Siemens SIWAREX WP251 User Manual

SIWAREX WP251

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Weighing systems

Electronic Weighing System SIWAREX WP251

Manual

12/2015

A5E37203357A

Introduction

1

Safety notes

2

Description

3

Application planning

4

Mounting

5

Connection

6

Commissioning

7

Scale parameters and

functions

8

Errors and messages

9

Command lists

10

Communication with

SIMATIC S7-1200

11

Operation requiring official

calibration

12

Technical specifications

13

Accessory

14

ESD guidelines

A

List of abbreviations

B

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E37203357A

Ⓟ

Copyright © Siemens AG 2015.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

12/2015 Subject to change

Table of contents

1 Introduction ........................................................................................................................................... 15

2 Safety notes .......................................................................................................................................... 17

3 Description ............................................................................................................................................ 19

4 Application planning .............................................................................................................................. 21

5 Mounting ............................................................................................................................................... 25

6 Connection ........................................................................................................................................... 29

1.1 Purpose of the manual ............................................................................................................ 15

1.2 Basic knowledge required ....................................................................................................... 15

1.3 Manual - range of validity ........................................................................................................ 15

1.4 Technical support .................................................................................................................... 15

2.1 General safety instructions ..................................................................................................... 17

2.2 Security messages .................................................................................................................. 17

3.1 Product overview .................................................................................................................... 19

3.2 Area of application .................................................................................................................. 19

3.3 System integration in SIMATIC ............................................................................................... 19

3.4 Scope of delivery .................................................................................................................... 20

4.1 Functions ................................................................................................................................ 21

4.2 Parameter assignment options ............................................................................................... 21

4.2.1 Parameter assignment with the PC ........................................................................................ 21

4.2.2 Parameter assignment with a SIMATIC Panel ....................................................................... 22

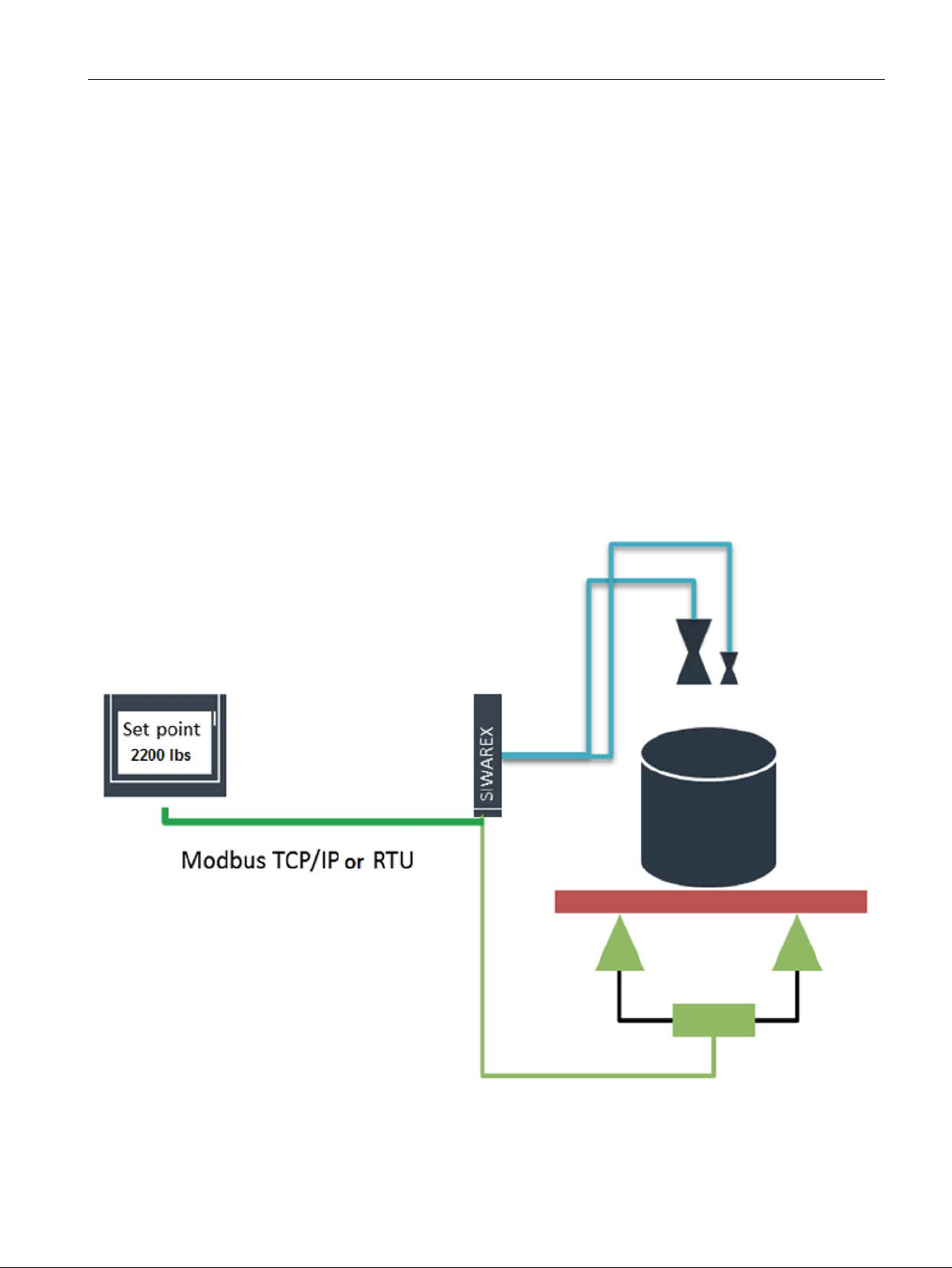

4.2.3 Parameter assignment by means of the Modbus interface .................................................... 23

5.1 Installation guideline ............................................................................................................... 25

5.2 EMC-compliant installation ..................................................................................................... 25

5.2.1 Introduction ............................................................................................................................. 25

5.2.2 Possible effects of interference ............................................................................................... 25

5.2.3 Coupling mechanisms............................................................................................................. 26

5.2.4 Five basic rules for securing EMC .......................................................................................... 26

5.3 Mounting on the SIMATIC S7-1200 ........................................................................................ 27

