Page 1

SIWAREX WP321

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Weighing systems

Electronic weighing system

SIWAREX WP321

Manual

07/2014

Introduction

1

Safety notes

2

Description

3

Application planning

4

Mounting

5

Connection

6

Commissioning

7

Scale parameters and

functions

8

Messages

9

Command lists

10

Communication in SIMATIC

S7-300/1200/1500

11

Technical data

12

Accessories

13

Appendix

A

ESD guidelines

B

List of abbreviations

C

A5E33715669A-02

Page 2

Legal information

Warning notice system

DANGER

will

WARNING

may

CAUTION

NOTICE

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

indicates that death or severe personal injury

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E33715669A

Ⓟ 12/2014 Subject to change

Copyright © Siemens AG 2014.

All rights reserved

Page 3

Table of contents

1 Introduction ............................................................................................................................................. 9

2 Safety notes .......................................................................................................................................... 11

3 Description ............................................................................................................................................ 13

4 Application planning .............................................................................................................................. 17

5 Mounting ............................................................................................................................................... 19

6 Connection ........................................................................................................................................... 25

1.1 Purpose of the manual .............................................................................................................. 9

1.2 Basic knowledge required ......................................................................................................... 9

1.3 Manual - range of validity .......................................................................................................... 9

2.1 General safety instructions ..................................................................................................... 11

2.2 IT Security ............................................................................................................................... 12

3.1 Product overview .................................................................................................................... 13

3.2 Area of application .................................................................................................................. 13

3.3 System integration in SIMATIC ............................................................................................... 13

3.4 Customer benefits ................................................................................................................... 15

3.5 Scope of delivery .................................................................................................................... 16

4.1 Functions ................................................................................................................................ 17

4.2 Parameter assignment options ............................................................................................... 18

4.2.1 Parameter assignment with the PC ........................................................................................ 18

4.2.2 Parameter assignment with the SIMATIC Panel .................................................................... 18

5.1 Installation guideline ............................................................................................................... 19

5.2 EMC-compliant setup.............................................................................................................. 20

5.2.1 Introduction ............................................................................................................................. 20

5.2.2 Possible effects of interference ............................................................................................... 20

5.2.3 Coupling mechanisms............................................................................................................. 20

5.2.4 Five basic rules for securing EMC .......................................................................................... 21

5.3 Mounting on the SIMATIC ET 200SP ..................................................................................... 23

5.4 Configuration of the hardware in SIMATIC ............................................................................. 24

6.1 24 V connection ...................................................................................................................... 26

6.2 Connecting the load cells ........................................................................................................ 26

6.3 Shield connection .................................................................................................................... 28

6.4 Connection of RS485 serial interface ..................................................................................... 29

6.5 Connection of Siebert display via RS485 ............................................................................... 30

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

3

Page 4

Table of contents

7 Commissioning ..................................................................................................................................... 31

8 Scale parameters and functions ............................................................................................................ 45

7.1 Factory-set parameters .......................................................................................................... 31

7.2 Commissioning tools .............................................................................................................. 31

7.3 5-minute quick start with the operator panel and the Ready-for-Use software ..................... 32

7.3.1 Start ........................................................................................................................................ 32

7.3.2 Factory setting of the parameters .......................................................................................... 33

7.3.3 Selecting the calibration method ............................................................................................ 34

7.3.4 Defining the calibration weights ............................................................................................. 35

7.3.5 Setting calibration points ........................................................................................................ 36

7.3.6 Calibrating the scale automatically ........................................................................................ 37

7.3.7 Performing the automatic calibration ..................................................................................... 38

7.3.8 Checking the scale following calibration ................................................................................ 38

7.4 5-minute quick start with SIWATOOL .................................................................................... 39

7.4.1 Activate service mode ............................................................................................................ 39

7.4.2 Load factory setting ................................................................................................................ 39

7.4.3 Input of required parameters .................................................................................................. 40

7.4.4 Complete automatic calibration .............................................................................................. 40

7.4.5 Receive all data...................................................................................................................... 41

7.4.6 Checking the scale following calibration ................................................................................ 41

7.5 Service with the SIWATOOL program ................................................................................... 42

7.5.1 Windows and functions of SIWATOOL .................................................................................. 42

7.5.2 Offline parameter assignment ................................................................................................ 43

7.5.3 Online parameter assignment ................................................................................................ 43

7.5.4 Available help options ............................................................................................................ 44

7.5.5 Entering parameters with SIWATOOL ................................................................................... 44

8.1 Parameters and functions ...................................................................................................... 45

8.2 DR 2 command code ............................................................................................................. 45

8.3 DR 3 calibration parameters .................................................................................................. 46

8.3.1 Scale name ............................................................................................................................ 48

8.3.2 Unit of weight ......................................................................................................................... 48

8.3.3 Gross identifier ....................................................................................................................... 48

8.3.4 Maximum weighing range ...................................................................................................... 49

8.3.5 Calibration weights 0, 1, 2 and calibration digits 0, 1, 2 ........................................................ 49

8.3.6 Scale interval .......................................................................................................................... 49

8.3.7 Automatic zero adjustment .................................................................................................... 49

8.3.8 Decimal places for process values ........................................................................................ 49

8.3.9 Maximum tare load ................................................................................................................ 49

8.3.10 Maximum negative zeroing limit ............................................................................................. 50

8.3.11 Maximum positive zeroing limit .............................................................................................. 50

8.3.12 Standstill range ...................................................................................................................... 51

8.3.13 Standstill time ......................................................................................................................... 51

8.3.14 Standstill waiting time ............................................................................................................ 52

8.3.15 Low-pass filter limit frequency ................................................................................................ 52

8.3.16 Low-pass filter number ........................................................................................................... 52

8.3.17 Mean value filter depth ........................................................................................................... 53

SIWAREX WP321

4 Manual, 07/2014, A5E33715669A-02

Page 5

Table of contents

8.4 Calibration procedure.............................................................................................................. 54

8.4.1 Calibration with calibration weights ......................................................................................... 54

8.4.2 Automatic calibration............................................................................................................... 57

8.5 DR 4 Output of calculated calibration digits ............................................................................ 58

8.5.1 Calibration digits 0, 1, 2 (calculated) ....................................................................................... 58

8.6 DR 5 zeroing memory ............................................................................................................. 59

8.6.1 Effective tare weight - from specification ................................................................................ 60

8.6.2 Effective tare weight (semi-automatic) .................................................................................... 60

8.6.3 Zero weight (semi-automatic) ................................................................................................. 60

8.6.4 Current zero tracking weight ................................................................................................... 60

8.6.5 Dead load ................................................................................................................................ 60

8.7 DR 6 limit value settings ......................................................................................................... 61

8.7.1 Limit value 1 ON, limit value 2 ON, limit value 1 OFF, limit value 2 OFF ............................... 63

8.7.2 Limit value "Empty" ON ........................................................................................................... 63

8.7.3 Delay time for limits ................................................................................................................. 64

8.8 DR 9 module information ........................................................................................................ 65

8.9 DR 10 load cell parameters .................................................................................................... 67

8.9.1 50/60 Hz toggling .................................................................................................................... 68

8.9.2 Number of support points ....................................................................................................... 68

8.9.3 Load cell characteristic value .................................................................................................. 68

8.9.4 Rated load of a load cell ......................................................................................................... 68

8.10 DR 13 RS485 parameters ...................................................................................................... 69

8.10.1 RS485 protocol ....................................................................................................................... 70

8.10.2 RS485 baud rate ..................................................................................................................... 70

8.10.3 RS485 character parity ........................................................................................................... 70

8.10.4 Decimal place for Siebert indicator ......................................................................................... 70

8.11 DR 14 SIMATIC interface parameters .................................................................................... 71

8.11.1 Selection of process value 1, 2 ............................................................................................... 72

8.12 DR 15 manual tare specification ............................................................................................. 73

8.12.1 Specification of tare weight ..................................................................................................... 73

8.13 DR 30 current process values ................................................................................................ 74

8.13.1 Gross process weight ............................................................................................................. 76

8.13.2 Net process weight ................................................................................................................. 76

8.13.3 Tare process weight ................................................................................................................ 76

8.13.4 Gross / net weight ................................................................................................................... 76

8.13.5 Gross / net weight with increased resolution (x 10)

................................................................ 76

8.13.6 Tare weight ............................................................................................................................. 76

8.13.7 Refresh counter for process values ........................................................................................ 76

8.14 DR 31 advanced current process values ................................................................................ 77

8.14.1 Unfiltered digit value ............................................................................................................... 77

8.14.2 Filtered digit value ................................................................................................................... 77

8.14.3 Refresh counter for process values ........................................................................................ 78

8.15 DR 32 Message display .......................................................................................................... 79

8.15.1 Error bytes 0 to 7 .................................................................................................................... 81

8.16 DR 34 ASCII main display value ............................................................................................. 82

8.16.1 Content of main display as ACII string .................................................................................... 83

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

5

Page 6

Table of contents

9 Messages ............................................................................................................................................. 85

10 Command lists ...................................................................................................................................... 91

11 Communication in SIMATIC S7-300/1200/1500 .................................................................................... 95

12 Technical data ..................................................................................................................................... 107

13 Accessories ......................................................................................................................................... 115

A Appendix ............................................................................................................................................. 119

B ESD guidelines .................................................................................................................................... 121

C List of abbreviations ............................................................................................................................. 123

Index ................................................................................................................................................... 125

9.1 Message types ....................................................................................................................... 85

9.2 Message paths ....................................................................................................................... 86

9.3 Evaluating messages with the help of SIWATOOL ............................................................... 86

9.4 Detecting messages with the help of FB SIWA ..................................................................... 86

9.5 Message list ........................................................................................................................... 87

9.5.1 System status message list ................................................................................................... 87

9.5.2 Technology error message list ............................................................................................... 87

9.5.3 Data and operating errors message list ................................................................................. 88

9.5.4 Messages by LEDs on the module ........................................................................................ 89

