Preface

Open Source Software

Table of Contents

SIPROTEC 4

Multifunction Paralleling

Devices 7VE61 and 7VE63

V4.6

Manual

Introduction

Functions

Mounting and Commissioning

Technical Data

Ordering Information and Accessories

Terminal Assignments

Connection Examples

Default Settings and Protocol-dependent

Functions

Functions, Settings, Information

1

2

3

4

A

B

C

D

E

C53000-G1176-C163-3

Literature

Glossary

Index

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

This document has been subjected to rigorous technical

review before being published. It is revised at regular intervals, and any modifications and amendments are included

in the subsequent issues. The content of this document has

been compiled for information purposes only. Although

Siemens AG has made best efforts to keep the document as

precise and up-to-date as possible, Siemens AG shall not

assume any liability for defects and damage which result

through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of

Siemens AG are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document from

time to time.

Document version: C53000-G1176-C163-3.01

Edition: 10.2017

Version of the product described: V4.6

Copyright

Copyright © Siemens AG 2017. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content

are not permitted, unless authorized in writing. All rights,

including rights created by patent grant or registration of a

utility model or a design, are reserved.

Registered Trademarks

SIPROTEC®, DIGSI®, SIGUARD®, SIMEAS®, and SICAM® are

registered trademarks of Siemens AG. Any unauthorized

use is illegal. All other designations in this document can

be trademarks whose use by third parties for their own

purposes can infringe the rights of the owner.

Preface

Purpose of this Manual

This manual describes the functions, operation, installation, and commissioning of devices 7VE61 and 7VE63.

In particular, one will find:

Information regarding the configuration of the scope of the device and a description of the device func-

•

tions and settings → Chapter 2;

Instructions for Installation and Commissioning → Chapter 3;

•

Compilation of the Technical Data → Chapter 4;

•

As well as a compilation of the most significant data for advanced users → Appendix A.

•

General information with regard to design, configuration, and operation of SIPROTEC 4 devices are set out in

the SIPROTEC 4 System Description /1/ SIPROTEC 4 System Manual.

Target Audience

Protection-system engineers, commissioning engineers, persons entrusted with the setting, testing and maintenance of selective protection, automation and control equipment, and operating personnel in electrical

installations and power plants.

Applicability of this Manual

This manual applies to: SIPROTEC 4 Multifunction Paralleling Devices 7VE61 and 7VE63; Firmware-Version

V4.6.

Indication of Conformity

Additional Standards IEEE Std C37.90 (see Chapter 4, “Technical Data”)

[ul-schutz-110602-kn, 1, --_--]

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility

(EMC Council Directive 2004/108/EC) and concerning electrical equipment for use within

specified voltage limits (Low-voltage directive 2006/95 EC).

This conformity is proved by tests conducted by Siemens AG in accordance with the Council

Directives in agreement with the generic standards EN61000-6-2 and EN 61000-6-4 for the

EMC directive, and with the standard EN 60255-27 for the low-voltage directive. The device

has been designed and produced for industrial use.

The product conforms with the international standard of the series IEC 60255 and the German

standard VDE 0435.

SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

3

!

!

!

Preface

Additional Support

For questions about the SIPROTEC 4 system, please contact your Siemens sales partner.

Our Customer Support Center provides a 24-hour service.

Phone: +49 (180) 524-8437

Fax: +49 (180) 524-2471

e-mail: support.ic@siemens.com

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldtstraße 59

90459 Nürnberg

Germany

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-7929

E-Mail: poweracademy@siemens.com

Internet: www.siemens.com/poweracademy

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment (module

or device). However, it comprises important information that must be followed for personal safety, as well as

to avoid material damage. Information is highlighted and illustrated as follows according to the degree of

danger:

DANGER

GEFAHR bedeutet, dass Tod oder schwere Verletzungen eintreten werden, wenn die angegebenen

Maßnahmen nicht getroffen werden.

²

²

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

²

Beachten Sie alle Hinweise, um Tod oder schwere Verletzungen zu vermeiden.

Danger indicates that death, severe personal injury or substantial material damage will result if proper

precautions are not taken.

Comply with all instructions, in order to avoid death or severe injuries.

CAUTION

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

Comply with all instructions, in order to avoid moderate or minor injuries.

²

4 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

i

i

NOTE

indicates information on the device, handling of the device, or the respective part of the instruction manual

which is important to be noted.

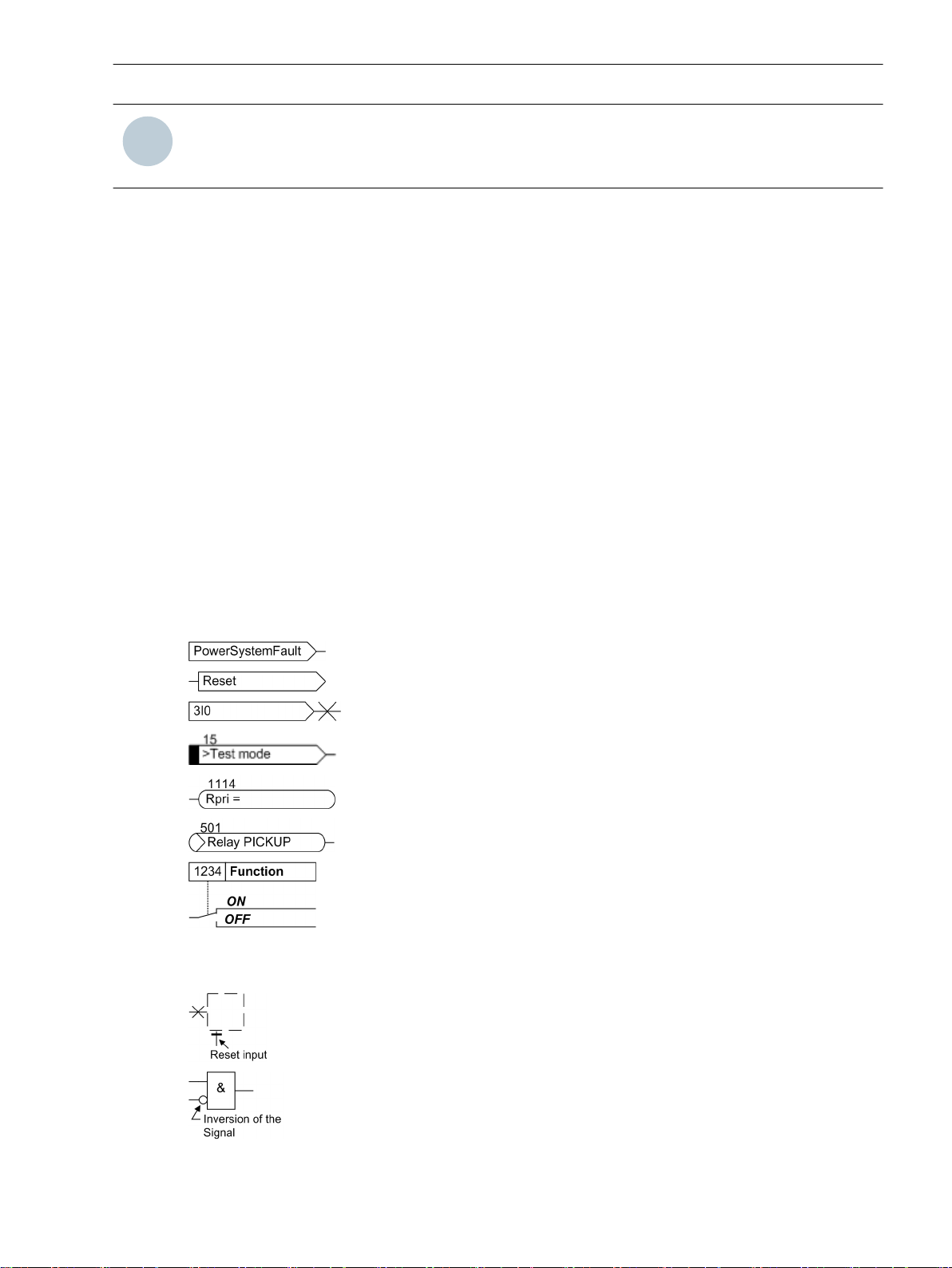

Typographic and Symbol Conventions

The following text formats are used when literal information from the device or to the device appear in the

text flow:

Parameter Names

Designators of configuration or function parameters which may appear word-for-word in the display of the

device or on the screen of a personal computer (with operation software DIGSI), are marked in bold letters in

monospace type style. The same applies to titles of menus.

