Siemens SIWAREX WL260 SP-S AA, SIWAREX WL260 SP-S SA, SIWAREX WL260 SP-S AB, SIWAREX WL260 SP-S AE, SIWAREX WL260 SP-S SB Operating Instructions Manual

...

IWAREX WL200

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Weighing systems

Load cells SIWAREX WL200

Operating Instructions

07/2016

A5E02199611B

Introduction

1

Safety instructions

2

Description

3

Installing

4

Connecting

5

Commissioning

6

Service and maintenance

7

Error messages and

troubleshooting

8

Technical data

9

Dimension drawings

10

Ordering data

11

Appendix

A

-03

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E02199611B-08

Ⓟ

Copyright © Siemens AG 2008 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

enance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maint

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2016 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Safety instructions ................................................................................................................................... 9

3 Description ............................................................................................................................................ 13

4 Installing ............................................................................................................................................... 17

5 Connecting ........................................................................................................................................... 21

6 Commissioning ..................................................................................................................................... 27

1.1 Purpose of this documentation ................................................................................................. 7

1.2 History ....................................................................................................................................... 7

1.3 Checking the consignment ....................................................................................................... 8

1.4 Transportation and storage ....................................................................................................... 8

1.5 Notes on warranty ..................................................................................................................... 8

2.1 Prerequisites for safe use ......................................................................................................... 9

2.1.1 Laws and directives .................................................................................................................. 9

2.1.2 Conformity with European directives ........................................................................................ 9

2.2 Improper device modifications ................................................................................................ 10

2.3 Requirements for special applications .................................................................................... 10

2.4 Use in hazardous areas .......................................................................................................... 10

3.1 Range of application ............................................................................................................... 13

3.2 Design and principle of operation ........................................................................................... 13

3.3 Nameplate layout .................................................................................................................... 15

4.1 Basic safety instructions ......................................................................................................... 17

4.2 Procedure for mounting the device ......................................................................................... 18

4.3 Dismantling ............................................................................................................................. 19

5.1 Basic safety instructions ......................................................................................................... 21

5.2 Connecting principle ............................................................................................................... 22

5.3 Connecting up ......................................................................................................................... 24

6.1 Basic safety instructions ......................................................................................................... 27

6.2 Application planning ................................................................................................................ 27

6.2.1 Planning .................................................................................................................................. 27

6.2.2 Transverse forces and overload protection ............................................................................ 29

6.2.3 Lengthening and shortening the connecting cable ................................................................. 31

6.3 Adjustment and initial commissioning ..................................................................................... 33

6.3.1 Height compensation .............................................................................................................. 33

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

3

Table of contents

7 Service and maintenance ...................................................................................................................... 39

8 Error messages and troubleshooting ..................................................................................................... 41

9 Technical data ...................................................................................................................................... 45

6.3.1.1 When is height compensation necessary? ............................................................................ 33

6.3.1.2 Procedure for height compensation ....................................................................................... 33

6.3.2 Initial commissioning .............................................................................................................. 34

6.3.3 Corner load adjustment .......................................................................................................... 34

6.3.3.1 When is corner load adjustment necessary? ......................................................................... 34

6.3.3.2 General procedure for corner load adjustment ...................................................................... 35

6.3.3.3 Example for corner load adjustment ...................................................................................... 35

7.1 Basic safety instructions ........................................................................................................ 39

7.2 Cleaning ................................................................................................................................. 39

7.3 Return procedure ................................................................................................................... 39

7.4 Disposal ................................................................................................................................. 40

8.1 Repair ..................................................................................................................................... 41

8.2 Error messages ...................................................................................................................... 41

8.3 Checking the mechanical and electrical configuration ........................................................... 41

8.4 Checking the load cells .......................................................................................................... 42

8.5 Measures in the event of overloaded load cells ..................................................................... 43

9.1 Functional data....................................................................................................................... 45

9.1.1 SIWAREX WL260 SP-S AA ................................................................................................... 45

9.1.2 SIWAREX WL260 SP-S AB ................................................................................................... 46

9.1.3 SIWAREX WL260 SP-S AE ................................................................................................... 47

9.1.4 SIWAREX WL260 SP-S SA ................................................................................................... 48

9.1.5 SIWAREX WL260 SP-S SB ................................................................................................... 49

9.1.6 SIWAREX WL260 SP-S SC ................................................................................................... 50

9.1.7 SIWAREX WL250 ST-S SA ................................................................................................... 51

9.1.8 SIWAREX WL230 BB-S SA ................................................................................................... 52

9.1.9 SIWAREX WL230 SB-S CA ................................................................................................... 53

9.1.10 SIWAREX WL230 SB-S SA ................................................................................................... 55

9.1.11 SIWAREX WL270 CP-S SA ................................................................................................... 56

9.1.12 SIWAREX WL270 CP-S SB ................................................................................................... 57

9.1.13 SIWAREX WL270 CP-S SC .................................................................................................. 58

9.1.14 SIWAREX WL270 K-S CA ..................................................................................................... 59

9.1.15 SIWAREX WL280 RN-S SA .................................................................................................. 62

9.1.16 SIWAREX WL290 DB-S CA .................................................................................................. 63

9.2 Electrical specifications .......................................................................................................... 64

9.3 Approval to OIML R60 ........................................................................................................... 65

9.4 Electromagnetic compatibility ................................................................................................ 66

9.5 Certificates and approvals for explosion protection ............................................................... 67

SIWAREX WL200

4 Operating Instructions, 07/2016, A5E02199611B-03

Table of contents

10 Dimension drawings .............................................................................................................................. 69

11 Ordering data ........................................................................................................................................ 91

A Appendix............................................................................................................................................... 99

Index................................................................................................................................................... 101

10.1 SIWAREX WL260 SP-S AA .................................................................................................... 69

10.2 SIWAREX WL260 SP-S AB .................................................................................................... 70

10.3 SIWAREX WL260 SP-S AE .................................................................................................... 70

10.4 SIWAREX WL260 SP-S SA .................................................................................................... 71

10.5 SIWAREX WL260 SP-S SB .................................................................................................... 72

10.6 SIWAREX WL260 SP-S SC ................................................................................................... 73

10.7 SIWAREX WL250 ST-S SA .................................................................................................... 74

10.8 SIWAREX WL230 BB-S SA .................................................................................................... 75

10.9 SIWAREX WL230 SB-S CA ................................................................................................... 76

10.10 SIWAREX WL230 SB-S SA .................................................................................................... 77

10.11 SIWAREX WL270 CP-S SA ................................................................................................... 78

10.12 SIWAREX WL270 CP-S SB ................................................................................................... 79

10.13 SIWAREX WL270 CP-S SC ................................................................................................... 80

10.14 SIWAREX WL270 K-S CA ...................................................................................................... 81

10.15 SIWAREX WL280 RN-S SA ................................................................................................... 83

10.16 SIWAREX WL290 DB-S CA ................................................................................................... 89

11.1 Load cells ................................................................................................................................ 91

11.2 Accessories ............................................................................................................................. 98

A.1 Technical support .................................................................................................................... 99

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

5

Table of contents

SIWAREX WL200

6 Operating Instructions, 07/2016, A5E02199611B-03

1

1.1

Purpose of this documentation

See also

1.2

History

Edition

Remarks/changes

Additions to explosion protection and ATEX approval

07/2010

Addition to WL280 RN-S SA 10 t; 13 t; 28 t and 60 t load cells.

