Siemens SlMATlC S5-010W Operating Instructions Manual

SIEMENS

Programmable Controller

S5-010W

Manual

Order No.: 6ES5 998-OCA21

Issue 1

lnstructions

Contents

Instructions

Programming Instructions

Programming lnstructions

Order No.:

GWA 4NEB 807 1021 -02

GWA4NEB 807 1071-02

SIEMENS

AKTIENGESELLSCHAFT

SIMATIC S5-O10W

Programmable

Controller

Operating

Instructions

SIEMENS

SlMATlC

S5-010W

Programmable Controller

Operating Instructions

Order

No.:

GWA

4NEB

807 1021-02

Fig. 1 S501OW programmable controller with three 110 modules

Contents

Page

Contents

Page

1.

Description

3.3 Programming

3.4 Start-up

3.5 Jumper settings on the modules

3.6 Address decoding

3.7 Assignment of address coding jumpers

1.1 Application

1.2 Construction

1.3 Principle of operation

1.4 Technical specification

2

2 and 3

4 to

8

9

and 10

4.

Maintenance

2.

Installation

4.1 Changing the lithium battery

4.2 Testing and troubleshooting

2.1 Mechanical design

2.2 Connecting the power supplies

2.3 Connecting the signal leads

2.4 Electrical design

2.5 General

2.6

Dimensions

5.

Appendix

5.1 Pin assignments

5.2 Memory interface

5.3 Timing

5.4

S5-010 machine code

3.

Operation

3.1 Controls and displays

3.2 Time setting

6.

Spare parts

1.

Description

1.1

Application

1.2

Construction

1

.l

Application

The S5-010W programmable controller belongs to the-SIMATIC S5

family of programmable controllers and has been designed for use

with small machine tools and adaptive control systems. It is suitable

for automation tasks for which contactors, relays or simple hardwired electronic systems have been used in the past. The range of

functions available permits the assembly of binary logic control

systems with memory and time functions.