1234A

Parameter addresses have the same character style as parameter names. Parameter addresses contain the

suffix A in the overview tables if the parameter can only be set in DIGSI via the option Display additional

settings.

Parameter Options

Possible settings of text parameters, which may appear word-for-word in the display of the device or on the

screen of a personal computer (with operation software DIGSI), are additionally written in italics. The same

applies to the options of the menus.

Indications

Designators for information, which may be output by the relay or required from other devices or from the

switch gear, are marked in a monospace type style in quotation marks.

Deviations may be permitted in drawings and tables when the type of designator can be obviously derived

from the illustration.

The following symbols are used in drawings:

Preface

Device-internal logical input signal

Device-internal logical output signal

Internal input signal of an analog quantity

External binary input signal with number (binary input,

input indication)

External binary output signal with number

(example of a value indication)

External binary output signal with number (device indication) used as

input signal

Example of a parameter switch designated FUNCTION with address

1234 and the possible settings Ein and Aus

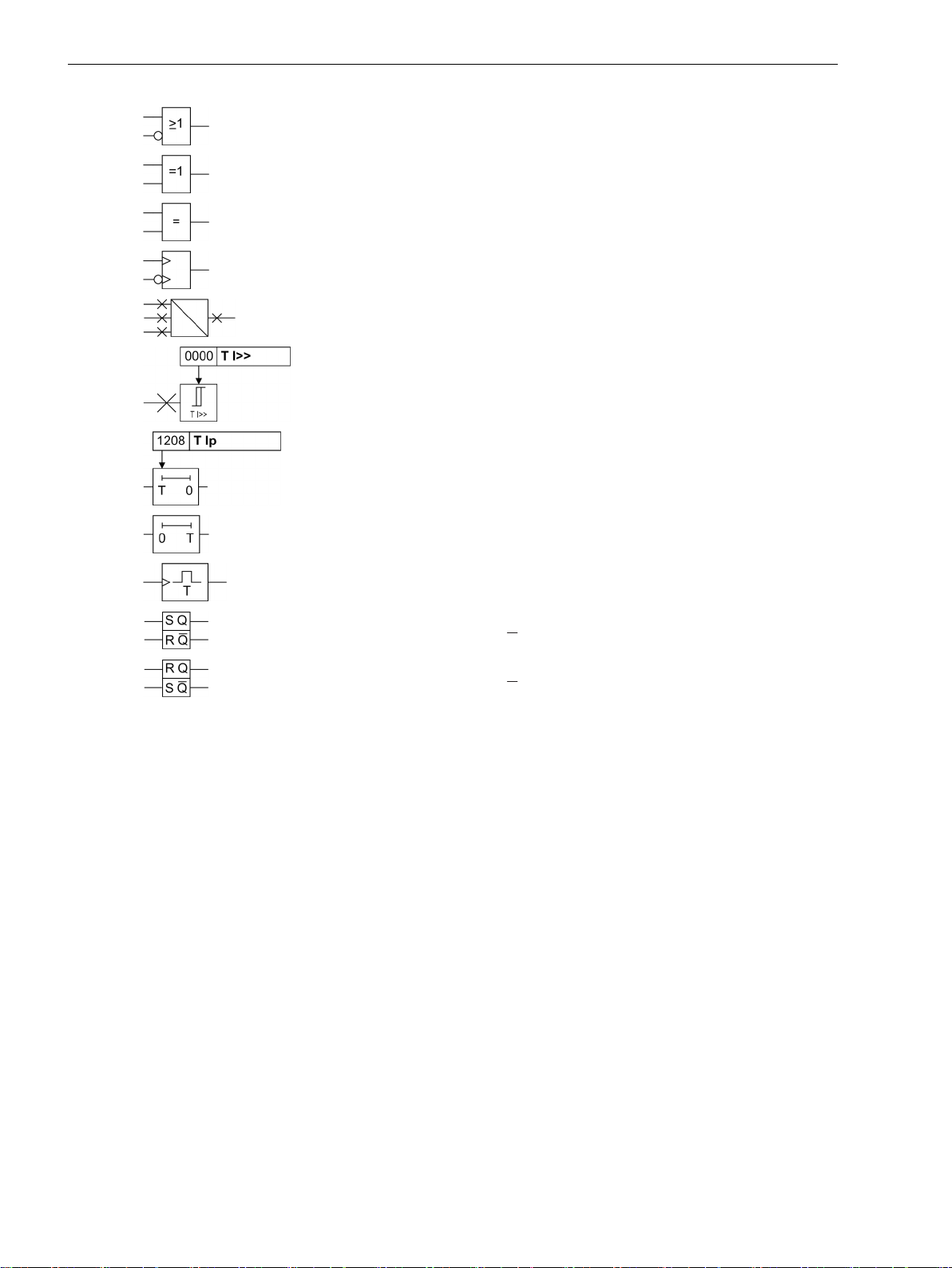

Besides these, graphical symbols are used in accordance with IEC 60617-12 and IEC 60617-13 or similar.

Some of the most frequently used are listed below:

Analog input variable

AND-gate operation of input values

SIPROTEC 4, 7VE61 and 7VE63, Manual 5

C53000-G1176-C163-3, Edition 10.2017

Preface

OR-gate operation of input values

Exclusive OR gate (antivalence): output is active, if only one of the

inputs is active

Coincidence gate: output is active, if both inputs are active or inactive

at the same time

Dynamic inputs (edge-triggered) above with positive, below with

negative edge

Formation of one analog output signal from a number of analog input

signals

Limit stage with setting address and parameter designator (name)

Timer (pickup delay T, example adjustable) with setting address and

parameter designator (name)

Timer (dropout delay T, example non-adjustable)

Dynamic triggered pulse timer T (monoflop)

Static memory (SR flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q), setting input dominant

Static memory (RS-flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q), resetting input dominant

6 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Open Source Software

The product contains, among other things, Open Source Software developed by third parties. The Open

Source Software used in the product and the license agreements concerning this software can be found in the

Readme_OSS. These Open Source Software files are protected by copyright. Your compliance with those

license conditions will entitle you to use the Open Source Software as foreseen in the relevant license. In the

event of conflicts between Siemens license conditions and the Open Source Software license conditions, the

Open Source Software conditions shall prevail with respect to the Open Source Software portions of the software. The Open Source Software is licensed royalty-free. Insofar as the applicable Open Source Software

License Conditions provide for it you can order the source code of the Open Source Software from your

Siemens sales contact - against payment of the shipping and handling charges - for a period of at least 3 years

since purchase of the Product. We are liable for the Product including the Open Source Software contained in

it pursuant to the license conditions applicable to the Product. Any liability for the Open Source Software

beyond the program flow intended for the Product is explicitly excluded. Furthermore any liability for defects

resulting from modifications to the Open Source Software by you or third parties is excluded. We do not

provide any technical support for the Product if it has been modified.

SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

7

8 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

Preface..........................................................................................................................................................3

Open Source Software..................................................................................................................................7

1 Introduction................................................................................................................................................15

1.1 Overall Operation..............................................................................................................16

1.2 Application Scope............................................................................................................. 18

1.3 Characteristics.................................................................................................................. 21

2 Functions.................................................................................................................................................... 25

2.1 General.............................................................................................................................26

2.1.1 Device......................................................................................................................... 26

2.1.1.1 Setting Notes......................................................................................................... 26

2.1.1.2 Settings................................................................................................................. 27

2.1.1.3 Information List..................................................................................................... 27

2.1.2 EN100-Modul 1........................................................................................................... 28

2.1.2.1 Functional Description........................................................................................... 28

2.1.2.2 Setting Notes......................................................................................................... 29

2.1.2.3 Information List..................................................................................................... 29

2.1.3 Functional Scope......................................................................................................... 29

2.1.3.1 Functional Description........................................................................................... 29

2.1.3.2 Setting Notes......................................................................................................... 29

2.1.3.3 Settings................................................................................................................. 30

2.1.4 Power System Data 1...................................................................................................32

2.1.4.1 Setting Notes......................................................................................................... 32

2.1.4.2 Settings................................................................................................................. 32

2.1.4.3 Information List..................................................................................................... 32

2.1.5 Change Group............................................................................................................. 33

2.1.5.1 Setting Notes......................................................................................................... 33

2.1.5.2 Settings................................................................................................................. 33

2.1.5.3 Information List..................................................................................................... 33

2.2 Paralleling Functions......................................................................................................... 35

2.2.1 Functional Description.................................................................................................35

2.2.1.1 Connection and definitions.................................................................................... 35

2.2.1.2 Synchronization via Transformers...........................................................................37

2.2.1.3

2.2.1.4 Monitoring Procedure............................................................................................ 40

