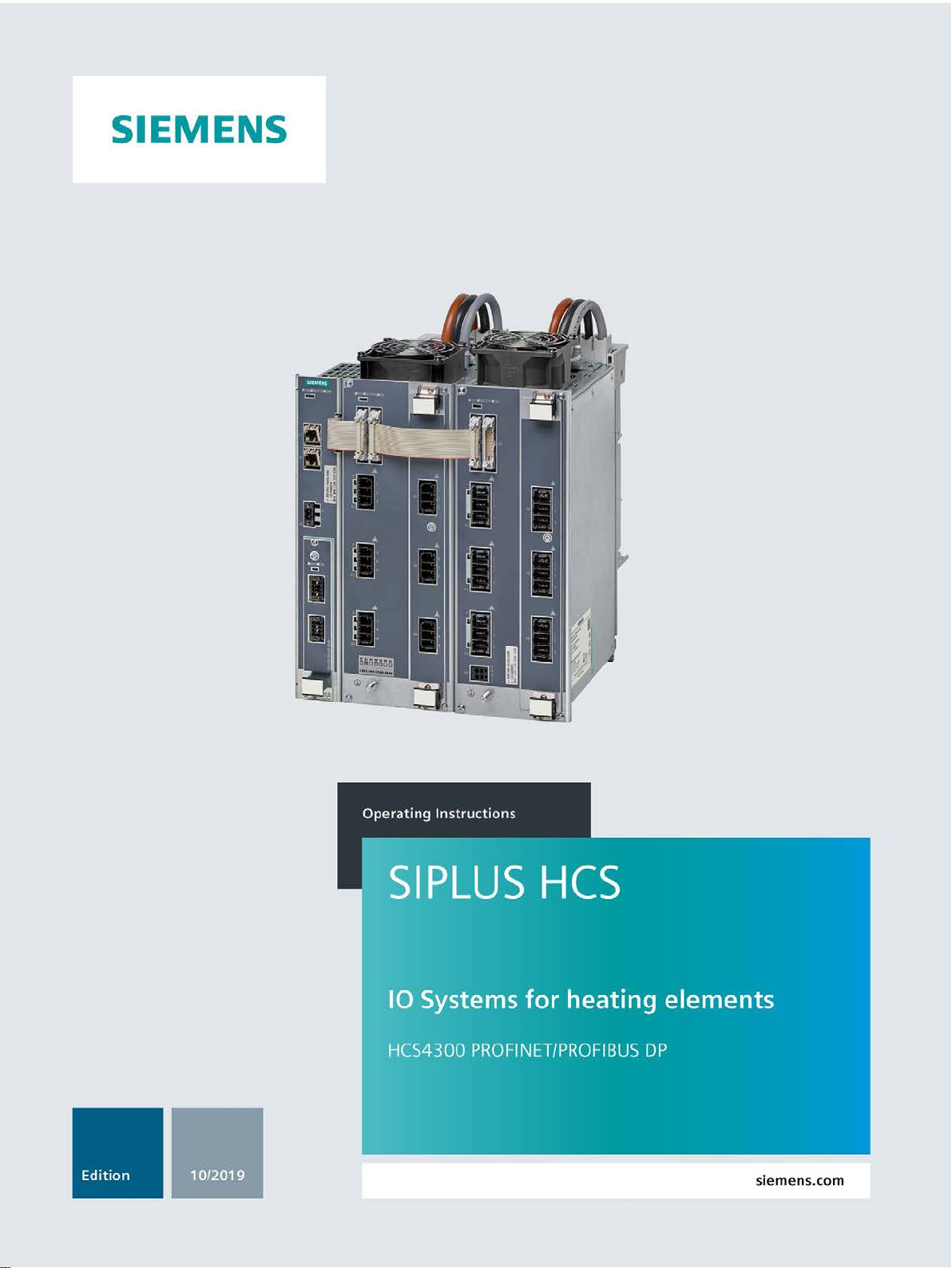

Siemens SIPLUS HCS Series, SIPLUS HCS4300 PROFINET, SIPLUS HCS4300 PROFIBUS Operating Instructions Manual

Page 1

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Page 2

Page 3

IO systems for heating elements

Heating control system

SIPLUS HCS4300

PROFINET/PROFIBUS DP

Operating Instructions

10/2019

A5E35452705A/005

Introduction

1

Safety guidelines

2

System overview

3

Application planning

4

Installing/mounting

5

Wiring

6

Commissioning

7

Configuring/Programming

8

Functions

9

Communications

10

Process and system

messages, error handling

11

Servicing and maintenance

12

Technical specifications

13

Appendix

A

Page 4

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E35452705A/005

Ⓟ

Copyright © Siemens AG 2014 - 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

11/2019 Subject to change

Page 5

Table of contents

1 Introduction ............................................................................................................................................. 9

1.1 Introduction ............................................................................................................................... 9

2 Safety guidelines ................................................................................................................................... 11

2.1 Safety notes ............................................................................................................................ 11

2.2 Security information ................................................................................................................ 13

2.3 Protective measures for the HCS4300 ................................................................................... 13

3 System overview ................................................................................................................................... 15

3.1 Area of application .................................................................................................................. 15

3.2 Features .................................................................................................................................. 16

3.3 System configuration .............................................................................................................. 18

3.4 Central interface module (CIM) ............................................................................................... 19

3.4.1 Function and design................................................................................................................ 19

3.5 Power output module (POM) .................................................................................................. 21

3.5.1 Function and design................................................................................................................ 21

3.6 I/O modules ............................................................................................................................. 25

3.6.1 PM4000 DI/DO ........................................................................................................................ 25

3.6.2 PM4000 U/I ............................................................................................................................. 26

3.6.3 PM4000 Temperature ............................................................................................................. 27

3.7 EM4315 expansion module .................................................................................................... 28

3.7.1 Design ..................................................................................................................................... 28

4 Application planning .............................................................................................................................. 29

4.1 Shipping .................................................................................................................................. 29

4.2 Storage ................................................................................................................................... 29

4.3 Scope of delivery .................................................................................................................... 30

4.4 Installation location ................................................................................................................. 31

4.5 POM4320 power rating ........................................................................................................... 34

4.6 Power rating of the POM4320 Highend .................................................................................. 36

4.7 POM4320 Highend power rating ............................................................................................ 38

4.7.1 POM4320 Highend for busbar adapter ................................................................................... 38

4.7.2 POM4320 Highend for wall mounting ..................................................................................... 40

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

3

Page 6

Table of contents

5 Installing/mounting ................................................................................................................................ 43

5.1 Requirements ......................................................................................................................... 43

5.2 Installing the Power Output Module (POM) ........................................................................... 44

5.2.1 Busbar mounting .................................................................................................................... 44

5.2.1.1 Preparations ........................................................................................................................... 44

5.2.1.2 Adjusting the busbar adapter ................................................................................................. 45

5.2.1.3 Mounting the POM (busbar adapter) ..................................................................................... 47

5.2.2 Panel mounting ...................................................................................................................... 48

5.2.2.1 POM mounting (panel mounting) ........................................................................................... 48

5.3 Installing the Central Interface Module .................................................................................. 49

5.4 Installing the EM4315 expansion module .............................................................................. 50

5.5 Installing the I/O module (PM) ............................................................................................... 51

6 Wiring ................................................................................................................................................... 53

6.1 Safety instructions and guidelines ......................................................................................... 53

6.2 Connecting the protective conductor ..................................................................................... 54

6.3 Connecting PROFINET and PROFIBUS fieldbus .................................................................. 55

6.4 Connect 24 V DC power supply ............................................................................................. 55

6.5 Connecting the heating elements and three-phase line supply ............................................. 57

6.5.1 Connecting the three-phase line supply ................................................................................ 57

6.5.2 Connecting heating elements ................................................................................................ 58