Signal input Processing Signal output

24

V

DC

Fig. 2 Application of SWlOW programmable controllers

,

Mech. sensor,

,\e.g. pushbutton,

pressure switch, temperature sensor

Inductive sensor

-1

zny0itive

other

SlMATlC controls

1.2

Construction

SlMATlC S5

S5-010W

PC

I+-$

valves

3

@

Alarm

indicators

other

SlMATlC controls

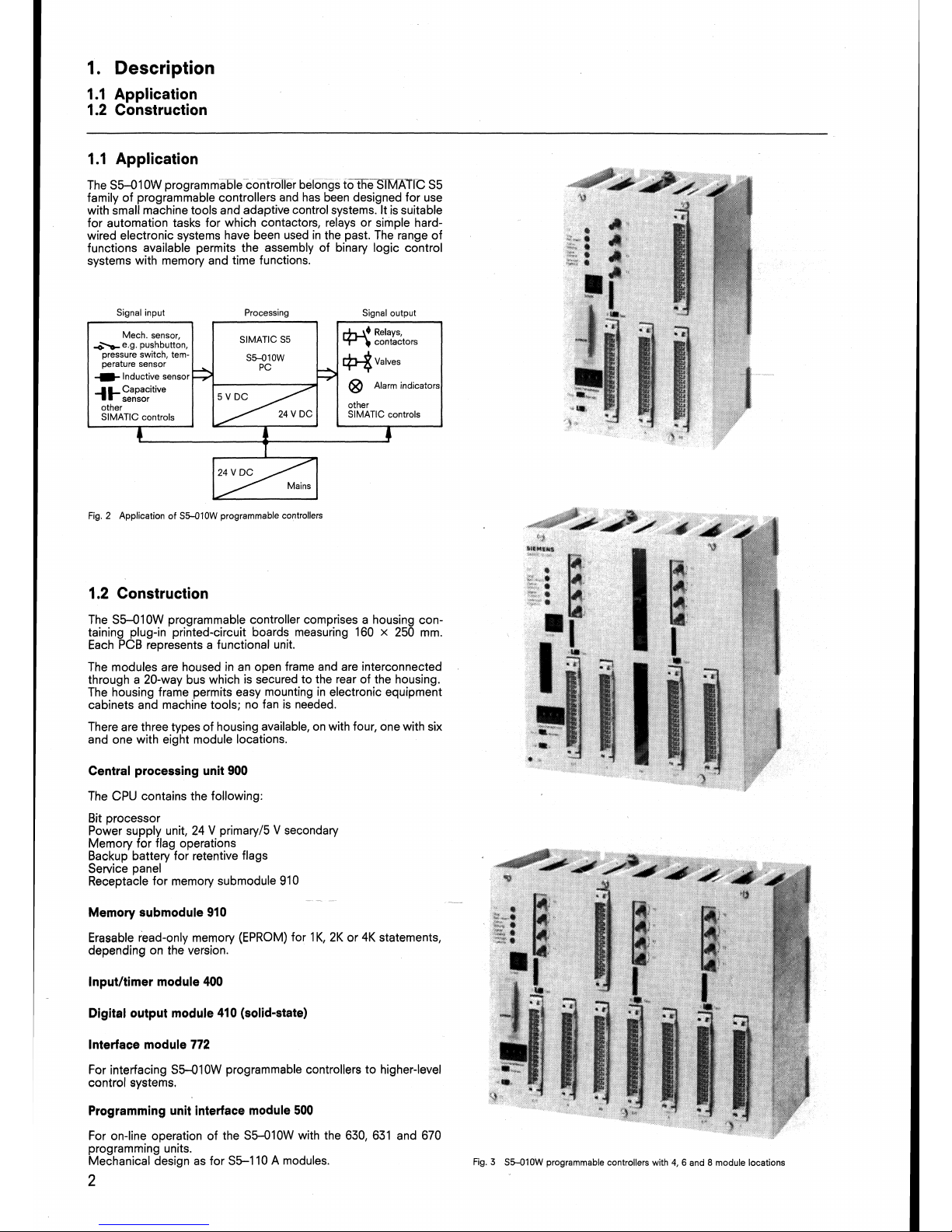

The S5-010W programmable controller comprises a housing containing plug-in printed-circuit boards measuring 160

X

250 mm.

Each PCB represents a functional unit.

k

1

The modules are housed in an open frame and are interconnected

through a 20-way bus which is secured to the rear of the housing.

The housing frame permits easy mounting in electronic equipment

cabinets and machine tools; no fan is needed.

There are three types of housing available, on with four, one with six

and one with eight module locations.

Central processing unit

900

The CPU contains the following:

Bit processor

Power supply unit,

24

V

primary15 V secondary

Memory for flag operations

Backup battery for retentive flags

Service panel

Receptacle for memory submodule

910

Memory submodule

910

Erasable read-only memory (EPROM) for 1

K,

2K

or

4K

statements,

depending on the version.

Inputltimer module 400

Digital output module 410 (solid-state)

Interface module

772

For interfacing S5-010W programmable controllers to higher-level

control systems.

Programming unit interface module

500

For on-line operation of the S5-010W with the 630, 631 and 670

programming

units.

Mechanical

des~gn as for S5-110 A modules.

Flg 3 S5-010W programmable controllers wlth

4,

6

and 8 module

locations

2

1.

