Siemens SINUMERIK 802D, SINUMERIK 802D sl Training Manual

SINUMERIK 802D solution line

Machine Controller Milling Handbook

Training Manual Edition 2006.7

Training Material

SINUMERIK 802D sl

Operating, Programming

and Service

Milling

Valid for

Control Software

SINUMERIK 802D sl 1.2

Edition 07.2006

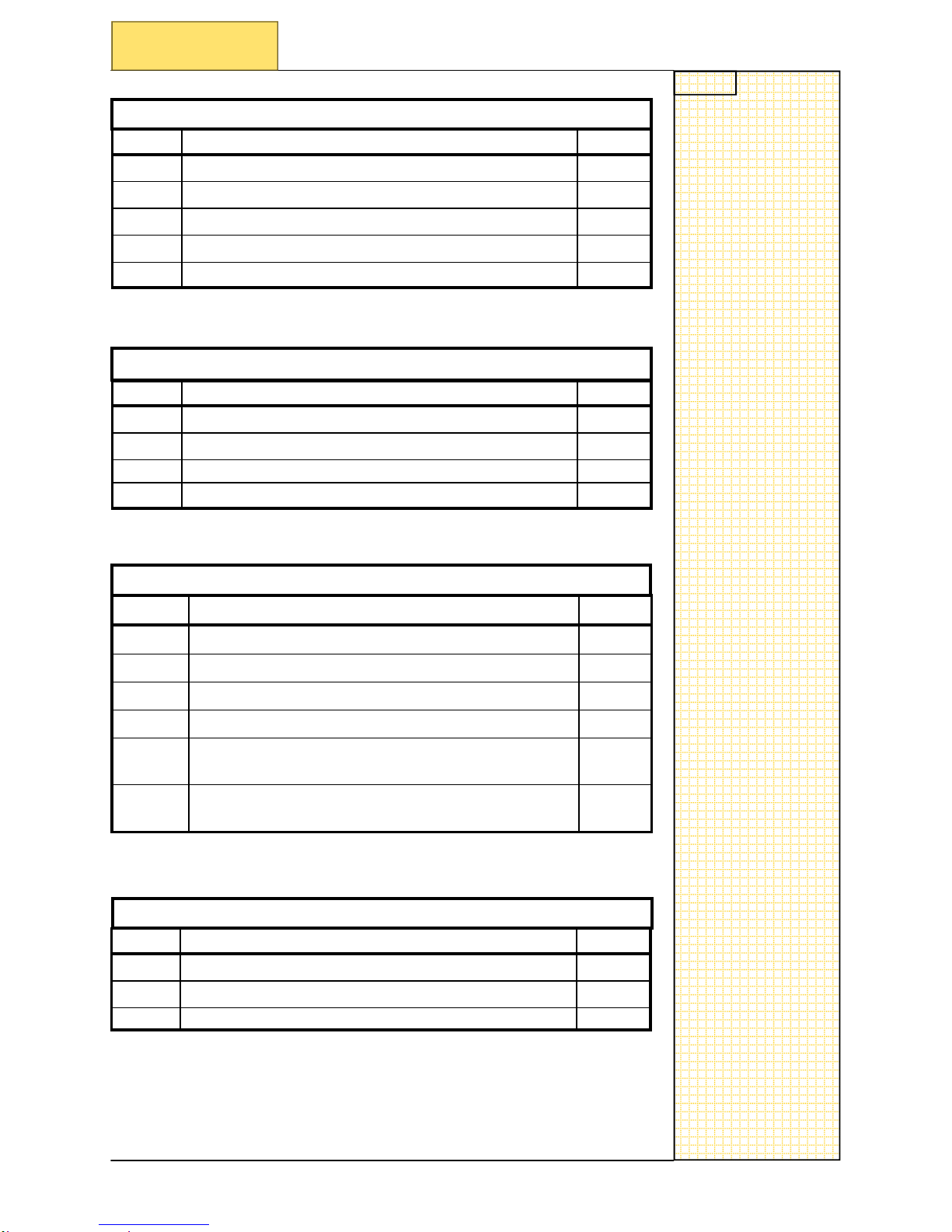

Module content for end users.

Operating and Programming

CNC Basic Principles Milling C102

Basic Program Structure C98

Modality (preparatory functions) C89

Commonly used G functions - M C92

Basic Miscellaneous Codes C97

Additional G functions - M C94

Create part program - Milling C77

Cycles - M C99

File Management - CF card C59

Power On and Referencing C69

Axis Control - Jog C82

Control Structure / Navigation C70

MDA - Milling C76

Tools Turning—Milling functions C83

Tools Milling - work planes C72

Work offsets - Milling C74

Automatic C81

RCS 802 Data transfer tool C1

ISO Dialect programming - M C95

Service

Pushbutton test (MCP) C8

LED Diagnosis Drive C9

LED Diagnosis HMI C10

MCPA signal test C11

Save Data Backup C17

Restore Data Backup C18

External data backup and restore C19

Diagnose PLC program C28

Diagnose PLC alarm C31

PLC periphery (HW diagnosis) C32

Alarm structure C37

Editing of NC Machine data C41

Drive Diagnostic parameters C53

SINUMERIK 802D sl Operating and Service Training Manual Page 1

C102

C102

CNC Basic Principles Milling

C102

1 Brief description

Module Objective:

Upon completion of this

module you can understand the basic functionality and requirements of a

CNC controller

Module description:

CNC

machines replicate the functions of a manual machine through the use of a sequential program,

this program replicates the move

ments of a m

anual machine through the so called “CNC program” .

Geometric relationship

s of the component to t

he

machine are achieved with (Tool and component)

numeric compensations. These co

mpensations mat

hematically compensate the dif

ference between

component, Tool and machine.

• Fundamentals of CNC Machines

Module Co

ntent:

Fundamentals of CNC

Machines

Section 2

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C102

C102

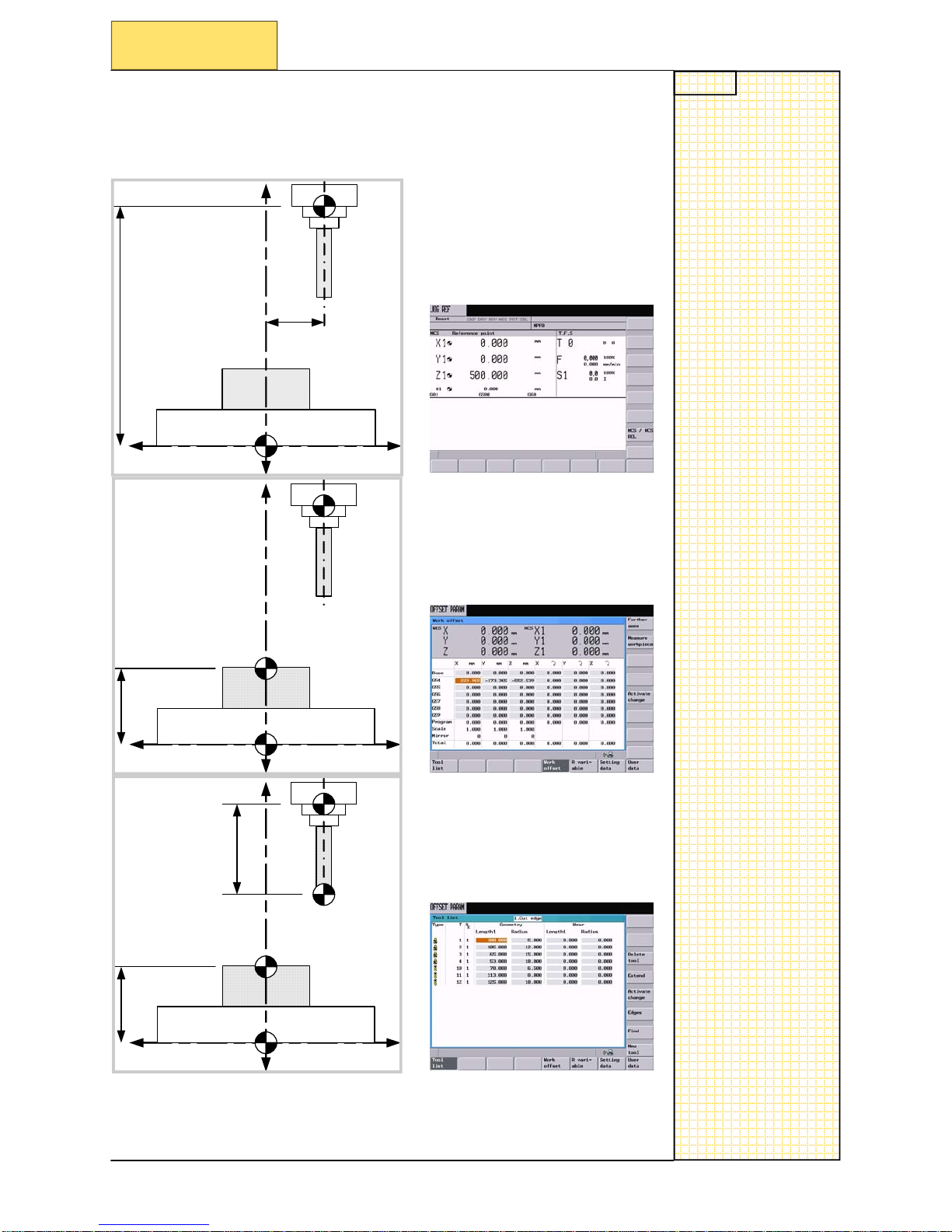

Fundamentals of CNC Machines

Section 2

The difference between a Manual machine and a CNC machine is a logical

difference b

ased upon numerical values. This overview module and the

following CNC modules

should help explain the myth of CNC.

ITS ONLY

NUMBERS. No magic !!

Reference position Z

Re

ference position X

Zero Offset

Tool Offset

Zero Offset

SINUMERIK 802D sl Operating and Service Training Manual Page 1

C98

C98

Basic program structure

C98

1 Brief description

• Basic structure

• Basic structure for turning

• Basic structure for milling

Basic structure for

turning

Basic structure for

milling

Section 3

Section 4

Basic structure

Section 2

Module objective:

Upon completion of this

module you will understand the basic structure of an NC program

Module description:

We use a b

asic structure when writing a program to give some kind of order to the program, this will

also help wh

en performing a “Block search”.

Module content:

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C98

C98

Section 2

Basic structure

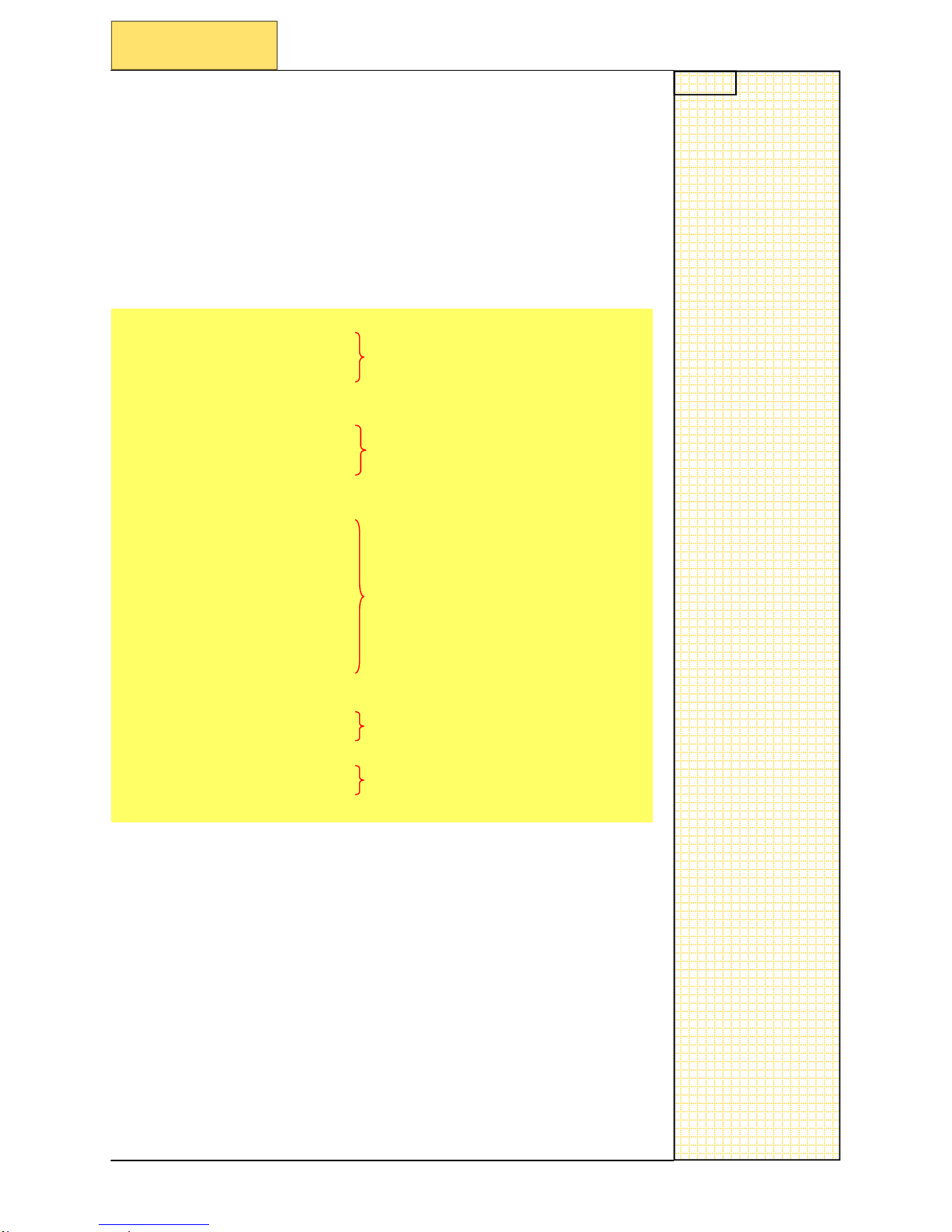

2.1 Basic structure of NC program

There are five basic parts to an NC program.

