Page 1

© Siemens AG 2012

Photovoltaics

SINVERT PVS 600Series Central Inverters

and Components for Photovoltaic Power Plants

Brochure · April 2012

SINVERT

Answers for the environment.

Page 2

© Siemens AG 2012

Sunny prospects for photovoltaic plants

The SINVERT PVS 600Series central inverters from 500 to 2 520 kW:

compact, robust, durable

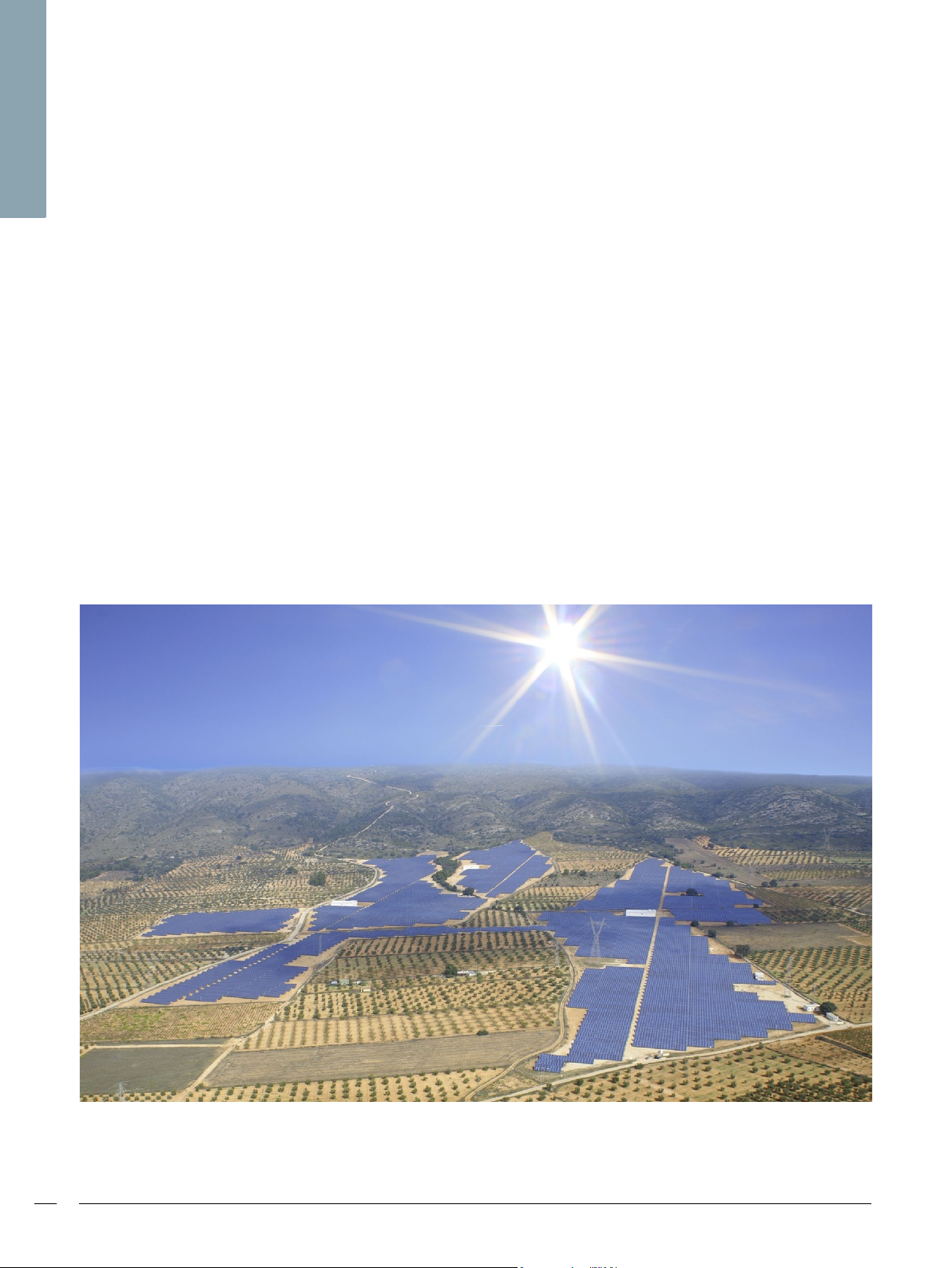

Whether on the roofs of large industrial facilities, in

ground-mounted PV systems, or solar power plants

– you can now utilize the power of the sun even more

efficiently: with the new three-phase SINVERT PVS

600Series photovoltaic inverters.

With these inverters you can achieve a peak efficiency of

98.7% and a European efficiency of 98.4% when converting

solar power for feeding into the grid.

The SINVERT PVS inverters operate in inverter stations

according to the Siemens master-slave concept that has

been proven in use now for more than a decade, and that

stands for maximum plant availability, a particularly long

service life, and optimized efficiency.

Peak efficiency you can count on!

Inverter stations with SINVERT PVS inverters are system

solutions for simple and fast implementation of photovoltaic

power plants. Additional system components and accessories

required for this purpose are available.

The SINVERT Select dimensioning program helps to find

the best possible configuration for a photovoltaic plant.

A modular service concept means that services can be

tailored to different needs as required.

The SINVERT PVS inverters are characterized by their

ruggedness and longevity, which we back up with a

five-year manufacturer's warranty as standard.

Sunny prospects for photovoltaic plants2

Page 3

© Siemens AG 2012

Contents

text

Introduction

Sunny prospects for photovoltaic plants . . . . . . . . . . . 2

SINVERT PVS 600Series central inverters . . . . . . . . . 4

Features and advantages at a glance. . . . . . . . . . . . . . 4

Technical data of the PVS500 (IEC) . . . . . . . . . . . . . . .6

Technical data of the PVS585 (IEC) . . . . . . . . . . . . . . .7

Technical data of the PVS600 (IEC) . . . . . . . . . . . . . . . 8

Technical data of the PVS630 (IEC) . . . . . . . . . . . . . . .9

Options for SINVERT PVS 600Series inverters . . . . . . 10

SINVERT PVS in power plants . . . . . . . . . . . . . . . . . 12

How solar power is fed into the AC grid. . . . . . . . . . . 12

SINVERT PVS CombinerBoxes for bundling:

single-stage concept, two-stage concept . . . . . . . . . 12

IEC-compliant inverter stations . . . . . . . . . . . . . . . . . 14

- Master-slave system with SINVERT PVS . . . . . . . . . . 15

- Medium-voltage components . . . . . . . . . . . . . . . . . 15

Establishing communication with PVS and system

components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

- SINVERT PVS ComBox 100 . . . . . . . . . . . . . . . . . . . . 16

- SINVERT PVS ControlBox 300 . . . . . . . . . . . . . . . . . . 16

- SINVERT PVS ComBox 200 . . . . . . . . . . . . . . . . . . . . 18

- SINVERT PVS WeatherStation 200 . . . . . . . . . . . . . . 18

PV plant dimensioning with SINVERT Select . . . . . 20

PV plant monitoring . . . . . . . . . . . . . . . . . . . . . . . . 21

with WinCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

with SINVERT WebMonitor . . . . . . . . . . . . . . . . . . . . . 22

Selection and ordering data for devices and

accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service & Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Spare parts service:

On-demand spare parts delivery, PVS SparesKits. . . .28

Service calls:

Commissioning, On-site service, Maintenance . . . . .28

Service contracts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

- SINVERT PVS SparesContract . . . . . . . . . . . . . . . . . . 30

- SINVERT PVS WarrantyExtension . . . . . . . . . . . . . . . 30

- SINVERT PVS MaintenanceContract . . . . . . . . . . . . . 31

- SINVERT PVS FullServiceContract. . . . . . . . . . . . . . . 31

Sunny prospects for photovoltaic plants 3

Page 4

© Siemens AG 2012

SINVERT PVS 600Series central inverters

Features and advantages at a glance

Transformerless, 3-phase SINVERT PVS inverters are

reliable, grid-compatible and cost-effective photovoltaic

inverters which are used to convert solar energy into

grid-compliant AC voltage for feeding into conventional

power grids – thereby achieving peak efficiency levels of

up to 98.7%.

The compact SINVERT PVS inverters are ideal for use in

medium and large-scale photovoltaic power plants.

The SINVERT PVS500, SINVERT PVS585, SINVERT PVS600 and

SINVERT PVS630 inverters are grouped together under the

name "SINVERT PVS 600Series".

They consist of between 1 and 4 subunits and are available for

outputs of between 500 and 2520 kW in the following power

levels:

– SINVERT PVS500:

500, 1 000, 1 500, 2 000 kW

– SINVERT PVS585:

585, 1 170, 1 755, 2 340 kW

– SINVERT PVS600:

600, 1 200, 1 800, 2 400 kW

– SINVERT PVS630:

630, 1 260, 1 890, 2 520 kW

The IEC-compliant devices are also available already integrated

in an inverter station (with two to four subunits), including

medium-voltage components. Besides SINVERT PVS and

inverter stations, additional system components and

accessories are available for implementing photovoltaic

power plants according to IEC standards (see page 12).

The modularity of the series and the free SINVERT Select

dimensioning software allow flexible planning of photovoltaic

plants (see page 20).

Photovoltaic plants in which SINVERT PVS inverters are used

can be monitored and controlled with the WinCC visualization

system installed on a Windows PC. WinCC gives transparency

to the status and energy flow of the entire plant, from the

photovoltaic array and the inverters right up to the grid

connection (see page 21).

The free SINVERT WebMonitor web application can also be

used for monitoring the photovoltaic plant with SINVERT PVS

inverters (see page 22).

With the MobileApp of the SINVERT WebMonitor, it is possible

to call up the current and historical data of the selected

photovoltaic plant remotely at any time, using a smartphone

or tablet computer (see page 22).

