Siemens SIPROTEC 4,7SJ80,7SK80 User Manual

Preface

Table of Contents

SIPROTEC 4

Modbus TCP Profile

7SJ80 / 7SK80

V4.7 and higher

Manual

Characteristic of the ModbusTCP Module

Configuration in DIGSI 4

Scaling of Measured Values

Time Synchronization

Modbus TCP Diagnosis for EN100+

Module

Redundant Modbus TCP

Technical Data

Index

1

2

3

4

5

6

7

C53000-L1840-C582-1

i

i

NOTE

For your own safety, observe the warnings and safety instructions contained in this document, if available.

Disclaimer of Liability

This document has been subjected to rigorous technical

review before being published. It is revised at regular intervals, and any modifications and amendments are included

in the subsequent issues. The content of this document

has been compiled for information purposes only. Although

Siemens AG has made best efforts to keep the document

as precise and up-to-date as possible, Siemens AG shall

not assume any liability for defects and damage which

result through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of

Siemens AG are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document

from time to time.

Document version: C53000-L1840-C582-1.00

Edition: 07.2015

Version of the product described: V4.7 and higher

Copyright

Copyright © Siemens AG 2015. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content

are not permitted, unless authorized in writing. All rights,

including rights created by patent grant or registration of a

utility model or a design, are reserved.

Registered Trademarks

SIPROTEC®, DIGSI®, SIGUARD®, SIMEAS®, and SICAM

are registered trademarks of Siemens AG. Any unauthorized use is illegal. All other designations in this document

can be trademarks whose use by third parties for their own

purposes can infringe the rights of the owner.

®

Preface

Purpose of the Manual

This manual describes the communication profile of the SIPROTEC Communication Module with MODBUS

TCP.

Target Audience

Protection system engineers, commissioning engineers, persons entrusted with the setting, testing and maintenance of automation, selective protection and control equipment, and operational crew in electrical installations and power plants.

Scope

This manual is valid for the SIPROTEC Communication Module with MODBUS TCP.

Additional Support

Should further information be desired or should particular problems arise which are not covered sufficiently

for the purchaser's purpose, the matter should be referred to the local Siemens representative.

Support

Our Customer Support Center provides a 24-hour service.

Phone:

Fax: +49 (180) 524-2471

E-Mail:

+49 (180) 524-7000

support.energy@siemens.com

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldtstraße 59

90459 Nürnberg

Germany

Phone: +49 (911) 433-7415

Fax: +49 (911) 433-7929

E-Mail:

Internet:

Notes on Safety

This document is not a complete index of all safety measures required for operation of the equipment

(module or device). However, it comprises important information that must be followed for personal safety, as

SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

poweracademy@siemens.com

www.siemens.com/poweracademy

3

!

!

!

i

i

Preface

well as to avoid material damage. Information is highlighted and illustrated as follows according to the degree

of danger:

DANGER

DANGER means that death or severe injury will result if the measures specified are not taken.

Comply with all instructions, in order to avoid death or severe injuries.

²

WARNING

WARNING means that death or severe injury may result if the measures specified are not taken.

Comply with all instructions, in order to avoid death or severe injuries.

²

CAUTION

CAUTION means that medium-severe or slight injuries can occur if the specified measures are not taken.

Comply with all instructions, in order to avoid moderate or minor injuries.

²

NOTICE

NOTICE means that property damage can result if the measures specified are not taken.

Comply with all instructions, in order to avoid property damage.

²

NOTE

Important information about the product, product handling or a certain section of the documentation which

must be given particular attention.

Qualified Electrical Engineering Personnel

Only qualified electrical engineering personnel may commission and operate the equipment (module, device)

described in this document. Qualified electrical engineering personnel in the sense of this manual are people

who can demonstrate technical qualifications as electrical technicians. These persons may commission,

isolate, ground and label devices, systems and circuits according to the standards of safety engineering.

Proper Use

The equipment (device, module) may be used only for such applications as set out in the catalogs and the

technical description, and only in combination with third-party equipment recommended and approved by

Siemens.

Problem-free and safe operation of the product depends on the following:

Proper transport

•

Proper storage, setup and installation

•

Proper operation and maintenance

•

4 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

Preface

When electrical equipment is operated, hazardous voltages are inevitably present in certain parts. If proper

action is not taken, death, severe injury or property damage can result:

The equipment must be grounded at the grounding terminal before any connections are made.

•

All circuit components connected to the power supply may be subject to dangerous voltage.

•

Hazardous voltages may be present in equipment even after the supply voltage has been disconnected

•

(capacitors can still be charged).

Operation of equipment with exposed current-transformer circuits is prohibited. Before disconnecting the

•

equipment, ensure that the current-transformer circuits are short-circuited.

