Siemens SIPROTEC 4 7UT6 Series Manual

Preface

Table of Contents

SIPROTEC 4

Differential Protection

7UT6x

V4.67

Manual

Introduction

Functions

Mounting and Commissioning

Technical Data

Ordering Information and Accessories

Terminal Assignments

Connection Examples

Current Transformer Requirements

Default Settings and Protocol-dependent

Functions

1

2

3

4

A

B

C

D

E

C53000-G1176-C230-5

Functions, Settings, Information

Literature

Glossary

Index

F

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

We have checked the text of this manual for conformity

with the hardware and software described. However, since

deviations cannot be ruled out entirely, we do not accept

liability for complete conformity or for any any errors or

omissions.

The information given in this document is reviewed regularly and any necessary corrections will be included in

subsequent editions. We appreciate any suggestions for

improvement.

We reserve the right to make technical improvements

without notice.

Document Version 4.04.00

Release date 09.2016

Copyright

Copyright© Siemens AG 2016. All rights reserved.

The reproduction, transmission or use of this document or

its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights

reserved, particularly for the purposes of patent application

or trademark registration.

Registered Trademarks

SIPROTEC, SINAUT, SICAM and DIGSI are registered trademarks of SIEMENS AG. Other designations in this manual

might be trademarks whose use by third parties for their

own purposes would infringe the rights of the owner.

Preface

Purpose of this Manual

This manual describes the functions, operation, installation, and commissioning of devices 7UT6x. In particular, one will find:

Information regarding the configuration of the scope of the device and a description of the device func-

•

tions and settings → Chapter 2;

Instructions for Installation and Commissioning → Chapter 3;

•

Compilation of the Technical Data → Chapter 4;

•

As well as a compilation of the most significant data for advanced users → Appendix A.

•

General information with regard to design, configuration, and operation of SIPROTEC 4 devices are set out in

the SIPROTEC 4 System Description /1/ SIPROTEC 4 System Manual.

Target Audience

Protection-system engineers, commissioning engineers, persons entrusted with the setting, testing and maintenance of selective protection, automation and control equipment, and operating personnel in electrical

installations and power plants.

Applicability of this Manual

This manual applies to: SIPROTEC 4 Differential Protection 7UT6x; Firmware-Version V4.67.

Indication of Conformity

This product is UL-certified according to the Technical Data:

[ul-schutz-110602-kn, 1, --_--]

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility

(EMC Council Directive 2004/108/EEC) and concerning electrical equipment for use within

specified voltage limits (Low-voltage directive 2006/95 EEC).

This conformity is proved by tests conducted by Siemens AG in accordance with the directives

in agreement with the generic standards EN 61000-6-2 and EN 61000-6-4 for EMC directive

and standard EN 60255-5 (for low-voltage directive).

This device was designed and produced for industrial use.

The product conforms to the international standards of the IEC 60255 series and the German

standard VDE 0435.

SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

3

!

!

!

i

i

Preface

Additional Support

For questions about the SIPROTEC 4 system, please contact your Siemens sales partner.

Our Customer Support Center provides a 24-hour service.

Phone: +49 (180) 524-8437

Fax: +49 (180) 524-2471

e-mail: support.ic@siemens.com

Training Courses

Enquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldt Street 59 59

90459 Nuremberg

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-5482

Internet: www.siemens.com/energy/power-academy

e-mail: poweracademy.ic-sg@siemens.com

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment (module

or device). However, it comprises important information that must be followed for personal safety, as well as

to avoid material damage. Information is highlighted and illustrated as follows according to the degree of

danger:

DANGER

GEFAHR bedeutet, dass Tod oder schwere Verletzungen eintreten werden, wenn die angegebenen

Maßnahmen nicht getroffen werden.

Beachten Sie alle Hinweise, um Tod oder schwere Verletzungen zu vermeiden.

²

Danger indicates that death, severe personal injury or substantial material damage will result if proper

²

precautions are not taken.

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

Comply with all instructions, in order to avoid death or severe injuries.

²

CAUTION

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

Comply with all instructions, in order to avoid moderate or minor injuries.

²

NOTE

indicates information on the device, handling of the device, or the respective part of the instruction manual

which is important to be noted.