Your benefits at a glance:

■ Cost-effectiveness

– Good price/performance ratio

– Low installation costs

– High plant yields thanks to maximum efficiency over

very large power ranges

– Low operating costs thanks to the robust, durable

and low-maintenance design

– Reduced operating costs throughout the entire

operating period thanks to the master-slave principle

with rot ating master, in which up to fou r inverte r subunits are interconnected (see page 15)

■ Reliability

– Use of fully developed, tried-and-tested industrial

standard components

– Automatic diagnosis and signaling of faults

– Competent, professional support, worldwide service

–Modular service concept

– Compliance with the relevant guidelines

To obtain early warning of faults and creeping change due to

aging and wear, monitoring and control of a PV power plant

via a central control room is absolutely essential. Only in this

way can the operator initiate repairs and maintenance

measures at an early stage and thus avoid costly downtimes.

Central monitoring and control is therefore also an essential

part of a preventive maintenance system.

SINVERT PVS 600Series central inverters4

■ Transparency

– Central unit of the photovoltaic plant

– Automatic diagnostics on site or by means of remote

monitoring

– Pixel-graphics display with touch screen on the front

of the control cabinet enables simple and intuitive

operation and visualization of infeed power data and

other information

Page 5

© Siemens AG 2012

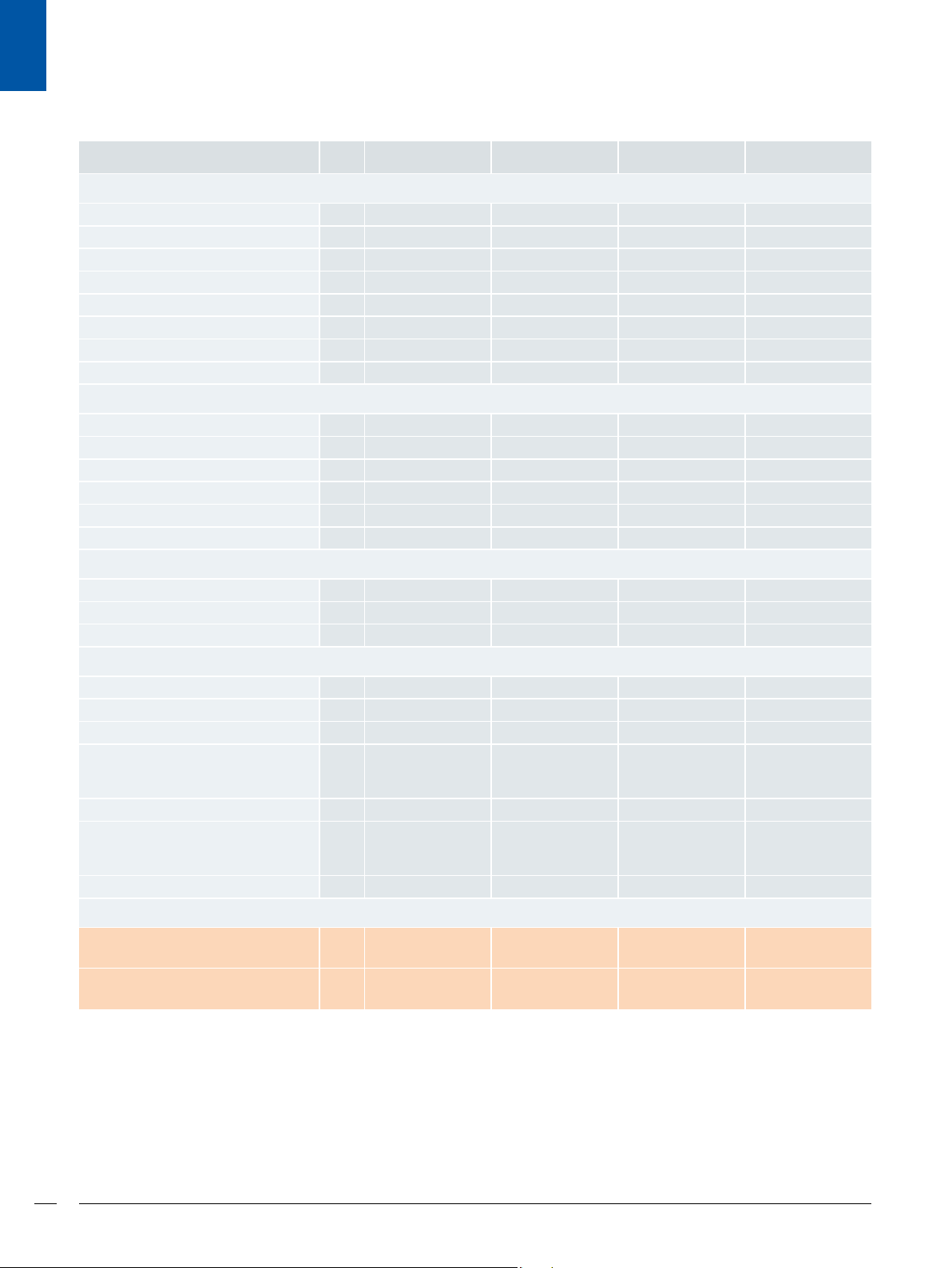

SINVERT PVS 600Series Power / kW

Inverter type 500 1000 1500 2000

PVS500

PVS585

PVS600

PVS630

PVS1000

PVS1170

PVS1200

PVS1260

PVS1500

PVS1755

PVS1800

PVS1890

PVS2000

PVS2340

PVS2400

PVS2520

Power levels of the SINVERT PVS 600Series central inverters

SINVERT PVS 600Series central inverter (subunit)

SINVERT PVS 600Series central inverters 5

Page 6

© Siemens AG 2012

Technical data of the SINVERT PVS500 inverter (according to IEC)1)

Inverter type PVS500 PVS1000 PVS1500 PVS2000

Input DC

MPP voltage V 450 ... 750 450 ... 750 450 ... 750 450 ... 750

Maximum input voltage2) V 820 820 820 820

Minimum input voltage V 450 450 450 450

Rated input power kW 513 1 026 1 539 2 052

Maximum input current A 1 103 2 206 3 309 4 412

Number of DC inputs 3 6 9 12

Maximum current per DC input A 368 368 368 368

Surge arrester Type 2 Type 2 Type 2 Typ e 2

Output AC

Grid connection 50/60 Hz 288 V 3 AC 50/60 Hz 288 V 3 AC 50/60 Hz 288 V 3 AC 50/60 Hz 288 V 3 AC

Rated power kW 500 1 000 1 500 2 000

Maximum output current A 1 002 2 004 3 006 4 008

Line voltage V 244.8 ... 316.8 244.8 ... 316.8 244.8 ... 316.8 244.8 ... 316.8

Power factor, inductive 0.8 0.8 0.8 0.8

Power factor, capacitive 0.8 0.8 0.8 0.8

Efficiency

European efficiency factor % 98.1 98.3 98.3 98.3

CEC efficiency factor % 98.2 98.3 98.3 98.3

Maximum efficiency factor % 98.4 98.4 98.4 98.4

Further data

Number of subunits 1 2 3 4

Dimensions (H/W/D) per subunit mm 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730

Weight per subunit kg 2 085 2 085 2 085 2 085

Ambient temperature

- during operation

- during storage and transport

Relative humidity % 0 ... 95 0 ... 95 0 ... 95 0 ... 95

Installation altitude

- maximum permissible

- at rated power

Data interface Ethernet Ethernet Ethernet Ethernet

°C

0 ... +50

°C

-25 ... +70

m

2 000

m

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

Order number

Order number (grid frequency 50 Hz) 6AG3111-1AH00-

Order number (grid frequency 60 Hz) 6AG3111-2AH00-

1)

Detailed technical information can be found at:

http://support.automation.siemens.com

2)

With the 1 000 V option, expandable to 1 000 V (see page 10 and 24).

3AB0

3AB0

6AG3111-1AH103AB0

6AG3111-2AH103AB0

6AG3111-1AH203AB0

6AG3111-2AH203AB0

6AG3111-1AH303AB0

6AG3111-2AH303AB0

SINVERT PVS 600Series central inverters6

Page 7

© Siemens AG 2012

Technical data of the SINVERT PVS585 inverter (according to IEC)1)

Inverter type PVS585 PVS1170 PVS1755 PVS2340

Input DC

MPP voltage V 530 ... 750 530 ... 750 530 ... 750 530 ... 750

Maximum input voltage2) V 820 820 820 820

Minimum input voltage V 530 530 530 530

Rated input power kW 598 1 196 1 794 2 392

Maximum input current A 1 104 2 208 3 312 4 416

Number of DC inputs 3 6 9 12

Maximum current per DC input A 368 368 368 368

Surge arrester Type 2 Type 2 Type 2 Typ e 2

Output AC

Grid connection 50/60 Hz 340 V 3 AC 50/60 Hz 340 V 3 AC 50/60 Hz 340 V 3 AC 50/60 Hz 340 V 3 AC

Rated power kW 585 1 170 1 755 2 340

Maximum output current A 995 1 990 2 985 3 980

Line voltage V 289 ... 374 289 ... 374 289 ... 374 289 ... 374

Power factor, inductive 0.8 0.8 0.8 0.8

Power factor, capacitive 0.8 0.8 0.8 0.8

Efficiency

European efficiency factor % 98.2 98.4 98.4 98.4

CEC efficiency factor % 98.3 98.3 98.4 98.4

Maximum efficiency factor % 98.6 98.6 98.6 98.6

Further data

Number of subunits 1 2 3 4

Dimensions (H/W/D) per subunit mm 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730

Weight per subunit kg 2 085 2 085 2 085 2 085

Ambient temperature

- during operation

- during storage and transport

Relative humidity % 0 ... 95 0 ... 95 0 ... 95 0 ... 95

Installation altitude

- maximum permissible

- at rated power

Data interface Ethernet Ethernet Ethernet Ethernet

°C

0 ... +50

°C

-25 ... +70

m

2 000

m

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

Order number

Order number (grid frequency 50 Hz) 6AG3111-1AH00-

Order number (grid frequency 60 Hz) 6AG3111-2AH00-

1)

Detailed technical information can be found at:

http://support.automation.siemens.com

2)

With the 1 000 V option, expandable to 1 000 V (see page 10 and 24).

