Page 1

SINVERT 350, SINVERT 420 and SINVERT 500 TL

Operating Manual – 11/2009

SINVERT

Answers for environment.

1

Page 2

Photovoltaic

SINVERT

SINVERT 350, SINVERT 420 and

SINVERT 500 TL

Introduction

Description

Hardware operation

Alarm and fault messages

Support

1

2

3

4

5

Page 3

Safety instructions

These Operating Instructions contain information which you should observe to ensure your own personal safety

as well as to protect the product and connected equipment. The notices referring to your personal safety are

highlighted in the manual by a safety alert symbol. Notices referring only to equipment damage have no safety

alert symbol. Warnings are shown in descending order according to the degree of danger as follows.

DANGER

indicates that death or serious injury will result if proper precautions are not taken.

WARNING

indicates that death or serious physical injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol indicates that damage to property may result if proper precautions are not taken.

CAUTION

indicates that an unwanted result or state may occur if the relevant instruction is not observed.

In the event of a number of levels of danger prevailing simultaneously, the warning corresponding to the highest

level of danger is always used. A warning that uses a safety alert symbol indicating possible personal injury may

also include a warning relating to material damage.

Qualified personnel

The associated equipment / system may only be set up and operated in conjunction with this documentation. The

equipment / system may only be commissioned and operated by qualified personnel. For the purpose of the

safety information in these Operating Instructions, a "qualified person" is someone who is authorized to energize,

ground, and tag equipment, systems, and circuits in accordance with established safety procedures.

Proper handling

Note the following:

WARNING

The equipment may only be used for single-purpose applications explicitly described in the catalog and in the

technical description, and only in conjunction with third-party devices and components approved by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and

operated and maintained as recommended.

Trademarks

All names shown with the trademark symbol ® are registered trademarks of Siemens AG. Third parties using for

their own purposes any other names in this document which refer to trademarks might infringe upon the rights of

the trademark owners.

Disclaimer of liability

We have checked that the contents of this document correspond to the hardware and software described.

However, since deviations cannot be precluded entirely, we cannot guarantee full consistency. The information

given in this publication is reviewed at regular intervals and any corrections that might be necessary are made in

the subsequent editions.

Siemens AG

A5E

Ⓟ 12/2009

Copyright © Siemens AG 2009

Subject to change

Page 4

Contents

1 Introduction................................................................................................................... 6

1.1 About this documentation........................................................................................ 6

1.1.1 Scope of validity .............................................................................................. 6

1.1.2 Target group.................................................................................................... 7

1.1.3 Document structure ......................................................................................... 7

1.1.4 History ............................................................................................................. 7

2 Description .................................................................................................................... 8

2.1 Application............................................................................................................... 8

3 Hardware operation ...................................................................................................... 9

3.1 Commissioning the inverter..................................................................................... 9

3.1.1 Instructions and safety information.................................................................. 9

3.1.2 Switching off and disconnecting the power supply........................................ 10

3.1.3 Switching on .................................................................................................. 11

3.2 Operating the inverter ........................................................................................... 12

3.2.1 Operator panel .............................................................................................. 12

3.2.2 Operating mode............................................................................................. 14

3.2.3 Switching the inverter on and off ................................................................... 14

3.2.4 Local/Remote selector switch........................................................................ 14

3.2.5 Fault reset ..................................................................................................... 15

3.2.6 Displaying currently active alarms and faults ................................................ 15

3.2.7 Adjusting the voltage ..................................................................................... 15

3.2.8 Grid LED indicator bar................................................................................... 15

3.2.9 Status display ................................................................................................ 15

3.2.10 Fault display .................................................................................................. 16

3.2.11 Numerical display.......................................................................................... 16

3.3 Communication with the inverter........................................................................... 17

3.3.1 WEB’log......................................................................................................... 17

3.3.2 WinCC ........................................................................................................... 17

3.3.3 PPsolar.......................................................................................................... 17

4 Alarm and fault messages ......................................................................................... 26

4.1 Fault handling........................................................................................................ 26

4.1.1 Fault types..................................................................................................... 26

4.1.2 Fault display / messages............................................................................... 26

5.2..................................................................................................................................... 26

4.2 Alarm and fault messages..................................................................................... 27

5.2.3.............................................................................................................................. 28

4.2.1 Faults – Causes/diagnostics/remedial measures.......................................... 29

5 Support ........................................................................................................................ 41

5.1 Contact addresses ................................................................................................ 41

Page 5

Tables

Table 3-1 Pin assignment X5 (SUB-D 9-pin/ RS422 for PPsolar)........................................... 13

Table 4-1 Alarm and fault messages................................................................................. 27

Table 4-2 ISO fault .......................................................................................................... 30

Table 4-3 Fault 0............................................................................................................. 31

Table 4-4 Faults 1 and 33 ................................................................................................ 31

Table 4-5 Faults 4 and 47 ................................................................................................ 32

Table 4-6 Fault 6............................................................................................................. 32

Table 4-7 Fault 12........................................................................................................... 32

Table 4-8 Fault 14........................................................................................................... 32

Table 4-9 Fault 36........................................................................................................... 33

Table 4-10 Fault 37......................................................................................................... 33

Table 4-11 Fault 39......................................................................................................... 34

Table 4-12 Fault 40......................................................................................................... 34

Table 4-13 Fault 43......................................................................................................... 35

Table 4-14 Fault 48......................................................................................................... 35

Table 4-15 Fault 62......................................................................................................... 35

Table 4-16 Fault 63......................................................................................................... 36

Table 4-17 Fault 64......................................................................................................... 36

Table 4-18 Fault 65......................................................................................................... 36

Table 4-19 Fault 91......................................................................................................... 37

Table 4-20 Fault 92......................................................................................................... 37

Table 4-21 Fault 93......................................................................................................... 37

Table 4-22 Fault 94......................................................................................................... 38

Table 4-23 Fault 95......................................................................................................... 38

Table 4-24 Fault 96......................................................................................................... 39

Table 4-25 Fault 97......................................................................................................... 39

Table 4-26 Fault 98......................................................................................................... 39

Figures

Figure 1-1 SINVERT 350/420/500 TL................................................................................... 6

Figure 2-1 Overview of PV system...................................................................................... 8

Figure 3-1 Front view of control panel ............................................................................. 12

Figure 3-2 Front view of control panel ............................................................................. 13

Figure 3-3 Fast ON button and local/remote selector switch .............................................. 14

Figure 3-4 Main menu PPsolar ......................................................................................... 17

Figure 3-5 System Diagram PPsolar .................................................................................. 18

Figure 3-6 Control Panel PPsolar ...................................................................................... 19

Figure 3-7 Oscilloscope function PPsolar .......................................................................... 20

Figure 3-8 Process Data window PPsolar........................................................................... 21

Figure 3-9 Data Storage PPsolar ....................................................................................... 24

Figure 3-10 Analysis window PPsolar ............................................................................... 25

Page 6

Introduction

1.1 About this documentation

1 Introduction

1.1 About this documentation

This manual will provide you with guidance in the use of SINVERT PV inverters. It provides you with a

detailed overview of all the information you need to know about SINVERT PV inverters.

