Siemens SIPART DR24, 6DR2410 User Manual

Manual Edition 12/2006

Controller

SIPART DR24

6DR2410

sipart

SIPART DR24

6DR2410

Edition 12/2006

Manual

SIPART DR24 6DR2410

C79000-G7476-C153-03

1

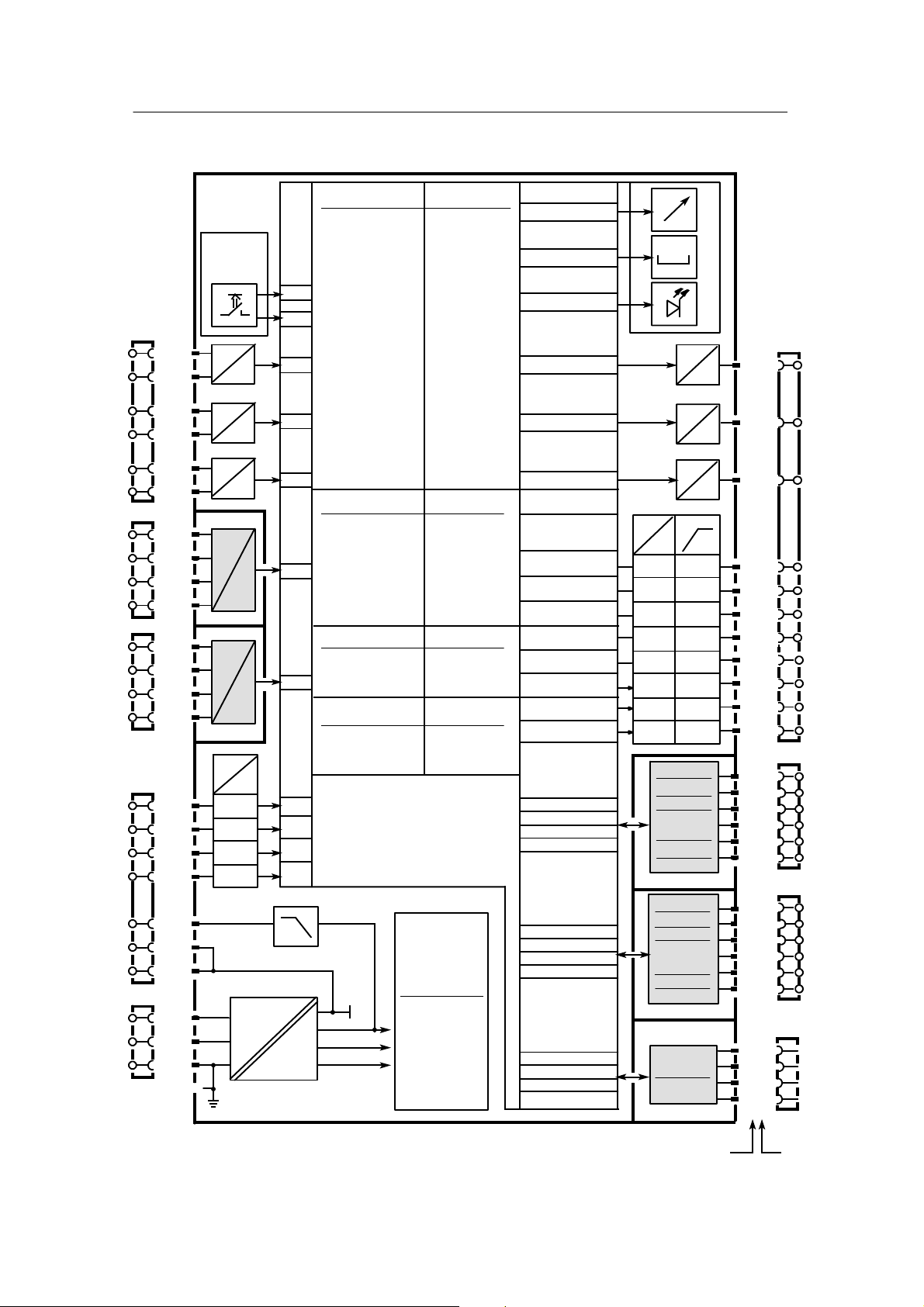

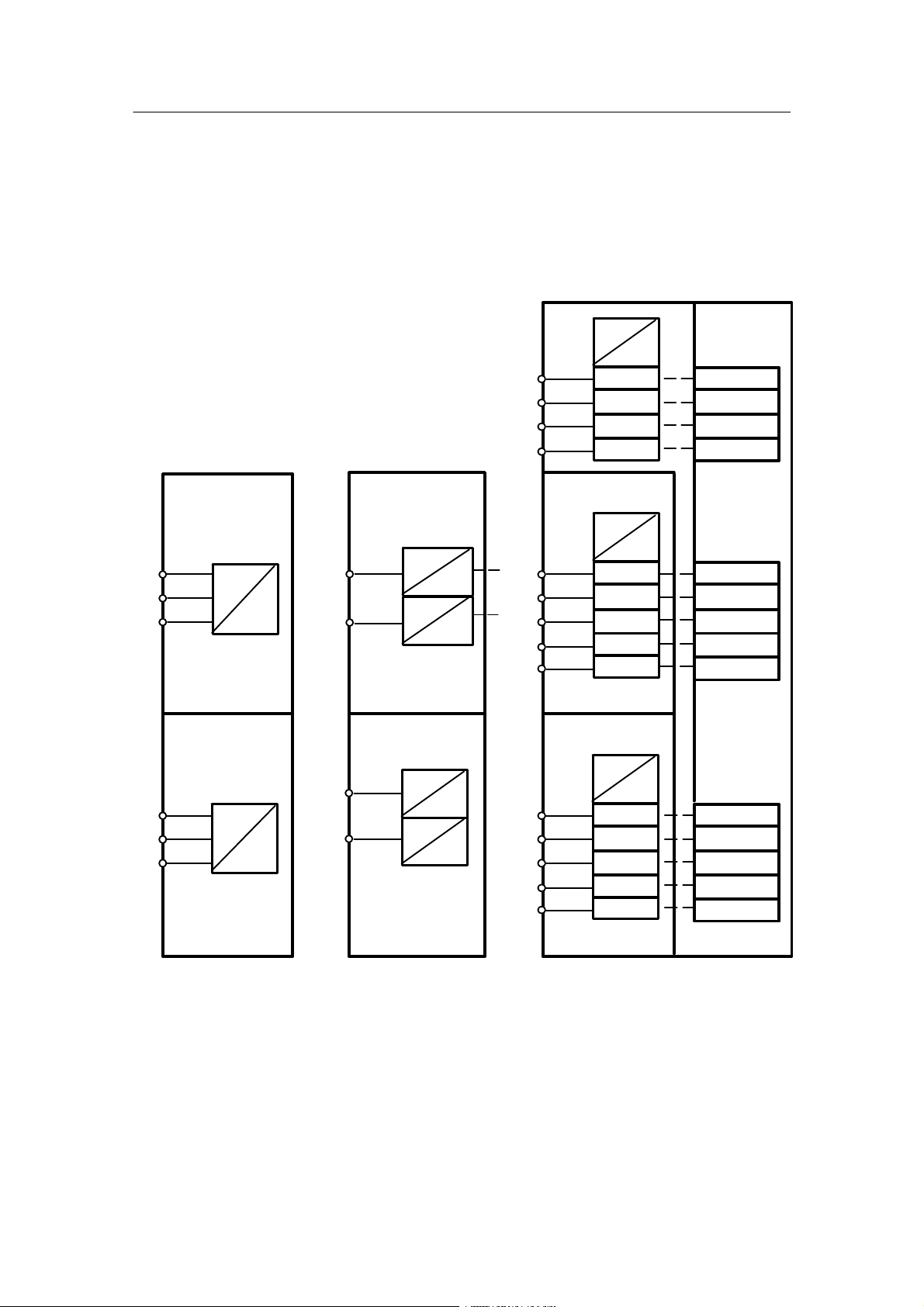

Block diagram

Manual

AE1

AE2

AE3

AE4

AE5

BE1

2

3

BE4

L+

M

+

-

+

-

+

-

Options

M

2

Front

module

1/20

1/19

1/22

1/21

1/24

1/23

2/4

2/3

2/2

2/1

3/4

3/3

3/2

3/1

1/15

1/16

1/17

1/18

1/3

1/2

1/1

PE

I,U

U

I,U

U

I,U

U

I,U,R

UNI,

P,

T,

V

U

Slot 2

I,U,R

UNI,

P,

T,

V

U

Slot 3

24 V

5V

S3

L

N

«

6DR2410-4 24 V UC

6DR2410-5 115/230 V AC switchable

32 Basic functions 109 arithmetic blocks

AbS, Add, AMEM,

AMPL, And,

ASo

bSo

CoMP, CoUn

dEbA, dEF, diF

tA1.1

div

#

Eor

tA7.F

FiLt b01.F...bh9.F

LG, LiMi, LinE with 3 inputs

Ln 1 output

AE1A

MAME, MASE

MiME, MiSE

MULt

nAnd, nor

AE2A

or

Pot

root

SUb

AE3A

tFF, tiME

33 complex funct. 33 arithmetic blocks

AFi1. AFi2

Ain1...Ain4

bin1...bin6 c01.F...c33.F

CPt1, CPt2 with 4 inputs

AE4A

dti1, dti2 1 output

FUL1, FUL2, FUL3

FUP1, FUP2

PUM1 - 4/SPR1 - SPR8

4 complex funct. 4 arithmetic blocks

CLoc d01.F...d04.F

MUP1, M UP2 with 12 inputs

AE5A

Cnt1 14 outputs

12 complex funct. 4 arithmetic blocks

Ccn1...Ccn4 h01. F...h04. F

CSE1...CSE4 with 18 inputs

CSi1...CSi4 4 outputs

bE01

bE02

bE03

bE04

I

M

+24V

+5V

U

–

REF

User

program

memory for:

onPA onAdAP line

oFPA

CLPA

hdEF offFdEF line

FCon

FPoS

APSt

CAE4

CAE5

dA1.1...dA2.4

dd1.1...dd3.4

L 1.1...L14.9

AA1.1...AA1.3

AA2.1...AA2.3

AA3.1...AA3.3

bA1.1...bA1.3

bA2.1...bA2.3

bA3.1...bA3.3

bA4.1...bA4.3

bA05

bA06

bA07

bA08

AE6A...AE8A

AA4...AA6

bE10...bE14

bA13...bA16

AE9A...AE11A

AA7...AA9

bE05...bE09

bA09...bA12

SA1.1...SA16.3

SAA1...SAA16

SbE1...SbE16

SbA1...SbA16

F

r

o

n

t

m

0000

o

d

u

l

e

5V

24 V I

3AE

1AA y

5BE

4BA24V

+2BE

2BA Rel.

3AO/3BE

Slot 6

3AE

1AA y

5BE

4BA 24V

+2BE

2BA Rel.