7AB0

7AB0

6AG3111-1AH107AB0

6AG3111-2AH107AB0

6AG3111-1AH207AB0

6AG3111-2AH207AB0

6AG3111-1AH307AB0

6AG3111-2AH307AB0

SINVERT PVS 600Series central inverters 7

Page 8

© Siemens AG 2012

Technical data of the SINVERT PVS600 inverter (according to IEC)1)

Inverter type PVS600 PVS1200 PVS1800 PVS2400

Input DC

MPP voltage V 570 ... 750 570 ... 750 570 ... 750 570 ... 750

Maximum input voltage2) V 820 820 820 820

Minimum input voltage V 570 570 570 570

Rated input power kW 613 1 226 1 839 2 452

Maximum input current A 1 104 2 208 3 312 4 416

Number of DC inputs 3 6 9 12

Maximum current per DC input A 368 368 368 368

Surge arrester Type 2 Type 2 Type 2 Typ e 2

Output AC

Grid connection 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC

Rated power kW 600 1 200 1 800 2 400

Maximum output current A 936 1 872 2 808 3 744

Line voltage V 314.5 ... 407 314.5 ... 407 314.5 ... 407 314.5 ... 407

Power factor, inductive 0.8 0.8 0.8 0.8

Power factor, capacitive 0.8 0.8 0.8 0.8

Efficiency

European efficiency factor % 98.4 98.6 98.6 98.6

CEC efficiency factor % 98.5 98.6 98.6 98.6

Maximum efficiency factor % 98.7 98.7 98.7 98.7

Further data

Number of subunits 1 2 3 4

Dimensions (H/W/D) per subunit mm 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730

Weight per subunit kg 2 085 2 085 2 085 2 085

Ambient temperature

- during operation

- during storage and transport

Relative humidity % 0 ... 95 0 ... 95 0 ... 95 0 ... 95

Installation altitude

- maximum permissible

- at rated power

Data interface Ethernet Ethernet Ethernet Ethernet

°C

0 ... +50

°C

-25 ... +70

m

2 000

m

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

Order number

Order number (grid frequency 50 Hz) 6AG3111-1AH00-

Order number (grid frequency 60 Hz) 6AG3111-2AH00-

1)

Detailed technical information can be found at:

http://support.automation.siemens.com

2)

With the 1 000 V option, expandable to 1 000 V (see page 10 and 24).

0AB0

0AB0

6AG3111-1AH100AB0

6AG3111-2AH100AB0

6AG3111-1AH200AB0

6AG3111-2AH200AB0

6AG3111-1AH300AB0

6AG3111-2AH300AB0

SINVERT PVS 600Series central inverters8

Page 9

© Siemens AG 2012

Technical data of the SINVERT PVS630 inverter (according to IEC)1)

Inverter type PVS630 PVS1260 PVS1890 PVS2520

Input DC

MPP voltage V 570 ... 750 570 ... 750 570 ... 750 570 ... 750

Maximum input voltage2) V 820 820 820 820

Minimum input voltage V 570 570 570 570

Rated input power kW 643 1 286 1 929 2 572

Maximum input current A 1 104 2 208 3 312 4 416

Number of DC inputs 3 6 9 12

Maximum current per DC input A 368 368 368 368

Surge arrester Type 2 Type 2 Type 2 Typ e 2

Output AC

Grid connection 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC 50/60 Hz 370 V 3 AC

Rated power kW 630 1 260 1 890 2 520

Maximum output current A 985 1 970 2 955 3 940

Line voltage V 314.5 ... 407 314.5 ... 407 314.5 ... 407 314.5 ... 407

Power factor, inductive 0.8 0.8 0.8 0.8

Power factor, capacitive 0.8 0.8 0.8 0.8

Efficiency

European efficiency factor % 98.3 98.5 98.5 98.5

CEC efficiency factor % 98.4 98.5 98.5 98.5

Maximum efficiency factor % 98.7 98.7 98.7 98.7

Further data

Number of subunits 1 2 3 4

Dimensions (H/W/D) per subunit mm 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730 2 100 x 2 700 x 730

Weight per subunit kg 2 085 2 085 2 085 2 085

Ambient temperature

- during operation

- during storage and transport

Relative humidity % 0 ... 95 0 ... 95 0 ... 95 0 ... 95

Installation altitude

- maximum permissible

- at rated power

Data interface Ethernet Ethernet Ethernet Ethernet

°C

0 ... +50

°C

-25 ... +70

m

2 000

m

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

0 ... +50

-25 ... +70

2 000

0 ... 1 000

Order number

Order number (grid frequency 50 Hz) 6AG3111-1AH00-

Order number (grid frequency 60 Hz) 6AG3111-2AH00-

1)

Detailed technical information can be found at:

http://support.automation.siemens.com

2)

With the 1 000 V option, expandable to 1 000 V (see page 10 and 24).

8AB0

8AB0

6AG3111-1AH108AB0

6AG3111-2AH108AB0

6AG3111-1AH208AB0

6AG3111-2AH208AB0

6AG3111-1AH308AB0

6AG3111-2AH308AB0

SINVERT PVS 600Series central inverters 9

Page 10

© Siemens AG 2012

Options for SINVERT PVS 600Series inverters

Basic versions and options

The SINVERT PVS 600Series of inverters can be adapted and

expanded by means of options in order to meet the individual

needs of the plant.

The following 4 options are available:

– PV array grounding

– 1 000 V option

– Symmetry monitoring

– Cabinet heating

PV array grounding

In most cases, PV systems constitute a DC IT system. In a DC IT

system, neither the positive nor negative pole is grounded.

When using certain module types, however, either a positive

or negative grounding of the PV generator is required. It is

only by this grounding that damage to modules and a steady

loss of power can be prevented, i.e. that the maximum yield

can be obtained on a continuous basis.

The "PV array grounding positive pole" option allows functional

grounding of the positive conductor inside the SINVERT PVS

inverter if this is a requirement of the photovoltaic modules

used (e.g. large number of thick-film modules).

The "PV array grounding negative pole" option allows

functional grounding of the negative conductor inside the

SINVERT PVS inverter if this is a requirement of the photovoltaic

modules used (e.g. large number of thin-film modules).

1 000 V option

The 1 000 V option increases the maximum permissible input

voltage of the SINVERT PVS inverter from 820 to 1 000 V.

Provision of this option ensures that the PV plant will enter

operation smoothly even with voltages in excess of 820 V

which can occur, for example, on cold days or in arrays

containing thin-film modules. The option thus maximizes the

potential yield of the installation. The MPP voltage range of

the SINVERT PVS inverter is not changed.

Symmetry monitoring

The "symmetry monitoring" option measures the normalized

currents at the DC inputs internally and cross-compares the

values. If this comparison indicates deviations over time, a

message is generated. The message can be used as a guide to

localizing faults early in sections of the PV generator (e.g. cell

failure).

Cabinet heating

The "cabinet heating" option minimizes the risk of condensation forming on the moisture-sensitive components in the

SINVERT PVS photovoltaic inverter at low ambient temperatures. Reliable operation and maximum energy yields to the

grid are dependent on compliance with the operating temperature range prescribed for the relevant SINVERT PVS inverter.

This function is recommended for locations at which the

ambient temperature can drop below 7 °C.

Order numbers for the options

PV systems no longer constitute a DC IT system when their

modules are grounded. For safety reasons, the PV system

must be fenced in and designated as an electrical operating

area. Only qualified electricians may be granted access.

Grounding an active conductor (positive pole or negative

pole) means that the inverter's insulation measuring function

no longer works in the normal way. A hazardous current can

start to flow as soon as the first insulation damage occurs. For

this reason, in the case of positive pole grounding, the current

between the positive pole and ground is measured, and in the

case of negative pole grounding, the current between the

negative pole and ground. When the current increases to a

critical level, the ground connection is automatically separated.

Each of the four options has its own order number which is

to be specified in addition to the order number of the basic

version (see "Selection and ordering data", page 23).

SINVERT PVS 600Series central inverters10

Page 11

© Siemens AG 2012

SINVERT PVS inverters for industrial roof systems

A SINVERT PVS2000 is used for the Aspropyrgos 2 MW roof system erected in Greece in 2011 for Big Solar

SINVERT PVS inverters for solar power plants

The 31 MW solar power plant at Les Mées in France was constructed in 2010/2011 for Eco Delta and connected to the grid in August 2011. For this project,

Siemens acted as a general contractor with an all-in-one concept from a single source, including maintenance, operation and warranty services.

SINVERT PVS500 inverters are in use at this PV solar plant with 112 400 solar modules installed over an area of 66 hectares. The SINVERT Select software

was used for the plant dimensioning, and the plant is monitored with WinCC software.

SINVERT PVS 600Series central inverters 11

Page 12

© Siemens AG 2012

SINVERT PVS in power plants

Link between solar power and public AC grid

How solar power is fed into the AC grid

Sunlight is transformed into solar energy in the photovoltaic

modules. The direct current obtained is bundled in the field

with the aid of SINVERT PVS CombinerBoxes and then fed into

a SINVERT PVS inverter (see diagrams on this page).

The alternating current supplied by the inverters is transformed

by medium-voltage transformers into the higher voltages of

20 kV, for example, that are needed for feed-in to the grid.

The inverters and the transformers are in a protected location in

inverter stations, as is the optional medium-voltage switchgear,

which allows energy to be distributed and fed into the

medium-voltage grid (see diagram on page 14).

SINVERT PVS CombinerBoxes for bundling partial currents

With the SINVERT PVS CombinerBox, the individual strings of

the photovoltaic generator are collected in the field, connected

in parallel and the energy conveyed via large cross-section

cables to the SINVERT PVS inverter or the inverter station.

Module strings can be "collected" and their energy transported

to the SINVERT PVS inverter or inverter station using a singlestage or two-stage connection concept:

With the single-stage concept, the energy supplied by the module strings to the inputs of the SINVERT PVS CombinerBoxes is transported directly to the SINVERT PVS inverter or the inverter station via one output in each case.

