Page 1

SIPROTEC 5 V7.30 and higher

Low-Impedance Busbar Protection 7SS85

Technical Data

Extract from manual C53000-G5040-C019-6, chapter 11

Energy Automation

Page 2

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

This document has been subjected to rigorous technical

review before being published. It is revised at regular intervals, and any modifications and amendments are included

in the subsequent issues. The content of this document has

been compiled for information purposes only. Although

Siemens AG has made best efforts to keep the document as

precise and up-to-date as possible, Siemens AG shall not

assume any liability for defects and damage which result

through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of

Siemens AG are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document from

time to time.

Document version: C53000-G5040-C019-6.01

Edition: 06.2016

Version of the product described: V07.30

Copyright

Copyright © Siemens AG 2016. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content

are not permitted, unless authorized in writing. All rights,

including rights created by patent grant or registration of a

utility model or a design, are reserved.

Registered Trademarks

SIPROTEC®, DIGSI®, SIGUARD®, SIMEAS®, and SICAM® are

registered trademarks of Siemens AG. Any unauthorized

use is illegal. All other designations in this document can

be trademarks whose use by third parties for their own

purposes can infringe the rights of the owner.

Page 3

Preface

Purpose of the Manual

This manual describes the protection, automation, control, and monitoring functions of the SIPROTEC 5

devices.

Target Audience

Protection system engineers, commissioning engineers, persons entrusted with the setting, testing and maintenance of automation, selective protection and control equipment, and operational crew in electrical installations and power plants.

Scope

This manual applies to the SIPROTEC 5 device family.

Further Documentation

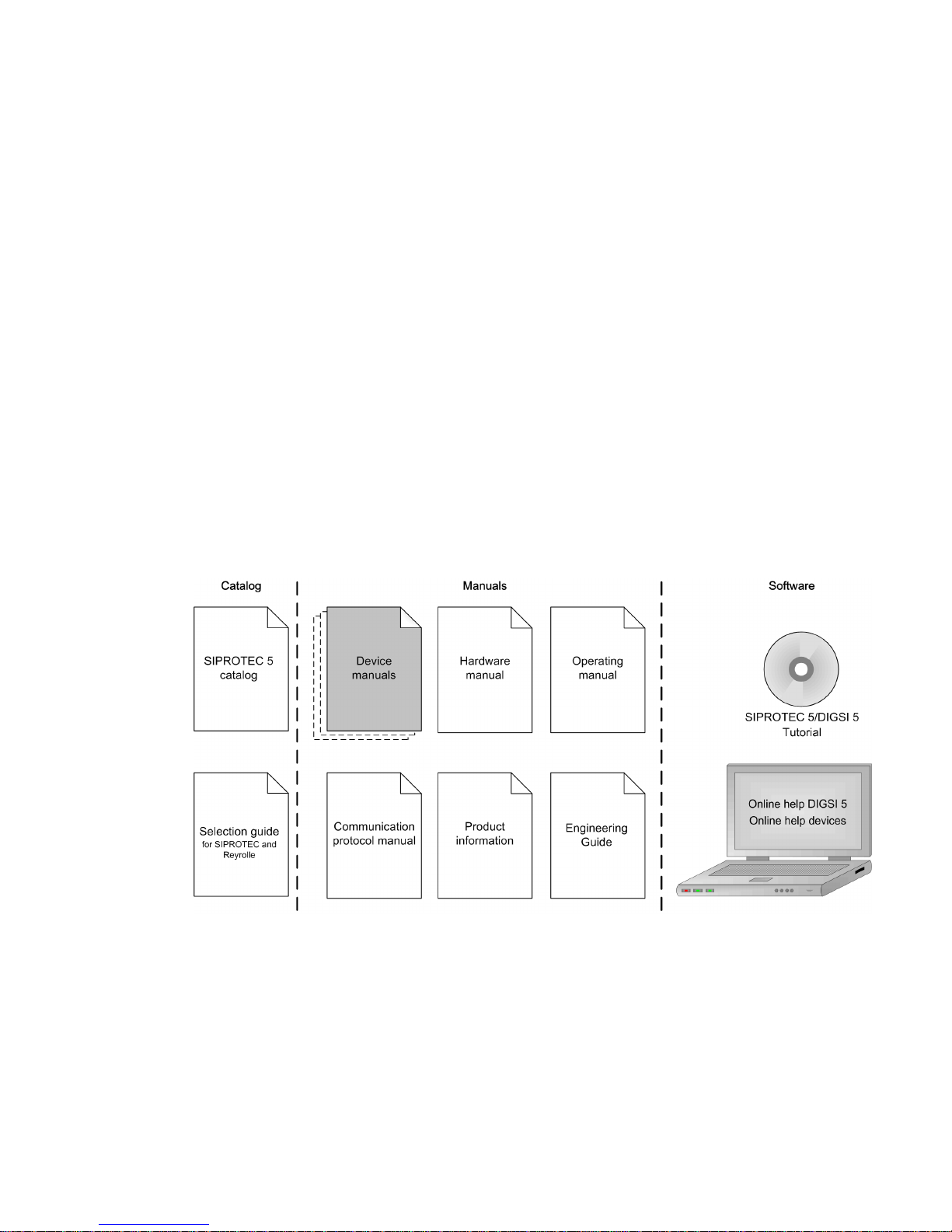

[dwprefdm-221012-01.tif, 3, en_US]

•

Device manuals

Each Device manual describes the functions and applications of a specific SIPROTEC 5 device. The printed

manual and the online help for the device have the same informational structure.

•

Hardware manual

The Hardware manual describes the hardware building blocks and device combinations of the SIPROTEC 5

device family.

•

Operating manual

The Operating manual describes the basic principles and procedures for operating and assembling the

devices of the SIPROTEC 5 range.

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

3

C53000-G5040-C019-6, Edition 06.2016

Page 4

•

Communication protocol manual

The Communication protocol manual contains a description of the protocols for communication within

the SIPROTEC 5 device family and to higher-level network control centers.

•

Product information

The Product information includes general information about device installation, technical data, limiting

values for input and output modules, and conditions when preparing for operation. This document is

provided with each SIPROTEC 5 device.

•

Engineering Guide

The Engineering Guide describes the essential steps when engineering with DIGSI 5. In addition, the Engi-

neering Guide shows you how to load a planned configuration to a SIPROTEC 5 device and update the

functionality of the SIPROTEC 5 device.

•

DIGSI 5 online help

The DIGSI 5 online help contains a help package for DIGSI 5 and CFC.

The help package for DIGSI 5 includes a description of the basic operation of software, the DIGSI princi-

ples and editors. The help package for CFC includes an introduction to CFC programming, basic examples

of working with CFC, and a reference chapter with all the CFC blocks available for the SIPROTEC 5 range.

•

SIPROTEC 5/DIGSI 5 Tutorial

The tutorial on the DVD contains brief information about important product features, more detailed infor-

mation about the individual technical areas, as well as operating sequences with tasks based on practical

operation and a brief explanation.

•

SIPROTEC 5 catalog

The SIPROTEC 5 catalog describes the system features and the devices of SIPROTEC 5.

•

Selection guide for SIPROTEC and Reyrolle

The selection guide offers an overview of the device series of the Siemens protection devices, and a

device selection table.

Indication of Conformity

This product complies with the directive of the Council of the European Communities

on harmonization of the laws of the Member States relating to electromagnetic

compatibility (EMC Council Directive 2014/30/EU) and concerning electrical equipment

for use within specified voltage limits (Low Voltage Directive 2014/35/EU).

This conformity has been proved by tests performed according to the Council Directive

in accordance with the product standard EN 60255-26 (for EMC directive) and with the

product standard EN 60255-27 (for Low Voltage Directive) by Siemens AG.

The device is designed and manufactured for application in an industrial environment.

The product conforms with the international standards of IEC 60255 and the German

standard VDE 0435.

Other Standards

IEEE Std C 37.90

The technical data of the product is approved in accordance with UL.

For more information about the UL database, see www.ul.com

Select Online Certifications Directory and enter E194016 as UL File Number.

IND. CONT. EQ.

69CA

[ul_listed_c_us, 1, --_--]

Preface

4 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 5

Additional Support

For questions about the system, please contact your Siemens sales partner.

Support

Our Customer Support Center provides a 24-hour service.

Phone: +49 (180) 524-7000

Fax: +49 (180) 524-2471

E-Mail: support.energy@siemens.com

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldtstraße 59

90459 Nürnberg

Germany

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-7929

E-Mail: poweracademy@siemens.com

Internet: www.siemens.com/poweracademy

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment (module

or device). However, it comprises important information that must be followed for personal safety, as well as

to avoid material damage. Information is highlighted and illustrated as follows according to the degree of

danger:

!

DANGER

DANGER means that death or severe injury will result if the measures specified are not taken.

²

Comply with all instructions, in order to avoid death or severe injuries.

!

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

²

Comply with all instructions, in order to avoid death or severe injuries.

!

CAUTION

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

²

Comply with all instructions, in order to avoid moderate or minor injuries.

Preface

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 5

C53000-G5040-C019-6, Edition 06.2016

Page 6

NOTICE

NOTICE means that property damage can result if the measures specified are not taken.

²

Comply with all instructions, in order to avoid property damage.

i

i

NOTE

Important information about the product, product handling or a certain section of the documentation

which must be given particular attention.

Qualified Electrical Engineering Personnel

Only qualified electrical engineering personnel may commission and operate the equipment (module, device)

described in this document. Qualified electrical engineering personnel in the sense of this manual are people

who can demonstrate technical qualifications as electrical technicians. These persons may commission,

isolate, ground and label devices, systems and circuits according to the standards of safety engineering.

Proper Use

The equipment (device, module) may be used only for such applications as set out in the catalogs and the

technical description, and only in combination with third-party equipment recommended and approved by

Siemens.

Problem-free and safe operation of the product depends on the following:

•

Proper transport

•

Proper storage, setup and installation

•

Proper operation and maintenance

When electrical equipment is operated, hazardous voltages are inevitably present in certain parts. If proper

action is not taken, death, severe injury or property damage can result:

•

The equipment must be grounded at the grounding terminal before any connections are made.

•

All circuit components connected to the power supply may be subject to dangerous voltage.

•

Hazardous voltages may be present in equipment even after the supply voltage has been disconnected

(capacitors can still be charged).

•

Operation of equipment with exposed current-transformer circuits is prohibited. Before disconnecting the

equipment, ensure that the current-transformer circuits are short-circuited.

•

The limiting values stated in the document must not be exceeded. This must also be considered during

testing and commissioning.

Preface

6 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 7

Open Source Software

The product contains, among other things, Open Source Software developed by third parties. The Open

Source Software used in the product and the license agreements concerning this software can be found in the

Readme_OSS. These Open Source Software files are protected by copyright. Your compliance with those

license conditions will entitle you to use the Open Source Software as foreseen in the relevant license. In the

event of conflicts between Siemens license conditions and the Open Source Software license conditions, the

Open Source Software conditions shall prevail with respect to the Open Source Software portions of the software. The Open Source Software is licensed royalty-free. Insofar as the applicable Open Source Software

License Conditions provide for it you can order the source code of the Open Source Software from your

Siemens sales contact - against payment of the shipping and handling charges - for a period of at least 3 years

since purchase of the Product. We are liable for the Product including the Open Source Software contained in

it pursuant to the license conditions applicable to the Product. Any liability for the Open Source Software

beyond the program flow intended for the Product is explicitly excluded. Furthermore any liability for defects

resulting from modifications to the Open Source Software by you or third parties is excluded. We do not

provide any technical support for the Product if it has been modified.

When using DIGSI 5 in online mode, you are provided with the option to go to the main menu Show Open

source information and read and display the Readme_OSS file containing the original license text and copyright information.

To do this, the following steps are necessary:

•

Switch to online mode.

•

Select the device.

•

Select online in the menu bar.

•

Click Show Open source information.

i

i

NOTE

To read the Readme_OSS file, a PDF viewer must be installed on the computer.

In order to operate SIPROTEC 5 devices, a valid DIGSI 5 license is required.