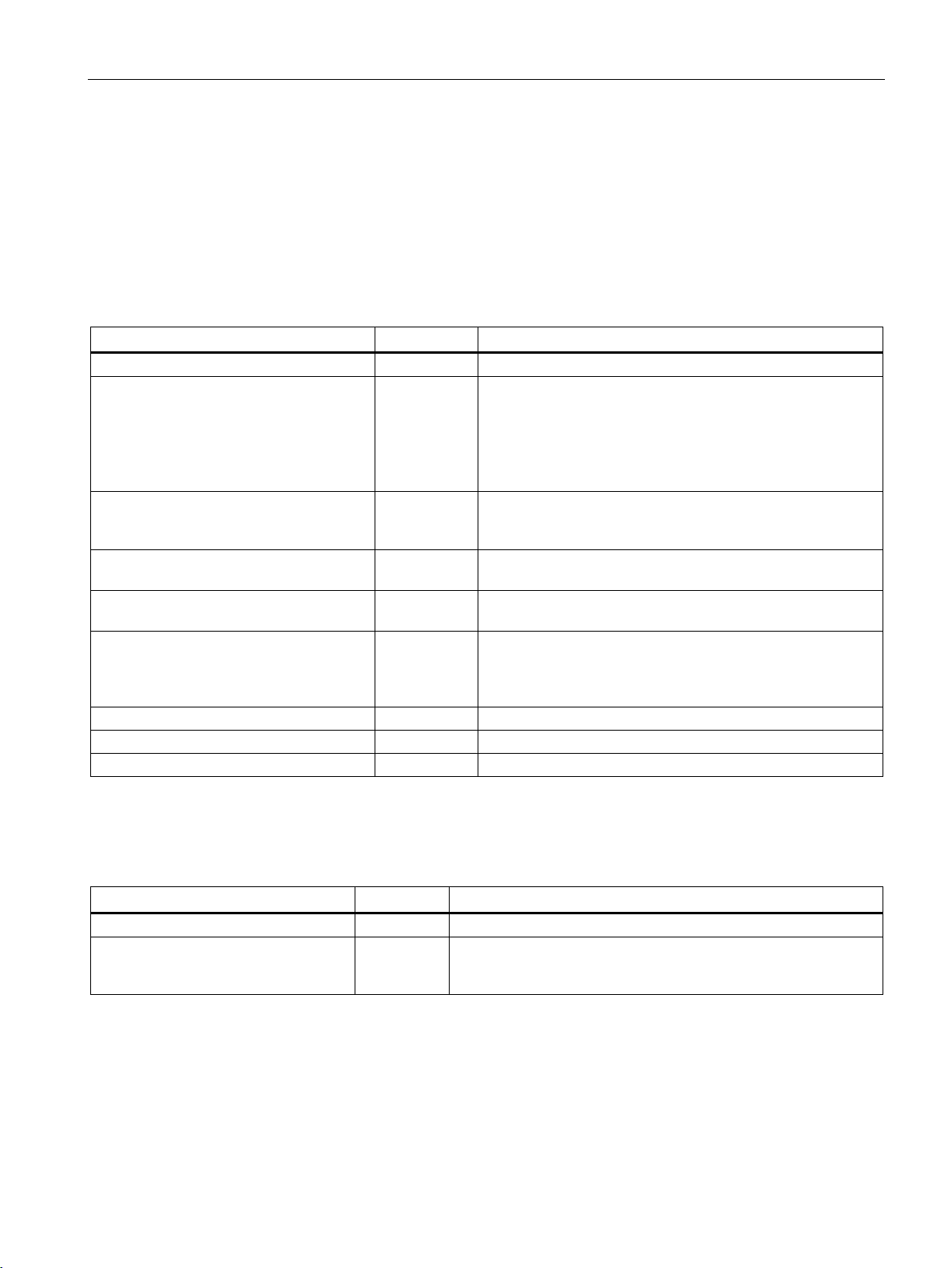

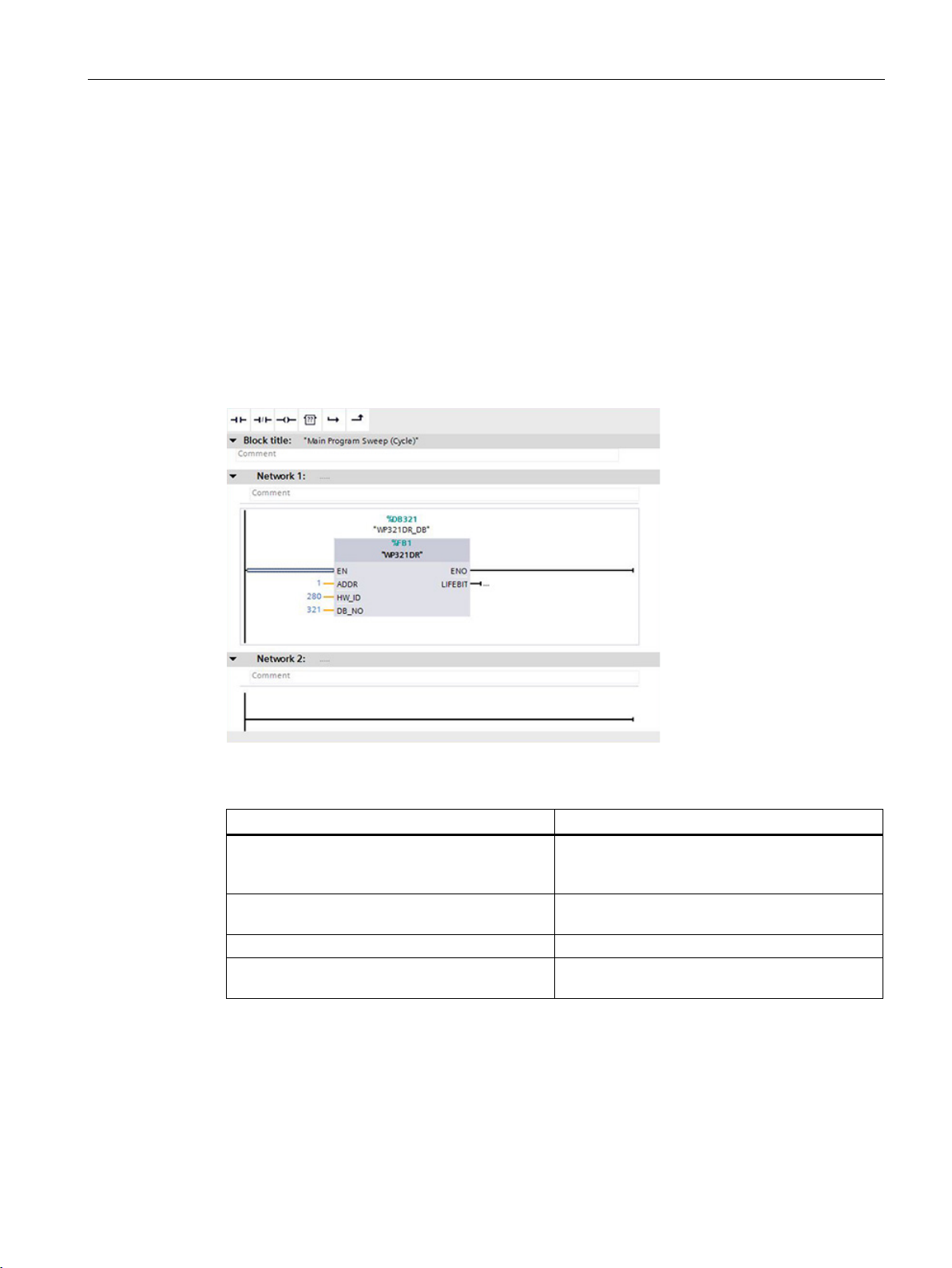

11.1 General information ............................................................................................................... 95

11.2 Structure of the program "Ready for use" .............................................................................. 95

11.3 Advantages of task sharing .................................................................................................... 96

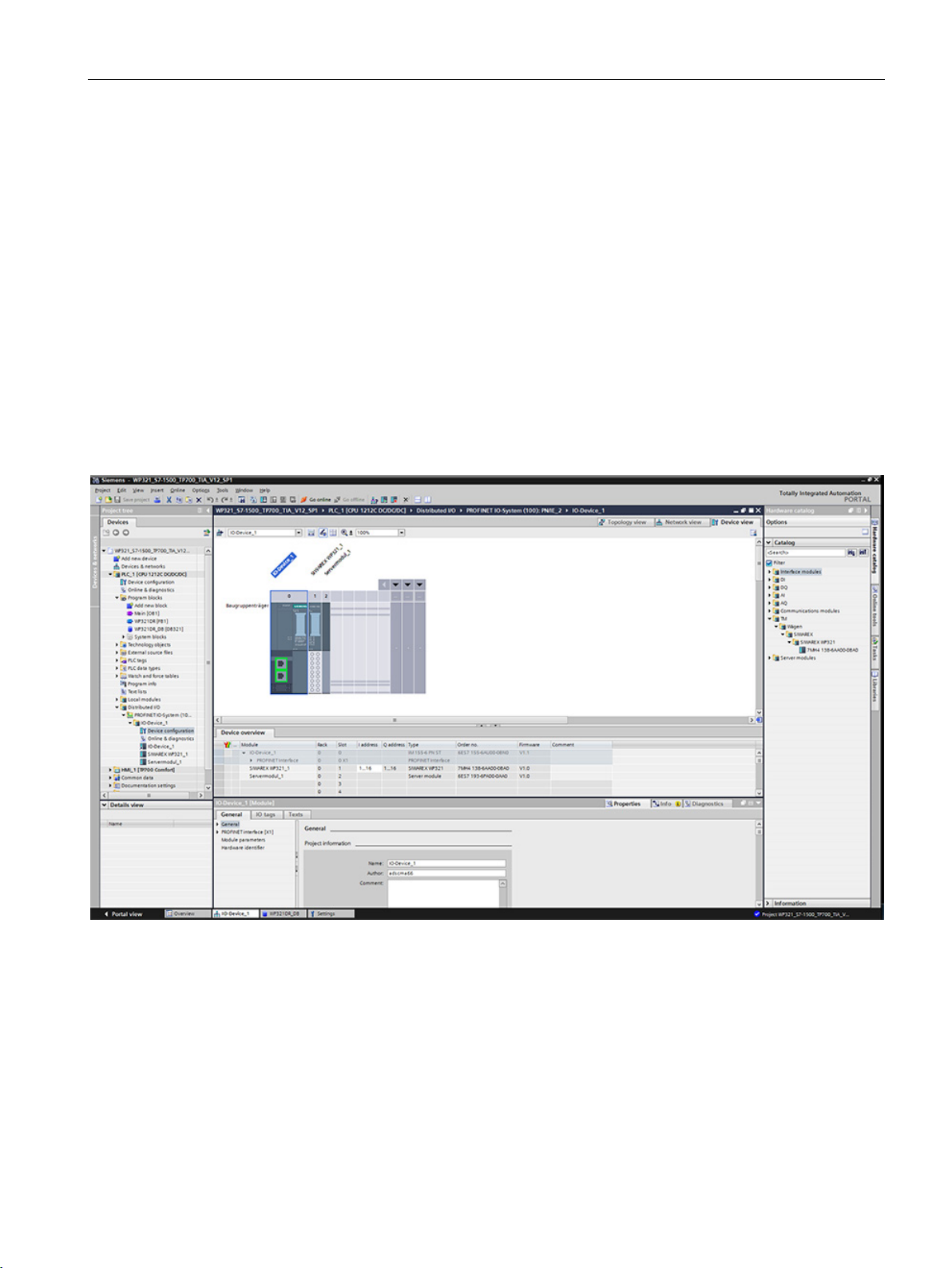

11.4 Hardware configuration of the electronic weighing system ................................................... 97

11.5 Calling of function block ......................................................................................................... 99

11.6 Working with the function block ........................................................................................... 100

11.7 I/O interface of function block .............................................................................................. 103

11.8 Error codes of function block ............................................................................................... 103

11.9 Diagnostics messages ......................................................................................................... 104

11.10 Diagnostics interrupts .......................................................................................................... 105

11.11 Hardware interrupts ............................................................................................................. 105

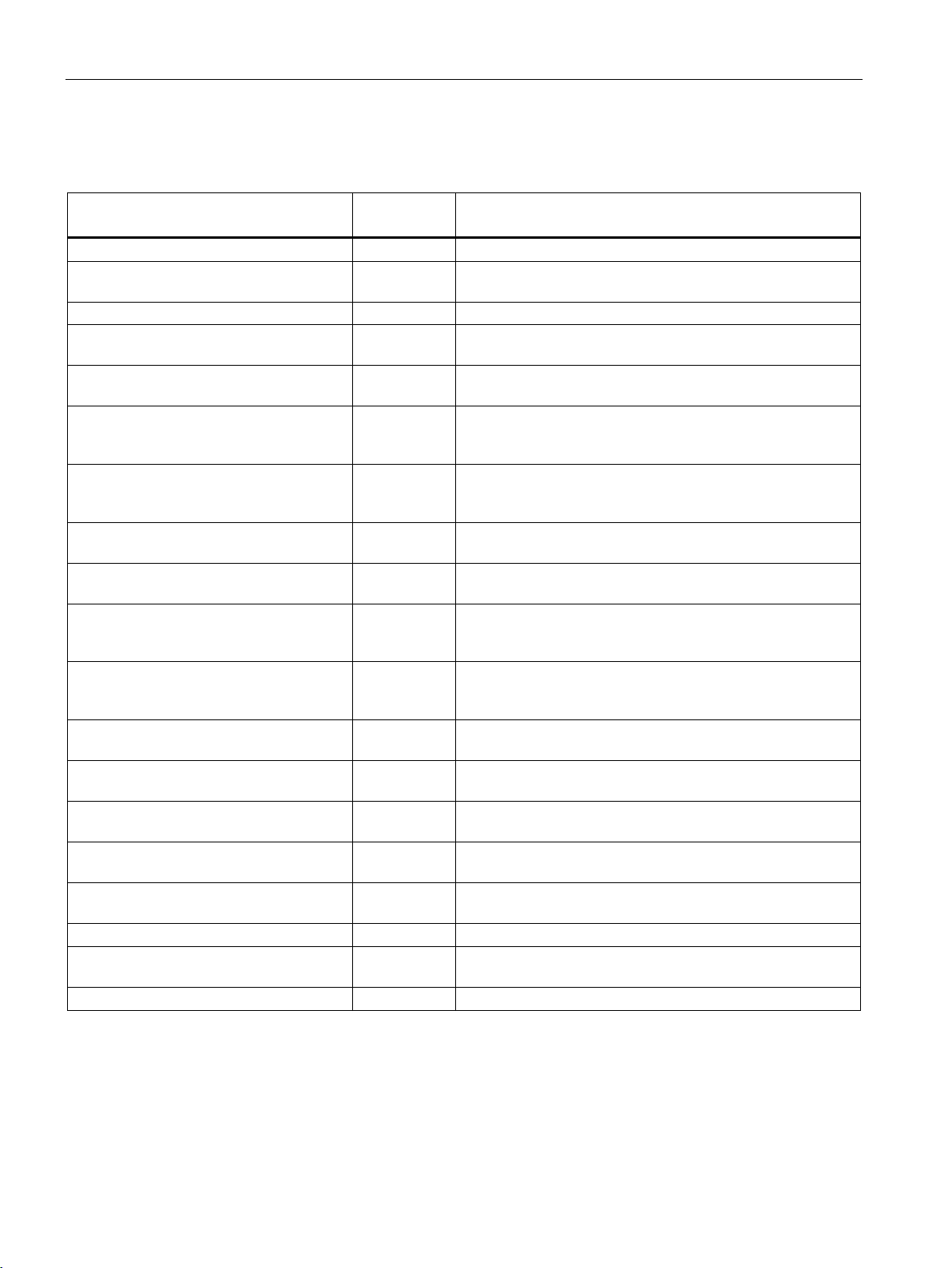

12.1 Technical specifications ....................................................................................................... 107