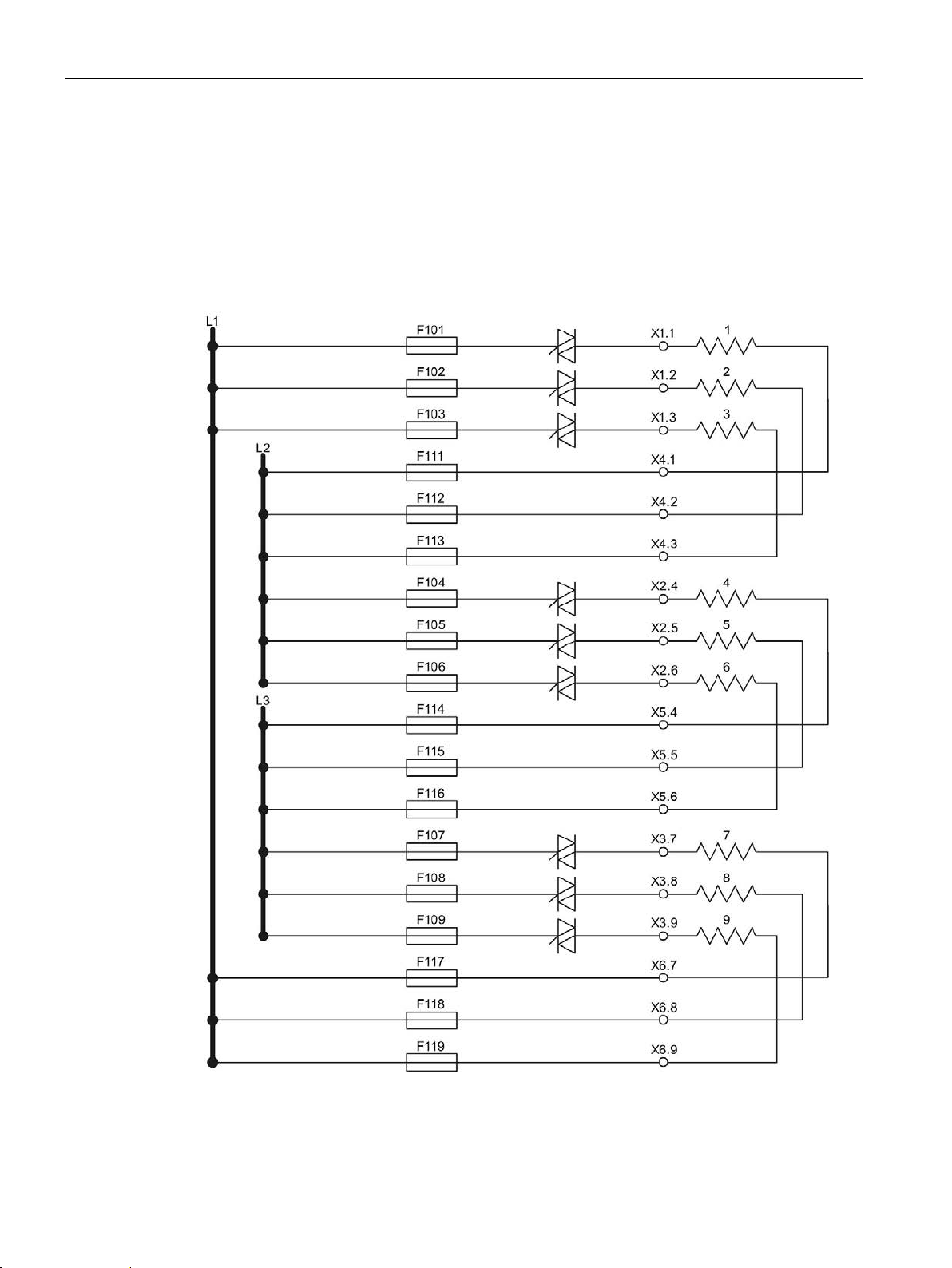

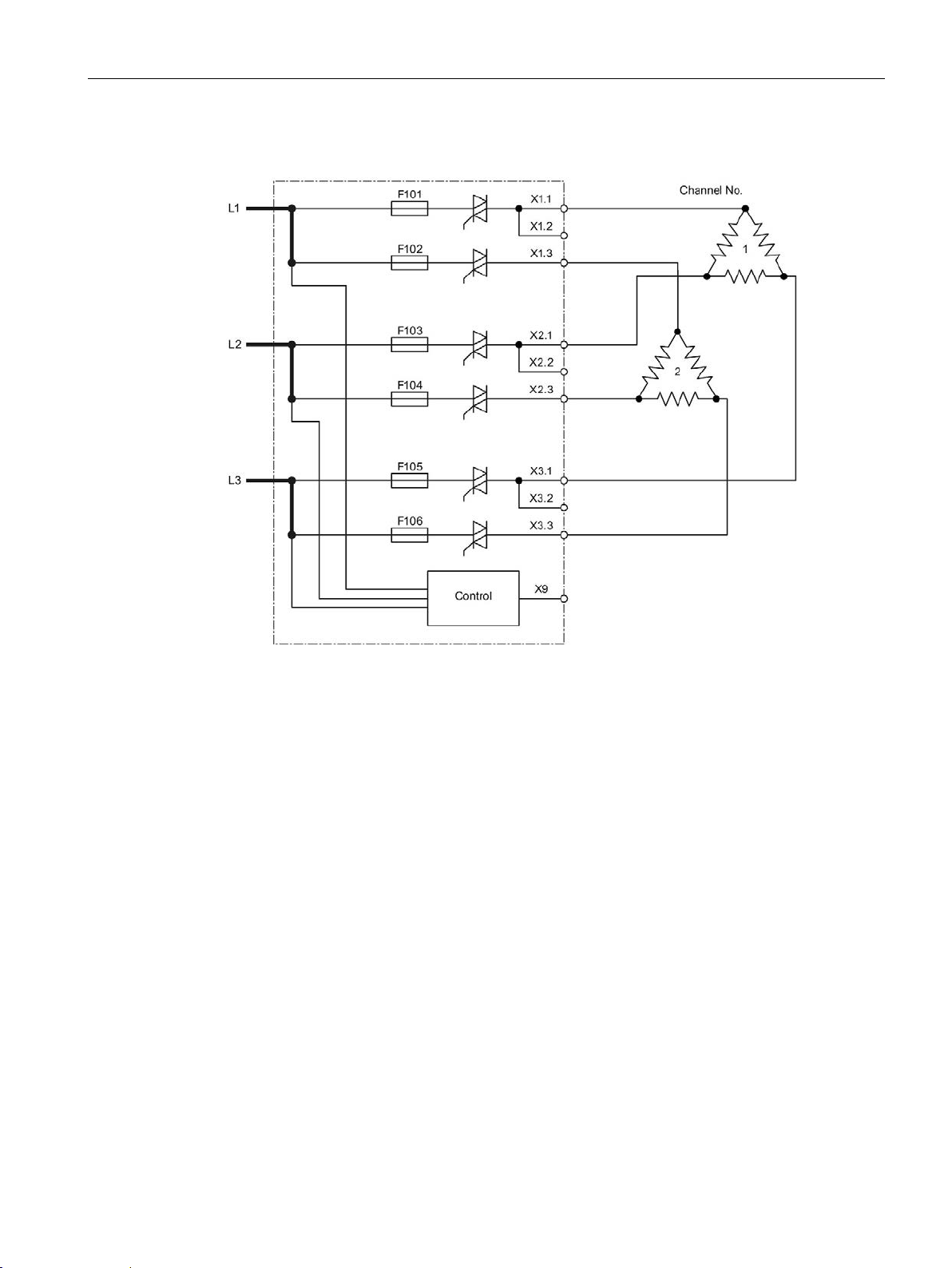

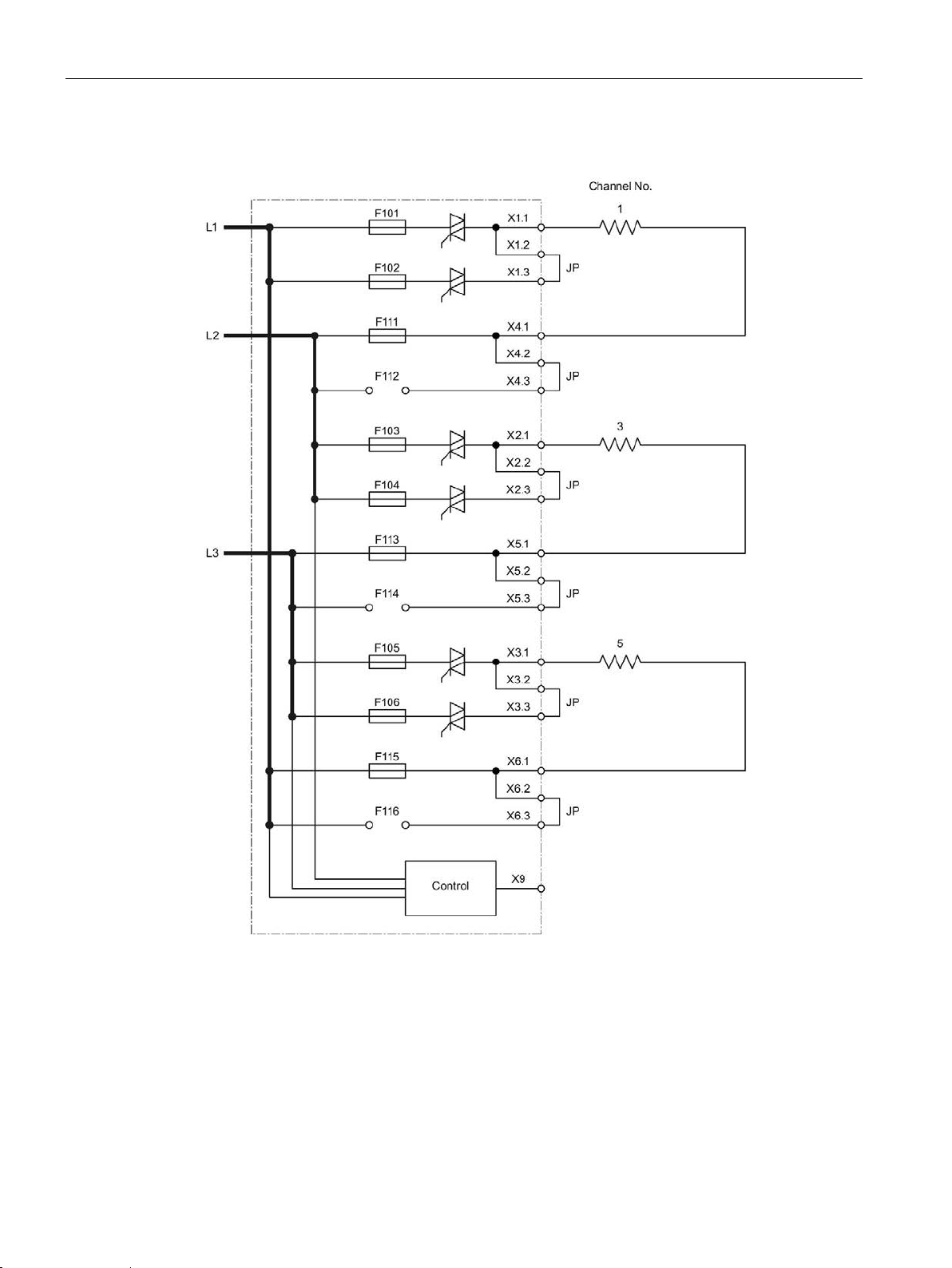

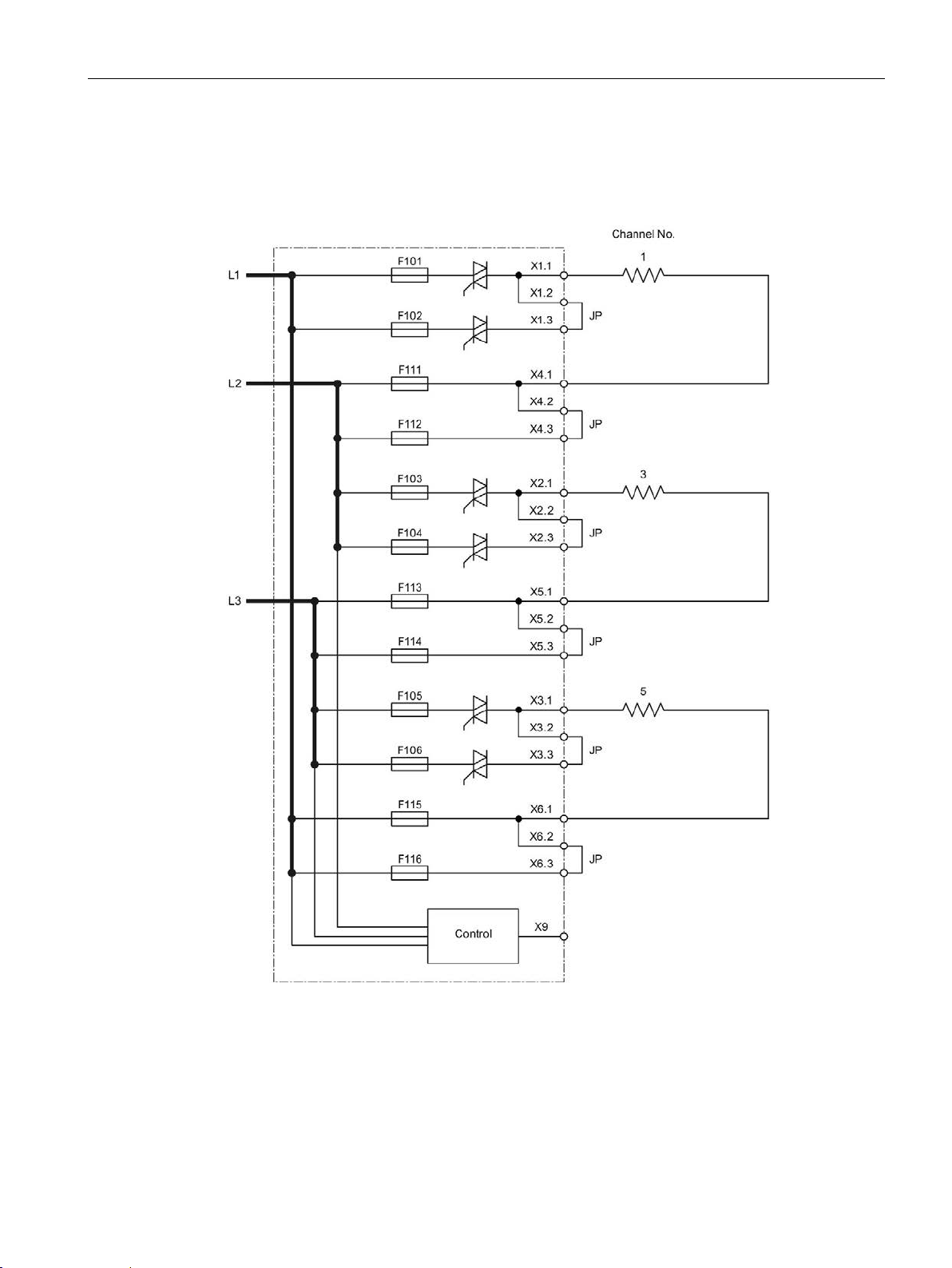

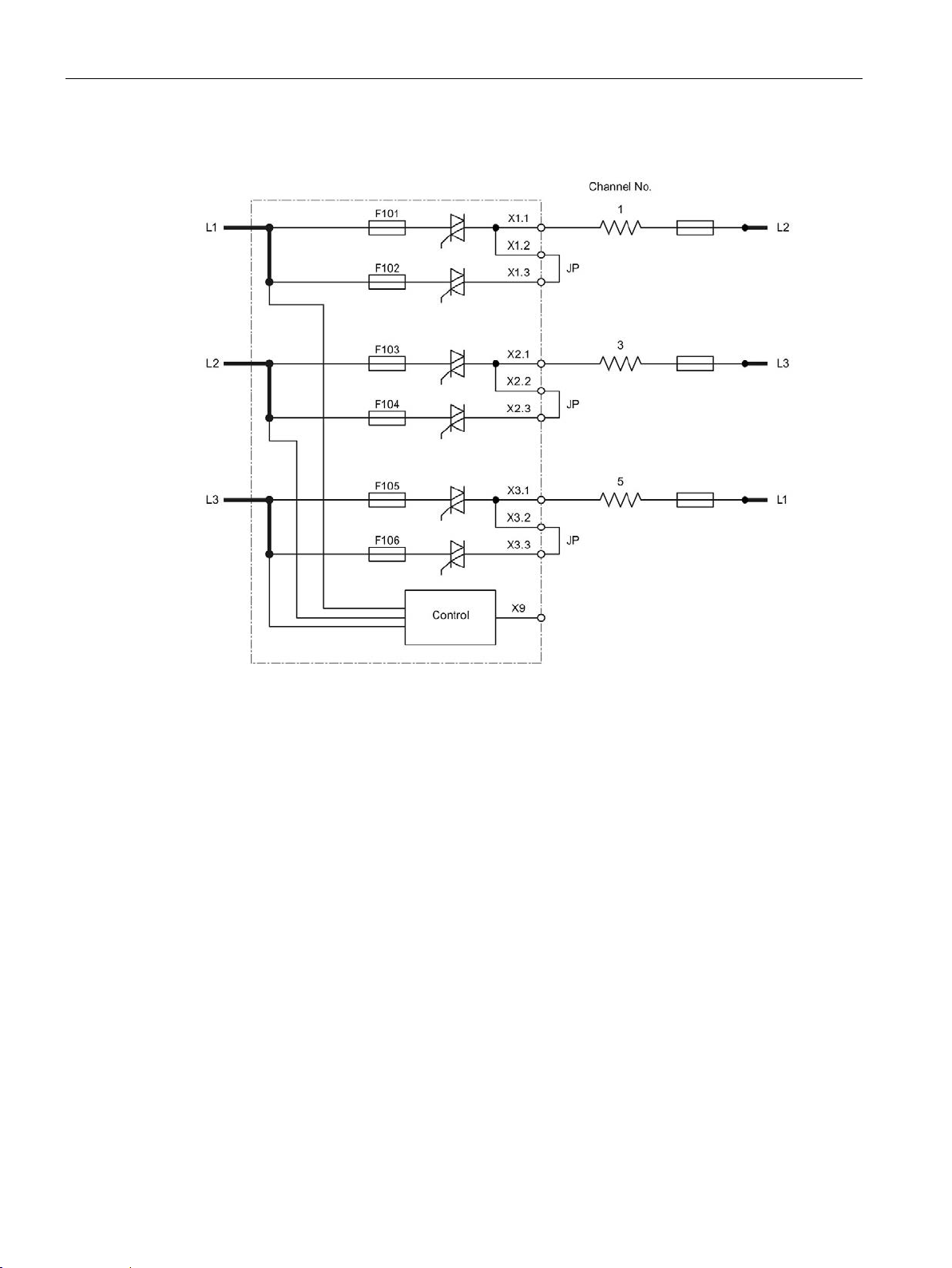

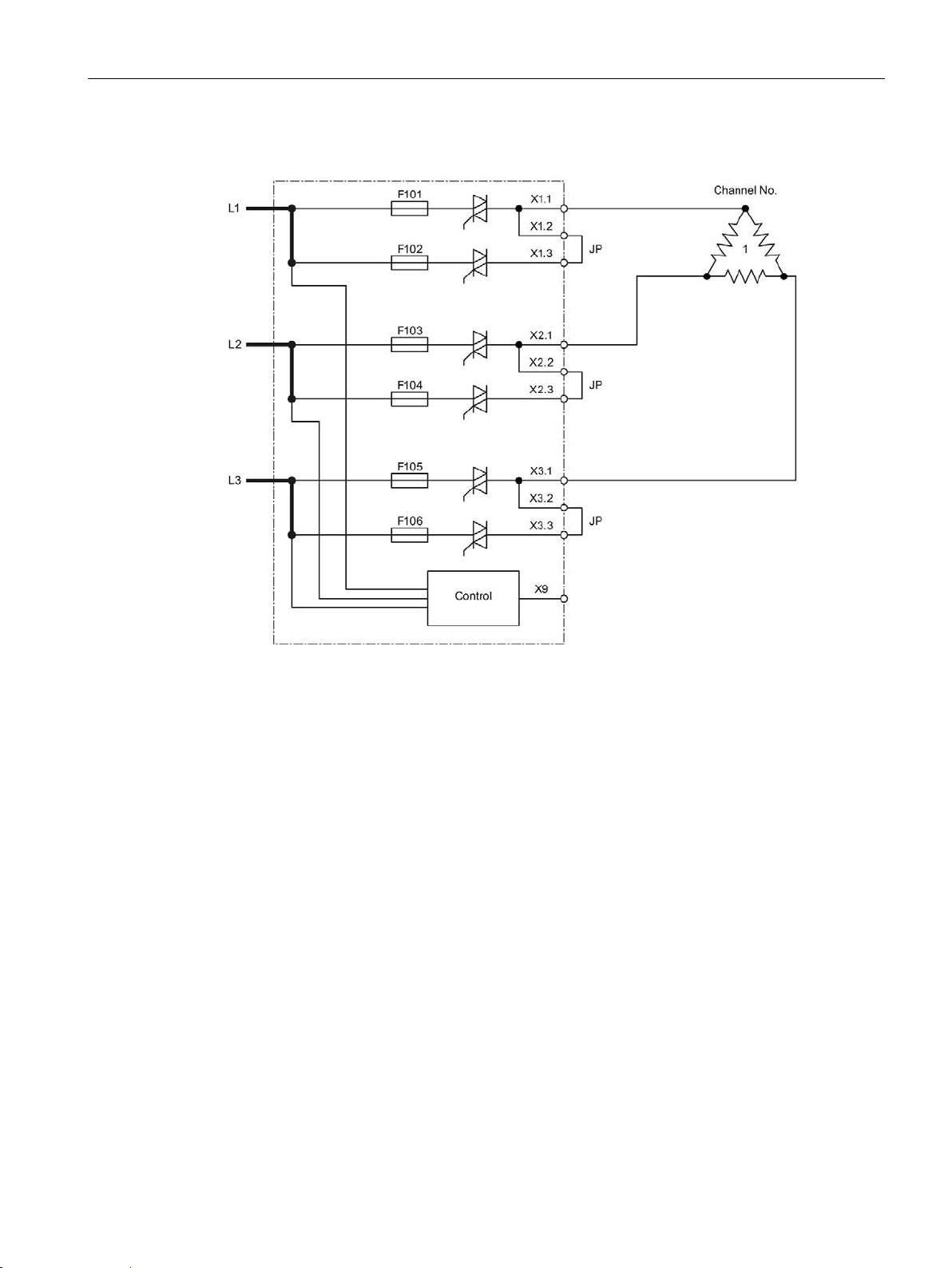

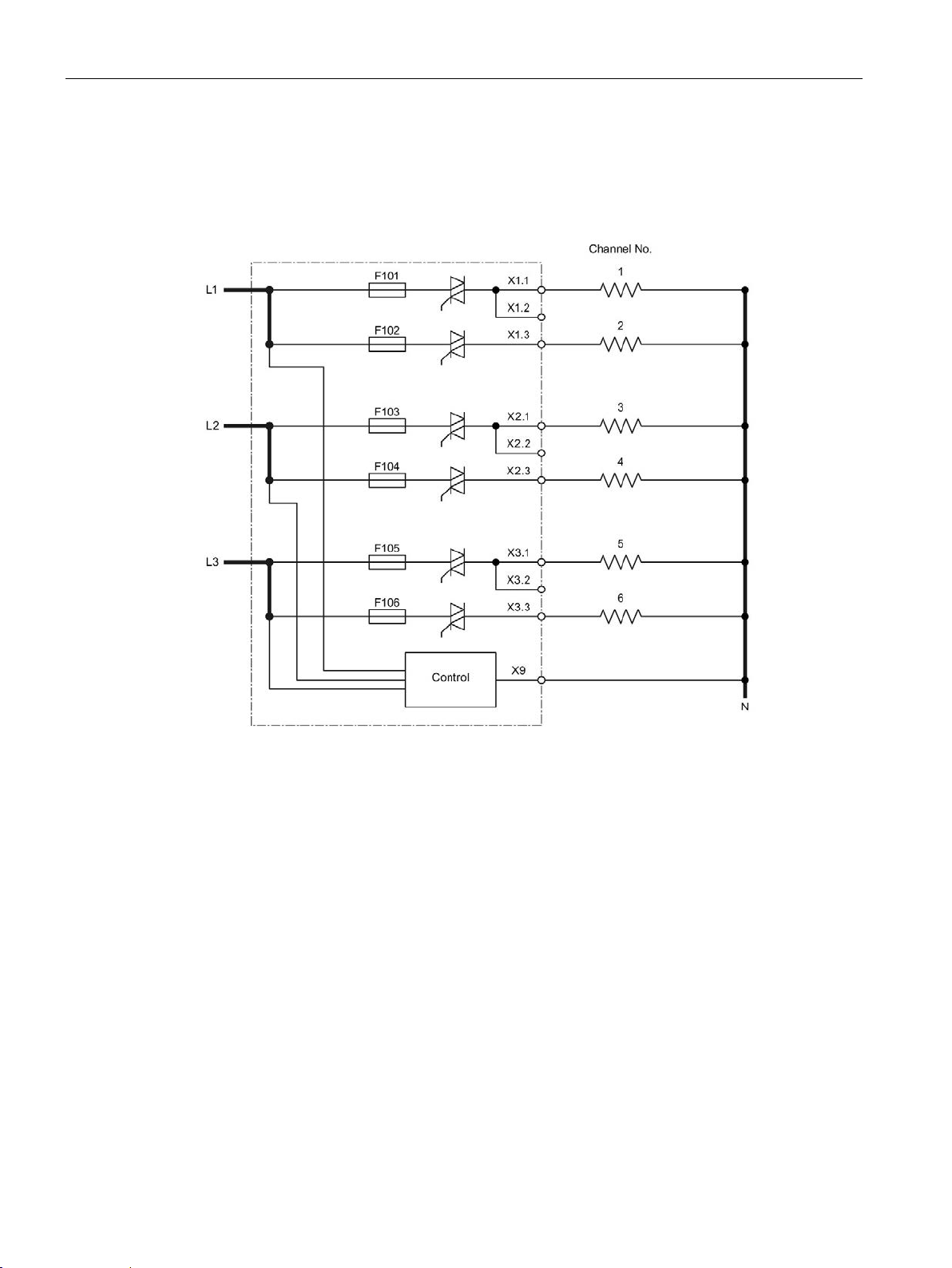

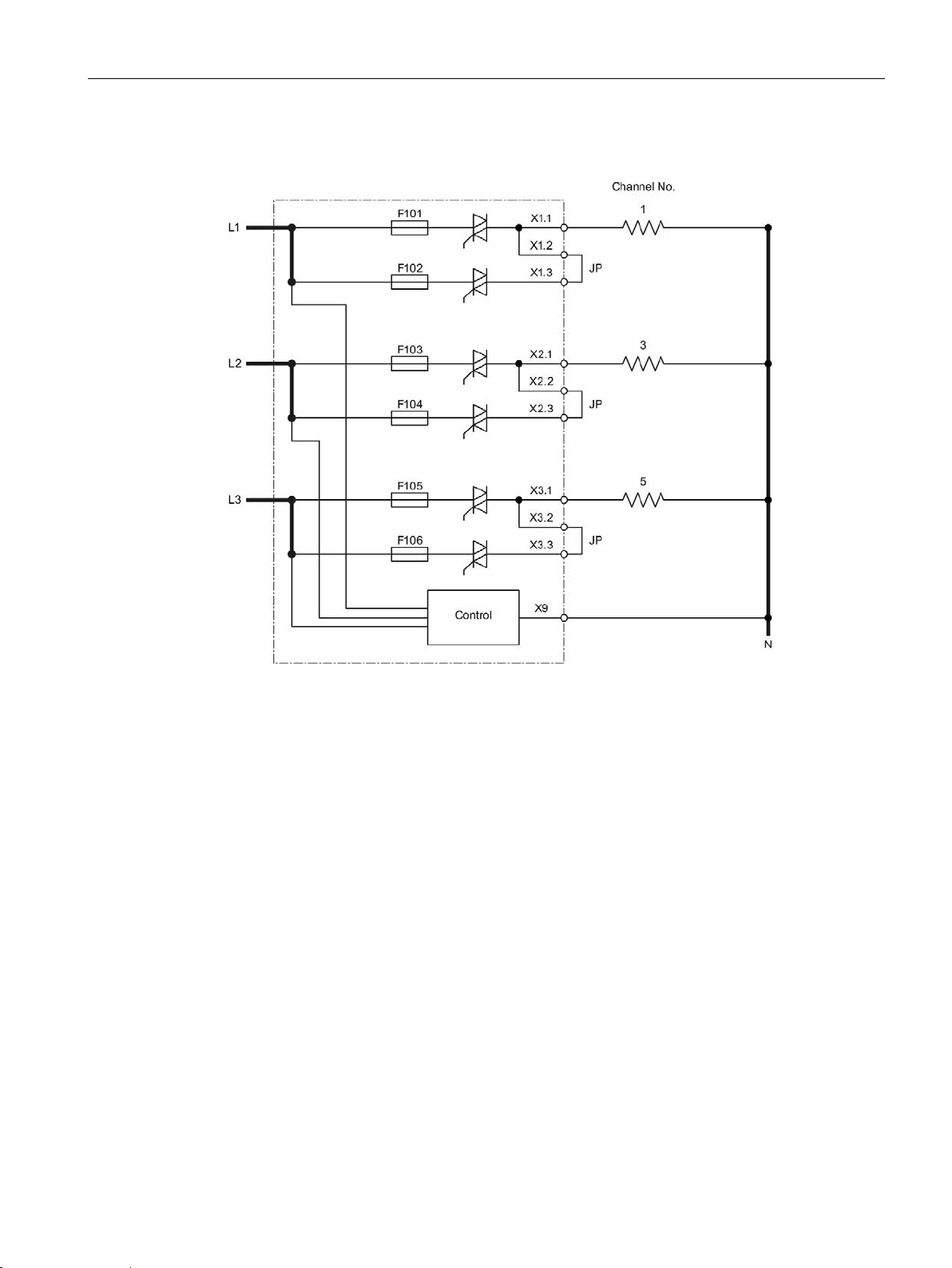

6.6 Block diagram POM4320 ....................................................................................................... 60

6.7 Block diagrams POM4320 Highend ....................................................................................... 61

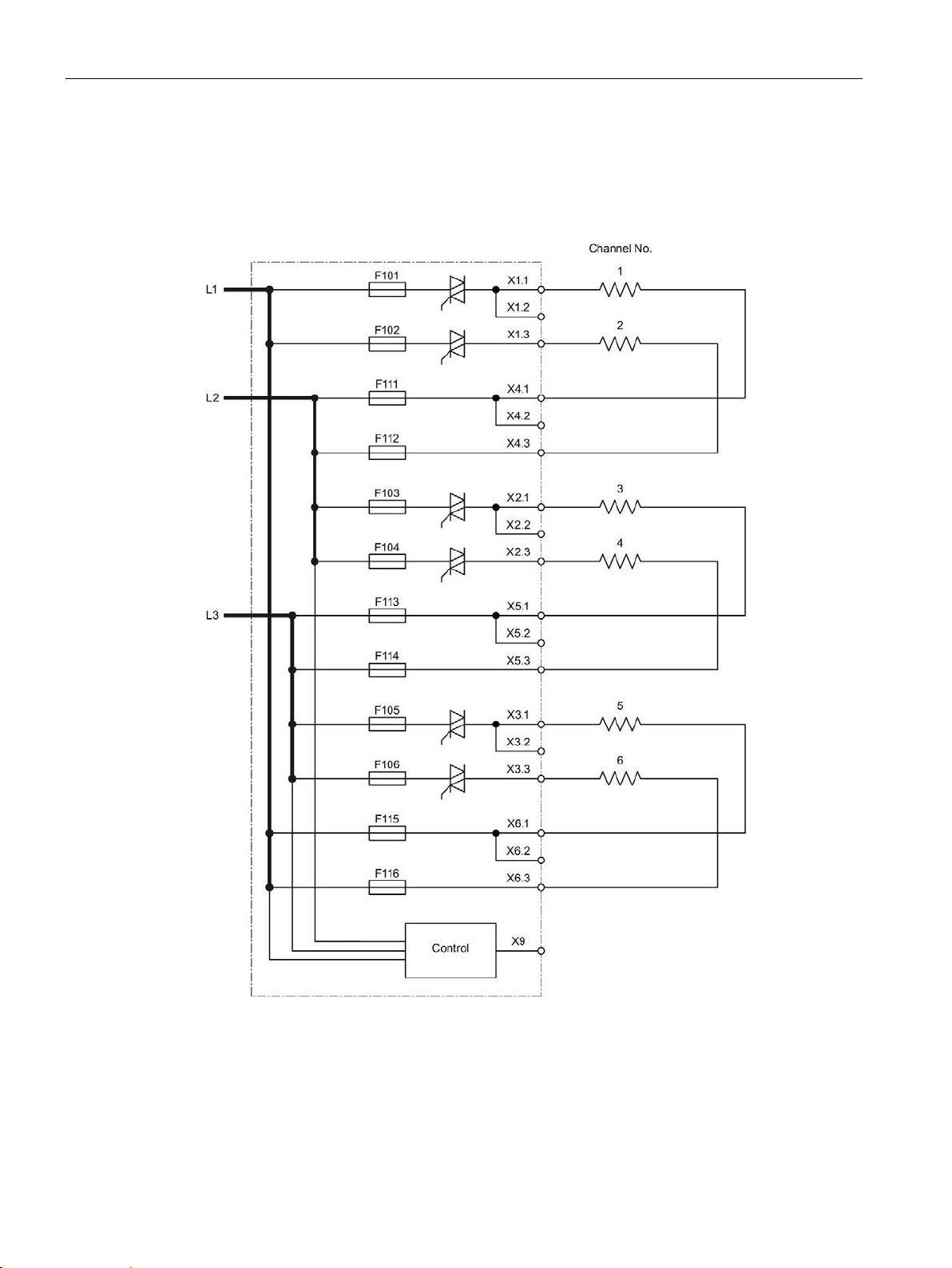

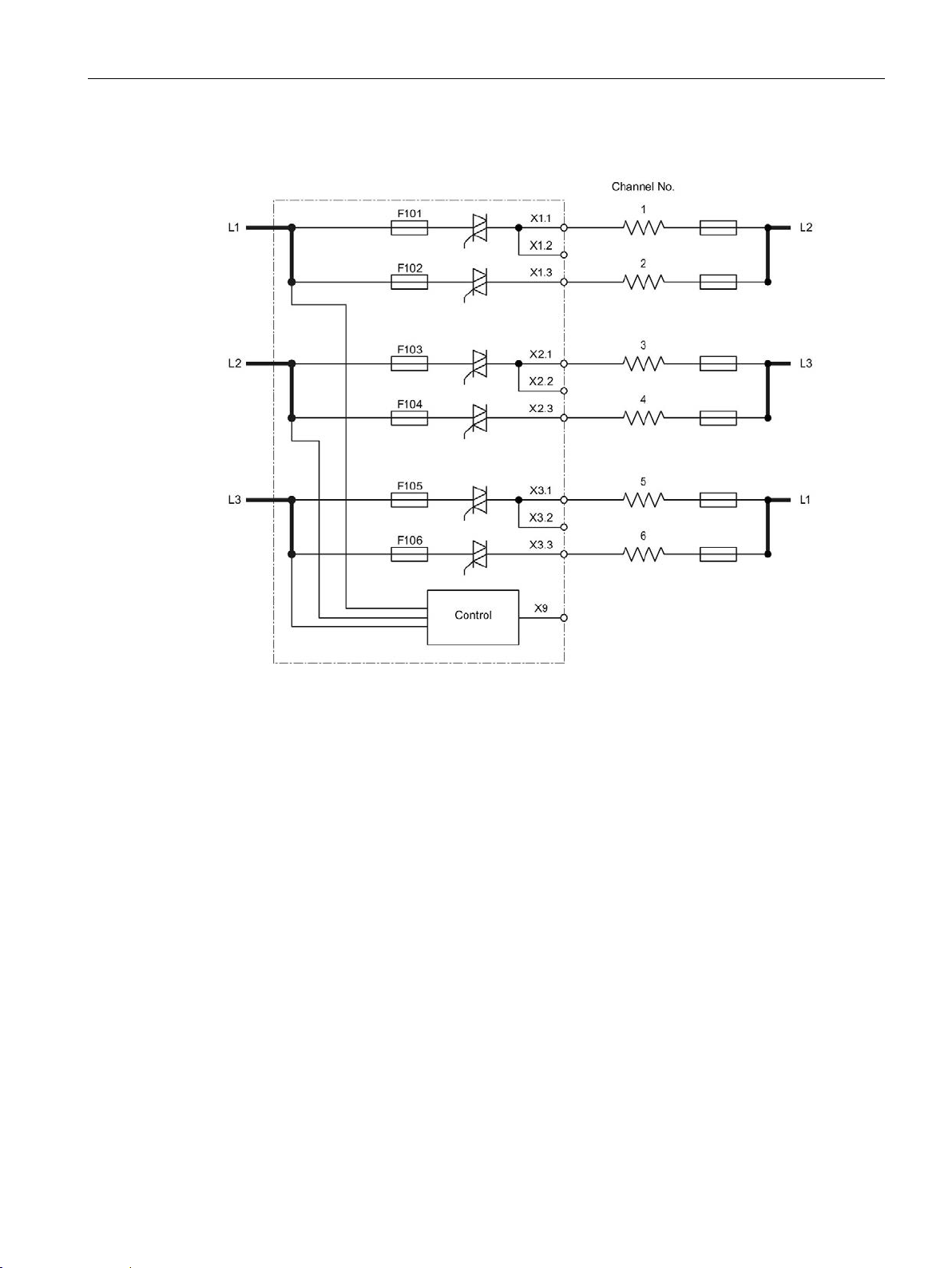

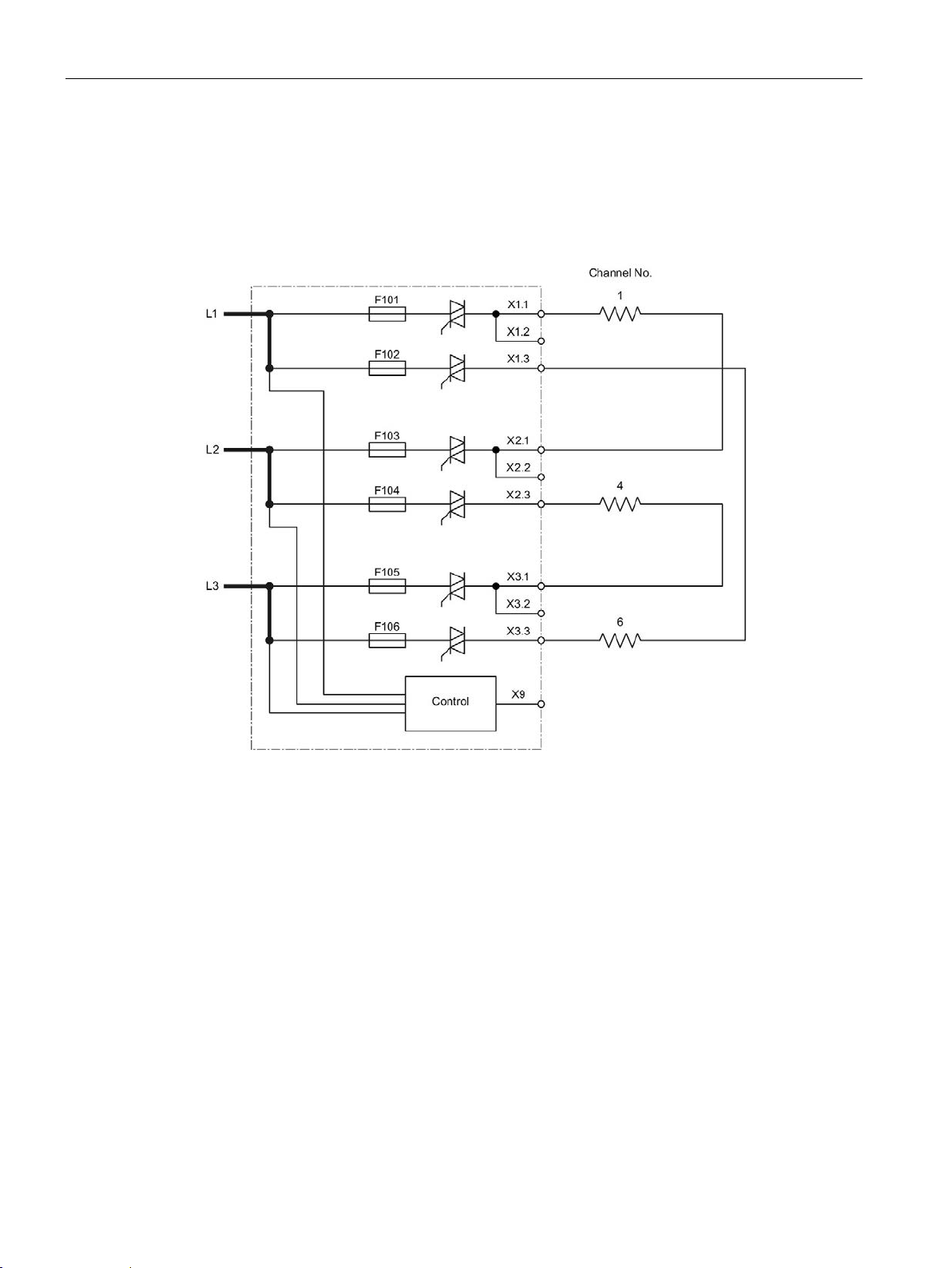

6.7.1 Overview of connection types ................................................................................................ 61

6.7.2 Connection between phase and phase (400/480 V).............................................................. 62

6.7.3 Connection between phase and neutral conductor (230/277 V) ........................................... 70

6.8 Connecting system interfaces ................................................................................................ 72

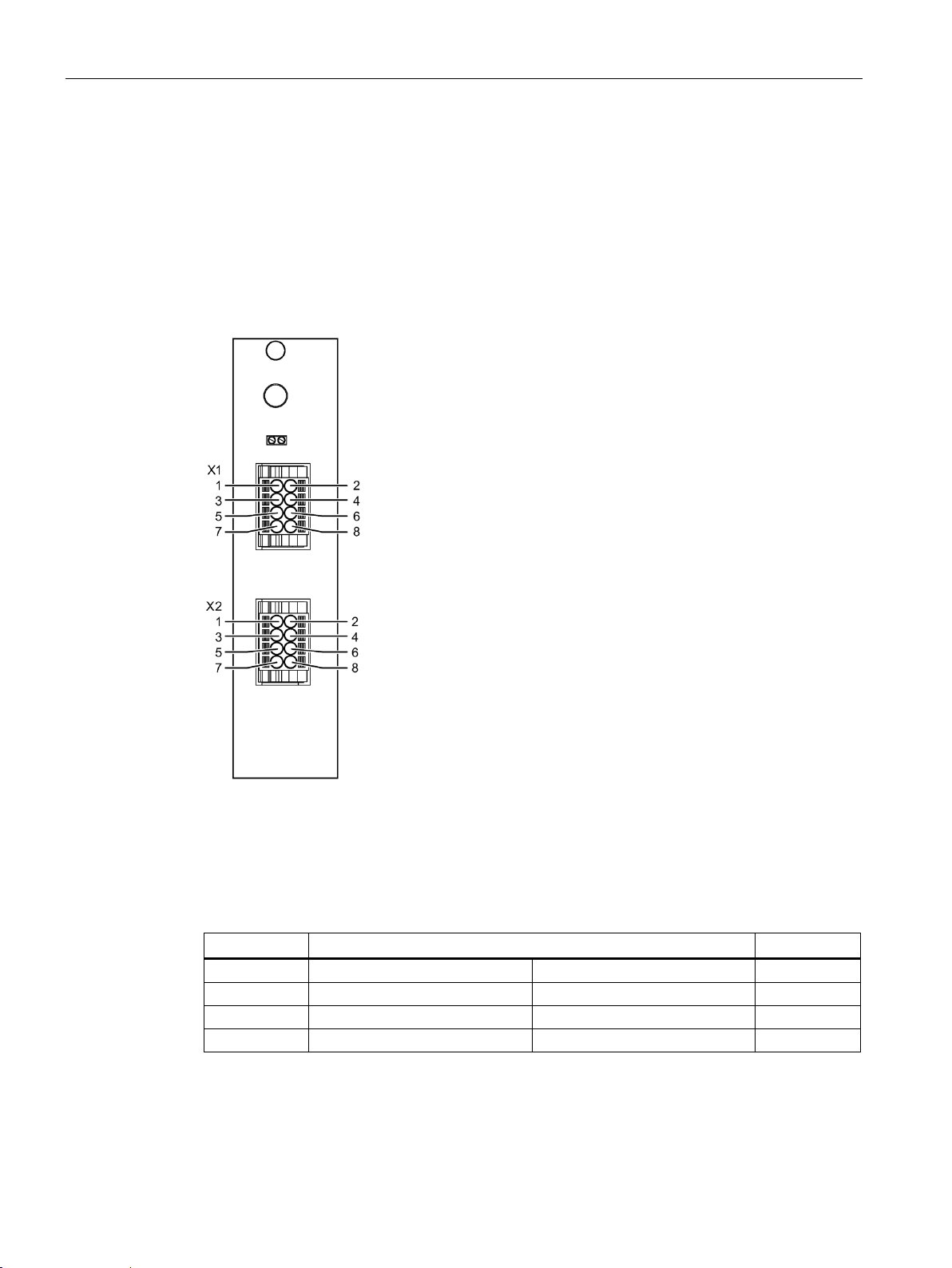

6.9 Connecting I/O modules ........................................................................................................ 74

6.9.1 PM4000 DI/DO ....................................................................................................................... 74

6.9.2 PM4000 U/I ............................................................................................................................ 76

6.9.3 PM4000 Temperature ............................................................................................................ 78

7 Commissioning ..................................................................................................................................... 81

7.1 Requirements ......................................................................................................................... 81

7.2 Commissioning....................................................................................................................... 81

7.3 Insulation test ......................................................................................................................... 82

SIPLUS HCS4300 PROFINET/PROFIBUS DP

4 Operating Instructions, 10/2019, A5E35452705A/005

Page 7

Table of contents

8 Configuring/Programming ..................................................................................................................... 83

8.1 Integrating the HCS4300 into the PROFINET configuration .................................................. 83

8.2 Integrating the HCS4300 into the PROFIBUS configuration .................................................. 83

8.3 Device/hardware configuration in the TIA Portal .................................................................... 84

8.3.1 PROFINET device configuration ............................................................................................. 84

8.3.2 PROFIBUS device configuration ............................................................................................ 85

8.3.3 Configuration parameters ....................................................................................................... 86

8.3.3.1 CIM / POM configuration parameters ..................................................................................... 86

8.3.3.2 Configuration parameters for I/O modules ............................................................................. 89

8.4 Software tools for commissioning support .............................................................................. 91

8.4.1 Overview of tools for commissioning support ......................................................................... 91

8.5 Configuration control ............................................................................................................... 93

8.5.1 Configuration control ............................................................................................................... 93

8.5.2 Configuring .............................................................................................................................. 94

8.5.3 Control .................................................................................................................................... 94

8.5.3.1 Slot assignment ...................................................................................................................... 94

8.5.3.2 Control data record ................................................................................................................. 95

8.5.3.3 Feedback data record ............................................................................................................. 97

8.5.3.4 Transferring control data record in the startup program of the CPU ...................................... 98

8.5.3.5 Behavior during operation ..................................................................................................... 100

8.5.4 Examples of configuration control ......................................................................................... 100

8.5.4.1 Station master HCS4300 ...................................................................................................... 100

9 Functions ............................................................................................................................................ 105

9.1 Function overview ................................................................................................................. 105

9.2 Status and actual displays .................................................................................................... 106

9.3 Power output control ............................................................................................................. 106

9.3.1 Half-wave control .................................................................................................................. 106

9.3.2 Phase angle control .............................................................................................................. 108

9.3.3 Soft starting function ............................................................................................................. 109

9.3.4 Switch on heating .................................................................................................................. 110

9.3.5 Soft start during heater operation ......................................................................................... 111

9.3.6 Channel control via setpoints ................................................................................................ 111

9.3.7 Channel control via fields ...................................................................................................... 112

9.3.8 Line voltage compensation ................................................................................................... 113

9.3.9 Behavior of the power outputs .............................................................................................. 113

9.3.10 Power control ........................................................................................................................ 114

9.3.11 Parallel connection of channels ............................................................................................ 115

9.4 Digital inputs/outputs............................................................................................................. 116

9.5 Recording of analog measured line values........................................................................... 117

9.6 Recording of analog measured values ................................................................................. 118

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

5

Page 8

Table of contents

9.7 Monitoring functions ............................................................................................................. 119

9.7.1 Phase connection monitoring ............................................................................................... 119

9.7.2 Rotating-field test ................................................................................................................. 119

9.7.3 Line supply voltage monitoring ............................................................................................ 120

9.7.4 Monitoring of the 24 V DC supply voltage ........................................................................... 120

9.7.5 Frequency monitoring .......................................................................................................... 120

9.7.6 Temperature monitoring ....................................................................................................... 121

9.7.7 Power channel monitoring ................................................................................................... 122

9.7.8 Power channel monitoring for loads connected in parallel .................................................. 123

9.7.9 Current load monitoring ....................................................................................................... 123

9.7.10 Fault current monitoring ....................................................................................................... 123

9.7.11 Power control monitoring ..................................................................................................... 124

9.7.12 Monitoring of adaptive soft start ........................................................................................... 124

10 Communications .................................................................................................................................. 125

10.1 Cyclic data exchange ........................................................................................................... 125

10.1.1 Cyclic output data................................................................................................................. 125

10.1.2 Cyclic input data ................................................................................................................... 128

10.2 Acyclic data exchange ......................................................................................................... 131

10.2.1 Acyclic data exchange - Overview ....................................................................................... 131

10.2.2 Acyclic output data ............................................................................................................... 132

10.2.3 Acyclic input data ................................................................................................................. 137

10.3 Transfer of diagnostic alarms to the controller ..................................................................... 140

10.3.1 Transferring diagnostic alarms to the controller: PROFINET .............................................. 140

10.3.2 Transferring diagnostic alarms to the controller: PROFIBUS .............................................. 141

10.3.3 Manufacturer-specific error codes ....................................................................................... 141

11 Process and system messages, error handling .................................................................................... 145

11.1 Central Interface Module (CIM) ............................................................................................ 145

11.2 Power Output Module (POM) ............................................................................................... 146

11.2.1 LED operating display for POM ........................................................................................... 146

11.2.2 Fault reporting through diagnostics data ............................................................................. 146

11.3 I/O modules .......................................................................................................................... 148

12 Servicing and maintenance .................................................................................................................. 149

12.1 Maintenance work ................................................................................................................ 149

12.2 Firmware update .................................................................................................................. 149

12.2.1 PROFINET firmware update ................................................................................................ 149