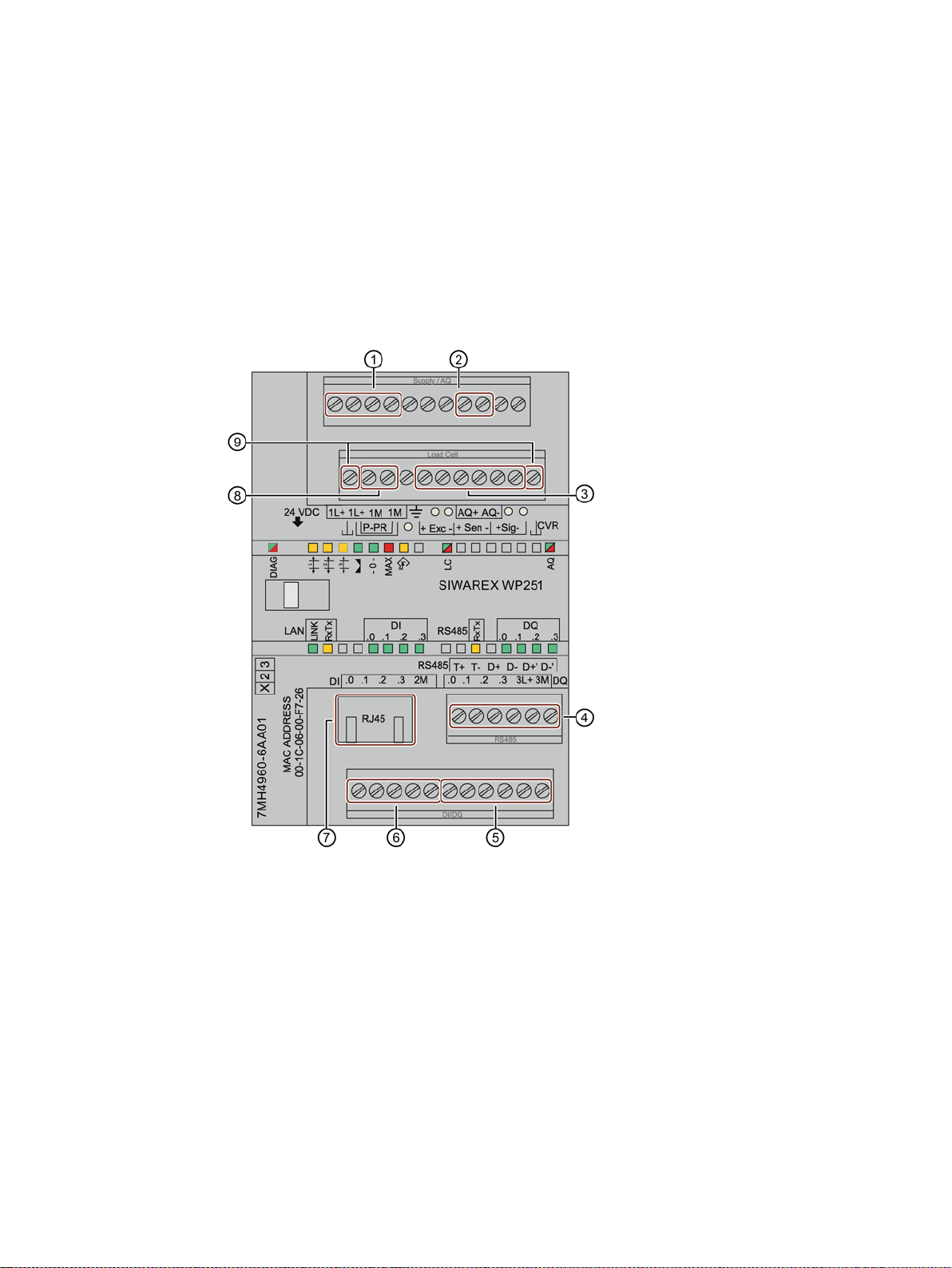

6.1 Overview ................................................................................................................................. 29

6.2 24 V connection ...................................................................................................................... 30

6.3 Connecting the load cells ........................................................................................................ 30

6.4 Shield connection .................................................................................................................... 31

6.5 Connection of digital outputs (4 x DQ) .................................................................................... 34

SIWAREX WP251

Manual, 12/2015, A5E37203357A

3

Table of contents

7 Commissioning ..................................................................................................................................... 41

8 Scale parameters and functions ............................................................................................................ 57

6.6 Connection of digital inputs (4 x DI) ....................................................................................... 35

6.7 Connection of the analog output (1 x AQ) ............................................................................. 36

6.8 Connection of RS485 serial interface .................................................................................... 36

6.9 Connection of Siebert display via RS485 .............................................................................. 37

6.10 Connection of the Ethernet interface ..................................................................................... 38

6.11 Activation of write protection .................................................................................................. 38

6.12 Attachment of calibration protection plate .............................................................................. 39

7.1 Introduction ............................................................................................................................ 41

7.2 Factory setting of the mode selector ...................................................................................... 41

7.3 Automatic quick calibration with SIWATOOL ......................................................................... 42

7.3.1 Overview ................................................................................................................................ 42

7.3.2 Activate service mode ............................................................................................................ 43

7.3.3 Load standard parameters ..................................................................................................... 43

7.3.4 Input of required parameters .................................................................................................. 44

7.3.5 Complete automatic calibration .............................................................................................. 45

7.3.6 Receive all data...................................................................................................................... 45

7.3.7 Checking the scale after calibration ....................................................................................... 45

7.4 Quick calibration with calibration weights and SIWATOOL ................................................... 46

7.4.1 Introduction ............................................................................................................................ 46

7.4.2 Activate service mode ............................................................................................................ 46

7.4.3 Load standard parameters ..................................................................................................... 46

7.4.4 Input of required parameters .................................................................................................. 46

7.4.5 Calibration .............................................................................................................................. 47

7.4.6 Receive all data...................................................................................................................... 48

7.4.7 Checking the scale following calibration ................................................................................ 48

7.5 Service with the SIWATOOL program ................................................................................... 48

7.5.1 General .................................................................................................................................. 48

