Siemens SIWAREX WL280 Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIWAREX WL280

Compact installation units and guide elements RN-S SA

Operating Instructions

09/2016

A5E32605810A

Introduction

1

Notes on handling the

product

2

Description

3

Application planning

4

Mounting

5

Service and maintenance

6

Technical data

7

Dimension drawings

8

Ordering data

9

Appendix

A

-03

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E32605810

Ⓟ

Copyright © Siemens AG 2014 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

10/2016 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 5

2 Notes on handling the product ................................................................................................................. 9

3 Description ............................................................................................................................................ 11

4 Application planning .............................................................................................................................. 21

5 Mounting ............................................................................................................................................... 27

1.1 Purpose of this documentation ................................................................................................. 5

1.2 History ....................................................................................................................................... 5

1.3 Scope of delivery ...................................................................................................................... 5

1.3.1 Compact installation unit ........................................................................................................... 6

1.3.2 Guide element ........................................................................................................................... 6

1.4 Security information .................................................................................................................. 7

1.5 Environmental protection .......................................................................................................... 7

3.1 Application .............................................................................................................................. 11

3.1.1 Use of compact installation units ............................................................................................ 11

3.1.2 Lifting protection ...................................................................................................................... 12

3.1.3 Overload protection ................................................................................................................. 12

3.1.4 Use of the grounding cable ..................................................................................................... 13

3.1.5 Application of guide elements ................................................................................................. 13

3.2 Design and function ................................................................................................................ 14

3.2.1 Design and mode of operation of the compact installation unit .............................................. 14

3.2.2 Design and function of the grounding cable ........................................................................... 18

3.2.3 Design and principle of operation of the guide element ......................................................... 19

4.1 Load cell dummies .................................................................................................................. 21

4.2 Lifting protection ...................................................................................................................... 21

4.3 Load pick-up ........................................................................................................................... 22

4.4 Overload protection ................................................................................................................. 23

4.5 Guide elements ....................................................................................................................... 25

4.6 Protection against explosion ................................................................................................... 26

5.1 Safety information/instructions ................................................................................................ 27

5.2 Installing the compact installation unit .................................................................................... 28

5.2.1 General installation information .............................................................................................. 28

5.2.2 Preparing the load cell ............................................................................................................ 29

5.2.3 Preparing the compact installation unit ................................................................................... 30

5.2.4 Installing the load cell in the compact installation unit ............................................................ 31

5.2.5 Installing the compact installation unit .................................................................................... 33

5.2.6 Lowering the top plate onto the load cells .............................................................................. 36

5.2.7 Compensation of height with four or more support points ...................................................... 37

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

3

Table of contents

6 Service and maintenance ...................................................................................................................... 45

7 Technical data ...................................................................................................................................... 47

8 Dimension drawings .............................................................................................................................. 49

9 Ordering data ........................................................................................................................................ 53

A Appendix .............................................................................................................................................. 55

Index .................................................................................................................................................... 57

5.2.8 Checking the installation ........................................................................................................ 38

5.3 Fixing of guide element .......................................................................................................... 39

5.3.1 General installation information ............................................................................................. 39

5.3.2 Preparing the guide element .................................................................................................. 40

5.3.3 Locking the top plate .............................................................................................................. 40

5.3.4 Fixing a guide element (or the first one) ................................................................................ 41

5.3.5 Lowering the top plate onto the load cells ............................................................................. 41

5.3.6 Fixing of second guide element ............................................................................................. 42

5.3.7 Checking the installation ........................................................................................................ 42

5.4 Dismantling ............................................................................................................................ 43

6.1 Servicing and maintenance .................................................................................................... 45

7.1 Stainless steel compact installation units .............................................................................. 47

7.2 Stainless steel guide elements .............................................................................................. 47

8.1 Dimension drawings of the compact installation units ........................................................... 49

8.2 Dimension drawing of guide elements ................................................................................... 52

A.1 Technical support ................................................................................................................... 55

RN-S SA

4 Operating Instructions, 09/2016, A5E32605810A-03

1

1.1

Purpose of this documentation

1.2

History

Edition

Comment / change

05/2015

Corrections in measurement tables

09/2016

Corrections in measurement tables

1.3

Scope of delivery

These instructions contain all the information you need for commissioning and using the

device.

It is aimed at persons who install the device mechanically and commission it, as well as at

service and maintenance engineers.