4 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

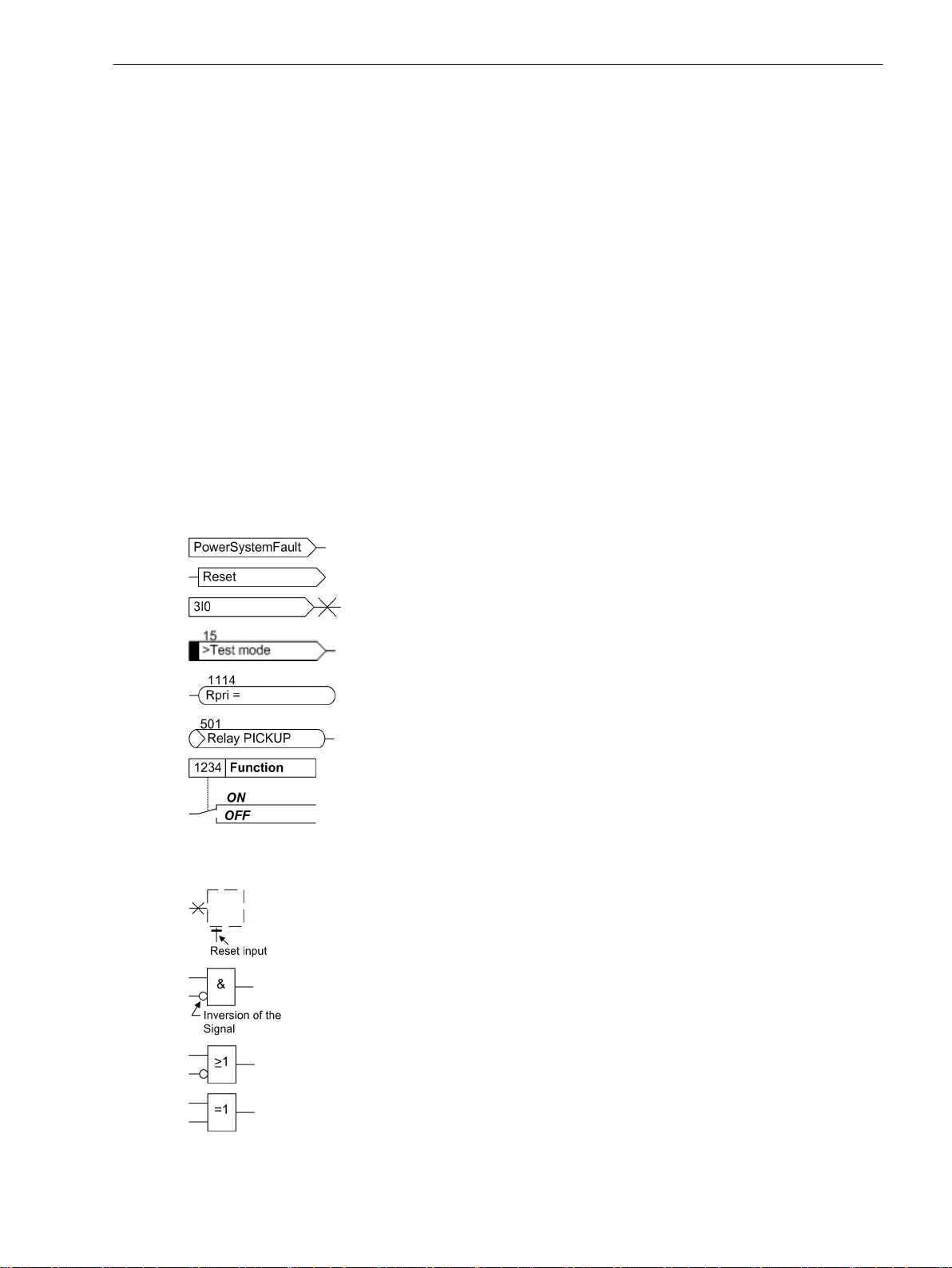

Typographic and Symbol Conventions

The following text formats are used when literal information from the device or to the device appear in the

text flow:

Parameter Names

Designators of configuration or function parameters which may appear word-for-word in the display of the

device or on the screen of a personal computer (with operation software DIGSI), are marked in bold letters in

monospace type style. The same applies to titles of menus.

1234A

Parameter addresses have the same character style as parameter names. Parameter addresses contain the

suffix A in the overview tables if the parameter can only be set in DIGSI via the option Display additional

settings.

Parameter Options

Possible settings of text parameters, which may appear word-for-word in the display of the device or on the

screen of a personal computer (with operation software DIGSI), are additionally written in italics. The same

applies to the options of the menus.

Indications

Designators for information, which may be output by the relay or required from other devices or from the

switch gear, are marked in a monospace type style in quotation marks.

Deviations may be permitted in drawings and tables when the type of designator can be obviously derived

from the illustration.

The following symbols are used in drawings:

Preface

Device-internal logical input signal

Device-internal logical output signal

Internal input signal of an analog quantity

External binary input signal with number (binary input,

input indication)

External binary output signal with number

(example of a value indication)

External binary output signal with number (device indication) used as

input signal

Example of a parameter switch designated FUNCTION with address

1234 and the possible settings Ein and Aus

Besides these, graphical symbols are used in accordance with IEC 60617-12 and IEC 60617-13 or similar.

Some of the most frequently used are listed below:

Analog input variable

AND-gate operation of input values

OR-gate operation of input values

Exclusive OR gate (antivalence): output is active, if only one of the

inputs is active

SIPROTEC 4, 7UT6x, Manual 5

C53000-G1176-C230-5, Edition 09.2016

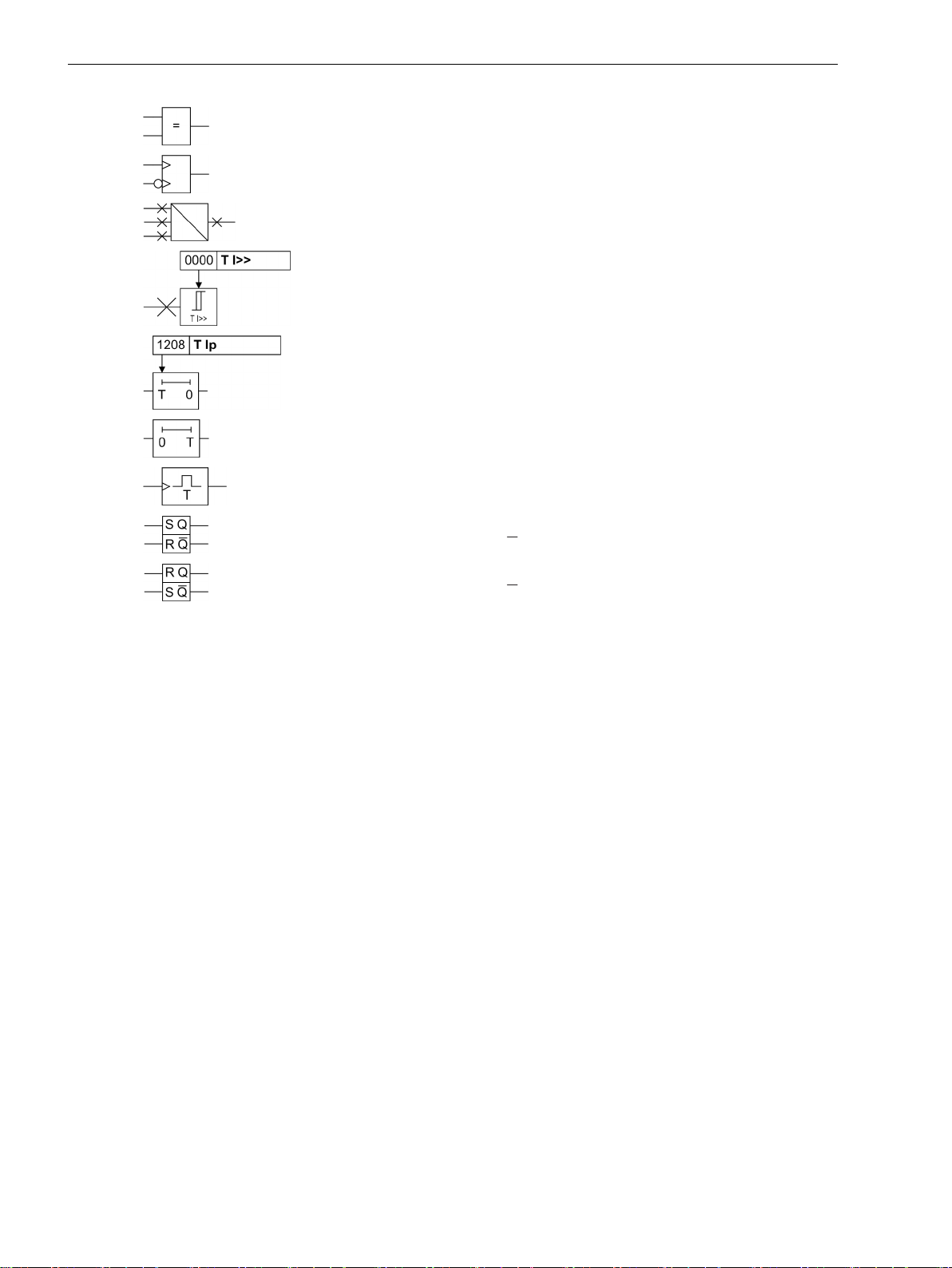

Preface

Coincidence gate: output is active, if both inputs are active or inactive

at the same time

Dynamic inputs (edge-triggered) above with positive, below with

negative edge

Formation of one analog output signal from a number of analog input

signals

Limit stage with setting address and parameter designator (name)

Timer (pickup delay T, example adjustable) with setting address and

parameter designator (name)

Timer (dropout delay T, example non-adjustable)

Dynamic triggered pulse timer T (monoflop)