The limiting values stated in the document must not be exceeded. This must also be considered during

•

testing and commissioning.

SIPROTEC 4, Modbus TCP Profile, Manual 5

C53000-L1840-C582-1, Edition 07.2015

6 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

Table of Contents

Preface................................................................................................................................................................3

1 Characteristic of the ModbusTCP Module.......................................................................................................... 9

1.1 General.................................................................................................................................10

1.2 Identification of Module and Firmware..................................................................................12

1.3 Supported Modbus Functions and Register Types...............................................................14

1.4 Table of Parameters............................................................................................................. 16

1.5 Further Ethernet Services and Protocols..............................................................................17

1.5.1 Services.......................................................................................................................... 17

1.5.2 Modbus TCP with IEC 61850 and GOOSE.................................................................... 17

2 Configuration in DIGSI 4................................................................................................................................... 19

2.1 Inserting and Adjusting a New Project..................................................................................20

2.2 Setting the Interfaces............................................................................................................27

2.3 Customization of the Allocations...........................................................................................30

3 Scaling of Measured Values............................................................................................................................. 41

3.1 Measurement conversion..................................................................................................... 42

3.2 Number representation depending on the parameterization................................................ 43

3.3 Counter-Value Scaling..........................................................................................................44

4 Time Synchronization....................................................................................................................................... 45

4.1 General.................................................................................................................................46

4.2 Time Synchronization with Modbus TCP..............................................................................47

4.3 Time/Date Transfer from Modbus TCP Master.....................................................................49

5 Modbus TCP Diagnosis for EN100+ Module.................................................................................................... 51

5.1 HTML Page...........................................................................................................................52

5.2 Modbus TCP Error Indication............................................................................................... 54

6 Redundant Modbus TCP.................................................................................................................................. 55

6.1 General Introduction and Requirements...............................................................................56

6.2 Configuration in DIGSI 4.......................................................................................................57

7 Technical Data.................................................................................................................................................. 59

7.1 Technical Data of EN100+....................................................................................................60

Index................................................................................................................................................................. 61

SIPROTEC 4, Modbus TCP Profile, Manual 7

C53000-L1840-C582-1, Edition 07.2015

8 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

1

Characteristic of the ModbusTCP Module

1.1 General 10

1.2 Identification of Module and Firmware 12

1.3 Supported Modbus Functions and Register Types 14

1.4 Table of Parameters 16

1.5 Further Ethernet Services and Protocols 17

SIPROTEC 4, Modbus TCP Profile, Manual 9

C53000-L1840-C582-1, Edition 07.2015

i

i

i

i

Characteristic of the ModbusTCP Module

1.1 General

1.1

General

With the EN100+ module firmware Modbus TCP from version V1.00, the Modbus TCP protocol is implemented in addition to other transmission protocols (e.g. IEC 61850 and GOOSE, see chapter 1.5.2) in the

100 Mbit Ethernet module EN100+.

NOTE

You can find all information about supporting the ModbusTCP protocol in the SIPROTEC 4 device manual.

NOTE

The required settings are made using the DIGSI 4 V4.90 and higher.

For the configuration of Modbus TCP a DIGSI 4 packet is required with IEC 61850 station configurator.

You can find detailed information on the EN100+ module and the IEC 61850 engineering in the following

manuals:

German edition: Ethernetmodul EN100+, Handbuch Bestellnr. C53000-G1100-C167

US-English edition: Ethernet Module EN100+, Manual Order no. C53000-G1140-C167

In the following text, the following abbreviations are used:

Abbreviation Meaning

EN100+ 100-MBit Ethernet module EN100+

Modbus TCP Modbus TCP over the internet protocol suite

Application

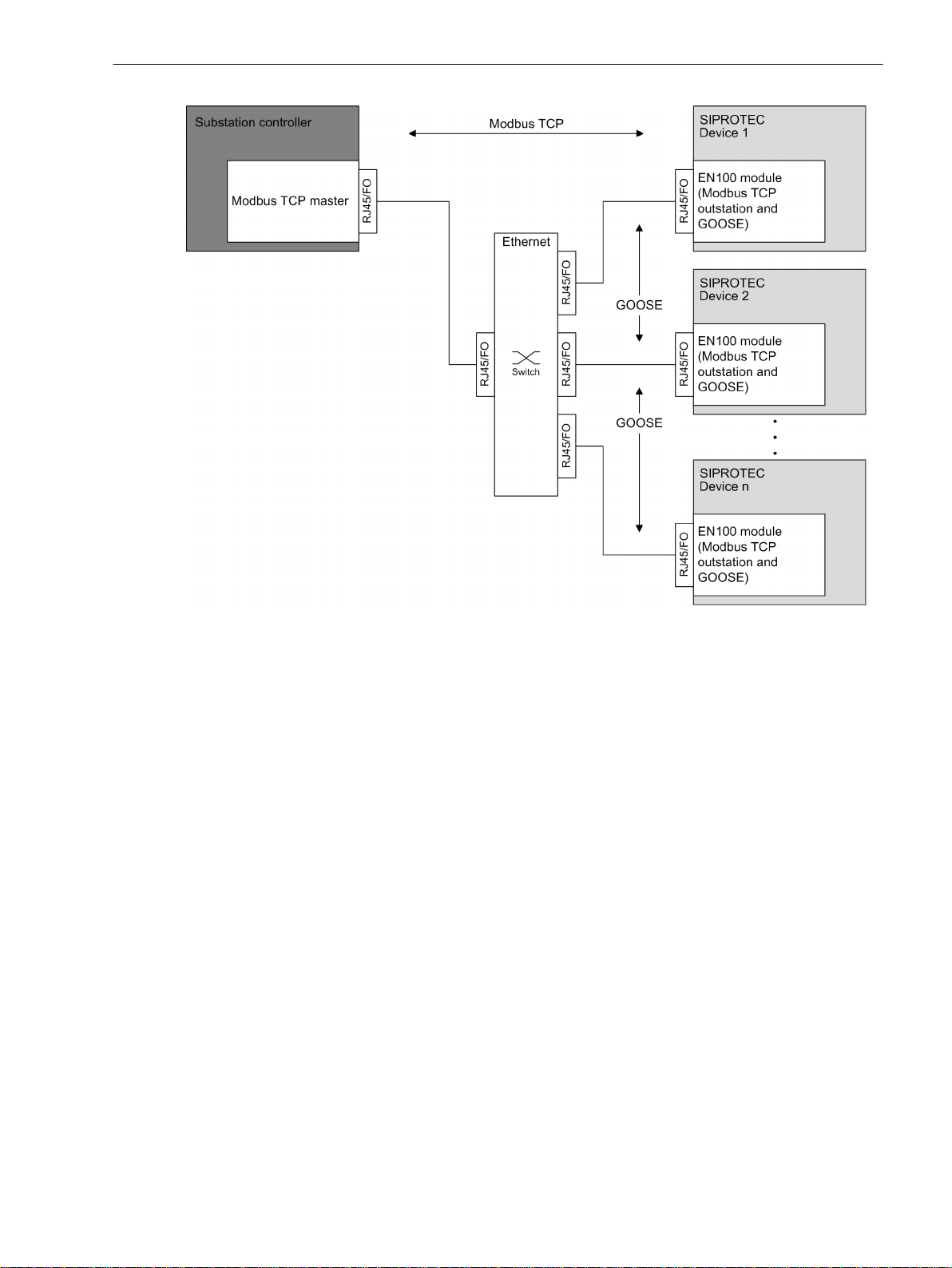

The application Communication shows an example of the SIPROTEC 4 devices with Modbus TCP and

GOOSE. Modbus TCP is used for communication to a substation controller and GOOSE is used for interdevice data exchange.

10 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

Characteristic of the ModbusTCP Module

1.1 General

[dw_appl_communication, 1, en_US]

Figure 1-1

Bus-Mapping Documents

You can download the bus mapping document for each device type at the following address:

http://siemens.siprotec.de/download_neu/index_e.html

The data objects, available via Modbus TCP, are described in the following manual:

7SJ80 / 7SK80 Modbus Bus Mapping, order number C53000-L1878-C581.

Accessories

The following Ethernet Patch Cables are available (double shielded (SFPT), LAN connector plugs on both

sides):