The following versions of this documentation have been released to date. The changes apply

to the previous version:

Table 1- 1 History

09/2014 Initial release

The scope of delivery is made up of the following components:

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

5

Introduction

1.3.1

Compact installation unit

Note

Other scope of delivery information

Drawings of the parts of the compact installation unit can be found in Section

compact installation unit

1.3.2

Guide element

1.4 Security information

Compact installation unit

Accessory kit 1

● 1 x pressure piece complete with flat seal

● 1 x pendulum support

Accessory kit 2

● 8 x washers

Preparing the

(Page 30)

2 x flanges

1 x turnbuckle complete

Accessory kit for

RN-S SA 60 kg to 280 kg

RN-S SA 0.5 t / 1 t

RN-S SA 2 t to 5 t

● 2 x hexagon bolts

● 2 x hexagon nuts

● 4 x washers

● 4 x cylinder head screws

Accessory kit for

RN-S SA 10 t / 13 t

● 2 x hexagon bolts

● 2 x hexagon nuts

● 4 x washers

● 6 x cylinder head screws

RN-S SA

6 Operating Instructions, 09/2016, A5E32605810A-03

Introduction

1.4

Security information

1.5

Environmental protection

Recycling

1.4 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under:

http://www.siemens.com/industrialsecurity

Devices described in this programming manual can be recycled owing to the low content of

noxious substances in their version.

Please contact a certified waste disposal company for eco-friendly recycling and to dispose

of your old devices.

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

7

Introduction

1.5 Environmental protection

RN-S SA

8 Operating Instructions, 09/2016, A5E32605810A-03

2

Proper use

Notes on liability for defects

Delivery information

Qualified personnel

Proper use means that this product must only be used within the limits of the technical

specifications and intended purposes of these operating instructions.

If this device is used properly in compliance with the safety notices, this device will not

present any danger.

This device can only function correctly and safely if it is transported, stored, set up and

mounted correctly.

Correct operation of the device must be ensured by complying with the technical

specifications.

Improper handling can result in death, personal injury or property damage.

We expressly point out that the product quality is exclusively and conclusively described in

the sales contract. The content of this product documentation is neither part of a previous or

existing agreement, promise or legal relationship, nor is it intended to modify these. All

obligations on the part of Siemens AG are contained in the respective sales contract, which

also contains the complete and solely applicable liability provisions. The provisions defined

in the sales contract for the responsibility for defects are neither extended nor limited by the

remarks in this document.

The current scope of delivery is listed on the shipping documents enclosed with the delivery

in accordance with the valid sales contract.

When opening the packaging, please observe the relevant information. Check the delivery

for completeness and undamaged condition. In particular, the order number on the rating

plate must be compared to the ordering data.

Before you start work, please read these operating instructions. They contain important

information and data whose observation ensures the general safety and functionality of this

device. The manual will help you to handle this product more easily and efficiently, allowing

you to achieve reliable results.

In the context of this documentation, qualified personnel are people who are familiar with the

installation, mounting, commissioning, and operation of the product.

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

9

Notes on handling the product

Protection against explosion

Trademarks

These people must have the following qualifications:

● They must be trained, instructed and authorized to operate and maintain devices and

systems in accordance with their place of work and in compliance with the safety

engineering standards for

– Electrical circuits

– High pressures

– Corrosive and hazardous media

● They must be trained, instructed and authorized to maintain and use appropriate safety

equipment according to the standards for safety engineering.

● In the case of devices with explosion protection, qualified persons must be trained,

instructed and authorized to perform work on electrical circuits in plants subject to

explosion hazards.

There is no potential risk of ignition from the installation units of the load cells. Therefore they

are not subject to the EC directive 94/9 EC (ATEX).

SIWAREX ® is a registered trademark of Siemens AG.

All other names appearing in these instructions may be trademarks; use of such names by

third parties for their own purposes may infringe upon owners rights.

RN-S SA

10 Operating Instructions, 09/2016, A5E32605810A-03

3

3.1

Application

3.1.1

Use of compact installation units

The compact installation unit handles the introduction of force into the load cells by means of

a pendulum support.

This pendulum support has the following effect:

● The weight force is introduced centrally into the load cell.

● The load cell is decoupled from the load bearing implement, e.g. of a container. The load

bearing implement can expand, e.g. as a result of changes in temperature, without

tensioning the load cell.

● The load bearing implement remains in the center in the event of thermal expansion.

● Following a lateral displacement, the load bearing implement returns to its rest position as

soon as the transverse force is no longer active.

The compact installation unit allows simple and exact installation of the load cell:

● It is not necessary to strip down the compact installation unit.

