Page 1

© Siemens Industry, Inc. 2018

Catalog

NC 81.1

US

Edition

2019

Motion Control

SINUMERIK 808

Equipment for Machine Tools

siemens.com/sinumerik

Page 2

Related catalogs

Motion Control NC 62

SINUMERIK 840

Equipment for Machine Tools

E86060-K4462-A101-A2-7600

Motion Control NC 82

SINUMERIK 828

Equipment for Machine Tools

E86060-K4482-A101-A6-7600

Motion Control Drives D 31.1

SINAMICS Inverters for Single-Axis Drives

Built-In Units

E86060-K5531-A111-A1-7600

Motion Control Drives D 31.2

SINAMICS Inverters for Single-Axis Drives

Distributed Inverters

© Siemens Industry, Inc. 2018

E86060-K5531-A121-A1-7600

SITRAIN

Training for Industry

www.siemens.com/sitrain

Products for Automation and Drives CA 01

Interactive Catalog

Download

www.siemens.com/ca01download

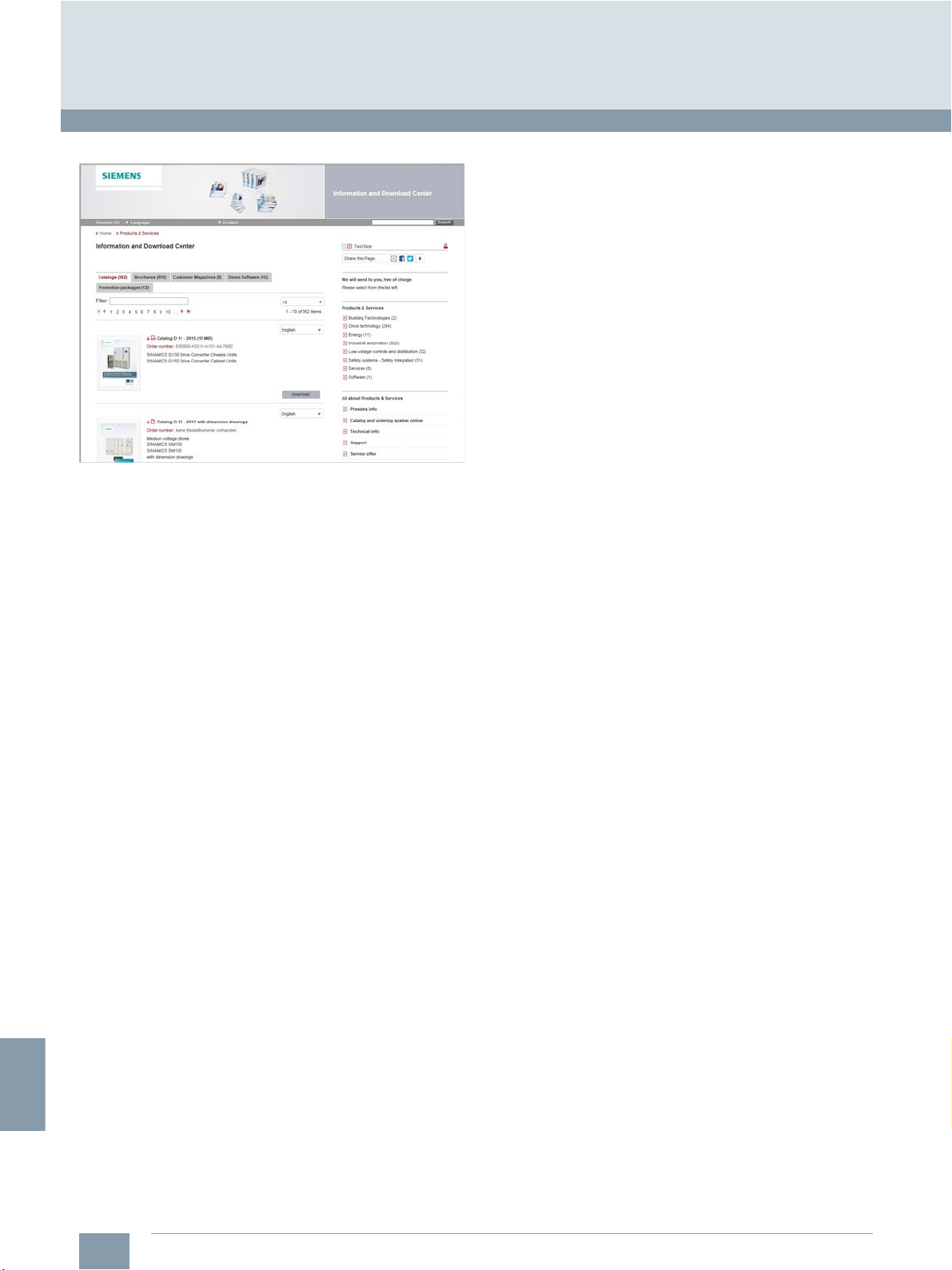

Industry Mall

Information and Ordering Platform

in the Internet:

www.siemens.com/industrymall

Page 3

SINUMERIK 808

Equipment for Machine Tools

© Siemens Industry, Inc. 2018

Motion Control

Catalog NC 81.1 · 2019

Supersedes:

Catalog NC 81.1 · 2018

Refer to the Industry Mall for current updates of

this catalog:

www.siemens.com/industrymall

The products contained in this catalog can also be found

in the Interactive Catalog CA 01.

Article No.: E86060-D4001-A510-D8-7500

Introduction

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

SINUMERIK 808D ADVANCED system

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

Operator components

Feed axis solutions

Spindle solutions

MOTION-CONNECT connection systems

Example packages

1

2

3

Please contact your local Siemens branch.

Click on an Article No. in the catalog PDF to call it up in the

Industry Mall and to obtain all the information.

Article No.

6SL3070-0AA00-0AG0

6SL3072-0AA00-0AG0

Or directly on the Internet, e.g.

www.siemens.com/product?6SL3070-0AA00-0AG0

The products and systems described in

this catalog are distributed under application

of a certified quality management system in

accordance with DIN EN ISO 9001 (Certified

Registration No. 001258 UM). The certificate

is recognized by all IQNet countries.

Accessories

Operator components

Supplementary components

Direct spindle encoder

Services and training

Services

Training

Documentation

Appendix

Certificates of suitability

Subject index

Conversion tables

Metal surcharges

Conditions of sale and delivery

Export regulations

4

5

6

Page 4

© Siemens Industry, Inc. 2018

Digital Enterprise

The building blocks that ensure

everything works together

perfectly in the digital enterprise

Digitalization is already changing all areas of life and existing

business models. It is placing greater pressure on industry

while at the same time creating new business opportunities.

Today, thanks to scalable solutions from Siemens, companies

can already become a digital enterprise and ensure their

competitiveness.

Industry faces tremendous challenges

Reduce

time-to-market

Today manufacturers

have to bring products to

market at an ever-increasing pace despite the

growing complexity of

these products. In the

past, a major manufacturer would push aside a

small one, but now it is a

fast manufacturer that

overtakes a slow one.

Boost

flexibility

Consumers want customized products, but at

a price they would pay

for a mass-produced

item. That only works

if production is more

flexible than ever

before.

Improve

quality

To ensure a high level of

quality while meeting

legal requirements,

companies have to

establish closed quality

loops and enable the

traceability of products.

Boost

efficiency

Today the product itself

needs to be sustainable

and environmentally

friendly, while energy

efficiency in production

has become a competitive advantage.

Increase

security

Increasing networking

escalates the threat to

production facilities

of cyberattacks. Today

more than ever, companies need suitable

security measures.

2

Siemens NC 81.1 · 2019

Page 5

© Siemens Industry, Inc. 2018

The digital enterprise has already

become a reality

To fully benefit from all the advantages of

digitalization, companies first have to

achieve complete consistency of their data.

Fully digitally integrated business processes,

including those of suppliers, can help to

create a digital representation of the entire

value chain. This requires

• the integration of industrial software

and automation,

• expansion of the communication networks,

• security in automation,

• and the use of business-specific

industrial services.

MindSphere

The cloud-based open IoT operating

system from Siemens

With MindSphere, Siemens offers a costeffective and scalable cloud platform as a

service (PaaS) for the development of applications. The platform, designed as an open

operating system for the Internet of Things,

makes it possible to improve the efficiency

of plants by collecting and analyzing large

volumes of production data.

Totally Integrated Automation (TIA)

Where digitalization becomes reality

Totally Integrated Automation (TIA) ensures

the seamless transition from the virtual to

the real world. It already encompasses all

the necessary conditions for transforming

the benefits of digitalization into true added

value. The data that will form the digital

twin for actual production is generated from

a common base.

Digital Plant

Learn more about the

digital enterprise for the

process industry

www.siemens.com/

digitalplant

Digital Enterprise Suite

Learn more about the

digital enterprise for the

discrete industry

www.siemens.com/

digital-enterprise-suite

Siemens NC 81.1 · 2019

3

Page 6

With Integrated Drive

Systems you can reduce

your main tenance costs

by up to

15 %

With TIA Portal you can

cut your engineering time

by up to

30 %

© Siemens Industry, Inc. 2018

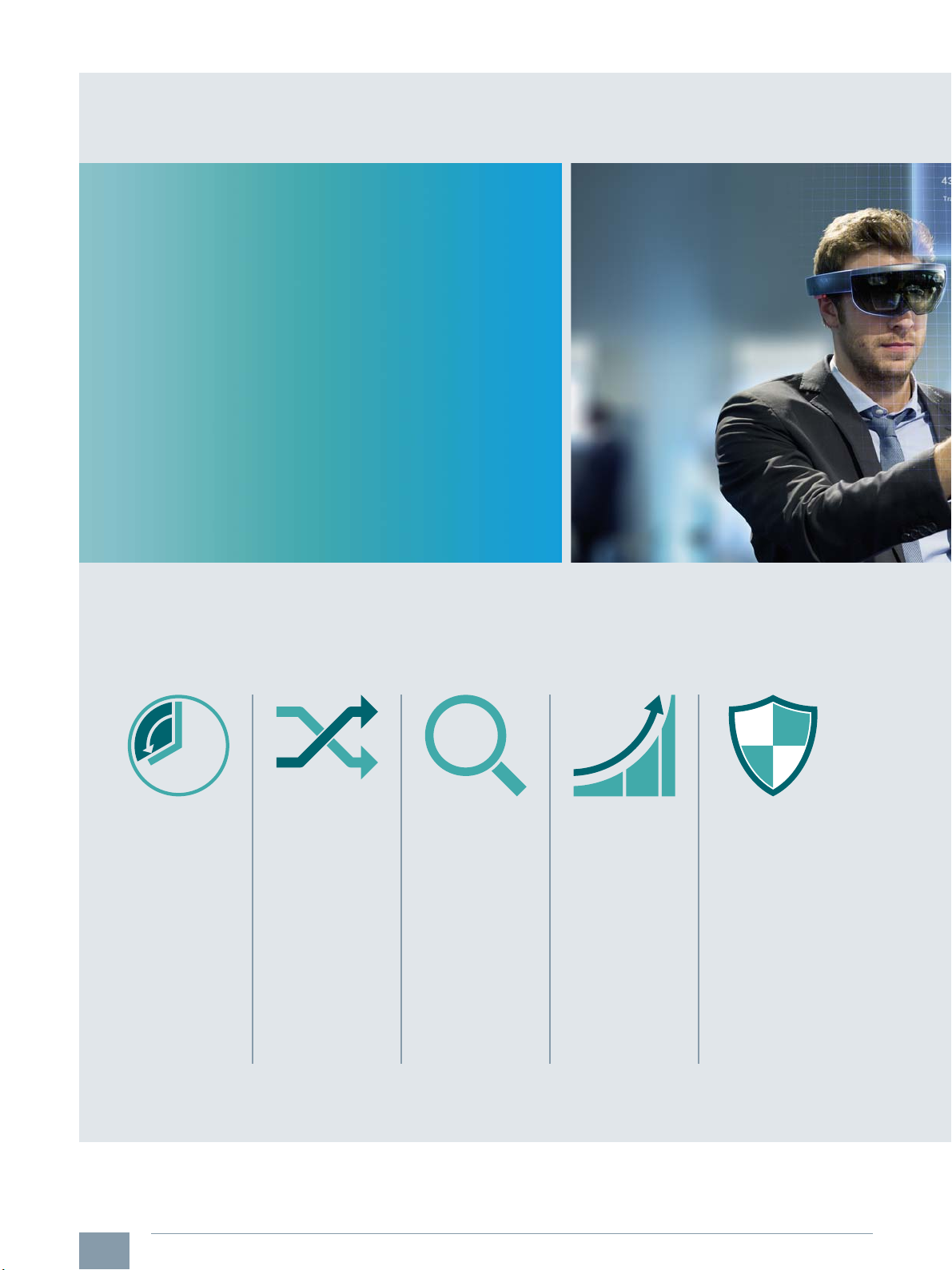

Integrated Drive Systems

Faster on the market and in the black with Integrated Drive Systems

Integrated Drive Systems are Siemens’ trendsetting answer to the high

degree of complexity that characterizes drive and automation technology

today. The world’s only true one-stop solution for entire drive systems is

characterized in particular by its threefold integration: Horizontal, vertical,

and lifecycle integration ensure that every drive system component fits

seamlessly into the whole system, into any automation environment, and

even into the entire lifecycle of a plant.

Horizontal integration

Integrated drive portfolio: The core elements of a fully integrated drive

portfolio are frequency converters, motors, couplings, and gear units.

At Siemens, they‘re all available from a single source. Perfectly integrated,

perfectly interacting. For all power and performance classes. As standard

solutions or fully customized. No other player in the market can offer a

comparable portfolio. Moreover, all Siemens drive components are

perfectly matched, so they are optimally interacting.

The outcome is an optimal workflow – from engineering all the way to

service that entails more productivity, increased efficiency, and better

availability. That’s how Integrated Drive Systems reduce time to market

and time to profit.

You can boost the avail ability

of your application or plant

to up to

*

99 %

*e.g., conveyor application

Vertical integration

Thanks to vertical integration, the complete drive train is

seamlessly integrated in the entire automation environment –

an important prerequisite for production with maximum

value added. Integrated Drive Systems are part of Totally

Integrated Automation (TIA), which means that they

are perfectly embedded into the system architecture

of the entire industrial production process. This

enables optimal processes through maximum

communication and control.

Lifecycle integration

Lifecycle integration adds the factor of time: Software and service

are available for the entire lifecycle of an Integrated Drive System.

That way, important optimization potential for maximum

productivity, increased efficiency, and highest availability

can be leveraged throughout the system’s lifecycle –

from planning, design, and engineering to operation,

maintenance, and all the way even to

modernization.

With Integrated Drive Systems, assets

become important success factors. They

ensure shorter time to market, maximum

productivity and efficiency in operation,

and shorter time to profit.

4

Siemens NC 81.1 · 2019

www.siemens.com/ids

Page 7

1

Introduction

© Siemens Industry, Inc. 2018

1/2 How to use this catalog

1/3 The system

1/4 SINUMERIK 808D ADVANCED

1/5 Feed and spindle drive solutions

1/6 MOTION-CONNECT

connection systems

Siemens NC 81.1 · 2019

Page 8

1

Introduction

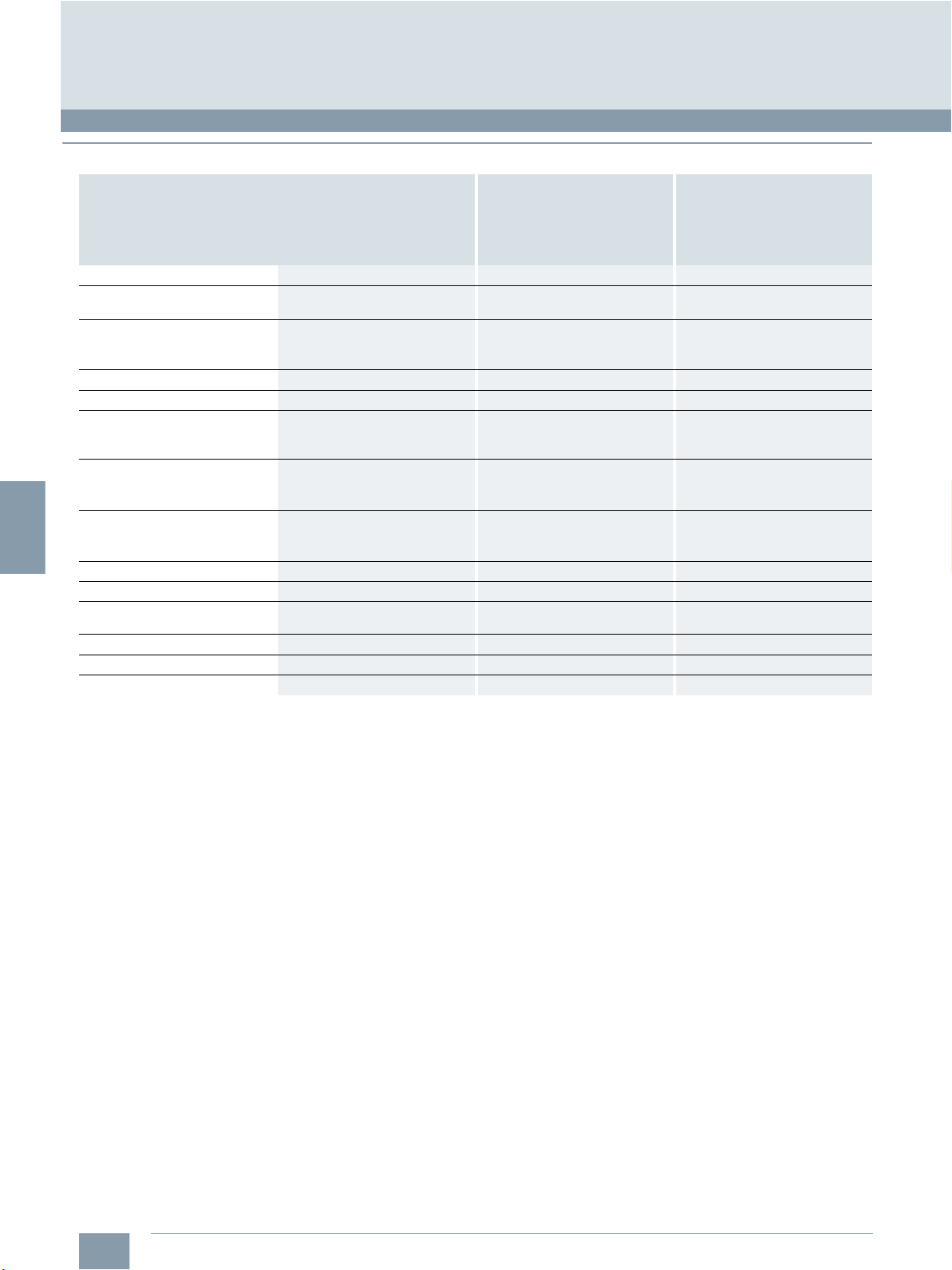

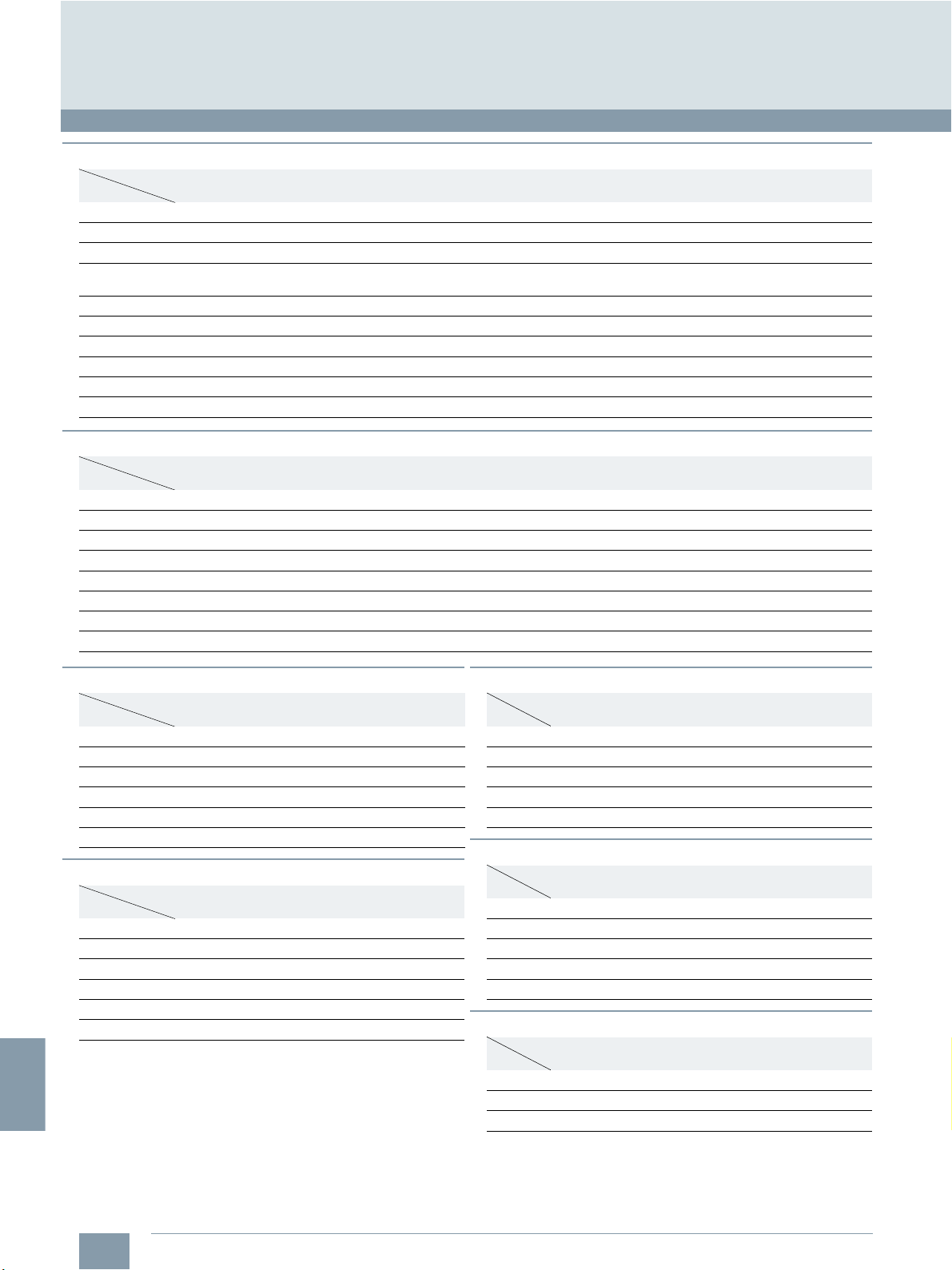

How to use this catalog

■

Overview

© Siemens Industry, Inc. 2018

See chapter

my CNC/drive/motor order list ?

Quick overview of the CNC/drive/motor system

SINUMERIK 808D ADVANCED

Overview of CNC functions

Technical specifications of CNC

Selection and ordering data of CNC

Feed and spindle drive solution SINAMICS V70/

SIMOTICS S-1FL6/SIMOTICS M-1PH1

Technical specifications of drive modules, motors and cables

Selection and ordering data of drive modules, motors and cables

Dimensional drawings of drive modules, motors and cables

Example packages to cross-check my order list

CNC accessories (MCP, handwheels, PLC I/O, power supply, direct spindle encoder)

Technical specifications of CNC accessories

Selection and ordering data of CNC accessories

Dimensional drawings of CNC accessories

1

2

3

3

3

4

1/2

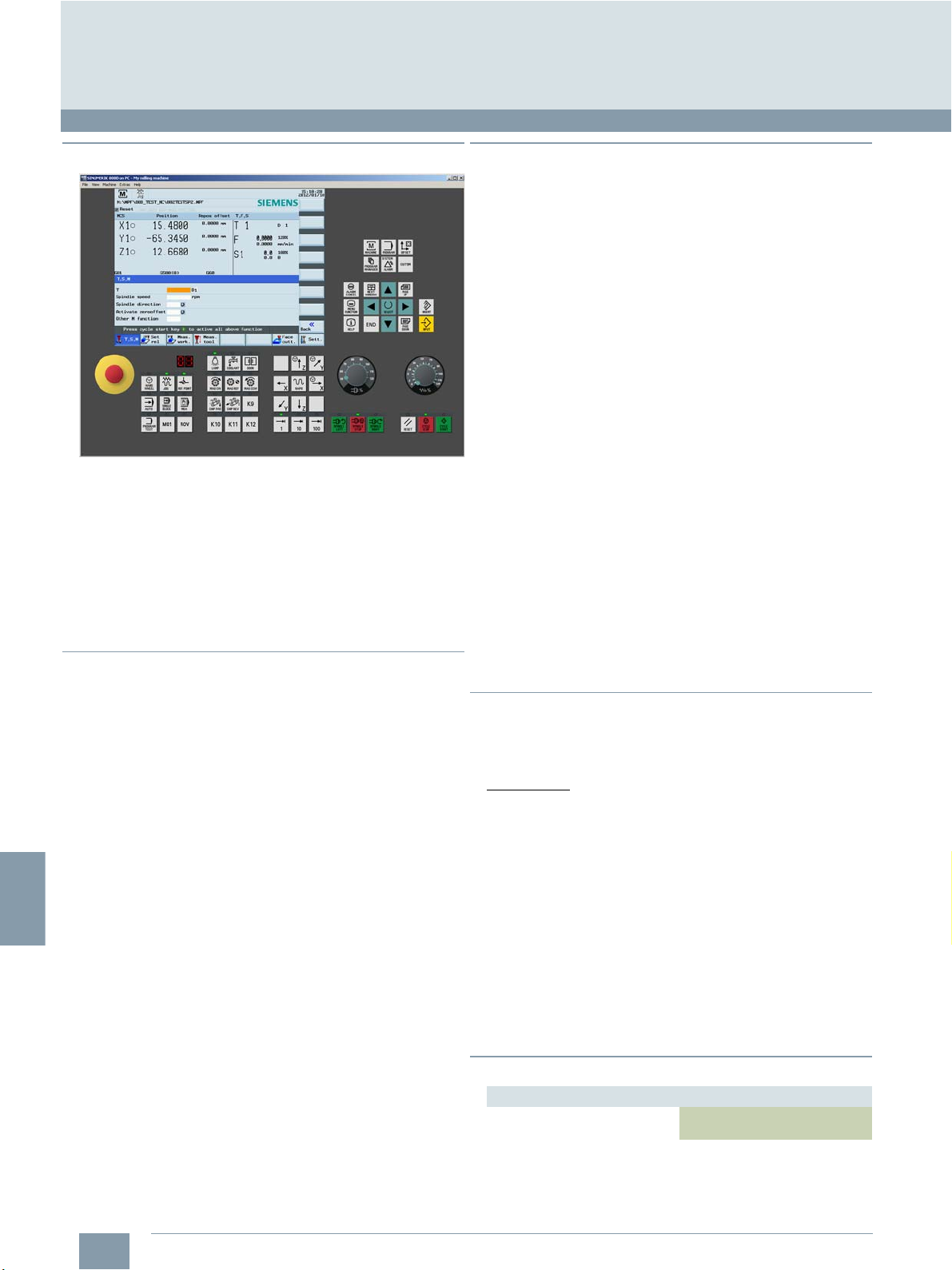

SINUMERIK 808D on PC (training and offline programming system for PC)

Siemens NC 81.1 · 2019

Services and training

Material warranty and on-site service

System documentation

Training portfolio

Spindle solution

my CNC/drive/motor order list

5

G_NC01_EN_00796

!

