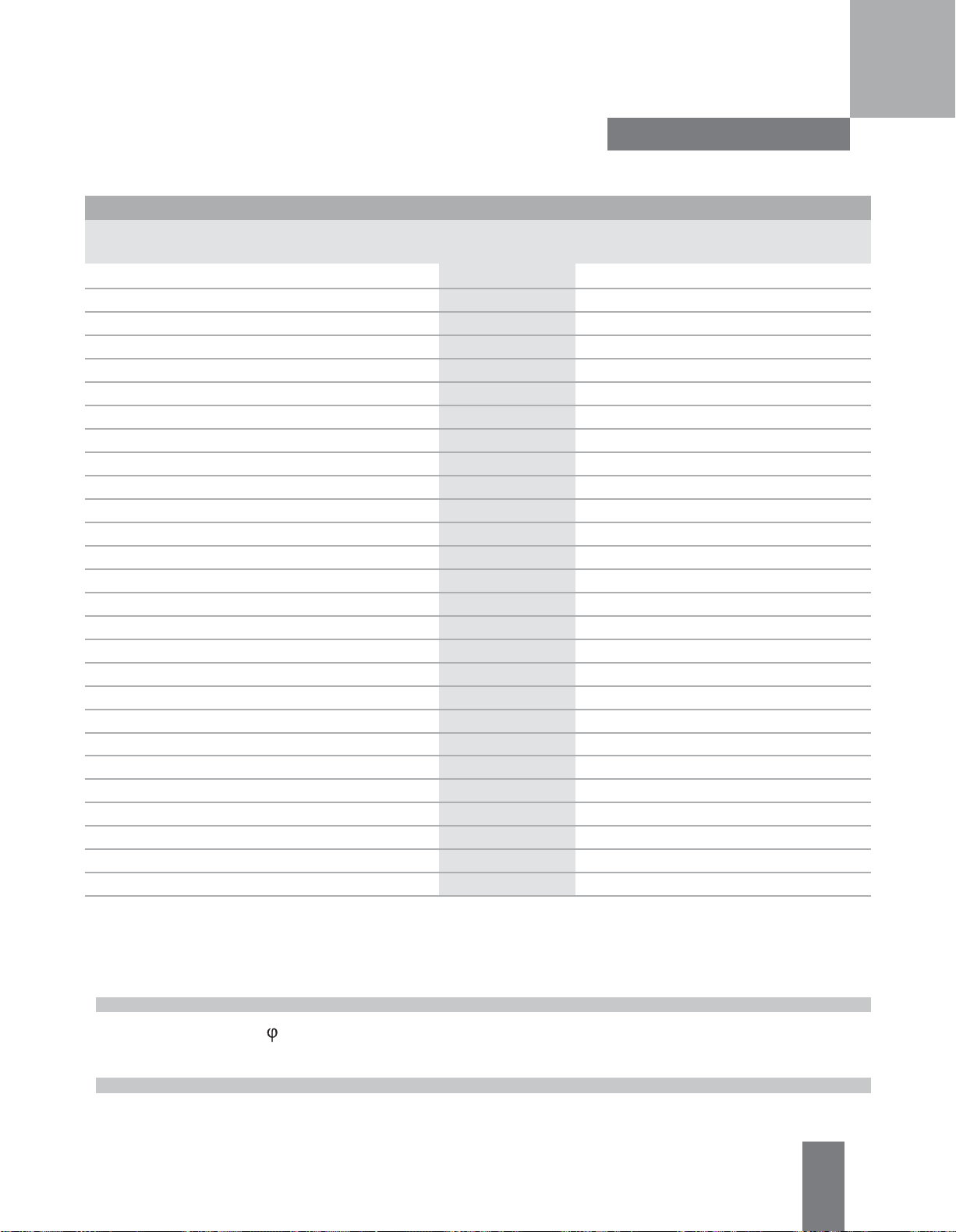

The following diagram:

• Provides an overview of the

different communication options

available with WL Circuit Breakers

and their modules.

• Illustrates the high level of system

flexibility, enabling new and

innovative ideas to be

implemented.

Connection Diagram

1 Breaker Data Adapter

(BDA)

2 Browser-capable input

and output device

(e.g. notebook)

3 WL Circuit Breaker

4 COM16 MODBUS

module or COM 15

PROFIBUS module

5 Breaker Status Sensor

(BSS)

6 Electronic Trip Unit

7 Metering function PLUS

8 Zone Selective

Interlocking (ZSI) module

9

Digital output module

with relay or optocoupler

outputs

10

Digital output module

with relay or optocoupler

outputs, remotely

configurable

11

Analog output module

Digital input module

12

13

WinPM.Net on PC

14 PLC (e.g. SIMATIC S7)

15 BDA Plus

Starting at the lowest level with

simple configuration of the circuit

breakers, to the field level with

a PLC and WinPM.Net software

tool, to a connection to the

Intranet/Internet, the potential for

saving on power costs by means of

intelligent power management is

achieveable.

The individual circuit breakers and

their modules are described in the

following chapters.

13

14

2

1

* The Siemens BDA Plus or meters, 9330, 9350, 95/9600

can be used as a gateway to enable Ethernet communication

to the WL Circuit Breaker.

The 9500 meter can also be used as a central display unit

for multiple WL breakers with metering capability.

13

9

10

8

4

5

6

7

3

12

11

15

WL MODBUS Communication and Electronic Accessories • January 2005

1/4

Page 10

Introduction and Overview

WL Circuit Breaker

Ethernet

The Industrial Ethernet is a highperformance network that conforms

to IEE 802.3 (ETHERNET). The highly

successful 10Mbit/s technology,

which has been used for over a

decade, and the new 100Mbit/s

technology (Fast Ethernet to IEEE

802.3u) in conjunction with

Switching Full Duplex and

Autosensing enable the required

network performance to be adapted

to different requirements. The

appropriate data rates are selected

as required because complete

compatibility enables the

technology to be implemented on

a step-by-step basis.

Used in 80% of networks, Ethernet

is currently the best of its kind in

LAN environments.

Ethernet does not function

according to a master-slave

principle. All the stations have equal

priority on the bus, which means

that any station can be the sender

or receiver. A sender can only send

on the bus if no other station is

sending at that time. This is due to

the fact that the stations are always

"listening in" to find out whether

any messages are being sent to

them or any senders are currently

active. If a sender has started

sending, it checks that the message

it has sent is not corrupt. If the

message is not changed, the send

operation continues.

If the sender detects that its data is

corrupt, another sender must have

already started sending data. In this

case, both senders abort their

respective send operations.

After a random time has elapsed,

the sender restarts the send

operation. This is known as

CSMA/CD and, as a "random" access

procedure, does not guarantee a

response within a certain time

frame. This largely depends on the

bus load, which means that realtime applications cannot yet be

implemented with Ethernet.

1/5

WL MODBUS Communication and Electronic Accessories • January 2005

Page 11

WL Circuit Breaker

Short description of WL Circuit Breaker

The CubicleBUS

Communication Function of the Trip Units

The COM16 MODBUS Module

Metering and Metering Plus

Description of Important Functions/Parameters

for Communication

External CubicleBUS Modules

External Power Consumption of a WL Circuit Breaker

with CubicleBUS

2

WL MODBUS Communication and Electronic Accessories • January 2005

Page 12

Communication-capable Circuit Breakers

WL Circuit Breaker

Introduction and Overview

The demands regarding

communications

capability, data

transparency, flexibility

and integration in power

distribution systems are

increasing all the time.

The WL Circuit Breaker

is a modular circuit

breaker that fulfills the

requirements of the

future today.

Brief Description of the

WL Circuit Breaker

Circuit breakers today are

no longer simply devices

for protecting plants,

transformers, generators

and motors. Many users

now require a complete

overview of the plant from

a central control room and

round-the-clock access to

all available information.

Modern power distribution

systems are characterized

by the methods used to

network circuit breakers—

both with each other and

other components. The

circuit breakers in the

WL Circuit Breaker family

have a lot to offer:

It is possible to carry out

analysis and maintenance

procedures remotely via

the Internet. Operating

staff can be given

immediate access to

information on system

status and alarms. This is

not just a vision of the

future, but reality.

The WL Circuit Breaker

covers the entire range

from 200A to 5000A. The

devices are available with

different interrupting

ratings, allowing shortcircuit currents of up to

00kA to be interrupted

2

reliably.

WL Circuit Breakers can be

adapted to different system

conditions, which means

that a rating plug can be

used to adapt each circuit

breaker to the appropriate

rated current. This ensures

that optimum protection is

provided, even if changes

have been made in the

system. The modules

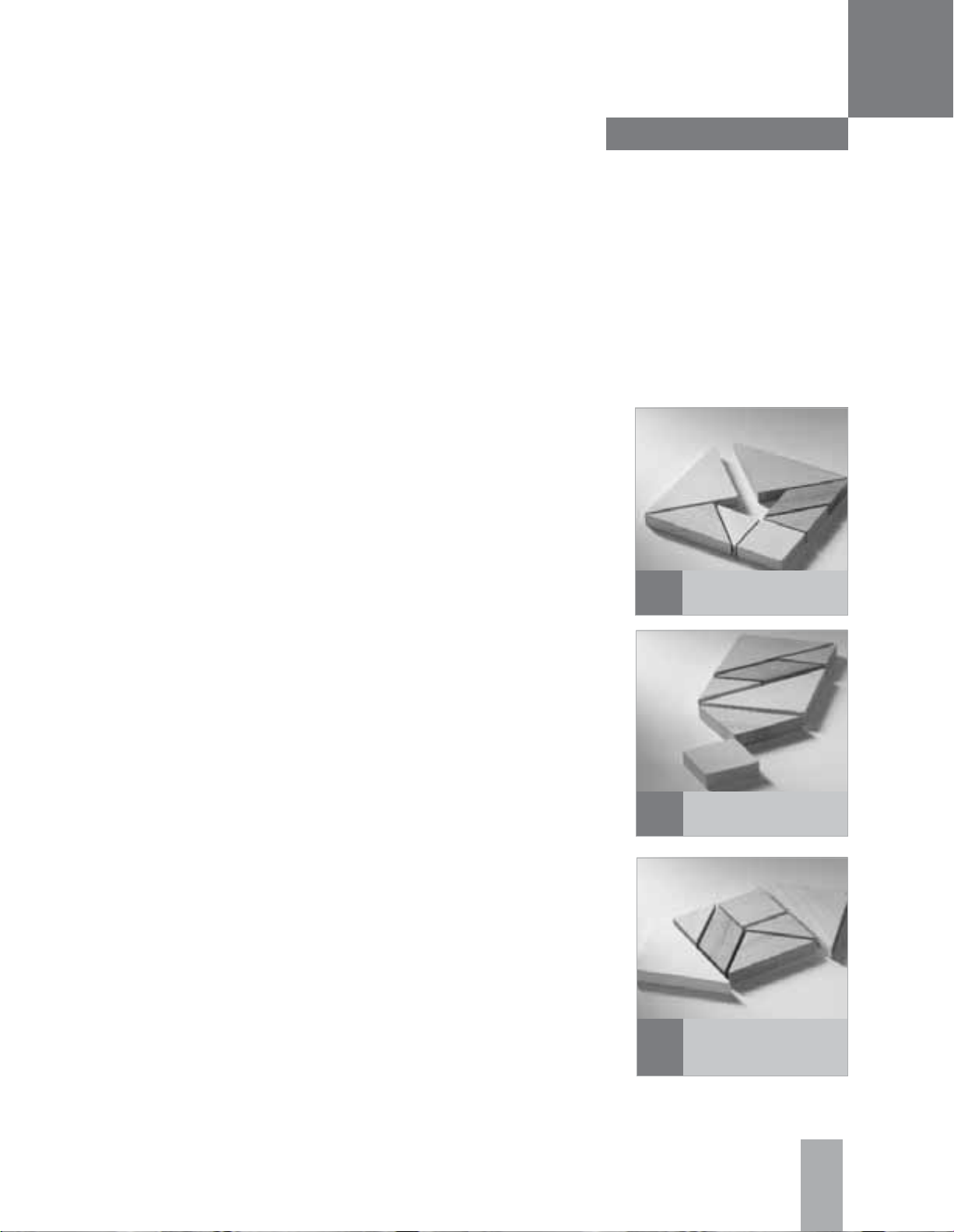

(reference Graphic 2-1) can

be replaced without the

need for the transformer

to be changed.

Note: Installation instructions related to the communication modules

described in this section can be found in the individual instruction sheets

and/or Section 9 of the Operator's Manual

PC with WinPM.Net

WL Circuit Breaker configuration

and monitoring software

Graphic 2-1 The system architecture of the WL Circuit Breaker with CubicleBUS enables simultaneous communication via MODBUS

and BDA with a laptop or Ethernet/Intranet/Internet.