12.2 Electrical, EMC and climatic requirements .......................................................................... 110

12.3 Approvals ............................................................................................................................. 114

A.1 Technical support ................................................................................................................. 119

B.1 ESD Guidelines .................................................................................................................... 121

C.1 List of abbreviations ............................................................................................................. 123

SIWAREX WP321

6 Manual, 07/2014, A5E33715669A-02

Page 7

Table of contents

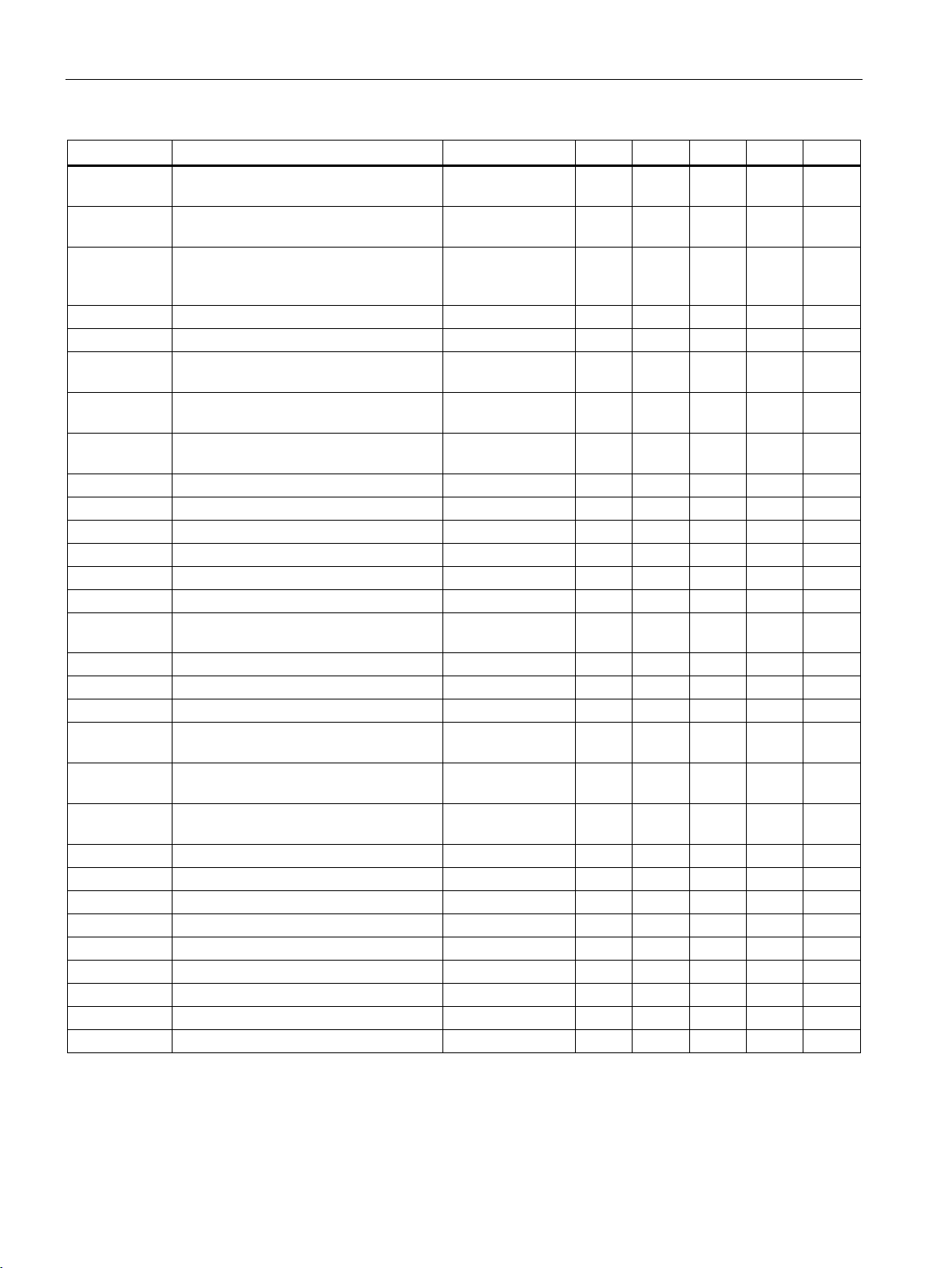

Tables

Table 6- 1 Connection of the 24 V supply ..................................................................................................... 26

Table 6- 2 Termination of RS485 serial interface.......................................................................................... 29

Table 6- 3 Settings of Siebert display S102 .................................................................................................. 30

Table 8- 1 Assignment of data record 3 ........................................................................................................ 46

Table 8- 2 Assignment of data record 4 ........................................................................................................ 58

Table 8- 3 Assignment of data record 5 ........................................................................................................ 59

Table 8- 4 Assignment of data record 6 ........................................................................................................ 61

Table 8- 5 Assignment of data record 9 ........................................................................................................ 65

Table 8- 6 Assignment of data record 10 ...................................................................................................... 67

Table 8- 7 Assignment of data record 13 ...................................................................................................... 69

Table 8- 8 Assignment of data record 14 ...................................................................................................... 71

Table 8- 9 Selection table for process value 1,2 ........................................................................................... 72

Table 8- 10 Assignment of data record 15 ...................................................................................................... 73

Table 8- 11 Assignment of data record 30 ...................................................................................................... 74

Table 8- 12 Assignment of data record 31 ...................................................................................................... 77

Table 8- 13 Assignment of data record 32 ...................................................................................................... 79

Table 8- 14 Assignment of data record 34 ...................................................................................................... 82

Table 10- 1 Command groups of the SIWAREX WP321 ................................................................................ 93

Table 11- 1 Memory requirements of the function block ................................................................................. 95

Table 11- 2 I/O data of the function block ..................................................................................................... 103

Table 11- 3 Statuses/errors when working with the function block ............................................................... 103

Table 11- 4 Diagnostics messages ............................................................................................................... 104

Table 12- 1 Interference emission (industrial area): EN 61000-6-4 .............................................................. 111

Table 12- 2 Interference immunity (industrial environment): EN 61000-6-2 ................................................. 112

Table 12- 3 Operating conditions to IEC 60721 ............................................................................................

113

Table 12- 4 Climatic requirements ................................................................................................................ 113

Table 13- 1 Essential accessories ................................................................................................................ 115

Table 13- 2 Optional accessories .................................................................................................................. 115

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

7

Page 8

Table of contents

Figures

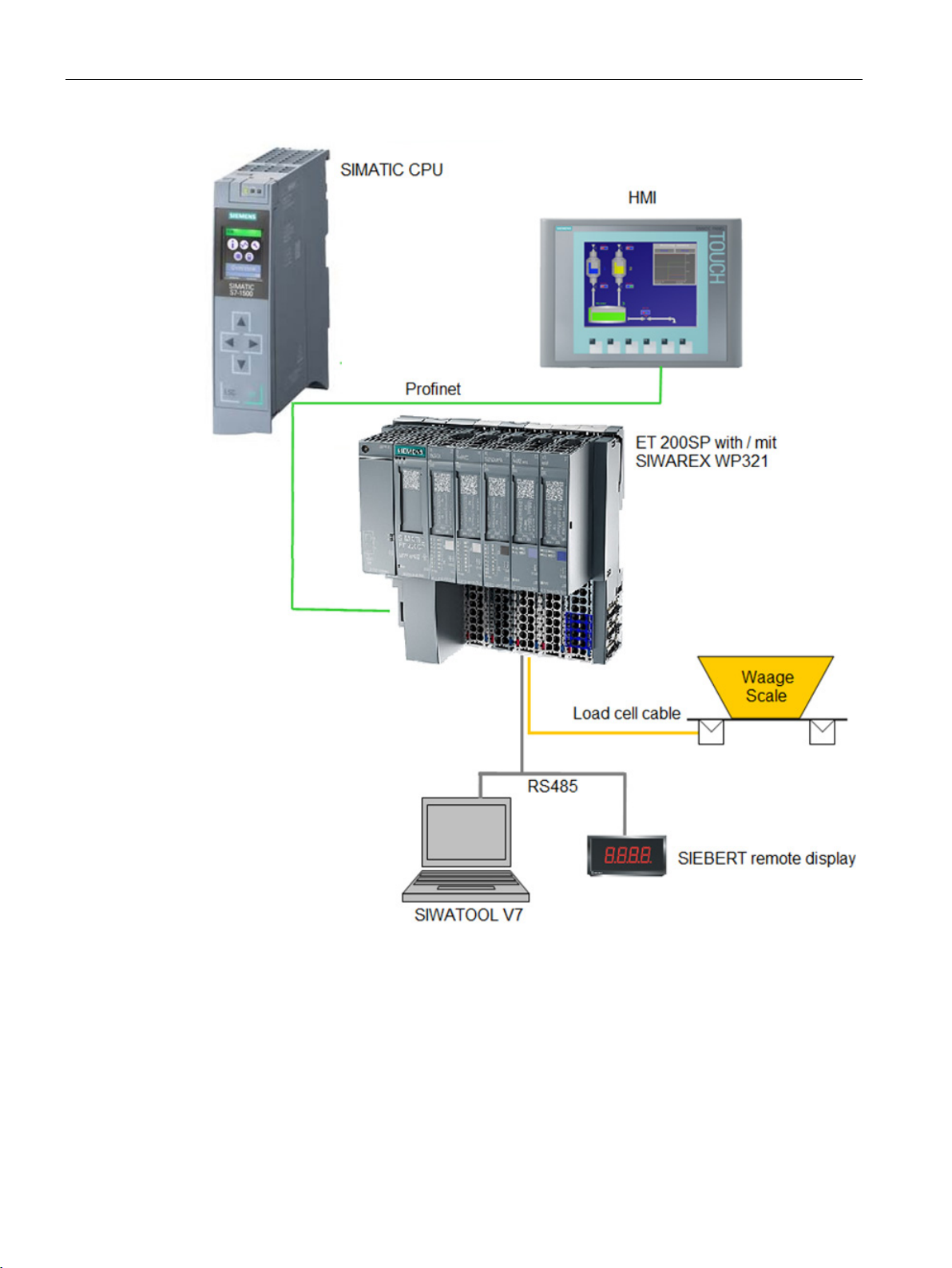

Figure 3-1 System overview .......................................................................................................................... 14

Figure 4-1 SIWATOOL overview ................................................................................................................... 18

Figure 5-1 Installation of the I/O or SIWAREX modules................................................................................ 23

Figure 6-1 SIWAREX WP321 process terminals on the base unit ................................................................ 25

Figure 6-2 Shielding in the screw gland ........................................................................................................ 27

Figure 6-3 Shield connection and shield terminal ......................................................................................... 28

Figure 6-4 Connection of Siebert display S102 ............................................................................................. 30

Figure 7-1 Quick start step 1 ......................................................................................................................... 32

Figure 7-2 Quick start step 2 ......................................................................................................................... 33

Figure 7-3 Quick start step 3 ......................................................................................................................... 34

Figure 7-4 Quick start step 4a ....................................................................................................................... 35

Figure 7-5 Quick start step 5a ....................................................................................................................... 36

Figure 7-6 Quick start step 4b ....................................................................................................................... 37

Figure 7-7 Quick start step 5b ....................................................................................................................... 38

Figure 7-8 Quick setup with marked parameters .......................................................................................... 39

Figure 7-9 Sending/receiving a data record with SIWATOOL V7 ................................................................. 40

Figure 7-10 Layout of the SIWATOOL user interface ..................................................................................... 42

