Siemens SIPROTEC 5, Siemens 7KE85 User Manual

Preface

Open Source Software

Table of Contents

SIPROTEC 5

Fault Recorder

7KE85

V7.50 and higher

Manual

Introduction

Basic Structure of the Function

System Functions

Applications

Power-System Data

Function-Group Types

Fault Recorder

Supervision Functions

Measured and Energy Values

1

2

3

4

5

6

7

8

9

C53000-G5040-C018-5

Functional Tests

Technical Data

Appendix

Glossary

Index

10

11

A

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

This document has been subjected to rigorous technical

review before being published. It is revised at regular intervals, and any modifications and amendments are included

in the subsequent issues. The content of this document has

been compiled for information purposes only. Although

Siemens AG has made best efforts to keep the document as

precise and up-to-date as possible, Siemens AG shall not

assume any liability for defects and damage which result

through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of

Siemens AG are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document from

time to time.

Document version: C53000-G5040-C018-5.03

Edition: 11.2017

Version of the product described: V7.50 and higher

Copyright

Copyright © Siemens AG 2017. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content

are not permitted, unless authorized in writing. All rights,

including rights created by patent grant or registration of a

utility model or a design, are reserved.

Registered Trademarks

SIPROTEC®, DIGSI®, SIGUARD®, SIMEAS®, and SICAM® are

registered trademarks of Siemens AG. Any unauthorized

use is illegal. All other designations in this document can

be trademarks whose use by third parties for their own

purposes can infringe the rights of the owner.

Preface

Purpose of the Manual

This manual describes the functions of the fault recorder 7KE85.

Target Audience

System configurers, commissioning engineers, and persons entrusted with the setting, testing and maintenance of fault recorder equipment, and operational crew in electrical installations and power plants.

Scope

This manual applies to the SIPROTEC 5 device family.

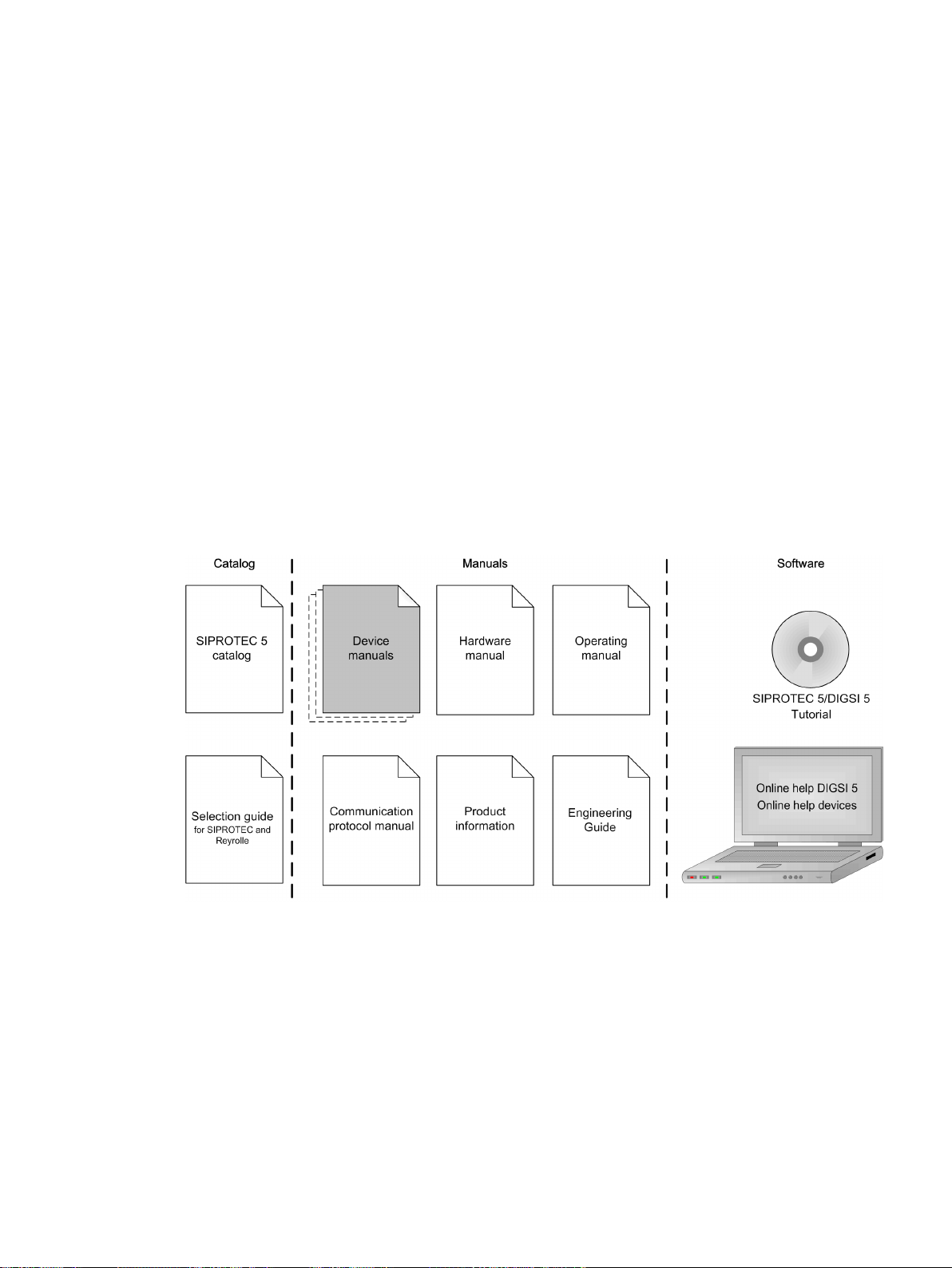

Further Documentation

[dwprefdm-221012-01.tif, 3, en_US]

Device manuals

•

Each Device manual describes the functions and applications of a specific SIPROTEC 5 device. The printed

manual and the online help for the device have the same informational structure.

Hardware manual

•

The Hardware manual describes the hardware building blocks and device combinations of the SIPROTEC 5

device family.

Operating manual

•

The Operating manual describes the basic principles and procedures for operating and assembling the

devices of the SIPROTEC 5 range.

SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

3

IND. CONT. EQ.

69CA

Preface

Communication protocol manual

•

The Communication protocol manual contains a description of the protocols for communication within

the SIPROTEC 5 device family and to higher-level network control centers.

Product information

•

The Product information includes general information about device installation, technical data, limiting

values for input and output modules, and conditions when preparing for operation. This document is

provided with each SIPROTEC 5 device.

Engineering Guide

•

The Engineering Guide describes the essential steps when engineering with DIGSI 5. In addition, the Engineering Guide shows you how to load a planned configuration to a SIPROTEC 5 device and update the

functionality of the SIPROTEC 5 device.

