Page 1

TH 188 Unit Mounted Thermostats

Product Description

The TH 188 Unit Mounted Thermostat is a remote

bulb, gradual acting pneumatic instrument that

maintains a preselected room temperature by

positioning pneumatic devices that control heating or

cooling medium. This thermostat has a liquid filled

thermal system.

Product Numbers

Installation Instructions

Document No. 129-129

Rev. 3, August, 2000

TH 188R Reverse Acting (RA)

20 scim (5.5 ml/s) restrictor

TH 188HC Heating (direct)/Cooling

(reverse) 40 scim (11 ml/s) restricto r

TH 188D Direct Acting (DA)

40 scim (11 ml/s) restrictor

Replacement for Honeywell models

LP916BXXXX

Heating (direct)/Cooling (reverse)

40 scim (11 ml/s) restrictor

Replacement for Johnson Controls

T-3300-2

Heating (direct)/Cooling (reverse)

40 scim (11 ml/s) restrictor

Required Tools

•

Medium flat-blade screwdriver

•

Small drill

Expected Installation Time

90 minutes (1 hour and 30 minutes)

188-0024

188-0030

188-0031

188-0033

188-0034

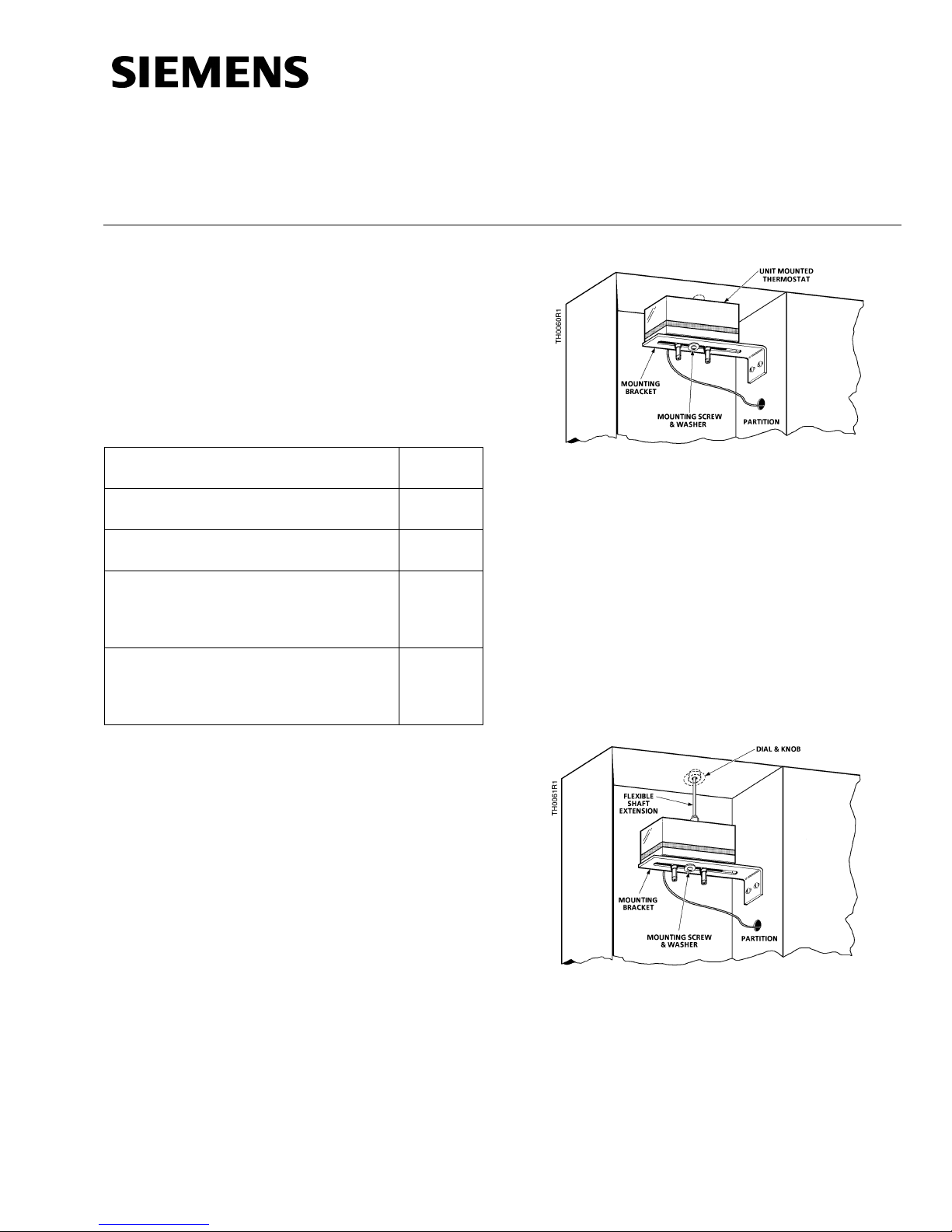

Figure 1. Thermostat and Mounting Bracket.

NOTE:

If there is not enough room to mount the

thermostat in a convenient location, or if

the set point dial must be in the same

compartment as the fan switch, order an

extension shaft kit (Part Number 188-101).

Figure 2

See

Using the extension shaft, mount the

thermostat in any convenient location