Photovoltaic modules

With the two-stage concept, the module strings are initially brought together in the SINVERT PVS CombinerBoxes (first stage). The outputs of these SINVERT PVS CombinerBoxes are then connected to other SINVERT PVS CombinerBoxes (second stage). The outputs of the SIN VERT PV S Combin erBoxes of the second stage are then connected to the inputs of the SINVERT PVS inverters or inverter stations. The advantage of this two-stage concept is that power losses are reduced thanks to the increased cable cross-sections.

Photovoltaic modules

SINVERT PVS

CombinerBoxes 108

SINVERT PVS

CombinerBoxes 204

Photovoltaic array

Service room

SINVERT PVS inverters

Bundling of the solar direct current using SINVERT PVS CombinerBoxes

(two-stage concept)

The SINVERT PVS CombinerBoxes 108, 120, 124 with eight,

twenty, and twenty-four inputs are used in the first stage. The

CombinerBox 204 with four inputs is used in the second stage.

RE10_00026b

SINVERT PVS

CombinerBoxes 120

Photovoltaic array

Service room

SINVERT PVS inverters

Bundling of the solar direct current using SINVERT PVS CombinerBoxes

(single-stage concept)

SINVERT PVS in power plants12

RE10_00027a

SINVERT PVS CombinerBoxes 124, 204, 120, 108 (from left to right)

Page 13

© Siemens AG 2012

The SINVERT PVS CombinerBoxes are designed for vertical

mounting.

The output side of the SINVERT PVS CombinerBoxes can be

optionally equipped with or without a switch disconnector.

CombinerBoxes with switch disconnectors are capable of

disconnecting the connected section of the photovoltaic

generator from the SINVERT PVS inverter, e.g. for maintenance work.

SINVERT PVS CombinerBox 108 120 124 204

Number of inputs 8 20 24 4

Maximum protection per input 15 A 20 A

Voltage 1 000 V

Switch disconnector optional --

Surge arrester opt. --

160 A

The SINVERT PVS CombinerBox 108 is optionally available

with or without overvoltage protection, which is designed

to protect the modules.

The inputs of the SINVERT PVS CombinerBoxes are protected by fuses. The fuses are not included in the scope of supply of the SINVERT PVS CombinerBox and must be ordered

separately (see Selection and ordering data on page 25).

The SINVERT PVS CombinerBox has IP54 degree of protection

and is rated for voltages up to 1 000 V.

SINVERT PVS in power plants 13

Page 14

© Siemens AG 2012

IEC-compliant inverter stations

The inverter stations are system solutions for fast, simple

implementation of turnkey photovoltaic stations. They are

ideally suited for photovoltaic power plants ("Power Plant"

segment) with outputs of 1 000 kW upwards.

They are typically employed in ground-mounted systems.

Inverter stations contain two to four SINVERT PVS inverters

and, depending on the selected type, also medium-voltage

switchgear and medium-voltage transformers. They are

designed to convert solar energy reliably and cost-effectively

into grid-compatible energy for infeed into conventional

power grids.

Inverter station

All individual components of the inverter stations, such as

SINVERT PVS inverters and medium-voltage transformers, are

technically fully developed, designed for extreme ruggedness

electrical and mechanical properties and completely wired

and tested.

The inverter stations are available in power levels from

1 000 to 2 520 kW with 2, 3 or 4 inverter subunits comprising

the PVS500, PVS585, PVS600 and PVS630 inverters

(see diagram on page 5).

SINVERT PVS inverters

Medium-voltage transformer

Medium-voltage switchgear

RE10_00025b

Basic interconnection of components in the inverter station in a configuration containing a SINVERT PVS2000, PVS2340, PVS2400 or PVS2520 inverter

(each consisting of four SINVERT PVS500, PVS585, PVS600 or PVS630 subunits)

SINVERT PVS in power plants14

Page 15

Intensity of solar irradiation

1st day

2nd day

3rd day

4th day

morning noon evening night

© Siemens AG 2012

The inverters integrated in the inverter stations operate with a rotating master according to the master-slave principle.

The diagram shows in simplified form that the master moves to the next inverter each day (see left column). In actual fact, the inverter with the fewest

operating hours is started as the master on the next day.

Master-slave system with SINVERT PVS

For technical data on the fully configured inverter stations,

the AC distribution, the medium-voltage transformer and the

The SINVERT PVS inverters integrated in the inverter stations

operate with a "rotating master" according to the master-slave

principle. This is a master-slave system comprising between

medium-voltage switchgear, please contact your local sales

partner:

www.siemens.com/sinvert/partner

two and four interconnected inverter subunits. It employs an

ingenious process to connect or disconnect inverter subunits,

Medium-voltage transformer

depending on the level of solar irradiation (determined

according to the sun's path, cloud conditions, etc.). The master is started up first and operates even when irradiation levels

are low. As irradiation levels increase, the next inverter

subunit is switched in as a slave when a set switching thresh-

The medium-voltage transformer transforms the low voltage

supplied by the SINVERT PVS photovoltaic inverter into a

defined medium voltage of 20 kV, for example, for feeding

into the grid.

old is exceeded. Depending on the configuration, up to three

slaves can be switched in. As irradiation levels drop again, the

subunits are disconnected in stages. One advantage of the

master-slave principle is that the efficiency factor is higher

when irradiation levels (which determine the PV generator

Several medium-voltage transformer brands are available,

e.g. the loss-optimized GEAFOL medium-voltage transformer

(cast-resin two-tier transformer), which has been specially

designed for photovoltaic applications.

output) are low than it would be if only a single inverter were

used.

Detailed information about GEAFOL medium-voltage trans-

formers can be found in the Catalog TV 1 "GEAFOL cast-resin

In master-slave systems, the "rotating master" function always

transformers 100 to 16 000 kVA".

starts the inverter subunit with the fewest operating hours as

the master. In this way, the total operating hours are evenly

distributed among all the subunits.

Medium-voltage switchgear

The medium-voltage switchgear is available as an option.

■ Individual components of the inverter stations

– SINVERT PVS inverters according to IEC and their

It distributes energy and feeds power into the medium-voltage

network.

components (for further information see Catalog

RE10 "Inverters and Components for Photovoltaic

Installations")

– AC distribution for voltage supply, control and

Detailed information about medium-voltage switchgear can

be found in the Catalog HA 40.2 "Switchgear Type 8DJH for

Secondary Distribution Systems up to 24 kV, Gas-Insulated".

monitoring of the components.

– Medium-voltage transformer

– Medium-voltage switchgear

SINVERT PVS in power plants 15

Page 16

WinCC PC

SCALANCE S

VPN Router

SINVERT PVS ComBox 100

Inverter - Station 1

Circle control

receiver

EVU

Inverter

SINVERT PVS

SINVERT PVS

ComBox 100

Inverter - Stations 2-n

Inverter

SINVERT PVS

SINVERT PVS ControlBox 300

Weather sensors

Internet

WinCC

WebNavigator

DSL-Router

Industrial Ethernet FOC ring

Industrial Ethernet

RE10_00029d

SINVERT PVS

WeatherStation 200

0 %

100 %

© Siemens AG 2012

Establishing communication with PVS and system components

Communication via Industrial Ethernet and plant monitoring with WinCC

Integration of SINVERT PVS inverters into a photovoltaic plant with communication via an Ethernet network, solar PV plant control by means of the

SINVERT PVS ControlBox 300, and monitoring with WinCC

The inverter stations have an Ethernet interface. If the inverter

station is linked to an Ethernet network, this interface permits

the exchange of data between the inverter station(s) and the

WinCC visualization system on a Microsoft Windows PC. The

data server on the ControlBox 300 collects the data from all

the inverters.

Remote access to the WinCC visualization system is also possible

over the Internet if the WinCC WebNavigator software has

been installed.

SINVERT PVS ComBox 100

The SINVERT PVS ComBox 100 communications box interconnects the inverter stations (in linear or ring topologies) with

copper or fiber-optic LAN cabling and also connects networkcapable components in the inverter stations, e.g. SINVERT PVS

inverters.

The ComBox 100 has the following connection options:

–4 x RJ45 ports

– 2 x fiber-optic ports, for cable lengths up to 5 km

SINVERT PVS ControlBox 300

The purpose of the SINVERT PVS ControlBox 300 is to regulate

the active and reactive power of a photovoltaic plant containing

SINVERT PVS inverters and to ensure compliance with legal

requirements (according to the current amendment of the

Renewable Energy Act (EEG), in force since January 2009).