Description

1.2

Construction

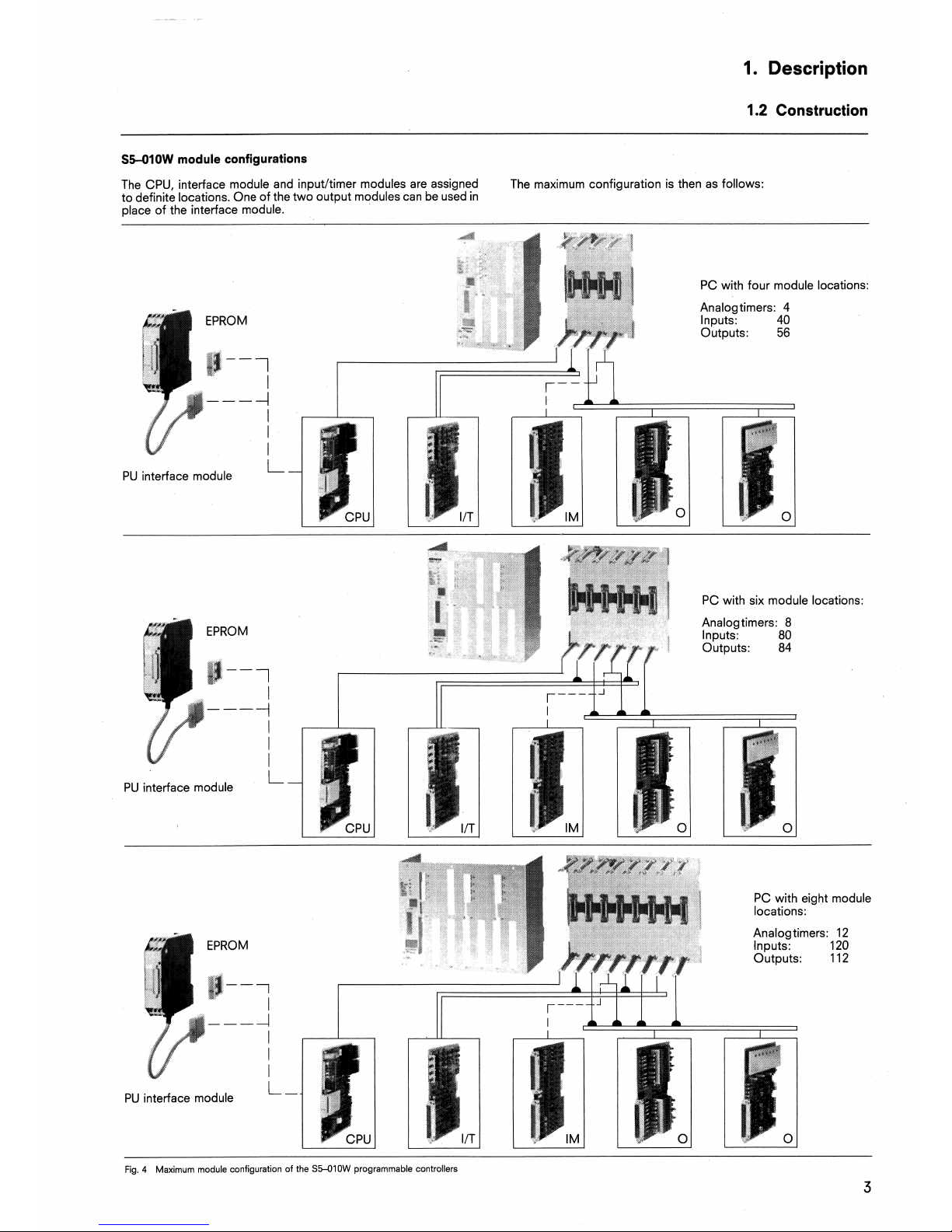

S5-010W

module configurations

The CPU, interface module and inputltimer modules are assigned

The maximum configuration is then as follows:

to definite locations. One of the two output modules can be used in

place of the interface module.

PC with four module locations:

Analog timers: 4

Inputs: 40

Outputs:

56

EPROM

($--l

--p

4

I

I

I

PU interface module

L

PC with six module locations

EPROM

Analogtimers

8

Outputs 84

I#--1

---

i

l

I

I

PU interface module

L

EPROM

I#--1

PC with six module locations.

Analogtimers

8

--

Inputs:

80

Outputs: 84

l

I

I

PU interface module

L

EPROM

(3-7

---

4

l

l

I

L-

PU interface module

l

PC with etght module

locat~ons

Analogtimers 12

Inputs. 120

Outputs 112

Fig. 4 Maximum module configuration of the

S55lOW

programmable controllers

3

1.