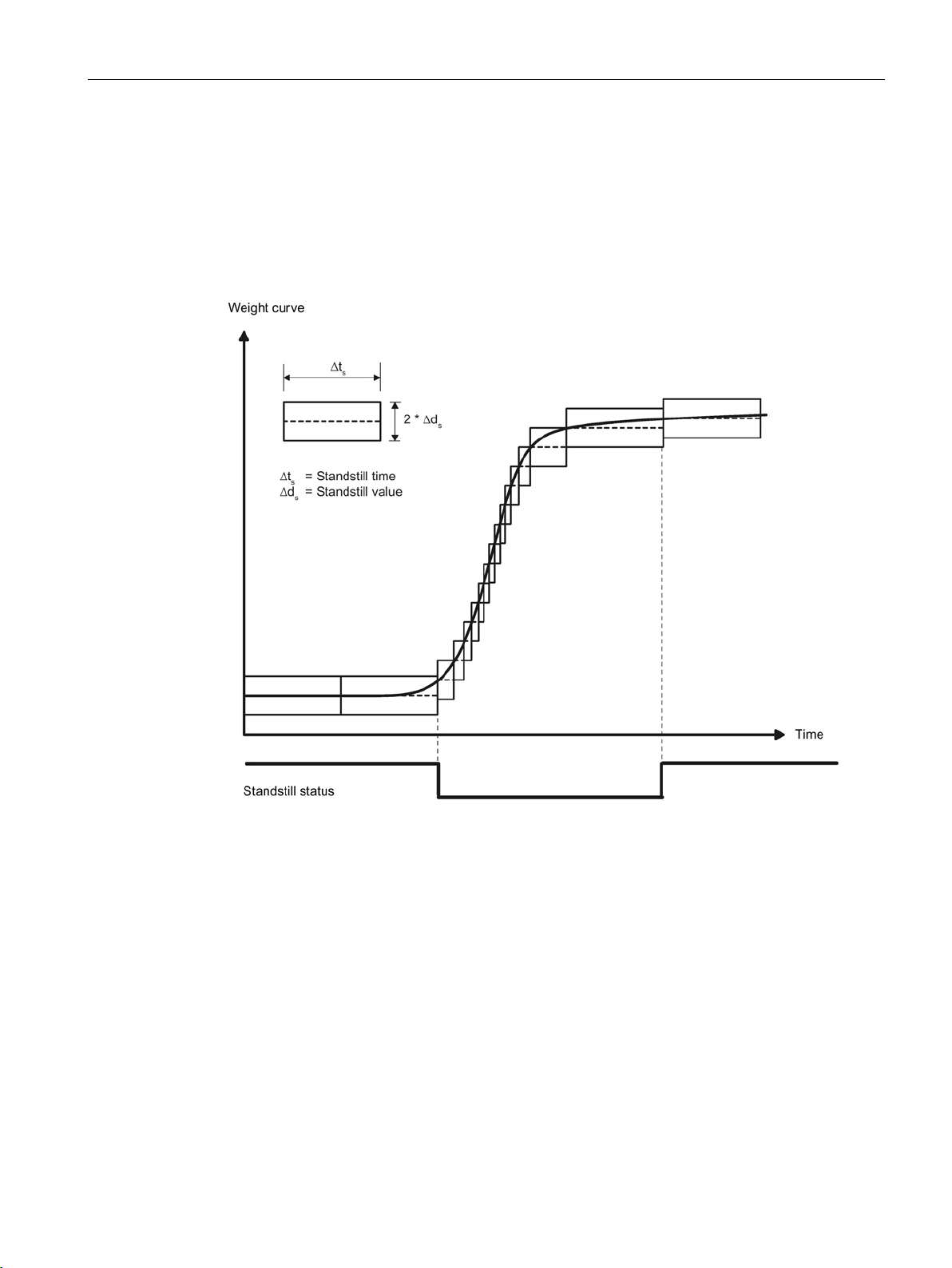

Figure 8-1 Standstill monitoring ..................................................................................................................... 51

Figure 8-2 Step response of the digital low-pass filter when fg = 2 Hz ......................................................... 52

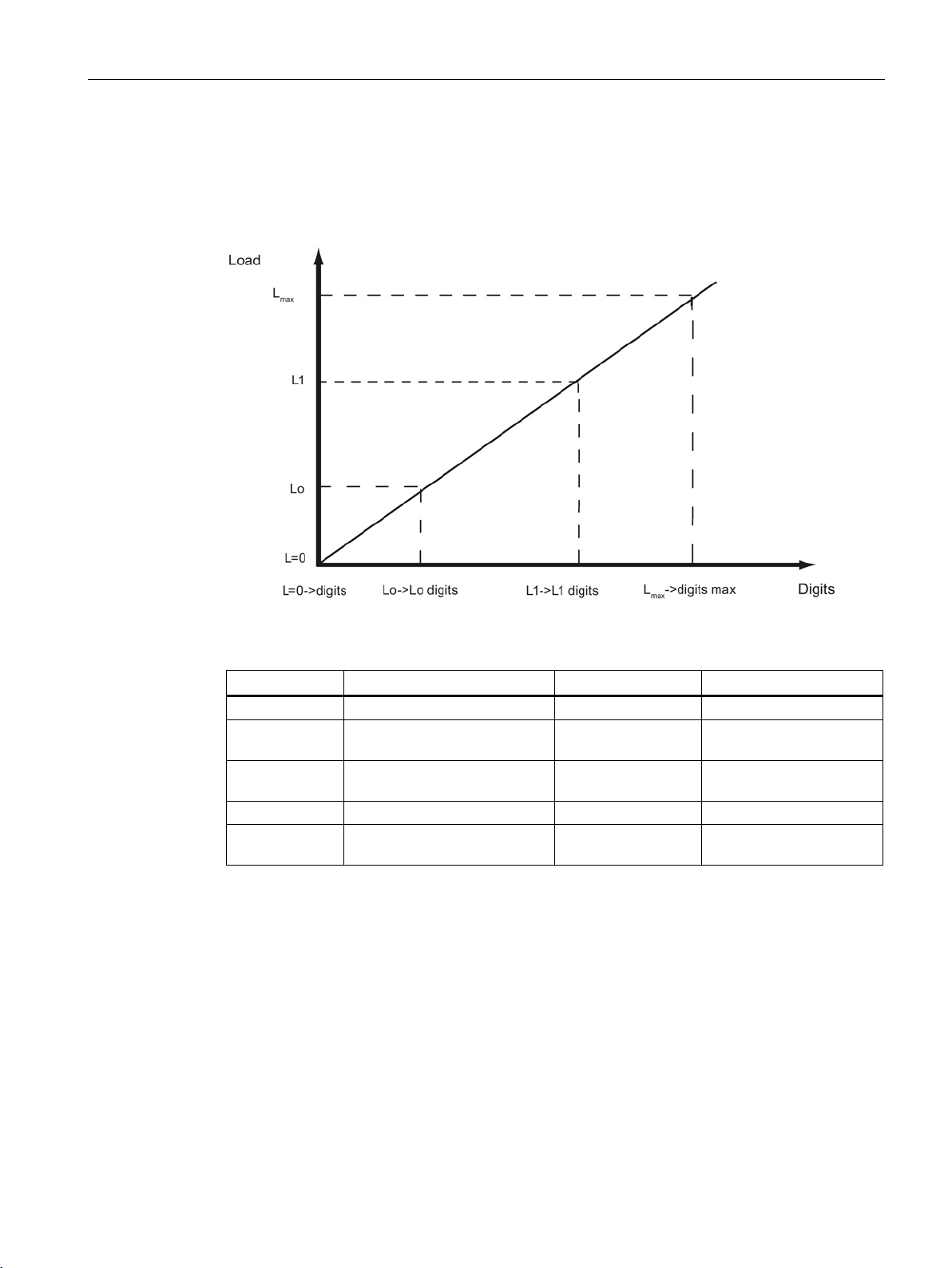

Figure 8-3 Calibration digits and calibration weight ....................................................................................... 55

Figure 8-4 Linearizing the scale's characteristic curve .................................................................................. 56

Figure 8-5 Limit value configuration .............................................................................................................. 63

Figure 11-1 Hardware configuration in the TIA Portal ..................................................................................... 97

Figure 11-2 Start address of module in TIA Portal .......................................................................................... 98

Figure 11-3 Configuration of interrupts in TIA Portal ....................................................................................... 98

Figure 11-4 HW ID of module in TIA Portal ..................................................................................................... 98

Figure 11-5

Figure 11-6 CMD command mailboxes ......................................................................................................... 100

Figure 11-7 Configuration of hardware interrupts for S7-1500 ...................................................................... 106

Figure B-1 Electrostatic voltages which an operator can be subjected to ................................................... 122

Calling of WP321DR block in user program ................................................................................ 99

SIWAREX WP321

8 Manual, 07/2014, A5E33715669A-02

Page 9

1

1.1

Purpose of the manual

1.2

Basic knowledge required

1.3

Manual - range of validity

Type designation

Order No.

as of version

Note

This manual contains all the necessary information on setting up, installing, wiring and

commissioning the SIWAREX WP321 electronic weighing system.

Knowledge of weighing technology as well as general knowledge of the SIMATIC system

including the TIA Portal are necessary in order to understand the manual.

This manual is valid for:

SIWAREX WP321 7MH4138-6AA00-0BA0 HW V.1 FW V. 1.0

This manual contains a description of all electronic weighing systems available at the time

the manual was published. We reserve the right to include a Product Information with the

latest information on the module.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

9

Page 10

Introduction

1.3 Manual - range of validity

SIWAREX WP321

10 Manual, 07/2014, A5E33715669A-02

Page 11

2

2.1

General safety instructions

WARNING

Non-compliance with warning notes or non-qualified handling of the system

WARNING

Permission for installation in machines

Note

itional

Note

Failure to observe the warning notes or handling of the device/system by non-qualified

personnel can result in serious injury or damage to property. This means only qualified

personnel are permitted to handle this device/system.

Start-up/commissioning is absolutely prohibited until it has been ensured that the machine

in which the component described here is to be installed fulfills the

regulations/specifications of Machinery Directive 89/392/EEC.

The specifications of the manual for the SIMATIC ET 200SP system apply for configuration,

installation and commissioning in the SIMATIC environment. This chapter includes add

information on hardware configuration, installation and preparation for operation of the

SIWAREX WP321.

The safety notes must be observed.

The device was developed, manufactured, tested and documented in compliance with the

relevant safety standards. The device does usually not pose any risks of material damage or

personal injury.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

11

Page 12

Safety notes

2.2

IT Security

2.2 IT Security

Siemens provides automation and drive products with industrial security functions that

support the secure operation of plants or machines. They are an important component in a

holistic industrial security concept. With this in mind, our products undergo continuous

development. We therefore recommend that you keep yourself informed with respect to our

product updates. Detailed technical information can be found at:

http://support.automation.siemens.com (http://www.siemens.de/automation/csi_en_WW).

To ensure the secure operation of a plant or machine it is also necessary to take suitable

preventive action (e.g. cell protection concept) and to integrate the automation and drive

components into a state-of-the-art holistic industrial security concept for the entire plant or

machine. Products used from other manufacturers should also be taken into account here.

You will find further information under:

http://www.siemens.com/industrialsecurity (http://www.siemens.com/industrialsecurity).

SIWAREX WP321

12 Manual, 07/2014, A5E33715669A-02

Page 13

3

3.1

Product overview

3.2

Area of application

3.3

System integration in SIMATIC

SIWAREX WP321 is a versatile and flexible weighing module that can be operated as a

static weighing instrument.

The electronic weighing system can be used in SIMATIC ET 200SP and uses all features of

a modern automation system, such as integrated communication, operation and monitoring,

the diagnostics system as well as the configuration tools in the TIA Portal or SIMATIC Step7

and WinCC flexible.

The electronic weighing system described here is the perfect solution for applications in

which signals from weighing or force sensors are acquired and processed. The

SIWAREX WP321 is a very accurate electronic weighing system.

It can be used in almost all industrial weighing applications not requiring official calibration.

Use in potentially explosive atmospheres (with Ex interface SIWAREX IS) it's also possible.

The electronic weighing system described here is a technology module for

SIMATIC ET 200SP. It can be used as desired in the configuration of the automation

solution, including the weighing application. You can create optimal solutions for small and

medium-sized plants by combining the suitable SIMATIC modules. You can create

customized or industry-specific solutions in no time with the help of the configuration

package available under the "Ready for use" application for SIMATIC.

Solutions are possible with S7-300, S7-1200 as well as S7-1500 CPUs. TIA Portal or Step 7

Classic can be used as the configuration software.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

13

Page 14

Description

3.3 System integration in SIMATIC

Figure 3-1 System overview

SIWAREX WP321

14 Manual, 07/2014, A5E33715669A-02

Page 15

Description

3.4

Customer benefits

3.4 Customer benefits

The electronic weighing system described here is characterized by decisive advantages:

● Uniform design technology and consistent communication in SIMATIC ET 200SP

● Parameter assignment by means of an operator panel, STEP7 user program or PC

● Uniform configuration option in the SIMATIC TIA Portal or SIMATIC Step7

● Measuring of weight with a resolution of up to +/- 2 million parts

● High accuracy 0.05%

● High measuring rate of 100 Hz

● Limit monitoring

● Flexible adaptation to varying requirements

● Easy adjustment of the scale using the SIWATOOL program

● Automatic calibration is possible without the need for calibration weights

● Module replacement is possible without recalibrating the scale

● Use in Ex Zone 2 / ATEX approval

● Intrinsically safe load cell supply for Ex Zone 1 (SIWAREX IS option)

● Diagnostics functions

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

15

Page 16

Description

3.5

Scope of delivery

Note

3.5 Scope of delivery

The scope of supply consists of the SIWAREX WP321 weighing module. Required

accessories → Accessories (Page 115)

The SIWAREX WP321 configuration package is required for configuration of the

SIWAREX WP321 electronic weighing system → Accessories (Page 115). The configuration

package is not included in the scope of delivery of the module.