12.2.2 PROFIBUS firmware update ................................................................................................ 151

12.3 Fuse replacement ................................................................................................................ 152

12.4 Replace fan .......................................................................................................................... 156

12.5 Replacing the Power Output Module (POM) ....................................................................... 158

12.6 Replacing the Central Interface Module (CIM) .................................................................... 160

12.7 Replacing an I/O module ..................................................................................................... 161

12.8 Recycling and disposal ........................................................................................................ 162

SIPLUS HCS4300 PROFINET/PROFIBUS DP

6 Operating Instructions, 10/2019, A5E35452705A/005

Page 9

Table of contents

13 Technical specifications ...................................................................................................................... 163

13.1 Technical specifications for CIM ........................................................................................... 163

13.2 Technical Specifications POM4320 ...................................................................................... 166

13.3 Technical Specifications POM4320 Highend ....................................................................... 176

13.4 Technical specifications for I/O module ................................................................................ 182

13.5 Technical specifications for EM4315 expansion module ...................................................... 192

13.6 Dimension drawings .............................................................................................................. 195

A Appendix............................................................................................................................................. 199

A.1 Certificates and approvals .................................................................................................... 199

A.1.1 Certificates and approvals .................................................................................................... 199

A.2 Article numbers for spare parts/accessories......................................................................... 200

A.2.1 Ordering data ........................................................................................................................ 200

A.3 ESD Guidelines ..................................................................................................................... 201

A.4 Service & Support ................................................................................................................. 203

A.4.1 Application example .............................................................................................................. 204

A.4.2 Frequently asked questions (FAQ) ....................................................................................... 204

Index................................................................................................................................................... 205

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

7

Page 10

Table of contents

SIPLUS HCS4300 PROFINET/PROFIBUS DP

8 Operating Instructions, 10/2019, A5E35452705A/005

Page 11

1

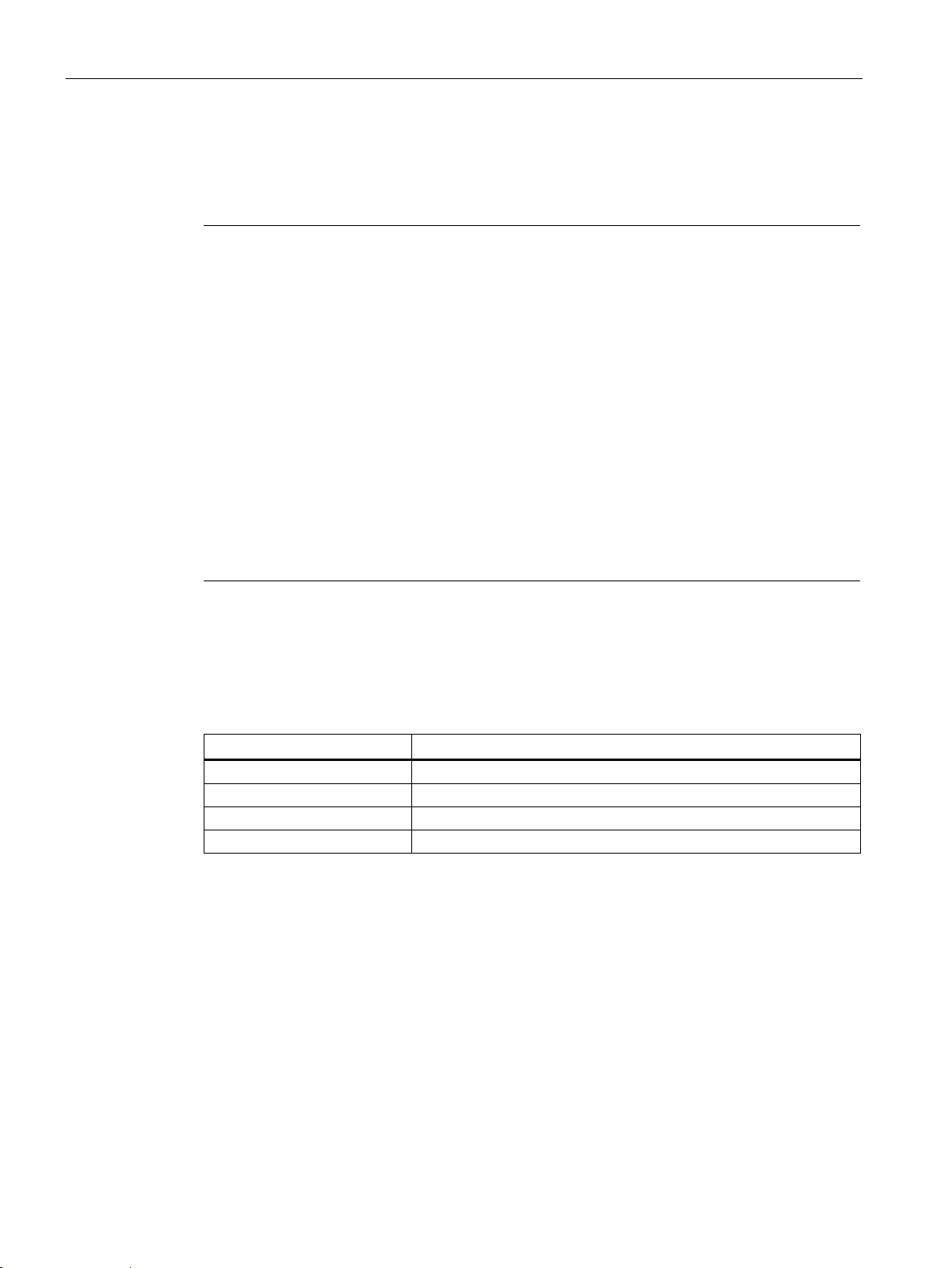

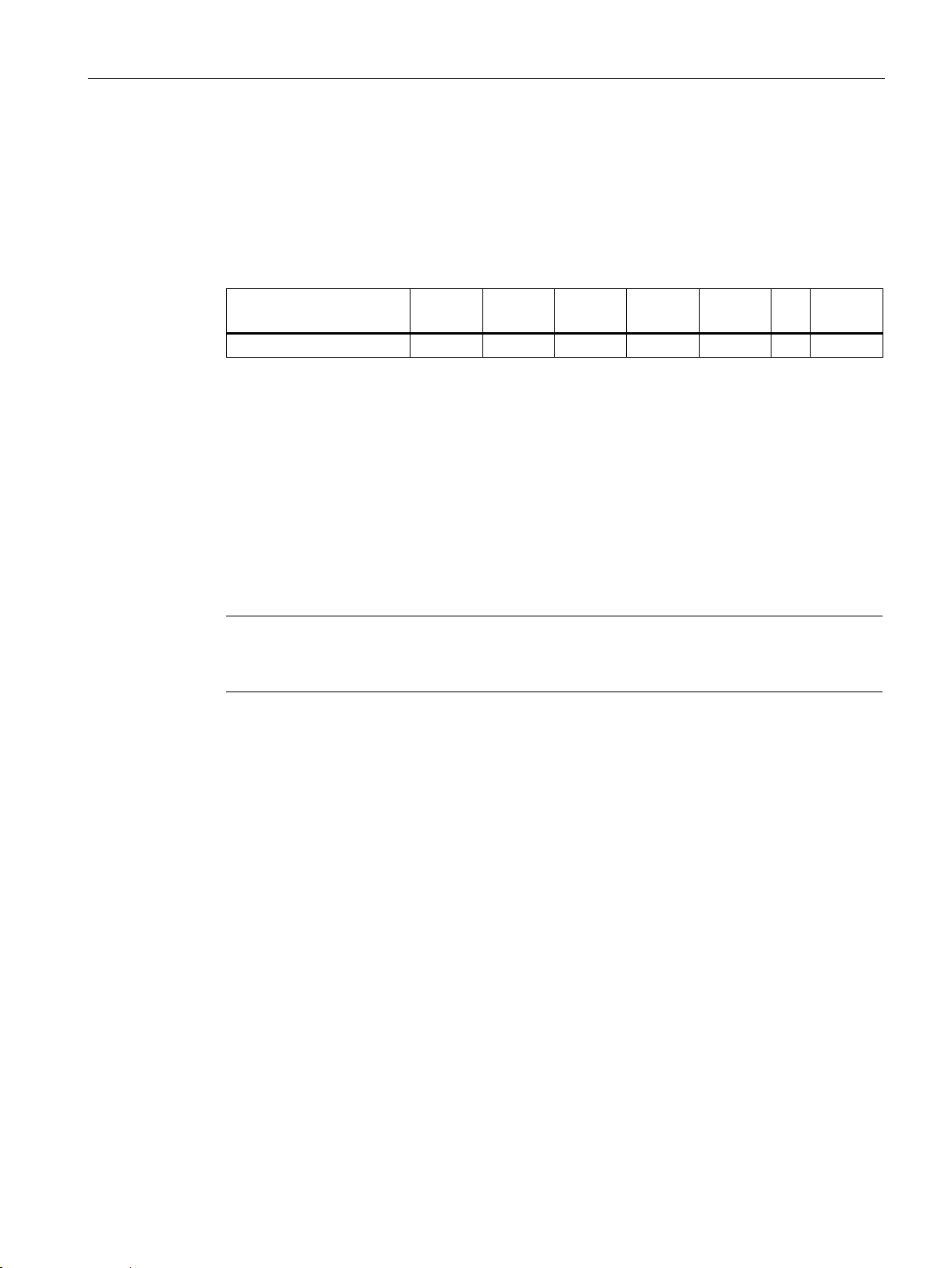

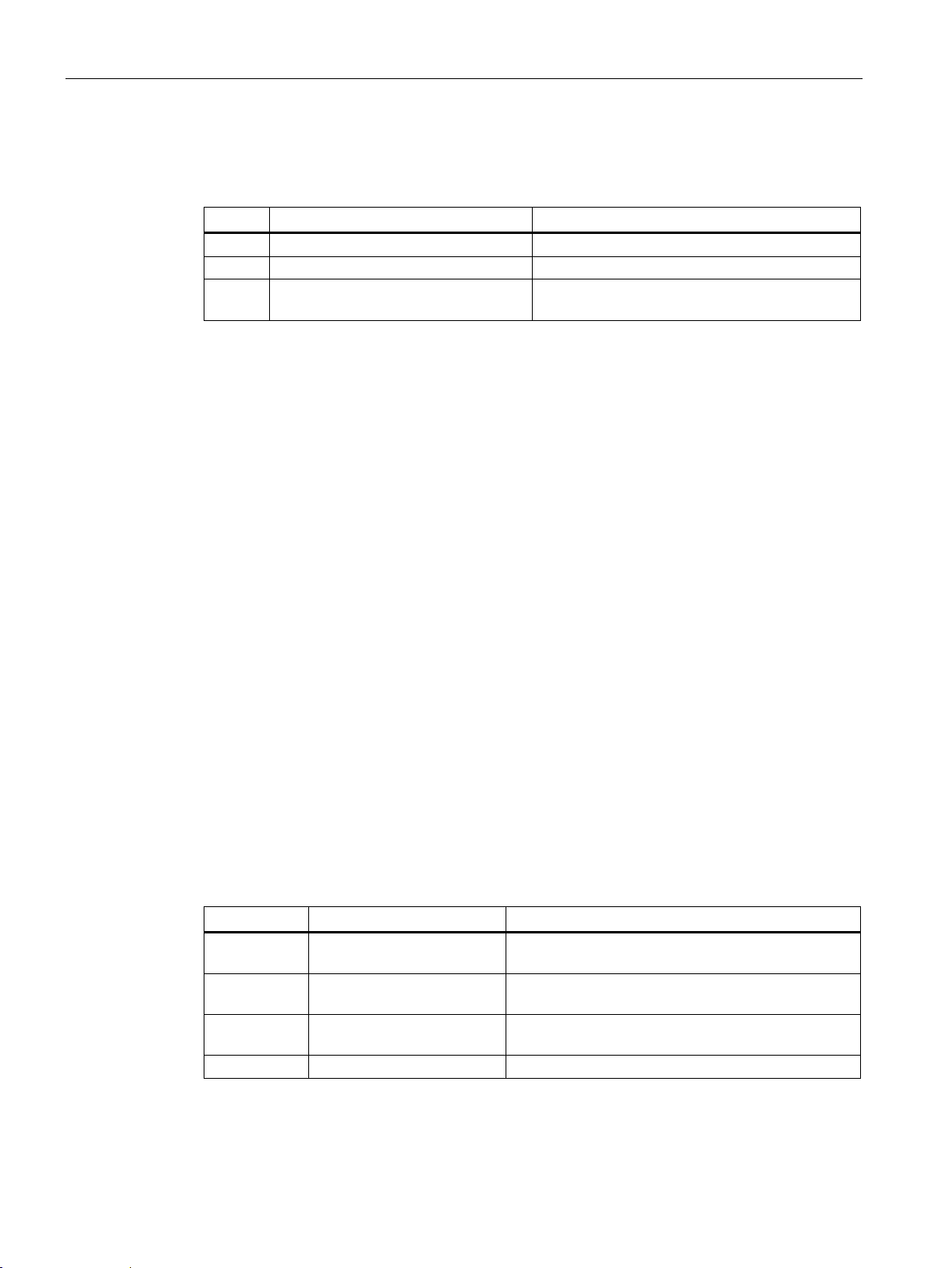

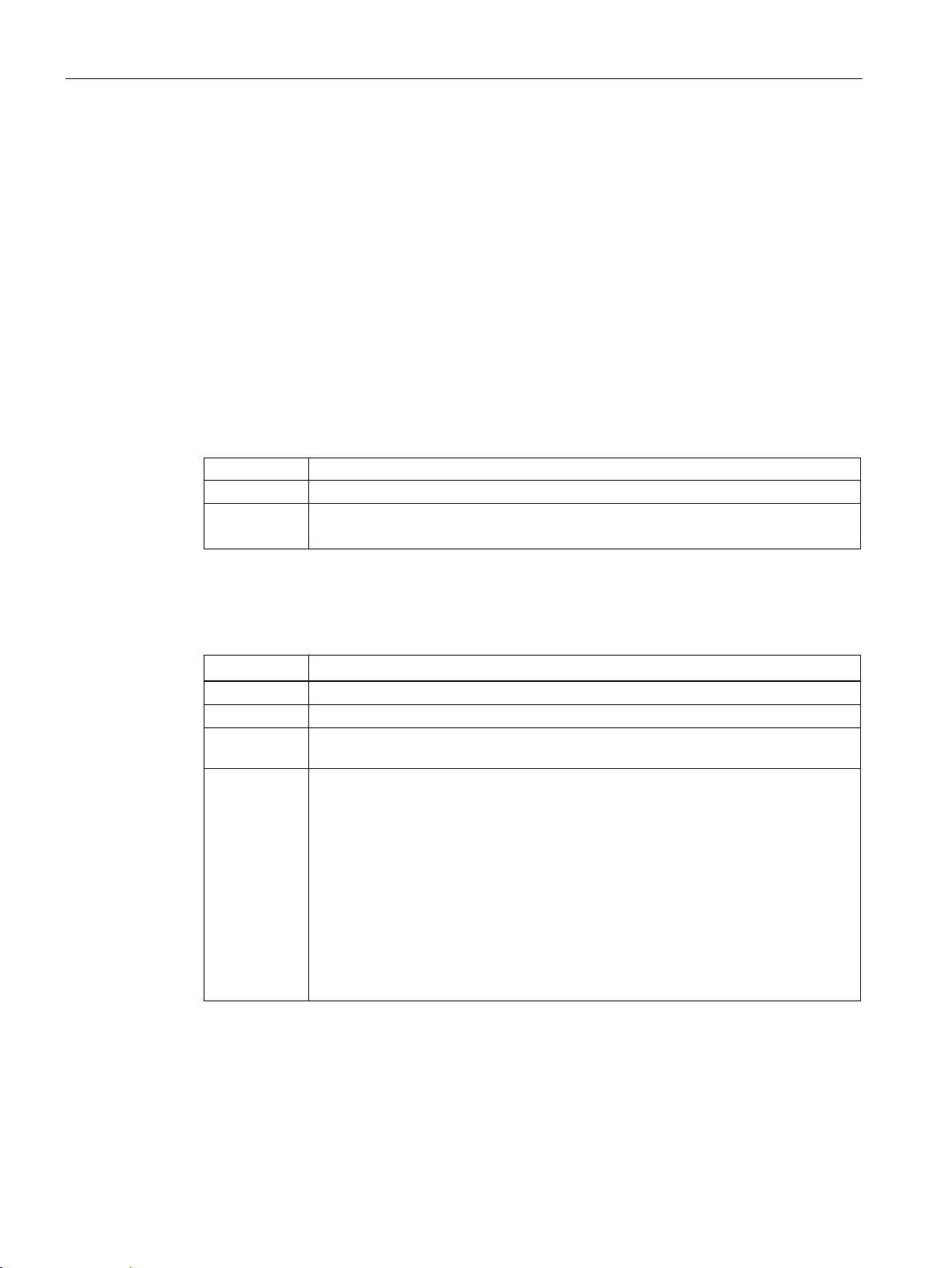

Edition

Comment

11/2014

First edition

module for additional 2 × 8 POMs

Commissioning support using PRONETA

04/2018

Expansion with phase control functionality for POM4320

10/2019

Expansion with POM4320 Highend

1.1 Introduction

Purpose of this documentation

These operating instructions contain the information you require to commission, operate and

service the HCS4300 heating control system.

Target group

The documentation is intended for qualified personnel in the following specialist fields:

● Operators, project engineers, programmers

● Electrically skilled personnel who assemble, connect and start up the device.

Required basic knowledge

● These operating instructions require prior knowledge of programming an S7 controller or

SIMOTION.

● Knowledge of working with the PROFINET or PROFIBUS fieldbus is also necessary.

History

The following earlier release versions of these operating instructions have been published:

10/2015 Expansion with POM with panel mounting, PROFIBUS, I/O modules, expansion

12/2016 Expansion with configuration control

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

9

Page 12

Introduction

Note

Applicable for devices up to firmware version 1.x of the CIM:

•

•

•

•

Applicable for devices up to firmware version 2.1 of the CIM:

•

•

Applicable for devices up to firmware version 2.3 of the CIM:

•

Applicable for devices as of firmware version 2.3 of the CIM:

•

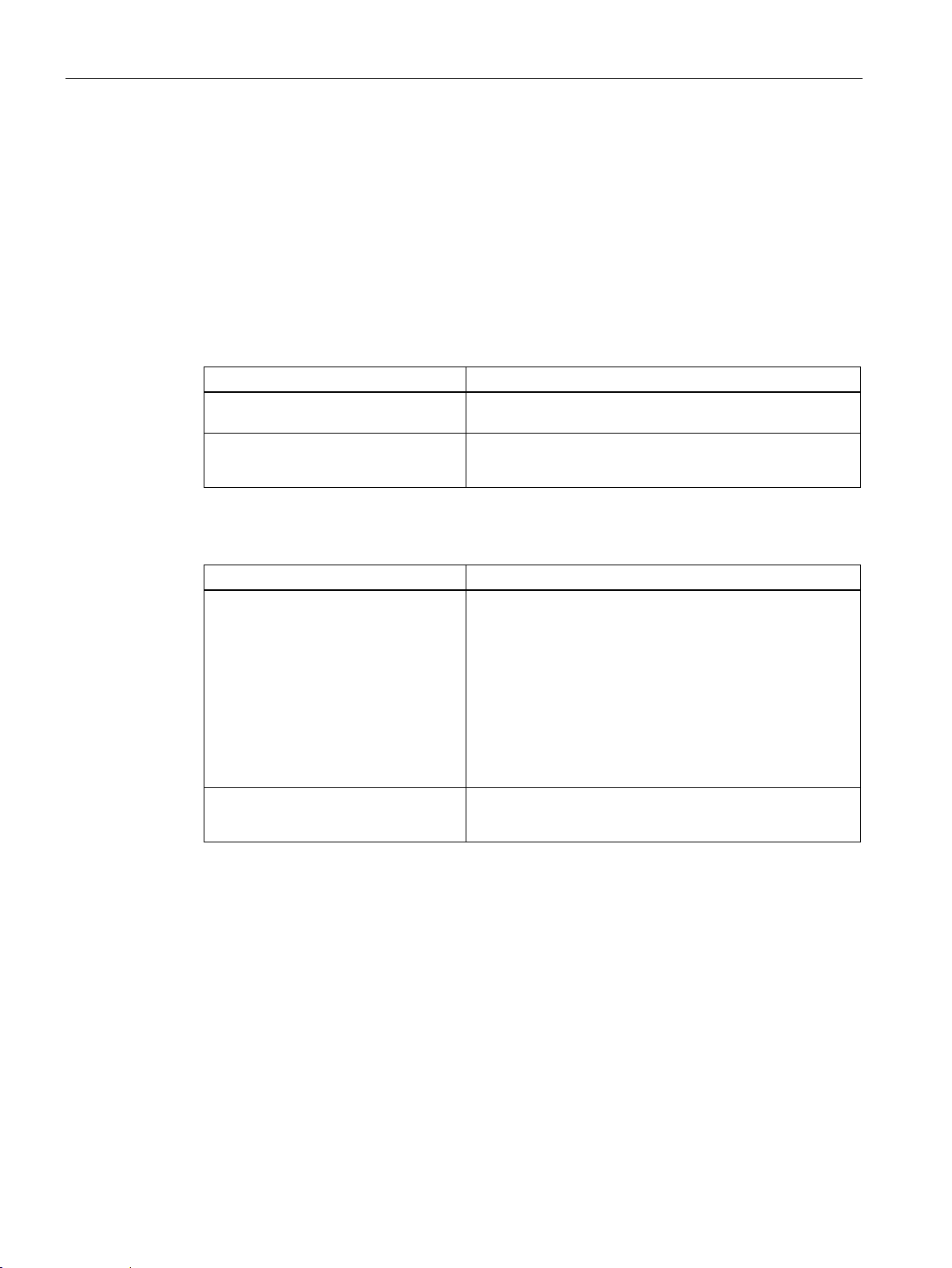

Product label

Abbreviation

Central Interface Module

CIM

I/O module

PM

Power Output Module

POM

SIPLUS HCS4300

HCS

1.1 Introduction

Scope of the document

This document is valid for all components of the SIPLUS HCS4300 specified below and

describes the current delivery state.

A maximum of 6 POMs can be operated.

Expansion module, PMs and the DP connection are not available

The following applies for reading data records 152, 200 and 201: The information that is

read is always for the full configuration, i.e. for 54 channels or 6 POMs.

The data records 160, 190 and 202 are not available.

No phase control can be configured for a POM4320.

Data record 50 is not available.

POM4320 Highend cannot be configured.

The "Phase control" mode is only available for POM4320 with MLFB -0AA2 as of

HW version 02.

Naming conventions and abbreviations

Instead of product labels, the following abbreviations are also used in this document.

The following product labels and abbreviations are used:

Registered trademarks

SIPLUS ® is a registered trademark of Siemens AG.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

10 Operating Instructions, 10/2019, A5E35452705A/005

Page 13

2

NOTICE

WARNING

Electric shock hazard

Can cause death or serious injury

WARNING

Electric shock hazard

Can cause death or serious injury

2.1 Safety notes

This device corresponds to the approvals printed on the type plate. If you have questions

about whether it is permissible to install the device in the planned environment, contact your

service representative.

• Alterations to the devices are not permitted. Failure to observe these guidelines shall

constitute a revocation of the approvals and manufacturer's warranty.

• The HCS4300 heating control system is not a safety product. In the event of a fault, the

machine must be brought to the safe state on the plant side.

Warning symbols on the device

When this warning symbol

instructions for the device. The operating instructions contain information about the

potential risks and enable you to recognize risks and implement countermeasures.

Note before connecting the device

The supply system to which the heating control system is connected must have a circuit

breaker. The device must be switched off and secured against switching on again, before

connecting to the line voltage. Otherwise, there is a risk of electric shock.

appears on the device, you must consult the operating

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

11

Page 14

Safety guidelines

WARNING

Electric shock hazard

Can cause death or serious injury

NOTICE

WARNING

No user-serviceable parts

Can cause death or serious injury

2.1 Safety notes

Working on the device or on components connected to it

• Voltages of more than 60 V can occur in the control cabinet. Suitable safety precautions

to prevent contact must therefore be taken before and during commissioning and

maintenance work.

• Before working on the heating control system or the connected components, ensure the

system is disconnected.

Fuse replacement

Use only the prescribed fuse types. If you operate a heating controller with unapproved

fuses, the device could be destroyed.

Repairs

Incorrectly performed repairs can result in substantial damage to equipment or endanger

the user. Return the device to Siemens for repair.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

12 Operating Instructions, 10/2019, A5E35452705A/005

Page 15

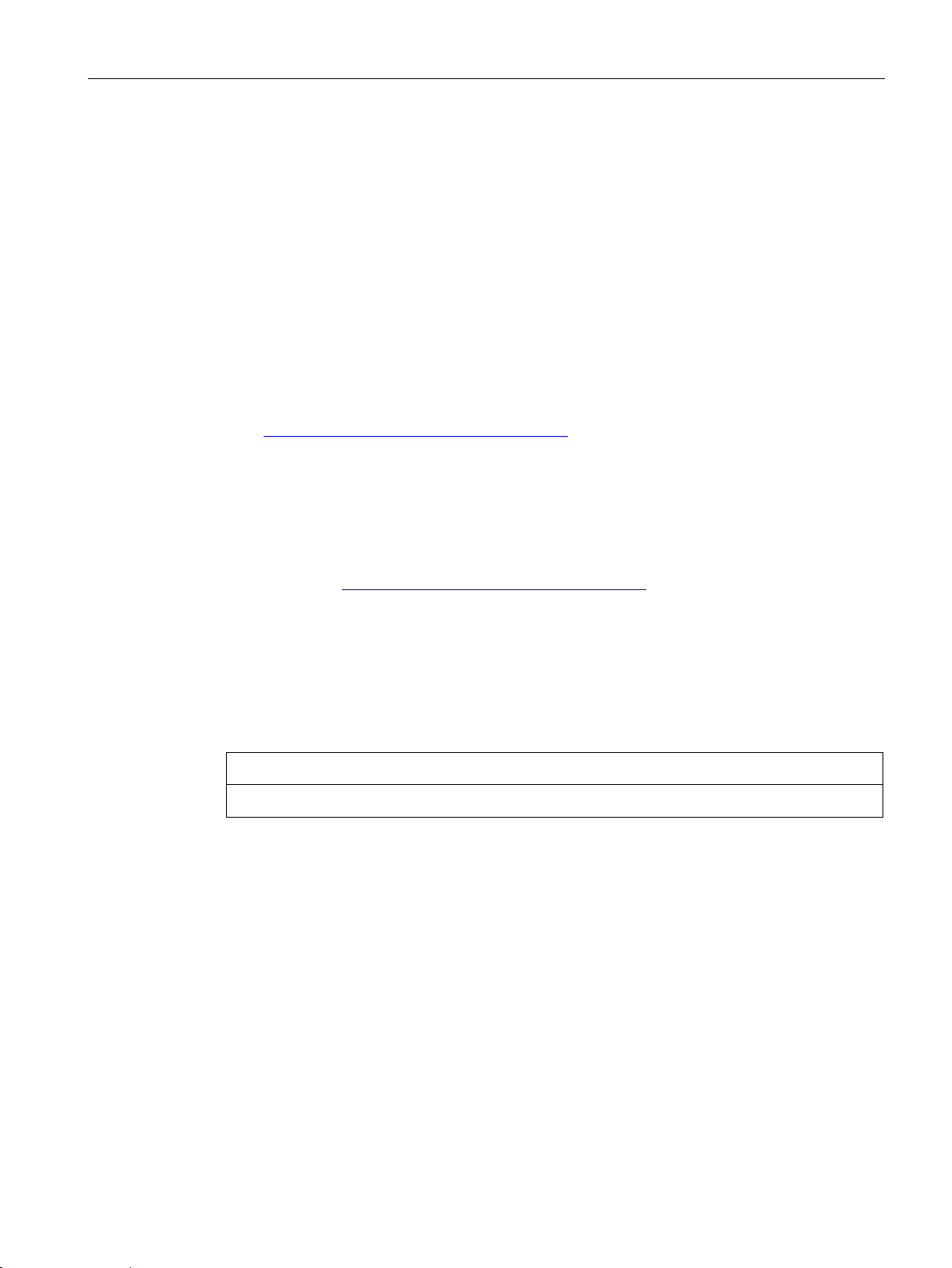

Safety guidelines

NOTICE

2.2 Security information

2.2 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (https://www.siemens.com/industrialsecurity).

Siemens' products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers' exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security

RSS Feed visit (https://www.siemens.com/industrialsecurity).

2.3 Protective measures for the HCS4300

Protective measures for the HCS4300 heating control system

Only authorized personnel are permitted to access the system and make changes to it.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

13

Page 16

Safety guidelines

2.3 Protective measures for the HCS4300

SIPLUS HCS4300 PROFINET/PROFIBUS DP

14 Operating Instructions, 10/2019, A5E35452705A/005

Page 17

3

3.1 Area of application

The SIPLUS HCS 4300 heating control system is used to activate and switch heating

elements in industry, such as quartz, ceramic, flash, halogen or infrared emitters. It is of

modular design and can be flexibly adapted to suit the specific requirements of the

respective application.

