Siemens SIPART Series, SIPART PS2 Series Operating Instructions Manual

SIPART

Electropneumatic positioners

SIPART PS2 with and without HART

Operating Instructions

Edition 10/2013

Answers for industry.

SIPART PS2 with and without HART

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIPART

Electropneumatic positioners

SIPART PS2 with and without

HART

Operating Instructions

6DR50.. - Positioner without HART

6DR51..

6DR52..

6DR53..

proof

10/2013

A5E00074631

Introduction

1

Safety information

2

Description

3

Installing/mounting

4

Connection

5

Operating

6

Commissioning

7

Functional safety

8

Parameterizing/addressing

9

Alarm, error, and system

messages

10

Service and maintenance

11

Technical data

12

Dimension drawings

13

Spare

parts/accessories/scope of

delivery

14

Appendix

A

Abbreviations

B

- Positioner with HART, not explosion-proof

- Positioner with HART, explosion-proof

- Positioner without HART, not explosion-

-11

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E00074631

Ⓟ

Copyright © Siemens AG 2013.

All rights reserved

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

Legal information

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

09/2013 Technical data subject to change

Table of contents

1 Introduction ............................................................................................................................................. 9

2 Safety information ................................................................................................................................. 13

3 Description ............................................................................................................................................ 17

4 Installing/mounting ................................................................................................................................ 31

1.1 Purpose of this documentation ...................................................................................................... 9

1.2 History ............................................................................................................................................ 9

1.3 Purpose ........................................................................................................................................ 10

1.4 Checking the consignment ........................................................................................................... 10

1.5 Transportation and storage .......................................................................................................... 11

1.6 Product information ...................................................................................................................... 11

1.7 Notes on warranty ........................................................................................................................ 11

2.1 Requirements for safe use ........................................................................................................... 13

2.1.1 Warning symbols on the device ................................................................................................... 13

2.1.2 Laws and directives ..................................................................................................................... 14

2.1.3 Conformity with European directives ........................................................................................... 14

2.2 Improper device modifications ..................................................................................................... 15

2.3 Requirements for special applications ......................................................................................... 15

2.4 Use in hazardous areas ............................................................................................................... 16

3.1 Function ....................................................................................................................................... 17

3.2 Structure ....................................................................................................................................... 18

3.2.1 Overview of structure ................................................................................................................... 18

3.2.2 Nameplate layout ......................................................................................................................... 21

3.3 Device components ..................................................................................................................... 23

3.3.1 Overview of device components .................................................................................................. 23

3.3.2 Basic electronics .......................................................................................................................... 25

3.4 Mode of operation ........................................................................................................................ 26

3.4.1 Control algorithm .......................................................................................................................... 27

3.4.2 Block circuit diagram for signal-acting or dual-acting drives ........................................................ 28

3.4.3 Mode of operation of the HART function ..................................................................................... 29

3.4.4 HART system configuration ......................................................................................................... 29

3.4.5 SIMATIC PDM .............................................................................................................................. 30

4.1 Basic safety instructions .............................................................................................................. 31

4.1.1 Proper mounting........................................................................................................................... 34

4.2 Mounting the linear actuator ........................................................................................................ 34

4.3 Mounting the part-turn actuator.................................................................................................... 40

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

3

Get more information

www.siemens.de/processautomation

www.siemens.de/sipartps2

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

www.siemens.com/automation

Subject to change without prior notice

A5E00074631-11

© Siemens AG 2013

A5E00074631-11

A5E00074631-11

Table of contents

7 Commissioning ................................................................................................................................... 113

8 Functional safety ................................................................................................................................. 141

9 Parameterizing/addressing .................................................................................................................. 147

6.2.1 Overview of operating modes .................................................................................................... 104

6.2.2 Changing the operating mode .................................................................................................... 105

6.2.3 Overview of configuration .......................................................................................................... 106

6.2.4 Description of operating modes ................................................................................................. 107

6.3 Optimizing the controller data .................................................................................................... 110

7.1 Basic safety instructions ............................................................................................................ 113

7.2 Sequence of automatic initialization .......................................................................................... 117

7.3 Purge air switching ..................................................................................................................... 122

7.4 Commissioning linear actuators ................................................................................................. 123

7.4.1 Preparing linear actuators for commissioning ............................................................................ 123

7.4.2 Automatic initialization of linear actuators .................................................................................. 124

7.4.3 Manual initialization of linear actuators ...................................................................................... 128

7.5 Commissioning part-turn actuators ............................................................................................ 132

7.5.1 Preparing part-turn actuators for commissioning ....................................................................... 132

7.5.2 Automatic initialization of part-turn actuators ............................................................................. 133

7.5.3 Manual initialization of part-turn actuators ................................................................................. 135

7.6 Device replacement ................................................................................................................... 138

8.1 Range of applications for functional safety ................................................................................ 141

8.2 Safety function ........................................................................................................................... 141

8.3 Safety Integrity Level (SIL) ......................................................................................................... 143

8.4 Settings ...................................................................................................................................... 144

8.5 Safety characteristics ................................................................................................................. 144

8.6 Maintenance/check .................................................................................................................... 145

9.1 Parameter chapter ..................................................................................................................... 147

9.2 Configuration schematic for parameter operating principle ....................................................... 148

9.3 Overview of parameters ............................................................................................................. 149

9.3.1 Overview of parameters 1 to 5 ................................................................................................... 149

9.3.2 Overview of parameters 6 to 51 ................................................................................................. 150

9.3.3 Overview parameters A to P ...................................................................................................... 154

9.4 Description of parameters .......................................................................................................... 158

9.4.1 Description of parameters 1 through 5 ...................................................................................... 158

9.4.2 Description of parameters 6 through 51 .................................................................................... 161

9.4.2.1 Description of parameters 6 ....................................................................................................... 161

9.4.2.2 Description of parameters 7 ....................................................................................................... 161

9.4.2.3 Description of parameters 8 and 9 ............................................................................................. 162

9.4.2.4 Description of parameters 10 and 11 ......................................................................................... 163

9.4.2.5 Description of parameters 12 ..................................................................................................... 163

9.4.2.6 Description of parameters 13 through 33 .................................................................................. 164

9.4.2.7 Description of parameters 34 ..................................................................................................... 165