SIWAREX WP321

16 Manual, 07/2014, A5E33715669A-02

Page 17

4

4.1

Functions

P

The primary task of the electronic weighing system is the measurement and registration of

the current weight value. The integration in SIMATIC gives you the option to process the

weight value directly in the PLC (

The SIWAREX WP321 is calibrated at the factory. This allows for automatic calibration of the

scale without the need for calibration weights and replacement of modules without the need

for recalibrating the scale.

A PC for setting the parameters of the electronic weighing system can be connected via the

RS485 interface.

The SIWAREX WP321 electronic weighing system can also be used in potentially explosive

atmospheres (Zone 2). The load cells are supplied intrinsically safe in Zone 1 applications

when you use the optional Ex interface SIWAREX IS.

rogrammabelLogic Controller).

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

17

Page 18

Application planning

4.2

Parameter assignment options

4.2.1

Parameter assignment with the PC

4.2.2

Parameter assignment with the SIMATIC Panel

4.2 Parameter assignment options

You can set the scale parameters with the convenience of the familiar Windows interface by

using the "SIWATOOL" PC parameter assignment software.

You can use the program for commissioning the scale without any knowledge of automation

technology. When servicing is required, you can analyze and test the processes in the scale

independently of the automation system or Operator Panel with the help of the PC. You can

read out the diagnostic buffer from the SIWAREX module to assist you in the event analysis.

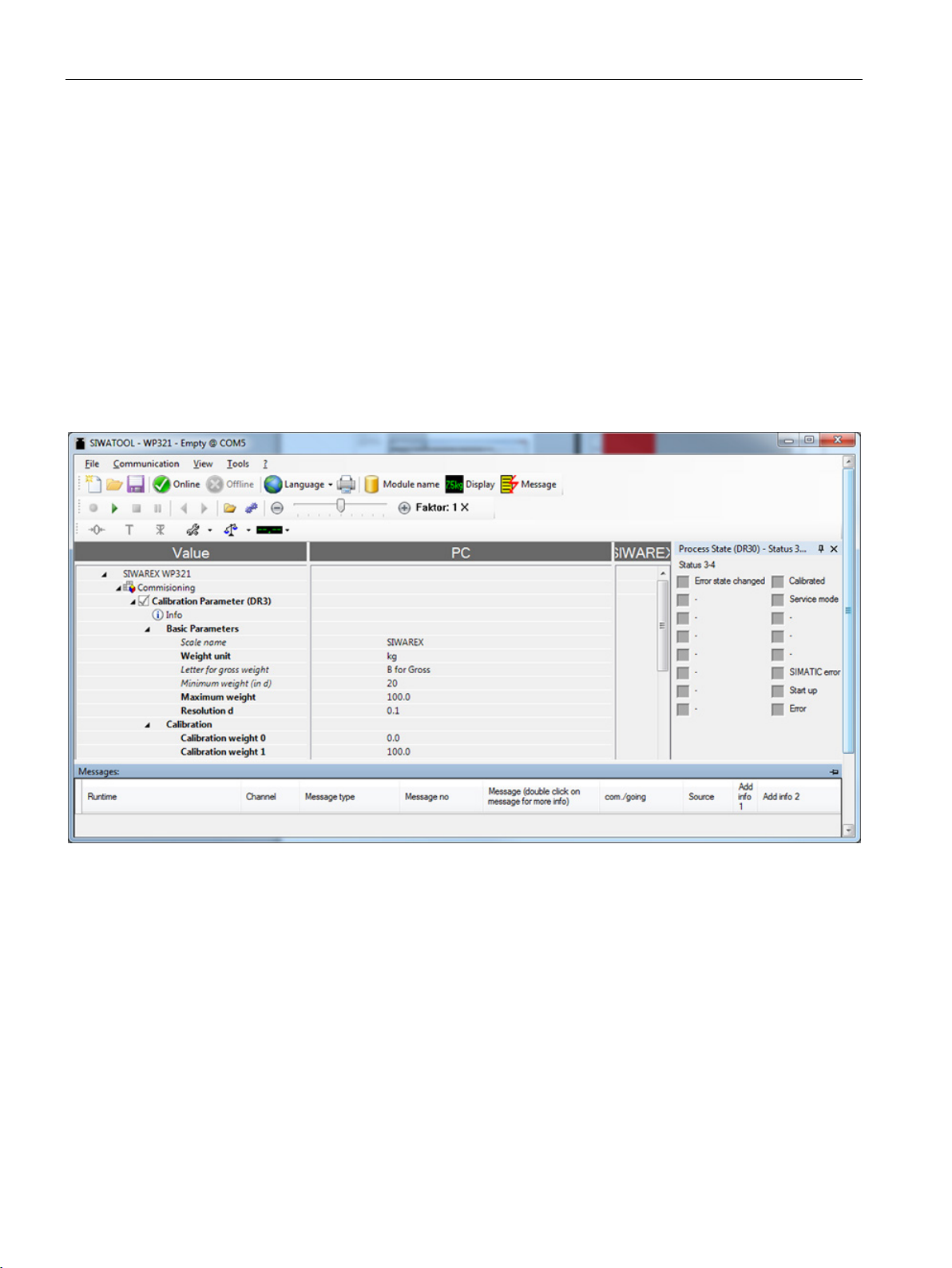

The figure below illustrates the structure of the individual program windows.

Figure 4-1 SIWATOOL overview

SIWATOOL does not only offer support when you set the scale but also when you analyze

the diagnostic buffer that can be saved after being read out of the module together with the

parameters. The display of the current scale status can be configured.

You can switch between several languages in the program.

You require an RS485/USB converter (see Accessories (Page 115)).

SIWAREX WP321

18 Manual, 07/2014, A5E33715669A-02

SIWAREX WP321 parameters can be assigned using a SIMATIC Panel connected to the

SIMATIC CPU. The "Ready-for-use" application software is used for this.

Page 19

5

5.1

Installation guideline

When assembling the SIMATIC components together with the electronic weighing system

described here, the setup, installation and wiring guidelines for the SIMATIC ET 200SP must

be observed (see system manual "SIMATIC ET 200SP, ET 200SP distributed I/O system",

order no.: A5E03576848).

This manual describes additional installation and wiring aspects specific to the electronic

weighing system.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

19

Page 20

Mounting

5.2

EMC-compliant setup

5.2.1

Introduction

EMC

5.2.2

Possible effects of interference

5.2.3

Coupling mechanisms

5.2 EMC-compliant setup

The electronic weighing system described here was developed for use in industrial

environments and complies with high EMC requirements. It ensures safe operation even in

harsh environmental conditions. Nevertheless, you should still carry out EMC planning

before installing your devices in order to determine any sources of interference and include

them in your considerations.

EMC (electromagnetic compatibility) describes the capability of electrical equipment to

operate without errors in a given electromagnetic environment, without being subject to

external influence and without influencing external devices in any way.

Electromagnetic interferences can influence the electronic weighing system described here

in various ways:

● Electromagnetic fields having a direct influence on the system

● Interferences transported by communication cables

● Interferences having an effect via process cables

● Interferences entering the system via the power supply and/or protective ground

Interferences can impair the fault-free functioning of the electronic weighing system.

Depending on the propagation medium (conducted or non-conducted) and the distance

between the interference source and the device, interferences can enter the faulty device

through four different coupling mechanisms:

● Electrical coupling

● Capacitive coupling

● Inductive coupling

● Radiation coupling

SIWAREX WP321

20 Manual, 07/2014, A5E33715669A-02

Page 21

Mounting

5.2.4

Five basic rules for securing EMC

Rule 1: Large area grounding contact

Rule 2: Proper cable routing

Rule 3: Fixing the cable shielding

Rule 4: Special EMC measures

5.2 EMC-compliant setup

Observe these five basic rules to secure EMC.

● When installing the devices, make sure that the surfaces of inactive metal parts are

properly bonded to chassis ground (see following sections).

● Bond all inactive metal parts to chassis ground, ensuring large area and low-impedance

contact (large cross-sections).

● When using screw connections on varnished or anodized metal parts, support contact

with special contact washers or remove the protective insulating finish on the points of

contact.

● Wherever possible, avoid the use of aluminum parts for ground bonding. Aluminum

oxidizes very easily and is therefore less suitable for ground bonding.

● Provide a central connection between chassis ground and the ground/protective

conductor system.

● Organize your wiring system into cable groups (high-voltage/power

supply/signal/measurement/data cables).

● Always route high-voltage and data cables in separate ducts or in separate bundles.

● Install the measurement cables as close as possible to grounded surfaces (e.g.

supporting beans, metal rails, steel cabinet walls).

● Ensure proper fixation of the cable shielding.

● Always use shielded data cables. Always connect both ends of the data cable shielding to

ground on a large area.

● Keep unshielded cable ends as short as possible.

● Always use metal/metalized connector housings only for shielded data cables.

● All inductors that are to be controlled should be connected with suppressors.

● For cabinet lighting in the immediate range of your controller, use interference

suppressed fluorescent lamps.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

21

Page 22

Mounting

Rule 5: Homogeneous reference potential

5.2 EMC-compliant setup

● Create a homogeneous reference potential and ground all electrical equipment.

● Use sufficiently dimensioned equipotential bonding conductors if potential differences

exist or are expected between your system components. Equipotential bonding is

absolutely mandatory for applications in hazardous areas.

SIWAREX WP321

22 Manual, 07/2014, A5E33715669A-02

Page 23

Mounting

5.3

Mounting on the SIMATIC ET 200SP

5.3 Mounting on the SIMATIC ET 200SP

The electronic weighing system described here is a module of the SIMATIC ET 200SP

series and can be directly connected to the automation system's bus system. The 15 mm

wide module has very low installation and cabling requirements.

The module is snapped onto the ET 200SP base unit (BU). You must use base units of type

A0 (→ Accessories (Page 115)).

The load cells, power supply and serial interfaces are connected via the terminal box.

Figure 5-1 Installation of the I/O or SIWAREX modules

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

23

Page 24

Mounting

5.4

Configuration of the hardware in SIMATIC

5.4 Configuration of the hardware in SIMATIC

A station has a maximum width of 1 m, and you can use up to 64 modules depending on the

type of PN head-end, or up to 15 modules with the Profibus version. Observe the system

conditions when planning the configuration.

Each SIWAREX electronic weighing system requires 16 bytes of the I/O area. Address

assignment is carried out in the TIA Portal or in the SIMATIC Manager during hardware

configuration.

SIWAREX WP321

24 Manual, 07/2014, A5E33715669A-02

Page 25

6

All external connections are made via the terminal box.