DIGSI 5 online help

•

The DIGSI 5 online help contains a help package for DIGSI 5 and CFC.

The help package for DIGSI 5 includes a description of the basic operation of software, the DIGSI princi-

ples and editors. The help package for CFC includes an introduction to CFC programming, basic examples

of working with CFC, and a reference chapter with all the CFC blocks available for the SIPROTEC 5 range.

SIPROTEC 5/DIGSI 5 Tutorial

•

The tutorial on the DVD contains brief information about important product features, more detailed information about the individual technical areas, as well as operating sequences with tasks based on practical

operation and a brief explanation.

SIPROTEC 5 catalog

•

The SIPROTEC 5 catalog describes the system features and the devices of SIPROTEC 5.

Selection guide for SIPROTEC and Reyrolle

•

The selection guide offers an overview of the device series of the Siemens protection devices, and a

device selection table.

Indication of Conformity

Other Standards

IEEE Std C 37.90

The technical data of the product is approved in accordance with UL.

For more information about the UL database, see certified.ul.com

Select Online Certifications Directory and enter E194016 as UL File Number.

This product complies with the directive of the Council of the European Communities

on harmonization of the laws of the Member States relating to electromagnetic

compatibility (EMC Directive 2014/30/EU) and concerning electrical equipment for use

within specified voltage limits (Low Voltage Directive 2014/35/EU).

This conformity has been proved by tests performed according to the Council Directive

in accordance with the product standard EN 60255-26 (for EMC directive) and with the

product standard EN 60255-27 (for Low Voltage Directive) by Siemens AG.

The device is designed and manufactured for application in an industrial environment.

The product conforms with the international standards of IEC 60255 and the German

standard VDE 0435.

[ul_listed_c_us, 1, --_--]

4 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Additional Support

!

!

!

For questions about the system, please contact your Siemens sales partner.

Support

Our Customer Support Center provides a 24-hour service.

Phone: +49 (180) 524-7000

Fax: +49 (180) 524-2471

E-Mail: support.energy@siemens.com

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldtstraße 59

90459 Nürnberg

Germany

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-7929

E-Mail: poweracademy@siemens.com

Internet: www.siemens.com/poweracademy

Preface

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment (module

or device). However, it comprises important information that must be followed for personal safety, as well as

to avoid material damage. Information is highlighted and illustrated as follows according to the degree of

danger:

DANGER

DANGER means that death or severe injury will result if the measures specified are not taken.

²

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

²

CAUTION

Comply with all instructions, in order to avoid death or severe injuries.

Comply with all instructions, in order to avoid death or severe injuries.

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

Comply with all instructions, in order to avoid moderate or minor injuries.

²

SIPROTEC 5, Fault Recorder, Manual 5

C53000-G5040-C018-5, Edition 11.2017

i

i

Preface

NOTICE

NOTICE means that property damage can result if the measures specified are not taken.

Comply with all instructions, in order to avoid property damage.

²

NOTE

Important information about the product, product handling or a certain section of the documentation

which must be given particular attention.

Qualified Electrical Engineering Personnel

Only qualified electrical engineering personnel may commission and operate the equipment (module, device)

described in this document. Qualified electrical engineering personnel in the sense of this manual are people

who can demonstrate technical qualifications as electrical technicians. These persons may commission,

isolate, ground and label devices, systems and circuits according to the standards of safety engineering.

Proper Use

The equipment (device, module) may be used only for such applications as set out in the catalogs and the

technical description, and only in combination with third-party equipment recommended and approved by

Siemens.

Problem-free and safe operation of the product depends on the following:

Proper transport

•

Proper storage, setup and installation

•

Proper operation and maintenance

•

When electrical equipment is operated, hazardous voltages are inevitably present in certain parts. If proper

action is not taken, death, severe injury or property damage can result:

The equipment must be grounded at the grounding terminal before any connections are made.

•

All circuit components connected to the power supply may be subject to dangerous voltage.

•

Hazardous voltages may be present in equipment even after the supply voltage has been disconnected

•

(capacitors can still be charged).

Operation of equipment with exposed current-transformer circuits is prohibited. Before disconnecting the

•

equipment, ensure that the current-transformer circuits are short-circuited.

The limiting values stated in the document must not be exceeded. This must also be considered during

•

testing and commissioning.

6 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Open Source Software

i

i

The product contains, among other things, Open Source Software developed by third parties. The Open

Source Software used in the product and the license agreements concerning this software can be found in the

Readme_OSS. These Open Source Software files are protected by copyright. Your compliance with those

license conditions will entitle you to use the Open Source Software as foreseen in the relevant license. In the

event of conflicts between Siemens license conditions and the Open Source Software license conditions, the

Open Source Software conditions shall prevail with respect to the Open Source Software portions of the software. The Open Source Software is licensed royalty-free. Insofar as the applicable Open Source Software

License Conditions provide for it you can order the source code of the Open Source Software from your

Siemens sales contact - against payment of the shipping and handling charges - for a period of at least 3 years

since purchase of the Product. We are liable for the Product including the Open Source Software contained in

it pursuant to the license conditions applicable to the Product. Any liability for the Open Source Software

beyond the program flow intended for the Product is explicitly excluded. Furthermore any liability for defects

resulting from modifications to the Open Source Software by you or third parties is excluded. We do not

provide any technical support for the Product if it has been modified.

When using DIGSI 5 in online mode, you are provided with the option to go to the main menu Show open

source software information and read and display the Readme_OSS file containing the original license text

and copyright information.

To do this, the following steps are necessary:

Switch to online mode.

•

Select the device.

•

Select Online in the menu bar.

•

Click Show open source software information.

•

NOTE

To read the Readme_OSS file, a PDF viewer must be installed on the computer.

In order to operate SIPROTEC 5 devices, a valid DIGSI 5 license is required.

SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

7

8 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

Preface..........................................................................................................................................................3

Open Source Software..................................................................................................................................7

1 Introduction................................................................................................................................................19

1.1 General.............................................................................................................................20

1.2 Properties of SIPROTEC 5................................................................................................... 21

1.3 Properties of the Fault Recorder.........................................................................................23

1.4 Parameterization and Analysis Software............................................................................ 25

1.4.1 DIGSI 5 ....................................................................................................................... 25

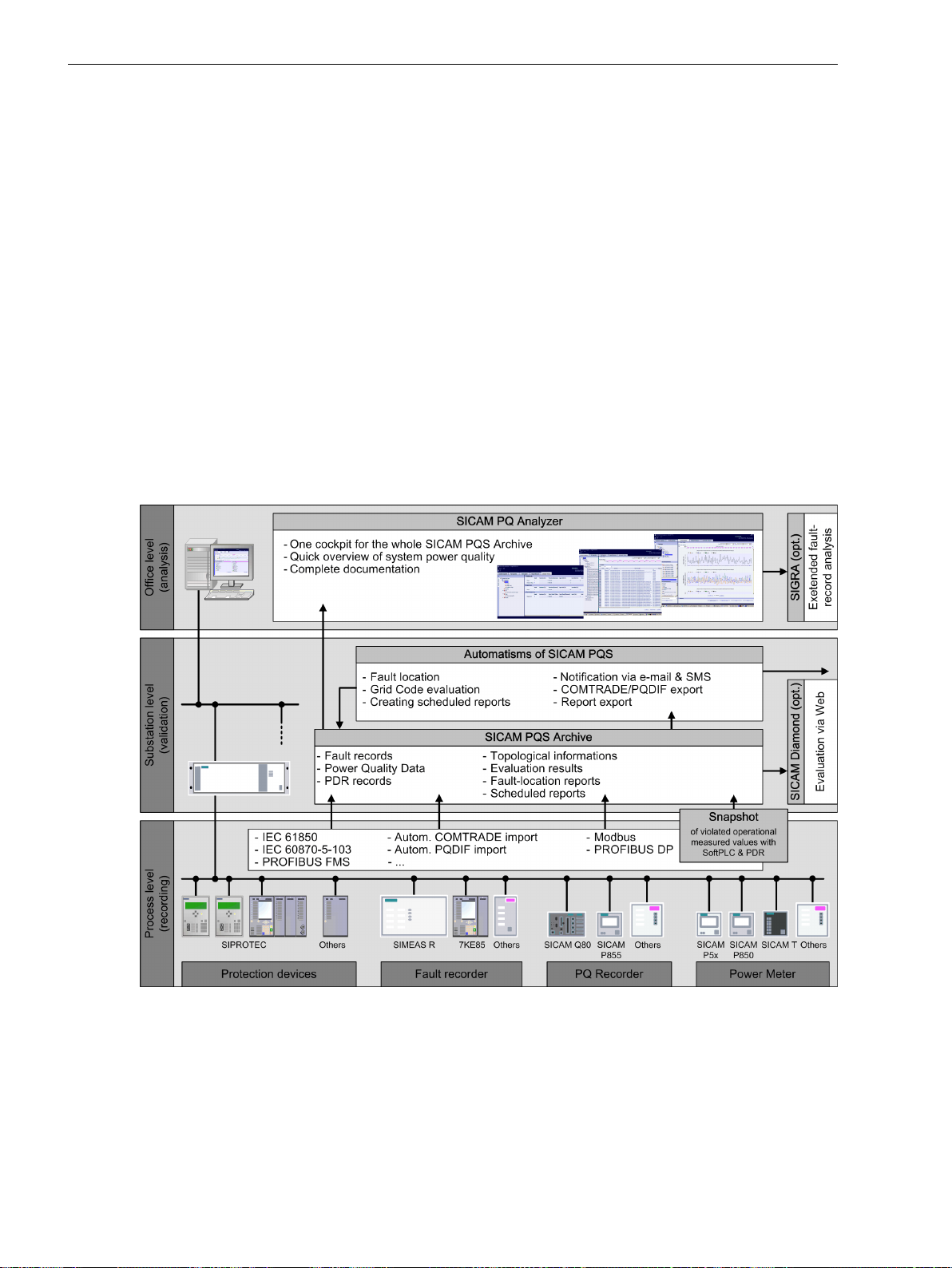

1.4.2 SICAM PQS/SICAM PQ Analyzer.................................................................................... 25

1.5 Scope of Functions............................................................................................................28

2 Basic Structure of the Function.................................................................................................................. 31

2.1 Function Embedding in the Device.................................................................................... 32

2.2 Adjustment of Application Templates/Functional Scope..................................................... 35

2.3 Function Control .............................................................................................................. 37

2.4 Text Structure and Reference Number for Parameter and Indications .................................39

3 System Functions....................................................................................................................................... 41

3.1 Indications........................................................................................................................42

3.1.1 General ...................................................................................................................... 42

3.1.2 Reading Indications on the On-Site Operation Panel .................................................... 42

3.1.3 Reading Indications from the PC with DIGSI 5...............................................................44

3.1.4 Display of Indications ..................................................................................................45

3.1.5 Logs............................................................................................................................ 46

3.1.5.1 General .................................................................................................................46

3.1.5.2 Operational Log .................................................................................................... 47

3.1.5.3 User-Defined Log .................................................................................................. 49

3.1.5.4 Sequence of Events Log......................................................................................... 52

3.1.6 Setting-History Log ..................................................................................................... 54

3.1.7 Communication Log.................................................................................................... 56

3.1.8 Security Log ................................................................................................................57

3.1.9 Device-Diagnosis Log .................................................................................................. 59

3.1.10 Saving and Deleting the Log ....................................................................................... 60

3.1.11 Stored Indications in the SIPROTEC 5 Device ................................................................62

3.1.12 Test Mode and Influence of Indications on Substation Automation Technology ............64

3.2 Measured-Value Acquisition ............................................................................................. 65

3.3 Processing Quality Attributes.............................................................................................67

3.3.1 Overview.....................................................................................................................67

3.3.2 Quality Processing/Affected by the User for Received GOOSE Values............................. 69

SIPROTEC 5, Fault Recorder, Manual 9

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

3.3.3 Quality Processing/Affected by the User in CFC Charts.................................................. 74

3.3.4 Quality Processing/Affected by the User in Internal Device Functions............................ 78

3.4 Date and Time Synchronization......................................................................................... 82

3.4.1 Overview of Functions.................................................................................................82

3.4.2 Structure of the Function.............................................................................................82

3.4.3 Function Description....................................................................................................82

3.4.4 Settings.......................................................................................................................85

3.4.5 Information List...........................................................................................................86

3.5 User-Defined Objects........................................................................................................ 87

3.5.1 Overview.....................................................................................................................87

3.5.2 Basic Data Types.......................................................................................................... 88

3.5.3 Energy Metered Values ............................................................................................... 91

3.5.4 Additional Data Types.................................................................................................. 91

3.5.5 External Signals........................................................................................................... 91

3.6 Other Functions................................................................................................................ 92

3.6.1 Indication Filtering and Chatter Blocking for Input Signals ........................................... 92

3.7 General Notes for Setting the Threshold Value of Trigger Functions................................... 95

3.7.1 Overview ....................................................................................................................95

3.7.2 Modifying the Transformer Ratios in DIGSI 5 ................................................................95

3.7.3 Changing the Transformation Ratios of the Transformer on the Device ...................... 102

4 Applications..............................................................................................................................................103

4.1 Overview........................................................................................................................ 104

4.2 Application Template and Functional Scope for the Fault Recorder ..................................105

5 Power-System Data...................................................................................................................................109

5.1 Overview........................................................................................................................ 110