Description

1.3

Principle of operation

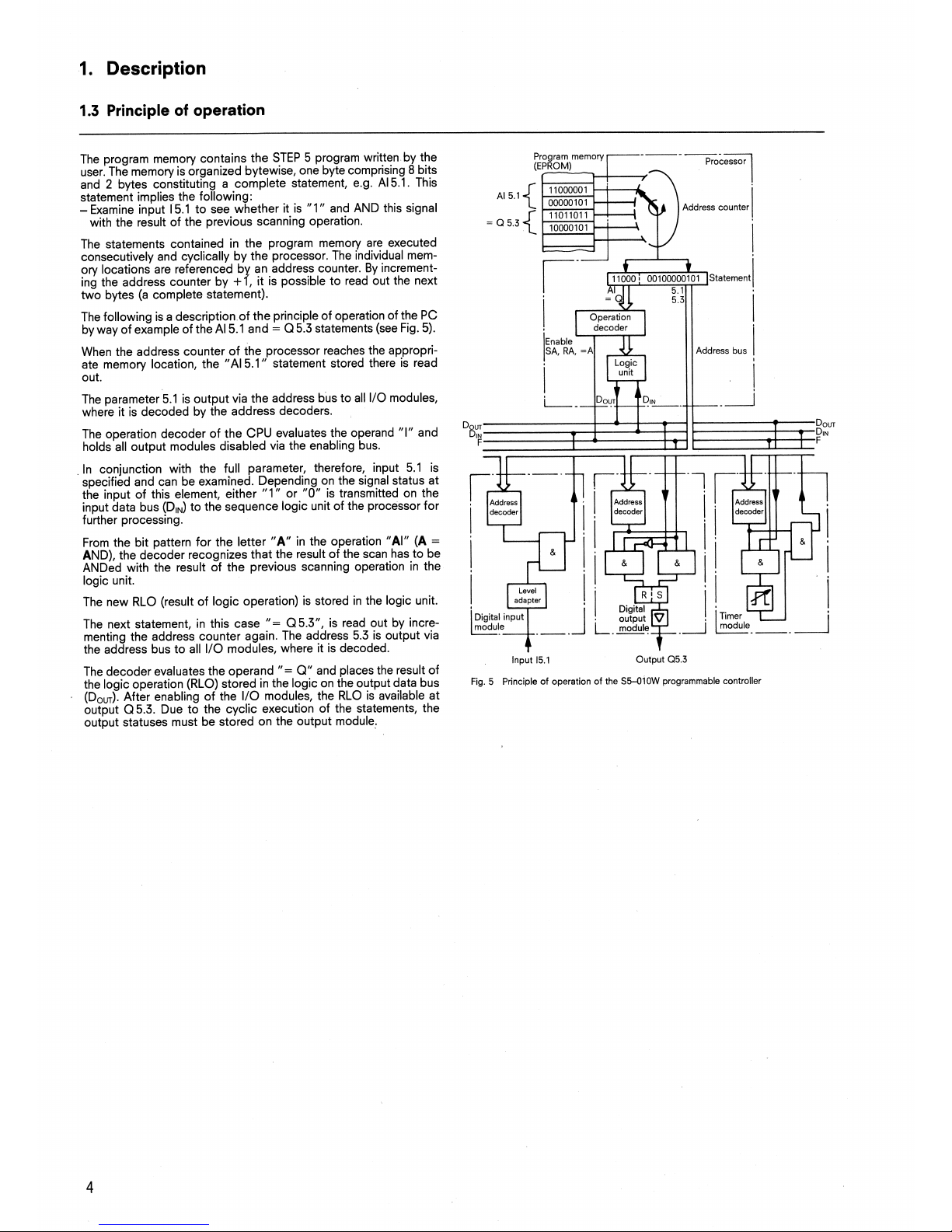

The program memory contains the STEP 5 program written by the

user. The memory is organized bytewise, one byte comprising

8

bits

and

2

bytes constituting a complete statement, e.g. A1 5.1. This

statement implies the following:

-Examine input 15.1 to see whether it is

"1

"

and AND this signal

with the result of the previous scanning operation.

The statements contained in the program memory are executed

consecutively and cyclically by the processor. The individual memory locations are referenced by an address counter. By

increment-

ing the address counter by

+l,

it

is possible to read out the next

two bytes (a complete statement).

The following is a description of the principle of operation of the PC

by way of example of the

A1 5.1 and = Q 5.3 statements (see Fig. 5).

When the address counter of the processor reaches the appropri-

ate memory location, the "AI 5.1" statement stored there is read

out.

The parameter 5.1 is output via the address bus to all

I10 modules,

where it is decoded by the address decoders.

The operation decoder of the CPU evaluates the operand "I" and

holds all output modules disabled via the enabling bus.

In conjunction with the full parameter, therefore, input 5.1 is

specified and can be examined.

