Page 1

s

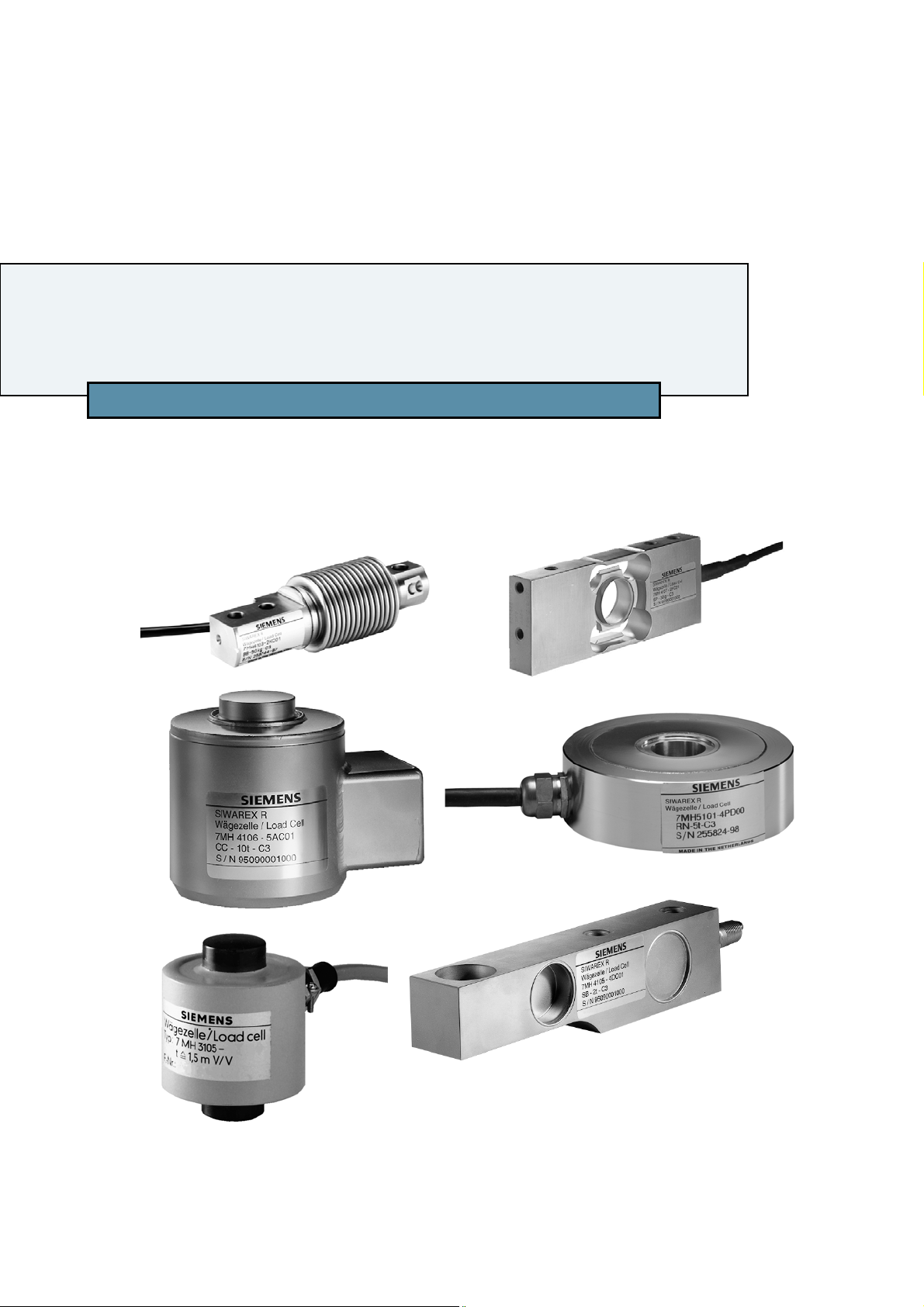

SIWAREX R

Load Cells

Operating Instructions Edition 06/2009

Page 2

Table of Contents:

Safety Instructions............................................................................3

General Information..........................................................................4

Notes on product liability.................................................................4

1 Technical Description.......................................................................5

1.1 Area of Application.............................................................................. 5

1.2 Structure ............................................................................................. 5

1.3 System Configuration.......................................................................... 7

2 Installation/Assembly..................................................................... 10

2.1 Installation......................................................................................... 10

2.2 Assembly .......................................................................................... 13

2.3 Disassembly...................................................................................... 16

3 Commissioning............................................................................... 17

4 Service.............................................................................................19

4.1 Care and Maintenance...................................................................... 19

4.2 Troubleshooting ................................................................................ 19

5 Technical Data.................................................................................22

5.1 Functional Data................................................................................. 22

5.2 Unit Version ...................................................................................... 24

5.3 Explosion Protection ......................................................................... 25

5.4 Electromagnetic Compatibility........................................................... 26

5.5 Dimensions ....................................................................................... 27

6 Ordering Data.................................................................................. 34

SIWAREX R Load Cells Operating Manual

A5E00159640

2

Page 3

Safety Instructions

DANGER

indicates that death, severe personal injury or substantial property damage will

result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury can result if proper precautions are

not taken.

CAUTION

This text accompanied by a warning triangle indicates that minor personal injury

can result if proper precautions are not taken.

Qualified personnel as used in the safety instructions in this manual and on the

Copyright © Siemens AG 2009 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschäftsgebiet Process Instrumentation and Analytics

D-76181 Karlsruhe

CAUTION

This text without an accompanying warning triangle means that property damage

may occur if proper precautions are not taken.

ATTENTION

indicates that an undesirable result or state may result if the proper steps are not

taken.

NOTE

indicates a potential benefit if recommendations are followed.

product itself are individuals who are familiar with the installation, assembly, initial

start-up and operation of this product. They must be authorized and qualified to

install, start and maintain devices, systems and circuits in accordance with

national safety rules and regulations.

Disclaimer of Liability

We have checked the contents of this manual for agreement with

the hardware and software described. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement. However,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

©Siemens AG 2009

Technical data subject to change.

SIWAREX R Load Cells Operating Manual

A5E00159640

3

Page 4

General Information

Use for the intended purpose

Use for the intended purpose means that this product may only be used within the

limits of the technical specifications and statement of purpose of this operating

manual.

This device will not be a source of danger provided it is used for the intended

purpose under consideration of the safety instructions.

Perfect, safe operation of this device is conditional upon proper transport, storage,

installation and assembly.

Proper operation of this device can only be ensured if the specifications provided in

technical data are observed.

Improper handling can result in death, severe personal injury and property

damage.

Notes on product liability

We expressly point out that the nature of the product is described exclusively and

conclusively in the contract of sale. The contents of this product documentation are

not part of an earlier or existing agreement, acceptance or legal relationship nor do

they affect these in any way. The particular contract of sale determines the sum of

obligations to be met by Siemens and the guarantee regulation container therein is

complete and is the sole regulation that shall apply. This contractual guarantee

regulation is neither extended nor limited by the information provided in this

document.

Information on delivery

The scope of delivery in accordance with the valid contract of sale is listed in the shipping

documents enclosed in the delivery.

Please observe any relevant instructions when opening the packaging. Check the

shipment for completeness and possible transportation damage. In particular,

compare the order number on the rating plate with the order information.

Please read this operating manual before starting work! It contains important

information and data that, if observed, ensure the overall safety and functionality of

this device. Following these instructions will make it easier for you to use handle

this product and ensure reliable measuring results.

SIWAREX R Load Cells Operating Manual

A5E00159640

4

Page 5

1 Technical Description

1.1 Area of Application

SIWAREX R load cells are used for static and dynamic measurements of forces

and weights. They can be used for almost all applications in industrial weighing

technology. These may be for example:

• container, hopper or platform scales,

• rollway, belt or crane scales,

• filling/packing plants, proportioning and mixing,

• filling level and completeness inspection,

• equipment for monitoring pressing and clamping procedures,

• dynamic scales

All applications can be located in areas with mandatory calibration or in hazardous

areas.

