Siemens SIPLUS RIC IEC on S7 User Manual

I IA CE

SIPLUS RIC IEC on S7

AddOn Nodal Blocks

Version V1.5

Functional description I IA CE

DANGER

indicates that death or serious injury will result if proper precautions are not taken.

WARNING

indicates that death or serious injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury may result if proper precautions are not taken.

NOTICE

means that material damage can occur if the appropriate precautions are not taken.

and SIPLUS®

2006

Safety instructions

Warning notices

These Operating Instructions contain information that you should observe in order to ensure your own

personal safety, as well to avoid material damage. The notices referring to your personal safety are highlighted in the manual by a warning triangle. Notices referring only to equipment damage have no safety

alert symbol. Warnings are shown in descending order according to the degree of danger as follows.

Note:

highlights important information about the product, handling the product, or part of the

documentation that is of particular importance.

Qualified personnel

Commissioning and operation of equipment described in this manual (module, device) may only be carried out by qualified personnel. Qualified personnel in the meaning of the technical safety instructions in

this manual are persons authorized to commission, isolate, earthing and marking devices, systems and

power circuits in accordance with the standards of security technology.

Please observe also the required basic knowledge mentioned in the preamble.

Trademarks

SIMATIC, SIMATIC HMI, SIMATIC NET, SIROTEC, SINUMERIK and USS are registered trademarks of

Siemens AG. Any other names used in this document may be brand names, the use of which by third

parties for their own purposes may infringe the rights of the legal owners.

SIPLUS RIC IEC on S7 V1.5 Page 2 of 28 ©SIEMENS AG 2013

Functional description I IA CE

WARNING

Siemens products may only be used for the applications indicated in the catalog and in

the relevant technical description. If third-party products and components are used,

these must be recommended or approved by Siemens. To ensure trouble-free and

safe operation of the products, they must be appropriately transported, stored, assembled, installed, commissioned, operated and maintained. The permitted environmental

and ambient conditions must be adhered to. Notices in the relevant documentation

must be observed.

CAUTION

Changes to cabinet wiring!

Changes to cabinet wiring may only be performed in zero-voltage state! An additional

or modified wiring realized outside of the manufacturing enterprise requires an addi-

tional functional and insulation test.

NOTICE

Electrostatic Sensitive Devices ESD

The presence of this symbol on cabinet, rack or packaging labels indicates the use of

electrostatically sensitive devices and thus the touch sensitivity of these components.

Copyright © Siemens AG 2013 All rights reserved

The forwarding and reproduction of this document, and the

reuse and distribution of its content is not permitted, unless

explicit permission has been granted. Damages will be

sought in all cases of infringement. All rights reserved, in

particular in the event of patents being granted or a utility

model being registered.

Siemens AG

I IA CE

P.O. Box 23 55

90713 Fürth

Germany

Exclusion of liability

We have checked the content of this printed document in

accordance with the hardware and software described.

Nevertheless, the risk of deviations cannot be excluded

completely, which is why we do not accept liability for

complete conformity. The details provided in this printed

document are checked on a regular basis, however, and

any corrections necessary are included in subsequent

editions. We would be happy to receive your suggestions

for improvement.

Technical data are subject to change.

Correct usage of Siemens products

Please observe the following:

Electrostatic Sensitive Devices ESD

Definition of ESD Almost all SIMATIC / FUM modules are equipped with highly integrated components or

elements in MOS technology. For technological reasons, these electronic components are very sensitive

to overvoltage and, consequently, to electrostatic discharge:

The short designation for such electrostatic sensitive components/modules is: "ESD", which is the commonly used international abbreviation of ”ESD” (Electrostatic Sensitive Device).

These modules can be destroyed by voltage and energy far below the limits of human perception. Voltages of this kind occur as soon as a device or an assembly is touched by a person who is not electrostatically discharged.

SIPLUS RIC IEC on S7 V1.5 Page 3 of 28 ©SIEMENS AG 2013

Functional description I IA CE

Preamble

Purpose of the functional description

This functional description describes all the steps required to use the software application SIPLUS RIC

IEC on S7. It assists in the rapid and effective familiarization of personnel in the functionality of the appli-

cation.