Addition to WL270 K-S CA load cells

S CA load cells with additional versions (high temperature, double

cells and WL260 SP-S SC load cells.

09/2013

Expansion of the load cells WL270 K and WL280 RN for hazardous areas

11/2013

Dimensions of WL250 ST-S SA changed.

11/2014

Integration of load cell WL260 SP-S AE

General formal changes.

05/2016

Addition to load cell WL290 DB-S CA

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

Technical support (Page 99)

The following versions of this documentation have been released to date. The changes apply

to the previous version:

Table 1- 1 History

10/2008 Initial release

04/2009 Addition to SP-S SA 30 t load cell.

Designation updated: WL200 instead of WL 200.

Corrections made mainly to the specifications.

09/2010 Addition to WL280 RN-S SA 60 kg to 5 t load cells

02/2013 WL270 K-

bridge) and extended operating range up to 500 t. WL260 SP-S SB load

03/2015 Integration of load cell WL230 SB-S CA. Description of nameplate und

ATEX label.

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

7

Introduction

1.3

Checking the consignment

WARNING

Using a damaged or incomplete device

1.4

Transportation and storage

CAUTION

Insufficient protection during storage

1.5

Notes on warranty

1.3 Checking the consignment

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 45).

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SIWAREX WL200

8 Operating Instructions, 07/2016, A5E02199611B-03

2

2.1

Prerequisites for safe use

Symbol

Explanation

2.1.1

Laws and directives

2.1.2

Conformity with European directives

Electromagnetic compatibi

ity EMC

2014/30/EU

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

Atmosphè

ATEX

2014/34/EU

Directive of the European Parliament and the Council on the

a

equi

ly explosive atmospheres.

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

The CE mark on the device is a sign of conformity with the following European directives:

l-

re explosible

pproximation of the laws of the Member States concerning

pment and protective systems intended for use in potential-

The standards applied can be found in the EC declaration of conformity for the device.

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

9

Safety instructions

2.2

Improper device modifications

WARNING

Improper device modifications

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device

development purposes.

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

2.2 Improper device modifications

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

is used for research and

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

SIWAREX WL200

10 Operating Instructions, 07/2016, A5E02199611B-03

Safety instructions

WARNING

Unsuitable device for the hazardous area

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

NOTICE

Damage to load cells, measurement errors

2.4 Use in hazardous areas

Danger of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Technical

data (Page 45).

Dirt must not be allowed to accumulate in the vicinity of a load cell.

Do not subject cable glands and seals to the jet from a pressure washer.

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

11

Safety instructions

2.4 Use in hazardous areas

SIWAREX WL200

12 Operating Instructions, 07/2016, A5E02199611B-03

3

3.1

Range of application

3.2

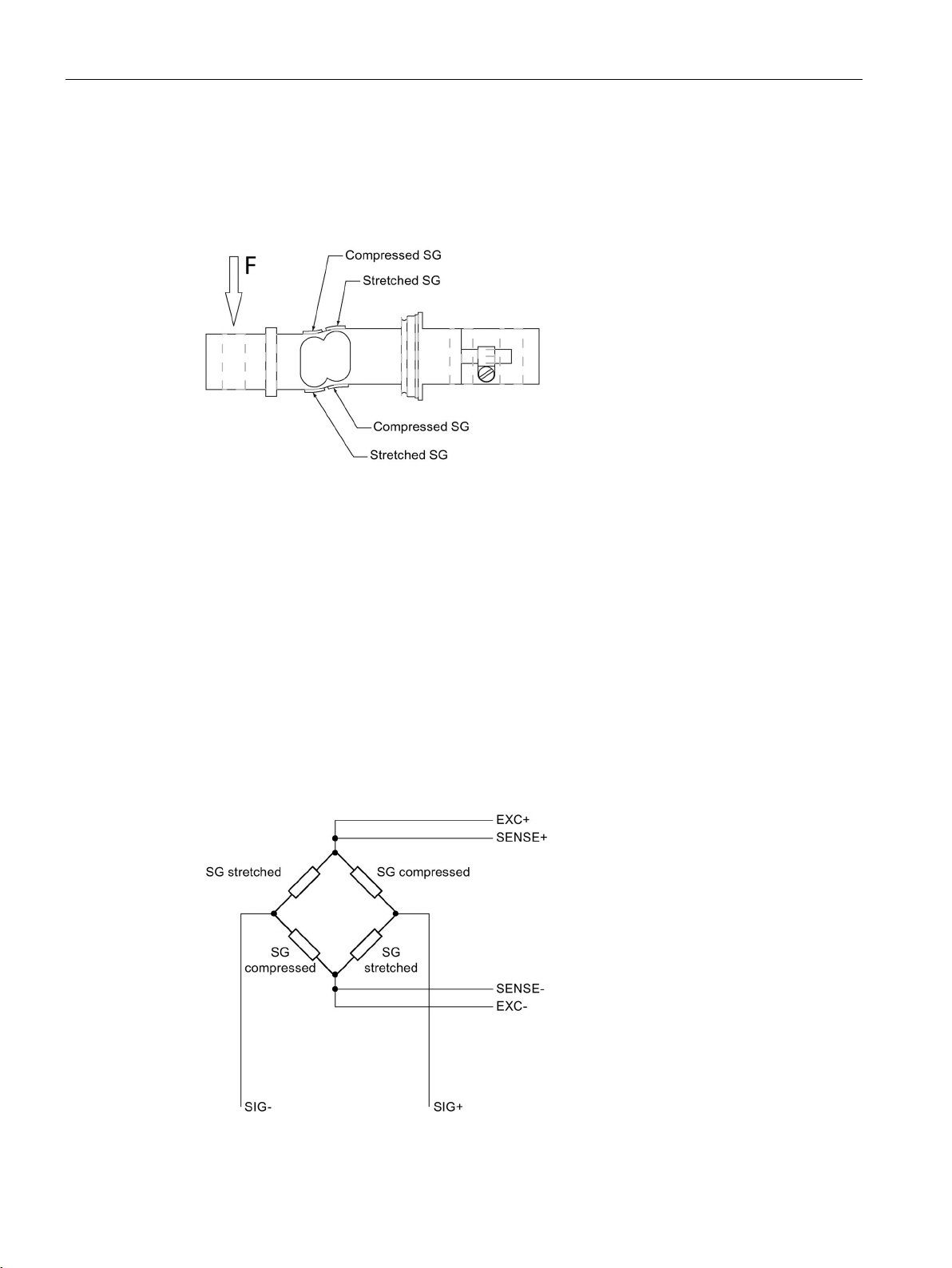

Design and principle of operation

Design

SIWAREX load cells are used for measuring forces and weights statically and dynamically.

You can use SIWAREX load cells for almost all applications in industrial weighing

technology. Examples include:

● Container weighers, hopper scales or platform scales,

● Roller table, conveyor or crane scales,

● Plants for bottling/packing, dosing and mixing,

● for checking levels and completeness,

● Equipment for monitoring pressing or stretching processes,

● Dynamic scales

All applications can be implemented in equipment requiring official calibration or in areas

subject to explosion hazards.

SIWAREX load cells are based on strain gauges. Strain-gauge load cells are transducers

which convert mechanical forces into electrical signals. The principle of operation is the

same regardless of variations in design.

Figure 3-1 Design, based on the example of an unloaded bending beam load cell

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

13

Description

Principle of operation

3.2 Design and principle of operation

The basic component in each case is a special type of spring body. The application of force

elastically deforms the spring body. The ohmic resistance of the strain gauges changes as a

result.