Cable Length

0.5 m 7KE6000-8G-D00-0AA5

1.0 m 7KE6000-8G-D00-1AA0

2.0 m 7KE6000-8G-D00-2AA0

3.0 m 7KE6000-8G-D00-3AA0

5.0 m 7KE6000-8G-D00-5AA0

10.0 m 7KE6000-8G-D01-0AA0

15.0 m 7KE6000-8G-D01-5AA0

20.0 m 7KE6000-8G-D02-0AA0

Application Communication

Order Number

SIPROTEC 4, Modbus TCP Profile, Manual 11

C53000-L1840-C582-1, Edition 07.2015

Characteristic of the ModbusTCP Module

1.2 Identification of Module and Firmware

1.2

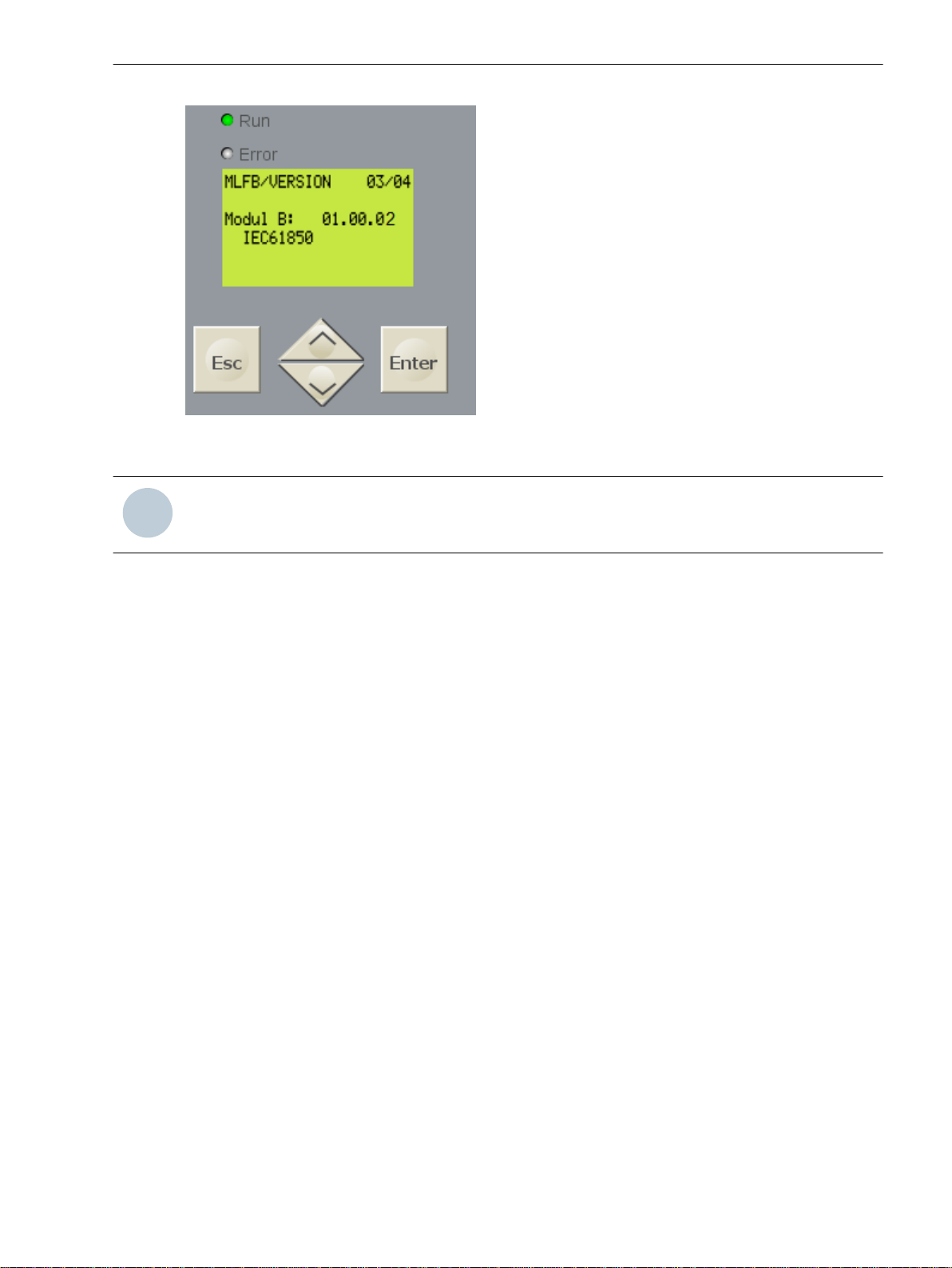

Modulinfo Menu

Identification of Module and Firmware

The Menu is available on the HMI display or via WebMonitor:

²

The menue shows for example module type, communication protocol, and network settings.

Select Enter → Test/Diagnosis → Modulinfo → Port B.

[sc_Modulinfo, 1, en_US]

Figure 1-2 Modulinfo

Module type:

EN100+ EN100+ module with electrical Ethernet interface

EN100_O+ EN100+ module with fiber-optic Ethernet interface

Communication protocol:

IEC61850 IEC 61850/GOOSE

EN100_O+Modbus TCP Modbus TCP with IEC61850/GOOSE option (see chapter Further Ethernet Serv-

MLFB/Version Menu

The Menue is available on the HMI display or via WebMonitor:

Select Enter → Settings → Setup/Extras → MLFB/Version.

²

Scroll down until the version number of the firmware on EN100+ module is shown.

²

ices and Protocols)

12 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

[sc_MLFBVersion, 1, en_US]

i

i

Figure 1-3 MLFB/Version

NOTE

Characteristic of the ModbusTCP Module

1.2 Identification of Module and Firmware

The firmware identification of IEC 61850 is shown here, even if the Modbus TCP firmware is loaded.