SINVERT PVS in power plants16

SINVERT PVS ControlBox 300

Page 17

© Siemens AG 2012

Regulation of the PV plant according to BDEW Guideline and the current amendment of the Renewable Energy Act (EEG) by means of

SINVERT PVS ControlBox 300 displayed with WinCC

The "Generating Plants in the Medium-Voltage Grid" BDEW

guideline stipulates this requirement for all systems feeding

in at the medium-voltage level. Its primary benefit is that it

enables grid operators to limit the output of the plant by

remote means in accordance with § 6 of the Renewable Energy

Act 2009.

point, to 0%, 30%, 60%, and 100% of the rated active

power of the PV plant. (Active power reduction in

accordance with § 6 of the Renewable Energy Act

– Regulation according to Q(U) characteristic

– Regulation according to Q(t) characteristic

– Regulation according to P(f) characteristic

– Ramps for system ramp-up and ramp-down, i.e. con-

The ControlBox 300 offers a wide range of open-loop and

tinuously approaching the setpoint

closed-loop control functions, e.g.:

– Specification of a fixed active power for all individual

SINVERT PVS inverters in the PV plant, e.g. setpoint

value = 2 MW (active power fixed value)

– Specification of a fixed reactive power for all individual

SINVERT PVS inverters in the PV plant, e.g.

setpoint value = 100 kvar inductive (reactive power

fixed value)

The SINVERT PVS ControlBox 300 offers the following

connection options:

– SIMATIC components with digital inputs

– SENTRON PAC3200 Power Monitoring Device for

measuring actual values at the grid feed-in point

–4 x RJ45 ports

– 2 x fiber-optic ports, for cable lengths up to 5 km

– Specification of a fixed power factor cos ϕ for all

individual SINVERT PVS inverters in the PV plant, e.g.

setpoint value = -0.95

– Regulation of the active power for the individual

SINVERT PVS inverters in the PV plant as a function of

the active power actually measured at the grid infeed

SINVERT PVS in power plants 17

Page 18

© Siemens AG 2012

Communication via Industrial Ethernet and plant monitoring by means of SINVERT WebMonitor

Internet

Industrial Ethernet

SCALANCE S

VPN Router

Inverter - Station 1

Inverter

SINVERT PVS

SINVERT PVS ComBox 200

Industrial Ethernet FOC ring

Integration of SINVERT PVS inverters into a photovoltaic plant without solar PV plant control with communication via an Ethernet network and

monitoring by means of SINVERT WebMonitor

Inverter - Stations 2-n

In the configuration example shown in the diagram without

solar PV plant control and with plant monitoring by means of

SINVERT WebMonitor, the required industrial PC is provided in

DSL-Router

SINVERT WebMonitor

Inverter

SINVERT PVS

SINVERT PVS

ComBox 100

Client

SINVERT PVS WeatherStation 200

Weather sensors

RE10_00033d

The ComBox 200 contains the following main components:

–4 x RJ45 ports

– 2 x fiber-optic ports, for cable lengths up to 5 km

the SINVERT PVS ComBox 200, which must be used in one of

the inverter stations instead of a ComBox 100.

SINVERT PVS ComBox 200

Weather station

The SINVERT PVS WeatherStation 200 acquires data

about the weather at the photovoltaic plant site. This weather

The SINVERT PVS ComBox 200 has the same scope of functions

as the ComBox 100, but also provides the capability of transferring data from the SINVERT PVS inverters and from additional

network-capable components to the SINVERT WebMonitor

web application for monitoring photovoltaic plants.

data is recorded by sensors connected to the station. The

following sensors are included in the scope of supply of the

WeatherStation 200:

– Insolation

– Module temperature

– Ambient temperature

Additional sensors such as wind speed or rain sensors can be

connected.

SINVERT PVS ComBox 200

SINVERT PVS in power plants18

Using the acquired data, it is possible to perform and transmit

extremely precise weather recordings. The target yield of the

photovoltaic plant can then be calculated from the recorded

weather data. By comparing the actual and target yield, it is

possible to make a quick assessment of the plant's operating

performance and detect any irregularities very promptly.

The SINVERT PVS WeatherStation 200 offers the following

connection options:

– 6 analog inputs for the sensors

– PROFINET communications interface

Page 19

© Siemens AG 2012

SINVERT puts sunshine into the grid. Worldwide.

Some examples of solar power plants using SINVERT inverters

Les Mées (France): 31 MW (2010/2011)

Beneixama (Spain): 20 MW (2007)

Desoto (Florida, USA): 27 MW (2009)

Serpa (Portugal): 11 MW (2007)

Shi Lin (China): 10 MW (2010)

Dobre Polé (Czech Republic): 4 MW (2010)

SINVERT PVS in power plants 19

Page 20

© Siemens AG 2012

PV plant dimensioning with SINVERT Select

For fast and easy dimensioning

The key features of SINVERT Select are:

■ The structure and workflow of the SINVERT Select

program means that photovoltaic plants containing

SINVERT inverters can be dimensioned quickly and sim-

ply in just a few steps.

■

The SINVERT Select program can be operated intuitively

thanks to the clear structure of the graphical user interface.

■ Extensive database for location selection, containing

over 400 locations in more than 30 countries

■ Database containing all the currently available SINVERT

inverters

SINVERT Select: Proposed solution for dimensioning a photovoltaic plant,

including plant details

SINVERT Select is a free program which facilitates the dimensioning, analysis and optimization of photovoltaic plants with

SINVERT inverters and outputs from a few kilowatts up to the

megawatt range.

Two different methods can be employed to dimension a

photovoltaic plant with SINVERT inverters:

■ With the automatic dimensioning method, the

SINVERT Select program first uses the information you

enter (string/central inverter, location, photovoltaic

module, rated power, etc.) to automatically identify the

best possible inverter variant. For this variant, it

calculates the performance ratio (PR) and the potential

energy yield per annum. Individual configurations can

be compared, assessed and optimized on the basis of

these parameters.

■ With the manual dimensioning method, you can input

one or two SINVERT inverter types in addition to the

information about location, photovoltaic module, and

rated power. Optionally, their quantity can also be

specified.

After you have registered, you can download the

SINVERT Select program free of charge at:

www.siemens.com/sinvert-select

■ Extensive database for module selection, which currently

contains over 6 700 different photovoltaic modules

available on the market (individual expansion is possible)

■ All the necessary data for dimensioning (locations,

SINVERT inverters, and PV modules) is constantly

updated.

■

The online update function of the SINVERT Select program

means that the latest version of the program is always

installed on your computer.

■ Numerous options for specifying the power (specification

of area, DC power, and number of modules)

■ Selectable calculation modes (automatic/manual

dimensioning, number of photovoltaic modules per

string, etc.)

■ Clear display of results of the possible configurations

depending on previously selected parameters

■ Project management

■ Creation of reports for presentation of calculation

results and printout

■ SINVERT Select also enables reactive power to be

accounted for when configuring inverters in accordance

with the Technical Guideline "Generating Plants in the

Medium-Voltage Grid" of the German Association of

Energy and Water Industries (BDEW).

■ Language support: English, German, French, Italian and

Spanish

PV plant dimensioning with SINVERT Select20

Page 21

© Siemens AG 2012

PV plant monitoring

For an instant, up-to-date overview and

rapid intervention

PV plant monitoring with WinCC

Visualization and operation of photovoltaic plants with WinCC

WinCC (Windows Control Center) is a visualization system

which runs on Microsoft Windows. It is used to monitor and

control photovoltaic plants in which SINVERT inverters are

installed.

WinCC provides all the functions required to visualize and

operate PV plants, from the PV generator itself to the inverters

and grid connection. It can also acquire data (e.g. energy

yields) and store it on a long term basis, acquire, store and visualize alarms and messages, and provide data interfaces to

external systems.

WinCC can run on a Microsoft Windows PC that is connected

to the Industrial Ethernet network of the PV plant. Remote

access to the WinCC visualization system is also possible over

the Internet if the WinCC WebNavigator software has been

installed (see graphic on page 16).

SINVERT WinCC enables consistently scalable plant configurations – from small PV power plants up to the GW range.

In addition, our visualization system can be configured easily

and efficiently. The use of a standardized PV library allows

customer-specific adaptations to be carried out. WinCC is

configured individually according to customer requirements

and specific features of the plant. For more information,

please contact your regional sales partner.

www.siemens.com/sinvert/partner

The key features of WinCC are:

■ A clearly designed user interface provides an instant

overview of all key data of the managed plants,

subplants and inverters, e.g. states, energy production,

and income

■ Graphical representation of the monitored data (see

graphic on page 17)

■ Graphics with configurable content for quick visual

access to customized displays of received and/or

calculated data, e.g. sorted according to day, month,

year.

■ Alarms and messages for quick and simple troubleshooting

and for ensuring that remedial measures can be quickly

taken to minimize loss of earnings

■ Remote monitoring over the Internet with the

WinCC/WebNavigator option

■ Acquisition, long-term storage and display of current

and historical data

■ Export of archived data to Excel using the DataMonitor

option

■ Plant monitoring (e.g. detection and display of faults in

the photovoltaic generator through section-by-section

measurement of the whole plant)

■ Safeguarding of yield and optimum protection by

monitoring the insulation value

■ Messaging services using email and text messaging with

the WinCC/AlarmControlCenter option

■ Fault messages can be specifically configured for

customized operations management

■ Establishment of as many as 128 user groups, each with

up to 128 individual users, and assignment of different

authorization levels to the users and/or user groups are

possible

■ Representation of monitored plants on a map

PV plant monitoring 21

Page 22

© Siemens AG 2012

PV plant monitoring with SINVERT WebMonitor

SINVERT WebMonitor for monitoring photovoltaic plants

SINVERT WebMonitor is a Web application for monitoring

photovoltaic plants in which SINVERT inverters are used (see

graphic on page 18).

It is used for transmitting the states of the photovoltaic plant,

for displaying production and income, or optionally for

reporting any problems that arise.

SINVERT WebMonitor MobileApp

With the MobileApp of the SINVERT WebMonitor, it is possible

to call up the current and historical data of the selected

photovoltaic plant remotely at any time using a smartphone

or tablet computer.

The key features of SINVERT WebMonitor

are:

■ Clear user interface layout provides a quick overview of

managed plants, subplants and inverters in a tree

structure.

■ Overview page (dashboard) and plant page provide

instant, up-to-date information about all key aspects of

the plants, subplants and inverters, e.g. states, energy

production (daily energy, total energy) and income.

■ Fault lists are provided to speed up and simplify

troubleshooting and to ensure that remedial measures

can be quickly taken to minimize loss of earnings.

■ Graphics with configurable content provide users with

quick visual access to customized displays of received

and/or calculated data, sorted according to day, month,

year and total.

■ Users can configure monitoring settings

(e.g. "daily energy deviation") and activate messaging

services (e.g. by e-mail) according to individual require-

ments to receive information about plant status, energy

production, income and irregularities.

■ User profiles can be defined so that plants and rights can

be individually assigned to users.

■ Display of current and historical data

■ Representation of monitored plants on a map

SINVERT WebMonitor MobileApp

Left: Bar chart indicating daily AC power yield

Right: Bar chart indicating annual energy yield

PV plant monitoring22

■ Language support: English, German, French, Italian,

Spanish, Czech, Greek and Romanian.