2/1

WL MODBUS Communication and Electronic Accessories • January 2005

Page 13

Communication-capable Circuit Breakers

WL Circuit Breaker

The ability to change between two

different parameter sets is also

possible. This function is particularly

useful in the event of a power

failure when an automatic transfer

is made from utility to generator

power, a process which can

involve changing many of the trip

unit parameters.

A wide range of lock-out systems

are available to improve reliability

during critical processes. All

accessories, such as shunt trips,

motor operators and communication

components, can be installed

quickly and easily; this is made

easier because the accessories are

identical across the entire product

line. The commitment to reducing

the overall number of parts results

in fewer spares to be ordered and

lower inventory costs.

The heart of each circuit breaker is

the electronic trip unit (ETU).

Several versions are available to

adapt the protective, metering, and

alarm functions to the system

requirements: from simple overload

and short-circuit protection to trip

units that can be configured

remotely and which feature a wide

range of metering and alarm

functions.

All circuit breakers with ETU745,

ETU748, ETU755 and ETU776

trip units are communications

capable, and allow additional

components to be internally

networked via the CubicleBUS.

The circuit breaker is connected to

MODBUS via the RS485 interface

on the COM16 module.

The breaker data adapter (BDA)

(see Chapter 4) also supports

higher-level networking/

communication (Intranet/Internet).

The CubicleBUS

The CubicleBUS, which connects all

the intelligent components within

the WL Circuit Breaker and enables

additional external components to

be connected quickly and reliably,

forms the backbone of the modular

architecture of the WL. The

CubicleBUS is already integrated in

and connected to all assembled

circuit breakers with the ETU745,

ETU748, ETU755, and ETU776

trip units.

The high level of system modularity

enables communication functions

(e.g. metering function) to be

retrofitted at any time. A WL Circuit

Breaker that is not communications

capable can be upgraded (e.g. by

exchanging ETU72

with CubicleBUS) quickly and easily

on site. All CubicleBUS modules can

access the existing data of the

circuit breaker directly, thereby

ensuring rapid access to information

and speedy responses to events.

By connecting additional, external

modules to the CubicleBUS, costeffective solutions for

communicating data from other

devices in the cubicle can be

implemented.

5 for ETU745

Communications Capability of the

Electronic Trip Units (ETUs)

The electronic trip units ETU745,

ETU748, ETU755, and ETU776 are

all communications capable. The

CubicleBUS is connected to the

circuit breaker terminals X8.1(-) to

X8.4(+)

Different versions of

communications-capable trip units

are available.

The front of the ETU745 has rotary

switches for setting protective

parameters. These can be read via

the communication device. The

ETU745 can also be installed with

a four-line display for the measured

values.

The ETU755 does not have rotary

switches or a display. The protective

parameters can only be changed

via communications. This trip unit

with remote-only parameter setting

is for special application demands.

The ETU776 features a graphical

display with a clearly structured,

key-driven menu. This not only

enables operators to display

measured values, status

information, and maintenance

information, but also to read all the

existing parameters and make

password-protected changes.