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

5

Table of contents

10 Alarm, error, and system messages ..................................................................................................... 201

9.4.2.8 Description of parameters 35 and 36 ........................................................................................ 165

9.4.2.9 Description of parameters 37 .................................................................................................... 165

9.4.2.10 Description of parameters 38 .................................................................................................... 167

9.4.2.11 Description of parameters 39 .................................................................................................... 167

9.4.2.12 Description of parameters 40 and 41 ........................................................................................ 168

9.4.2.13 Description of parameters 42 and 43 ........................................................................................ 168

9.4.2.14 Description of parameters 44 .................................................................................................... 170

9.4.2.15 Description of parameters 45 and 46 ........................................................................................ 171

9.4.2.16 Description of parameters 47 .................................................................................................... 171

9.4.2.17 Description of parameters 48 .................................................................................................... 172

9.4.2.18 Description of parameters 49 .................................................................................................... 172

9.4.2.19 Description of parameters 50 .................................................................................................... 173

9.4.2.20 Description of parameters 51 .................................................................................................... 174

9.4.3 Description of parameters A through P ..................................................................................... 176

9.4.3.1 Description of parameter A ....................................................................................................... 176

9.4.3.2 Description of parameter b ........................................................................................................ 179

9.4.3.3 Description of parameter C ....................................................................................................... 181

9.4.3.4 Description of parameter d ........................................................................................................ 183

9.4.3.5 Description of parameter E ....................................................................................................... 185

9.4.3.6 Description of parameter F........................................................................................................ 186

9.4.3.7 Description of parameter G ....................................................................................................... 188

9.4.3.8 Description of parameter H ....................................................................................................... 190

9.4.3.9 Description of parameter J ........................................................................................................ 192

9.4.3.10 Description of parameter L ........................................................................................................ 194

9.4.3.11 Description of parameter O ....................................................................................................... 196

9.4.3.12 Description of parameter P ....................................................................................................... 198

10.1 Output of system messages in the display ............................................................................... 201

10.1.1 System messages before initialization ...................................................................................... 201

10.1.2 System messages during initialization ...................................................................................... 202

10.1.3 System messages when exiting the Configuration mode ......................................................... 205

10.1.4 System messages during operation .......................................................................................... 206

10.2 Diagnosis................................................................................................................................... 208

10.2.1 Display of diagnostics values .................................................................................................... 208

10.2.2 Overview of diagnostics values ................................................................................................. 208

10.2.3 Meaning of the diagnostics values ............................................................................................ 211

10.2.4 Meaning of diagnostic value 53 ................................................................................................ 218

10.3 Online diagnostics ..................................................................................................................... 219

10.3.1 Overview of online diagnostics ................................................................................................. 219

10.3.2 Overview of error codes ............................................................................................................ 220

10.3.3 XDIAG parameter ...................................................................................................................... 222

10.3.4 Meaning of error codes ............................................................................................................. 222

10.4 Fault correction ......................................................................................................................... 225

10.4.1 Fault identification ..................................................................................................................... 225

10.4.2 Remedial measures table 1 ...................................................................................................... 226

10.4.3 Remedial measures table 2 ...................................................................................................... 227

10.4.4 Remedial measures table 3 ...................................................................................................... 228

10.4.5 Remedial measures table 4 ...................................................................................................... 229

10.4.6 Remedial measures table 5 ...................................................................................................... 230

SIPART PS2 with and without HART

6 Operating Instructions, 10/2013, A5E00074631-11

Table of contents

11 Service and maintenance .................................................................................................................... 231

12 Technical data .................................................................................................................................... 235

13 Dimension drawings ............................................................................................................................ 255

14 Spare parts/accessories/scope of delivery ........................................................................................... 259

11.1 Basic safety instructions ............................................................................................................ 231

11.2 Cleaning of the screens ............................................................................................................. 232

11.2.1 Positioner in macrolon enclosure ............................................................................................... 232

11.2.2 Positioner in stainless steel, aluminum and flameproof aluminum enclosure ........................... 233

11.3 Repair/Upgrading ....................................................................................................................... 233

11.4 Return procedure ....................................................................................................................... 234

12.1 Rated conditions ........................................................................................................................ 235

12.2 Pneumatic data .......................................................................................................................... 236

12.3 Construction ............................................................................................................................... 237

12.4 Controller .................................................................................................................................... 239

12.5 Certificates, approvals, explosion protection for all device versions ......................................... 239

12.6 Electrical data ............................................................................................................................. 241

12.7 Technical data for natural gas as actuator medium ................................................................... 243

12.8 Option modules .......................................................................................................................... 244

12.8.1 Alarm module ............................................................................................................................. 244

12.8.2 Iy module .................................................................................................................................... 246

12.8.3 SIA module ................................................................................................................................. 247

12.8.4 Limit value contact module ........................................................................................................ 248

12.8.5 EMC filter module....................................................................................................................... 249

12.8.6 Non-contacting position sensor .................................................................................................. 250

12.8.7 External position sensing system ............................................................................................... 252

12.8.7.1 Operating conditions for all device versions .............................................................................. 252

12.8.7.2 Constructional design for all device versions ............................................................................. 252

12.8.7.3 Certificates, approvals, explosion protection for all device versions ......................................... 253

13.1 Positioner with Makrolon enclosure 6DR5..0 and stainless steel enclosure 6DR5..2 ............... 255

13.2 Terminal strip for positioner with Macrolon enclosure ............................................................... 256

13.3 Positioner with aluminum enclosure 6DR5..1 ............................................................................ 257

13.4 Positioner with flameproof enclosure 6DR5..5 ........................................................................... 258

14.1 Overview .................................................................................................................................... 259

14.2 Spare parts ................................................................................................................................. 261

14.3 Scope of delivery of small part sets ........................................................................................... 263

14.4 Scope of delivery of external position detection system ............................................................ 265

14.5 Scope of delivery of mechanical limit switch module ................................................................. 265

14.6 Scope of delivery EMC filter module .......................................................................................... 265

14.7 Accessories ................................................................................................................................ 267

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

7

Table of contents

A Appendix ............................................................................................................................................. 269

B Abbreviations ....................................................................................................................................... 273

Glossary .............................................................................................................................................. 277

Index ................................................................................................................................................... 285

A.1 Operation with boosters ............................................................................................................ 269

A.2 Certificates ................................................................................................................................ 270

A.3 Literature and catalogs .............................................................................................................. 270

A.4 Technical support ...................................................................................................................... 271

SIPART PS2 with and without HART

8 Operating Instructions, 10/2013, A5E00074631-11

1

1.1

Purpose of this documentation

1.2

History

Edition

Firmware identifier nameplate

10/2013

From FW 4.00.02

Edition

Remark

6DR5..5 (Page 258)": New graphic, new dimensions

See also

These instructions contain all information required to commission and use the device. It is

your responsibility to read the instructions carefully prior to installation and commissioning. In

order to use the device correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

This history establishes the correlation between the current documentation and the valid

firmware of the device.