We have checked that the contents of this document correspond to the hardware and software described.

However, since deviations cannot be precluded entirely, we cannot guarantee full consistency. The

information given in this publication is reviewed at regular intervals and any corrections that might be

necessary are made in subsequent editions.

We would be pleased to receive any feedback or suggestions for improvements from you. You will find

our contact details in Chapter 5, "Support".

1.1.1 Scope of validity

This system manual is valid for the following basic models of the SINVERT PV inverter:

• SINVERT 350 M

• SINVERT 420 M

• SINVERT 500 M TL

Figure 1-1 SINVERT 350/420/500 TL

6

Page 7

1.1 About this documentation

and their master-slave variants:

• SINVERT 700 MS (two SINVERT 350 inverters in parallel)

• SINVERT 1000 MS (three SINVERT 350 inverters in parallel)

• SINVERT 1400 MS (four SINVERT 350 inverters in parallel)

• SINVERT 850 MS (two SINVERT 420 inverters in parallel)

• SINVERT 1300 MS (three SINVERT 420 inverters in parallel)

• SINVERT 1700 MS (four SINVERT 420 inverters in parallel)

• SINVERT 1000 MS TL (two SINVERT 500 TL inverters in parallel)

• SINVERT 1500 MS TL (three SINVERT 500 TL inverters in parallel)

• SINVERT 2000 MS TL (four SINVERT 500 TL inverters in parallel)

1.1.2 Target group

This documentation contains information of interest to the following target groups:

Introduction

• Operators

• Service personnel

1.1.3 Document structure

These installation and operating instructions are divided into five chapters:

Chapter Contents

Introduction Information about the operating manual, overview of inverter types,

target group

Description Applications of SINVERT PV inverters

Hardware operation Inverter operating guide

Alarm and fault messages

Support Contact details and information about support for SINVERT inverters

1.1.4 History

Currently released editions of this manual:

Edition Remark

List of alarm and fault messages, causes and measures

and products by Siemens I IA S PV

11/2009 First edition

7

Page 8

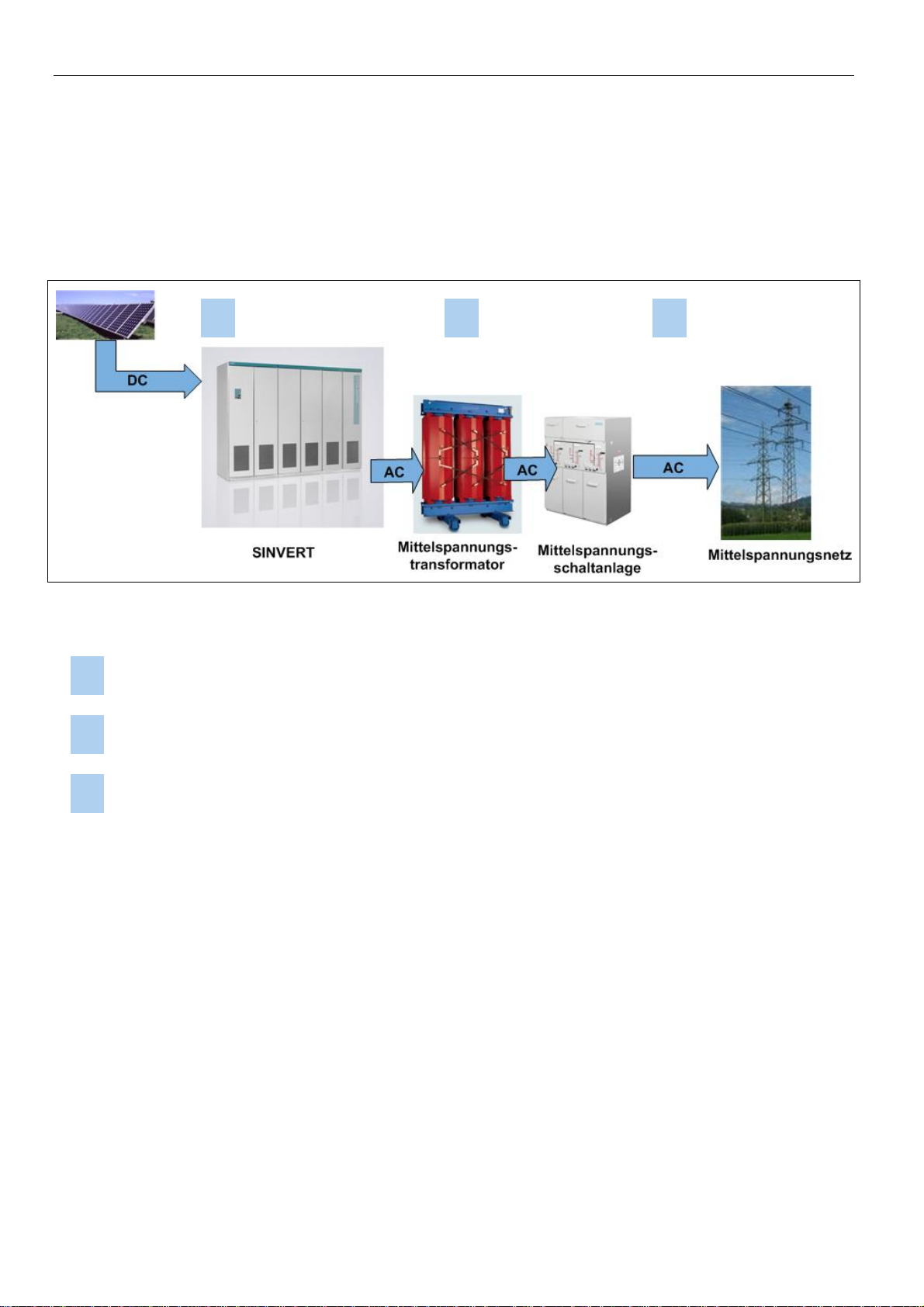

Description

2.1 Application

2 Description

2.1 Application

The SINVERT PV inverter is a fully assembled, ready-to-connect inverter unit for PV installations.

1 2 3

Figure 2-1 Overview of PV system

1

2

3

The inverter transforms the DC voltage produced by the PV modules into an AC voltage.

The AC output voltage is transformed to the grid voltage by a medium-voltage transformer.

The PV solar system can thus be connected to the medium-voltage grid.

8

Page 9

Hardware operation

3.1 Commissioning the inverter

3 Hardware operation

3.1 Commissioning the inverter

Commissioning an installation requires certain switching operations to be performed. This type of work

must always be undertaken by qualified, properly trained personnel. Failure to perform switching

operations correctly can result in significant property damage and serious physical injury. The

components described in this manual operate at hazardous voltages and currents. Proper precautions

must be taken during the commissioning process. This manual describes only the manual process of

switching the PV system on and off.