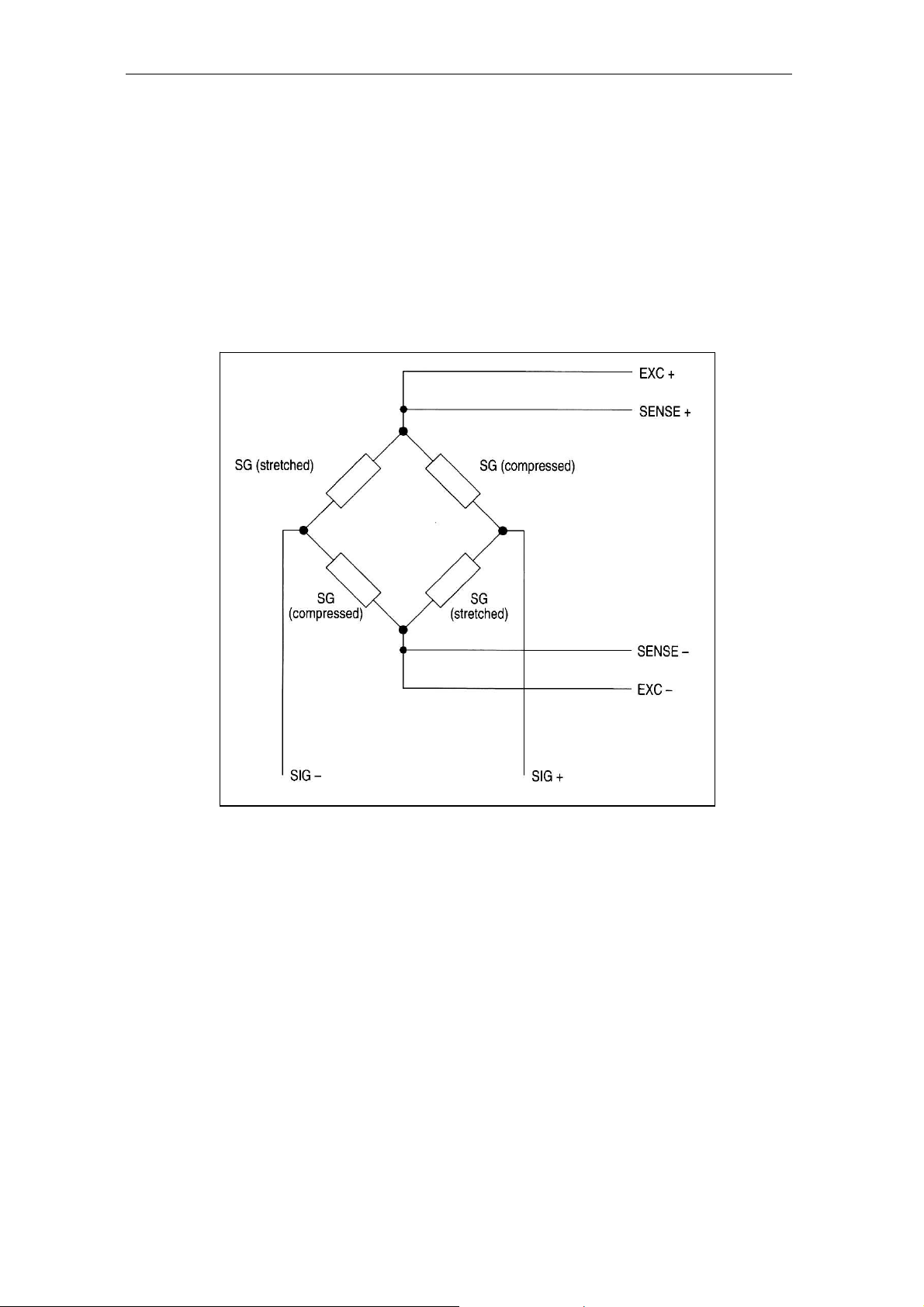

1.2 Structure

The SIWAREX R load cells are equipped with wire strain gauges (WSG). WSG

load cells are transducers for converting mechanical forces into electrical signals.

The functional principle is always the same despite different designs.

The basic element is a special spring body. The spring body is deformed elastically

when a force is applied. The integrated WSGs then change their ohmic resistance

(figure 1-1)

Figure 1-1 Principle diagram shown by the example of a bending rod load cell

SIWAREX R Load Cells Operating Manual

A5E00159640

5

Page 6

Edition 06/2009

At least four WSGs per load cell are connected in a full Wheatstone bridge. The

stretched or upset WSGs are wired so that the positive or negative changes in

resistance add up to a total upset of the bridge.

The feed voltage (in 6-wire technology also the sensor voltage, SENSE) is applied

at one bridge diagonal. The measuring voltage is tapped at the other diagonal.

At a constant feed voltage (EXC), the measured voltage (SIG) changes

proportionally to the applied load (figure 1-2). In practice load cells contain other

resistors for temperature compensation, zero point and parameter adjustment.

These may be in the input or output of the load cell depending on the type and on

requirements.

Technical Description

Figure 1-2 Principle diagram of a Wheatstone bridge

The SIWAREX R load cells are usually made of high-grade steel and are welded

hermetically sealed. This provides high corrosion protection and protection rating.

Most series are licensed for use in scales with mandatory calibration of class III

according to DIN EN 45501 and comply with OIML R60 3000d. Load cells with

greater accuracy and/or EEx (i) approval are available on request.

SIWAREX R load cells are electrically calibrated as standard. As a result, no

reference load adjustment is necessary for example when commissioning a

platform scales. A load cell can also be exchanged without readjustment.

An exception to this rule is the series K and possibly load cells delivered outside

the standard scope of delivery. The respective technical data apply for these load

cell types.

SIWAREX R Load Cells Operating Manual

A5E00159640

6

Page 7

Edition 06/2009

1.3 System Configuration

In weighing technical systems one or more load cells are connected to a weighing

module for evaluation of the measured signal. Several load cells of a scales are

connected in parallel in a junction box to supply a common output signal.

Load cells may only be connected in parallel when they have the same

characteristic value, the same rated load and the same internal resistance.

ATTENTION

The total resistance in parallel connected load cells may not drop below the

minimum resistance specified in the technical data of the weighing module.

The maximum number of load cells that can be connected to a weighing module

depends on the total resistance of the parallel connected load cells. This must be

within limits of the weighing module specified for the load resistance. The length of

the lines and the data of other elements, e.g. Ex i-Interface, must also be taken into

account.

CAUTION

If several load cells are connected in a scales it cannot be determined whether

individual load cells are overloaded in the event of uneven load distribution.

The maximum cable length between the load cell and the weighing module can be

found in the technical data of the weighing module. For Ex applications the data of

the Ex-i interface must also be taken into account.

A shielded 6-wire cable, e.g.. Li2Y(ST)CY 6x0.75 mm

702-8AB or, for Ex applications, 7MH4 702-8AA must be used to connect the

junction box to the weighing module, to extend a load cell connecting cable or for a

cross-connection between two junction boxes.

Overloads should be avoided in the layout of load cells by creating a safety

reserve. The safety reserve for three application points should be 20%. In the case

of statically aspecific use of more than three application points, the safety reserve

must be at least 50% if it cannot be ruled out that the load is only resting on two

diagonally opposite load cells. The reason for this may be drops in the foundation

or improper assembly. Accidental overloads or overloads due to the process must

be taken into account or kept away from the load cells by overload protection

devices. Overloads are caused for example:

• in the case of uneven load distribution as a result of attachments or tipping

mounds,

• when rolling/pushing the load onto platform or rollway scales,

• by hard setting down of the load,

• by setting down the load in free fall,

• when persons are leaning/standing on the scales,

• by wind forces on the side of a silo facing away from the wind.

Technical Description

2

, Siemens order no.: 7MH4

SIWAREX R Load Cells Operating Manual

A5E00159640

7

Page 8

Edition 06/2009

Overloads may also occur in lifting direction when the force application is

permanently mounted to the load cell such as elastomer bearings on load cells of

series BB.

Lift off protection is necessary where there is a risk of the load carrier lifting off or

tipping over. This is essential for lightweight containers or high silos outdoors.

CAUTION

Overload protection devices must always be provided for load cells with low rated

loads to protect the cells from being damaged.

Use of the load cells beyond the maximum working load or maximum transverse

load can lead to irreparable faults and even breakage of the load cell.

Load cells may not be overloaded, e.g. by tightening screws, when adding

installation components.

NOTE

If load cells are loaded beyond their rated load this can lead to an error message

in the weighing module.

If load surges during the measuring mode cannot be ruled out, for example when

the load is set down in free fall, suitable precautions must be taken to avoid

damage to the load cell (e.g. elastomer bearings or higher load cells).

The load must be applied in exact measuring direction of the load cell. Torsion and

bending torques, off-center loads and transverse loads are disturbances which on

the one hand falsify the measuring result and on the other hand can damage the

load cell when they exceed the permissible limits. Load cells must therefore be

installed with suitable installation components (e.g. SIWAREX R installation

components). The possible errors mentioned above are then largely avoided. The

installation components allow enough freedom of movement to prevent heat

expansion leading to transverse loads.

Transverse forces such as are caused by wind, acceleration or conveyor belt

friction must be compensated by deflections or stops. Deflections must be installed

exactly vertical to the direction of action of the load cells so that no force

components occur in measuring direction. The deflections must be installed in such

a way that they do not twist for example when the application points expand. This

is most easily avoided by arranging the deflections in the same direction of

rotation.

The deflections to be installed should correspond to the principles used in weighing

technology. Ball-jointed deflections are available for most SIWAREX R combiinstallation units. Ball bolt deflectors up to a transverse load of 1000 kN are

available on request.

No parallel forces may be applied by filling and emptying devices and supply lines.

Technical Description

SIWAREX R Load Cells Operating Manual

A5E00159640

8

Page 9

Edition 06/2009

DANGER

Load cells are machine elements not constructed with the usual safety factors.

Therefore appropriate crash protection or catastrophe protection must be provided

which suit the danger potential.

CAUTION

For protection against undesirable electrical currents such as they occur when

welding or from lightning, the load cells must be bridged with a highly flexible

grounding cable (e.g. SIWAREX R grounding cable 7MH3 701-1AA1).

The substructure must withstand the planned loads. The application surface must

have a roughness of a max. 1.6 µm.

The values in the technical data must be observed for the ambient conditions.

Note

The load cell must be protected from direct sunlight. The permissible operating

temperature could otherwise be exceeded and thus the accuracy impaired.

Technical Description

SIWAREX R Load Cells Operating Manual

A5E00159640

9

Page 10

2 Installation/Assembly

2.1 Installation

SIWAREX R load cells may only be assembled and connected by qualified

personnel.

If a scales is equipped with a single load cell, this can be connected directly to the

weighing module if space allows. To bridge greater distances the connecting cable

can be extended through a junction box.

Several load cells are connected in parallel in a junction box.

Load cells can be fitted with 4 or 6-wire connecting cables.