5.2 Structure of the Power-System Data................................................................................ 111

5.3 Application and Setting Notes – General Settings............................................................ 112

5.4 Application and Setting Notes for Measuring Point Current 3-Phase (I-3ph)......................113

5.5 Application and Setting Notes for Measuring Point Current 1-Phase (I-1ph)......................116

5.6 Application and Setting Notes for Measuring Point Voltage 3-Phase (V-3ph).....................118

5.7 Application and Setting Notes for Measuring Point Voltage 1-Phase (V-1ph).....................122

5.8 Settings.......................................................................................................................... 124

5.9 Information List.............................................................................................................. 131

6 Function-Group Types.............................................................................................................................. 135

6.1 Function-Group Type Voltage 3-Phase............................................................................. 136

6.1.1 Overview...................................................................................................................136

6.1.2 Structure of the Function Group................................................................................ 136

6.1.3 Application and Setting Notes....................................................................................138

6.1.4 Settings.....................................................................................................................138

6.1.5 Information List.........................................................................................................139

6.2 Function-Group Type Voltage/current 1-Phase................................................................. 140

6.2.1 Overview of Functions...............................................................................................140

6.2.2 Structure of the Function Group................................................................................ 140

6.2.3 Application and Setting Notes....................................................................................143

10 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

6.2.4 Write-Protected Settings............................................................................................ 144

6.2.5 Settings.....................................................................................................................144

6.2.6 Information List.........................................................................................................144

6.3 Function-Group Type Voltage/current 3-Phase................................................................. 145

6.3.1 Overview...................................................................................................................145

6.3.2 Structure of the Function Group................................................................................ 146

6.3.3 Application and Setting Notes ................................................................................... 149

6.3.4 Settings.....................................................................................................................150

6.3.5 Information List.........................................................................................................150

6.4 Function-Group Type Phasor Measurement Unit (PMU)....................................................152

6.4.1 Overview of Functions...............................................................................................152

6.4.2 Structure of the Function Group................................................................................ 152

6.4.3 Function Description..................................................................................................152

6.4.4 Transmitted Data.......................................................................................................157

6.4.5 PMU Communication (IEEE C37.118)......................................................................... 157

6.4.6 Parameterizing the PMU with DIGSI............................................................................158

6.4.7 Parameterizing the PMU on the Device.......................................................................167

6.4.8 Application and Setting Notes....................................................................................169

6.4.9 Settings.....................................................................................................................170

6.4.10 Information List.........................................................................................................170

6.5 Function-Group Type Analog Units.................................................................................. 171

6.5.1 Overview...................................................................................................................171

6.5.2 Structure of the Function Group................................................................................ 171

6.5.3 20-mA Unit Ethernet..................................................................................................173

6.5.3.1 Overview ............................................................................................................ 173

6.5.3.2 Structure of the Function..................................................................................... 173

6.5.3.3 Communication with 20-mA Unit Ethernet .......................................................... 174

6.5.3.4 Application and Setting Notes ............................................................................. 175

6.5.3.5 20-mA Channel....................................................................................................175

6.5.3.6 Application and Setting Notes.............................................................................. 178

6.5.3.7 Settings............................................................................................................... 179

6.5.3.8 Information List................................................................................................... 180

6.5.4 20-mA Unit Serial...................................................................................................... 180

6.5.4.1 Overview ............................................................................................................ 180

6.5.4.2 Application and Setting Notes.............................................................................. 180

6.5.4.3 Settings............................................................................................................... 182

6.5.4.4 Information List................................................................................................... 183

6.5.5 Communication with 20-mA Unit...............................................................................183

6.5.5.1 Integration of a Serial 20-mA Unit ........................................................................183

6.5.5.2 Integration of a 20-mA Unit Ethernet ...................................................................186

6.5.6 V/I-Measuring-Transducer Unit with Fast Inputs..........................................................188

6.5.6.1 Overview............................................................................................................. 188

6.5.6.2 Structure of the Function..................................................................................... 189

6.5.6.3 Function Description............................................................................................ 189

6.5.6.4 Application and Setting Notes.............................................................................. 190

6.5.6.5 Settings............................................................................................................... 194

6.5.6.6 Information List................................................................................................... 196

6.5.7 RTD Unit Ethernet......................................................................................................196

6.5.7.1 Overview............................................................................................................. 196

6.5.7.2 Structure of the Function..................................................................................... 196

6.5.7.3 Communication with an RTD Unit ........................................................................ 197

SIPROTEC 5, Fault Recorder, Manual 11

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

6.5.7.4 Application and Setting Notes.............................................................................. 198

6.5.7.5 Temperature Sensor.............................................................................................199

6.5.7.6 Application and Setting Notes ............................................................................. 199

6.5.7.7 Settings............................................................................................................... 200

6.5.7.8 Information List................................................................................................... 201

6.5.8 RTD Unit, Serial..........................................................................................................203

6.5.8.1 Overview ............................................................................................................ 203

6.5.8.2 Application and Setting Notes ............................................................................. 203

6.5.8.3 Settings............................................................................................................... 203

6.5.8.4 Information List................................................................................................... 204

6.5.9 Communication with RTD Unit................................................................................... 206

6.5.9.1 Integration of a Serial RTD Unit (Ziehl TR1200) .....................................................206

6.5.9.2 Integration of an RTD-Unit Ethernet (TR1200 IP) .................................................. 208

6.5.9.3 Temperature Simulation without Sensors ............................................................ 211

7 Fault Recorder.......................................................................................................................................... 213

7.1 Introduction to DIGSI 5....................................................................................................214

7.1.1 General..................................................................................................................... 214

7.1.2 Step 1: Creating a New Project and Adding a New Device .......................................... 214

7.1.3 Step 2: Setting the Parameters and Routing in DIGSI 5 ...............................................217

7.1.4 Step 3: Evaluating Recordings.................................................................................... 225

7.1.5 Working with IEC 61850............................................................................................ 228

7.2 Function-Group Type Recorder........................................................................................ 231

7.2.1 Overview of Functions .............................................................................................. 231

7.2.2 Structure of the Function Group................................................................................ 231

7.2.3 Function Description..................................................................................................232

7.2.4 Application and Setting Notes – General Settings....................................................... 234

7.2.5 Time Jumps............................................................................................................... 235

7.2.6 Fast-Scan Recorder.................................................................................................... 236

7.2.6.1 Overview of Functions......................................................................................... 236

7.2.6.2 Structure of the Function .................................................................................... 236

7.2.6.3 Function Description ........................................................................................... 236

7.2.6.4 Application and Setting Notes ............................................................................. 238

7.2.6.5 Settings............................................................................................................... 240

7.2.6.6 Information List................................................................................................... 240

7.2.7 Slow-Scan Recorder................................................................................................... 241

7.2.7.1 Overview of Functions .........................................................................................241