3AO/3BE

Slot 5

RS 232/

RS 485

PROFIBUS

Slot 4

U

U

U

hold

hold

Slot Term i n al

1/12

I

1/13

I

1/14

I

1/10

1/11

4/2

4/7

4/8

4/3

SIPART DR24 6DR2410

C79000-G7476-C153-03

1/4

1/5

1/6

1/7

1/8

1/9

6/6

6/5

6/4

6/3

6/2

6/1

Options

5/6

5/5

5/4

5/3

5/2

5/1

Options

AA1

AA2

AA3

BA1

2

3

4

5

6

7

BA8

Manual

dA1

tA7

*) or dA2

dd1

dd2

green

red

yellow

gray

L14.0

L14.1

L14.2

L14.3

L14.4*)

L14.5

L14.6

L14.7

L14.8

L14.9

L13

dd3 L12

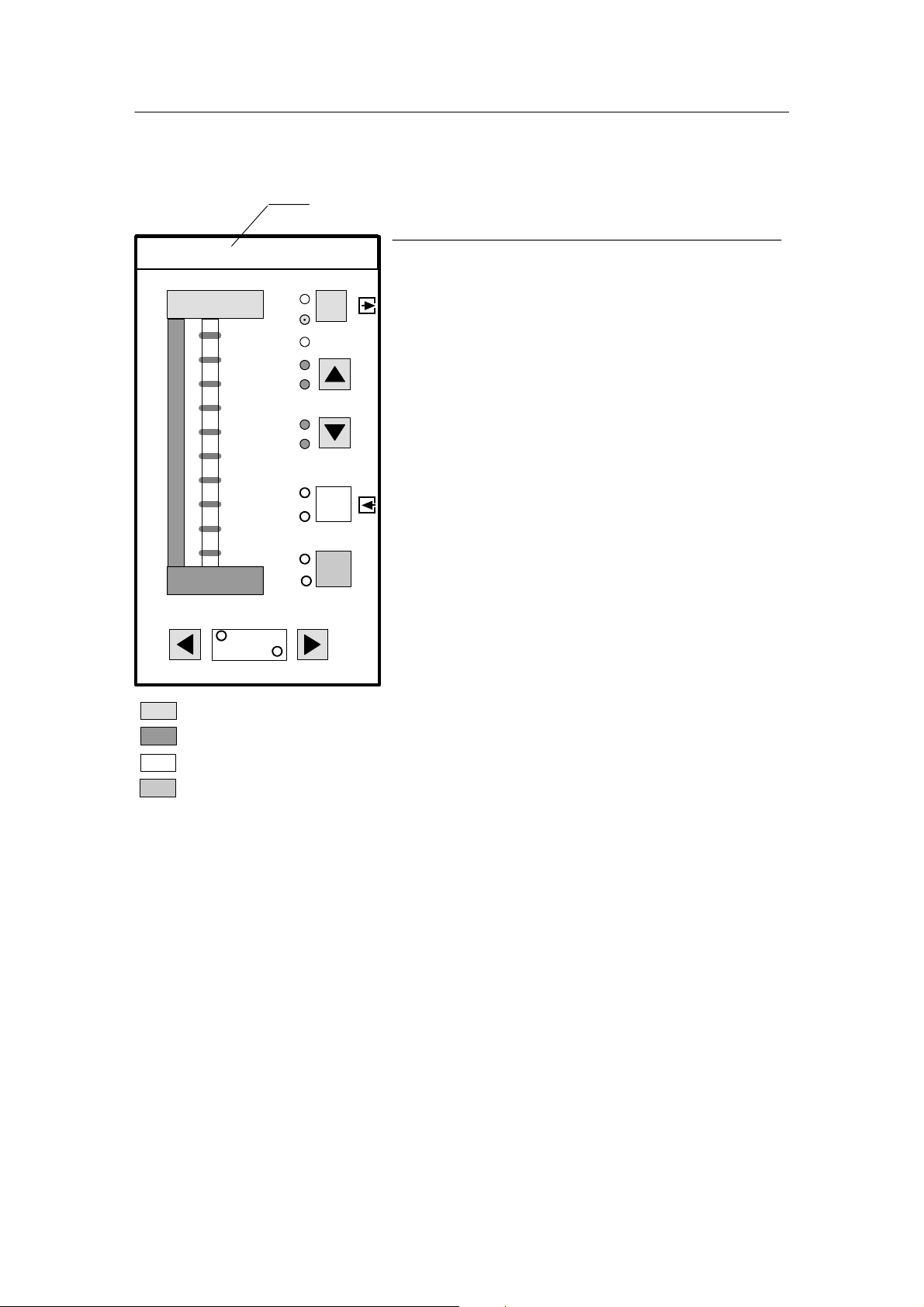

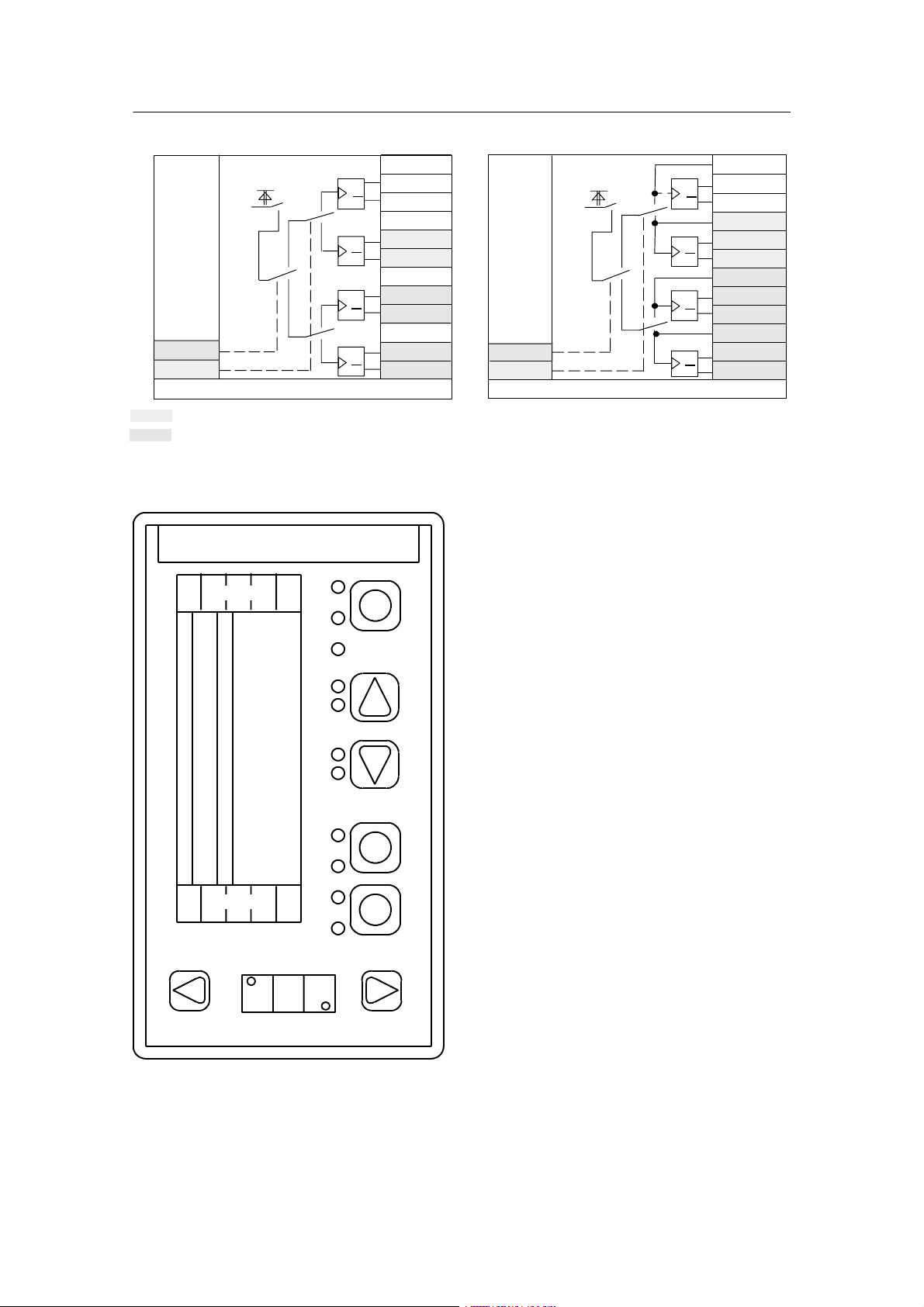

Measuring point label with cover, changeable

Process operation Parameterization/configuring

L1 LED green -tA1 Key green Exit key

L2 LED green Exit LED

L3 LED yellow -L4 LED red -L5 LED red -tA2/3 Key green Adjustment of the variables shown in

L6 LED red -L7 LED red -L8 LED yellow -tA4 Key yellow Enter key

L9 LED yellow Enter LED

L10 LED green -tA5 Key gray Shift key; start of configuration

L11 LED green -L12 LED yellow -tA6/7 Adjustment of the variables show in the

L13 LED yellow -L14.0 bis L14.9 Striped pattern in configuring

LEDs green (only as

an alternative to digital

display dA2)

dd1 Digital display green Parameter value/answer

dd2 Digital display red Function, parameter name, question

dd3 Didital display yellow Parameter name

dA1 Analog display red - dA2 Analog display green Striped pattern in configuring

(only as an alternative

to L14)

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

tA1

tA2

tA3

tA4

tA5

tA6

the digital display dd1

digital displays dd2 and dd3

Figure 3-1 Connectable control and display elements in the process operation mode and fixed