Four-wire connecting cables should not be shortened or lengthened because the

line resistance is temperature-compensated. If the length of the connecting cable is

altered, the input and output resistance also changes. This change can be

corrected by adjusting the scales but this does not compensate temperaturerelated changes in resistance of the missing or lengthened piece of cable. The

value of the remaining temperature error is shown in the table below. The

SIWAREX measuring cable 7MH4702-8AA / -8AB is used as the basis for these

observations. The feed lines are connected in parallel (double).

Table 2-1 Remaining temperature error of a cell per 10 K in %:

Change in Series

length K RN BB CC SB

3 m 0.0012 0.0003 0.0007 0.0007 0.0009

5 m 0.0020 0.0005 0.0012 0.0011 0.0014

10 m 0.0040 0.0009 0.0024 0.0022 0.0029

If 3 or 4 cells are operated in parallel and the cable of a cell is lengthened, the

additional error is about a third or a quarter. Prerequisite is an even load

distribution on the cells.

ATTENTION

Only EMC-safe housings (e.g. SIWAREX JB) may be used to

extend connecting cables.

On 6-wire connecting cables, the feed voltage is fed back as a reference voltage to

the weighing module. Shortening or lengthening has no effect on the measuring

result.

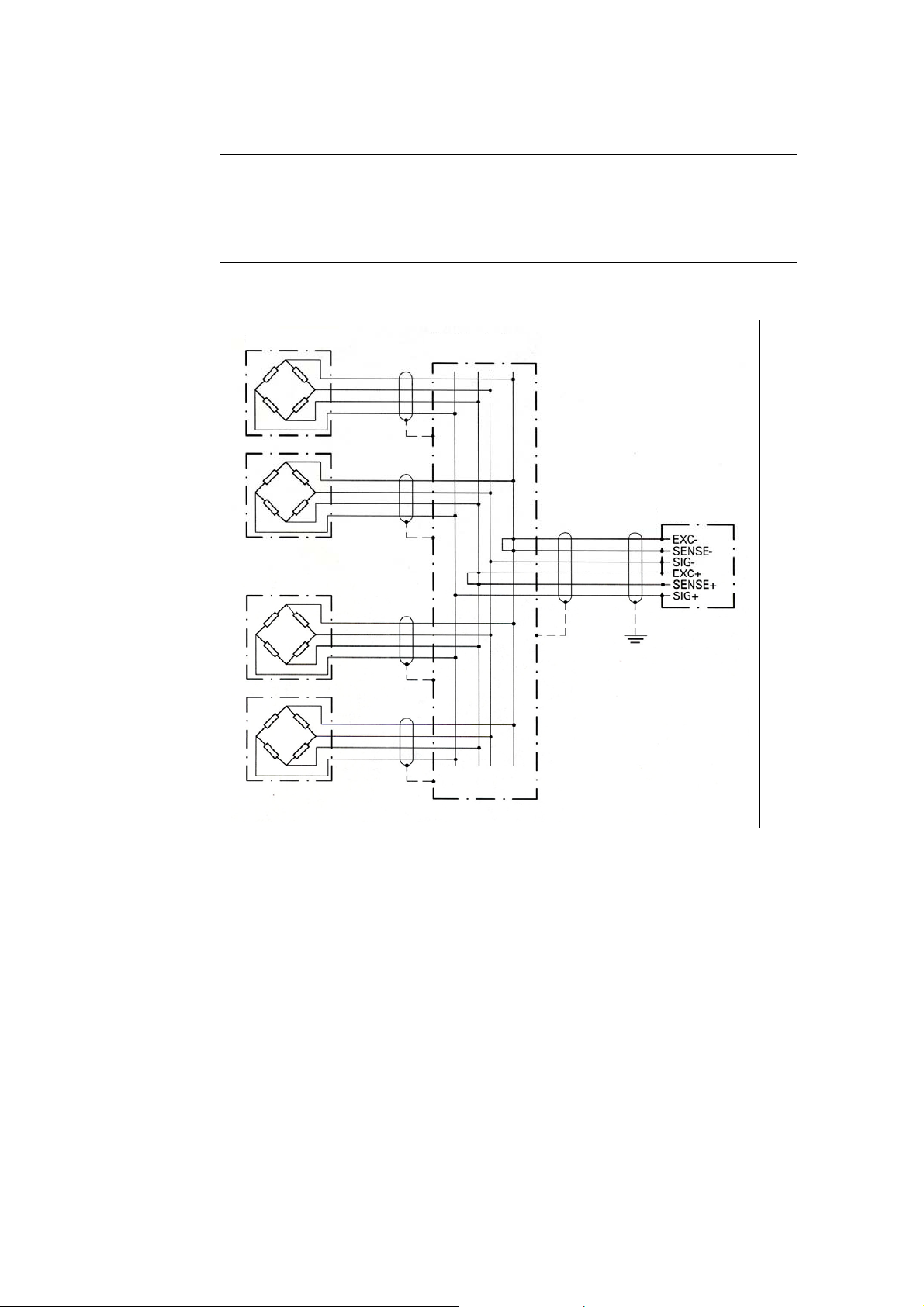

Figures 2-1 and 2-2 show the parallel connections of load cells in 4 and 6-wire

technology.

SIWAREX R Load Cells Operating Manual

A5E00159640

10

Page 11

Edition 06/2009

ATTENTION

If load cells with 4-wire connecting cables are used, two bridges must be inserted

additionally:

Bridge 1: EXC- to SENSEBridge 2: EXC+ to SENSE+

Installation/Assembly

Load cells

Junction box

Weighing

module

Figure 2-1 Parallel connection in 4-wire technology

SIWAREX R Load Cells Operating Manual

A5E00159640

11

Page 12

Edition 06/2009

Load cells Junction box

Installation/Assembly

Weighing

module

Figure 2-2 Parallel connection in 6-wire technology

SIWAREX R Load Cells Operating Manual

A5E00159640

12

Page 13

Edition 06/2009

Table 2-2 shows the color codes and signal assignment of the connecting cables.

Table 2-2 Color codes and signal assignment

1)

Load cell series Cable connection

Function Color

BB EXC+ green

EXC- black

SIG+ white

SIG- red

Shield transparent

SB EXC+ green

EXC- black

SIG+ white

SIG- red

Shield transparent

RN EXC+ pink

EXC- gray

SIG+ brown

SIG- white

Shield1) transparent

CC EXC+ green

EXC- black

SIG+ white

SIG- red

Shield transparent

SP EXC+ green

EXC- black

SIG+ white

SIG- red

Sens+ yellow

Sens- blue

Shield transparent

K EXC+ red

EXC- white

SIG+ black

SIG- blue

Shield transparent

RN 0.5 to 10t:

- Shield placed on load cell housing

- Shield not fed out of connecting cable

Installation/Assembly

See the data sheet for color codes of load cells not listed.

2.2 Assembly

Load cells are high-precision components and must be handled with care

especially during transportation and assembly.

SIWAREX R Load Cells Operating Manual

A5E00159640

CAUTION

Mechanical shock or dropping can cause irreparable damage to the load cell.

Load cells may not be carried by the connecting cables.

13

Page 14

Edition 06/2009

As long as the assembly work on the scales has not been completed, the load cells

should be replaced by dummies to protect them against impact or welding currents.

CAUTION

If welding should be necessary after load cells have been installed, make

absolutely sure that the welding current is not conducted through the load cell.

The ground clamp of the welding gear should be attached directly next to the

welding point with a safe contact. The load cells must be bridged with the

grounding cable. The individual load cells must be disconnected.

Load cells may not be overloaded. The load carrier should be set down slowly. IN

load cells with low rated loads in particular there is a danger that the load cell body

could be distorted by application of force, e.g. tightening lock nuts.

WARNING

The bearing is statically indefinite in the case of more than three load cells or

application points. The force application points should be at the same height. The

output signals of all load cells should be approximately the same at even load or

correspond to the load distribution in the case of uneven load. Proceed as follows

to measure the load on the load cells:

• Disconnect load cell cables SIG+ and SIG-.

• Supply load cells with the feed voltage (e.g. 10.2V).

• Measure the output voltages between SIG+ and SIG- of the individual load

Spacer plates should be placed beneath the load cell with the lowest value until the

output voltages are adjusted equally.

The load cell seat must be horizontal, completely level and, like the load cell base,

absolutely clean.

The contact surfaces of the force applications must be lubricated with highperformance grease.

Installation/Assembly

Suitable lifting gear must be used for lifting the load carrier. The

appropriate safety regulations must be observed.

cells.

The measured voltage corresponds in proportion to the product of

characteristic value times supply voltage to the weight percentage at the

rated load which is applied to the load cell.

Example: feed voltage U

characteristic value C

rated load E

output voltage U

10.2V

s

2mV/V

n

5t

max

4mV

a

Calculation: 4mV / (10,2V x 2mV/V) = 0.196

0.196 x 5t = 0.98t

Result: The load cell is loaded with 0.98t

SIWAREX R Load Cells Operating Manual

A5E00159640

14

Page 15

Edition 06/2009

If overload protection devices are available, these must be set so that they still

accommodate the desired load safely. They must allow an unhindered increase in

weight up to the nominal weight.

Overload protection devices must be protected against soiling and freezing.

The perfect functioning of overload protection devices must be checked in the

course of regular maintenance work.

DANGER

Soiled, frozen or incorrectly set overload protection devices block and lead to

faulty measurements or can cause overflowing of the scales with property

damage and injury to persons.

Special features of bending ring scales series RN, RH, RC, RS

CAUTION

Correct assembly of the load cell and installation element must be checked by

inspecting the installation dimensions and pendulum travel for example.

Make sure the cable is not damaged or cut.

The cable must be laid at the cable glands in the form of a vertical downward loop

to avoid penetration by water.

CAUTION

The installation regulations of the installation element must also be taken into

account in assembly.