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

7

C53000-G5040-C019-6, Edition 06.2016

Page 8

8 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 9

Technical Data

11.1 General Device Data 555

11.2 Date and Time Synchronization 563

11.3 Busbar Differential Protection 564

11.4 Circuit-Breaker Failure Protection 1-Pole/3-Pole 565

11.5 Circuit-Breaker Failure Protection 3-Pole 567

11.6 Inherent Circuit-Breaker Failure Protection 569

11.7 End-Fault Protection 570

11.8 External Tripping Busbar Section (Direct) 571

11.9 External Tripping Busbar Section (from Bay) 572

11.10 Bus Coupler Differential Protection 573

11.11 Differential Current Supervision 574

11.12 Zero-Crossing Supervision 575

11.13 Disconnector Supervision 576

11.14 Circuit-Breaker Supervision 577

11.15 Stage with Definite-Time Characteristic Curve 578

11.16 Stage with Inverse-Time Characteristic Curve 580

11.17 Stage with Definite-Time Characteristic Curve 588

11.18 Stage with Inverse-Time Characteristic Curve 590

11.19 Overvoltage Protection with 3-Phase Voltage 598

11.20 Overvoltage Protection with Positive-Sequence Voltage 600

11.21 Overvoltage Protection with Negative-Sequence Voltage 601

11.22 Overvoltage Protection with Zero-Sequence Voltage/Residual Voltage 602

11.23 Overvoltage Protection with Any Voltage 603

11.24 Undervoltage Protection with 3-Phase Voltage 604

11.25 Undervoltage Protection with Positive-Sequence Voltage 606

11.26 Undervoltage Protection with Any Voltage 607

11.27 Overfrequency Protection 608

11.28 Underfrequency Protection 609

11.29 Rate of Frequency Change Protection 610

11.30 Inrush-Current Detection 611

11.31 Voltage-Jump Detection 612

11.32 Trip-Circuit Supervision 613

11.33 Analog Channel Supervision via Fast Current Sum 614

11.34 Operational Measured Values and Statistical Values 615

11

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 553

C53000-G5040-C019-6, Edition 06.2016

Page 10

11.35 Analog-Units Function Group 617

11.36 Temperature Supervision 618

11.37 Protection Interface and Protection Topology 619

11.38 CFC 621

Technical Data

554 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 11

General Device Data

Analog Inputs

Current Inputs

All current, voltage, and power data are specified as RMS values.

Rated frequency f

rated

50 Hz, 60 Hz

Protection-class current transformers

Rated current I

rated

Measuring range

5 A

1 A

0 A to 500 A

0 A to 100 A

Power consumption per current

circuit at rated current

Approx. 0.1 VA

Thermal rating

(protection-class current trans-

formers)

500 A for 1 s

150 A for 10 s

20 A continuously

25 A for 3 min

30 A for 2 min

Dynamic load-carrying capacity 1250 A one half wave

Voltage Input

All current, voltage, and power data are specified as RMS values.

Rated frequency f

rated

50 Hz, 60 Hz

Input and output modules IO202/IO208/IO211/IO214 IO215

Measuring range 0 V to 200 V 0 V to 7.07 V

Input impedance < 0.1 VA < 0.01 VA

Thermal rating 230 V continuously 20 V continuously

Measuring-Transducer Inputs (via Module ANAI-CA-4EL)

Connector type

8-pin multiple contact strip

Differential current input channels 4

Measuring range DC -24 mA to +24 mA

Fault < 0.5 % of measuring range

Input impedance 140 Ω

Conversion principle Delta-sigma (16 bit)

Permissible potential difference

between channels

DC 20 V

Galvanic separation from ground/

housing

DC 700 V

Permissible overload DC 100 mA continuously

Measurement repetition 200 ms

Measuring-Transducer Inputs (via Module ARC-CD-3FO)

Connector type

AVAGO AFBR-4526Z

Number of transceivers 3

Fiber type Polymer Optical Fiber (POF) 1 mm

Receiver

Maximum -10 dBm ± 2 dBm

11.1

11.1.1

Technical Data

11.1 General Device Data

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 555

C53000-G5040-C019-6, Edition 06.2016

Page 12

Minimum -40 dBm ± 2 dBm

Spectrum 400 nm to 1100 nm

Attenuation In the case of plastic optical fibers, you can expect a path attenuation of

0.2 dB/m Additional attenuation comes from the plug and sensor head.

Optical budget

1

Minimal 25 dB

Analog sampling rate 16 kHz

ADC type 10-bit successive approximation

Transmitter

Type LED

Wavelength λ = 650 nm

Transmit power Minimum 0 dBm

Maximum 2 dBm

Numerical aperture

0.5

2

Signal rate connection test 1 pulse per second

Pulse duration connection test 11 μs

Comment:

1

All values in combination with sensors approved by Siemens.

2

Numerical aperture (NA = sin θ (launch angle))

High-Speed Measuring-Transducer Inputs, Voltage/Current (via IO210, IO212)

i

i

NOTE

Current and voltage may not be connected to a measuring-transducer input at the same time; only either

current or voltage may be connected. Due to EMC, no line may be connected to an input that is not used

(current or voltage).

Use shielded cables.

Table 11-1 High-Speed Measuring-Transducer Inputs, Voltage

Differential voltage input channels

8

9

Measuring range DC -10 V to +10 V

Fault < 0.5 % of the measuring range

Input impedance

48 kΩ

Conversion principle Delta-sigma (16 bit)

Permissible potential difference

between channels

DC 3.5 kV

Galvanic separation from ground/

housing

DC 3.5 kV

Permissible overload DC 20 V continuously

DC 60 V continuously (IO210 MT3 terminal point C9)

Measurement repetition 62.5 μs

Table 11-2 High-Speed Measuring-Transducer Inputs, Current

Differential current input channels

8

10

Measuring range DC -20 mA to +20 mA

Fault < 0.5 % of the measuring range

Input impedance, current

12 Ω

9

The IO212 has 8 high-speed measuring-transducer inputs. They can be used either as a voltage or as a current input.

10

The IO212 has 8 high-speed measuring-transducer inputs. They can be used either as a voltage or as a current input.

Technical Data

11.1 General Device Data

556 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 13

Conversion principle Delta-sigma (16 bit)

Permissible potential difference

between channels

DC 3.5 kV

Galvanic separation from ground/

housing

DC 3.5 kV

Permissible current overload DC 100 mA continuously

Measurement repetition 62.5 μs

Supply Voltage

Integrated Power Supply

For modular devices, the following printed circuit-board assemblies have a power supply:

PS201 – Power supply of the base module and of the 1st device row

PS203 – Voltage supply of 2nd device row

CB202 – Plug in module assembly with integrated power supply, for example, to accommodate communica-

tion modules

Permissible voltage

ranges

(PS201, PS203, CB202)

DC 19 V to DC 60 V DC 48 V to DC 300 V

AC 80 V to AC 265 V, 50 Hz/60 Hz

Auxiliary rated voltage V

H

(PS201, PS203, CB202)

DC 24 V/DC 48 V DC 60 V/DC 110 V/DC 125 V/DC 220 V/

DC 250 V or

AC 100 V/AC 115 V/AC 230 V, 50 Hz/60 Hz

Permissible voltage

ranges (PS101)

DC 19 V to DC 60 V DC 48 V to 150 V DC 88 V to DC 300 V

AC 80 V to AC 265 V,

50 Hz/60 Hz

Auxiliary rated voltage V

H

(PS101)

DC 24 V/DC 48 V DC 60 V/DC 110 V/

DC 125 V

DC 110 V/ DC 125 V/

DC 220 V/DC 250 V

or

AC 100 V/AC 115 V/

AC 230 V, 50 Hz/60 Hz

Superimposed alternating voltage, peak-to-peak,

IEC 60255-11

≤ 15% of the DC auxiliary rated voltage (applies only

to direct voltage)

Inrush current ≤ 18 A

Recommended external protection Miniature circuit breaker 6 A, characteristic C

according to IEC 60898

Internal fuse

– DC 24 V to DC 48 V DC 60 V to DC 125 V DC 24 V to DC 48 V

AC 100 V to AC 230 V

PS101 4 A intert, AC 250 V,

DC 150 V,

UL recognized

SIBA type 179200 or

Schurter type SPT 5x20

2 A time-lag, AC 250 V, DC 300 V, UL recognized

SIBA type 179200 or Schurter type SPT 5x20

PS201, PS203, CB202 2 A time-lag, AC 250 V, DC 300 V, UL recognized

SIBA type 179200 or Schurter type SPT 5x20

Power consumption (life relay active)

– DC AC 230 V/50 Hz AC 115 V/50 Hz

1/3 base module, non-

modular

Without plug-in modules

7.0 W 16 VA 12.5 VA

11.1.2

Technical Data

11.1 General Device Data

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 557

C53000-G5040-C019-6, Edition 06.2016

Page 14

Integrated Power Supply

1/3 base module, modular

Without plug-in modules

13 W 33 VA 24 VA

1/6 expansion module 3 W 6 VA 6 VA

1/6 plug-in module

assembly without plug-in

modules (modules CB202)

3.5 W 14 VA 7 VA

Plug-in module for base

module or plug-in module

assembly (for example,

communication module)

< 5 W < 6 VA < 6 VA

Stored-energy time for auxiliary voltage outage or

short circuit, modular devices

For V ≥ DC 24 V ≥ 50 ms

For V ≥ DC 110 V ≥ 50 ms

For V ≥ AC 115 V ≥ 50 ms

Stored-energy time for auxiliary voltage outage or

short circuit, non-modular devices

For V ≥ DC 24 V ≥ 20 ms

For V ≥ DC 60 V/DC 110 V ≥ 50 ms

For V ≥ AC 115 V ≥ 200 ms

Binary Inputs

Rated voltage range DC 24 V to 250 V

The binary inputs of SIPROTEC 5 are bipolar with the exception of the

binary inputs on the IO230 and on the IO231.

Current consumption, excited Approx. DC 0.6 mA to 1.8 mA (independent of the operating voltage)

Power consumption, max. 0.6 VA

Pickup time Approx. 3 ms

Dropout time Approx. 4 ms

Switching thresholds Adjustable with DIGSI 5

Range 1 for 24 V, 48 V, and 60 V

Operating voltage

V

low

≤ DC 10 V

V

high

≥ DC 19 V

Range 2 for 110 V and 125 V

Operating voltage

V

low

≤ DC 44 V

V

high

≥ DC 88 V

Range 3 for 220 V and 250 V

Operating voltage

V

low

≤ DC 88 V

V

high

≥ DC 176 V

Maximum permitted voltage DC 300 V

The binary inputs contain interference suppression capacitors. In order to ensure EMC, use the terminals

shown in the terminal diagrams/connection diagrams to connect the binary inputs to the common potential.

Relay Outputs

Standard Relay (Type S)

Switching capacity

On: 1000 W/VA

Off: 30 VA; 40 W ohmic;

30 W/VA at L/R ≤ 40 ms

AC and DC contact voltage 250 V

Permissible current per contact (continuous) 5 A

Permissible current per contact (switching on and

holding)

30 A for 1 s (make contact)

11.1.3

11.1.4

Technical Data

11.1 General Device Data

558 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 15

Short-time current across closed contact 250 A for 30 ms

Total permissible current for contacts connected to

common potential

5 A

Switching time OOT (Output Operating Time)

Additional delay of the output medium used

≤ 10 ms, typically 8 ms

Max. rated data of the output contacts in accordance

with UL certification

DC 24 V, 8 A, General Purpose

DC 48 V, 0.8 A, General Purpose

DC 240 V, 0.1 A, General Purpose

AC 240 V, 5 A, General Purpose

AC 120 V, 1/3 hp

AC 250 V, 1/2 hp

B300

R300

Interference suppression capacitors across the

contacts

4.7 nF, ± 20 %, AC 250 V

Fast Relay (Type F)

Switching capacity On: 1000 W/VA

Off: 30 VA; 40 W ohmic;

30 W/VA at L/R ≤ 40 ms

AC and DC contact voltage 250 V

Permissible current per contact (continuous) 5 A

Permissible current per contact (switching on and

holding)

30 A for 1 s (make contact)

Short-time current across closed contact 250 A for 30 ms

Total permissible current for contacts connected to

common potential

5 A

Switching time OOT (Output Operating Time)

Additional delay of the output medium used

Closing time, typical: 4 ms

Opening time, typical: 2 ms

≤ 5 ms

Rated data of the output contacts in accordance with

UL certification

AC 120 V, 8.5 A, General Purpose

AC 277 V, 6 A, General Purpose

AC 277 V, 0.7 hp

AC 347 V, 4.5 A, General Purpose

B300

R300

Interference suppression capacitors across the

contacts

4.7 nF, ± 20 %, AC 250 V

Supervision 2-channel activation with cyclic testing (only for make

contact)

High-Speed Relay with Semiconductor Acceleration (Type HS)

Switching capacity

On/Off: 1000 W/VA

Contact voltage AC 200 V, DC 250 V

Permissible current per contact (continuous) 5 A

Permissible current per contact (switching on and

holding)

30 A for 1 s (make contact)

Short-time current across closed contact 250 A for 30 ms

Technical Data

11.1 General Device Data

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 559

C53000-G5040-C019-6, Edition 06.2016

Page 16

Total permissible current for contacts connected to

common potential

5 A

Switching time OOT (Output Operating Time)