?pending on the signal status at

the input of this element, either

1"

or

"0"

is transmitted on the

input data bus

(DIN) to the sequence logic unit of the processor for

further processing.

From the bit pattern for the letter "A" in the operation

"AI" (A

=

AND), the decoder recognizes that the result of the scan has to be

ANDed with the result of the previous scanning operation in the

logic unit.

The new RLO (result of logic operation) is stored in the logic unit.

The next statement, in this case

"=

Q5.3", is read out by incre-

menting the address counter again. The address 5.3 is output via

the address bus to all

I10 modules, where it is decoded.

The decoder evaluates the operand

"=

Q"

and places the result of

the logic operation

(RLO)

stored in the logic on the output data bus

(DouT). After enabling of the I10 modules, the RLO is available at

output Q5.3. Due to the cyclic execution of the statements, the

output statuses must be stored on the output module.

Program memory

(EPROM)

Address counter

11000 8 00100000101

Statement

r,2e

=Q

5

3

1

i

Operation

I

Dour

11

1

DIN

F

T

l

7

T-\

I

Input 15.1 Output Q5.3

Fig.

5

Principle of operation of the

S5OlOW

programmable controller

1.

Description

1.3

Principle

of

operation

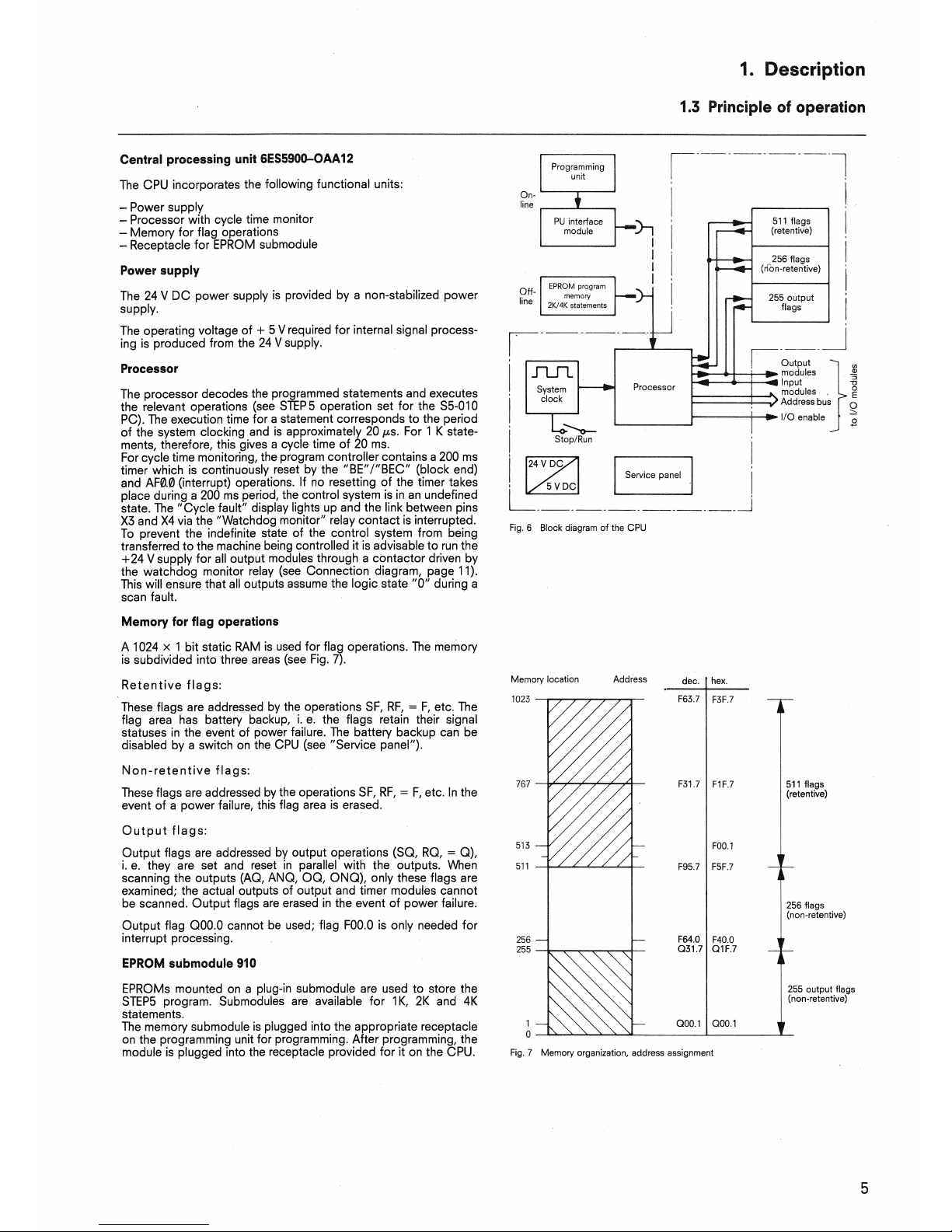

Central processing unit 6ES5900-OAA12

The CPU incorporates the following functional units:

-

Power supply

-

Processor with cycle time monitor

-

Memory for flag operations

-

Receptacle for EPROM submodule

Power supply

The 24 V DC power supply is provided by a non-stabilized power

supply.

The operating voltage of + 5 V required for internal signal processing is produced from the 24

V

supply.

Processor

The processor decodes the programmed statements and executes

the relevant operations (see STEP5 operation set for the S5-010

PC). The execution time for a statement corresponds to the period

of the system clocking and is approximately 20 ys. For 1

K

state-

ments, therefore, this gives a cycle time of 20 ms.

For cycle time monitoring, the program controller contains a 200 ms

timer which is continuously reset by the

"BE"/"BEC" (block end)

and AFO.O (interrupt) operations. If no resetting of the timer takes

place during a 200

rns period, the control system is in an undefined

state. The "Cycle fault" display lights up and the

link between pins

X3

and

X4

via the "Watchdog monitor" relay contact is interrupted.

To prevent the indefinite state of the control system from being