WL MODBUS Communication and Electronic Accessories • January 2005

2/2

Page 14

Communication-capable Circuit Breakers

WL Circuit Breaker

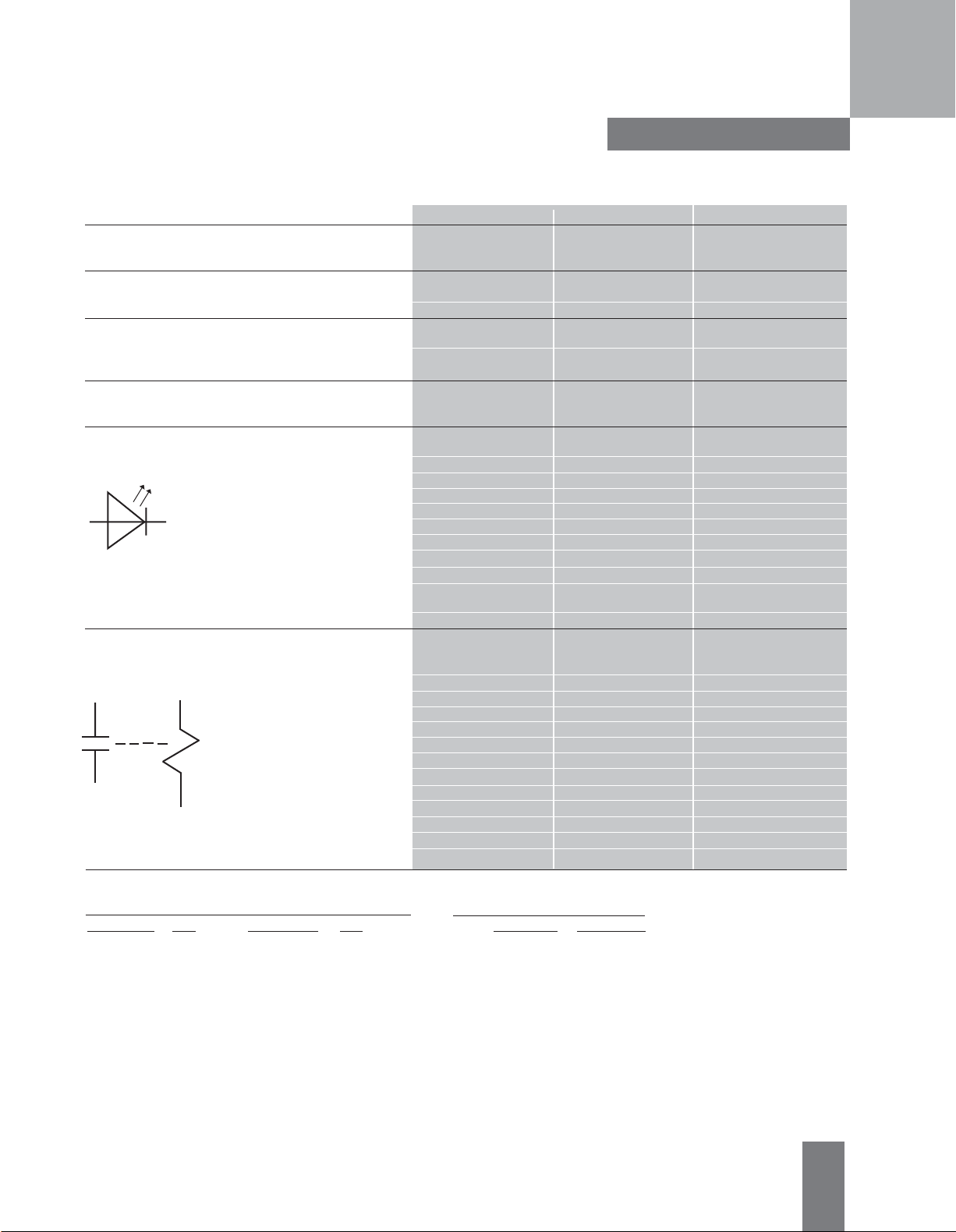

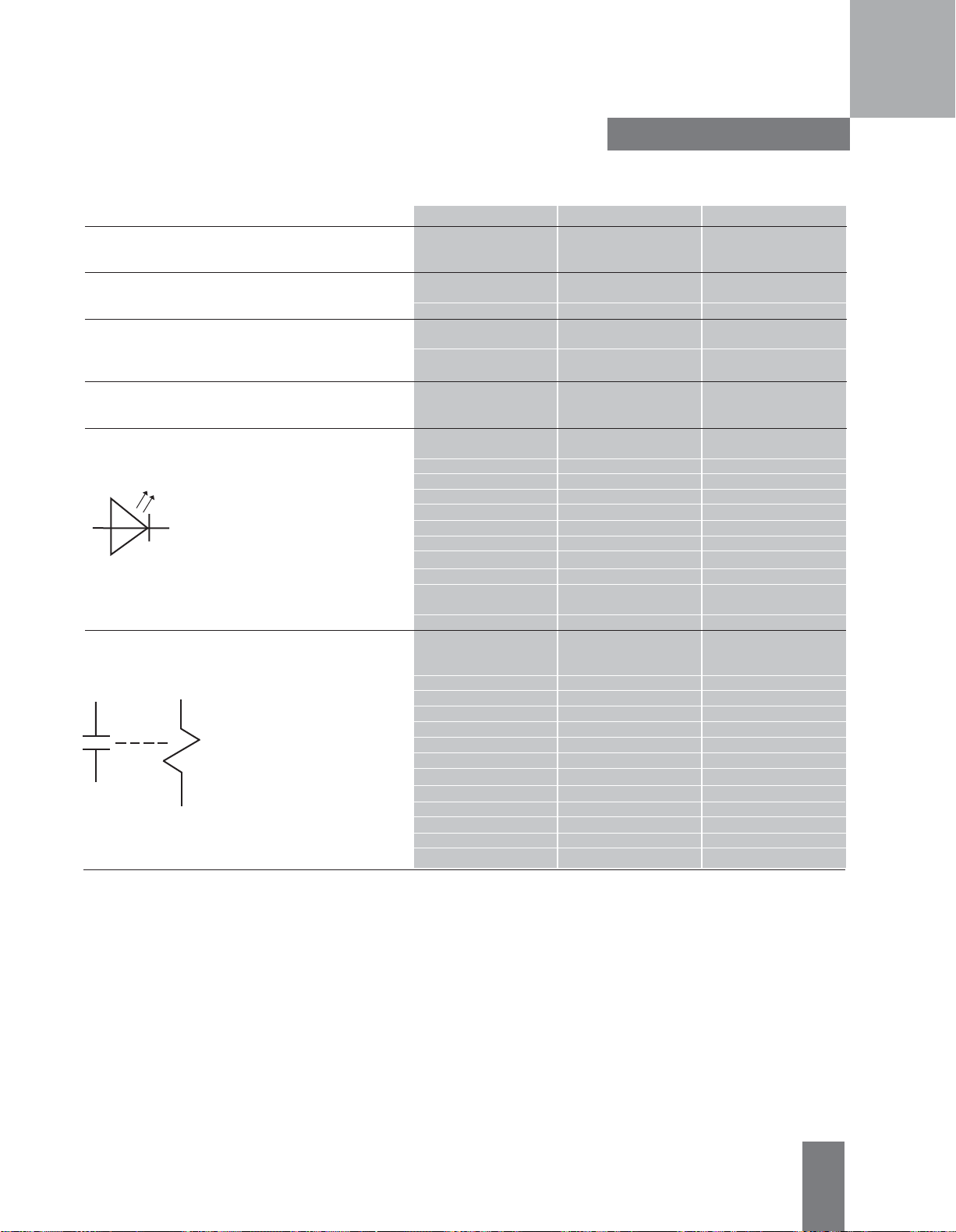

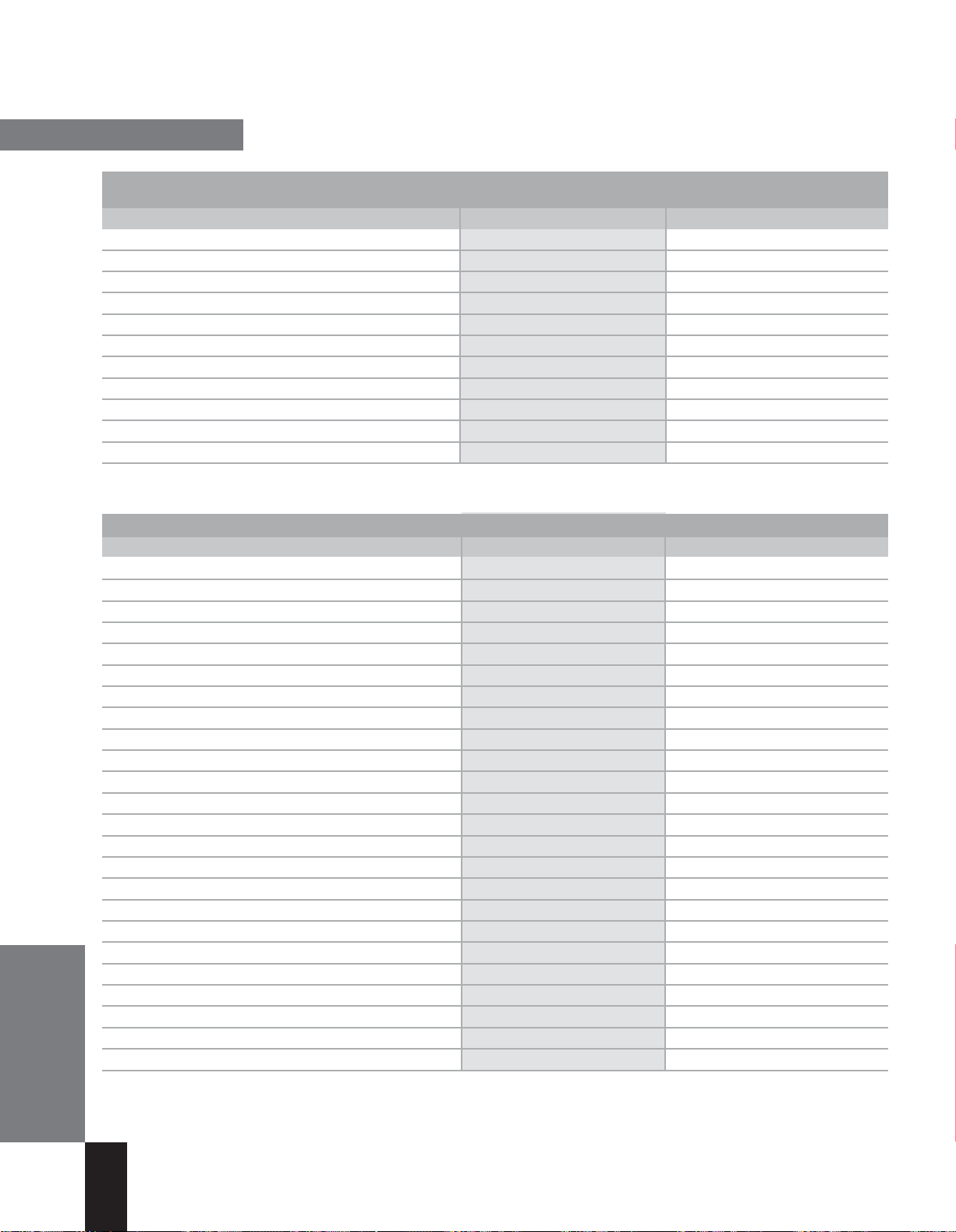

Functional overview of the trip unit system

Basic Functions ETU725 ETU727 ETU745

I

n

Long-time overcurrent protection ✔✔✔

Function can be switched ON/OFF – – –

Setting range

Switch-selectable overload protection

2

t or

I

(

L

Setting range of time delay class

(seconds) 10s, set at 6 x

Setting range of time delay

(seconds) – – 1, 2, 3, 4, 5

Thermal memory – – ✔ (via slide switch)

Phase loss sensitivity at

Neutral protection – ✔✔

Function can be switched ON/OFF – ✔ (via slide switch) ✔ (via slide switch)

N

N-conductor setting range

Short-time delayed overcurrent protection ✔✔✔

Function can be switched ON/OFF – – ✔ (via rotary switch)

Setting range

Setting range of time delay

(seconds) 0, 0.02 (M), 0.1, 0, 0.02 (M), 0.1, 0.02 (M), 0.1, 0.2,

S

Switch-selectable short-time delay

short-circuit protection

I2t

dependent function) – fixed only – fixed only ✔ (via rotary switch)

(

Setting range of time delay

(seconds) – – 0.1, 0.2, 0.3, 0.4

Zone Selective Interlocking (ZSI) function – – per CubicleBUS module

Instantaneous overcurrent protection ✔✔✔

Function can be switched ON/OFF,

Extended Instantaneous Protection

I

is enabled when OFF – – ✔ (via rotary switch)

Setting range

Ground fault protection – ✔ (standard)

Trip and alarm function – – ✔

Detection of the ground fault current

by residual summing method – ✔✔

Detection of the ground fault current

by direct sensing method – – ✔

Setting range of the

G

Setting range of the

Setting range of the time delay

(seconds) – 0.1, 0.2, 0.3, 0.4, 0.5 0.1, 0.2, 0.3, 0.4, 0.5

Switch-selectable

ground fault protection

I2t

/ fixed) – – ✔

(

Setting range time delay

ZSI ground function – – per CubicleBUS module

I

=

I

x … 0.4, 0.45, 0.5, 0.55, 0.4, 0.45, 0.5, 0.55, 0.4, 0.45, 0.5, 0.55, 0.6,

R

n

4

t dependent function) – – ✔

I

I

I

=

x … 1.25, 1.5, 2, 2.5, 1.25, 1.5, 2, 2.5, 1.25, 1.5, 2, 2.5,

sd

n

I

=

I

x …

i

n

I

for trip – A, B, C, D, E A, B, C, D, E

g

I

for alarm – – A, B, C, D, E

g

t

R

at

t

I4t

R

I

=

I

x … – 1 0.5 … 1

N

n

, fixed

t

sd

at

t

I2t

sd

2

t

g

t

at

I2t

g

0.6, 0.65, 0.7, 0.8, 0.6, 0.65, 0.7, 0.8, 0.65, 0.7, 0.8, 0.9, 1

0.9, 1 0.9, 1

2

at

I

t

I

r

t

=20 ms (M) at

sd

3, 4, 6, 8, 10, 12 3, 4, 6, 8, 10, 12 3, 4, 6, 8, 10, 12

0.2, 0.3, 0.4 0.2, 0.3, 0.4 0.3, 0.4, OFF

I

= 0.8 x

I

i

50kA max 50kA max 0.8 x

– – 0.1, 0.2, 0.3, 0.4, 0.5

cw

10s, set at 6 x

t

sd

I

= 0.8 x

i

I

r

=20 ms (M) at

I

cw

2, 3.5, 5.5, 8, 10,

14, 17, 21, 25, 30

t

=20 ms (M)

sd

1.5, 2.2, 3, 4, 6, 8, 10, 12

I

= max, OFF=

cw

(field installable module)

O

1

I

= EIP

cw

2/3

1

Extended Instantaneous Protection (EIP) allows the WL breaker to be applied at the withstand rating

of the breaker with minus 0% tolerance; that means no instantaneous override whatsoever. EIP further

enables the circuit breaker to be applied up to the full instantaneous rating of the breaker on systems

where the available fault current exceeds the withstand rating.

2

Ground Fault Module cannot be removed after installation.

WL MODBUS Communication and Electronic Accessories • January 2005

✔ available

– not available

O optional

Page 15

Communication-capable Circuit Breakers

WL Circuit Breaker

Basic Functions ETU725 ETU727 ETU745

Parameter sets

Selectable between

parameter set A and B – – –

LCD

LCD, alphanumeric (4-line) – –

LCD, graphic – – –

Communication

CubicleBUS integrated – – ✔

Communication capability via

MODBUS or PROFIBUS – – ✔

Metering function

Metering function capability with

Metering Function PLUS – – ✔

Display by LED

Trip unit active ✔✔✔

Alarm ✔✔✔

ETU error ✔✔✔

L trip ✔✔✔

S trip ✔✔✔

I trip ✔✔✔

N trip – ✔✔

G trip – ✔✔

G alarm – – ✔ (only with ground fault module)

Tripped by extended protection or

protective relay function – – ✔

Communication – – ✔

Signal contacts with external CubicleBUS modules

(Opto or relay)

Overcurrent warning – – ✔

Load shedding ON/OFF – – ✔

Early signal of long-time trip (200 ms) – – ✔

Temperature alarm – – ✔

Phase unbalance – – ✔

Instantaneous trip – – ✔

Short-time trip – – ✔

Long-time trip – – ✔

Neutral conductor trip – – ✔

Ground fault protection trip – – ✔

Ground fault alarm – – ✔ (only with ground fault module)

Auxiliary relay – – ✔

ETU error – – ✔

O

(only with ground fault module)

(only with ground fault module)

Step for Settings via Communications or ETU Key Pad

from … to step from … to step

0 … 1 0.1 1000 … 1600 50

1 … 100 1 1600 … 10000 100

100 … 500 5 10000 … max 1000

500 … 1000 10

WL MODBUS Communication and Electronic Accessories • January 2005

Setting range of the I

Frame Size II Frame Size III

A 100 A 400 A

B 300 A 600 A

C 600 A 800 A

D 900 A 1000 A

E 1200 A 1200 A

g

✔ available

– not available

O

optional

2/4

Page 16

Communication-capable Circuit Breakers

WL Circuit Breaker

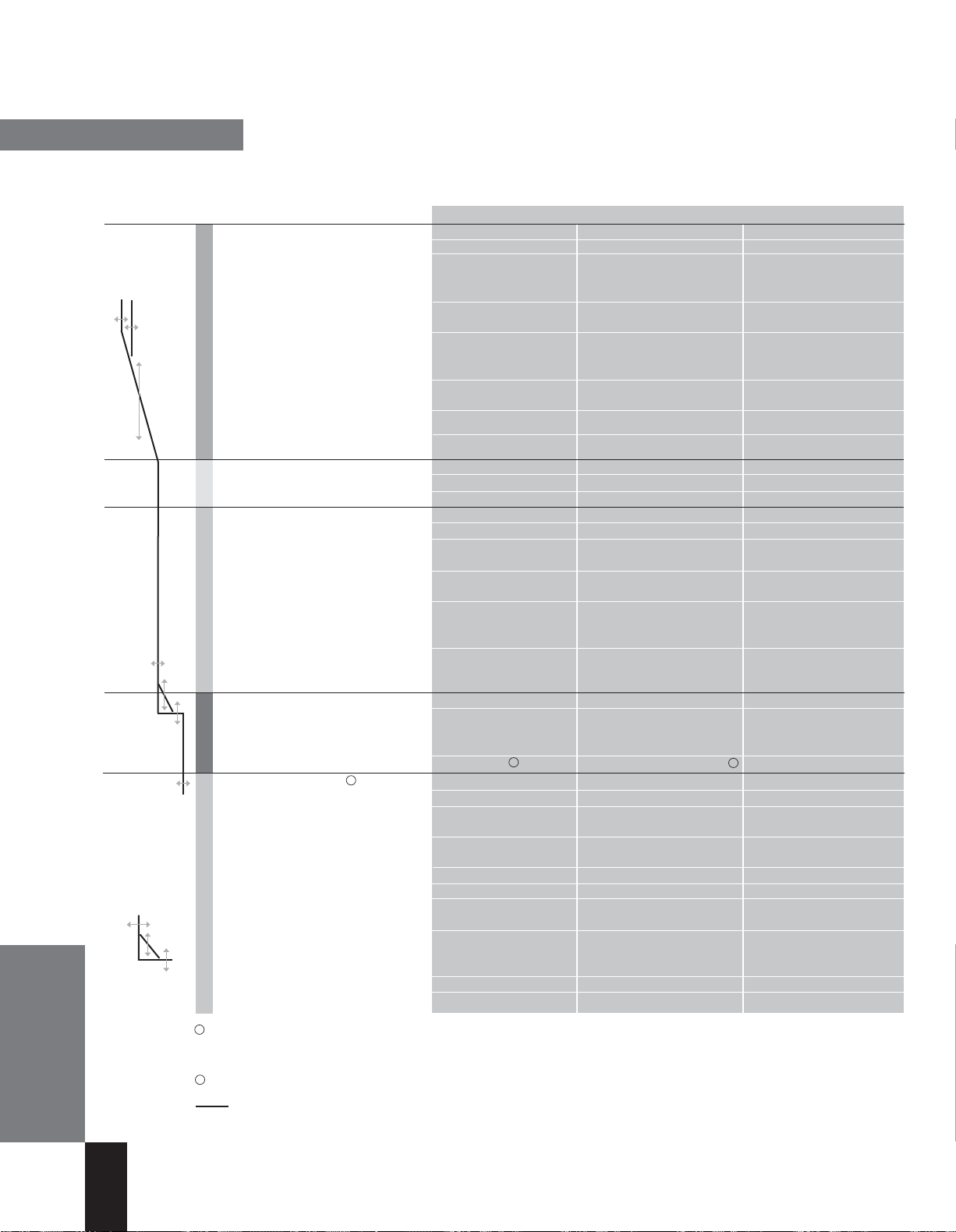

Functional overview of the trip unit system

Basic Functions ETU748 ETU755 ETU776

I

n

Long-time overcurrent protection ✔✔ ✔

Function can be switched ON/OFF – – –

I

I

=

Setting range

x … 0.4, 0.45, 0.5, 0.55, 0.4 … 1 (step: 1A) 0.4 … 1 (step: 1A)

R

n

0.6, 0.65, 0.7, 0.8,

0.9, 1

Switch-selectable overload protection

2

4

I

t or

I

t dependent function) ✔✔(via communications) ✔

(

L

Setting range of time delay class

(seconds) 2, 3.5, 5.5, 8, 10, 2 … 30 (step: 0.1s) 2 … 30 (step: 0.1s)

2

t

at

I

t

R

14, 17, 21, 25, 30

t

at

Setting range of time delay

(seconds) 1, 2, 3, 4, 5 1 … 5 (step: 0.1s) 1 … 5 (step: 0.1s)