The documentation of this edition is applicable for the following firmware:

The most important changes in the documentation as compared to the respective previous

edition are given in the following table.

10/2013 Chapter 3 "Description" > 3.2 "Structure (Page 18)": Nameplates revised.

Chapter 8 "Functional safety"

Chapter 13 "Dimensional drawings" > 13.4 "

Construction (Page 237)

Positioner with flameproof enclosure

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

9

Introduction

1.3

Purpose

1.4

Checking the consignment

WARNING

Using a damaged or incomplete device

1.3 Purpose

The electropneumatic positioner is used for the continuous control of process valves with

pneumatic drives in the following industries.

● Chemicals

● Oil and gas

● Energy production

● Food and beverages

● Pulp and paper

● Water/waste water

● Pharmaceutical industry

● Offshore plants

Operate the device according to the specifications in Chapter "Technical data (Page 235)".

For additional information, refer to the operating instructions for the device.

1. Check the packaging and the device for visible damage caused by inappropriate handling

during shipping.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

SIPART PS2 with and without HART

10 Operating Instructions, 10/2013, A5E00074631-11

Introduction

1.5

Transportation and storage

CAUTION

Insufficient protection during storage

1.6

Product information

See also

1.7

Notes on warranty

1.5 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in "Technical data"

(Page 235).

The programming manual is an integral part of the CD, which is either supplied or can be

ordered. The programming manual is also available on the Siemens homepage.

On the CD, you will also find the catalog extract with the ordering data, the Software Device

Install for SIMATIC PDM for additional installation, and the required software.

SIPART PS2 product information (http://www.siemens.com/sipartps2)

Contacts (http://www.siemens.com/processinstrumentation/contacts)

Process instrumentation catalog (http://www.siemens.com/processinstrumentation/catalogs)

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

11

Introduction

1.7 Notes on warranty

SIPART PS2 with and without HART

12 Operating Instructions, 10/2013, A5E00074631-11

2

2.1

Requirements for safe use

2.1.1

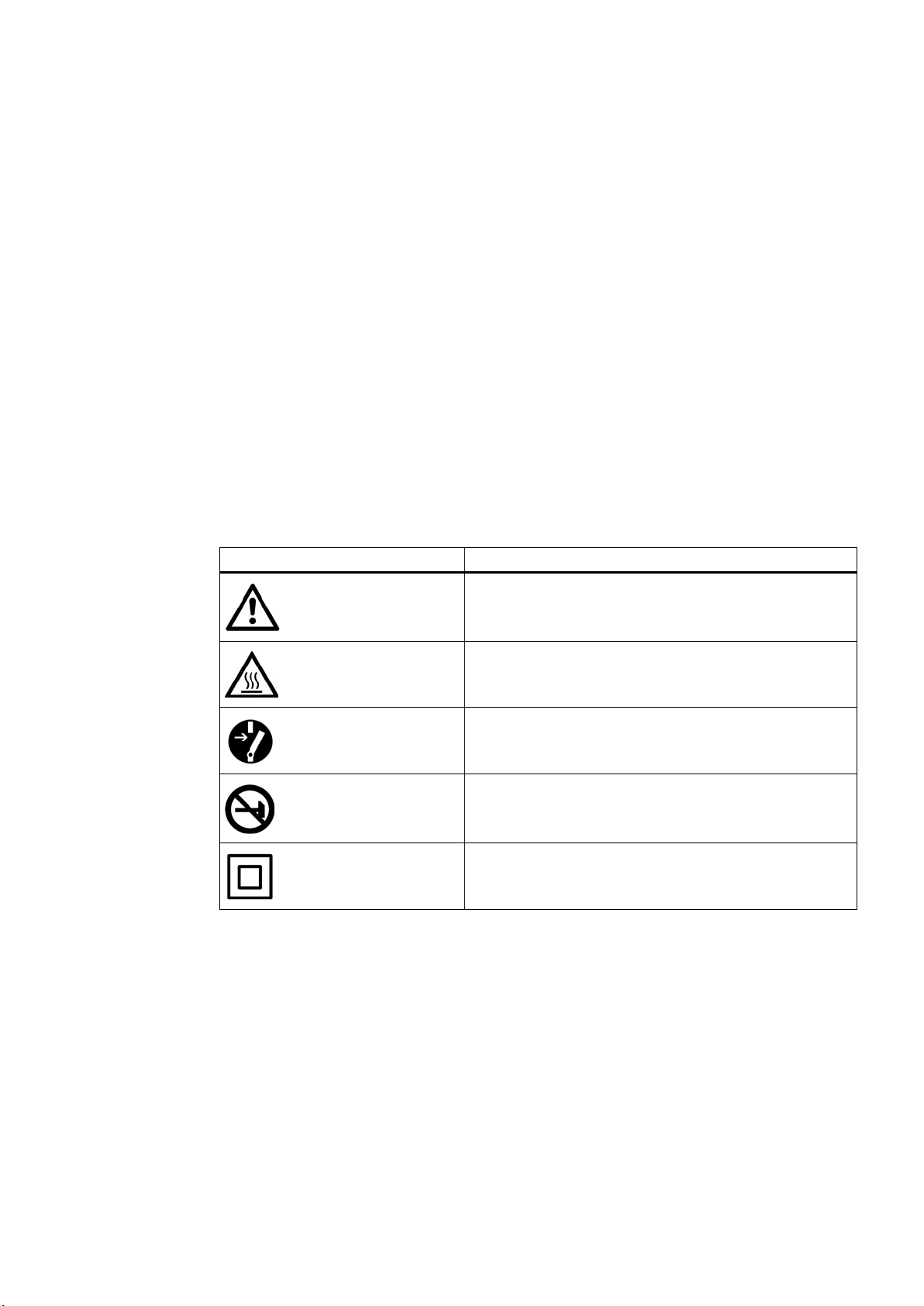

Warning symbols on the device

Symbol

Meaning

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Hot surface

Isolate the device from power using a circuit-breaker

Protect the device from shocks (otherwise the specified

degree of protection is not guaranteed)