Contents of the functional description

This functional description contains the following topics

- Principles of communication with the telecontrol protocols conforming to IEC60870-5-101and

IEC60870-5-104

- Configuration of communication

- Description of the communication blocks and application blocks

- Parameterization of the blocks

- Appendices

Basic knowledge required

Comprehension of this manual requires basic knowledge in the field of telecontrol and the IEC60870-5

protocols as well as general knowledge of automation technology with SIMATIC S7. Users should also

have sufficient knowledge of computers, or of tools similar to PCs (e.g. programming devices), and of the

Windows operating system.

As the S7 is configured using the STEP 7 basic software, you should also have sufficient experience in

handling the basic software.

Target group

This manual is aimed at people with the required qualifications to commission, operate and maintain the

products described:

- Installation engineers

- Programmers

- Commissioning engineers

- Servicing and maintenance personnel

Validity of the functional description

This functional description contains the description of the software application valid at the time of publication of the manual. We reserve the right to describe changes in the functionality of the software application in a special product information document.

SIPLUS RIC IEC on S7 V1.5 Page 4 of 28 ©SIEMENS AG 2013

Functional description I IA CE

Contents:

1. General ..................................................................................................................................................6

2. Overview Nodal function .....................................................................................................................6

3. Application blocks for nodal functionality ........................................................................................7

3.1. Nodal blocks MAoSLi / SLoMAi ...................................................................................................8

3.1.1. Nodal block for the monitoring direction MAoSLi .................................................................. 10

3.1.1.1. Nodal block MAoSLi_MD_pDB (FB161) ....................................................................... 11

3.1.1.2. Block parameter with its default assignment and short comment ................................. 12

3.1.1.3. Parameter and functions details: ................................................................................... 13

3.1.1.4. General notes about function and handling of the block: .............................................. 16

3.1.2. Nodal block for the command direction SLoMAi ................................................................... 22

3.1.2.1. Nodal block SLoMAi_CD_pDB (FB166) ........................................................................ 23

3.1.2.2. Block parameter with its default assignment and short comment ................................. 24

3.1.2.3. Parameter and functions details: ................................................................................... 24

3.1.2.4. Additional references for the processing of commands / setpoint commands .............. 28

SIPLUS RIC IEC on S7 V1.5 Page 5 of 28 ©SIEMENS AG 2013

Functional description I IA CE

1. General

This manual describes the functionality of the AddOn function blocks FB161 and FB166. They allow the

low effort realization of an IEC nod with the software SIPLUS RIC Application IEC on S7 V1.5.

The present description has to be perceived as a supplement of the SIPLUS RIC IEC on S7 manual V1.5.

You’ll receive the blocks in the form of a SIMATIC block library.

2. Overview Nodal function

The nodal function is a configuration with a SIPLUS RIC IEC on S7 station connected between two IEC

telecontrol equipments for enabling the transmission of information via the telecontrol protocols IEC101

resp. IEC104.

Depending on the case of operation classical control center / substation interlinkings as well as interconnections between several substations can be carried out.

In practice the classical control center / substation link with exchange of information between one or several subordinated RTUs and one control center will be the most used application. Therefore the instructions and figures in the subsequent description apply to this configuration.

In this case SIPLUS RIC IEC on S7 has IEC-Slave function compared to the control center and IECMaster function compared to the subordinated RTU.

The nodal blocks support the easy and extensively non parameterized projection of the information to be

transferred.

The following blocks are available:

FB161 for the control direction

subordinated RTU SIPLUS RIC IEC on S7 Control center

FB166 for the monitoring direction

Control center SIPLUS RIC IEC on S7 subordinated RTU

In control direction the blocks are designed for realization of a “transparent” node:

- for direct passing of information (exception: time stamp, ASDU address conversion).

- automatically update of the image (created during operation)

- In order to transmit measured values not with each change of a bit a global programmable

threshold for slowdown of the measurands was added.

as well as user configurable by assigning of a parameter data block. This implicates the essential features:

- defining the information which has to be transferred (defined quantity structure)

- individual conversion of the information object addresses

- parameterizable threshold for measured values per information

- possibility for image access (diagnosis / further processing)

Interrogation and disturbances are processed out of the image.