HTML page of the EN100+ module:

If Modbus TCP firmware is loaded, the menu Modbus TCP is available in the navigation pane.

The firmware version is shown on the homepage.

Refer to chapter

5.1 HTML Page

SIPROTEC 4, Modbus TCP Profile, Manual 13

C53000-L1840-C582-1, Edition 07.2015

i

i

Characteristic of the ModbusTCP Module

1.3 Supported Modbus Functions and Register Types

1.3

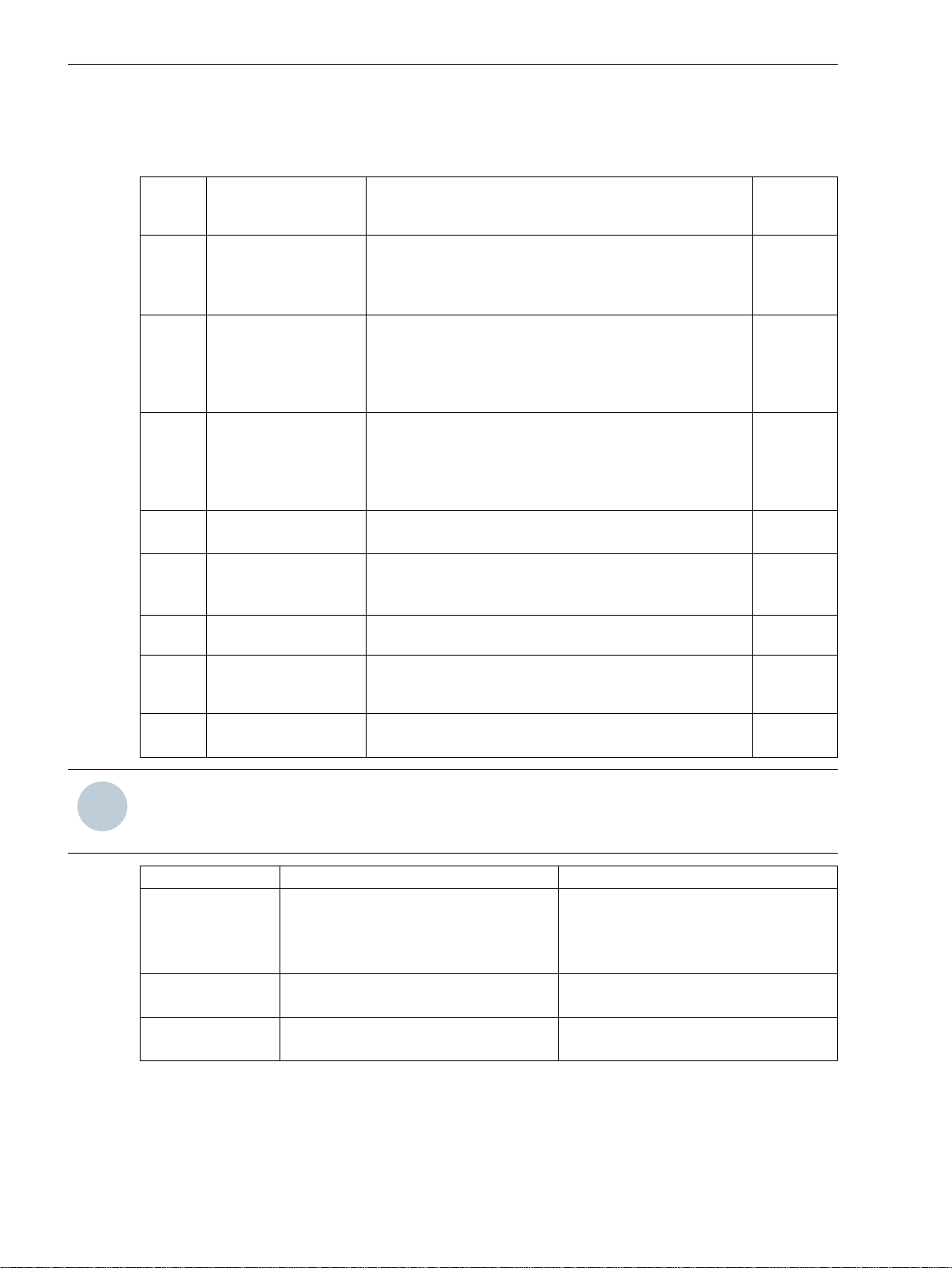

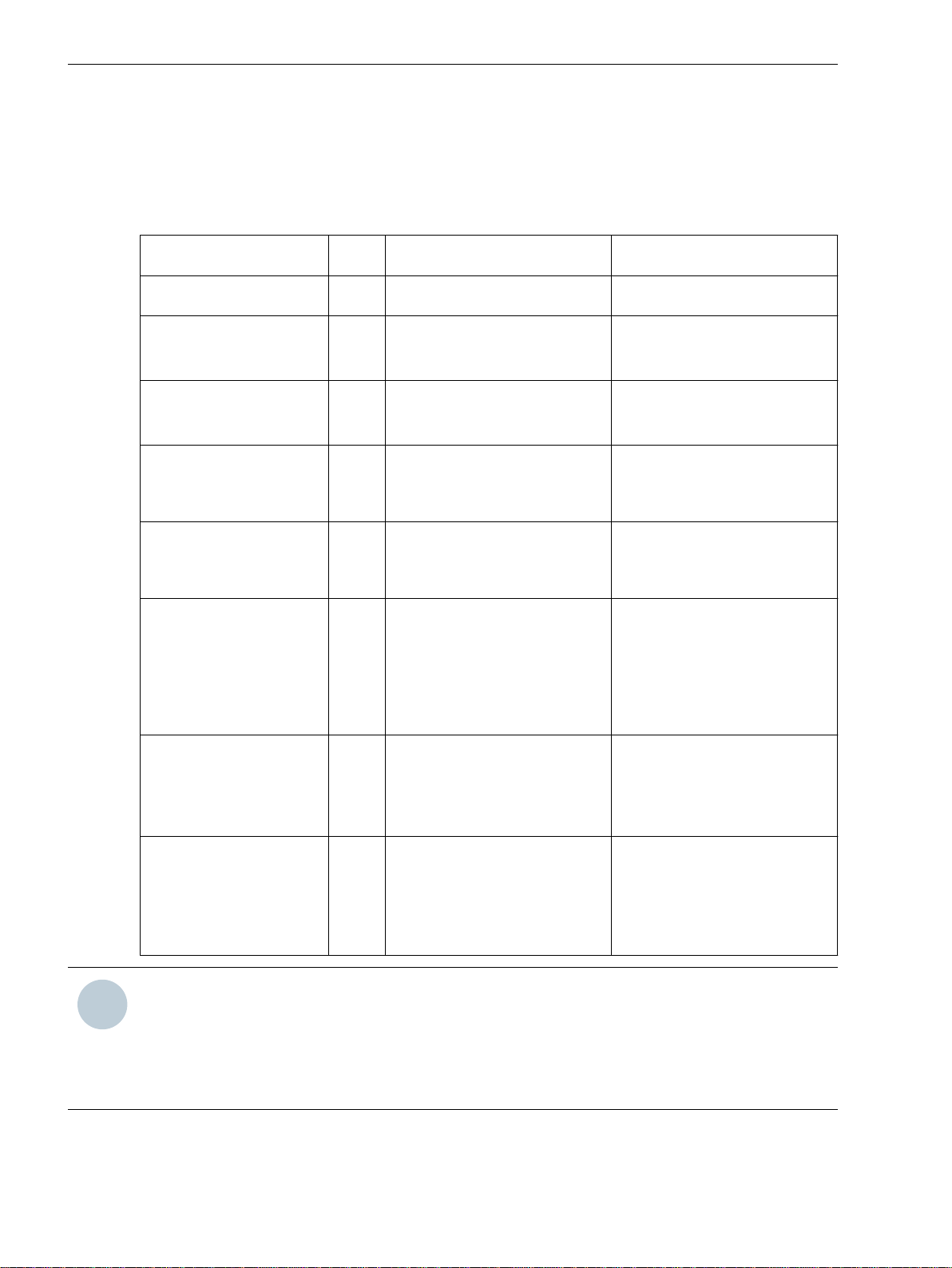

Supported Modbus Functions and Register Types

The Modbus TCP interface of the SIPROTEC 4 device supports the following function and register types:

Function

Code

Function Name Description Broadcast

1 Read Coil Status

(0X references)

2 Read Input Status

(1X references)

3 Read Holding Registers

(4X references)

4 Read Input Registers

(3X references)

5 Force Single Coil

(0X references)

7 Read Exception Status This function responds the value of the 8 Coil Status regis-

15 Force Multiple Coils

(0X references)

16 Preset Multiple Regs

(4X references)

Reading 1 or several Coil Status registers of the Modbus

slave.

The Coil Status registers reflect the ON/OFF status of

discrete outputs of the SIPROTEC 4 device.

Reading 1 or several Input Status registers of the Modbus

slave.

The Input Status registers reflect the ON/OFF status of

discrete inputs and the status of the protection function of

the SIPROTEC 4 device.

Reading 1 or several Holding Registers of the Modbus

slave.

The Holding Registers contain device-status information,

mean values of measured values, metered measurands

and others.