● It is not necessary to remove the compact installation unit.

● The compact installation unit can be used as dummy.

● The top plate is secured by means of two countersunk head screws.

● As a result of the two countersunk head screws, the position of the top plate with regard

to the base plate is adjusted ideally.

● The load cell can be inserted before or after installation of the compact installation unit.

● The load cell is protected during installation work.

● The load bearing implement can be lowered safely and controlled onto the load cell.

The compact installation units have the following characteristics:

● Easy installation of the load cell

● Easy adjustment of the load cell under the load bearing implement

● Self-centering on the load bearing implement

● Can be used as a dummy for light installation work

● Safe and controlled lowering of the load bearing implement

● Can be used as a transport lock by fixing the top plate

● Integrated lifting protection

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

11

Description

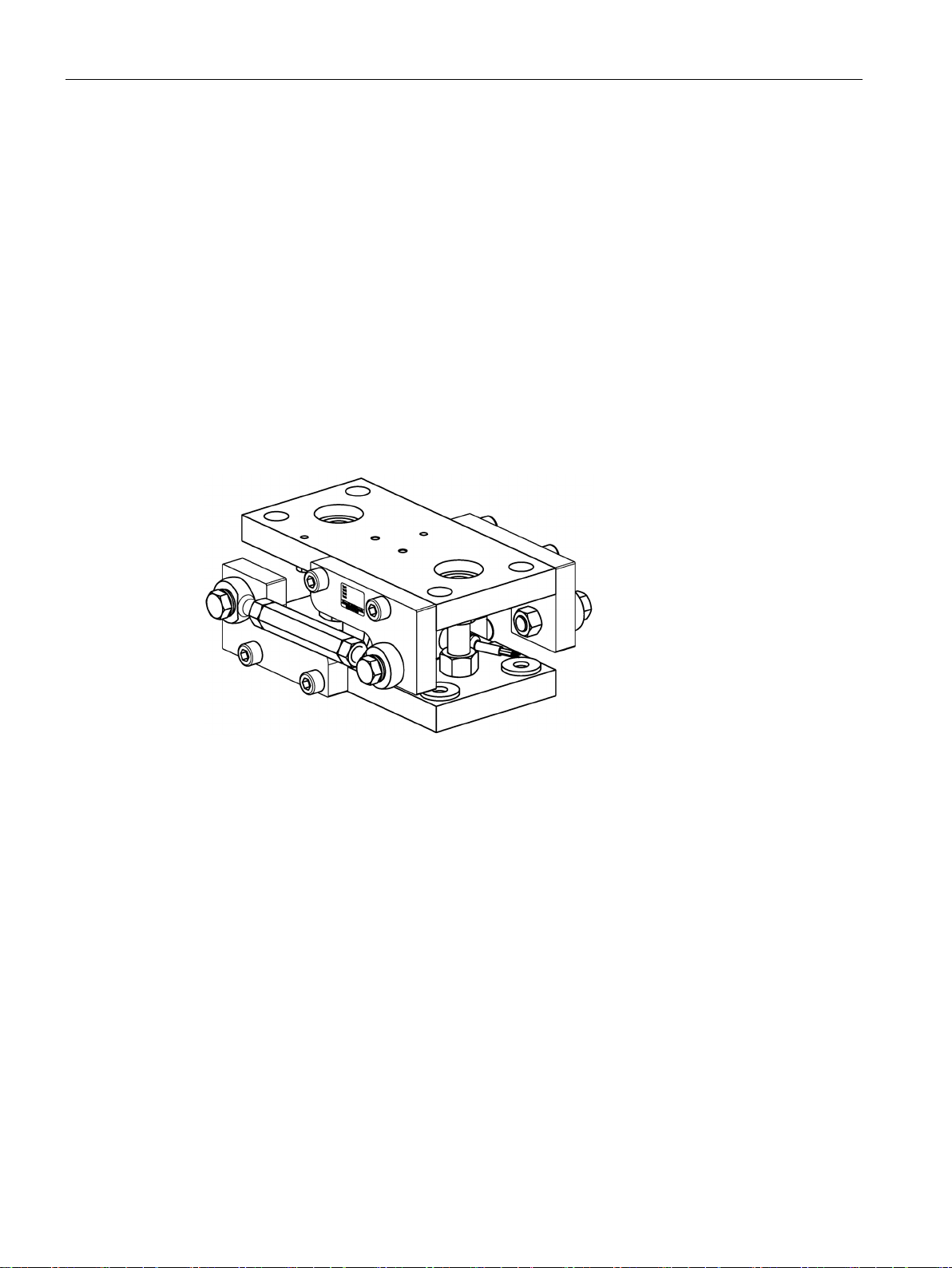

Compact installation unit for SIWAREX WL280 RN-S SA

3.1.2

Lifting protection

3.1.3

Overload protection

3.1 Application

● Designed relief of the load cell during installation

● Overload protection of the load cell during installation

● Prepared for the attachment of guide elements: single-sided or double-sided

● Compensation of tolerance of connection holes through mounting with spring washers