Typical application areas are:

● PET blow molding

● Drying of enamels and coatings

● Thermal treatment of fabric and plastics

● Welding of plastic parts

● Handling of carbon materials

In general, the HCS4300 can be used wherever compact or modular concepts are required

with high levels of power output.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

15

Page 18

System overview

3.2 Features

3.2 Features

An HCS4300 system comprises one Central Interface Module (CIM) and up to

24 Power Output Modules (POM). As an option, one I/O module can be operated on

the CIM.

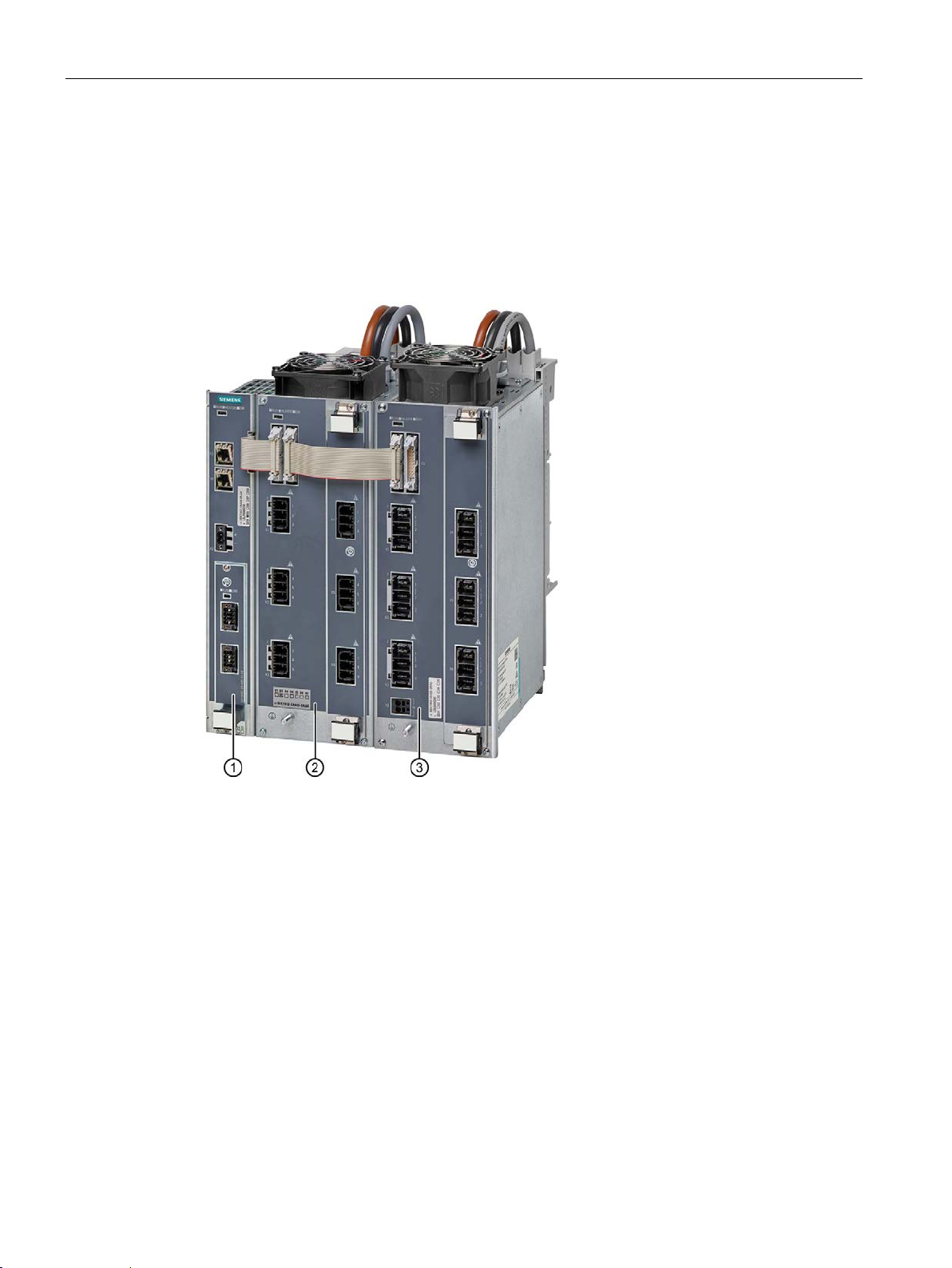

The following figure shows an example of an HCS4300, consisting of a CIM4310 for

PROFINET, a POM4320, as well as a POM4320 Highend for busbar mounting.

Figure 3-1 HCS4300 consisting of CIM ①, POM4320 ② and POM4320 Highend ③

SIPLUS HCS4300 PROFINET/PROFIBUS DP

16 Operating Instructions, 10/2019, A5E35452705A/005

Page 19

System overview

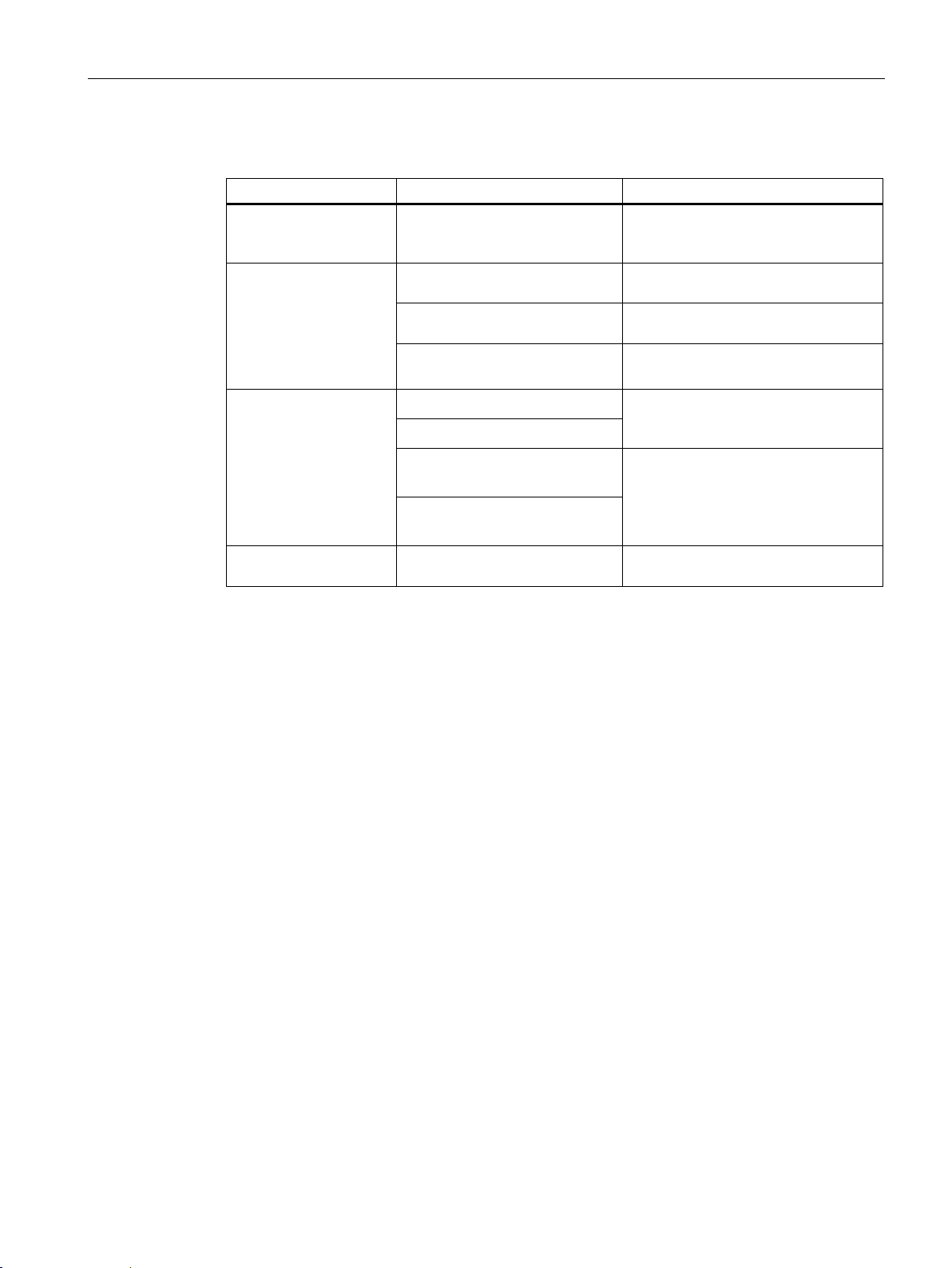

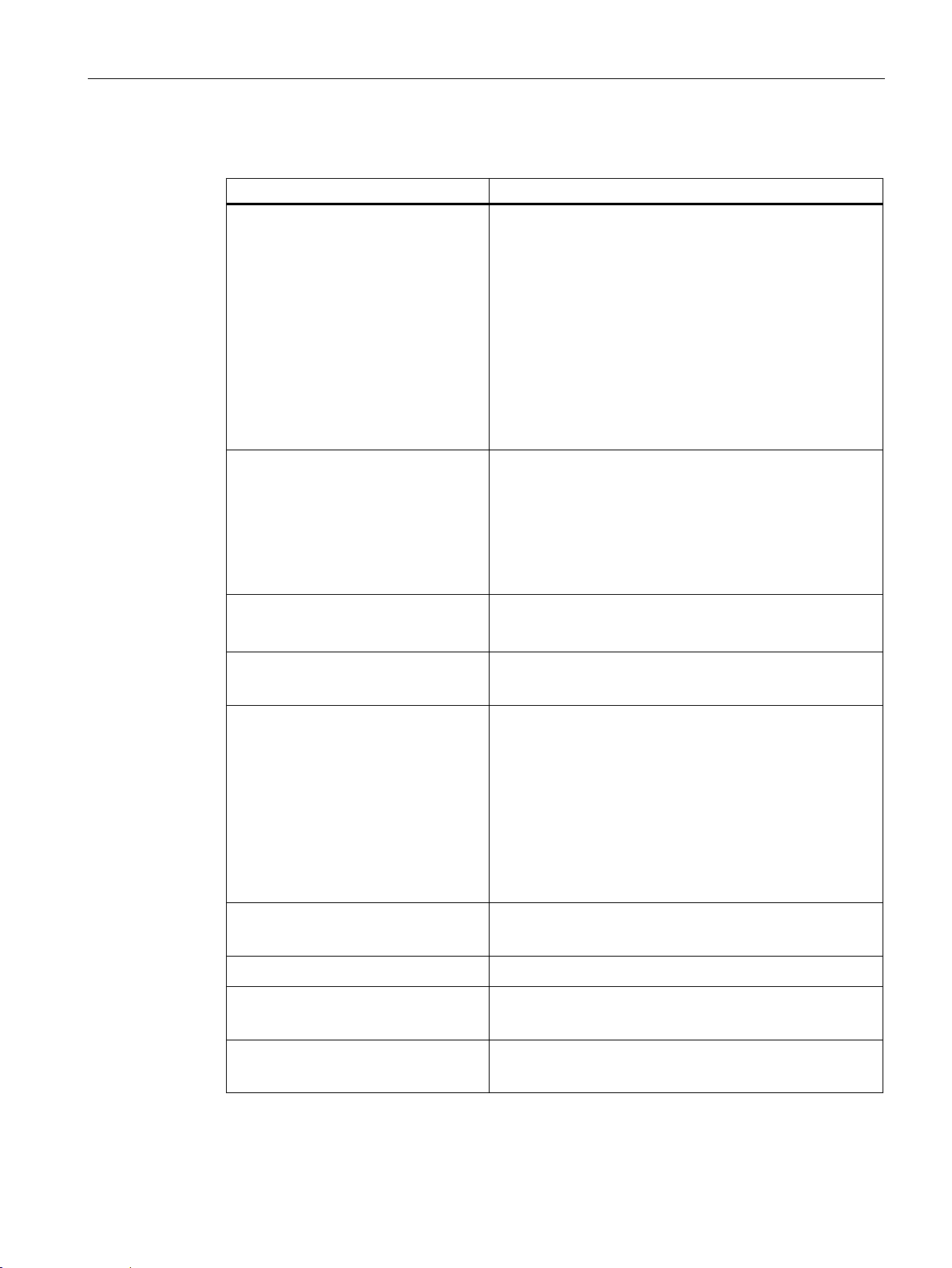

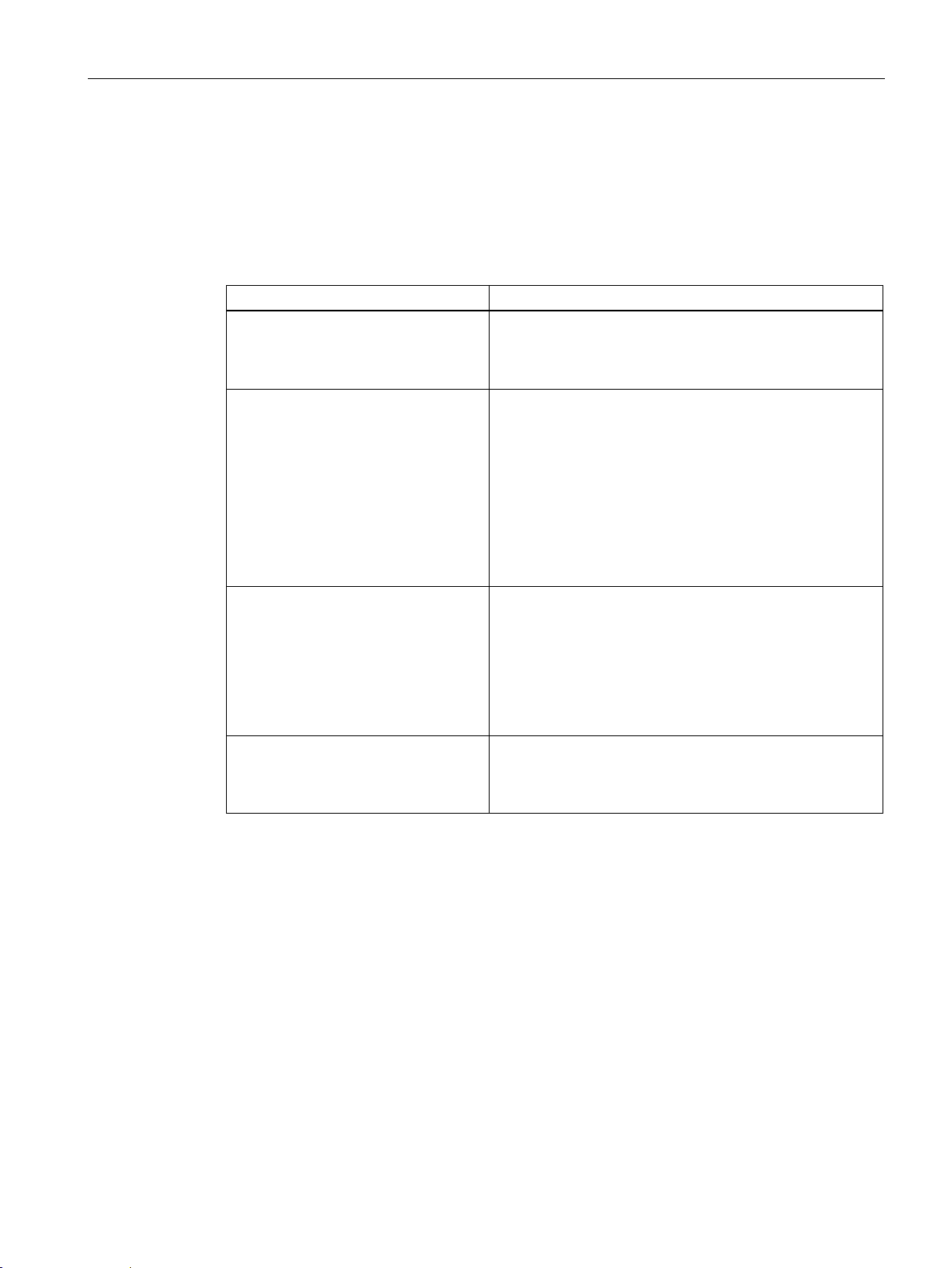

System component

Version

Description

a CIM.

line current.

4 measuring inputs for temperature

POM4320 or 6 POM4320 Highend.

3.2 Features

The following types of system component are available:

Features

Central Interface Module

(CIM)

I/O module

Power Output Module

(POM)

Expansion module

• CIM4310 PROFINET

• CIM4310 PROFIBUS

• PM4000 DI/DO

• PM4000 U/I

• PM4000 Temperature

• POM4320 busbar mounting

• POM4320 panel mounting

• POM4320 Highend busbar

mounting

• POM4320 Highend for panel

mounting

• EM4315

A maximum of 8 POM4320 or 6

POM4320 Highend can be operated at

8 digital outputs and 8 configurable

inputs/outputs.

Inputs for measuring line voltage and

4 analog inputs for 0 mA to 20 mA and

9 power outputs with diagnostic function and fault indication per channel.

6 power outputs with diagnostics and

error display per channel.

Enables operation of up to 8 additional

● Modular (centralized) and compact (distributed) configurations possible

● Communication via PROFINET/PROFIBUS

● Parameter assignment, commissioning, visualization and diagnostics via

Siemens TIA Portal

● Support of configuration and commissioning of the PROFINET network with PRONETA

● Integrated diagnostics and monitoring functions

● Control modes: Half-wave control, soft start and phase control

● Line voltage compensation for smoothing line voltage fluctuations integrated

● Only one 24 V power supply required for up to 8 POM4320 or 6 POM4320 Highend

● Slot for one I/O module (PM)

● Expansion module (optional) with 24 V power supply for operation of an additional

2 x 8 POM4320 or 2 x 6 POM4320 Highend

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

17

Page 20

System overview

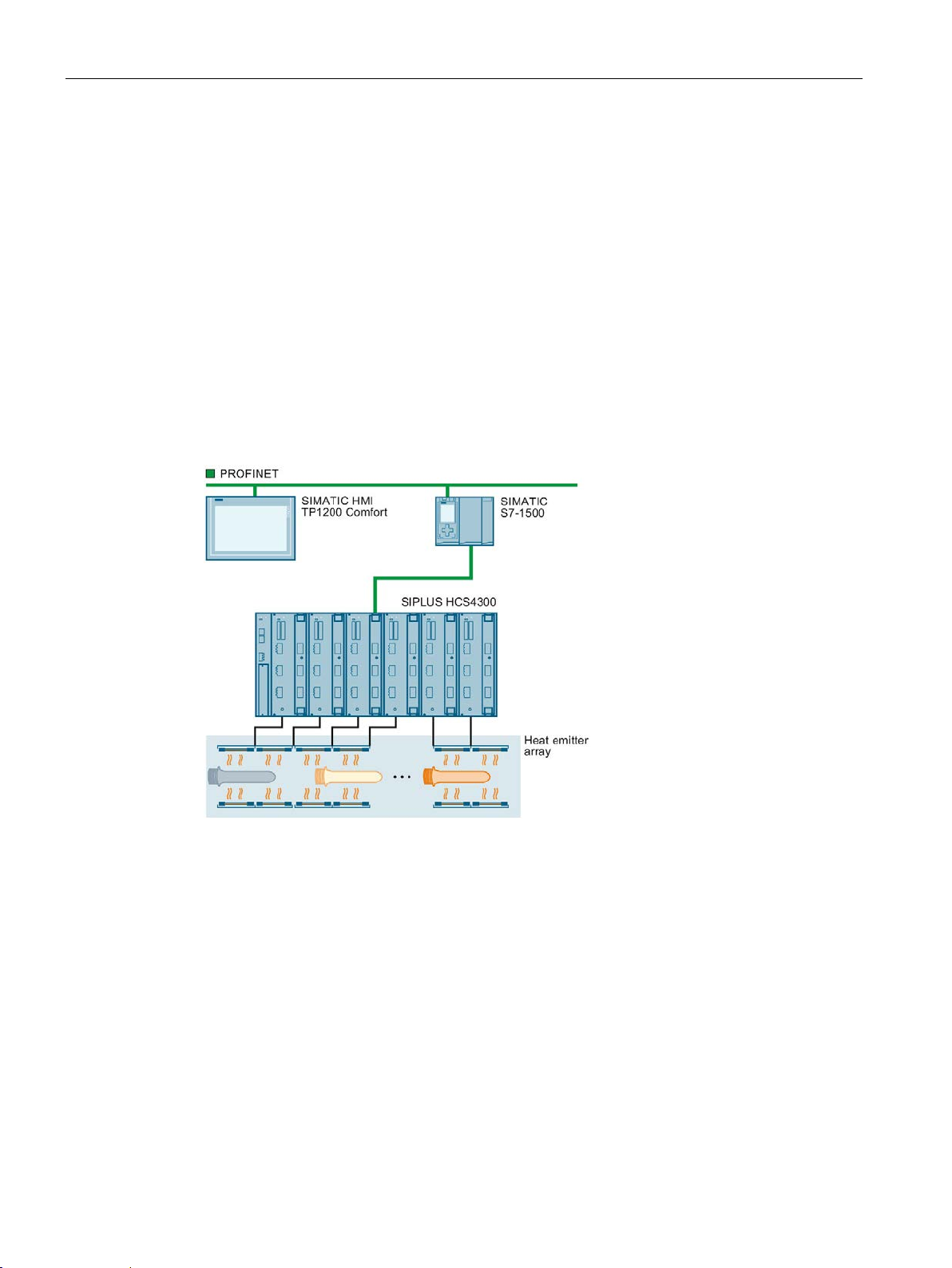

3.3 System configuration

3.3 System configuration

System components

A complete heating control system with HCS4300 includes the following components:

● Central Interface Module (CIM) 4310 with PROFINET or PROFIBUS

● Power Output Module (POM) 4320 for busbar or panel mounting

● Higher-level controller, e.g. SIMATIC S7-1500 automation system with

PROFINET/PROFIBUS

● Field PG, optional for commissioning and diagnostics

● HMI panel, optional, e.g. SIMATIC HMI TP1500

● Heat emitter array

Figure 3-2 System components

Centralized and distributed heating application

A maximum of 8 POM4320 or 6 POM4320 Highend can be operated at a CIM. In the

maximum configuration with 2 expansion modules, up 24 POM4320 or

18 POM4320 Highend can be operated.

System configurations can be realized for distributed, decentralized heating applications,

such as PET blow molding, where the heating controller is located below the heating boxes,

as well as central heating applications, for example, in thermoforming, where the heating

elements are implemented in numerous arrays and the modular heating control system is

located in a central control cabinet.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

18 Operating Instructions, 10/2019, A5E35452705A/005

Page 21

System overview

3.4 Central interface module (CIM)

Communication via PROFINET or PROFIBUS

PROFINET combines the industrial experience of PROFIBUS with the openness and flexible

options of Ethernet. PROFINET enables high-speed and secure data exchange at all levels,

thus making it possible to implement innovative machine and plant concepts.

PROFIBUS has been established for years as the fieldbus for machines and plants. Based

on serial bus technology, it is the foundation for the distributed concepts that are common

today.

Combined operation with HCS4200 heating controller

You can operate a POM4320 with the HCS4200. See SIPLUS HCS4200

PROFINET/PROFIBUS DP operating instructions.

Combined operation of a POM4320 Highend with the HCS4200 heating controller is not

possible.

3.4 Central interface module (CIM)

3.4.1 Function and design

Function

The Central Interface Module (CIM) handles the communication with the higher-level

controller and with the connected Power Output Modules (POM). In addition, the CIM

provides the 24 V DC power supply for the connected POMs. The CIM is available in two

versions: with a PROFINET interface or with a PROFIBUS interface.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