7.2.7.2 Structure of the Function .................................................................................... 241

7.2.7.3 Function Description ........................................................................................... 241

7.2.7.4 Application and Setting Notes ............................................................................. 244

7.2.7.5 Settings............................................................................................................... 246

7.2.7.6 Information List................................................................................................... 246

7.2.8 Continuous Recorder................................................................................................. 247

7.2.8.1 Overview of Functions .........................................................................................247

7.2.8.2 Structure of the Function .................................................................................... 247

7.2.8.3 Function Description ........................................................................................... 247

7.2.8.4 Application and Setting Notes ............................................................................. 248

7.2.8.5 Settings............................................................................................................... 249

7.2.8.6 Information List................................................................................................... 250

7.2.9 Trend Recorder.......................................................................................................... 250

7.2.9.1 Overview of Functions .........................................................................................250

7.2.9.2 Structure of the Function .................................................................................... 250

7.2.9.3 Function Description ........................................................................................... 250

7.2.9.4 Application and Setting Notes ............................................................................. 252

12 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

7.2.9.5 Settings............................................................................................................... 252

7.2.9.6 Information List................................................................................................... 253

7.2.10 Sequence of Events................................................................................................... 253

7.2.10.1 Overview of Functions......................................................................................... 253

7.2.11 Flow Control of Fault Records (Fast-Scan and Slow-Scan Recorder)............................. 253

7.2.11.1 Function Description of the Retrigger Blocking Time ............................................ 253

7.2.11.2 Triggering Without the Retrigger Blocking Time ................................................... 254

7.2.11.3 Triggering With the Retrigger Blocking Time......................................................... 255

7.3 Function Description Analog and Binary Triggers............................................................. 262

7.3.1 Overview of Functions .............................................................................................. 262

7.3.2 Function Description Analog Trigger.......................................................................... 262

7.3.2.1 Structure of the Analog Trigger............................................................................ 262

7.3.2.2 Trigger Functions of the Analog Trigger ...............................................................263

7.3.2.3 Level Trigger ....................................................................................................... 264

7.3.2.4 Gradient Trigger (dM/dt) ......................................................................................264

7.3.3 Function Description Binary Trigger........................................................................... 265

7.3.3.1 Manual Trigger Start............................................................................................ 265

7.3.3.2 External Trigger Start ...........................................................................................268

7.3.3.3 GOOSE Trigger .................................................................................................... 268

7.3.3.4 Trigger Start Using Logic Block Chart.................................................................... 269

7.3.3.5 Triggers on Indications ........................................................................................ 269

7.4 Trigger Functions 1-Phase............................................................................................... 271

7.4.1 Voltage Trigger..........................................................................................................271

7.4.1.1 Overview of Functions......................................................................................... 271

7.4.1.2 Structure of the Function..................................................................................... 271

7.4.1.3 Function Description............................................................................................ 271

7.4.1.4 Application and Setting Notes Trig V RMS (RMS Value)..........................................273

7.4.1.5 Application and Setting Notes Trig V Fund (Fundamental Component)..................274

7.4.1.6 Settings............................................................................................................... 276

7.4.1.7 Information List................................................................................................... 277

7.4.2 Current Trigger..........................................................................................................277

7.4.2.1 Overview of Functions......................................................................................... 277

7.4.2.2 Structure of the Function .................................................................................... 277

7.4.2.3 Function Description............................................................................................ 278

7.4.2.4 Application and Setting Notes I RMS Trig.............................................................. 279

7.4.2.5 Application and Setting Notes I Fund. Trig............................................................ 281

7.4.2.6 Settings............................................................................................................... 282

7.4.2.7 Information List................................................................................................... 284

7.4.3 Frequency Trigger..................................................................................................... 285

7.4.3.1 Overview of Functions......................................................................................... 285

7.4.3.2 Structure of the Function..................................................................................... 285

7.4.3.3 Function Description............................................................................................ 285

7.4.3.4 Application and Setting Notes - Frequency Trigger................................................287

7.4.3.5 Settings............................................................................................................... 288

7.4.3.6 Information List................................................................................................... 289

7.4.4 Power Trigger............................................................................................................289

7.4.4.1 Overview of Functions......................................................................................... 289

7.4.4.2 Structure of the Function..................................................................................... 289

7.4.4.3 Function Description............................................................................................ 290

7.4.4.4 Application and Setting Notes – Trigger P............................................................. 291

7.4.4.5 Application and Setting Notes – Trigger Q............................................................ 293

7.4.4.6 Settings............................................................................................................... 294

7.4.4.7 Information List................................................................................................... 296

SIPROTEC 5, Fault Recorder, Manual 13

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

7.5 Trigger Functions 3-Phase............................................................................................... 297

7.5.1 Voltage Trigger..........................................................................................................297

7.5.1.1 Overview of Functions .........................................................................................297

7.5.1.2 Structure of the Function .................................................................................... 297

7.5.1.3 Function Description............................................................................................ 297

7.5.1.4 Application and Setting Notes Trig V Fund (Fundamental Component)..................299

7.5.1.5 Application and Setting Notes Trig V RMS (RMS Value)..........................................302

7.5.1.6 Application and Setting Notes - V0 Trigger (Zero-Sequence System)......................305

7.5.1.7 Application and Setting Notes - V1 Trigger (Positive-Sequence System)................. 306

7.5.1.8 Application and Setting Notes - V2 Trigger (Negative-Sequence System)............... 307

7.5.1.9 Settings............................................................................................................... 308

7.5.1.10 Information List................................................................................................... 312

7.5.2 Current Trigger..........................................................................................................312

7.5.2.1 Overview of Functions .........................................................................................312

7.5.2.2 Structure of the Function .................................................................................... 312

7.5.2.3 Function Description............................................................................................ 313

7.5.2.4 Application and Setting Notes I Fund. Trig............................................................ 315

7.5.2.5 Application and Setting Notes Trigger I RMS......................................................... 317

7.5.2.6 Application and Setting Notes - I0 Trigger (Zero-Sequence System).......................320

7.5.2.7 Application and Setting Notes I1 Trigger (Positive-Sequence System).................... 321

7.5.2.8 Application and Setting Notes - I2 Trigger (Negative-Sequence System)................ 322

7.5.2.9 Settings............................................................................................................... 323

7.5.2.10 Information List................................................................................................... 330

7.5.3 Frequency Trigger..................................................................................................... 331

7.5.3.1 Overview of Functions......................................................................................... 331

7.5.3.2 Structure of the Function .................................................................................... 331

7.5.3.3 Function Description............................................................................................ 332

7.5.3.4 Application and Setting Notes - Frequency Trigger................................................333

7.5.3.5 Settings............................................................................................................... 334

7.5.3.6 Information List................................................................................................... 335

7.5.4 Power Trigger............................................................................................................335