within eight inches of the control

compartment.

.

Installation

A mounting bracket is included for mounting the

thermostat in various units.

1. Fasten the mounting bracket to the partition

with two sheet metal screws included with the

thermostat.

installation.

Figure 1

shows a typical

Figure 2. Use of Shaft Extension.

2. Mount the remote sensing bulb in the air stream

of the return air (near the inlet of the fan).

Avoid metal to metal contact between the bulb

and the unit to prevent damage to the soft

copper sensing bulb from unit vibration.

Page 1 of 3

Page 2

Document No. 129-129

Installation Instructions

Rev. 3, August, 2000

Installation, Continued

3. Fasten the capillary and/or bulb in the return air

stream using the adhesive backed cable clip

included in the kit.

4. Make air connections to the "S" (supply) Port

and "R" (return) Port. Thermostats have a

barbed fitting for 1/4-inch (6.4 mm) O.D. poly

tubing.

Calibration

The thermostats are factory calibrated at 72°F

(22°C) and 7-1/2 psi (52 kPa) control pressure.

General

1. Determine the temperature at the remote bulb.

2. Set knob pointer to the temperature found. Dial

increments are approximately 5 degrees on the

major divisions with 1 degree subdivisions,

beginning at 60°F clockwise to 85°F.

3. Loosen (do not remove) return line test port

screw. Slip rubber line over test port and

connect to a test gauge (

Figure 3

).