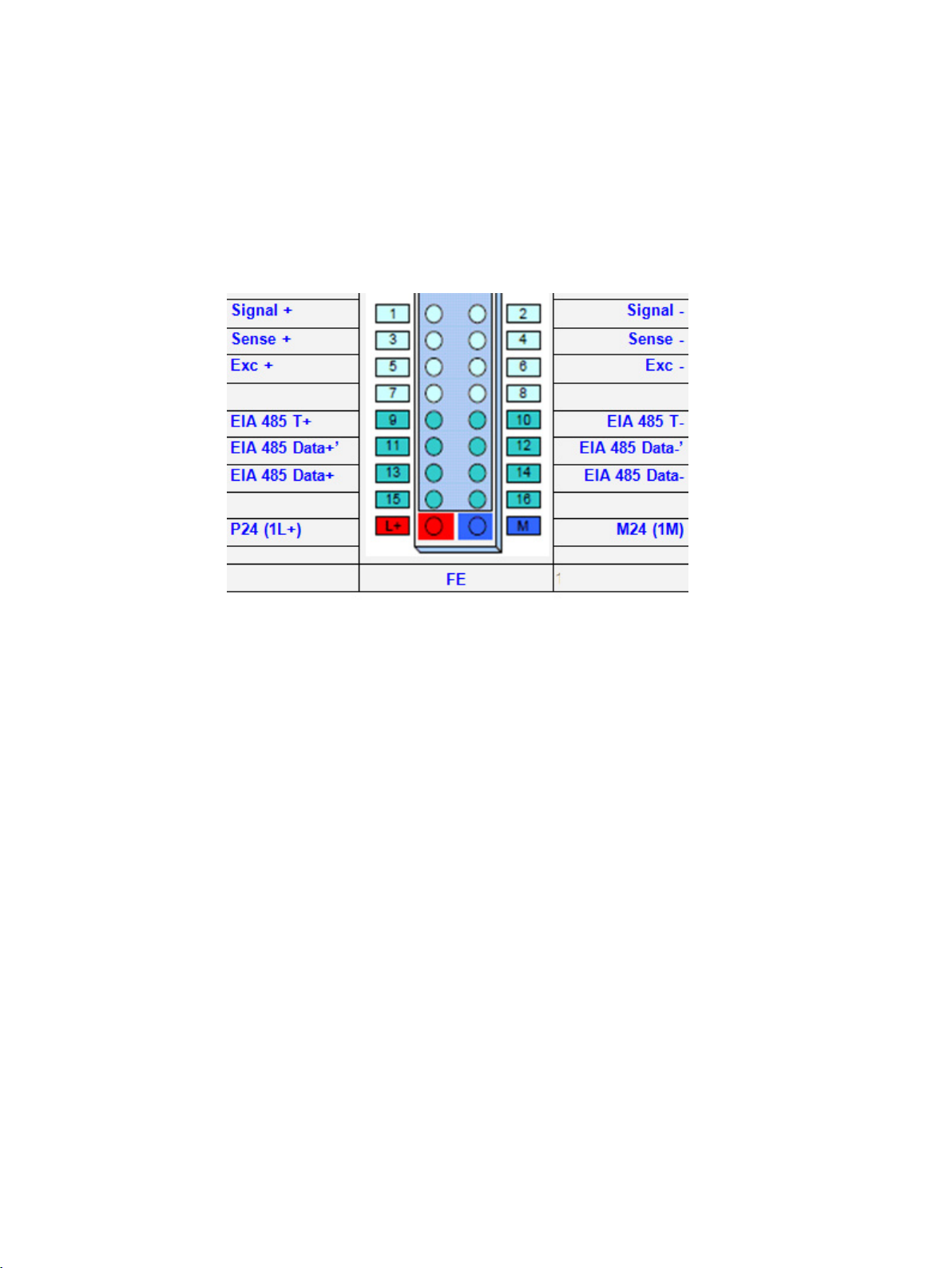

Figure 6-1 SIWAREX WP321 process terminals on the base unit

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

25

Page 26

Connection

6.1

24 V connection

Labeling

Function

6.2

Connecting the load cells

Observe the following rules for connection of analog (DMS) load cells

6.1 24 V connection

The 24 V DC supply voltage is connected by means of the corresponding terminals on the

base unit.

Table 6- 1 Connection of the 24 V supply

L + +24 V voltage supply

M Ground voltage supply

Pickups can be connected to the SIWAREX WP321 electronic weighing system which are

equipped with strain gauges (full bridge) and meet the following requirements.

● Characteristic value 1 to 4 mV/V

● A supply voltage of 5 V is permitted

The power supply for the load cells is 4.85 V.

1. The use of a junction box (SIWAREX JB junction box) is required when more than one

load cell is connected (the load cells must be connected in parallel). If the distance of a

load cell to the SIWAREX WP321 or the junction box is greater than the available length

of the load cell connection cable, use the SIWAREX EB extension box.

2. The cable shield is always applied at the cable gland of the junction box (SIWAREX JB)

or the extension box. If there is a risk of equipotential bonding through the cable shield,

connect a equipotential equalization conductor parallel to the load cell cable.

SIWAREX WP321

26 Manual, 07/2014, A5E33715669A-02

Page 27

Connection

Labeling

Function

Connection pin

6.2 Connecting the load cells

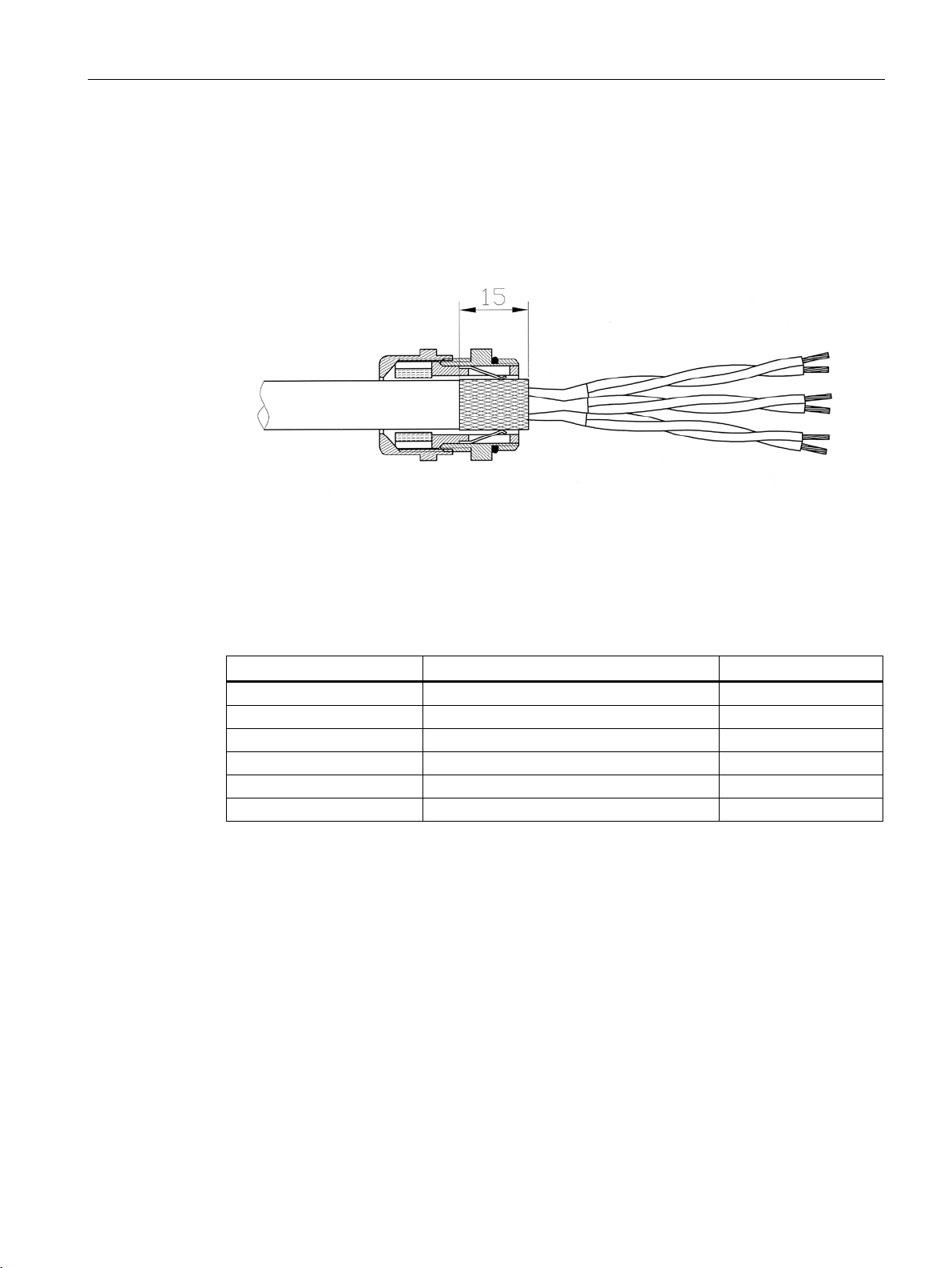

3. Twisted wire pairs that are also shielded are required for the specified cables:

– Sensor cable (+) and (-)

– Measuring voltage cable (+) and (-)

– Supply voltage cable (+) and (-)

Figure 6-2 Shielding in the screw gland

We recommended that you use the cables listed in chapter Accessories (Page 115).

4. The shield must be applied to the ground in close proximity to the SIWAREX WP321.

The maximum distance between the SIWAREX WP321 and the load cell is relevant when

you use the recommended cables.

Sig- Measurement cable load cell - 2

Sig+ Measurement cable load cell - 1

Sen- Sensor cable load cell - 4

Sen+ Sensor cable load cell + 3

Exc- Supply load cell - 6

Exc+ Supply load cell + 5

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

27

Page 28

Connection

6.3

Shield connection

6.3 Shield connection

Make sure you observe the correct design of the shield support for the shielded cables. It is

the only way to ensure immunity of the system.

A cable is shielded to attenuate the effects of magnetic, electrical and electromagnetic

interference on the cable. Interference currents on cable shielding are diverted to ground by

conductive isolation rails. To avoid interference as a result of these currents, it is imperative

to provide a low-impedance connection to the ground.

Only use cables equipped with a shielding braid. Shielding density must be at least 80%.

Figure 6-3 Shield connection and shield terminal

SIWAREX WP321

28 Manual, 07/2014, A5E33715669A-02

Page 29

Connection

6.4

Connection of RS485 serial interface

Labeling

Function

Connection pin

mination jumpers and in between for looping through the

mination jumpers and in between for looping through the

6.4 Connection of RS485 serial interface

The following devices can be connected to the serial interface:

● Siebert display type S102 (connections: see chapter Connection of Siebert display via

RS485 (Page 30))

● PC with RS485/USB converter (see accessories) for use of SIWATOOL

Table 6- 2 Termination of RS485 serial interface

RS485: T+ RS485 termination +:

Is used at the physical end of the bus for inserting termination jumpers

RS485: T- RS485 termination -:

Is used at the physical end of the bus for inserting termination jumpers

RS485: D+' RS485 data line +':

Is used at the physical end of the bus for inserting ter-

bus cables

RS485: D-' RS485 data line -':

Is used at the physical end of the bus for inserting ter-

bus cables

RS485: D+ RS485 data cable + 13

RS485: D- RS485 data cable - 14

9

10

11

12

If a SIWAREX WP321 module is connected to SIWATOOL or a Siebert display, insert wire

jumpers between the T+ and D+' terminals and between the T- and D-' terminals.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

29

Page 30

Connection

6.5

Connection of Siebert display via RS485

Menu item

Setting

Meaning

485

Address

Weight value

2

0.0

----*

8.8.8

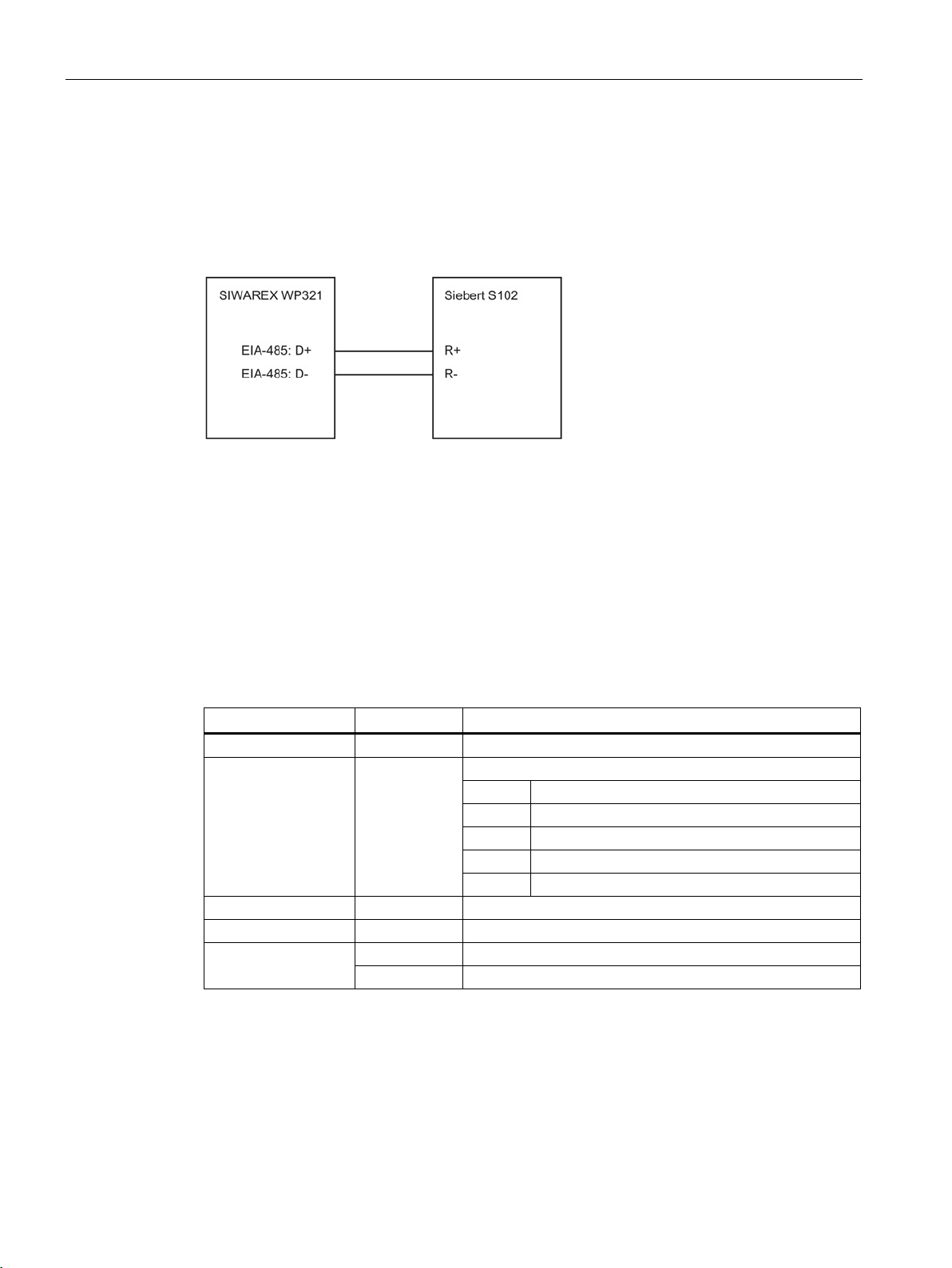

6.5 Connection of Siebert display via RS485

A Siebert display S102 with the order no. S102-W6/14/0R-000/0B-SM can be connected to

the RS485 interface of the weighing module. Connect a 24 V DC supply to the Siebert

display, and connect the latter to the RS485 interface of the weighing module as shown in

the following diagram.