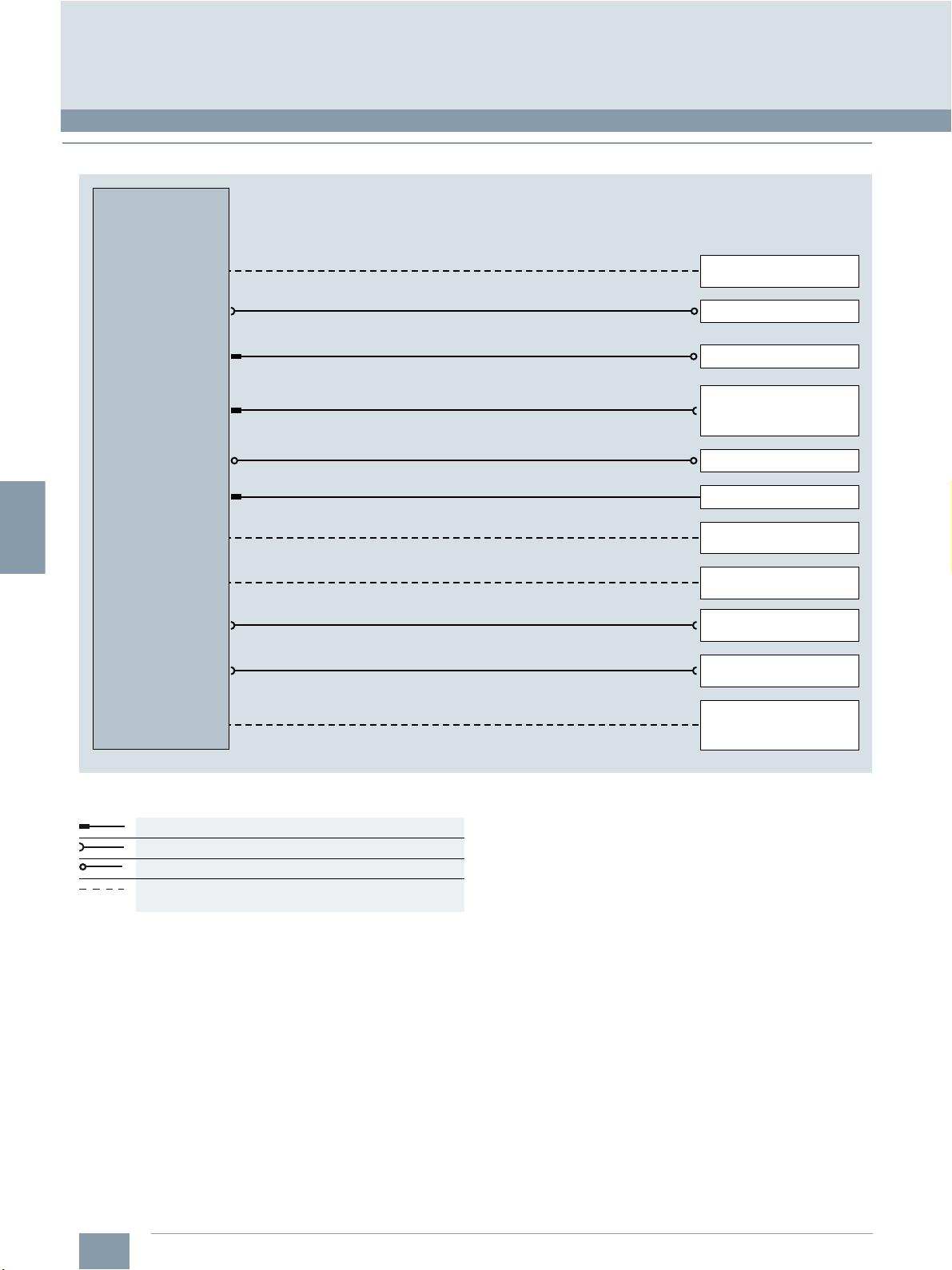

Page 9

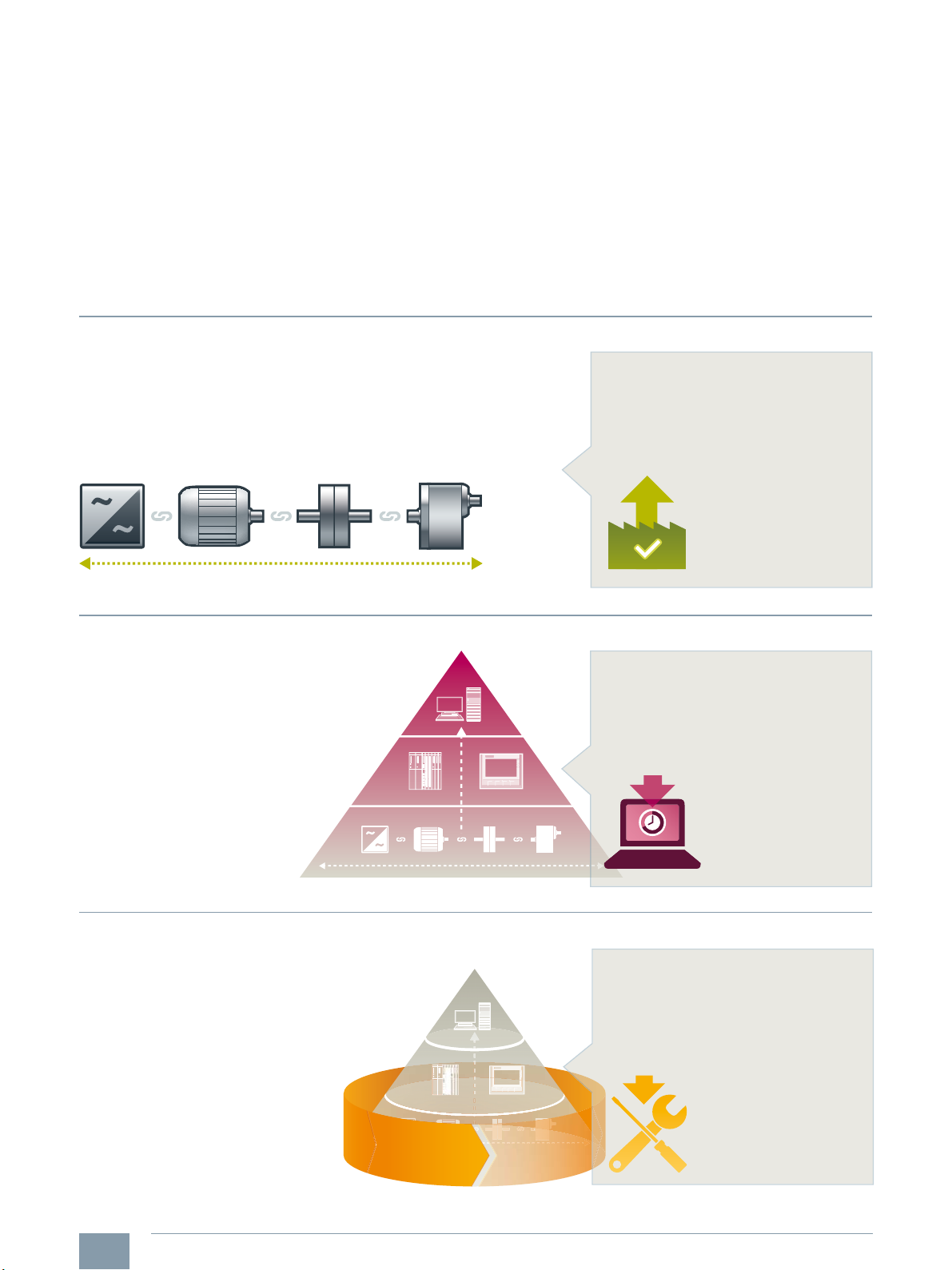

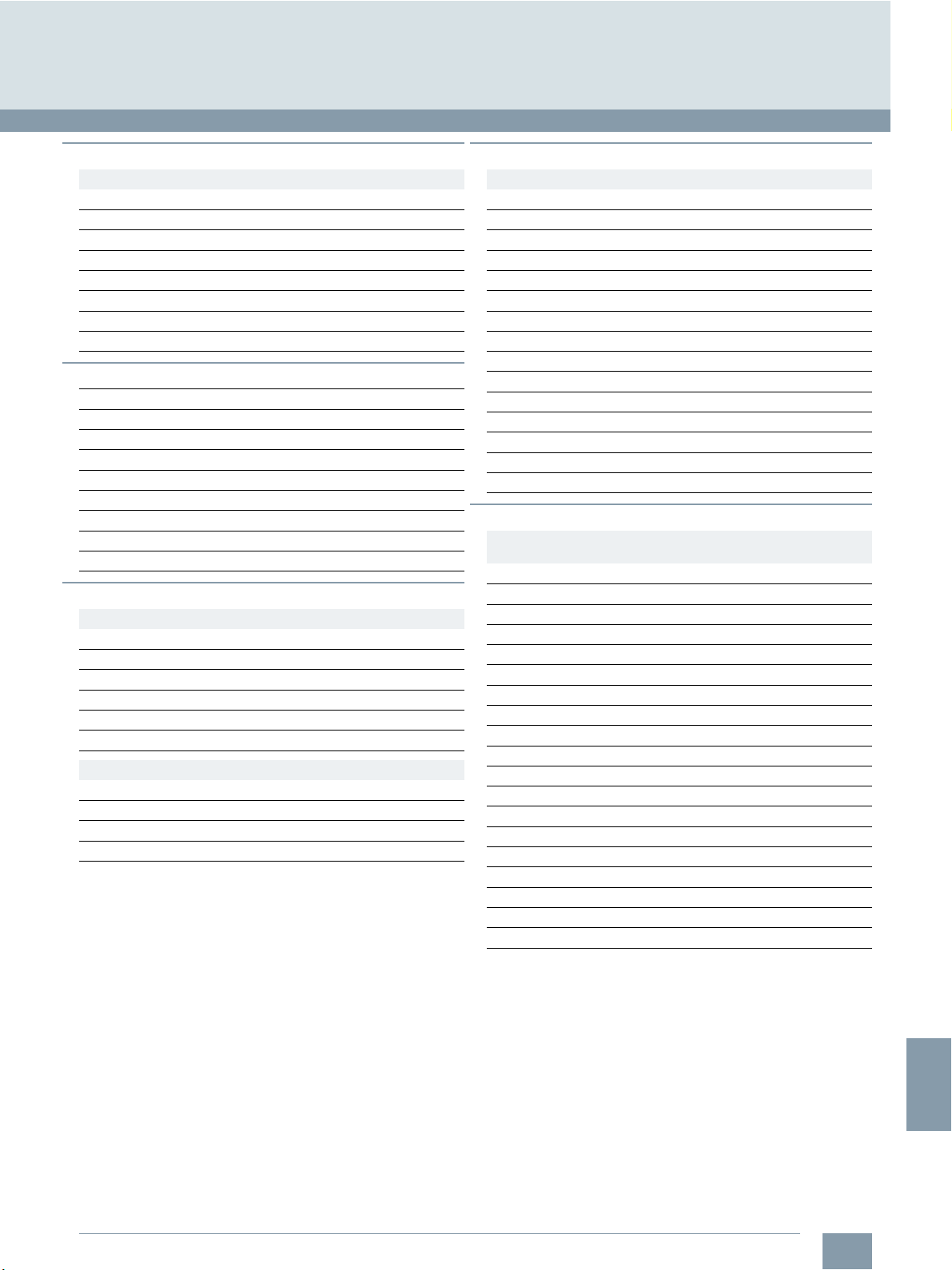

1

■

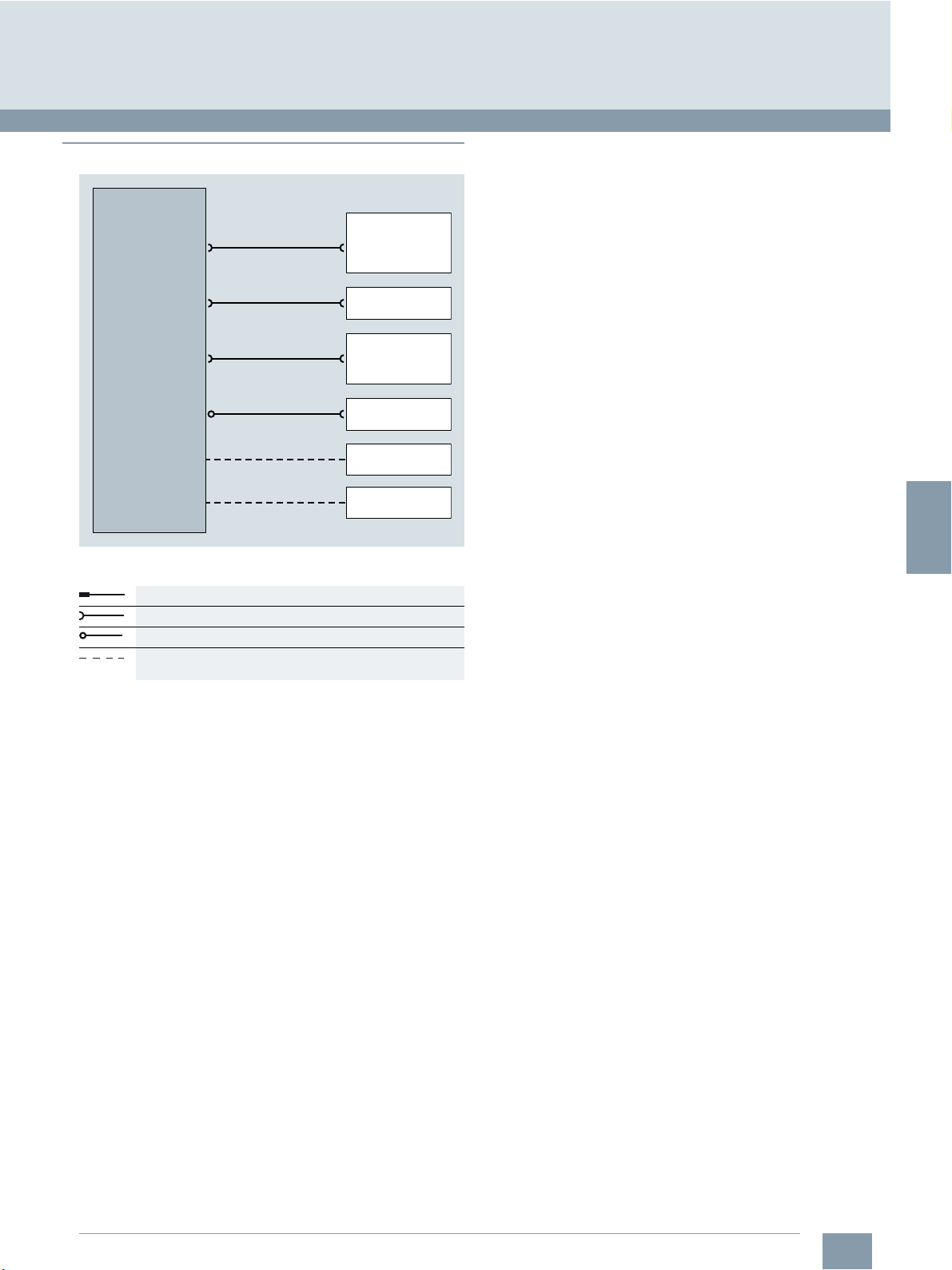

Overview

Digital tool probe

USB stick

Terminal strip

converter

Ribbon cable

© Siemens Industry, Inc. 2018

Introduction

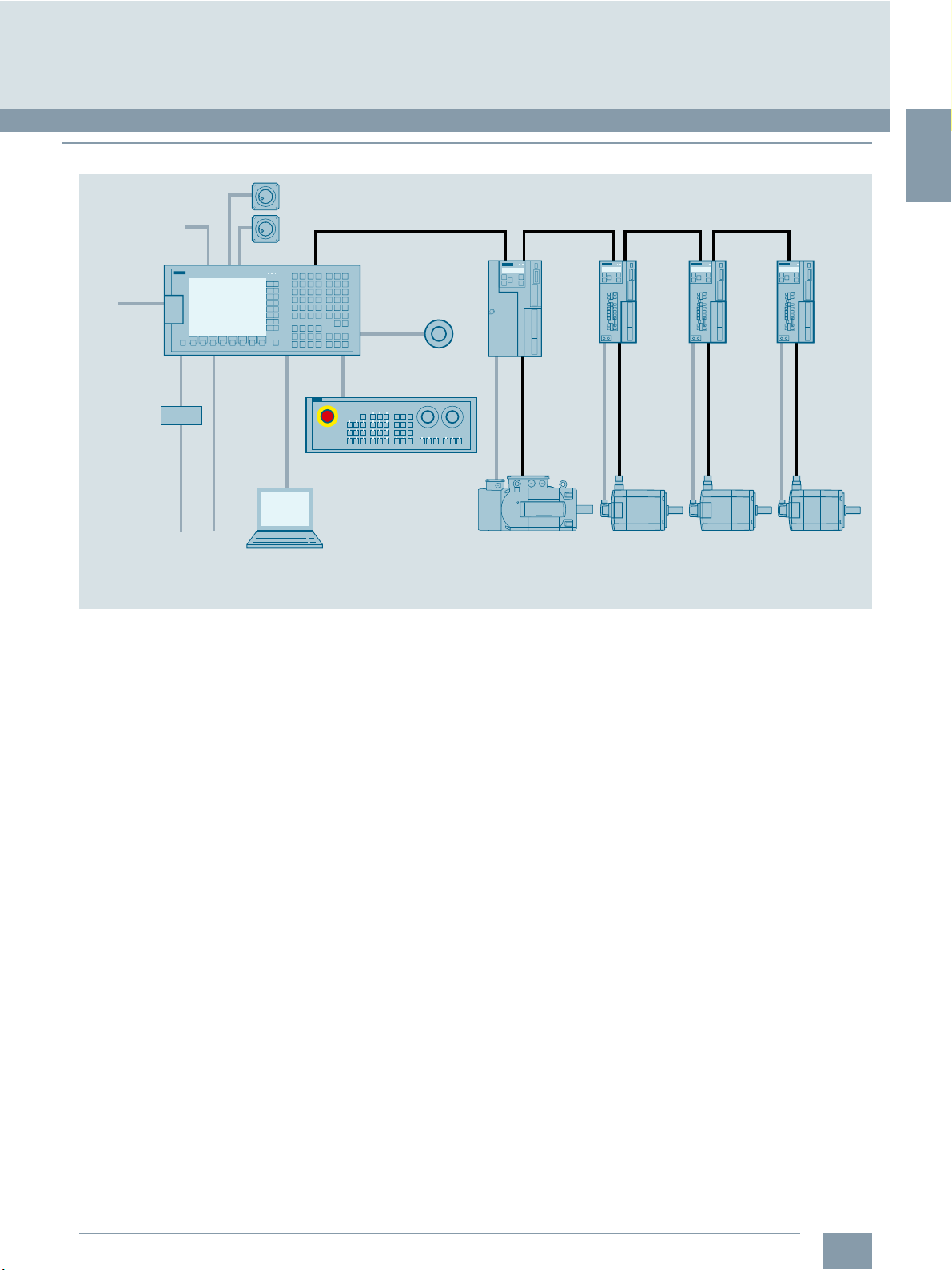

The system

Handwheels

SINAMICS V70

1)

Ethernet/

factory

network

Drive bus

SINUMERIK 808D

ADVANCED

TTL

USB

SINUMERIK 808D MCP

spindle drive

Spindle

encoder

SINAMICS V70

servo drive

SINAMICS V70

servo drive

SINAMICS V70

servo drive

G_NC01_EN_00548b

PLC

process signals

1)

Only used for milling version

Notebook

SINUMERIK 808D ADVANCED system

SIMOTICS

M-1PH1

asynchronous

main spindle motor

SIMOTICS

S-1FL6

synchronous

feed motor

SIMOTICS

S-1FL6

synchronous

feed motor

SIMOTICS

S-1FL6

synchronous

feed motor

Siemens NC 81.1 · 2019

1/3

Page 10

1

© Siemens Industry, Inc. 2018

Introduction

SINUMERIK 808D ADVANCED

■

Overview

Small, robust, easy, simply smart

The operator-panel-based CNC SINUMERIK 808D ADVANCED

is extremely compact, rugged and very easy to maintain.

With variable software options and high-dynamic servo drive

systems, the SINUMERIK 808D ADVANCED system is offering

the latest CNC solution for high-performance basic machines.

Preconfigured for basic standard turning machines …

The SINUMERIK 808D ADVANCED T CNC is perfectly preconfigured to meet the requirements of modern standard turning

machines. Intelligent CNC features such as full servo controlled

rigid tapping or the flying switchover between spindle and C axis

enable most precise and fastest turning operation.

Perfectly preconfigured for:

7 SINUMERIK 808D ADVANCED T:

Up to 6 axes/spindles in one machining channel with/without

driven tool

7 Preconfigured system software for inclined bed fully

automated lathes and flat bed semi-automatic lathes

... and basic standard milling machines

The SINUMERIK 808D ADVANCED M CNC is perfectly preconfigured to meet the requirements of modern standard milling

machines.

7 SINUMERIK 808D ADVANCED M:

Up to 6 axes/spindles in one machining channel

7 Preconfigured system software for vertical machining centers

G_NC01_XX_00494

1/4

Siemens NC 81.1 · 2019

Page 11

1

■

Overview

© Siemens Industry, Inc. 2018

Introduction

Feed and spindle drive solutions

SINAMICS V70, SIMOTICS S-1FL6 and SIMOTICS M-1PH1

SINAMICS V70 servo drives, SIMOTICS S-1FL6 feed motors and

SIMOTICS M-1PH1 main spindle motors are designed for the

maximum cutting performance for the basic turning and milling

machine tool applications. The bus communication with the

SINUMERIK 808D ADVANCED CNC system, threefold overload

capacity and the 20 bit high-resolution absolute encoder installed in SIMOTICS S-1FL6 feed motors and SIMOTICS M-1PH1

main spindle motors allow to increase the precision and

efficiency of the machines.

With a robust design, SINAMICS V70 together with

SIMOTICS S-1FL6 feed motors and SIMOTICS M-1PH1 main

spindle motors are perfectly prepared for maximum availability

even in harsh environments.

Up to 36 months material warranty and on-site service

Siemens offers a standard material warranty and free

on-site service period of 24 months for the

SINUMERIK 808D ADVANCED and the associated components.

Warranty can be easily extended up to 36 months by end user

registration.

Moreover, Siemens ensures elimination of any defects on the

components free of cost on site during the warranty period.

Further information about the conditions and the scope of the

warranty and the on-site service can be found at:

www.siemens.com/automation/oss

Siemens NC 81.1 · 2019

1/5

Page 12

1

© Siemens Industry, Inc. 2018

Introduction

MOTION-CONNECT connection systems

■

Overview

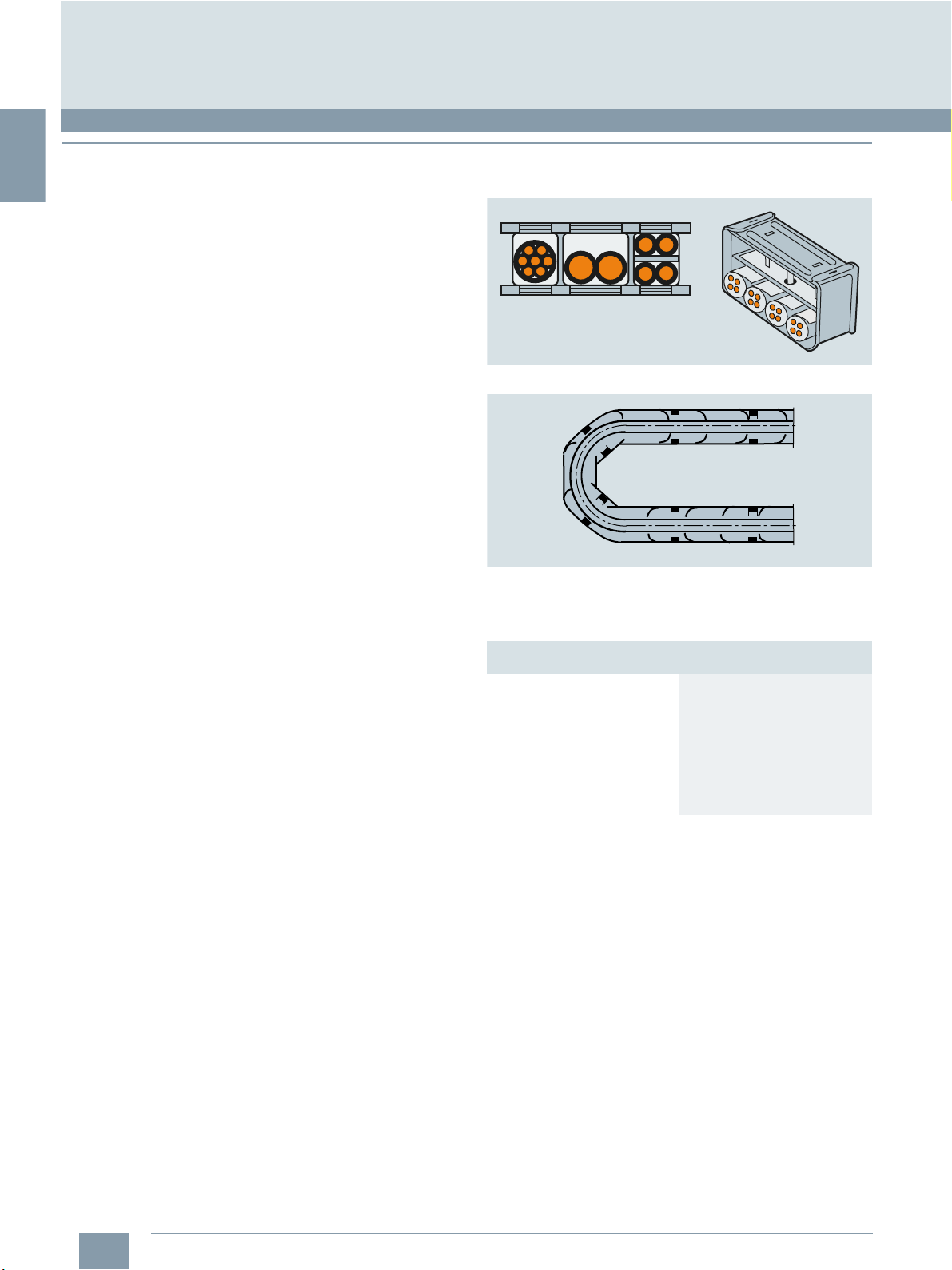

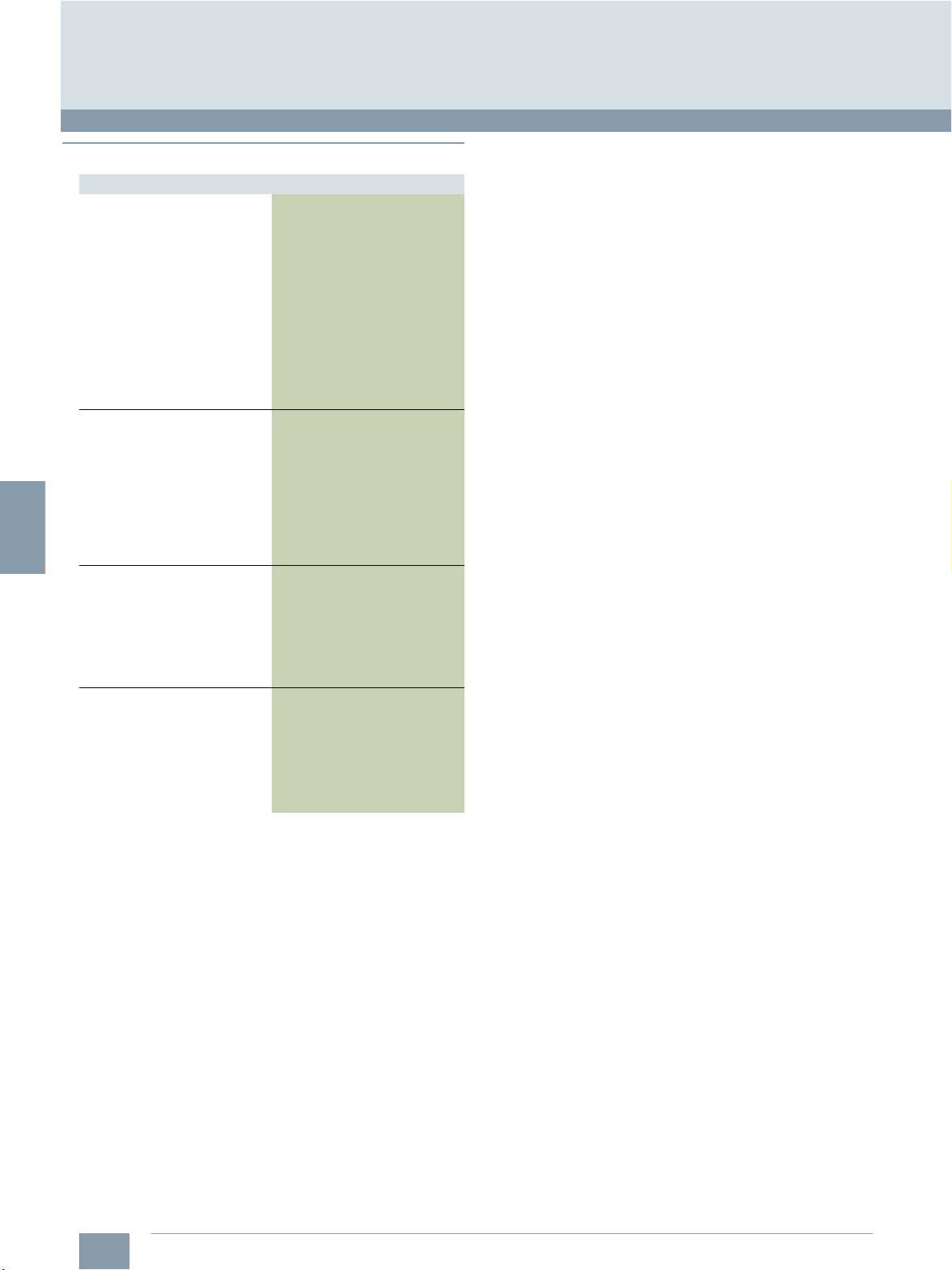

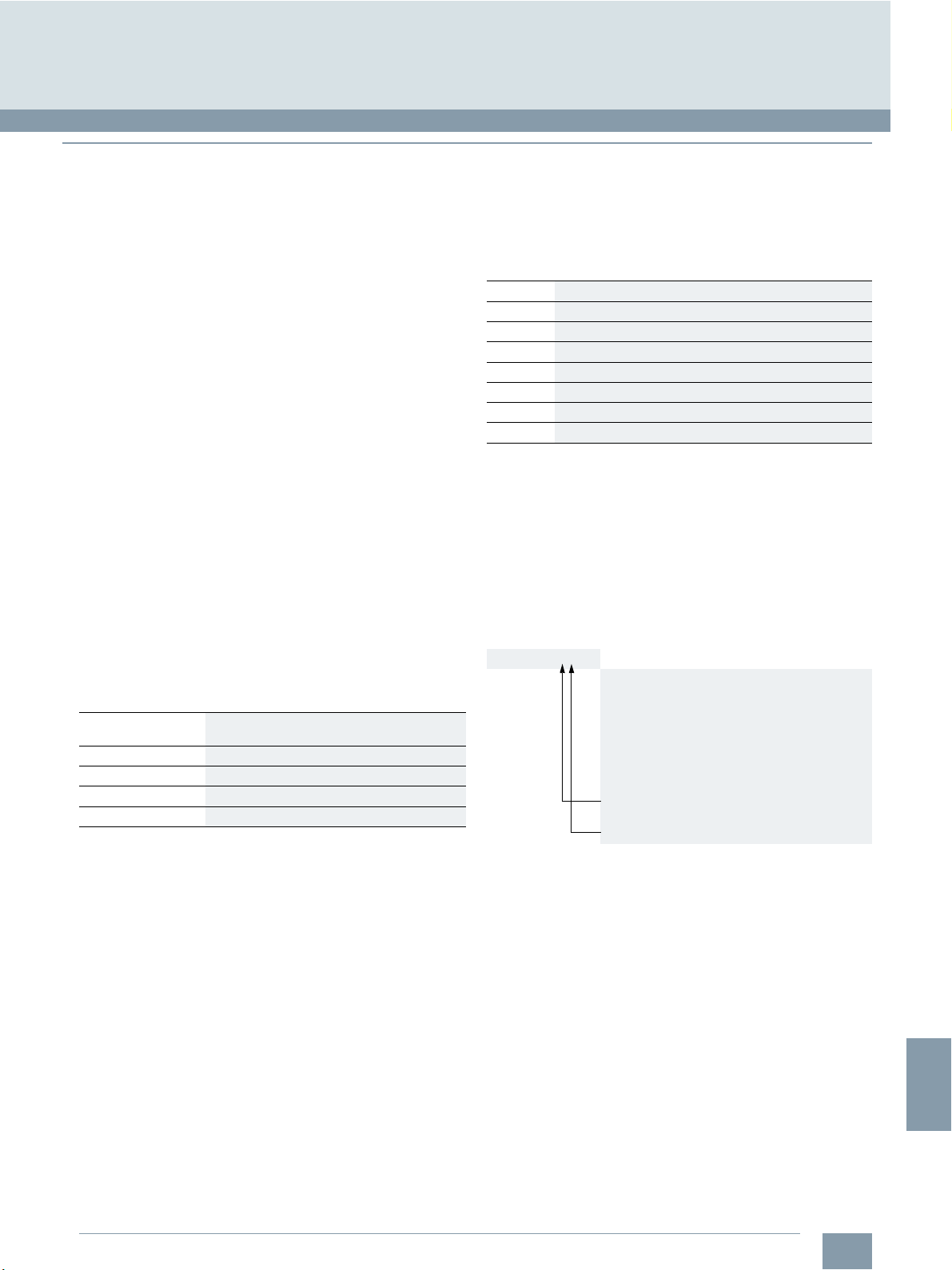

MOTION-CONNECTION 300 connection system

The MOTION-CONNECT 300 cables in this catalog are suitable

for use with standard turning and milling machines.

The use of pre-assembled MOTION-CONNECT 300 cables ensures high quality and system-tested, problem-free operation.

Degree of protection of pre-assembled power and signal cables

and their extensions is IP65 when closed and connected unless

otherwise stated.

MOTION-CONNECT 300 cables are not suitable for outdoor use.

MOTION-CONNECT cables are approved for a maximum

horizontal traverse path of 5 m.

To maximize the service life of the cable carrier and cables,

cables in the carrier made from different materials must be

separated in the cable carrier using spacers. The spacers must

be filled evenly to ensure that the position of the cables does not

change during operation. The cables should be distributed as

symmetrically as possible according to their weights and dimensions. Cables with different outer diameters should be separated

by spacers as well.

When inserting pre-assembled cables into the cable carrier, do

not pull at the connector, as this may damage the strain relief or

cable clamping.

The cables must not be fixed in the cable carrier. They must be

freely movable.

The cables must be unwound without twisting.

G_NC01_XX_00455

G_NC01_XX_00290

The cables must be able to be moved without applying force,

specifically in the bending radii of the carrier. The specified

minimum bending radii must be adhered to.

The cable fixings must be attached at both ends at an appropriate distance from the end points of the moving parts in a dead

zone.

Cables must be installed in accordance with the instructions

supplied by the cable carrier manufacturer.

In case of vibration load and with horizontal or vertical cable

entries, we recommend that the cable is additionally fixed if

between the cable strain relief on the cable carrier and the

terminal at the motor part of the cable is hanging loose or is not

routed. To prevent machine vibrations being transmitted to the

connectors, the cable should be fixed at the moving part where

the motor is mounted.

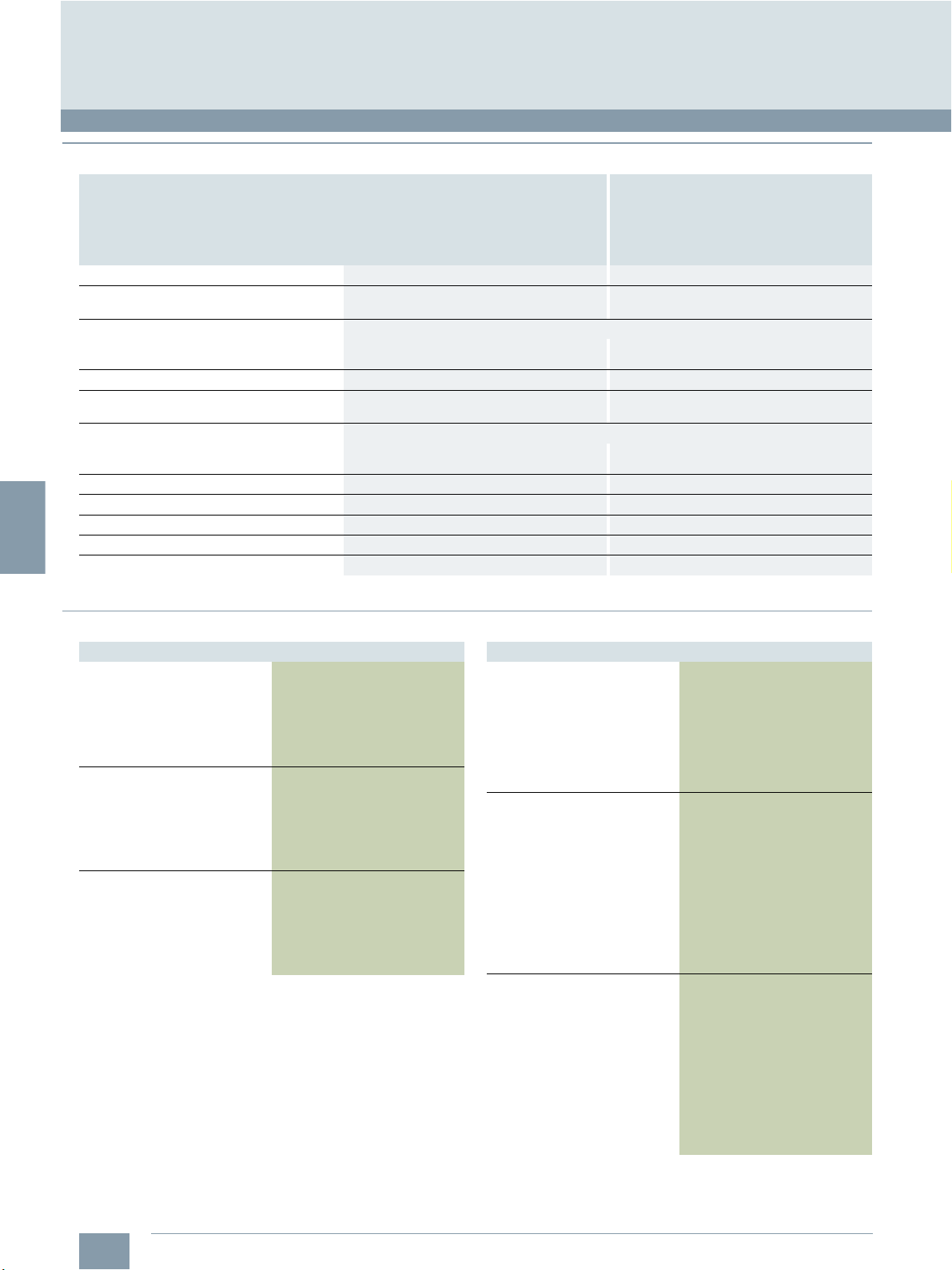

Derating factors for power and signal cables

Ambient air temperature

°C (°F)

30 (86) 1.15

35 (95) 1.08

40 (104) 1.00

45 (113) 0.91

50 (122) 0.82

55 (131)

60 (140)

Derating factor

according to EN 60204-1 Table D.1

0.71

0.58

1/6

Siemens NC 81.1 · 2019

Page 13

2

Overview of functions

© Siemens Industry, Inc. 2018

2/2 SINUMERIK 808D ADVANCED

CNC controls

2/2 Control structure and configuration

2/2 Connectable drives

2/2 Connectable measuring systems

2/3 Operation

2/3 Axis functions

2/4 Spindle functions

2/4 Interpolations

2/4 Measuring functions

2/4 Motion-synchronous actions

2/5 Open Architecture

2/5 CNC programming language

2/6 Technology cycles

2/6 Canned cycles

2/7 Program and workpiece management

2/7 Programming support

2/7 Simulations

2/8 Operating modes

2/8 Tools

2/9 Communication and data management

2/10 HMI functions

2/10 Monitoring functions

2/10 Compensations

2/11 PLC area

2/12 Commissioning and serial production

2/12 Diagnostic functions

2/12 Service and maintenance

2/12 Training and offline programming

The functionality of the SINUMERIK 808D

ADVANCED CNCs PPU 15x and PPU 16x

complies with the export list restrictions.

Accordingly, these CNC controls do not

require official approval as a result of their

type in accordance with EU or German

law.

The following overview lists all the

functions that are available with

SINUMERIK 808D ADVANCED controls.

The information in the overview of

SINUMERIK 808D ADVANCED functions

is based on the following software

version:

CNC Software

SINUMERIK 808D

ADVANCED

PPU 15x.3/PPU 16x.3

Siemens NC 81.1 · 2019

version

4.90

Page 14

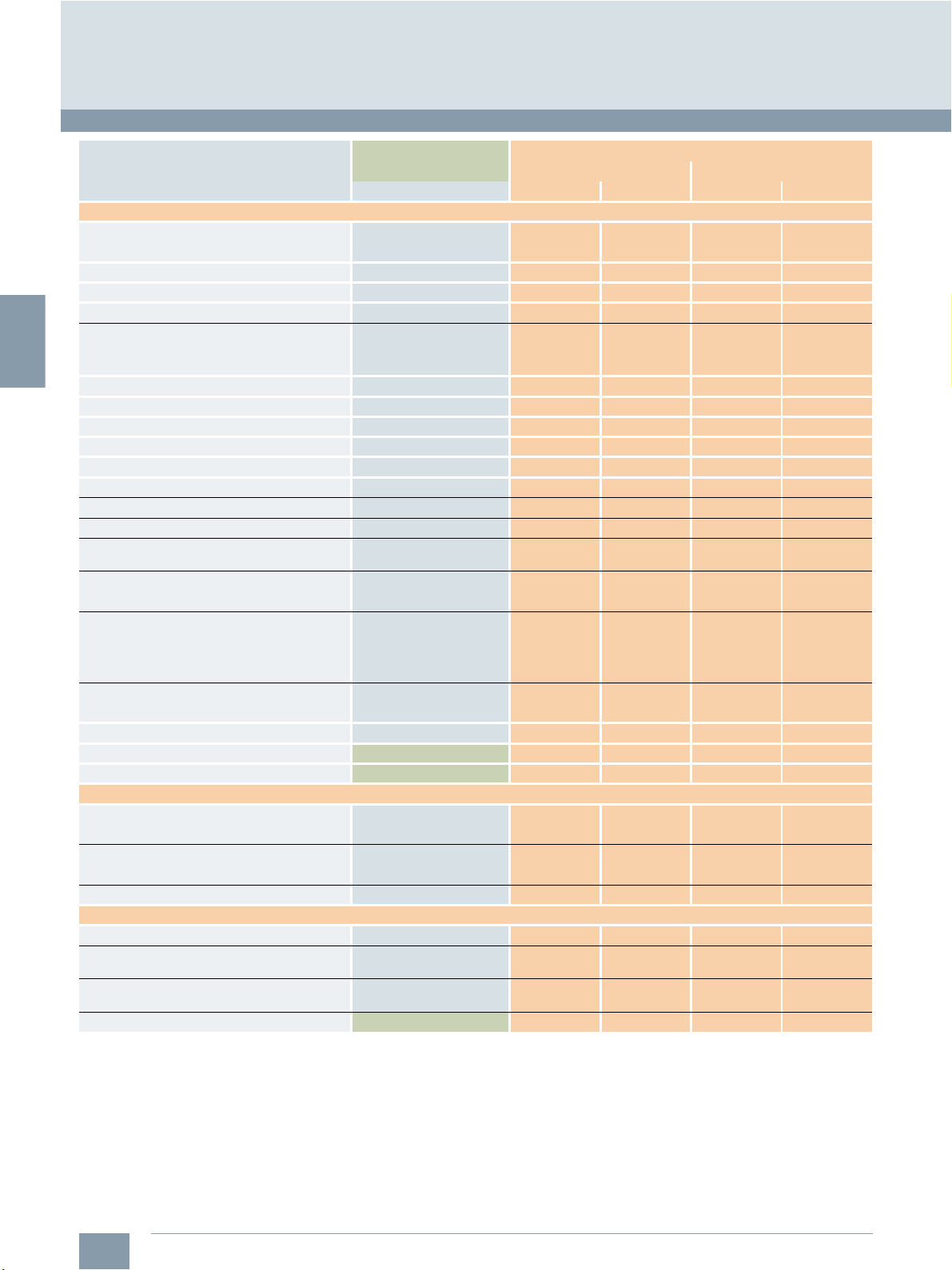

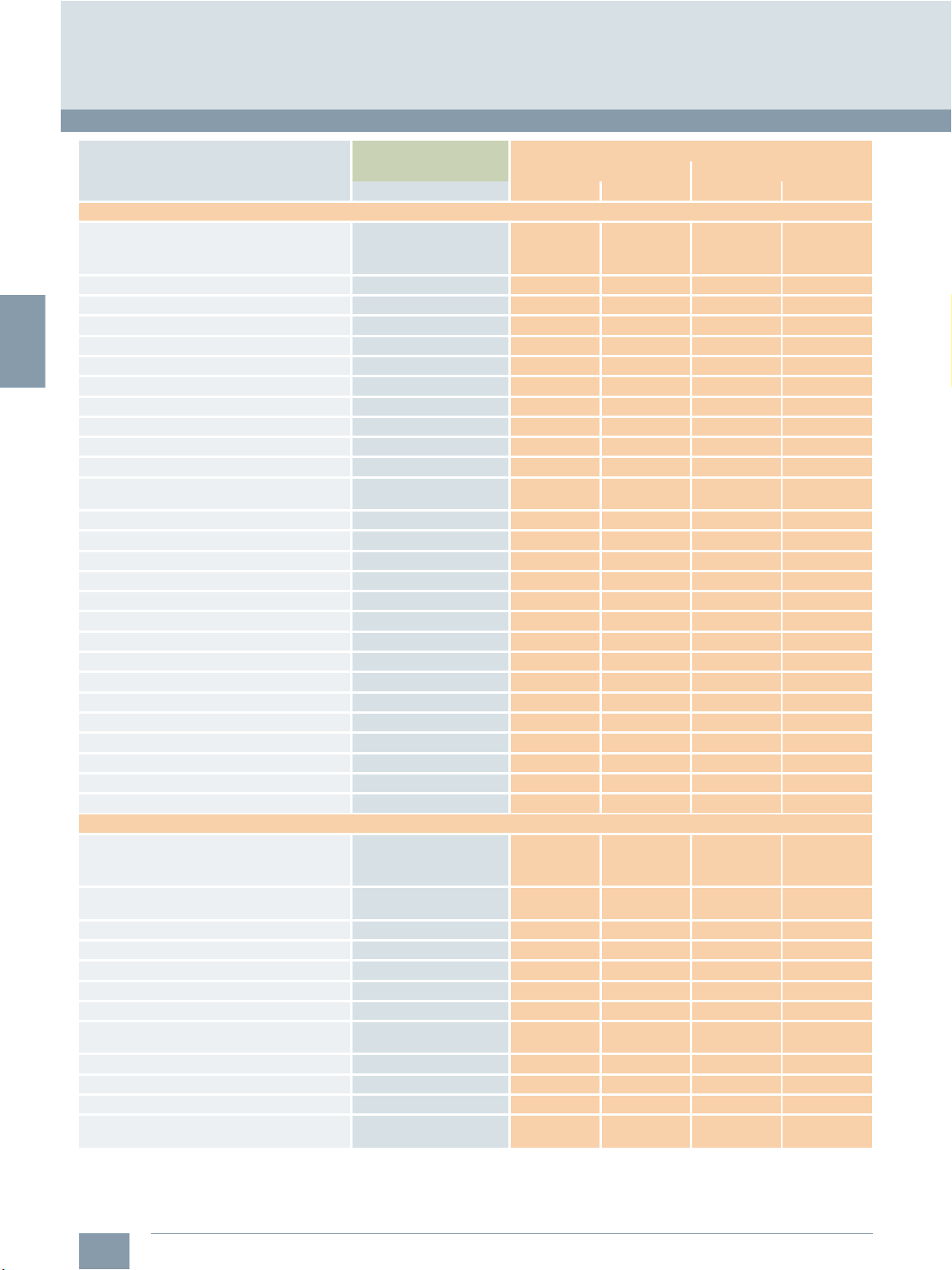

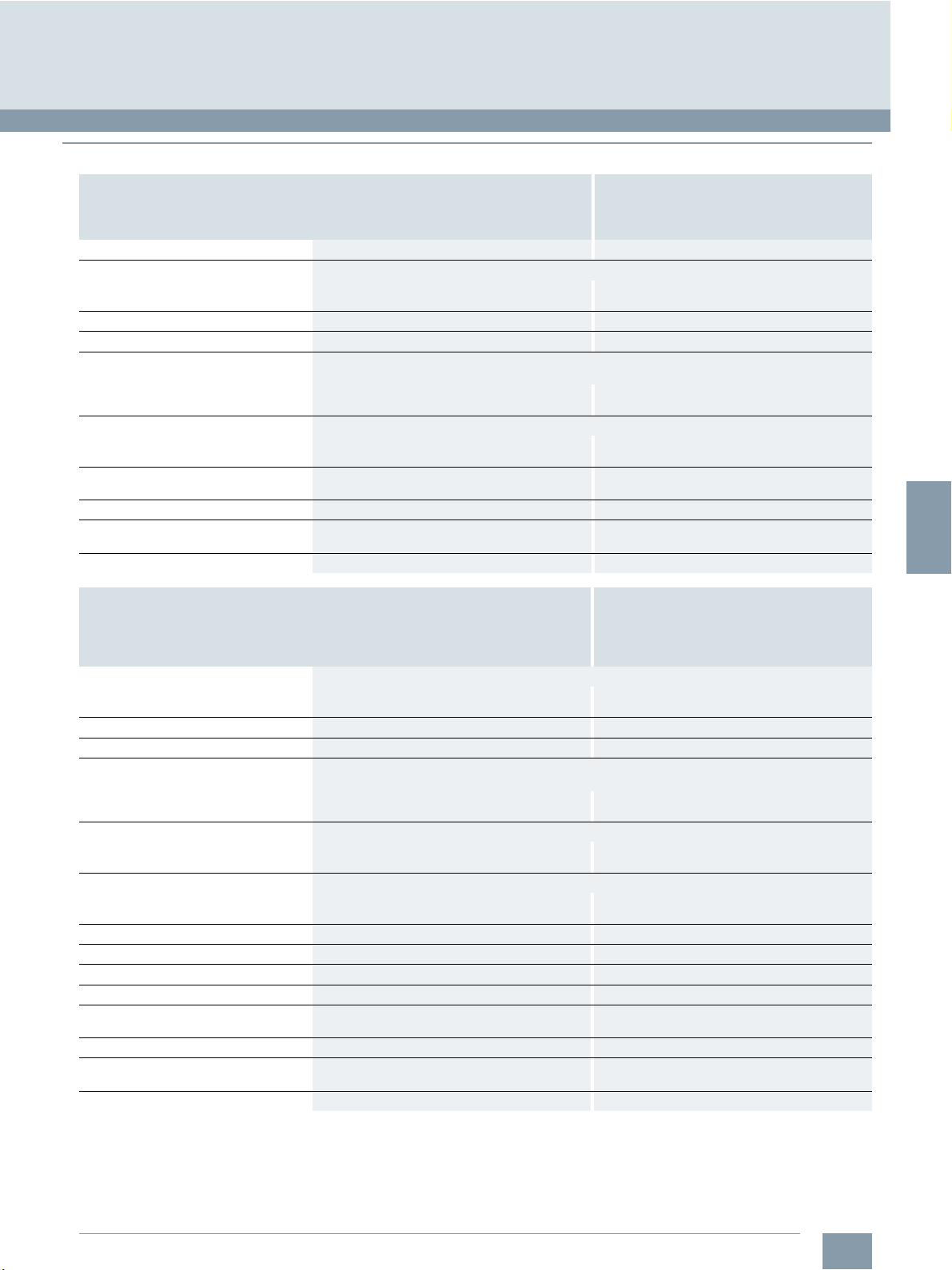

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

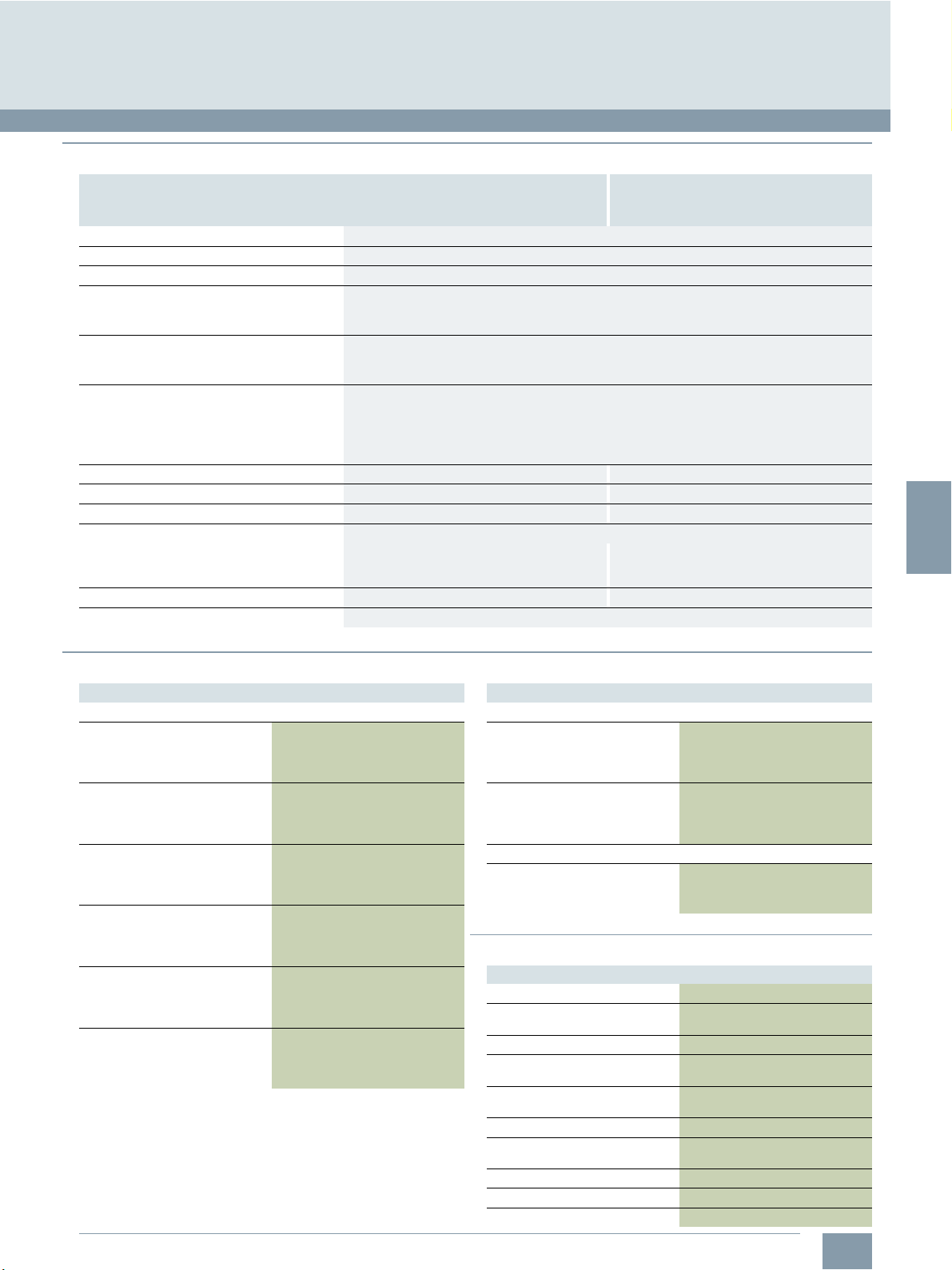

Control structure and configuration/Connectable drives/Connectable measuring systems