1.

Basic startup G functions.

2.

Call tool and set spindle speed, feed, coolant.

3.

Set geometry to cut component.

4.

Tool to safe position

5.

End of program

G00 G90 G94 G40 G17

G71

Basic G functions for pr

ogram

T1

M

6

Call tool etc

G95 S1500 F0.15 M08

G00 G54 X0

.0 Y0.0 Z50.0

….

….

….

…

.

Geometry fo

r component

….

….

….

G00 G40 Z5

0.0

X0.0 Y200.0 Z200.0

Safe positio

n for tool change

M30

End of program

You will note that for each tool there is always :

• Call tool etc

• Geometry for component

• Safe position for tool change

This will be t

he same for ever tool that is written in the NC program

If you keep to a good ba

sic structure, this will make the program safer to

run and easier to perform a block search.

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 3

C98

C98

Section 3

Basic structure for turning

3.1 Basic structure of NC program for turning

N10 G00 G90 G95 G40

G18 G71

N20

LIMS=2500

Basic G functions for pr

ogram

N30 G54

N40 T1 D1

N50

G18

Call tool etc

N60 G96 S2

50 M03 M08

N70 G00 X5

2.0 Z0.1

N80 G01 X-2.0 F0.15

N90 G00 Z2

.0

N100 X20.0

N110 G01 Z

-20.0

Geometry fo

r component

N120 X30.0 Z-25.0

N130 X45.0

N140 Z-50.0

N150 X52.0

N160 G00

G40 Z2.0

N170 X200.0 X1200.0

Safe positio

n for tool change

N180 T4 D1

N190

G17

Call tool etc

N200 G95 S1500 M04 M08

N210 G00 X0.0 Z2.0

N220 G01 Z

-25.0 F0.25

Geometry fo

r component

N230 G00 Z

2.0

N240 G00

G40 Z2.0

N250 X0.0 Z200.0

Safe positio

n for tool change

N260 M30

End of program

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 4

C98

C98

Section 4

Basic structure for milling

4.1 Basic structure of NC program for milling

N10 G00 G90 G94 G40

G17 G71

Basic G functions for pr

ogram

N20 T1

N30

M6

Call tool etc

N40 G95 S2

500 F0.25 M03 M08

N50 G00 G54 X0.0 Y0.0 Z50.0

N60 MCAL

L CYCLE82(5.0. 0.0, 2.0, -2.0, 0.0, 0.0)

N70 X10.0

N80 X20.0

N90

X20.0

Geometry fo

r component

N100 X30.0

N110 X40.0

N120 X50.0

N130 MCAL

L

N140 G00

G40 Z50.0

N150 X0.0 Y200.0 Z200.0

Safe positio

n for tool change

N160 T4

N170

M06

Call tool etc

N180 G95 S1500 F0.25

M05 M08

N190 G00

G54 X0.0 Y0.0 Z50.0

N200 MCALL CYCLE8

2(5.0. 0.0, 2.

0, -10.0, 0.

0, 0.0)

N210 X10.0

N220 X20.0

N230

X20.0

Geometry fo

r component

N240 X30.0

N250 X40.0

N260 X50.0

N270 MCAL

L

N280 G00

G40 Z50.0

N290 X0.0 Y200.0 Z200.0

Safe positio

n for tool change

N300 M30

End of program

SINUMERIK 802D sl Operating and Service Training Manual Page 1

C89

C89

Modality (Preparatory functions)

C89

1 Brief description

Module objective:

Upon completion of this

module you will understand Preparatory functions (G-Codes).

Module description:

We use pre

paratory G functions according to there appropriate functional group to instruct a machine

what to do via the custo

mers NC program.

Module content:

• G function overview

• G function window display

G function window display

Section 3

G function overview

Section 2

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C89

C89

Section 2

G function overview

2.1 G function overview

G function (preparatory function).

The G functions are divided into G groups.

Only one G

function from each group can be written in a single block.

A G function can either be modal (until cance

led by another function from

the same group), or non-modal (only effective for that block it is written

in).

Modal example:

G00 G90 G94 G40 G17

T1 D1

G54 S1000 M03

G01 X0.0 Y0.0 Z0.0 F2

00

X

100.0

Y100.0

X0

.0

Y0.0

G00 Z50.0

M30

These blocks are per-

formed at a given feed

rate, because G01 is

modal and will not

change until another

code from the same

group is ent

ered

At this block the speed

of motion will change

due to the change of the

G function group, from

G01 to G00.

Non-modal example:

G00 G90 G94 G40 G17

T2 D1

G54 S1000 M03

X

0.0 Y0.0 Z50.0

G01 Z0.0 F200

G04 F10.0

G00 Z50.0

M30

This G function is only

effective in t

his block, to

use this fun

ction again

you must type it in again

in another block.