Static memory (SR flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q), setting input dominant

Static memory (RS-flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q), resetting input dominant

6 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

Preface..........................................................................................................................................................3

1 Introduction................................................................................................................................................15

1.1 Overall Operation..............................................................................................................16

1.2 Application Scope............................................................................................................. 19

1.3 Characteristics.................................................................................................................. 21

2 Functions.................................................................................................................................................... 27

2.1 General.............................................................................................................................28

2.1.1 Device......................................................................................................................... 28

2.1.1.1 Setting Notes......................................................................................................... 28

2.1.1.2 Settings................................................................................................................. 29

2.1.1.3 Information List..................................................................................................... 29

2.1.2 EN100-Modul 1........................................................................................................... 30

2.1.2.1 Function Description.............................................................................................. 30

2.1.2.2 Setting Notes......................................................................................................... 30

2.1.2.3 Information List..................................................................................................... 30

2.1.3 Functional Scope......................................................................................................... 30

2.1.3.1 Setting Notes......................................................................................................... 30

2.1.3.2 Settings................................................................................................................. 37

2.1.4 Power System Data 1...................................................................................................40

2.1.4.1 Topology of the Protected Object........................................................................... 40

2.1.4.2 General Power System Data....................................................................................55

2.1.4.3 Assignment of Protection Functions to Measuring Locations / Sides.........................68

2.1.4.4 Circuit Breaker Data................................................................................................71

2.1.4.5 Settings................................................................................................................. 72

2.1.4.6 Information List..................................................................................................... 84

2.1.5 Setting Groups............................................................................................................ 85

2.1.5.1 Purpose of Setting Groups......................................................................................85

2.1.5.2 Setting Notes......................................................................................................... 85

2.1.5.3 Settings................................................................................................................. 85

2.1.5.4 Information List..................................................................................................... 85

2.1.6 Power System Data 2...................................................................................................86

2.1.6.1 Setting Notes......................................................................................................... 86

2.1.6.2 Settings................................................................................................................. 88

2.1.6.3 Information List..................................................................................................... 89

2.2 Differential Protection....................................................................................................... 92

2.2.1 Functional Description of the Differential Protection.....................................................92

2.2.2 Differential Protection for Transformers..................................................................... 101

2.2.3 Differential Protection for Generators, Motors, and Series Reactors.............................108

2.2.4 Differential Protection for Shunt Reactors...................................................................109

2.2.5 Differential Protection for Mini-Busbars and Short Lines..............................................110

2.2.6 Single-phase Differential Protection for Busbars......................................................... 111

SIPROTEC 4, 7UT6x, Manual 7

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

2.2.7 Setting Notes.............................................................................................................115

2.2.8 Settings.....................................................................................................................121

2.2.9 Information List.........................................................................................................122

2.3 Restricted Earth Fault Protection......................................................................................125

2.3.1 Application Examples.................................................................................................125

2.3.2 Function Description..................................................................................................128

2.3.3 Setting Notes.............................................................................................................133

2.3.4 Settings.....................................................................................................................134

2.3.5 Information List.........................................................................................................134

2.4 Time Overcurrent Protection for Phase and Residual Currents...........................................136

2.4.1 General..................................................................................................................... 136

2.4.1.1 Definite Time, Instantaneous Overcurrent Protection............................................ 136

2.4.1.2 Inverse Time Overcurrent Protection.....................................................................140

2.4.1.3 Manual Close Command.......................................................................................143

2.4.1.4 Dynamic Cold Load Pickup....................................................................................143

2.4.1.5 Inrush Restraint....................................................................................................143

2.4.1.6 Fast Busbar Protection Using Reverse Interlocking.................................................145

2.4.2 Time Overcurrent Protection for Phase Currents......................................................... 146

2.4.2.1 Setting Notes....................................................................................................... 146

2.4.2.2 Settings............................................................................................................... 152

2.4.2.3 Information List................................................................................................... 154

2.4.3 Time Overcurrent Protection for Residual Current.......................................................155

2.4.3.1 Setting Notes....................................................................................................... 155

2.4.3.2 Settings............................................................................................................... 159

2.4.3.3 Information List................................................................................................... 160

2.5 Time Overcurrent Protection for Earth Current.................................................................161

2.5.1 General..................................................................................................................... 161

2.5.2 Definite Time, Instantaneous Overcurrent Protection..................................................161

2.5.3 Inverse Time Overcurrent Protection.......................................................................... 163

2.5.4 Manual Close Command............................................................................................ 165

2.5.5 Dynamic Cold Load Pickup......................................................................................... 165

2.5.6 Inrush Restraint......................................................................................................... 165

2.5.7 Setting Notes.............................................................................................................166

2.5.8 Settings.....................................................................................................................169

2.5.9 Information List.........................................................................................................171

2.6 Dynamic Cold Load Pickup for Time Overcurrent Protection............................................. 172

2.6.1 Functional Description...............................................................................................172

2.6.2 Setting Notes.............................................................................................................174

2.6.3 Settings.....................................................................................................................175

2.6.4 Information List.........................................................................................................175

2.7 Single-Phase Time Overcurrent Protection....................................................................... 177

2.7.1 Functional Description...............................................................................................177

2.7.2 High-impedance Differential Protection......................................................................178

2.7.3 Tank Leakage Protection............................................................................................180

2.7.4 Setting Notes.............................................................................................................181

2.7.5 Settings.....................................................................................................................185

2.7.6 Information List.........................................................................................................185

8 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

2.8 Unbalanced Load Protection............................................................................................187

2.8.1 Functional Description...............................................................................................187

2.8.2 Setting Notes.............................................................................................................193

2.8.3 Settings.....................................................................................................................198

2.8.4 Information List.........................................................................................................199

2.9 Thermal Overload Protection...........................................................................................200

2.9.1 General..................................................................................................................... 200

2.9.2 Overload Protection Using a Thermal Replica..............................................................200

2.9.3 Overload protection using a thermal replica with ambient temperature influence.......202

2.9.4 Hot-Spot Calculation and Determination of the Ageing Rate ...................................... 203

2.9.5 Setting Notes.............................................................................................................205

2.9.6 Settings.....................................................................................................................209

2.9.7 Information List.........................................................................................................210

2.10 RTD-Boxes for Overload Detection................................................................................... 211

2.10.1 Functional Description...............................................................................................211

2.10.2 Setting Notes.............................................................................................................211

2.10.3 Settings.....................................................................................................................211

2.10.4 Information List.........................................................................................................216

2.11 Overexcitation Protection................................................................................................218

2.11.1 Functional Description...............................................................................................218

2.11.2 Setting Notes.............................................................................................................219

2.11.3 Settings.....................................................................................................................222

2.11.4 Information List.........................................................................................................222

2.12 Reverse Power Protection................................................................................................ 224

2.12.1 Functional Description...............................................................................................224

2.12.2 Setting Notes.............................................................................................................225

2.12.3 Settings.....................................................................................................................227

2.12.4 Information List.........................................................................................................228

2.13 Forward Power Supervision............................................................................................. 229