Protective insulation; device in protection class II

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

13

Safety information

2.1.2

Laws and directives

See also

2.1.3

Conformity with European directives

Electromagnetic

Compatibility EMC

2004/108/EC

Directive of the Euro

approximation of the laws of the Member States relating to

electromagnetic compatibility and repealing Directive

89/336/EEC.

Atmosphère explosible

ATEX

94/9/EC

Directive of the European Parliament and the Council

approximation of the laws of the Member States concerning

equipment and protective systems intended for use in

potentially explosive atmospheres.

2.1 Requirements for safe use

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

Certificates (http://www.siemens.com/processinstrumentation/certificates)

The CE marking on the device shows conformity with the regulations of the following

European guidelines:

pean Parliament and of the Council on the

on the

The applied standards can be found in the EC conformity declaration of the device.

SIPART PS2 with and without HART

14 Operating Instructions, 10/2013, A5E00074631-11

Safety information

2.2

Improper device modifications

WARNING

Improper device modifications

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special amb

encountered in nuclear power plants or when the device is used for research and

development purposes.

2.2 Improper device modifications

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

ient conditions as can be

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

15

Safety information

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

WARNING

Unsuitable device for the hazardous area

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.4 Use in hazardous areas

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

Danger of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and in Chapter

"Technical data (Page 235)".

SIPART PS2 with and without HART

16 Operating Instructions, 10/2013, A5E00074631-11

3

3.1

Function

● The electropneumatic positioner, in combination with the drive, forms a regulation system.

The current position of the actuator is detected using a potentiometer and returned as the

actual value x. The setpoint and actual value are output simultaneously on the display.

● The setpoint w forms a current applied to the positioner, which in two-wire mode is also

used to power the positioner. In 3- and 4-wire mode, power is supplied through a 24-V

power input.

● The positioner works as a predictive five-point positioner, through whose output value

±Δy the integrated valves can be controlled by pulse length modulation.

● These positioning signals cause pressure changes in the drive chamber(s) and thus a

repositioning of the drive until the regulation deviation returns to zero.

● Using three buttons and the display with the enclosure cover removed, operation (manual

mode) and configuration (structuring, initialization, and parameter assignment) can be

performed.

● By default, the basic unit has a binary input (BE1). This binary input can be individually

configured and used e.g. to block the control levels.

● To be able to use the positioner in a variety of mechanically different rotational and linear

actuators, it has a friction clutch and a switchable gear.

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

17

Description

3.2

Structure

3.2.1

Overview of structure

3.2 Structure

The following sections describe the mechanical and electrical structure, components, and

principle functionality of the positioner.

The positioner is available in the following configurations:

● SIPART PS2 without explosion protection in stainless steel, aluminum or Makrolon

enclosure

● SIPART PS2 with Ex i protection in stainless steel, aluminum or Makrolon enclosure

● SIPART PS2 with Ex d protection in flameproof aluminum enclosure

The positioner is used to move and control pneumatic actuators. The positioner works

electropneumatically, using compressed air as auxiliary power. The positioner is used to

control valves, for example, with:

● Linear actuator

● Part-turn actuator VDI/VDE 3845

Various add-on extensions are available for linear actuators:

● IEC 60534-6-1 (NAMUR)

● Integrated addition to ARCA

● Integrated addition to SAMSON in non-flameproof aluminum enclosure

SIPART PS2 with and without HART

18 Operating Instructions, 10/2013, A5E00074631-11

Description

①

Pressure gauge block, single-acting

②

Valve

③

Yoke / actuator yoke

④

Single-acting positioner in non-flameproof aluminum enclosure

⑤

Actuator

①

Part-turn actuator

②

Pressure gauge block, double-acting

③

Double-acting positioner in macrolon enclosure

3.2 Structure

Figure 3-1 Positioner attached to a single-acting linear actuator

Figure 3-2 Positioner attached to double-acting part-turn actuator

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

19

Description

①

Single-acting positioner in flameproof aluminum enclosure

②

Pressure gauge block, single-acting

③

Yoke / actuator yoke

④

Actuator

①

Part-turn actuator

②

Double-acting positioner in flameproof aluminum enclosure

③

Pressure gauge block, double-acting

3.2 Structure

Figure 3-3 Positioner in flameproof aluminum enclosure attached to linear actuator

Figure 3-4 Positioner in flameproof aluminum enclosure attached to part-turn actuator