Thermal memory ✔

Phase loss sensitivity at

I4t

R

(via slide switch) ✔ (on/off via communications) ✔ (on/off via key pad

t

=20ms (M) ✔

sd

(on/off via communications) ✔ (on/off via key pad

or communications)

or communications)

Neutral protection – ✔✔

Function can be switched ON/OFF – ✔

N

N-conductor setting range

I

I

=

x …

N

n

0.5, 1, OFF 0.5, 1, OFF 0.5 … 2, OFF

(via communications) ✔

(via key pad or communications)

Short-time delayed overcurrent protection ✔✔ ✔

Function can be switched ON/OFF

Setting range

Setting range of time delay

(seconds) M, 0.1, 0.2, 0.3, 0.4

S

I

=

I

x … 1.25, 1.5, 2, 2.5, 1.25 … 0.8 x Icw= max 1.25 … 0.8 x Icw= max

sd

n

t

,fixed

sd

–

✔ (via communications) ✔

(via key pad or communications)

3, 4, 6, 8, 10, 12 (step: 10A) (step: 10A)

M, 0.08 … 0.4,OFF (step: 0.001s) M, 0.08… 0.4, OFF (step:0.001s)

Switch-selectable short -time delay

short-circuit protection

I2t

dependent function) ✔ (via rotary switch) ✔ (via communications) ✔ (via key pad or communications)

(

Setting range of time delay

(seconds) 0.1, 0.2, 0.3, 0.4 0.1 … 0.4 (step: 0.001s) 0.1 … 0.4 (step: 0.001s)

t

at

I2t

sd

Zone Selective Interlocking (ZSI) function per CubicleBUS module per CubicleBUS module per CubicleBUS module

Instantaneous overcurrent protection ✔✔ ✔

Function can be switched ON/OFF,

Extended Instantaneous Protection

I

is enabled when OFF – ✔

Setting range

Ground fault protection

I

=

I

x … –

i

n

2

I

=

i

O

(field installable module)O(field installable module)

1

I

= EIP 1.5 x

cw

Trip and alarm function ✔✔

(via communications) ✔ (via key pad or communications)

I

… 0.8 x

I

= max, OFF=

n

cs

(via communications)

1

I

= EIP 1.5 x

cw

I

… 0.8 x

I

= max, OFF=

n

cs

O

(field installable module)

(via key pad or communications)

✔

Detection of the ground fault current

by residual summing method ✔✔ ✔

Detection of the ground fault current

by direct sensing method ✔✔ ✔

I

Setting range of the

G

Setting range of the

Setting range of the time delay

(seconds) 0.1, 0.2, 0.3, 0.4, 0.5 0.1 … 0.5 (step: 0.001s) 0.1 … 0.5 (step: 0.001s)

for trip A, B, C, D, E A … E (step: 1A) A … E (step: 1A)

g

I

for alarm A, B, C, D, E A … E (step: 1A)- A … E (step: 1A)

g

t

g

Switch-selectable

ground fault protection

I2t

/ fixed) ✔✔ ✔

(

Setting range time delay

ZSI ground function per CubicleBUS module per CubicleBUS module per CubicleBUS module

t

at

I2t

g

0.1, 0.2, 0.3, 0.4, 0.5 0.1 … 0.5 (step: 0.001s) 0.1 … 0.5 (step: 0.001s)

I

=EIP

cw

2/5

1

Extended Instantaneous Protection (EIP) allows the WL breaker to be applied at the withstand rating of

the breaker with minus 0% tolerance; that means no instantaneous override whatsoever. EIP further

enables the circuit breaker to be applied up to the full instantaneous rating of the breaker on systems

where the available fault current exceeds the withstand rating.

2

Ground Fault Module cannot be removed after installation.

✔ available

– not available

O optional

Notes:

M = Indicates phase loss sensitivity is enabled. LT pickup reduced 80% when phase unbalance > 50%. ST delay = 20ms

Communications = Setting the parameters of the trip unit via the Breaker Data Adapter, MODBUS, or PROFIBUS

Key pad = Direct input at the trip unit

WL MODBUS Communication and Electronic Accessories • January 2005

Page 17

Communication-capable Circuit Breakers

WL Circuit Breaker

Basic Functions ETU748 ETU755 ETU776

Parameter sets

Selectable between

parameter set A and B – ✔✔

LCD

LCD, alphanumeric (4-line)

LCD, graphic – – ✔

Communication

CubicleBUS integrated ✔✔✔

Communication capability via

MODBUS or PROFIBUS ✔✔ ✔

Metering function

Metering function capability with

Metering Function PLUS ✔✔✔

Display by LED

Trip unit active ✔✔✔

Alarm ✔✔✔

ETU error ✔✔✔

L trip ✔✔✔

S trip ✔✔✔

I trip - ✔✔

N trip ✔✔✔

G trip ✔

G alarm ✔ (only with ground fault module) ✔ (only with ground fault module) ✔ (only with ground fault module)

Tripped by extended protection or

protective relay function ✔✔ ✔

Communication ✔✔✔

Signal contacts with external CubicleBUS modules

(Opto or relay)

Overcurrent warning ✔✔✔

Load shedding ON/OFF ✔✔✔

Early signal of long-time trip (200 ms) ✔✔✔

Temperature alarm ✔✔✔

Phase unbalance ✔✔ ✔

Instantaneous trip ✔✔✔

Short-time trip ✔✔✔

Long-time trip ✔✔✔

Neutral conductor trip ✔✔✔

Ground fault protection trip ✔

Ground fault alarm ✔ (only with ground fault module) ✔ (only with ground fault module) ✔ (only with ground fault module)

Auxiliary relay ✔✔ ✔

ETU error ✔✔✔

O ––

(only with ground fault module) ✔ (only with ground fault module) ✔ (only with ground fault module)

(only with ground fault module) ✔ (only with ground fault module) ✔ (only with ground fault module)

WL MODBUS Communication and Electronic Accessories • January 2005

✔ available

– not available

O optional

2/6

Page 18

Communication-capable Circuit Breakers

WL Circuit Breaker

Data Availability on the CubicleBUS

All modules connected to the CubicleBUS can request data

from other modules via the bus and generate data

themselves that can be read by other modules.

Each data point in the comprehensive WL Circuit Breaker

data dictionary can only be generated by a single

module—the data source. If this data source (module)

exists, the data points assigned to it also exist.

This information is described and communicated in the

If a data source (module) does not exist, the data point

does not exist either.

Again, the relevant property byte contains this

information.

The following table provides an overview of the internal

CubicleBUS modules and the data point groups (collection

of several data points) assigned to them.

See Chapter 3 Register List for a detailed description of

the individual data points.

property bytes.

CubicleBUS Modules

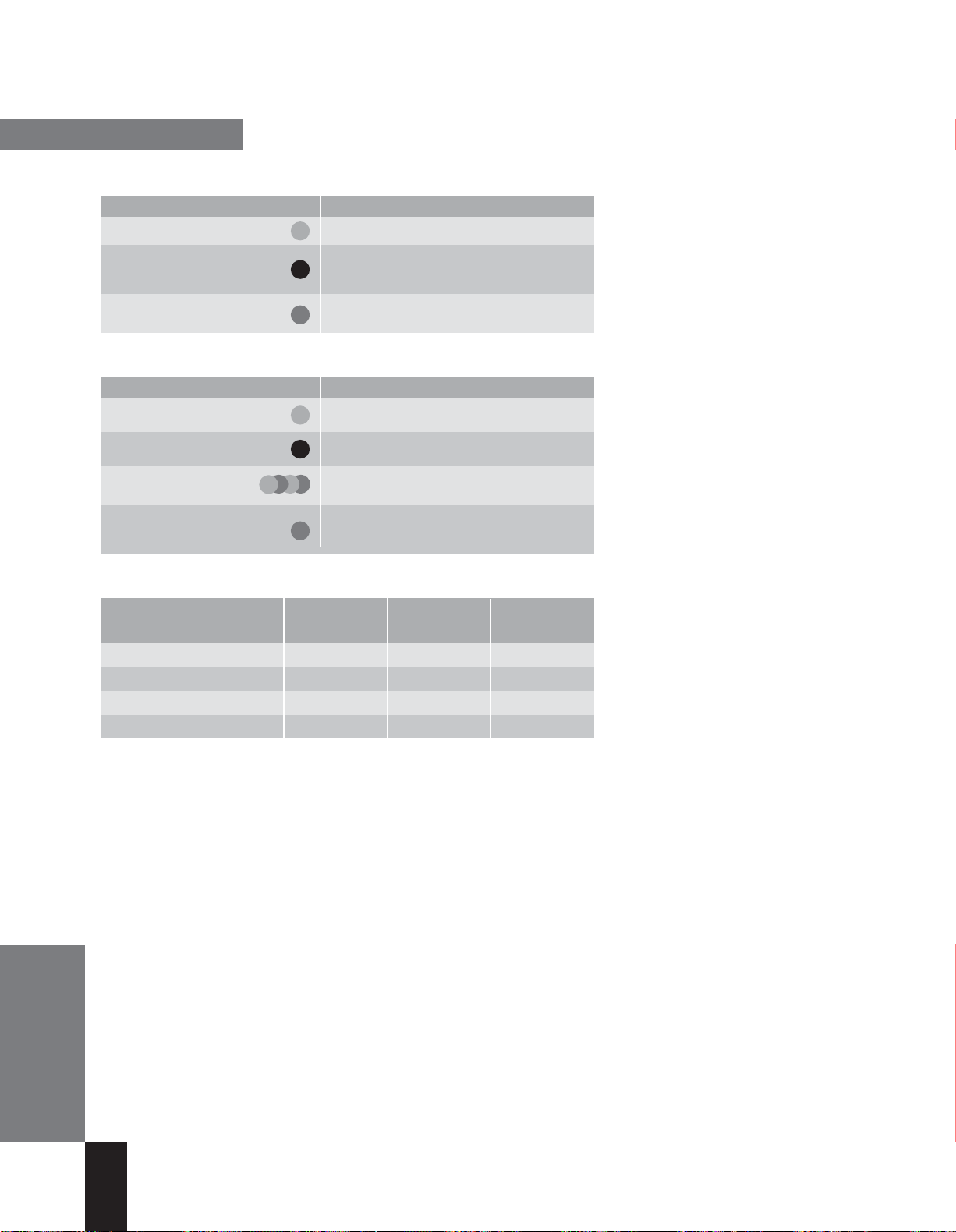

Data point group ETU745, 748, BSS COM16 Metering

Data points with the same source 755 or 776 Function

Protection parameter set A ✓

Protection parameter set B (N/A for ETU745 or 748) ✓

Extended protection parameters ✓

Parameter for setpoints ✓

MODBUS communication parameters ✓

Parameters for metering settings ✓

Device identification data ✓✓

Circuit breaker position specifications ✓

Status info. (circuit breaker open/closed, storage spring, etc.) ✓

Alarms ✓

Trip log ✓✓

Setpoint messages ✓

Maintenance information ✓✓

Circuit breaker temperature ✓

Temperature in the cubicle ✓

3-phase currents ✓

Current in neutral, ground-fault current; equip. spec. ✓

3-phase voltage ✓

Power KW, KVAR, KVA ✓

Power factor ✓

Frequency, total harm. distortion, form factor, crest factor ✓

Harmonic analysis ✓

Waveform buffer ✓

Event log ✓

System time ✓

Plus

Table 2-2 The table shows which data points from the data dictionary are generated by which CubicleBUS module,

enabling you to quickly find out which modules are required for which system.

2/7

WL MODBUS Communication and Electronic Accessories • January 2005

Page 19

Communication-capable Circuit Breakers

The MODBUS COM16 Module and the BSS

The COM16 module enables the

WL Circuit Breaker to exchange

data via MODBUS to supervisory

systems and MODBUS masters.

The COM16 module retrieves

some of the key data on the

status of the circuit breaker

(circuit breaker open/closed,

closing spring charged, ready-to-

close, etc.) via the CubicleBUS

from the BSS (breaker status

sensor). Both modules are,

therefore, offered together as

a MODBUS communication

package.

MODBUS Module COM16

The COM16 module for the WL

enables the circuit breaker to be

connected to any MODBUS master

network. This makes it easy to add

WL and a COM16 to existing

MODBUS networks.

If required, control/write access to

the circuit breaker can be locked

using hardware and software to

prevent any switching operations

taking place via MODBUS (manual

or automatic operation) or

parameters from being changed.

All key events are assigned a time

stamp from the integrated clock to

enable operators to keep track of

alarms. This device clock can be

synchronized with the clock in the

automation system.

A temperature sensor integrated in

the COM16 module measures the

temperature surrounding the

breaker in the switchgear cubicle.

Three integrated microswitches

located in the COM16 module are

used to detect the position of the

circuit breaker (connect, test,

disconnect and not present) and

communicate via MODBUS. The

circuit breaker can be remotely

operated only in the test or

connect position.

