Siemens SLX-ASC-PFCU,SLX-ASC-PFCU-A,SLX Series,SLX-P-PTU-A,SLX-P-PTU Installation Instructions Manual

Installation Instructions

SLX Series

Document No. 997-1002

February 12, 2009

Power Fan Coil Unit Controllers

(SLX-ASC-PFCU and SLX-ASC-PFCU-A)

Power Terminal Unit Controllers

(SLX-P-PTU and SLX-P-PTU-A)

1. Product Description

This document describes the hardware installation procedures

for the SLX Series Power Fan Coil Unit (PFCU) controllers and

Power Terminal Unit Free Programmable (PTU) controllers.

The PFCU controllers are powered by 85-265VAC (24VAC

power generation is also available on SLX-ASC-PFCU-A

models). These controllers are designed to control fan coil unit

applications with up to three fan speeds and to meet the

requirements of both a two-pipe shared heating and cooling

coil, and four-pipe heating and cooling coil system.

The PTU controllers are powered by 85-265VAC (24VAC

power generation is also available on SLX-P-PTU-A models).

These controllers are designed to control and monitor various

HVAC equipment such as fan coils, heat pumps, and ventilator

units, as well as chillers and boilers. Moreover, they are

suitable for any lighting control and power measurement

applications.

All of the controllers are based on the L

for peer-to-peer communication between controllers and are

LONMARK® certified.

Unless otherwise indicated, the term PFCU is used

in this document to represent both the SLX-ASCPFCU and SLX-ASC-PFCU-A models. Likewise,

PTU represents both the SLX-P-PTU and SLX-PPTU-A models.

All of these controllers are built on a similar

platform, but have different numbers of outputs.

Moreover, each individual model has different

amounts of digital and/or universal outputs. For

more information on the specific layout and

functionality of each controller, please refer to their

individual technical specification sheets.

ONWORKS

®

technology

SLX Series Page 1 of 8

Figure 1: SLX-ASC-PFCU-A.

Figure 2: SLX-P-PTU.

Document No. 997-1002

Installation Instructions

February 12, 2009

2. General Installation Requirements

4. General Wiring Recommendations

For proper installation and subsequent operation of each

controller, pay special attention to the following

recommendations:

- It is recommended that the controller(s) be kept at room

temperature for at least 24 hours before installation to

allow any condensation that may have accumulated, due

to low temperature during shipping or storage, to

evaporate.

- Upon unpacking the product, inspect the contents of the

carton for shipping damages. Do not install damaged

controllers.

- Allow for proper clearance of controller enclosure, wiring

terminals and service pin for easy access, hardware

configuration and maintenance. Remember to record the

®

Neuron

and barcode format) for later commissioning.

ID located on both sides of the controller (in text

- The controller is designed to operate under the following

environmental conditions:

Ambient temperature from 32°F to 122°F (0°C to 50°C)

Relative humidity from 0% to 90%, non-condensing.

- Ensure proper ventilation for the controller and avoid

areas where corroding, deteriorating or explosive vapors,

fumes or gases may be present. The controller must be

oriented with the ventilation slots and power supply/output

terminal block connector towards the top, for safety and to

permit proper heat dissipation.

- The plastic enclosure has a back plate that is separable

from the front plate, allowing the back plate (with the

connectors) to be shipped directly to the installation site

while all the engineering is done in the office.

- If the controller is used and/or installed in a manner not

specified, the functionality and the protection provided by

the controller may be impaired.

Any type of modification to any SLX Series product

will void the product’s warranty.

Take special care to keep the front and back plate

aligned when separating and joining them.

Take reasonable precautions to prevent

electrostatic discharges to the controller when

installing, servicing or operating the controller.

Discharge accumulated static electricity by

touching your hand to a securely grounded object

before working with this controller.

- All wiring must comply with electrical wiring diagrams as

well as national and local electrical codes.

- To connect the wiring to the controller, use the terminal

connectors. It is recommended to remove the front plate

from the back plate to facilitate the wiring process;

however, it is possible to do all wiring with the front and

back plates together. Use a small flat screwdriver to

tighten the terminal connector screws after the wires are

inserted.