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 3

C89

C89

Section 2

G function overview

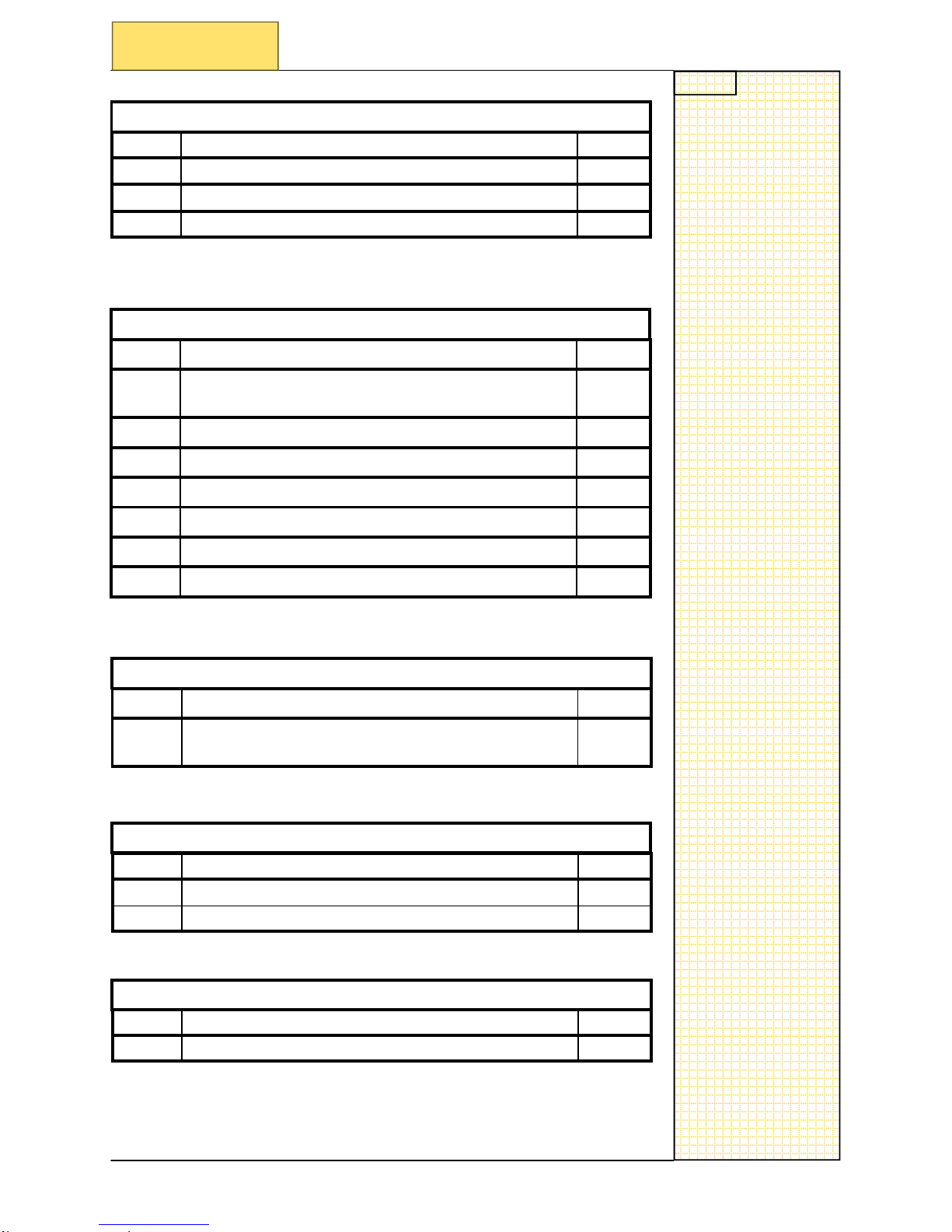

Group 1: Modally valid motion commands

Name Meaning

Machine

G00 Rapid

traverse

M/T

G01*# Linear interpolation

M/T

G02 Circular interpolation clockwise

M/T

G03 Circular interpolation counter-clockwise

M/T

G33 Thread cutting with constant lead

M/T

Group 2: Non-modally valid motion, dwell

Name Meaning

Machine

G04

Dwell time preset

M/T

G63 Tapping without synchronization

M/T

G74 Reference point approach with synchronization

M/T

G75 Fixed point approach

M/T

Group 3: Programmable frame, working area limitation

Name Meaning

Machine

TRANS Translation,

programmable

M/T

ROT Rotation, programmable

M/T

SCALE Scaling, programmable

M/T

MIRROR Mirroring, programmable

M/T

G26

Maxi

mum working area limitation/spindle speed limi-

tation

M/T

G25

Minimu

m working area limitation/spindle speed limita-

tion

M/T

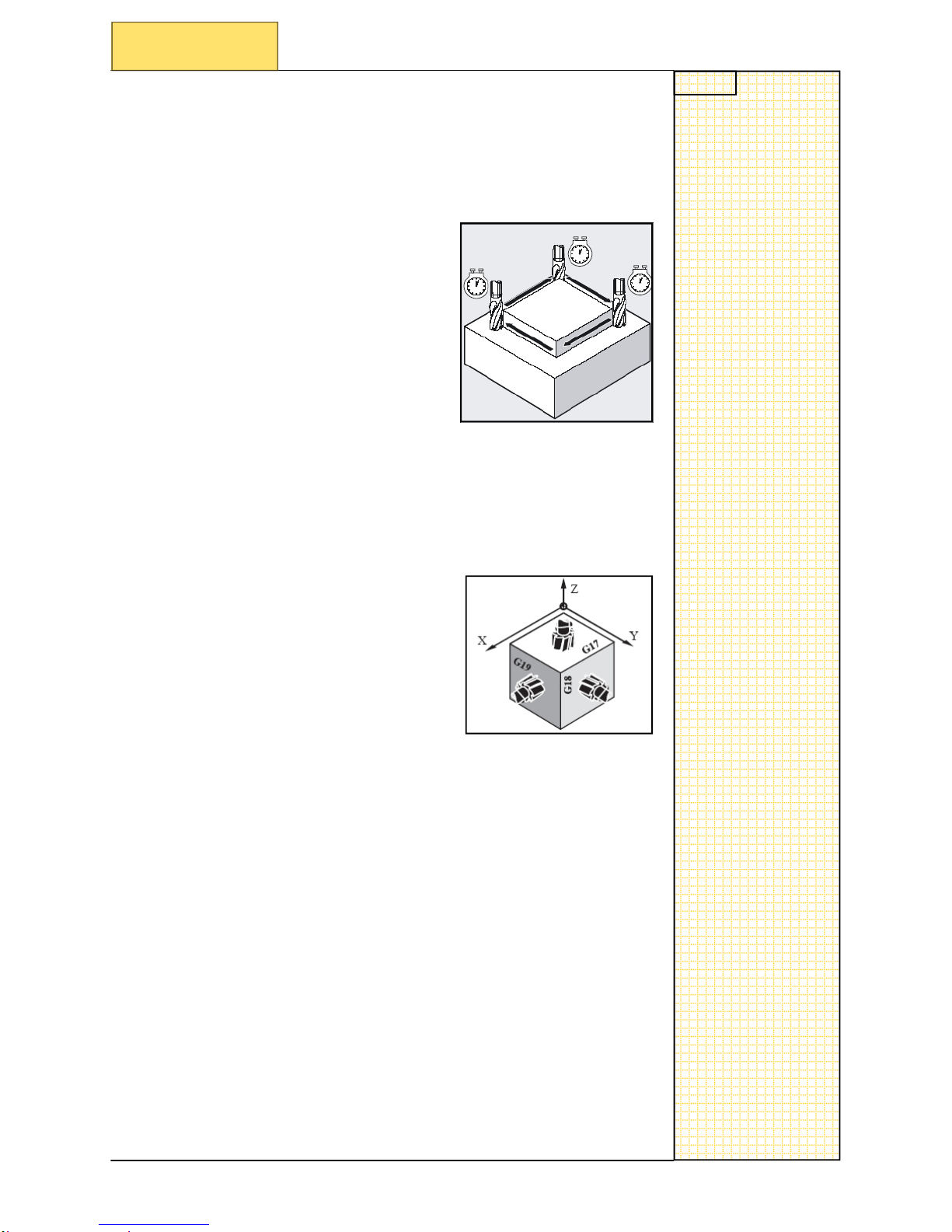

Group 6: Plane selection

Name Meaning

Machine

G17#

Plane selection 1st - 2nd geometry axis

M/T

G18* Plane selection 3rd - 1st geometry axis

M/T

G19 Plane selection 2nd - 3rd geometry axis

M/T

Default for turning * / default for milling #

M = milling / T = turnin

g

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 4

C89

C89

Section 2

G function overview

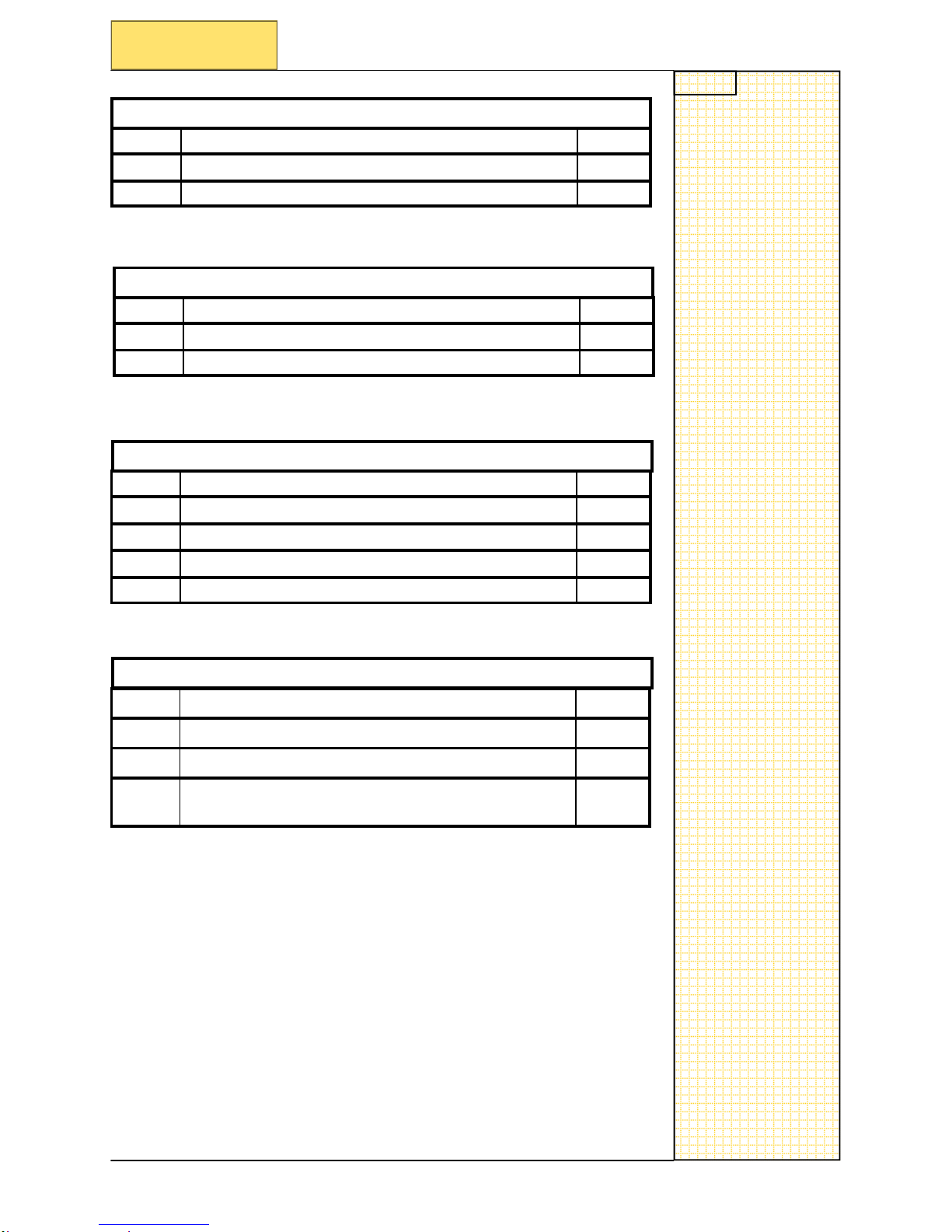

Group 11: Exact stop, non-modal

Name Meaning

Machine

G09

Velocity reduction, exact positioning

M/T

Group 10: Exact stop - continuous-path mode

Name Meaning

Machine

G60*#

Velocity reduction, exact positioning

M/T