SIPLUS RIC IEC on S7 V1.5 Page 6 of 28 ©SIEMENS AG 2013

Functional description I IA CE

Notice!

All application blocks are designed exclusively for the OB1 priority level. The FB100

communication blocks ('S7_IEC_Config') also have to be operated in priority level OB1!

Note to the CFC plan view

The CFC views included in the manual are used exclusively for explanation purposes. CFC

is not required for using the blocks. The standard programming options in SIMATIC are

sufficient.

3. Application blocks for nodal functionality

Basically two packages are available for the SIPLUS RIC IEC on S7: Slave and Master function.

Slave (SL) blocks perform the classical substation functions like capture of indication / measured values

or command output.

Master (MA) blocks perform control center tasks like taking over of states in images, initiation of com-

mands etc.

The FB161 and FB166 blocks described here are application blocks performing Master as well as Slave

functions.

For more detailed information about Slave and Master blocks we refer you to the SIPLUS RIC IEC on S7

manual V1.4.

SIPLUS RIC IEC on S7 V1.5 Page 7 of 28 ©SIEMENS AG 2013

Functional description I IA CE

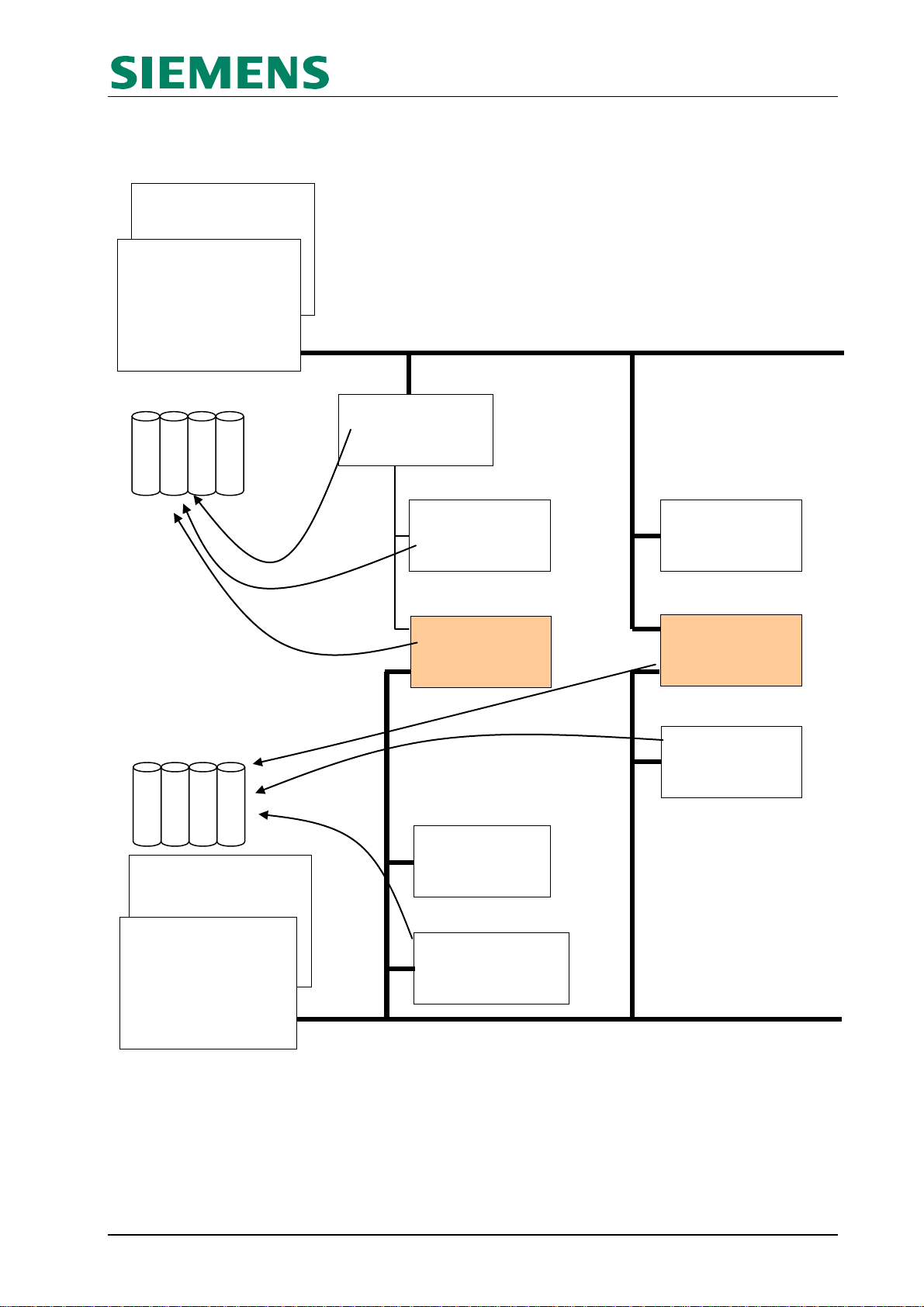

FB_xy -> e.g.

S7_IEC_S101

L1_xy

L2_xy

L7_T101_104_B

P_Application (Slave)

Send buffer

Slave

P_SLi (Slave)

ASDU-

Address

SL_Org_Asdu_1

(FB12x)

SLi_…

(FB130ff)

MAoSLi_MD

(FB161)

SLo_...

(FB135ff)

All blocks are multiple usable.

FB_xy -> e.g.

S7_IEC_S104

L1_xy

L2_xy

L7_T101_104_B

Slave-blocks (SL)

FB_100 -> e.g.

S7_IEC_M101

L1_xy

L2_xy

L7_T101_104_B

P_Application (Master)

FB_100 -> e.g.

S7_IEC_M104

L1_xy

L2_xy

L7_T101_104_B

MAo_…

(FC14xff)

MA_Org_Asdu_1

(FB12x)

MAi_...

(FB14xff)

Master-blocks (MA)

SLoMAi_CD

(FB166)

Send buffer

Master

3.1. Nodal blocks MAoSLi / SLoMAi

Slave

--------------------------------------------------------------------------------------------------------------------------------------------

Nodal-blocks

-------------------------------------------------------------------------------------------------------------------------------------------Master

SIPLUS RIC IEC on S7 V1.5 Page 8 of 28 ©SIEMENS AG 2013