SIPART PS2 with and without HART

20 Operating Instructions, 10/2013, A5E00074631-11

Description

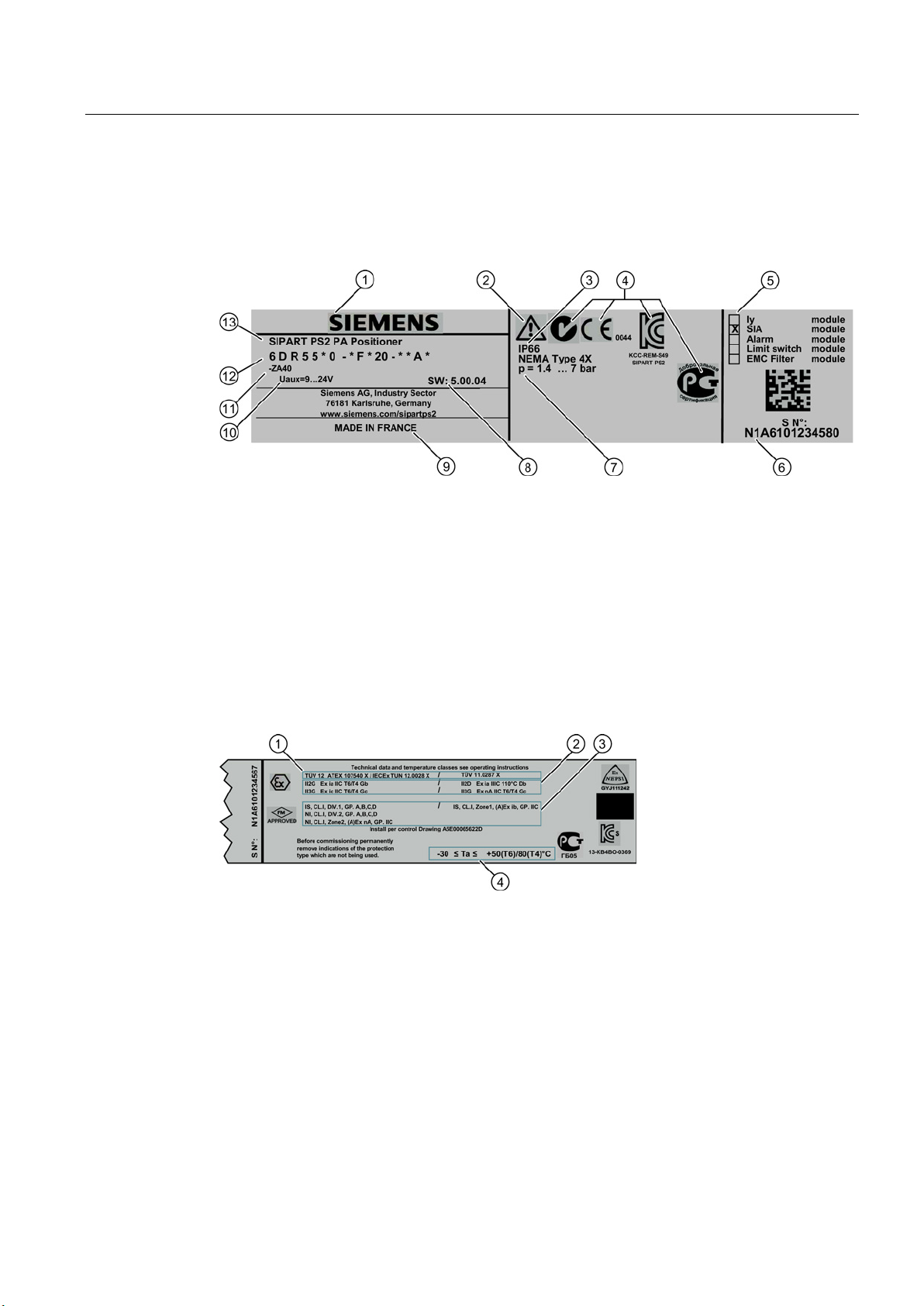

3.2.2

Nameplate layout

Design of the nameplate

①

Manufacturer

⑧

Software version

②

Consult operating instructions

⑨

Place of manufacture

③

Safety class

⑩

Auxiliary power

④

Conformity with country-specific directives

⑪

Ordering supplement (Order code)

⑤

Built-in option module

⑫

Order no.

⑥

Manufacturer serial number

⑬

Product name

⑦

Auxiliary power (air supply)

Layout of Ex nameplate

①

Approvals

③

FM/CSA marking for hazardous area

②

④

temperature class

3.2 Structure

Figure 3-5 Nameplate_design, example

ATEX/IECEX marking for hazardous area

Figure 3-6 Layout of Ex nameplate

Permissible ambient temperature for the

hazardous area of the corresponding

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

21

Description

Explanation of Ex information

①

④

(temperature class)

②

Type of protection

⑤

Device protection level

③

Group (gas, dust)