2.13.1 Functional Description...............................................................................................229

2.13.2 Setting Notes.............................................................................................................230

2.13.3 Settings.....................................................................................................................232

2.13.4 Information List.........................................................................................................232

2.14 Undervoltage Protection................................................................................................. 233

2.14.1 Functional Description...............................................................................................233

2.14.2 Setting Notes.............................................................................................................234

2.14.3 Settings.....................................................................................................................235

2.14.4 Information List.........................................................................................................235

2.15 Overvoltage Protection....................................................................................................236

2.15.1 Functional Description...............................................................................................236

2.15.2 Setting Notes.............................................................................................................237

2.15.3 Settings.....................................................................................................................237

2.15.4 Information List.........................................................................................................238

2.16 Frequency Protection...................................................................................................... 239

2.16.1 Functional Description...............................................................................................239

2.16.2 Setting Notes.............................................................................................................240

SIPROTEC 4, 7UT6x, Manual 9

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

2.16.3 Settings.....................................................................................................................242

2.16.4 Information List.........................................................................................................242

2.17 Circuit Breaker Failure Protection.....................................................................................244

2.17.1 Functional Description...............................................................................................244

2.17.2 Setting Notes.............................................................................................................247

2.17.3 Settings.....................................................................................................................250

2.17.4 Information List.........................................................................................................250

2.18 External Trip Commands................................................................................................. 251

2.18.1 Functional Description...............................................................................................251

2.18.2 Setting Notes.............................................................................................................252

2.18.3 Settings.....................................................................................................................252

2.18.4 Information List.........................................................................................................252

2.19 Monitoring Functions......................................................................................................254

2.19.1 Measurement Supervision......................................................................................... 254

2.19.1.1 Hardware Monitoring...........................................................................................254

2.19.1.2 Software Monitoring............................................................................................ 254

2.19.1.3 Monitoring of Measured Quantities...................................................................... 255

2.19.1.4 Setting Notes....................................................................................................... 257

2.19.1.5 Settings............................................................................................................... 257

2.19.1.6 Information List................................................................................................... 258

2.19.2 Trip Circuit Supervision.............................................................................................. 259

2.19.2.1 Functional Description......................................................................................... 259

2.19.2.2 Setting Notes....................................................................................................... 261

2.19.2.3 Settings............................................................................................................... 262

2.19.2.4 Information List................................................................................................... 262

2.19.3 Monitoring................................................................................................................ 262

2.19.3.1 Broken Wire Detection, Fuse Failure Monitoring....................................................262

2.19.3.2 Setting Notes....................................................................................................... 265

2.19.3.3 Settings............................................................................................................... 266

2.19.3.4 Information List................................................................................................... 266

2.19.4 Malfunction Responses of the Monitoring Functions.................................................. 268

2.19.4.1 Summary of the most important Monitoring Functions.........................................268

2.19.5 Parameterisation Error............................................................................................... 270

2.20 Function Control............................................................................................................. 271

2.20.1 Pickup Logic for the Entire Device.............................................................................. 271

2.20.2 Tripping Logic for the Entire Device............................................................................271

2.21 Disconnection of Measuring Locations.............................................................................273

2.21.1 Functional Description...............................................................................................273

2.21.2 Information List.........................................................................................................274

2.22 Auxiliary Functions..........................................................................................................276

2.22.1 Processing of Messages............................................................................................. 276

2.22.1.1 General................................................................................................................276

2.22.1.2 Operational Annunciations (Buffer: Event Log)..................................................... 277

2.22.1.3 Fault Annunciations (Buffer: Trip Log).................................................................. 277

2.22.1.4 Spontaneous Annunciations.................................................................................278

2.22.1.5 General Interrogation...........................................................................................278

2.22.1.6 Switching Statistics.............................................................................................. 278

2.22.2 Measurement............................................................................................................278

2.22.2.1 Display and Transmission of Measured Valuables..................................................278

2.22.2.2 Settings............................................................................................................... 282

2.22.2.3 Information List................................................................................................... 282

10 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

2.22.3 Thermal Measurement...............................................................................................285

2.22.3.1 Functional Description......................................................................................... 285

2.22.3.2 Information List................................................................................................... 286

2.22.4 Differential and Restraining Measured Values.............................................................287

2.22.4.1 Functional Description......................................................................................... 287

2.22.4.2 Information List................................................................................................... 287

2.22.5 Set Points for Measured Values.................................................................................. 288

2.22.5.1 User Defined Set-Points........................................................................................288

2.22.6 Energy Metering........................................................................................................288

2.22.6.1 Functional Description......................................................................................... 288

2.22.6.2 Information List................................................................................................... 289

2.22.7 Flexible Function....................................................................................................... 289

2.22.7.1 Functional Description......................................................................................... 289

2.22.7.2 Setting Notes....................................................................................................... 290

2.22.7.3 Settings............................................................................................................... 294

2.22.7.4 Information List................................................................................................... 297

2.22.8 Oscillographic Fault Recording...................................................................................298

2.22.8.1 Functional Description......................................................................................... 298

2.22.8.2 Setting Notes....................................................................................................... 298

2.22.8.3 Settings............................................................................................................... 299

2.22.8.4 Information List................................................................................................... 299

2.22.9 Commissioning Aids.................................................................................................. 299

2.22.9.1 Web-Monitor........................................................................................................299

2.23 Average Values, Minimum and Maximum Values.............................................................301

2.23.1 Demand Measurement Setup.....................................................................................301

2.23.1.1 Setting Notes....................................................................................................... 301

2.23.1.2 Settings............................................................................................................... 302

2.23.2 Min/Max Measurement Setup.................................................................................... 302

2.23.2.1 Setting Notes....................................................................................................... 302

2.23.2.2 Settings............................................................................................................... 302

2.23.2.3 Information List................................................................................................... 302

2.24 Command Processing......................................................................................................303

2.24.1 Control Authorization................................................................................................ 303

2.24.1.1 Type of Commands.............................................................................................. 303

2.24.1.2 Sequence in the Command Path...........................................................................303

2.24.1.3 Interlocking......................................................................................................... 304

2.24.1.4 Recording and Acknowledgement of Commands.................................................. 307

2.24.1.5 Information List................................................................................................... 307

3 Mounting and Commissioning................................................................................................................. 309

3.1 Mounting and Connections............................................................................................. 310

3.1.1 Configuration Information......................................................................................... 310

3.1.2 Hardware Modifications.............................................................................................314

3.1.2.1 General................................................................................................................314

3.1.2.2 Disassembly.........................................................................................................316

3.1.2.3 Switching Elements on Printed Circuit Boards....................................................... 320

3.1.2.4 Interface Modules................................................................................................ 336

3.1.2.5 Reassembly..........................................................................................................342

3.1.3 Mounting.................................................................................................................. 343

3.1.3.1 Panel Flush Mounting...........................................................................................343

3.1.3.2 Rack and Cubicle Mounting.................................................................................. 344

3.1.3.3 Panel Surface Mounting....................................................................................... 347