Functional description I IA CE

Notice!

All application blocks are designed exclusively for the OB1 priority level. The FB100

communication blocks ('S7_IEC_Config') also have to be operated in priority level OB1!

Pre-condition for using the nodal blocks is the existence of minimum two IEC-channels in the system.

They mostly consist of an IEC-Slave (as interface to the control center) and an IEC-Master (interface to

the subordinated RTU).

Figure Nodal blocks:

The figure shows the „classical“ information flow from an subordinated station via the node to the control

center (monitoring direction, _MD) resp. from the control center via the node to the subordinated station

(command direction _CD).

Each of the node application blocks (,MaoSLi_MD and ,SloMAi_CD’) have one interface each to the

source and to the target application available, which have to be interconnected according to the following

description

MAoSLi_MD, for the monitoring direction

The flow direction of the information is:

Master (source) -> node -> Slave (target)

The application block , MAoSLi_MD’ is connected via the pointer ‚P_Application (Master)’ with the

‚S7_IEC_Config’ of the Master protocol version (information source) like the MAo-blocks. i.e. the func-

tional block will be linked directly to the IEC-Master-activation.

The link to the Slave-application (information target) is carried out like the activation of the SLi-blocks with

the pointer ‚P_SLi (Slave)’ via an organization block ‚SL_Org_Asdu_1’. The parameterized ASDUaddress from the ‚SL_Org_Asdu_1’ will be also used for the information of the nodal block.

SLoMAi_CD, for the command direction

The flow direction of the information is:

Slave (source) -> node -> Master (target)

The application block ,SLoMAi_CD’ is connected via the pointer ‚P_Application (Slave)’ with the

‚S7_IEC_Config’ of the Slave protocol version (information source) like the SLo-blocks.

The link to the Master-application (information target) is carried out with the pointer ‚P_Application (Mas-

ter)’ to the ‚S7_IEC_Config’ of the Master protocol version like the MAi-blocks.

SIPLUS RIC IEC on S7 V1.5 Page 9 of 28 ©SIEMENS AG 2013

Loading...

Loading...