Additional delay of the output medium used

Closing time, typical: 0.2 ms

Opening time, typical: 6 ms

Maximum: ≤ 9 ms

Rated data of the output contacts in accordance with

UL certification

B150

Q300

Design Data

Masses

Device Size

Weight of the Modular Devices

Type of construction 1/3 1/2 2/3 5/6 1/1

Flush-mounting device 4.8 kg 8.1 kg 11.4 kg 14.7 kg 18.0 kg

Surface-mounted device with inte-

grated on-site operation panel

7.8 kg 12.6 kg 17.4 kg 22.2 kg 27.0 kg

Surface-mounted device with

detached on-site operation panel

5.1 kg 8.7 kg 12.3 kg 15.9 kg 19.5 kg

Size Weight

Detached on-site operation panel 1/3 1.9 kg

Detached on-site operation panel 1/6 1.1 kg

Dimensions of the Basic and 1/3 Modules

Type of Construction (Maximum Dimensions)

Width over all x Height over all x Depth 11(in

Inches)

Flush-mounting device 150 mm x 268 mm x 229 mm (5.91 x 10.55 x 9.02)

Surface-mounted device with integrated on-site oper-

ation panel

150 mm x 314 mm x 337 mm (5.91 x 12.36 x 13.27)

Surface-mounted device with detached on-site operation panel

150 mm x 314 mm x 230 mm (5.91 x 12.36 x 9.06)

Dimensions of Device Rows

Type of

Construction

(Maximum

Dimensions)

Width over all x Height over all x Depth 12(in Inches)

Type of construction

1/3 1/2 2/3 5/6 1/1

Flush-mounting

device

150 mm x

268 mm x

229 mm (5.91 x

10.55 x 9.02)

225 mm x

268 mm x

229 mm (8.86 x

10.55 x 9.02)

300 mm x

268 mm x

229 mm(11.81 x

10.55 x 9.02)

375 mm x

268 mm x

229 mm (14.76

x 10.55 x 9.02)

450 mm x

268 mm x

229 mm (17.72

x 10.55 x 9.02)

11.1.5

11

Width and depth rounded to whole numbers in mm

12

Width and depth rounded to whole numbers in mm

Technical Data

11.1 General Device Data

560 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 17

Type of

Construction

(Maximum

Dimensions)

Width over all x Height over all x Depth 12(in Inches)

Surfacemounted device

with integrated

on-site operation

panel

150 mm x

314 mm x

337 mm (5.91 x

12.36 x 13.27)

225 mm x

314 mm x

337 mm (8.86 x

12.36 x 13.27)

300 mm x

314 mm x

337 mm (11.81

x 12.36 x 13.27)

375 mm x

314 mm x

337 mm (14.76

x 12.36 x 13.27)

450 mm x

314 mm x

337 mm (17.72

x 12.36 x 13.27)

Surfacemounted device

with detached

on-site operation

panel

150 mm x

314 mm x

230 mm (5.91 x

12.36 x 9.06)

225 mm x

314 mm x

230 mm (8.86 x

12.36 x 9.06)

300 mm x

314 mm x

230 mm (11.81

x 12.36 x 9.06)

375 mm x

314 mm x

230 mm (14.76

x 12.36 x 9.06)

450 mm x

314 mm x

230 mm (17.72

x 12.36 x 9.06)

Expansion Module Dimensions

Type of Construction (Maximum Dimensions)

Width x Height x Depth 13 (in Inches)

Flush-mounting device 75 mm x 268 mm x 229 mm (2.95 x 10.55 x 9.02)

Surface-mounted device with integrated on-site oper-

ation panel

75 mm x 314 mm x 337 mm (2.95 x 12.36 x 13.27)

Surface-mounted device with detached on-site operation panel

75 mm x 314 mm x 230 mm (2.95 x 12.36 x 9.06)

Plug-In Module Dimensions

Type of Construction (Maximum Dimensions)

Width x Height x Depth (in Inches)

USART-Ax-xEL, ETH-Bx-xEL 61 mm x 45 mm x 120.5 mm (2.4 x 1.77 x 4.74)

USART-Ax-xFO, ETH-Bx-xFO (without protection

cover)

61 mm x 45 mm x 132.5 mm (2.4 x 1.77 x 5.22)

ANAI-CA-4EL 61 mm x 45 mm x 119.5 mm (2.4 x 1.77 x 4.7)

ARC-CD-3FO 61 mm x 45 mm x 120.5 mm (2.4 x 1.77 x 4.74)

Minimum Bending Radii of the Connecting Cables Between the On-Site Operation Panel and the Base Module

Fiber-optic cable

R = 50 mm

Pay attention to the length of the cable protection

sleeve, which you must also include in calculations.

D-Sub cable R = 50 mm (minimum bending radius)

Degree of Protection to IEC 60529

For equipment in the surface-mounting housing

IP50

For equipment in the flush-mounting housing Front IP51

Back side of the modular devices IP50

Back side of the non-modular devices IP40

For operator protection IP2x for current terminal (installed removed)

IP1x for voltage terminal (removed/without cover)

IP2x for voltage terminal (removed/with cover)

IP2x for voltage terminal (installed)

Degree of pollution, IEC 60255-27 2

12

Width and depth rounded to whole numbers in mm

13

Width and depth rounded to whole numbers in mm

Technical Data

11.1 General Device Data

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 561

C53000-G5040-C019-6, Edition 06.2016

Page 18

Maximum altitude above sea level 2000 m (6561.68 ft)

UL Note

Type 1 if mounted into a door or front cover of an enclosure.

When expanding the device with the 2nd device row, then they must be mounted completely inside an

enclosure.

Tightening Torques for Terminal Screws

Type of Line Current Terminal Voltage Terminal with

Spring-Loaded Terminals

Voltage Terminal with

Screw Connection

Litz wire with ring-type

lug

2.7 Nm No ring-type lug No ring-type lug

Stranded wires with bootlace ferrules or pin-type

lugs

2.7 Nm 1.0 Nm 0.6 Nm

Solid conductor, bare

(2 mm2)

2.0 Nm 1.0 Nm –

i

i

NOTE

Use copper cables only.

Torques for Other Screw Types

Screw Type

Torque

M4 x 20 1.2 Nm

M4 x 8 1.2 Nm

M2.5 x 6 0.39 Nm

Countersunk screw, M2.5 x 6 0.39 Nm

Countersunk screw, M2.5 x 8 0.39 Nm

Collar screw, M4 x 20 0.7 Nm

Technical Data

11.1 General Device Data

562 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 19

Date and Time Synchronization

Date format DD.MM.YYYY (Europe)

MM/DD/YYYY (USA)

YYYY-MM-DD (China)

Time source 1, time source 2 None

IRIG-B 002(003)

IRIG-B 006(007)

IRIG-B 005(004) with extension according to

IEEE C37.118-2005

DCF77

PI (protection interface)

14

SNTP

IEC 60870-5-103

DNP3

IEEE 1588

Time zone 1, time zone 2 Local

UTC

Failure indication after 0 s to 3600 s

Time zone and daylight saving time Transfer of PC settings

Manually setting the time zones

Time zone offset with respect to GMT -720 min to 840 min

Switching over to daylight saving time Active

Inactive

Beginning of daylight saving time Input: day and time

End of daylight saving time Input: day and time

Offset daylight saving time -120 to 120 [steps of 15]

11.2

14

If provided

Technical Data

11.2 Date and Time Synchronization

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 563

C53000-G5040-C019-6, Edition 06.2016

Page 20

Busbar Differential Protection

General Differential Protection Setting Values

Rated object current I

rated obj.

100 A to 50 000 A Increments of 1

Check Zone Setting Values

Threshold value I

diff

0.20 to 4.00 Increments of 0.01

Threshold value I

diff

(sensitive characteristic curve) 0.05 to 4.00 Increments of 0.01

Threshold value I

rest

(sensitive characteristic curve) 0.00 to 25.00 Increments of 0.01

Threshold value I

rest

(sensitive characteristic curve/

CBFP)

0.00 to 25.00 Increments of 0.01

Stabilization factor k 0.10 to 0.80 Increments of 0.01

General Busbar Section Setting Values

Threshold value I

diff

0.20 to 4.00 Increments of 0.01

Threshold value I

diff

(sensitive characteristic curve) 0.05 to 4.00 Increments of 0.01

Threshold value I

rest

(sensitive characteristic curve) 0.00 to 25.00 Increments of 0.01

Threshold value I

rest

(sensitive characteristic curve/

CBFP)

0.00 to 25.00 Increments of 0.01

Stabilization factor k 0.10 to 0.80 Increments of 0.01

Setting Values for Differential Current Supervision

Limiting value of current I/I

rated, obj

(I

rated, obj

= Rated object current)

0.05 to 0.80 Increments of 0.01

Time delay

for check zone and busbar-selective protection

1.00 s to 10.00 s Increments of 0.01

Setting Values for Cross-Stabilization

Restraint current ratio, selective zones

0.00 to 1.00 Increments of 0.01

Restraint current ratio, check zone 0.00 to 1.00 Increments of 0.01

Operate Time

Minimum operate time

High-speed relay (type HS) approx. 3 ms

Fast relay (type F) approx. 7 ms

Frequency

Frequency range

50 Hz or 60 Hz

Tolerances

Current

5 % of the setting value or 50 mA

k factor 5 % of the setting value

Times 5 % of the setting value or 50 ms

Frequency - 10 %, + 5 %

11.3

Technical Data

11.3 Busbar Differential Protection

564 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 21

Circuit-Breaker Failure Protection 1-Pole/3-Pole

Starting Conditions

For circuit-breaker failure protection

1-pole tripping internal or external

15

3-pole tripping internal or external

16

Setting Values

Phase-current threshold

values

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.150 A to 175.000 A Increments of 0.010 A

Threshold value sensitive 1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.150 A to 175.000 A Increments of 0.010 A

Supervision time of release signal 0.06 s to 1.00 s Increments of 0.01 s

Time delays 0.05 s to 60.00 s Increments of 0.001 s

Supervision time of binary inputs 0.05 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Circuit-Breaker Supervision

Supervision of circuit-breaker auxiliary-contact position

For 3-pole CB tripping 1 input each for make contact and break contact

For 1-pole CB tripping 1 input each for auxiliary contact per pole or

1 input for each series connection make contact and

break contact

i

i

NOTE

The circuit-breaker failure protection can also work without the circuit-breaker auxiliary contacts stated.

Auxiliary contacts are required for circuit-breaker failure protection in cases where the current flow is

absent or too low for tripping (for example with a transformer or a Buchholz protection).

Times

Pickup time, in the case of an internal start

Pickup time, in the case of an external start

< 1 ms

< 5 ms

Dropout time for Unbalancing operating mode Approx. 2 ms

Typical dropout time < 15 ms

11.4

15

Via binary inputs

16

Via binary inputs

Technical Data

11.4 Circuit-Breaker Failure Protection 1-Pole/3-Pole

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 565

C53000-G5040-C019-6, Edition 06.2016

Page 22

Dropout time, via circuit-breaker auxiliary-contact

criterion

< 5 ms

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Threshold values, dropout thresholds 2 % of the setting value or 1 % of the rated current

Times 1 % of the setting value or 10 ms

Technical Data

11.4 Circuit-Breaker Failure Protection 1-Pole/3-Pole

566 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 23

Circuit-Breaker Failure Protection 3-Pole

Starting Conditions

For circuit-breaker failure protection

3-pole tripping internal or external

17

Setting Values

Phase-current threshold

values

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.150 A to 175.000 A Increments of 0.01 A

Sensitive threshold value 1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.150 A to 175.000 A Increments of 0.01 A

Supervision time of release signal 0.06 s to 1.00 s Increments of 0.01 s

Time delays 0.05 s to 60.00 s Increments of 0.001 s

Supervision time of binary inputs 0.05 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Circuit-Breaker Supervision

Position supervision via circuit-breaker auxiliary contacts

For 3-pole CB tripping 1 input each for make contact and break contact

i

i

NOTE

The circuit-breaker failure protection can also work without the circuit-breaker auxiliary contacts stated.

Auxiliary contacts are required for circuit-breaker failure protection in cases where the current flow is

absent or too low for tripping (for example with a transformer or a Buchholz protection).

