Siemens SMG 71 Installation Instructions Manual

s

SMG 71

SLG 71 UK

20 800 650.0-010

Installation instructions

1

p

2

3

o

4

+5

i

-6

B4+

B3

u

B2

B1-

-7

y

+8

t

r

e

w

q

}

{

P

O

I

Fig. 1

8AA11448 - E0 - 11/03/2002 - UK - SNR 811448.0-001

Fig. 2

+9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

A B

S6

2

4

-

3

2

-

1

B4+

1

B3

ST1

B2

S2

S1

S5

B1-

1. Product Description

The Card reader Gateway SMG 71 replaces one standard

Q

S4

S3

W

E

R

transponder (SMT 12) and Mirrors a Keypad with the same

address. 2 cardreaders may be connected for door opening/

closing and setting/unsetting.

2. Supply package

The SMG 71 package contains the following:

- One circuit board SMG 71

- 6 mounting studs

T

Y

- 8 terminating resistors (4.7 kOhm)

- One SLG 71 language kit

3. Mounting Instructions

The SMG 71 is designed for mounting inside a remote power

supply or other suitable box, within a dry room.

It must not be exposed to either dripping or splashing water.

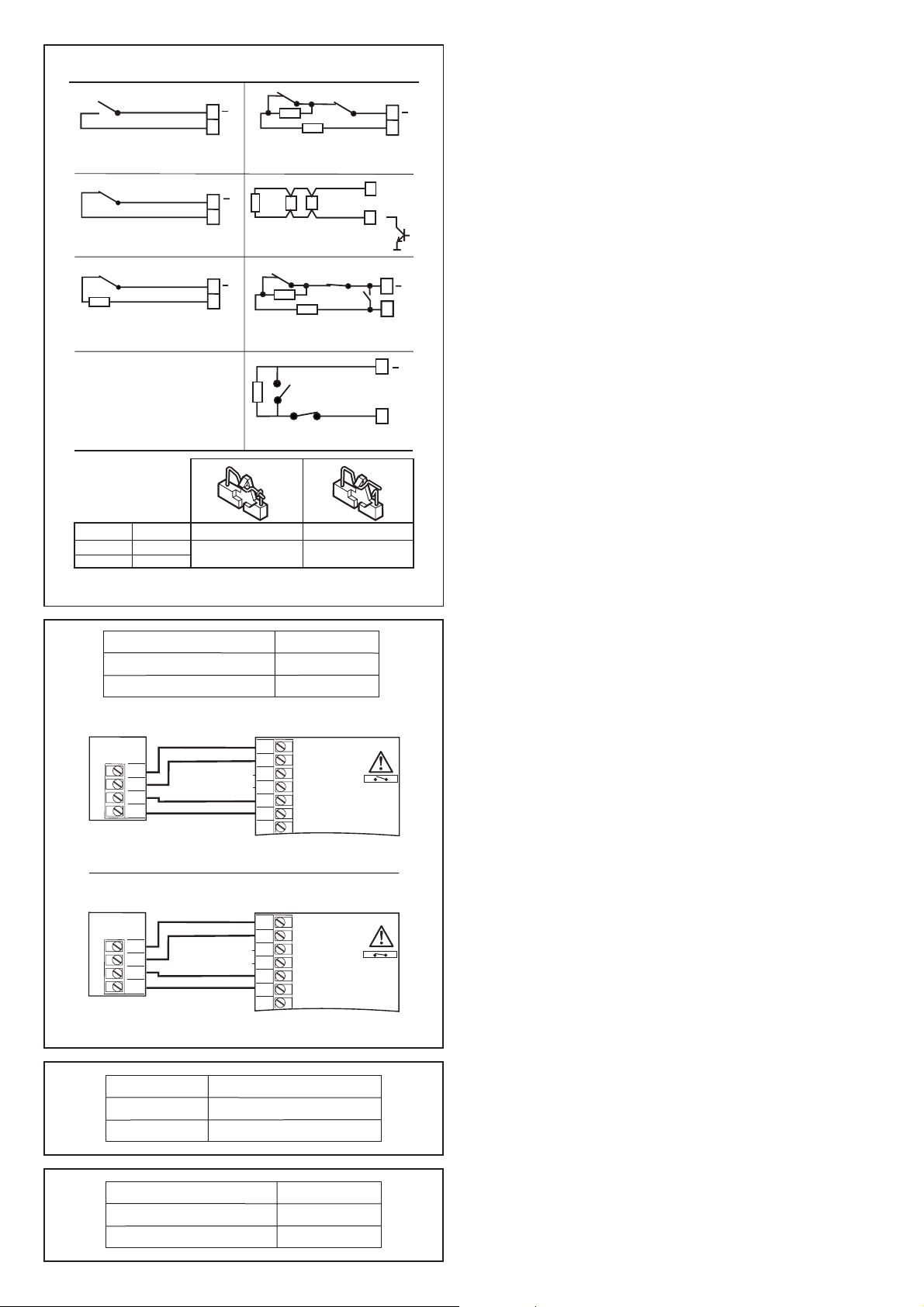

3.1 Product overview (fi g. 1)

- Q Switch for the «auto shunt» function

U

- W Switch for the type of reader

- E Addressing button

- R Thermofuse 12 V; 650 mA

- T Plug connector for external tamper contact

- Y Tamper contact

- U Switch for programming glass breaks alarm inputs

- I Stand alone Input

Embedded Transponder:

- O 4 programmable inputs (1 to 4)

- P Open collector output 2

- { Relay output 1

Open collector outputs with dedicated functions:

- } Auto shunt function running

- q Cannot set

- w Set/Unset

- e Buzzer

Ward status

information of

}

mirrored keypad

- r Alarm in memory

- t Error information

(site code not programmed/parity error/E-Bus failure)

- y 12 V power supply for outputs

- u E-Bus connection

- i 12 V power supply for card reader

- o Connection to card reader 2

- p Connection to card reader 1

Fig. 3

3.2 Fit circuit boards (fi g. 2)

1 - Engage the mounting studs (provided with the circuit

A

B

boards) in the holes provided (A).

2 - Fit circuit boards .

4. Wiring

4.1 E-Bus (fi g. 3)

The E-Bus (A) must be connected to the central control unit (B1-,

B2, B3, B4+). It may be routed in parallel to other accessories

(B). For additional information see the Control panel installation

manual.

1. Normally open contact

2. Normally closed contact

4k7

3. Normally closed contact

monitored

Z1

Z2

Switches SW 1 and SW 2 must be open.

To connect a maximum

SW 1

of 20 glass break sensor

SW 2

Fig. 4

Type of card reader

Wiegand (26 bits)

ABA track 2 (Data + clock)

Wiegand

Reader 1

D0

D1

+12V

0V

ABA ANSI Track 2

Reader 1

CLK

DATA

+12V

0V

Reader 2

Fig. 5

Card reader 1

On line

Stand alone

Fig. 6

Input modes

Alarm

Z

Z

Z

ClosedInput

Reader 2

CLK

DATA

Stand alone input ( fig. 1)I

Open

Closed (-)

4k7

4. Alarm & tamper monitored

4k7

5. Glass break sensor

Alarm

4k7

6. Emergency exit

Alarm

4k7

7. Fire input

Switch S3

Open

Closed

1

2

3

D0

D1

4

+5

-6

B4+

D0 and D1 can be either

open collectors, 5V or 12 V signals

1

2

3

4

+5

-6

B4+

CLK and Data can be either

open collectors, 5 V or 12 V signals

4k7

Tamper

Reset

4k7

Trouble

OpenSwitch

All other modes

Tamper

SMG 71

SMG 71

Z

O

S3 open

S3 close

4.2 Tamper contact

The Tamper connector (fi g. 1; T) must be connected to an

external tamper contact or be short-circuited.

Z

4.3 Inputs (fi g. 4)

All inputs can be operated in modes 1 to 4 and 6 to 7 (fi g. 4).

Inputs 1 to 2 can also be operated with glass break alarms.

To do this, the relevant switches S1 to S2 must be closed

and one terminal of each glass break detectors connected

to one of outputs 1 or 2, which must be programmed for

«Latching sensor reset». When wiring fi re detectors, any

trouble output present can be looped directly into the line.

For fi re detectors where the power has to be disconnected

to reset the alarm, the negative can be connected via

an output which is programmed as a «Latching sensor

Z

reset» output.

The emergency exit has to be wired like mode 6. A short

circuit of the input will reset the corresponding signalling

output.

4.4 Card reader (fi g. 5)

Z

Two type of card readers (ABA Track 2 / Wiegand ) can be

selected by the switch S3 .

5. Addressing

Since the replaced transponder takes the same address as

the card reader gateway only free transponder addresses

are accepted as gateway addresses.

6. Card reader Test menu

A special menu is available in the Engineer menu to test

the card reader.

The Site code and user number are displayed on the

keypad.

7. Special function

7.1 Stand alone mode (fi g. 6)

In the stand alone mode, a valid card(site code) read by

reader 1 (fi g. 1; p), Will activate the relay output 1(fi g. 1;

{) directly for 5 seconds.

In this mode there is no interaction with the control panel,

the site code is Checked locally in the Gateway.

7.2 Auto-Shunt mode (fi g. 7)

In the auto-shunt mode, an activation of the output 1(fi g. 1; {)

bypasses the Input 1(fi g.1; O) until it is in a quite state again.

The bypass time is max. 40 s after which the Input 1 will

be restored.

If Input 1 is not in a quite state after 30 s the buzzer output

(fi g.1; e) will be activated.

The open collector output «Auto-Shunt function» (fi g.1; })

is activated as long as Input 1 is bypassed.

8. Technical data

Supply 12 VDC from the E-Bus

Power consumption min. 11 mA

Power consumption max. 35 mA

7 open collector outputs 12 V, 150 mA

1 relay output 12 V, 1 A

4 inputs Programmable

8 terminating resistors 4.7 kOhm

Operating temperature -10° C to +55° C

Dimensions in mm, SMG 71 H 54,5 x W 156 x D 20

Weight, SMG 71 65 g

Fig. 7

Auto-Shunt

Off

On

Switch S4

Open

Closed

The right to make technical changes to the described equipment without prior notice

is reserved.

Loading...

Loading...