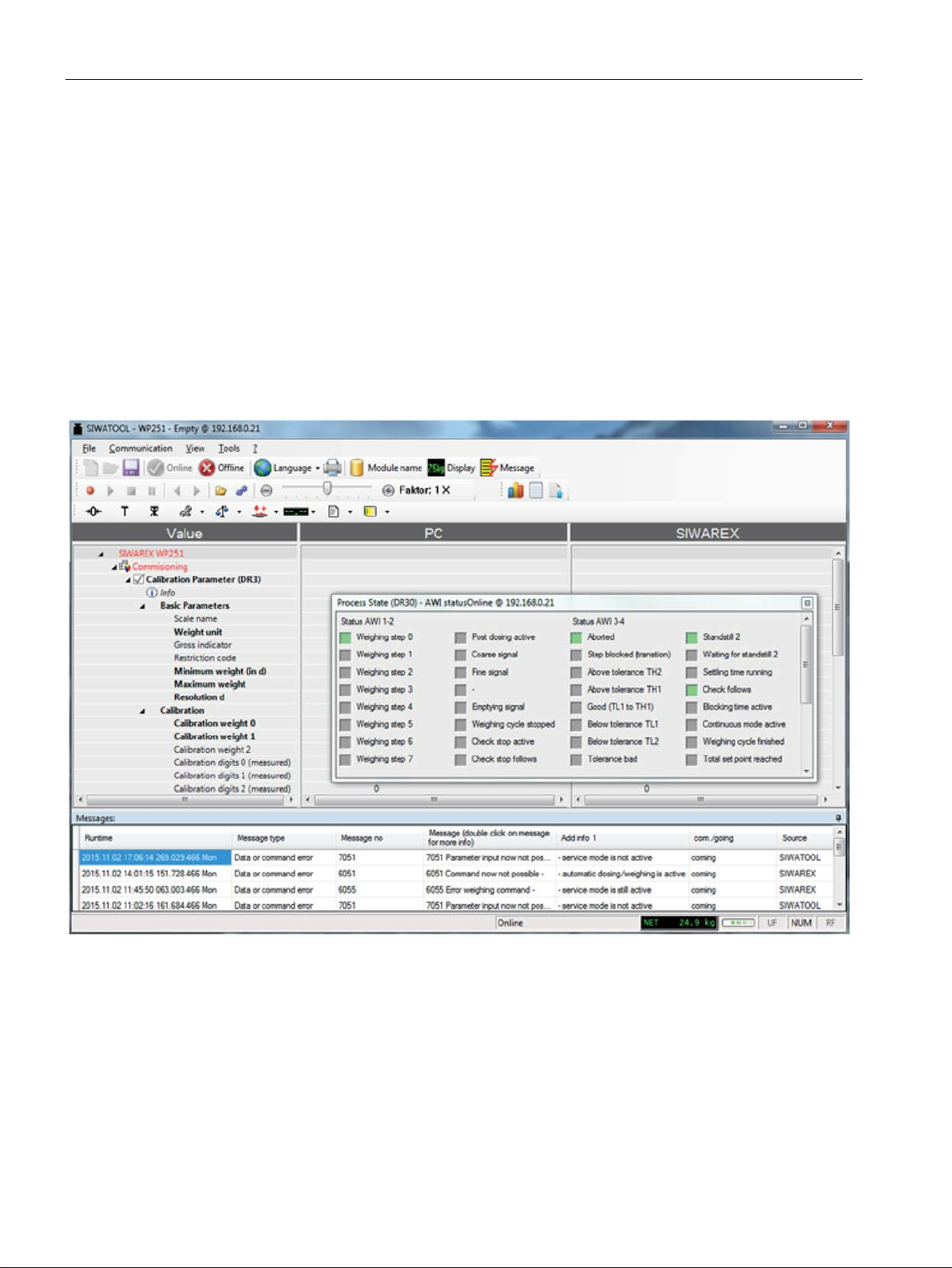

7.5.2 Windows and functions of SIWATOOL .................................................................................. 49

7.5.3 Offline parameter assignment ................................................................................................ 50

7.5.4 IP address for SIWAREX ....................................................................................................... 50

7.5.4.1 Introduction ............................................................................................................................ 50

7.5.4.2 E

ntering a known SIWAREX IP address ............................................................................... 51

7.5.4.3 Determining an unknown IP address ..................................................................................... 51

7.5.4.4 Setting up a network .............................................................................................................. 51

7.5.5 Online parameter assignment ................................................................................................ 51

7.5.6 Entering parameters with SIWATOOL ................................................................................... 52

7.5.7 Recording scale traces .......................................................................................................... 52

7.5.8 Firmware update .................................................................................................................... 53

7.5.9 Reading out the saved scale logs .......................................................................................... 55

8.1 Parameters and functions ...................................................................................................... 57

8.2 Weighing steps....................................................................................................................... 58

8.2.1 Introduction ............................................................................................................................ 58

8.2.2 Operating mode NAWI (non-automatic weighing instrument) - Filling ................................... 58

SIWAREX WP251

4 Manual, 12/2015, A5E37203357A

Table of contents

8.2.3 Operating mode NAWI (non-automatic weighing instrument) - Removal ............................... 59

8.2.4 Operating mode AWI (automatic weighing instruments) ........................................................ 59

8.2.5 Operating mode ACI (automatic catchweighing instruments) - Filling .................................... 60

8.2.6 Operating mode ACI (automatic catchweighing instruments) - Removal ............................... 61

8.3 DR 3 Calibration parameters .................................................................................................. 61

8.3.1 Overview ................................................................................................................................. 61

8.3.2 Scale name ............................................................................................................................. 66

8.3.3 Unit of weight .......................................................................................................................... 66

8.3.4 Gross identifier ........................................................................................................................ 66

8.3.5 Code for regulations................................................................................................................ 67

8.3.6 Minimum weighing range ........................................................................................................ 67

8.3.7 Maximum weighing range ....................................................................................................... 67

8.3.8 Calibration weights 0, 1, 2 and calibration digits 0, 1, 2 ......................................................... 67

8.3.9 Scale interval .......................................................................................................................... 68

8.3.10 Zero by power-on .................................................................................................................... 68

8.3.11 Zero by power-on when tare ≠ 0 ............................................................................................. 68

8.3.12 Automatic zero adjustment ..................................................................................................... 68

8.3.13 Subtractive / additive tare device ............................................................................................ 69

8.3.14 Weight simulation allowed ...................................................................................................... 69

8.3.15 Automatic zero tracking .......................................................................................................... 69

8.3.16 Maximum tare load ................................................................................................................. 70

8.3.17 Maximum negative zero setting limit (power-on) .................................................................... 70

8.3.18 Maximum positive zero setting limit (power-on) .....................................................................

8.

3.19 Maximum negative zero setting limit (semi-automatically) ..................................................... 70

70

8.3.20 Maximum positive zero setting limit (semi-automatically) ....................................................... 71

8.3.21 Standstill monitoring ................................................................................................................ 71

8.3.22 Standstill 1 - range .................................................................................................................. 72

8.3.23 Standstill 1 - time .................................................................................................................... 72

8.3.24 Max. waiting time for standstill 1 ............................................................................................. 72

8.3.25 Standstill 2 - range .................................................................................................................. 73

8.3.26 Standstill 2 - time .................................................................................................................... 73

8.3.27 Setting time before standstill 2 ................................................................................................ 73

8.3.28 Frequency low pass filter 1 ..................................................................................................... 74

8.3.29 Order no. low pass filter 1 ....................................................................................................... 74

8.3.30 Depth average filter ................................................................................................................. 74

8.3.31 Weighing operating mode ....................................................................................................... 75

8.3.32 SecureDisplay including weighing range data ........................................................................ 75

8.3.33 SecureDisplay interface .......................................................................................................... 75

8.3.34 SecureDisplay version ............................................................................................................ 75

8.3.35 Smallest zoom factor of SecureDisplay .................................................................................. 75

8.3.36 Grid frequency ........................................................................................................................ 75

8.4 Calibration ............................................................................................................................... 76

8.4.1 Calibration with calibration weights ......................................................................................... 76

8.4.2 Automatic calibration............................................................................................................... 78

8.5 DR 4 Output of calculated calibration digits ............................................................................

8.

5.1 Overview ................................................................................................................................. 79

5.2 Calibration digits 0, 1, 2 (calculated) ....................................................................................... 80

8.

8.6 DR 5 Tare / zero memory ....................................................................................................... 80

8.6.1 Overview ................................................................................................................................. 80

8.6.2 Effective tare weight - from specification 1, 2 or 3 .................................................................. 81

SIWAREX WP251

Manual, 12/2015, A5E37203357A

79

5

Table of contents

8.6.3 Effective tare weight (semi-automatic) ................................................................................... 81

8.6.4 Zero by power-on (value when switching on) ........................................................................ 82

8.6.5 Zero weight (semi-automatic) ................................................................................................ 82

8.6.6 Current zero tracking weight .................................................................................................. 82

8.6.7 Dead load ............................................................................................................................... 82

8.7 DR 6 Limits ............................................................................................................................. 82

8.7.1 Overview ................................................................................................................................ 82

8.7.2 Limit value 1 ON, limit value 2 ON, limit value 1 OFF, limit value 2 OFF .............................. 84

8.7.3 Switch-on delay limit 3 (empty) .............................................................................................. 85

8.7.4 Limit 3 - empty ........................................................................................................................ 85

8.8 DR 7 Process interfaces ........................................................................................................ 86

8.8.1 Overview ................................................................................................................................ 86

8.8.2 Assignment of digital input DI.0, DI.1, DI.2, DI.3 ................................................................... 90

8.8.3 Input filtering (hardware setting) ............................................................................................ 91

8.8.4 Assignment of digital output DQ.0, DQ.1, DQ.2, DQ.3 .......................................................... 91

8.8.5 Response of digital outputs to faults or SIMATIC STOP ....................................................... 92

8.8.6 Substitute value for DQ 0, 1, 2, 3 following fault or SIMATIC STOP ..................................... 92

8.8.7 Analog output range ............................................................................................................... 93

8.8.8 Analog output source ............................................................................................................. 93

8.8.9 Response of analog output to faults or SIMATIC STOP........................................................ 93

8.8.10 Start value for the analog output ............................................................................................ 93

8.8.11 End value for the analog output ............................................................................................. 93

8.8.12 Output value following fault or SIMATIC STOP ..................................................................... 94

8.8.13 Trace recording cycle .............................................................................................................