transferred to the machine being controlled it is advisable to run the

+24

V

supply for all output modules through a contactor driven by

the watchdog monitor relay (see Connection diagram, page 11).

This will ensure that all outputs assume the logic state

"0" during a

scan fault.

Memory for flag operations

A 1024 X 1 bit static RAM is used for flag operations. The memory

is subdivided into three areas (see Fig.

7).

Retentive flags:

These flags are addressed by the operations SF, RF,

=

F, etc. The

flag area has battery backup,

i.

e. the flags retain their signal

statuses in the event of power failure. The battery backup can be

disabled by a switch on the CPU (see "Service panel").

Non-retentive flags:

These flags are addressed by the operations SF, RF,

=

F, etc. In the

event of a power failure, this flag area is erased.

Output flags:

Output flags are addressed by output operations (SQ, RQ,

=

Q),

i.

e. they are set and reset in parallel with the outputs. When

scanning the outputs (AQ, ANQ, OQ, ONQ), only these flags are

examined; the actual outputs of output and timer modules cannot

be scanned. Output flags are erased in the event of power failure.

Output flag

000.0 cannot be used; flag FOO.O is only needed for

interrupt processing.

EPROM submodule 910

EPROMs mounted on a plug-in submodule are used to store the

STEP5 program. Submodules are available for

IK,

2K and

4K

statements.

The memory submodule is plugged into the appropriate receptacle

on the programming unit for programming. After programming, the

module is plugged into the receptacle provided for it on the CPU.

Online

~

i

Oif-

line

Processor

256

flags

1

;do.,te",e)

I

,

Fig. 6 Block diagram

of

the CPU

Memory

locatlon Address dec. I hex.

F1F

7

51

1 flags

(retentive)

256

flags

(non-retentive)

255

output flags

(non-retentive)

Q00.1

Fig. 7 Memory

organization,

address assignment

1.

Description

1.3

Principle of operation

Inputltimer module

6ES5400-OAAI

1

The module contains the following:

40 inputs for 24

V

DC

Four of these can be used as interrupt inputs. Interrupts can be

initiated by either the leading edge or trailing edge of the input

signal and can be disabled by removing a jumper.

Four analog timers:

Time ranges: 10 ms

-

100 ms

looms- 1 s

Is -10s

10s

-

100s

Time setting:

Coarse setting by thumbwheel switch

Fine adjustment by built-in potentiometers

Displays:

LEDs light up while the timer is running.