Figure 3-2 Principle of operation, based on the example of a loaded bending beam load cell

For each load cell, at least four strain gauges are connected together as a complete

Wheatstone bridge. The stretched or compressed strain gauges are connected in such a

manner that the positive or negative resistance changes are summed to produce an overall

imbalance of the bridge.

The supply voltage is applied across one diagonal of the bridge and, in the case of the sixwire connection method, also the sensor voltage SENSE. The measured voltage is tapped

across the other diagonal.

For a constant supply voltage EXC, therefore, the measured voltage SIG changes

proportionally to the introduced load. In practice, load cells contain additional resistors for

temperature compensation and for zero-signal and characteristic-value compensation.

Depending on their type and the requirements, these resistors can be arranged at the input

or output of the load cell.

Figure 3-3 The principle of a Wheatstone bridge

SIWAREX WL200

14 Operating Instructions, 07/2016, A5E02199611B-03

Description

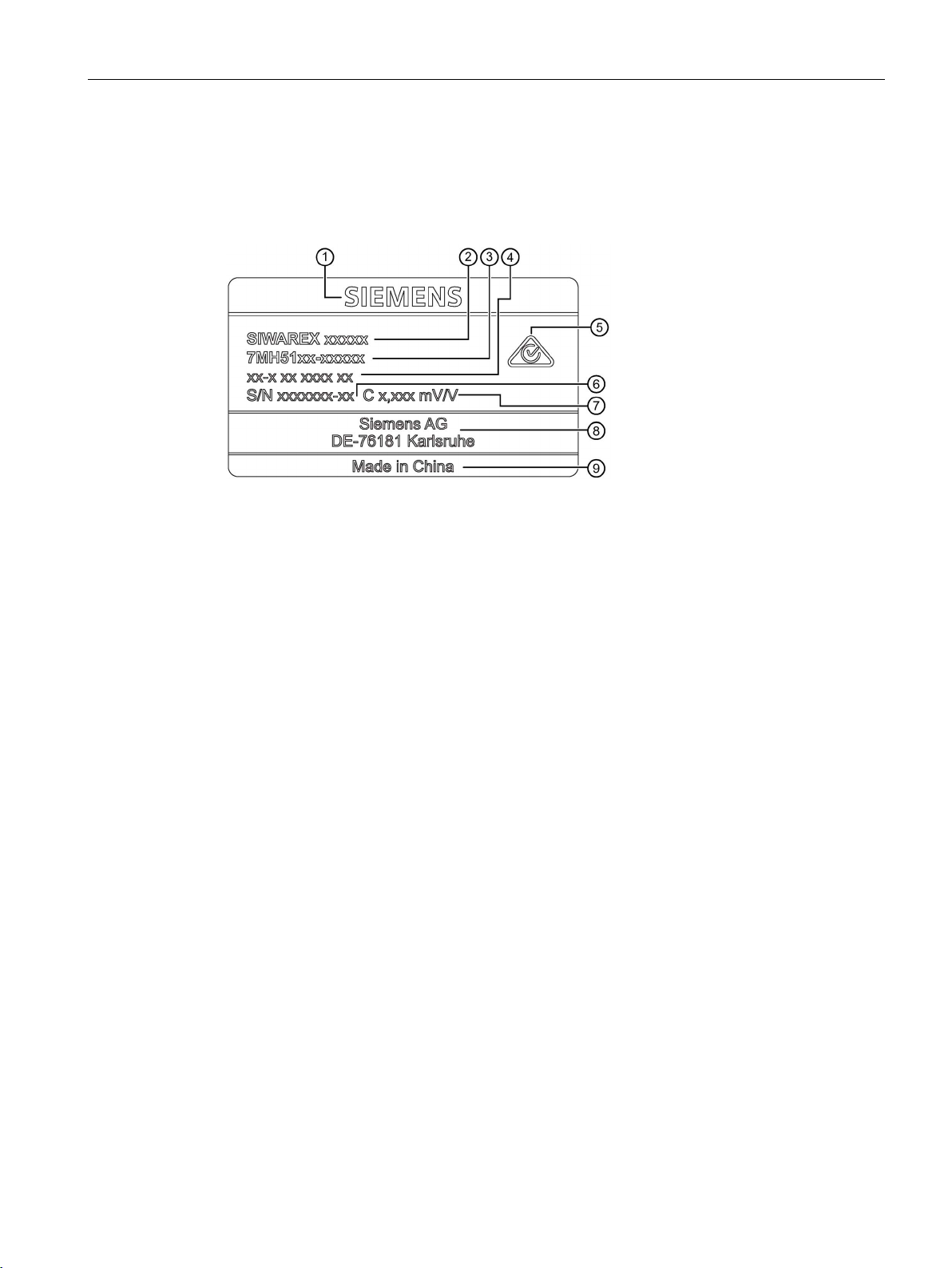

3.3

Nameplate layout

①

Company logo

②

Product group designation

③

Order number

④

Product designation

⑤

RCM

⑥

Serial number

⑦

Rated characteristic value Cn of load cell

⑧

Manufacturer's address

⑨

Country of origin

nameplate layout with general information

3.3 Nameplate layout

Nameplate layout with general information

Figure 3-4 Example of

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

15

Description

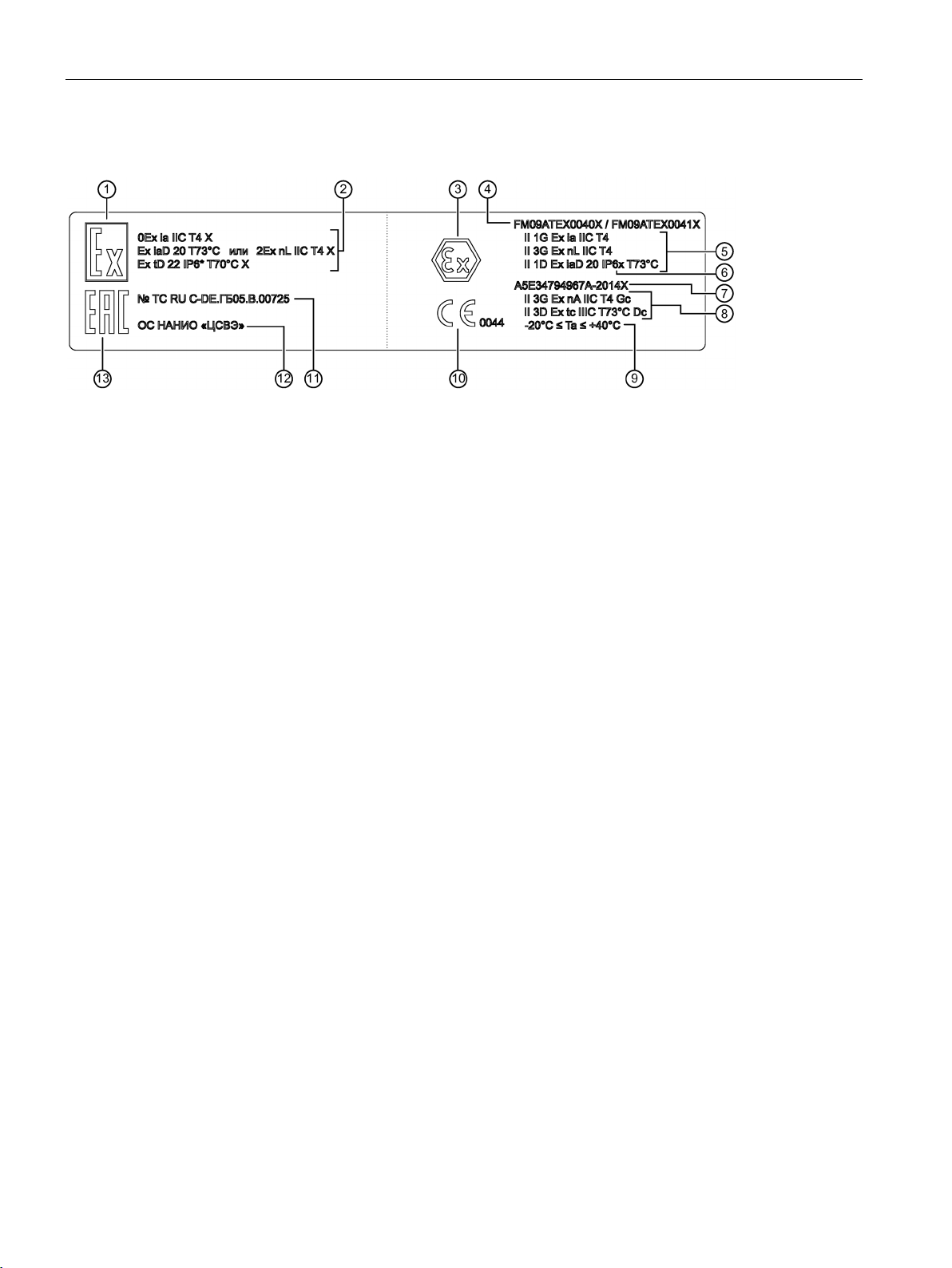

Nameplate layout with approval information

①

Ex marking of the customs union

②

Types of protection of the customs union

③

Ex marking (ATEX)

④

Numbers of ATEX approvals

⑤

Type of protection according to ATEX

⑥

Degree of protection according to EN 60 529, e.g. IP67. The degree of protection depends on the type of load cell.

⑦

Number of the manufacturer's declaration for zone 2

⑧

Type of protection according to ATEX

⑨

Permitted temperature range

⑩

CE mark

⑪

Number of the certificate of the customs union

⑫

Notified body of the customs union

⑬

EAC marking of the customs union

See also

3.3 Nameplate layout

Figure 3-5 Example of nameplate layout with approval information

Adjustment and initial commissioning (Page 33)

SIWAREX WL200

16 Operating Instructions, 07/2016, A5E02199611B-03

4

4.1

Basic safety instructions

DANGER

Danger to life from falling loads

NOTICE

Damage to load cells through incorrect handling

NOTICE

Damage to load cells through high currents

Load cells are precision components and must therefore be handled carefully. Particular

care must be taken during transport and installation.

• Load cells are not machine components which have been constructed with the normal

safety factors. For this reason, appropriate protection against falling and catastrophes

must be implemented in accordance with the potential risks.

• Use suitable hoisting equipment to lift the load carrier. Observe the appropriate safety

regulations.

• SIWAREX load cells are only permitted to be mounted and connected by qualified

personnel.

• Mechanical shocks or falls can irreparably damage the load cell.

• When mounting the load cell, ensure that you do not damage or cut the cables of the

load cell. Load cells must not be carried by their connecting cables.

• Protect the load cells from shocks and welding currents. Replace the load cells with

dummies until the installation work on the scale structure is completed.

• If welding is undertaken after the load cells have been installed, ensure that the welding

current is not diverted through the load cells.

– You can do this by attaching the grounding clamp of the welding unit making reliable

contact close to the weld.

– Bridge the load cells with a ground cable, for more on this, see Accessories

(Page 98)

– Disconnect the individual load cells.

• Undesirable electrical currents can arise during lightning. Bridge the load cells with a