Times

Pickup time, in the case of an internal start

Pickup time, in the case of an external start

< 1 ms

< 5 ms

Dropout time for unbalancing operating mode Approx. 2 ms

Typical dropout time < 15 ms

Dropout time via circuit-breaker auxiliary-contact

criterion

< 5 ms

11.5

17

Via binary inputs

Technical Data

11.5 Circuit-Breaker Failure Protection 3-Pole

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 567

C53000-G5040-C019-6, Edition 06.2016

Page 24

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Threshold values, dropout thresholds 2 % of the setting value or 1 % of the rated current

Times 1 % of the setting value or 10 ms

Technical Data

11.5 Circuit-Breaker Failure Protection 3-Pole

568 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 25

Inherent Circuit-Breaker Failure Protection

Setting Values

Phase-current threshold

values

For I

rated

= 1 A 0.03 A to 35.00 A Increments of 0.01 A

For I

rated

= 5 A 0.15 A to 175.00 A

Threshold value sensitive For I

rated

= 1 A 0.03 A to 35.00 A Increments of 0.01 A

For I

rated

= 5 A 0.15 A to 175.00 A

Delay T2 for 3-pole trip 0.05 s to 60 s Increments of 0.001 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Threshold values

2 % of the setting value or 1 % of the rated current

Times 1 % of the setting value or 10 ms

11.6

Technical Data

11.6 Inherent Circuit-Breaker Failure Protection

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 569

C53000-G5040-C019-6, Edition 06.2016

Page 26

End-Fault Protection

Setting Values

Phase-current threshold

values

For I

rated

= 1 A 0.03 A to 35.00 A Increments 0.01 A

For I

rated

= 5 A 0.15 A to 175.00 A

Delay T, CB open 0.00 s to 15.00 s Increments of 0.01 s

Tripping delay 0.00 s to 60.00 s Increments of 0.01 s

Minimum operate time 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Threshold values, dropout thresholds

2 % of the setting value or 1 % of the rated current

Times 1 % of the setting value or 10 ms

11.7

Technical Data

11.7 End-Fault Protection

570 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 27

External Tripping Busbar Section (Direct)

Setting Values

Supervision Time 0.00 s to 60.00 s Increments of 0.01 s

Operate Time

Minimum operate time High speed relay (type HS) approx. 4 ms

Fast relay (type F) approx. 8 ms

Tolerance

Process tolerance for the supervision time 1 % of the setting value or 10 ms

11.8

Technical Data

11.8 External Tripping Busbar Section (Direct)

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 571

C53000-G5040-C019-6, Edition 06.2016

Page 28

External Tripping Busbar Section (from Bay)

Setting Values

Supervision Time 0.06 s to 1.00 s Increments of 0.01 s

Operating Ranges

10 Hz < f < 80 Hz Operating range (normal behavior, normal tolerance

values)

Operate Time

Minimum operate time High speed relay (type HS) approx. 5 ms

Fast relay (type F) approx. 9 ms

Tolerances

Process tolerance for the supervision time 1 % of the setting value or 10 ms

11.9

Technical Data

11.9 External Tripping Busbar Section (from Bay)

572 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 29

Bus Coupler Differential Protection

The vast majority of settings for the bus coupler differential protection is identical to the settings of the

busbar-selective protection of the busbar differential protection 11.3 Busbar Differential Protection.

Setting Values

Curr. thresh. for CT overl. 1.00 I/IrObj to 10.00 I/

IrObj; ∞

Increments of 0.01

11.10

Technical Data

11.10 Bus Coupler Differential Protection

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 573

C53000-G5040-C019-6, Edition 06.2016

Page 30

Differential Current Supervision

You can find information on the Technical Data of the Differential-current supervision in chapter 11.3 Busbar

Differential Protection.

11.11

Technical Data

11.11 Differential Current Supervision

574 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 31

Zero-Crossing Supervision

Times

Pickup time 32 ms for f

rated

= 50 Hz

27 ms for f

rated

= 60 Hz

Setting Values

Threshold for zero-crossing supervision 0.5 * I

diff

busbar section

11.12

Technical Data

11.12 Zero-Crossing Supervision

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 575

C53000-G5040-C019-6, Edition 06.2016

Page 32

Disconnector Supervision

Setting Values

Disconnector runtime 1.00 s to 180.00 s Increments of 0.01 s

11.13

Technical Data

11.13 Disconnector Supervision

576 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 33

Circuit-Breaker Supervision

Setting Values

Supervision time 1.00 s to 180.00 s Increments of 0.01 s

11.14

Technical Data

11.14 Circuit-Breaker Supervision

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 577

C53000-G5040-C019-6, Edition 06.2016

Page 34

Stage with Definite-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value

18

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.15 A to 175.00 A Increments of 0.01 A

Dropout ratio 0.90 to 0.99 Increments of 0.01

Time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout delay 0.00 s to 60.00 s Increments of 0.01 s

Pickup delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Times

Operate time with time delay = 0 ms

Approx. 25 ms + OOT 19 at 50 Hz

Approx. 22 ms + OOT at 60 Hz

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

Dropout time Approx. 20 ms + OOT

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Currents, method of measurement = fundamental

component

1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

11.15

18

If you have selected the method of measurement = RMS value, do not set the threshold value under 0.1 l

rated,sec

.

19

OOT (Output Operating Time) additional delay of the output medium used, for example 5 ms with fast relays

Technical Data

11.15 Stage with Definite-Time Characteristic Curve

578 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 35

Currents, method of measurement = RMS value

(33 % harmonics, in relation to fundamental component)

Up to 30th harmonic 1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 50 Hz 3 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 60 Hz 4 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Time delays 1 % of the setting value or 10 ms

Influencing Variables for Thresholds

Transient excess pickup in method of measurement =

fundamental component, for τ > 100 ms (with

complete unbalance)

< 5 %

Technical Data

11.15 Stage with Definite-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 579

C53000-G5040-C019-6, Edition 06.2016

Page 36

Stage with Inverse-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value 1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.15 A to 175.00 A Increments of 0.01 A

Dropout Disk emulation

Instantaneous

–

Time multiplier 0.00 to 15.00 Increments of 0.01

Pickup delay 0.00 s to 60.00 s Increments of 0.01 s

Minimum time of the curve 0.00 s to 1.00 s Increments of 0.01 s

Additional time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout

95 % of 1.1 ⋅ threshold value

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Reset of the Integration Timer