Reading 1 or several Input registers of the Modbus slave.

The Input registers contain recorded measured values.

Writing (force to ON or OFF) 1 Coil Status registers (and

the assigned binary input of the SIPROTEC 4 device).

Use function code 15 to force multiple Coil Status registers.

ters 257..264 as Exception Status to the Modbus master.

Writing (force to ON or OFF) 1 or several Coil Status registers (and the assigned binary input of the SIPROTEC 4

device).

Function presets 1 or several Holding Registers. yes

is

supported

no

no

no

no

yes

no

yes

NOTE

Broadcast messages from the Modbus master to the Modbus slaves using slave address 0 in the Modbus

message.

Type Number Register Name Object Type

0 Coil Status

(0x references)

1 Input Status

(1X references)

3 Input Registers

(3X references)

14 SIPROTEC 4, Modbus TCP Profile, Manual

Double-point command,

Single-point command,

Double-point indication,

Single-point indication

Protection indication,

Device-status indication

Measurement values

C53000-L1840-C582-1, Edition 07.2015

Characteristic of the ModbusTCP Module

1.3 Supported Modbus Functions and Register Types

Type Number Register Name Object Type

4 Holding Registers

(4X references)

System information,

Time synchronization,

Diagnostic information,

Metered measurands,

Statistic values,

Min/Max values of measured values

SIPROTEC 4, Modbus TCP Profile, Manual 15

C53000-L1840-C582-1, Edition 07.2015

i

i

Characteristic of the ModbusTCP Module

1.4 Table of Parameters

1.4

Table of Parameters

The following Modbus TCP-specific configuration settings are available in the SIPROTEC 4 device. For

further Information to the Modbus TCP mapping file see chapter 2).

Table 1-1 Modbus TCP-Specific Settings

Parameter Default

Setting

Slave Address 1 1 to 247 Modbus TCP station address of

TCPPortNumber 502,

504

EnableTimeSynchronization 0 0,1

CoilBroadcastMsg 1 0,1

HoldingBroadcastMsg 1 0,1

UseSetTimeAndDateReg 0 0,1

SingleBitDoubleCmdCtrl 0 0,1

ExceptionMsgAtInvalidData 0 0,1

Setting Range Description

the device

100 to 65535

TcpPortNumber1 = 502

TcpPortNumber2 = 504

1 = Enable Modbus-IP time sync.

0 = Disable Modbus-IP time sync.

0 = no

1 = yes

0 = no

1 = yes

1 = Use Set Date and Time

register for acceptance of

previous written time synchronization data.

0 = time synchronization data are

valid at the time of writing.

1 = using functions Force Single

Coil or Force Multiple Coils.

0 = using function Force Multiple

Coils only

1 = yes; only Read Input Register

and write commands are

executed.

0 = no; a bit in the Diagnostics

Register indicates Data Invalid.

The TCP ports to listen on

Enable Modbus-IP time synchronization

Accept broadcast messages for

Coil Status Register using functions Force Single Coil and Force

Multiple Coils

Accept broadcast messages for

Holding Register using functions

Preset Single Register and Preset

Multiple Regs

Two methods of data acceptance

for time synchronization of the

SIPROTEC 4 device via Modbus

are possible.

Control mode of double

commands.

Respond with Modbus exception

SLAVE_DEVICE_BUSY to

Modbus TCP master during the

period of Data Invalid error.

NOTE

The settings above are valid for all Modbus TCP connections in the same way; they cannot be configured

individually for each Modbus TCP connection or for each connected Modbus TCP master..

During startup of the Ethernet module, the configuration of all Modbus TCP parameters is checked. If a

parameter value is detected outside the valid range, an error-log entry is issued on the EN100+ module

and the parameter is set to its default value (see

16 SIPROTEC 4, Modbus TCP Profile, Manual

Figure 5-2

).

C53000-L1840-C582-1, Edition 07.2015

Characteristic of the ModbusTCP Module

1.5 Further Ethernet Services and Protocols

1.5

1.5.1

1.5.2

Further Ethernet Services and Protocols

The following additional services and protocols are supported on the EN100+ module.

With DIGSI 4 these services can be switched ON or OFF.

For security reasons, Siemens recommends switching OFF unused services.

Services

Module homepage (HTTP)

•

Firmware upgrade (HTTP)

•

DIGSI 4 over EN100+

•

IEC 61850 and GOOSE

•

SNTP (see Chapter

•

For further information, refer to the manual

Ethernet Module EN100+ for IEC 61850 with electrical/optical 100 Mbit Interface, Order number C53000-

G1140-C167.