Pin Configuration

The COM16 module is connected to

the auxiliary conductor plug-in

system at X7.

The electrical connections to the

circuit breaker and the CubicleBUS

connection to the internal

CubicleBUS modules (ETU, BSS,

metering function, etc.) are defined

in Section 9 of the Operator's

Manual and the individual

instruction sheets.

WL Circuit Breaker

Interposing relays must be used if

the opening and closing solenoids

are designed for voltages other than

24V DC.

Terminals X9.1 and X9.2 must be

used if the second shunt trip rather

than the first shunt trip is used to

open the circuit breaker via

communication.

The unassigned user output can be

used as required and must be

connected in the same way as a

coupling device (see Graphic 2-4).

It can be used, for example, to reset

the trip indicator if the remote reset

option has been installed. As with

Open and Close, only voltages of up

to 24V DC are permitted (note the

polarity); coupling devices must be

used for higher voltages.

The communications line is

connected to the 9-pin interface on

the front of the COM16 module.

The CubicleBUS connection for a

RJ45 plug is located at the rear and

is used to connect the external

CubicleBUS modules. If no external

CubicleBUS module is connected,

the terminating resistor supplied

must be used as an RJ45 plug.

The unassigned user input can be

connected using a contact element

with the 24V DC from pin 1 to

transmit the status of the contact

element.

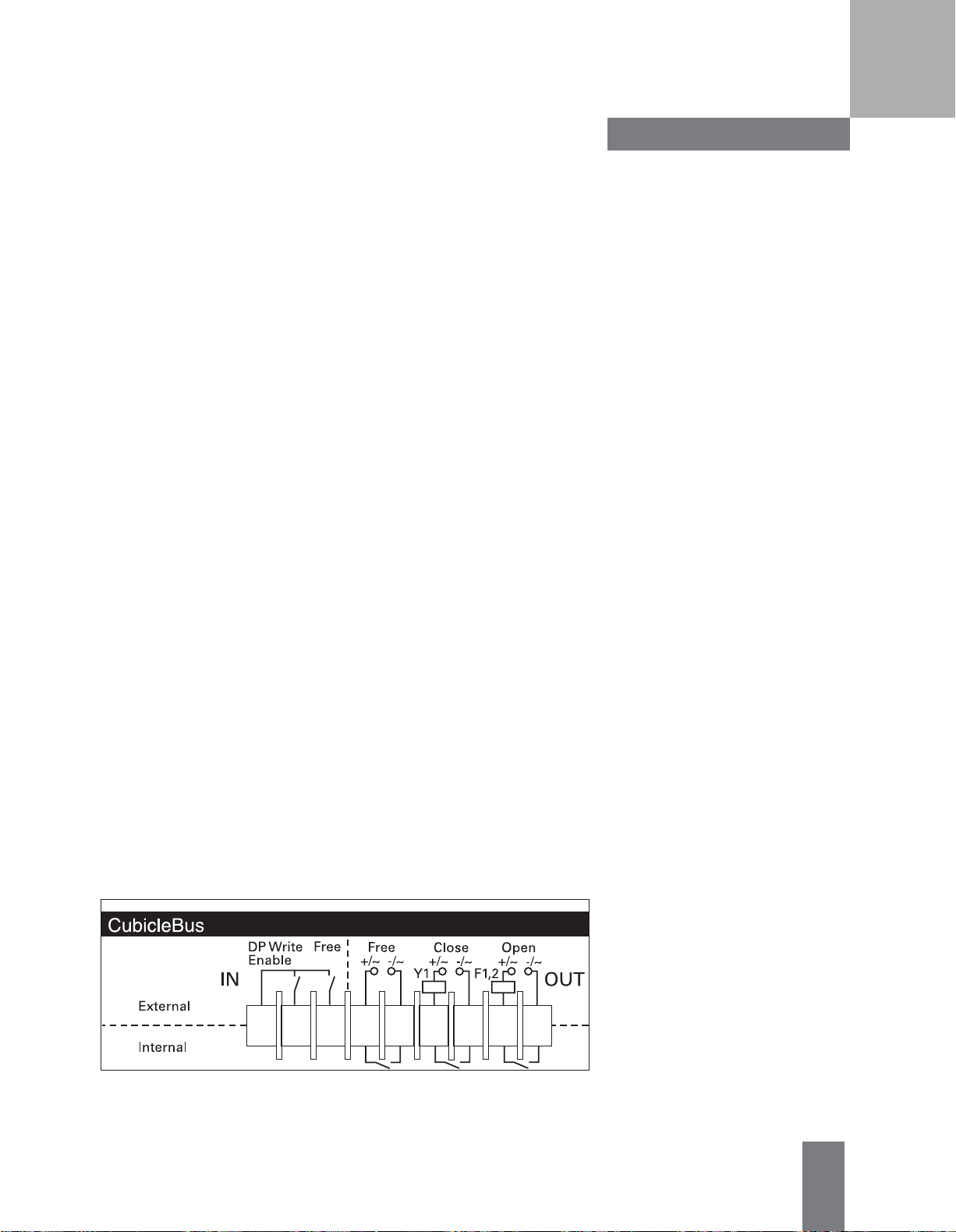

Graphic 2-2 The text on the COM16 module shows the external pin

configuration for connecting the closing solenoid and the shunt trips, as well as

the MODBUS write protection function and the unassigned input/output.

WL MODBUS Communication and Electronic Accessories • January 2005

2/8

Page 20

Communication-capable Circuit Breakers

WL Circuit Breaker

MODBUS Write Protection (DPWriteEnable)

Write access via communications can be blocked either

temporarily or permanently.

The COM16 module features a hardware input for this

purpose. Pin 1 provides the 24V DC supply, which can

be connected to pin 2.

If this input is not bridged, write access and control is

disabled.

The following actions are blocked if the input of the

write-protect function has not been enabled:

• Breaker open/close

• Reset the last trip

• Change the protective parameters

• Change the parameters for the extended protection

function (metering function)

• Change the communication parameters

• Settings of the metering options

• Reset maintenance information (counters)

• Force the digital outputs from WinPM.Net

The following control functions are available even if

the write protection function has not been enabled:

• Change and set the trigger functions for the

waveform buffer

• Read the content of the waveform buffer

• Change the setpoint parameters

• Set/change the system time

• Change the free texts (comments, system IDs)

• Reset the min./max. values

• Change the unassigned user output

Graphic

2-3

This diagram illustrates how to wire the COM16 module if MODBUS is to

be used to switch the device open and closed. This diagram only applies

to 24V DC control voltage.

MODBUS Installation Guideline

The COM16 must be assembled and connected

as described in the WL Operating Instructions.

Of particular importance is the requirement to

ground the shield of the MODBUS cable.

2/9

Graphic

Interposing relays are required if a control voltage different than 24V DC

is used. If the 1st shunt trip is not used to switch off the device, use

2-4

terminals X9.1 and X9.2 to utilize the 2nd shunt trip.

WL MODBUS Communication and Electronic Accessories • January 2005

Page 21

The write-protect function ensures that all the

required information can be transmitted, but

prevents any changes to the status of the circuit

breaker. Changes can then only be made locally.

Why does the write protection function permit

certain actions?

All actions that are not blocked are for remote

analysis only and do not have any effect on the

current status.

Data Exchange via the COM16 Module

When the COM16 module is configured to

exchange data, it is important to note that it is

shipped as standard with MODBUS address 126.

This can be changed during system configuration

(e.g. with the BDA, WinPM.Net, WL Config

software or ETU776 display).

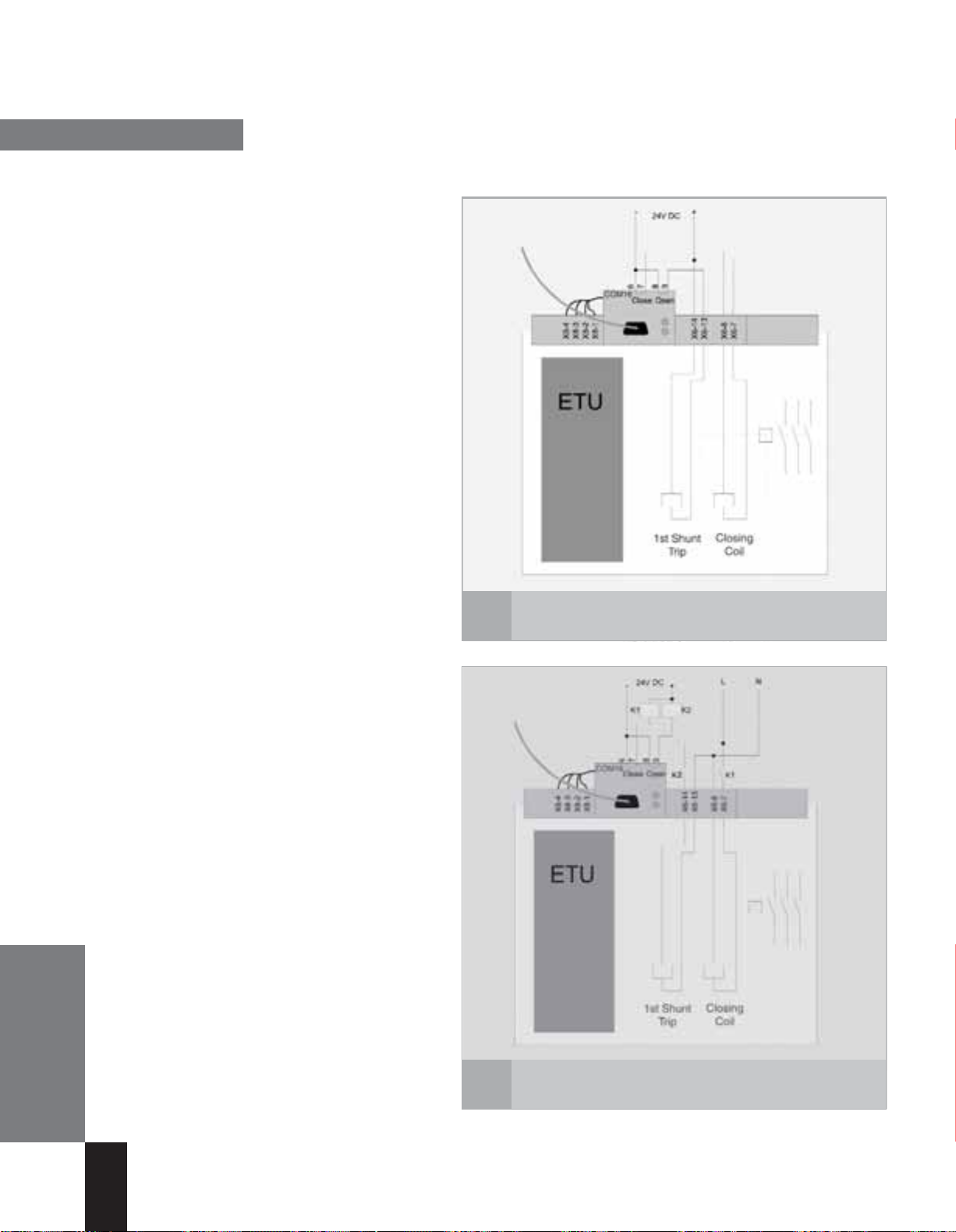

The COM16 module has two LEDs (MODBUS and

CubicleBUS) for diagnostic purposes. These

indicate the operating status of the

communication line and the CubicleBUS networks.

Two LEDs are used to determine whether a

CubicleBUS module in the circuit breaker is

operational. First, the "COMM" LED on the trip

unit must be green, that is, the trip unit has

recognized at least one other CubicleBUS module.

At a minimum, this would only be the Metering

Function PLUS if the CubicleBUS was then

interrupted. Second, the CubicleBUS LED on the

COM16 module must be taken into account. If

this is lit with a steady green light, a connection

exists from the COM16 module to at least the

metering function Plus module.

If both LEDs are green (steady light for CubicleBUS

on the COM16 module and COMM on the trip

unit), communication is fully established between

the trip unit and the COM16 module.

Data is exchanged according to the following

principle: an up-to-date copy of all WL Circuit

Breaker data (apart from the waveform buffer) is

always stored in the COM16 module. A response

to a data query from the COM16 module to the

supervisory system can, be typically transmitted

in just a few milliseconds. Write data from the

supervisory system is forwarded to the

appropriate addressee on the CubicleBUS.

Communication-capable Circuit Breakers

WL Circuit Breaker

Figure

Graphic

Meaning Position and text on the cable

CubicleBUS - X7.1

CubicleBUS + X7.2

24V DC + X7.3

24V DC ground X7.4

Table 2-3 The 4 black cables from the COM16 module must be connected to

terminal strip X7, which is used to connect the COM16 module to the modules on

the CubicleBUS in the circuit breaker.