● Checking of correct installation using conical washer

● Highly flexible ground wire for protection of load cell against parasitic currents

● Parts made of stainless steel for applications in the food and pharmaceutical industries

The type SIWAREX WL280 RN-S SA self-centering compact installation unit for load cells is

especially well suited for installation in container scales, platform scales and roller table

scales.

RN-S SA

12 Operating Instructions, 09/2016, A5E32605810A-03

The lifting protection prevents the load bearing implements from being lifted off the load

cells.

If there is a risk of the load bearing implement being lifted or toppled, then lifting protection is

required. This is required in the case of lightweight containers and tall, outdoor silos.

The overload protection protects load cells from a load that is too great.

There is overload protection against excessive loads in the measuring direction and overload

protection against excessive transverse forces.

Transverse forces are caused by, for example, wind, filling processes, acceleration, or

conveyor belt friction. If these forces exceed certain values, the load cells must be protected

from them.

Description

3.1.4

Use of the grounding cable

3.1.5

Application of guide elements

3.1 Application

The grounding cable is used to protect the load cells from undesired currents. The causes of

such currents are, for example:

● Equalizing currents with missing or faulty equipotential bonding conductors

● A lightning strike nearby

● Welding work

● Static charge

Figure 3-1 Example usage of the grounding cable

Guide elements route horizontal forces acting on load bearing implements directly into the

foundation. Transverse forces onto the load cells do not occur as a result. The result of the

load cells is not falsified by this influence.

Guide elements are used in the following cases:

● Horizontal forces occur during the weighing procedure. This is the case with all dynamic

weighing procedures or if containers are weighed outdoors where wind can have an

effect.

● Movement of the load bearing implement as a result of horizontal forces should be

prevented. This is the case with braking or acceleration forces of belt or roller table scales

or with mixing tanks in which unbalance can occur as a result of an agitator.

The SIWAREX WL280 RN-S SA guide elements are used together with the compact

installation units. The guide elements have the following characteristics:

● Subsequent attachment to the compact installation unit

● The single-sided attachment of a guide element can be made either on the front or rear of

the compact installation unit.

● The double-sided attachment of two guide elements doubles the possible transverse

force.

● Parts made of stainless steel for applications in the food and pharmaceutical industries

The weighing equipment must not be tensioned by guide elements. The guide elements

must not prevent changes in the dimensions of the load bearing implement resulting from

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

13

Description

3.2

Design and function

3.2.1

Design and mode of operation of the compact installation unit

Design

3.2 Design and function

changes in temperature. This can principally be achieved by always using three guide

elements.