19

Page 22

System overview

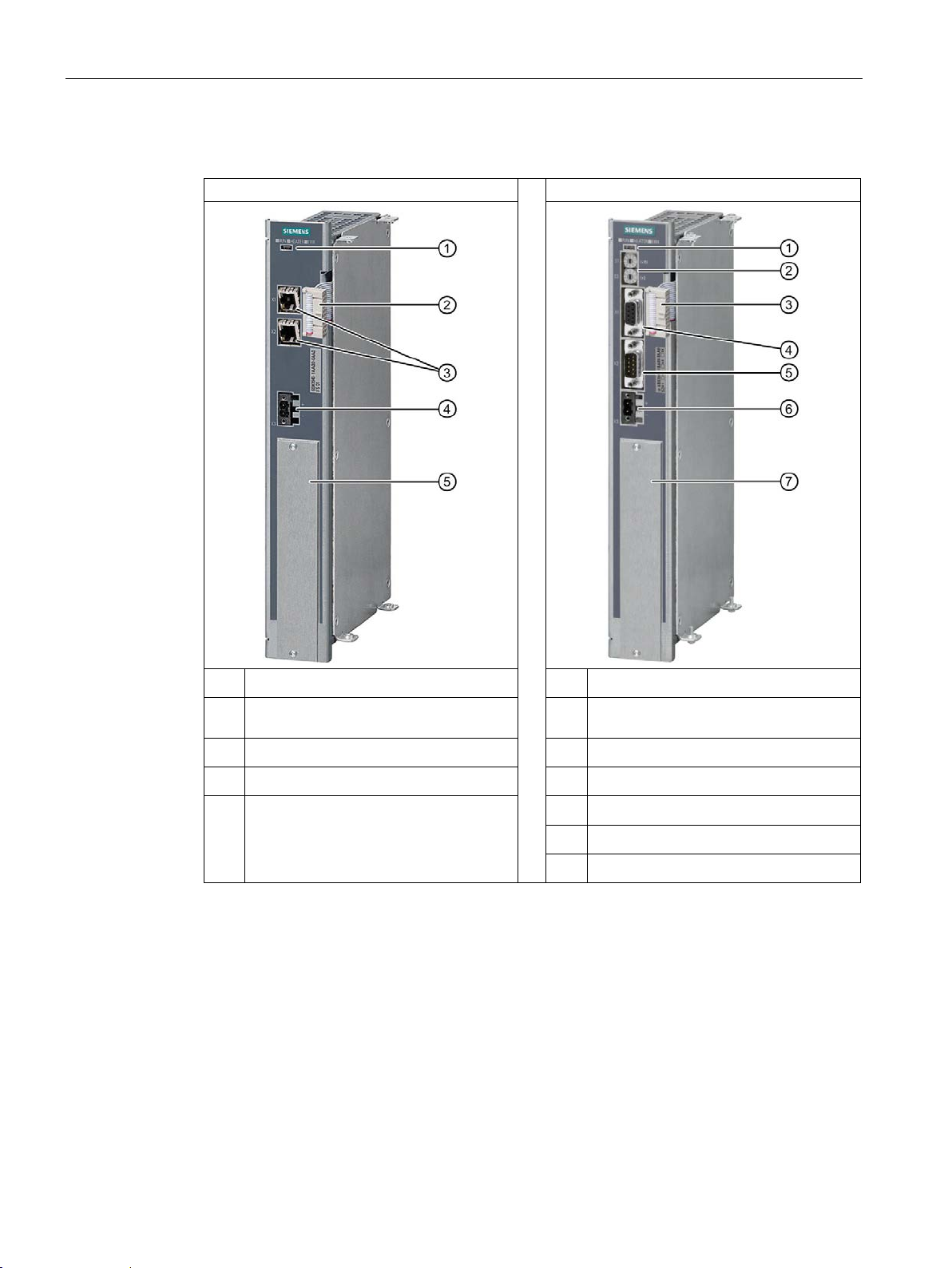

CIM4310 PROFINET

CIM4310 PROFIBUS

①

①

PROFIBUS

③

③

④

④

⑤

⑤

⑥

⑦

3.4 Central interface module (CIM)

Design

Status LEDs

System interface for POM

②

PROFINET interface X1 and X2

24 V DC supply X3

Slot for I/O module

Status LEDs

Address selector switches S1 and S2 for

②

System interface for POM

PROFIBUS DP interface X1

Service interface X2

24 V DC supply X3

Slot for I/O module

SIPLUS HCS4300 PROFINET/PROFIBUS DP

20 Operating Instructions, 10/2019, A5E35452705A/005

Page 23

System overview

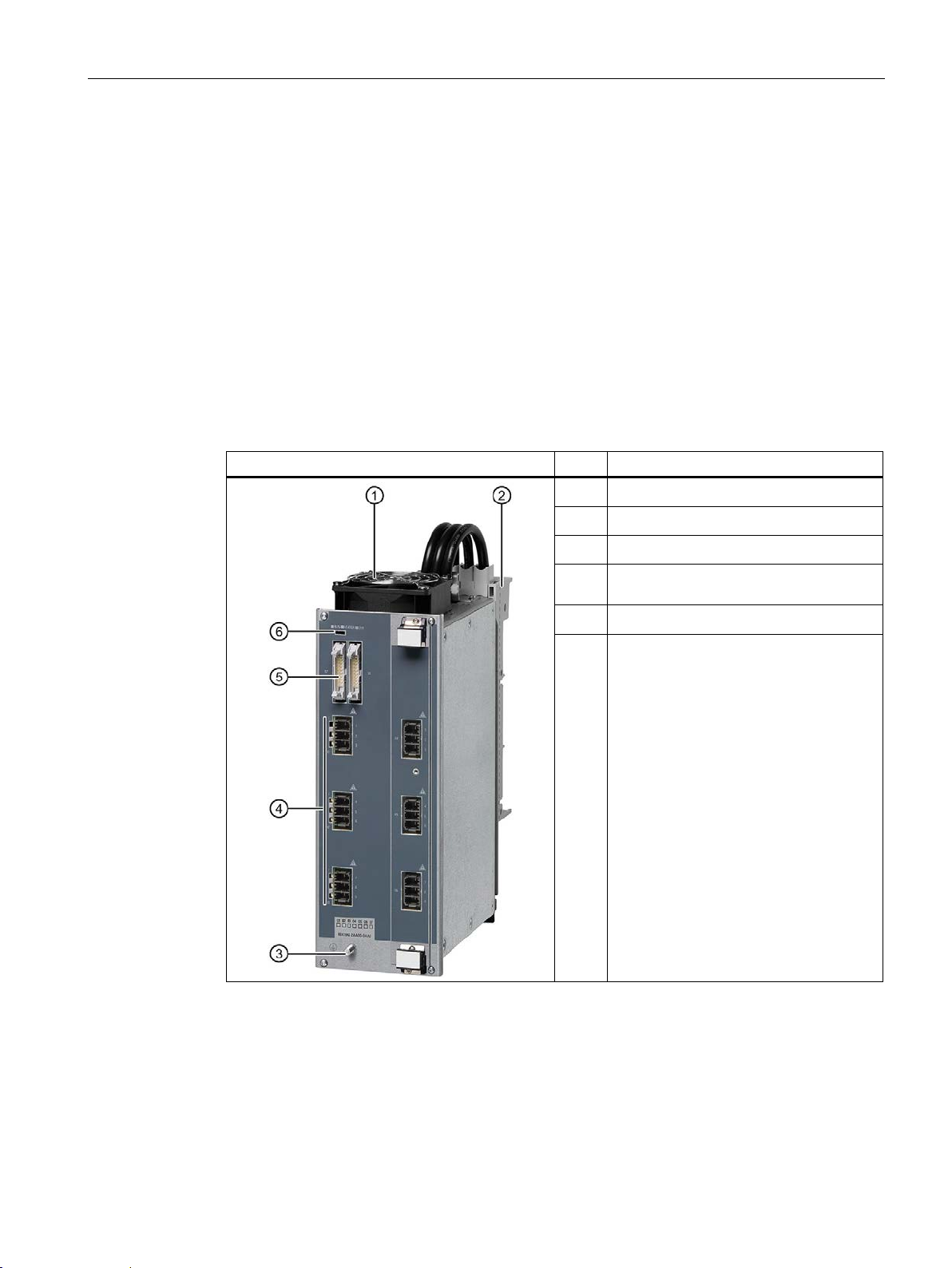

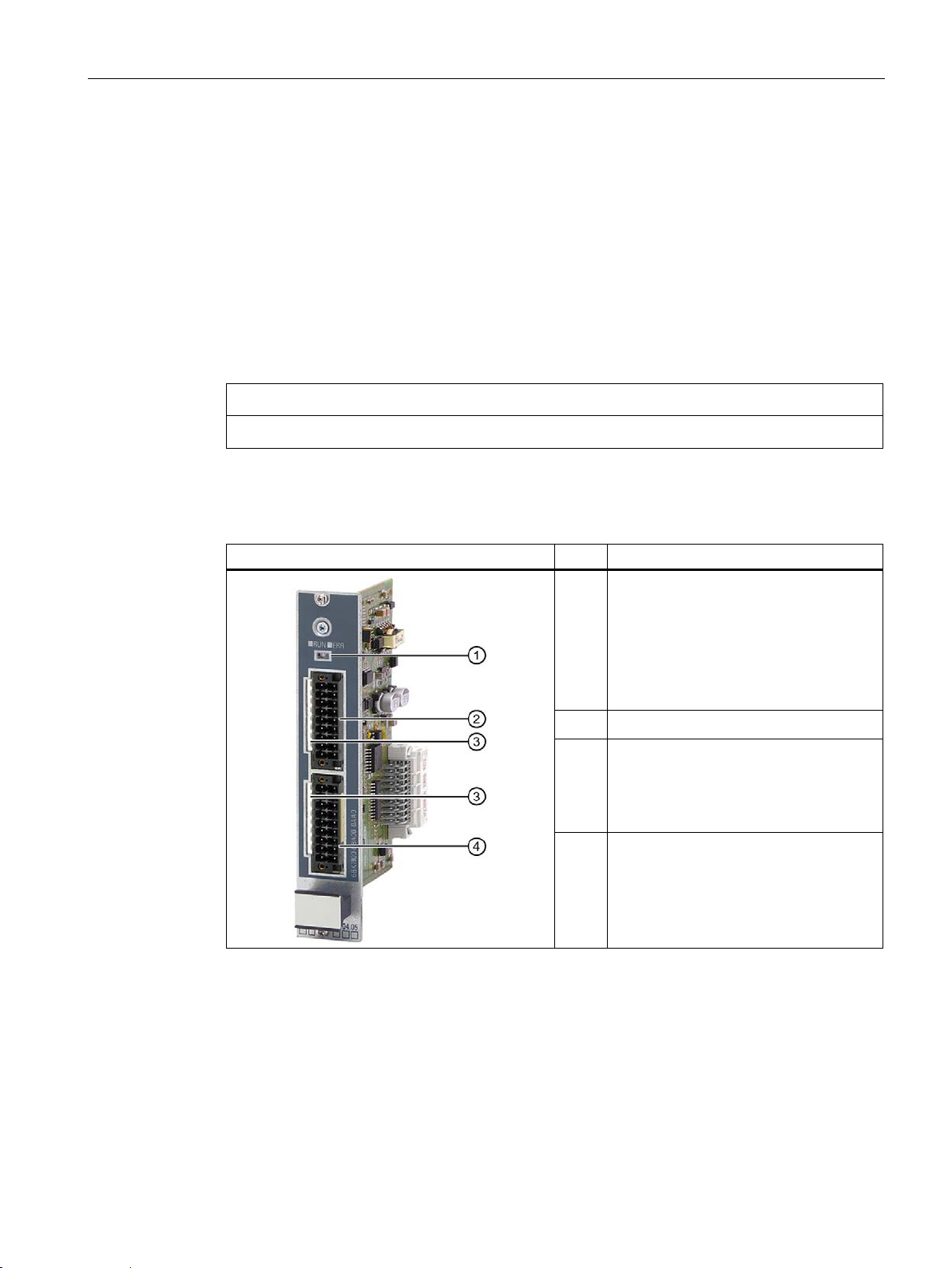

POM4320 for busbar mounting

Item

Description

①

②

③

④

error LED for each power output

⑤

3.5 Power output module (POM)

3.5 Power output module (POM)

3.5.1 Function and design

Function

The Power Output Module (POM) offers power outputs for resistive loads and can be

operated in TN and TT networks. The POM is available in versions for busbar or panel

mounting.

POM4320 design for busbar mounting

Fan

Busbar adapter

Protective conductor connector

3 x 3 power outputs including incoming,

HCS system interface

Status LEDs

⑥

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

21

Page 24

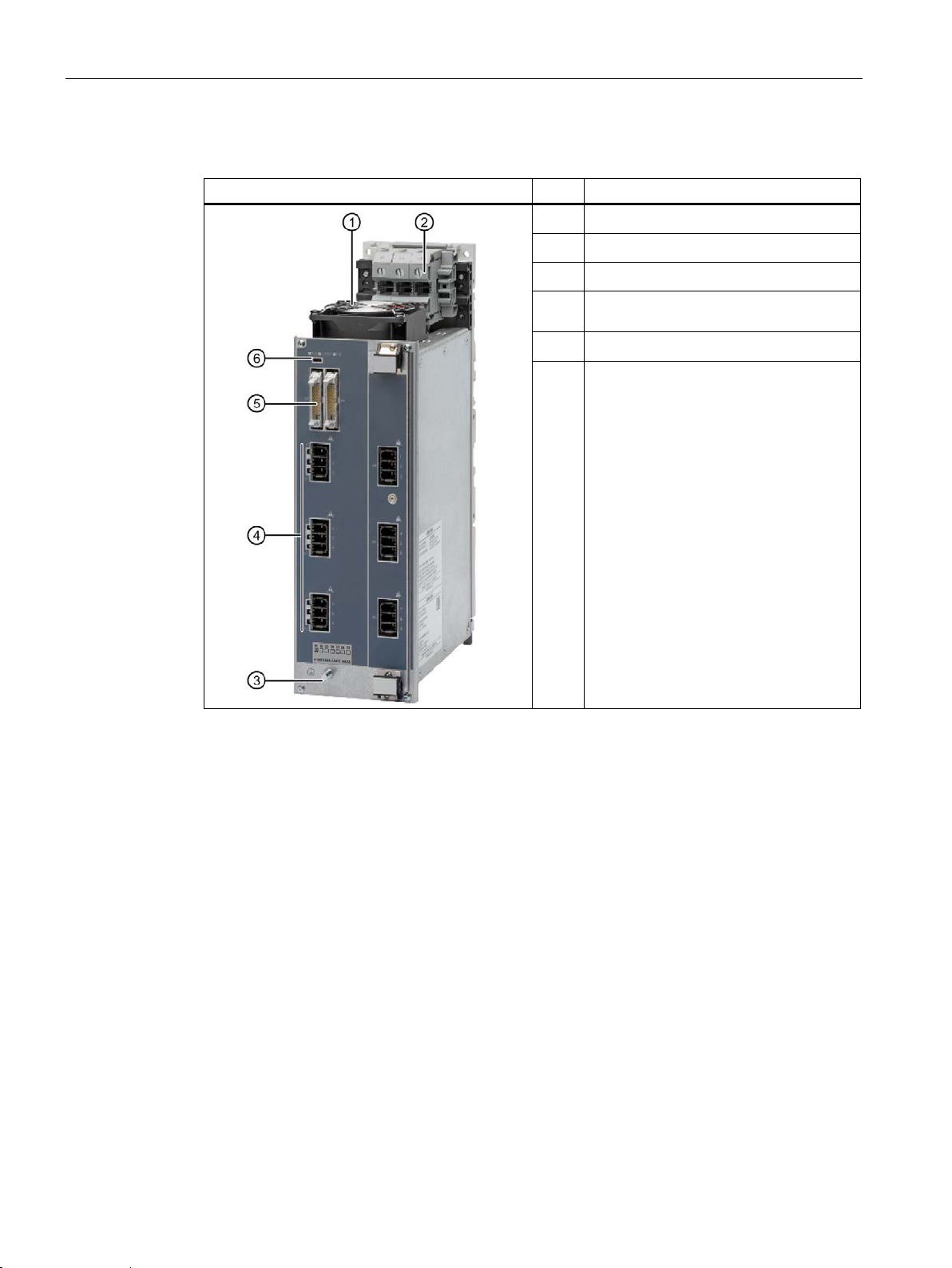

System overview

POM4320 for panel mounting

Item

Description

①

②

③

④

error LED for each power output

⑤

3.5 Power output module (POM)

POM4320 design for panel mounting

Fan

Mains connection L1, L2, L3

Protective conductor connector

3 x 3 power outputs including incoming,

HCS system interface

Status LEDs

⑥

SIPLUS HCS4300 PROFINET/PROFIBUS DP

22 Operating Instructions, 10/2019, A5E35452705A/005

Page 25

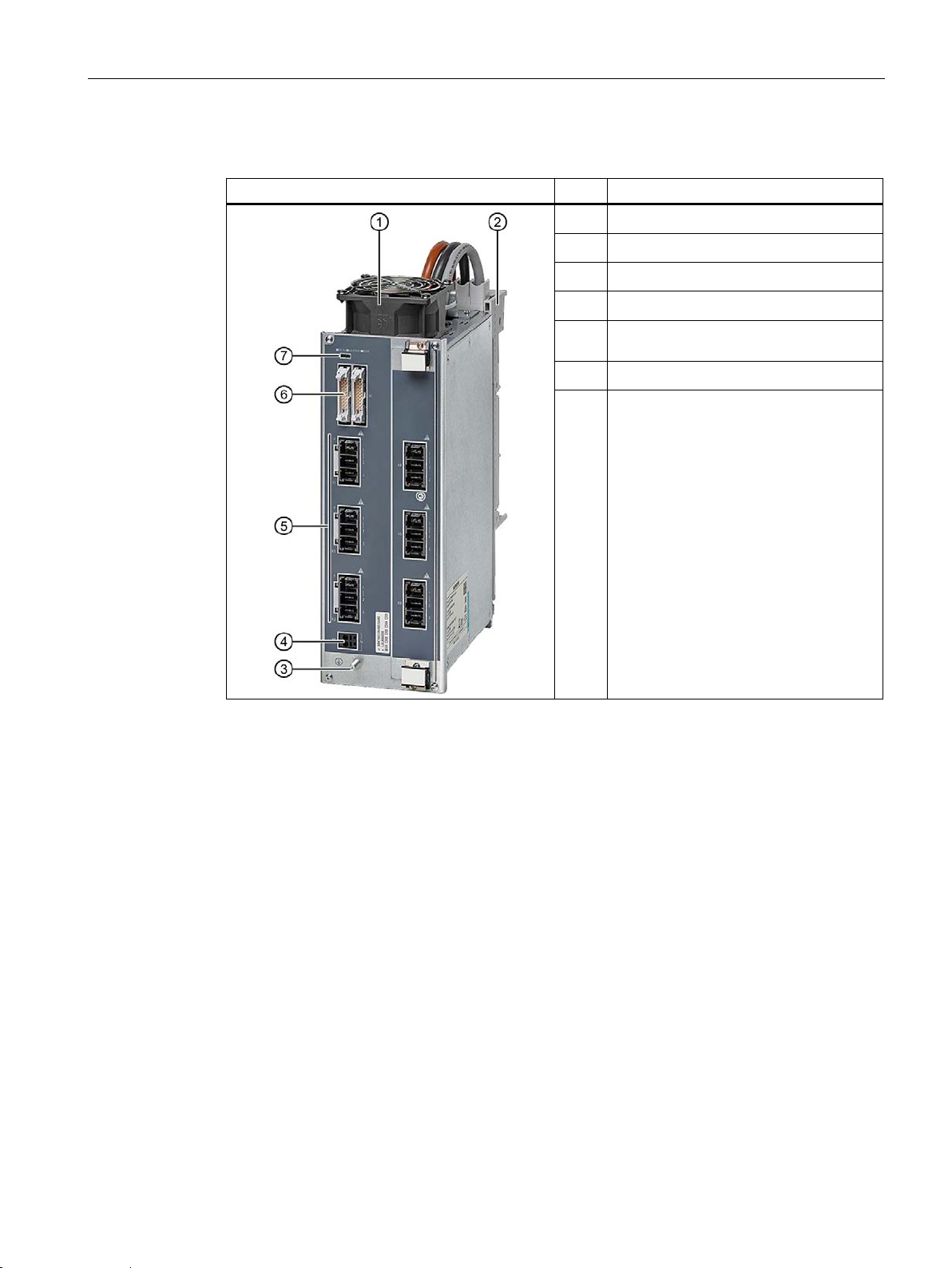

System overview

POM4320 Highend for busbar mounting

Item

Description

①

②

③

④

⑤

error LED for each power output

⑥

3.5 Power output module (POM)

POM4320 Highend design for busbar mounting

Fan

Busbar adapter

Protective conductor connector

Neutral conductor

3 x 2 power outputs including incoming,

HCS system interface

Status LEDs

⑦

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

23

Page 26

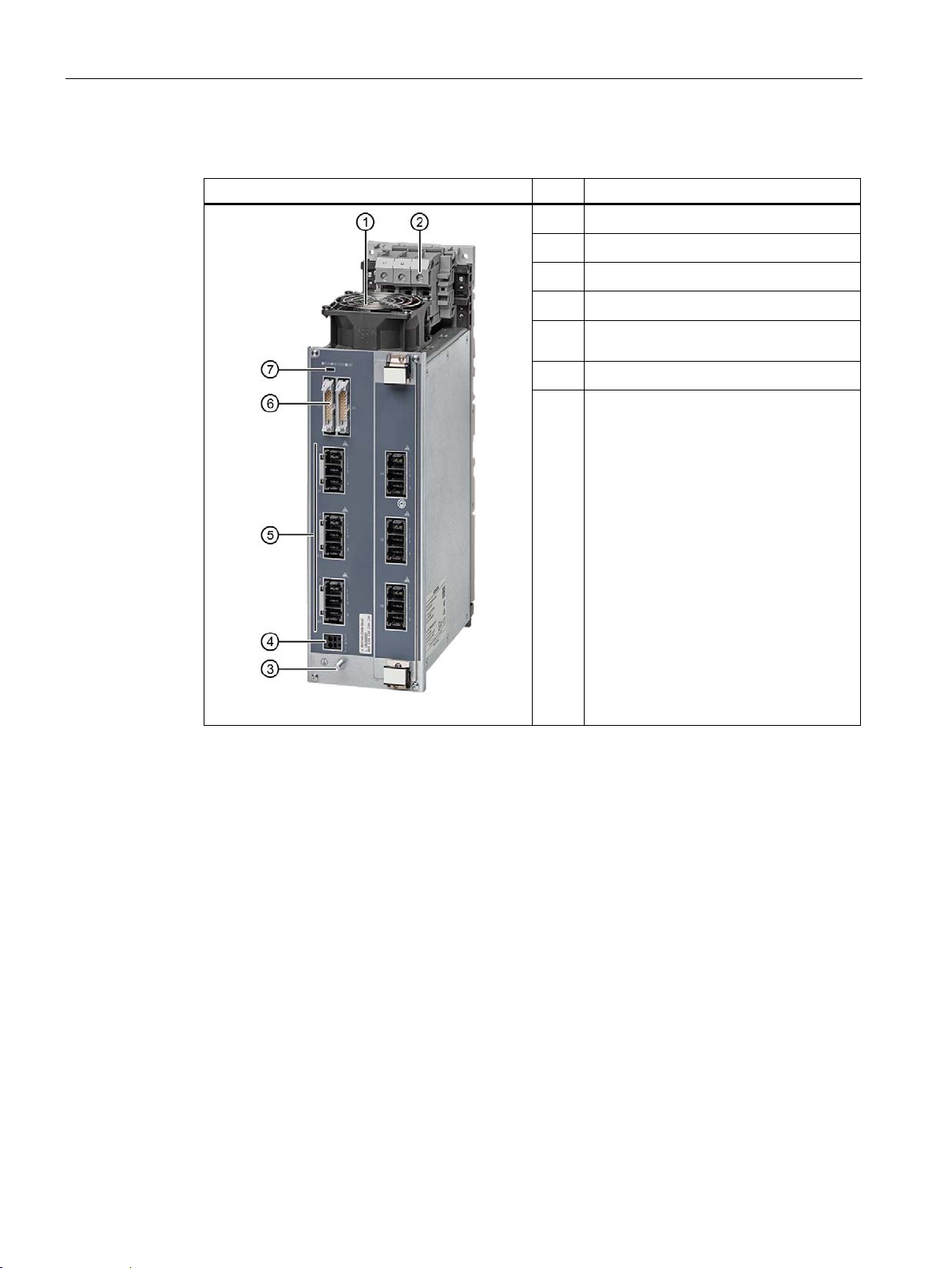

System overview

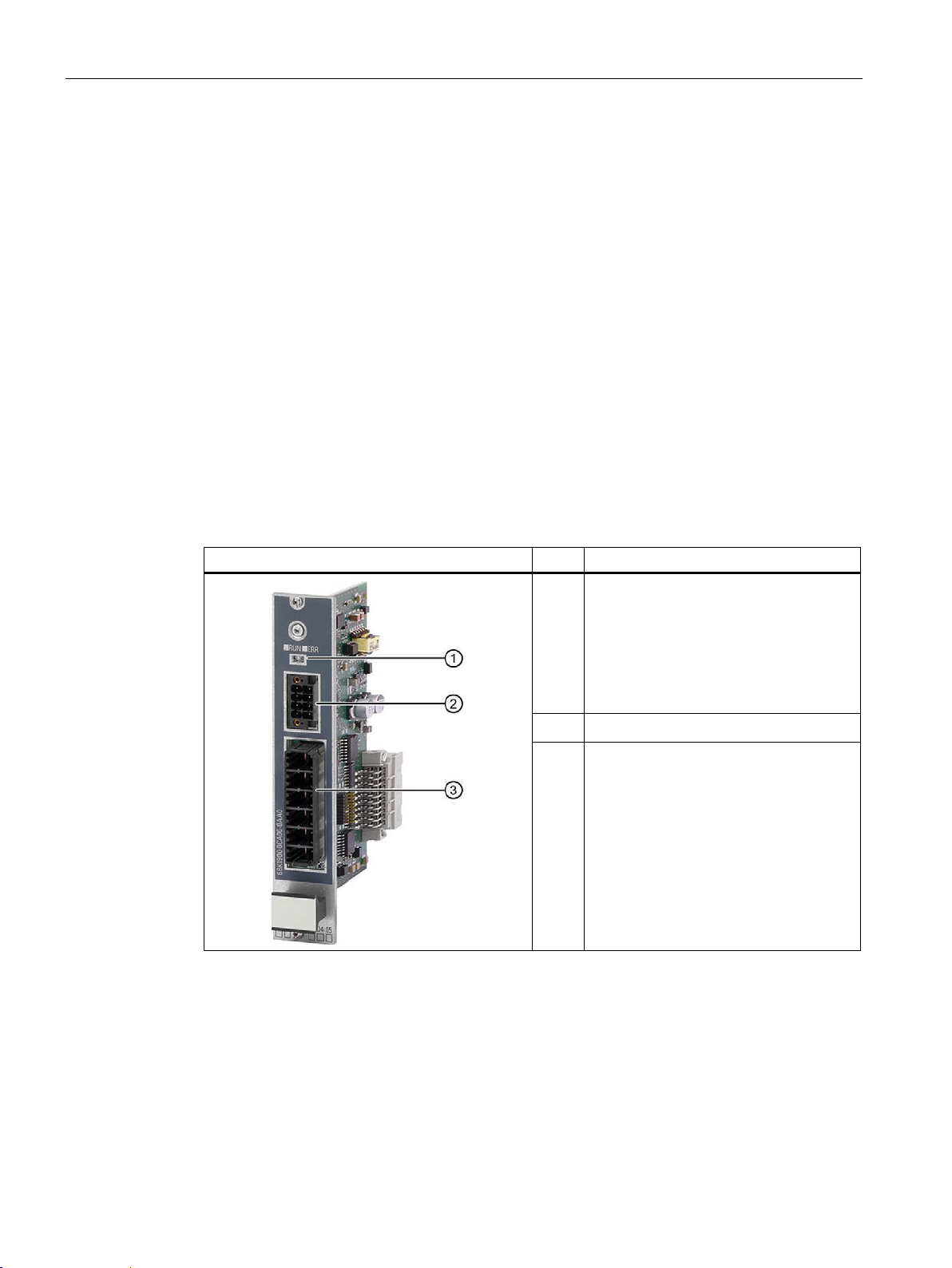

POM4320 Highend for panel mounting

Item

Description

①

②

③

④

⑤

error LED for each power output

⑥

3.5 Power output module (POM)

POM4320 Highend design for panel mounting

Fan

Mains connection L1, L2, L3

Protective conductor connector

Neutral conductor

3 x 2 power outputs including incoming,

HCS system interface

Status LEDs

⑦

SIPLUS HCS4300 PROFINET/PROFIBUS DP

24 Operating Instructions, 10/2019, A5E35452705A/005

Page 27

System overview

NOTICE

PM4000 DI/DO

Item

Description

②

3.6 I/O modules

3.6 I/O modules

3.6.1 PM4000 DI/DO

Function

The I/O module PM4000 DI/DO provides 8 digital outputs and 8 configurable inputs/outputs.

The digital I/O modules are controlled by the S7-CPU using the process image.

The PM4000 DI/DO must not be used for safety-relevant functions.

Design

Status LEDs

①

• RUN LED lights up green:

– Power ON

– Initialization status

• ERR LED lights up red:

fault

Digital outputs 1 … 8

LED to display switching status,

③

one LED each per input/output

• LED on: H state

• LED off: L state

Digital inputs/outputs 9 … 16,

④

switchable per channel

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

25

Page 28

System overview

PM4000 U/I

Item

Description

②

③

3.6 I/O modules

3.6.2 PM4000 U/I

Function

The I/O module PM4000 U/I provides inputs for measuring mains voltage and mains current.

● Voltage measurement

Either the supplied line-to-line voltage or the star voltage is measured (parameterizable)

The rms effective value is calculated from the measured values.

● Phase current measurement

Three current transformers can be connected to the module (L1, L2, L3). The rms

effective value is calculated from the measured values. The measuring accuracy depends

on the current transformers used.

The measured values are transferred via the fieldbus and can be evaluated and further

processed by the user.

Design

Status LEDs

①

• RUN LED lights up green:

– Power ON

– Initialization status

• ERR LED lights up red:

Fault

Measuring inputs, line current

Measuring inputs mains voltage

SIPLUS HCS4300 PROFINET/PROFIBUS DP

26 Operating Instructions, 10/2019, A5E35452705A/005

Page 29

System overview

PM4000 Temperature

Item

Description

②

③

3.6 I/O modules

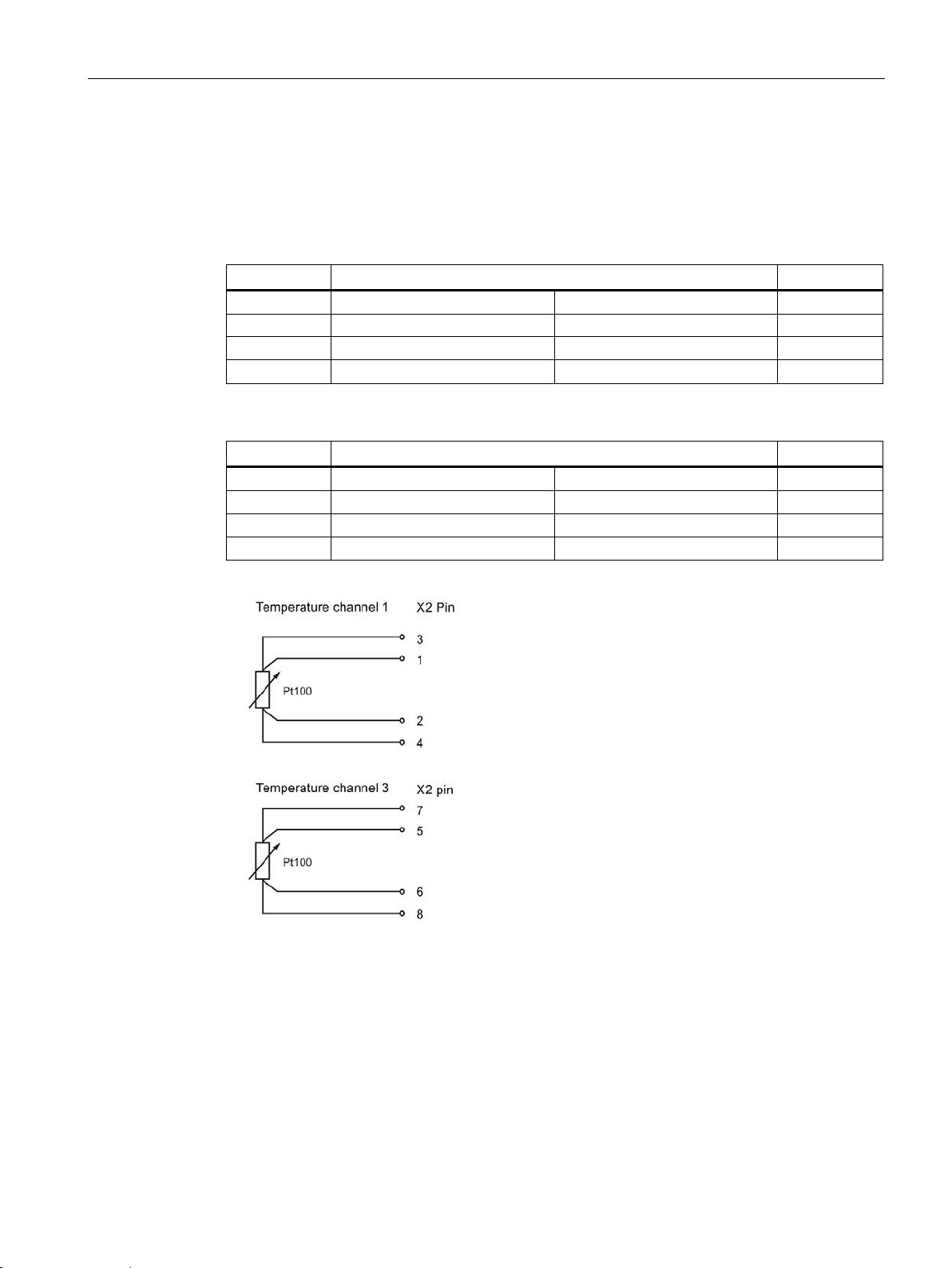

3.6.3 PM4000 Temperature

Function

I/O module temperature for HCS Central Interface Module (CIM).

● Four measuring inputs for temperature in two-wire technology or two measuring inputs for

temperature in four-wire technology.

● Four analog inputs for 0 mA to 20 mA

The measured values are transferred via the fieldbus and can be evaluated and further

processed by the user.