Figure 6-4 Connection of Siebert display S102

The RS485 interface in the DR13 of the SIWAREX WP321 is set as follows:

● Baud rate: 9 600 bit/s

● Character parity: Even

● Number of data bits: 8

● Number of stop bits: 1

The S102 is set as follows:

Table 6- 3 Settings of Siebert display S102

1 Interface

9 Station address

t Timeout

C

F Segment test

01

RS485 interface

Address meaning:

01 Weight

02 Total

03 Net

04 Tare

e.g. timeout after 2 seconds

No decimal point

No segment test when switching on

Segment test when switching on

SIWAREX WP321

30 Manual, 07/2014, A5E33715669A-02

Page 31

7

7.1

Factory-set parameters

7.2

Commissioning tools

Commissioning essentially comprises:

● Checking the scale construction

● Specifying the parameters

● Calibration

● Verifying the envisaged functionality

The electronic weighing system described here is provided with factory-set parameters. The

parameters have been provided for a typical 100 kg scale based on three load cells.

Parameters which can be entered in % or time are preset in such a way that they provide

good results for most applications.

With these default parameters, commissioning can be carried out in 5 minutes (see chapter

5-minute quick start with the operator panel and the Ready-for-Use software (Page 32)).

The following options are available for commissioning the electronic weighing system:

● Operator panel via SIMATIC CPU

● SIWATOOL

If the SIWAREX is only connected to the ET 200SP station, commissioning of the scale can

be carried out using the SIWATOOL program. Operator panel and automation system are

unnecessary. In the event of a fault, additional SIWATOOL diagnostics functions enable fast

analysis of the cause.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

31

Page 32

Commissioning

7.3

5-minute quick start with the operator panel and the Ready-for-Use

software

7.3.1

Start

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

The 5-minute quick start is carried out in this example using a TP700 Comfort Panel

connected to the SIMATIC CPU. The panel communicates with the SIWAREX module via

the SIMATIC CPU.

To carry out the quick start, select the "1.0 Setup" function in the main menu and then "1.2

Quick Start". You will be guided through the individual tasks for setting the most important

parameters.

The remaining parameters are factory-set in such a way that they can be used in most cases

without any changes.

Figure 7-1 Quick start step 1

SIWAREX WP321

32 Manual, 07/2014, A5E33715669A-02

Page 33

Commissioning

7.3.2

Factory setting of the parameters

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

The quick start is based on the factory setting of the parameters. Therefore, the previous

parameter settings must be reset prior to the quick setup. Service mode must be switched on

first. Resetting to the factory setting can then be carried out.

Figure 7-2 Quick start step 2

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

33

Page 34

Commissioning

7.3.3

Selecting the calibration method

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

Figure 7-3 Quick start step 3

The module can always be calibrated in two different ways:

● Using reference weights: in the case of a calibration with weights, mechanical influences

of the scale construction are also partially taken into account.

● Without weights, using the technical specifications of the connected load cell(s): in the

case of automatic calibration, the accuracy of the scale is influenced by the mechanical

properties to a greater extent than with calibration using reference weights.

With both methods, make sure that the mechanical properties of the scale are flawless prior

to calibration.

SIWAREX WP321

34 Manual, 07/2014, A5E33715669A-02

Page 35

Commissioning

7.3.4

Defining the calibration weights

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

Figure 7-4 Quick start step 4a

In step 4 you enter the calibration weights which are to be positioned on the scale during the

calibration. If the scale is not empty and the current contents are known, you can define an

"Calibration weight 0" with the current contents of the scale. With an empty scale, this

parameter remains as 0 kg. "Calibration weight 1" usually defines the first reference point of

the scale characteristic. A further reference point ("Calibration weight 2") can also be set in

addition. This is optional, and may not be necessary depending on the mechanical properties

of the scale.

Note that the interval between the calibration weights must be at least 2% of the nominal

load of the scale. With a 1 000 kg scale, a calibration weight of at least 20 kg must therefore

be used.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

35

Page 36

Commissioning

7.3.5

Setting calibration points

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

Figure 7-5 Quick start step 5a

Carry out the calibration commands at the end of the quick start:

1. Carry out the "Set calibration weight 0" command. The "Calibration weight 0" defined in

step 4 is now visible in the display.

2. Place the "Calibration weight 1" defined in step 4 on the scale construction, and execute

the "Set calibration weight 1" command.

3. If an "Calibration weight 2" was selected:

Place "Calibration weight 2" defined in step 4 on the scale construction, and execute the

"Set calibration weight 2" command.

4. Calibration of the scale is now complete. Return to the start screen by clicking on the

house icon.

SIWAREX WP321

36 Manual, 07/2014, A5E33715669A-02

Page 37

Commissioning

7.3.6

Calibrating the scale automatically

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

The scale can also be calibrated without weights. To do this, it is necessary to enter data

specific to the load cells. In addition, it is essential that the scale is empty.

Figure 7-6 Quick start step 4b

The number of points of support corresponds with a silo, for example, to the number of

clamps or feet of the silo. A quadratic platform scale with a load cell at each corner has 4

support points. The characteristic values of the individual load cells are required to calculate

the average characteristic value of the cells.

The equation for the calculation is as follows:

(characteristic of cell 1 + characteristic of cell 2 + characteristic of cell n) / n

If the exact characteristic values are unknown, it is permissible to also use rounded-off

numbers (e.g. 1.0 mV/V, 2.0 mV/V). The nominal load of an individual load cell (not the

nominal load of the complete scale!) must subsequently be defined.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

37

Page 38

Commissioning

7.3.7

Performing the automatic calibration

7.3.8

Checking the scale following calibration

7.3 5-minute quick start with the operator panel and the Ready-for-Use software

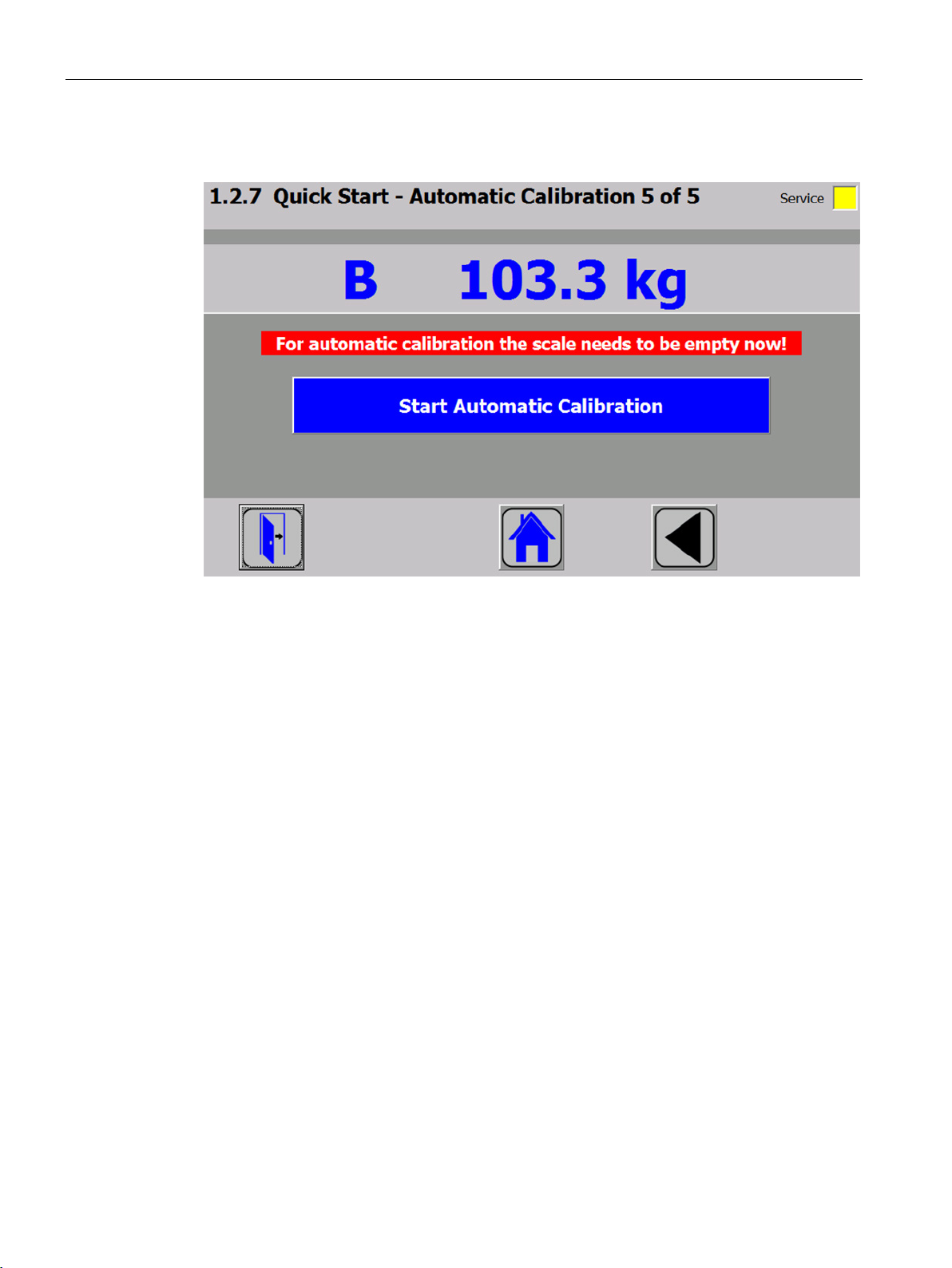

Figure 7-7 Quick start step 5b

Subsequently enter the "Perform automatic calibration" command with the scale empty. The

scale is calibrated directly, and clicking on the house icon returns you to the start screen.

If the scale is only used for company-internal purposes, a simple check is sufficient.

Perform the following steps:

1. The scale is unloaded and shows "0 kg".

2. Place a known reference weight on the scale.

Check the displayed value.

3. If a second known reference weight is available, place it on the scale in addition.

Check whether the scale displays the sum of the reference weights.

4. Remove the reference weights from the scale.

Check that the display is "0 kg" again.

SIWAREX WP321

38 Manual, 07/2014, A5E33715669A-02

Page 39

Commissioning

7.4

5-minute quick start with SIWATOOL

7.4.1

Activate service mode

7.4.2

Load factory setting

7.4 5-minute quick start with SIWATOOL

General information on using the SIWATOOL program can be found in chapter "Service with

the SIWATOOL program (Page 42)".

For the quick setup, the required parameters are marked in bold font in data records DR 3

and DR 10. The procedure is described below.

Figure 7-8 Quick setup with marked parameters

Service mode must be activated in order to change the calibration parameters. You can find

the command in the "Service Commands" group (spanner icon).

The quick setup is based on the standard settings of the weighing module. The factory

setting must therefore be reset prior to the quick start. Firstly, service mode is activated; the

factory setting is subsequently loaded using the "Load factory setting (11)" command.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

39

Page 40

Commissioning

7.4.3

Input of required parameters

7.4.4

Complete automatic calibration

7.4 5-minute quick start with SIWATOOL

For commissioning, you must enter the following parameters in data record DR 3 and send

these to the module:

● Unit of weight

● Required maximum weighing range of the scale

● Scale interval

Sending/receiving a data record is always carried out by right-clicking on the data record

name in the "Value" column in the tree structure.