2.2.1.5 Multiple Synchronizing Points................................................................................ 42

2.2.1.6 Operating Range/Measured values..........................................................................42

2.2.1.7 Synchrocheck.........................................................................................................43

2.2.1.8 Switching to Dead Line/Busbar............................................................................... 46

2.2.1.9 Switching Synchronous Systems.............................................................................49

2.2.1.10 Switching Asynchronous Systems...........................................................................50

2.2.1.11 Control and Closure Logic.......................................................................................52

2.2.1.12 Automatic Synchronizing of Generators..................................................................54

11/2– and 2–channel Version.................................................................................. 38

SIPROTEC 4, 7VE61 and 7VE63, Manual 9

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

2.2.1.13 Interaction with Control Functionality.....................................................................59

2.2.1.14 Commissioning Tools............................................................................................. 60

2.2.2 SYNC Function group 1................................................................................................61

2.2.2.1 Setting Notes......................................................................................................... 61

2.2.2.2 Settings................................................................................................................. 76

2.2.2.3 Information List..................................................................................................... 78

2.2.3 SYNC General.............................................................................................................. 78

2.2.3.1 Setting Notes......................................................................................................... 78

2.2.3.2 Settings................................................................................................................. 79

2.2.3.3 Information List..................................................................................................... 79

2.3 Protection and Automation Functions................................................................................81

2.4 Undervoltage Protection................................................................................................... 82

2.4.1 Functional Description.................................................................................................82

2.4.2 Setting Notes...............................................................................................................82

2.4.3 Settings.......................................................................................................................83

2.4.4 Information List...........................................................................................................83

2.5 Overvoltage Protection......................................................................................................85

2.5.1 Functional Description.................................................................................................85

2.5.2 Setting Notes...............................................................................................................85

2.5.3 Settings.......................................................................................................................86

2.5.4 Information List...........................................................................................................86

2.6 Frequency Protection........................................................................................................ 88

2.6.1 Functional Description.................................................................................................88

2.6.2 Setting Notes...............................................................................................................89

2.6.3 Settings.......................................................................................................................90

2.6.4 Information List...........................................................................................................91

2.7 Rate-of-frequency-change protection................................................................................ 92

2.7.1 Functional Description.................................................................................................92

2.7.2 Setting Notes...............................................................................................................93

2.7.3 Settings.......................................................................................................................95

2.7.4 Information List...........................................................................................................96

2.8 Jump of Voltage Vector..................................................................................................... 97

2.8.1 Functional Description.................................................................................................97

2.8.2 Setting Notes...............................................................................................................99

2.8.3 Settings.....................................................................................................................100

2.8.4 Information List.........................................................................................................100

2.9 Threshold supervision..................................................................................................... 101

2.9.1 Functional Description...............................................................................................101

2.9.2 Setting Notes.............................................................................................................102

2.9.3 Settings.....................................................................................................................102

2.9.4 Information List.........................................................................................................103

2.10 External Trip Functions....................................................................................................104

2.10.1 Functional Description...............................................................................................104

2.10.2 Setting Notes.............................................................................................................104

2.10.3 Settings.....................................................................................................................104

2.10.4 Information List.........................................................................................................105

10 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

2.11 AnalogOutputs................................................................................................................106

2.11.1 Functional Description...............................................................................................106

2.11.2 Setting Notes.............................................................................................................106

2.11.3 Settings.....................................................................................................................109

2.12 Supervision.....................................................................................................................112

2.12.1 Hardware Monitoring................................................................................................ 112

2.12.2 Software Monitoring................................................................................................. 112

2.12.3 Monitorings of the Synchronizing Function................................................................113

2.12.4 Malfunction Responses of the Monitoring Functions.................................................. 114

2.12.5 Information List.........................................................................................................116

2.13 Function Control............................................................................................................. 118

2.13.1 Pickup Logic for the Entire Device.............................................................................. 118

2.13.1.1 Functional Description......................................................................................... 118

2.13.2 Tripping Logic for the Entire Device............................................................................118

2.13.2.1 Functional Description......................................................................................... 118

2.13.2.2 Setting Notes....................................................................................................... 119

2.14 Auxiliary Functions..........................................................................................................120

2.14.1 Processing of Messages............................................................................................. 120

2.14.1.1 Functional Description......................................................................................... 120

2.14.2 Measurement............................................................................................................122

2.14.2.1 Functional Description......................................................................................... 122

2.14.2.2 Information List................................................................................................... 123

2.14.3 Commissioning..........................................................................................................124

2.14.3.1 Information List................................................................................................... 124

2.14.4 Min/Max Measurement Setup.................................................................................... 124

2.14.4.1 Functional Description......................................................................................... 124

2.14.4.2 Information List................................................................................................... 124

2.14.5 Limit-Measured Values...............................................................................................125

2.14.5.1 Setting Notes....................................................................................................... 125

2.14.6 Statistics....................................................................................................................125

2.14.6.1 Functional Description......................................................................................... 125

2.14.6.2 Setting Notes....................................................................................................... 126

2.14.6.3 Information List................................................................................................... 126

2.14.7 Set Points (Statistic)...................................................................................................126

2.14.7.1 Functional Description......................................................................................... 126

2.14.7.2 Setting Notes....................................................................................................... 126

2.14.7.3 Information List................................................................................................... 126

2.14.8 Oscillographic Fault Records...................................................................................... 126

2.14.8.1 Functional Description......................................................................................... 126

2.14.8.2 Setting Notes....................................................................................................... 127

2.14.8.3 Settings............................................................................................................... 128

2.14.8.4 Information List................................................................................................... 128

2.14.9 Time Setup................................................................................................................128

2.14.9.1 Functional Description......................................................................................... 128

2.14.10 Commissioning Aids.................................................................................................. 129

2.14.10.1 Functional Description......................................................................................... 129

2.15 Command Processing......................................................................................................131

2.15.1 Control Device...........................................................................................................131

2.15.1.1 Functional Description......................................................................................... 131

2.15.2 Types of Commands.................................................................................................. 132

2.15.2.1 Functional Description......................................................................................... 132

SIPROTEC 4, 7VE61 and 7VE63, Manual 11

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

2.15.3 Sequence in the Command Path................................................................................ 133

2.15.3.1 Functional Description......................................................................................... 133

2.15.4 Interlocking............................................................................................................... 133

2.15.4.1 Functional Description......................................................................................... 134

2.15.5 Command Logging.................................................................................................... 140

2.15.5.1 Functional Description......................................................................................... 140

2.15.5.2 Functional Description......................................................................................... 141

3 Mounting and Commissioning................................................................................................................. 143

3.1 Mounting and Connections............................................................................................. 144

3.1.1 Configuration Information......................................................................................... 144

3.1.2 Hardware Modifications.............................................................................................145

3.1.2.1 General................................................................................................................145

3.1.2.2 Disassembly.........................................................................................................146

3.1.2.3 Switching Elements on the Printed Circuit Boards................................................. 148

3.1.2.4 Interface Modules................................................................................................ 155

3.1.2.5 Reassembly..........................................................................................................158

3.1.3 Mounting.................................................................................................................. 159

3.1.3.1 Panel Flush Mounting...........................................................................................159

3.1.3.2 Rack and Cubicle Mounting.................................................................................. 160

3.2 Checking Connections.....................................................................................................163

3.2.1 Checking Data Connections of Interfaces................................................................... 163

3.2.2 Checking the Device Connections.............................................................................. 165

3.2.3 Checking System Incorporation..................................................................................167

3.3 Commissioning............................................................................................................... 169

3.3.1 Test Mode and Transmission Block.............................................................................170

3.3.2 Checking System Interfaces ...................................................................................... 170

3.3.3 Checking the Binary Inputs and Outputs ....................................................................171

3.3.4 Checking the Analog Output......................................................................................174

3.3.5 Checking the User-Defined Functions.........................................................................174

3.3.6 Trip/Close Tests for the Configured Operating Devices................................................ 175

3.3.7 Commissioning Check................................................................................................175

3.3.8 Checking the Control and Measured Voltages Circuits................................................ 175

3.3.9 Measuring the Operating Time of the Circuit Breaker..................................................182

3.3.10 Test Operation with the Synchronization Function..................................................... 183

3.3.11 Synchronization Test................................................................................................. 187

3.3.12 Commissioning-Help using the Web-Tool................................................................... 187

3.3.13 1st Parallel Switching with the Synchronization Function........................................... 188

3.3.14 Creating Oscillographic Recordings for Test................................................................190

3.4 Final Preparation of the Device........................................................................................191

4 Technical Data.......................................................................................................................................... 193