• Bending ring scales up to 13t are delivered with a pressure piece. The

pressure piece is inserted in the load cell and secured against falling out by

adhesive tape. It may not be lost when handling the load cell.

• Bending ring load cells have a very small measuring distance. An overload

protection is integrated in load cells with rated loads up to 13t. The standing

area of the load cell restricts the movement of the force application tube. For

this reason the standing area of the load cell must be checked carefully for

soiling prior to installation. If there is a risk that the bottom of the load cell could

become soiled or frozen, appropriate inspection and/or sealing measures must

be taken. The bottom can be protected by a grease ring or sealing compound

for example. When these measures are taken it must be considered that the

force application also needs to be well sealed at the top of the load cell to

effectively prevent penetration by moisture.

Installation/Assembly

SIWAREX R Load Cells Operating Manual

A5E00159640

15

Page 16

Edition 06/2009

2.3 Disassembly

The same safety regulations and conditions apply for disassembly of the load cells

as for installation and assembly.

• Switch off all energy and power supplies.

• Secure the load carrier against falling.

• Use suitable lifting gear and tools.

• Relieve load on the load cell and remove carefully without using force.

• Do not cut the cable if the load cell is to be used again or sent in for repair.

• Do not carry or pull the load cell by the cable.

Installation/Assembly

SIWAREX R Load Cells Operating Manual

A5E00159640

16

Page 17

3 Commissioning

The load cells are passive sensors. The manual of the weighing module should

therefore be consulted primarily for commissioning. When using in the Ex area, the

instructions for the Ex-i interface or Ex barrier must be observed.

If the reference load of a scales needs to be checked, impermissibly great

deviations in the weight display may occur in load cells which are not electrically

calibrated. This reference load error can be electrically compensated. To do this,

the individual measured values are adjusted to the smallest measured value by

additional wiring. The resistors are connected in series with the load cell measuring

signal. The measuring voltage is reduced by the appropriate resistance until it is

equal to the smallest voltage. Because the resistors are connected in the

measuring circuit, the temperature coefficient must be accordingly low (0.25ppm/K

to 10ppm/K )

Example for reference load adjustment:

Platform scales with 4 load cells, series RN, rated load L

characteristic value C

=2.0mV/V, test weight =150kg.

n

=500kg, rated

n

LC 1

160kg

LC 3

155kg

Figure 3-1 Test diagram

Procedure:

• Measure output resistances R

LC 1 = 1004.52 Ω

LC 2 = 1003.64 Ω

LC 3 = 1010.70 Ω

LC 4 = 1028.12 Ω

LC 2

148kg

150kg

LC 4

152kg

of the LC or take them from the data sheet

a

SIWAREX R Load Cells Operating Manual

A5E00159640

17

Page 18

Edition 06/2009

• Apply test weight to all 4 corners and note values:

• Determine differences to the smallest value (148kg):

• Calculate correction resistance:

R

corr

SIG+)

R

a

state)

L

error

L

test

• Install resistors and repeat test

Commissioning

LC 1 = 160kg

LC 2 = 148kg

LC 3 = 155kg

LC 4 = 152kg

LC 1 - LC 2 = 160kg - 148kg = 12kg

LC 3 - LC 2 = 155kg - 148kg = 7kg

LC 4 - LC 2 = 152kg - 148kg = 4kg

R

corr

= Ra x L

error

/ L

test

LC 1: R

= R1 = 1004.52 Ω x 12kg / 150kg = approx. 80 Ω

corr

LC 2: smallest value -> no resistance necessary

LC 3: R

LC 4: R

= R3 = 1010.70 Ω x 7kg / 150kg = approx.47 Ω

corr

= R4 = 1028.12 Ω x 4kg / 150kg = approx. 27 Ω

corr

= determined correction resistance (to be installed in the measuring line

= output resistance of the load cells (can also be measured in the loaded

= weight error (difference value from the smallest weight value)

= test load (applied at all corners)

EXC+ 10VDC

EXC- 0VDC

SIG+

SIG-

LC 4

EXC+

SIG+

R4

Ω

27

SIG-

EXC-

47

R3

Ω

LC 3

EXC+

SIG+

EXC-

SIG-

SIG+

Figure 3-2 Circuit diagram reference load adjustment

EXC-

EXC+

LC 2

LC 1

EXC+

SIG-

SIG+

EXC-

R1

80

Ω

SIG-

SIWAREX R Load Cells Operating Manual

A5E00159640

18

Page 19

4 Service

4.1 Care and Maintenance

Load cells are principally maintenance-free. However, regular inspections with

checking of the force applications, pendulum limits, lift off and overload protections

increase the reliability. The inspections should also be carried out after serious

events such as thunderstorms, floods or earthquakes.

If signs of corrosion appear, these can be counteracted by suitable protective

coatings.

Accumulation of dirt in the vicinity of a load cell should not be tolerated.

When cleaning with a high-pressure water jet, the jet may not be directed at the

cable gland or other sealing elements.

4.2 Troubleshooting

If errors or wrong measuring results occur which can be traced to the load cells,

the following points should be checked:

• Are there parallel forces, e.g. due to cables, pipes or guides which exert force

in measuring direction?

• Are there any other disturbances caused by soiling or thermal expansion?

• Are all the load cells aligned correctly horizontally and at the same height?

• Has moisture penetrated the junction box?

• Are the cables connected correctly?

• Are cables damaged?

A defective load cell of a weighing system can be localized by corner loading or

disconnection of the individual load cells. To check load cells for a defect, the

following measurements are necessary:

Zero signal:

• Remove load completely from the load cell to be tested.

• Disconnect all load cells.

• Supply the load cell to be tested with approx. 10V DC (weighing module or

external power supply).

• Measure voltage between SIG+ and SIG-.

• Divide measured voltage by the feed voltage.

The result must match the value in the data sheet.

SIWAREX R Load Cells Operating Manual

A5E00159640

19

Page 20

Edition 06/2009

Insulation resistance

• Disconnect the load cell.

• Connect all lines.

• Measure insulation resistance between lines and load cell housing

• Measure insulation resistance between lines and cable shield

• Measure insulation resistance between cable shield and load cell housing (This

measurement is not possible in load cells in which the shield is connected to

the load cell housing).

The insulation resistance must match the value in the technical data

Input and output resistance

• Disconnect the load cell.

• Measure the input resistance between EXC+ and EXC-.

• Measure the output resistance between SIG+ and SIG-.

The resistances must match the values in the data sheet or the technical data.

Bridge resistance

• Disconnect load cell.

• Measure resistance between SIG- and EXC-

• Measure resistance between SIG+ and EXC+

The difference between the two values may not be greater than 1Ω.

The measurement cannot be made in the series K load cell.

DANGER

Measurements may not be made on the load cells in the Ex area.

CAUTION

Do not use ohmmeters which feed more voltage into the load cell than permitted

in the technical data to measure the resistance.

A frequent cause of error which leads to failure of the load cells is their

overloading. If overloading is diagnosed as the cause of the error, further

measures are necessary. Damage is often caused by one of the following:

1. Dynamic overloading, e.g. by accidental falling of a relatively small weight onto

the load carrier from a great height.

Possible remedies:

• Fit shock-absorbing components, e.g. elastomer bearings

• Overdimension the load cells

Service

SIWAREX R Load Cells Operating Manual

A5E00159640

20

Page 21

Edition 06/2009

2. Transverse forces, e.g. by pushing on or braking loads on a platform.

NOTE

Only send in defective load cells to our repair workshop with an exact description

of the error. This makes troubleshooting and analysis easier.

Possible remedies:

• Install deflectors

• Install pendulum limits or set closer together.