7.5.4.1 Overview of Functions......................................................................................... 335

7.5.4.2 Structure of the Function..................................................................................... 335

7.5.4.3 Function Description ........................................................................................... 336

7.5.4.4 Application and Setting Notes Trigger Psum..........................................................338

7.5.4.5 Application and Setting Notes Qsum Trig..............................................................339

7.5.4.6 Application and Setting Notes Trigger Ssum..........................................................341

7.5.4.7 Function Description Trigger Power Swing............................................................342

7.5.4.8 Application and Setting Notes, Trigger Power Swing............................................. 343

7.5.4.9 Settings............................................................................................................... 344

7.5.4.10 Information List................................................................................................... 346

7.6 Measurands and Recorder Routing Functions...................................................................348

7.6.1 Measurands...............................................................................................................348

7.6.1.1 Properties of Measurands .................................................................................... 348

7.6.1.2 Using Measurands ...............................................................................................348

7.6.1.3 Routing the Measurands in DIGSI 5 for Processing in SICAM PQS........................... 353

7.6.2 Recorder Routing V.................................................................................................... 353

7.6.2.1 Overview of Functions......................................................................................... 353

7.6.2.2 Structure of the Function..................................................................................... 353

7.6.2.3 Indications .......................................................................................................... 353

7.6.2.4 Application and Setting Notes.............................................................................. 354

7.6.2.5 Settings............................................................................................................... 354

7.6.2.6 Information List................................................................................................... 355

7.6.3 Recorder Routing VI 1-Phase...................................................................................... 356

7.6.3.1 Overview of Functions......................................................................................... 356

7.6.3.2 Structure of the Function..................................................................................... 356

14 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

7.6.3.3 Application and Setting Notes ............................................................................. 356

7.6.3.4 Information List................................................................................................... 356

7.6.4 Recorder Routing VI 3-Phase...................................................................................... 357

7.6.4.1 Overview of Functions......................................................................................... 357

7.6.4.2 Structure of the Function..................................................................................... 357

7.6.4.3 Application and Setting Notes.............................................................................. 357

7.6.4.4 Settings............................................................................................................... 358

7.6.4.5 Information List................................................................................................... 358

7.6.5 V/I Measuring-Transducer Unit with Fast Inputs..........................................................360

7.6.5.1 Overview of Functions......................................................................................... 360

7.6.5.2 Information List................................................................................................... 360

8 Supervision Functions.............................................................................................................................. 361

8.1 Overview........................................................................................................................ 362

8.2 Resource-Consumption Supervision.................................................................................363

8.2.1 Load Model............................................................................................................... 363

8.2.2 Function Points..........................................................................................................364

8.2.3 CFC Resources........................................................................................................... 365

8.3 Supervision of the Secondary System.............................................................................. 367

8.3.1 Signaling-Voltage Supervision....................................................................................367

8.3.1.1 Overview of Functions......................................................................................... 367

8.3.1.2 Structure of the Function..................................................................................... 367

8.3.1.3 Function Description............................................................................................ 367

8.3.1.4 Application and Setting Notes.............................................................................. 369

8.3.1.5 Settings............................................................................................................... 370

8.3.1.6 Information List................................................................................................... 372

8.3.2 Voltage-Balance Supervision...................................................................................... 372

8.3.2.1 Overview of Functions .........................................................................................372

8.3.2.2 Structure of the Function..................................................................................... 372

8.3.2.3 Function Description............................................................................................ 372

8.3.2.4 Application and Setting Notes.............................................................................. 374

8.3.2.5 Settings............................................................................................................... 374

8.3.2.6 Information List................................................................................................... 374

8.3.3 Voltage-Sum Supervision........................................................................................... 375

8.3.3.1 Overview of Functions .........................................................................................375

8.3.3.2 Structure of the Function .................................................................................... 375

8.3.3.3 Function Description............................................................................................ 375

8.3.3.4 Application and Setting Notes.............................................................................. 377

8.3.3.5 Settings............................................................................................................... 377

8.3.3.6 Information List................................................................................................... 377

8.3.4 Voltage Phase-Rotation Supervision........................................................................... 378

8.3.4.1 Overview of Functions .........................................................................................378

8.3.4.2 Structure of the Function .................................................................................... 378

8.3.4.3 Function Description............................................................................................ 378

8.3.4.4 Application and Setting Notes ............................................................................. 379

8.3.4.5 Settings............................................................................................................... 379

8.3.4.6 Information List................................................................................................... 379

8.3.5 Broken-Wire Detection...............................................................................................380

8.3.5.1 Overview of Functions .........................................................................................380

8.3.5.2 Structure of the Function..................................................................................... 380

8.3.5.3 Function Description............................................................................................ 381

8.3.5.4 Application and Setting Notes.............................................................................. 383

8.3.5.5 Settings............................................................................................................... 383

8.3.5.6 Information List................................................................................................... 383

SIPROTEC 5, Fault Recorder, Manual 15

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

8.3.6 Current-Balance Supervision...................................................................................... 384

8.3.6.1 Overview of Functions .........................................................................................384

8.3.6.2 Structure of the Function .................................................................................... 384

8.3.6.3 Function Description............................................................................................ 384

8.3.6.4 Application and Setting Notes.............................................................................. 385

8.3.6.5 Settings............................................................................................................... 386

8.3.6.6 Information List................................................................................................... 386

8.3.7 Current-Sum Supervision........................................................................................... 386

8.3.7.1 Overview of Functions .........................................................................................386

8.3.7.2 Structure of the Function..................................................................................... 387

8.3.7.3 Function Description............................................................................................ 387

8.3.7.4 Application and Setting Notes.............................................................................. 389

8.3.7.5 Settings............................................................................................................... 389

8.3.7.6 Information List................................................................................................... 390

8.3.8 Current Phase-Rotation Supervision........................................................................... 390

8.3.8.1 Overview of Functions .........................................................................................390

8.3.8.2 Structure of the Function .................................................................................... 390

8.3.8.3 Function Description............................................................................................ 391

8.3.8.4 Application and Setting Notes ............................................................................. 392

8.3.8.5 Settings............................................................................................................... 392

8.3.8.6 Information List................................................................................................... 392

8.4 Supervision of the Device Hardware................................................................................ 393

8.4.1 Overview...................................................................................................................393

8.4.2 Analog-Channel Supervision via Fast Current-Sum......................................................394

8.4.2.1 Overview of Functions......................................................................................... 394

8.4.2.2 Structure of the Function..................................................................................... 395

8.4.2.3 Function Description............................................................................................ 395

8.5 Supervision of Device Firmware.......................................................................................398

8.6 Supervision of Hardware Configuration........................................................................... 399

8.7 Supervision of Communication Connections....................................................................400

8.8 Error Responses and Corrective Measures........................................................................ 401

8.8.1 Overview...................................................................................................................401