Front view of the MODBUS module for the WL Circuit Breaker with the

MODBUS connection and the two LEDs. The figure below shows a section

2-1

of the ETU745 and its LEDs for displaying status.

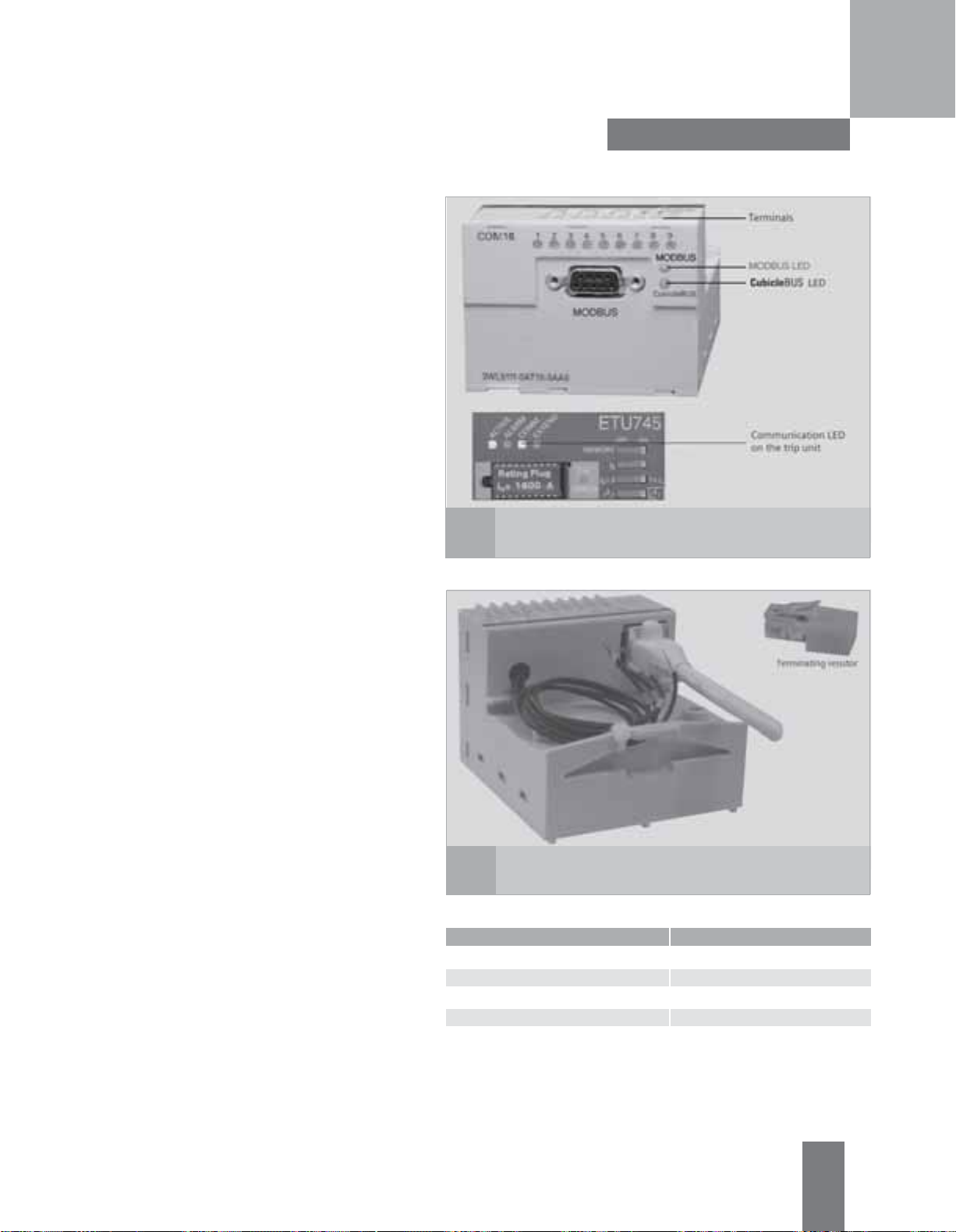

Rear view of the COM16 module. The RJ45 connection for the external

CubicleBUS modules can be clearly seen here. If no external CubicleBUS module

2-2

is connected, the bus must be terminated with the terminating resistor.

WL MODBUS Communication and Electronic Accessories • January 2005

2/10

Page 22

Communication-capable Circuit Breakers

WL Circuit Breaker

MODBUS LED Meaning

Off No voltage on the COM16 module

Red Bus error

Communication not possible

No communication with class 1 master

Green MODBUS communication OK

Cyclic data transmission with class 1 master

Table 2-4 The MODBUS LED provides information on the state of MODBUS communication in the

COM16 module.

CubicleBUS LED Meaning

Off No CubicleBUS modules found

Red CubicleBUS error

Green flashing CubicleBUS module found, but no metering

function Plus or trip unit

Steady green light CubicleBUS module found and connection

with the metering function Plus and/or

trip unit

Table 2-5 The CubicleBUS LED provides information on the state of CubicleBUS communication in

the COM16 module.

Position Rear Middle Front

microswitch microswitch microswitch

(S46) (S47) (S48)

Connect position 1 0 0

Test position 0 1 0

Disconnect position 0 0 1

Circuit breaker fully withdrawn 0 0 0

Table 2-6 The COM16 module has 3 microswitches for determining the position of the circuit

breaker in the guide frame. Depending on which switch is actuated, the position described above

is communicated via the comm. system (1=contact closed, 0=contact open).

When the circuit breaker is fully

withdrawn, no further microswitches

are actuated. "Circuit breaker fully

withdrawn" is communicated

immediately.

The sequence described above

provides hysterisis for communicating

contact position and avoids

intermittent contact postitions

from being communicated.

With UL 489 fixed-mounted circuit

breakers, a heel plate is screwed to

the COM16 module to transmit

operating position.

The COM16 module features a builtin temperature sensor, which is

installed outside the circuit breaker,

and measures the temperature

surrounding the breaker.

It also contains a clock that provides

a time stamp for all events, such as

minimum and maximum measured

values, as well as warnings and trips.

Three microswitches located in the

COM16 module can determine the

position of a drawout circuit breaker

in the guide frame, which is then

communicated via the COM16

module. The positions are defined in

Table 2-6. When the position of the

circuit breaker has changed, the

microswitch that has been actuated

is opened before the next microswitch

is actuated. No microswitches are

actuated if the breaker is between

two of the three positions. The

previous state is communicated until

a new position is reached when the

circuit breaker is moved (see Table 2-6).

2/11

There is no way of determining the

direction in which the circuit breaker

is being moved once the "disconnect

position" microswitch has been

opened.

When the circuit breaker is initially

racked in, the next microswitch to be

actuated is the "test position." The

COM16 module communicates

"circuit breaker not present" until the

"test position" key is actuated. The

new event message is delayed by 10

seconds to ensure that the breaker is

firmly seated.

WL MODBUS Communication and Electronic Accessories • January 2005

Page 23

Communication-capable Circuit Breakers

WL Circuit Breaker

Breaker Status Sensor (BSS)

BSS stands for "breaker status

sensor." All microswitches that

contain information on the state of

the circuit breaker are either

installed directly to the BSS or

connected to it. The BSS makes this

digital information available on the

CubicleBUS.

If the status of the circuit breaker in

the switchgear is to be displayed or

read via communications, the BSS

module and the appropriate

signaling switch must be installed

(if they are not already). The circuit

breaker must be installed with an

electronic trip unit of type ETU745

or higher.

The BSS can also be field installed.

The BSS indicates the following

information:

• Closing spring

(charged/discharged)

• Position of the main contacts

(open/closed)

• Ready-to-close signal

• Bell Alarm switch on the trip unit

(connected to the red mechanical

trip indicator)

• Signaling switch on the first

shunt trip

• Signaling switch on the second

shunt trip

The BSS is included when you order

the communications option with

with the assembled circuit breaker.

If a BSS is required without

communication (e.g. for operating

the BDA), it can be ordered

seperately.

Figure

This picture shows the BSS signaling contacts and how they have to be connected.

The BSS is factory installed when the communications option is ordered with the

2-3

assembled breaker.

WL MODBUS Communication and Electronic Accessories • January 2005

2/12

Page 24

Communication-capable Circuit Breakers

WL Circuit Breaker

Metering Function Plus

The integrated metering function

can be used with all trip units

with a CubicleBUS connection. It

not only extends the range of

protection functions of the trip

unit but also provides additional

warnings and diagnostic options.

With its comprehensive range of

measured values, the integrated

WL Circuit Breaker metering

function is an excellent

alternative to external multi-

function metering devices.

General

In addition to the current values

supplied by the trip unit, the

metering function provides the

measured values in the power

distribution system required for

Power Management (voltage, power,

etc.). With its extended protection

function (e.g. undervoltage), the

metering function also provides

further options for monitoring and

protecting the power distribution

system.

The option of generating warnings if

setpoints are exceeded, speeds up

response to system alerts. As a

result, the metering function can

significantly increase system up-time.

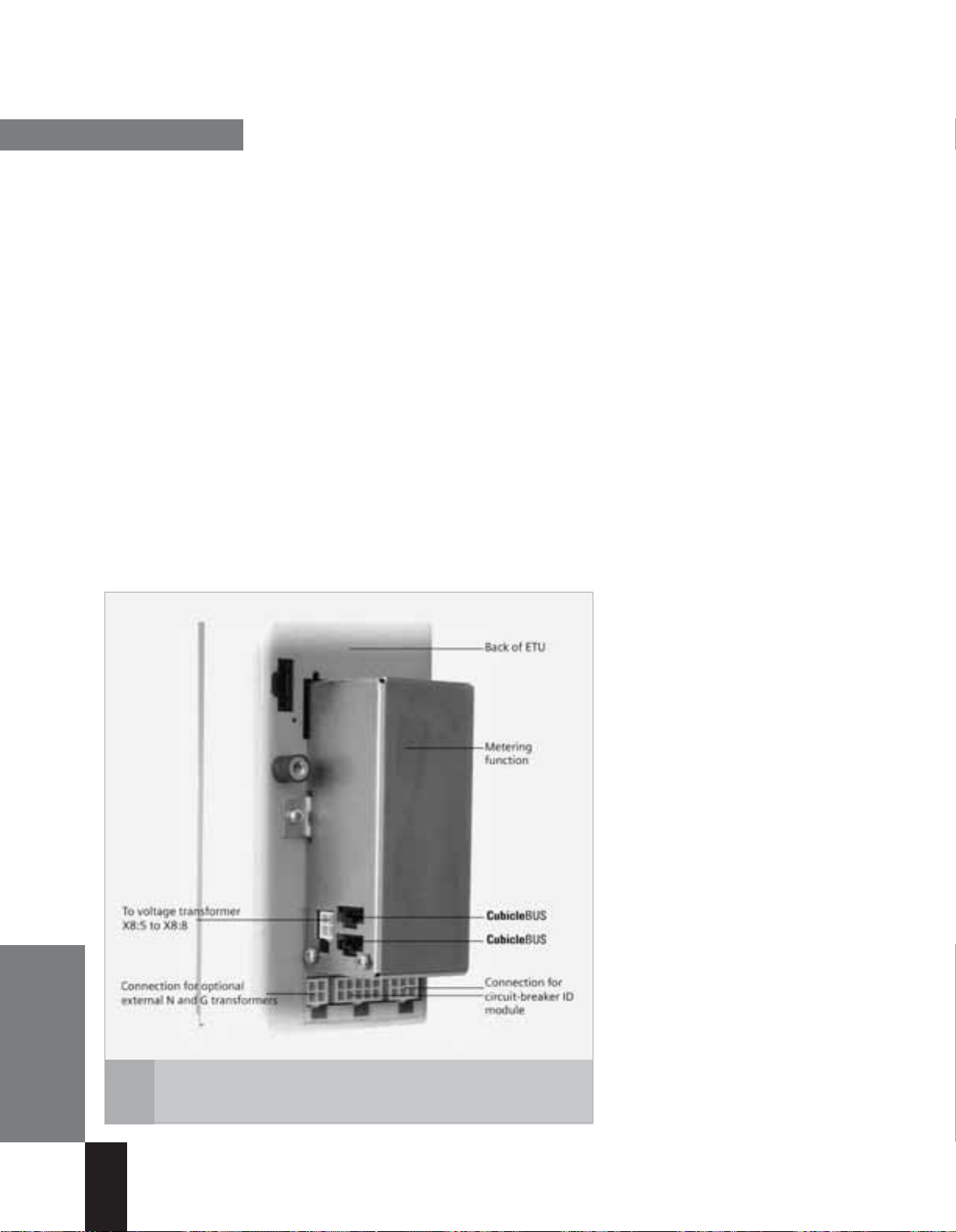

The metering function module is

installed on the back of the trip unit

(ETU), as shown in Fig. 2-4. The trip

unit and metering function module

exchange all current data via a highspeed synchronous interface. The

metering function module provides

all the connected modules (e.g. the

COM16 module or BDA) with the

parameters for the protective relay

functions, the setpoints, measured

value settings, and the measured

values via the CubicleBUS, so that

they can be processed further. Using

the two CubicleBUS connections,

the metering function module is

connected to the trip unit and either

the BSS or directly to X7.