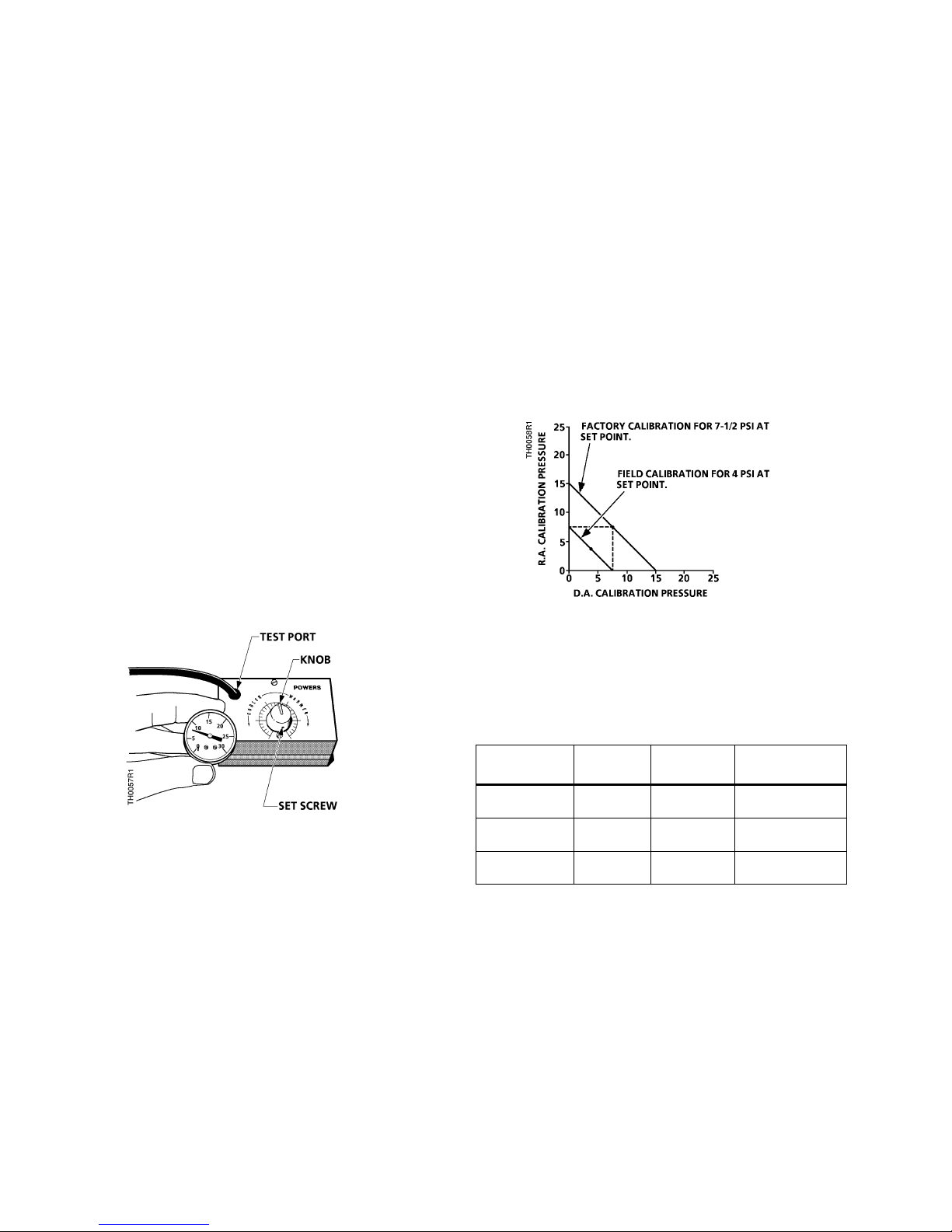

Dual action

On the HC thermostat, calibration should be at

7-1/2 psi (52 kPa) for both DA and RA. The unit has

one thermal system with a reversing relay to give the

action desired. If calibrated at 7-1/2 psi (52 kPa) for

winter, the summer calibration will be 7-1/2 psi

(52 kPa). If 9 psi (62 kPa) is used for winter, 6 psi

(41 kPa) will be summer's calibrated pressure.

Figure 4

calibration points. If the same pressure is desired for

both seasons, the RA section of the thermostat

needs to be recalibrated (follow the RA calibration

procedures).

shows the relationship of the DA and RA

Figure 4. Dual Action Calibration Points.

Figure 3. Test Port and Gauge Used for Calibration.

4. With the knob pointer set at the temperature of

the remote bulb, the output (return line) pressure

should be 7 to 8 psi (48 & 55 kPa) for all models.

If the output pressure is not 7 to 8 psi (48 to

55 kPa), remove knob after loosening its set

screw. Then, rotate the set point adjustment

post until output pressure is 7 to 8 psi.

5. Replace knob and set pointer to temperature of

the bulb, lock, and then turn to desired setting.

The thermostat is now in calibration.

Single action

The direct acting or reverse acting thermostat may

be calibrated at any pressure. It is suggested that

7-1/2 psi (52 kPa) be used.

Reverse acting stage

Table 1

See

pressure.

Table 1. Air Supply Pressure and Changeover.

Type and

Model No.