Instantaneous

With dropout

Disk emulation

Approx. < 0.90 ⋅ threshold value

Operate Curves and Dropout-Time Characteristic Curves according to IEC

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

11.16

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

580 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 37

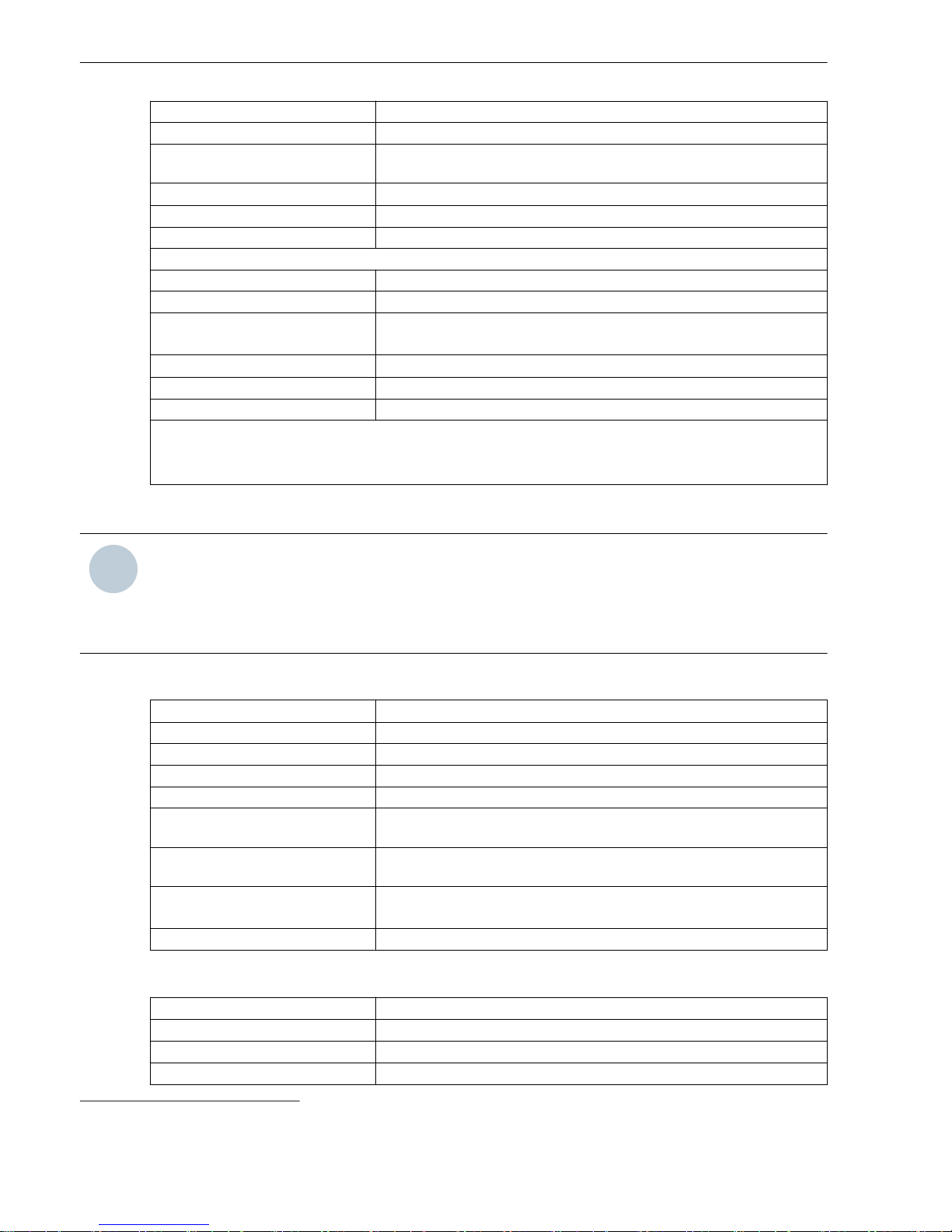

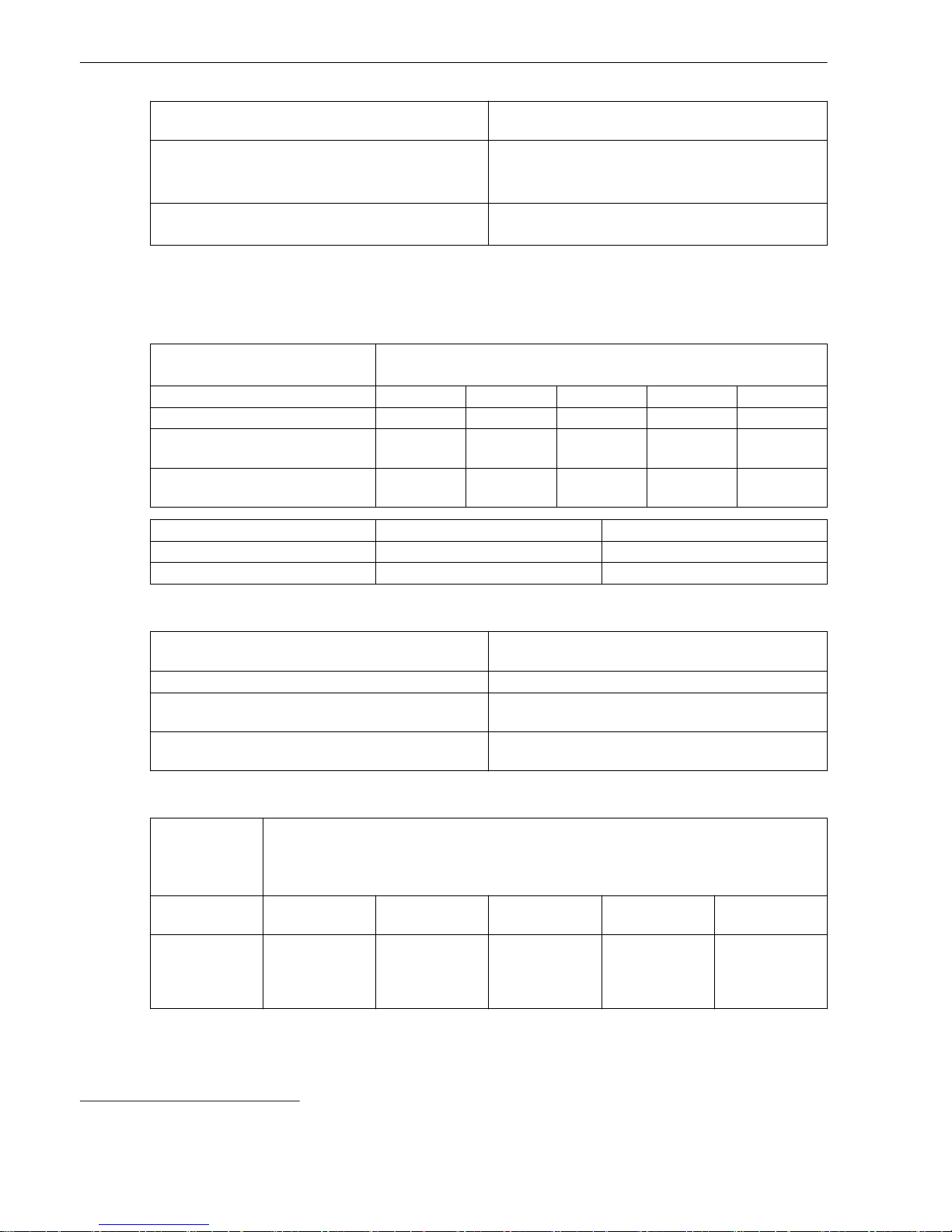

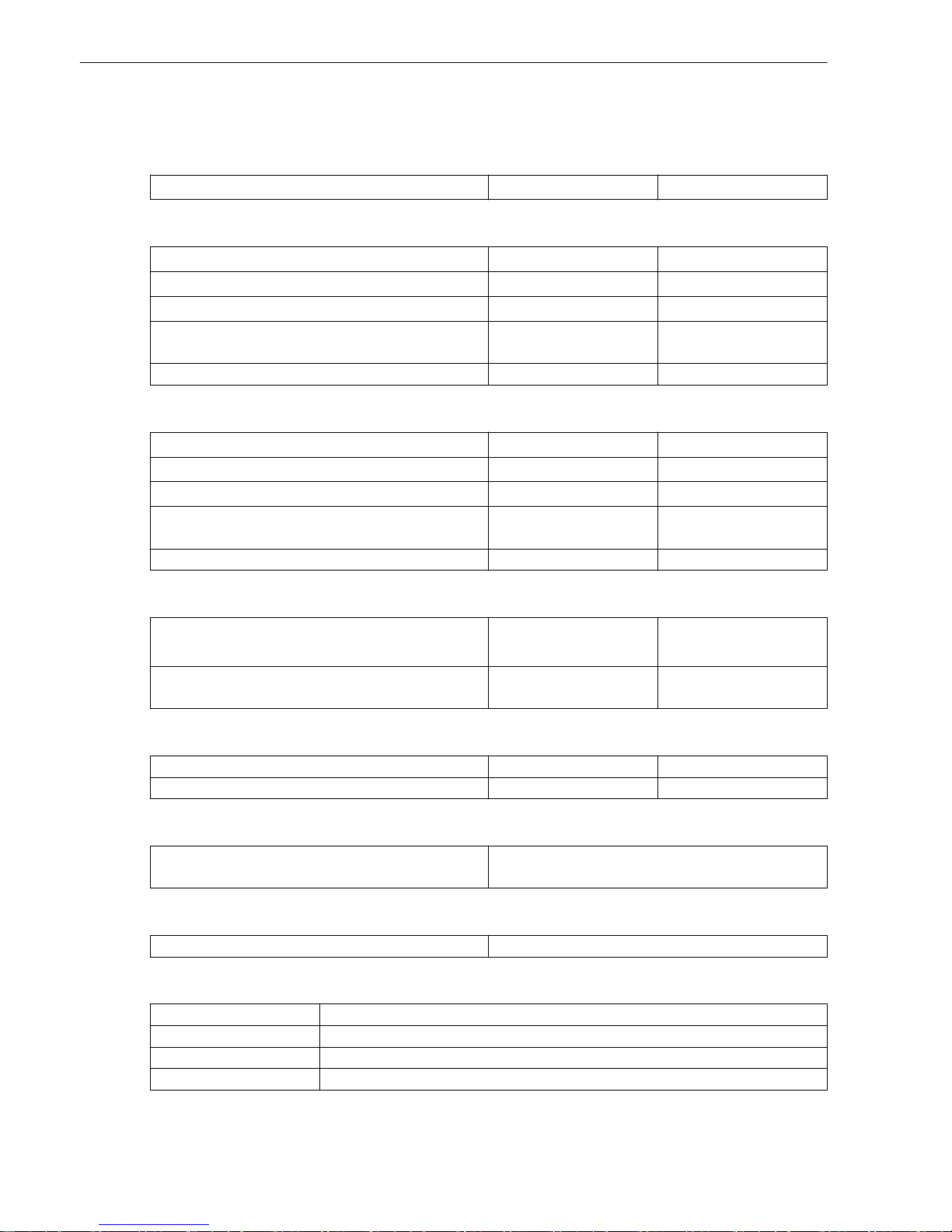

[dwocpki1-080213-01.tif, 1, en_US]