assignment in parameterization/configuring

SIPART DR24 6DR2410

C79000-G7476-C153-03

3

Manual

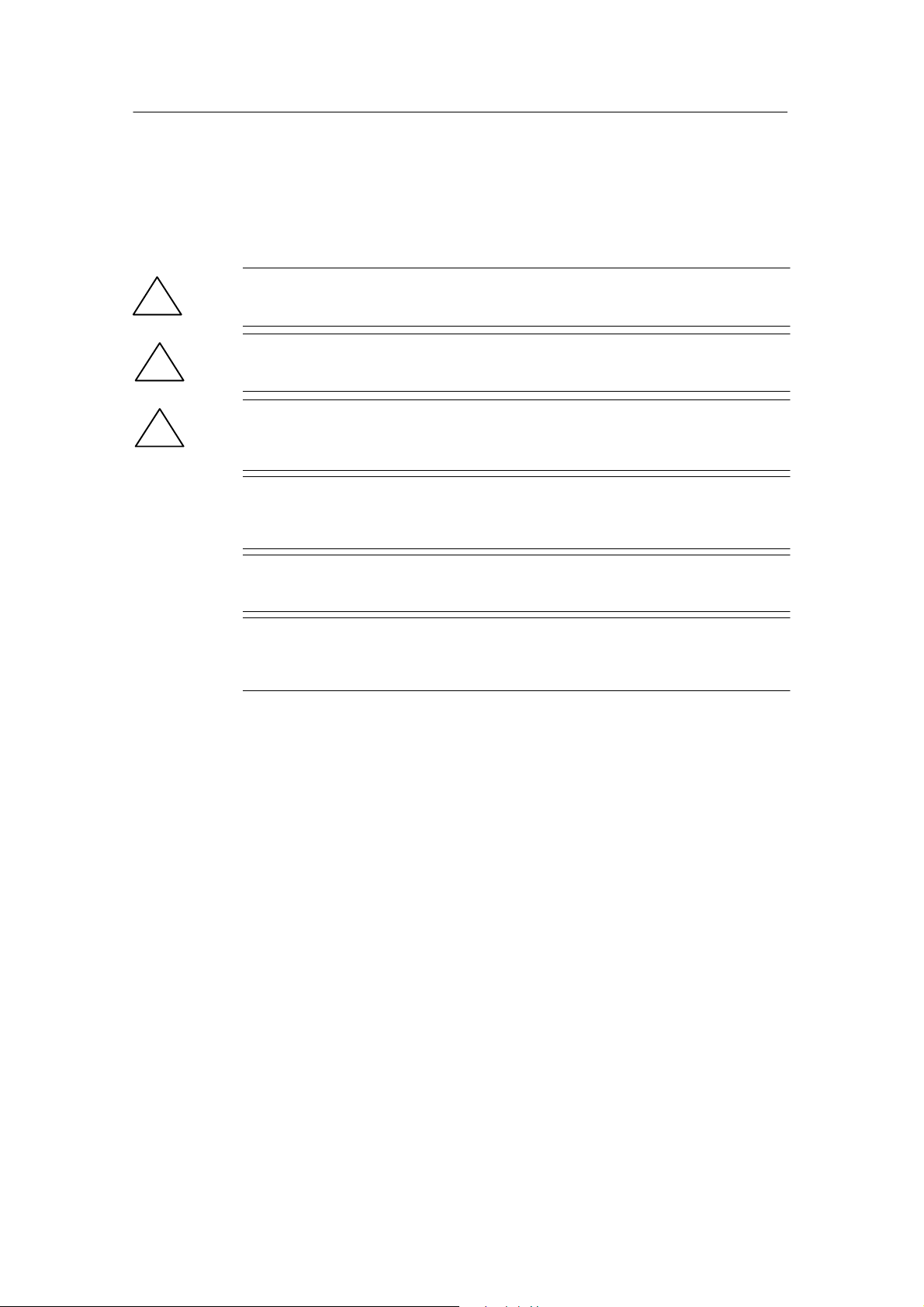

Classification o f safety--related notices

This manual contains notices which you shouldobserve toensure your own personalsafety, as well

as to protect the product and connected equipment. These notices are highlighted in the manual

by a warning triangle and are marked as follows according to the level of danger:

DANGER

!

!

!

indicates an immenently hazardous situation which, if not avoided, will result in death or serious inury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION

used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

NOTICE

indicates a potential situation which, if not avoided, may result in an undesirable result or state.

.

Copyright e Siemens AG 2006 All rights reserved

The reproduction, transmission or use of this document or

its contents is not permitted without express written authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration of a utility

model or design, are reserved.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

DEUTSCHLAND

NOTE

highlights important information on the product, using the product, or part of the documentation that is of

particular importance and that will be of benefit to the user.

Trademarks

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and software described. Since

deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data in this manual are

reviewed regularly and any necessary corrections included

in subsequent editions. Suggestions for improvement are

welcomed.

e Siemens AG 2006

Technical data subject to change.

SIMATICR,SIPARTR,SIRECR, SITRANSR registered trademarks of Siemens AG.

Third parties using for their own purposes any other names in this document which refer to trademarks might infringe upon the

rights of the trademark owners.

4

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual Contents

Contents

Page

1 Technical Description 7........................................................

1.1 Safety Notes and Scope of Delivery 7......................................................

1.2 Range of Application 8...................................................................

1.3 Design (Hardware) Software 8............................................................

1.4 Function Principle 11....................................................................

1.4.1 Standard Controller 11.......................................................................

1.4.2 Description of the Option Module 12...........................................................

1.4.3 Self-diagnostics of the CPU 19................................................................

1.4.4 Data Storage, User Program Memory 20.......................................................

1.5 Functional Description 21................................................................

1.5.1 Basic Structure 21..........................................................................

1.5.2 Input Functions 24..........................................................................

1.5.3 Output Functions 29.........................................................................

1.5.4 Serial Interface (SES) and PROFIBUS DP (Input/Output Functions) 34..............................

1.5.5 Data Sources with Message Function (Digital Outputs #) 36.......................................

1.5.6 Error Messages 38..........................................................................

1.5.7 Basic Functions (Arithmetic blocks b) 42........................................................

1.5.7.1 General 42.............................................................................

1.5.7.2 Mathematical Functions 44...............................................................

1.5.7.3 Logical Functions 46.....................................................................

1.5.7.4 Timing Functions 49.....................................................................

1.5.7.5 Comparison and Switching Functions 50....................................................

1.5.8 Complex Functions (Arithmetic blocks c, d, h) 52.................................................

1.5.8.1 General 52.............................................................................

1.5.8.2 Arithmetic Blocks c01.F to c33.F 53........................................................

1.5.8.3 Arithmetic Blocks d01.F to d04.F 66........................................................

1.5.8.4 Arithmetic Blocks h01.F to h04.F 75........................................................

1.5.9 Restart Conditions 91.......................................................................

1.5.10 Arithmetic 91...............................................................................

1.6 Technical Data 93.......................................................................

1.6.1 General Data 93............................................................................

1.6.2 Standard Controller 95.......................................................................

1.6.3 Technical Data of the Options Modules 99......................................................

2 Installation 107................................................................

2.1 Mechanical Installation 107..............................................................

2.2 Electrical Connection 107...............................................................

2.2.1 Block Diagram 111..........................................................................

2.2.2 Wiring of the standard Controller 112...........................................................

2.2.3 Wiring of the Option Modules 115..............................................................

2.2.4 Alternative Wiring for I- and U Input 123........................................................

2.2.5 Wiring of the Interface 128...................................................................

3 Operation 131.................................................................

3.1 Process Operation Mode 131............................................................

3.2 Selection Mode 131....................................................................

3.3 Configuring Mode (Parameterization and Configuring Mode) 135..............................

3.3.1 Parameterization Mode onPA (Online Parameters) 136...........................................

3.3.2 Parameterization Mode AdAP (Adaptation) 138..................................................

3.3.3 Configuring Mode oFPA (Offline Parameters) 145................................................

3.3.4 Configuring Mode CLPA (Clock Parameters) 148................................................

3.3.5 Configuring Mode hdEF (Define Hardware) 150..................................................

3.3.6 Configuring Mode FdEF (Define Functions) 152..................................................

3.3.7 Configuring Mode FCon (Switch Functions, Connection) 155.......................................

3.3.8 Configuring Mode FPoS (Position Functions) 159................................................

3.3.9 Configuring Mode APSt (All Preset, Factory Setting) 162..........................................

SIPART DR24 6DR2410

C79000-G7476-C153-03

5

Contents

3.3.10 Configuring Mode CAE4/CAE5 -- Setting UNI Module(s) 163.......................................

3.3.10.1 Measuring Range for mV (SEnS=Mv.) 164...................................................

3.3.10.2 Measuring Range for U, I (SEnS=Mv.) 164..................................................

3.3.10.3 Measuring Range for Thermocouple with Internal Reference Point (SEnS=tc.in) 165................

3.3.10.4 Measuring Range for Thermocouple with External Reference Point (SEnS=tc.EH) 165..............

3.3.10.5 Measuring Range for PT100--4--wire and PT100--3--wire Connection (SEnS=Pt.3L/PT.4L) 165.......

3.3.10.6 Measuring Range for PT100--2--wire Connection (SEnS=Pt.2L) 166.............................

3.3.10.7 Measuring Range for Resistance Transmitter (SEnS=r._ for R < 600 Ω, SEnS=r. for R< 2.8 kΩ) 166..

Manual

4 Commissioning 167...........................................................

4.1 General Information 167.................................................................

4.2 Test 167..............................................................................

5 Maintenance 169..............................................................

5.1 General Information and Handling 169....................................................

5.2 Spare Parts List 173....................................................................

6 Ordering Data 175.............................................................

7 User Examples 177............................................................

7.1 Maximum Selection (Example 1) 177......................................................

7.2 Mathematical Link (Example 2) 180.......................................................

7.3 Set Value Controller K (Example 3) 184....................................................

7.4 Two-position Controller for Heating and Cooling (Example 4) 188..............................

7.5 Switching Over the Display Levels (Process Operation Mode) (Example 5) 191.................

8 Programming Aids 195........................................................

9 List of Abbreviations 261......................................................

Index 267..........................................................................

6

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.1 Safety Notes and Scope of Delivery

1.1 Safety Notes and Scope of Delivery

1 Technical Description

!

WARNING

When operating electrical equipment, certain parts of this equipment

automatically carry dangerous voltages. Failure to observe these

instructions could therefore lead to serious injury or material damage.

Only properly trained and qualified personnel are allowed to work on this

equipment. This personnel must be fully conservant with all the

warnings and commissioning measures as described in this Manual.

The perfect and safe operation of this equipment is conditional upon

proper transport, proper storage, installation and assembly as well as on

careful operation and commissioning.

D Scope of delivery

When the controller is delivered the box also contains:

1 Controller as ordered

1 three--pin plug at 115/230 V AC or special plug at 24 V UC

2 Clamps, pluggable

1 Assembly and installation instructions German/English, order number

C79000-M7474-C38

D Basic equipment

The following variants of the SIPART DR24 are available:

Order number Power supply

6DR2410-4

6DR2410-5

24 V UC

115/230 V AC, switchable

D Option module

Signal converters have separate ordering and delivery items. For handling reasons basic

equipment and signal converters which were ordered at the same time may be delivered by

separate mail.

D Documentation

This user’s guide is available in the following languages:

English C79000-G7476-C153

German C79000-G7400-C153

SIPART DR24 6DR2410

C79000-G7476-C153-03

7

1 T echnical Description

1.2 Range of Application

Manual

D Subject to change

The manual has been compiled with great care. However, it may be necessary within the

scope of product care to make changes to the product and its operation without prior notice

which are not contained in this manual. We are not liable for any costs ensuing for this reason.

1.2 Range of Application

The SIPART DR24 is a digitally operating device in the top class range. Its program memory

contains a large number of prepared function blocks for calculating, controlling, regulating in

chemical engineering processes which the user can implement without programming knowledge

and additional tools. Mathematical functions, logical functions, comparison and switching functions, timing functions, memory functions, control functions and a program generator are stored.

All function blocks are freely connectable with each other and with different inputs and outputs

of the controller by the software.

The controller can therefore be used to solve a wide range of different problems. A large number of display elements (digital, analog displays, LEDs) and control elements allow display and

control of the processes on the front panel.

This controller contains a rugged adaptation procedure for the stored controller components

which noticeably simplifies commissioning of even critical control loops. The controller determines the optimized control parameters independently on request without the user being expected to have any prior knowledge of how the control loop may respond.

The SIPART DR24 can operate with up to 4 independent control loops. Tasks in which it is necessary to use interconnected control equipment (e.g. cascaded control, cascaded ratio controls

or override controls) can therefore be performed with one controller .

The extensive hardware equipment of the controller allows its universal application and provides

a large number of interfaces to the control loop.

The controller can be connected to master systems through a pluggable serial interface

(RS 232/RS 485 or PROFIBUS DP) or operated and monitored centrally by a Personal

Computer.

1.3 Design (Hardware) Software

The SIPART DR24 has a modular design and is therefore service friendly and easy to convert

and retrofit. Other signal converters can be installed in the generously equipped, fully functional

standard controller to expand the range of application. These modules are installed in slots at

the back of the closed device (Figure 1--2, page 10).