Service

SIWAREX R Load Cells Operating Manual

A5E00159640

21

Page 22

5 Technical Data

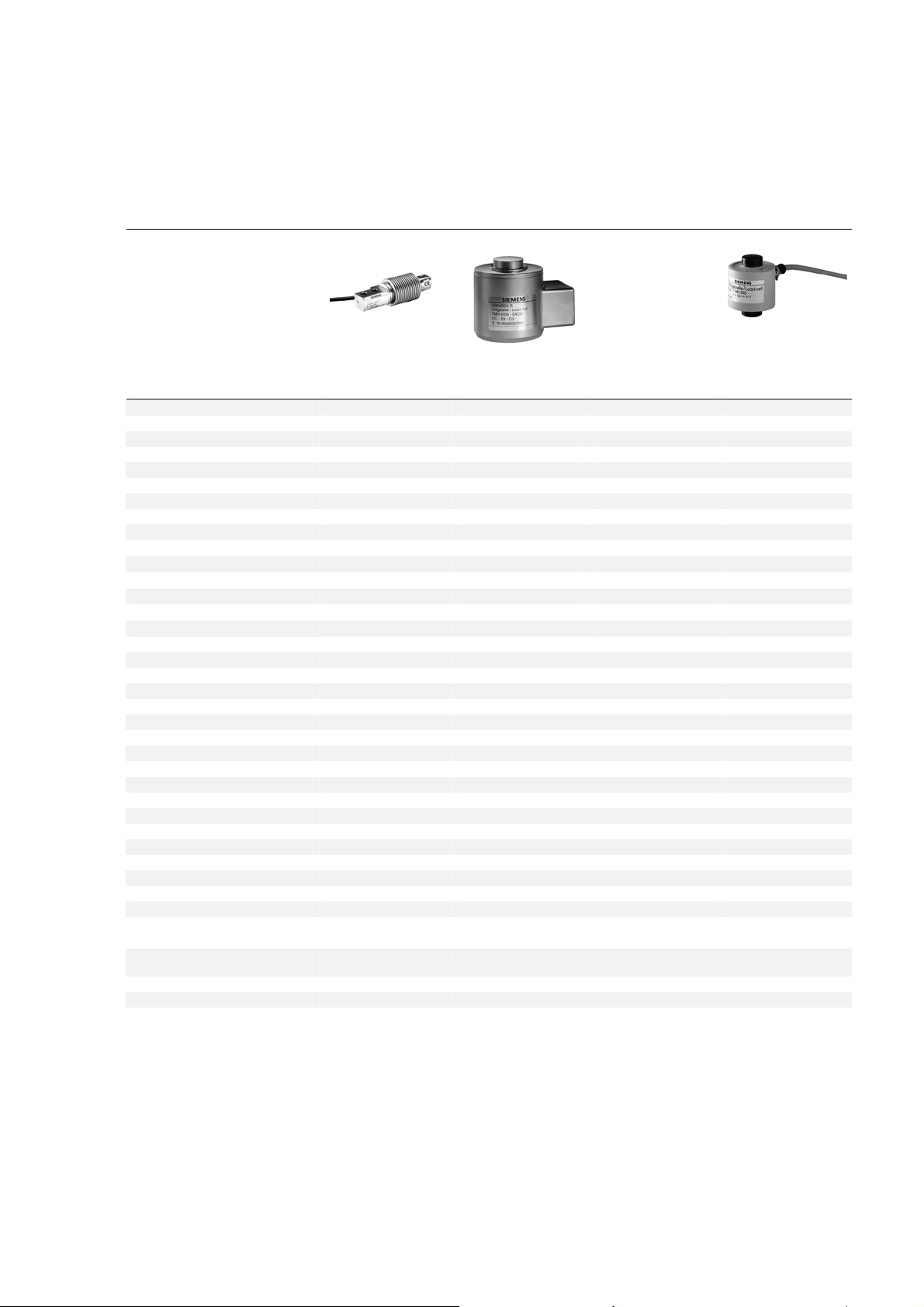

5.1 Functional Data

BB series CC series K series

Possible applicatons Container, Conveyor,

platform scales

Container, hopper,

vehicle scales

Container, hopper scales

Type Bending beam Pressure force Pressure force

Rated load/maximum load E

10/20/50/100/200/350 kg 10/25/40/60 t 100 t 2.8/6/13/28/60/130/280 t

max

Accuracy class according to OIMLR60 C3 C3 C1 0.2%

Max. scale interval n

Min. scale interval V

Minimum application range R

Combined error F

Deviation F

≤ ± 0.01 % Cn ≤ ± 0.01 % Cn ≤ ± 0.02 % C

v

Return of zero signal ≤ ± 0.0167 % C

Creepage error F

• 30 min

• 20 to 30 min

3000 3000 1000

LC

E

min

≤ ± 0.02 % Cn ≤ ± 0.02 % Cn ≤ ± 0.03 % Cn < 0.2 % C

comb

cr

20 % 24 % 10 %

min(LC)

/15000 E

max

1)

n

≤ ± 0.0245 % C

≤ ± 0.0053 % C

1)

n

1)

n

/12500 E

max

≤ ± 0.0167 % C

≤ ± 0.0245 % C

≤ ± 0.0053 % C

/10000

max

1)

≤ ± 0.05 % C

n

1)

≤ ± 0.049 % C

n

1)

≤ ± 0.0105 % C

n

-

n

1)

-

n

1)

-

n

1)

-

n

n

Temperature coefficient

• Zero signal T

Ko

• Characteristic value T

Min. initial loading E

0 % E

min

Kc

≤ ± 0.0045 % C

≤ ± 0.0045 % Cn/5K ≤ ± 0.0045 % Cn/5K ≤ ± 0.0085 % Cn/5K ≤ ± 0.25 % C

Max. work load Lu 150 % E

Break load L

300 % E

d

Max. lateral load Llq 100 % E

Rated measuring path h

at E

0.3 ± 0.03 mm max. 0.36 mm 0.23 to 2.67 mm

n

max

max

/5K ≤ ± 0.0056 % Cn/5K ≤ ± 0.007 % Cn/5K ≤ ± 0.25 % C

n

0 % E

150 % E

max

400 % E

max

10 % E

max

0 % E

max

120 % E

max

300 % E

max

10 %

max

max

Emax

max

max

Overload protection - - Supply voltage U

(reference value) 10 V 10 V 6 V

sr

Supply voltage (range) 5 to 15 V 5 to 25 V 6 to 12 V

Rated characteristic value C

Tolerance D

Tolerance D

Input resistance R

of characteristic value ± 1 % ± 1 % ± 0.5 %

c

of zero signal ≤ ± 1 % Cn ≤ ± 1 % Cn ≤ ± 1.5 % C

o

460 Ω ± 50 Ω 450 Ω ± 4.5 Ω etwa 275 Ω

e

Output resistance R

2 mV/V 2 mV/V 1.5 mV/V

n

350 Ω ± 3.5 Ω 480 Ω ± 4.8 Ω 245 Ω ± 0.2 Ω

a

n

Insulation resistance Ris ≥ 5000 MΩ ≥ 5000 MΩ ≥ 20 MΩ

Rated temperature range B

Operating temperature range B

Storage temperature range B

-10 to +40 °C -10 to +40 °C -10 to +60 °C

tn

-40 to +80 °C -40 to +80 °C -20 to +70 °C

tu

-40 to +90 °C -40 to +90 °C -30 to +80 °C

ts

Sensor material (DIN) Stainless steel 1.4542 Stainless steel 1.4542 Steel. painted

Degree of protection to DIN EN 60529,

IP 66/IP 68 IP 66/IP 68 IP 65

IEC 60529

Max. tightening torque of the fixing

screws

Current calibration

EEx (i) certification

1)

For rated temperature -10 to +40 °C

2)

Current calibration: nominal characteristic value and output resistance are adjusted so that the output current is calibrated within

0.05 % of a reference value. This makes it easier to connect several load cells in parallel.

3)

Optional

4)

EEx(d) version on request (only 40/60 t)

2)

Standard Standard -

3)