3.2 Structure

Category for operating range

Figure 3-7 Explanation of Ex information

Maximum surface temperature

SIPART PS2 with and without HART

22 Operating Instructions, 10/2013, A5E00074631-11

Description

3.3

Device components

3.3.1

Overview of device components

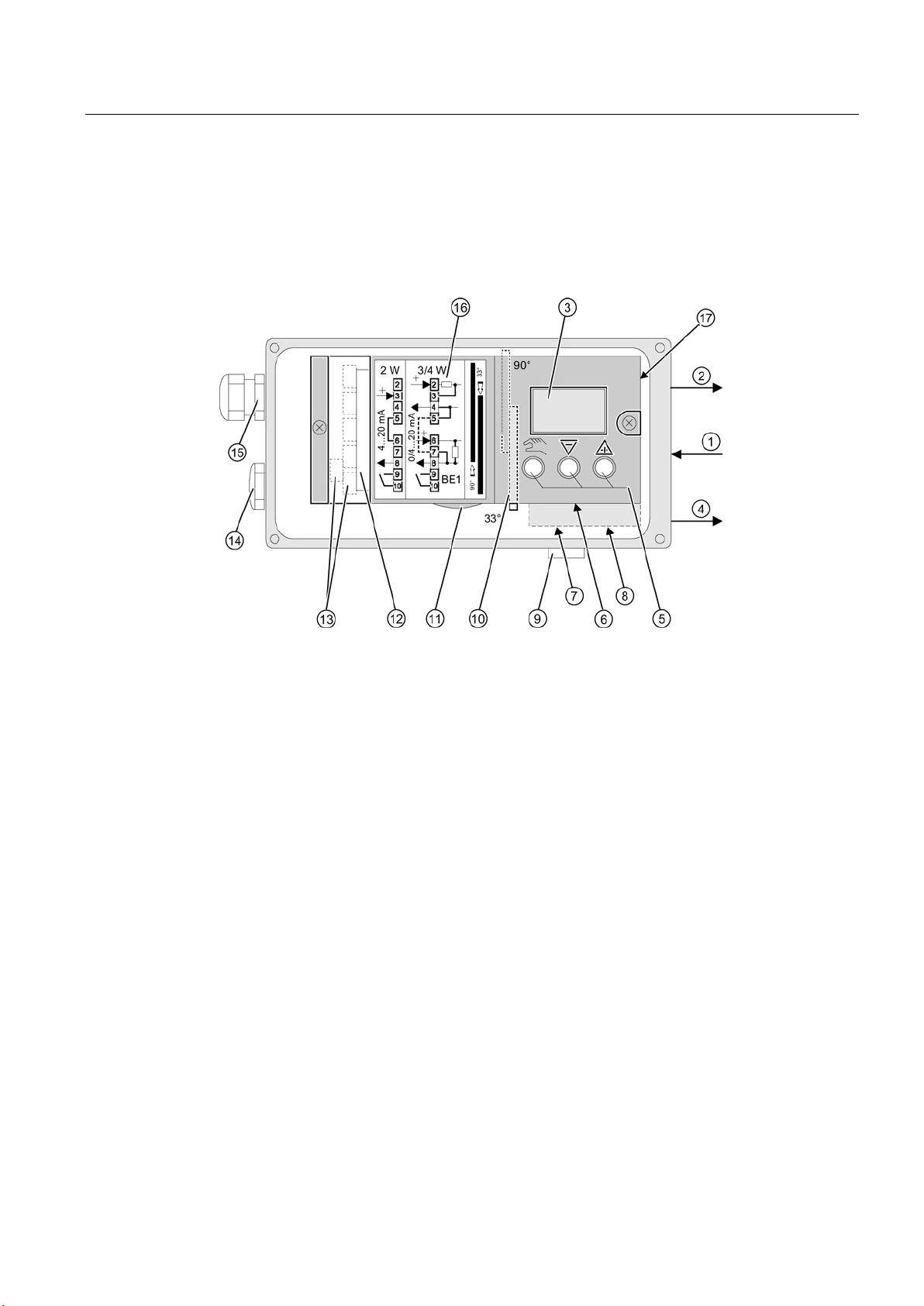

①

Input: Supply air

⑩

Transmission ratio selector

②

Output: Actuating pressure Y1

⑪

Friction clutch adjustment wheel

③

Display

⑫

Basic electronics

④

Output: Actuating pressure Y2

⑬

Connecting terminals of option modules

⑤

Buttons

⑭

Dummy plug

⑥

Restrictor Y1 for single-acting actuators

⑮

Cable gland

⑦

Restrictor Y1 for double-acting actuators

⑯

Wiring diagram on module cover

⑧

Restrictor Y2 for double-acting actuators

⑰

Purging air selector

⑨

Exhaust air outlet with a sound absorber

3.3 Device components

Figure 3-8 View of basic positioner with cover open

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

23

Description

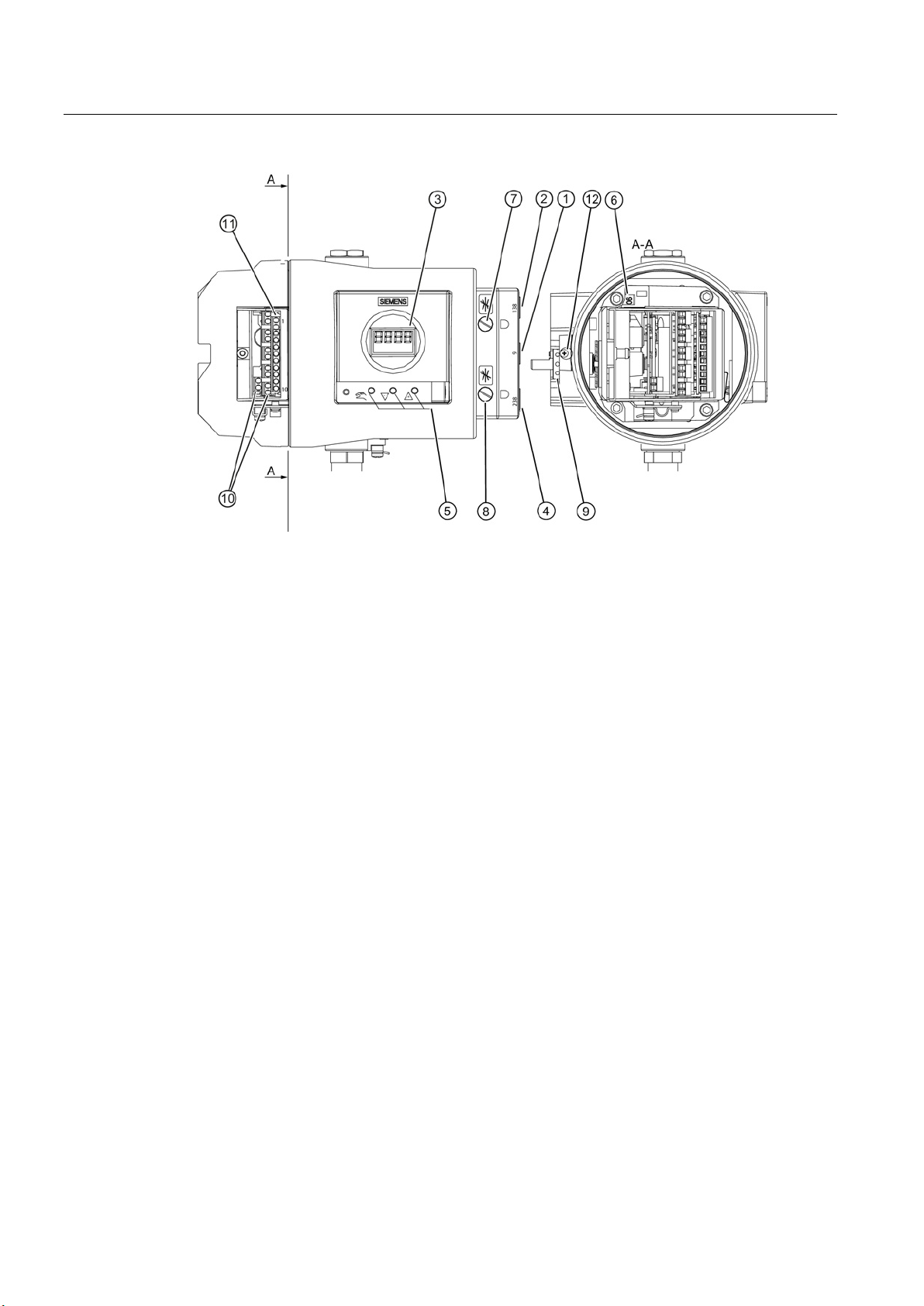

①

Input: Supply air

⑦

Restrictor Y1

②

Output: Actuating pressure Y1

⑧

Restrictor Y2 1)