The standard controller consists of

-- the front module with the control and display elements

-- the main board with CPU and terminal strips

-- the plastic housing with an interface board

-- the power supply unit.

8

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1.3 Design (Hardware) Software

1 Technical Description

The electrical connections between the modules are made by an interface board screwed into

the housing. The main board is pushed into rear slot 1 and locked. It holds a 10--pin and a

14--pin terminal strip to which all inputs and outputs of the standard controller are connected.

Five other slots can be equipped with option modules if the number of terminals to the process

available in the standard controller are not sufficient for the planned task.

The basic device always has three permanently installed analog inputs (AE) with electronic potential isolation which can be wired alternatively with standardized voltage signals (0/0.2 to 1 V

or 0/2 to 10 V) or current signals (0/4 to 20 mA). There are also four digital inputs (BE, 0/24 V)

and eight digital outputs (BA, 0/24 V, 50 mA) which can be used for different functions depending on the configuration.

The SIPART DR24 also has three analog outputs which can all supply a current signal from 0 to

20 mA or 4 to 20 mA and be assigned to different variables.

A short--circuit--proof L+--output (DC 24 V , 100 mA) is available for supplying transmitters.

The power supply unit is located in a fully enclosed metal casing and is screwed tightly to the

plastic housing of the controller.

Many applications can be implemented with the three permanently available analog inputs of

the standard controller alone. Two additional input modules can be inserted in slots 2 and 3 for

complex jobs or for the connection of other input signals. These input modules are available in

addition to for processing normalized current and voltage signals for the direct connection of

resistance thermometers Pt100 and all common thermocouples and resistance sensors or potentiometers. In addition a module with three analog inputs (equipment as in the standard controller) can be inserted in slots 5 and 6. This increases the number of inputs to a total of 11.

Slot 4 serves to accommodate an interface module (SES) with V.28 point-to-point output or

SIPART bus interface for serial communication with a master system. A PROFIBUS interface

module can be equipped optionally here.

The slots 5 and 6 can accommodate signal converters of different functions and can be

equipped optionally with modules for expanding digital inputs or digital outputs.

Following assemblies are possible:

2 relays

4 digital outputs/2 digital inputs

5 digital inputs

3 analog outputs/3 digital inputs

1 analog output with digital fault output (y

function) with remote supply

hold

3 analog inputs

SIPART DR24 6DR2410

C79000-G7476-C153-03

9

1 T echnical Description

1.3 Design (Hardware) Software

Manual

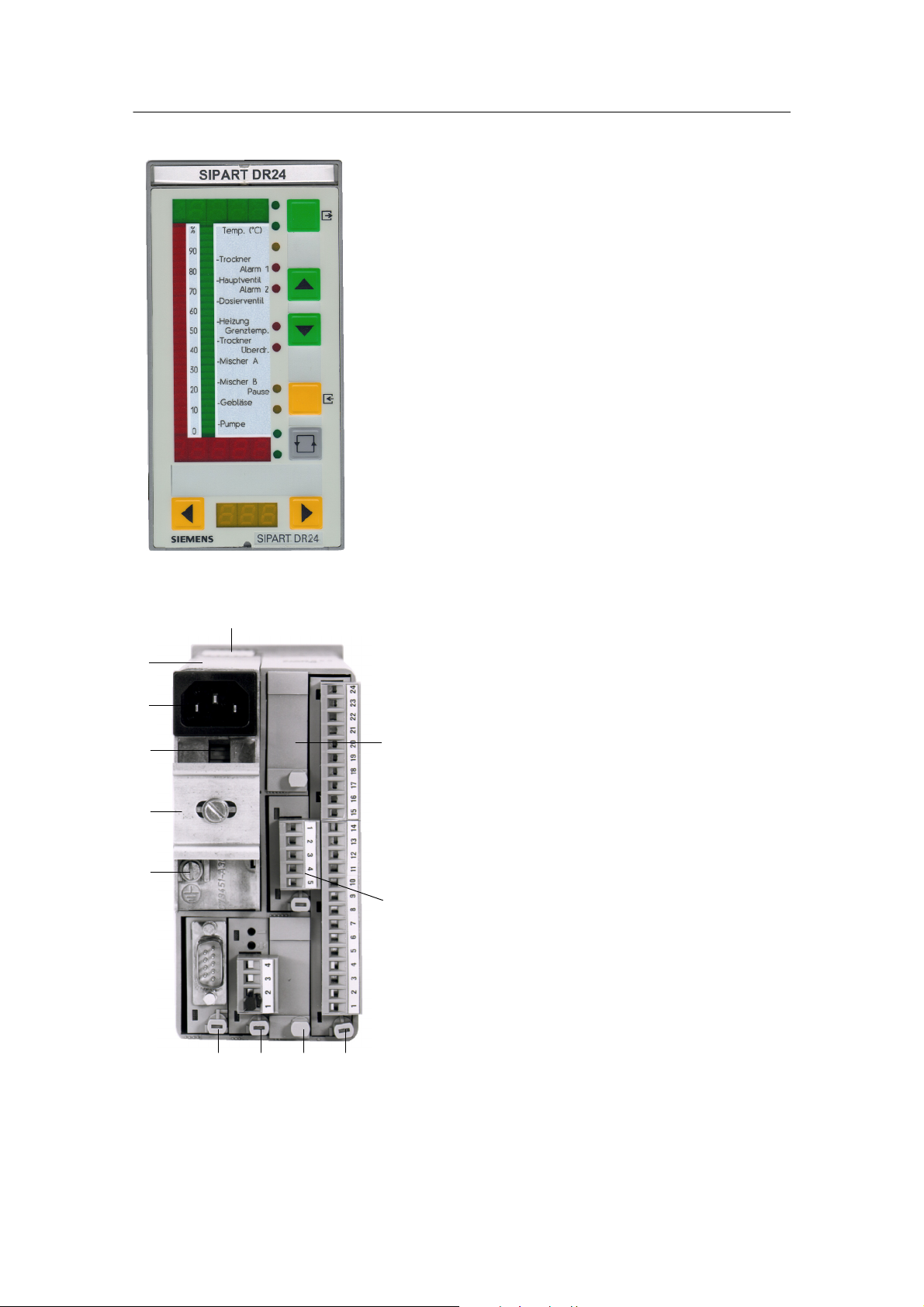

Figure 1--1 Front view of the SIPART DR24

1

12

11

10

9

8

2

3

Legend:

2. PE conductor contact spring

3. Slot 6

4. Slot 5

5. Slot 1 (main board)

6. Slot 2

7. Slot 3

8. Slot 4 (SES: RS 232/

RS 485, Profibus DP)

9. Grounding screw

10. DIN rail (DIN rail delivered with

interface relays)

11. Selection switch Mains voltage

12. Mains plug

13. Power supply unit

7 6 5 4

Figure 1--2 Rear view of the SIPART DR24

10

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.4 Function Principle

1.4.1 Standard Controller

1.4 Function Principle

1.4.1 Standard Controller

The standard controller consists of three function blocks:

-- Power supply unit

-- Front module

-- Main board

Power supply unit

Primary clocked power supply unit with high efficiency for AC 115/230 V (switchable) or for

UC 24 V. It generates the secondary internal supply voltages +24 V and +5 V from the power

supply. The metal body is mounted on PE conductors (protection class I). The power supply

and internal supply voltages are isolated from each other by safe separation by a protective

shield. The internal supply voltages are functional extra--low voltages due to overvoltage cutoff

in the event of an error. Since no further voltages are generated in the controller, these statements apply for all field signal lines (used standards, see chapter 1.6, page 93). A total of

450 mA are available for the outputs L+, AA and BA due to the design for a high power output.

Front module

The front module contains the control and display elements and the appropriate trigger components for the displays.

All display elements are designed in LED technology which provides a longer service life and

higher light density as well as a good viewing angle. The control elements are short--stroke

switches with a tangible ”pressure” and high return force. They are actuated by flexible actuators through the cover foil which are designed so that the foil is not subjected to any excess

stress.

The SIPART DR24 has a great number of functional variants. The configured buttons and display elements are activated depending on the function in the front module.

There is a foil behind the front foil which can be labeled to suit requirements. In this way the

display and control elements can be assigned to the functions.

Main board

The main board contains the field signal conditioning of the standard controller, the CPU

(Central Processing Unit) and the connections (through the interface board) to the module slots.

The field signals are fed through protective circuits for external static or dynamic overvoltages

and then adapted to the signal levels of the CPU by the appropriate circuits. This adaptation is

performed for the analog inputs, the analog outputs and the digital outputs by modern thick--film

circuits.

The microcontroller used has integrated AD- and DA converters and operates with 32k battery-backed RAM. The user--specific configuration is stored in an exchangeable user program

memory with a serial 4k EEPROM. This makes it possible to plug the user program memory in

the new controller to be installed when servicing. This then does not need to be re--configured.

SIPART DR24 6DR2410

C79000-G7476-C153-03

11

1 T echnical Description

1.4 Function Principle

1.4.2 Description of the Option Module

Manual

The whole CPU is designed in C--MOS technology. The program of the SIPART DR24 operates

with a variable cycle time which depends on the scope of the program (see chapter 1.5.1,

page 21).

A process image is generated at the start of every routine. The analog and digital inputs and

actuation of the front buttons is included and the process variables received from the serial interface are accepted. All calculations are performed with these input signals according to the

stored functions. Then the data are output to the display elements, the analog outputs and the

digital outputs as well as storage of the calculated variables on standby for the serial interface

transmitter. The interface traffic runs in interrupt mode.

A large number of arithmetic and function blocks is stored in the set value memory of the

SIPART DR24. The user programs the controller himself by selecting, connecting and timing the

desired functions by configuration. The entire function of the controller results from the combination of the individual function blocks (basic functions, complex functions) and the corresponding input and output circuits. Programming knowledge is not necessary for the settings.

All settings are made without an additional programming device at the operating panel of the

SIPART DR24 or via the serial interface. The job--specific program written in this way is saved

in the non--volatile user program memory.

There are 32 basic function blocks b**.F and a total of 59 complex functions c**.F, d0*.F, h0*.F

which can be used with varying frequency.

No function is stored when the controllers are delivered (factory setting, all preset) The displays

are not connected. (Flashing message APSt MEM appears after switching on.)

1.4.2 Description of the Option Module

The following option modules are described in this chapter

6DR2800--8A 3 AE module

6DR2800-8J I/U module

6DR2800-8R R module

6DR2800-8V UNI module

6DR2805-8A Reference point

6DR2805-8J Measuring range plug

6DR2801-8D Module with 2 BA (relays)

6DR2801-8E Module 2 BE and 4 BA

6DR2801-8C Module with 5 BE

6DR2802-8A Analog output module with y-hold function

6DR2802-8B Module with 3AA and 3BE

6DR2803-8P Serial interface PROFIBUS-DP

6DR2803-8C Serial interface RS 232/RS 485

6DR2804-8A 4 BA relays

6DR2804-8B 2 BA relays

12

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1.4.2 Description of the Option Module

1 Technical Description

1.4 Function Principle

6DR2800-8A 3 AE module

D Inputs for current and voltage

To expand the analog inputs.