3.1.3.4 Removing the Transport Protection.......................................................................348

SIPROTEC 4, 7UT6x, Manual 11

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

3.2 Checking Connections.....................................................................................................349

3.2.1 Checking Data Connections of Interfaces................................................................... 349

3.2.2 Checking the System Connections............................................................................. 351

3.3 Commissioning............................................................................................................... 354

3.3.1 Test Mode / Transmission Block..................................................................................355

3.3.2 Test Time Synchronisation Interface...........................................................................355

3.3.3 Testing the System Interface......................................................................................355

3.3.4 Checking the switching states of the binary Inputs/Outputs........................................357

3.3.5 Checking the Setting Consistency.............................................................................. 359

3.3.6 Secondary Tests.........................................................................................................365

3.3.7 Circuit Breaker Failure Protection Tests.......................................................................370

3.3.8 Symmetrical, Primary Current Tests on the Protected Object.......................................372

3.3.9 Zero Sequence Current Tests on the Protected Object.................................................378

3.3.10 Current Tests for Busbar Protection............................................................................ 383

3.3.11 Testing of the Non-Assigned 1-Phase Current Inputs.................................................. 385

3.3.12 Checking the Voltage Connections and Polarity Check................................................386

3.3.13 Testing User-defined Functions..................................................................................390

3.3.14 Stability Check and Triggering Oscillographic Recordings............................................391

3.4 Final Preparation of the Device........................................................................................393

4 Technical Data.......................................................................................................................................... 395

4.1 General...........................................................................................................................396

4.1.1 Analogue Inputs........................................................................................................ 396

4.1.2 Auxiliary Voltage....................................................................................................... 396

4.1.3 Binary Inputs and Outputs .........................................................................................397

4.1.4 Frequency Measurement via the Positive Phase-sequence Voltage U1.........................398

4.1.5 Communications Interfaces....................................................................................... 399

4.1.6 Electrical Tests...........................................................................................................403

4.1.7 Mechanical Tests....................................................................................................... 405

4.1.8 Climatic Stress Test....................................................................................................405

4.1.9 Service Conditions..................................................................................................... 406

4.1.10 Construction .............................................................................................................406

4.2 Differential Protection..................................................................................................... 408

4.3 Restricted Earth Fault Protection......................................................................................414

4.4 Time Overcurrent Protection for Residual Current............................................................ 416

4.5 Time Overcurrent Protection for Earth Current.................................................................428

4.6 Dynamic Cold Load Pickup for Time Overcurrent Protection............................................. 430

4.7 Single-Phase Time Overcurrent Protection....................................................................... 431

4.8 Unbalanced Load Protection............................................................................................432

4.9 Thermal Overload Protection...........................................................................................440

4.10 RTD-Boxes for Overload Detection................................................................................... 443

4.11 Overexcitation Protection................................................................................................444

4.12 Reverse Power Protection................................................................................................ 446

4.13 Forward Power Supervision............................................................................................. 447

4.14 Undervoltage Protection................................................................................................. 449

4.15 Overvoltage Protection....................................................................................................450

12 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

4.16 Frequency Protection...................................................................................................... 451

4.17 Circuit Breaker Failure Protection.....................................................................................453

4.18 External Trip Commands................................................................................................. 454

4.19 Monitoring Functions......................................................................................................455

4.20 User-defined Functions (CFC).......................................................................................... 456

4.21 Flexible Function.............................................................................................................459

4.22 Additional Functions....................................................................................................... 461

4.23 Dimensions.....................................................................................................................465

4.23.1

4.23.2

4.23.3

4.23.4

4.23.5

4.23.6

Panel surface mounting (housing size 1/3).................................................................. 465

Panel Surface Mounting (housing Size 1/2)..................................................................465

Panel Surface Mounting (housing Size 1/1)..................................................................466

Panel flush mounting or cubicle mounting (housing size 1/3)...................................... 467

Panel flush mounting or cubicle mounting (housing size 1/2)...................................... 468

Panel flush mounting or cubicle mounting (housing size 1/1)...................................... 469

4.23.7 RTD box.....................................................................................................................470

A Ordering Information and Accessories.....................................................................................................471

A.1 Differential Protection 7UT612 for 2 Measuring Locations................................................472

A.2 Differential Protection 7UT613 for 3 Measuring Locations................................................474

A.3 1.1.3 Differential Protection 7UT633 and 7UT635 for 3 to 5 measuring locations.............477

A.4 Accessories.....................................................................................................................480

B Terminal Assignments..............................................................................................................................483

B.1 Panel Flush and Cubicle Mounting...................................................................................484

B.2 Panel Surface Mounting.................................................................................................. 494

C Connection Examples............................................................................................................................... 505

C.1 Current Transformer Connection Examples......................................................................506

C.2 Voltage Transformer Connection Examples......................................................................519

C.3 Assignment of Protection Functions to Protected Objects.................................................521

D Current Transformer Requirements......................................................................................................... 523

D.1 General Requirements.....................................................................................................524

E Default Settings and Protocol-dependent Functions............................................................................... 529

E.1 Default Settings LEDs...................................................................................................... 530

E.2 Default Settings Binary Inputs......................................................................................... 531

E.3 Default Settings Binary Outputs.......................................................................................532

E.4 Default Settings Function Keys........................................................................................ 533

E.5 Default Display................................................................................................................534

E.6 Pre-defined CFC Charts....................................................................................................536

E.7 Protocol-dependent Functions.........................................................................................537

F Functions, Settings, Information..............................................................................................................539

F.1 Functional Scope............................................................................................................ 540

F.2 Settings.......................................................................................................................... 543

F.3 Information List.............................................................................................................. 587

SIPROTEC 4, 7UT6x, Manual 13

C53000-G1176-C230-5, Edition 09.2016

Table of Contents

F.4 Group Alarms..................................................................................................................654

F.5 Measured Values.............................................................................................................656

Literature.................................................................................................................................................. 665

Glossary.................................................................................................................................................... 667

Index.........................................................................................................................................................677

14 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

1

Introduction

The device family SIPROTEC 7UT6x devices is introduced in this section. An overview of the devices is

presented in their application, characteristics, and scope of functions.