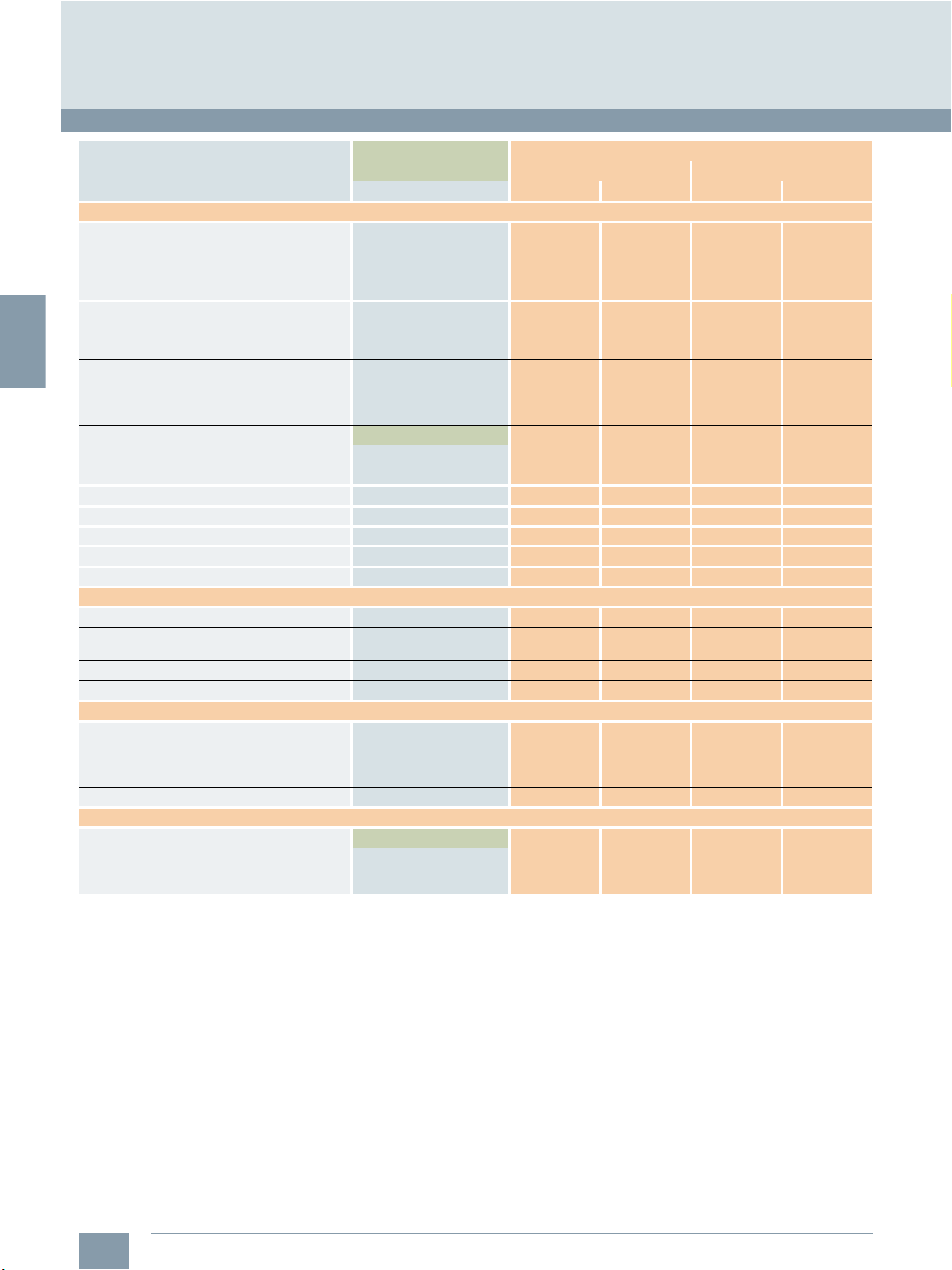

Basic version

O Option

– Not available

Control structure and configuration

Panel-based control system comprising:

• Compact operator panel

• CNC/PLC Control Unit

• Onboard digital PLC inputs/outputs

• CF card with system software Export version Tur ni ng Milling Tur ni ng Milling

SINUMERIK operator panel CNC:

• Operator panel layout

horizontal/vertical

• Color display 8.4" 8.4" 8.4" 8.4"

• Display resolution 800 × 600 800 × 600 800 × 600 800 × 600

• Integrated CNC keyboard with hard keys

• Specific CNC keyboard layout for Tur ni ng Milling Tur ni ng Milling

• Operator panel with Simplified Chinese layout

• Operator panel with English layout

SINUMERIK Operate BASIC

Quantity of bus interfaces for axis converter 1 1 1 1

Quantity of analog ±10 V interfaces for

spindle converter

Channels/mode groups MG:

• Maximum configuration 1 1 1 1

CNC user memory (buffered) for

CNC part programs

Axes/spindles:

• Basic quantity of axes/spindles 3 4 3 4

• Maximum configuration axes/spindles 4 4 6 6

• Axis/spindle, each additional 6FC5800-0AK70-0YB0 O – O O

• Additional 1 positioning axis/auxiliary spindle 6FC5800-0AK80-0YB0 O – O O

Connectable drives

Feed drives:

• SINAMICS V70 via bus interface O O O O

Spindles:

• Analog Drive Interface O O O O

SINAMICS V70 spindle via bus interface O O O O

Connectable measuring systems

Number of measuring systems per axis, max. 1 1 1 1

Encoder installed in

SIMOTICS S-1FL6 feed motors

Encoder installed in

SIMOTICS M-1PH1 main spindle motors

RS422 (TTL) direct incremental spindle encoder 6FX2001-2E... O O O O

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

/ / / /

1 1 1 1

The 1.25 MB memory is for

storing and editing the user

program. There is another

500 MB memory for NC

program storage.

1.25 MB 1.25 MB 1.25 MB 1.25 MB

2/2

Siemens NC 81.1 · 2019

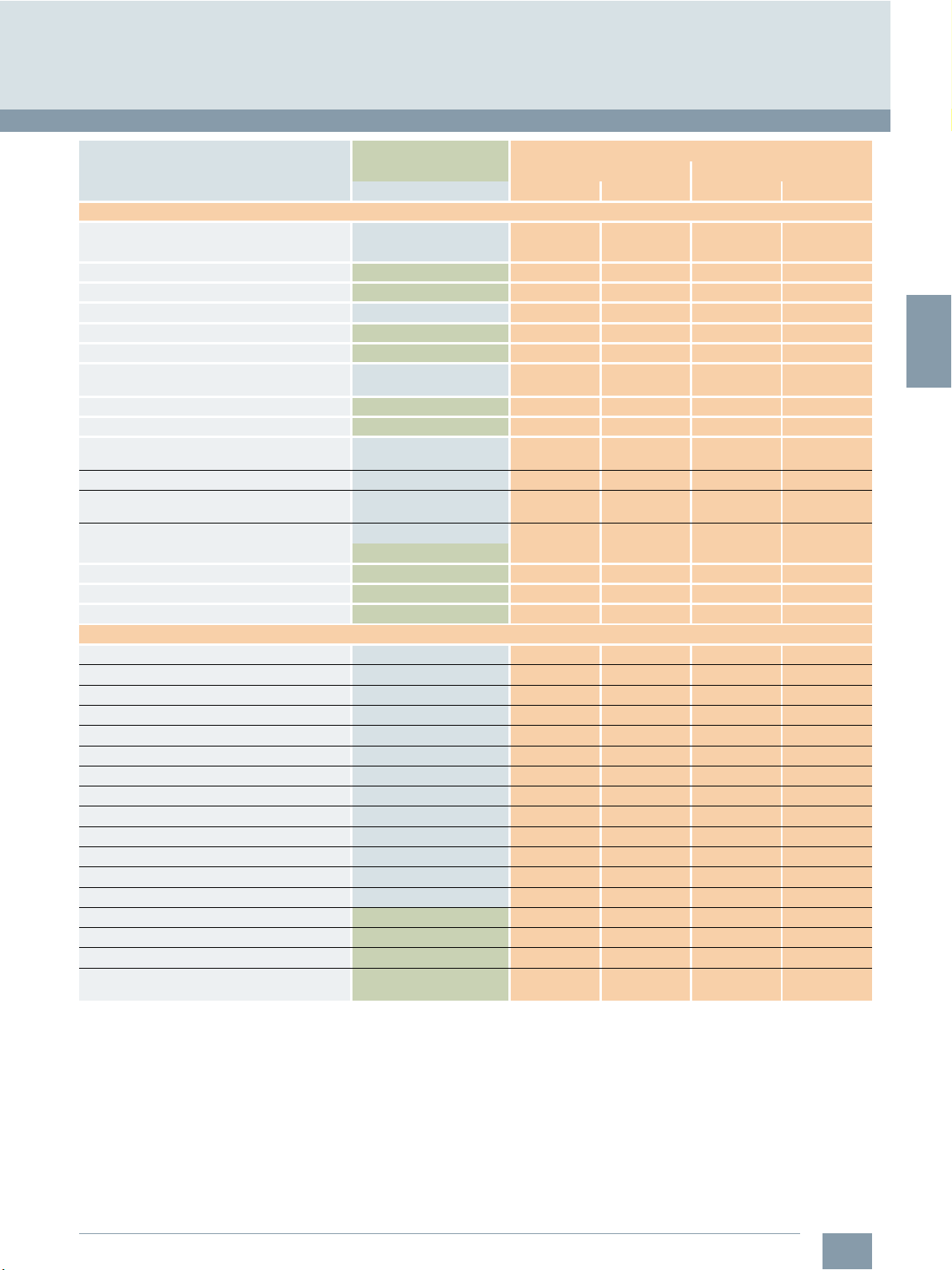

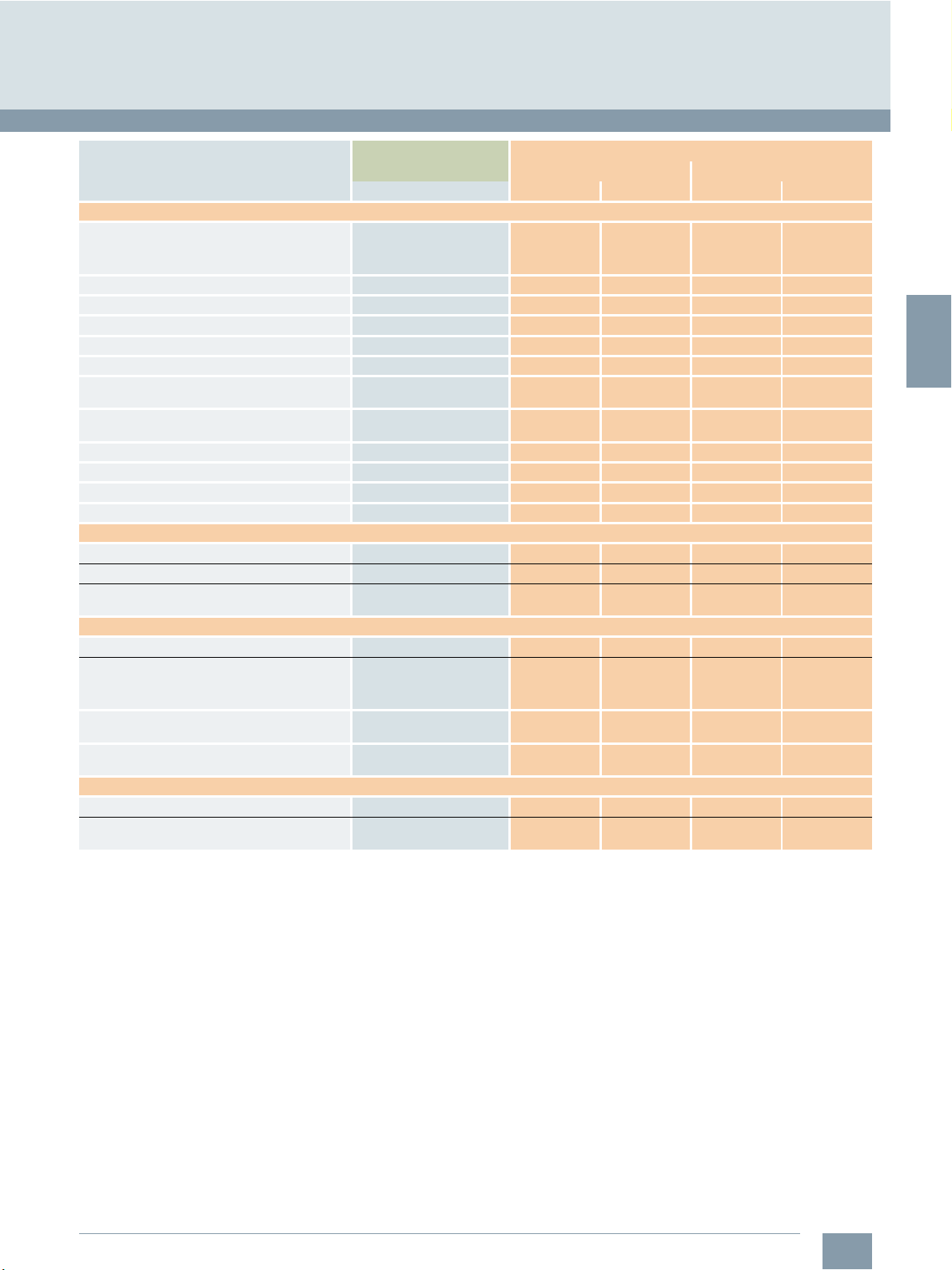

Page 15

2

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED CNC controls

Overview of functions

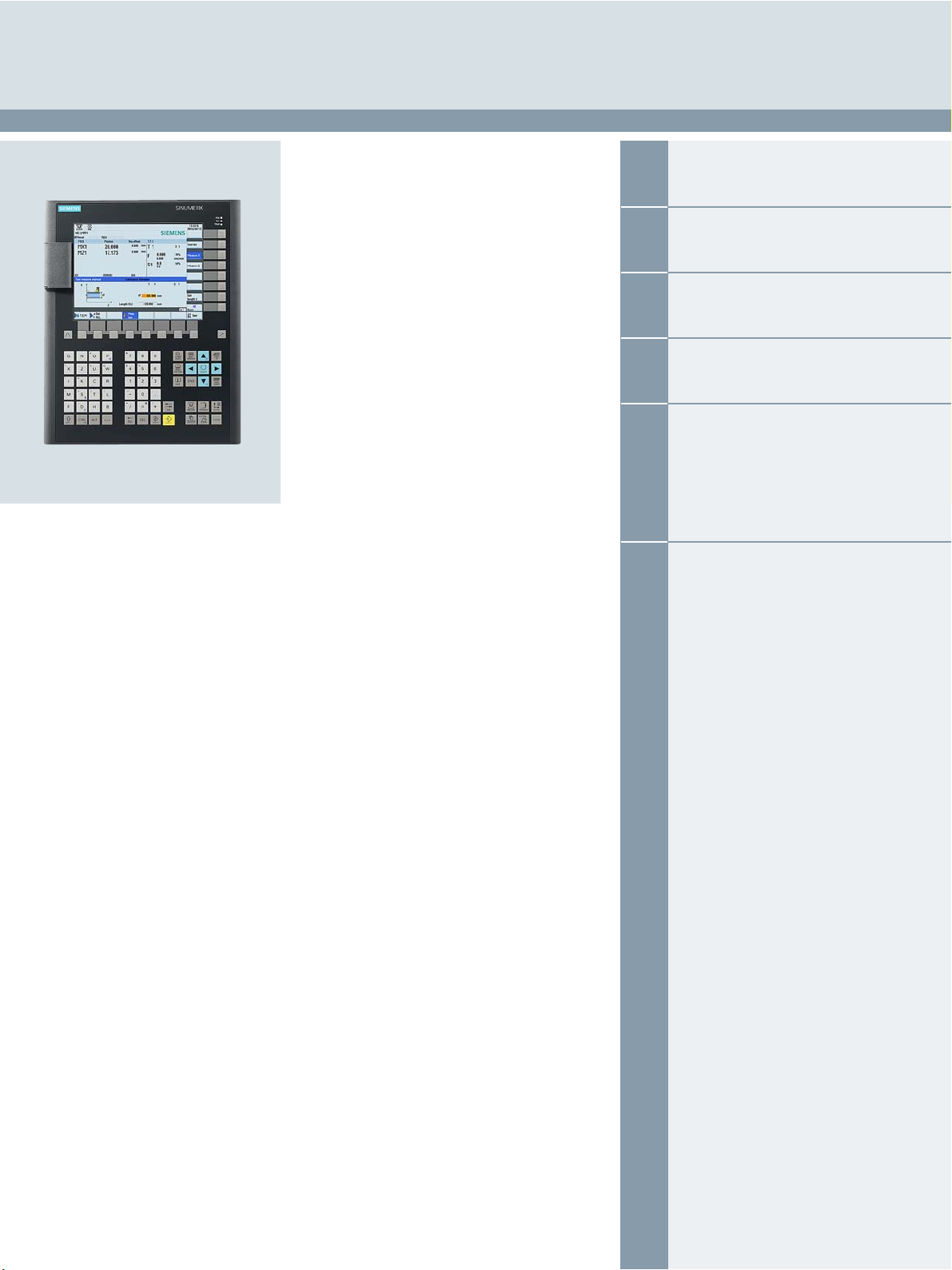

Operation/Axis functions

Basic version

O Option

– Not available

Operation

Machine Control Panel:

• SINUMERIK 808D MCP horizontal:

- English layout 6FC5303-0AF35-0AA0 O O O O

- Simplified Chinese layout 6FC5303-0AF35-0CA0 O O O O

• SINUMERIK 808D MCP vertical:

- English layout 6FC5303-0AF35-2AA0 O O O O

- Simplified Chinese layout 6FC5303-0AF35-2CA0 O O O O

• SINUMERIK 808D MCP vertical:

with handwheel slot

- English layout 6FC5303-0AF35-3AA0 O O O O

- Simplified Chinese layout 6FC5303-0AF35-3CA0 O O O O

• 3rd-party MCP via onboard digital

PLC inputs/outputs

Number of digital tool probes, max. – 1 – 1

Number of electronic handwheels

RS422 5 V DC, max.

Electronic handwheels 5 V DC:

• With 120 mm × 120 mm front panel 6FC9320-5DB01 O O O O

• With 76.2 mm × 76.2 mm front panel 6FC9320-5DC01 O O O O

• Without front panel, without setting wheel 6FC9320-5DF01 O O O O

• Without front panel, with setting wheel 6FC9320-5DM00 O O O O

Axis functions

Feedrate override 0 ... 200 % 0 ... 200 % 0 ... 200 % 0 ... 200 %

Feedrate override axis-specific 0 ... 200 % 0 ... 200 % 0 ... 200 % 0 ... 200 %

Traversing range decades ± 9 ± 9 ± 9 ± 9

Rotary axis, turning endlessly

Velocity, max. 300 m/s 300 m/s 300 m/s 300 m/s

Acceleration with jerk limitation

Programmable acceleration

Feedrate interpolation

Separate path feed for corners and chamfers

Velocity-dependent feed forwad control

Friction compensation

Auto Servo Tuning AST

Direct Servo Control DSC

TRANSMIT/TRACYL Transformation without Y axis 6FC5800-0AS50-0YB0 – – O O

Pair of synchronized axes (gantry axes), basic 6FC5800-0AS51-0YB0 – – O O

Contour handwheel 6FC5800-0AM08-0YB0 O O O O

Generic coupling, CP-Basic, e.g. multi-edge

turning

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

O O O O

2 2 2 2

6FC5800-0AM72-0YB0 – – O –

Siemens NC 81.1 · 2019

2/3

Page 16

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Spindle functions/Interpolations/Measuring functions/Motion-synchronous actions

Basic version

O Option

– Not available

Spindle functions

Spindle speed, analog

Spindle speed, max. programmable value range

(display ± 999999999.9999)

Spindle override 0 ... 200 % 0 ... 200 % 0 ... 200 % 0 ... 200 %

Gear stages 5 5 5 5

Intermediate gear

Automatic gear stage selection

Oriented spindle stop Requires direct spindle

Spindle speed limitation min./max.

Constant cutting rate

Spindle control via PLC (positioning, oscillation)

Changeover to axis mode Requires servo spindle and

Axis synchronization on-the-fly Requires servo spindle and

Thread run-in and run-out programmable

Thread cutting with constant or variable pitch

Tapping with compensating chuck/rigid tapping Requires servo spindle and

Interpolations

Linear interpolation axes, max. 3 3 3 4

Circle via center point and end point

Circle via interpolation point

Helical interpolation

Continuous-path mode with programmable

rounding clearance

Advanced Surface look ahead, velocity control

and CNC block compression

High-speed setting cycle CYCLE832 – – –

Look ahead (number of blocks) 1 50 1 150

Measuring functions

Measuring in JOG:

• Number of probes (switching)

with/without deletion of distance-to-go

Motion-synchronous actions

CNC inputs/outputs, high-speed:

• Digital inputs CNC onboard 3 3 3 3

- Digital inputs cycle time 0.2 ms 0.2 ms 0.2 ms 0.2 ms

• Digital outputs CNC onboard 1 1 1 1

- Digital outputs cycle time 0.3 ms 0.3 ms 0.3 ms 0.3 ms

Synchronized actions and high-speed auxiliary

function output incl. 3 synchronous functions

Positioning axes and spindles via

synchronized actions (command axes)

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

encoder.

direct encoder.

direct encoder.

direct encoder.

-4

106 ... 10

– – –

– 1 – 1

106 ... 10

-4

106 ... 10

-4

106 ... 10

-4

2/4

Siemens NC 81.1 · 2019

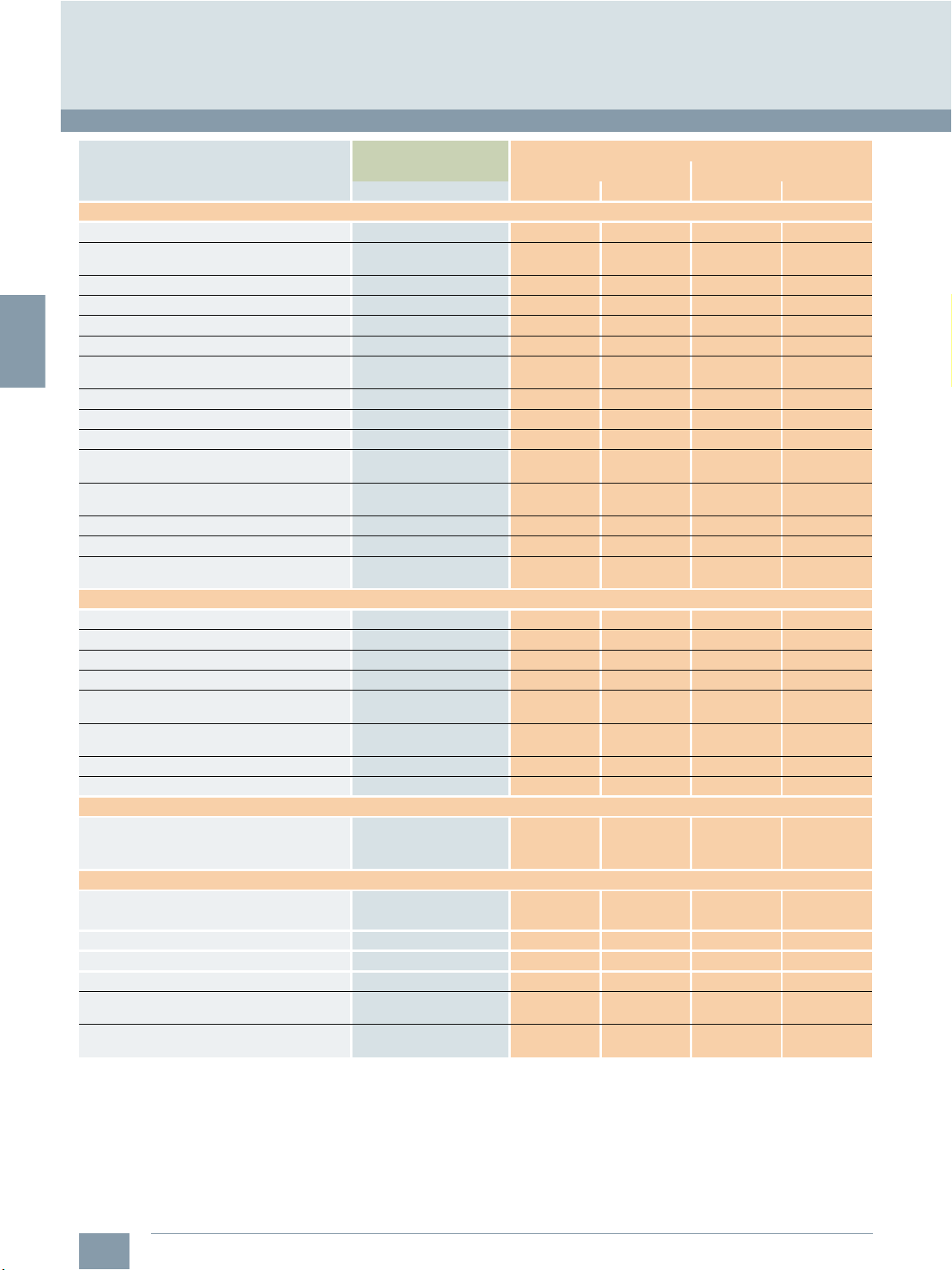

Page 17

2

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED CNC controls

Overview of functions

Open Architecture/CNC programming language

Basic version

O Option

– Not available

Open Architecture

Customizable HMI:

• Customizable screens in the HMI

• Input screens for customized user cycles

CNC programming language

Programming methods:

• SINUMERIK style programming language

(DIN 66025 and high-level language expansion)

• ISO code

Main program call from main program and

subroutine

Subprogram levels, max. 11 11 11 11

Number of subprogram passes 9999 9999 9999 9999

Number of levels for skip blocks 1 1 1 1

Polar coordinates

Dimensions metric/inch, changeover:

• Manually

•Via program

Inverse-time feedrate

Auxiliary function output:

• Via M word, max. programmable value range INT 231-1 INT 231-1 INT 231-1 INT 231-1

• Via H word, max. programmable value range

REAL ± 3.4028 ex 38

(display ± 999999999.9999)

Basic frames, max. number 1 1 1 1

Settable offsets, max. number 6 6 32 32

Work offsets, programmable (frames)

Global and local user data

Global program user data

SINUMERIK high-level CNC language with:

• Frame concept

TRANS/ROT/SCALE/MIRROR

• User variables, configurable

• Predefined user variables

(arithmetic parameters)

• Predefined user variables

(arithmetic parameters), configurable

• Read/write system variables

• Indirect programming

• Program jumps and branches

• Arithmetic and trigonometric functions

• Compare operations and logic combinations

• Macro techniques

• Control structures IF-ELSE-ENDIF

• Control structures WHILE, FOR, REPEAT, LOOP

• STRING functions

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

INT -231 ...

-1

231

INT -231 ...

-1

231

INT -231 ...

-1

231

INT -231 ...