G64 Continuous – path mode

M/T

Group 9: Frame suppression

Name Meaning

Machine

G53

Suppression of current zero offset: including active

settable fra

me G54 - G59

M/T

Group 8: Settable zero offset

Name Meaning

Machine

G500*#

Deactivate all settable G54—G59 if G500 not contain

a value

M/T

G54 Settable zero offset

M/T

G55 Settable zero offset

M/T

G56 Settable zero offset

M/T

G57 Settable zero offset

M/T

G58 Settable zero offset

M/T

G59 Settable zero offset

M/T

Group 7: Tool radius compensation

Name Meaning

machine

G40*#

No tool radius compensation

M/T

G41 Tool radius compensation left of contour

M/T

G42 Tool radius compensation right of contour

M/T

Default for turning * / default for milling #

M = milling / T = turnin

g

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 5

C89

C89

Section 2

G function overview

Group 16: Feed override on inside and outside curvature

Name Meaning

Machine

CFC*#

Constant feed at contour

M/T

CFTCP Constant feed in tool center point (center-point path)

M/T

CFIN

Constant feed at interna

l radius, acceleration at exter-

nal radius

M/T

Group 15: Feed type

Name Meaning

Machine

G94#

Linear feed mm/min, inch/min

M/T

G95* Rotational feed in mm/rev, inch/rev

M/T

G96 Constant cutting speed (type of feed as for G95) ON

T

G97 Constant cutting speed (type of feed as for G95) OFF

T

Group 14: Workpiece measuring absolute/incremental

Name Meaning

Machine

G90*#

Absolute dimensions input

M/T

G91 Incremental dimension input

M/T

Group 13: Workpiece measuring inch/metric

Name Meaning

Machine

G70

Input system inches (lengths)

M/T

G71*# Input system metric (lengths)