1.1 Overall Operation 16

1.2 Application Scope 19

1.3 Characteristics 21

SIPROTEC 4, 7UT6x, Manual 15

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.1 Overall Operation

1.1

Overall Operation

The digital differential protection devices SIPROTEC 4 7UT6x are equipped with a powerful microprocessor

system. This provides fully numerical processing of all functions in the device, from the acquisition of the

measured values up to the output of commands to the circuit breakers

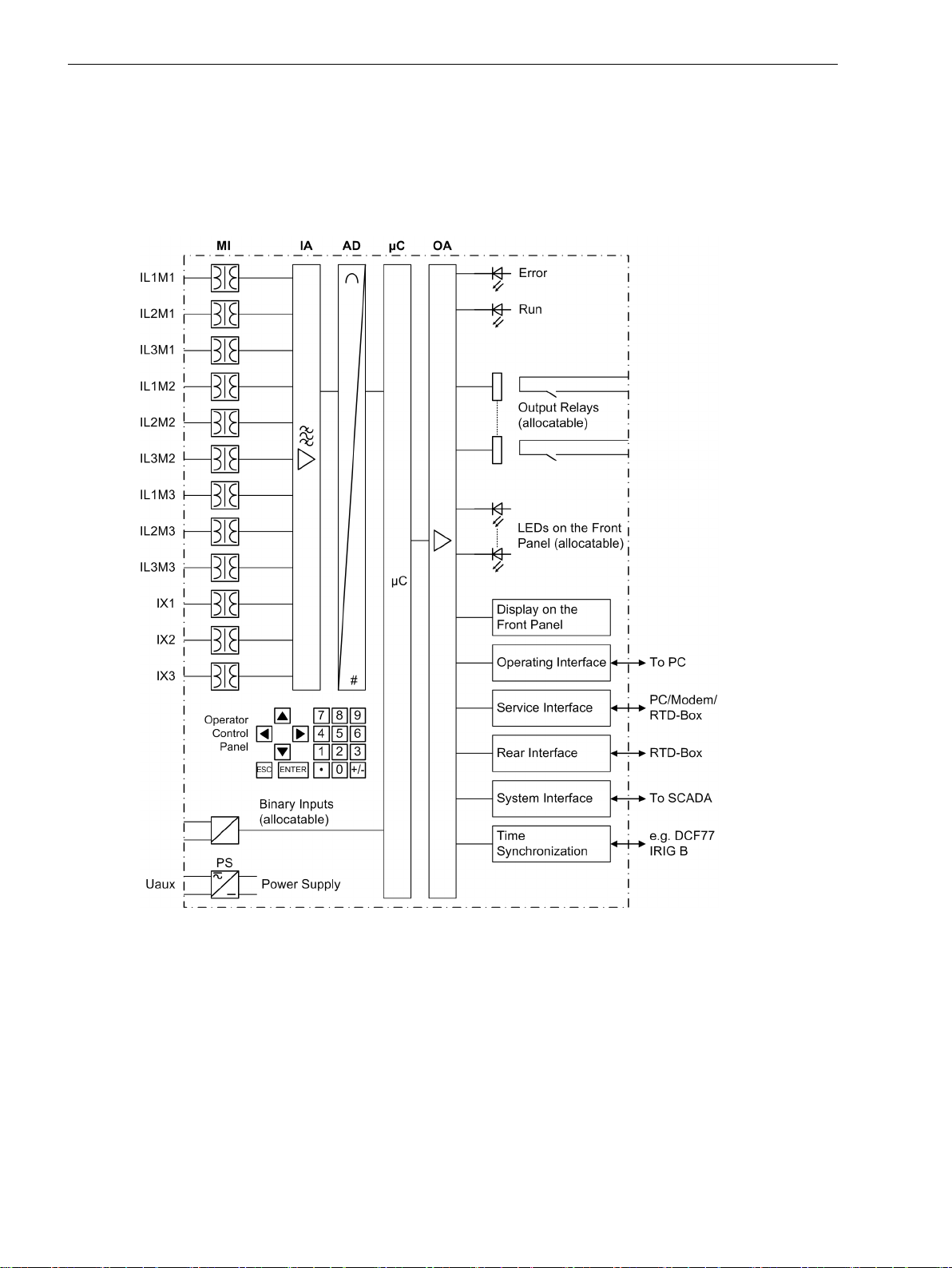

[hardwarestruktur-270203-st, 1, en_GB]

Figure 1-1

Analogue Inputs

The measuring inputs MI transform the currents and voltages derived from the instrument transformers and

match them to the internal signal levels for processing in the device. Depending on the version, the device

features between 8 current inputs (7UT612), 12 current inputs (7UT613/7UT633) and 16 current inputs

(7UT635). Three current inputs are provided for the input of the phase currents at each end of the protected

zone (= measuring points) of a 3-phase protected object; depending on the version, one or more further

single-phase measuring inputs (= additional inputs) may be used for any desired current, e.g. the earth current

measured between the starpoint of a transformer winding and earth, or other single-phase measuring

16 SIPROTEC 4, 7UT6x, Manual

Hardware structure of the digital differential current protection relay 7UT6x — Example of a

7UT613 for a three-winding transformer with measuring locations M1, M2 and M3, with 3

auxiliary 1-phase inputs X1, X2 and X3

C53000-G1176-C230-5, Edition 09.2016

currents. One or two additional inputs can be designed for highly sensitive current detection. thus allowing,

for example, the detection of small tank leakage currents of power transformers or reactors, or — with an

external series resistor — processing of a voltage (e.g. for high-impedance unit protection).

The versions 7UT613 and 7UT633 are available with 4 voltage inputs. 3 of these inputs can be connected to

the phase-to-earth voltages. Another voltage input can be used for a single-phase voltage, such as a displacement voltage or any other voltage. In principle, the differential protection is designed such that it can operate

without measured voltages. However, the integrated voltage protection functions use the measuring voltage

inputs, as for example the overexcitation protection, to calculate the induction in transformers or shunt reactors. In addition, the measuring voltages and the quantities derived from them (induction, power, power

factor) can be displayed, annunciated and/or monitored by the device if the voltages are connected.

The analogue signals are then routed to the input amplifier group IA.

The input amplifier group IA provides high-resistance termination for the analogue input quantities and

contains filters that are optimised for measured value processing with regard to bandwidth and processing

speed.

The analogue-to-digital (AD) stage consists of a multiplexor, an analogue-to-digital (A/D) converter and

memory components for the transmission of digital signals to the microcomputer system.

Microcomputer system

In addition to the control of the measured values, the actual protection and control functions are processed in

the μC microcomputer system. In particular, the following is included:

filtering and conditioning of measured signals

•

continuous monitoring of measured signals

•

monitoring of the pickup conditions of the individual protective functions

•

Conditioning of the measured signals: i.e. conversion of currents according to the connection group of

•

the protected transformer (when used for transformer differential protection) and matching of the

current amplitudes

Introduction

1.1 Overall Operation

formation of the differential and restraint quantities

•

Frequency analysis of the phase currents and restraint quantities

•

calculation of the RMS values of the currents for overload detection and adjustment of the temperature

•

rise of the protected object

retrieval of threshold values and time sequences

•

processing of signals for the logic functions

•

processing User-defined Logic Functions

•

reaching trip command decisions

•

check of control commands and output to switching devices

•

storage of indications, fault data and fault values for fault analysis purposes

•

calculation and display/annunciation of measured values and the quantities derived from them

•

management of the operating system and its functions, e.g. data storage, real-time clock, communica-

•

tion, interfaces, etc.

The information is provided via output amplifier OA.

Binary Inputs and Outputs

Binary inputs and outputs from and to the computer system are routed via the I/O modules (inputs and

outputs). The computer system obtains the information from the system (e.g remote resetting) or from other

devices (e.g. blocking commands). These outputs include, in particular, trip commands to switchgear and

signals for remote annunciation of important events and conditions.