8.14 Trace storage method ............................................................................................................ 94

8.

94

8.9 DR 8 date and time ................................................................................................................ 95

8.10 DR 9 module information ....................................................................................................... 95

8.11 DR 10 Load cell parameters .................................................................................................. 96

8.11.1 Overview ................................................................................................................................ 96

8.11.2 Number of support points ....................................................................................................... 97

8.11.3 Load cell characteristic value ................................................................................................. 98

8.11.4 Rated load of a load cell ........................................................................................................ 98

8.12 DR 12 Ethernet parameters ................................................................................................... 98

8.12.1 Overview ................................................................................................................................ 98

8.12.2 Device MAC address ............................................................................................................. 99

8.12.3 Port MAC address .................................................................................................................. 99

8.12.4 IP address .............................................................................................................................. 99

8.12.5 Subnet mask ........................................................................................................................ 100

8.12.6 Gateway ............................................................................................................................... 100

8.12.7 Device name ........................................................................................................................ 100

8.13 DR 13 RS485 parameters .................................................................................................... 100

8.13.1 Overview .............................................................................................................................. 100

8.13.2 RS485 protocol .................................................................................................................... 102

8.13.3 RS485 baud rate .................................................................................................................. 102

8.13.4 RS485 character parity ........................................................................................................ 102

8.13.5 RS485 number of data bits .................................................................................................. 102

8.13.6 RS485 number of stop bits .................................................................................................. 103

8.13.7 RS485 Modbus address ......................................................................................................

13.8 Decimal place for Siebert indicator ...................................................................................... 103

8.

103

SIWAREX WP251

6 Manual, 12/2015, A5E37203357A

Table of contents

8.14 DR 14 Selection process value 1, 2 ...................................................................................... 103

8.15 DR 15 Preset tare ................................................................................................................. 104

8.15.1 Overview ............................................................................................................................... 104

8.15.2 Preset tare weight 1 .............................................................................................................. 105

8.16 DR 16 Weight simulation ...................................................................................................... 105

8.16.1 Overview ............................................................................................................................... 105

8.16.2 Weight simulation specification ............................................................................................. 106

8.17 DR 17 Control analogue output ............................................................................................ 106

8.17.1 Overview ............................................................................................................................... 106

8.17.2 Analog output specification ................................................................................................... 106

8.18 DR18 Control digital outputs ................................................................................................. 107

8.18.1 Overview ............................................................................................................................... 107

8.18.2 Specification for digital outputs DQ.0, DQ.1, DQ.2, DQ.3 .................................................... 108

8.18.3 Transitions for weighing steps 0 to 7 .................................................................................... 108

8.19 DR 20 Single set point .......................................................................................................... 109

8.19.1 Overview ............................................................................................................................... 109

8.19.2 Single set point ..................................................................................................................... 109

8.20 DR 21 Total set point ............................................................................................................ 110

8.20.1 Overview ............................................................................................................................... 110

8.20.2 Total set point ....................................................................................................................... 110

8.21 DR 22 Tolerance parameters ............................................................................................... 111

8.21.1 Overview ............................................................................................................................... 111

8.21.2 Parameter relation ................................................................................................................ 115

8.21.3 Tolerance limit TH2 ...............................................................................................................

21.4 Tolerance limit TH1 ............................................................................................................... 116

8.

116

8.21.5 Tolerance limit TL1 ............................................................................................................... 116

8.21.6 Tolerance limit TL2 ............................................................................................................... 116

8.21.7 Behavior in case of TH1 error ............................................................................................... 116

8.21.8 Behavior in case of TL1 error ............................................................................................... 116

8.21.9 Pulse duration for pulse post dosing ..................................................................................... 116

8.21.10 Number of not controlled weighings ..................................................................................... 117

8.21.11 Capture of weighings into statistics ...................................................................................... 117

8.22 DR 23 Material parameters ................................................................................................... 118

8.22.1 Overview ............................................................................................................................... 118

8.22.2 Parameter relation ................................................................................................................ 119

8.22.3 Fine weight ............................................................................................................................ 119

8.22.4 Trailing weight ....................................................................................................................... 119

8.22.5 Blocking time coarse signal .................................................................................................. 120

8.22.6 Blocking time fine signal ....................................................................................................... 120

8.22.7 Shut-off correction weight ..................................................................................................... 121

8.23 DR 24 Controller and filter parameters ................................................................................. 121

8.23.1 Overview ............................................................................................................................... 121

8.23.2 Parameter relation ................................................................................................................ 123

8.23.3 Type of controller .................................................................................................................. 123

8.23.4 Control factor of proportional controller ................................................................................

8.

23.5 Maximum corrective action ................................................................................................... 123

8.23.6 Controller deadband - upper limit ......................................................................................... 124

8.23.7 Controller deadband - lower limit ..........................................................................................

SIWAREX WP251

Manual, 12/2015, A5E37203357A

123

124

7

Table of contents

8.23.8 Reaction when max. corrective action is exceeded ............................................................. 124

8.23.9 Selection for dosing filter ...................................................................................................... 124

8.23.10 Frequency low pass filter 2 .................................................................................................. 125

8.23.11 Order no. low pass filter 2 .................................................................................................... 125

8.23.12 Depth average filter .............................................................................................................. 126

8.23.13 Adopt corrected fine/trailing value to DR 23 automatically .................................................. 126

8.24 DR 25 Dosing device parameters ........................................................................................ 126

8.24.1 Overview .............................................................................................................................. 126

8.24.2 Maximum single set point .................................................................................................... 128

8.24.3 "Coarse" set value for analogue output ............................................................................... 128

8.24.4 "Fine" set value for analogue output .................................................................................... 129

8.24.5 Minimum automatic tare weight ........................................................................................... 129

8.24.6 Maximum automatic tare weight .......................................................................................... 129

8.24.7 Maximum weighing time ...................................................................................................... 129

8.24.8 Weighing start options ......................................................................................................... 130

8.24.9 Cycle time for automatic zero setting ................................................................................... 130

8.24.10 Number of weighings without automatic taring/zero setting ................................................ 130

8.24.11 Check stop ........................................................................................................................... 130

8.24.12 Automatic emptying ............................................................................................................. 131

8.24.13 Emptying time ...................................................................................................................... 131

8.24.14 Maximum emptying time ...................................................................................................... 131

8.25 DR 28 Additional strings for log ........................................................................................... 132

8.25.1 Overview .............................................................................................................................. 132

8.25.2 Strings 1, 2, 3 and 4 .............................................................................................................