4.1 General...........................................................................................................................194

4.1.1 Analog Inputs/Outputs...............................................................................................194

4.1.2 Auxiliary Voltage....................................................................................................... 194

4.1.3 Binary Inputs and Outputs......................................................................................... 195

4.1.4 Communication Interfaces.........................................................................................195

4.1.5 Electrical Tests...........................................................................................................199

4.1.6 Mechanical Tests....................................................................................................... 200

4.1.7 Climatic Stress Tests.................................................................................................. 201

12 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

4.1.8 Service Conditions..................................................................................................... 202

4.1.9 Design.......................................................................................................................202

4.2 Paralleling Functions....................................................................................................... 203

4.3 Balancing Commands for the Synchronizing Function......................................................205

4.4 Undervoltage Protection................................................................................................. 206

4.5 Overvoltage Protection....................................................................................................207

4.6 Frequency Protection...................................................................................................... 208

4.7 Rate-of-frequency-change protection.............................................................................. 209

4.8 Jump of Voltage Vector................................................................................................... 210

4.9 Threshold supervision..................................................................................................... 211

4.10 External Trip Functions....................................................................................................212

4.11 User-defined functions (CFC)...........................................................................................213

4.12 Auxiliary Functions..........................................................................................................217

4.13 Dimensions.....................................................................................................................220

4.13.1

4.13.2

4.13.3

4.13.4

Panel Flush and Cubicle Mounting (Housing Size 1/3).................................................. 220

Panel Flush and Cubicle Mounting (Housing Size 1/2).................................................. 220

Panel Flush Mounting (Housing Size 1/3).....................................................................221

Panel Flush Mounting ( Housing Size 1/2)....................................................................221

A Ordering Information and Accessories.....................................................................................................223

A.1 Ordering Information 7VE61........................................................................................... 224

A.2 Ordering Information 7VE63........................................................................................... 226

A.3 Zubehör..........................................................................................................................228

B Terminal Assignments..............................................................................................................................231

B.1 Housing for Panel Flush and Cubicle Mounting................................................................ 232

B.2 Housing for Panel Surface Mounting................................................................................234

B.3 Assignment of the D-subminiature Connectors................................................................ 236

C Connection Examples............................................................................................................................... 237

C.1 7VE61 complete connection examples............................................................................ 238

C.2 Voltage Connectors.........................................................................................................240

C.3 Traction Power Systems in 16.7 Hz.................................................................................. 244

C.4 Special for Synchrocheck Applications............................................................................. 245

D Default Settings and Protocol-dependent Functions............................................................................... 247

D.1 LEDs............................................................................................................................... 248

D.2 Binary Input.................................................................................................................... 249

D.3 Binary Output................................................................................................................. 250

D.4 Function Keys................................................................................................................. 251

D.5 Default Display................................................................................................................252

D.6 Pre-defined CFC Charts....................................................................................................254

D.7 Protocol-dependent Functions.........................................................................................255

E Functions, Settings, Information..............................................................................................................257

E.1 Functional Scope............................................................................................................ 258

E.2 Settings.......................................................................................................................... 260

SIPROTEC 4, 7VE61 and 7VE63, Manual 13

C53000-G1176-C163-3, Edition 10.2017

Table of Contents

E.3 Information List.............................................................................................................. 284

E.4 Group Alarms..................................................................................................................308

E.5 Measured Values.............................................................................................................309

Literature.................................................................................................................................................. 315

Glossary.................................................................................................................................................... 317

Index.........................................................................................................................................................327

14 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

1

Introduction

This chapter introduces the SIPROTEC 4 7VE61 and 7VE63. It provides an overview of the scopes of application, features and of the functional scope.

1.1 Overall Operation 16

1.2 Application Scope 18

1.3 Characteristics 21

SIPROTEC 4, 7VE61 and 7VE63, Manual 15

C53000-G1176-C163-3, Edition 10.2017

Introduction

1.1 Overall Operation

1.1

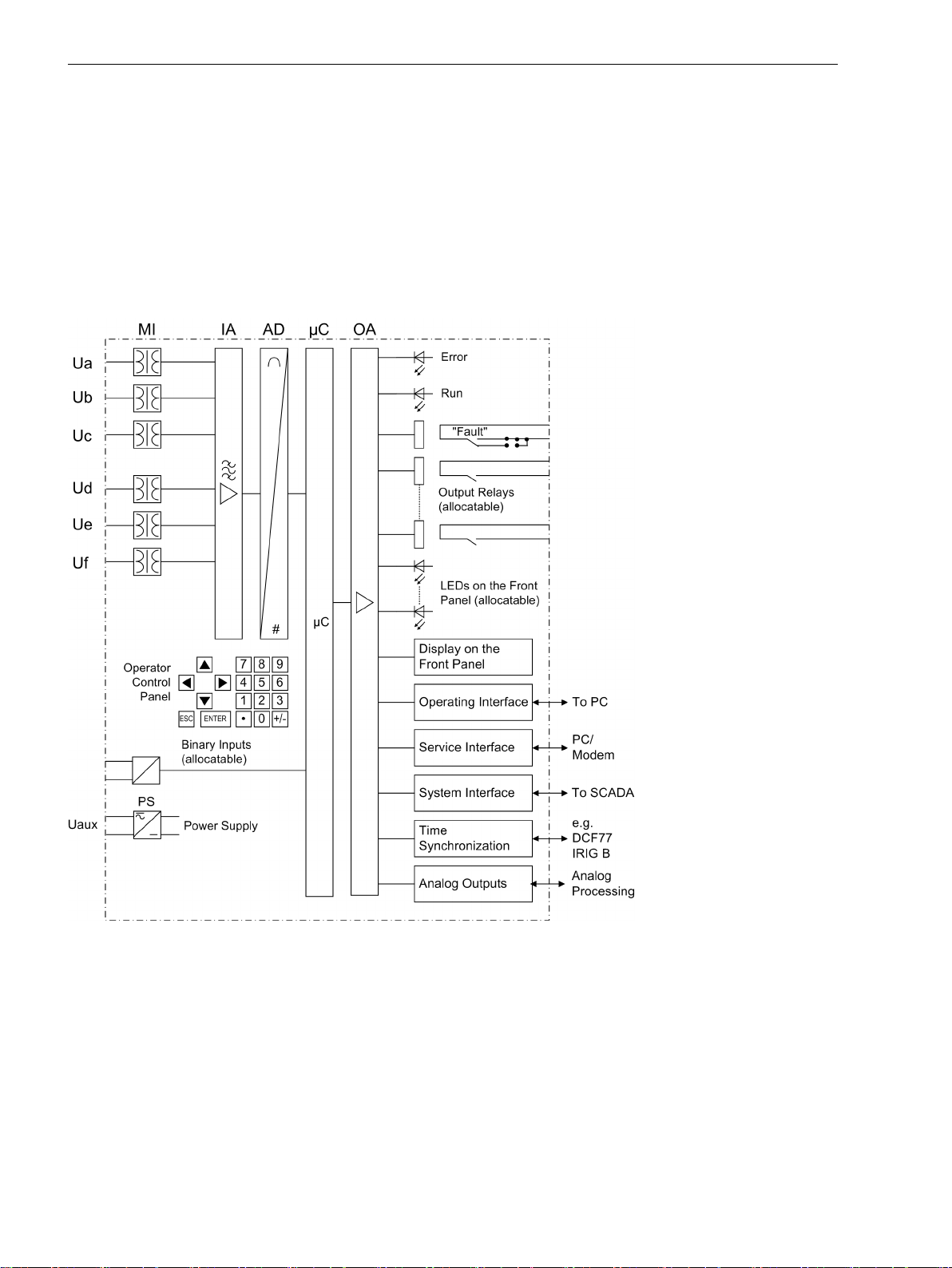

Analog Inputs

Overall Operation

The multi-functional protection devices SIPROTEC 4 7VE61 and 7VE63 are equipped with a powerful microprocessor. All tasks, such as the acquisition of the measured quantities, issuing of commands to circuit

breakers and other primary power system equipment, are processed fully digitally. Figure 1-1 shows the basic

structure of the device.

The measuring inputs (MI) are galvanically isolated, transform the voltages from the primary transformers and

adapt them to the internal processing level of the device. Six voltage inputs are available in the MI section.

[hardwarestruktur-ve6-200303-kn, 1, en_GB]

Figure 1-1

The IA input amplifier group allows high impedance connection for analog input values and contains filters

optimized for measured value processing bandwidth and speed.

The AD analog digital converter group contains high resolution ΣΔ digital converters (22 bits) and memory

components for data transfer to the microcomputer.