Figure 11-1

Operate Curves and Dropout-Time Characteristic Curves According to IEC

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 581

C53000-G5040-C019-6, Edition 06.2016

Page 38

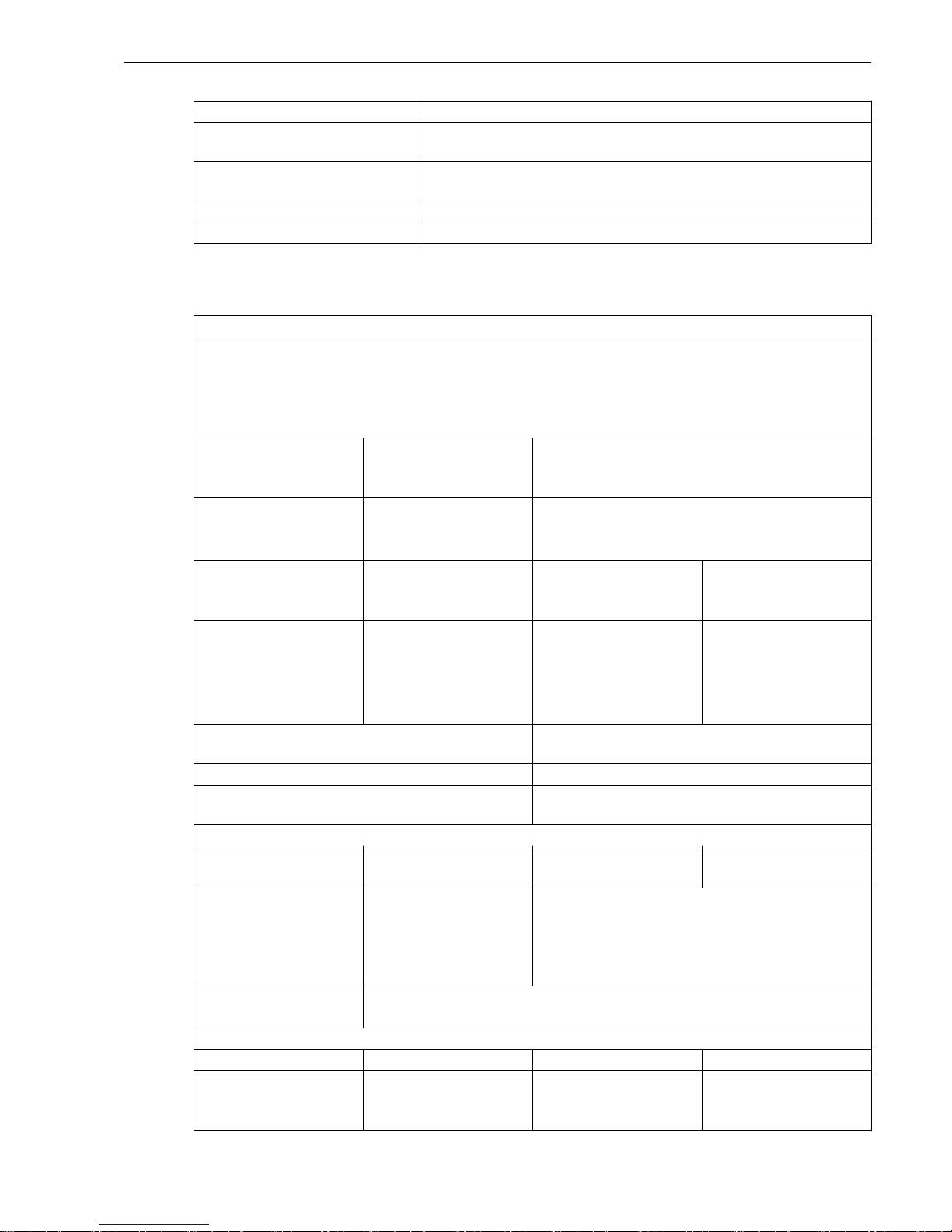

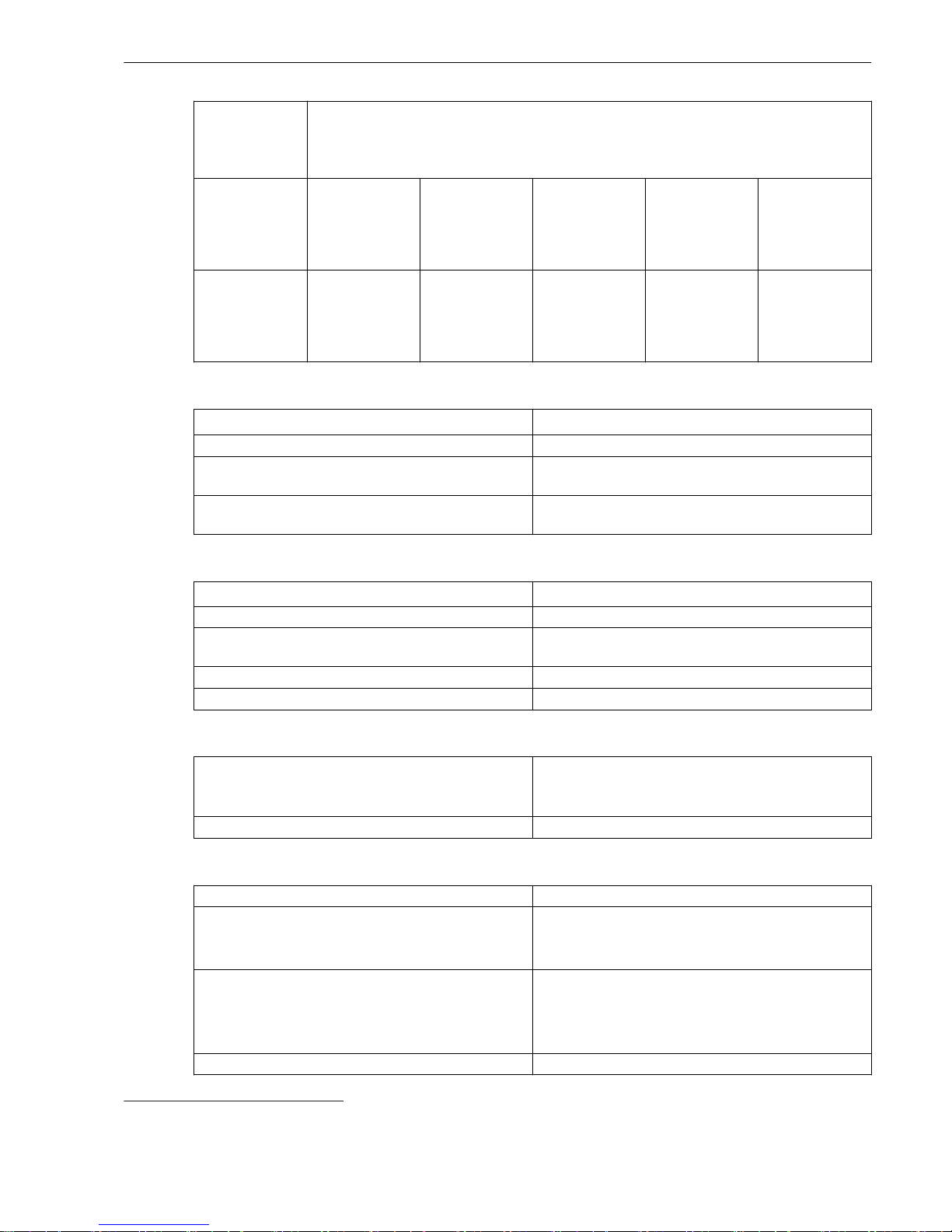

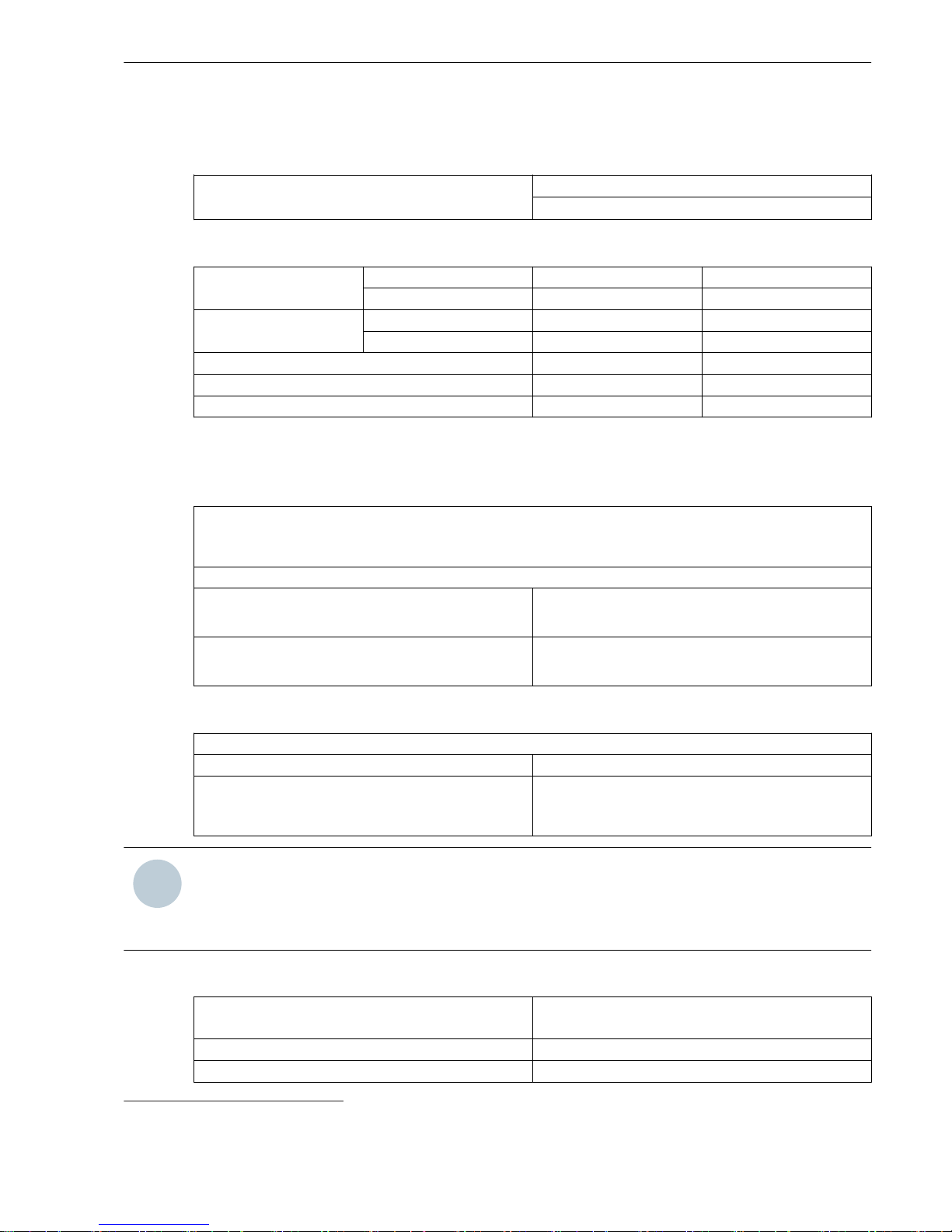

[dwocpki2-080213-01.tif, 1, en_US]

Figure 11-2

Operate Curves and Dropout-Time Characteristic Curves According to IEC

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

582 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 39

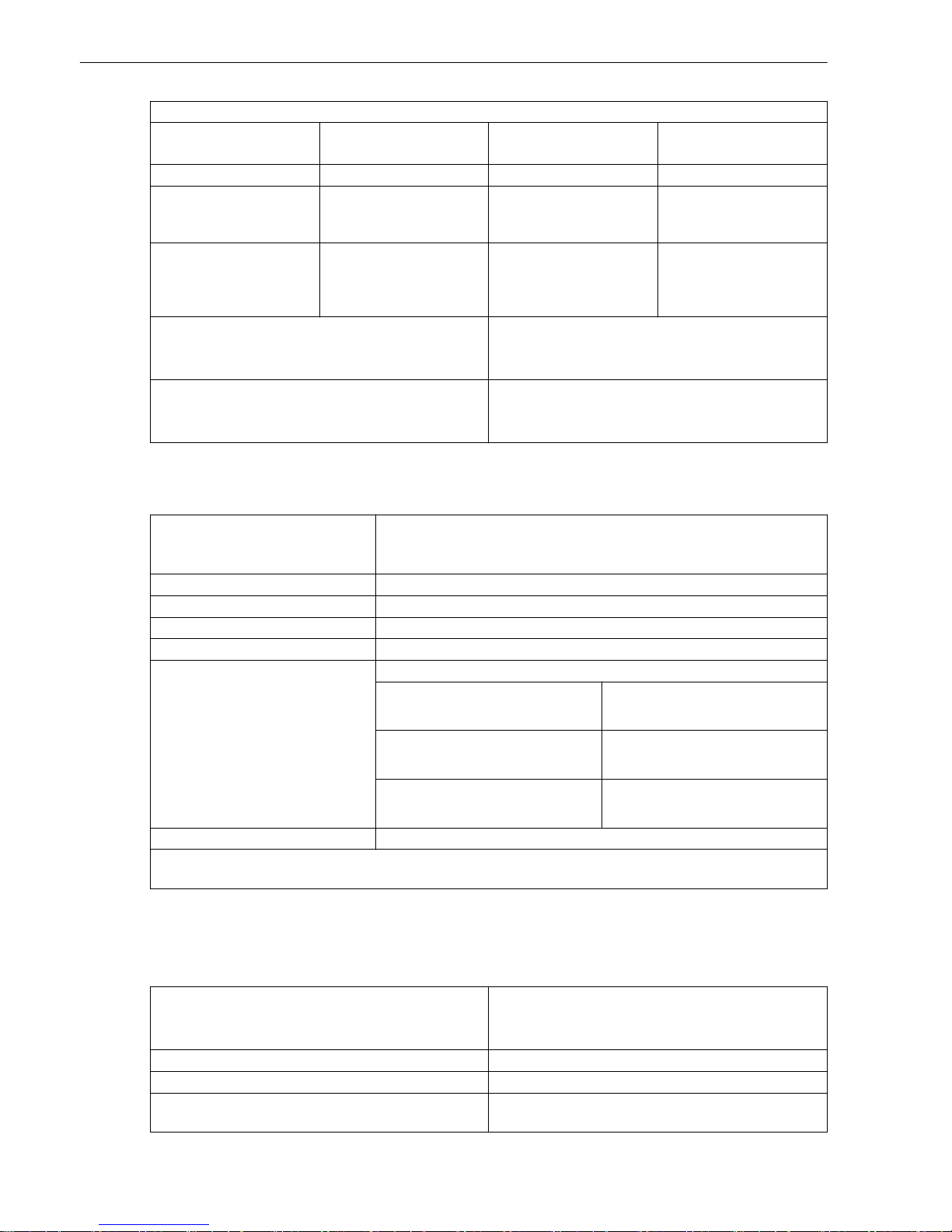

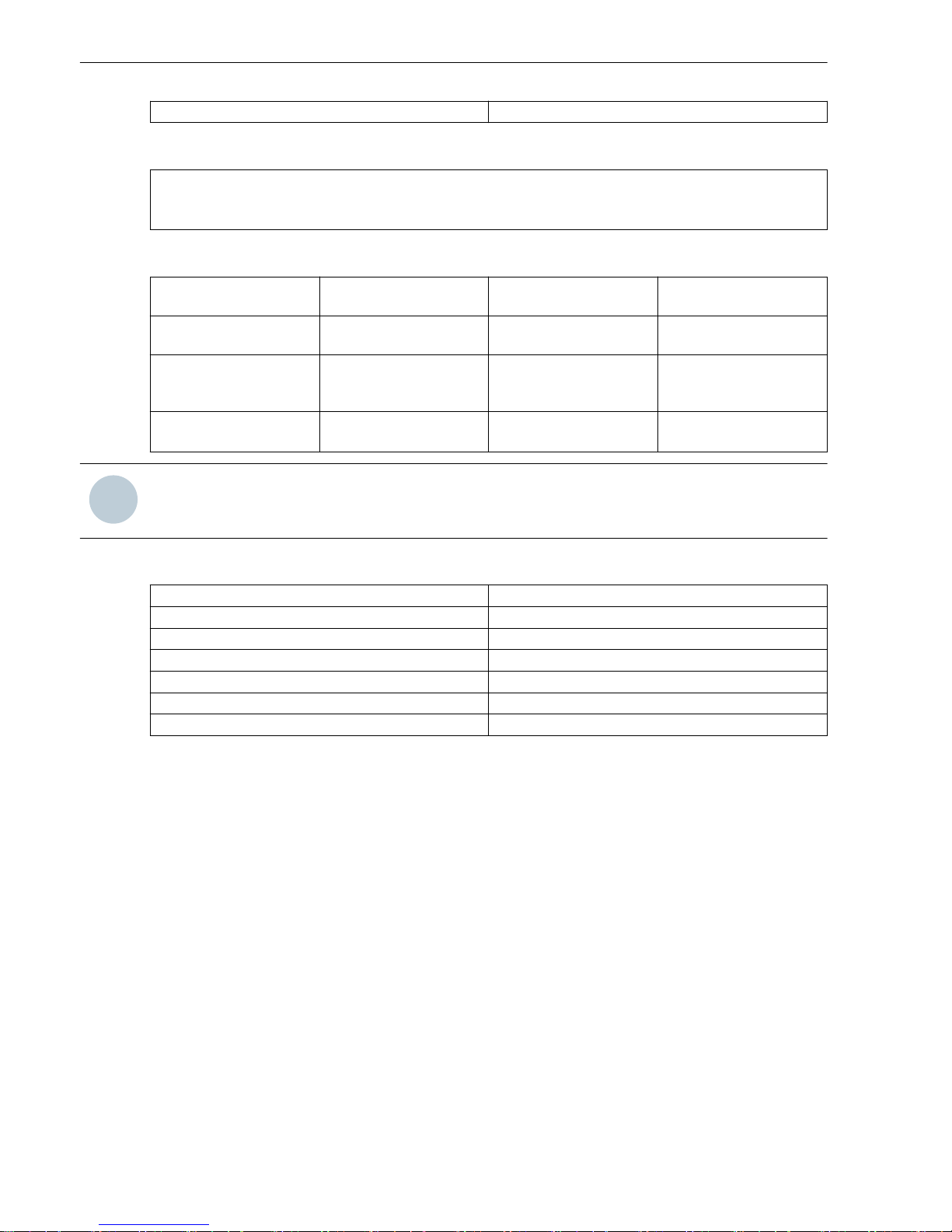

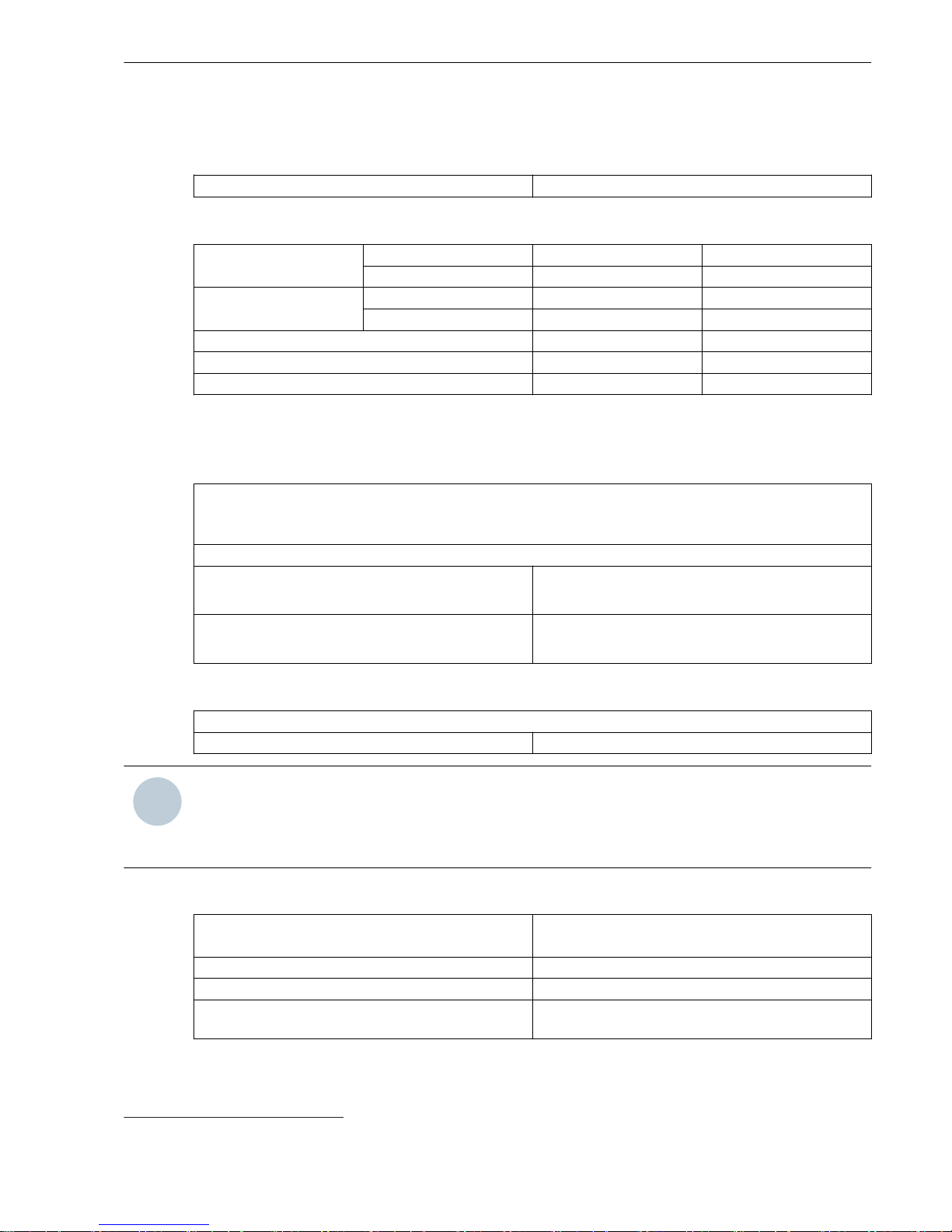

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

[dwocpka1-080213-01.tif, 2, en_US]