The system must be switched on and off manually in order to carry out performance tests and

maintenance procedures.

3.1.1 Instructions and safety information

In accordance with the relevant standards and legislation (e.g. DIN VDE 0105), properly trained

specialists must always be employed to operate and control electrical equipment.

All employees authorized to undertake switching tasks must receive instruction in accordance with the

relevant standards and legislation (in Germany, at least once annually in accordance with BGV A1 §4

(Institute for Statutory Accident Insurance and Prevention/Instruction of Insured Persons)).

Follow all safety guidelines and work instructions stipulated by the relevant legislation and standards.

Never take any action which would endanger either yourself or others.

The five safety rules in Germany:

1. Isolate from power supply

2. Provide a safeguard to prevent unintentional reclosing

3. Make sure that the equipment is de-energized

4. Ground and short

5. Cover or place guards around adjacent live parts

CAUTION

The instructions and guidelines relating to operation and control of the installation contained in the operating

manuals for the switching equipment and other devices described here must be adhered to.

CAUTION

The safety rules (for example, DIN VDE 0105 – 100 § 6.2 in Germany) are especially applicable to switching or

voltage disconnection operations.

If you are working abroad, you must adhere to the relevant local safety rules. Always pay particular care and

attention when working on or around electrical equipment.

9

Page 10

Hardware operation

3.1 Commissioning the inverter

3.1.2 Switching off and disconnecting the power supply

The entire system must be disconnected from the power supply before test and maintenance work can

be carried out in the containers. Carry out these tasks in the sequence given below:

1. Press the OFF key briefly on the control panel of every inverter.

2. For reasons of safety, also press the Fast Stop button (if one is installed) in the inverter room.

3. Disconnect the external power supply (most commonly in the AC distribution cabinet) by opening

the fuse switch disconnector or by switching off the miniature circuit breaker.

4. Open the AC-side and DC-side fuse switch disconnectors in all inverters and remove the fuses,

including the fuse holder, or remove the fuse cartridge with a fuse tong. This means that the

inverter cannot be switched on again (remember the five safety rules).

DANGER

The AC and DC connections are still live externally!

5. In order to disconnect the AC end completely from the power supply, the relevant medium-voltage

transformer must be switched off at the medium-voltage switchgear. After switching off, open the

medium-voltage isolator and close the medium-voltage grounding switch. The machine switching

operations on the medium-voltage components must be performed via the power supply company

or an authorized person.

6. In order to disconnect the DC end completely from the power supply, all relevant junction boxes of

the generator and coupling boxes (if installed) must be disconnected. The disconnectors in the

generator junction boxes and/or coupling boxes (if installed) can be switched under load. In

contrast, fuse switch disconnectors must not be switched under load. Likewise, fuse cartridges in

fuse holders must not be removed under load.

DANGER

Fuse switch disconnectors in the inverters and junction boxes must not be switched under load! Do not remove

fuse cartridges when they are under load!

10

Page 11

Hardware operation

3.1 Commissioning the inverter

3.1.3 Switching on

The inverter is switched on in the same way as it is switched off, but in the reverse sequence.

1. Check that all connections have been made correctly (including polarity).

2. Switch on the junction boxes in the PV field.

3. Switch on the external power supply for the medium-voltage switchgear.

4. Switch on the external power supply for the inverter container.

5. Close the medium-voltage breaker.

o Open the grounding switch.

o Close the switch disconnector.

o Close the circuit breaker.

o Note: Depending on the type of MV switchgear installed, the step sequence might vary.

6. Close the DC fuse switch disconnectors in all inverters.

7. Close the AC fuse switch disconnectors in all inverters.

8. Unlock the "Fast Stop" button.

9. Turn the keyswitch on all inverters from "Auto" to "Test" and back to "Auto" in order to reset

settings.

10. If insolation levels are sufficiently high, the system will restart automatically after 30 minutes.

11. To start the system immediately, you must turn the keyswitch on the master to the test position.

Then press the internal key "S111".

12. The DC contactors are automatically closed one after the other. The inverter is then started and

the AC contactor is immediately closed. Now turn the keyswitch to "Auto".