25.3 Sting selection for automatic logging ................................................................................... 133

8.

132

8.26 DR 29 Configuration of technology messages .................................................................... 133

8.27 DR 30 Process state ............................................................................................................ 135

8.27.1 Overview .............................................................................................................................. 135

8.27.2 Gross, net and tare process values ..................................................................................... 140

8.27.3 Gross, net and tare weights ................................................................................................. 140

8.27.4 Gross/Net weight x10 ........................................................................................................... 140

8.27.5 Gross/Net process weight 2 ................................................................................................. 140

8.27.6 Refresh counter.................................................................................................................... 140

8.27.7 Actual weight of last dosing ................................................................................................. 140

8.27.8 Totalizer 1 and Totalizer 2 ................................................................................................... 140

8.27.9 Youngest protocol-ID ........................................................................................................... 141

8.27.10 Date & time .......................................................................................................................... 141

8.27.11 Current weighing step .......................................................................................................... 141

8.28 DR 31 Process state extended ............................................................................................ 141

8.28.1 Overview .............................................................................................................................. 141

8.28.2 Unfiltered digit value ............................................................................................................ 143

8.28.3 Digits filtered by F1 .............................................................................................................. 143

8.28.4 Filtered digit value 2 ............................................................................................................. 143

8.28.5 Current analog output (mA) ................................................................................................. 144

8.28.6 Current analog output (digits) ..............................................................................................

28.7 Current status digital input DI.0, DI.1, DI.2 and DI.3 ............................................................ 144

8.

144

8.28.8 DIP switch 1 and 2 ............................................................................................................... 144

8.28.9 Current status digital output DQ.0, DQ.1, DQ.2 and DQ.3 ..................................................

28.10 Refresh counter.................................................................................................................... 144

8.

144

8.28.11 Current load cell signal in mV .............................................................................................. 145

SIWAREX WP251

8 Manual, 12/2015, A5E37203357A

Table of contents

9 Errors and messages .......................................................................................................................... 163

10 Command lists .................................................................................................................................... 179

8.28.12 Current fine weight ................................................................................................................ 145

8.28.13 Current trailing weight ........................................................................................................... 145

8.28.14 Tolerance limits TH2, TH1, TL1 and TL2.............................................................................. 145

8.29 DR 32 Error messages ......................................................................................................... 145

8.29.1 Overview ............................................................................................................................... 145

8.29.2 Operating errors, technology messages, data/command errors .......................................... 150

8.30 DR 34 ASCII weight display .................................................................................................. 150

8.30.1 Overview ............................................................................................................................... 150

8.30.2 Content of the display string ................................................................................................. 150

8.31 DR 35 SecureDisplay data ................................................................................................... 151

8.32 DR 38 Min/max pointer ......................................................................................................... 152

8.33 DR 39 Statistics .................................................................................................................... 152

8.34 DR 41/42 Data memory ........................................................................................................ 154

8.35 DR 45 Protocol request......................................................................................................... 155

8.35.1 Overview ............................................................................................................................... 155

8.35.2 Protocol ID to be read ........................................................................................................... 156

8.36 DR 46 Protocol content ......................................................................................................... 157

8.36.1 Overview ............................................................................................................................... 157

8.36.2 Oldest report ID ..................................................................................................................... 158

8.36.3 Newest report ID ................................................................................................................... 158

8.36.4 Selected protocol-ID ............................................................................................................. 158

8.36.5 Protocol ................................................................................................................................. 158

8.36.6 Date, time .............................................................................................................................. 159

8.

37 DR 47 Logbook ..................................................................................................................... 159

8.38 DR 48 date and time 2 (for Modbus) .................................................................................... 160

9.1 Message and error types ...................................................................................................... 163

9.2 Message paths ...................................................................................................................... 163

9.3 Evaluating errors/messages with the help of SIWATOOL .................................................... 164

9.4 Evaluating errors/messages with the help of the function block ........................................... 164

9.5 Evaluating errors/messages using Modbus .......................................................................... 164

9.6 Operating errors .................................................................................................................... 164

9.6.1 Operating errors .................................................................................................................... 164

9.6.2 Technology messages .......................................................................................................... 165

9.6.3 Data and command errors .................................................................................................... 167

9.6.4 Data and command errors - Additional information .............................................................. 172

9.6.5 Messages by LEDs on the module ....................................................................................... 177

10.1 Overview ............................................................................................................................... 179

10.2 Command lists ...................................................................................................................... 179

10.3 Command groups of the SIWAREX WP251 ......................................................................... 184

SIWAREX WP251

Manual, 12/2015, A5E37203357A

9

Table of contents

11 Communication with SIMATIC S7-1200 ............................................................................................... 185

12 Operation requiring official calibration ................................................................................................... 197

13 Technical specifications ....................................................................................................................... 203

14 Accessory ............................................................................................................................................ 213

A ESD guidelines .................................................................................................................................... 215

B List of abbreviations ............................................................................................................................. 217

Index ................................................................................................................................................... 219

Tables

11.1 Integration in SIMATIC S7-1200 .......................................................................................... 185

11.1.1 General information ............................................................................................................. 185

11.1.2 Creating the hardware configuration .................................................................................... 186

11.1.3 Calling of function block ....................................................................................................... 188

11.1.4 Working with the function block ........................................................................................... 189

11.1.5 I/O interface of function block .............................................................................................. 191

11.1.6 Error codes of function block ............................................................................................... 192

11.2 Communication via Modbus ................................................................................................. 193

11.2.1 Introduction .......................................................................................................................... 193

11.2.2 Principle of data transmission .............................................................................................. 193

11.2.3 Data record concept ............................................................................................................. 194

11.2.4 Command mailboxes ........................................................................................................... 195

11.2.5 Reading registers ................................................................................................................. 195

11.2.6 Writing registers ................................................................................................................... 196

12.1 Preparing for calibration ....................................................................................................... 197

12.1.1 Calibration set ...................................................................................................................... 197

12.1.2 Scale design ......................................................................................................................... 197

12.1.3 Installation and parameter assignment of the calibratable SecureDisplay main display

in the HMI ............................................................................................................................. 197

12.1.4 Parameterization of the scale .............................................................................................. 198

12.1.5 Adjustment and preliminary checking of the scale ............................................................... 198

12.1.6 Calibration label ................................................................................................................... 198

12.2 Verification ........................................................................................................................... 198

12.2.1 Checking of parameters relevant to the verification............................................................. 198

12.2.2 Checking of parameters relevant to the device ................................................................... 200

13.1 Technical specifications ....................................................................................................... 203

13.2 Electrical, EMC and climatic requirements .......................................................................... 207

13.3 Approvals ............................................................................................................................. 211

A.1 ESD Guidelines .................................................................................................................... 215

B.1 List of abbreviations ............................................................................................................. 217

Table 6- 1 Connection of the 24 V supply ..................................................................................................... 30

Table 6- 2 Load cell connections on the module ........................................................................................... 31

Table 6- 3 Connection of the digital outputs .................................................................................................. 35