-1

231

Siemens NC 81.1 · 2019

2/5

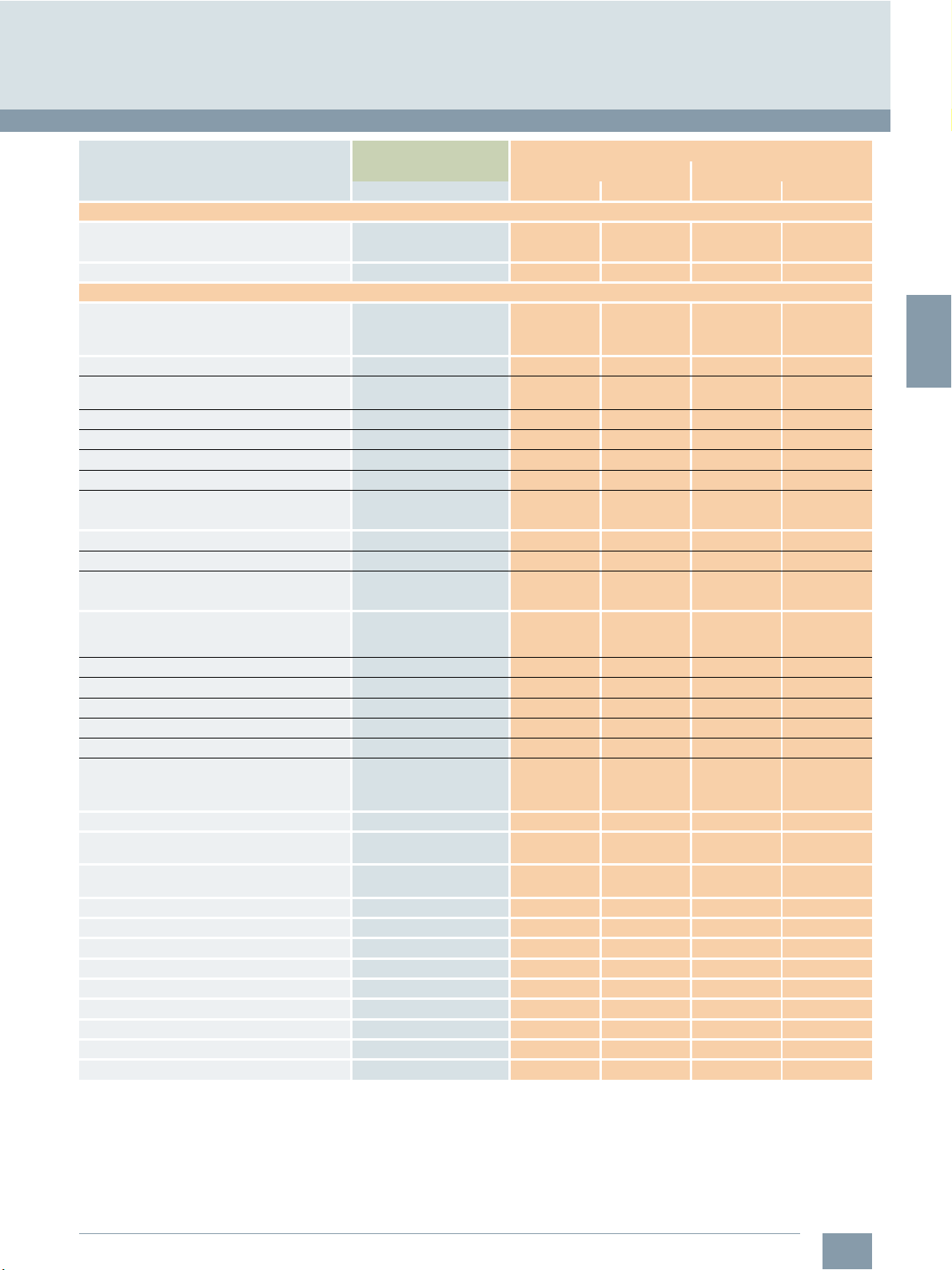

Page 18

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Technology cycles/Canned cycles

Basic version

O Option

– Not available

Technology cycles

Technology cycles for SINUMERIK style

programming language:

• Drilling, centering – CYCLE81

• Drilling, counterboring – CYCLE82

• Deep-hole drilling – CYCLE83

• Rigid tapping – CYCLE84

• Tapping with compensating chuck – CYCLE840

• Reaming 1 – CYCLE85

• Boring – CYCLE86

• Position pattern: Row of holes – HOLES1 – –

• Position pattern: Circle of holes – HOLES2 – –

• Cutoff - CYCLE92 – –

• Groove – CYCLE93 – –

• Undercut (forms E and F according to DIN) –

CYCLE94

• Contour cutting with relief cut – CYCLE95 – –

• Thread undercut – CYCLE96 – –

• Thread chaining – CYCLE98 – –

• Thread cutting – CYCLE99 – –

• Face milling – CYCLE71 – –

• Contour milling – CYCLE72 – –

• Milling a rectangular spigot – CYCLE76 – –

• Milling a circular spigot – CYCLE77 – –

• Long holes located on a circle – LONGHOLE – –

• Slots on a circle – SLOT1 – –

• Circumferential slot – SLOT2 – –

• Milling a rectangular pocket – POCKET3 – –

• Milling a circular pocket – POCKET4 – –

• Thread milling – CYCLE90 – –

• High-speed settings – CYCLE832 – –

Canned cycles

Canned cycles for ISO code milling:

• High-speed deep hole drilling cycle with chip

breakage (G73)

• Drilling a left-hand thread without any

compensating chuck cycle (G74)

• Fine drilling cycle (G76) – –

• Deselection of a fixed cycle (G80) – –

• Drilling cycle, counterboring (G81) – –

• Countersink drilling cycle (G82) – –

• Deep hole drilling cycle with chip removal (G83) – –

• Drilling a right-hand thread without any

compensating chuck cycle (G84)

• Boring cycle (G85) – –

• Boring cycle, retraction with G00 (G86) – –

• Boring cycle, reverse countersinking (G87) – –

• Boring cycle, retraction with machining feedrate

(G89)

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

– –

– –

– –

– –

– –

2/6

Siemens NC 81.1 · 2019

Page 19

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Canned cycles/Program and workpiece management/Programming support/Simulations

Basic version

O Option

– Not available

Canned cycles (continued)

Canned cycles for ISO code turning

(G code system A):

• Thread cutting with constant lead (G32) – –

• Thread cutting with variable lead (G34) – –

• Finishing cycle (G70) – –

• Stock removal cycle longitudinal axis (G71) – –

• Stock removal cycle transverse axis (G72) – –

• Closed cutting cycle (G73) – –

• Multiple repetitive grooving cycles in the

longitudinal axis (G74)

• Deep hole drilling and recessing in

facing axis (G75)

• Multiple thread cutting (G76) – –

• Axial cutting (G90) – –

• Thread cutting (G92) – –

• Radial cutting (G94) – –

Program and workpiece management

Part programs on PPU, max. number 255 255 255 255

Readable part program names

Sub-folders for part programs with

readable names

Programming support

Background editing

Program editor:

• Full screen CNC editor with cut, copy and

paste functionality

• Programming support programGUIDE BASIC

for SINUMERIK technology cycles

• Contour computer with programming

graphics/free contour input (contour calculator)

Simulations

2D simulation

Real-time simulation of current machining

operation

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

– –

– –

Siemens NC 81.1 · 2019

2/7

Page 20

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Operating modes/Tools

Basic version

O Option

– Not available

Operating modes

Manual Machine plus for manual controlled

semi-CNC lathes

JOG:

• T, S, M screen for quick activation of machine

functions

• Face milling cycle for workpiece preparation – –

• Handwheel selection

• Switchover: inch/metric

• Manual measurement of work offset

• Manual measurement of tool offset

• Semi-automatic tool measurement with

tool probe

MDI:

• Input in text editor

Automatic:

• Execution from memory stick connected to

USB interface on operator panel front

• Program control

(dry-run feed, block skip etc.)

• Program editing

• Block search with/without calculation

Repos (repositioning on the contour):

• With operator command/semi-automatically

• Program-controlled

Preset:

• Set actual value

Too ls

Tools/cutting edges, max. 64/128 64/128 64/128 64/128

Tool types:

• Turning – –

• Drilling

• Milling

Tool radius compensations in plane:

• With approach and retract strategies

• With transition circle/ellipse on outer edges

Tool offset selection via T and D numbers

Look-ahead detection of contour violations

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

6FC5800-0AP07-0YB0 O – O –

– –

2/8

Siemens NC 81.1 · 2019

Page 21

2

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED CNC controls

Overview of functions

Communication and data management

Basic version

O Option

– Not available

Communication and data management

USB interface on panel front for memory stick

and USB PC keyboard:

• Transfer of:

- Machine and setting data

-PLC data

- Compensation data

- Tool and work offset data

- R parameter

-HMI data

- User cycles

- Part programs

- PLC program (*.pte)

• Execute part program

Ethernet interface:

• Transfer of:

- Machine and setting data

-PLC data

- Compensation data

- Tool and work offset data

- R parameter

-HMI data

- User cycles

- Part programs

• Execute part program

• Part program send/receive

• PLC program upload/download

• PLC status monitoring

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

Siemens NC 81.1 · 2019

2/9

Page 22

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

HMI functions/Monitoring functions/Compensations

Basic version

O Option

– Not available

HMI functions

CNC lock function 6FC5800-0AS71-0YB0 O O O O

Lock MyCycles 6FC5800-0AP54-0YB0 O O O O

SINUMERIK 808D startGUIDE:

• Startup assistant

Built-in graphical interactive assistant for

1st commissioning of machines with

SINUMERIK 808D

• Series startup assistant

Built-in graphical interactive assistant for

the series production of machines with

SINUMERIK 808D

• Sales assistant

Built-in viewer for bitmaps with sales arguments

for SINUMERIK 808D, extendable by customerspecific sales arguments for the machine

Online help for programming, alarms and

machine data

CNC program messages

Screen saver

Access protection level support

Chinese input method editor for part program

names, sub-directory names and CNC comments

Operating software languages:

• Chinese Simplified, Czech, English, French,

German, Italian, Korean, Polish, Portuguese,

Russian, Spanish, Turkish, Hungarian

• Language switchover online

Monitoring functions

Working area limitation

Limit switch monitoring

Software and hardware limit switches

Position monitoring

Standstill (zero-speed) monitoring

Clamping monitoring

Contour monitoring

Axis limitation from the PLC

Spindle speed limitation

Compensations

Backlash compensation

Leadscrew error compensation

Bidirectional leadscrew error compensation 6FC5800-0AM54-0YB0 O O O O

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

2/10

Siemens NC 81.1 · 2019

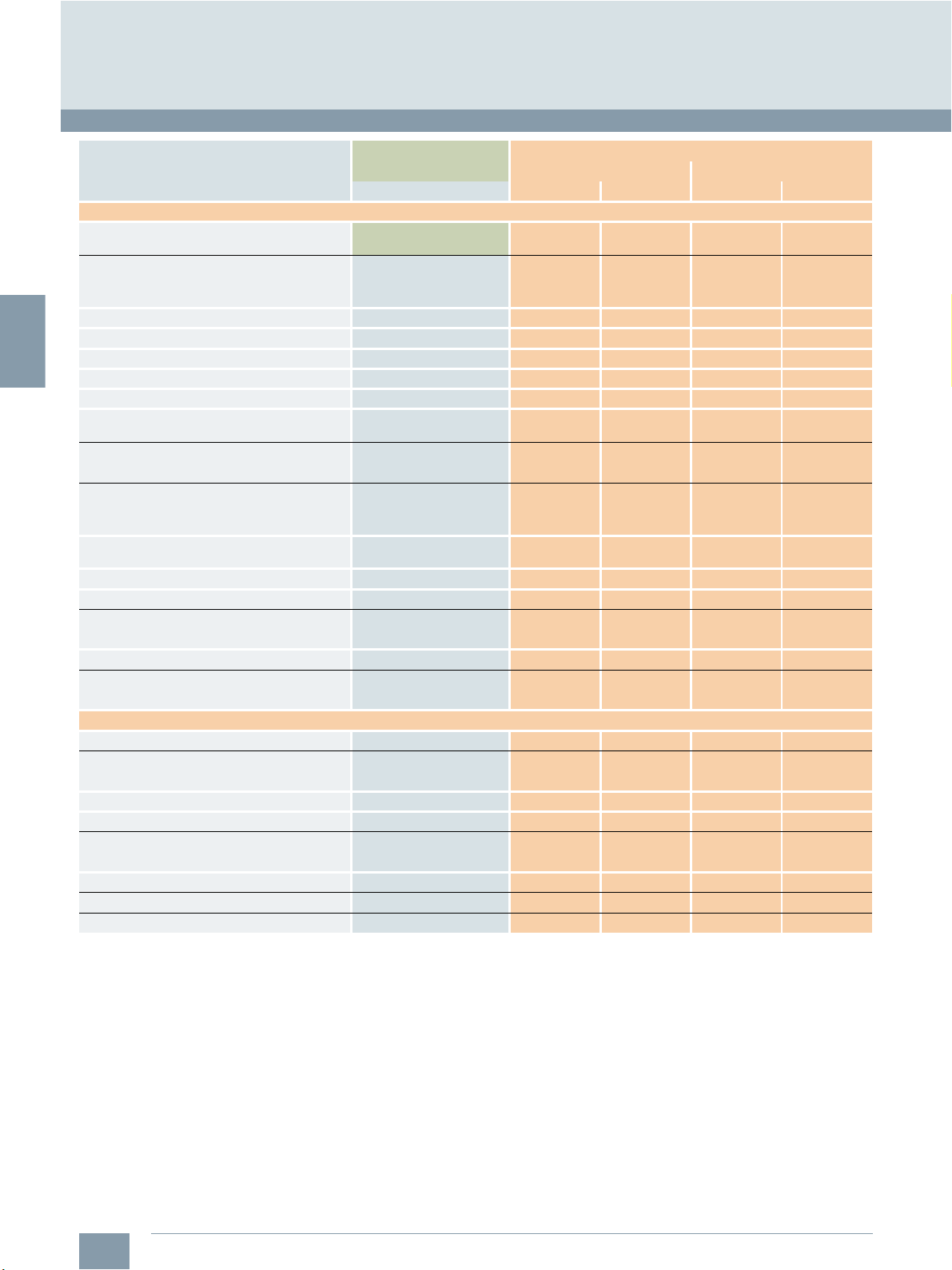

Page 23

2

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED CNC controls

Overview of functions

PLC area

Basic version

O Option

– Not available

PLC area

Integrated PLC

Style of PLC program:

• Prepared and ready to run PLC program

on board

• Fully customized PLC programs by

offline PLC programming tool

Fixed cycle time for PLC 12 ms 12 ms 12 ms 12 ms

Maximum number of ladder steps 6000 6000 6000 6000

PLC programming language:

• LAD ladder diagram

Offline PLC programming tool 6FC5811-0CY00-0YA8 O O O O

PLC Ladder Viewer on PPU

PLC I/O:

• On-board digital PLC: Connection via screw-clamp

- Inputs 24 V 24 24 24 24

- Outputs 24 V, 0.2 A 16 16 16 16

• On-board digital PLC: Connection via 50-pole

- Inputs 24 V 48 48 48 48

- Outputs 24 V, 0.2 A 32 32 32 32

Connection via 50-pole ribbon cable

connector to PPU:

• Terminal strip converter 6EP5406-5AA00 O O O O

• Cable set 6EP5306-5BG00 O O O O

PLC alarms/messages, max. number 128 128 128 128

Bit memories, number 256 bytes 256 bytes 256 bytes 256 bytes

Timers, number 64 64 64 64

Counters, number 64 64 64 64

Subroutines 64 64 64 64

User machine data for configuring the

PLC user program

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

On toolbox DVD-ROM

connector on PPU.

ribbon cable connector.

Siemens NC 81.1 · 2019

2/11

Page 24

2

© Siemens Industry, Inc. 2018

Overview of functions

SINUMERIK 808D ADVANCED CNC controls

Commissioning and serial production/Diagnostic functions/Service and maintenance/Training and offline programming

Basic version

O Option

– Not available

Commissioning and serial production

SINUMERIK 808D startGUIDE

• Startup assistant

Built-in graphical interactive assistant for

1st commissioning of machines with

SINUMERIK 808D controls

• Series startup assistant

Built-in graphical interactive assistant for the

series production of machines with

SINUMERIK 808D controls

Backup/restore of system software via

USB memory stick

Cloning of serial startup files for serial production

via USB memory stick

SINUMERIK 808D family toolbox with: 6FC5811-0CY00-0YA8 O O O O

• Offline PLC programming tool O O O O

• Sample PLC program O O O O

• MCP strip template O O O O

• MCP icon library O O O O

• User manuals O O O O

• Access My Machine AMM

Diagnostic functions

Alarms and messages

Action log can be activated for diagnostic

purposes

PLC status

LAD display

Service and maintenance

Integrated service planner for monitoring of

service intervals

One touch system backup

(Ctrl + S)

CNC memory buffering via battery

Training and offline programming

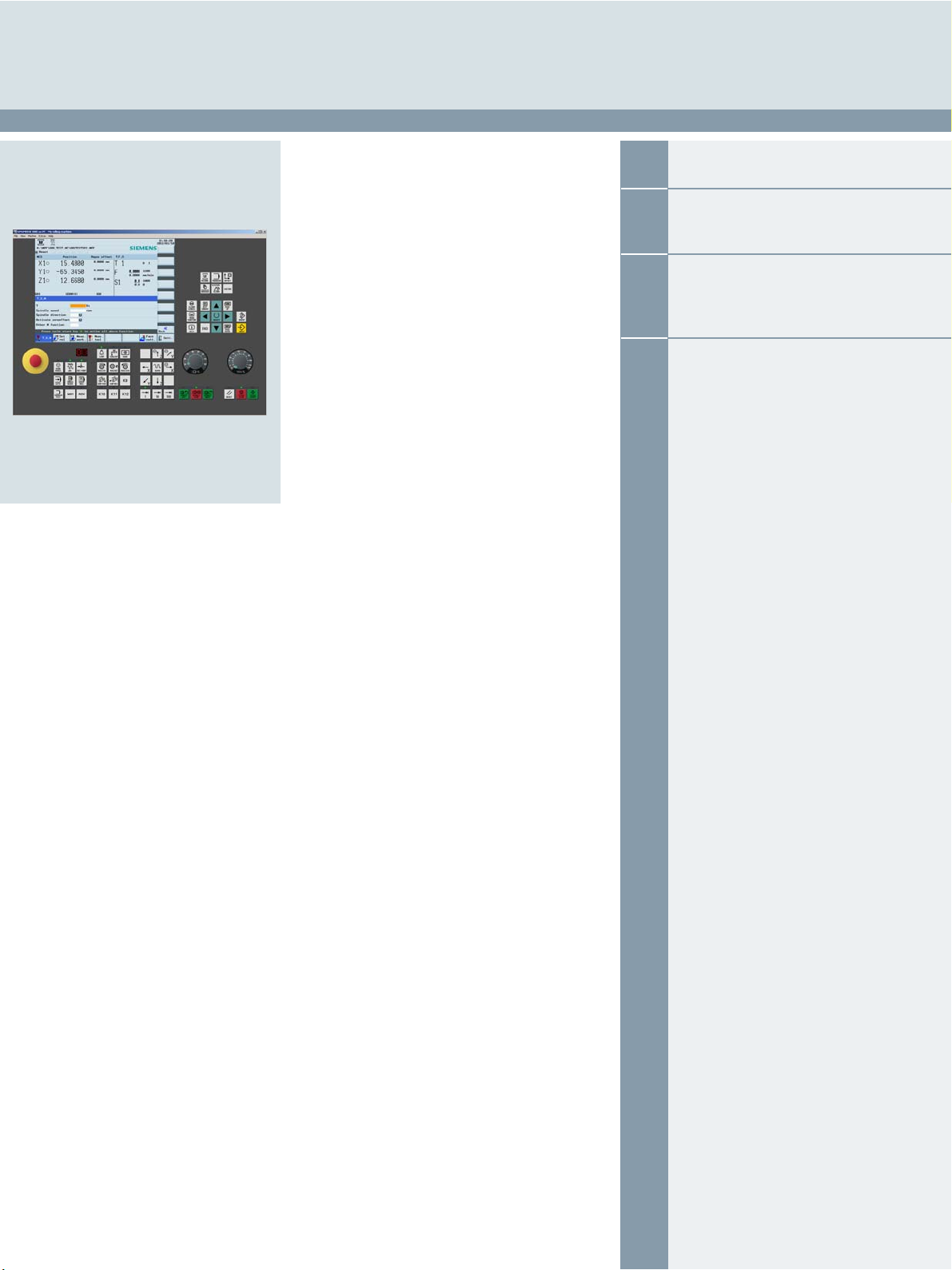

SINUMERIK 808D on PC 6FC5870-0YC40-0YT0 O O O O

Article No. SINUMERIK 808D ADVANCED

PPU 15x.3 PPU 16x.3

Note Turn in g Milling Tu rn in g Milling

On toolbox DVD-ROM.

Free download of trial

version from:

www.cnc4you.com

2/12

Siemens NC 81.1 · 2019

Page 25

3

SINUMERIK 808D ADVANCED system

© Siemens Industry, Inc. 2018

3/2

3/2

3/5 Operator components

3/5 SINUMERIK 808D MCP

3/8 Feed axis solutions

3/8 SINAMICS V70 servo drive

3/12 SIMOTICS S-1FL6 feed motor

3/16 Spindle solutions

3/16 SINAMICS V70 spindle drive

3/20 SIMOTICS M-1PH1 main spindle motor

3/26 MOTION-CONNECT connection systems

3/26 MOTION-CONNECT cables for

3/29 MOTION-CONNECT cables for

3/31 MOTION-CONNECT cables for

3/33 Sample packages

3/33 Sample package for Turning with

3/34 Sample package for Milling with

CNC control

SINUMERIK 808D ADVANCED

PPU 15x.3/PPU 16x.3

horizontal/vertical

SINUMERIK 808D ADVANCED

SINAMICS V70 servo drive

SINAMICS V70 spindle drive

SINUMERIK 808D ADVANCED T

SINUMERIK 808D ADVANCED M

Siemens NC 81.1 · 2019

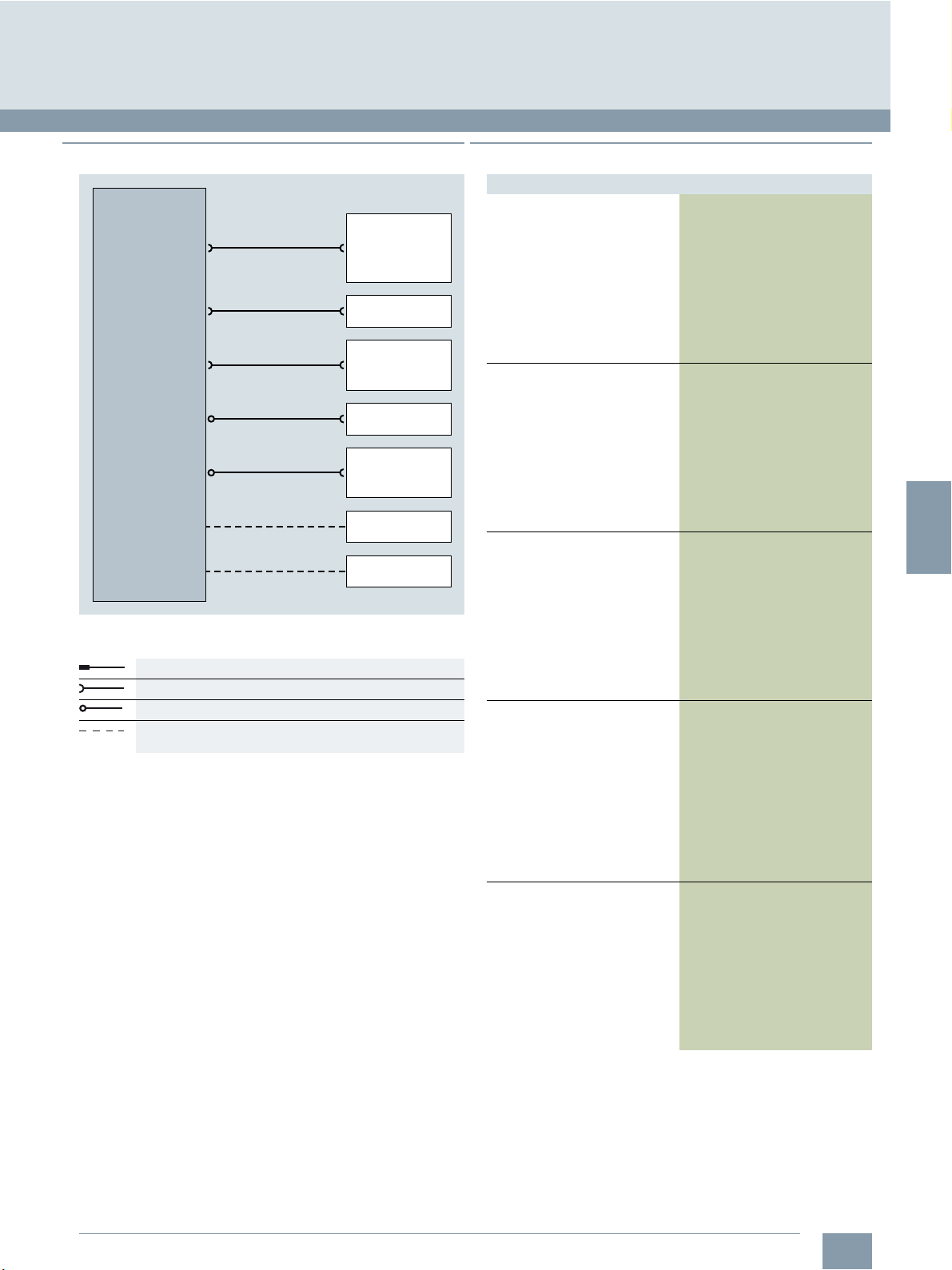

Page 26

3

1)

Only for turning

2)

Only for PPU 16x.3 milling

3)

Up to 4 axes/spindle for PPU 15x.3

4)

Only for milling

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

CNC control

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

■

Overview

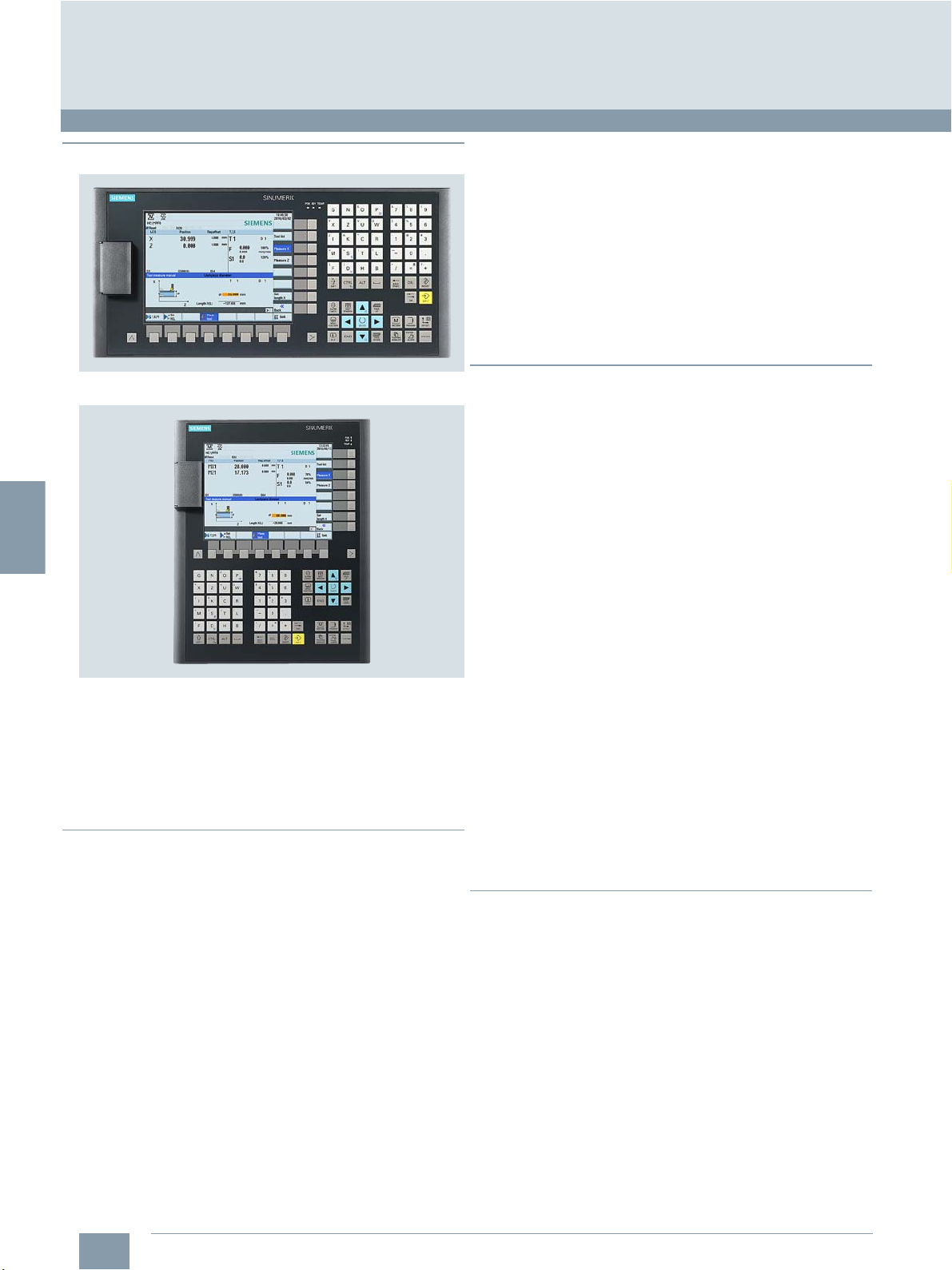

SINUMERIK 808D ADVANCED PPU 151.3/PPU 161.3 horizontal

SINUMERIK 808D ADVANCED PPU 150.3/PPU 160.3 vertical

The SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3 is an

operator-panel-based CNC, preconfigured for use in modern

basic standard turning and milling machines.