Micro Computer System

The implemented software is processed in the microcomputer system (μC) Essential functions are:

16 SIPROTEC 4, 7VE61 and 7VE63, Manual

Hardware structure of the digital Multifunction Paralleling Devices 7VE61 and 7VE63 (maximal

configuration)

C53000-G1176-C163-3, Edition 10.2017

Filtering and preparation of the measured quantities

•

Continuous monitoring of the measured quantities

•

Processing of the algorithms for the synchrocheck function

•

Monitoring of the pickup conditions for the individual protective functions

•

Interrogation of limit values and sequences in time

•

Controlling signals for logic functions

•

Output of control commands for switching devices

•

Signalling of synchronization and protection behaviour via LEDs, LCD, relays or serial interfaces

•

Recording of messages, fault data and fault values for analysis

•

Management of the operating system and the associated functions such as data recording, real-time

•

clock, communication, interfaces, etc.

Binary Inputs and Outputs

Binary inputs and outputs from and to the computer system are routed via the I/O modules (inputs and

outputs). The computer system obtains the information from the system (e.g remote resetting) or the external

equipment (e.g. blocking commands). Outputs are mainly commands that are issued to the switching devices

and messages for remote signalling of events and states.

Introduction

1.1 Overall Operation

Front Elements

Light-emitting diodes (LEDs) and a display (LCD) on the front panel provide information on the functional

status of the device and report events, states and measured values. The integrated control keys and numeric

keys in conjunction with the LCD enable local interaction with the device. They allow the user to retrieve any

kind of information from the device such as configuration and setting parameters, operational indications and

fault messages (see also /1/ SIPROTEC 4 System Manual) and to change setting parameters.

Serial Interfaces

A personal computer running the DIGSI software can be connected to the serial

the front panel to conveniently operate all device functions.

A separate service interface can be provided for remote communication with the device via a personal

computer using DIGSI 4. This interface is especially well suited for a permanent connection of the devices to

the PC or for operation via a modem.

All data can be transferred to a central control or monitoring system via the serial

protocols and physical arrangements are available for this interface to suit the particular application.

A further interface is provided for

sources.

Further communication protocols can be implemented via additional interface modules.

Analog Outputs

Depending on the ordering variant and configuration, ports B and D can be equipped with analog output

modules for the output of selected measured values (0 to 20 mA or 4 to 20 mA).

Power Supply

operator interface (PC port) on

system interface. Various

time synchronization of the internal clock through external synchronization

The functional units described are supplied by a power supply PS with the necessary power in the different

voltage levels. Voltage dips may occur if the voltage supply system (substation battery) becomes shortcircuited. Usually, they are bridged by a capacitor (see also Technical Data).

SIPROTEC 4, 7VE61 and 7VE63, Manual 17

C53000-G1176-C163-3, Edition 10.2017

Introduction

1.2 Application Scope

1.2

Application Scope

The digital paralleling devices 7VE61 and 7VE63 of the SIPROTEC 4 family are multifunctional compact

devices, which may be used for parallel switching systems and generators. Its technical version warrants a

high security during parallel switching. This can be reached by means of the 11/2 channel measurement tech-

nique in device 7VE61 or the two-channel measurement technique in 7VE63 and a special hardware design.

Additionally, numerous monitoring functions serve as support.

Except for the synchronizing functions, in the devices 7VE61 and 7VE63 are available optional voltages and

frequency functions. Thus, the devices can be used for the protection function and for network decoupling

tasks.

The devices are recommended for the different applications:

7VE61:

Synchrocheck monitoring for systems and manual synchronization. In this option a total of 3 synchron-

•

izers can parallel operate.

Parallel switching for systems

•

Systems Disconnection and Automatic Re-synchronization

•

Automatic synchronization of small to medium generators.

•

7VE63:

Operation with increased safety requirements through a two-channel feature

•

Parallel switching for high-voltage and extra high-voltage systems

•

Automatic synchronization of large generators

•

Operation of several synchronizers by a device (up to 8 are possible)

•

Visualization of the condition system through a graphic display and local control.

•

Synchronization Functions

The devices recognize automatically the operating conditions and react depending on the pre-settings.

In the operation mode “Synchrocheck” will be checked the validity of a restart according to different

•

considerations.

In the operation mode “Switching Synchronous Systems” will be determined the frequency difference

•

with high accuracy. The connection will take place if the difference frequency is for a long time near to 0.

If asynchronous conditions are available as in the case of synchronization for generators and systems,

•

thus the speed can bring near automatically at the system frequency and the generator voltage at the

system voltage. A considering factor of the circuit breaker closing time is that the generator will be

switched to a point of synchronism.

A very high security for recognition of a de-energized line or bus is achieved via the multi-voltage circuit

•

and the multiple inquiries of the voltage. As a result, a connection of the network is trouble-free reestablished.

Protection and Automation Functions

Except for the synchronizing functions, in the devices 7VE61 and 7VE63 are available optional voltages and

frequency functions. Thus, the devices can be used for the protection function and for network decoupling

tasks.

The devices include the following basic functions:

Overvoltage protection U>

•

Undervoltage protection U<

•

Overfrequency f>

•

Underfrequency protection f<

•

Rate-of-frequency df/dt>; –df/dt<

•

18 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Vector jump protection Δφ

•

Fast threshold supervision of the voltages (U>; U<)

•

Control Functions

The device is equipped with control functions which operate, close and open, switchgear via the integrated

operator panel, the system interface, binary inputs, and using a personal computer with DIGSI software.

The status of the primary equipment can be transmitted to the device via auxiliary contacts connected to

binary inputs. The present status (or position) of the primary equipment can be displayed on the device, and

used for interlocking or plausibility monitoring. The number of the operating equipment to be switched is

limited by the binary inputs and outputs available in the device or the binary inputs and outputs allocated for

the switch position indications. Depending on the primary equipment being controlled, one binary input

(single point indication) or two binary inputs (double point indication) may be used for this process.

The capability of switching primary equipment can be restricted by a setting associated with switching

authority (Remote or Local), and by the operating mode (interlocked/non-interlocked, with or without password request).

Processing of interlocking conditions for switching (e.g. system interlocking) can be established with the aid of

integrated, user-configurable logic functions.

Messages and Measured Values; Fault Recording

The indication list provides information about conditions in the power system and the device. Measurement

quantities and values that are calculated can be displayed locally and communicated via the serial interfaces.

Device messages can be allocated to a number of LEDs, externally processed via output contacts, linked with

user-definable logic functions and/or issued via serial interfaces.

During a generator or network fault (fault in the power system), important events and state changes are

stored in a fault annunciation buffer. The instantaneous or rms measured values during the fault are also

stored in the device and are subsequently available for fault analysis.

Introduction

1.2 Application Scope

Communication

Serial interfaces are available for the communication with operating, control and memory systems.

Front Interface

A 9-pin DSUB socket on the front panel is used for local communication with a personal computer. By means

of the SIPROTEC 4 operating software DIGSI, all operational and evaluation tasks can be executed via this

ator interface, such as specifying and modifying configuration parameters and settings, configuring userspecific logic functions, retrieving operational and fault messages and measured values, readout and display of

fault recordings, querying of devices statuses and measured values.

Rear Interfaces

Depending on the individual ordering variant, additional interfaces are located at the rear side of the device.

They serve to establish an extensive communication with other digital operating, control and memory components:

The

this reason, remote operation is possible via personal computer and the DIGSI operating software, e.g. to

operate several devices via a central PC.

The

can be operated via data lines or fibre optic cables. Several standard protocols are available for the data

transfer:

•

oper-

service interface can be operated via electrical data lines and also allows communication via modem. For

system interface ensures the central communication between the device and the substation controller. It

IEC 61850

An EN 100 module allows to integrate the devices into 100 Mbit Ethernet communication networks used

by process control and automation systems and running IEC 61850 protocols. In parallel to the process

control integration of the device, this interface can also be used for communication with DIGSI and for

inter-relay communication via GOOSE.

SIPROTEC 4, 7VE61 and 7VE63, Manual 19

C53000-G1176-C163-3, Edition 10.2017

Introduction

1.2 Application Scope

IEC 60870-5-103

•

This profile also integrates the devices into the substation automation systems SINAUT LSA and SICAM.

Profibus DP

•

This protocol of automation technology allows transmission of indications and measured values.

Modbus ASCII/RTU

•

This protocol of automation technology allows transmission of indications and measured values.

DNP 3.0

•

This protocol of automation technology allows transmission of indications and measured values.

It is also possible to provide an analog output (2 x 20 mA) for output of measured values.