M/T

Default for turning * / default for milling #

M = milling / T = turnin

g

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 6

C89

C89

Section 3

G function window display

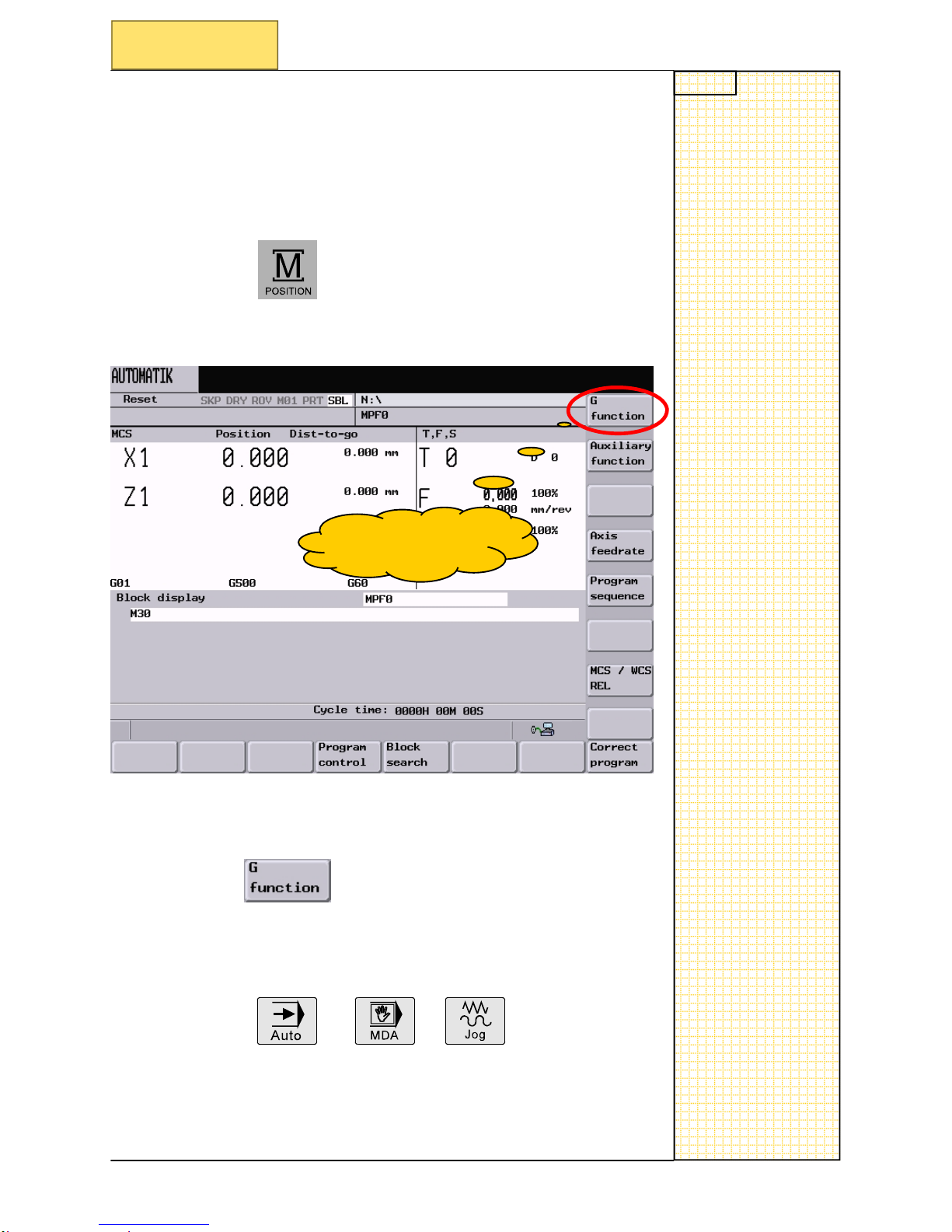

3.1 G function window display

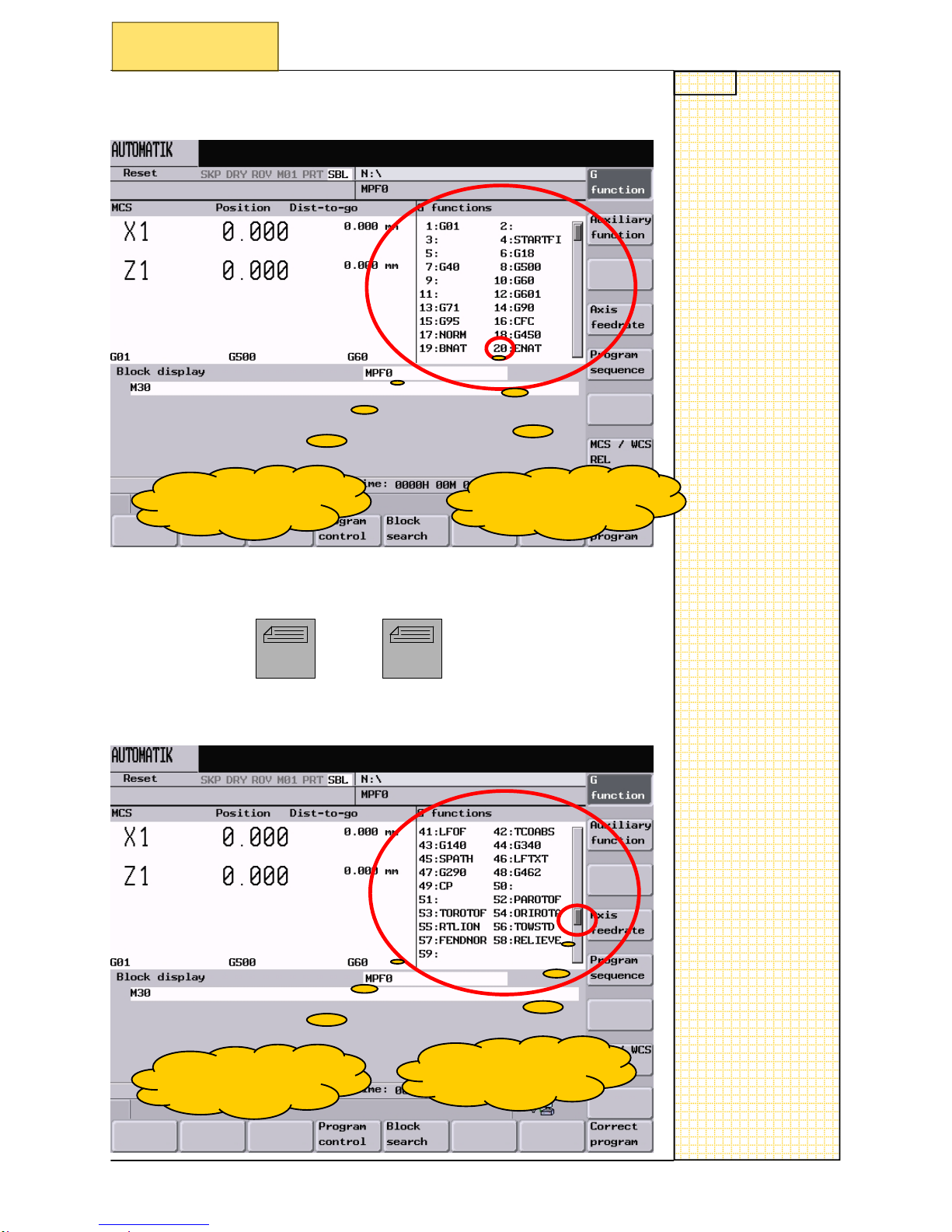

To look at the active G-codes, you can activate a window called

G FUNCTION.

PRES

S

PRESS

This “G function” softkey is present in modes:

Softkey G function

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 7

C89

C89

Section 3

G function window display

This is what you will see:

This is the window

that is show

n.

In this windo

w, it will show you every group number and the active G-code

for that group at that pre

sent time.

Use the button

to scroll d

own or up to search for the required G-code group.

This shows you the

group number.

Page

up

Page

Do

wn

This is the window

that is show

n.

The slide bar has

now mo

ved.