Description of the module and technical data, see chapter 1.6.2, page 95 (Inputs standard controller).

6DR2800-8J I/U module

D Input variables current 0/4 to 20 mA or voltage 0/0.2 to 1 V or 0/2 to 10 V

The input amplifier of the module is designed as a differentiating amplifier with jumperable gain

for 0 to 1 V or 0 to 10 V input signal. For current input signals the 49.9 W 0.1 % impedance is

switched on by plug--in bridges on the module. The start value 0 mA and 4 mA or 0 V or 0.2 V

(2 V) is defined by configuration in the standard controller. The differentiating amplifier is designed for common mode voltages up to 10 V and has a high common mode suppression.

As a result it is possible to connect the current inputs in series as for electrical isolation when

they have common ground. At voltage inputs this circuit technique makes it possible to suppress the voltage dips on the ground rail by two--pole wiring on non floating voltage supplies.

We refer to an electronic potential isolation.

6DR2800-8R R module

D Input for resistance or current transmitter

Potentiometers with rated values of 80 Ω to 1200 Ω can be connected as resistance

transmitters. A constant current of Is = 5 mA is fed to the potentiometer wiper. The wiper

resistance is therefore not included in the measurement. Resistances are switched parallel to

the potentiometer by a slide switch on the module and a rough range selection made. Range

start and end are set with the two adjusting pots on the back of the module.

This fine adjustment can be made via the displays on the front module (with the appropriate

configuring). For adjustment with a remote measuring device, the analog output can be assigned to the appropriate input.

The external wiring must be changed for resistance transmitters which cannot withstand the

5 mA wiper current or which have a rated resistance > 1 kΩ. The constant current is then not

fed through the wiper but through the whole resistance network of the potentiometer. A voltage

divider measurement is now made through the wiper. Coarse adjustment is made by a remote

parallel resistor to the resistance transmitter.

This module can also be used as a current input with adjustable range start and end. The load

is 49.9 Ω and is referred to ground.

SIPART DR24 6DR2410

C79000-G7476-C153-03

13

1 T echnical Description

1.4 Function Principle

1.4.2 Description of the Option Module

Manual

6DR2800-8V UNI module

D Direct connection of thermocouple or Pt100 sensors, resistance or mV transmitters

Measured value sensors such as thermocouples (TC), resistance thermometers Pt100 (RTD),

resistance transmitters (R) or voltage transmitters in the mV range can be connected directly.

The measuring variable is selected by configuring the controller in the HdeF level (AE4/AE5);

the range and the other parameters are set in the CAE4/CAE5 menu. The sensor--specific characteristics (linearization) for thermocouples and Pt100 resistance thermometers are stored in

the contoller’s program memory and are automatically taken into account. No settings need to

be made on the module itself.

The signal lines are connected via a plug terminal block with screw terminals. When using thermocouples with internal reference point, this terminal block must be replaced by the terminal

6DR2805-8A. With the measuring range plug 6DR2805--8J in place of the terminal block, the

range of the direct input (0/20...100 mV) can be extended to 0/2...10 V or 0/4...20 mA.

The UNI module operates with an AD converter with 18 bit resolution. The measuring inputs

and ground of the standard controller are electrically isolated with a permissible common mode

voltage of 50 V UC.

6DR2805-8A Reference point

D Terminal with internal reference point for thermocouples

This terminal is used in connection with the UNI module for temperature measuring with thermocouples at an internal reference point. It consists of a temperature sensor which is pre--assembled on a terminal block and plated to avoid mechanical damage.

6DR2805-8J Measuring range plug

D Measuringrangeplugforcurrent0/4to20mAorvoltage0/2to10V

The measuring range plug is used in connection with the UNI module to measure current or

voltage. The input variable is reduced to 0/20 to 100 mV by a voltage divider or shunt resistors

in the measuring range plug.

Loop resistances with 250 Ω or 50 Ω are available optionally at 2 different terminals for 0/4 to

20 mA signals.

The electrical isolation of the UNI module is retained even when the measuring range plug is

used.

6DR2801-8D 2 BA relays

D Digital output module with 2 relay contacts

To convert 2 digital outputs to relay contacts up to 35 V UC.

This module is equipped with 2 relays whose switching contacts have potential free outputs.

The RC combinations of the spark quenching elements are respectively parallel to the rest and

working contacts.

14

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1.4.2 Description of the Option Module

1 Technical Description

1.4 Function Principle

In AC consumers with low power the current flowing through the capacitor of the spark quenching element when the contact is open may interfere (e.g. the hold current of some switching elements is not dropped below). In this case the capacitors (1 μF) must be removed and replaced

with low capacitance capacitors.

The 68 V suppressor diodes parallel to the capacitors act additionally to reduce the induced

voltage.

!

WARNING

The relays used on the digital output module are designed for a

maximum rating up to UC 35 V. The same applies for the air and creep

lines on the circuit board. Higher voltages may therefore only be

switched through appropriately approved series connected circuit

elements under observance of the technical data and the pertinent

safety regulations.

6DR2801-8E Module 2 BE and 4 BA

D Digital signal module with 2 digital inputs and 4 digital outputs

The module serves to extend the digital inputs and digital outputs already existing in the standard controller.

The inputs are designed for the 24 V logic and are non--floating. The functions are assigned to

the inputs and outputs by configuration of the controller.

The digital outputs are short--circuit--proof and can drive commercially available relays or the

interface relays 6DR2804--8A/8B directly.

6DR2801-8C 5 BE

D Digital input module with 5 digital inputs

The module serves to extend the digital inputs already existing in the standard controller.

The inputs are designed for the 24 V logic and are non--floating. The function is assigned to the

input by configuration of the controller.

6DR2802-8A Analog output module with y-hold function

For auxiliary control device function when servicing and for extending the analog outputs AA1 to

AA3 existing in the standard controller.

Can be used in slot 5/6, oP5/oP6 = 1 AA must be set in the hdEF structure mode

Start value of the outputs can be set with AA4/AA7 = 0/4 mA in hdEF

SIPART DR24 6DR2410

C79000-G7476-C153-03

15

1 T echnical Description

1.4 Function Principle

1.4.2 Description of the Option Module

Manual

The y

module contains a microprocessor which maintains serial data communication with the

hold

processor on the main board through the Rxd/Txd lines. The processor feeds the U/I converter

and the CPU fault message output St

through its analog output. The module can be externally

supplied through an auxiliary voltage input which is OR--linked with the controller power supply.

The analog output of the module is freely available.

-y

function

hold

If data communication to the y

processor is interrupted, the analog output receives its last

hold

value. When data communication is restored, the slave processor reads the current variable

first. The output current is maintained if:

- the self--diagnostics of the CPU (see chapter 1.4.3, page 19) respond.

- the power supply of the SIPART fails and the y

- all modules except the power supply unit are removed (if the y

module is powered externally.

hold

module is not powered

hold

externally).

-they

module is removed (Attention: electrostatically sensitive module! Observe the

hold

safety precautions!), if it is powered externally (error message on the front module

oP. *.6 Err/oP.*.5, see chapter 1.4.3, page 19).

This makes it possible to carry out all service work up to changing the controller, e.g. in the

case of a controller (arithmetic block h0*.F), and to still maintain the controller manipulated

variable.

Handling during module replacement, see chapter 5, page 169.

Fault message output

-St

This digital output is always high when there is no error and becomes low in the event of an

error. It responds when:

- the self--diagnostics of the CPU (see chapter 1.4.3, page 19) respond.

- the controller power supply fails,

-they

module is removed,

hold

- the main board is removed.

6DR2802-8B Module with 3AA and 3BE

To extend the analog outputs (0/4 to 20 mA) and the digital inputs

Can be inserted in slot 5: AA4, AA5, AA6 BE5, BE6, BE7

and in slot 6: AA7, AA8, AA9 BE10, BE11, BE12

6DR2803-8P Interface PROFIBUS-DP

The module 6DR2803-8P is a PROFIBUS--DP interface module with RS 485 driver and electrical isolation to the controller. It operates as an intelligent converter module and adapts the private SIPART- to the open PROFIBUS-DP protocol.

This optional card can be inserted in all SIPART--DR controllers in slot 4. The following settings

must be made with the appropriate configurations for the serial interface:

16

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1.4.2 Description of the Option Module

1 Technical Description

1.4 Function Principle

-- Interface on

-- Even parity

-- LRC without

-- Baud rate 9600

-- Parameters/process values writable (as desired)

-- Station number according to selection 0 to 125

Make sure that the station number is not assigned double on the bus. The PROFIBUS module

serves to connect the SIPART controllers to a master system for operating and monitoring. In

addition the parameters and configuring switches of the controller can be read and written. Up

to 32 process variables can be selected and read out cyclically by configuration of the PROFIBUS module.

The process data are read out of the controller in a polling procedure with an update time

< 300 ms. If the master writes process data to the slave, these become active after a maximum

1 controller cycle.

A technical description including the controller base file (*.GSD) is available for creating a master--slave linking software for interpreting the identifications and useful data from and to the

SIPART controller.

The discription and the GSD file can be downloaded from the INTERNET.

www.siemens.com/sipartdr

The programs SIPART S5 DP and S7 DP are offered for certain hardware configurations.

Controller base file and type file, general

The controller base file (GSD file) is necessary for connecting the controllers SIPART DR to any

remote systems.

The type file is required at present when connecting to a CPU of the SIMATIC S5/S7.

The DP master connection is parameterized with these files.

6DR2803-8C Serial interface RS 232/RS 485

D Serial interface for RS 232 or RS 485 with electrical isolation

Canbeinsertedinslot4.

For connecting the controller SIPART DR24 to a master system for operating and monitoring.

All process variables can be sent, the external setpoint, tracking variable, operating modes, parameters and configurations sent and received.

The interface traffic can take place as follows:

RS 232

SIPART Bus

RS 485

SIPART DR24 6DR2410

C79000-G7476-C153-03

As point-to-point connection

The SIPART bus driver is no longer available.

Therefore, please realize multi--couplings via RS 485 or PROFIBUS DP.

As a serial data bus with up to 32 users.

17

1 T echnical Description

1.4 Function Principle

1.4.2 Description of the Option Module

Manual

The interface module 6DR2803--8C offers electrical isolation between Rxd/Txd and the controller. Switching can be performed between RS 232, SIPART bus and RS 485 with a plug--in

bridge.

A detailed technical description of the telegram traffic is available for creating an interface software.