③

Display

⑨

Friction clutch adjustment wheel

④

Output: Actuating pressure Y2 1)

⑩

Connecting terminals of option modules

⑤

Buttons

⑪

Connecting terminals of basic device

⑥

Transmission ratio selector 2)

⑫

Safety catch

for double-acting actuators

only possible when positioner is open

3.3 Device components

1)

2)

Figure 3-9 View of positioner in flameproof enclosure

SIPART PS2 with and without HART

24 Operating Instructions, 10/2013, A5E00074631-11

Description

3.3.2

Basic electronics

3.3 Device components

Figure 3-10 Basic electronics

The basic electronics contains:

● CPU

● Memory

● Analog-to-digital converter

● Display

● Buttons

● Terminal strips to connect the option module to the basic electronics

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

25

Description

3.4

Mode of operation

Control loop

N

See also

3.4 Mode of operation

The electropneumatic positioner forms a control loop with the pneumatic drive:

● The actual value x represents the position of the drive spindle for linear actuators or the

position of the drive shaft for part-turn actuators.

● The control value w represents the positioning current of a closed-loop controller or a

manual control station from 0/4 to 20 mA.

The lifting or rotary movement of the actuator is transferred to a potentiometer using suitable

attachments, positioner axis and a backlash-free, switchable gear drive, and then to the

analog input of the microcontroller. The current position can also be forwarded to the

positioner using an external sensor. A

record the lifting or rotation angle directly on the actuator.

The microcontroller:

● Corrects the angle error of the shaft pick-up if necessary.

on-Contacting Position Sensor (NCS) is used to

● Compares the potentiometer voltage as actual value x with the setpoint w. The setpoint w

is connected to terminals 6 and 7 by means of PROFIBUS communication.

● Calculates the manipulated variable increments ±∆y.

The piezo-controlled inlet or exhaust air valve is opened depending on the magnitude and

direction of the control deviation (x-w). The actuator volume integrates the controller

increment for the actuating pressure y which is proportional to the drive rod or the drive

shaft. This controller increment change the actuating pressure until the control deviation

becomes zero.

Pneumatic actuators are available in single and double-acting versions. In a single-acting

version, only one pressure chamber is ventilated and depressurized. The pressure

developed works against a spring. In a double-acting version, two pressure chambers work

against each other. Ventilating the volume of one chamber simultaneously depressurizes the

volume of the other.

Block circuit diagram for signal-acting or dual-acting drives (Page 28)

SIPART PS2 with and without HART

26 Operating Instructions, 10/2013, A5E00074631-11

Description

3.4.1

Control algorithm

3.4 Mode of operation

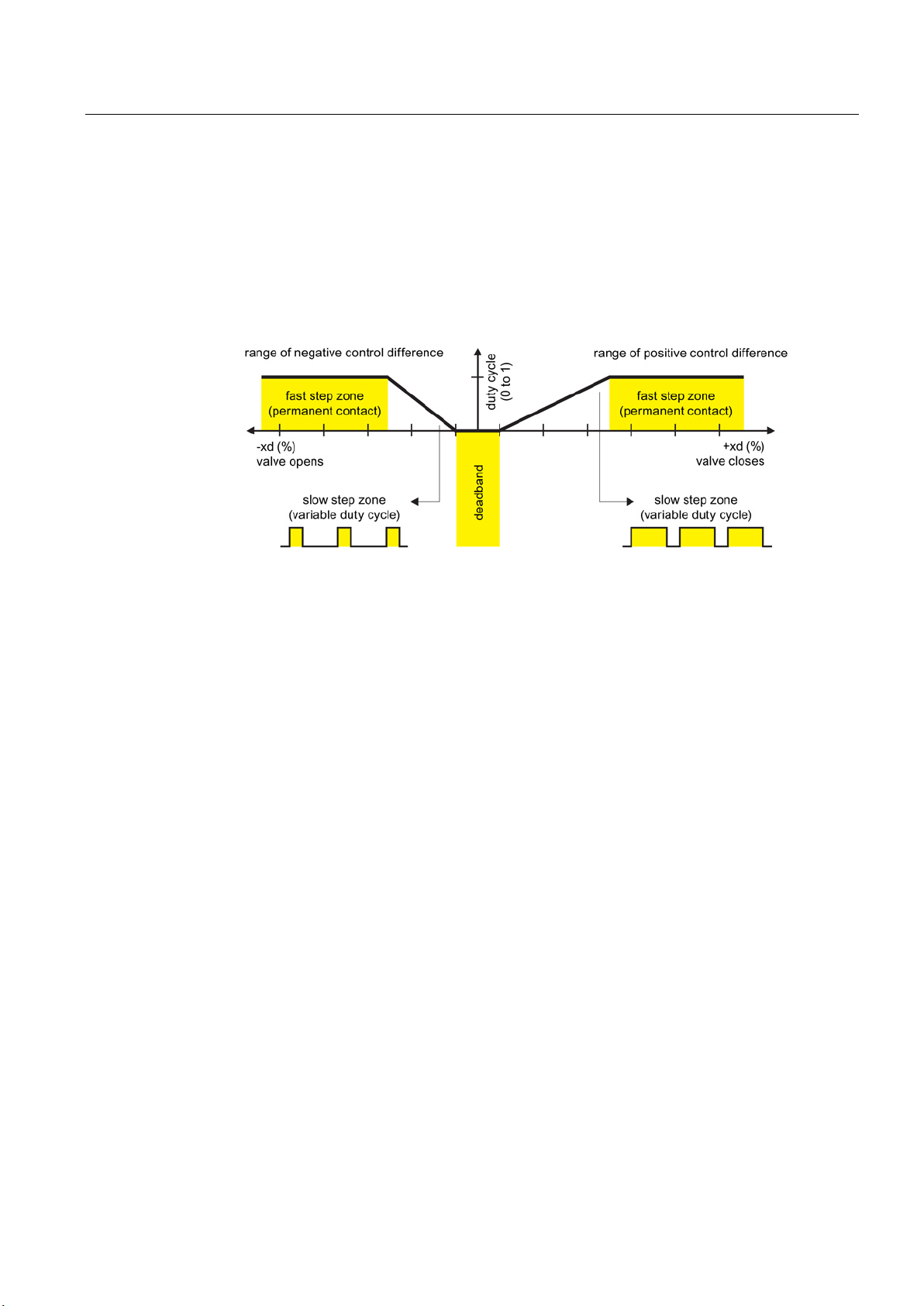

The control algorithm is an adaptive, predictive five-point controller.