SIWAREX WP251

10 Manual, 12/2015, A5E37203357A

Table of contents

Table 6- 4 Connection of the digital inputs .................................................................................................... 35

Table 6- 5 Connection of analog output ........................................................................................................ 36

Table 6- 6 Connection of RS485 serial interface .......................................................................................... 36

Table 6- 7 Settings of Siebert display S102 .................................................................................................. 37

Table 6- 8 Activation of write protection ........................................................................................................ 38

Table 8- 1 Assignment of data record 3 ........................................................................................................ 62

Table 8- 2 Assignment of data record 4 ........................................................................................................ 79

Table 8- 3 Assignment of data record 5 ........................................................................................................ 80

Table 8- 4 Assignment of data record 6 ........................................................................................................ 82

Table 8- 5 Assignment of data record 7 ........................................................................................................ 86

Table 8- 6 Bit 0 defines digital output 0 (DQ 0) ............................................................................................. 92

Table 8- 7 Bit 1 defines digital output 2 (DQ 2) ............................................................................................. 92

Table 8- 8 Assignment of data record 8 ........................................................................................................ 95

Table 8- 9 Assignment of data record 9 ........................................................................................................ 95

Table 8- 10 Assignment of data record 10 ...................................................................................................... 96

Table 8- 11 Assignment of data record 12 ...................................................................................................... 98

Table 8- 12 Assignment of data record 13 .................................................................................................... 100

Table 8- 13 Selection table for process value 1,2 ......................................................................................... 103

able 8- 14 Structure of status of analog output, digital outputs, and digital inputs ..................................... 104

T

Table 8- 15 Assignment of data record 15 .................................................................................................... 104

Table 8- 16 Assignment of data record 16 .................................................................................................... 105

Table 8- 17 Assignment of data record 17 .................................................................................................... 106

Table 8- 18 Assignment of data record 18 .................................................................................................... 107

Table 8- 19 Assignment of data record 20 .................................................................................................... 109

Table 8- 20 Assignment of data record 21 .................................................................................................... 110

Table 8- 21 Assignment of data record 22 .................................................................................................... 111

Table 8- 22 Assignment of data record 23 .................................................................................................... 118

Table 8- 23 Assignment of data record 24 .................................................................................................... 121

Table 8- 24 Assignment of data record 25 .................................................................................................... 126

Table 8- 25 Assignment of data record 28 .................................................................................................... 132

Table 8- 26 Assignment of data record 29 .................................................................................................... 133

Table 8- 27 Assignment of data record 30 .................................................................................................... 136

Table 8- 28 Assignment of data record 31 .................................................................................................... 141

Table 8- 29 Assignment of data record 32 .................................................................................................... 146

Table 8- 30 Assignment of data record 34 .................................................................................................... 150

Table 8- 31 Assignment of data record 35 .................................................................................................... 151

SIWAREX WP251

Manual, 12/2015, A5E37203357A

11

Table of contents

Table 8- 32 Assignment of data record 38 .................................................................................................... 152

Table 8- 33 Assignment of data record 39 .................................................................................................... 152

Table 8- 34 Assignment of data record 41 .................................................................................................... 154

Table 8- 35 Assignment of data record 42 .................................................................................................... 155

Table 8- 36 Assignment of data record 45 .................................................................................................... 155

Table 8- 37 Assignment of data record 46 .................................................................................................... 157

Table 8- 38 Assignment of data record 47 .................................................................................................... 159

Table 8- 39 Assignment of data record 48 .................................................................................................... 160

Table 9- 1 Technology messages ............................................................................................................... 165

Table 9- 2 Data and command errors ......................................................................................................... 167

Table 10- 1 Service commands ..................................................................................................................... 180

Table 10- 2 Protocol commands, statistics, logbook ..................................................................................... 181

Table 10- 3 Trace commands ....................................................................................................................... 181

Table 10- 4 Display changeover for DR 34 and SecureDisplay .................................................................... 181

Table 10- 5 Scale commands ........................................................................................................................ 183

Table 10- 6 Scale commands ........................................................................................................................ 183

Table 10- 7 Command groups of the SIWAREX WP251 .............................................................................. 184

Table 11- 1 Memory requirements of the function block ...............................................................................

185

Table 11- 2 Statuses/errors when working with the function block ............................................................... 192

Table 11- 3 Command mailbox 1: Highest priority ........................................................................................ 195

Table 11- 4 Command mailbox 2: Average priority ....................................................................................... 195

Table 11- 5 Command mailbox 3: Low priority .............................................................................................. 195

Table 13- 1 Technical specifications: 24 V power supply ............................................................................. 203

Table 13- 2 Technical specifications: Power supply from SIMATIC S7 backplane bus ................................ 203

Table 13- 3 Technical specifications: Analog load cell interface connection ................................................ 203

Table 13- 4 Technical specifications: ............................................................................................................ 204

Table 13- 5 Technical specifications: Digital outputs .................................................................................... 205

Table 13- 6 Technical specifications: Digital inputs ...................................................................................... 205

Table 13- 7 Technical specifications: Real-time clock .................................................................................. 206

Table 13- 8 Technical specifications: RS485 interface ................................................................................. 206

Table 13- 9 Technical specifications: Ethernet ............................................................................................. 206

Table 13- 10 Technical specifications: ............................................................................................................ 206

Table 13- 11 Technical specifications: Mechanical requirements and data .................................................... 207

Table 13- 12 Requirements: Electrical protection and safety requirements ................................................... 207

Table 13- 13 Requirements: Interference emission in industrial area in accordance with EN 61000-6-4 ...... 208

Table 13- 14 Requirements: Interference immunity in industrial area in accordance with EN 61000-6-2 ...... 209

SIWAREX WP251

12 Manual, 12/2015, A5E37203357A

Table of contents

Images

Table 13- 15 Operating conditions in accordance with IEC 60721 ................................................................. 210

Table 13- 16 Climatic requirements ................................................................................................................ 210