SIPROTEC 4, 7UT6x, Manual 17

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.1 Overall Operation

Front Elements

Devices with operator panel have light emitting diodes (LEDs) and a display screen (LCD) on the front panel to

provide information such as measured values, messages related to events or faults, status, and functional

status.

Integrated control and numeric keys in conjunction with the LCD facilitate local interaction with the 7UT6. All

information of the device can be accessed using the integrated control and numeric keys. The information

includes protective and control settings, operating and fault messages, and measured values.

In addition, control of circuit breakers and other equipment is possible from the 7UT6 front panel.

The versions 7UT612 and 7UT613 have a 4-line LC display in front, whereas the versions 7UT633 and 7UT635

have a graphic display. The latter devices also have integrated keyswitches and control buttons for on-site

control.

Serial interfaces

Via the serial operator interface in the front panel, communication with a personal computer using the operating program DIGSI is possible. This facilitates a comfortable handling of all device functions.

A serial service interface can likewise make communication via PC with the device possible by using DIGSI.

This port is especially well suited for the fixed wiring of the devices to the PC or operation via a modem.

All data can be transferred to a central control or monitoring system via the serial system port. This interface

may be provided with various protocols and physical transmission schemes to suit the particular application.

A further interface is provided for the time synchronization of the internal clock via external synchronization

sources.

Further communication protocols can be realized via additional interface modules.

The service port, or an optional additional interface, can also be used to connect a RTD-Box (= resistance

temperature detector) for entering external temperatures (e.g. for overload protection). The additional interface is available for all 7UT6x devices.

Power Supply

The functional units described are supplied by a power supply PS with the necessary power in the different

voltage levels. Transient dips of the supply voltage, which may occur during short-circuit in the power supply

system, are bridged by a capacitor (see also Technical Data).

18 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.2 Application Scope

1.2

Application Scope

The numerical differential protection SIPROTEC 4 7UT6x is a selective short-circuit protection for transformers

of all voltage levels, for rotating machines, for series and shunt reactors, or for short lines and mini-busbars

with 2 to 5 feeders (depending on the version). Being a single-phase device, it can also be used for small

busbars with up to 7, 9 or 12 feeders (depending on the version). The individual application can be configured, which ensures optimum matching to the protected object.

The devices 7UT613, 7UT633 and 7UT635 can also be run with 2-phase connection for 16.7 Hz applications.

A major advantage of the differential protection principle is the instantaneous tripping in the event of a short-

circuit at any point within the entire protected zone. The current transformers limit the protected zone at the

ends towards the network. This rigid limit is the reason why the differential protection scheme shows such an

ideal selectivity.

For use as transformer protection, the device is normally connected to the current transformer sets which limit

the power transformer windings against the remainder of the system. The phase displacement and the interlinkage of the currents due to the winding connection of the transformer are matched in the device by calculation algorithms. The earthing conditions of the starpoint(s) can be adapted to the user's requirements and are

automatically considered in the matching algorithms. Also, the currents from multiple measuring points on

one side of the protected object can be combined.

For use as generator or motor protection, the device compares the currents in the starpoint leads of the

machine and at its terminals. Similar applies for series reactors.

Short lines or mini-busbars with 2 to 5 ends or feeders (depending on the version) can be protected as well.

Short means that the current transformer connections from the CTs to the device cause no impermissible

burden for the current transformers.

For transformers, generators, motors, or shunt reactors with earthed starpoint, the current between the starpoint and earth can be measured and used for highly sensitive earth fault protection.

The 7, 9 or 12 standard current inputs (depending on the version) of the device allow for a single-phase

protection for busbars with up to 7, 9 or 12 feeders. One 7UT6x is used per phase in this case. Alternatively,

(external) summation transformers can be installed in order to allow a busbar protection for up to 7, 9 or 12

feeders with one single 7UT6x relay.

Where not all analog measuring inputs are needed for the measured values of the protected object, the

remaining inputs can be used for other, independent measurement or protection tasks. If a 7UT635 (with 5

threephase measuring inputs) is used, for instance, on a three-winding transformer, the two remaining measuring inputs c

One or two additional current inputs designed for very high sensitivity are also available. They may be used

e.g. for detection of small leakage currents between the tank of transformers or reactors an earth, thus recognising even high-resistance faults. High-resistance voltage measurement is also possible using an external

series resistor.

For transformers (including auto-transformers), generators, and shunt reactors, a high-impedance unit protection system can be formed using high-impedance earth fault protection. In this case, the currents of all current

transformers (of equal design) at the ends of the protected zone feed a common (external) high-ohmic

resistor. The current of this resistor is measured using one of the high-sensitive current inputs of the device.

The device provides backup time overcurrent protection functions for all types of protected objects. The functions can be enabled for any side or measuring location.

A thermal overload protection function is available for any type of machine. The functions can be enabled for

any side. External detectors account for the coolant temperature (by means of an external RTD-box). This

allows to calculate and output the hot-spot temperature and the relative ageing rate.

An unbalanced load protection function is provided for the detection of unsymmetrical currents. Phase failures

and negative sequence currents, which are especially dangerous for rotating machines, can thus be detected.

Performance functions allow devices with voltage measuring inputs to implement a reverse power protection

or monitor the forward power supply(in the power station sector). In the system they can be used for network

decoupling. Power results and their components can be emitted as measured values.

The versions with voltage inputs are provided with an integrated overexcitation protection for the detection of

excessive induction states in shunt reactions (transformers, shunt reactors). This protection function monitors

the ratio U/f, which is proportional to the induction B in the iron core. An imminent iron core saturation, which

SIPROTEC 4, 7UT6x, Manual 19

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.2 Application Scope

can occur especially in power stations following (full) load shutdown and/or frequency reduction, is thus

detected.

An undervoltage and overvoltage protection is to be integrated into devices with voltage measuring inputs. A

4-stage frequency protection monitors the frequency from the measured voltages.

A version for two-phase application is available for traction supply (transformers or generators) which provides

all functions suited for this application (differential protection, restricted earth fault protection, overcurrent

protection, overload protection).

A circuit breaker failure protection checks the reaction of one circuit breaker after a trip command.

Further-reaching protection, monitoring and measuring functions can be configured individually by means of

flexible functions. For up to 12 such functions, you determine yourself which measuring quantities to process

and how to process them, and also which reactions the device is to trigger when settable limit values are

overor undershot. Thus you can, for instance, create further time overcurrent protection functions and process

voltages, powers or symmetrical components.

One can configure the calculation of minimum, maximum and/or average values and/or minimum, maximum

of the average values of up to 20 selectable measured quantities, thus receiving one's own statistical data.

For the devices 7UT613, 7UT633 and 7UT635, you can optionally create some protective functions several

times and assign them flexibly to the measuring locations of the protected object. Examples: Time overcurrent

protection, breaker failure protection, and the like (see Technical Data).