If you are using SINVERT PVM und SINVERT PVS inverters

in your photovoltaic plant and you want to use

SINVERT WebMonitor as a plant monitor, you can register

and log in at:

www.siemens.com/sinvert/webmonitor

The SINVERT WebMonitor MobileApp is started by calling

the Internet address of the SINVERT WebMonitor from a

smartphone or tablet computer. The SINVERT WebMonitor

user name is used for the login.

Page 23

© Siemens AG 2012

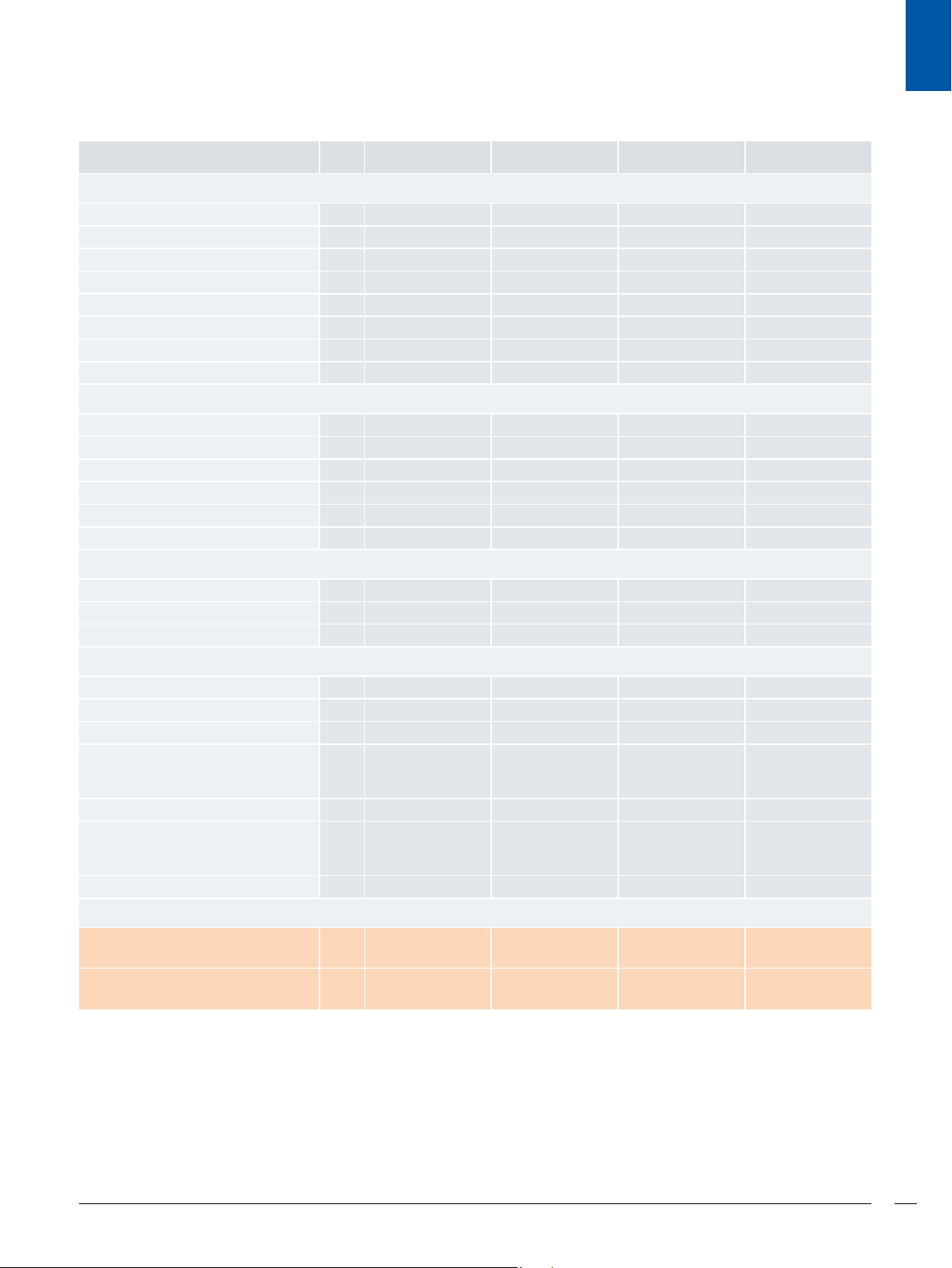

Selection and ordering data

for devices and accessories

SINVERT PVS 600Series inverters

Product type

identification

Number of

masters/slaves

Active power

output (rated

value)

kW V V V

Output voltage

(rated value)

MPP voltage Input voltage

(max. permissi-

Order No.

ble)

SINVERT PVS inverters (IEC-compliant)

Grid frequency 50Hz (rated value)

PVS500 1M 500 288 450 ... 750 820 6AG3111-1AH00-3AB0

PVS585 1M 585 340 530 ... 750 820 6AG3111-1AH00-7AB0

PVS600 1M 600 370 570 ... 750 820 6AG3111-1AH00-0AB0

PVS630 1M 630 370 570 ... 750 820 6AG3111-1AH00-8AB0

PVS1000 1M, 1S 1 000 288 450 ... 750 820 6AG3111-1AH10-3AB0

PVS1170 1M, 1S 1 170 340 530 ... 750 820 6AG3111-1AH10-7AB0

PVS1200 1M, 1S 1 200 370 570 ... 750 820 6AG3111-1AH10-0AB0

PVS1260 1M, 1S 1 260 370 570 ... 750 820 6AG3111-1AH10-8AB0

PVS1500 1M, 2S 1 500 288 450 ... 750 820 6AG3111-1AH20-3AB0

PVS1755 1M, 2S 1 755 340 530 ... 750 820 6AG3111-1AH20-7AB0

PVS1800 1M, 2S 1 800 370 570 ... 750 820 6AG3111-1AH20-0AB0

PVS1890 1M, 2S 1 890 370 570 ... 750 820 6AG3111-1AH20-8AB0

PVS2000 1M, 3S 2 000 288 450 ... 750 820 6AG3111-1AH30-3AB0

PVS2340 1M, 3S 2 340 340 530 ... 750 820 6AG3111-1AH30-7AB0

PVS2400 1M, 3S 2 400 370 570 ... 750 820 6AG3111-1AH30-0AB0

PVS2520 1M, 3S 2 520 370 570 ... 750 820 6AG3111-1AH30-8AB0

Grid frequency 60Hz (rated value)

PVS500 1M 500 288 450 ... 750 820 6AG3111-2AH00-3AB0

PVS585 1M 585 340 530 ... 750 820 6AG3111-2AH00-7AB0

PVS600 1M 600 370 570 ... 750 820 6AG3111-2AH00-0AB0

PVS630 1M 630 370 570 ... 750 820 6AG3111-2AH00-8AB0

PVS1000 1M, 1S 1 000 288 450 ... 750 820 6AG3111-2AH10-3AB0

PVS1170 1M, 1S 1 170 340 530 ... 750 820 6AG3111-2AH10-7AB0

PVS1200 1M, 1S 1 200 370 570 ... 750 820 6AG3111-2AH10-0AB0

PVS1260 1M, 1S 1 260 370 570 ... 750 820 6AG3111-2AH10-8AB0

PVS1500 1M, 2S 1 500 288 450 ... 750 820 6AG3111-2AH20-3AB0

PVS1755 1M, 2S 1 755 340 530 ... 750 820 6AG3111-2AH20-7AB0

PVS1800 1M, 2S 1 800 370 570 ... 750 820 6AG3111-2AH20-0AB0

PVS1890 1M, 2S 1 890 370 570 ... 750 820 6AG3111-2AH20-8AB0

PVS2000 1M, 3S 2 000 288 450 ... 750 820 6AG3111-2AH30-3AB0

PVS2340 1M, 3S 2 340 340 530 ... 750 820 6AG3111-2AH30-7AB0

PVS2400 1M, 3S 2 400 370 570 ... 750 820 6AG3111-2AH30-0AB0

PVS2520 1M, 3S 2 520 370 570 ... 750 820 6AG3111-2AH30-8AB0

Selection and ordering data 23

Page 24

© Siemens AG 2012

Options for SINVERT PVS 600Series inverters

The number of slaves of the respective SINVERT PVS 600Series

inverters is to be specified by the 11th digit of the order

When ordering an inverter, the order numbers of the respective

option are added to the order number of the basic version, i.e.

if all four possible options are utilized, five order numbers

must be specified for ordering the inverter concerned.

numbers of the inverters and of the associated options. This

simplifies the assignment of the options. The number x of

slaves is also specified in the identifications of the options in

the suffix MxS (M = Master, S = Slaves)

For a description of the options see page 10

Product type identification For inverter Order No.