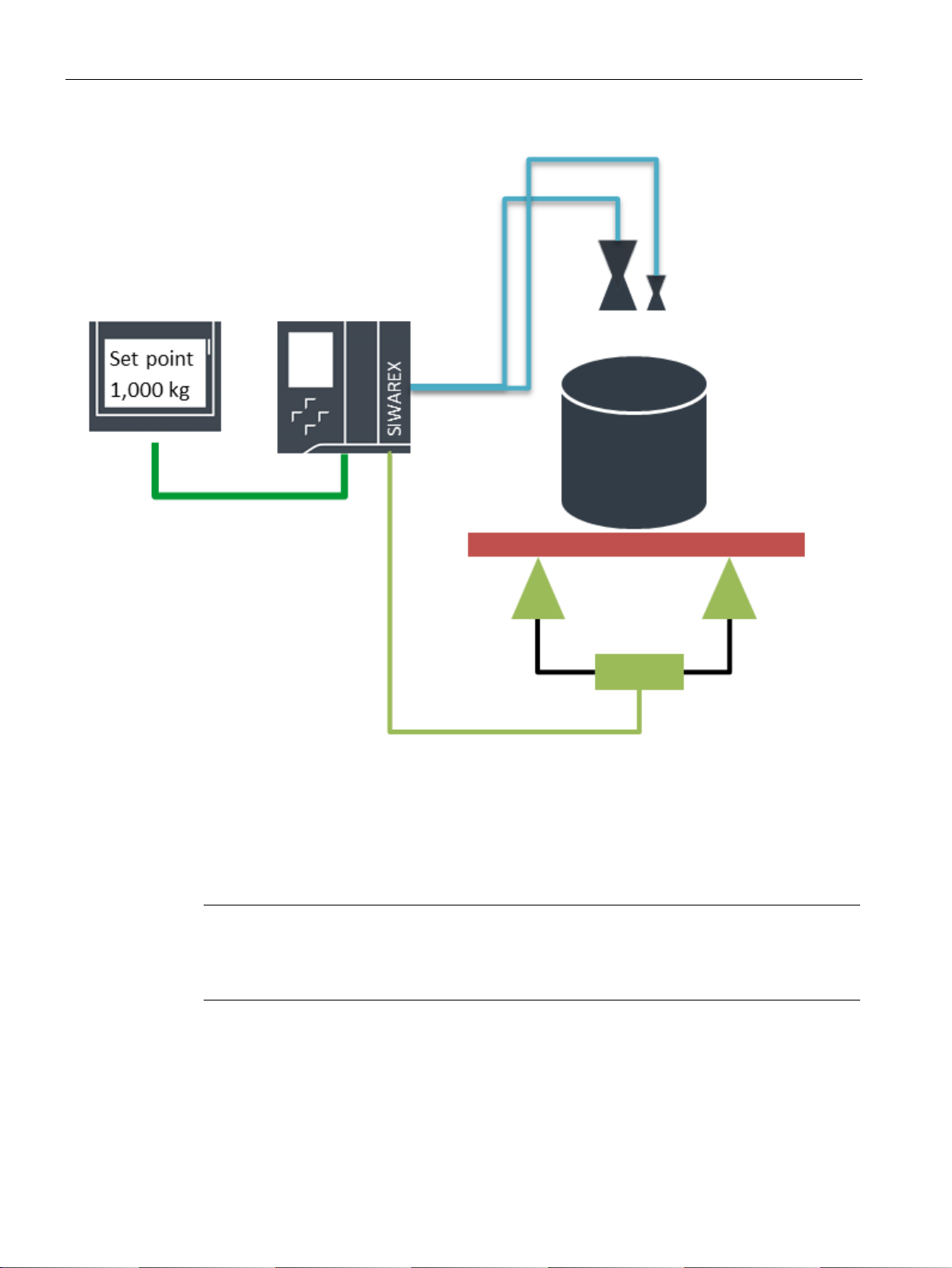

Image 3-1 System overview .......................................................................................................................... 20

Image 4-1 SIWATOOL overview ................................................................................................................... 22

Image 4-2 SIWAREX WP251 in stand-alone operation ................................................................................ 23

Image 6-1 SIWAREX WP251 connection areas ........................................................................................... 29

Image 6-2 Shielding in the screw gland ........................................................................................................ 31

Image 6-3 Installation of the shield connection element (example) .............................................................. 32

Image 6-4 Connection of strain gauge load cell with 4-wire system ............................................................. 33

Image 6-5 Connection of strain gauge load cell with 6-wire system ............................................................. 34

Image 6-6 Connection of Siebert display S102 ............................................................................................. 37

Image 6-7 Attachment of the calibration protection plates ............................................................................ 39

Image 7-1 Mode switch ................................................................................................................................. 41

Image 7-2 Quick calibration with marked parameters ................................................................................... 43

Image 7-3 Sending/receiving a data record / in SIWATOOL V7 ................................................................... 44

Image 7-4 Sending/receiving a data record / in SIWATOOL V7 ................................................................... 47

Image 7-5 Layout of the SIWATOOL user interface ..................................................................................... 49

Image 7-6 Sending/receiving a data record in SIWATOOL V7 ..................................................................... 50

Image 7-7 Trace export ................................................................................................................................. 53

Image 7-8 Downloading the firmware with SIWATOOL ................................................................................ 55

Image 8-1 Standstill monitoring ..................................................................................................................... 72

Image 8-2 Step response of digital low pass filter at f = 2 Hz .......................................................................

74

Image 8-3 Calibration digits and calibration weight ...................................................................................... 77

Image 8-4 Linearizing the scales' characteristic curve.................................................................................. 78

Image 8-5 Limit value configuration .............................................................................................................. 85

Image 8-6 Trailing weight ............................................................................................................................ 120

Image 8-7 Step response of digital low pass filter at f = 2 Hz ..................................................................... 125

Image 11-1 Configuring in the TIA Portal ...................................................................................................... 186

Image 11-2 Configuring with S7 .................................................................................................................... 186

Image 11-3 Start address of the module ....................................................................................................... 187

Image 11-4 Hardware identifier ..................................................................................................................... 187

Image 11-5 Block WP251PR......................................................................................................................... 188

SIWAREX WP251

Manual, 12/2015, A5E37203357A

13

Table of contents

Image 11-6 CMD command mailboxes ......................................................................................................... 189

Image 11-7 s_IO_DATA................................................................................................................................. 191

Image 13-1 Current ranges for signal level according to Namur recommendation NE43 ............................ 205

Image A-1 Electrostatic voltages which an operator can be subjected to ................................................... 216