8.8.2 Defect Severity 1....................................................................................................... 402

8.8.3 Defect Severity 2....................................................................................................... 405

8.8.4 Defect Severity 3....................................................................................................... 406

8.8.5 Defect Severity 4 (Group Alarm).................................................................................407

8.9 Group Indications............................................................................................................409

9 Measured and Energy Values................................................................................................................... 411

9.1 Overview of Functions.................................................................................................... 412

9.2 Structure of the Function................................................................................................ 413

9.3 Operational Measured Values..........................................................................................414

9.4 Fundamental and Symmetrical Components....................................................................416

9.5 Average Values............................................................................................................... 417

9.5.1 Function Description of Average Values..................................................................... 417

9.5.2 Application and Setting Notes for Average Values...................................................... 417

9.6 Minimum/Maximum Values.............................................................................................420

9.6.1 Function Description of Minimum/Maximum Values...................................................420

9.6.2 Application and Setting Notes for Minimum/Maximum Values....................................421

16 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Table of Contents

10 Functional Tests........................................................................................................................................423

10.1 Overview ....................................................................................................................... 424

10.2 Directional Test .............................................................................................................. 425

11 Technical Data.......................................................................................................................................... 427

11.1 General Device Data........................................................................................................428

11.1.1 Supply Voltage.......................................................................................................... 428

11.1.2 Binary Inputs............................................................................................................. 429

11.1.3 Relay Outputs............................................................................................................430

11.1.4 Design Data...............................................................................................................432

11.1.5 Influencing Variables for Measured Values ................................................................ 434

11.1.6 SDHC Memory Card .................................................................................................. 434

11.2 Date and Time Synchronization ...................................................................................... 436

11.3 Phasor Measurement Unit............................................................................................... 437

11.4 Recorder Functions......................................................................................................... 438

11.4.1 Fast-Scan Recorder.................................................................................................... 438

11.4.2 Slow-Scan Recorder................................................................................................... 438

11.4.3 Continuous Recorder................................................................................................. 439

11.4.4 Trend Recorder.......................................................................................................... 439

11.4.5 Measured Values and Binary Inputs ........................................................................... 439

11.5 Supervision Functions..................................................................................................... 441

11.5.1 Voltage-Balance Supervision ..................................................................................... 441

11.5.2 Voltage-Sum Supervision........................................................................................... 441

11.5.3 Voltage Phase-Rotation Supervision .......................................................................... 441

11.5.4 Broken-Wire Detection .............................................................................................. 442

11.5.5 Current-Balance Supervision...................................................................................... 442

11.5.6 Current-Sum Supervision........................................................................................... 442

11.5.7 Current Phase-Rotation Supervision ...........................................................................443

11.5.8 Analog Channel Supervision via Fast Current Sum ..................................................... 443

11.6 Operational Measured Values and Statistical Values.........................................................444

11.7 CFC.................................................................................................................................448

A Appendix.................................................................................................................................................. 453

A.1 Order Configurator and Order Options.............................................................................454

A.2 Typographic and Symbol Conventions.............................................................................455

A.3 Standard Variants for 7KE85............................................................................................458

A.4 Connection Examples for Current Transformers............................................................... 462

A.5 Connection Examples of Voltage Transformers for Modular Devices.................................465

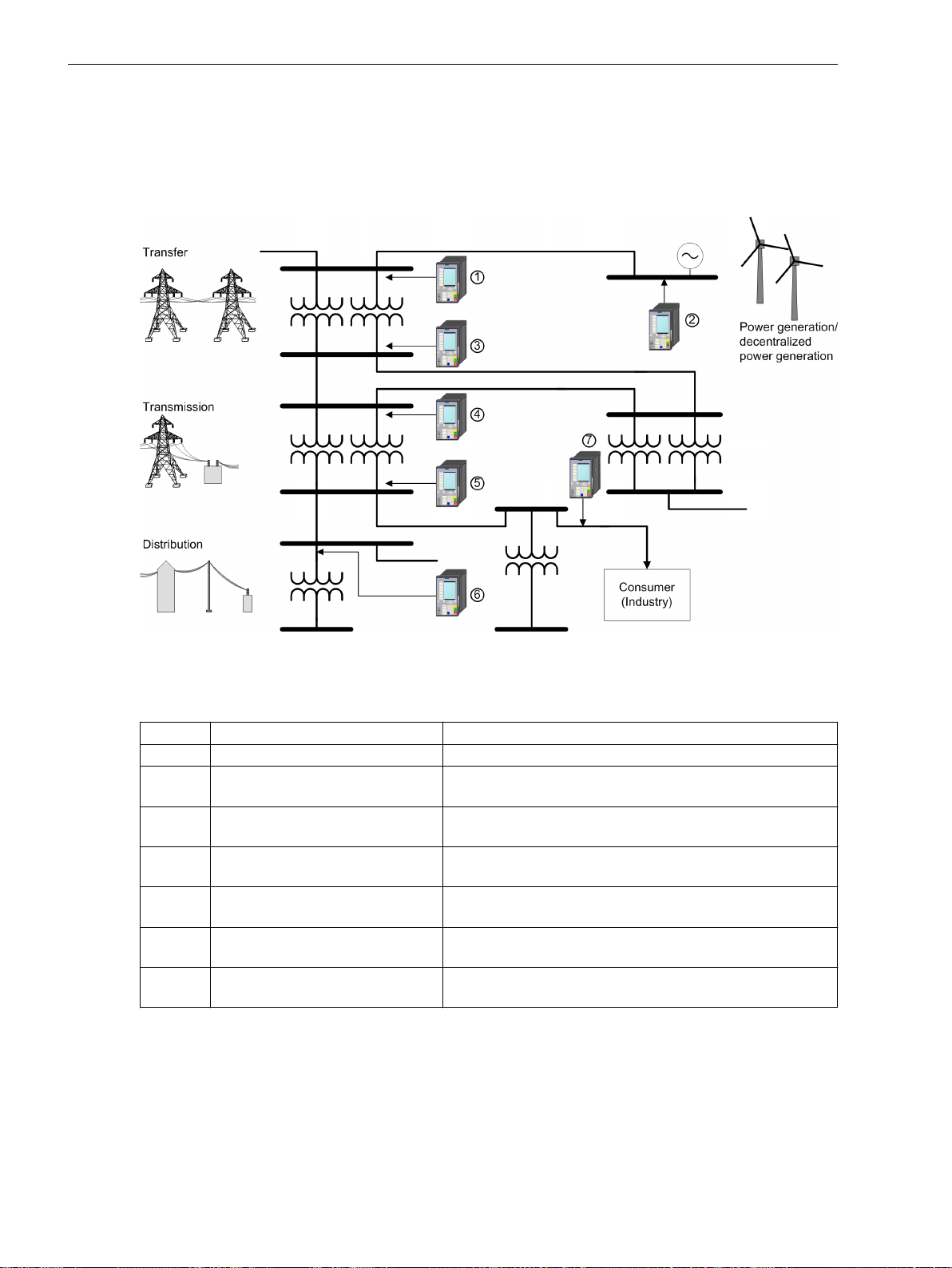

A.6 Application Examples of the Fault Recorder .................................................................... 468