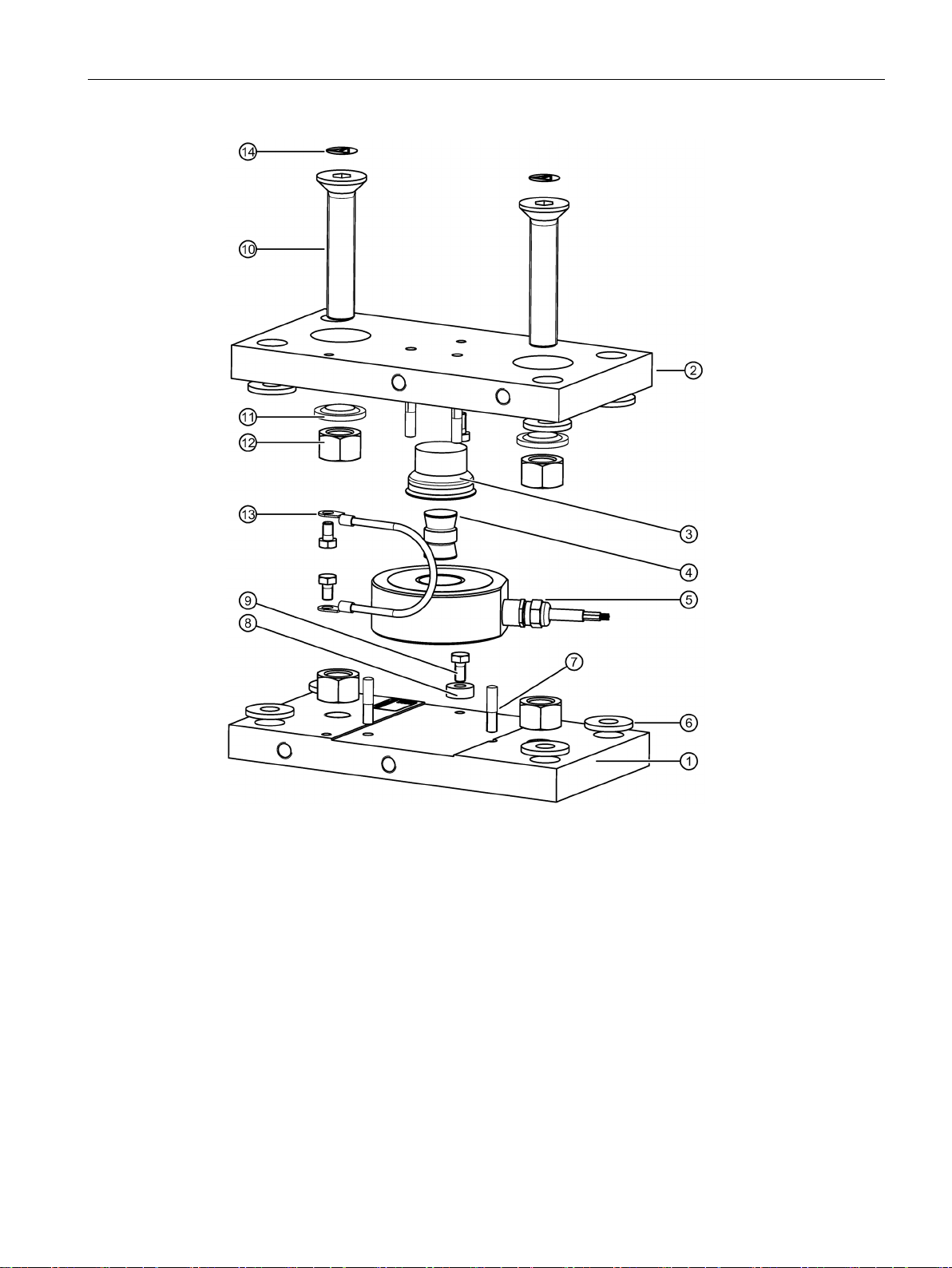

The compact installation unit comprises the following main components:

● Base plate

● Top plate

● Pendulum support

● Two countersunk head screws

Together with the load cell, the compact installation unit represents a self-centering bearing

unit.

①

②

④

⑩ as aids to installation and adjustment

RN-S SA

14 Operating Instructions, 09/2016, A5E32605810A-03

Description

①

Base plate

⑧

Clamping washers

②

Top plate

⑨

Hexagon-head bolts

③

Pressure piece with flat seal

⑩

Countersunk head screws

④

Pendulum support

⑪

Centering washers

⑤

ery)

⑫

⑥

Spring washers

⑬

Grounding cable

⑦

Half length taper-grooved pins

⑭

Plug

Principle of operation

3.2 Design and function

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

Load cell (not included in scope of deliv-

Figure 3-2 Exploded view: compact installation unit with built-in load cell

The top plate is exactly aligned and secured through the base plate using the two

countersunk head screws. This results in a stable unit.