20 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.3 Characteristics

1.3

General Features

Transformer Differential Protection

Characteristics

Powerful 32-bit microprocessor system

•

Complete digital measured value processing and control, from the sampling and digitalization of the

•

analogue input quantities to the initiation of outputs for tripping or closing circuit breakers

Complete galvanic and reliable separation between the internal processing circuits of the device and the

•

external measurement, control, and power supply circuits because of the design of the analog input

transducers, binary input and output modules, and the DC/DC or AC/DC converters

Suitable for power transformers, generator, motors, reactors, or smaller busbar arrangements, as well as

•

for multi-terminal lines and multi-winding transformers

Easy device operation through an integrated operator panel or by means of a connected personal

•

computer running DIGSI.

Current restraint tripping characteristic

•

Restraint feature against high inrush currents with 2nd harmonic

•

Restraint feature against high inrush currents with Current waveform analysis CWA

•

Restraint feature against transient and steady-state fault currents caused e.g. by overexcitation of trans-

•

formers, using a further harmonic (3rd or 5th harmonic)

Insensitivity to DC components and current transformer saturation

•

High level of stability even with different degrees of current transformer saturation

•

High-speed instantaneous trip in case of high-current transformer faults

•

Independent of the conditioning of the starpoint(s) of the power transformer

•

Adjustable to the conditioning of the starpoint(s) of the power transformer

•

Increased earth-fault sensitivity during detection of the ground current of an earthed transformer

•

winding

Integrated matching of the transformer connection group

•

Integrated matching of the transformation ratio including different rated currents of the transformer

•

windings.

Differential Protection for Generators and Motors

Current restraint tripping characteristic

•

High sensitivity

•

Short tripping time

•

Insensitivity to DC components and current transformer saturation

•

High level of stability even with different degrees of current transformer saturation

•

Independent of the conditioning of the starpoint

•

Differential Protection for Mini-Busbars and Short Lines

Tripping characteristic with current restraint

•

Short tripping time

•

Insensitivity to DC components and current transformer saturation

•

SIPROTEC 4, 7UT6x, Manual 21

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.3 Characteristics

High level of stability even with different degrees of current transformer saturation

•

Monitoring of the current connections with operation currents

•

Busbar Protection

Single-phase differential protection for a busbar with up to 7 or 9 or 12 feeders (depending on the

•

variant ordered)

Either one relay per phase or one relay connected via interposed summation current transformers

•

Tripping characteristic with current restraint

•

Short tripping time

•

Insensitivity to DC components and current transformer saturation

•

High level of stability even with different degrees of current transformer saturation

•

Monitoring of the current connections with operation currents.

•

Earth Fault Differential Protection

Earth fault protection for earthed transformer windings, generators, motors, shunt reactors, or starpoint

•

formers

Short command duration

•

High sensitivity for earth faults within the protected zone

•

High stability against external earth faults using the magnitude and phase relationship of through-

•

flowing earth current

2 restricted earth fault protection functions possible (only 7UT613/63x)

•

High-impedance Differential Protection

Highly sensitive fault current detection using a common (external) burden resistor

•

Short tripping time

•

Insensitive against DC components and current transformer saturation

•

High stability with optimum matching

•

Suitable for earth fault detection on earthed generators, motors, shunt reactors, and transformers,

•

including auto-transformers, with or without earthed starpoint

Suitable for any voltage measurement (via the resistor current) for application of high-impedance unit

•

protection

Tank Leakage Protection

For transformers or reactors the tank of which is installed isolated or with high resistance

•

Monitoring of the current flowing between the tank and ground

•

Can be connected via a „normal“ current input of the device or the special highly sensitive current input

•

(3 mA smallest setting)

Earth Fault Differential Protection

Earth fault protection for earthed transformer windings, generators, motors, shunt reactors, or starpoint

•

formers

Short command duration

•

High sensitivity for earth faults within the protected zone

•

22 SIPROTEC 4, 7UT6x, Manual

C53000-G1176-C230-5, Edition 09.2016

High stability against external earth faults using the magnitude and phase relationship of through-

•

flowing earth current

2 restricted earth fault protection functions possible (only 7UT613/63x)

•

Time Overcurrent Protection for Earth Current

Two definite time delayed overcurrent stages for the earth current, e.g. current between starpoint and

•

earth

Additionally, one inverse time delayed overcurrent stage for the earth current

•

Selection of various inverse time characteristics of different standards is possible, alternatively a user

•

defined characteristic can be specified

The 3 stages can be combined as desired

•

External blocking facility for any desired stage (e.g. for reverse interlocking)

•

Instantaneous trip when switching on a dead fault with any desired stage

•

Inrush restraint function with 2nd harmonic

•

Dynamic switchover of the time overcurrent parameters, e.g. during cold-loaded start-up of the power

•

plant

2 time overcurrent protection functions for earth current possible (only 7UT613/63x)

•

Introduction

1.3 Characteristics

1-phase Overcurrent Protection

Two definite time delayed overcurrent stages which can be combined as desired

•

For any 1-phase overcurrent detection

•

Can be assigned to the “normal” 1-phase current input or to the highly sensitive current input

•

Suitable for detection of very small current (e.g. for high-impedance unit protection or tank leakage

•

protection)

Suitable for detection of any desired AC voltage using an external series resistor (e.g. for high-impedance

•

unit protection)

External blocking facility for any stage

•

Unbalanced Load Protection

Evaluation of the negative sequence system of the three phase currents of any desired side of the

•

protected object or any three-phase measuring point

Two definite time delayed negative sequence current stages and one additional inverse time delayed

•

negative sequence current stage

Selection of various inverse time characteristics of different standards is possible, alternatively a user

•

defined characteristic can be specified

The stages can be combined as desired

•

Trip blocking on detection of broken wire

•

Thermal characteristic with adjustable negative sequence factor and adjustable cooldown time

•

Thermal Overload Protection

Thermal replica of current-initiated heat losses

•

True RMS current calculation

•

Can be assigned to any desired side of the protective object

•

Adjustable thermal warning stage

•

Adjustable current warning stage

•

SIPROTEC 4, 7UT6x, Manual 23

C53000-G1176-C230-5, Edition 09.2016

Introduction

1.3 Characteristics

With or without including the ambient or coolant temperature (by means of external resistance tempera-

•

ture detector via RTD-box)

Alternative evaluation of the hot-spot temperature according to IEC 60354 with calculation of the reserve

•

power and ageing rate (by means of external resistance temperature detector via RTD-box)

2 overload protection functions possible (only 7UT613/63x)

•

Overexcitation protection (only 7UT613 and 7UT633)

Processing of the voltage/frequency ration U/f, which represents the induction B of a shunt reactance

•

(transformer, shunt reactor)

Adjustable warning and tripping stage (with independent delay time)

•

Inverse standard characteristic or user-defined trip characteristic for calculation of the thermal stress,

•

selectable

Reverse power protection (only 7UT613 and 7UT633)

Real power calculation from positive sequence components

•

Short operating time or exact calculation of the active power via 16 cycles

•

Exact real power calculation for small power factor by compensating the error angle of the measuring

•

locations

Insensitive to power fluctuations

•

Short-time stage with external criteria, e.g. with closed emergency tripping

•

Forward power supervision (only 7UT613 and 7UT633)