Options for SINVERT PVS 600Series inverters

PV array grounding

PV array grounding positive pole 600Series M PVS500, PVS585, PVS600, PVS630 6AG3911-3FA00-0AH0

PV array grounding positive pole 600Series M1S PVS1000, PVS1170, PVS1200, PVS1260 6AG3911-3FA10-0AH0

PV array grounding positive pole 600Series M2S PVS1500, PVS1755, PVS1800, PVS1890 6AG3911-3FA20-0AH0

PV array grounding positive pole 600Series M3S PVS2000, PVS2340, PVS2400, PVS2520 6AG3911-3FA30-0AH0

PV array grounding negative pole 600Series M PVS500, PVS585, PVS600, PVS630 6AG3911-3FB00-0AH0

PV array grounding negative pole 600Series M1S PVS1000, PVS1170, PVS1200, PVS1260 6AG3911-3FB10-0AH0

PV array grounding negative pole 600Series M2S PVS1500, PVS1755, PVS1800, PVS1890 6AG3911-3FB20-0AH0

PV array grounding negative pole 600Series M3S PVS2000, PVS2340, PVS2400, PVS2520 6AG3911-3FB30-0AH0

1 000 V option

1000 V option 600Series M PVS500, PVS585, PVS600, PVS630 6AG3911-3GA00-0AH0

1000 V option 600Series M1S PVS1000, PVS1170, PVS1200, PVS1260 6AG3911-3GA10-0AH0

1000 V option 600Series M2S PVS1500, PVS1755, PVS1800, PVS1890 6AG3911-3GA20-0AH0

1000 V option 600Series M3S PVS2000, PVS2340, PVS2400, PVS2520 6AG3911-3GA30-0AH0

Symmetry monitoring

Symmetry monitoring 600Series M PVS500, PVS585, PVS600, PVS630 6AG3911-3EA00-0AH0

Symmetry monitoring 600Series M1S PVS1000, PVS1170, PVS1200, PVS1260 6AG3911-3EA10-0AH0

Symmetry monitoring 600Series M2S PVS1500, PVS1755, PVS1800, PVS1890 6AG3911-3EA20-0AH0

Symmetry monitoring 600Series M3S PVS2000, PVS2340, PVS2400, PVS2520 6AG3911-3EA30-0AH0

Cabinet heating

Cabinet heating 600Series M PVS500, PVS585, PVS600, PVS630 6AH3911-3HA00-1AH0

Cabinet heating 600Series M1S PVS1000, PVS1170, PVS1200, PVS1260 6AH3911-3HA10-1AH0

Cabinet heating 600Series M2S PVS1500, PVS1755, PVS1800, PVS1890 6AH3911-3HA20-1AH0

Cabinet heating 600Series M3S PVS2000, PVS2340, PVS2400, PVS2520 6AH3911-3HA30-1AH0

Selection and ordering data24

Page 25

© Siemens AG 2012

System components, accessories, spare parts for SINVERT PVS 600Series inverters

Product type

identification

Number of

inputs

Typ e of fus e

protection at

input

Input current

per input

(maximum)

A

Isolating

device at the

output

Surge arrester Order No.

SINVERT PVS CombinerBoxes

Array junction box

CombinerBox 108 8 Fuse holder 10 -- -- 6AG3611-3FF21-1AA0

CombinerBox 108 8 Fuse holder 10 -- ✓ 6AG3611-3FF21-1BA0

CombinerBox 108 8 Fuse holder 10 ✓ -- 6AG3611-3FF21-1CA0

CombinerBox 108 8 Fuse holder 10 ✓ ✓ 6AG3611-3FF21-1DA0

CombinerBox 120 20 Fuse holder 13 -- -- 6AG3611-3FL21-1AA0

CombinerBox 120 20 Fuse holder 13 ✓ -- 6AG3611-3FL21-1CA0

CombinerBox 124 24 Fuse holder 13 -- -- 6AG3611-3FM21-1AA0

CombinerBox 124 24 Fuse holder 13 ✓ -- 6AG3611-3FM21-1CA0

Generator junction box

CombinerBox 204 4 Fuse holder 125 -- -- 6AG3611-3FD01-1AA0

✓ included

-- not included

Size Operating class Operational

current

(rated value)

A V W

Operational

voltage

(rated value)

Power loss Order No.

Fuses for SINVERT PVS CombinerBox

LV HRC fuse kit

Size 1 gPV 80 1 000 23 3NE1 220-4

Size 1 gPV 100 1 000 25 3NE1 221-4

Size 1 gPV 125 1 000 28 3NE1 222-4

Size 1 gPV 160 1 000 3NE1 224-4

Product type identification Order No.

SINVERT PVS weather station

WeatherStation 200 6AG3611-3BA00-2AA0

SINVERT PVS ComBox

ComBox 100 6AG3611-3AB00-1AA0

ComBox 200 6AG3611-3AB00-2AA0

SINVERT PVS ControlBox

ControlBox 300 6AG3611-3AA00-3AA0

SparesKit for SINVERT PVS

SINVERT PVS SparesKit 100 6AG3911-3JA00-1AG0

SINVERT PVS SparesKit 200 6AG3911-3JA00-2AG0

Selection and ordering data 25

Page 26

© Siemens AG 2012

Service & Support

Unique range of complete services for the entire life cycle

Techn i ca l

Service

Service

Programs

Programs

Technical

Consulting

Consulting

Online Support

Online Support

Field

Field

Service

Service

Support

Support

Tech n ic a l

Technical

Trainin g

Training

Spare Parts

Spare Parts

Engineering

Engineering

Support

Support

Modernization

Modernization

Services

Services

The range of services offered by Siemens Industry Automation

and Drive Technologies includes comprehensive Service and

Support for a very broad range of users.

To accompany our products and systems, we offer integrated

and structured services that provide valuable support in every

phase of the lifecycle of your photovoltaic plant – from

planning, implementation and commissioning to maintenance and modernization.

Online Support

The comprehensive online

information platform supports

you in all aspects of our Service

& Support at any time and from

any location in the world. For

example, you can find technical

product information here.

www.siemens.com/sinvert/

support

Optimization

Optimization

Services

Services

Our Service & Support accompanies you in all matters

concerning our products and systems for photovoltaic plants.

We provide direct on-site support through all phases of the

lifecycle of your photovoltaic plants.

An experienced team of specialists with a pool of expertise is

at your side to provide active support. Regular training courses

and intensive contact with our employees – even across

continents – ensure reliable service in a wide variety of areas.

Technical assistance / hotline

Competent consulting in technical questions covering a wide

range of customer-oriented

services for all our products

and systems.

www.siemens.com/sinvert/

technical-assistance

technical-assistance@

siemens.com

SINVERT Hotline

(in English and German):

Tel.: +49 (911) 895-5900

Service & Support26

Page 27

Training

© Siemens AG 2012

Extend your competitive edge

–

with practical know

-how

directly from the manufacturer.

Familiarize yourself with the

technical details and advantages

of SINVERT solar inverters so

that you can work out the best

plant configuration for any

situation.

www.siemens.com/sinvert/

training

Service programs

■ Spare parts service

– Spare parts

–SparesKits

■ Service calls

– Commissioning

– On-site service

–Maintenance

■ Service contracts

–SparesContract

– WarrantyExtension

– MaintenanceContract

– FullServiceContract

Our service programs comprise

selected packages of services

for photovoltaic plants.

The individual services of a

service program can be flexibly

adapted and used separately.

Advantages at a glance:

■ Comprehensive service from a single source, fewer

interfaces and greater expertise

■ Reliability of service due to assured response times and

spare part delivery times

■ Minimized downtimes

■ Optimized service costs due to a tailored scope of

services

Service & Support 27

Page 28

© Siemens AG 2012

Tailored program of services for SINVERT PVS

Spare parts service

Security of supply of necessary spares - without contractual obligations

The spare parts service for SINVERT PVS offers you two ways

of ordering spares:

– On-demand spare parts delivery

–SparesKits

On-demand spare parts delivery

Spare parts service for SINVERT PVS: On-demand spare parts delivery

The relevant spare part can if necessary be ordered directly

from your regional contact person. Spare parts can be delivered

to anywhere in the world, by express courier if requested.

There is a large selection of individual spare parts available for

SINVERT PVS. Further information can be requested from your

regional contact person.

SINVERT PVS SparesKits

Service calls

Service specialists assure plant availability

Three different types of service call are available:

– Commissioning

– On-site service

–Maintenance

Service calls for SINVERT PVS inverters

Commissioning

The following work is carried out during a commissioning

callout:

– Checking the correct connection of the inverters

– Setting up the inverters

– Testing and documentation

– Professional contact persons on site

On-site service

If troubleshooting via remote access by the Siemens SINVERT

hotline fails to resolve a problem, our specialists can visit your

site on request to offer you advice and assistance.

Spare parts service for SINVERT PVS: SparesKit on-site

Kits stored on site containing spares for the most important

components ensure even greater security of supply:

– SINVERT PVS SparesKit 100 recommended for photo-

voltaic plants containing up to 10 inverter subunits

– SINVERT PVS SparesKit 200 recommended for PV

plants containing more than 10 inverter subunits

– Order numbers see page 25

Service & Support28

Maintenance

You can ask us to dispatch specialists to your site to carry out

preventive maintenance on a date of your choice (in this case,

materials will be supplied by our engineer).

Page 29

Service contracts

© Siemens AG 2012

SINVERT PVS service contracts can be concluded within the

first 24 months following commissioning of the installation.

Depending on the contract type, a contract term of 10, 15

or 20 years can be selected.

24h

New:

24/7 hotline

for contract

customers

Service contracts for SINVERT PVS inverters

The sales contact person in the respective region must be

contacted for specific orders:

SINVERT PVS service contracts safeguard investments.

www.siemens.com/sinvert/partner

Customers can choose between a number of contract

types to suit their individual requirements.