11

Page 12

Hardware operation

3.2 Operating the inverter

3.2 Operating the inverter

3.2.1 Operator panel

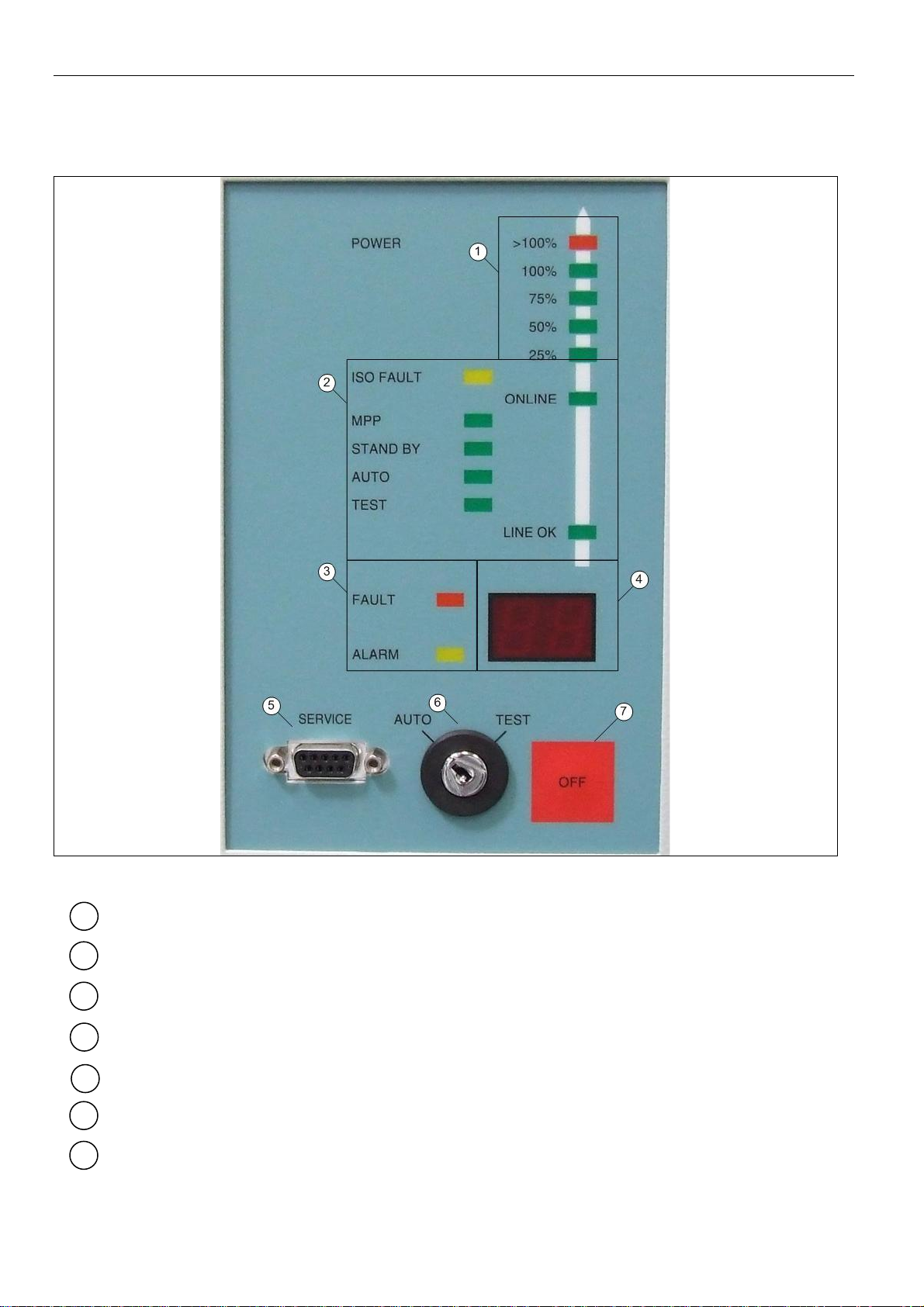

Figure 3-1 Front view of control panel

Grid LED indicator bar

1

Status display

2

Fault display

3

Display

4

Service interface (RS 232)

5

Keyswitch (operating mode)

6

OFF key

7

12

Page 13

Hardware operation

3.2 Operating the inverter

Figure 3-2 Front view of control panel

Table 3-1 Pin assignment X5 (SUB-D 9-pin/ RS422 for PPsolar)

Pin Signal

1 RRS485P

5 TRS485N

6 TRS485P

9 RRS485N

13

Page 14

Hardware operation

3.2 Operating the inverter

3.2.2 Operating mode

You can choose between modes "Automatic" and "Test".

In Test mode, you can adjust the DC voltage manually. In Automatic mode, the inverter determines the

Maximum Power Point (MPP) automatically. It also displays currently active fault messages.

To select Test mode, turn the keyswitch to the "TEST" position. To select Automatic mode, turn the

keyswitch to the "AUTO" position.

3.2.3 Switching the inverter on and off

The inverter switches on and off automatically in AUTO mode. Manual switching on and off is possible in

both TEST mode and AUTO mode.

The control electronics and control panel of the inverter are switched off temporarily in order to save

energy. When the inverter is in this state, it cannot be operated via the panel. However, you can switch

on the control electronics and control panel for maintenance and commissioning purposes. To do so,

open the cabinet door and press the Fast ON button inside the inverter. Once you have switched on the

panel, you can switch the inverter on and off as described below.

To switch off the inverter during operation, briefly press the OFF button on the operator panel (less than 3

seconds).

To switch on the inverter, briefly press the OFF button on the operator panel (less than 3 seconds) in

TEST mode.

3.2.4 Local/Remote selector switch

If the selector switch is set to Local, errors can only be acknowledged locally and the inverter can be

started manually. Remote access is blocked in this switch position.

In the Remote position, errors can also be acknowledged and the inverter started by a plant monitoring

system (such as WinCC). In this position, the inverter can also be operated locally and started manually.

Figure 3-3 Fast ON button and local/remote selector switch

14

Page 15

Hardware operation

3.2 Operating the inverter

3.2.5 Fault reset

You can reset a fault by turning the keyswitch from "AUTO" to "TEST" and back to "AUTO" or vice versa.

If the inverter has been disabled due to a fault, it can now be activated again.

3.2.6 Displaying currently active alarms and faults

In Automatic mode, you can display the last ten alarm and fault codes. To do this, press the OFF key in

Automatic mode for more than 3 seconds. The alarm and fault codes will then appear in sequence on the

two-digit display.

3.2.7 Adjusting the voltage

In Test mode, you can adjust the voltage at the DC connections for test and commissioning purposes. To

do this, press the OFF key in Test mode for more than 3 seconds. The voltage is then adjusted in

increments of 10°V across the entire voltage window. The two-digit display shows the first two digits of

the DC voltage value (for example, 55 represents a voltage of 550 V DC).

3.2.8 Grid LED indicator bar

The grid LED indicator bar shows the power output of the inverter system in increments of 25%. The

display refers to the output of the relevant individual inverter. In Automatic mode, the total system output

of the master/slave unit is shown on the two-digit display.

3.2.9 Status display

The status display indicates the status of the whole system.

Insulation fault/alarm (LED "ISO FAULT")

If the insulation resistance between the PV field and ground is too low, there is a risk of electric shock if

you touch the PV modules. The inverter is equipped with an insulation monitoring device which detects

this hazard and outputs an alarm.

If the insulation resistance is in the range that is dangerous for people, an insulation warning is triggered

and the "ISO FAULT" LED flashes.

If the insulation value is in the range that is dangerous for the system, the "ISO FAULT" LED lights

continuously and the inverter releases the relevant inputs. Even when switched off, a system with an

insufficient insulation value represents a danger.

The cause of the low insulation value must be immediately rectified.

DANGER

The cause of the low insulation value must be immediately rectified.

Even when switched off, a system with an insufficient insulation value represents a danger.

CAUTION

Insulation faults reduce system yield!

The cause of the low insulation value must be immediately rectified.

Ready to run (LED "ONLINE")

The "ONLINE" LED lights up steadily while the inverter is in operation. The DC contactors and the main

AC contactor are closed and the power unit is generating voltage.

15

Page 16

Hardware operation

3.2 Operating the inverter

Maximum Power Point (LED "MPP")

The power which can be generated by a PV system depends on the level of insolation and the

temperature of the PV modules. The inverter control unit is equipped with a "Tracker" which automatically

tracks the MPP (Maximum Power Point) of the PV field in Automatic mode. As soon as the inverter

tracker has found the MPP, the LED "MPP" lights up.

A flashing "MPP" LED indicates throttling of the inverter due to overtemperature of the cooling element.

Standby operation (LED "STANDBY")

The LED "STANDBY" lights up if the power unit of the inverter is switched off, but the control electronics

and control panel are switched on (for example, if the PV field output is not sufficient to compensate for

the losses, or if the inverter has been switched off manually). The AC contactor is open, and the DC

contactors are open, closed or switching between these two states (in order to check whether sufficient

voltage/output is available to start operation).

Automatic mode / Test mode

The LEDs "AUTO" and "TEST" indicate the current operating mode of the inverter.

Line (grid) status (LED "LINE OK")

The inverter is equipped with a monitoring unit for the three-phase AC grid. This can detect grid faults or

failures. If a fault is detected, the inverter shuts the system down to prevent the regeneration of

hazardous voltages to the grid. The LED "LINE OK" indicates that the grid voltage and frequency are

within the programmed limit values.