•

20 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Introduction

1.3 Characteristics

1.3

General Characteristics

Characteristics

Powerful 32-bit microprocessor system.

•

Complete digital measured value processing and control, from sampling and digitalizing of measured

•

values up to the switchon and switchoff decisions for power breakers and other switchgear.

Total electrical separation between the internal processing stages of the device and the external trans-

•

former, control and DC supply circuits of the system because of the design of the binary inputs, outputs,

and the DC converters.

Easy device operation via an integrated operator panel or by means of a connected personal computer

•

with the DIGSI operating program.

Continuous computation and display of measured quantities.

•

Storage of fault messages and instantaneous or rms values for fault recording.

•

Continuous monitoring of measured values as well as of the hardware and software of the device.

•

Communication with central control and memory storage equipment via serial interfaces, optionally via

•

data cable, modem, or optic fibre lines.

Battery-buffered real time clock that can be synchronized with an IRIG-B (or DCF77) signal, binary input

•

signal, or system interface command.

Statistics: Starting and trip commands from the device are counted.

•

Commissioning aids such as connection check, field rotation check, status display of all binary inputs and

•

outputs, and test measurement recording.

Synchrocheck, Dead Line/Bus

Settable minimum and maximum voltage

•

Verification of the synchronous conditions or the de-energized state is also possible before the manual

•

closing of the circuit breaker, with separate limit values

Fast measuring of voltage difference U

•

Measurement via transformer (integrated vector group adaptation)

•

Measuring voltages optionally for phase-phase or phase-earth.

•

Controlling Synchronous Networks

Fast measuring of the voltage difference U

•

The operating mode is automatically activated (pre-settings), if the frequency difference is f

•

Measurement via transformer (integrated vector group adaptation)

•

Measuring voltages optionally for phase-phase or phase-earth.

•

Controlling Asynchronous Networks

Fast measuring of the voltage difference U

•

Consideration of the angle difference with prediction of the point of synchronism

•

Measurement via transformer (integrated vector group adaptation)

•

Measuring voltages optionally for phase-phase or phase-earth.

•

, of the phase angle difference α

diff

and of the phase angle difference α

diff

and of the frequency difference f

diff

and frequency difference f

diff

diff

≈ 0

diff

;

diff

diff

SIPROTEC 4, 7VE61 and 7VE63, Manual 21

C53000-G1176-C163-3, Edition 10.2017

Introduction

1.3 Characteristics

Undervoltage Protection 27

Two-stage undervoltage measurement for one of the 6 input voltages of the device

•

Separated tripping delay time

•

Settable drop-off to pickup for both stages

•

Overvoltage Protection 59

Two-stage overvoltage measurement for one of the 6 input voltages of the device

•

Separated tripping delay time

•

Settable drop-off to pickup for both stages

•

Frequency Protection 81 O/U

Monitoring on undershooting (f<) and/or overshooting (f>) with 4 frequency limits and delay times that

•

are independently adjustable

Insensitive to harmonics and abrupt phase angle changes

•

Settable undervoltage threshold.

•

Frequency Change Protection

Monitors whether the frequency overshoots (df/dt>) and/or undershoots (-df/dt<) a set limit value, with 4

•

individually settable limit values or delay times

Variable measuring windows

•

Coupling to frequency protection pickup

•

Settable undervoltage threshold.

•

Vector Jump

Sensitive phase jump detection to be used for network disconnection.

•

Analog Outputs

Output of up to four analog operational measured values (depending on the variant ordered).

•

Threshold Value Monitoring

6 freely assignable messages for threshold monitoring

•

Implementation of fast monitoring tasks via CFC.

•

User-defined Functions

Internal and external signals can be logically combined to establish user-defined logic functions

•

All common logic functions (AND, OR, NOT, Exclusive OR, etc.)

•

Time delays and limit value interrogations

•

Processing of measured values, including zero suppression, adding a knee characteristic for a transducer

•

input, and live-zero monitoring.

Breaker Control

Circuit breakers can be opened and closed manually via programmable function keys, via the system

•

interface (e.g. by SICAM or LSA), or via the operating interface (using a PC with DIGSI)

Feedback information on circuit breakers states via the breaker auxiliary contacts

•

Plausibility monitoring of the circuit breaker position and monitoring of interlocking conditions for

•

switching operations.

22 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Monitoring

1.3 Characteristics

Availability of the device is greatly increased by monitoring of the internal measurement circuits, auxiliary

•

power supply, hardware, and software

Monitoring of the input voltage circuit through double connection and opposite control

•

Checking of the phase sequence

•

Permanent monitoring of both closing relays BO1 and BO2

•

Opposite monitoring of the parallel starting algorithms.

•

Introduction

SIPROTEC 4, 7VE61 and 7VE63, Manual 23

C53000-G1176-C163-3, Edition 10.2017

24 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

2

Functions

This chapter describes the individual functions of the SIPROTEC 4 device 7VE61 and 7VE63. It shows the

setting possibilities for each function in maximum configuration. Guidelines for establishing setting values

and, where required, formulae are given.

Based on the following information, it can also be determined which of the provided functions should be

used.

2.1 General 26

2.2 Paralleling Functions 35

2.3 Protection and Automation Functions 81

2.4 Undervoltage Protection 82

2.5 Overvoltage Protection 85

2.6 Frequency Protection 88

2.7 Rate-of-frequency-change protection 92

2.8 Jump of Voltage Vector 97

2.9 Threshold supervision 101

2.10 External Trip Functions 104

2.11 AnalogOutputs 106

2.12 Supervision 112

2.13 Function Control 118

2.14 Auxiliary Functions 120

2.15 Command Processing 131

SIPROTEC 4, 7VE61 and 7VE63, Manual 25

C53000-G1176-C163-3, Edition 10.2017

Functions

2.1 General

2.1

2.1.1

General

The settings associated with the various device functions may be modified by using the operating or service

interface in DIGSI. The procedure is set out in detail in the /1/ SIPROTEC 4 System Manual. For changing configuration parameters in the device, password no. 7 (for parameter set; default setting: 000000) is required.

Without the password, the settings may be read, but may not be modified and transmitted to the device.

The settings associated with the various device functions, limit values, etc. can be modified using the controls

on the front panel of the device or by using the operator interface with DIGSI in conjunction with a personal

computer. Password No. 5 (for single parameter; default setting: 000000).

Device

The device can issue a serie of general annunciations about itself and the substation. These annunciations are

listed in the following information list. Most annunciations are self-explanatory. The special cases are

described below:

Reset: Device is reset on each Power ON.

Initial Start: Initial start occurs after initialization of the device by DIGSI.

Restart: Restart occurs after loading a parameter set or after reset.

The indication of messages masked to LEDs, and the maintenance of spontaneous messages, can be made

dependent on whether the device has issued a trip command. In this situation, messages are not reported, if

one or more protective functions have picked up on a fault, but a trip signal has not been issued yet by the

7VE61 and 7VE63, because the fault was cleared by another device (for example, outside the own protection

range). These messages are then limited to faults in the line to be protected.