EEx ib II C T6 EEx ib II C T6 4) -

23 Nm - -

n

n

/5K

/5K

SIWAREX R Load Cells Operating Manual

A5E00159640

22

Page 23

Edition 06/2009

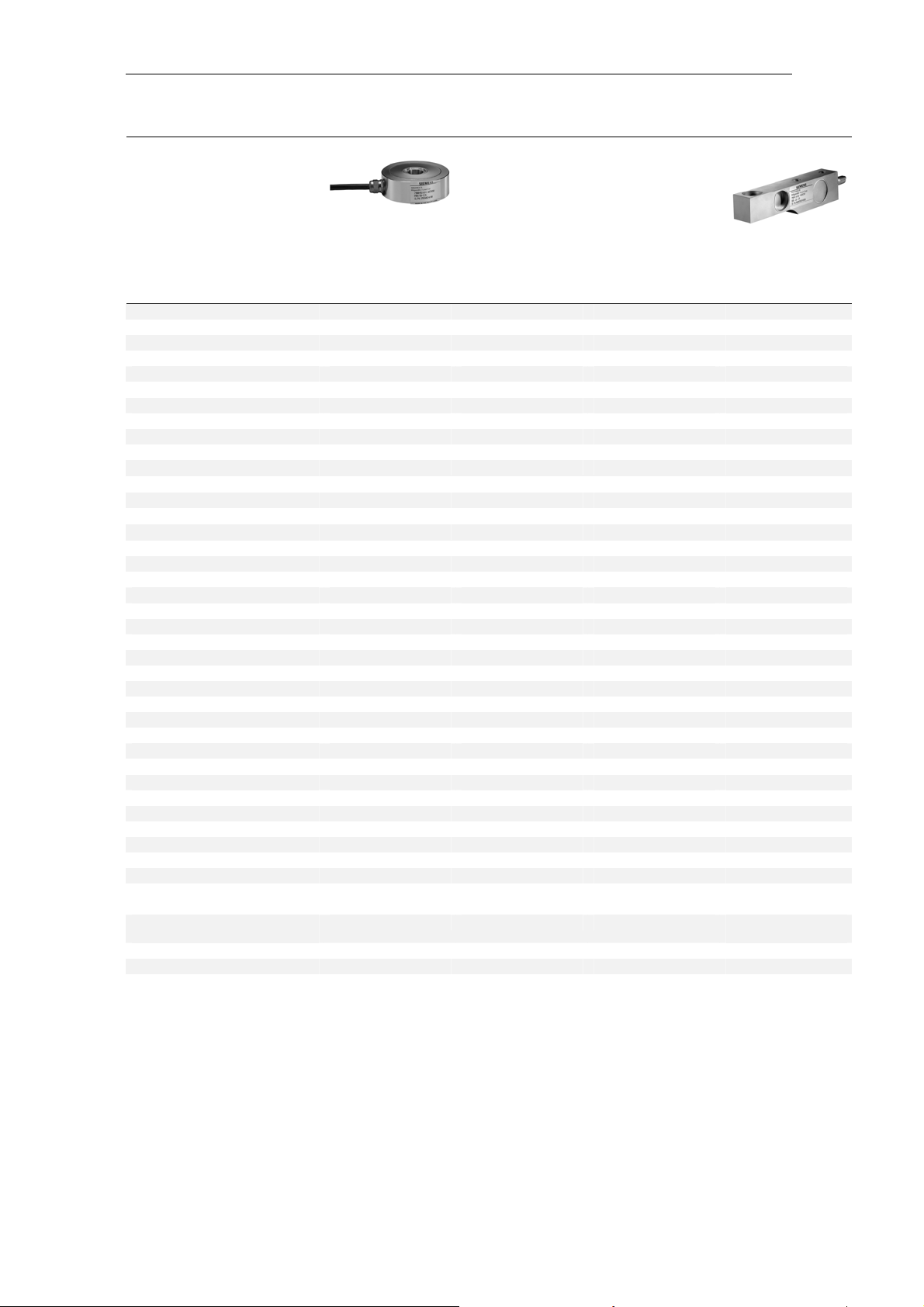

Technical Data

RN series SB series

Possible applicatons Container, conveyor,

platform and roller table

scales

Container, conveyor,

overhead rail and

platform scales

Type Bending ring Shear beam

Rated load/maximum load E

60/130/280 kg 0.5/1/2/3.5/5/10 t 13/28/60 t 0.5/1/2/5 t

max

Accuracy class according to OIMLR60 C3 C3 C3 C3

Max. scale interval n

Min. scale interval V

Minimum application range R

Combined error F

Deviation F

≤ ± 0.01 % Cn ≤ ± 0.01 % Cn ≤ ± 0.01 % Cn ≤ ± 0.01 % C

v

Return of zero signal ≤ ± 0.0167 % C

Creepage error F

• 30 min

• 20 to 30 min

3000 3000 3000 3000

LC

E

min

≤ ± 0.018 % Cn ≤ ± 0.023 % Cn ≤ ± 0.018 % Cn ≤ ± 0.02 % C

comb

cr

17 % 30 % 17 % 30 %

min(LC)

/17500 E

max

1)

n

≤ ± 0.0120 % C

≤ ± 0.0053 % C

1)

n

1)

n

/10000 E

max

≤ ± 0.0167 % C

≤ ± 0.0245 % C

≤ ± 0.0053 % C

/17500 E

max

1)

≤ ± 0.0167 % C

n

1)

≤ ± 0.0120 % C

n

1)

≤ ± 0.0053 % C

n

max

1)

≤ ± 0.0167 % C

n

1)

≤ ± 0.0245 % C

n

1)

≤ ± 0.0053 % C

n

/10000

n

n

1)

n

1)

n

1)

n

Temperature coefficient

• Zero signal T

Ko

• Characteristic value T

Min. initial loading E

0 % E

min

Kc

≤ ± 0.007 % C

≤ ± 0.0045 % Cn/5K ≤ ± 0.0045 % Cn/5K ≤ ± 0.0045 % Cn/5K ≤ ± 0.0045 % C

Max. work load Lu 200 % E

Break load L

500 % E

d

Max. lateral load Llq 75 % E

at E

Rated measuring path h

0.07 mm 0.1 ± 0.02 mm 0.11 - 0.2 mm ≤ 0.5 mm

n

max

max

/5K ≤ ± 0.007 % Cn/5K ≤ ± 0.007 % Cn/5K ≤ ± 0.007 % C

n

0 % E

150 % E

max

300 % E

max

100 % E

max

0 % E

max

150 % E

max

300 % E

max

75 % E

max

0 % E

max

150 % E

max

300 % E

max

100 % E

max

max

max

max

max

/5K

n

/5K

n

Overload protection Integrated Integrated Integrated for 13 t Supply voltage U

(reference value) 15 V 10 V 15 V 10 V

sr

Supply voltage (range) 5 to 30 V 5 to 30 V 5 to 30 V 5 to 18 V

Rated characteristic value C

1 mV/V 2 mV/V 2 mV/V 2 mV/V

n

Tolerance Dc of characteristic value ± 0.01 mV/V ± 0.1 mV/V ± 0.1 mV/V ± 1 %

Tolerance D

Input resistance R

of zero signal ≤ ± 1 % Cn ≤ ± 1 % Cn ≤ ± 1 % Cn ≤ ± 1 % C

o

1260 Ω ± 100 Ω 1110 Ω ± 50 Ω 13 t 1200 Ω ± 100 Ω 350 Ω ± 3.5 Ω

e

n

28 t 1075 Ω ± 100 Ω

60 t 1350 Ω ± 100 Ω

Output resistance R

1020 Ω ± 0.5 Ω 1025 Ω ± 25 Ω 13 t 1000 Ω ± 0.5 Ω 350 Ω ± 3.5 Ω

a

28 t 930 Ω ± 0.5 Ω

60 t 1175 Ω ± 0.5 Ω

Insulation resistance Ris ≥ 20 MΩ ≥ 5000 MΩ ≥ 20 MΩ ≥ 5000 MΩ

Rated temperature range B

Operating temperature range B

Storage temperature range B

-10 to +40 °C -10 to +40 °C -10 to +40 °C -10 to +40 °C

tn

-30 to +85 °C -30 to +70 °C -30 to +85 °C -40 to +80 °C

tu

-50 to +95 °C -50 to +80 °C -50 to +95 °C -40 to +90 °C

ts

Sensor material (DIN) Stainless steel 1.4542 Stainless steel 1.4542 Stainless steel 1.4542 Stainless steel 1.4542

Degree of protection to DIN EN 60529,

IP 66/IP 68 IP 66/IP 68 IP 66/IP 68 IP 66/IP 68

IEC 60529

Max. tightening torque of the fixing

screws

Current calibration

EEx (i) certification

1)

For rated temperature –10 to +40 °C

2)

Current calibration: nominal characteristic value and output resistance are adjusted so that the output current is calibrated within

0.05 % of a reference value. This makes it easier to connect several load cells in parallel.

3)

Optional

2)

Standard Standard Standard Standard

3)

EEx ib II C T6 EEx ib II C T6 EEx ib II C T6 EEx ib II C T6

8 Nm 14 Nm (0.5 t to 5 t) - 110 Nm (0.5 to 2 t)

540 Nm (5 t)

See the data sheet for technical data of unlisted load cells.

SIWAREX R Load Cells Operating Manual

A5E00159640

23

Page 24

Edition 06/2009

SP series

Technical Data

Possible applicatons Small platform scales,

small conveyor scales

Type Single point

Rated load/maximum load E

6/12 kg

max

Accuracy class according to OIMLR60 C3

Max. scale interval n

Min. scale interval V

Minimum application range R

Combined error F

Deviation F

≤ ± 0,01 % C

v

Return of zero signal ≤ ± 0,0167 % C

Creepage error F

• 30 min

• 20 to 30 min

3000

LC

E

min

min(LC)

≤ ± 0,02 % C

comb

cr

max

25 %

≤ ± 0,0245 % C

≤ ± 0,0053 % C

/12000

n

n

1)

n

1)

n

1)

n

Temperature coefficient

• Zero signal T

Ko

• Characteristic value T

Min. initial loading E

0 % E

min

Kc

≤ ± 0,0058 % C

≤ ± 0,0045 % C

Max. work load Lu 150 % E

Break load L

300 % E

d

Max. lateral load Llq 100 % E

Rated measuring path h

Rated measuring path hn at E

Supply voltage U

at E

6 kg 0,24 ± 0,02 mm

n

max

12 kg 0,19 ± 0,01 mm

(reference value) 10 V

sr

max

max

max

max

max

/5K

n

/5K

n

Supply voltage (range) 5 to 15 V

Rated characteristic value C

2 mV/V

n

Tolerance Dc of characteristic value ± 10 %

Tolerance D

Input resistance R

Output resistance R

of zero signal ≤ ± 1 % C

o

410 Ω ± 6 Ω

e

350 Ω ± 7 Ω

a

n

Insulation resistance Ris ≥ 5000 MΩ

Rated temperature range B

Operating temperature range B

Storage temperature range B

-10 to +40 °C

tn

-40 to +80 °C

tu

-40 to +90 °C

ts

Sensor material (DIN) Edelstahl 1.4542

Degree of protection to DIN EN 60529,

IP 66/68

IEC 60529

Max. tightening torque of the fixing

screws

Current calibration

EEx (i) certification

2

Standard

3)

EEx ib II C T6

6 Nm

1)

For rated temperature –10 to +40 °C

2)

Current calibration: nominal characteristic value and output resistance are adjusted so that the output current is calibrated within

0.05 % of a reference value. This makes it easier to connect several load cells in parallel.

3)

Optional

See the data sheet for technical data of unlisted load cells.

SIWAREX R Load Cells Operating Manual

A5E00159640

24

Page 25

Edition 06/2009

5.2 Unit Version

SIWAREX R load cells are made of high-grade steel as a standard. They are

hermetically sealed which allows them to be used in a rugged or aggressive

environment. Their compact structure makes them mostly easy to install.

SIWAREX R load cells are licensed for use in scales with mandatory calibration of

class III DIN EN 45501 and comply with OIML R60 3000d.

SIWAREX R load cells are available alternatively with EEx (i) approval for

applications in hazardous areas.

The connecting cables are generally 4-wire cables.

The above specifications do not apply for the K series and load cells outside the

standard scope of delivery.

The housing of the SIWAREX R high-load cells of the K series are made of

varnished steel.

Descriptions of load cell models not belonging to the standard delivery program

can be found in the respective data sheet.

5.3 Explosion Protection

Only load cells and components with the appropriate Ex approval may be used in

hazardous areas. SIWAREX R load cells are approved according to

II 2 G EEx ib II C T6 or T4

II 3 G EEx nA II T6 or T4

II 3 G EEx nL IIC T6 or T4

II 1 D T 70 °C

II 2 D T 70 °C

II 3 D T 70 °C

. The K series and load cell types outside the standard scope of delivery are

exceptions.

The circuits of the load cells of series CC must be considered grounded. They are

equipped with an integrated overload protection as standard. For this reason, they

cannot be tested for dielectric breakdown with 500 VAC.