3.2.10 Fault display

If malfunctions in the PV installation develop which affect only certain parts of the system and do not

prevent it from regenerating energy to the grid, operation continues and the inverter triggers an alarm. If a

malfunction develops which affects the entire system, the inverter is switched off with a fault message.

The LED "ALARM" flashes to indicate an alarm.

The LED "FAULT" lights up steadily to indicate a fault.

3.2.11 Numerical display

In Automatic mode, the output of the whole PV system as a percentage of rated output is shown on the

two-digit display. If the output is more than 99%, a value of "00" is displayed. At the same time, the LED

">100%" lights up in the grid indicator bar.

In Test mode, the two-digit display shows the first two digits of the set DC voltage value (for example, 55

represents a voltage of 550 V DC).

Codes for malfunctions

In the event of a fault or alarm (in Test or Automatic mode), a corresponding code appears on the

display. The meaning of these codes can be found in table 4-1. The code will remain displayed until the

operator resets the alarm or fault by means of the keyswitch.

16

Page 17

Hardware operation

3.3 Communication with the inverter

3.3 Communication with the inverter

Various possible methods of communicating with the inverter are presented below.

3.3.1 WEB’log

WEB’log is generally used to log inverter data, i’checker data and meteorological data which has been

recorded while the inverter is in operation. This data can be represented graphically in an Internet portal.

In systems with WinCC, WEB’log serves as an interface for the i'checker sensors.

3.3.2 WinCC

The description of functions and directions for use of WinCC can be found in a separate document.

3.3.3 PPsolar

By selecting button "New" in the main menu, you can access the screen for entering the names of the

connected SINVERT units. You must enter the relevant names (up to maximum 40 characters in length)

in the box "SINVERT name". The slave addresses are automatically incremented from 0 to 31, which

means that you can register up to 32 SINVERT inverters in this program. The maximum permissible

length of data cable to the local PC is 100 m. Up to four SINVERT units can be displayed at one time. If

more than four are displayed, the transmission rate decreases significantly.

Figure 3-4 Main menu PPsolar

By double clicking on the name of an inverter, you will branch to submenus System Diagram, Control

Panel, Oscilloscope, Process Data, Data Storage, etc. Double click on one of these to open the relevant

window.

The System Diagram (Figure 3-5) shows the entire PV plant, including the PV generator, DC contactor,

inverter, AC contactor and grid interface. The status of the system components and the energy flow

within the system are represented by different colors in the diagram.

17

Page 18

Hardware operation

3.3 Communication with the inverter

Gray: No information available about the system components

Blue: System components are ready; no energy flowing

Green: System components are running; energy is flowing

Red: System components are malfunctioning

Figure 3-5 System Diagram PPsolar

The System Diagram contains the electrical data of the entire PV installation plus all important

information about the operating status of the system (voltage, current, output, frequency). Additional

meteorological measured data, such as insolation, temperature and wind speed, can also be displayed (if

the corresponding sensors are installed). The windows for faults and alarms contain a list in plain text of

all malfunctions and alarms.

18

Page 19

Hardware operation

3.3 Communication with the inverter

The Control Panel (Figure 3-6) contains the same display and control elements as the control panel of

the SINVERT PV inverter.

Figure 3-6 Control Panel PPsolar

19

Page 20

Hardware operation

3.3 Communication with the inverter

The Oscilloscope function (Figure 3-7) enables you to record data in two channels and to print output

voltages, output currents, inverter currents and the PV generator voltage. The right to use this special

function is reserved for Siemens customer service personnel.

The trigger control function enables you to choose the events which will trigger measured data

recordings. A measurement can be triggered by a malfunction, a grid (mains) failure or when the inverter

is switched on or off. You can also manually trigger a recording.

You can set the X axis scaling to one of three values:

Fine: approx. 2 ms per division

(scan rate 12 kHz with 255 pixels = 21.25 ms)

Medium: approx. 25 ms per division

(scan rate 1 kHz with 255 pixels = 255 ms)

Coarse: approx. 100 ms per division

(scan rate 250 Hz with 255 pixels = 1020 ms)

Figure 3-7 Oscilloscope function PPsolar

20

Page 21

Hardware operation

3.3 Communication with the inverter

The Process Data window (Figure 3-8) displays information about the inverter. For the sake of better

clarity, the window is divided into a number of panes. You can specify the number of panes and their

content in a configuration file. In the default configuration, the content of the individual panes is as

follows:

Device Information

The device information box displays the software version of the CU4 control unit. The date of software

creation (day, month and year) is specified. In addition, the box also shows the performance class,

MLFB, operating hours and status of the inverter (sequence control status).

Figure 3-8 Process Data window PPsolar

SINVERT-Settings

You can adjust the inverter settings in this screen, e.g. normal operation, standard and expert mode

(depending on access authorization).

The setting Normal Operation permits access only to monitoring functions, but inhibits changes to

parameter values.

The setting Standard permits parameter values to be changed.

The setting Experts permits special, extensive changes to parameter values.

Various functions can be selected for the settings. When you select the Return function, values cannot

be changed. This means that a pure monitoring function is assigned to the setting. The function Initial

Program Loading essentially initializes the inverter and is generally only used to restore the Siemens

factory settings. The function Commissioning permits parameters to be changed during the

commissioning process.

21

Page 22

Hardware operation

3.3 Communication with the inverter

Actual Value Summary

The window with the overview of actual values displays a summary of key data of the PV system.

You can alter data (e.g. reactive power transfer from SINVERT to the three-phase AC grid) in this window

when it is active.

Actual values

The Actual Values window displays all electrical data of the PV system, as well as information about

weather and insolation.

You can alter data (e.g. reactive power transfer from SINVERT to the three-phase AC grid) in this window

when it is active.

22

Page 23

Hardware operation

3.3 Communication with the inverter

The Data Storage window (Figure 3-9) is used to start, stop and configure the data archiving function of

the PowerProtect solar system. The data to be archived, the scan rate, the data length and archiving path

are specified in this window.

The scan rate (t

archive file, can be freely selected (t

> xxs) and the data length, i.e. the period for which the data will remain stored in the

scan

> 1 day). Furthermore, you can define the number of panes and

file

their content to suit your own needs by means of parameters in a configuration file. In the default

configuration, the following panes are available:

• Weather conditions

• PV generator

• Mains interface

• Energy

The archiving function in PowerProtect solar is purely a data archiving function, but does not allow

visualization or analysis of data.