The metering function can be

implemented in all circuit breakers

with ETU745, ETU755, ETU748 and

ETU776. If the Metering Function

PLUS module is ordered with the

assembled circuit breaker, it will

already be installed and ready for

operation. The metering function

can be retrofitted at any time if the

circuit breaker is equipped with one

of the trip units listed above. It is

simply screwed onto the trip unit and

the CubicleBUS lines are snapped in.

Note: If installed by the customer,

the metering function is not

calibrated with the trip unit;

therefore, the accuracy of the

specifications in Table 2-7 cannot

be guaranteed.

2/13

Figure

2-4

The Metering Function Plus is located on the back of the trip unit. When ordered as

part of an assembled breaker catalog number, it is already installed and ready for

operation.

WL MODBUS Communication and Electronic Accessories • January 2005

Page 25

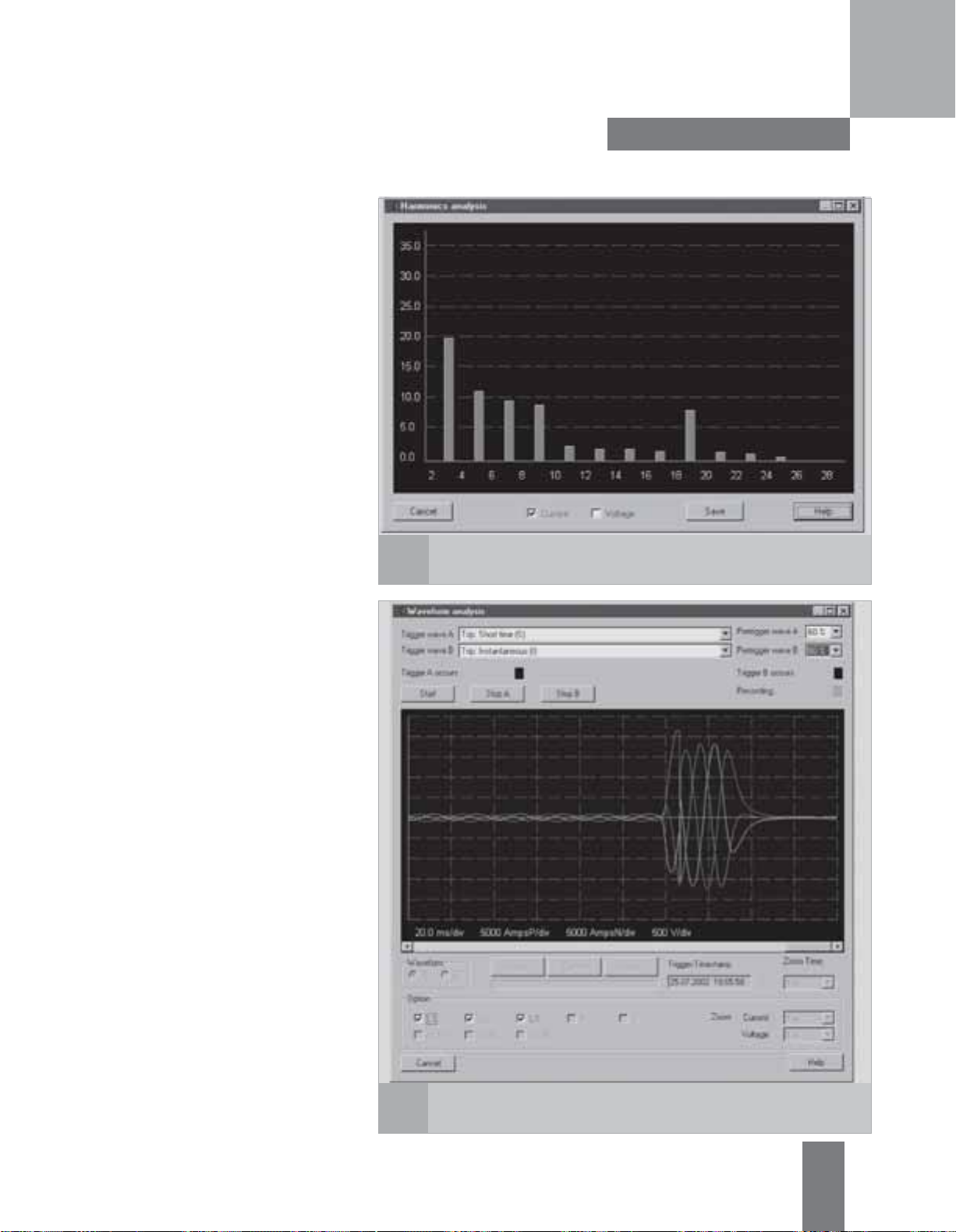

Metering Function Plus

The Metering Function Plus module

extends the range of metering

functions to include harmonic and

waveform analysis.

Harmonic analysis

The Metering Function Plus module

senses the current and voltage, saves

the measured values, and carries out a

fast Fourier transformation. The result is

the distribution of the harmonics (in %)

up to the 29th harmonic. The

calculated values are made available via

the CubicleBUS and can be displayed in

WinPM.Net and the BDA (see Chapters 3

and 4). They can also be saved as an

Excel-compatible *.csv file for

subsequent diagnosis. On the ETU776

trip unit, the measured and calculated

values can also be displayed.

The harmonic analysis enables not

only the quality of the network to be

analyzed and logged but also provides

settable alarm levels.

Waveform buffer

The Metering Function Plus module

features two independent waveform

buffers (A and B). Each one has 8

channels, one each for currents I

, IN, and Ig, and voltages Va, Vb, and

I

c

. Each channel is sensed with a

V

c

a

, Ib,

frequency of 1,649 kHz and the values

are "pushed" through a shift register

(length: 1 second). The process of

pushing data through the shift register

can be aborted by a configurable

trigger event. Trigger events include

trips, warnings and setpoint alarms

so that the voltage waveform, for

example, can be recorded in the

event of undervoltage tripping.

Figure

2-5

Communication-capable Circuit Breakers

WL Circuit Breaker

The Metering Function Plus analyzes the harmonics. This screenshot from the WinPM.Net

system shows how the analysis results are displayed.

Figure

WL MODBUS Communication and Electronic Accessories • January 2005

Metering Function PLUS can record the current waveform. This can be displayed and

exported using WinPM.Net. A value of trip current is shown here.

2-6

2/14

Page 26

Communication-capable Circuit Breakers

WL Circuit Breaker

The trigger event can be set

individually for each waveform

buffer. The point at which the trigger

event is to take place in the

waveform buffer can also be defined.

This setting can be used to set the

ratio of the pre-event history to the

post-event history. If the pre-trigger

event history is to be analyzed, the

position can be set to 80%. When the

event occurs, 0.8 seconds of preevent history and 0.2 seconds of

post-event history are available in the

waveform buffer, and an existing

COM16 module adds a time stamp to

the trigger event.

Each waveform buffer stops

independently, depending on the

trigger event and can be activated

again once the analysis is complete.

A large amount of data (approx. 25

kByte for each waveform) can be

downloaded and analyzed using

WinPM.Net, the BDA and the ETU776

display. Depending on the option,

a range of zoom options and export

functions are available.

600:120 = 5:1

(ITI Part # 460-600 or 468-600)

VT Accuracy

Each Metering Module presents a

purely resistive (unity power factor)

load to the transformer. Assuming no

other devices connected to the VT, a

ITI type 486 VT can safely feed 10

metering modules and and still

maintain 0.6% accuracy assuming the

wiring from the VT to the individual

metering modules is twisted pair and

kept to a minimum length.

This data applies to ambient

temperatures from 30ºC to 50ºC and

a primary voltage from 80% to 120%

.

V

n

Maximum distance from voltage

transformer

The maximum distance between the

metering function and the voltage

transformer depends on the cable

size and the desired accuracy class.

For a 14AWG cable, the maximum

distance should not exceed 50 m for

class 0.5 and 100 m for class 3. In

areas with high EMC exposure,

shielded cable should be used.

Parameters for the settings of the

metering function

The trip unit settings which must be

made are:

1)VT Primary Voltage (240V, 480V,

600V)

2)VT Secondary Voltage (100V,

110V, 120V)

3) VT Connection (Wye / LG, Delta / LL)

The following tools and functions are

available if the parameters have to be

changed:

• WinPM.Net

• WL Config

• BDA/BDA Plus

• ETU776 display

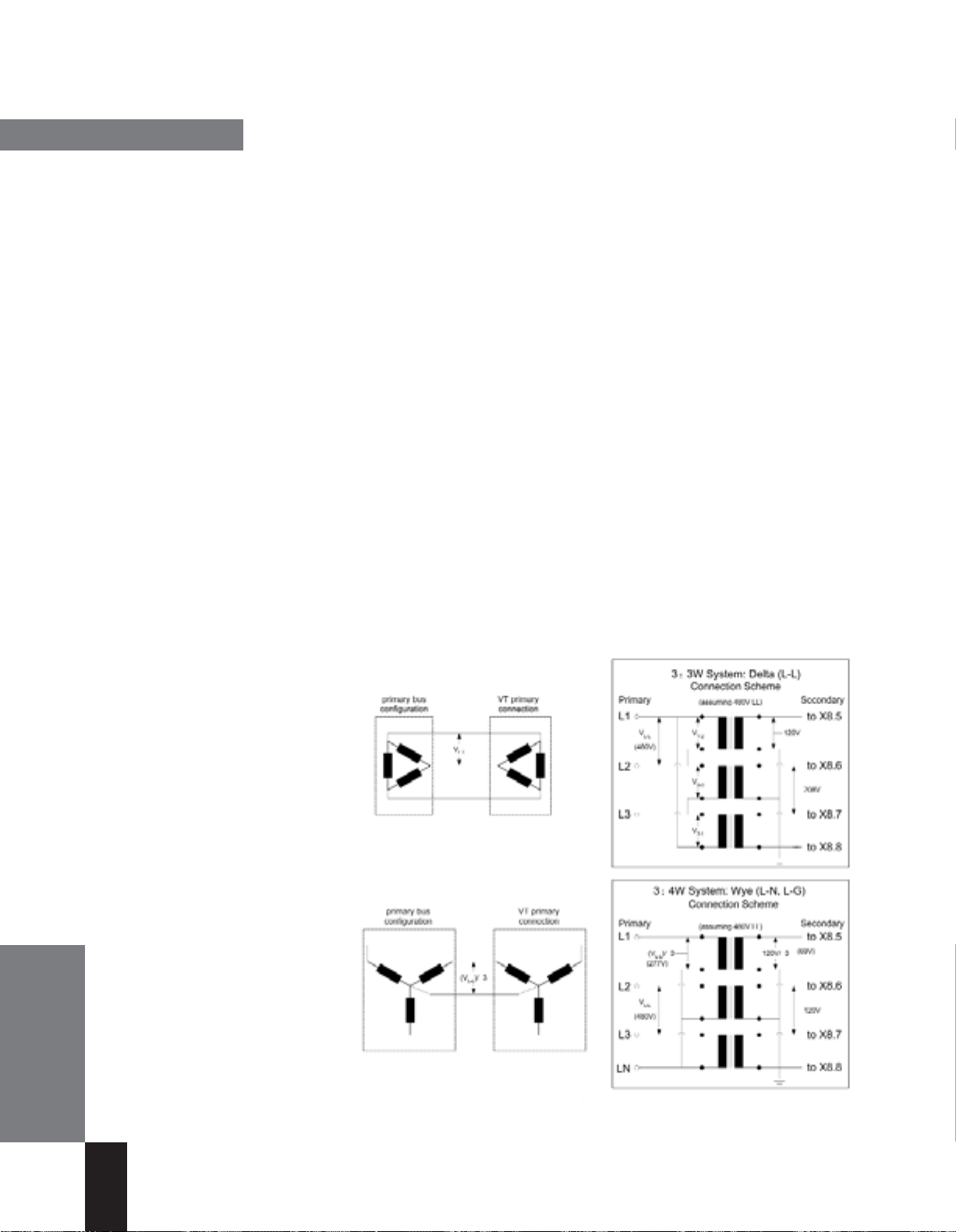

Voltage Transformers

For isolation reasons, a voltage

transformer is used in conjunction

with the Metering Function Plus

module. This prevents voltage signals

of up to 1kV from reaching the ETU

directly via the auxiliary secondary

connections.