To connect the load cells in the hazardous area, the EC type examination

certificates KEMA 00ATEX1133X and KEMA 00ATEX1134X, and their

supplements, must be observed.

NOTE

If an Ex-approved load cell i used in a non-hazardous area, the license is

annulled. The Ex label must be endorsed. The load cell may no longer be used in

a hazardous area.

Technical Data

SIWAREX R Load Cells Operating Manual

A5E00159640

25

Page 26

Edition 06/2009

WARNING

To be observed when using in hazardous areas:

- The decree governing electrical systems in hazardous rooms (according to the

valid national standard, in Germany ElexV §§ 9,15).

- The conditions for installing electrical systems in hazardous areas DIN EN

60079-14 (VDE0165) or DIN EN1127-1.

- The specifications of the EC certificate of conformity.

- All work on electrical circuits for systems where there is a risk of explosion

must be performed by qualified personnel.

5.4 Electromagnetic Compatibility

To maintain EMC, e.g.

- an EMC-compatible laying of cables (also inside cabinets) must be

observed .

- the signal cable must be laid separately from cables with voltages > 60 V or

high currents.

- the vicinity of large electrical installations must be avoided.

- shielded cables must be used.

- proper grounding must be observed.

Technical Data

SIWAREX R Load Cells Operating Manual

A5E00159640

26

Page 27

Edition 06/2009

5.5 Dimensions

Nennlast ØA ØB ØC D

10 – 200 kg 8,2 8,2

350 kg 10,3 10,3

Figure 5-1 BB series

Technical Data

+0,1

23,0 20,0

+0,1

24,0 19,0

SIWAREX R Load Cells Operating Manual

A5E00159640

27

Page 28

Edition 06/2009

Technical Data

Rated load A B C D E ØF G H J ØK ØL M

0,5 – 2 t 203,2 36,5 98,4 63,5 19,1 30,2

5 t 235,0 47,5 123,8 66,7 20,6 41,3

Figure 5-2 SB series

+0,2

36,5 11,9 47,6 17,5

+0,2

47,6 15,8 69,9 25,5

H11

14 101,6

H11

22 111,2

SIWAREX R Load Cells Operating Manual

A5E00159640

28

Page 29

Edition 06/2009

Technical Data

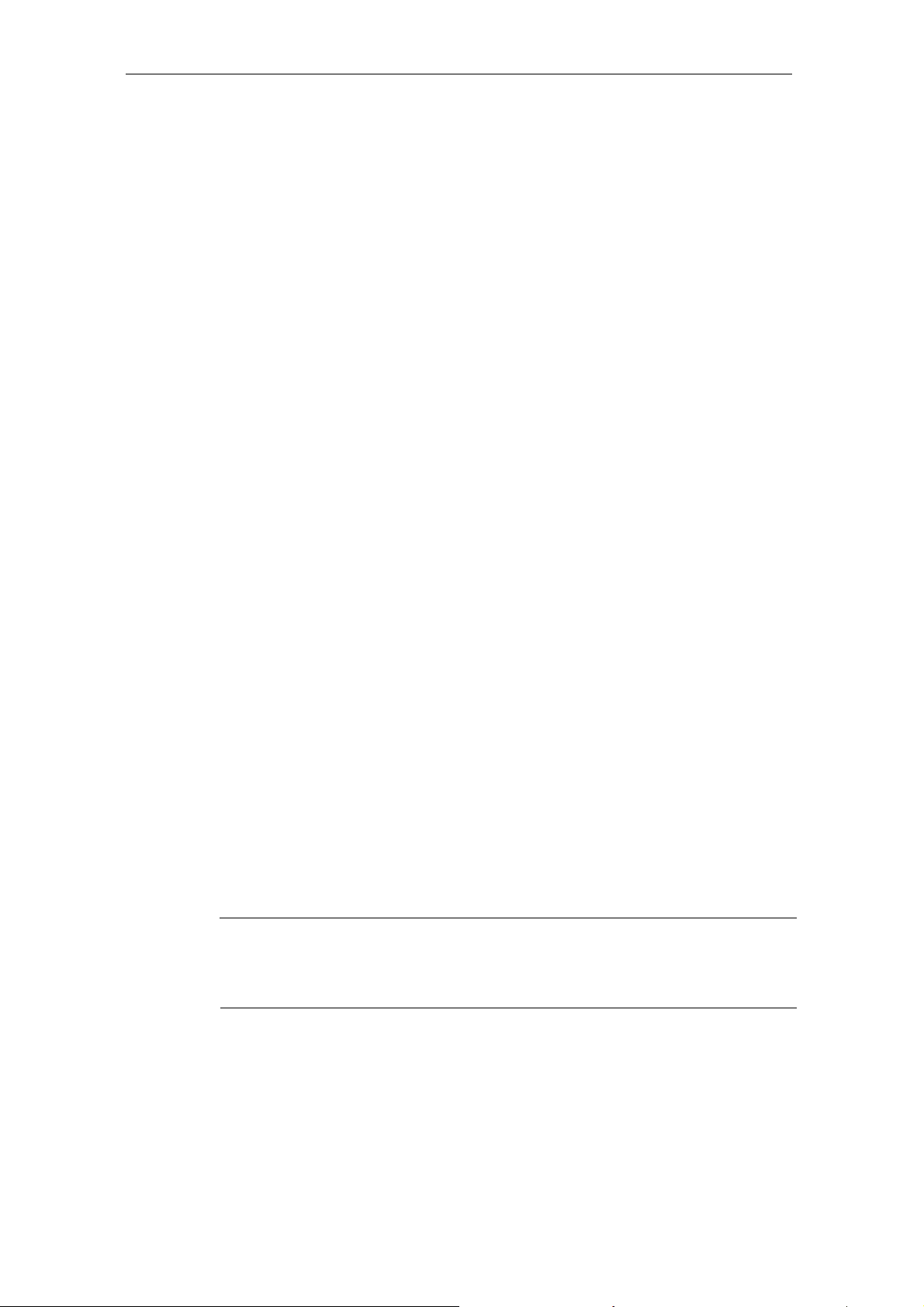

Rated load ØA B ØC ØD E ØF G

60, 130, 280 kg 63 22 15,1 3,2 15 55,5 M5 8 34 6,5

0,5, 1 t 80 25 19 M10 - 70 M6 13 17,5 6,2

2, 3,5, 5 t 80 30 19 15

10 t 95 35 29,1 24,9 - - - - 17,5 6,2

13 t 95 35 29,1 24,9 20 - - - 40 6,5

H7

- 70 M6 13 17,5 6,2

Max. tightening

torque [Nm]