Accuracy of the timers:

Due to the cyclic execution of the statements, the PC does not

detect until some time later that a time has elapsed. The relative

error of a timer in relation to its delay time

tZs and the cycle time

t,,,,,

of the STEP 5 program is shown in Fig. 8.

Analog timers cannot be used for times that are shorter than the

cycle time.

At

The maximum relative error is

-

max. = 100

[%I,

t zs tzs

The maximum absolute error is always equal to the cycle time.

In the case of programs with interrupt processing and when using

the "BEC" (block end conditionally) statements,

it

must be remem-

bered that the cycle time

tCYqLE is not constant. The maximum

relative error can always be

estrmated from

At

-

max. = IOO~

[%I.

tzs tzs

Digital output module

6ES5410-OM12

The module contains the following:

-

24 outputs, 24 V DCl0.8 A; simultaneity factor 50

%

-

4 outputs, 24 V DC12 A

Each of the 0.8

A

outputs is electronically protected against shortcircuit.

Extra-fast fuses (FF

2.51250 G) are fitted for protecting the

2

A

outputs.

The voltage induced when disconnecting inductive loads is limited

to -15

V

by internal suppression elements. With inductive loading

and rated current, the maximum switching frequency is 1

Hz.

Higher

switching frequencies are permissible with partial loading of the

outputs or if the load is predominantly resistive.

Digital output module

6ES5410-OAA41

The module contains the following:

-

16

outputs, 24 V DC12 A; simultaneity factor 50

%

Each of the outputs is protected by an integral extra-fast fuse (FF

2.51250 G). The voltage induced when interrupting inductive loads

is limited to -15

V

by internal suppression elements. To special

order, each output can also be fitted with a freewheeling diode

which can be cut out if

it

is not needed. The circuit-breaking

characteristics (qualitative) with and without a freewheeling diode

are shown in Fig.

9.

It must be pointed out that the use of freewheeling diodes can

cause the current in the inductive load to increase again due to the

extended disconnection time. This will cause pumping of the contactor contacts and therefore increased wear.

Start

T~me elapsed

Relative error: 0.. ,100

[%l

when tZs

>

tCYCLE

tzs tzs

Fig. 8 Relative error of timer

Contactor

contact

-----

t

with I freerherlmg d~ode

1

--3

without

)

t7

On

-----

Off

t

+

24

V

-

0.7

V

t

-

15v

L

Output module disconnected

(Q)

A-

Fig. 9 Interrupting inductive loads (qualitative characteristics)

1.