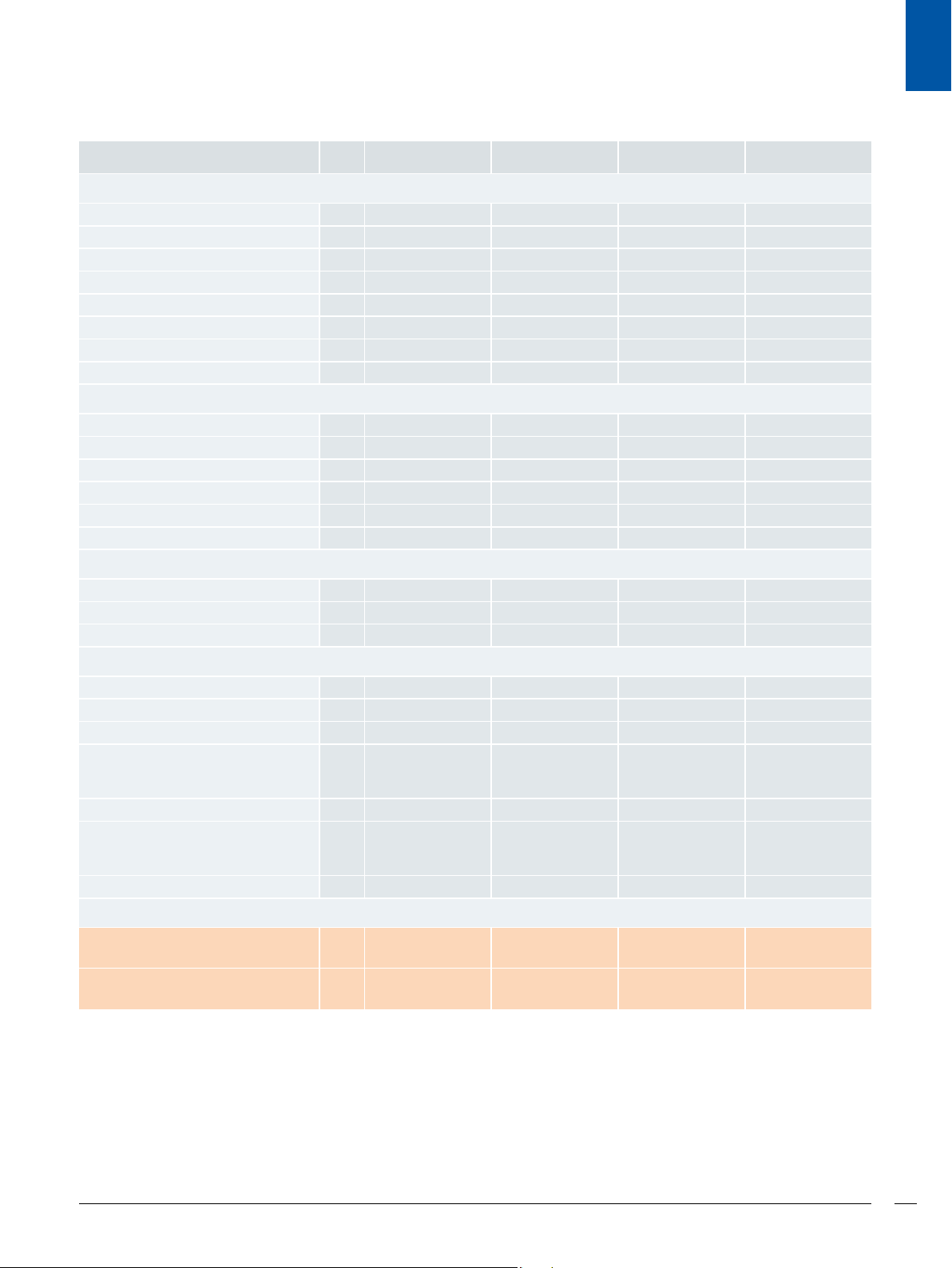

Contract variants and contents SparesContract Warranty

Extension

Benefits level 100 200 300 100 100 100

Spare parts availability over term of contract 9 9 9 9 9 9

Spare parts -- 9 9 9 -- 9

Contractually assured delivery time for spare parts -- -- 3 WD1) -- -- --

Routine maintenance: Maintenance parts -- 9 9 -- 9 9

Routine maintenance: Engineer -- -- -- -- 9 9

Site service calls: Engineer -- -- -- 9 -- 9

Contractually assured response time for technical

support on site

Contractually assured response time for remote

support

Assured repair time -- -- -- -- -- 3 WD1)

Telephone support 24/7 9 9 9 9 9 9

Reimbursement for loss of earnings -- -- 9 -- -- 9

Agreed contract periods in years 15, 20 10, 15, 20 10, 15, 20 10, 20 10, 15, 20 10, 15, 20

9

yes

-- no

1)

WD = working day

-- -- 3 WD1) -- -- --

-- -- -- -- -- 1 WD1)

Maintenance

Contract

FullService

Contract

Service & Support 29

Page 30

© Siemens AG 2012

SINVERT PVS SparesContract –

Spares stocking as a low-cost alternative

SINVERT PVS SparesContract

For large-scale photovoltaic plants operated by customers

who employ their own on-site maintenance personnel, it

might make more sense economically to conclude a spares

contract which would assure availability of spare parts over

the entire contract term.

Three benefits levels

spare part requirements. Any spare parts required shall be tak-

en from the spares kit and replacement parts then ordered

free of charge from Siemens.

All repair and maintenance work shall be carried out by the

customer's own trained service personnel.

In the event that on-site troubleshooting support by a

Siemens specialist is required, a service call must be ordered

separately.

SINVERT PVS WarrantyExtension –

Extends the period of the standard warranty

SINVERT PVS Spares Contracts are available with three

benefits levels (100, 200 and 300) and with contract terms

of 10, 15 or 20 years to suit the individual requirements of the

customer (a contract term of 15 or 20 years must be selected

in combination with benefits level 100).

■ The following applies to all three benefits levels:

– Assured availability of spare parts over the entire

term of the contract

– A 24-hour hotline has been set up to provide technical

support by our Technical Assistance team and to

arrange service calls. Troubleshooting support by

means of remote access will be offered where

necessary.

■ Additional services with benefits levels 200 and 300:

– All spares and routine maintenance parts which are

needed on site over the contract term shall be

provided free of charge by Siemens.

– Siemens will supply the required parts free of charge

on receipt of notification that routine maintenance is

due.

■ Additional services with benefits level 300:

– Contractually assured spare parts delivery time of 3

working days

– Contractually assured response time of 3 working

days for provision of on-site support by a Siemens

engineer

– Reimbursement of loss of earnings in the event that

Siemens cannot respond within the assured times.

A basic condition for conclusion of a SINVERT PVS SparesContrac t

is that the customer purchases a spares kit to cover initial

SINVERT PVS WarrantyExtension service contract

The SINVERT PVS WarrantyExtension option can be selected

as a quick and simple means of extending the standard

5-year manufacturer warranty for the SINVERT PVS inverters.

The customer can choose to extend the warranty to 10 or 20

years depending on individual requirements.

This service contract is intended for customers who wish to

call on support from Siemens specialists when servicing is

required.

The SINVERT PVS WarrantyExtension offers:

■ Spare parts

– The availability of spare parts is assured over the

entire contract term.

– All spare parts which are needed to repair defects

during service calls over the contract term shall be

provided free of charge by Siemens.

■ Telephone support

– A 24-hour hotline has been set up to provide technical

support by our Technical Assistance team and to

arrange service calls.

■ Field support

– After Siemens has received a fault notification,

Siemens specialists will rectify the fault via remote

access or will dispatch service personnel free of

charge to the site in question if this is deemed

necessary.

Service & Support30

Page 31

© Siemens AG 2012

SINVERT PVS MaintenanceContract –

Routine maintenance by Siemens

SINVERT PVS MaintenanceContract

The SINVERT PVS MaintenanceContract ensures that routine

maintenance is provided by Siemens specialists. This service

contract is intended for customers who want to use preventive

maintenance by Siemens specialists as a means of ensuring

that their plant remains fully functional at all times.

The SINVERT PVS MaintenanceContract can be selected with a

contract term of 10, 15 or 20 years depending on the individual

requirements of the customer.

The SINVERT PVS MaintenanceContract offers:

The SINVERT PVS FullServiceContract can be selected with a

contract term of 10, 15 or 20 years depending on the individual

requirements of the customer.

SINVERT PVS FullServiceContract

The SINVERT PVS FullServiceContract offers:

■ Spare parts

– The availability of spare parts is assured over the

entire contract term.

– All routine maintenance parts required to carry out all

the prescribed routine maintenance as well as any

spare parts needed to repair defects during service

callouts will be supplied free of charge by Siemens

over the term of the contract.

■ Spare parts

– The availability of spare parts is assured over the

entire contract term.

– All spare parts required to perform routine mainte-

nance at the prescribed routine maintenance intervals over the term of the contract will be provided

free of charge by Siemens.

■ Telephone support

– A 24-hour hotline has been set up to provide technical

support by our Technical Assistance team and to

arrange service calls. Troubleshooting support by

means of remote access will be offered where

necessary.

■ Field support

– Siemens shall bear all the costs of service engineer

callouts to site required to carry out the prescribed

routine maintenance during the term of the contract.

SINVERT PVS FullServiceContract –

All-inclusive package for all-round service

The all-inclusive SINVERT PVS FullServiceContract is intended

for customers who rely on the support of Siemens specialists

in every case and who wish to enjoy the benefits of all-round

service for their plant.

■ Telephone support

– A 24-hour hotline has been set up to provide technical

support by our Technical Assistance team and to

arrange service calls.

– A response time of one working day for providing

troubleshooting support via hotline/remote access is

guaranteed.

■ On-site service

– Siemens shall bear all the costs of service engineer

callouts to site required to carry out the prescribed

routine maintenance or to eliminate faults during the

term of the contract.

■ The SINVERT PVS FullServiceContract ensures the

following in particular:

– The inverter shall be repaired within three working

days of receipt of notification of a fault from the

customer

– Any loss of earnings shall be reimbursed in the event

that Siemens cannot respond within the guaranteed

times

A basic condition for conclusion of a SINVERT PVS Full Service

Contract is that the customer purchases a spares kit to cover

initial spare part requirements. Any spare parts required shall

be taken from the spares kit and replacement parts then o

rdered free of charge from Siemens.

Service & Support 31

Page 32

© Siemens AG 2012

Get more information:

Technical Assistance

Phone: +49 (911) 895-5900

Fax: +49 (911) 895-5907

E-mail: technical-assistance@siemens.com

Siemens AG

Industry Sector

Control Components and

Systems Engineering

Postfach 2355

90713 FÜRTH

GERMANY

www.siemens.com/sinvert

Subject to change without notice

Order No.: E86060-T1818-A101-A2-7600

MP.R3.XT.0000.00.2.07 / Dispo 46371

BR 0512 3. WÜ 32 En

Printed in Germany

© Siemens AG 2012

The information provided in this brochure contains descriptions

or characteristics of performance which in case of actual use do

not always apply as described or which may change as a result

of further development of the products. An obligation to provide

the respective characteristics shall only exist if expressly agreed

in the terms of contract. Availability and technical specifications

are subject to change without notice.

All product designations may be trademarks or product names

of Siemens AG or supplier companies whose use by third

parties for their own purposes could violate the rights of

the owners.

Loading...

Loading...