Design

Status LEDs

①

• RUN LED lights up green:

– Power ON

– Initialization status

• ERR LED lights up red:

fault

Analog inputs 1 … 4

Measuring inputs 1 … 4 for temperature

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

27

Page 30

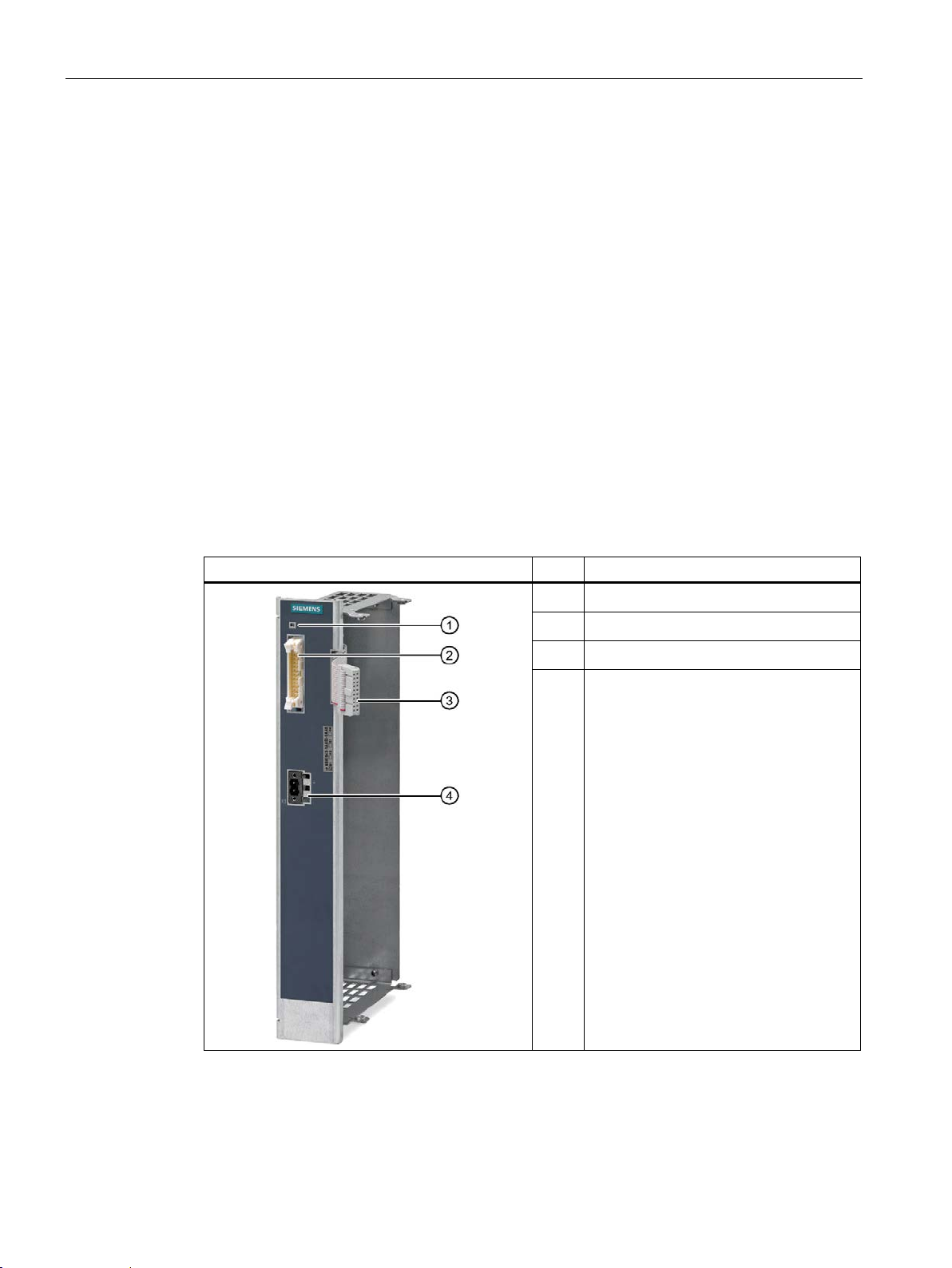

System overview

EM4315 expansion module

Item

Description

①

②

③

④

3.7 EM4315 expansion module

3.7 EM4315 expansion module

3.7.1 Design

Function

In the basic configuration with one CIM, a maximum of 8 POM4320 or 6 POM4320 Highend

can be operated. An EM4315 expansion module enables operation of up to 8 additional

POM4320 or 6 POM4320 Highend is possible.

Two EM4315 expansion modules can be used in the maximum configuration. This means

the following can be operated on one CIM in total:

● 24 POM4320 or

● 18 POM4320 Highend

Design

Status LEDs

System interface to last POM

System interface to next POM

24 V DC supply

SIPLUS HCS4300 PROFINET/PROFIBUS DP

28 Operating Instructions, 10/2019, A5E35452705A/005

Page 31

4

NOTICE

Damage to the device

NOTICE

Damage to the device

4.1 Shipping

Shipping

The device can be damaged by inappropriate shipping. Transport the device, therefore,

only in the original packaging. This will give it the necessary protection against shock and

impact.

Lifting and carrying the power output module (POM)

The power output module (POM) is connected to the busbar adapter with 3 leads.

Do not use these leads to lift or carry the POM.

4.2 Storage

It is absolutely essential that the device is stored in compliance with the storage conditions

as described in Chapter Technical specifications (Page 163). In the event of ingress of dirt or

liquid into the equipment, formation of condensation, damage or any other failures to comply

with the prescribed storage conditions, the equipment must not be commissioned until the

correct remedial procedure has been discussed with Siemens AG.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

29

Page 32

Application planning

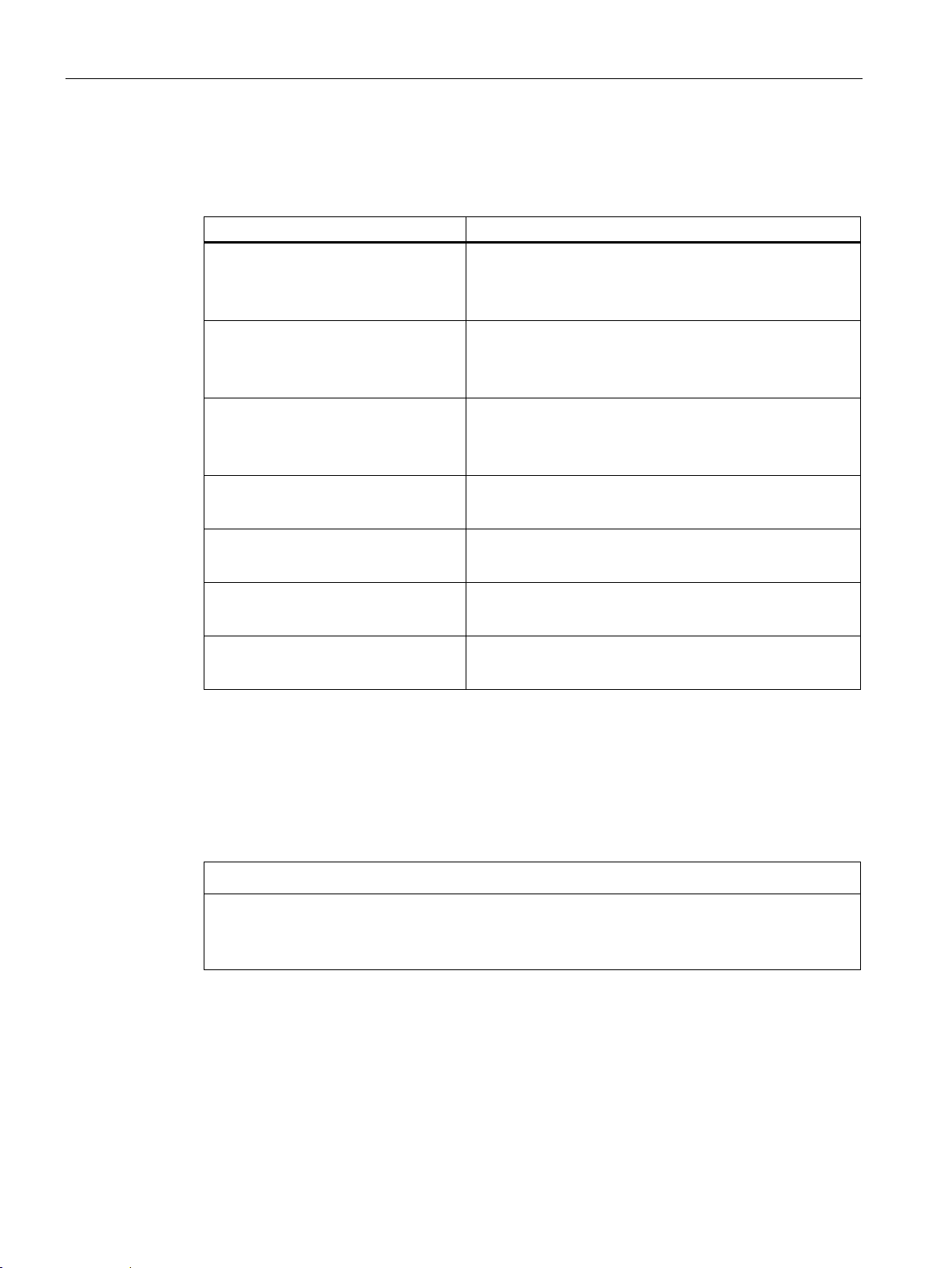

Component

Included in the scope of supply

NOTICE

Damage to the system

4.3 Scope of delivery

4.3 Scope of delivery

Depending on the components ordered, the scope of delivery includes:

HCS4300 CIM

HCS POM4320

HCS POM4320 Highend

EM4315 expansion module

HCS PM4000 temperature

HCS PM4000 DI/DO

HCS PM4000 U/I

• CD with license information (CIM PROFINET)

• 1 plug connector, 2-pin

• Compact operating instructions

• Connecting cables 100 mm for system interface

• 6 plug connectors for connecting heating elements

• Compact operating instructions

• Connecting cables 100 mm for system interface

• 3 plug connectors for connecting heating elements

• Compact operating instructions

• Compact operating instructions

• 1 plug connector, 2-pin

• Compact operating instructions

• 2 plug connectors, 8-pin

• Compact operating instructions

• 2 plug connectors, 18-pin

• Compact operating instructions

• One 6-pin and one 8-pin plug connector

Unpacking and checking the delivery

SIPLUS HCS4300 PROFINET/PROFIBUS DP

30 Operating Instructions, 10/2019, A5E35452705A/005

1. Unpack the device.

2. Make sure that the package is complete.

3. Check the device for transport damage by visual inspection.

Damaged parts can result in damage to the system. Only put undamaged parts into

operation.

Page 33

Application planning

Note

Installation in control cabinet/device connection box

The SIPLUS HCS4300 heating control system is intended for installation in a control cabinet

or a device connection box.

•

•

•

NOTICE

Damage due to overheating

4.4 Installation location

4.4 Installation location

Installation location requirements

In these cases, only the LEDs on the front of the device will remain visible during

commissioning. Take this into consideration for subsequent operation of the device.

The control cabinet / device connection box must satisfy the regulations regarding fire-

protection housing.

Ensure that all cables and leads that protrude externally are equipped with adequate

strain relief.

Mounting position and clearance dimensions

You must comply with all the instructions regarding the installation site and mounting

position. Otherwise the device might malfunction or incur permanent damage as a result of

overheating.

● The device is installed and operated vertically.

● Ensure that the permissible ambient temperature range is not exceeded

(see section Technical specifications (Page 163)).

● Maintain the minimum clearances from walls and other devices:

– Sides 0 mm (side-by-side mounting permitted), top 100 mm, bottom 100 mm for

ventilation and deaeration

Degree of pollution

SIPLUS HCS4300 is designed for pollution degree 2. According to the EN 50178 standard,

pollution degree 2 is non-conductive pollution under normal circumstances, which can,

however, become temporarily conductive as a result of condensation when the device is not

in service.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

31

Page 34

Application planning

NOTICE

Damage to the device

4.4 Installation location

Overvoltage protection 24 V DC power supply

Inadequately dimensioned overvoltage protection can result in severe damage to the

device.

Always ensure, therefore, that the overvoltage protection is adequate (see section

Connect 24 V DC power supply (Page 55)).

Power loss of the POM4320

When planning and designing the cabinet cooling, take into consideration the power loss of

the POMs. The power loss of a POM is calculated as follows:

P

P

= P

LossPOM

vChannel (x)

LossChannel1

= I(x)2 • 0.04 Ω + I(x) • 0.8 V

x represents the channel number

This power loss occurs at 100% activation of the channels. If the channels are not 100%

activated, the power loss P

Power loss of the POM4320 Highend

The calculation formula specified for the POM4320 also applies to the POM4320 Highend

with internal incoming fuse.

If the incoming fuse is missing (e.g. with star connection or the fuse is implemented

externally), the following formula applies:

P

vChannel (x)

= I(x)2 • 0.033 Ω + I(x) • 0.8 V

+ P

LossChannel2

LossChannel (x)

+ ... + P

LossChannel9

+ 6 W

reduces proportionately.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

32 Operating Instructions, 10/2019, A5E35452705A/005

Page 35

Application planning

NOTICE

Restriction of the switching power

4.4 Installation location

Restriction of the switching power

Due to the different physical properties of heat emitters, restrictions can be imposed on their

permissible switching capacity depending on the type of heat emitter.

Short-wave halogen or infrared emitters ("flash emitters") have a high starting current due to

their relatively low cold resistance. The starting current can be several times the rated

current, especially during the first half waves.

Overloading of the internal fuses of the POM can occur depending on the number of

switching operations as well as the duration of switching operations and pause times.

The power limit for each POM is set by the technical parameter "Current carrying capacity

per output, max. for heating elements with high inrush current"

(see Technical specifications (Page 163)) for each POM.

Therefore, we recommend you to have Siemens AG measure radiation sources with a high

inrush current

In this regard, read the information about using Category AC 3 contactors (see

Connecting the three-phase line supply (Page 57)).

Selection of the incoming fuse for POM4320 Highend

Depending on the selected connection type, an incoming fuse is also required for the

POM4320 Highend. This fuse must only meet the requirements for line protection. This

means that gG fuses of size 14x51 can be used. The nominal value of the current depends

on the connected load.

Recommended fuses: e.g. Siemens SENTRON, cylindrical fuse-link, 14x51 mm, 3NW61

If you connect channels in parallel, only one fuse is possible up to a current of 50 A. You

must use 2 identical fuses for higher values. For UL applications, use the same fuses as for

fusing the outgoing line.

Derating of fuses

Note that fuses are subject to derating at high ambient temperatures, i.e. the rated current

for a fuse is reduced.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

33

Page 36

Application planning

4.5 POM4320 power rating

4.5 POM4320 power rating

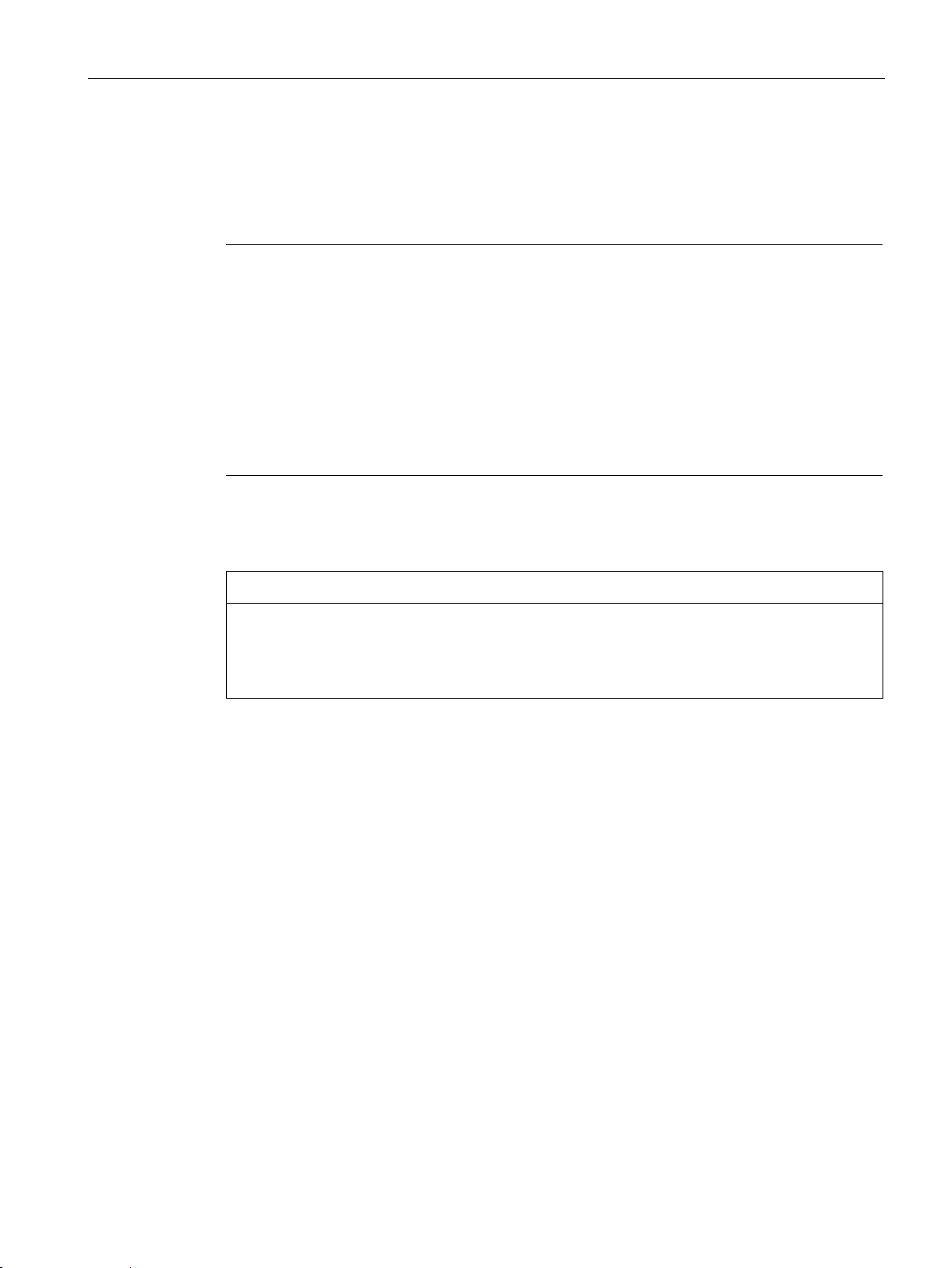

POM4320 IEC power rating

Figure 4-1 POM4320 IEC power rating

SIPLUS HCS4300 PROFINET/PROFIBUS DP

34 Operating Instructions, 10/2019, A5E35452705A/005

Page 37

Application planning

4.5 POM4320 power rating

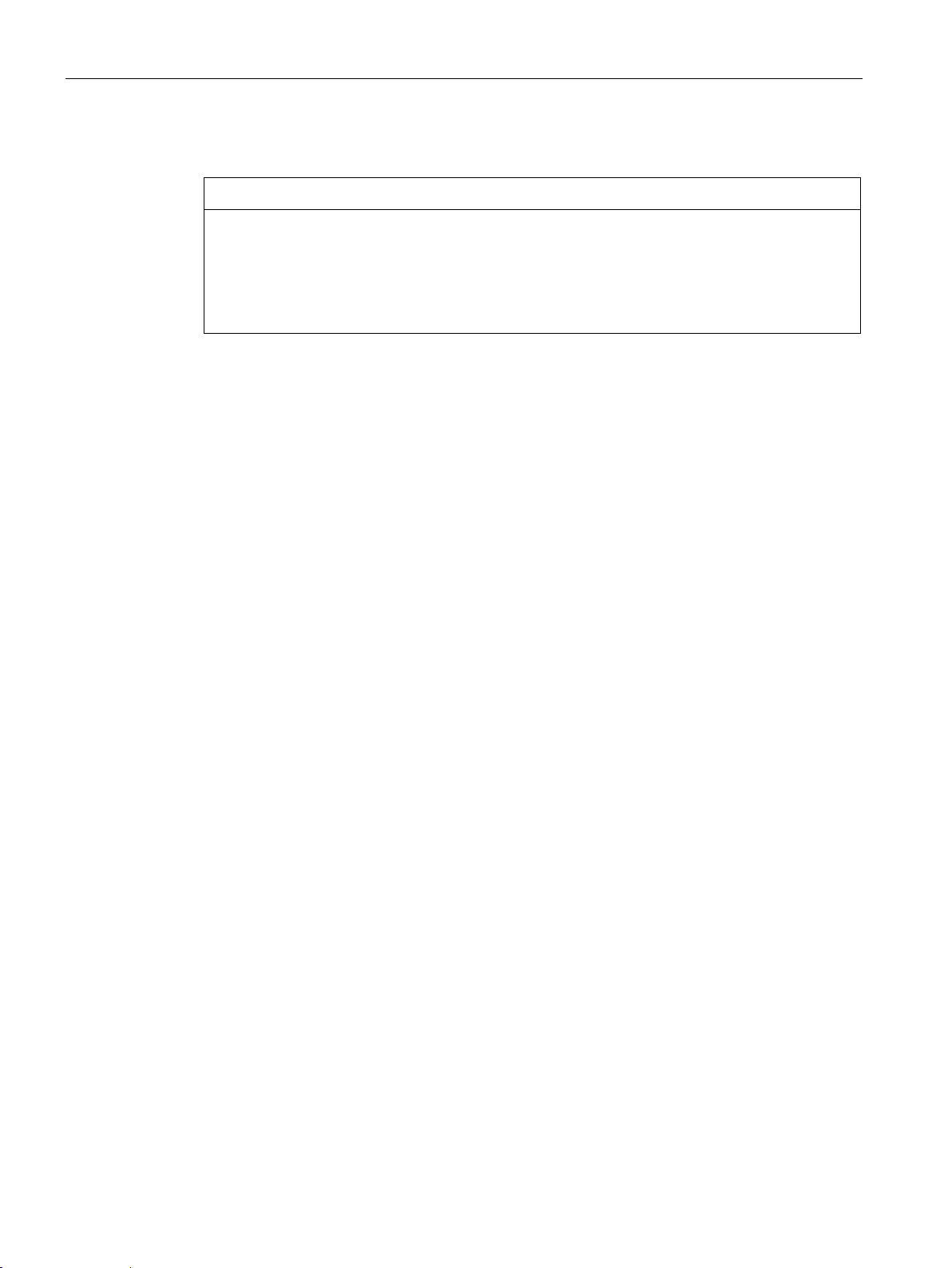

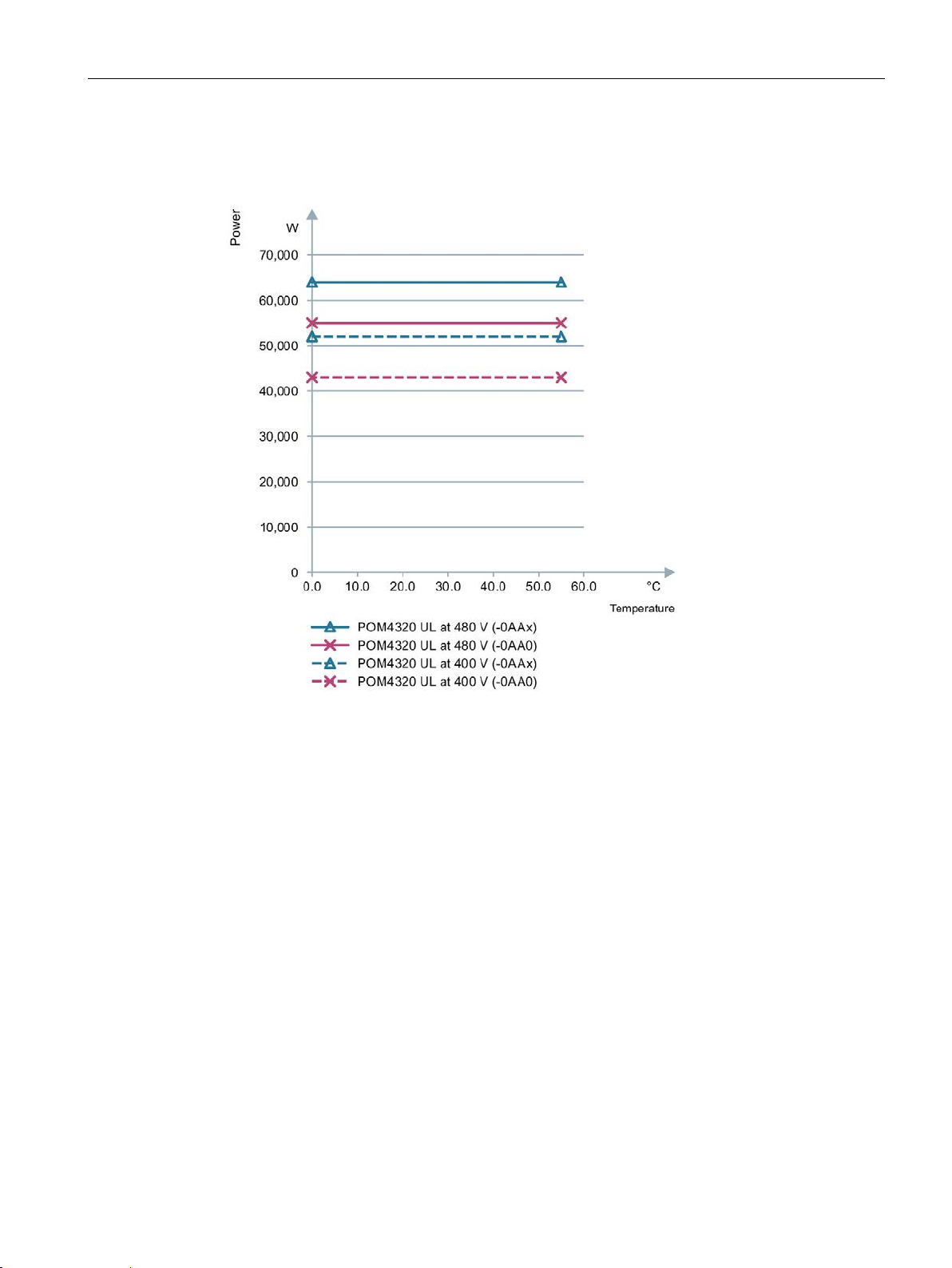

Power rating POM4320 UL

Figure 4-2 POM4320 UL power rating

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

35

Page 38

Application planning

4.6 Power rating of the POM4320 Highend

4.6 Power rating of the POM4320 Highend

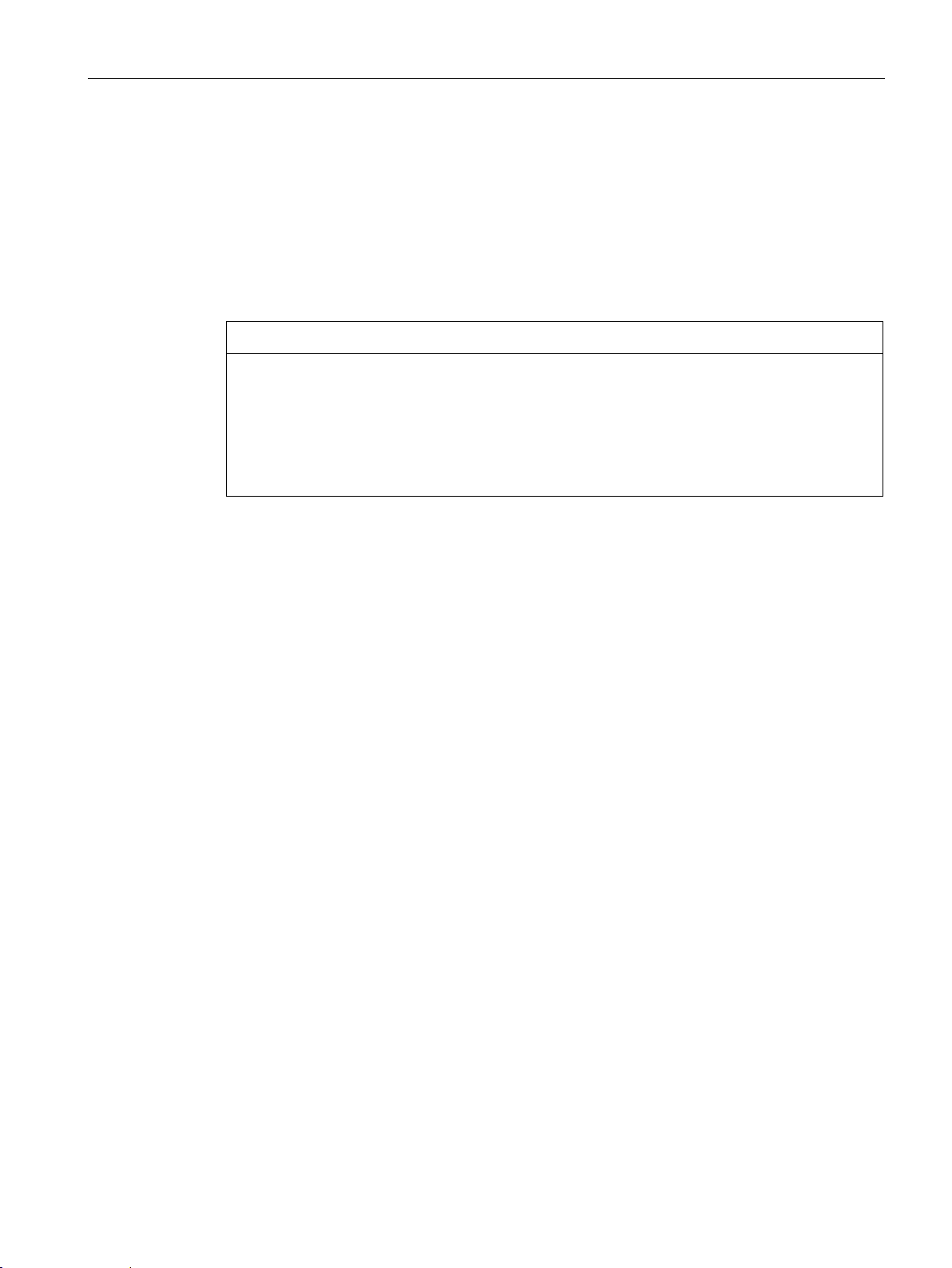

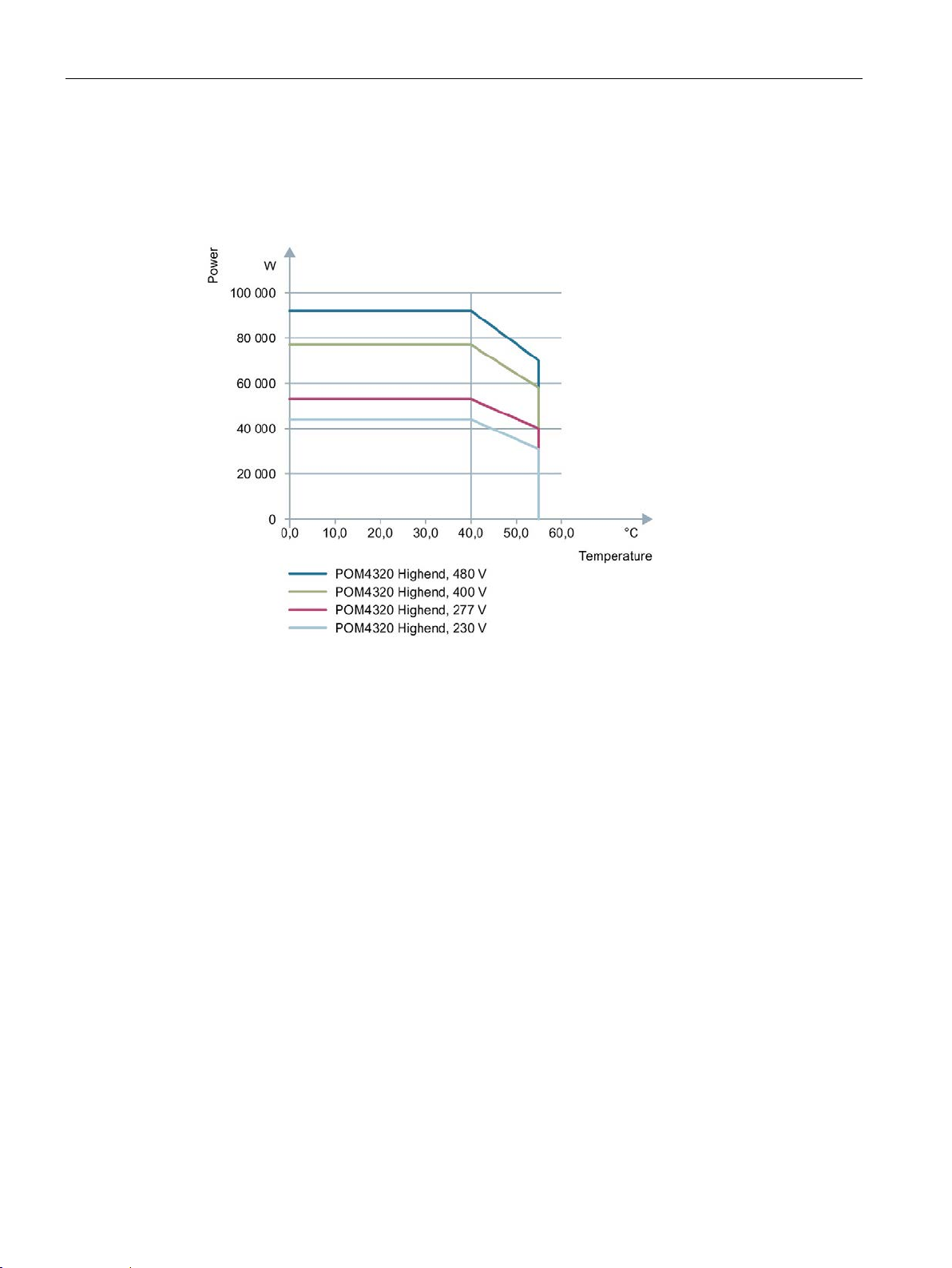

Power rating of the POM4320 Highend

Figure 4-3 Power rating of the POM4320 Highend depending on ambient temperature and line