There are two variants of SINUMERIK 808D ADVANCED PPU's –

PPU 15x.3 and PPU 16x.3 – with same appearance and different

functionalities. The differences are described between PPU

15x.3 and PPU 16x.3 in chapter 2 - Overview of functions.

■

Benefits

7 Compact, rugged, and maintenance-friendly operator-panel

CNC

7 Actual position feedback to CNC

7 Intelligent clamp mounting without drilling holes into the

cabinet

7 Minimum commissioning efforts due to plug and play machine

control panel connected via USB interface

7 Direct commissioning on HMI for feed drives and automatic

servo tuning (AST)

7 Maximum performance and accuracy due to most modern

CNC features

7 SINUMERIK 808D startGUIDE: assists all process steps of the

machine – from engineering to production, from sales to operation and programming at the push of a button

7 SINUMERIK Operate BASIC: maximum operator convenience

similar to SINUMERIK 828D and SINUMERIK 840D sl

7 SINUMERIK programGUIDE BASIC: wide range of

technology cycles for turning, milling and drilling with

graphical input screens

7 Manual Machine plus: easy semi-automatic machining with

handwheel controlled flat-bed lathes

7 Fast data transmission via USB stick and high-speed Ethernet

1)

interface

7 More software options can cover more applications and

enhance the machine performance

7 Maximum performance and accuracy due to the Advanced

Surface function

■

Function

2)

• 2 operator panel variants for horizontal and vertical operator

panel housings

• IP65 protection for CNC front panel and machine control panel

• Integrated CNC keyboard with mechanical keys

• Simplified Chinese or English panel layout

• 8.4” color LCD display

• USB user interface on the operator panel front

• Drive bus interface for feed drives and spindle

• Analog ±10 V interface for spindle drive

• Data buffering without battery

• Pre-configured system software for turning and milling

technologies

• Up to 6 axes/spindles

3)

• Automatic servo tuning AST

• Ethernet interface for commissioning and data transfer

• Graphically guided SINUMERIK CNC programming and

standard ISO-code programming with canned cycles

• Graphical CNC simulation

• Integrated contour computer

• Integrated PLC based on the SIMATIC S7-200 command set

with ladder logic programming

• Integrated/distributed PLC I/O concept with 72 digital PLC

inputs and 48 digital PLC outputs

• CNC options subject to license

• Customized user screens

• Machine maintenance tasks are accomplished by integrated

service planner

■

Integration

The following components can be connected to the

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3:

• Up to 2 electronic handwheels

• Up to 72 digital PLC inputs and 48 digital PLC outputs

• 1 TTL direct spindle encoder

• SINUMERIK 808D MCP via USB interface

• SINAMICS V70 drive system for feed axes and spindle

• Spindle drives via ±10 V analog output

• PC via Ethernet interface

• 1 digital tool probe

4)

3/2

Siemens NC 81.1 · 2019

Page 27

3

1)

Only for PPU 15x.3 turning and PPU 16x.3

2)

Only for turning

3)

Only for PPU 16x.3

4)

Only for PPU16x.3 turning

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

■

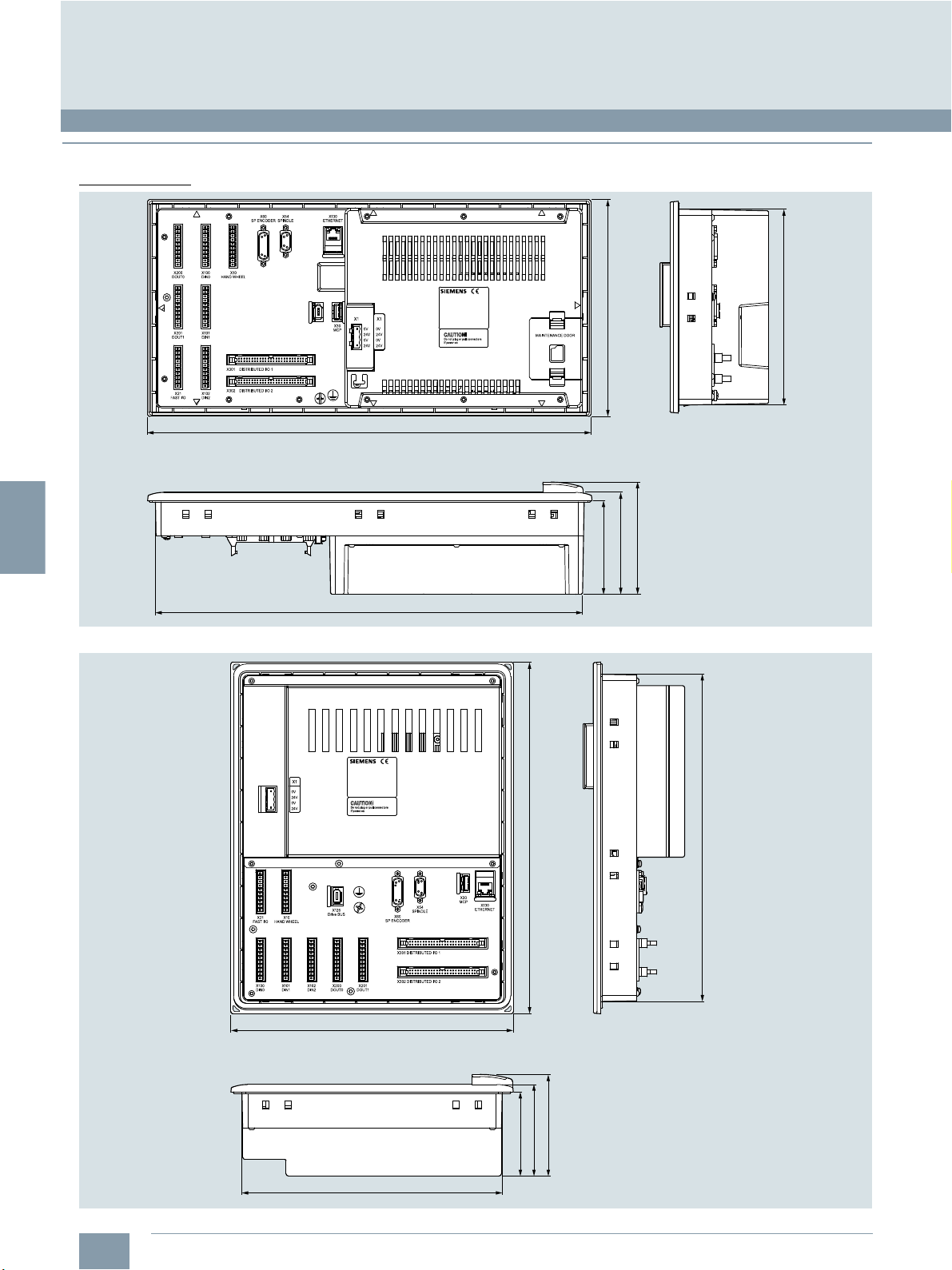

Technical specifications

Article No. 6FC5370-.B.03-0.A0 6FC5370-.A.03-0.A0

Product name SINUMERIK 808D ADVANCED

PPU 150.3/PPU 160.3 vertical

Supply voltage at DC 24 V + 20 %/- 15 %

Active power consumption maximum 50 W

Buffering time in the event of power failure 3 ms (20 ms with SITOP smart power supply)

Degree of protection

• Front, with the front flap closed IP65

•Rear IP20

Relative humidity at 25 °C, during

• storage and transport 5…95%

•operation 5…90%

Ambient temperature, during

• storage and transport -20 ... +60 °C

•operation

-front 0...45°C

-rear 0...50°C

Width 265 mm 420 mm

Height 330 mm 200 mm

Depth 104 mm 104 mm

Mounting surface

• Section width 244.1 mm 406 mm

• Section height 307.1 mm 186 mm

• Tolerance + 1 mm + 1 mm

Net weight 2.9 kg 3.0 kg

Certificate of suitability CE, EAC, KC

SINUMERIK 808D ADVANCED

PPU 151.3/PPU 161.3 horizontal

CNC control

■

Selection and ordering data

Description Article No.

Hardware components

SINUMERIK 808D ADVANCED T

PPU 160.3 vertical

• English layout 6FC5370-2BT03-0AA0

• Simplified Chinese layout 6FC5370-2BT03-0CA0

SINUMERIK 808D ADVANCED T

PPU 161.3 horizontal

• English layout 6FC5370-2AT03-0AA0

• Simplified Chinese layout

SINUMERIK 808D ADVANCED M

PPU 160.3 vertical

• English layout 6FC5370-2BM03-0AA0

• Simplified Chinese layout 6FC5370-2BM03-0CA0

SINUMERIK 808D ADVANCED M

PPU 161.3 horizontal

• English layout 6FC5370-2AM03-0AA0

• Simplified Chinese layout 6FC5370-2AM03-0CA0

SINUMERIK 808D ADVANCED T

PPU 150.3 vertical

• English layout 6FC5370-3BT03-0AA0

• Simplified Chinese layout 6FC5370-3BT03-0CA0

SINUMERIK 808D ADVANCED T

PPU 151.3 horizontal

• English layout 6FC5370-3AT03-0AA0

• Simplified Chinese layout 6FC5370-3AT03-0CA0

6FC5370-2AT03-0CA0

Description Article No.

Hardware components (continued)

SINUMERIK 808D ADVANCED M

PPU 150.3 vertical

• English layout 6FC5370-3BM03-0AA0

• Simplified Chinese layout 6FC5370-3BM03-0CA0

SINUMERIK 808D ADVANCED M

PPU 151.3 horizontal

• English layout 6FC5370-3AM03-0AA0

• Simplified Chinese layout

Software components

SINUMERIK 808D T/M

toolbox

On DVD-ROM

■

Options

Description Article No.

Additional NC axis

Additional 1 positioning axis/

auxiliary spindle

Manual Machine plus (MM+)

TRANSMIT/TRACYL

Transformation without Y axis

Pair of synchronized axes

(gantry axes), basic

Generic coupling CP-Basic

Bidirectional leadscrew error

compensation

Contour handwheel

Lock MyCycles

CNC lock function

1)

1)

3)

4)

6FC5370-3AM03-0CA0

6FC5811-0CY00-0YA8

6FC5800-0AK70-0YB0

6FC5800-0AK80-0YB0

2)

6FC5800-0AP07-0YB0

6FC5800-0AS50-0YB0

3)

6FC5800-0AS51-0YB0

6FC5800-0AM72-0YB0

6FC5800-0AM54-0YB0

6FC5800-0AM08-0YB0

6FC5800-0AP54-0YB0

6FC5800-0AS71-0YB0

Siemens NC 81.1 · 2019

3/3

Page 28

3

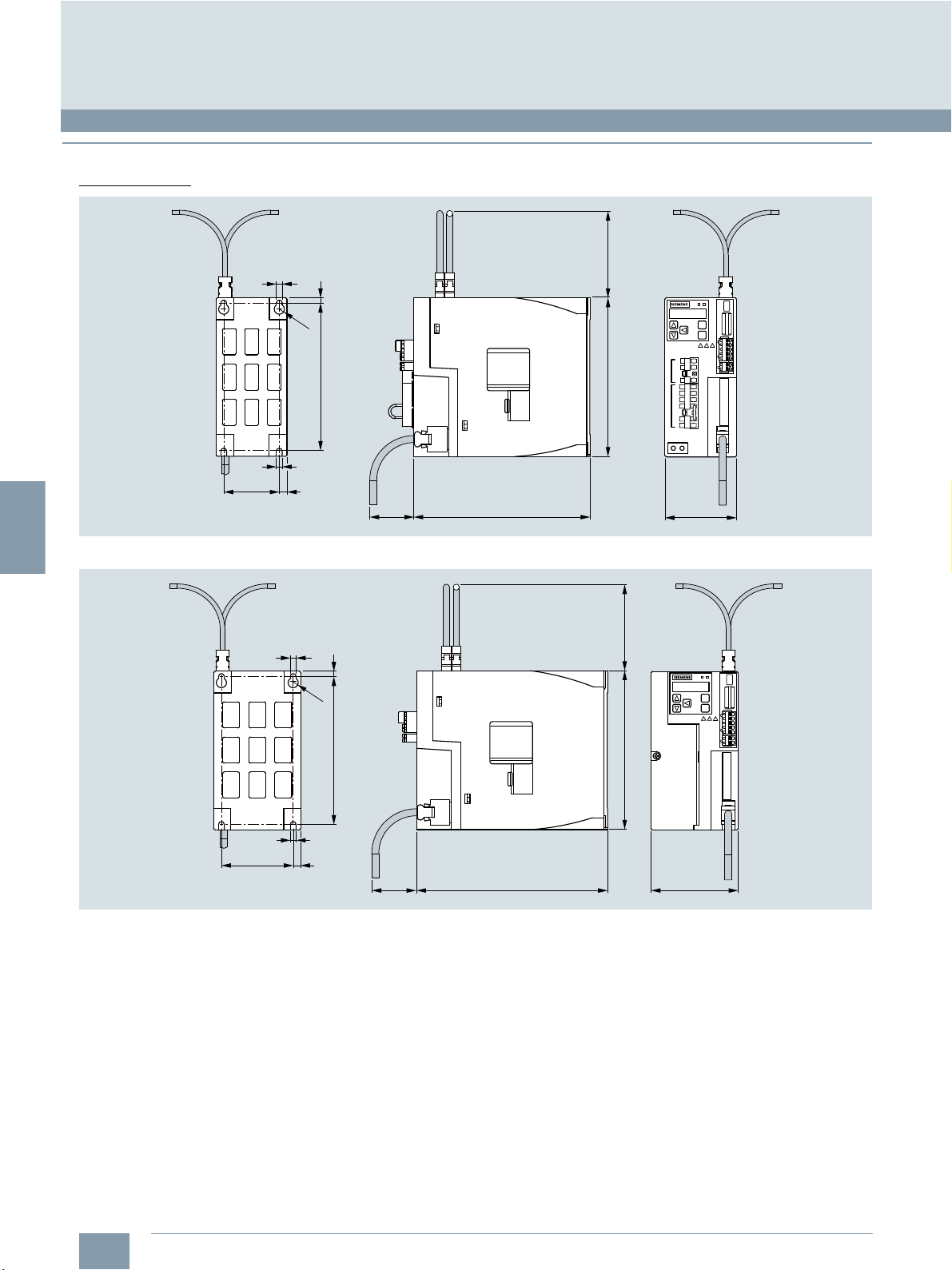

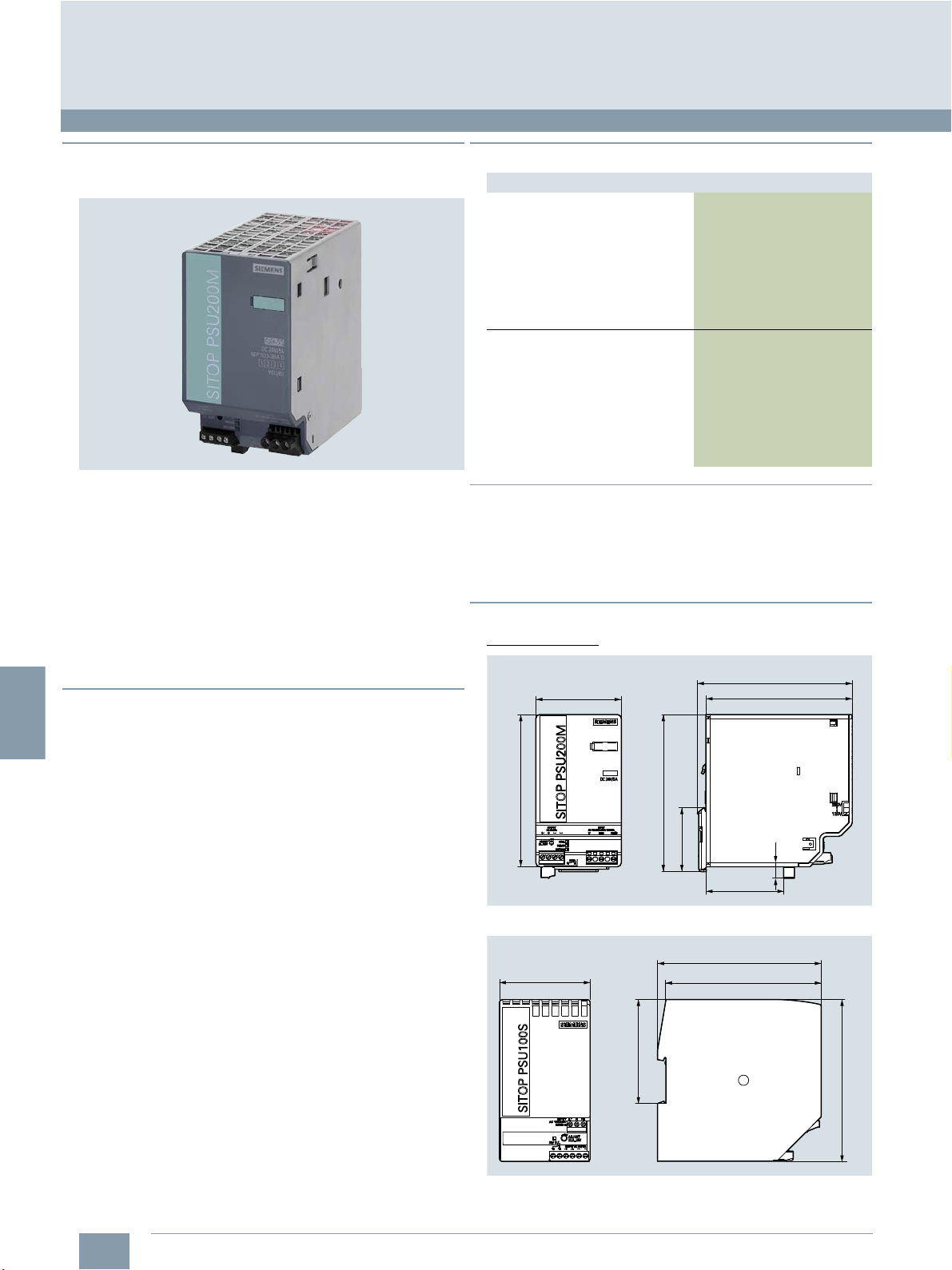

SINUMERIK 808D ADVANCED system

G_NC01_XX_00741

87

95

104

200

185

420

405

CNC control

SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

■

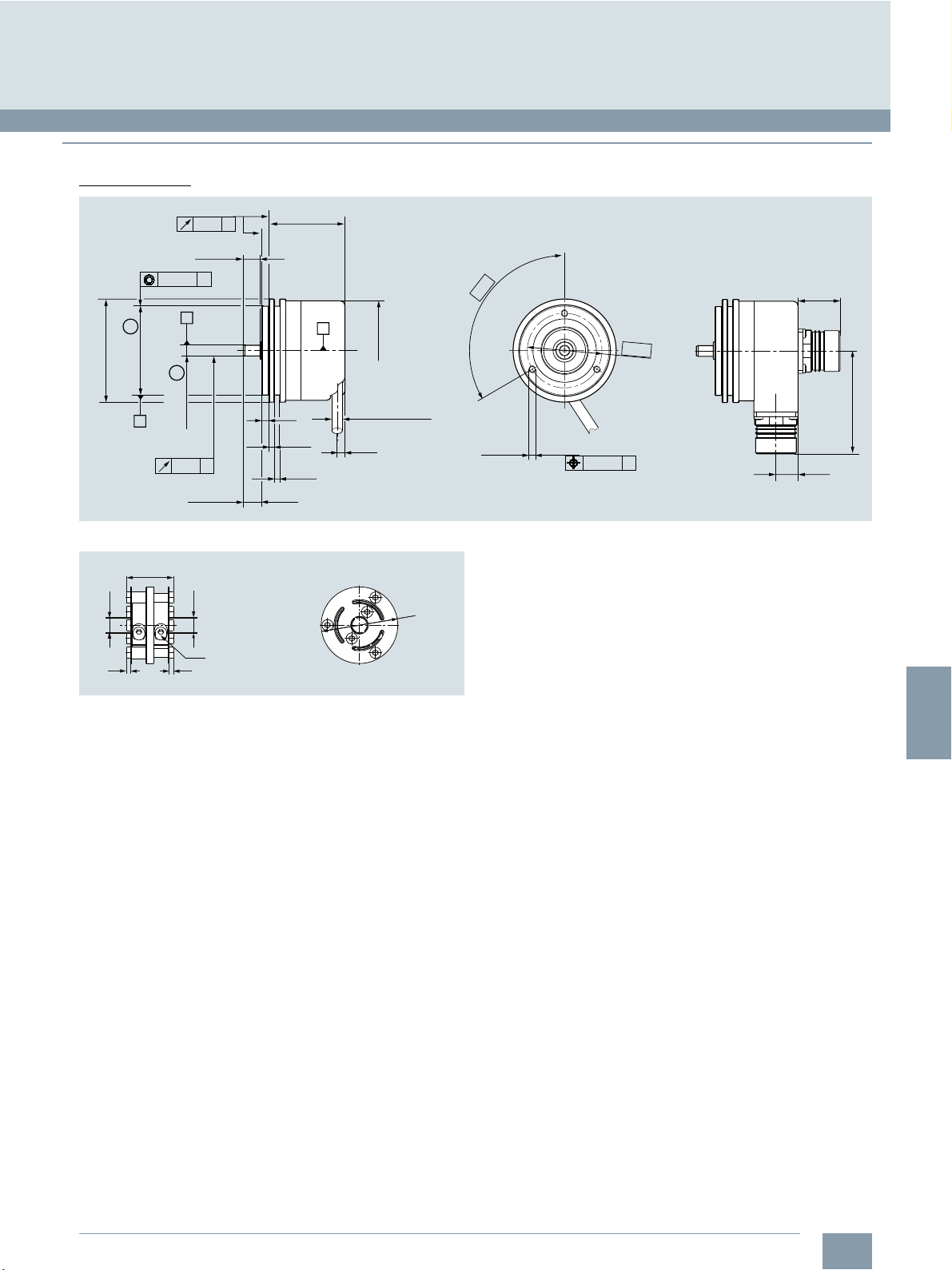

Dimensional drawings

Dimensions in mm

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED T/M horizontal

265

330

307

G_NC01_XX_00742

SINUMERIK 808D ADVANCED T/M vertical

3/4

Siemens NC 81.1 · 2019

244

96

86

79

Page 29

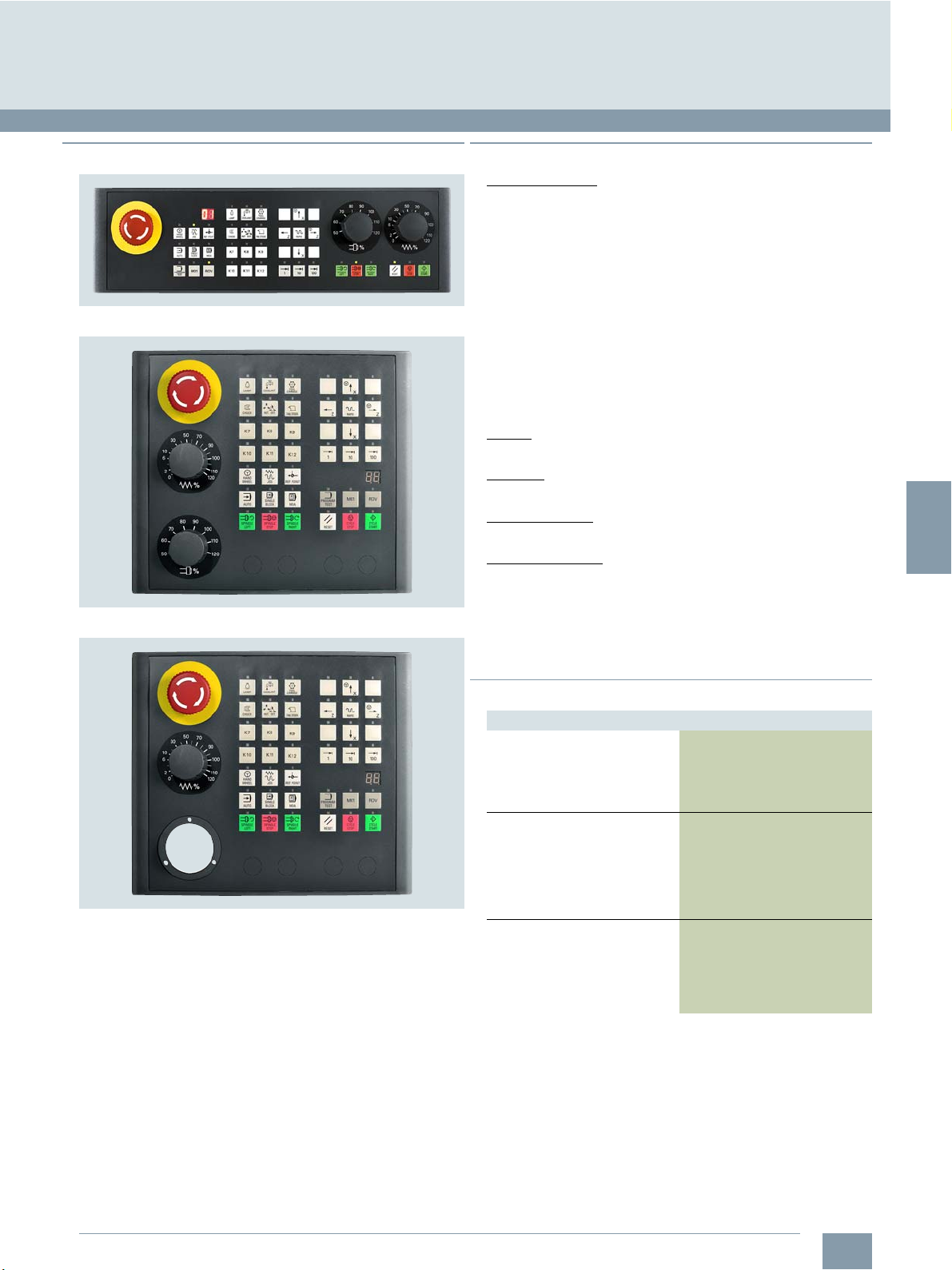

3

■

Overview

SINUMERIK 808D MCP horizontal

SINUMERIK 808D MCP vertical

© Siemens Industry, Inc. 2018

■

Design

Operator controls:

• Mode selectors and function keys

- 39 keys (horizontal version: of which 30 keys with LEDs,

vertical version: 39 keys with LEDs)

- Direction keys for machines with rapid traverse override

(The machine control panel is equipped with slide-in labels

for turning at the factory – slide-in labels for milling are

enclosed.)