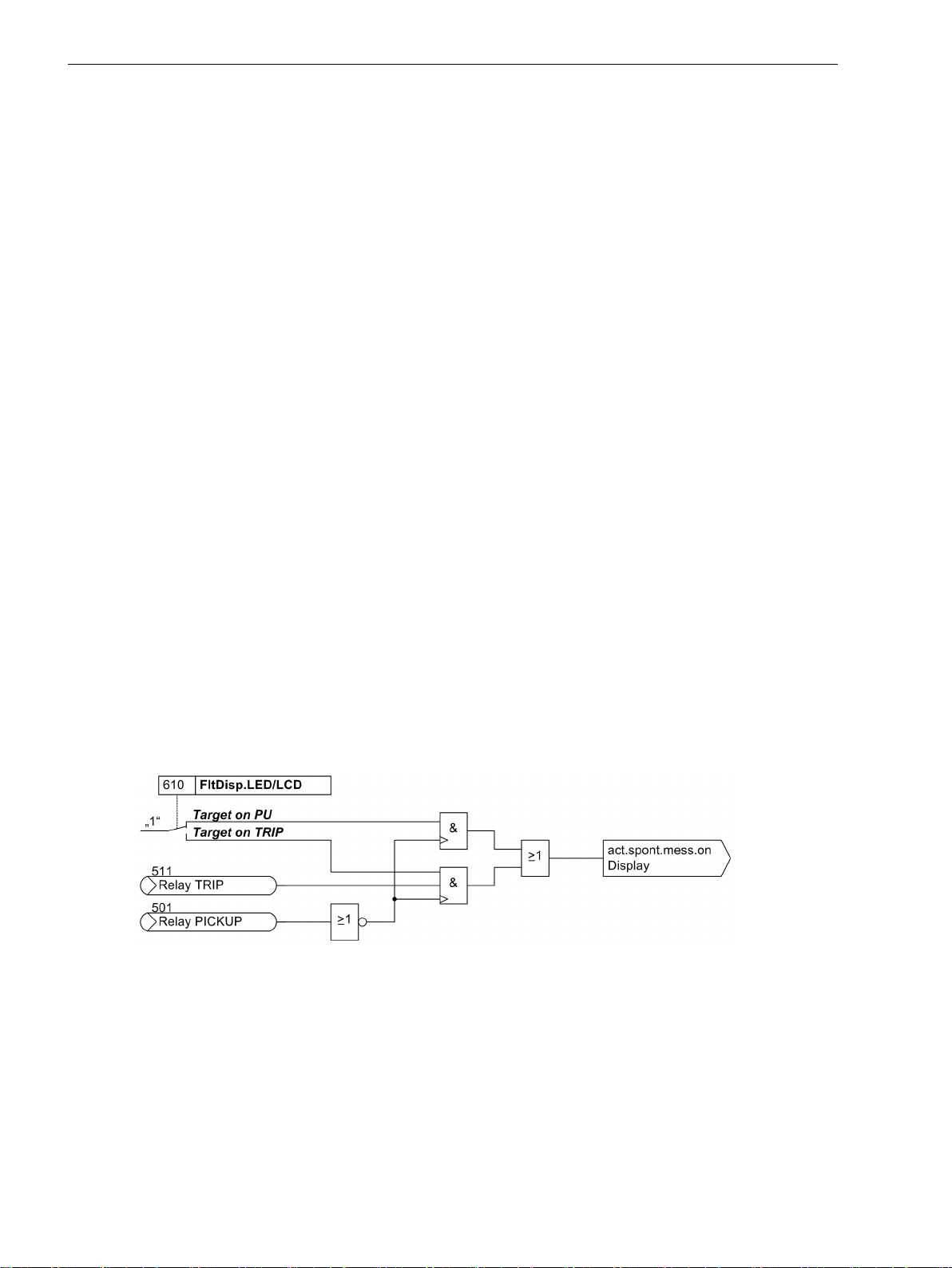

2.1.1.1

Spontaneous Fault Display

Resetting stored LEDs / relays

Setting Notes

After a fault has occurred, the device display spontaneously shows the most important fault data. In address

610 FltDisp.LED/LCD you can select whether the spontaneous fault display is updated for each fault

(Target on PU) or only for faults that included a trip (Target on TRIP).

For devices with graphical display use parameter 611 Spont. FltDisp. to specify whether a spontaneous

fault display will be shown automatically YES) or not (NO). For devices featuring a text display such displays

will always appear a power system fault.

[logik-spondanmeld-display-081024, 1, en_GB]

Figure 2-1 Generation of spontaneous fault indications on the display

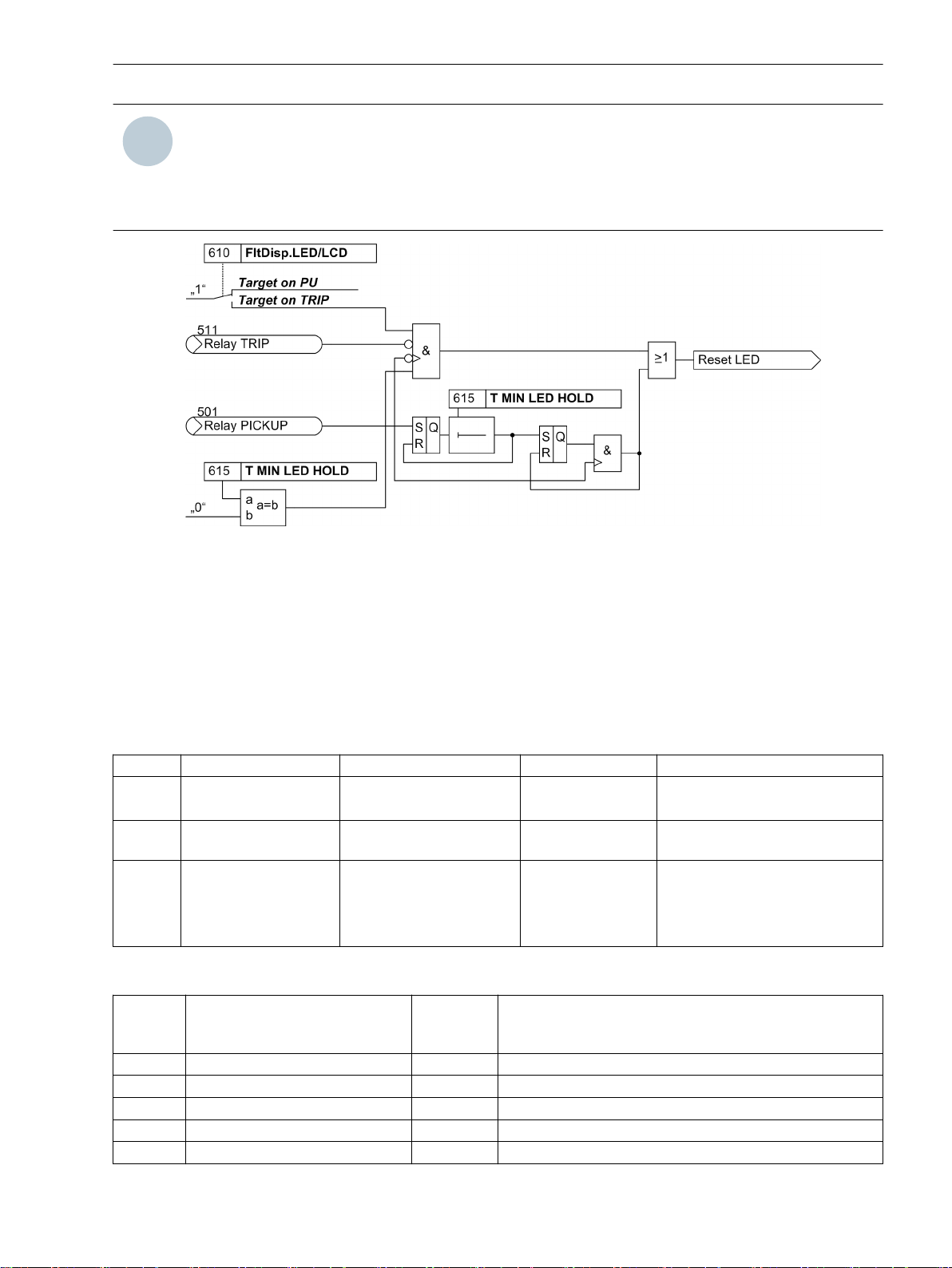

A new pickup will generally erase any stored LEDs/relays so that only the latest fault information is displayed at

any time. A time can be set in address 615 T MIN LED HOLD during which the stored LEDs and relays will

not be deleted. Any information occurring during that period of time will be linked via OR.

The option Target on TRIP in address 610 FltDisp.LED/LCD allows you to delete the information of the

most recent fault stored on LEDs and relays provided that this fault has not resulted in a trip command of the

device.

26 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

i

i

Functions

2.1 General

NOTE

Setting address 610 FltDisp.LED/LCD to (Target on TRIP) is only reasonable if address 615 T MIN

LED HOLD is set to 0.

Die Einstellung der Adresse 610 FltDisp.LED/LCD auf (Target on TRIP) ist nur sinnvoll bei Einstellung von Adresse 615 T MIN LED HOLD auf 0.

[logik-ruecksetz-gesp-led-081024, 1, en_GB]

Figure 2-2 Creation of the resetting command for stored LEDs / relays

Default display of a 4-line display

After startup of the device featuring a 4-line display, measured values are displayed by default. The arrow keys

on the device front allow different displays of the measured values to be selected for the so-called default

display. The start image of the default display, which is displayed by default after startup of the device, can be

selected via parameter 640 Start image DD. The available representation types for the measured value are

listed in the Appendix.

2.1.1.2

Addr.

610 FltDisp.LED/LCD Target on PU

615 T MIN LED HOLD 0 .. 60 min 5 min Minimum hold time of latched

640 Start image DD image 1

2.1.1.3

Settings

Parameter Setting Options Default Setting Comments

Target on PU Fault Display on LED / LCD

Target on TRIP

LEDs

image 1 Start image Default Display

image 2

image 3

image 4

Information List

No.