highly flexible ground cable to protect the load cells against such currents, for more on

this, see Accessories (Page 98).

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

17

Installing

NOTICE

Damage to load cells through incorrect mounting

expansion will not result in lateral loading.

NOTICE

Destruction of load cells

4.2

Procedure for mounting the device

Procedure for mounting the device

See also

4.2 Procedure for mounting the device

• Provide indented claws or crane eyebolts on the load bearer to ensure that hoisting gear

can be used safely.

• Load cells must never be overloaded. Put the load carrier down slowly for this reason.

With load cells of smaller rated loads in particular, there is a risk of stretching the load

cell bodies when attaching force transfer devices, e.g. when tightening locknuts.

• Adjust the existing overload protection to ensure that it can still reliably sense transfer of

the required load. The overload protection must permit a rise in weight unhindered until

the setpoint weight is reached.

• Protect the gap between the load cell and overload protection from the build up of dirt or

ice.

• The load must be introduced in the measuring direction of the load cell. Torsional and

bending moments, eccentric loads and lateral forces are disturbances. These

disturbances falsify the measured result and can damage the load cell if the permissible

limits of the load cell and mounting components are exceeded.

The mounting components normally allow so much room for movement that heat

Proceed carefully with installation. The load cells can be destroyed if they are installed

incorrectly.

1. Observe the installation guidelines for the mounting components.

– You can find dimension drawings of installation elements under Dimension drawings

(Page 69).

– Lay the cables for the load cells through cable glands in the form of a vertical

downwards loop to discourage the penetration of water.

2. Check that the load cells and mounting components are installed correctly, e.g. by

checking the mounting dimensions and oscillation distances.

Nameplate layout (Page 15)

SIWAREX WL200

18 Operating Instructions, 07/2016, A5E02199611B-03

Installing

4.3

Dismantling

4.3 Dismantling

For the disassembly of load cells, the same safety rules and requirements apply as for

installation and assembly.

1. Disconnect all the supply voltages and auxiliary voltages.

2. Secure the load carrier against falling.

3. Use appropriate hoisting gear and tools.

4. Take the load off the load cell.

5. Carefully remove the load cell without using force. Do not pull on the cable of the load

cell.

6. Do not cut the cable if the load cell is to be re-used or sent in for repair.

7. Do not carry the load cell by the cable.

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

19

Installing

4.3 Dismantling

SIWAREX WL200

20 Operating Instructions, 07/2016, A5E02199611B-03

5

5.1

Basic safety instructions

WARNING

Incorrect selection of type of protection

WARNING

Improper power supply

Note

Electromagnetic compatibility (EMC)

You can

For metal housings there is an increased electromagnetic compatibility compared to high

frequency radiation. This protection can be increased by grounding the housing, see

Connecting

Danger of explosion in areas subject to explosion hazard.

This device is approved for several types of protection.

1. Decide in favor of one type of protection.

2. Connect the device in accordance with the selected type of protection.

3. In order to avoid incorrect use at a later point, make the types of protection that are not

used permanently unrecognizable on the nameplate.

Danger of explosion in hazardous areas as result of incorrect power supply, e.g. using

direct current instead of alternating current.

• Connect the device in accordance with the specified power supply and signal circuits.

The relevant specifications can be found in the certificates, in Technical data (Page 45)

or on the nameplate.

use this device in industrial environments, households and small businesses.

-

(Page 21).