- Preassigned keys for common functions, such as handwheel

selection, tool change, coolant control or program testing

• Horizontal version and vertical version without handwheel slot:

Spindle control with spindle override (rotary switch with

15 positions)

• Feedrate control with feedrate/rapid traverse override (rotary

switch with 18 positions)

• 7-segment display for tool number

Layout:

• English or Chinese Simplified

Key type:

• Mechanical keys with protection film

Interface to CNC:

•USB

Expansion options:

• 1 slot for emergency stop button (d = 22 mm)

• Horizontal version: 3 slots for control devices (d = 16 mm)

• Vertical version: 4 slots for control devices (d = 16 mm)

• 1 slot for handwheel (d = 44 mm), only for the vertical version

with handwheel slot. The handwheel with a diameter of 44 mm

must be ordered separately

SINUMERIK 808D ADVANCED system

Operator components

SINUMERIK 808D MCP horizontal/vertical

SINUMERIK 808D MCP vertical, with handwheel slot

The SINUMERIK 808D MCP machine control panels with

mechanical keys are designed to permit user-friendly, wellstructured operation of the machine functions. They are suitable

for machine-level operation of turning and milling machines.

Customized keys can be individually labeled using slide-in

strips.

The machine control panel is available as vertical and horizontal

version for different machine designs. Depending on the design

of the machine, the SINUMERIK 808D MCP can also be ordered

with a handwheel slot.

The machine control panel can be mounted from the rear using

special clamps without drilling holes into the cabinet.

■

Selection and ordering data

Description Article No.

SINUMERIK 808D MCP

machine control panel, horizontal

With USB cable

• English layout 6FC5303-0AF35-0AA0

• Simplified Chinese layout 6FC5303-0AF35-0CA0

SINUMERIK 808D MCP

machine control panel, vertical

with rotary switch for spindle

override

With USB cable

• English layout 6FC5303-0AF35-2AA0

• Simplified Chinese layout 6FC5303-0AF35-2CA0

SINUMERIK 808D MCP

machine control panel, vertical

with handwheel slot

With USB cable

• English layout 6FC5303-0AF35-3AA0

• Simplified Chinese layout 6FC5303-0AF35-3CA0

The following are included in the scope of delivery of the

SINUMERIK 808D MCP horizontal/vertical machine control

panel:

• USB cable 0.5 m

• Mounting clamps

• Slide-in labels for turning application (already inserted)

• Slide-in labels for milling applications

• Blank labeling strips for individual inscription

Siemens NC 81.1 · 2019

3/5

Page 30

3

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Operator components

SINUMERIK 808D MCP horizontal/vertical

■

Integration

The SINUMERIK 808D MCP machine control panel can be used for:

• SINUMERIK 808D ADVANCED T

• SINUMERIK 808D ADVANCED M

■

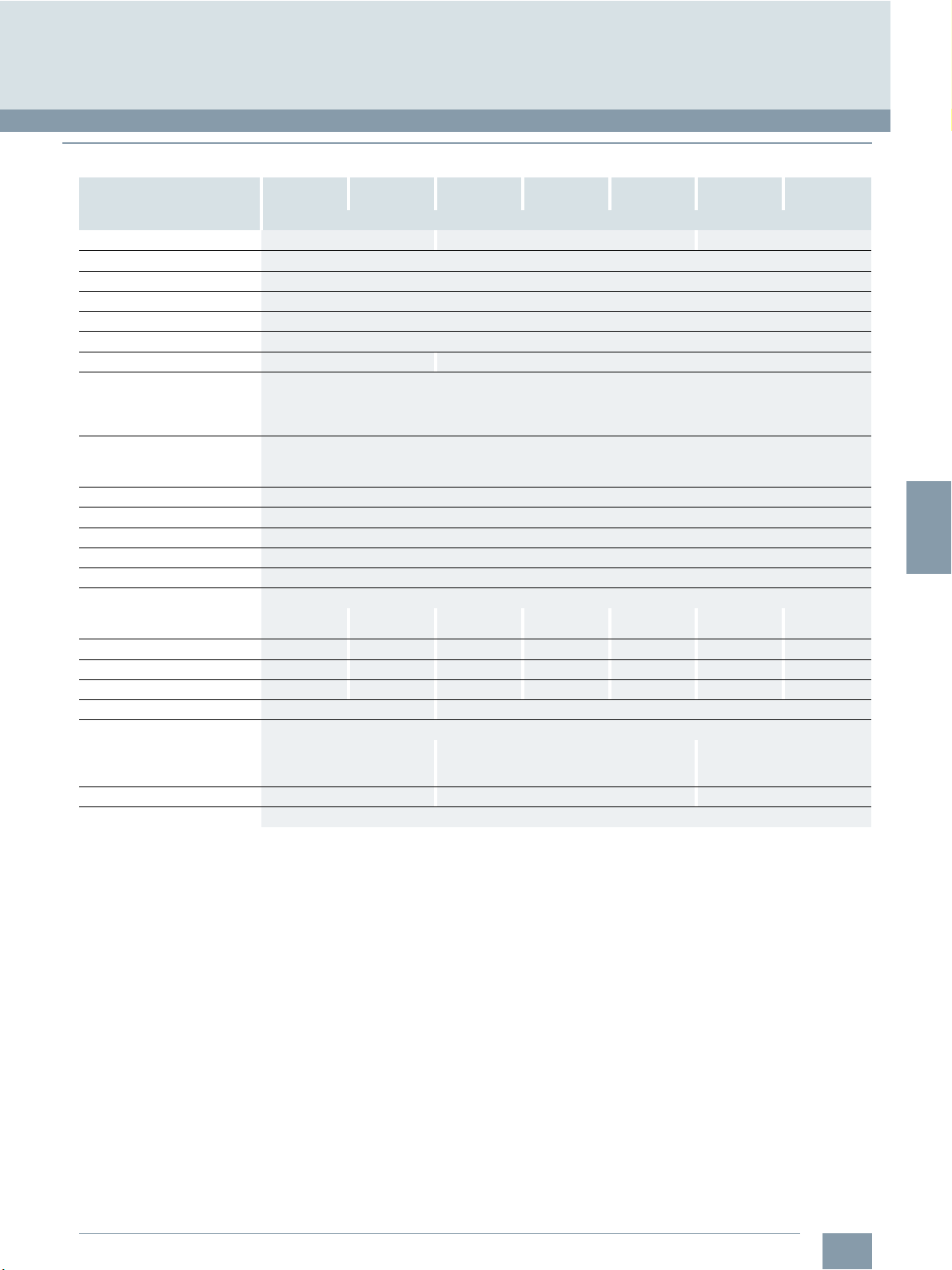

Technical specifications

Article No. 6FC5303-0AF35-0.A0 6FC5303-0AF35-..A0

Product name SINUMERIK 808D MCP

Supply voltage at DC 5 V via USB interface of PPU

Active power consumption maximum 5W

Degree of protection

•Front IP65

•Rear IP00

Environmental category acc. to IEC 60721-3-3 Condensation and icing excluded. Low air temperature 0 °C.

Relative humidity at 25 °C, during

•storage 5…95%

•transport 5…95%

•operation 5…90%

Ambient temperature, during

•storage -20 ... +60 °C

•transport -20 ... +60 °C

•operation

-front 0...45°C

-rear 0...50°C

Transmission link to PCU maximum 0.5 m

Width 420 mm 265 mm

Height 120 mm 230 mm

Depth 58 mm 58 mm

Mounting surface

• Section width 406 mm 245 mm

• Section height 106 mm 211 mm

• Tolerance + 1 mm + 1 mm

Net weight 0.86 kg

• With handwheel slot – 0.79 kg

• With rotary switch

Certificate of suitability

machine control panel

horizontal version

– 0.93 kg

CE, EAC

SINUMERIK 808D MCP

machine control panel

vertical version

3/6

Siemens NC 81.1 · 2019

Page 31

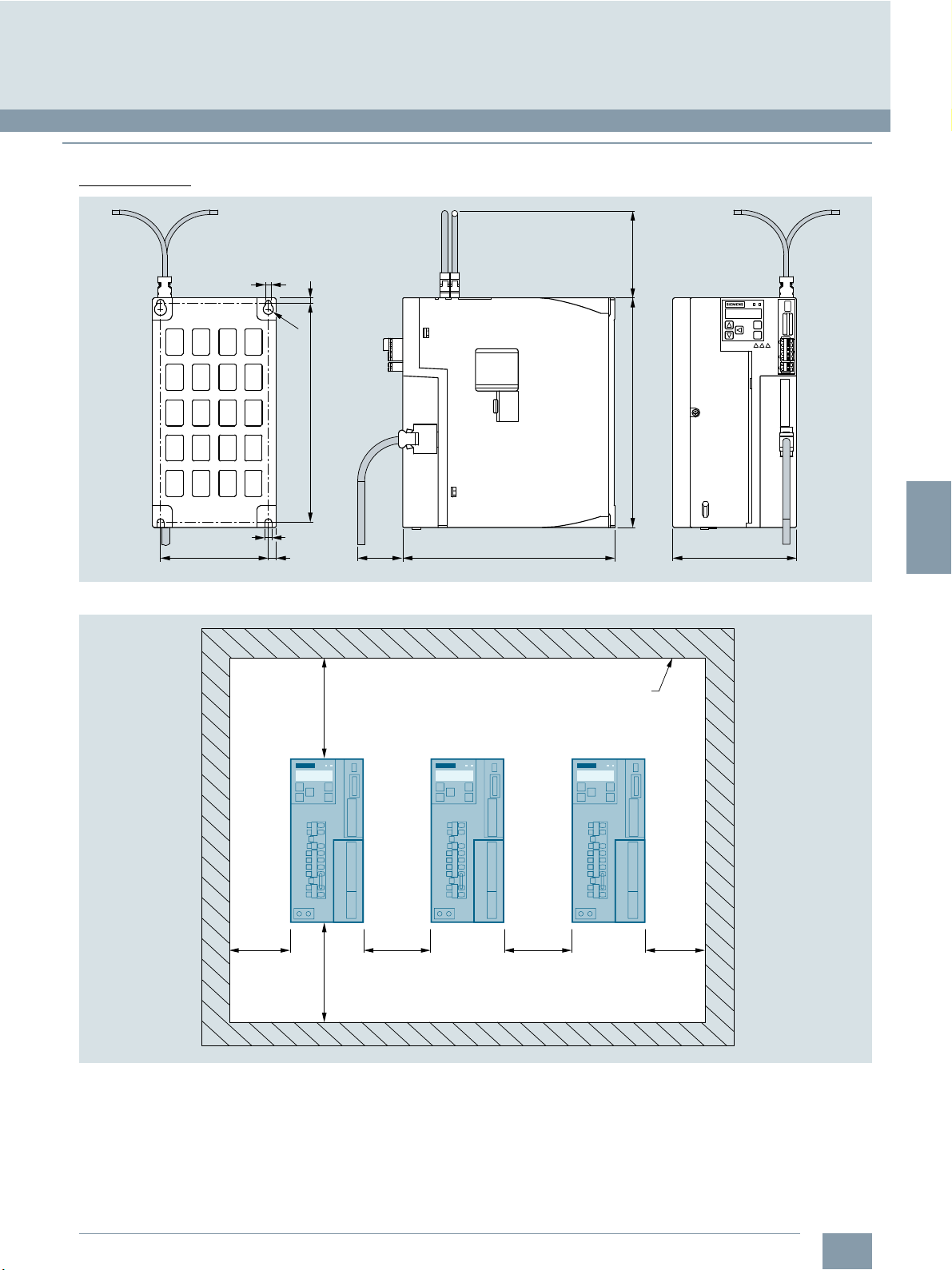

3

■

Dimensional drawings

Dimensions in mm

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Operator components

SINUMERIK 808D MCP horizontal/vertical

X10

NC

SINUMERIK 808D MCP horizontal

405

420

265

120

58

38

30

X10

NC

BB

230

210

105

G_NC01_XX_00552

G_NC01_XX_00551

244

SINUMERIK 808D MCP vertical with handwheel slot/without handwheel slot

30

38

58

Siemens NC 81.1 · 2019

3/7

Page 32

3

SINUMERIK 808D ADVANCED system

Feed axis solutions

SINAMICS V70 servo drive

■

Overview

© Siemens Industry, Inc. 2018

■

Selection and ordering data

SINAMICS V70, frame sizes FSC/FSB/FSA

The SINAMICS V70 servo drive is specially designed to control

the feed axes in standard machine tool applications. The system

is designed essentially for applications where cost effectiveness

is the primary consideration. The key performance data of the

drive are aligned to perfectly fit to the solution provided by the

SINUMERIK 808D ADVANCED.

■

Benefits

7 Compact module with integrated infeed, inverter and closed-

loop position control for one feed axis

7 Coated electronic modules

7 Commissioning on CNC directly

7 Faster commissioning thanks to pre-configured motor data

stored in the drive.

7 CE certified

Rated output

current

A Article No.

1.2 FSA

3.0 FSA 6SL3210-5DE13-5UA0

4.6 FSB 6SL3210-5DE16-0UA0

5.3 FSB 6SL3210-5DE17-8UA0

7.8 FSB 6SL3210-5DE21-0UA0

11 FSC 6SL3210-5DE21-4UA0

13.2 FSC 6SL3210-5DE21-8UA0

Description Article No.

Spare parts

SINAMICS V70/V90

fan kits

• Frame size FSB 6SL3200-0WF00-0AA0

• Frame size FSC 6SL3200-0WF01-0AA0

SINAMICS V70

drive bus terminator

Frame size SINAMICS V70

servo drive

6SL3210-5DE12-4UA0

6FC5548-0BA21-0AA0

■

Function

• 7 versions cover power range from 0.4 kW to 7 kW

• Supply voltage 380 V to 480 V 3 AC

• 300 % overload capability

• Drive bus communication to the

SINUMERIK 808D ADVANCED

• Integrated motor brake switch

• Safe Torque Off (STO)

■

Integration

The following components can be connected to the

SINAMICS V70:

• SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

• SIMOTICS S-1FL6 feed motor

• Encoder in SIMOTICS S-1FL6 feed motor

• Brake in SIMOTICS S-1FL6 feed motor

3/8

Siemens NC 81.1 · 2019

Page 33

3

■

1)

Minimum distance between drive modules: 10 mm.

Technical specifications

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Feed axis solutions

SINAMICS V70 servo drive

Article No.

Product name SINAMICS V70 servo drive

Frame size

Input voltage 380... 480V3AC -15%/+10%

Input frequency 50...60Hz ±10%

Infeed Non-stabilized

Electronics power supply 24 V DC ± 10 %

24 V DC supply 2.0 A (4.0 A) combined with motors without brake (with brake)

Cooling Natural cooling Forced ventilation

Ambient temperature

• Storage/transport -40 ... +70 °C

• Operation 0 ... 45 °C without derating,

Air humidity

• Storage/transport 90 % (non-condensing)

• Operation < 90 % (non-condensing)

Ambient conditions Indoor (without sunshine), without corrosive gas, combustible gas, oil gas, nor dust

Installation altitude Up to 1000 m without derating

Connectable motors SIMOTICS S-1FL6

Degree of protection IP20

Encoder evaluation Absolute encoder 20 bit/incremental encoder with 2500 S/R (13 bit resolution through electronic multiplication)

Output current

• Rated current I

• Peak current I

Rated output power P

Power loss 36 W 47 W 54 W 70 W 47 W 54 W 70 W

Cooling air required 0.005 m3/s 0.005 m3/s 0.005 m3/s 0.005 m3/s 0.005 m3/s 0.005 m3/s 0.005 m3/s

Conductor cross-section, max. 1.5 mm

Dimensions

• Width 80 mm 100 mm 140 mm

•Height 180 mm 180 mm 260 mm

•Depth 200 mm 200 mm 240 mm

Weight, approx. 1.85 kg 2.45 kg 5.65 kg

Certificate of suitability CE, EAC

S/R = Signals/Revolution

rated

max

rated

1)

6SL32105DE12-4UA0

FSA FSB FSC

> 45 ... 55 °C with derating (derating by 0 % at 45 °C up to 20 % at 55 °C)

1.2 A 3.0 A 4.6 A 5.3 A 7.8 A 11.0 A 13.2 A

3.6 A 9.0 A 13.8 A 15.9 A 23.4 A 33.0 A 39.6 A

0.4 kW 1kW 1.5 kW 1.75 kW 2.5 kW 3.5 kW 7kW

2

6SL32105DE13-5UA0

6SL32105DE16-0UA0

2

2.5 mm

6SL32105DE17-8UA0

6SL32105DE21-0UA0

6SL32105DE21-4UA0

6SL32105DE21-8UA0

Siemens NC 81.1 · 2019

3/9

Page 34

3

SINUMERIK 808D ADVANCED system

G_NC01_XX_00555

100

180

6

6

Ø11

168

6

9

63

50

200

80

Feed axis solutions

SINAMICS V70 servo drive

■

Dimensional drawings

Dimensions in mm

© Siemens Industry, Inc. 2018

SINAMICS V70, frame size FSA

SINAMICS V70, frame size FSB

82

100

Ø11

6

168

9

50

220

180

G_NC01_XX_00556

100

6

6

3/10

Siemens NC 81.1 · 2019

Page 35

3

■

Dimensional drawings (continued)

Dimensions in mm

6

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Feed axis solutions

SINAMICS V70 servo drive

100

6

Ø11

122

SINAMICS V70, frame size FSC

248

6

9

> 100 mm

50

SINAMICS V70 Servo drive

240 140

260

G_NC01_XX_00557

Cabinet wall

Mounting clearance

> 10 mm > 10 mm> 10 mm> 10 mm

> 100 mm

G_NC01_EN_00558

Siemens NC 81.1 · 2019

3/11

Page 36

3

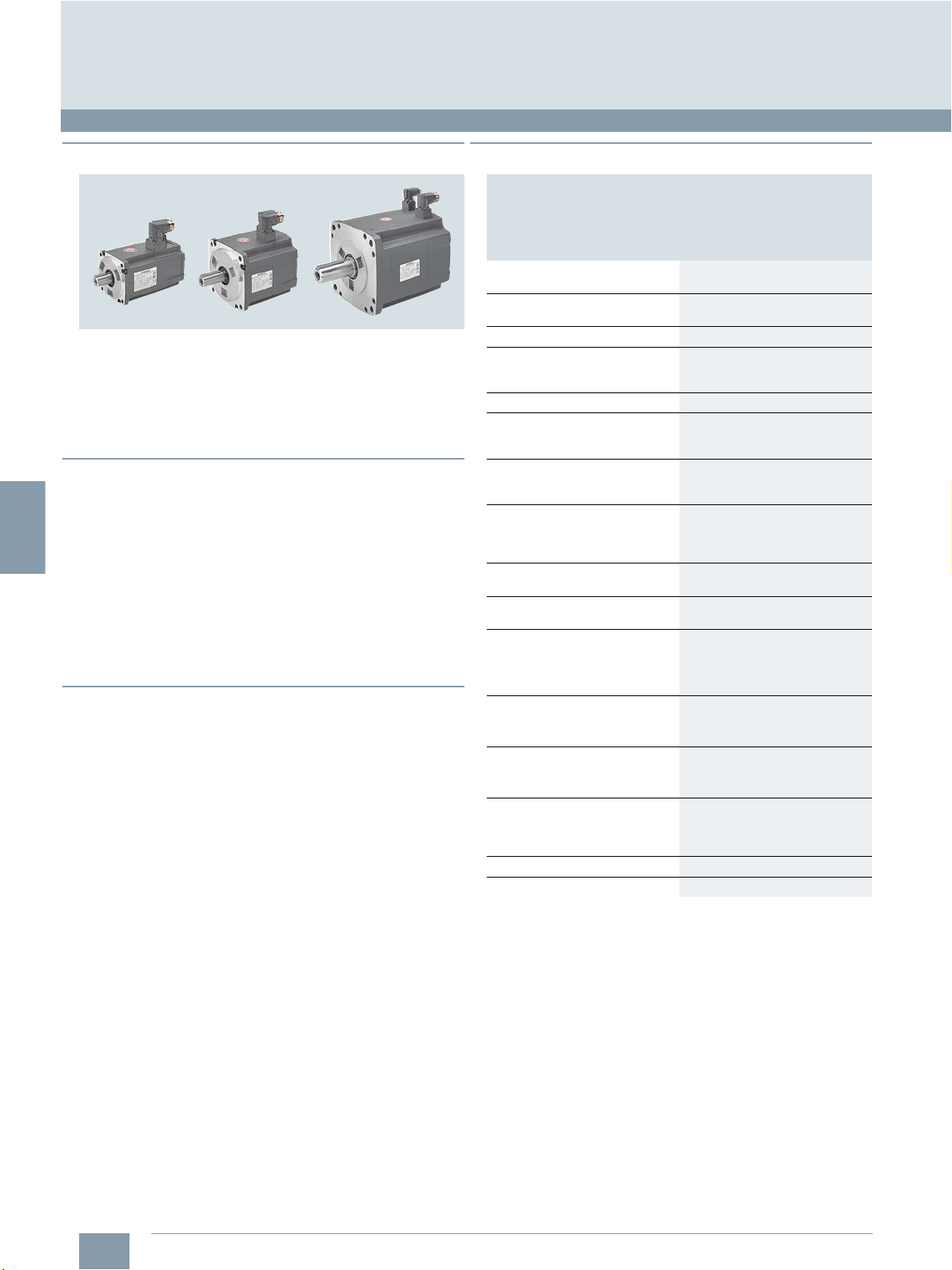

1)

It is not permissible to use the holding brake for an emergency stop.

2)

Shaft extension run-out, concentricity of centering ring and shaft, and

perpendicularity of flange to shaft.

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Feed axis solutions

SIMOTICS S-1FL6 feed motor

■

Overview

SIMOTICS S-1FL6 motors

SIMOTICS S-1FL6 motors are permanent-magnet synchronous

motors and designed for operation without external cooling.

The heat is dissipated through the motor surface. Quick and

easy mounting of the motors is possible. Together with the

SINAMICS V70, the SIMOTICS S-1FL6 feed motors provide a

highly dynamic solution for the machine tool application.

■

Benefits

7 High-performance magnet material

7 Rugged design with IP65 degree of protection for complete

motor including connectors

7 Smooth running quality thanks to low torque ripple

7 High rated speed for some variants

7 High acceleration due to the 300 % overload capacity

7 Rotatable connectors

7 Maximum flexibility due to variants with

incremental encoder/20 bit absolute encoder,

with/without brake and plain shaft/feather key,

half-key balancing

■

Function

• 3 motor shaft heights: SH 45, SH 65 and SH 90

• Rated speed of 2000 rpm/3000 rpm

• Max. speed up to 4000 rpm

• 300 % overload capacity

• Integrated 20 bit absolute encoder or incremental encoder

with 2500 S/R (13 bit resolution through electronic multiplication of the V70 drive)

• Degree of protection IP65, natural cooling

• Optional holding brake

• With plain shaft or feather key, half-key balancing

1)

■

Technical specifications

Article No. 1FL6...

Product brand name SIMOTICS

Product type designation S-1FL6

Product designation Feed motor

Type of motor Synchronous motor

Type of motor Permanent-magnet

Magnet material High-performance magnet

Cooling Natural cooling

Insulation of the stator winding in

accordance with EN 600034-1

(IEC 60034-1)

Thermal class B (130 °C)

Type of construction in

accordance with EN 60034-7

(IEC 60034-7)

Degree of protection in

accordance with EN 60034-5

(IEC 60034-5)

Shaft extension in accordance with

IEC 60072-1

Shaft and flange accuracy in

accordance with IEC 60072-12)

Vibration severity in accordance

with IEC 60034-14

Sound pressure level, max.

• 1FL604 65 dB

• 1FL606 70 dB

• 1FL609 70 dB

Ambient temperature

• Storage/transport -20 ... +65 °C

• Operation 0 ... 40 °C without derating

Humidity

• Storage/transport 90 % at 30 °C

• Operation 90 % at 30 °C

Installation altitude

Paint finish

Certificate of suitability CE, EAC

synchronous motor

material

Temperature class 130 (B)

IM B5 (IM V1, IM V3)

IP65, with oil seal

Plain shaft/feather key (C type,

motors with a keyway are

balanced with a half-fitted key

by the manufacturer)

Tolerance N

Grade A

Up to 1000 m above sea level

without power derating

>1000m...5000m

with power derating

Black

3/12

Siemens NC 81.1 · 2019

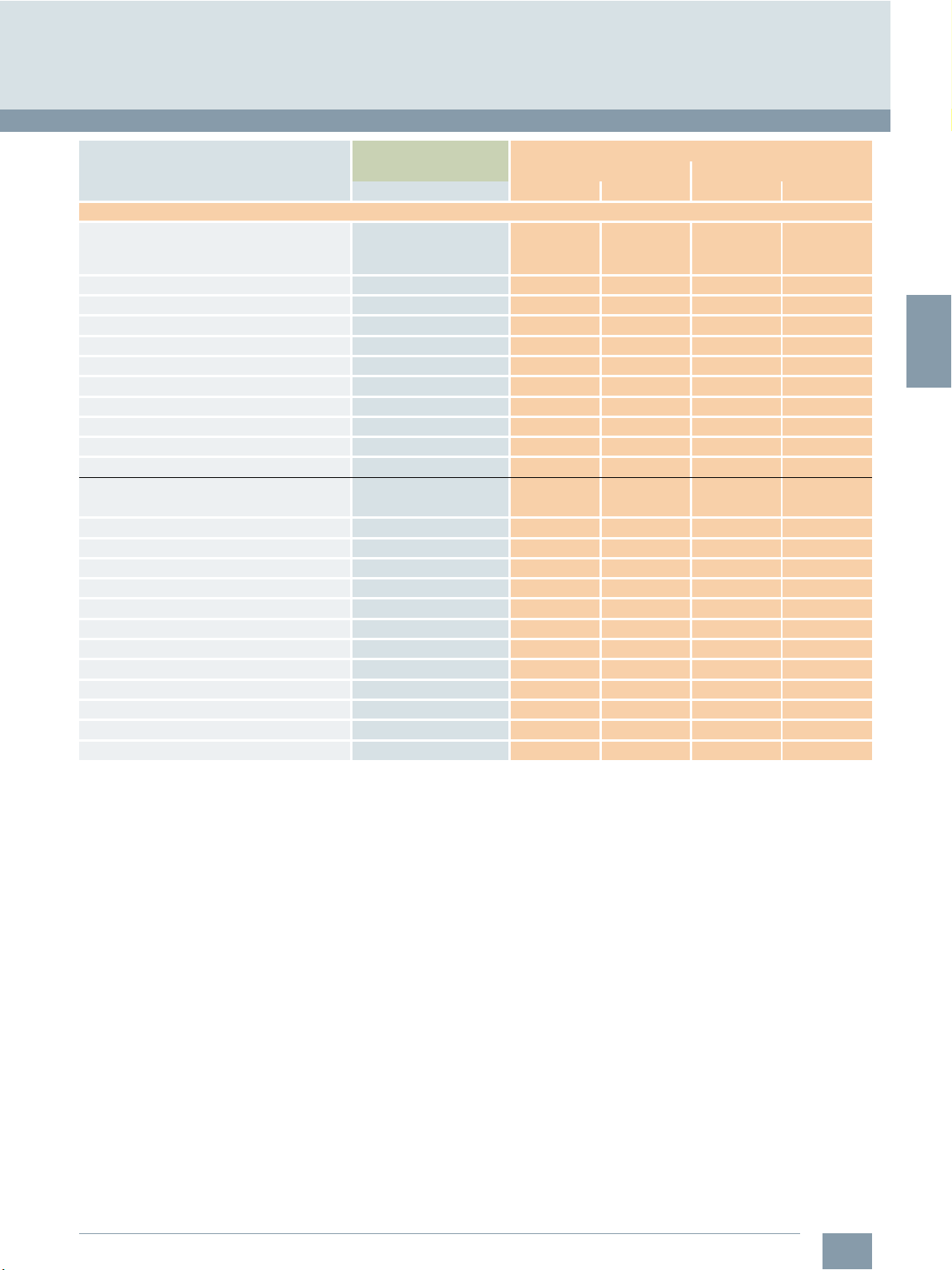

Page 37

3

1)

Rated power allows for a production tolerance of 10 %.

2)

Motor weight with incremental encoder.

3)

For SIMOTICS S-1FL6096-... motors with brake, when the ambient

temperature exceeds 30 ºC, the power should be derated by 10 %.

Power derating is not required for other motors.