- Power type cables (i.e. for power, 2- and 3-wire voltage

and current inputs and outputs, as well as relay and triac

outputs) should be kept apart from other types of wiring for

safety and to avoid any ambient noise transmission to

other wires.

- The board connectors accept wires or flat cables ranging

from 22 to 14AWG (0.644 to 1.630mm diameter) per pole.

However, power cables must remain between 18 and

14AWG (1.024 to 1.630mm diameter).

- Do not connect the universal inputs, analog outputs or

common terminals to earth or chassis ground (unless

stated otherwise).

- Keep all wires away from high speed data transmission

cables (ie. Ethernet, etc.).

- Keep input and output wiring in conduits or trays, or close

to the building frame if possible.

5. Mounting Instructions

Each controller can be mounted on a DIN rail to speed up the

installation process. The controllers are also equipped with two

mounting holes of 0.25” (6.35mm) by 0.165” (4.191mm). They

can be mounted in a panel or on a wall by using appropriate

screw types (use sheet metal, thread forming or self-tapping

screws accordingly).

3. Controller Markings (Symbols)

Certain markings (symbols) can be found on the back plate of

the controller and are defined as:

HIGH VOLTAGE Symbol: Direct contact will cause

electrical shock or burn.

Warning Symbol: Significant information required.

Refer to Hardware Installation Guide.

Double Insulation Symbol: These controllers are

built with double insulation.

Page 2 of 8 SLX Series

DIN Rail-Mounted Installation

1. Make sure that the DIN rail is properly mounted on the wall.

2. Simply clip controller onto the DIN rail.

Wall-Mounted Installation

1. Open the controller by separating the front and back plate

using the side clips.

2. From within the back plate use the mounting holes to mark

the location of any holes that need to be drilled.

Due to HIGH VOLTAGE, direct contact will

cause electrical shock or burn. Turn off power

before any kind of servicing.

It is recommended to use a 2-line main power

disconnect to be located near the controller (the

minimum power requirements: 300VAC, 20A).

Minimum cable temperature rating of all cables

must be 80°C.

Do not mount the controller on a flat surface where

the front plate would be facing up. It must be

mounted on a vertical surface such as a wall.

3. Remove the back plate and drill holes.

4. Finally, clean the perforated surface and fasten the

controller using the appropriate screw types.

For safety reasons it is recommended to install the

controller inside the fan coil unit box. Refer to

national and local electrical codes.