voltage

SIPLUS HCS4300 PROFINET/PROFIBUS DP

36 Operating Instructions, 10/2019, A5E35452705A/005

Page 39

Application planning

4.6 Power rating of the POM4320 Highend

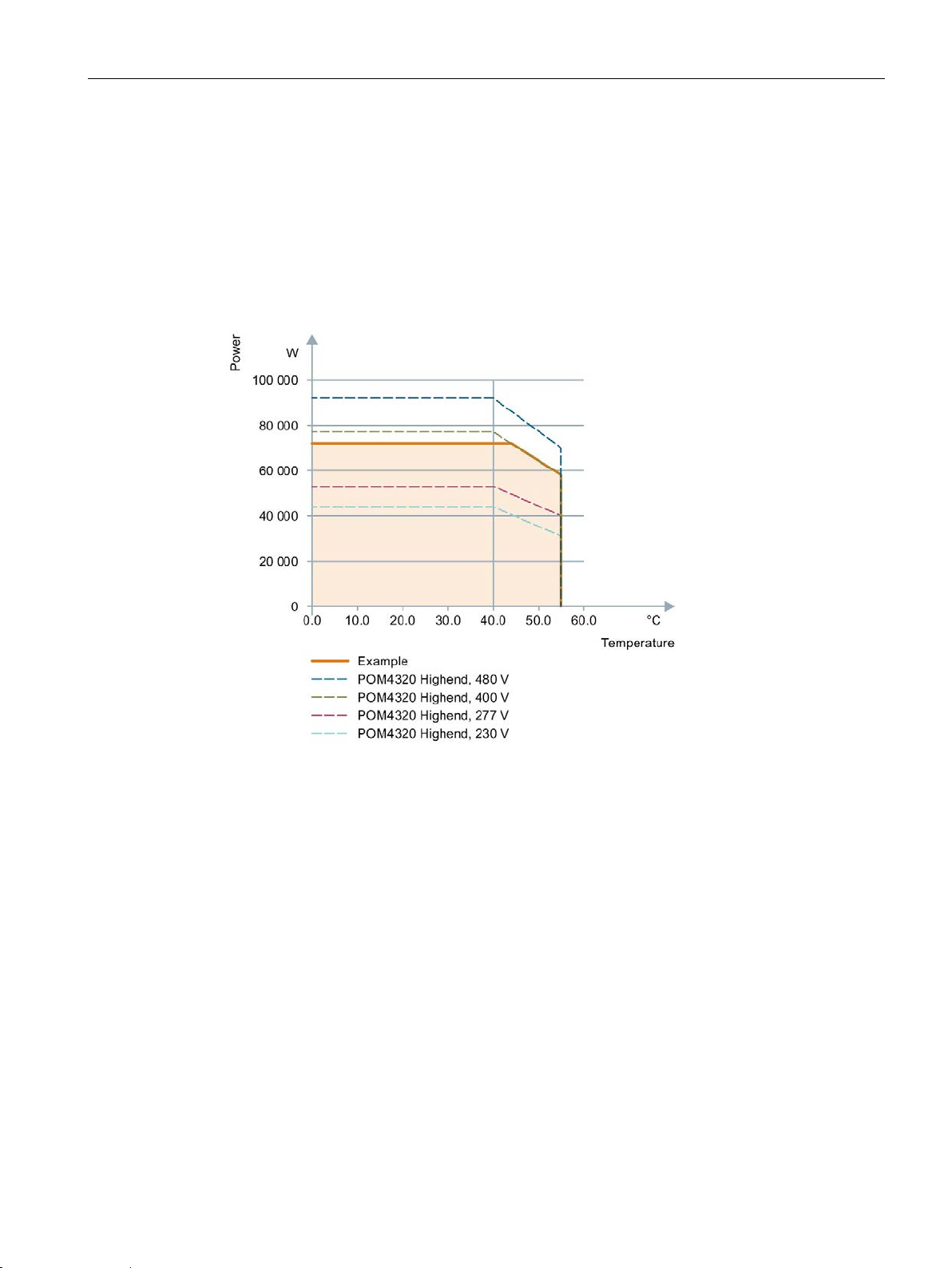

Example

You can find the power ratings for the example in section POM4320 Highend for wall

mounting (Page 40), section "Connecting between phase and phase (400/480 V), single

connection of outputs".

● Incoming fuse, internal, IEC

● Delta connection, open

● Total device performance at 400 V

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

37

Page 40

Application planning

Line voltage

400 V and 480 V

Incoming fuse

Internal, IEC

External, IEC

Not required, IEC

Delta connection, open

Total device performance at 400 V

57,600 W

76,800 W

–

Total device performance at 480 V

69,120 W

92,160 W

–

Delta connection, closed

Total device performance at 480 V

–

–

53,209 W

2-pin switching, phase – phase

Total device performance at 400 V

–

–

38,400 W

Total device performance at 480 V

–

–

46,080 W

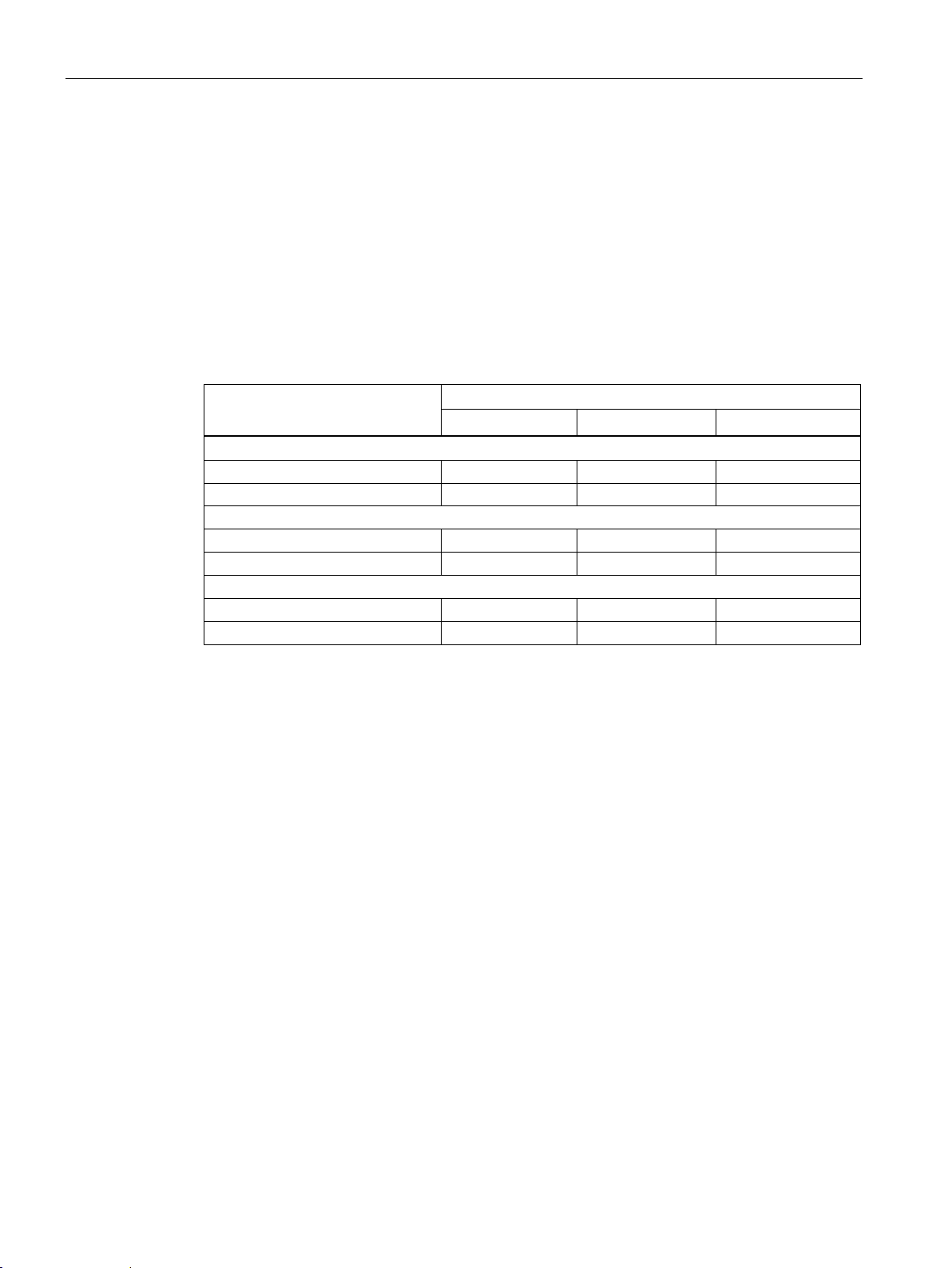

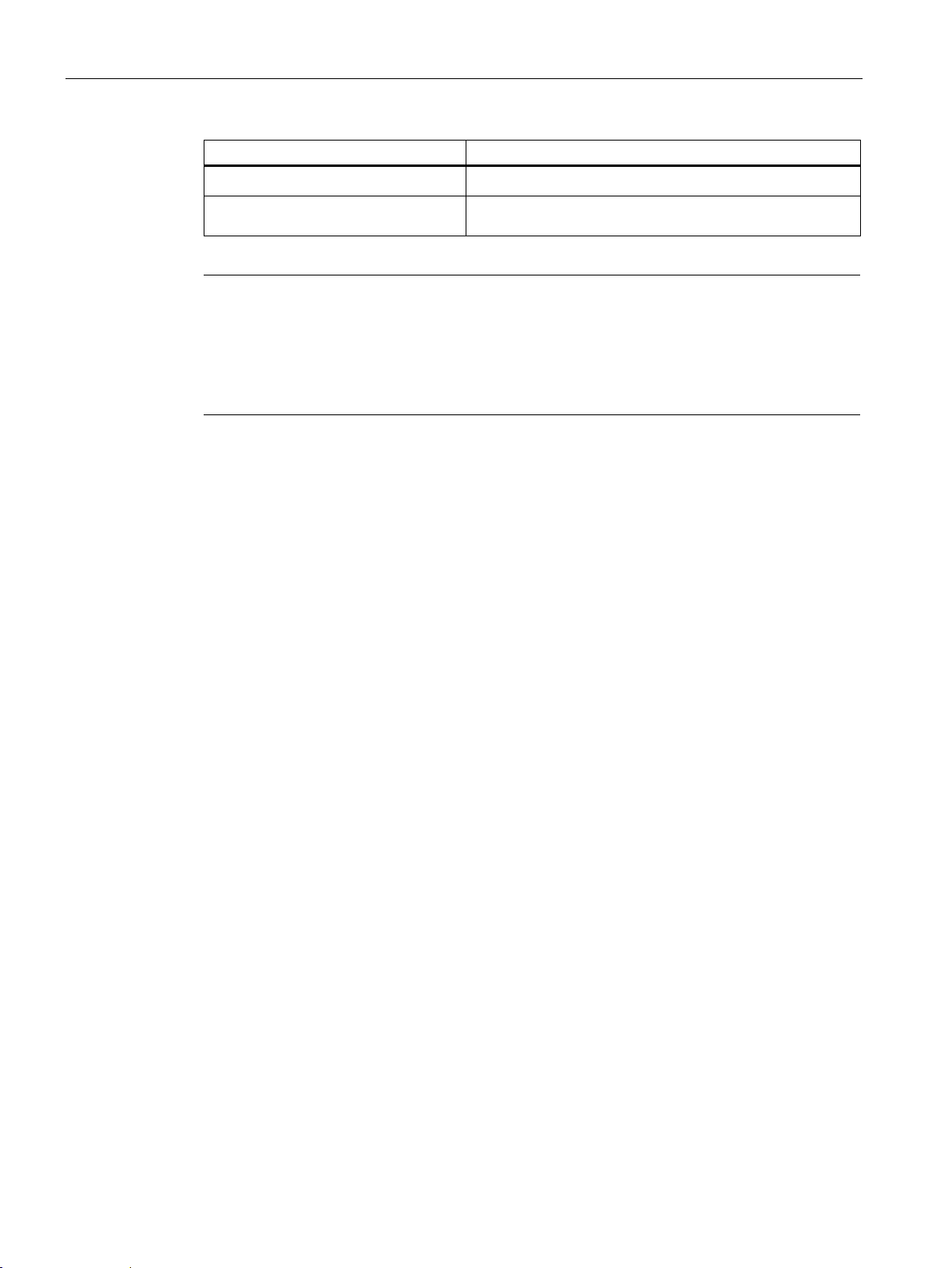

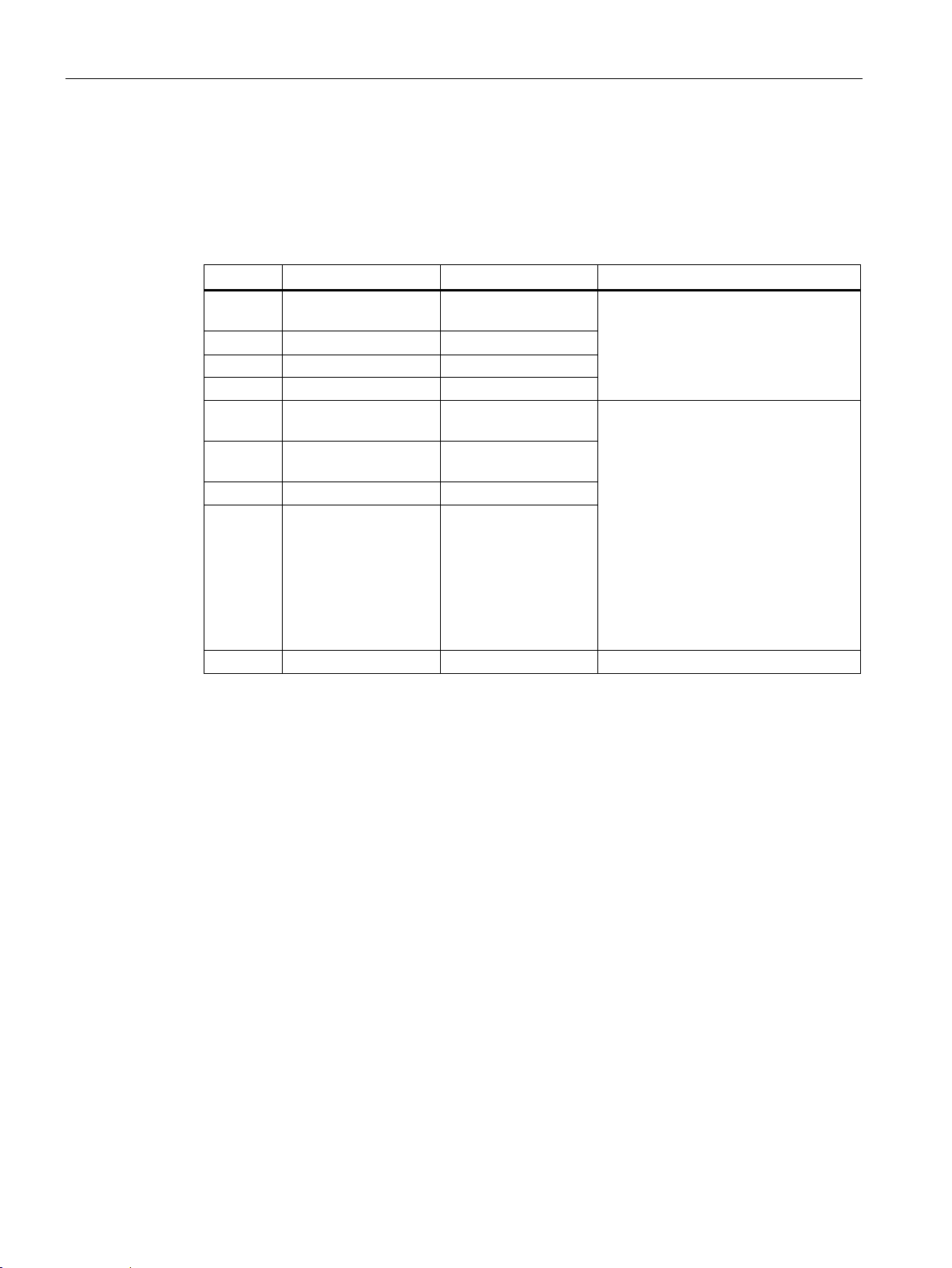

4.7 POM4320 Highend power rating

4.7 POM4320 Highend power rating

4.7.1 POM4320 Highend for busbar adapter

Connection between phase and phase (400 V/480 V), single connection of outputs

Table 4- 1 POM4320 Highend for busbar adapter. connection between phase and phase

(400 V/480 V), single connection of outputs

Total device performance at 400 V – – 44,341 W

You can find block diagrams for the connection types in the section Connection between

phase and phase (400/480 V) (Page 62).

SIPLUS HCS4300 PROFINET/PROFIBUS DP

38 Operating Instructions, 10/2019, A5E35452705A/005

Page 41

Application planning

Line voltage

400 V and 480 V

Incoming fuse

Internal, IEC

External, IEC

Not required, IEC

Delta connection, open

Total device performance at 400 V

57,600 W

72,000 W

–

Delta connection, closed

Total device performance at 480 V

–

–

49,883 W

Line voltage

230 V and 277 V

Single connection of outputs,

IEC

Parallel connection of outputs,

IEC

Star connection, open

Total device performance at 230 V

44,160 W

41,400 W

Total device performance at 277 V

53,184 W

49,860 W

4.7 POM4320 Highend power rating

Connection between phase and phase (400 V/480 V), parallel connection of outputs

Table 4- 2 POM4320 Highend for busbar adapter. connection between phase and phase

(400 V/480 V), parallel connection of outputs

Total device performance at 480 V 69,120 W 86,400 W –

Total device performance at 400 V – – 41,569 W

You can find block diagrams for the connection types in the section Connection between

phase and phase (400/480 V) (Page 62).

Connection between phase and neutral conductor (230 V/277 V)

Table 4- 3 POM4320 Highend for busbar adapter, connection between phase and neutral conductor

(230 V/277 V)

You can find block diagrams for the connection types in the section Connection between

phase and neutral conductor (230/277 V) (Page 70).

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

39

Page 42

Application planning

Line voltage

400 V and 480 V

Incoming fuse

Internal,

IEC

Internal,

UL

External,

IEC

External,

UL

Not required,

IEC

Not required,

UL

Delta connection, open

400 V

W

480 V

W

Delta connection, closed

400 V

W

480 V

W

2-pin switching, phase – phase

400 V

W

480 V

W

4.7 POM4320 Highend power rating

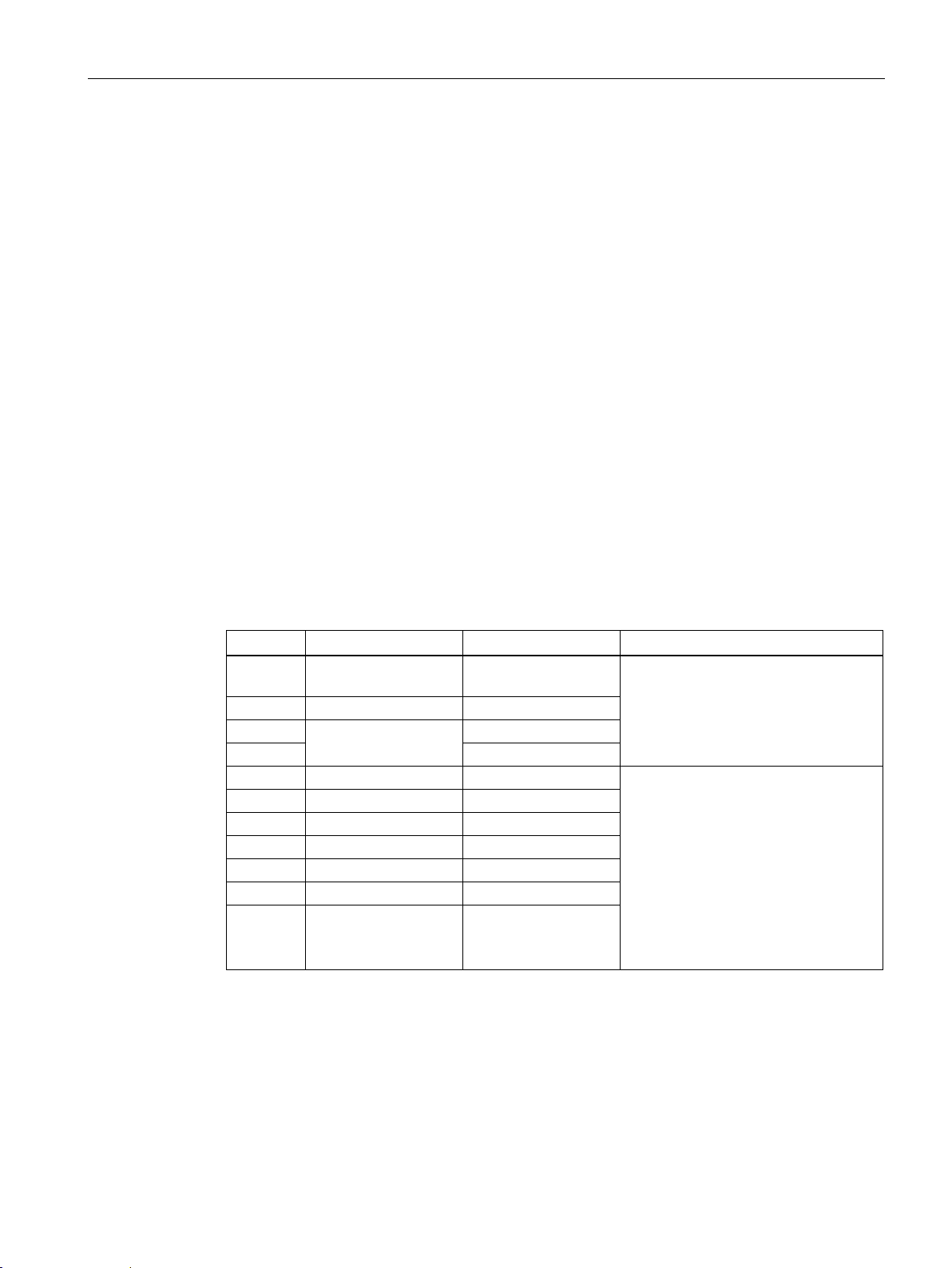

4.7.2 POM4320 Highend for wall mounting

Connection between phase and phase (400 V/480 V), single connection of outputs

Table 4- 4 POM4320 Highend for wall mounting, connection between phase and phase

(400 V/480 V), single connection of outputs

Total device performance at

Total device performance at

Total device performance at

Total device performance at

Total device performance at

Total device performance at

72,000 W 62,400 W 76,800 W 72,000

86,400 W 74,880 W 92,160 W 86,400

– – – – 44,341 W 41,569

– – – – 53,209 W 49,883

– – – – 38,400 W 36,000

– – – – 46,080 W 43,200

– –

– –

You can find block diagrams for the connection types in the section Connection between

phase and phase (400/480 V) (Page 62).

SIPLUS HCS4300 PROFINET/PROFIBUS DP

40 Operating Instructions, 10/2019, A5E35452705A/005

Page 43

Application planning

Line voltage

400 V and 480 V

Incoming fuse

Internal,

IEC

Internal,

UL

External,

IEC

External,

UL

Not required,

IEC

Not required,

UL

Delta connection, open

400 V

W

480 V

W

Delta connection, closed

400 V

W

480 V

W

Line voltage

230 V and 277 V

Single-channel connection

Parallel connection, IEC

IEC

UL

IEC

UL

Star connection, open

230 V

277 V

4.7 POM4320 Highend power rating

Connection between phase and phase (400 V/480 V), parallel connection of outputs

Table 4- 5 POM4320 Highend for wall mounting, connection between phase and phase

(400 V/480 V), parallel connection of outputs

Total device performance at

Total device performance at

Total device performance at

Total device performance at

72,000 W 62,400 W 72,000 W 64,800

86,400 W 74,880 W 86,400 W 77,760

– – – – 41,569 W 37,412

– – – – 49,883 W 44,895

You can find block diagrams for the connection types in the section Connection between

phase and phase (400/480 V) (Page 62).

Connection between phase and neutral conductor (230 V/277 V)

Table 4- 6 POM4320 Highend for wall mounting, connection between phase and neutral conductor

(230 V/277 V)

Total device performance at

44,160 W 41,400 W 41,400 W 37,260 W

– –

– –

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

Total device performance at

You can find block diagrams for the connection types in the section Connection between

phase and neutral conductor (230/277 V) (Page 70).

53,184 W 49,860 W 49,860 W 44,874 W

41

Page 44

Application planning

4.7 POM4320 Highend power rating

SIPLUS HCS4300 PROFINET/PROFIBUS DP

42 Operating Instructions, 10/2019, A5E35452705A/005

Page 45

5

WARNING

Hazardous voltages on the heating control system

Can cause death, serious injury or damage to property

5.1 Requirements

Safety guidelines

Before starting installation or connection work on the HCS4300 heating control system, you

must switch off the heating control system and secure it from being switched on again.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

43

Page 46

Installing/mounting

WARNING

Dangerous voltages on the busbar system

Can cause death, serious injury or damage to property

NOTICE

Clockwise rotating field

Note

Residual current protective device

If

circuit breaker of Type A is sufficient for the HCS4300.

Note

Due to the weight of the POM4320 we recommend

devices.