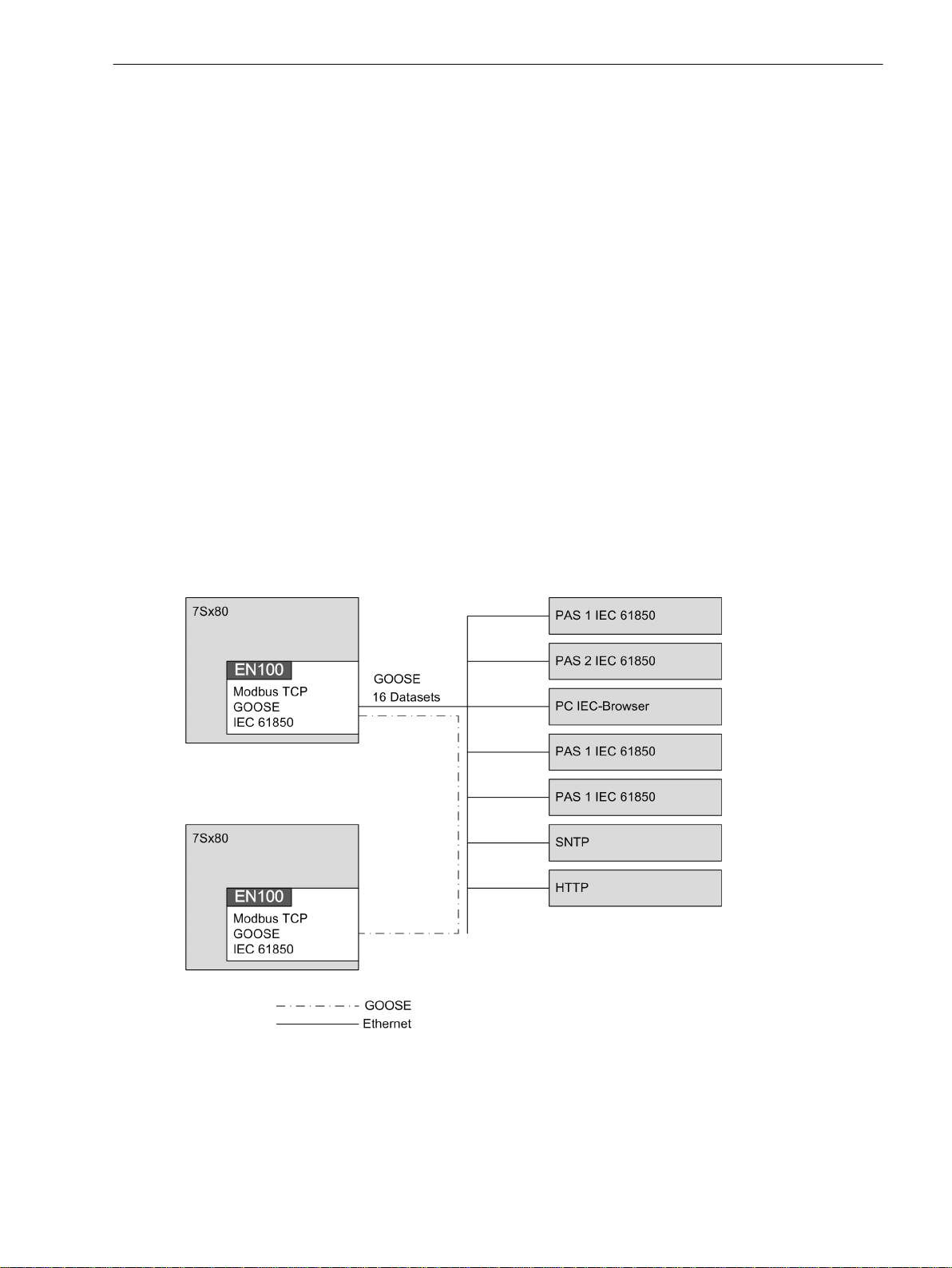

Modbus TCP with IEC 61850 and GOOSE

The following figure shows the communication the communication via Modbus TCP with IEC 61850 and

GOOSE.

4.2 Time Synchronization with Modbus TCP

)

[dw_modbus-tcp-with-iec61850, 1, en_US]

Figure 1-4

SIPROTEC 4, Modbus TCP Profile, Manual 17

C53000-L1840-C582-1, Edition 07.2015

Modbus TCP with IEC 61850 and GOOSE

18 SIPROTEC 4, Modbus TCP Profile, Manual

C53000-L1840-C582-1, Edition 07.2015

2

Configuration in DIGSI 4

2.1 Inserting and Adjusting a New Project 20

2.2 Setting the Interfaces 27

2.3 Customization of the Allocations 30

SIPROTEC 4, Modbus TCP Profile, Manual 19

C53000-L1840-C582-1, Edition 07.2015

Loading...

Loading...