In case of large control deviations, the valves are controlled using permanent contact. This

takes place in the so-called fast step zone.

In case of medium control deviations, valves are controlled using pulse-length modulated

pulses. This takes place in the so-called slow step zone.

Figure 3-11 Functional principle of five-point controller

Small control deviations do not send control pulses in the zone. This takes place in the socalled adaptive deadband. The deadband adaptation and the continuous adaptation of

minimum pulse lengths in the automatic mode ensure the best possible control accuracy with

the smallest number of operating cycles. The start parameters are determined during the

initialization phase and stored in the non-volatile memory. The most important start

parameters are:

● The real actuator travel with mechanical end stops

● Actuating times

● The deadband size

The number of fault messages, changes in direction and the stroke number are continuously

determined during operation and saved after every 15 minutes. You can read and document

these parameters using communication programs such as PDM and AMS. By comparing the

old values with the current ones, you can draw conclusions about the wear and tear of the

control valve. You can use the diagnostics function for this.

SIPART PS2 with and without HART

Operating Instructions, 10/2013, A5E00074631-11

27

Description

3.4.2

Block circuit diagram for signal-acting or dual-acting drives

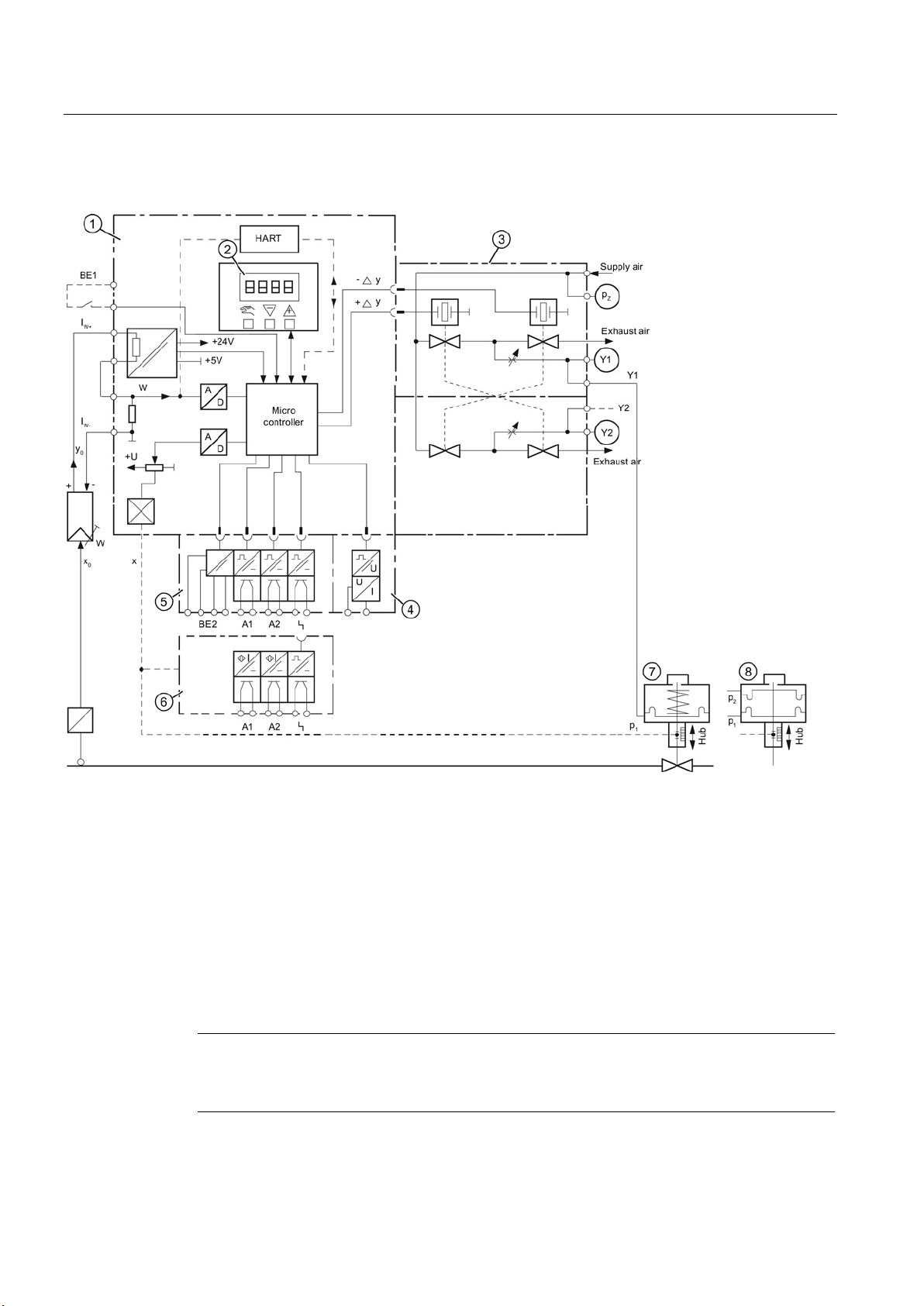

①

Basic electronics with microcontroller and input circuit

②

Control pad with display and buttons

③

Single-acting (6DR5.1.) or double-acting (6DR5.2.) pneumatic block

④

Iy module for positioner

⑤

Alarm module for three alarm outputs and one binary input

⑥

SIA module (slot initiator alarm module)

⑦

Spring-loaded pneumatic positioning drive (single-acting)

⑧

Pneumatic actuator (double-acting)

Note

Alarm module and SIA module

Alarm module

3.4 Mode of operation

Figure 3-12 Block circuit diagram for the electropneumatic positioner, functional diagram

⑥ and SIA module ⑦ can only be alternatively used.

SIPART PS2 with and without HART

28 Operating Instructions, 10/2013, A5E00074631-11

Loading...

Loading...