Figure 11-3

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 583

C53000-G5040-C019-6, Edition 06.2016

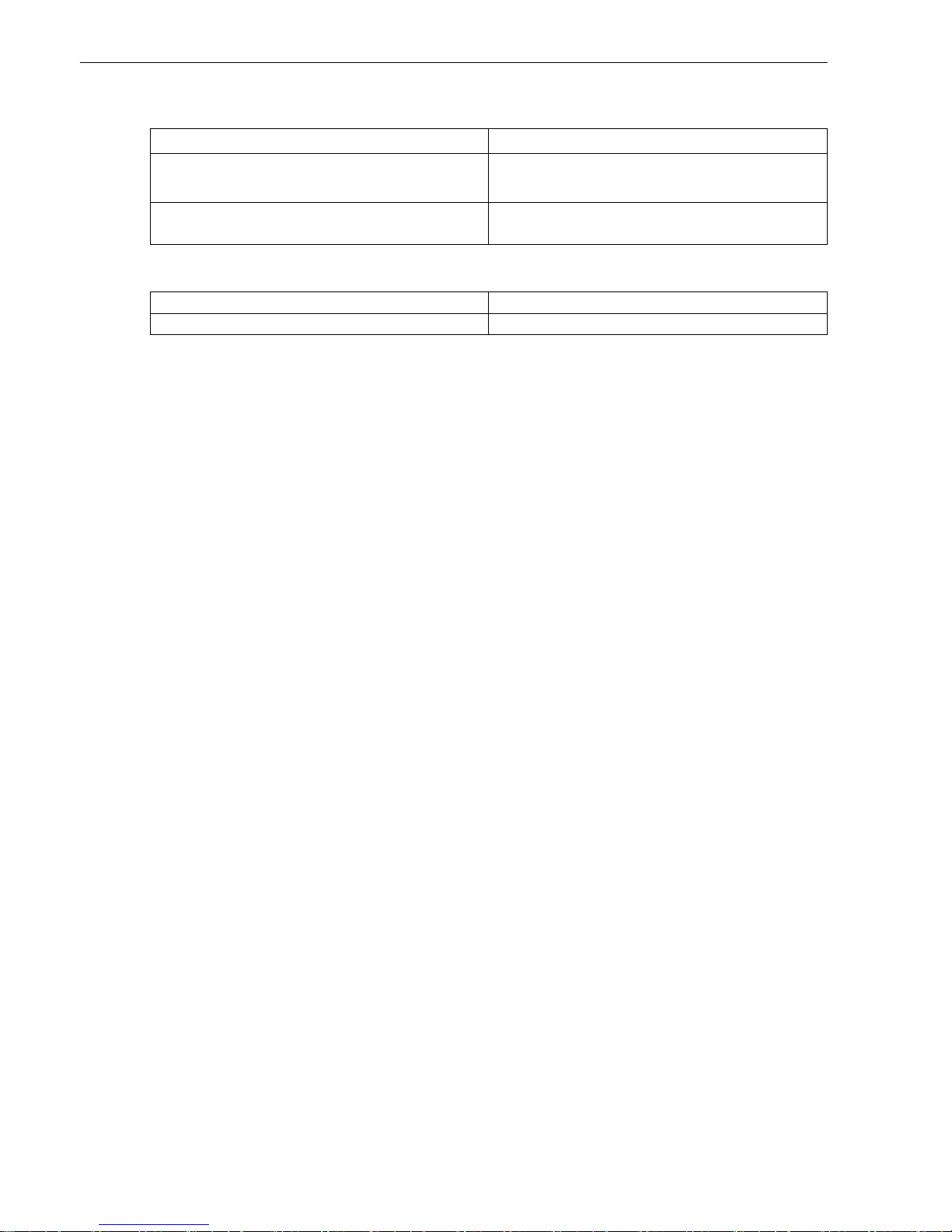

Page 40

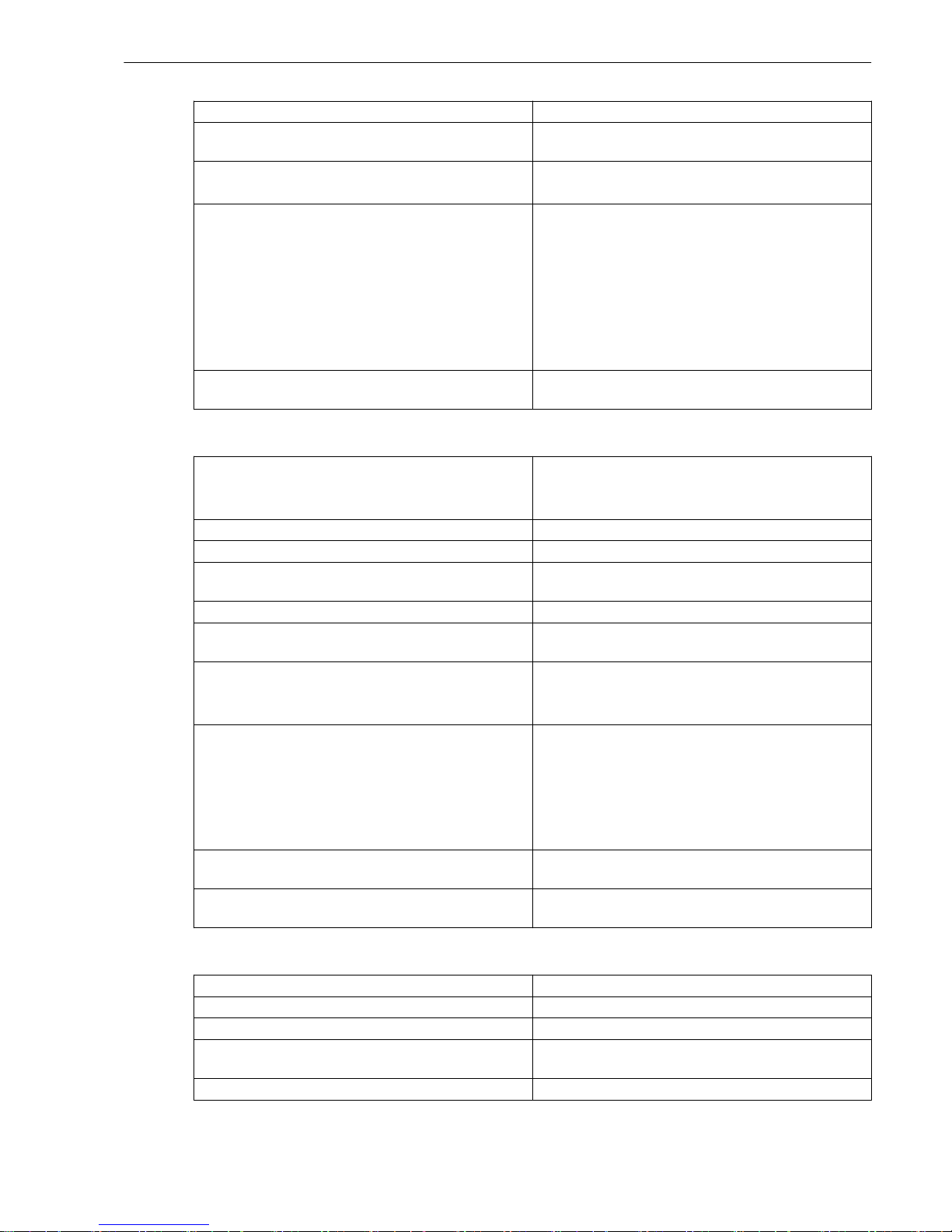

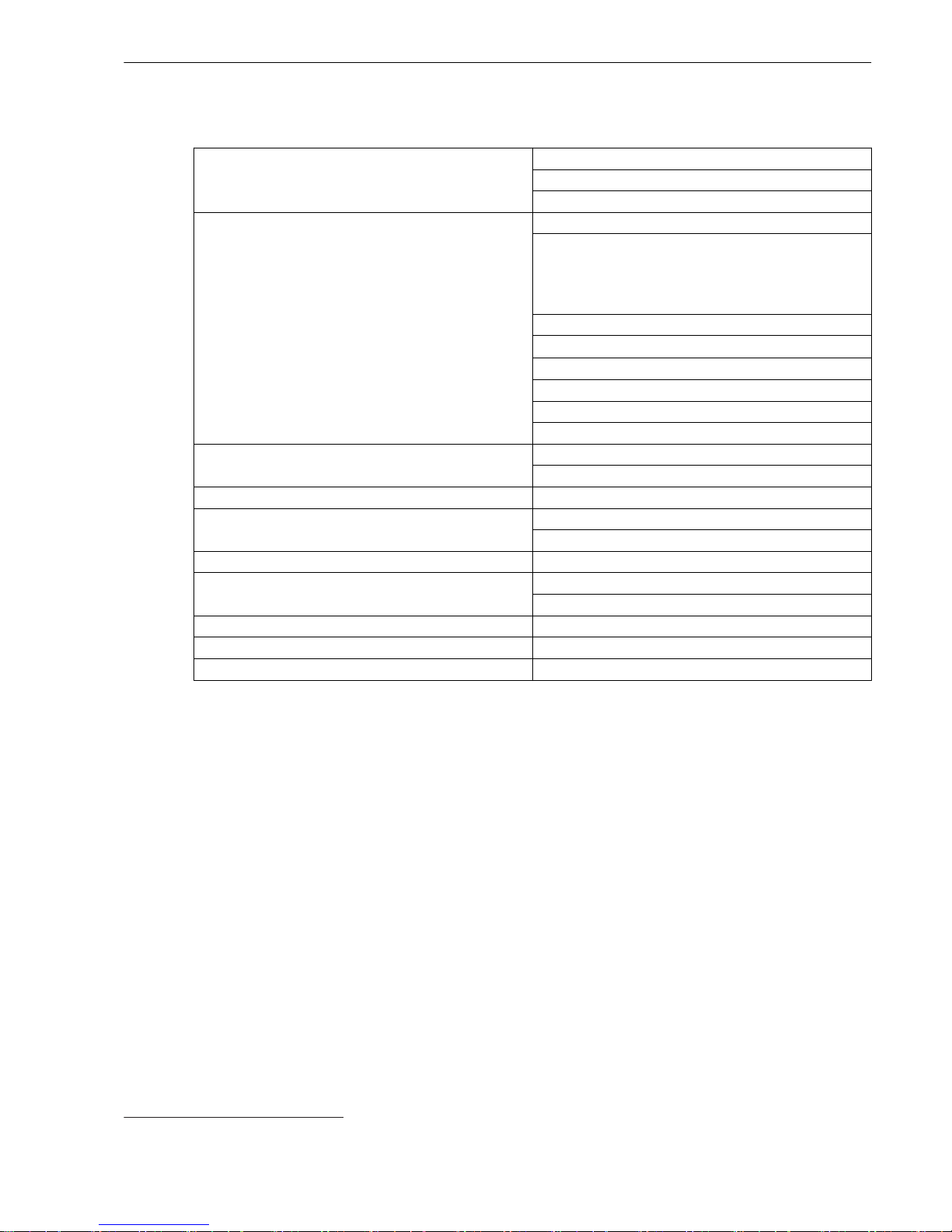

[dwocpka2-080213-01.tif, 2, en_US]

Figure 11-4

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

584 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 41

[dwocpka3-080213-01.tif, 2, en_US]

Figure 11-5

Tripping Characteristic Curves and Dropout Characteristic Curves According to ANSI/IEEE

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 585

C53000-G5040-C019-6, Edition 06.2016

Page 42

[dwocpka4-080213-01.tif, 2, en_US]

Figure 11-6

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Currents, method of measurement = fundamental

component

1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

Currents, method of measurement = RMS value

(33% harmonics, in relation to fundamental component)

Up to 30th harmonic 1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 50 Hz 3 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 60 Hz 4 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Operate time for 2 ≤ I/I threshold value ≤ 20 5 % of the reference (calculated) value

+2 % current tolerance or 30 ms

Dropout time for I/I threshold value ≤ 0.90 5 % of the reference (calculated) value

+2 % current tolerance or 30 ms

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

586 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 43

Influencing Variables for Thresholds

Transient excess pickup in method of measurement =

fundamental component, for τ > 100 ms (with

complete unbalance)

< 5 %

Technical Data

11.16 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 587

C53000-G5040-C019-6, Edition 06.2016

Page 44

Stage with Definite-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value

20

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.15 A to 175.00 A Increments of 0.01 A

Dropout ratio 0.90 to 0.99 Increments of 0.01

Time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercurrent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Times

Operate time with time delay = 0 ms

Approx. 25 ms + OOT21 at 50 Hz

Approx. 22 ms + OOT at 60 Hz

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

Dropout time Approx. 20 ms + OOT

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

3I0 measured via I4

22

, method of measurement =

fundamental component

1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

11.17

20

If you have selected the method of measurement = RMS value, do not set the threshold value under 0.1 l

rated,sec

.