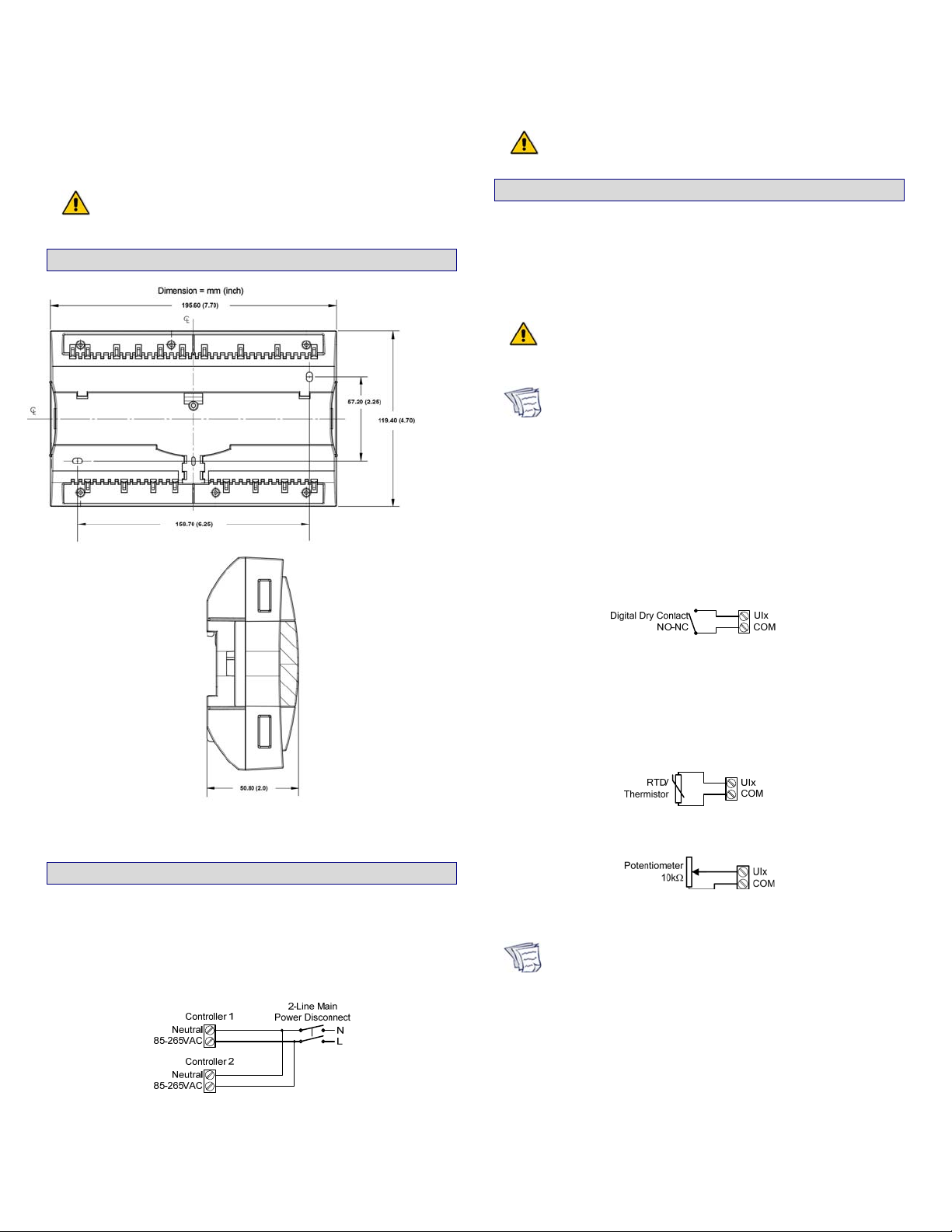

6. Controller Dimensions

Document No. 997-1002

Installation Instructions

February 12, 2009

The power wires must be at least 18AWG

(1.024mm).

8. Input Wiring

Each controller has physical connections for six (6) inputs that

are software configurable from within the controller's LNS

plug-in. Each input can be configured for digital, resistive,

current or voltage signals. Input types must be configured

properly in the software plug-in to ensure proper input

readings.

Before connecting any input equipment to the

controller, refer to the installation guide of the

equipment manufacturer.

®

For a wire length less than 75’ (23m), either a

•

shielded or unshielded 18AWG wire may be

used.

• For a wire length between 75’ and 200’ (23 to

61m), a shielded 18AWG wire is recommended.

• The wire should be shielded on the controller

side and the shield length should be kept as

short as possible.

Wiring Digital Inputs

This input configuration is used to monitor digital dry

contacts, as well as pulsed contacts (PTU controllers only).

Figure 3: PFCU and PTU Dimensions.

7. Power Wiring

Voltage: 85-265VAC; 50-60Hz

Max. Consumption: 33VA (SLX-ASC-PFCU-A and SLX-P-PTUA)

20VA (SLX-ASC-PFCU and SLX-P-PTU)

The controller is internally fuse-protected.

Figure 4: Power Wiring.

Figure 5: Digital Dry Contact (NO and NC).

Wiring Resistive Inputs

This input configuration is used to monitor 100Ω and 1000Ω

RTDs, 10kΩ type II and III thermistors, as well as 10kΩ and

100kΩ (PTU controllers only) potentiometers.

Figure 6: RTD /Thermistor Input.

Figure 7: 10kΩ Potentiometer Input.

When using a 100Ω input, the wire length should be

kept short so as to avoid a possible temperature

offset. For example, an 18AWG wire, 25’ (7.6m) in

length can create an offset of 2°F (1.1°C).

Wiring Current Inputs

Current inputs have a range of 4 to 20mA. Connect the

current input according to the following figure if a 2-wire, 420mA transducer is being used.

SLX Series Page 3 of 8

Loading...

Loading...