K ØL

Figure 5-3 RN series 60 kg to 13 t

SIWAREX R Load Cells Operating Manual

A5E00159640

29

Page 30

Edition 06/2009

Rated load ØA B ØC E

28 t 120 46 35,9 25

60 t 140 62 47,9 34

Figure 5-4 RN series 28 und 60 t

Technical Data

SIWAREX R Load Cells Operating Manual

A5E00159640

30

Page 31

Edition 06/2009

Technical Data

Rated load ØA B C ØD E F G ØH J SRK

10 t; 25 t 73,0 82,5 12,0 58,0 6,5 1,8 64,0 31,8 M12x1,75

40 t; 60 t 105,0 127,0 34,0 82,5 8,0 11,0 87,0 58,7 M20x2,5

100 t 152,4 184,2 72,3 123,8 23,6 21,8 108,2 79,2 M20x2,5

Figure 5-5 CC series

11 deep

20 deep

20 deep

152

152

432

SIWAREX R Load Cells Operating Manual

A5E00159640

31

Page 32

Edition 06/2009

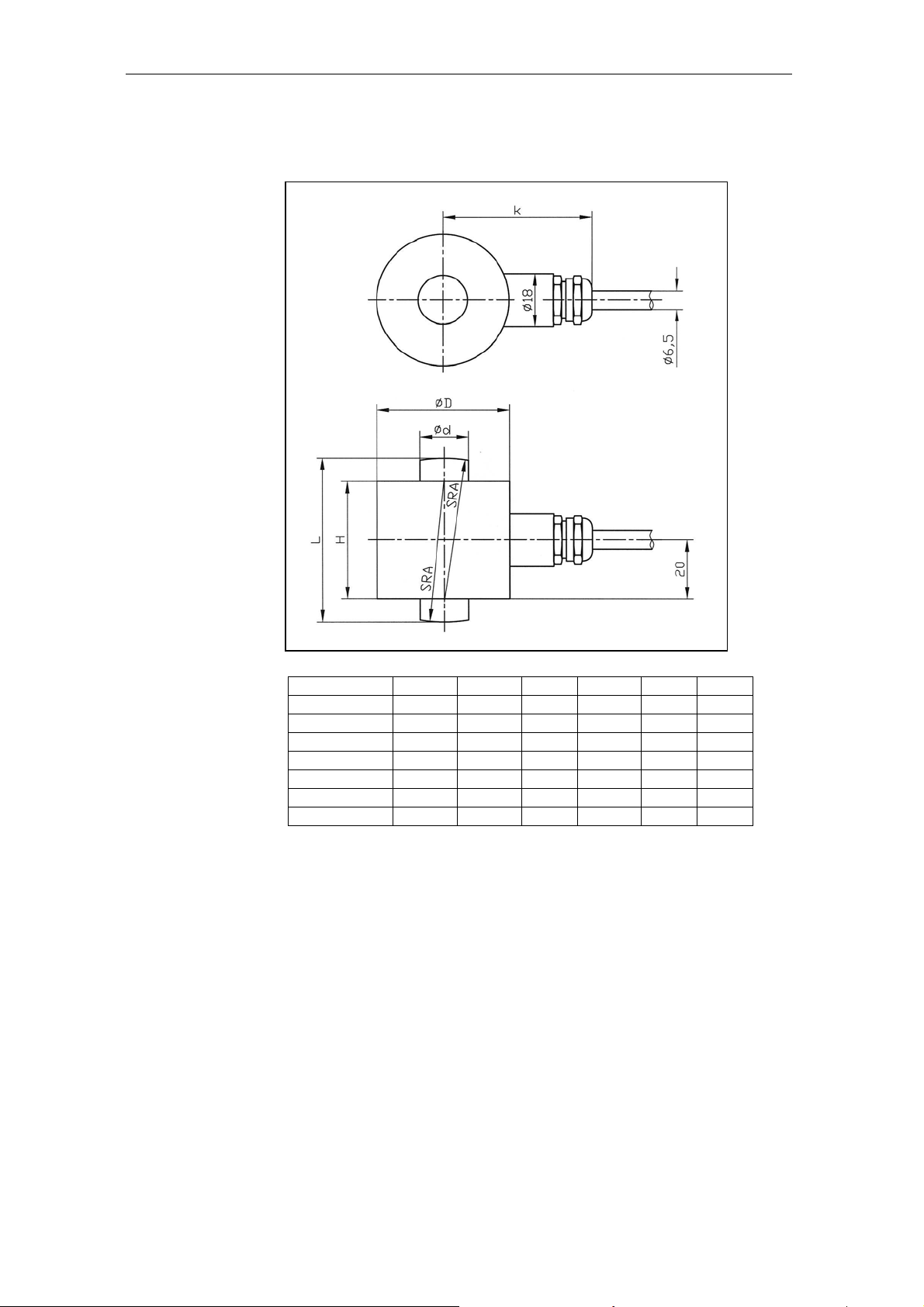

Rated load Ød ØD H K L SRA

2,8t 16,7 45 40 54 56 50

6 t 16,7 45 40 54 56 50

13 t 24,5 55 44 59 68 66

28 t 36 64 46 63,5 74 72

60 t 52,7 90 50 76,5 90 100

130 t 77,5 121 64 92 116 125

280 t 114 165 80 114 170 183

Figure 5-6 K series

Technical Data

SIWAREX R Load Cells Operating Manual

A5E00159640

32

Page 33

Edition 06/2009

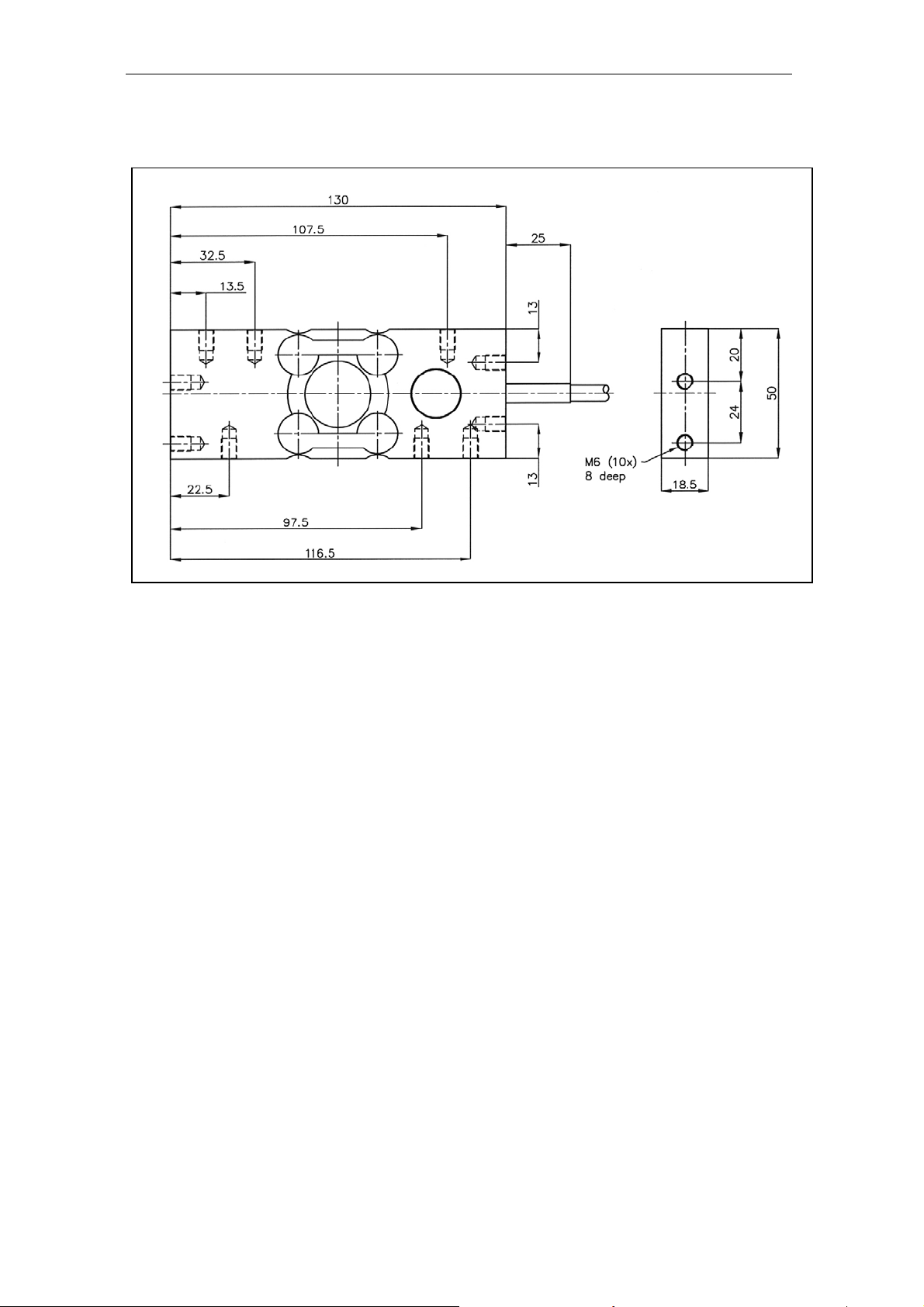

Figure 5-7 SP series

See data sheet for dimensions

of unlisted load cells.

Technical Data

SIWAREX R Load Cells Operating Manual

A5E00159640

33

Page 34

6 Ordering Data

BB series

Verification capability to

OIML R60 up to 3000 d,

Connecting cable3 m

(4-wire)

4)

Order No.: 7MH4 103 - ■ ■ C ■ 1

Nominal load: 10 kg 2 A

20 kg 2 D

50 kg 2 K

100 kg 3 A

200 kg 3 D

350 kg

Explosion protection

• Without

• With degree of protection EEx ib II C T6 for

connection to intrinsically-safe circuits

Order No.: 7MH4 105 - ■ ■ C ■ 1

Nominal load: 500 kg 3 K

1 t 4 A

2 t 4 D

5 t 4 K

Explosion protection

• Without

• With degree of protection EEx ib II C T6 for

connection to intrinsically-safe circuits

1)

3 G

0

1

SB series

Verification capability to

OIML R60 up to 3000 d,

Connecting cable5 m

(4-wire)

0

1

4)

CC series

Verification capability to

OIML R60 up to 3000 d,

Connecting cable

(4-wire)

Order No.: 7MH4 106 - ■ ■ ■ ■ 1

connecting cable

Nominal load: 10 t Length

25 t 20 m 5 E C

40 t 20 m 5 H C

60 t 20 m 5 L C

100 t

Explosion protection

• Without

• With degree of protection EEx ib II C T6 for

connection to intrinsically-safe circuits

Order No.: 7MH3 105 - ■ ■ C0

connecting cable

Nominal load: 2,8 t Length

6 t 5 m 3 A

13 t 10 m 1 B

28 t 10 m 2 B

60 t 10 m 3 B

130 t 10 m 1 C

280 t 10 m 2 C

4)

: 10 m 5 A C

2)

20 m 6 A A

0

1

K series

Accuracy class 0.2,

Without explosion protection,

connecting cable

(4-wire)

4)

: 5 m 2 A

3)

Order No.: 7MH5 101 - ■ ■ D 0 ■

connecting cable

Nominal load: 60 kg Length

130 kg 3 m 3 D

280 kg 3 m 3 J

500 kg 3 m 3 P

1 t 3 m 4 A

2 t 5 m 4 G

3,5 t 5 m 4 L

5 t 5 m 4 P

10 t 5 m 5 A

13 t 10 m 5 D

28 t 10 m 5 J

60 t 15 m 5 Q

Explosion protection

• Without

• With degree of protection EEx ib II C T6 for

connection to intrinsically-safe circuits

SIWAREX R Load Cells Operating Manual

A5E00159640

RN series

Verification capability to

OIML R60 up to 3000 d,

Connecting cable

(4-wire)

4)

: 3 m 2 Q

0

1

SP series

Verification capability to

OIML R60 up to 3000 d,

Connecting cable

(6-wire)

Order No.: 7MH4 107 - ■ ■ C 0 ■

Connection cable

Nomnal load: 6 kg Length

12 kg 7 m 2 B

Explosion protection

• Without

• With degree off protection EEx ib II C T6 for

connection to intrinsically-safe circuits

1)

Mounting accessories on request.

2)

Verification capability to OIML R60 up to 1000 d.

3)

Cables heat-resistant: -60 °C to +180 °C.

4)

Length tolerance: +/- 100 mm; cable length 20 m or more:

+/- 300 mm.

4)

: 7 m 1 L

Furhter models of load cells on inquiry.

0

1

34

Loading...

Loading...