- Reset LED IntSP Reset LED

- Test mode IntSP Test mode

- DataStop IntSP Stop data transmission

- UnlockDT IntSP Unlock data transmission via BI

- >Light on SP >Back Light on

SIPROTEC 4, 7VE61 and 7VE63, Manual 27

C53000-G1176-C163-3, Edition 10.2017

Information Type of

Information

Comments

Functions

2.1 General

No. Information Type of

Information

- SynchClock IntSP_Ev Clock Synchronization

- HWTestMod IntSP Hardware Test Mode

- Distur.CFC OUT Disturbance CFC

1 Not configured SP No Function configured

2 Non Existent SP Function Not Available

3 >Time Synch SP_Ev >Synchronize Internal Real Time Clock

5 >Reset LED SP >Reset LED

15 >Test mode SP >Test mode

16 >DataStop SP >Stop data transmission

51 Device OK OUT Device is Operational and Protecting

52 ProtActive IntSP At Least 1 Protection Funct. is Active

55 Reset Device OUT Reset Device

56 Initial Start OUT Initial Start of Device

67 Resume OUT Resume

69 DayLightSavTime OUT Daylight Saving Time

70 Settings Calc. OUT Setting calculation is running

71 Settings Check OUT Settings Check

72 Level-2 change OUT Level-2 change

73 Local change OUT Local setting change

110 Event Lost OUT_Ev Event lost

113 Flag Lost OUT Flag Lost

125 Chatter ON OUT Chatter ON

301 Pow.Sys.Flt. OUT Power System fault

302 Fault Event OUT Fault Event

320 Warn Mem. Data OUT Warn: Limit of Memory Data exceeded

321 Warn Mem. Para. OUT Warn: Limit of Memory Parameter exceeded

322 Warn Mem. Oper. OUT Warn: Limit of Memory Operation exceeded

323 Warn Mem. New OUT Warn: Limit of Memory New exceeded

545 PU Time VI Time from Pickup to drop out

546 TRIP Time VI Time from Pickup to TRIP

Comments

2.1.2

2.1.2.1

28 SIPROTEC 4, 7VE61 and 7VE63, Manual

EN100-Modul 1

Functional Description

An Ethernet Ethernet EN100-Module allows for the integration of the 7VE61 and 7VE63 into 100 Mbit

Ethernet communication networks used by process control and automation systems according to the IEC

61850 protocols. This standard enables integrated inter-relay communication without using gateways or

protocol converters. This allows open and interoperable use of SIPROTEC 4 devices even in heterogeneous

environments. In addition to the process control integration of the device, this interface can also be used for

communication with DIGSI and for interrelay communication via GOOSE messaging.

C53000-G1176-C163-3, Edition 10.2017

i

i

Functions

2.1 General

2.1.2.2

Interface selection

2.1.2.3

No. Information Type of

009.0100 Failure Modul IntSP Failure EN100 Modul

009.0101 Fail Ch1 IntSP Failure EN100 Link Channel 1 (Ch1)

009.0102 Fail Ch2 IntSP Failure EN100 Link Channel 2 (Ch2)

2.1.3

Setting Notes

No settings are required for operation of the Ethernet system interface module (IEC 61850 Ethernet EN100Modul). If the device is equipped with such a module (see MLFB), the module is automatically configured to

the interface available for it.

Information List

Comments

Information

Functional Scope

The devices 7VE61 and 7VE63 can have depending on the order variant except for the synchronization function over numerous protective and additional functions. The hardware and firmware is designed for this scope

of functions.

Also individual functions can be enabled or disabled during configuration. Functions not needed can be thus

be deactivated.

The available protection and synchronizing functions must be configured as Enabled or Disabled. For individual functions a choice between several alternatives is possible, as described below.

Functions that are configured as disabled are not processed by the 7VE61 and 7VE63: There are no indications, and corresponding settings (functions, limit values) are not queried during configuration.

2.1.3.1

Setting of the Functional Scope

2.1.3.2

Special Cases

Functional Description

Configuration settings can be entered using a PC and the software program DIGSI and transferred via the front

operator interface or the rear service interface. The procedure is described in detail in the /1/ SIPROTEC 4

System Manual.

Entry of password No. 7 (for parameter set) is required to modify configuration settings. Without the password, the settings may be read, but may not be modified and transmitted to the device.

The functional scope with the available alternatives is set in the Device Configuration dialog box to match

equipment requirements.

NOTE

Available functions and default settings depend on the device variant ordered (see Appendix A Ordering

Information and Accessories for details). Also, not all combinations of protective functions are possible

because of certain restrictions imposed by the hardware (see Section 2.1.1.1 Setting Notes).

Setting Notes

Most settings are self-explanatory. The special cases are described below.

If the setting group change function has to be used, address 103 Grp Chge OPTION must be set to

Enabled. In service, simple and fast change, over between up to four different groups of settings is possible.

Only one setting group may be selected and used if this option is Disabled.

SIPROTEC 4, 7VE61 and 7VE63, Manual 29

C53000-G1176-C163-3, Edition 10.2017

i

i

i

i

Functions

2.1 General

Parameter 104 FAULT VALUE is used to specify whether the oscillographic fault recording should record

Instant. values or RMS values. If RMS values are stored, the available recording time increases by

the factor 10.

The parameter 145 df/dt Protect. establishes for the frequency change protection whether this is to

contain two or four stages or is Disabled.

Up to 8 SYNC function groups are available for the synchronizing function. They are enabled in addresses 016x

(x = 1 ... 8). Parameters 161 SYNC function 1 to 168 SYNC function 8 are used in addition to preselect

the mode of operation:

1ph Sync check corresponds to the classical synchronizing function with in each case single-phase connection of the voltages to be compared.

3ph Sync check corresponds to the classical synchronizing function with in each case multi-phase connection of the voltages to be compared.

NOTE

A mixed parametrization of single-phase and three-phase synchrocheck between function groups is inadmissible and leads to an error indication.

1,5chan.Synchr

device. Connection is multiphase, processing of data command issuing is done 11/2-channel with the 7VE61 or

2-channel with the 7VE63.

NOTE

A mixed parametrization of three-phase synchrocheck and 11/2 or 2-channel synchronising function is

possible due to the identical connection.

If a function is not needed,Disabled is set. A synchronizing function group thus rendered ineffective is

excluded in the menu item Synchronization, all other groups are displayed. The maximum number of the

existing synchronising function groups is established by the device variant (see section “Function description

of the synchronizing function”).

2.1.3.3

Addr.

103 Grp Chge OPTION Disabled

104 FAULT VALUE Disabled

140 UNDERVOLTAGE Disabled

141 OVERVOLTAGE Disabled

142 FREQUENCY Prot. Disabled

145 df/dt Protect. Disabled

146 VECTOR JUMP Disabled

160 BALANC. (MLFB) Disabled

Settings

Parameter Setting Options Default Setting Comments

with the 7VE61 or 2chan.Synchr. with the 7VE63 corresponds to operation as a parallel

Enabled

Instant. values

RMS values

Enabled

Enabled

Enabled

2 df/dt stages

4 df/dt stages

Enabled

Enabled

Disabled Setting Group Change Option

RMS values Fault values

Enabled Undervoltage Protection

Enabled Overvoltage Protection

Enabled Over / Underfrequency Protection

2 df/dt stages Rate-of-frequency-change protec-

tion

Enabled Jump of Voltage Vector

Disabled Balancing Commands (Siemens

only MLFB)

30 SIPROTEC 4, 7VE61 and 7VE63, Manual

C53000-G1176-C163-3, Edition 10.2017

Addr. Parameter Setting Options Default Setting Comments

161 SYNC function 1 Disabled

Disabled SYNC Function group 1

1ph Sync check

3ph Sync check

1,5chan.Synchr

2chan.Synchr.

162 SYNC function 2 Disabled

Disabled SYNC Function group 2

1ph Sync check

3ph Sync check

1,5chan.Synchr

2chan.Synchr.

163 SYNC function 3 Disabled

Disabled SYNC Function group 3

1ph Sync check

3ph Sync check

1,5chan.Synchr

2chan.Synchr.

164 SYNC function 4 Disabled

Disabled SYNC Function group 4

3ph Sync check

1,5chan.Synchr

2chan.Synchr.

165 SYNC function 5 Disabled

Disabled SYNC Function group 5

3ph Sync check

2chan.Synchr.

166 SYNC function 6 Disabled

Disabled SYNC Function group 6

3ph Sync check

2chan.Synchr.

167 SYNC function 7 Disabled

Disabled SYNC Function group 7

3ph Sync check

2chan.Synchr.

168 SYNC function 8 Disabled