The metering module (“Metering

Function Plus”) can be set to expect

3W or 4W (LL/LG) connections and

will adjust the amplitude and phase

of the signal as necessary.

Three VTs must be used at all times.

All three VTs should be rated for the

nominal system L-L voltage (e.g.

480V) and may have either 100V,

110V or 120V secondary voltages.

The following ratios and suggested

and equivalent VTs can be used:

240:120 = 2:1

(ITI Part # 460-240 or 468-240)

480:120 = 4:1

(ITI Part # 460-480 or 468-480)

Metering VT Settings:

Delta/Wye : Delta

VT Primary: 480 (for example)

VT Secondary: 120 (for example)

Metering VT Settings:

Delta/Wye : Delta

VT Primary: 480 (for example)

VT Secondary: 120 (for example)

Note: Required primary and secondary

overcurrent protection (fusing) not shown

for clarity.

2/15

WL MODBUS Communication and Electronic Accessories • January 2005

Page 27

Communication-capable Circuit Breakers

The metering function provides the following measured values for communication system:

WL Circuit Breaker

Measured value Value range Accuracy (with direct order: circuit breaker +

1

Currents Ia, Ib, Ic, I

Ground-fault current I

Line-to-line voltages V

Line-to-neutral voltages V

N

(measure with external G transformer) 100 ... 1200A ± 5%

g

, Vbc, V

ab

, Vbn, V

an

ca

cn

Average value of phase-to-phase voltages V

LLAVG

trip unit + met. function or met. function Plus)

30 ... 8000A ± 1%

80 ... 120% V

80 ... 120% V

80 ... 120% V

n

n

n

± 1%

± 1%

± 1%

Apparent power kVA per phase 13 ... 8000kVA ± 2%

Total apparent power KVA 13 ... 24000kVA ± 2%

Active power kW per phase -8000 ... 8000kW ± 3% (power factor > 0.6)

Total active power kW

total

-24000 ... 24000kVA ± 3% (power factor > 0.6)

Reactive power kvar -6400 ... 6400kvar ± 4% (power factor > 0.6)

Total reactive power kvar -20000 ... 20000kvar ± 4% (power factor > 0.6)

Power factor per phase -0.6 ... 1 ... 0.6 ± 0.04

Power factor total -0.6 ... 1 ... 0.6 ± 0.04

Demand of currents I

, Ib, I

a

c

30 ... 8000A ± 1%

Average demand of 3-phase current 30 ... 8000A ± 1%

Demand kWD per phase 13 ... 8000kW ± 3% (power factor > 0.6)

kW demand 3-phase active power kWD total 13 ... 8000kW ± 3% (power factor > 0.6)

kVA demand kVA total 13 ... 8000kVA ± 2%

kVAR demand kVAR per phase 13 ... 8000kVA ± 2%

kVAR demand total -24000 ... 24000kvar ± 4% (power factor > 0.6)

kWhr imported 1 ... 10000MWh ± 2%

kWhr exported 1 ... 10000MWh ± 2%

kVARh imported 1 ... 10000Mvarh ± 4%

kVARh exported 1 ... 10000Mvarh ± 4%

Frequency 15 ... 440 Hz ± 0.1 Hz

Total harmonic distortions for current and voltage 2 ... 100% ± 3% from the meas. range up to the 29th harmonic

Phase unbalance for current and voltage 2 ... 150% ± 1%

Table 2-7 The metering function provides a minimum and maximum measured value for each measured value specified above. If the metering

function is retrofitted by the customer, the accuracy of the values specified cannot be ensured, since it will not have been calibrated with the trip unit.

1. Accuracy is specified as follows: ± (x%) from the upper limit of effective range + 2 LSD (Least Significant Digit))

as shipped from the factory

Measurement conditions:

Frequency f = 60 Hz

Power factor cos = 1

Waveform Total harmonic distortion≤ 5%; symmetrical load

Power supply UL Listed 24V DC class 2

Warm-up period 2 hours

Relative air humidity Up to 90%

Ambient temperature 35°C ± 5°C

Metering range:

Current 0.2 ... 1.2 I

Voltage 0.8 ... 1.2 V

WL MODBUS Communication and Electronic Accessories • January 2005

nmax

nmax

2/16

Page 28

Communication-capable Circuit Breakers

WL Circuit Breaker

The extended protective relay functions of the metering function can monitor the following criteria and initiate a trip

if values are exceeded.

Protective Relay Function ANSI Device Number Setting range Possible delay

Current unbalance 46 5 ... 50% 0 ...15 s

Total harmonic distortion - current 81THDC 5 ... 50% 5 ...15 s

Voltage unbalance 47 5 ... 50% 0 ...15 s

Undervoltage 27 100 ... 1100V 0 ...15 s

Overvoltage 59 200 ... 1200V 0 ...15 s

Total harmonic distortion - voltage 81THDV 5 ... 50% 5 ...15 s

Direction of phase rotation 47N - -

Active power in normal direction 32 13 ... 4000kW 0 ...15 s

Active power in reverse direction 32R 13 ... 4000kW 0 ...15 s

Under frequency 81U 40 ... 70 Hz 0 ...15 s

Over frequency 81O 40 ... 70 Hz 0 ...15 s

Table 2-8 Additional trip criteria can be set using the extended protective relay functions. A delay time can be set to prevent transient events from

causing nuisance trips: the circuit breaker will not trip unless the condition is present for longer than the delay time.

The metering function supplies the following Alarm Setpoint Functions:

Alarm Function Setting range Possible delay

Over current 30 ... 10000A 0 ... 255 s

Over current - ground fault 30 ... 10000A 0 ... 255 s

Over current - N-conductor 30 ... 10000A 0 ... 255 s

Phase unbalance - current 5 ... 50% 0 ... 255 s

Demand - current 30 ... 10000A 0 ... 255 s

Total harmonic distortion - current 5 ... 50% 5 ... 255 s

Undervoltage 15 ... 1200V 0 ... 255 s

Overvoltage 200 ... 1200V 0 ... 255 s

Phase unbalance - voltage 5 ... 50% 0 ... 255 s

Total harmonic distortion - voltage 5 ... 50% 5 ... 255 s

Crest factor 1 ... 3,000 0 ... 255 s

Form factor 1 ... 3,000 0 ... 255 s

Active power in normal direction 13 ... 10000kW 0 ... 255 s

Active power in reverse direction 13 ... 10000kW 0 ... 255 s

Leading power factor 0 ... -0.99 0 ... 255 s

Lagging power factor 0 ... 0.99 0 ... 255 s

Demand - active power -10000 ... 10000kW 0 ... 255 s

Apparent power 13 ... 10000kVA 0 ... 255 s

Reactive power in normal direction 13 ... 10000kvar 0 ... 255 s

Reactive power in reverse direction 13 ... 10000kvar 0 ... 255 s

Demand - apparent power 13 ... 10000kVA 0 ... 255 s

Demand - reactive power 13 ... 10000kvar 0 ... 255 s

Underfrequency 40 ... 70 Hz 0 ... 255 s

Overfrequency 40 ... 70 Hz 0 ... 255 s

Table 2-9 Alarm and setpoint functions allow events to be generated when system conditions deviate from their nominal values. The generation of the

events can be delayed to prevent transient conditions from “chattering”. These alarms are communicated via

to close in the configurable output module and can freeze the waveform buffer in the metering function. Alarms are communicated to the COM16/15

where they can be transmitted to the master.

CubicleBUS and can cause output contacts

2/17

WL MODBUS Communication and Electronic Accessories • January 2005

Page 29

Communication-capable Circuit Breakers

Important functions/parameters for communications

Thanks to their modular

construction and numerous I/O

modules, WL Circuit Breakers

offer flexible system solutions.

These solutions include load

management, alarms and

additional tripping conditions

via the extended protective

functions. Although the

utilization of these functions is

also possible without the use of

communications, their benefits

can be fully utilized when used

in communication applications.

Load Management

A circuit breaker with ETU745 or

higher, offers two current setpoint

values for local load management,

the upper setpoint being that of

load shedding, the lower setpoint

being that of load restore.

Note: These setpoints will not effect

the circuit breaker tripping function.

If the current exceeds the set load

shedding value in one phase, a

load shedding warning will be

generated. A load restore will only

be generated when this value drops

below the setpoint in all three

phases. The warning messages are

directly displayed by the BDA.

However, they are also stored in the

event log where they are labeled

with a time stamp.

Note: The event log is only available

with the COM16.

WL Circuit Breaker

The respective process for the load

restore threshold is reversed if all

three phases fall short of the

setpoint, and a load shed warning

will be generated. If only one of the

three currents exceeds the setpoint,

a load restore event will not be

generated.

In order to avoid load shedding on

the basis of short-time current

peaks and valleys, they can be

delayed by a delay time t

can be set to between 1 s and 15 s.

The load management parameters

can be found in the parameter tree

of the BDA.

The load shedding/load restore

signals are available as outputs of

the digital output module, which

are provided with a rotary selection

switch.

Extended Protective Function

The extended protective function

of the metering modules adds

additional tripping functions. The

options listed in table 2-8 can be

used as additional monitoring

functions.

which

x

Figure

Load shedding and restore are explained in this graphic. It’s based on the assumption

of a WL Circuit Breaker with an overload setpoint of 1000 A.

2-8

WL MODBUS Communication and Electronic Accessories • January 2005

2/18

Page 30

Communication-capable Circuit Breakers

WL Circuit Breaker

Setpoints

In addition to the load management

option (load shedding/load restore),

the metering modules offer an

option for an automatic monitoring

of operating data and the

generation of an alarm.

Two setpoints can be defined (e.g.

for overvoltage). With the lower

setpoint, an alarm can be generated

via the setpoint value (e.g. > 410V),

whereas, with a voltage increase, a

tripping event (e.g. > 430V) can be

generated.

Minimum for Communicated

Currents

In order to avoid the detection,

display and communication of very

low currents generated by system

noise, even with the circuit breaker

in the disconnect position, the

"Minimum for Communicated

Currents" parameter offers the

option of setting all detected

current values smaller than this

parameter to zero. The factory

setting is 50A. This means that all

values smaller than 50A are

displayed as "0" on the display,

interpreted as "0" for internal

calculations (power) and also

transmitted as "0" via the

communications. If this parameter

is changed to "0", this function is

deactivated and all detected current

measuring values will be directly

used.

The parameter can be found in the

parameter tree of the BDA.

Normal Positive Power Flow

Direction

The current direction of the energy

"flow" and the question, "How much

energy has, up to now, flowed in

both directions?" is of particular

interest for tie breaker applications.

For a determination, it is important

to define a "normal direction". This

direction can either be "from top to

bottom" or "from bottom to top".

The measured real power is either

assigned to a positive polarity (in

normal direction) or a negative

polarity (opposite normal direction).

In contrast, the measured currents

are always assigned a positive

polarity.

With energy, the transmitted energy

values are incorporated in two

counters, real energy and real

energy opposite to normal

direction. The two energy counters

are not assigned a polarity.

Event and Trip Log

All events (except for tripping

events) are labeled with a time

stamp and an ON (+) or OFF (-)

indication and entered in the

event log.

The event log has a depth of 10

events and works like a FiFo

memory (first in, first out), i.e. the

oldest event is deleted from the

event log upon the occurrence of

a new event.

Figure

In the event log the last 10 events on the CubicleBUS are listed. The trip log

2-9

contains the last 5 trips. Both of them can be displayed with the BDA.

The trip log is similar to the event

log, however, only the last 5 trips

are recorded with a time stamp

and entered in the trip log.

Note: The event and the trip log are

only available with the COM16

module.

2/19

WL MODBUS Communication and Electronic Accessories • January 2005

Page 31

External CubicleBUS Modules

By connecting additional,

external modules to the

CubicleBUS, breaker status

information can be displayed

and data read from the

switchgear to the system. This

enables cost-effective solutions

to be implemented

for automating other devices in

the switchgear.

General

External CubicleBUS modules enable

the WL Circuit Breaker to

communicate with secondary

devices in the switchgear. They can

be used, for example, to activate

analog displays, transmit circuit

breaker status and cause of trip, and

read additional control signals. One

module is also available for zoneselective interlocking.

Five different CubicleBUS modules

can output data from the CubicleBUS

system (four digital output modules

and one analog output module). A

digital input module can transmit

data from the switchgear to the

MODBUS master, and a ZSI module

enables zone selective interlocking

among the circuit breakers.

Communication-capable Circuit Breakers

Rotary Switches

With the exception of the

configurable output module, all

external CubicleBUS modules are

configured using rotary switches.

The arrow on the rotary switch

points to the function that is

currently active. With certain