Weather conditions

All weather data available for the PV system are displayed in the Weather Conditions window. Check the

boxes for the values that you want PowerProtect solar to store. You can select the following data (*

provided the relevant sensors are installed in the PV system):

• Temperature *

• Wind velocity *

• Global insolation *

PV Generator

The PV Generator window displays all available information about the PV generator. Check the boxes for

the values that you want PowerProtect solar to archive. You can select the following data (* provided the

relevant sensors are installed in the PV system):

• Module temperature *

• Module irradiation *

• Voltage (V) PV Generator

• Current (I) PV Generator

• Power (P) PV Generator

Mains Interface

The Mains (Grid) Interface window displays all the available data about the grid connection. Check the

boxes for the values that you want PowerProtect solar to archive. You can choose from the following

values:

• Phase voltage

• Phase current

• Phase reactive current

• Phase apparent power

• Total active power

• Total reactive power

• Total apparent power

23

Page 24

Hardware operation

3.3 Communication with the inverter

Energy

The Energy window displays all the available energy data of the PV system. Check the boxes for the

values that you want PowerProtect solar to archive. You can select the following data (* provided the

relevant sensors are installed in the PV system):

• Energy - day

• Energy - month

• Energy - year

• Energy - total

Figure 3-9 Data Storage PPsolar

24

Page 25

Hardware operation

3.3 Communication with the inverter

The Analysis window (Figure 3-10) displays the data archived by PowerProtect solar. The data are saved

in Microsoft Access database format by the data storage function. You can access this information at any

time, even while the archiving function is active. The Analysis window also provides functions for printing

out data, copying data to the Windows clipboard or editing data in MS Excel or Access.

You can choose one of four different display modes:

• Graphical Trend

• Tabular Trend

• Momentary Values

• Text Messages

You can display individual trends simultaneously in different windows.

Figure 3-10 Analysis window PPsolar

25

Page 26

Alarm and fault messages

4.1 Fault handling

4 Alarm and fault messages

4.1 Fault handling

4.1.1 Fault types

There are two different types of fault, i.e. plant faults and operational faults. Plant faults are caused by

malfunctioning of an inverter component, while operational faults occur as a result of unexpected external

influences or logical conditions of the control software.

Examples of plant faults:

• F48

• F65

• F97

Examples of operational faults:

• F94

• F96

It is however possible for an operational fault to be caused by a defective component.

Example: Fault 96 can be caused by a defective capacitor or transformer at the AC output.

4.1.2 Fault display / messages

Faults are displayed at the following locations:

• Inverter control panel

• Control panel in PPsolar

• S7 software modules

• WinCC

Fault messages are transferred to the following locations:

• FAX Alarm

• WEB’log

• WinCC

Sequential faults: In some cases, the first fault can trigger further sequential faults which are

superimposed on the first fault or overwrite it on the display.

26

Page 27

Alarm and fault messages

4.2 Alarm and fault messages

4.2 Alarm and fault messages

The table below provides an overview of alarm and fault messages supplied on the inverter.

Table 4-1 Alarm and fault messages

No. Meaning Category Main cause

0 Manual Off Fault

1

4

Inverter power unit is signaling

overtemperature, stage 1

Inverter overload; i

2

-t protection

(alarm), stage 1

Alarm

Alarm Parameter setting error

Ambient temperature too high, fan defect,

interruption in auxiliary supply to fans

6 Overload Alarm Parameter setting error

12 Inverter is in commissioning mode Alarm Parameter setting error

14

33

36

37

Fans have exceeded useful life,

replacement required

Inverter power unit is signaling

overtemperature, stage 2

Fast Stop (1) activated, AC contactor

defective (no checkback signal from

contactor)

Several start attempts in quick

succession

Alarm Replace fans

Fault

Fault

Fault

Ambient temperature too high, fan defect,

interruption in auxiliary supply to fans

Fast Stop button pressed or AC contactor

defective

DC link voltage too low, current too high, inverter

in test mode, no Vdc setpoint

39 Overvoltage in the DC link (VDCgg) Fault PV field is incorrectly connected

40

Fast Stop (2), Fast Stop via customer

terminal block

Fault Fast Stop button pressed

43 VCE protection activated Fault Defective component in the power unit

2

47

48

Inverter overload; i

(fault), stage 2

Regeneration to the DC link or

defective AC contactor

-t protection

Fault Parameter setting error

Fault Parameter setting error, AC contactor defective

49 Undervoltage in the DC link Alarm PV field is disconnected from the inverter

62 No checkback signal "Inverter ON" Fault Signal cable is not connected correctly

63

Direct current too high or signal cable

is defective

Fault

Parameter setting error, fault at S7 analog input,

signal cable defective

64 Vdc too high or Vdc/dt too high Fault PV field is incorrectly connected

No checkback "AC contactor closed"

65

or no checkback "DC contactor

Fault Contactor defective, signal cable defective

closed"

66 General inverter fault Fault Defective component in the power unit

91 Fuse tripped Fault

Overvoltage or short circuit has occurred,

hardware may be defective

27

Page 28

Alarm and fault messages

4.2 Alarm and fault messagesAlarm and fault messagesAlarm and fault messages

DC overvoltage protection has

92

93

94 Profibus error Fault

responded (or fuse (if installed) has

tripped)

Fast Stop activated or overvoltage on

medium-voltage transformer

Fault Overvoltage (lightning strike) has occurred

Fault

Fast Stop button pressed, fault in cooling system

of medium-voltage transformer

95 Grid frequency outside tolerance Fault

96 Grid voltage outside tolerance Fault

No checkback from DC link contactor

97

98 Symmetry fault in the PV field Fault Fault in at least one PV field string

100 Image in the display (WinCC) No fault (generated by the control unit)

LED

"ISO"

flashing

LED

"ISO" lit

steadily

or failure of cooling fan in the

container

Insulation fault in the PV field (alarm) Alarm Cable damaged, module damaged, rain

Insulation fault in the PV field (fault) Fault Cable damaged, module damaged, rain

Fault

Phase sequence is anti-clockwise, grid failure,

parameter setting error

Grid voltage outside tolerance (possibly grid

failure as well), voltage measurement error,

parameter setting error

DC link contactor defective, signal cable

defective, container fan defective

28

Page 29

Alarm and fault messages

4.2 Alarm and fault messages

4.2.1 Faults – Causes/diagnostics/remedial measures

First acknowledge the fault with the keyswitch on the control panel.

Check the following if the inverter has not been in operation:

• Polarity of the PV field input

• Polarity of the DC link connection

• AC phase sequence

• AC voltage (phase-phase, phase-N)

Check the following if the inverter has been in operation:

• Is the Fast Stop button in the locked position?

• Is the external power supply available?

• Is the control voltage (24 V DC) present at the relevant terminals?

• Is the grid voltage within tolerance?

• Have fuses blown or have automatic fuses tripped? If yes, find the cause of the problem.

If none of the reasons above is the source of the fault, it may have been caused by a problem on the

control unit.

If a CU printed circuit board is defective, it must be replaced with a new one. Never install a CU in a

different device to check whether it is defective or not.

This could cause very serious damage to the other device.

(Read out and check all CU parameters.)

(Read out and check the S7 HW Config.)

Differences in potential in the PV field

If a PV system is not yielding the required output, the problem could indicate a difference in potential.

This means that there is a difference in voltage between the field segments. Because the field segments

are connected in parallel, an average voltage value is supplied under these conditions and this means in

turn that the field segments are not operating at the MPP.