RS 485+150R

RS 485

8

3

Rxd/

Txd A

Rxd/

Txd B

Txd

24 V

0V

+7.5 V

---7.5 V

+7.5V

+1

---7.5 V

RS 232

SIPART

bus

24 V

0V

Txd

2

Txd

7

Rxd

+7.5 V

+7.5 V

+7.5 V

Rxd

-1

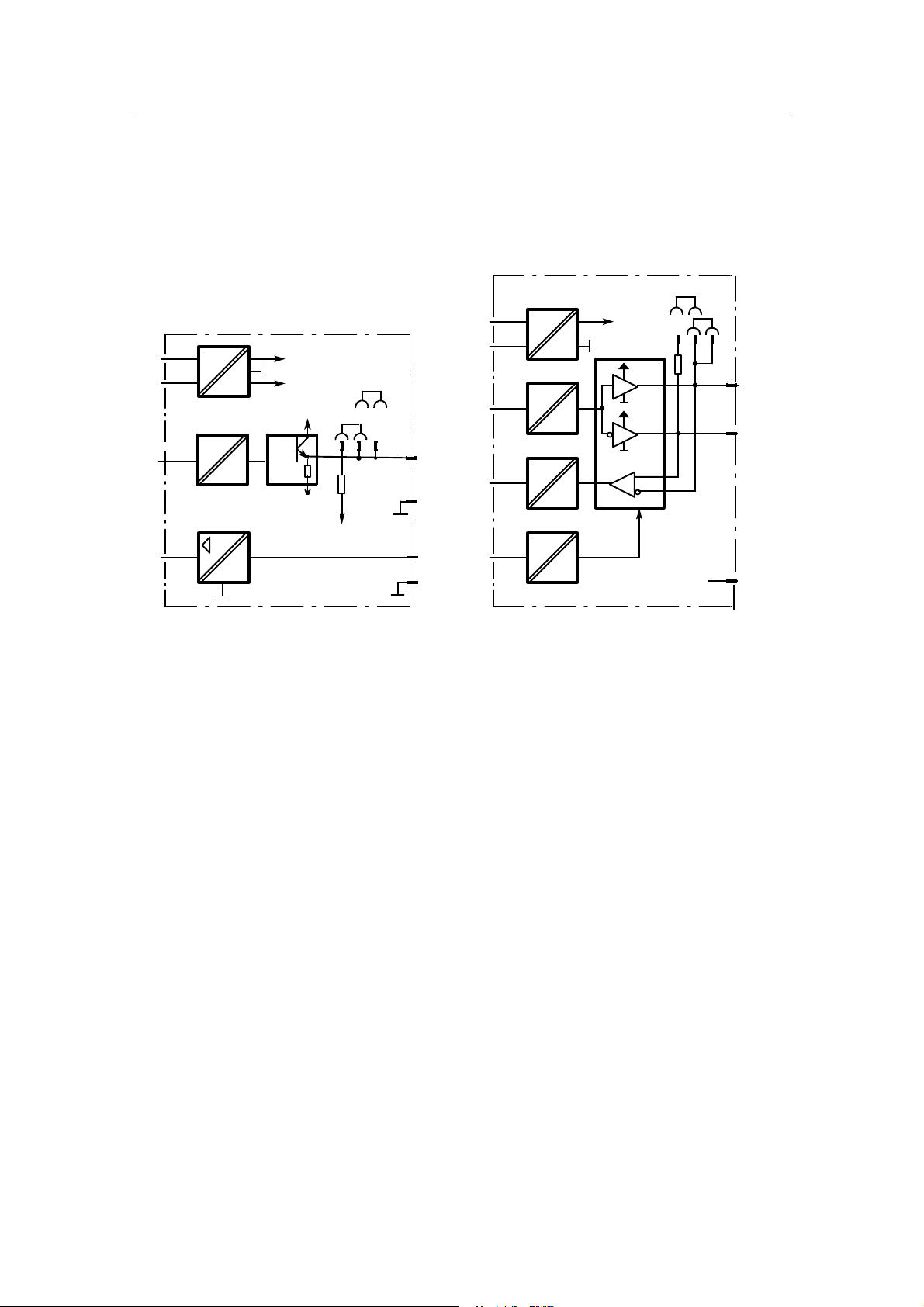

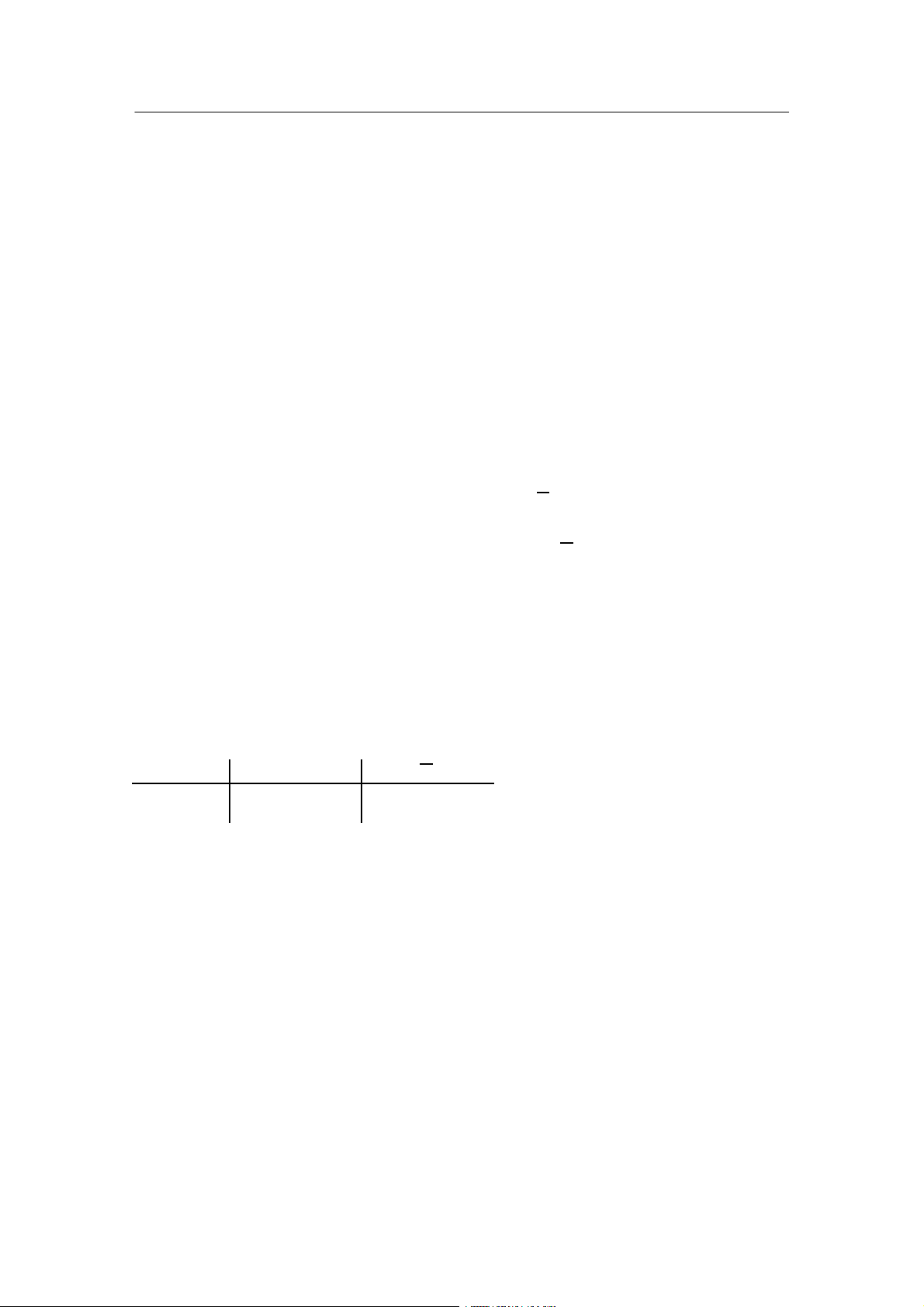

Figure 1--3 Block diagram of serial interface for

RS 232/SIPART BUS

-7.5 V

Other connections: NC

3

Rxd

8

Rxd/

Txd

NC2, 7

Other connections: NC

Figure 1--4 Block diagram of serial interface for

RS 485

6DR2804-8A 4 BA relays

6DR2804-8B 2 BA relays

D Interface relay module with 2 or 4 relays

To convert 2 or 4 digital outputs to relay contacts up to 230 V UC.

The module can be snapped onto a mounting rail on the back of the controller. The mounting

rail is delivered with the interface relay module.

One or two relay modules with 2 relays each are installed depending on the version. Every relay

has a switching contact with spark quenching in both switching branches. In AC consumers with

a very low power, it is possible that the current flowing (e.g. hold current in contactors) through

the spark quenching capacitor (33nF) when the contact is open interferes. In this case they

should be replaced by capacitors of the same construction type, voltage strength and lower

value.

The switching contact is fed to the plug terminals with 3 poles so that rest and working circuits

can be switched. The relays can be controlled directly from the controller’s digital outputs by

external wiring.

18

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.4 Function Principle

1.4.3 Self-diagnostics of the CPU

!

WARNING

The relays used on the interface relay module are designed for a

maximum rating of AC 250 V in overvoltage class III and

contamination factor 2 according to DIN EN 61010 Part 1.

The same applies for the air and creep lines on the circuit board.

Resonance increases up to twice the rated operating voltage may

occur when phase shift motors are controlled. These voltages are

available at the open relay contact. Therefore such motors may only

be controlled under observance of the technical data and the

pertinent safety conditions via approved switching elements.

1.4.3 Self-diagnostics of the CPU

The CPU runs safety diagnostics routines which run after only a reset or cyclically. The CPU is

familiar with two different types of reset.

- Power on reset

Power on reset always takes place when the 5 V supply drops below 4.45 V, i.e. the power

supply is interrupted for longer than specified in the technical data.

All parameters and configurations are reloaded from the user program memory into the

RAM. At batt = YES (factory setting) the current process variables and status signals are

loaded from the battery- -backed RAM. At batt = no the startup conditions are fixed (see

chapter 1.5.9, page 91).

At dPon = YES in hdEF the digital displays flash as identification after a power--on reset,

acknowledgement is given by the shift key (tA5).

Flashing is suppressed with dPon = no.

The fault message source nPon is set to low at power on reset. (See chapter 1.5.5,

page 36).

- Watch dog reset

When a watch-dog-reset occurs the parameters and configurations from the user program

memory are re-loaded into the RAM. The current process variables and the status signals

are read out of the RAM for further processing.

There are no flashing signals on the front module.

CPU--tESt appears in the digital displays dd1 and dd2 for a maximum 5 s after every reset.

Every error detected by the self--diagnostics leads to a flashing error message on the digital

displays dd1 and dd2 with defined states of the analog and digital outputs. The fault message

output St

of the y

module becomes low. The reactions listed in the table are only possible of

hold

course (since this is a self- -test) if the errors occur in such a way that the appropriate outputs or

the front module can still be controlled properly or the outputs themselves are still functioning.

SIPART DR24 6DR2410

C79000-G7476-C153-03

19

1 T echnical Description

1.4 Function Principle

1.4.4 Data Storage, User Program Memory

Manual

There are other error messages for the input range which suggest defective configurations

within this area (see chapter 1.5.6, page 38).

Error messages are also output in the adaptation (see chapter 3.3.2, page 138).

All error messages are shown by flashing digital displays.

1.4.4 Data Storage, User Program Memory

All data are written in the RAM first and then transfered to the user program memory

(EEPROM) when returning to the process operation mode (manually or via the SES).

When exchanging the main board, the user memory from the old module can be inserted into

the new module.

Writing time

The writing time after leaving the parameterization and configuring modes is up to 30 s. Then

the data are stored in a non--volatile memory.