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Feed axis solutions

SIMOTICS S-1FL6 feed motor

■

Selection and ordering data

Rated

Max.

speed

speed

n

ratednmax.

rpm rpm kW Nm Article No. 10

3000 4000 45 0.4 1.9 1FL6042-1AF61-2 ■ ■ 1 2.7 3.2 3.4 4.8 5DE12-4UA0 FSA

4000 0.75 3.5 1FL6044-1AF61-2 ■ ■ 1 5.2 5.7 5.2 6.6 5DE13-5UA0 FSA

2000 3000 65 0.75 4 1FL6061-1AC61-2 ■ ■ 1 8.0 9.1 5.7 8.8 5DE13-5UA0 FSA

3000 1 6 1FL6062-1AC61-2 ■ ■ 1 11.7 13.5 7 10.1 5DE13-5UA0 FSA

3000 1.5 8 1FL6064-1AC61-2 ■ ■ 1 15.3 16.4 8.4 11.5 5DE16-0UA0 FSB

3000 1.75 11 1FL6066-1AC61-2 ■ ■ 1 22.6 23.7 11.1 14.2 5DE17-8UA0 FSB

3000 2 15 1FL6067-1AC61-2 ■ ■ 1 29.9 31.0 13.7 16.8 5DE21-0UA0 FSB

2000 3000 90 2.5 15 1FL6090-1AC61-2 ■ ■ 1 47.4 56.3 15.4 21.5 5DE21-0UA0 FSB

3000 3.5 22 1FL6092-1AC61-2 ■ ■ 1 69.1 77.9 19.8 25.9 5DE21-4UA0 FSC

2500 5 30 1FL6094-1AC61-2 ■ ■ 1 90.8 99.7 24.4 30.5 5DE21-8UA0 FSC

2000 7

Encoder type

Incremental encoder 2500 S/R

Absolute encoder 20 bit

Shaft extension Holding brake

Feather key, half-key balancing

Feather key, half-key balancing

Plain shaft

Plain shaft

Shaft

height

SH P

Rated

1)

power

rated

at

T=100K

3)

Static

torque

M

0

at

T = 100 K

40 1FL6096-1AC61-2 ■ ■1 134.3 143.2 33.3 39.3 5DE21-8UA0 FSC

SIMOTICS S-1FL6

Feed motors

Synchronous motors

Natural cooling

Without

With

Without

With

Moment of

inertia of rotor

without

brake

J J m m

kgm

A

L

A

B

G

H

with

brake

-4

-4

10

2

kgm

2

2)

Weight

without

brake

kg kg Article No.

with

brake

SINAMICS V70

6SL3210-...

Frame

size

Siemens NC 81.1 · 2019

3/13

Page 38

3

SINUMERIK 808D ADVANCED system

Feed axis solutions

SIMOTICS S-1FL6 feed motor

■

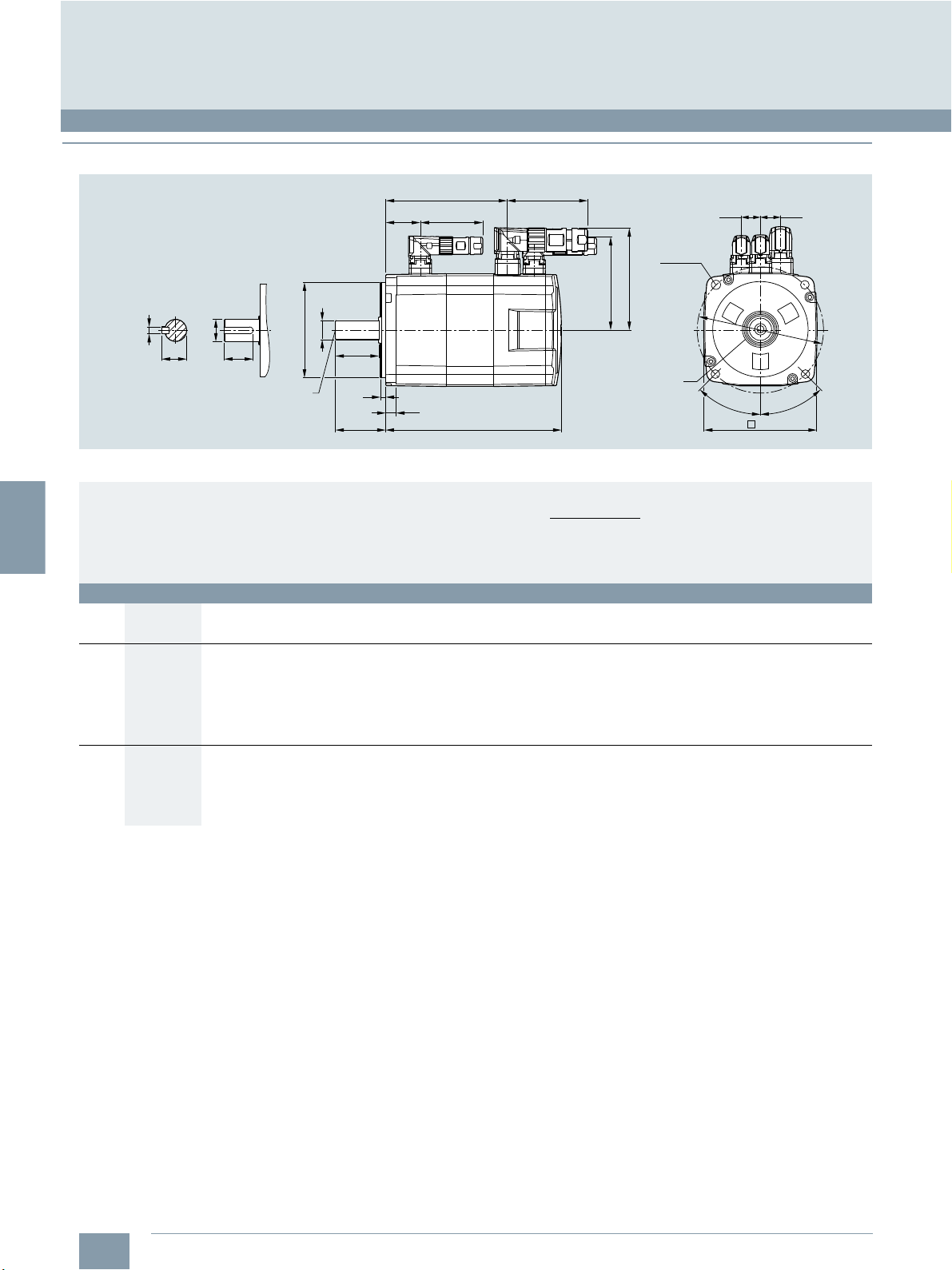

Dimensional drawings

© Siemens Industry, Inc. 2018

KB1

KB2

Version with feather key

F

DB

ØD

ØLB

E

T

LR

DE shaft extension Encoder system:

ØD

GA

SIMOTICS S-1FL6 feed motor with incremental encoder

For motor Dimensions in mm

Shaft

height

1FL6 natural cooling without/with brake

45 1FL6042 90 100 7 80 35 4 10 19 M6×16 30 25 21.5 6 154.5 93.5 – 201 140 31.5 96.2 84.6 13 14

65 1FL6061 130 145 9 110 58 6 12 22 M8×16 50 44 25 8 148 85.5 – 202.5 140 39.5 118 108 23 22

90 1FL6090 180 200 13.5 114.3 80 3 18 35 M12×25 75 60 38 10 189.5 140 – 255 206 44.5 143 133 34 34

Typ e without brake with brake

1FL6044 201.5 140.5 – 248 187

1FL6062 164.5 102 – 219 156.5

1FL6064 181 118.5 – 235.5 173

1FL6066 214 151.5 – 268.5 206

1FL6067 247 184.5 – 301.5 239

1FL6092 211.5 162 – 281 232

1FL6094 237.5 188 – 307 258

1FL6096 289.5 240 – 359 310

QK

LC LA LZ LB LR T LG D DB E QK GA F LL KB1 KB2 LL KB1 KB2 KL1 KL2 KL3 KL4

71

LG

LL

87.5

4 x ØLZ

KL1

KL2

Oil seal

Incremental encoder 2500 S/R

KL4 KL3

ØLA

45°

45°

LC

G_D011_EN_00526

3/14

Siemens NC 81.1 · 2019

Page 39

3

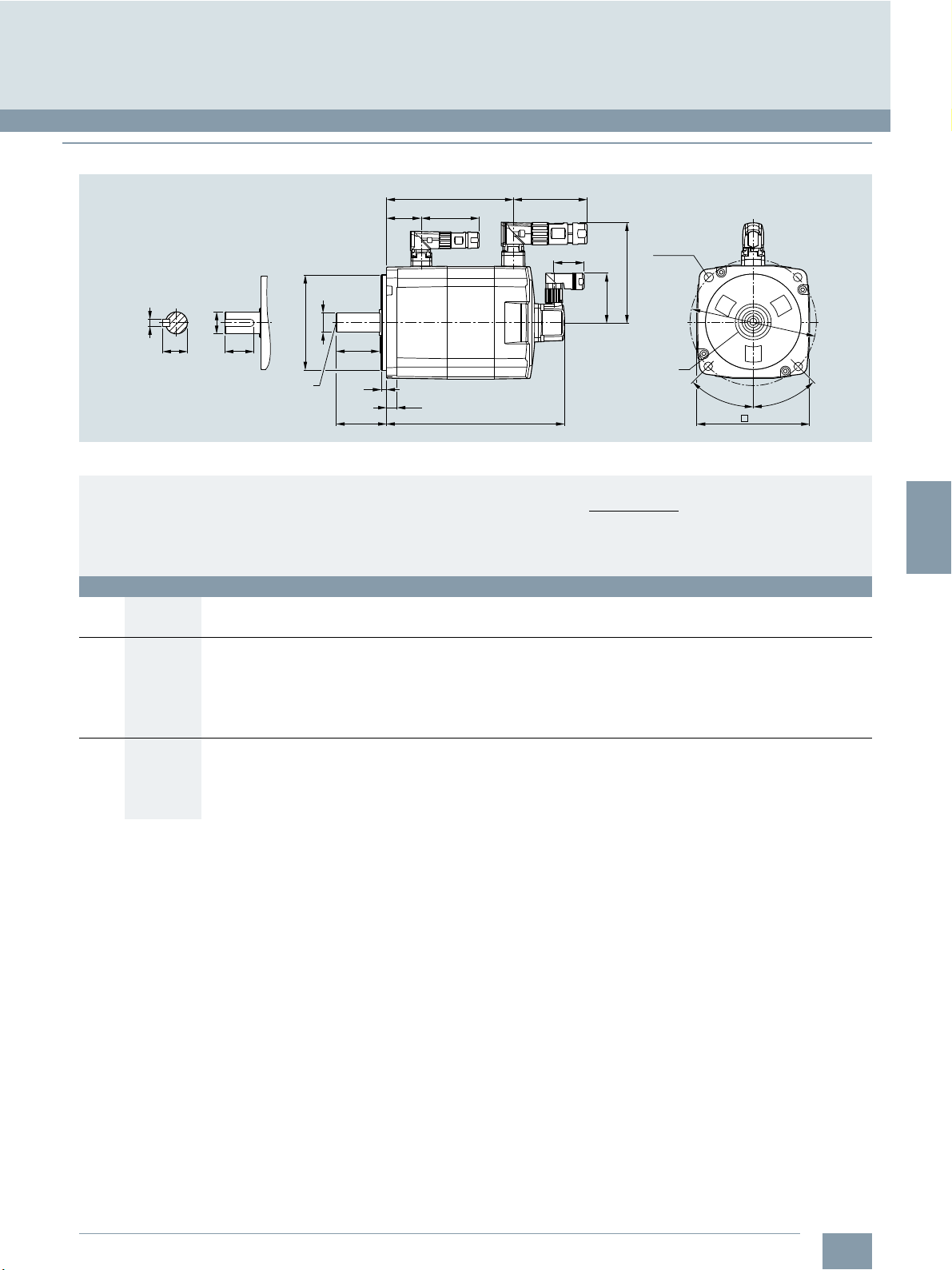

■

Dimensional drawings (continued)

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Feed axis solutions

SIMOTICS S-1FL6 feed motor

KB1

KB2

Version with feather key

F

DB

ØD

ØLB

E

T

LR

ØD

GA

SIMOTICS S-1FL6 feed motor with absolute encoder

For motor Dimensions in mm

Shaft

height

1FL6 natural cooling without/with brake

45 1FL6042 90 100 7 80 35 4 10 19 M6×16 30 25 21.5 6 157 100 – 203.5 147 31.5 96.2 60

65 1FL6061 130 145 9 110 58 6 12 22 M8×16 50 44 25 8 151 92 – 205.5 147 39.5 117.5 60

90 1FL6090 180 200 13.5 114.3 80 3 18 35 M12×25 75 60 38 10 197 135 – 263 201 44.5 143 60

Typ e without brake with brake

1FL6044 204 147 – 250.5 194

1FL6062 167.5 108.5 – 222 163.5

1FL6064 184 125 – 238.5 180

1FL6066 217 158 – 271.5 213

1FL6067 250 191 – 304.5 246

1FL6092 223 161 – 289 227

1FL6094 249 187 – 315 253

1FL6096 301 239 – 367 305

QK

LC LA LZ LB LR T LG D DB E QK GA F LL KB1 KB2 LL KB1 KB2 KL1 KL2

71

LG

LL

DE shaft extension Encoder system:

87.5

38

KL1

KL2

Oil seal

Absolute encoder 20 bit

4 x ØLZ

45°

LC

ØLA

45°

G_D011_EN_00527

Siemens NC 81.1 · 2019

3/15

Page 40

3

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Spindle solutions

SINAMICS V70 spindle drive

■

Overview

SINAMICS V70 spindle drive, frame sizes FSD/FSC/FSB

The SINAMICS V70 spindle drive controls the spindle in standard machine tool applications. The system is designed essentially for applications where cost effectiveness is the primary

consideration. The key performance data of the drive are

aligned to perfectly fit to the solution provided by the

SINUMERIK 808D ADVANCED.

■

Benefits

7 Compact module with integrated infeed, inverter and closed-

loop for spindle

7 Coated electronic modules

7 Commissioning on CNC directly

7 Faster commissioning thanks to pre-configured motor data

stored in the drive

7 CE certified

■

Function

• Power range from 3.7 kW to 15 kW

• Supply voltage 380 V to 480 V 3 AC

• Drive bus communication to the

SINUMERIK 808D ADVANCED

• Safe Torque Off (STO)

■

Integration

The following components can be connected to the

SINAMICS V70 spindle drive:

• SINUMERIK 808D ADVANCED PPU 15x.3/PPU 16x.3

• SIMOTICS M-1PH1 main spindle motor

• Encoder in SIMOTICS M-1PH1 main spindle motor

■

Technical specifications

Article No.

Product brand name

Product type designation

Product designation

Frame size

Rated output current

Max. output current

Max. supported motor power

Output frequency

Power supply

• Voltage/frequency 380 V... 480 V 3 AC, 50/60 Hz

• Permissible voltage fluctuation -15 % ... +10 %

• Permissible frequency fluctuation

• Rated input current

• Power supply capacity 8.7 kVA 10.7 kVA 16.1 kVA 24.5 kVA 30.9 kVA

• Inrush current 4A 2.5 A 2.5 A 2.5 A 2.5 A

24 V DC power supply

• Voltage 24 V (-15 % ... +20 %)

• Maximum current 3A

Overload capability

Control system

Braking resistor

• Resistance 70 27 18

•Max. power 9.1 kW 23.7 kW 37.4 kW

• Rated power 229 W 1185 W 1870 W

• Max. energy 18.3 kJ 189.6 kJ 299.2 kJ

Protective functions • Earthing fault protection

6SL32105DE21-1UA0

SINAMICS

V70

Spindle drive

FSB FSC FSD

10.5 A 12.9 A 19.6 A 29.8 A 37.6 A

21 A 24.6 A 39.2 A 59.6 A 75.2 A

3.7 kW 3.7 kW 7.5 kW 11 kW 15 kW

0 Hz to 400 Hz

-10 % ... +10 %

13.2 A 16.2 A 24.5 A 37.3 A 47 A

The overload capability is 150 % by default. It can be set up to 200 % via p0640, but the corresponding overload

duration might be reduced under the circumstances.

Servo control

Braking resistor is not included in the standard system package.

Choose an external braking resistor according to the technical specifications as listed below from Siemens product

portfolio or from 3rd party.

• Output short-cut protection

• Overvoltage/undervoltage protection

•I2t detection

• IGBT overtemperature protection

6SL32105DE21-3UA0

6SL32105DE22-0UA0

6SL32105DE23-0UA0

6SL32105DE24-0UA0

3/16

Siemens NC 81.1 · 2019

Page 41

3

© Siemens Industry, Inc. 2018

■

Technical specifications (continued)

Article No.

Product brand name

Product type designation

Product designation

Cooling method

Degree of protection

Degree of pollution

Operating environment

Relative humidity, during

•storage 90 % (non-condensing)

•operation < 90 % (non-condensing)

Ambient temperature, during

•storage -40°C...+70°C

•operation 0 °C ... 45 °C without power derating

Installation altitude

Vibration

• transport and storage 5 Hz ... 9 Hz: 3.5 mm deflection

•operation Operational area II/3M2

Shock

• transport and storage Covered by vibration test

•operation Operational area: II

Width

Height

Depth

Net weight

Certificate of suitability

6SL32105DE21-1UA0

SINAMICS

V70

Spindle drive

Fan-cooled

IP20

Class 2

Indoor (without direct sunlight), free from corrosive gas, combustible gas, oil gas, or dust

45 °C ... 55 °C with power derating

< 1000 m above sea level (without derating)

9Hz...200Hz: 1g vibration

Ambient Classification: 1M2

10 Hz ... 58 Hz: 0.075 mm deflection

58 Hz ... 200 Hz: 1 g vibration

Ambient classification: 3M2

Peak acceleration: 5 g + 15 g

Duration: 30 ms + 11 ms

Quantity of shocks: 3

Summed shocks: 18

Cycle time: 1 s

100 mm 140 mm 140 mm 190 mm 190 mm

180 mm 260 mm 260 mm 350 mm 350 mm

220 mm 240 mm 240 mm 185 mm 185 mm

2.35 kg 5.05 kg 5.05 kg 8.05 kg 8.3 kg

CE, EAC, RCM

6SL32105DE21-3UA0

SINUMERIK 808D ADVANCED system

Spindle solutions

SINAMICS V70 spindle drive

6SL32105DE22-0UA0

6SL32105DE23-0UA0

6SL32105DE24-0UA0

■

Selection and ordering data

Motor output

power

kW

Line voltage 380 V ... 480 V 3 AC

3.7 FSB 6SL3210-5DE21-1UA0

3.7 FSC 6SL3210-5DE21-3UA0

7.5 FSC 6SL3210-5DE22-0UA0

11 FSD 6SL3210-5DE23-0UA0

15 FSD 6SL3210-5DE24-0UA0

Frame size

SINAMICS V70

spindle drive

Article No.

■

Accessories

A shield plate can be ordered as an option for FSD devices.

Description Article No.

Shield plate

for V70 spindle drive

Frame size FSD 6SL3266-1ED00-0VA0

Siemens NC 81.1 · 2019

3/17

Page 42

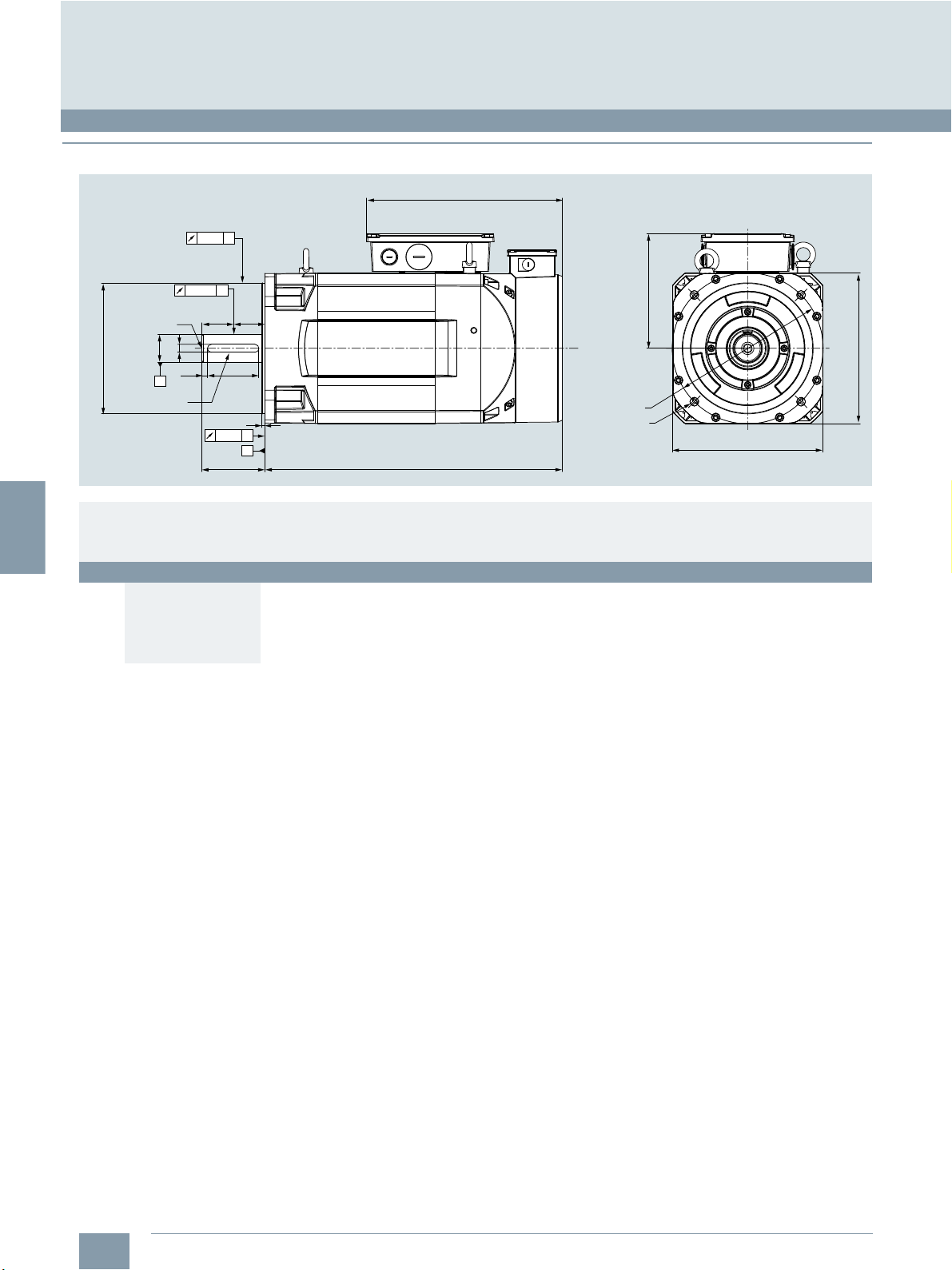

3

SINUMERIK 808D ADVANCED system

G_NC01_XX_00557

100

260

6

6

Ø11

248

6

9

122

240 140

50

Spindle solutions

SINAMICS V70 spindle drive

■

Dimensional drawings

Dimensions in mm

6

6

Ø11

© Siemens Industry, Inc. 2018

100

6

82

SINAMICS V70 spindle drive, frame size FSB

168

9

50

220

180

G_NC01_XX_00556

100

SINAMICS V70 spindle drive, frame size FSC

Siemens NC 81.1 · 2019

3/18

Page 43

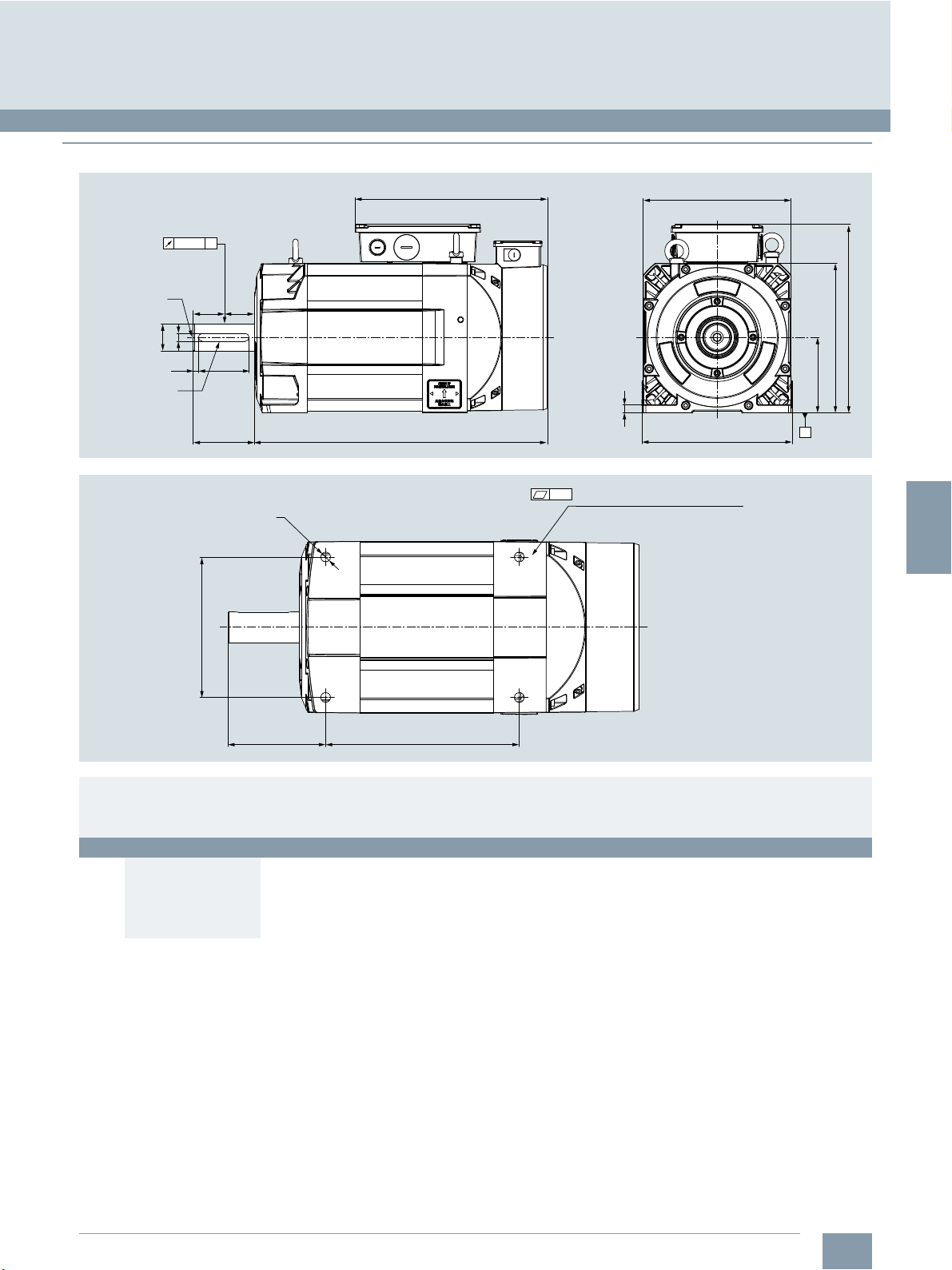

3

■

Dimensional drawings (continued)

Dimensions in mm

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Spindle solutions

SINAMICS V70 spindle drive

4-

140

Ø 6.5

25

6

337

SINAMICS V70 spindle drive, frame size FSD

19085 185

100

Ø 13

2-

G_NC01_EN_00724

140. 5

20

32612

304.5

20

Siemens NC 81.1 · 2019

3/19

Page 44

3

1)

This lifetime is only for reference. When a motor keeps running at rated

speed under rated load, replace its bearing after 20000 hours to

30000 hours of service time. Even if the time is not reached, the bearing

must be replaced when unusual noise, vibration, or faults are found.

© Siemens Industry, Inc. 2018

SINUMERIK 808D ADVANCED system

Spindle solutions

SIMOTICS M-1PH1 main spindle motor

■

Overview

SIMOTICS M-1PH1 main spindle motors SH 132/SH 100

1PH1 main spindle motors have been especially designed for

use as main drives in machine tools. These motors are available

as asynchronous version with forced fan cooling. Together with