To identify this type of fault, measure the no-load voltage and the MPP voltage at the inverter inputs and

compare the measured values. A deviation of more than 10 V is an effective difference in potential which

will cause a reduction in output.

29

Page 30

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-2 ISO fault

ISO fault

Causes

Diagnostics

Measures

Damaged, worn-through cables (loose, buffeted by

wind)

Cables damaged by animals

Water in junction box

Damaged insulation and ingress of water to cable

duct

Defective power unit

Bending device defective

Defect in PV module (damaged)

High air humidity (causes high leakage currents)

Check the sensitivity (limit values) of the insulation

monitor using a decade resistor

Repair the cabling

Empty and dry out the junction boxes and / or cable

ducts

Repair / replace the drive

30

Page 31

Table 4-3 Fault 0

(Alarm) General fault on transformer

Table 4-4 Faults 1 and 33

Message 1 (alarm): Inverter is signaling overtemperature, stage 1

Fault 33 (alarm): Inverter is signaling overtemperature, stage 2

Condition

Causes

Measures

Condition

Causes

The hardware contact in the power unit has tripped.

There is a defect in the inverter.

Replace the affected components.

Replace the drive.

An excessive heatsink temperature in the inverter has

been detected.

The thermoclick circuit for the reactors and transformers

has been interrupted.

Cooling system is not working properly

o Drive fan is not running

o Heatsink is blocked

o Drive fan speed is too low

Heat generation is exceeding tolerance

o Current is too high

o IGBT module defective

Fault in measured-value sensing

o Temperature sensor in heatsink is defective

o Temperature sensor connection is defective

o CU data input is defective

Reactor or transformer is overheating (fault 33 only,

without preceding warning level 1 in the PPsolar

event memory)

o Cooling system is not working properly

Alarm and fault messages

4.2 Alarm and fault messages

⇒ Fan motor is defective

⇒ Start capacitor is defective

⇒ No power supply to fan

⇒ USI is defective

⇒ Infeed transformer is defective

⇒ Infeed transformer is connected to tap

460 V instead of 400 V

⇒ Parameter setting error (CU software –

current limit value)

⇒ Housing fans are not running

⇒ Fans are defective

⇒ Thermostat is defective

⇒ Thermostat is incorrectly set

⇒ Air intake is restricted

⇒ Air inlet grille on housing is clogged

up

⇒ Air outlet is restricted

31

Page 32

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-5 Faults 4 and 47

Fault 4 (alarm): Inverter overload, I²t monitoring, stage 1

Fault 33 (alarm): Inverter is signaling overtemperature, stage 2

Causes Inlet air temperature too high

Measures

Condition

Causes

Measures

Replace the defective components

Check the parameter settings

Clean or enlarge the air inlet

The CU has detected a current which is higher than the

permissible l²t limit.

Excessive current

Fault in measured-value sensing

Adjust the parameter settings

o Air inlet to switchroom is blocked

o Air outlet from switchroom is restricted

o Ambient temperature is too high

o Parameter setting error (CU software –

current limit value)

o Parameter setting error (CU software - limit

value I

2

t)

Table 4-6 Fault 6

(Alarm) overload

Table 4-7 Fault 12

(Alarm) System is in commissioning mode

Table 4-8 Fault 14

(Alarm) Fan has exceeded its useful life

Condition

Causes

Measures

Condition

Causes

Measures

Condition

Causes

Measures

The CU has detected a current which is higher than the

selected permissible value.

USI is defective

AC current transformer defective

Parameter setting error

Adjust the parameter settings

The CU has detected that commissioning mode is

selected

The CU is in commissioning mode

Set the CU operating mode to "Reversion"

The hours counter in the CU has reached "0" (hours are

counted backwards)

The fan has operated for 35,000 hours since initial

commissioning

The value set initially for the hours counter was too low

Replace the fan.

Set the hours counter to 35,000 hours.

The fans do not necessarily develop defects after working for this number of hours.

32

Page 33

Table 4-9 Fault 36

(Alarm) AC contactor defective (no checkback), or Fast Stop button pressed

Condition

Causes

Measures

There is no signal at input 11/12 of the CU (green

connector); transferred via Profibus to the S7; drive has

received an ON command.

No power supply for Fast OFF

o Fast Stop button has been pressed

o Wire break in the Fast OFF circuit

o Defect in power supply for Fast OFF

o Fire alarm system has been activated (if

installed)

No checkback signal from the AC contactor

o Defect in AC contactor control circuit (power

pack)

o Defect in AC contactor coil

o Defect in auxiliary contacts of AC contactor

o Wire break

Unlock the Fast Stop button.

Replace the AC contactor

Unlatch the contacts of the AC contactor

Repair the cabling

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-10 Fault 37

(Alarm) Several restart attempts in succession

Condition

Causes

Measures

The S7 has tried several times without success to

restart the drive

Fault in the drive

Operational fault (might be rectified automatically)

Repair the drive

33

Page 34

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-11 Fault 39

(Alarm) DC link overvoltage

Condition

Causes

The CU has detected a DC voltage in excess of the

permissible value

The measured DC voltage is too high

o The available DC voltage is too high

⇒ The PV field has been connected

incorrectly (the voltage rises too sharply at

high temperatures, mostly under no load)

o DC voltage measurement error

⇒ Parameter setting error (CU software)

⇒ Power pack defective (measured-value

sensing)

Measures

Table 4-12 Fault 40

(Alarm) Fast Stop 2; Fast Stop via customer terminal block

Condition

Causes

Measures

Adjust the parameter settings

Replace the power pack

Change the connection and/or the cabling of the PV field

Connect a braking resistor

There is no signal at input 11/12 of the CU (green

connector); transferred via Profibus to the S7; drive has

not received an ON command.

No line voltage for Fast OFF

o Fast Stop button has been pressed

o Wire break in the Fast OFF circuit

o No power supply for Fast OFF

o Fire alarm system has been activated (if

installed)

o No jumper on terminal strip X50 (if no Fast

Stop button is connected)

Unlock the Fast Stop button.

Repair the cabling

34

Page 35

Table 4-13 Fault 43

(Alarm) Vce monitor has responded

Table 4-14 Fault 48

(Alarm) Regeneration to the DC link

Condition

Causes

Measures

Condition

Causes

Measures

Alarm and fault messages

4.2 Alarm and fault messages

The CU has detected an inadmissible circuit voltage

(voltage on semiconductor module between emitter and

collector).

Power unit is defective (various components could be

the source of the problem)

Transformer is defective

AC capacitors are incorrectly connected (connection

does not comply with circuit diagram)

Repair or replace the power unit

Replace the transformer

Connect up the AC capacitors correctly

The CU has detected current flowing to the PV field

(from AC to DC) which is higher than the set permissible

current value.