Hexagon nut

15

Description

s

Excess length = lifting path

3.2 Design and function

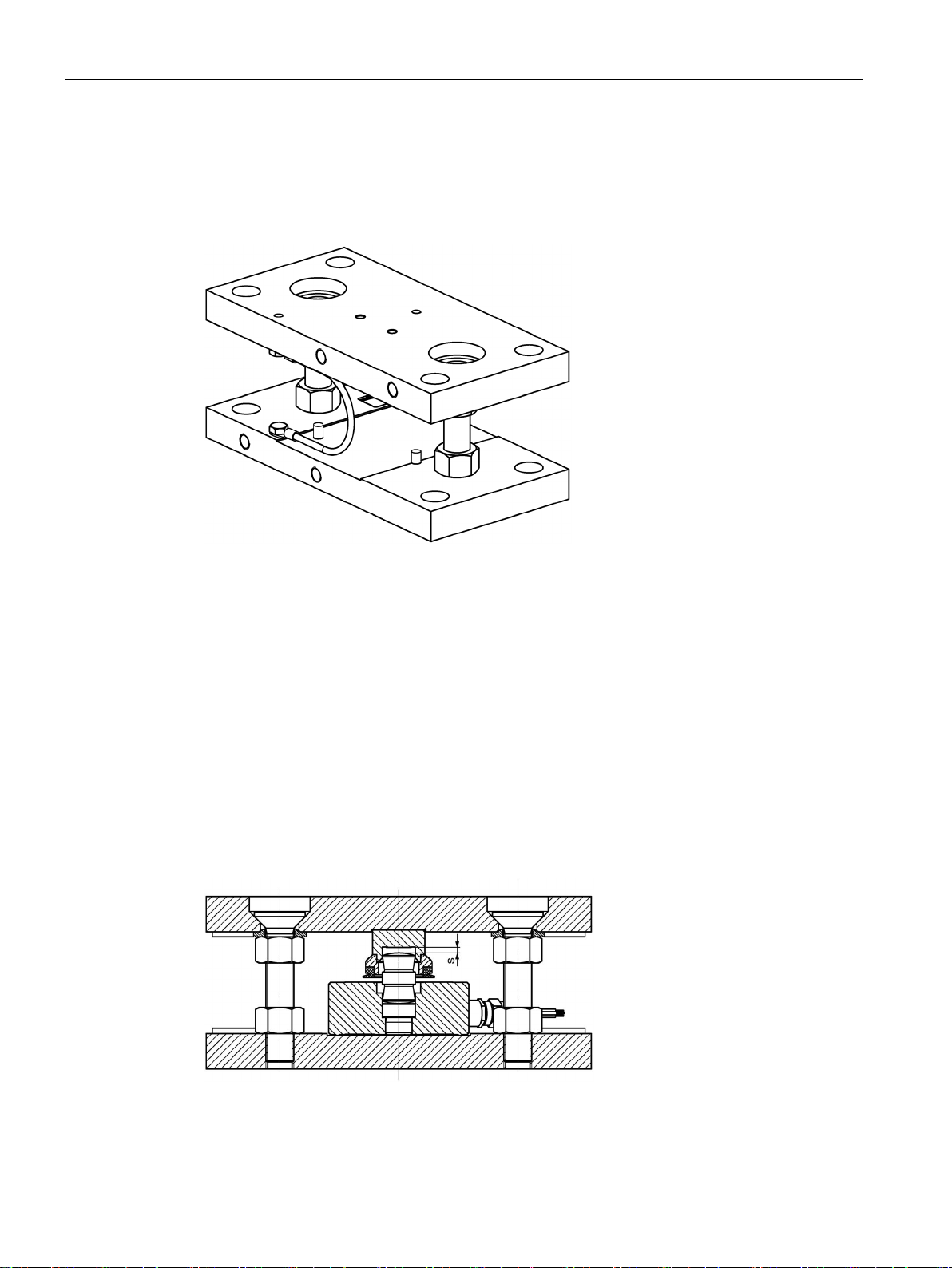

When delivered, the height of the top plate is set with an excess length. The excess length

corresponds to the lifting path (see Stainless steel compact installation units (Page 47)).

In this condition, the compact installation unit serves as an installation aid and can be used

as a dummy for lighter installation work.

Figure 3-3 Compact installation unit: pre-assembled upon delivery

Prior to installation, the load cell with pendulum support and pressure piece is inserted into

the compact installation unit. The load cell and pressure piece are secured in position using

one clamping washer each.

In the next step, the complete compact installation units are fitted into the scale.

The fixing holes of the compact installation unit are 6 mm larger than the thread of the fixing

screws to be used. The fixing holes are covered by the supplied spring washers. Tolerance

errors in the fixing holes of the brackets can then be compensated to a certain extent.

Compensate angular and/or flatness errors as well as differences in height between the

brackets using spacer plates. Make sure that the connection plates are not tensioned and

that the base/top plates are not concave in the center.

The compact installation units are optimally aligned when screwed tight. The load cells are

not yet loaded.