SINUMERIK 802D sl Operating and Service Training Manual Page 8

C89

C89

SINUMERIK 802D sl Operating and Service Training Manual Page 1

C92

C92

Commonly used G functions Milling

C92

1 Brief description

• G functions in detail

• Example contour program

• Example drilling program

Example contour program

Example drilling program

Section 3

Section 4

G functions in detail

Section 2

Module objective:

Upon completion of this

module you will understa

nd commonl

y used G functions (G-Codes) for mill-

ing in detail.

Module description:

We use G functions a

ccording to their appropriate functional group to instruct a machine what do ,

but a certain

structure should be kept to.

Module content:

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C92

C92

Section 2

G functions in detail

2.1 G functions “Milling” in detail

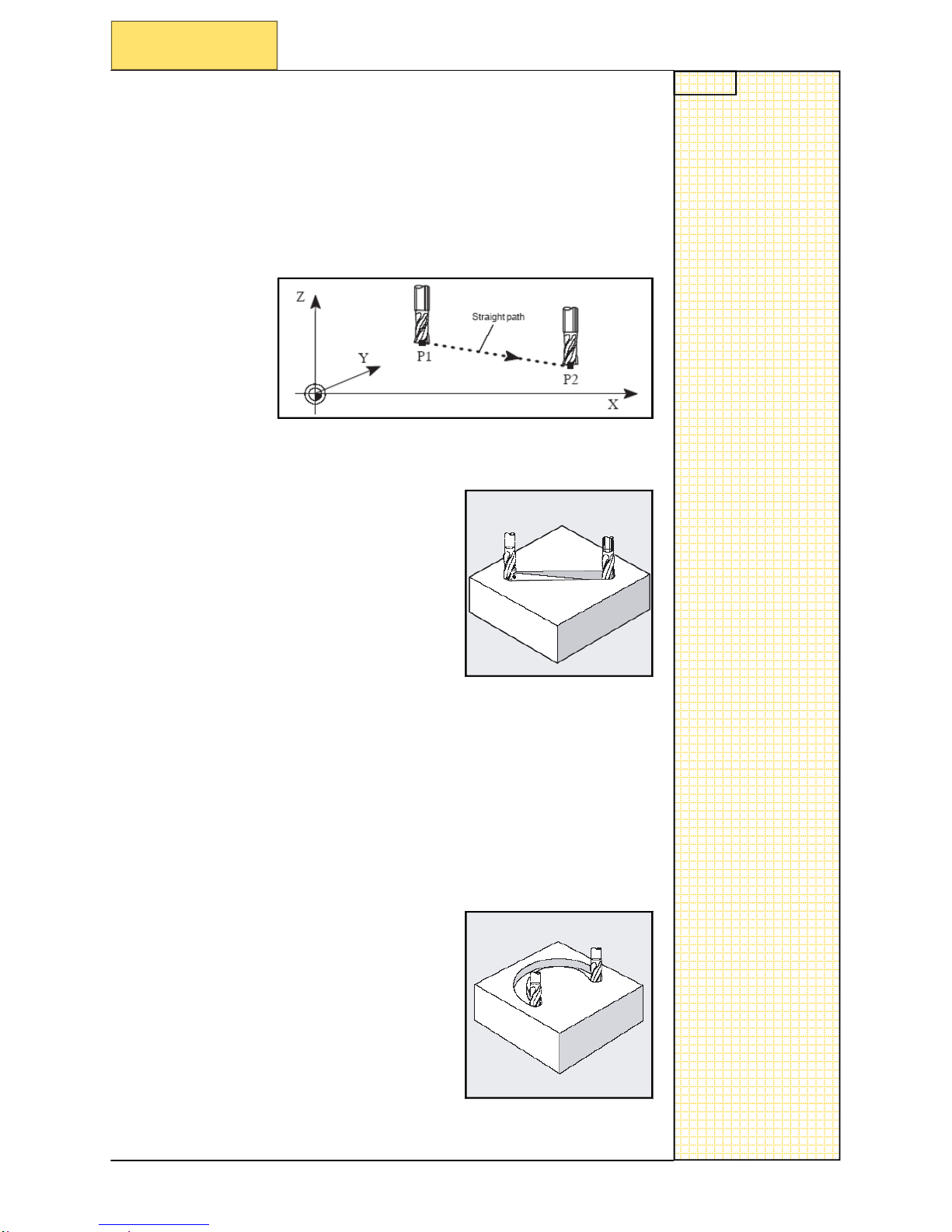

Rapid traverse movement G00

Function

You can use

rapid traverse movement, to position the tool rapidly, to

travel around the workpiece or to ap

proach tool change locations.

Note: when there is a tw

o axis movement, both axis interpolate to

their end po

sition, arriving at the same time.

Programming

G00 X

.. Y.. Z..

Or

G0

X.. Y.. Z..

————

—————————————————————————————

Linear interpolation G01

Function

With G01, the tool travels along a str

aight

line.

Programming

G01 X

.. Y.. Z.. F..

Or

G1

X.. Y.. Z.. F..

————

—————————————————————————————

Circular interpolation, G02/G03

Function

This funct

ion

allows you to program an arc either

in clockwise (G02)

or counter-clockwise (G03) direction.

Programming

G02/G03

X.. Y.. Z.. I=AC(..) J-AC(..) K=AC(..)

absolute ce

ntre point

Or

G02/G03

X.. Y.. Z.. I.. J.. K..

Incremental centre point

Or

G02/G03

X.. Y.. Z.. CR=..

Circle radius CR=

————

—————————————————————————————

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 3

C92

C92

Dwell time G4

Function

You can use G4 to interrupt workpiece machining between two NC

blocks for the programmed length of time, e.g. dwell at bottom of

hole.

Programming

G4 F.. F = Time

Or

G4 S.. S = Rotations

—————————————————————————————————

Plane selection G17

Function

To select the infeed feed axis when milling or drilling, this is the default G function.