Parameter setting error (CU software)

Drive is defective

Adjust the parameter setting

Repair the drive

Table 4-15 Fault 62

(Alarm) No checkback signal "Inverter ON"

Condition

Causes

Measures

The S7 is not receiving a checkback signal in response

to the ON command to the drive

CU defective

Defective power unit

Profibus error

Replace the defective components

Set up a Profibus connection

35

Page 36

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-16 Fault 63

(Alarm) Direct current too high

Table 4-17 Fault 64

(Alarm) Vdc or dVdc/dt too high

Condition

Causes

Measures

Condition

Causes

Measures

The CU / S7 has detected a direct current in excess of

the set permissible limit

Parameter setting error (S7 software)

Parameter setting error (CU software)

Open circuit (detected by the S7 and indicated by this

fault code)

Isolation amplifier is incorrectly set

Adjust the parameter settings

Repair the cabling

Set the isolation amplifier correctly

The CU has detected a DC voltage or an abrupt change

in the DC voltage in excess of the permissible maximum

value

Parameter setting error

Connected DC voltage is too high

Adjust the parameter settings

Replace the power pack

Check the connection and/or the cabling of the PV field

Install a braking resistor

Table 4-18 Fault 65

(Alarm) No checkback signal from the AC or DC contactor

Condition

Causes

Measures

Signal is missing at the relevant S7 inputs

S7 relay output module defective

Incorrect setting in the S7

DC contactor is defective

AC contactor is defective

Fault in power supply

Wire break

Replace the S7 relay output module

Adjust the parameter setting

Replace the defective contactor

Repair the power supply

Repair the cabling

36

Page 37

Table 4-19 Fault 91

(Alarm) Fuse has tripped

Table 4-20 Fault 92

Condition

Causes

Measures

Alarm and fault messages

4.2 Alarm and fault messages

No power supply available for signaling circuit

A contact in the signaling circuit is open

o A fuse has tripped

o Fuse is not inserted, or not correctly inserted

o Other contacts (AC cabinet, medium voltage)

are open

No power supply for the signal

Wire break

Temporary Profibus failure

Replace the fuse (always replace plus and minus at the

same time)

Repair the power supply

Repair the cabling

(Alarm) Overvoltage protection has responded

Condition

Causes

Measures

Table 4-21 Fault 93

(Alarm) Fast Stop button has been pressed

Condition

Causes

Measures

No power supply available for the signaling circuit of the

surge arrester monitor

Open signal contact on a surge arrester

o Surge arrester has tripped

o Plug-in module is not inserted, or not correctly

inserted

o No AC auxiliary power supply connected to the

surge arrester in the AC distribution board

(DEHN valve) (if installed)

Fault in signal power supply

Wire break

Temporary Profibus failure

Replace the surge arresters (always replace plus and

minus or all three phases at the same time)

Repair the power supply

Repair the cabling

No voltage connected to the Fast Stop contact on the

S7

Fast Stop button has been pressed

Fault in power supply for Fast OFF

Wire break in the Fast OFF circuit

Fire alarm system has been activated (if installed)

Unlock the Fast Stop button.

Repair the power supply

Repair the cabling

37

Page 38

Alarm and fault messages

4.2 Alarm and fault messages

Table 4-22 Fault 94

(Alarm) Profibus system has failed

Table 4-23 Fault 95

Condition

Causes

Possible

remedial

measures

The S7 has detected serious errors on the Profibus

Equalizing current on the Profibus cable shield

The Profibus cable shield is not properly connected

Terminating resistors are not correctly set

No power supply available at the beginning or end of the

Profibus line

External conducted interference

Defect on Profibus node(s)

Provide equipotential bonding between individual

inverters

Connect the cable shields correctly

Change the Profibus cabling

Replace the defective printed circuit boards

(Alarm) Grid voltage outside tolerance

Condition

Causes

Measures

The CU has detected that the measured grid frequency

is outside the set tolerance limits

Incorrect phase sequence

Fluctuations of the line frequency

Connect up the cables correctly (change the phases,

phase sequence must be clockwise)

38

Page 39

Table 4-24 Fault 96

(Alarm) Grid voltage outside tolerance

Condition

Causes

Measures

Alarm and fault messages

4.2 Alarm and fault messages

The CU has detected that the grid voltage is outside the

set tolerance limits

Grid voltage outside tolerance

o No power supply

o Unstable power supply

o Medium-voltage breaker has tripped (if

installed)

o Control oscillations

o Supply point overloaded (voltage rise as a

result of additional load)

o Control (CU software) is not working correctly

Defective components

o Transformer

o AC capacitors

o Restrictor

o AC fuses

o Drive

Adjust the parameter settings

Close the medium-voltage breaker

Replace the defective components

Table 4-25 Fault 97

(Alarm) No checkback signal from the DC link contactor

Condition

Causes

Measures

The CU has detected that the grid voltage is outside the

set tolerance limits

No checkback signal on the S7

Interface contactor has not responded

o Interface contactor is defective

o Interface contactor has not operated

o Interface contactor is blocked

o Insufficient current supply to contactor coils

Fault in signal power supply

Wire break

S7 relay output module defective

Repair the interface contactor

Replace the interface contactor

Repair the power supply

Use a higher-capacity power supply

Replace the cabling

Replace the S7 relay output module

Table 4-26 Fault 98

39

Page 40

Alarm and fault messages

4.2 Alarm and fault messages

(Alarm) Symmetry fault

Condition

Causes

Measures

The S7 routine for monitoring symmetry has detected an

imbalance

Alarm in the PV field

o Automatic fuse or fusible link in the junction

box has tripped

o Fuse at the DC input has tripped

o PV module is defective

o Defect in the PV field cabling

Alarm activated during measured-value sensing

o Isolation amplifier defective

o Wire break

Replace the fuses (plus and minus at the same time)

Close the automatic fuse

Replace the PV module

Replace the PV cabling

Alarm without fault

The system uses alarms which do not have individual messages (codes). This can be identified

according to certain alarm conditions.

Inverter does not start, PPsolar signals "Manual Bypass ON"

Cause: Power pack defective

Inverter does not start; PPsolar is not displaying a DC voltage even though a DC voltage is present

(manual measurement)

Cause: Power pack defective

Inverter does not start, PPsolar is not displaying a DC voltage

Cause: The DC inverter PSU or the Masterdrives DC link fuse is defective.

No DC voltage is present (the junction boxes are switched off, it is dark outside).

Inverter is shut down completely

Cause: No AC voltage present (infeed, external infeed)

40

Page 41

Support

5.1 Contact addresses

5 Support

5.1 Contact addresses

The support hotline for SINVERT can be reached via the contact methods listed below from Monday to

Friday between 8 am and 5 pm CET:

Phone: +49 911 750-2211

Fax: +49 911 750-2246

E-mail:

Internet: www.siemens.de/sinvert

www.siemens.com/sinvert

sinvert-service.i-ia@siemens.com

41

Page 42

Siemens AG

Industry Sector, IA SE S PV

P.O. Box 2355

90766 Fuerth

GERMANY

www.siemens.com

Subject to change

© Siemens AG 2009

42

Loading...

Loading...