RN-S SA

16 Operating Instructions, 09/2016, A5E32605810A-03

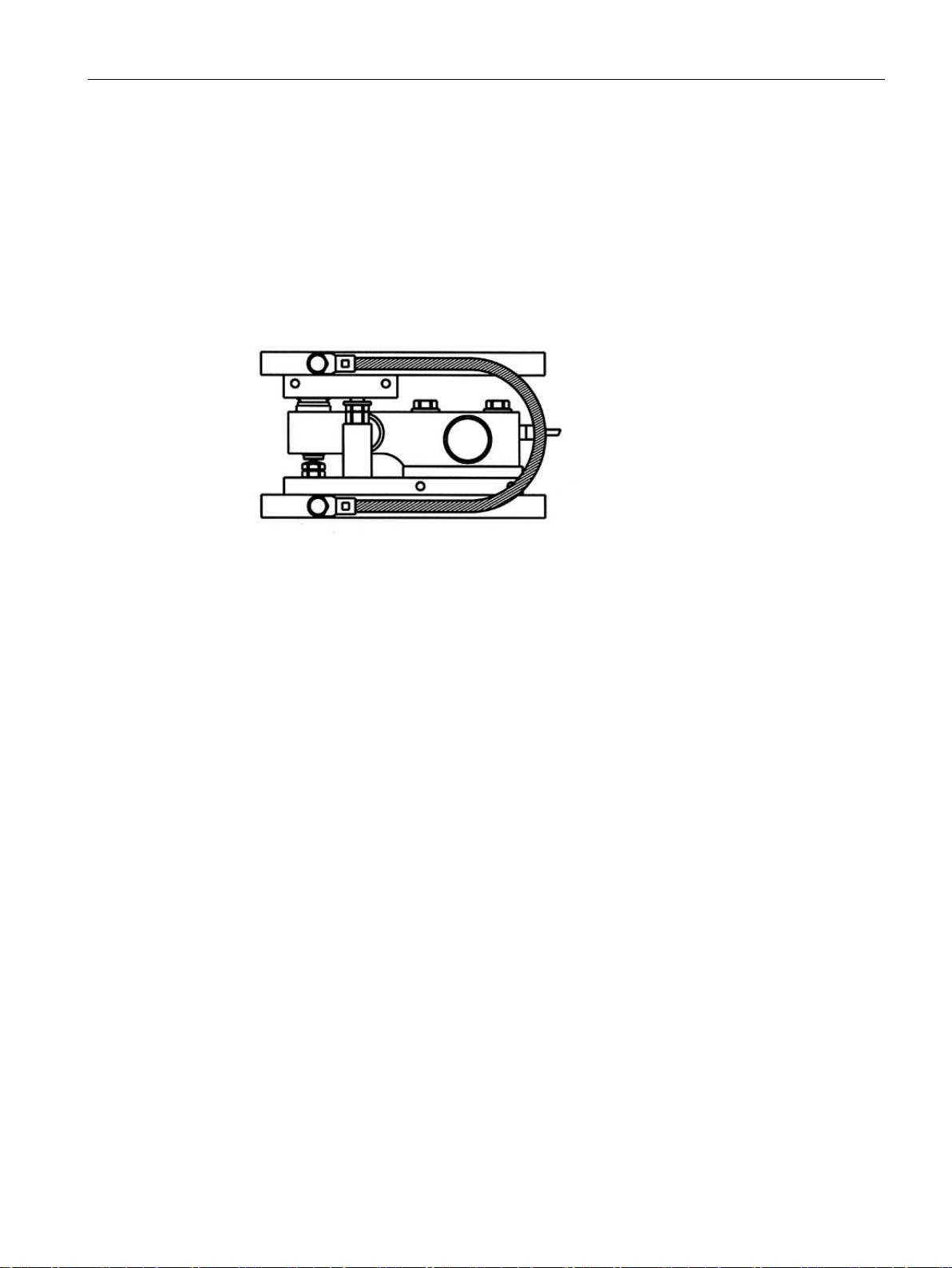

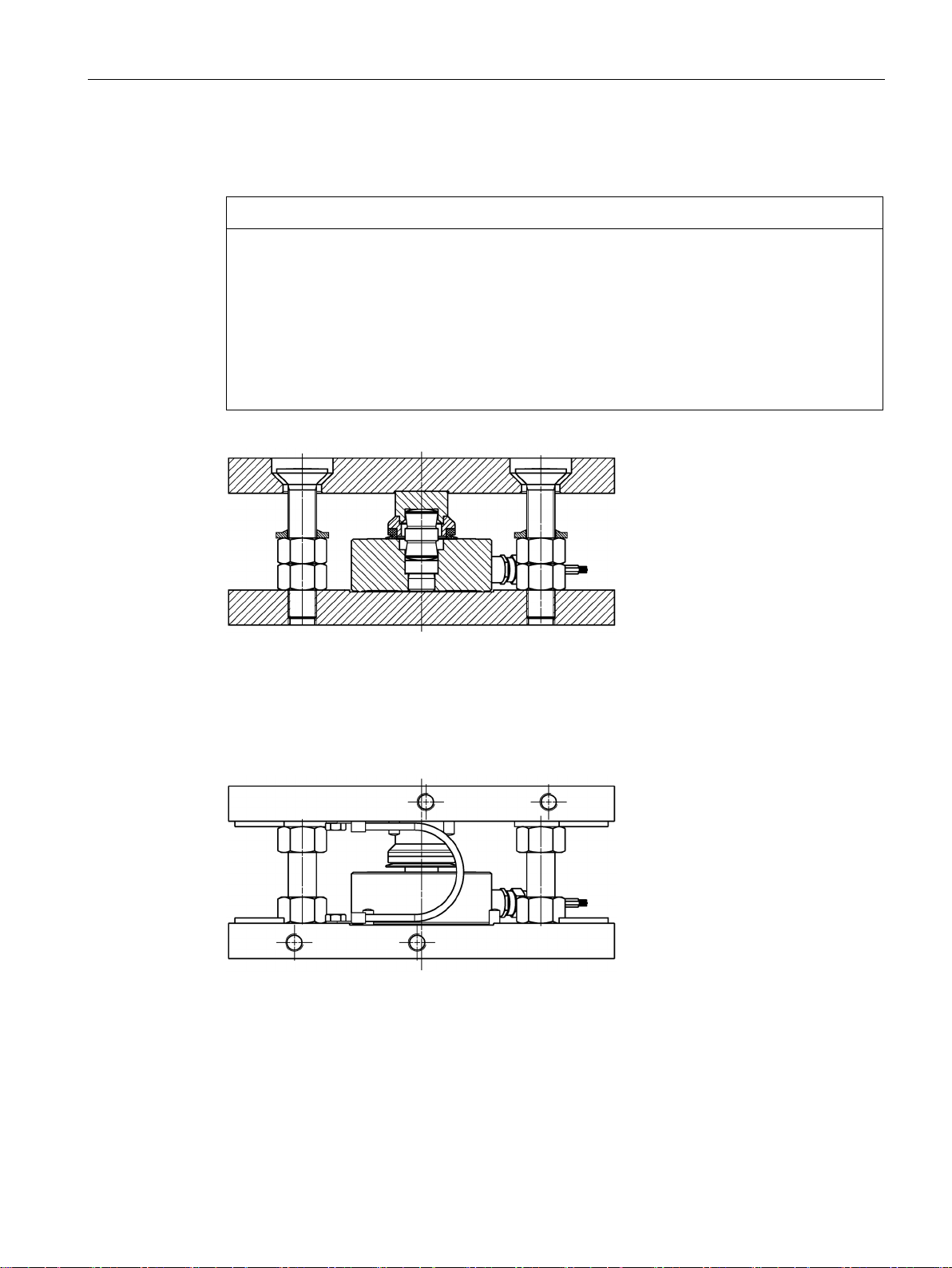

Figure 3-4 Installation state

Description

NOTICE

Loosening the hexagon nuts

3.2 Design and function

In the next step, lower the load bearing by loosening the top hexagon nuts. The top plate is

lowered onto the pendulum support. The weight is now on the load cells.

Loosen the hexagon nuts in turn in small steps.

Note:

• The compact installation units are screwed tight to the brackets.

• By loosening a hexagon nut, the weight of the bearing implement is distributed among

the other hexagon nuts and is partially increased.

Avoid overloading individual hexagon nuts.

Figure 3-5 Operating state

In this state, the load cells with the pressure pieces form self-centering units. The compact

installation units allow the top plates and the load bearing implement to be deflected to the

side. The countersunk head screws provide lifting protection and, to a limited extent,

pendulum limitation.

Figure 3-6 Compact installation unit with load cell and grounding cable

RN-S SA

Operating Instructions, 09/2016, A5E32605810A-03

17

Description

3.2.2

Design and function of the grounding cable

Structure

Principle of operation

3.2 Design and function

The grounding cables in the compact installation units are made up of fine-core flexible

copper wires. The flexible copper wires are tin-coated to additionally protect the copper from

corrosion.

The grounding cable represents an electrical by-pass via the load cell. High weld currents

can destroy the load cell, installation unit or the electronics. The electronics can be affected

by voltage sparkovers of static discharges.

RN-S SA

18 Operating Instructions, 09/2016, A5E32605810A-03

Loading...

Loading...