5.2 Installing the Power Output Module (POM)

5.2 Installing the Power Output Module (POM)

5.2.1 Busbar mounting

5.2.1.1 Preparations

Busbar system

The mains infeed for the power output module is connected via a 3-phase busbar system.

These include the following busbar systems:

● Siemens AG, SENTRON 60 mm

● Wöhner GmbH & Co. KG, 60 mm EQUES

Dangerous voltages can be present on the busbar system.

The busbar system must therefore be isolated and secured against reclosing before work

begins for mounting and connecting the HCS4300 heating control system.

When connecting the busbar system, make sure that the energy system is connected

clockwise.

a residual current protective device is provided for the busbar system, a residual current

mounting a busbar support after three

SIPLUS HCS4300 PROFINET/PROFIBUS DP

44 Operating Instructions, 10/2019, A5E35452705A/005

Page 47

Installing/mounting

POM busbar adapter

5.2 Installing the Power Output Module (POM)

5.2.1.2 Adjusting the busbar adapter

Tool

You need a Phillips screwdriver, size 0.6 x 3.5 mm.

Adjusting the busbar adapter to the thickness of the busbar

The busbar adapter of the POM can be adjusted for the following busbar thicknesses:

● 5 mm (delivery state)

● 10 mm

On the busbar adapter of the POM, there are four fastening blocks, which you can use to

adjust the busbar adapter to the rail thickness. The following figure shows the position of the

fastening blocks.

Fastening block set to 5 mm

Fastening block set to 10 mm

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

45

Page 48

Installing/mounting

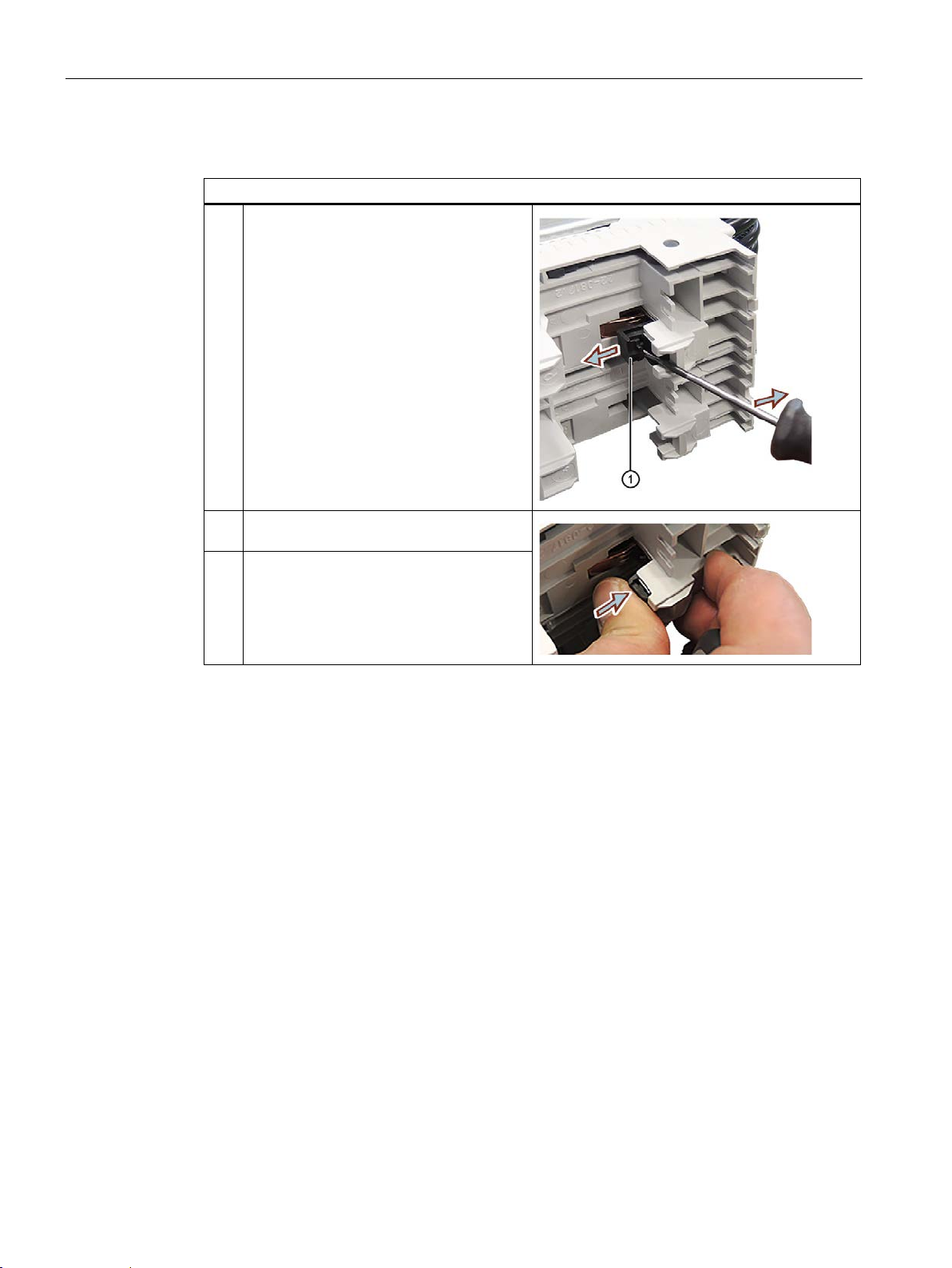

Steps

the rail thickness at 5 mm or 10 mm.

5.2 Installing the Power Output Module (POM)

Proceed as follows for each of the four fastening blocks:

1 Use the screwdriver to push out the fas-

tening block

2 Position the mounting block according to

①.

3 Push the mounting block inwards until it

clicks into place.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

46 Operating Instructions, 10/2019, A5E35452705A/005

Page 49

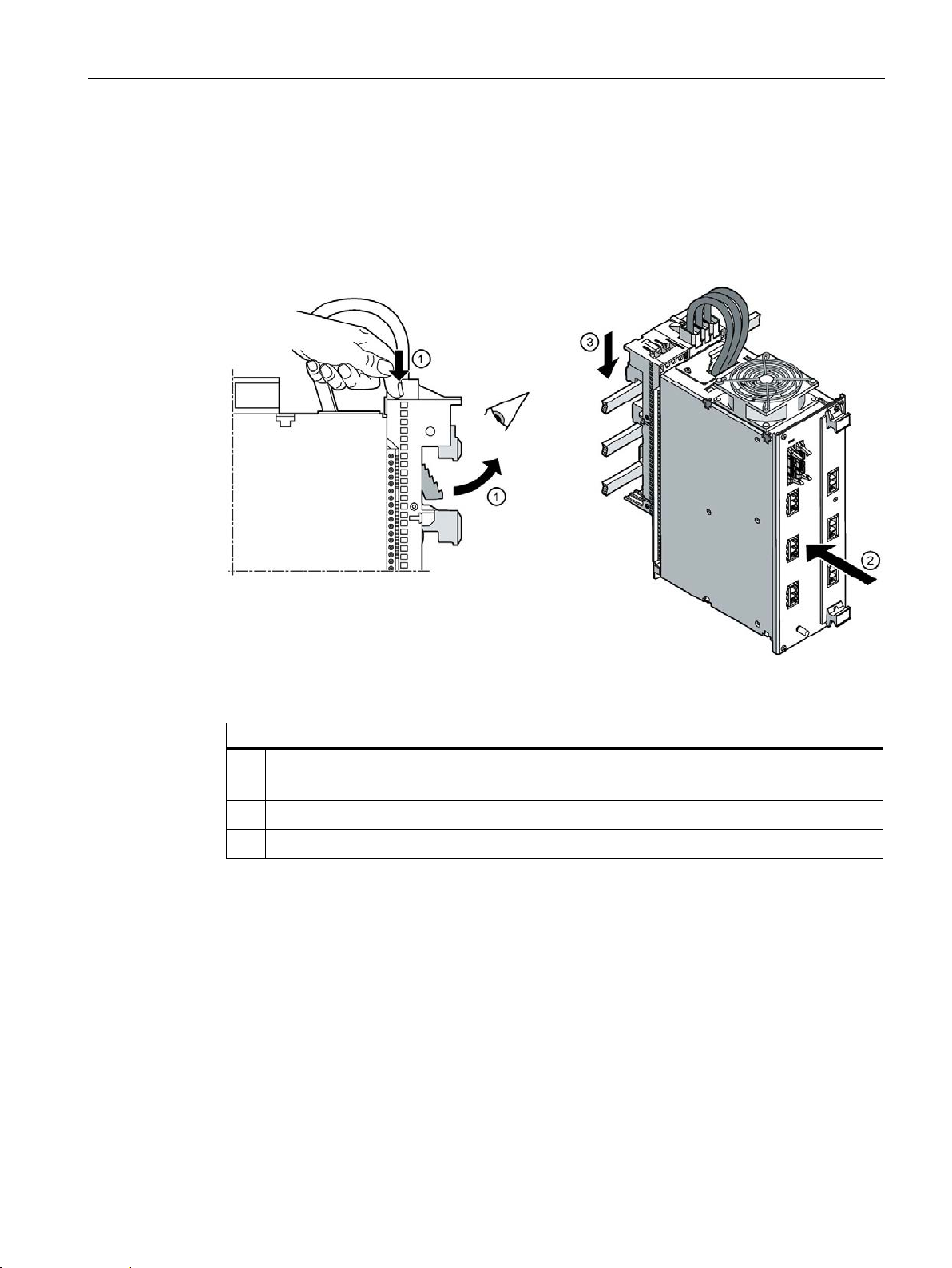

Installing/mounting

Steps

The holder must protrude beyond the busbar adapter as shown in the figure.

②

③

5.2 Installing the Power Output Module (POM)

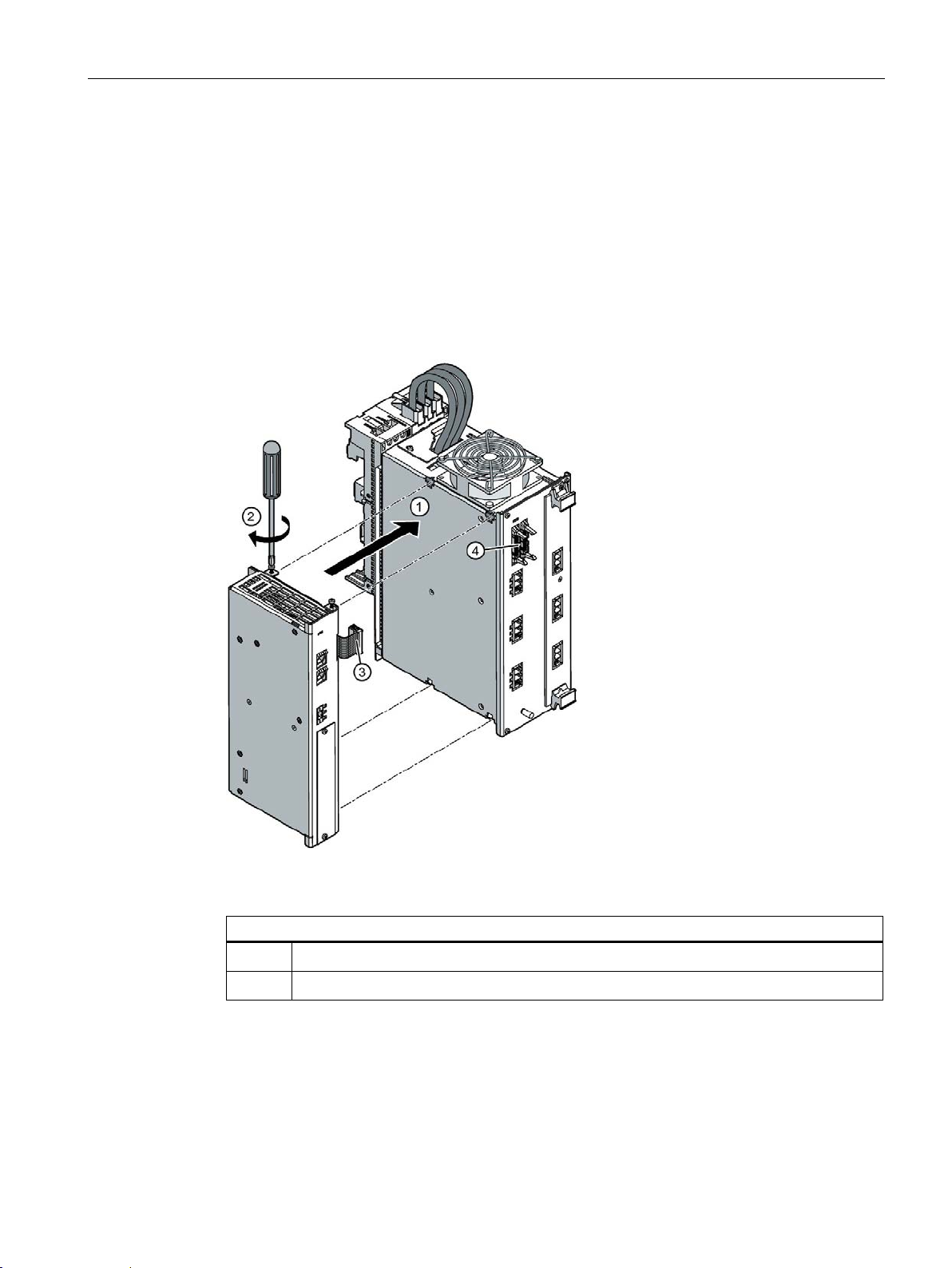

5.2.1.3 Mounting the POM (busbar adapter)

The mounting of the POM on the busbar is carried out without the need for tools via the

POM busbar adapter.

Installing the POM

Figure 5-1 Installing the POM

1

Press the button on the top of the busbar adapter

2

Place the busbar adapter on the busbar from above

3

Press on the busbar adapter from above until the busbar adapter engages

①.

.

.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

47

Page 50

Installing/mounting

5.2 Installing the Power Output Module (POM)

5.2.2 Panel mounting

5.2.2.1 POM mounting (panel mounting)

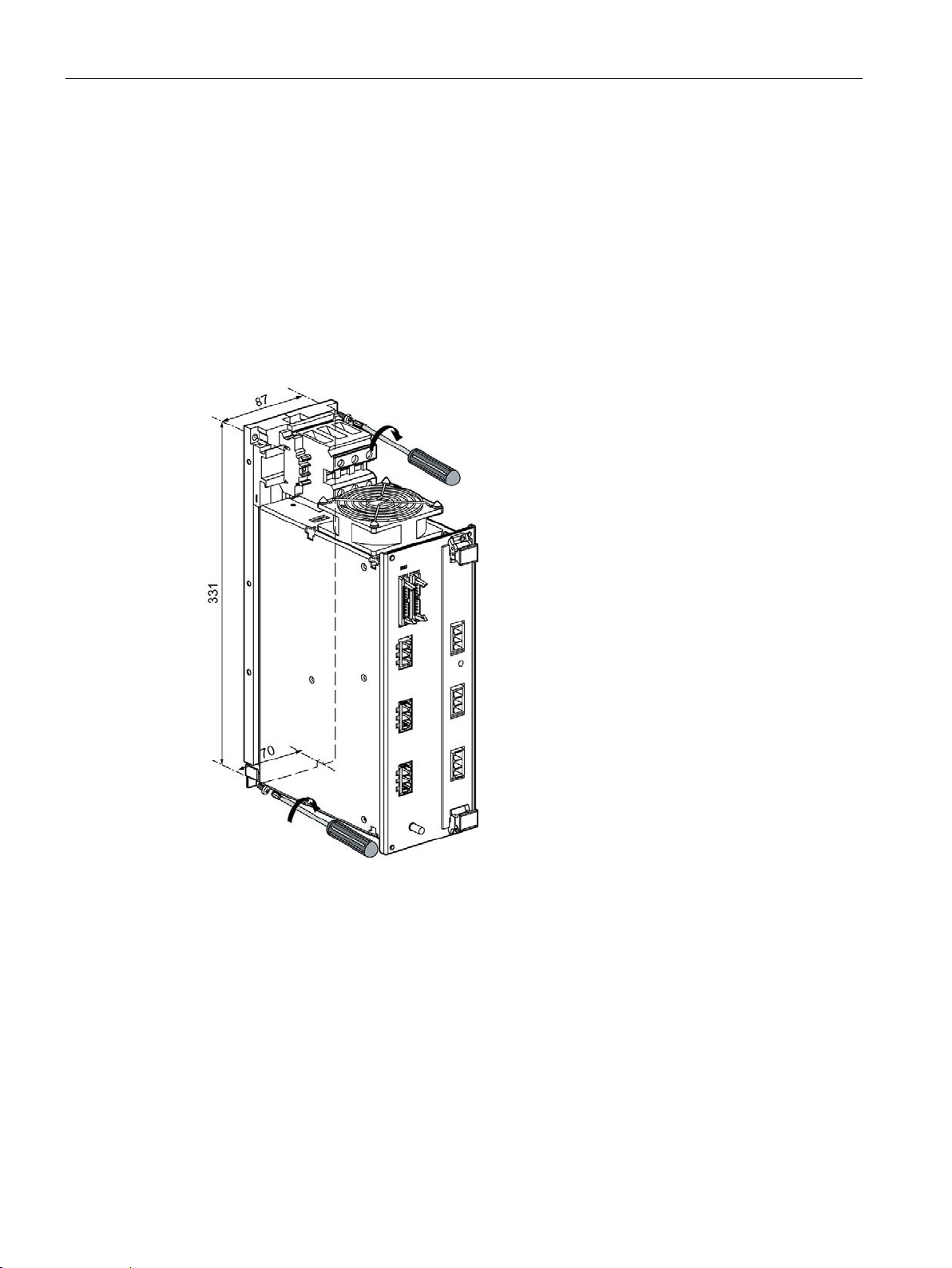

Installing the Power Output Modul (POM)

1. Predrill the holes in the rear panel for mounting.

The required hole spacing is shown in the diagram below.

2. Screw the POM into place on the rear panel with four screws M5.

Figure 5-2 POM4320: Position of the mounting holes

Minimum spacing

Natural convection must be possible above and below the device. A clearance of 100 mm

must be observed in both cases.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

48 Operating Instructions, 10/2019, A5E35452705A/005

Page 51

Installing/mounting

Steps

①

②

5.3 Installing the Central Interface Module

5.3 Installing the Central Interface Module

Tool

You will need a Torx T10 screwdriver.

Mounting the Central Interface Module (CIM)

The CIM is screwed directly onto the POM. The mounting procedure is described below:

Figure 5-3 Mounting the CIM

1

Plug the CIM into the POM by means of the four connecting lugs

2

Tighten the four screws

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

.

.

49

Page 52

Installing/mounting

5.4 Installing the EM4315 expansion module

5.4 Installing the EM4315 expansion module

Tool

You will need a Torx T10 screwdriver.

Installing the EM4315 expansion module

Proceed as described in Section Installing the Central Interface Module (Page 49).

SIPLUS HCS4300 PROFINET/PROFIBUS DP

50 Operating Instructions, 10/2019, A5E35452705A/005

Page 53

Installing/mounting

Note

The I/O module may only be inserted or removed when the power

Steps

1

Dismantling the blanking cover of the receptacle on the CIM

2

Insert the I/O module into the receptacle and push it in as far as it will go.

①

5.5 Installing the I/O module (PM)

5.5 Installing the I/O module (PM)

The CIM is equipped with a receptacle for one I/O module.

is off.

Tool

You will need a Torx T8 screwdriver.

Installing an I/O module

The steps for mounting an I/O module are described below:

Figure 5-4 Installing an I/O module

3

Secure module tightly with screws

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

51

Page 54

Installing/mounting

5.5 Installing the I/O module (PM)

SIPLUS HCS4300 PROFINET/PROFIBUS DP

52 Operating Instructions, 10/2019, A5E35452705A/005

Page 55

6

WARNING

Hazardous voltages from the mains power input or heating element feeder cables

Will cause death, serious injury or damage to property

WARNING

Electric shock hazard

Can cause death or serious injury

WARNING

Electric shock hazard

Can cause death or serious injury

The following apples to the UL version of the heating control system:

6.1 Safety instructions and guidelines

Safety instruction

Dangerous voltages might be present on mains from the supply and to heating elements.

Before work starts on connecting the HCS4300 heating control system, the mains and

heating element lines must be disconnected and secured against being switched on again.

• Voltages of more than 60 V can occur in the control cabinet. Suitable safety precautions

to prevent contact must therefore be taken before and during commissioning and

maintenance work.

• Before working on the heating control system or the connected components, ensure the

system is disconnected.

The mains supply to which the device is connected must have a circuit breaker or a fuse.

The circuit breaker or fuse must be easily accessible and clearly assigned to the device.

We recommend locating the circuit breaker or fuse near to the device. Take the maximum

current consumption of the heating control system into consideration when selecting the

circuit breaker or fuse.

• The mains supply to which the device is connected must have a circuit breaker

(according to UL489) or a fuse (UL-listed branch circuit fuse).

• Observe the SCCR rating on the rating plate. Only use the device in circuits limited

accordingly.

• Only use 60/75°C copper cables for the cabling.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

53

Page 56

Wiring

WARNING

Electric shock hazard

Can cause death or serious injury

6.2 Connecting the protective conductor

Connection requirements

● The device is installed.

● The mains supply is disconnected at the installation location of the device and secured

against secured against reconnection.

● The mains voltage is secured by an easily accessible isolating mechanism. It is

recommended that the external isolating mechanism is located close to the device.

● The cables to be connected are not live.

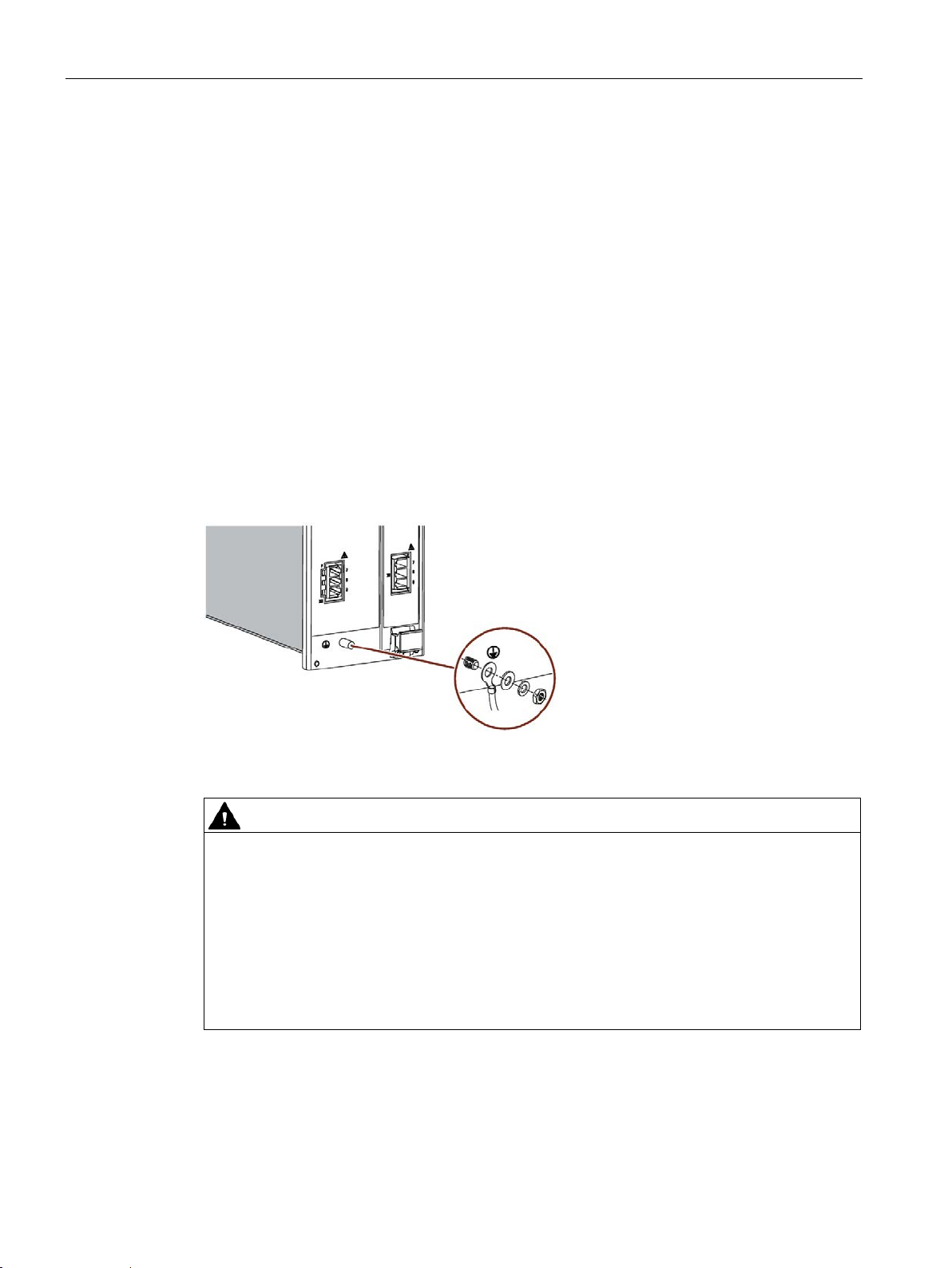

6.2 Connecting the protective conductor

Connecting the protective conductor

Connect the POM to the protective conductor (PE). An M6 threaded bolt ① is provided on

the front of the POM for connection of the protective conductor.

Figure 6-1 POM4320: Connecting the protective conductor

• The protective conductor must be connected to the threaded bolt indicated.

• The cross-section of the lead to the protective conductor must be at least 16 mm

• The cable lug used must have a tinned surface to guarantee corrosion protection.

• When connecting the protective conductor, the applicable national or local regulations

• Torque for protective conductor connection: 6 Nm

SIPLUS HCS4300 PROFINET/PROFIBUS DP

54 Operating Instructions, 10/2019, A5E35452705A/005

must be complied with.

2

.

Page 57

Wiring

CIM PROFINET connection X1 / X2

CIM PROFIBUS connection X1

6.3 Connecting PROFINET and PROFIBUS fieldbus

6.3 Connecting PROFINET and PROFIBUS fieldbus

Connecting PROFINET

Connect X1 / X2 to the higher-level controller and/or the next

PROFINET device using an Ethernet cable according to the

PROFINET specification.

Use shielded Ethernet cables for this purpose.

Connecting PROFIBUS / setting PROFIBUS address

• The PROFIBUS address is assigned using the S1 / S2 address

selector switches. Addresses can be set from 0 to 99.

• Connect X1 to the higher-level controller and/or the next

PROFIBUS device via cable in accordance with the PROFIBUS

specification.

6.4 Connect 24 V DC power supply

Power is supplied to the Central Interface Module (CIM) and EM4315 expansion module via

an external 24 V DC supply. Use a power supply unit which conforms to IEC 60536,

protection class III (PELV). Power supply units from the SITOP product line are suitable, for

example.

SIPLUS HCS4300 PROFINET/PROFIBUS DP

Operating Instructions, 10/2019, A5E35452705A/005

The CIM and the EM4315 can both also supply up to 8 POM4320 or 6 POM4320 Highend

via the HCS system interface.

55

Page 58

Wiring

24 V connection CIM and EM4315

Connect the 24 V DV supply voltage to the device as follows:

+

+24 V DC

Note

An external lightning protection element should be connected upstream in the 24

supply line:

Dehn, Blitzductor BVT Type AD24, No. 918402 or equivalent.

When using other items, you must ensure that the model used is equivalent

lightning

The lightning protection module must be installed and used in accordance with the

manufacturer's specifications.

6.4 Connect 24 V DC power supply

Design of the 24 V DC power supply

You can determine the design of the 24 V DC power supply using the following calculation

formula:

Minimum power =

3 W + (number of POM4320 • 8 W) + (number of POM4320 Highends • 10 W) +

(number of I/O modules • 1 W)

Example:

Supply of an HCS4300 consisting of CIM4310 PROFINET with one I/O module and

6 connected POM4320.

The minimum power rating in accordance with the formula above is 52 W, i.e. the

power pack must be able to supply current of at least 2167 mA.

Connect 24 C DC supply voltage to CIM and EM4315

External lightning protector

protection manufacturer).

● The following interference immunity is obtained with a lightning protection component:

– 1.0 kV symmetrical with R

– 2.0 kV asymmetrical with R

- GND

V DC

(consult with

= 2 Ω; assessment criterion B

i

= 12 Ω; assessment criterion B

i

● Without lightning protection, the following interference immunity is obtained:

– 0.5 kV symmetrical with R

– 0.5 kV asymmetrical with R

= 2 Ω; assessment criterion B

i

= 12 Ω; assessment criterion B

i

SIPLUS HCS4300 PROFINET/PROFIBUS DP

56 Operating Instructions, 10/2019, A5E35452705A/005

Page 59

Wiring

Note

When using radiation sources with inrush current, we recommend using

Category AC

Note

The permissible tightening torque for the terminals of the devices for panel mounting is

3.5 Nm.

6.5 Connecting the heating elements and three-phase line supply

6.5 Connecting the heating elements and three-phase line supply

6.5.1 Connecting the three-phase line supply

In the case of POM4320 for busbar mounting, the network infeed is via a 3-phase busbar

system. See section Busbar mounting (Page 44).

With the POM4320 for panel mounting, three screw terminals, L1, L2 and L3, provide the

mains supply. The position of the screw terminals on the POM is shown in section Function