21

OOT (Output Operating Time) additional delay of the output medium used, see Chapter 11.1.4 Relay Outputs

22

Slightly expanded tolerances will occur during the calculation of 3I0, maximum factor of 2

Technical Data

11.17 Stage with Definite-Time Characteristic Curve

588 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 45

3I0 measured via I423, method of measurement = RMS value

(33 % harmonics, in relation to fundamental component)

Up to 30th harmonic 1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 50 Hz 3 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 60 Hz 4 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Time delays 1 % of the setting value or 10 ms

Influencing Variables for Thresholds

Transient excess pickup in method of measurement =

fundamental component, for τ > 100 ms (with

complete unbalance)

< 5 %

23

Slightly expanded tolerances will occur during the calculation of 3I0, maximum factor of 2

Technical Data

11.17 Stage with Definite-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 589

C53000-G5040-C019-6, Edition 06.2016

Page 46

Stage with Inverse-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value

24

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.15 A to 175.00 A Increments of 0.01 A

Dropout Disk emulation

Instantaneous

–

Time multiplier 0.00 to 15.00 Increments of 0.01

Minimum time of the curve 0.00 s to 1.00 s Increments of 0.01 s

Additional time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout

95 % of 1.1 ⋅ threshold value

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Reset of the Integration Timer

Instantaneous

With dropout

Disk emulation

Approx. < 0.90 ⋅ threshold value

Operate Curves and Dropout-Time Characteristic Curves According to IEC

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

11.18

24

If you have selected the method of measurement = RMS value, do not set the threshold value under 0.1 l

rated,sec

.

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

590 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 47

[dwocpki1-080213-01.tif, 1, en_US]

Figure 11-7

Operate Curves and Dropout-Time Characteristic Curves According to IEC

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 591

C53000-G5040-C019-6, Edition 06.2016

Page 48

[dwocpki2-080213-01.tif, 1, en_US]

Figure 11-8

Operate Curves and Dropout-Time Characteristic Curves According to IEC

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

592 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 49

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

[dwocpka1-080213-01.tif, 2, en_US]

Figure 11-9

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 593

C53000-G5040-C019-6, Edition 06.2016

Page 50

[dwocpka2-080213-01.tif, 2, en_US]

Figure 11-10

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

594 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 51

[dwocpka3-080213-01.tif, 2, en_US]

Figure 11-11

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 595

C53000-G5040-C019-6, Edition 06.2016

Page 52

[dwocpka4-080213-01.tif, 2, en_US]

Figure 11-12

Operate Curves and Dropout-Time Characteristic Curves According to ANSI/IEEE

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

3I0 measured via I4

25

, method of measurement =

fundamental component

1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

3I0 measured via I426, method of measurement = RMS value

(33 % harmonics, in relation to fundamental component)

Up to 30th harmonic 1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 50 Hz 3 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Up to 50th harmonic, f

rated

= 60 Hz 4 % of the setting value or 20 mA (I

rated

= 1 A)

or 100 mA (I

rated

= 5 A), (f

rated

± 10 %)

Operate time for 2 ≤ I/I threshold value ≤ 20 5 % of the reference (calculated) value

+2 % current tolerance or 30 ms

25

Insignificantly increased tolerances will occur during the calculation of 3I0, maximum factor of 2

26

Insignificantly increased tolerances will occur during the calculation of 3I0, maximum factor of 2

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

596 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 53

Dropout time for 2 ≤ I/threshold value I ≤ 0.90 5 % of the reference (calculated) value

+2 % current tolerance or 30 ms

Influencing Variables for Thresholds

Transient excess pickup in method of measurement =

fundamental component, for τ > 100 ms (with

complete unbalance)

< 5 %

Technical Data

11.18 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 597

C53000-G5040-C019-6, Edition 06.2016

Page 54

Overvoltage Protection with 3-Phase Voltage

Setting Values for Stage Type Definite Time-Overvoltage Protection

Measured value Phase-to-phase

Phase-to-ground

Method of measurement Fundamental component

RMS value

Pickup mode 1 out of 3

3 out of 3

Pickup value

27

0.300 V to 340.000 V Increments of 0.001 V

Time delay 0.00 s to 300.00 s Increments of 0.01 s

Dropout ratio 0.90 to 0.99 Increments of 0.01

Setting Values for Stage Type Inverse Time-Overvoltage Protection

Measured value Phase-to-phase

Phase-to-ground

Method of measurement Fundamental component

RMS value

Pickup mode 1 out of 3

3 out of 3

Pickup value 0.300 V to 340.000 V Increments of 0.001 V

Pickup factor 1.00 to 1.20 Increments of 0.01

Characteristic constant k 0.00 to 300.00 Increments of 0.01

Characteristic constant α

0.010 to 5.000 Increments of 0.001

Characteristic constant c 0.000 to 5.000 Increments of 0.001

Time multiplier 0.05 to 15.00 Increments of 0.01

Additional time delay 0.00 s to 60.00 s Increments of 0.01 s

Reset time 0.00 s to 60.00 s Increments of 0.01 s

Operate Curve for Stage Type Inverse Time-Overvoltage Protection

Where

T

op

Operate delay

T

inv

Inverse-time delay

T

add

Additional time delay (parameter Additional time delay)

Where

T

inv

Inverse-time delay

T

p

Time multiplier (parameter Time dial)

V Measured voltage

11.19

27

If you have selected the method of measurement = RMS value, do not set the threshold value under 10 V.

Technical Data

11.19 Overvoltage Protection with 3-Phase Voltage

598 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 55

V

thresh

Threshold value (parameter Threshold)

k Curve constant k (parameter Charact. constant k)

α Curve constant α (parameter Charact. constant α)

c Curve constant c (parameter Charact. constant c)

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for the overvoltage and of 105 % for the

undervoltage functionality.

Minimum absolute dropout differential 150 mV sec.

Times

Operate time with time delay = 0 ms

Approx. 25 ms + OOT28 at 50 Hz

Approx. 22 ms + OOT at 60 Hz

Dropout time Approx. 20 ms + OOT

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances for Stage Type Definite Time-Overvoltage Protection

Voltages

0.5 % of the setting value or 0.05 V

Time delays 1 % of the setting value or 10 ms

Tolerances for Stage Type Inverse Time-Overvoltage Protection

Voltages

0.5 % of the setting value or 0.05 V

Operate time for

1.2 ≤ V/V threshold value ≤ 20

5 % of the setting value or 30 ms

Reset time delay 1 % of the setting value or 10 ms

28

OOT (Output Operating Time) additional delay of the output medium used, see chapter 11.1.4 Relay Outputs

Technical Data

11.19 Overvoltage Protection with 3-Phase Voltage

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 599

C53000-G5040-C019-6, Edition 06.2016

Page 56

Overvoltage Protection with Positive-Sequence Voltage

Setting Values

Pickup value 0.300 V to 200.000 V Increments of 0.001 V

Time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout ratio 0.90 to 0.99 Increments of 0.01

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for the overvoltage and of 105 % for the

undervoltage functionality.

Minimum absolute dropout differential 150 mV sec.

Times

Operate time with time delay = 0 ms

Approx. 25 ms + OOT29 at 50 Hz

Approx. 22 ms + OOT at 60 Hz

Dropout time Approx. 20 ms + OOT

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Voltages

0.5 % of the setting value or 0.05 V

Time delays 1 % of the setting value or 10 ms

11.20

29

OOT (Output Operating Time) additional delay of the output medium used, see Chapter 11.1.4 Relay Outputs

Technical Data

11.20 Overvoltage Protection with Positive-Sequence Voltage

600 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 57

Overvoltage Protection with Negative-Sequence Voltage

Setting Values for the Function

Measuring window 1 cycle to 10 cycles Increments of 1 cycle

Setting Values

Pickup value of V2 0.300 V to 200.000 V Increments of 0.001 V

Operate delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout ratio 0.90 to 0.99 Increments of 0.01

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for the overvoltage and of 105 % for the

undervoltage functionality.

Minimum absolute dropout differential 150 mV sec.

Times

Pickup times

55 ms to 210 ms + OOT

30

(depends on the measuring-window length) at 50 Hz

48 ms to 185 ms + OOT

(depends on the measuring-window length) at 60 Hz

Dropout time 20 ms to 70 ms + OOT

(depends on the measuring-window length)

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Inactive

Tolerances

Voltages

0.50 % of the setting value or 0.050 V

Time delays 1.00 % of the setting value or 10 ms

11.21

30

OOT (Output Operating Time) additional delay of the output medium used, for example 5 ms with fast relays

Technical Data

11.21 Overvoltage Protection with Negative-Sequence Voltage

SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual 601

C53000-G5040-C019-6, Edition 06.2016

Page 58

Overvoltage Protection with Zero-Sequence Voltage/Residual

Voltage

Setting Values

Method of measurement RMS value

Fundamental component

Fundamental component over 2 cycle filters

Block. on measuring-voltage

outage

Yes

No

Determ. ph. aff. by grd. flt. Yes

No

Threshold value

31

0.300 V to 200.000 V Increments of 0.001 V

Time delay 0.00 s to 60.00 s Increments of 0.01 s

Pickup delay 0.00 s to 320.00 s Increments of 0.01 s

Dropout ratio 0.90 to 0.99 Increments of 0.01

V< faulted ph-gnd vltg. 0.300 V to 200 000 V Increments of 0.001 V

V> healthy ph-gnd. vltg. 0.300 V to 200 000 V Increments of 0.001 V

Times

Operate time with time delay = 0 ms

Standard filter, true RMS

Approx. 25 ms + OOT32 at 50 Hz

Approx. 22 ms + OOT at 60 Hz

2 cycle filters Approx. 45 ms + OOT at 50 Hz

Approx. 39 ms + OOT at 60 Hz

Dropout time

Standard filter, true RMS Approx. 20 ms + OOT at 50 Hz

Approx. 16.6 ms + OOT at 60 Hz

2 cycle filters Approx. 31.06 ms + OOT at 50 Hz

Approx. 27.06 ms + OOT at 60 Hz

Frequency Operating Range

0.9 f/f

rated

to 1.1 f/f

rated

According to specified tolerances

10 Hz to 0.9 f/f

rated

1.1 f/f

rated

to 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

Voltages

0.5 % of the setting value or 0.05 V

Time delays 1 % of the setting value or 10 ms

11.22

31

If you have selected the method of measurement = RMS value, do not set the threshold value under 10 V.

32

OOT (Output Operating Time) additional delay of the output medium used, see Chapter 11.1.4 Relay Outputs

Technical Data

11.22 Overvoltage Protection with Zero-Sequence Voltage/Residual Voltage

602 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Page 59

Overvoltage Protection with Any Voltage

Setting Values

Measured value Measured phase-to-ground voltage V

A

Measured phase-to-ground voltage V

B

Measured phase-to-ground voltage V

C

Measured phase-to-phase voltage V

AB

Measured phase-to-phase voltage V

BC

Measured phase-to-phase voltage V

CA

Measured phase-to-phase voltage V

AB

Measured phase-to-phase voltage V

BC

Measured phase-to-phase voltage V

CA

Calculated voltage V0

Method of measurement Fundamental component

RMS value

Pickup value

33