Description

1.3

Principle of operation

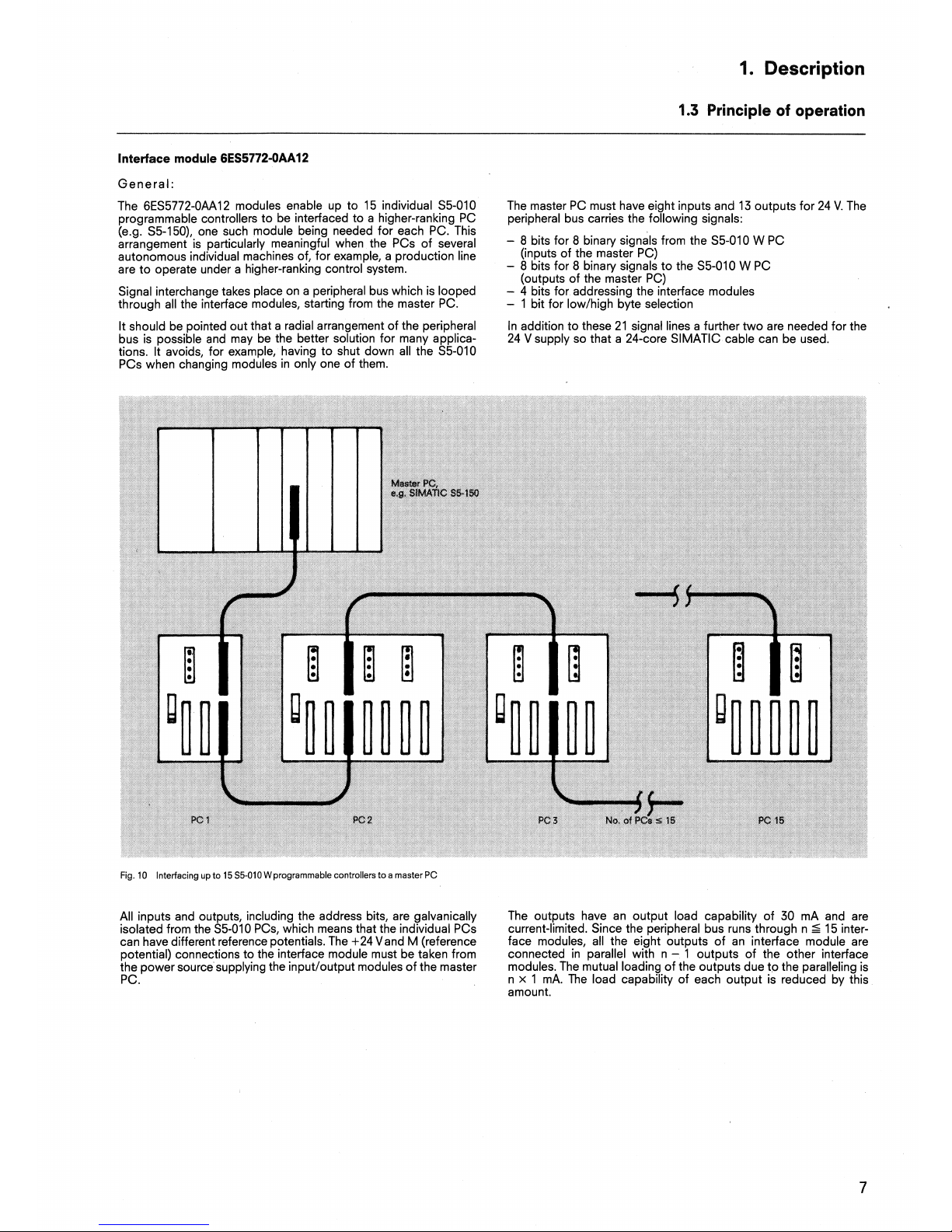

Interface

module

6ES5772-OAA12

General:

The

6ES5772-OAA12 modules enable up to 15 individual S5-010

The master PC

must have eiaht inputs and

13

outputs for 24 V. The

programmable controllers to be interfaced to a higher-ranking PC peripheral bus carries the

fdlowing signals:

(e.g.

S5-150), one such module being needed for each PC. This

arrangement is particularly meaningful when the

PCs of several

-

8

bits for 8 binary signals from the SS-010 W PC

autonomous individual machines of, for example, a production line

(inputs of the master PC)

are to oaerate under a hiaher-rankina control svstem.

-

8

bits for 8 binary signals to the S5-010 W PC

v

(outputs of the master PC)

Signal interchange takes place on a peripheral bus which is looped

-

4 bits for addressing the interface modules

through all the interface modules, starting from the master PC.

-

1 bit for lowlhigh byte selection

It should be pointed out that a radial arrangement of the peripheral

In addition to these 21 signal lines a further two are needed for the

bus is possible and may be the better solution for many applica-

24 V supply so that a 24-core

SlMATlC cable can be used.

tions. It avoids, for example, having to shut down all the S5-010

PCs when changing modules in only one of them.

Fig.

10 Interfacing

up

to 15 55-010 Wprogrammable controllers to a master

PC

PC

2

PC;

3

No

of

Es

5

15

All inputs and outputs, including the address bits, are galvanically The outputs have an output load capability of 30 mA and are

isolated

from the S5-010 PCs, which means that the individual PCs

current-limited. Since the peripheral bus runs through n d 15 inter-

can have different reference potentials. The +24 Vand

M

(reference face modules, all the eight outputs of an interface module are

potential) connections to the interface module must be taken from

connected in parallel with n

-

1

outputs of the other interface

the power source supplying the

inputloutput modules of the master

modules. The mutual loading of the outputs due to the paralleling is

PC.

n

X

1 mA. The load capability of each output is reduced by this

amount.

Loading...

Loading...