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

21

Connecting

5.2

Connecting principle

WARNING

Risk of explosion

5.2 Connecting principle

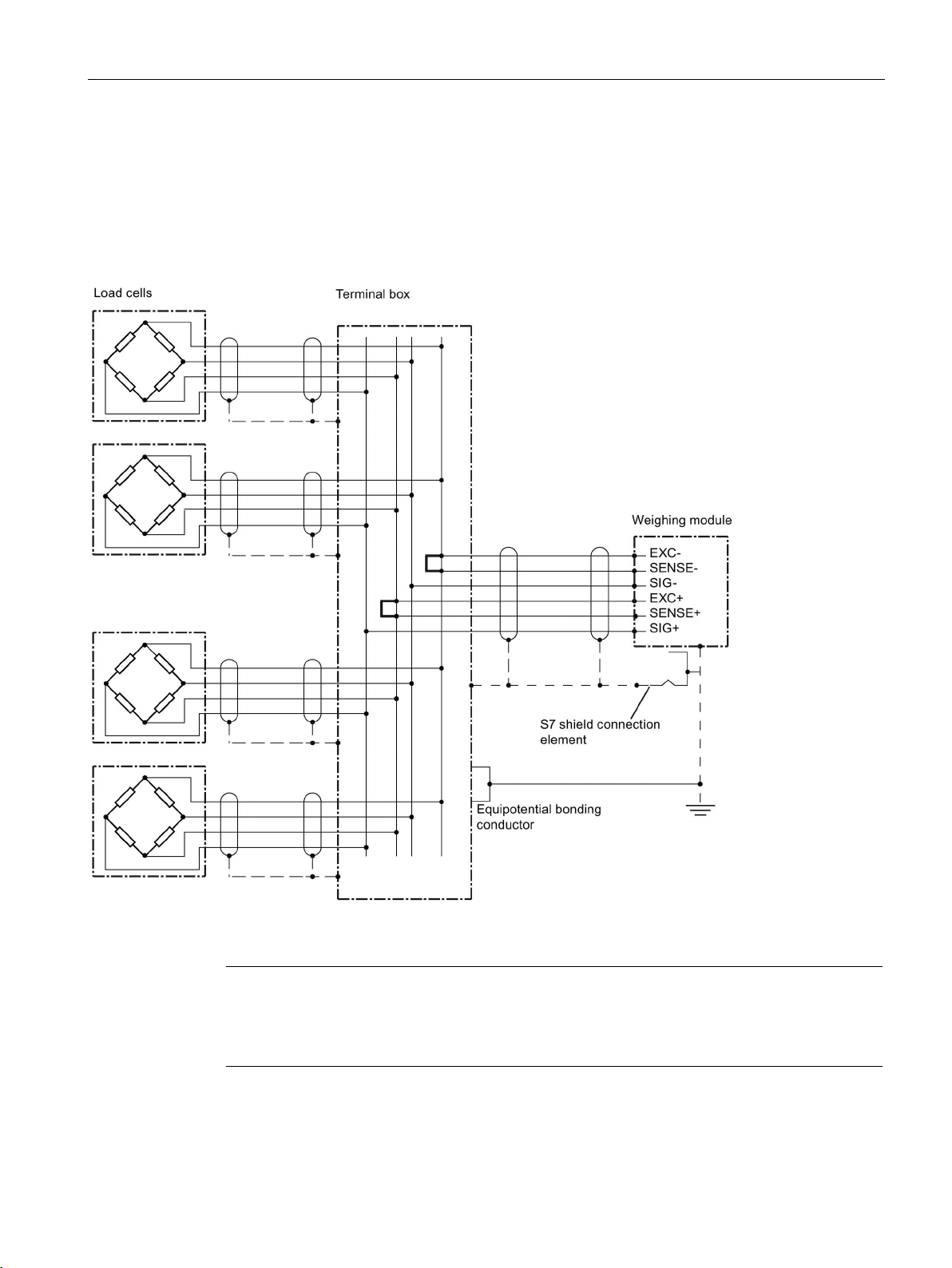

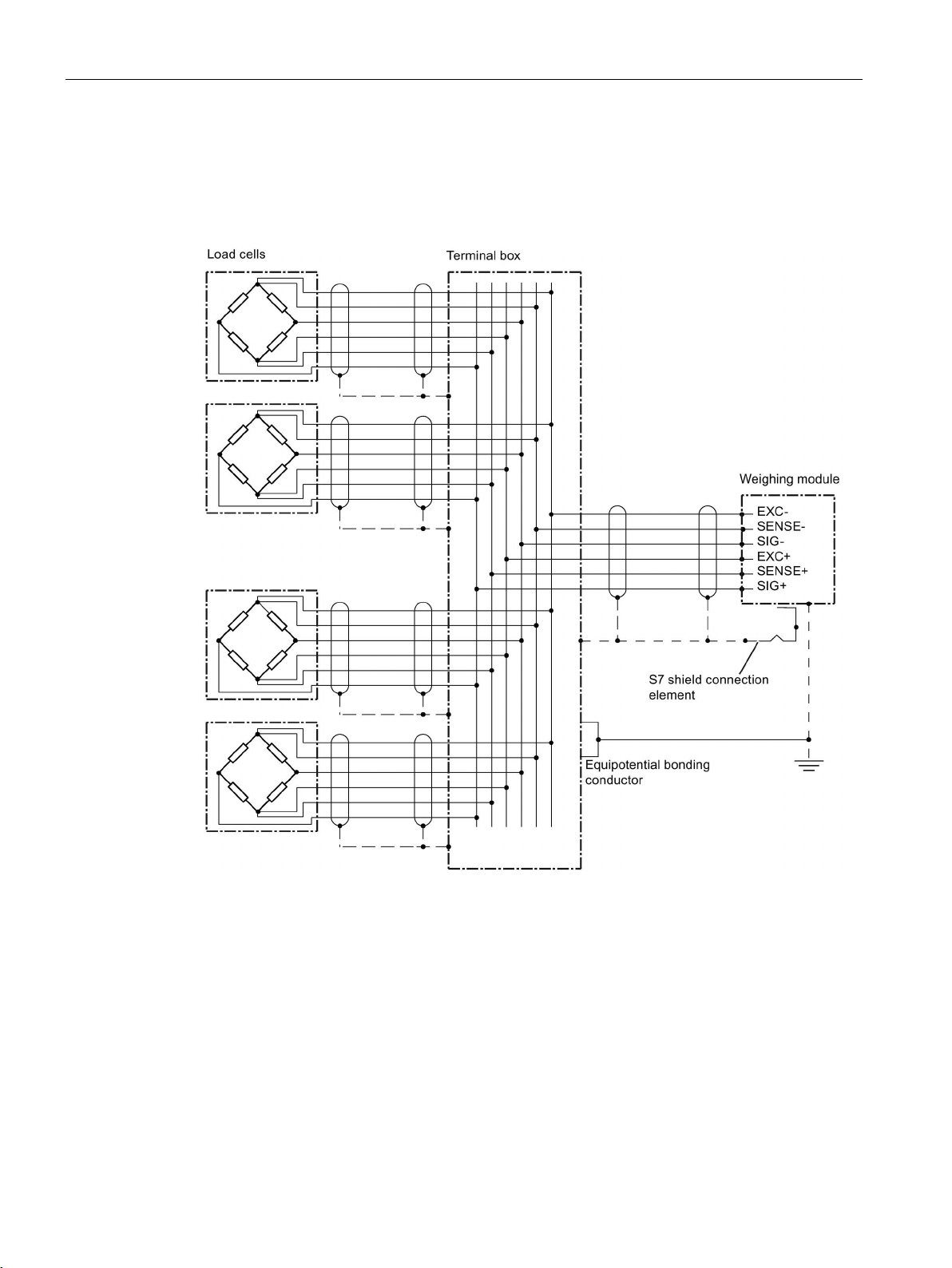

Load cells can be equipped with connecting cables with four or six cores.