A.7 Shielding Concept ..........................................................................................................471

A.8 SDHC Memory Card ........................................................................................................472

A.9 Troubleshooting SDHC Memory Card ..............................................................................474

Glossary.................................................................................................................................................... 475

Index.........................................................................................................................................................487

SIPROTEC 5, Fault Recorder, Manual 17

C53000-G5040-C018-5, Edition 11.2017

18 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

1

Introduction

1.1 General 20

1.2 Properties of SIPROTEC 5 21

1.3 Properties of the Fault Recorder 23

1.4 Parameterization and Analysis Software 25

1.5 Scope of Functions 28

SIPROTEC 5, Fault Recorder, Manual 19

C53000-G5040-C018-5, Edition 11.2017

Introduction

1.1 General

1.1

General

The protection of power distribution equipment is crucial in assuring a reliable electricity supply. The user

expects full availability of electrical energy at a consistently high standard of quality. Thus, for power-system

protection, for example, it is becoming increasingly difficult to distinguish between critical load cases and

short-circuits with minimum fault currents. The demands on optimum use and the corresponding parameterization of protection devices are rising. Intensive evaluation of available information from secondary equipment (using fault recorders) is therefore essential. This is the only way to ensure today's currently high levels

of reliability and availability in electricity transmission and distribution systems for the future as well.

A new era has begun for fault recording with the introduction of the SIPROTEC 5 series. The 7KE85 fault

recorder was developed especially for the requirements of the changing energy market, both current and

future. Powerful, reliable monitoring, combined with the flexible engineering and communication options,

offers the basis for maximum reliability of supply.

20 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Introduction

1.2 Properties of SIPROTEC 5

1.2

General Properties

Properties of SIPROTEC 5

The SIPROTEC 5 devices at the bay level are compact and can be installed directly in medium- and high-voltage

switchgear. They are characterized by seamless integration of fault recorder, protection, and control functions.

Powerful microprocessor

•

Fully digital measured-value processing and control, from sampling and digitizing of measurands to

•

closing and tripping decisions for the circuit breaker

Complete galvanic and interference-free isolation of the internal processing switches from the system

•

measuring, control, and supply circuits through instrument transformers, binary input and output

modules, and DC and AC voltage converters

Easy operation via an integrated operation and display panel, or via a connected personal computer with

•

user interface

Continuous calculation and presentation of measured values on the front display

•

Storage of min/max measured values and storage of long-term average values

•

Storage of fault indications for system incidents (faults in system) with real-time assignment and instan-

•

taneous values for fault recording

Continuous monitoring of the measurands as well as the device hardware and software

•

Communication with central control and storage devices possible via the device interface

•

Battery-buffered, synchronizable clock

•

Microcomputer System

All device functions are processed in the microcomputer system.

This includes, for example:

Filtering and preparation of the measurands

•

Constant monitoring of the measurands

•

Monitoring of the trigger conditions for the individual functions

•

Querying of limiting values and time-outs

•

Controlling of signals for the logic functions

•

Storage of indications, fault data, and fault values for fault analysis

•

Administration of the operating system and its functions, such as data storage, real-time clock, communi-

•

cation, interfaces, etc.

External distribution of information

•

Modular Concept

The SIPROTEC 5 modular concept ensures the consistency and integrity of all functionalities across the entire

device series. Significant features here include:

Modular system design in hardware, software, and communication

•

The same expansion and communication modules for all devices in the SIPROTEC 5 family

•

Innovative terminal technology with easy assembly and interchangeability and the highest possible

•

degree of safety

The same functions can be configured individually across the entire family of devices

•

Ability to upgrade with innovations possible at all times through libraries

•

Open, scalable architecture for IT integration and new functions

•

SIPROTEC 5, Fault Recorder, Manual 21

C53000-G5040-C018-5, Edition 11.2017

Introduction

1.2 Properties of SIPROTEC 5

Multi-layered security mechanisms in all links of the security chain

•

Self-monitoring routines for reliable localization and indication of device faults

•

Automatic logging of access attempts and safety-critical operations on the devices and systems

•

Analog Inputs

The measuring inputs transform the currents and voltages coming from the instrument transformers and

adapt them to the internal processing level of the device. A SIPROTEC 5 device has current and/or voltage

transmitters. The current inputs are therefore intended for the detection of phase currents and ground

current. The ground current can be detected sensitively using a core balance current transformer. In addition,

phase currents can be detected very sensitively for a particularly precise measurement.

The voltage inputs detect the measuring voltage of device functions requiring current and voltage measured

values.

The analog values are digitized in the internal microcomputer for data processing.

Binary Inputs and Outputs

The device receives information from the system or from other devices via the binary inputs and outputs. Indications are generated for the remote signaling of important events and states.

Front Elements

For devices with an integrated or detached operation panel, LEDs and an LC display on the front provide information on the device function and report events, states, and measured values. In conjunction with the LC

display, the integrated keypad enables on-site operation of the device. All device information such as setting

parameters, operating and fault indications or measured values can be displayed, and setting parameters

changed.

USB Interface and Serial Interfaces

The USB interface in the front cover enables communication with a personal computer when using the DIGSI 5

operating program. As a result, the operation of all device functions is possible. Additional interfaces on the

back are used to realize various communication protocols.

Redundant Communication

SIPROTEC 5 devices maintain complete communication redundancy:

Multiple redundant communication interfaces

•

Redundant and independent protocols for control centers possible (such as IEC 61850, either single or

•

redundant)

Redundant time synchronization (such as IRIG-B and SNTP)

•

Power Supply

The individual functional units of the device are powered by an internal power supply. Brief interruptions in

the supply voltage, which can occur during short circuits in the system auxiliary voltage supply, are bridged by

capacitor storage (see also the Technical Data).

22 SIPROTEC 5, Fault Recorder, Manual

C53000-G5040-C018-5, Edition 11.2017

Introduction

1.3 Properties of the Fault Recorder

1.3

Properties of the Fault Recorder

The 7KE85 fault recorder is built on the flexible and powerful SIPROTEC 5 modular system and can thus also be

used universally in the scope of system solutions. The 7KE85 fault recorder is able to acquire extensive data,

such as measured values and sampled values (SAV), with high precision. It features a large number of analog

and binary inputs and a high sampling frequency. All data are recorded either by way of continuous criteria or

by way of different trigger criteria. Besides storing the data on internal mass storage, they can also transmit it