Powers HC

(TH188HC)

Honeywell

HC (LP916B)

Johnson HC

(T-3300-2)

The reverse acting stage is factory adjusted and

does not require field adjustment. If the adjustment

is disturbed, re-adjust as follows:

1. With the main air supply set for 25 psi

(172 kPa), connect a Pressure Reducing Valve

(PRV) with gauge to the supply side of

thermostat and set at 25 psi (172 kPa).

2. Remove knob and cover from thermostat, as

shown in

3. Open bleed screw on test port and connect

gauge (

for air pressure and changeover

Heating

(Da)

25 psi

(172 kPa)

18 psi

(124 kPa)

20 psi

(138 kPa)

Figure 3

Figure 5

).

.

Cooling

(Ra)

18 psi

(124 kPa)

13 psi

(124 kPa)

15 psi

(103 kPa)

Changeover

(145 kPa)

(103 kPa)

(117 kPa)

21 psi

15 psi

17psi

Page 2 of 3

Siemens Building Technologies, Inc.

Page 3

Document No. 129-129

Installation Instructions

Rev. 3, August, 2000

Installation, Continued

Heat–cool thermostat changeover

Table 1

See

for air pressure and changeover

pressure.

The changeover is a factory adjustment; it is sealed

with ambroid and does not require field adjustment.

If, for some reason, this adjustment is disturbed, readjust as follows (See

Figure 5

):

1. Supply the thermostat with an air supply

pressure equal to the appropriate changeover

pressure (

Figure 5. Heating/Cooling Changeover.

4. Rotate adjustment post to give an output within

1/2 psi (3.4 kPa) of calibration pressure.

5. Adjust PRV for 18 psi (124 kPa) air supply;

observe the control pressure. If not within

1/2 psi (3.4 kPa) of calibration pressure, adjust

the reverse acting adjustment until it is. Apply

ambroid to the screw setting.

6. Remove test port gauge; close bleed screw.

7. Replace cover and knob.

8. Lock knob in place with pointer at bulb

temperature.

9. Set knob at desired temperature setting.

Table 2. Troubleshooting.

Complaint Check Possible Cause Corrective Action

Supply Air No Air As Required

Return line

pressure

0 psi

(0 kPa)

Return line

pressure

18 psi

(124 kPa) or

greater

Excessive cycling Lever assembly Sticking or binding of levers As required

Table 1

* See

*Heating

25 psi

(172 kPa)

*Cooling

18 psi

(124 kPa)

Supply Air Pressure Too High As Required

*Heating

25 psi

(172 kPa)

*Cooling

18 psi

(124 kPa)

for Honeywell and Johnson Controls pressures.

Calibration Out of calibration Recalibrate

Restrictor Clogged or dirty Clean or replace

Sensing element Loss of charge Replace sensing element

Direct acting stage Internal binding or leaking Replace thermostat

Calibration Out of calibration Recalibrate

Throttling pin Dirt built up around pin Clean or replace nozzle assembly

Reverse acting stage Internal binding or leaking Replace thermostat

Calibration Out of calibration Recalibrate

Throttling Pin Dirt built up around pin Clean or replace nozzle assembly

Direct acting stage Internal binding Repla ce therm osta t

Calibration Out of calibration Recalibrate

Restrictor Clogged or dirty Clean or replace

Sensing element Loss of charge Replace sensing element

Reverse acting stage Improperly adjusted Re-adjust

Reverse acting stage Internal leaks or binding Replace thermostat

2. With the exhaust adjustment (center screw)

backed out several turns, turn the switch spring

adjustment (outer screw) down snug, and then

back off until air can be heard bleeding out.

3. Turn the exhaust adjustment down snug and

back off approximately 1/8 turn.

4. Seal both screws with ambroid to prevent

further movement.

The installation is now complete.

Reference

Technical Inst ructions

TH 188-2

155-064P25

Table 1

).

Information in this publication is based on current specifications. The company reserves the right to make changes in specifica tions and

models as design improvements are introduced. © 2000 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

Landis & Staefa Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@sbt.siemens.com

Document No. 129-129

Printed in the U.S.A.

Page 3 of 3

Loading...

Loading...