Please observe that in the case of shielded cables of intrinsically safe circuits in hazardous

areas only one grounding is permissible.

If grounding is to be on both sides an equipotential bonding conductor with at least 4 mm²

must be connected.

SIWAREX WL200

22 Operating Instructions, 07/2016, A5E02199611B-03

Connecting

Load cells with four-wire system

Note

No calibration approval

In scales requiring official calibration, the connecting cables for load cells in a four

system must not be shortened or lengthened.

5.2 Connecting principle

Do not shorten or length connecting cables in the four-wire system, because the cable

resistance is temperature compensated. When the length of the connecting cable is altered,

the input and output resistances change. This change can be corrected by adjusting the

scale, but temperature-dependent resistance changes are not compensated for the missing

or additional length of cable.

Figure 5-1 Connecting principle for load cells with four-wire system

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

-wire

23

Connecting

Load cells with six-wire system

5.3

Connecting up

Signal assignment for the load cell connecting cable

5.3 Connecting up

For connecting cables in the six-wire system, the supply voltage is fed back to the weighing

module as the reference voltage. Shortening or lengthening has no effect on the measuring

result.

Figure 5-2 Connecting principle for load cells with six-wire system

Identifying colors and signal assignment for the connecting cables of load cells not listed:

See the data sheet for the appropriate load cell.