20

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.5 Functional Description

1.5.1 Basic Structure

1.5 Functional Description

1.5.1 Basic Structure

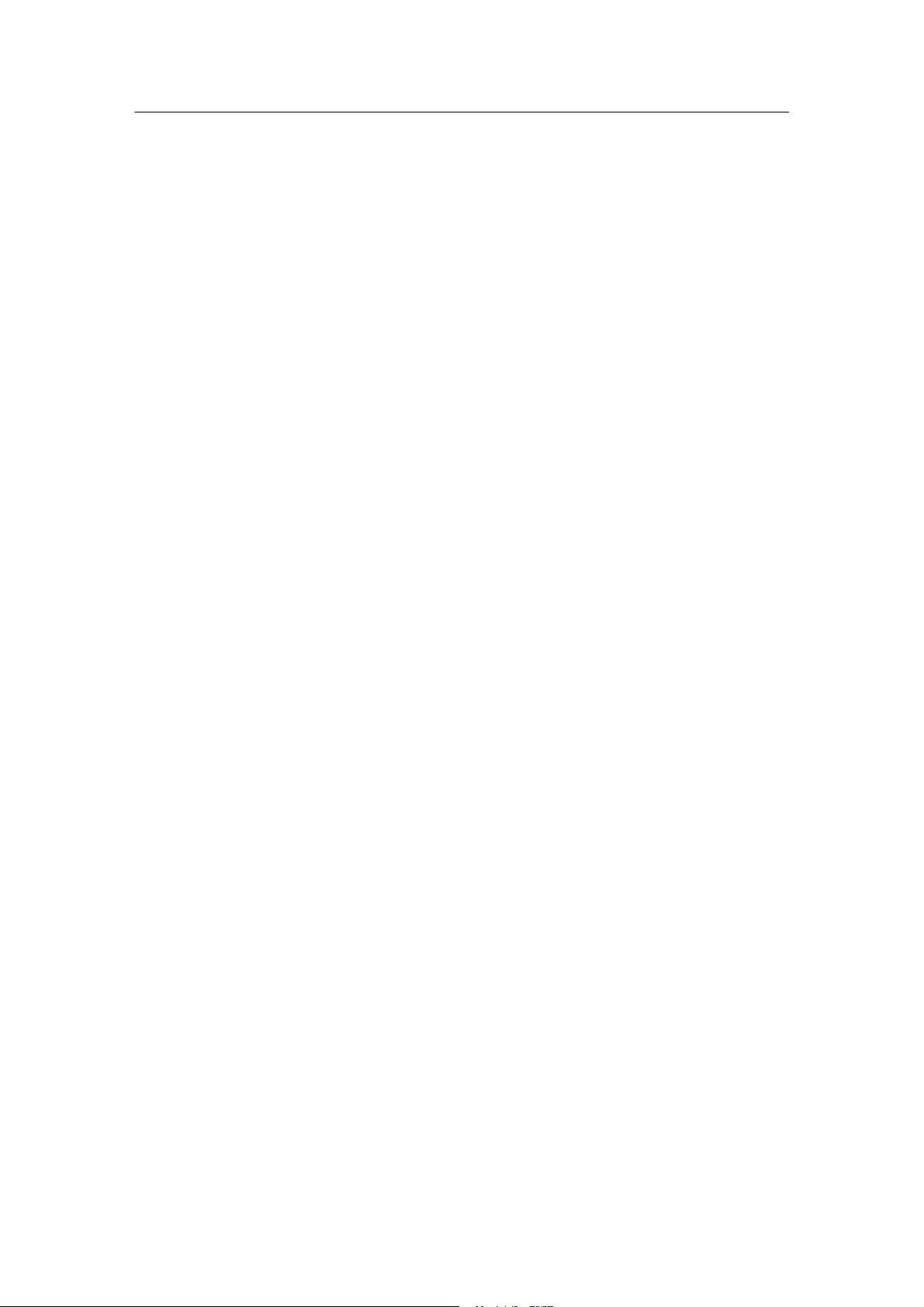

The SIPART DR24 is a freely programmable regulation, arithmetic and control unit. It consists

of the input section, the functional section and the output section. The functional structure is

illustrated in figure 1--5, page 22. The table on page 23 gives an overview of the functions which

canbeused.

The input section contains the input functions for the 11 analog inputs, the 14 digital inputs, the

7 keys and the input part of the serial interface. (Not all analog and digital inputs can be used at

thesametime!)

In configuring mode hdEF the function of the slots 5 and 6 and thus the number of BE, BA, AA

and AE functions are defined. The input functions convert the process signals (analog and digital inputs) and the manual inputs (keys) into freely connectable data sources.

The output section contains the output functions for the 9 analog outputs, the 16 digital outputs,

the 5 displays, the 13 LEDs and the output part of the serial interface.

The output functions convert the freely connectable data sinks into process signals (analog and

digital outputs) and visual outputs (displays, LEDs).

The function section is between the input and output sections. It contains 109 arithmetic blocks,

in which 32 basic functions can be freely selected and 59 complex functions which can be used

with varying frequency. In addition adjustable parameters and a number of constants and fault

messages are available for free connection. The freely connectable parameters can be used for

the standard functions which have no parameters of their own whereas the complex functions

and some of the input and output functions have private (permanently assigned) parameters.

The basic functions have a standardized input/output format, i.e. they have a maximum 3 data

sinks (inputs) and 1 data source (output).

The complex functions and the input and output functions have different input/output formats,

i.e. the number of data sinks and sources depends on the function depth.

The parameters, constants and fault messages are data sources.

By configuring on the front module, the necessary functions are selected and defined (configuring mode FdEF and hdEF), wired (configuring mode FCon) and timed in the processing (configuring mode FPoS).

Wiring is absolutely free, i.e. any data source can be connected with any data sink. The operating effort is minimized by fading out the data sources and sinks of undefined function blocks

and assigning digital data sinks to digital data sources or analog data sinks to analog data

sources. In addition the data sinks not absolutely necessary for a function can be defaulted with

constants (example: the 3rd input of an adder is defaulted with 0.000).

SIPART DR24 6DR2410

C79000-G7476-C153-03

21

1 T echnical Description

1.5 Functional Description

1.5.1 Basic Structure

Manual

The connectable parameters and most private parameters can be set during operation in the

parameterization mode (online parameters). The other part of the private parameters is set offline in the configuring mode oFPA and CLP A.

The parameter and configuration data are stored in a non-volatile plug-in user program memory

with an EEPROM.

The cycle time in online operation depends on the scope of the user program and is a minimum

60 ms. About 2 ms are necessary on average per basic function, and about 5 ms per complex

function. The cycle time in offline operation is 100 ms.

Addition of the individual times gives the total cycle time t

which changes in 10 ms steps.

c

The current cycle time can be displayed during the lamp test (see chapter 5.1, page 169) by

additionally pressing tA1. dd3 shows the cycle time in ms.

On average you can reckon on 80 to 120 ms cycle time.

User program memory

Analog inputs

AE1...11

32 basic functions

can be used in 109 arithmetic blocks

Digital inputs

bE1...14

b**.F

59 complex functions with

private parameters can be

used in blocks

Keys

ta1...7

c**.F

d0*.F

h0*.F

with varying frequency

Connectable parameters

Write SES

Analog inputs

SA(E)1...16

Constants

Fault messages

Digital inputs

Sb(E)1...16

Operating modes: Process operation

Parameterization (Online)

AdAP Adaptation

Configuring (Offline)

oFPA Offline parameters

CAE4 Parameterize UNI-module for AE4

CAE5 Parameterize UNI-module for AE5

CLPA Clock parameters

hdEF Define hardware

FdEF Define functions

FCon Wire functions

FPoS Position functions

APSt Load factory setting (all preset)

Analog outputs

AA1...9

Digital outputs

bA1...16

Displays dA1, dA2,

dd1 to dd3

LEDs

L01...13

Read SES

Analog outputs

SAA1...16

Digital outputs

Sb(A)1...16

Figure 1--5 Block diagram of the SIPART DR24

22

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

Functional overview SIPART DR24

1 Technical Description

1.5 Functional Description

1.5.1 Basic Structure

b = Basic function, blocks b

d = complex function, blocks d

Mathematical functions Func tion

D

AbS

Add

AMPL

CPt

div

FUL

FUP

LG

LinE

LN

MUlt

Pot

root

SUb

Comparison and switching functions Funct ion

D

AMPL

ASo

bSo

Cnt

CoMP

dEbA

LiMi

MASE

MiSE

MUP

Absolute value

Adder

Differential amplifier

P/T correction computer

Divider

Function transmitter (linear)

Function transmitter (parabola)

Decadic logarithmer

Linear equation

Natural logarithmer

Multiplier

Exponential function

Rooter

Subtractor

Differential amplifier

Analog switch over

Digital switch over

Demultiplexer

Comparator with hysteresis

Response threshold (dead band)

Limiter

Maximum selection

Minimum selection

Measuring point switch over

(analog)

c = complex function, blocks c

h = complex function, blocks h

Logical functions Fun ction

block

b

b

b

c

b

c

c

b

b

b

b

b

b

b

block

b

b

b

d

b

b

b

b

b

d

D

And

CoUn

dFF

Eor

nAnd

nor

or

SPR

tFF

tiME

Timer functions Func tion

D

AFi

Ain

bin

diF

dti

FiLt

PUM

tiME

AND

Counter

D--flip--flop

EXOR

NAND

NOR

OR

Split range

T--flip--flop

Timer (monoflop)

Adaptive filter

Integrator with analog input

Integrator with digital input

Differentiator

Dead time element

Filter (low pass)

Pulse width modulator

Timer (monoflop)

block

b

b

b

b

b

b

b

c

b

b

block

c

c

c

b

c

b

c

b

Memory functions Func tion

D

Ain

AMEM

bin

dFF

MAME

MiME

tFF

Program transmitter Func tion

D

CLoc Clock d

SIPART DR24 6DR2410

C79000-G7476-C153-03

Integrator with analog input

Analog memory

Integrator with digital input

D--flip--flop

Maximum memory (drag pointer)

Minimum memory (drag pointer)

T--flip--flop

block

c

b

c

b

b

b

b

block

Control functions Function

D

Ccn

CSE

CSi

K controller

S controller external feed

back

S controller internal feedback

block

h

h

h

23

1 T echnical Description

1.5 Functional Description

1.5.2 Input Functions

Manual

1.5.2 Input Functions

The following input functions are dealt with in detail in this chapter:

Analog inputs AE1 to AE11

Digital inputs BE1 to BE14

Data sinks bLS, bLPS, bLb

Keys tA1totA7

Analog inputs AE1 to AE11

The analog inputs AE1 to AE3 are located on the basic board and can be jumpered there.

Ranges: 1 V, 10 V, 20 mA. (The zero point can be selected via configuring mode hdEF (AE1 to

AE11).) The inputs AE4, AE5 are realized with a module card in slots 2 and 3. The inputs AE6

to AE8 are realized with a module in slot 6. The inputs AE9 to AE11 are realized with a module

in slot 5. Ranges same as AE1 to AE3.

The A/D converter inputs have a signal range from --5 % to +105 % or as an absolute value

--0.05 bis +1.05. If the evaluation of the inputs is to be changed you can switch the basic function “Multiply” (MULt) for weakening or strengthening the basic function and the basic function

“Linear equation” (LinE) to hide a range by configuring (see chapter 1.5.6, page 38).