SIWAREX WP251

14 Manual, 12/2015, A5E37203357A

Introduction

1

1.1

Purpose of the manual

1.2

Basic knowledge required

1.3

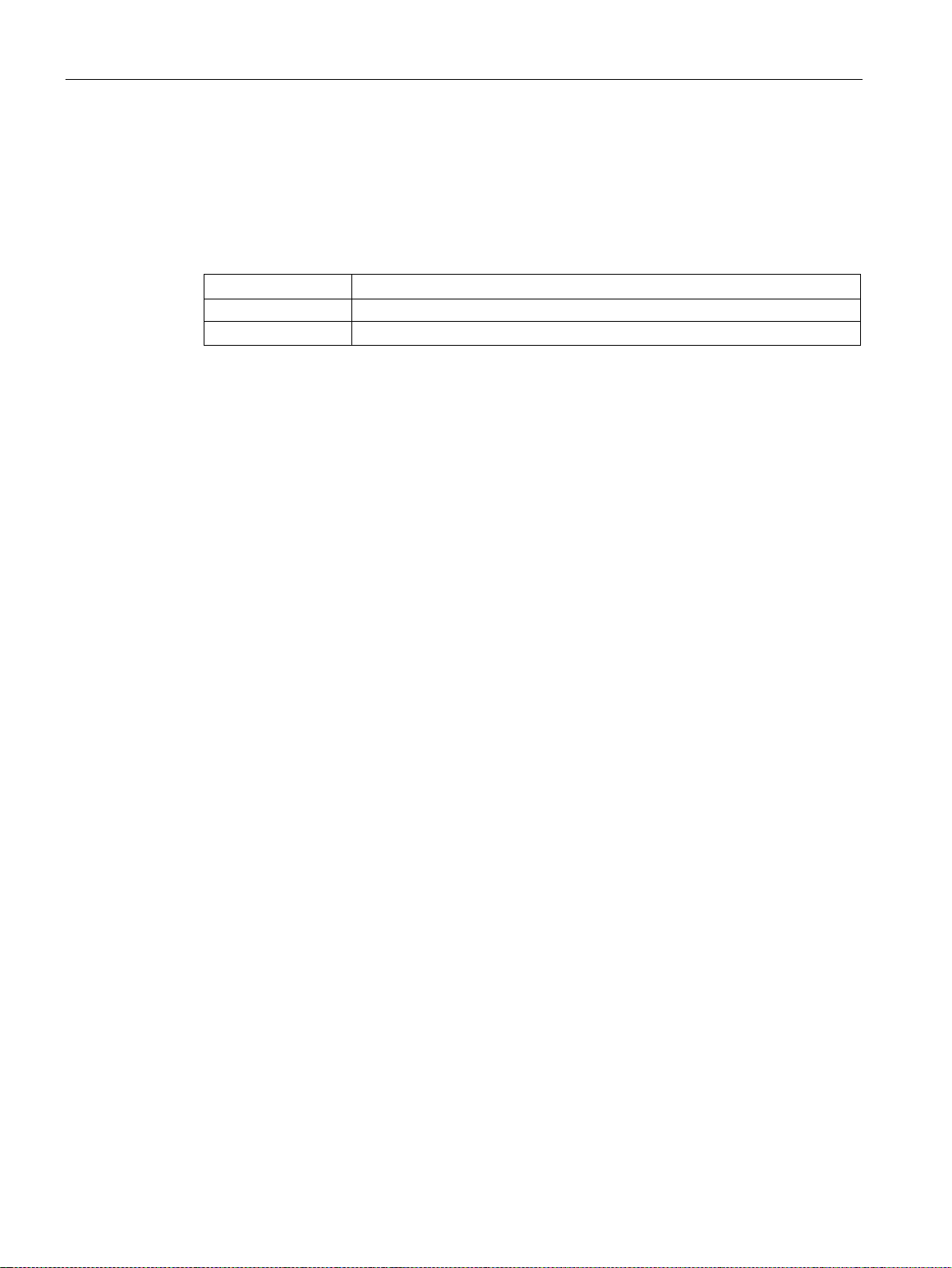

Manual - range of validity

Type designation

Order No.

as of version

Note

This manual contains a description of all electronic weighing systems available at the date of

publication. We reserve th

on the module.

1.4

Technical support

Technical Support

This manual contains all the information required for assembling installing, wiring and

commissioning the SIWAREX WP251 electronic weighing system.

This manual requires basic knowledge of weighing technology. When used in the

SIMATIC S7-1200, basic knowledge of the SIMATIC S7-1200 automation system and the

TIA Portal are required.

This manual is valid for:

SIWAREX WP251 7MH4960-6AA01 HW: FS 3 FW: V.1.0.0

e right to include a Product Information with the latest information

SIWAREX WP251

Manual, 12/2015, A5E37203357A

You can contact Technical Support for weighing technology:

● E-mail (mailto:support.automation@siemens.com

● Phone: +49 (721) 595-2811

)

15

Introduction

Support Request:

Service & Support on the Internet

Additional Support

1.4 Technical support

You can contact Technical Support for S7-1200 products:

● Via the Internet using the

E-mail Weighing Technology (mailto:hotline.siwarex@siemens.com)

● By phone: +49 (911) 895-7222

● By fax: +49 (911) 895-7223

Additional information about our technical support is available on the Internet at

Support request (http://www.siemens.de/automation/support-request

In addition to our documentation, we offer a comprehensive knowledge base online on the

Internet at:

Technical support (http://www.siemens.de/automation/csi/service

There you will find:

● The latest product information, FAQs, downloads, tips and tricks.

● Our newsletter, providing you with the latest information about your products.

● A Knowledge Manager to find the right documents for you.

● Our bulletin board, where users and specialists share their knowledge worldwide.

● You can find your local contact partner for Industry Automation and Drives Technologies

in our partner database.

)

)

● Information about field service, repairs, spare parts and lots more under "Services".

Please contact your local Siemens representative and offices if you have any questions

about the products described in this manual and do not find the right answers.

Find your contact partner at:

Partner (http://www.automation.siemens.com/partner

A signpost to the documentation of the various products and systems is available at:

Documentation

(https://support.industry.siemens.com/cs/products?dtp=Manual&pnid=17781&lc=en-WW

)

)

SIWAREX WP251

16 Manual, 12/2015, A5E37203357A

Safety notes

2

2.1

General safety instructions

WARNING

WARNING

Note

The specifications o

installation and commissioning in the SIMATIC environment. This section provides additional

information on hardware configuration, installation and preparation for operation of the

SIWARE

The safety notes must be observed.

Note

The device was developed, manufactured, tested and documented in compliance with the

relevant safety standards. The device does usually not pose any risks of material damage or

personal injury.

2.2

Security messages

Handling of the device/system by persons other than qualified personnel or ignoring the

warning instructions can result in severe injuries or damages. This means only qualified

personnel are permitted to handle this device/system.

Commissioning is absolutely prohibited until it has been ensured that the machine in which

the component described here is to be installed fulfills the regulations/specifications of

Machinery Directive 89/392/EEC.

f the manual for the SIMATIC S7-1200 system apply for configuration,

X WP251.

SIWAREX WP251

Manual, 12/2015, A5E37203357A

Siemens provides automation and drive products with industrial security functions that

support the secure operation of plants or machines. They are an important component in a

holistic industrial security concept. With this in mind, our products undergo continuous

development. We therefore recommend that you keep yourself informed with respect to our

product updates. Detailed technical information can be found at:

(http://www.siemens.de/automation/

To ensure the secure operation of a plant or machine it is also necessary to take suitable

preventive action (e.g. cell protection concept) and to integrate the automation and drive

components into a state-of-the-art holistic industrial security concept for the entire plant or

).

17

Safety notes

2.2 Security messages

machine. Products used from other manufacturers should also be taken into account here.

You will find further information under:

(http://www.siemens.de/industrialsecurity

).

SIWAREX WP251

18 Manual, 12/2015, A5E37203357A

Description

3

3.1

Product overview

3.2

Area of application

3.3

System integration in SIMATIC

Note

The direct use of SIWAREX WP251 with fail

supported.

SIWAREX WP251 is a versatile and flexible weighing module that can be used for operation

as a non-automatic weighing instrument.

The electronic weighing system can be used in SIMATIC S7-1200 and uses all features of a

modern automation system, such as integrated communication, operator control and

monitoring, the diagnostic system as well as the configuration tools in the TIA Portal.

SIWAREX WP251 is the optimum solution wherever fast and precise dosing and filling are

required. The typical applications of SIWAREX WP251 are:

Automatic catchweighing instruments

●

Gravimetric filling instruments (AWI)

●

on-automatic weighing instrument (NAWI)

● N

● Weighing instruments in hazardous areas (with Ex interface SIWAREX IS)

The electronic weighing system described here is a technology module for SIMATIC S7-

1200. The system, including the weighing application, can be configured as desired in the

automation solution. You can create optimal solutions for small and medium-sized plants by

combining the suitable SIMATIC modules. You can create customized or industry-specific

solutions in no time with the help of the configuration package available under the "Ready for

use" application for SIMATIC.

SIWAREX WP251

Manual, 12/2015, A5E37203357A

-safe SIMATIC S7-1200 controllers is not yet

19

Description

3.4

Scope of delivery

Note

We recommend that you use the SIWAREX WP251 configuratio

the SIWAREX WP251 electronic weighing system. The configuration package is not included