SIWAREX WL200

24 Operating Instructions, 07/2016, A5E02199611B-03

Connecting

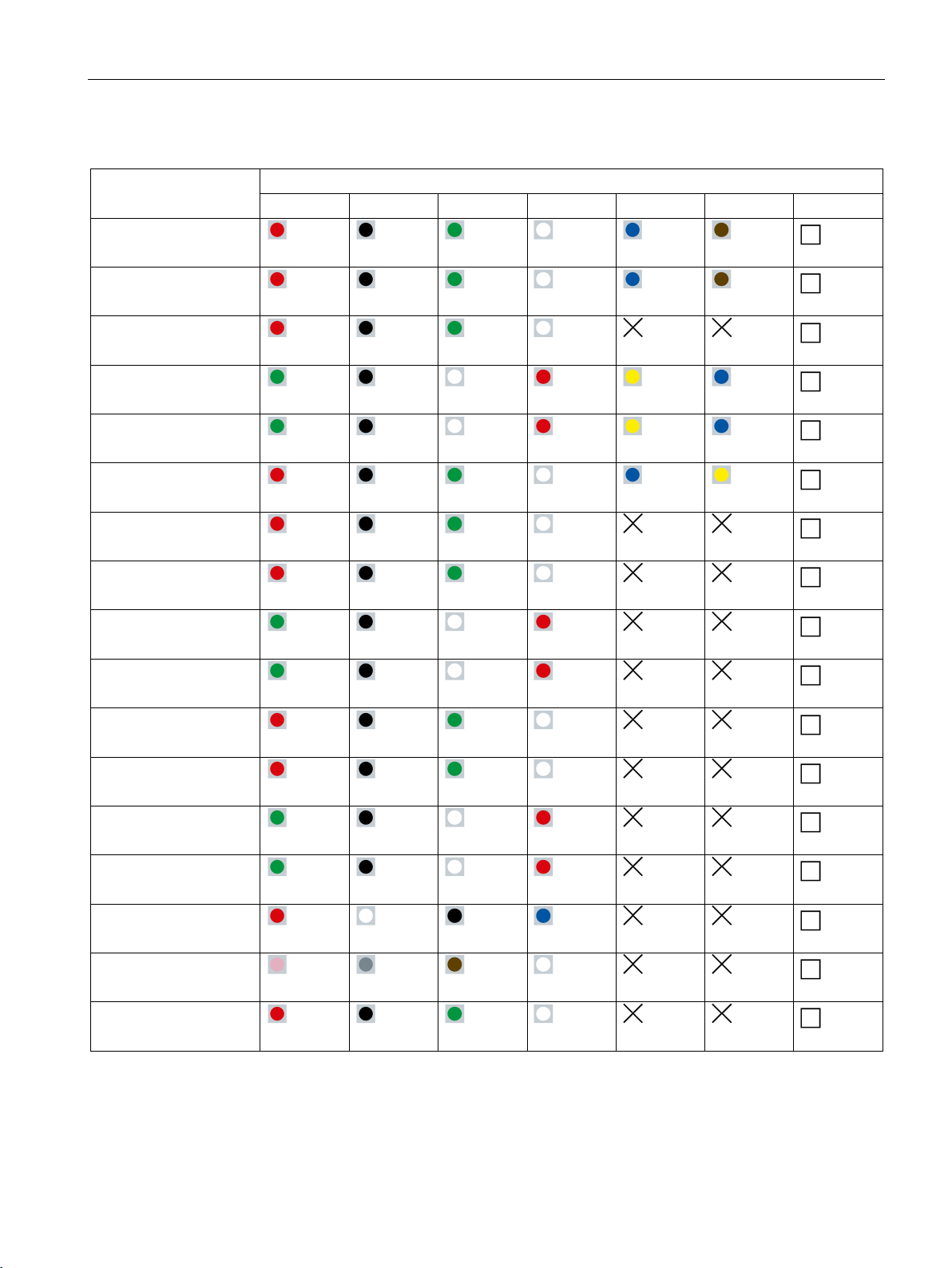

Load cell

Function/color of connecting cable

EXC+

EXC-

SIG+

SIG-

Sense+

Sense-

Shield

parent

parent

parent

parent

parent

parent

parent

5.3 Connecting up

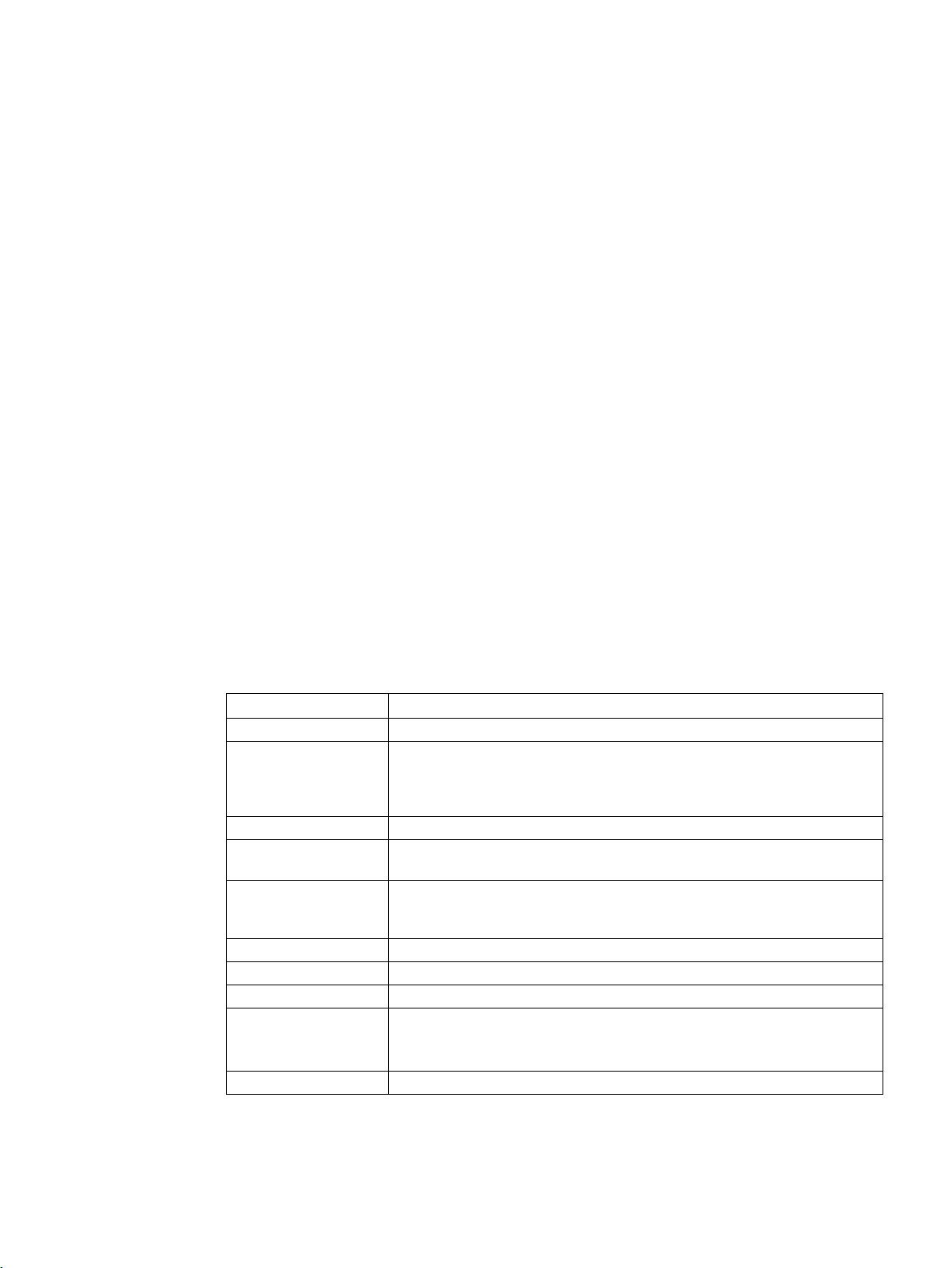

Table 5- 1 Signal assignment for the load cell connecting cable

SIWAREX WL260

SP-S AA

SIWAREX WL260

SP-S AB

SIWAREX WL260

SP-S AE

SIWAREX WL260

SP-S SA

SIWAREX WL260

SP-S SB

SIWAREX WL260

SP-S SC 10 ... 50 kg

SIWAREX WL260

SP-S SC 100 ... 200 kg

SIWAREX WL250

ST-S SA

SIWAREX WL230

BB-S SA

SIWAREX WL230

SB-S SA

SIWAREX WL230

SB-S CA

SIWAREX WL270

CP-S SA

Red Black Green White Blue Brown

Red Black Green White Blue Brown

Red Black Green White n.a. n.a.

Green Black White Red Green Blue

Green Black White Red Green Blue

Red Black Green White Blue Green

Red Black Green White n.a. n.a.

Red Black Green White n.a. n.a.

Green Black White Red n.a. n.a.

Green Black White Red n.a. n.a.

Red Black Green White n.a. n.a.

Red Black Green White n.a. n.a.

Trans-

parent

Trans-

Trans-

Trans-

parent

Trans-

Trans-

Trans-

parent

Trans-

parent

Trans-

Trans-

parent

Trans-

parent

Trans-

SIWAREX WL270

CP-S SB

SIWAREX WL270

CP-S SC

SIWAREX WL270

K-S CA

SIWAREX WL280

RN-S SA

SIWAREX WL290

DB-S CA

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

Green Black White Red n.a. n.a.

Green Black White Red n.a. n.a.

Red White Black Blue n.a. n.a.

Pink Gray Brown White n.a. n.a.

Red Black Green White n.a. n.a.

Trans-

parent

Trans-

parent

Trans-

Trans-

parent

Trans-

parent

25

Connecting

Procedure

Note

Measurement errors

Observe the warnings concerning extending or shortening the connecting cables in section

→

If at all possible, do not shorten the connecting cables in a four

Note

No calibration approval

In scales requiring official calibration, the connecting cables for load cells in a four

system must not be shortened or lengthened.

Wire jumper

From terminal

To terminal

1

EXC-

SENSE-

2

EXC+

SENSE+

Note

Malfunction

If the wire jumpers are missing, the SIWAREX weighing module signals a wire break.

5.3 Connecting up

Lengthening and shortening the connecting cable (Page 31).

-wire system.

-wire

1. Connect the recommended grounding cables: → Planning (Page 27)

2. Connect the load cells in accordance with the connection principle and with reference to

the specified signal assignments: → Connecting principle (Page 22)

3. For load cells with a four-wire system, position the wire jumpers in the junction box as

follows:

Table 5- 2 Wire jumpers for load cells with four-wire system

SIWAREX WL200

26 Operating Instructions, 07/2016, A5E02199611B-03

6

6.1

Basic safety instructions

WARNING

Improper commissioning in hazardous areas

6.2

Application planning

6.2.1

Planning

WARNING

Danger to life from falling loads

Version

Device failure or danger of explosion in hazardous areas.

• Do not commission the device until it has been mounted completely and connected in

accordance with the information in Technical data (Page 45).

• Before commissioning take the effect on other devices in the system into account.

Load cells are not machine components which have been constructed with the normal

safety factors. For this reason, appropriate protection against falling and catastrophes must

be implemented in accordance with the potential risks.

SIWAREX load cells are usually manufactured from stainless steel and hermetically sealed.

This provides a high degree of corrosion resistance and a high degree of protection.

Most type series are approved for use in scales requiring official calibration of Class III to

DIN EN 45501 and comply with the accuracy class OIML R60 C3.

If necessary, load cells can be supplied with ATEX approval.

SIWAREX load cells are current-calibrated as standard. This means that, for example, when

a platform scale is commissioned, corner load adjustment is not necessary. A load cell can

therefore be replaced without recalibration of the scale.

This may not apply to load cells that are available outside the standardized delivery

spectrum. For these load cell types, the relevant technical specifications apply.

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

27

Commissioning

Parallel connection of load cells

NOTICE

Overloading of load cells

Note

Measurement errors

Load cells are only permitted to be connected in parallel when they have the same

characteristic value, the same rated load and the same internal resistance.

The total resistance of load

resistance from the technical data of the weighing module to which it should be connected.

Environmental requirements at the mounting location

Note

Measurement errors

The load cell must be protected against direct solar radiation. Otherwise, the permissible

operating temperature may be exceeded. One

measurements or even measurement errors.

6.2 Application planning

In weighing systems, one or more load cells are connected to a weighing module for

evaluation of the measured signal. Several load cells of a scale are connected in parallel to a

junction box to supply a joint output signal.

When more than one load cell is connected to a scale, if the load distribution is uneven, it

cannot be established whether individual load cells are overloaded.

cells connected in parallel must not undershoot the minimum

The maximum number of load cells that can be connected to a weighing module depends on

the total resistance of the load cells connected in parallel. This must lie within the load

resistance limits specified for the weighing module.

The maximum length of the cables and the specifications for other components, e.g. Ex i

interface, must also be complied with. For details, see the section Lengthening and

shortening the connecting cable (Page 31)

The foundations must be unyielding when the expected loads are applied. The maximum

roughness permitted for the mounting surface is 1.6 µm.

The values specified in the technical data for the ambient conditions must be complied with.