For example, if data record 3 is to be sent, right-click on "Calibration parameter (DR3)". A

submenu is then opened with the option for sending the respective data record to the

weighing module or for reading it from the module. All data records can only be sent as

complete packets to the SIWAREX or read from it. It is not possible to read or write individual

parameters within a data record. Therefore the complete data record must initially be

received for every change to parameters within it. The desired parameter can then be edited,

and the data record returned. If the data record is not received, the danger exists that

different offline parameters will be sent to the scale and overwrite previously active and

intentionally defined parameters.

Figure 7-9 Sending/receiving a data record with SIWATOOL V7

You must subsequently enter the required parameters in data record DR 10 and send these

to the module.

● Number of support points

● Characteristic value of a load cell in mV/V, or the mean value of the characteristic values

if there is more than one load cell

● Rated load of a load cell

● The scale must be empty (only mechanical dead load).

● Activate the "Automatic Calibration 82" command.

SIWAREX WP321

40 Manual, 07/2014, A5E33715669A-02

Page 41

Commissioning

7.4.5

Receive all data

7.4.6

Checking the scale following calibration

7.4 5-minute quick start with SIWATOOL

Activate the "Receive all data" function in the communication menu.

All parameters can now been saved as a backup file on the hard disk. If a module is

replaced, the backup file can be downloaded to the new module within a few seconds. At the

time of input of the backup file, the scale is directly in the calibrated state again – without a

new calibration.

If the scale is only used for company-internal purposes, a simple check is sufficient.

Perform the following steps:

1. The scale is unloaded and shows "0 kg".

2. Place a known reference weight on the scale.

Check the displayed value.

3. If a second known reference weight is available, place it on the scale in addition.

Check whether the scale displays the sum of the reference weights.

4. Remove the reference weights from the scale.

Check that the display is "0 kg" again.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

41

Page 42

Commissioning

7.5

Service with the SIWATOOL program

See also

7.5.1

Windows and functions of SIWATOOL

①

③

②

④

7.5 Service with the SIWATOOL program

You can use the SIWATOOL program to commission the scale independently of the

SIMATIC automation system. You require an RS485/USB converter (see section

"Accessories") in order to connect the PC to the SIWAREX. You can then connect the

RS485 interface of the SIWAREX to the USB port of the PC.

The SIWATOOL program is included in the configuration package.

Install the SIWATOOL program (SIWATOOL catalog) on your PC for commissioning.

Accessories (Page 115)

Control elements for SIWATOOL and operation of

the scale

Parameter list of the SIWATOOL module

Figure 7-10 Layout of the SIWATOOL user interface

For sending, receiving and transferring, select the corresponding data record and call the

command list with a right mouse click.

The complete data record (all parameters of the data record) is always transferred, not just

individual parameters.

SIWAREX WP321

42 Manual, 07/2014, A5E33715669A-02

Offline values of the SIWAREX module

Online values of the connected SIWAREX module

Page 43

Commissioning

7.5.2

Offline parameter assignment

7.5.3

Online parameter assignment

Note

7.5 Service with the SIWATOOL program

All scale parameters can be edited and saved without an electronic weighing system.

This reduces the setup time. You can thus prepare the parameters for several scales in your

office, and subsequently transfer them to the electronic weighing system during setup.

Data from one scale currently in operation can be exported and used to set up another scale.

To switch to online mode, connect the PC to the SIWAREX module via an RS485/USB

converter. Set the appropriate interface in the communication menu.

You can change all parameters in the SIWAREX module in online mode. The message

window shows the current contents of the message buffer of the SIWAREX module. The

current process values are displayed in the "Online" column.

For test purposes, you can send various commands to the SIWAREX module. Differences

between the online/offline data are marked in red by SIWATOOL. This affects both the

associated data record and the individual parameter.

In order to archive data, all data can be exported from the SIWAREX module and saved as a

file or printed.

You can edit all data in the SIWAREX module in online mode. The changes are not

automatically imported to the corresponding scale data block in the SIMATIC CPU.

To download the data to the SIWAREX module, select the data record with a right mouse

click and send it explicitly to the SIWAREX module.

Online parameter trends can be recorded and played back using the recorder function

located at the top right-hand edge of SIWATOOL. You can use the "Configure recorder"

button to select the data records to be recorded and to set the save parameters. The

playback speed can be set using a slider.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

43

Page 44

Commissioning

7.5.4

Available help options

7.5.5

Entering parameters with SIWATOOL

7.5 Service with the SIWATOOL program

SIWATOOL offers various help options for operation:

● Info card

You can select the "Info" item directly underneath the individual data records in the

navigation tree. This info card explains how the data record influences the scale behavior.

● Tooltip

If you move the mouse over a button or parameter, a corresponding help text is

displayed.

● Help

Click on the menu option "Help" to call up the SIWATOOL help. The Help can be opened

separately.

There is a defined procedure for handling parameters. The current parameters in the

SIWAREX module are displayed in the right-hand window, while the parameter values on the

PC are displayed in the left-hand window. The new parameter value is entered first in the

left-hand window. If several parameters of the data record are to be changed, they are

entered consecutively. The data record is subsequently selected in the tree view and sent to

the SIWAREX modules using the right mouse button.

Parameters are always changed as complete data records, rather than individually.

SIWAREX WP321

44 Manual, 07/2014, A5E33715669A-02

Page 45

8

8.1

Parameters and functions

8.2

DR 2 command code

All parameters are set to default values in the factory. You can restore the configuration to

factory settings using the "Load factory settings" command.

The scales are ready for operation with the default parameter settings. You do not need to

re-enter all parameters. The advantage of this solution is that you can decide the default

values to be retain and the parameters that need to be adapted for your application.

All parameters are divided into data records (DR). The data records are organized in steps

(tasks) to be implemented during commissioning or during the process.

The scale functions governed by the parameters are also described in the parameter

description below.

First, the parameters of a given data record are displayed in a table. The detailed parameter

description for the parameters of this data record then follows.

When it receives new parameters, the SIWAREX module runs a validation check. In the

event of a parameter assignment error, the data record is not applied (not saved) by the

SIWAREX module and a data/operator error is reported.

DR 2 is a special data record used to transfer commands to the SIWAREX module by

SIWATOOL.

SIWAREX WP321

Manual, 07/2014, A5E33715669A-02

45

Page 46

Scale parameters and functions

8.3

DR 3 calibration parameters

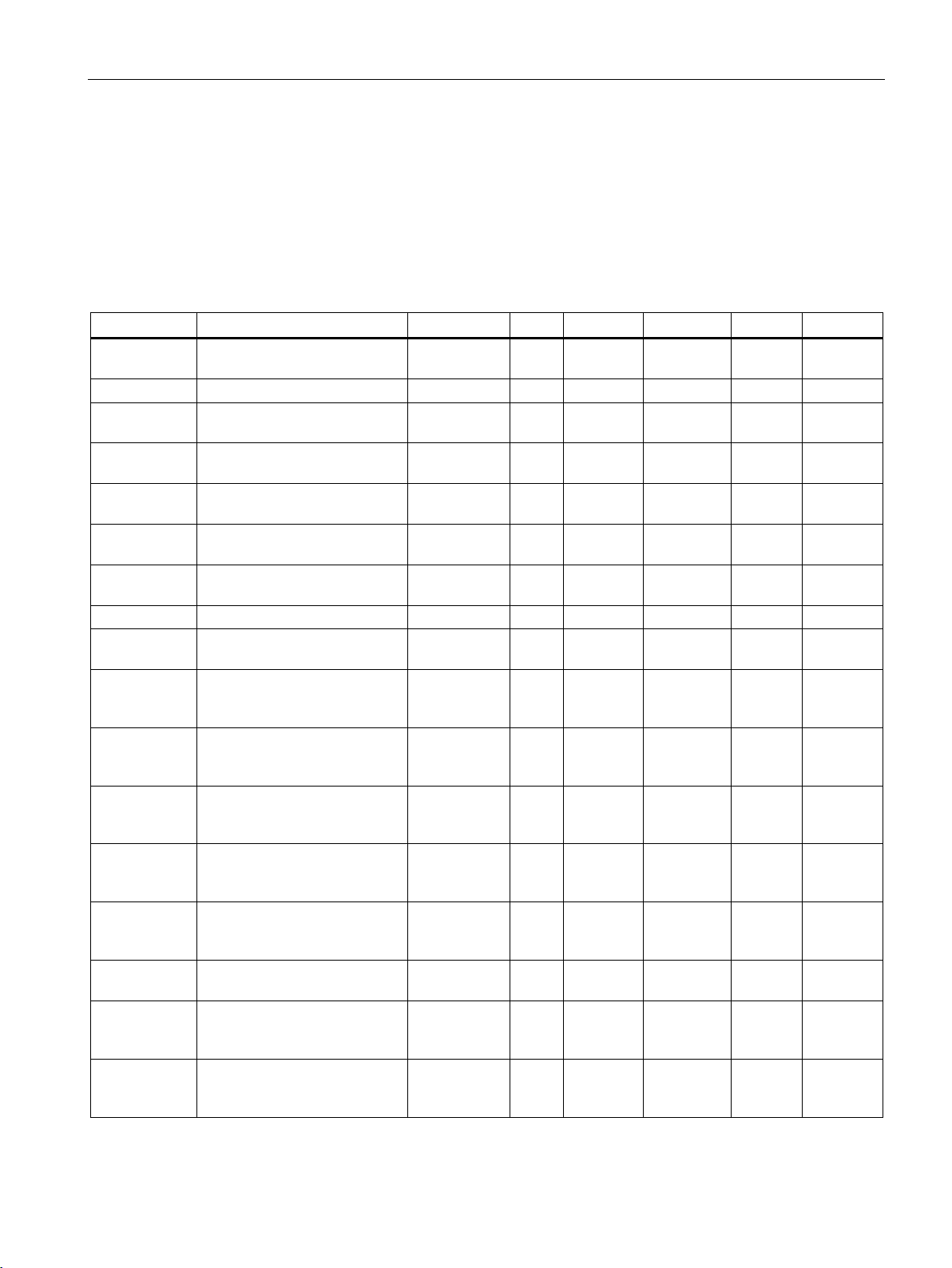

Procedure

Variable

Note

Type

Length

(bytes)

Rw

Default

Min.

Max.

8.3 DR 3 calibration parameters

The calibration parameters need to be checked and if necessary modified for all scales.

The scale is basically defined by calibration parameters and calibration operation.

● Check all parameters and modify them as required.

● Transfer the DR 3 data record from SIWATOOL to the scale.

● Calibrate the scale.

● Transfer the DR 3 data record from the scale to SIWATOOL.

Table 8- 1 Assignment of data record 3

Data record

number

Length Data record length information USHORT 2 r 124 - Application Information about which application

Version identifier

Scale name

header

Scale name

(Page 48)

Unit of

weight header

Unit of

weight

(Page 48)1)

Gross identifier header

Gross identifier

(Page 48)

Reserve Reserve USHORT 8 rw 0 - Maximum

weighing

range

(Page 49)

Calibration

weights 0, 1,

2 and calibration digits

Contains no. of data record USHORT 2 r 3 - -

USHORT 2 r 201 - -

the DR belongs to

Information on the current data rec-

ord version

Maximum length and actual length of

string for scale name

Scale name specified by user CHAR[12] 12 rw " " - -

Maximum length and actual length of

string for unit of weight (e.g.: g, kg, t,

...)

Unit of weight CHAR[4] 4 rw "kg••" - -

Maximum length and actual length of

string for unit of weight

Abbreviation of gross

(B or G), only one byte is used!

Maximum weight FLOAT 4 rw 100 > wb_min*

1)

Calibration weight 01) (usually the

zero point)

Calibration weight 11) FLOAT 4 rw 100 1 9 999 999

Calibration weight 2 FLOAT 4 rw 0 1 9 999 999

USHORT 2 r 1 1 65 635

UBYTE[2] 2 rw 12,12 - -

UBYTE[2] 2 rw 04,04 - -

UBYTE[2] 2 rw 02,02 - -

CHAR[2] 2 rw "B" "B" "G"

ZIF.step

FLOAT 4 rw 0 1 9 999 999

maximum

number

range

SIWAREX WP321

46 Manual, 07/2014, A5E33715669A-02

Page 47

Scale parameters and functions

Variable

Note

Type

Length

(bytes)

Rw

Default

Min.

Max.

0, 1, 2

8.3 DR 3 calibration parameters

(Page 49)

Calibration digits 0 determined during calibration with calibration weight