The analog inputs AE* (*= 1 to 11) have a mains frequency suppression (configuring level

hdEF)

AEFr 50or60Hz

and the transmitter monitor AE1

to AE11 as a data source with a threshold at --3 % and

103%. The thresholds have a hysteresis of 1 %. The data source can be switched in FCon. The

fault message nAE

is set to low when the values exceed or drop below the limit. This signal

is also freely switchable in FCon.

24

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.5 Functional Description

1.5.2 Input Functions

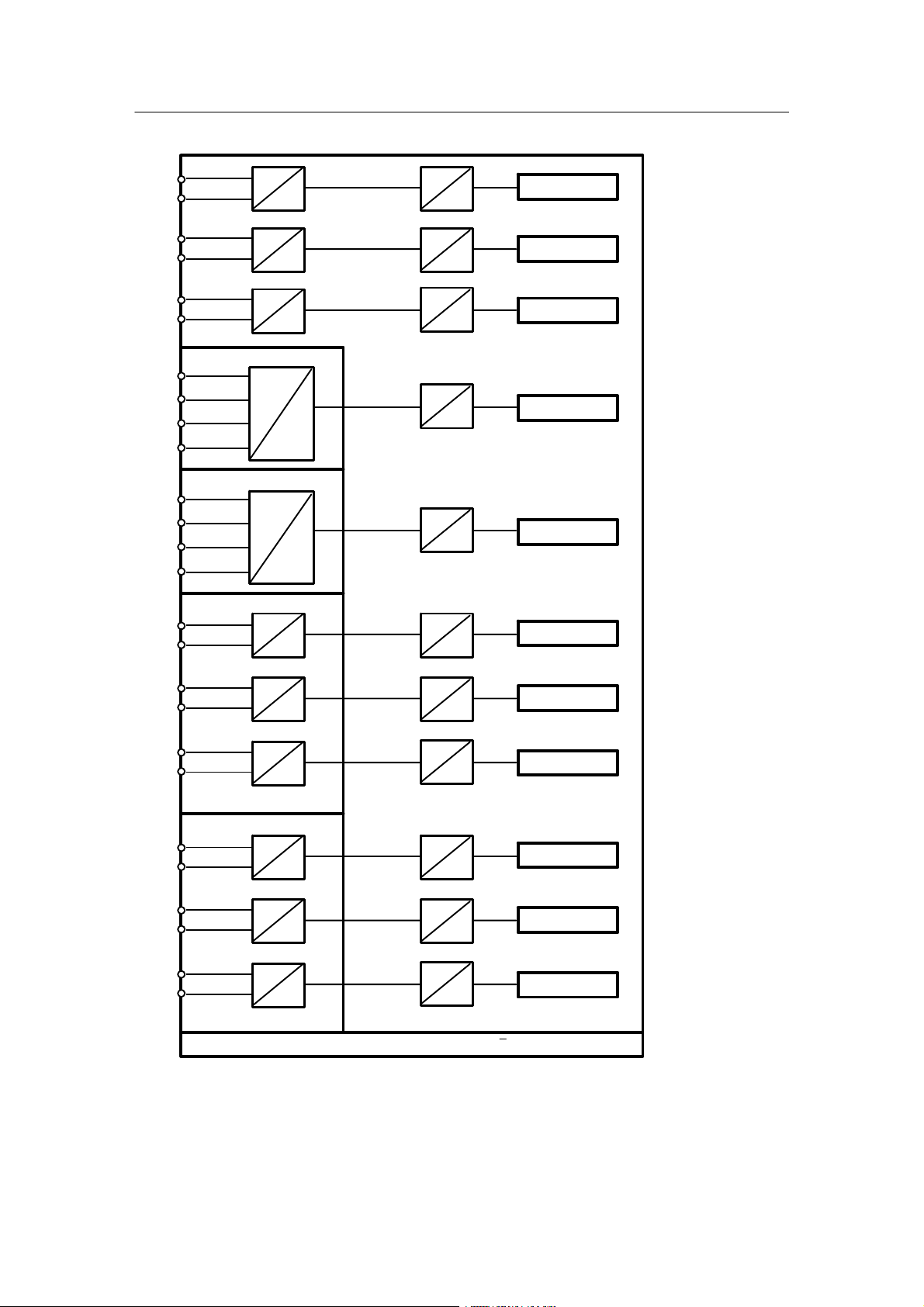

AE1+

AE1--

AE2+

AE2--

AE3+

AE3--

AE4

AE5

AE6+

AE6--

AE7+

AE7--

AE8+

AE8--

1/20

1/19

1/22

1/21

1/24

1/23

2/1

2/2

2/3

2/4

3/1

3/2

3/3

3/4

6/2

6/1

6/4

6/3

6/6

6/5

I,U

I,U

I,U

Slot 2

I

U

R

P

T

Slot 3

I

U

R

P

T

Slot 6

I,U

3AE

I,U

6DR2800-8A

I,U

oP6 = 3AE (hdEF)

∩

U

U

U

U

U

U

U

U

#

∩

#

∩

#

∩

#

∩

#

∩

#

∩

#

∩

#

AE1A ∩

AE2A ∩

AE3A ∩

AE4A ∩

AE5A ∩

AE6A ∩

AE7A ∩

AE8A ∩

Slot 5

AE9+

AE9--

AE10+

AE10- -

AE11+

AE11--

6/2

6/1

6/4

6/3

6/6

6/5

AE1...AE11 = 0 or 4 mA / AE4...AE5 = Uni_. or Uni

I,U

U

3AE

I,U

U

6DR2800-8A

I,U

U

oP5 = 3AE (hdEF)

Figure 1--6 Input function analog inputs

SIPART DR24 6DR2410

C79000-G7476-C153-03

∩

#

∩

#

∩

#

AE9A ∩

AE10A ∩

AE11A ∩

(hdEF)

25

1 T echnical Description

1.5 Functional Description

1.5.2 Input Functions

Manual

Digital inputs BE1 to BE14

The inputs BE1 to BE4 are located on the basic board. BE5 to 9 and 10 to 14 are connected to

the module 6DR2801--8C at the slots 5 or 6. The digital output modules 6DR2801--8E also contain another two digital inputs in addition to the outputs so that in this case the two digital inputs

BE5/BE6 or BE10/BE11 can be used.

The modules are assigned to the slots in the configuring mode hdEF.

24 V

Slot 5

3AA + 3BE

6DR2802--8B

BE5 BE5

5/1

5/2

5/3

6/1

6/2

6/3

24 V

BE6

BE7

oP5 = 3AA

(hdEF)

Slot 6

3AA + 3BE

6DR2802--8B

BE10

24 V

BE11

BE12

oP6 = 3AA

(hdEF)

5V

5V

5/1

5/6

6/1

6/6

Slot 5

4BA + 2BE

6DR2801-8E

BE6

oP5 = 4BA

(hdEF)

Slot 6

4BA + 2BE

6DR2801-8E

BE10

BE11

oP6 = 4bA

(hdEF)

24 V

24 V

24 V

24 V

5V

5V

5V

5V

1/15

1/16

1/17

1/18

5/1

5/2

5/3

5/4

5/5

6/1

6/2

6/3

6/4

6/5

BE1

BE2

BE3

BE4

Slot 5

6DR2801--8C

5BE

24 V

BE5

BE6

BE7

BE8

BE9

oP5 = 5BE

(hdEF)

Slot 6

6DR2801--8C

5BE

24 V

BE10

BE11

BE12

BE13

BE14

oP6 = 5bE

(hdEF)

5V

bE01 #

bE02 #

bE03 #

bE04 #

5V

bE05 #

bE06 #

bE07 #

bE08 #

bE09 #

5V

bE10 #

bE11 #

bE12 #

bE13 #

bE14 #

Figure 1--7 Input function digital inputs

26

SIPART DR24 6DR2410

C79000-G7476-C153-03

Manual

1 Technical Description

1.5 Functional Description

1.5.2 Input Functions

Data sinks bLS, bLPS, bLb

These sinks serve to block operation (bLb), the parameter and configuration adjustment (bLPS)

or just the configuration adjustment (bLS). At bLPS = high an error message no(dd1) PS(dd3) is

displayed when attempting to enter the parameterization mode.

At bLS = high no error message appears but the StrU level in the parameterization preselection

is hidden. The sinks bLS, bLPS and bLB can only be switched by the binary inputs BE1 to

BE14 (bE** = source) and the SES sources SbE1 to SbE8. When the CB time monitor responds or at Cbt = oFF, the SES sources connected with bLS, bLPS or bLb are set to low. See

also chapter 3.3.7, table 3--8, page 157.

The factory setting is low.

Keys tA1 to tA7

The keys (see figure 1--9, page 28) are available as key function tA*.1, tA*.2 or as switching

functions tA*.3, tA*.4 or tA*.5, tA*.6 (see figure 1--8, page 28). The keys are provided primarily

for incremental adjustment of the complex functions „Integrator with digital input” (bin) or controller inputsΔy. They can be switched by the control inputs tA*U/tA*M for quadruple applications whereby the status of the switched off outputs Q and Q

remains unchanged.

The key tA5 has no key output to other operating levels because of the universal function; i.e.

tA5.1 and possibly tA5.2 are not available. The outputs Q and Q

are switched at key 5 with the

low edge (release the key). “PS” flashes in dd3 after pressing tA5 continuously for about 5 s. All

keys lose their function in the process operating level when the display flashes in dd3.

You can now switch to the other levels (parametering, configuring). See chapter 3.3.1 (page

136), 3.3.2 (page 138) and 3.3, page 135.

When the function tA*.U is assigned „no” in the configuring mode hdEF, the shaded data

sources and sinks do not appear in the configuring mode FCon. Since the sink tA*.U is pre--assigned with low, the drawn switch position is active.

Restart conditions

Power on Q

bAtt = no

bAtt = YES

last status

0

Q

1

last status

SIPART DR24 6DR2410

C79000-G7476-C153-03

27

1 T echnical Description

1.5 Functional Description

1.5.2 Input Functions

Hi

gr

Lo

#tA5.M

Lo

#tA5.U

#tA5.U = no/YES/Four

arehiddeninFCon,if tA*.U = no

arehiddeninFCon,if tA*.U = no/YES

Figure 1--8 Input function keys

Q

Q

Q

Q

Q

Q

Q

Q

tA5.3#

tA5.5#

tA5.4#

tA5.6#

tA5.C#

tA5.E#

tA5.d#

tA5.F#

(hdEF)

Hi

gn

Lo

#tA1.M

Lo

#tA1.U

#tA1.U = no/YES/Four

tA2, 3, 4, 6, 7 functionally identical with tA1

Q

Q

Q

Q

Q

Q

Q

Q

Manual

tA1.1#

tA1.3#

tA1.5#

tA1.2#

tA1.4#

tA1.6#

tA1.A#

tA1.C#

tA1.E#

tA1.b#

tA1.d#

tA1.F#

(hdEF)

dA1

tA7

dd1

dd2

dA2/

L14

L13

dd3

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

tA1

tA2

tA3

tA4

tA5

tA6

Figure 1--9 Description of the displays, keys and LEDs on the front module of the SIPART DR24

28

SIPART DR24 6DR2410

C79000-G7476-C153-03

Loading...

Loading...