-sided heating will result in less accurate

SIWAREX WL200

28 Operating Instructions, 07/2016, A5E02199611B-03

Commissioning

Grounding protection

NOTICE

Damaging of load cells

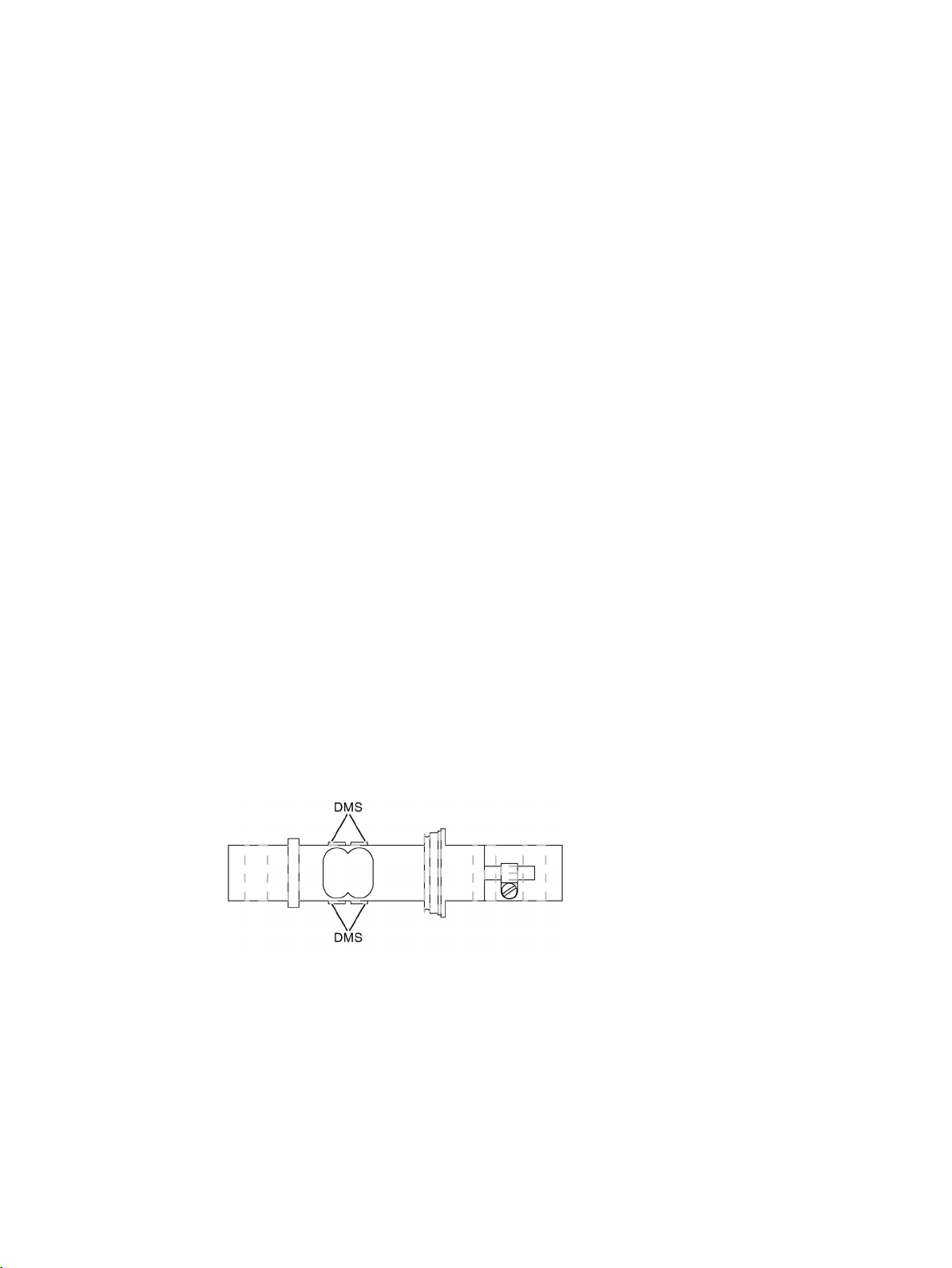

6.2.2

Transverse forces and overload protection

Overloading of load cells

NOTICE

Risk of overloading

NOTICE

Damage to load cells through overloading

Note

Error message on overload

If load cells are loaded beyond their rated load, this can result in an error message

weighing module.

6.2 Application planning

Undesirable electrical currents can arise during welding or lightning. To protect the load

cells against such currents, bridge the load cells using highly flexible grounding cables, see

also Accessories (Page 98).

If you connect more than one load cell to a scale, if the load distribution is uneven, it cannot

be established whether individual load cells are overloaded.

In the case of load cells with small rated loads, overload protection must be implemented to

protect the cells against damage.

If load cells are used beyond the maximum working load or the maximum lateral load, this

can cause irreparable errors and even fracturing of the load cell.

When mounting components are fitted, the load cells must not be overloaded, e.g. by

overtightening bolts.

in the

Overloading can occur as a result of:

● Uneven load distribution due to mounted components or cones of bulk material

● Rolling/pushing up the load on platform or roller table scales

● Forceful application of the load

● Application of the load in free fall

SIWAREX WL200

Operating Instructions, 07/2016, A5E02199611B-03

29

Commissioning

Dimensioning for overload

Lifting protection

Mounting components and guide elements to counteract lateral forces, torsional and bending

moments

6.2 Application planning

● Persons supporting themselves on or climbing onto the scale

● Wind against the leeward side of a silo

When step changes in load cannot be excluded during measuring, for example, due to

application of a load in free fall, you must take appropriate precautions to avoid damage to

the load cell, e.g. by using elastomer bearings or load cells dimensioned for higher rated

loads.

When dimensioning load cells, include a safety margin to guard against overloading:

● Use a safety margin of 20% in the case of three support points.

● If more than three support points are used in a statically indeterminate manner, the safety

margin must be a minimum of 50% if it is not possible to rule out a situation in which the

load rests on two diagonally opposite load cells only. Reasons for this include sinking of

the foundations or incorrect mounting.

● When calculating the safety margin, include unintentional overloads or overloading

caused by the course of the process, or use overload protection.

Overloads can also occur in the lifting direction when the force introducer is attached to the

load cell.

If there is a risk of the load bearing being lifted or toppled, lifting protection may be

necessary. This is required in the case of lightweight containers and tall, outdoor silos.

The load must be introduced in the measuring direction of the load cell. Torsional and

bending moments, eccentric loads and lateral forces are disturbances that on the one hand

falsify the measured result and on the other hand can damage the load cell if the permissible

limits are exceeded. Load cells must therefore be fitted with specially adapted mounting

components, e.g. with SIWAREX mounting parts. This largely prevents the above-mentioned

sources of error. The mounting components allow so much room for movement that heat

expansion will not result in lateral loading.

Lateral forces which are generated by wind, acceleration or conveyor friction can be diverted

by guide elements or stops.

Guide elements must be installed perpendicular to the measuring direction to ensure that no

force components are generated in the measuring direction. The guide elements must be

installed such that they do not stretch if, for example, the mounting points spread apart. This

is easily achieved by arranging the guide elements in the same direction of rotation.

Ensure that the selected guide elements comply with the principles applicable to weighing

technology.

Force bypasses must not arise due to filling and emptying devices or supply lines.

SIWAREX WL200

30 Operating Instructions, 07/2016, A5E02199611B-03

Loading...

Loading...