Programming

G17

—————————————————————————————————

Section 2

G functions in detail

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 4

C92

C92

Section 2

G functions in detail

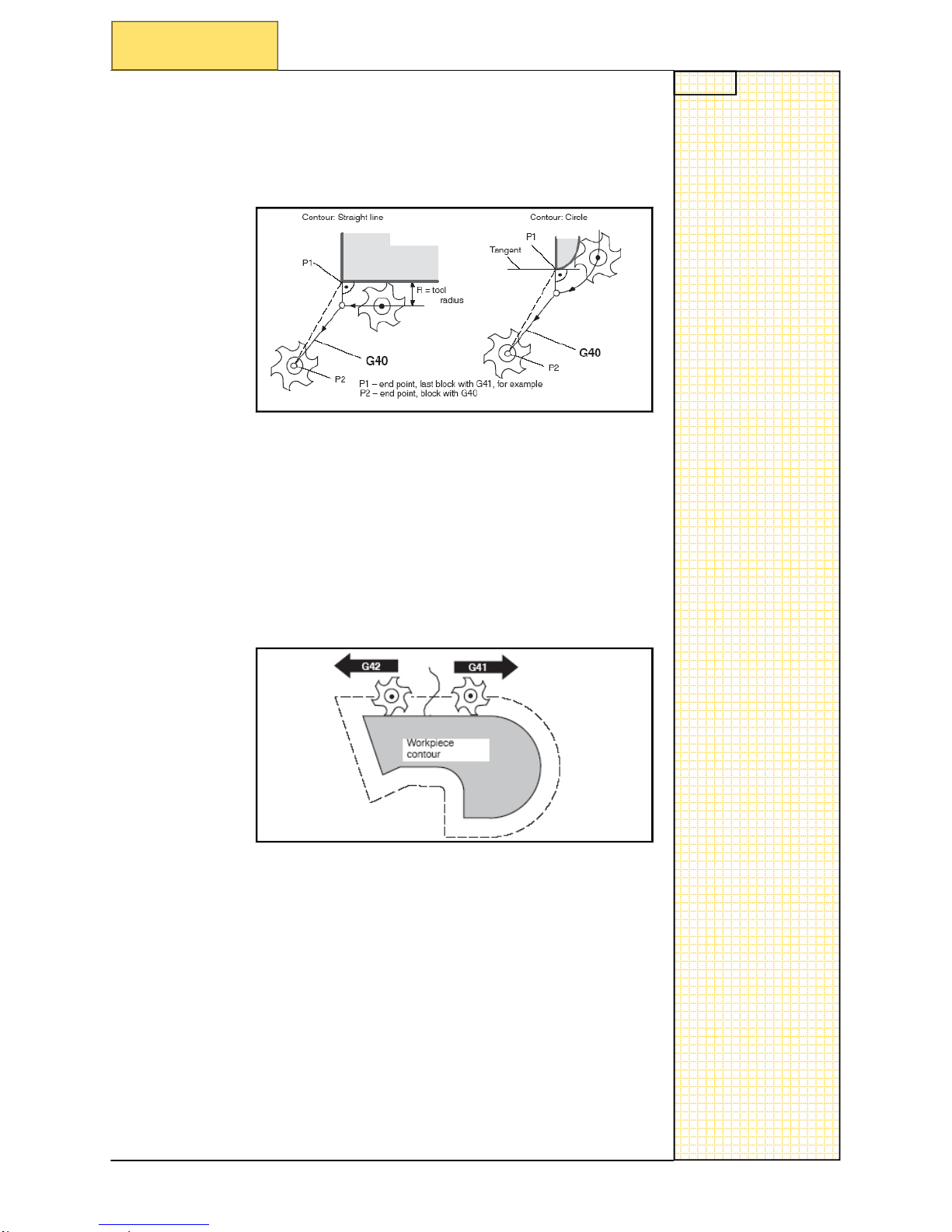

Tool radius compensation G40

Function

To deactivate tool compensation

Programming

G40

————

—————————————————————————————

Tool radius compensation G41

Function

To activate tool compensation, with t

he tool operating to the left of

the contour in the machining directio

n.

Programming

G41

Tool radius compensation G42

Function

To activate tool compensation, with t

he tool operating to the right of

the contour in the machining directio

n.

Programming

G42

————

—————————————————————————————

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 5

C92

C92

Section 2

G functions in detail

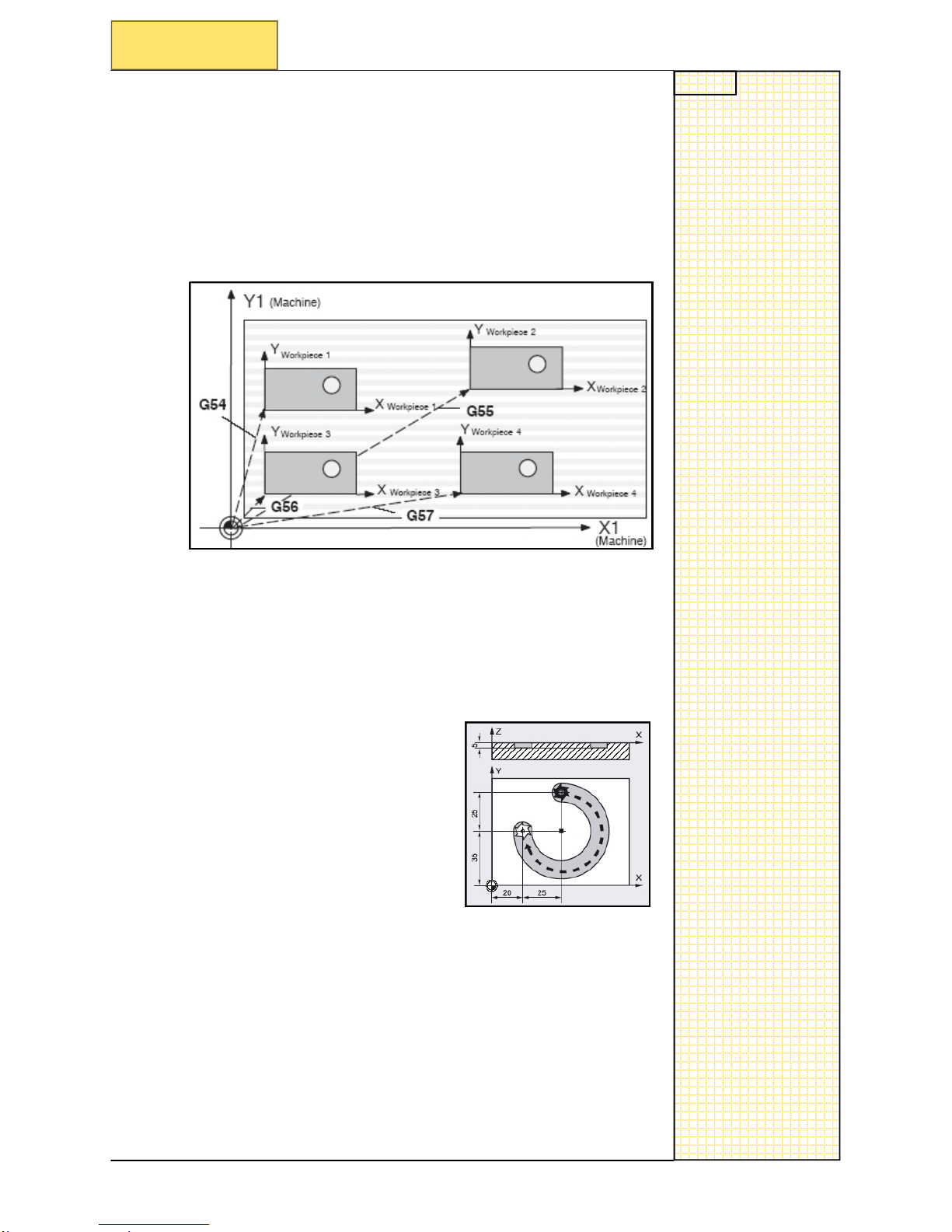

Zero offset G54 to G59

Function

The settable

zero offset re

lates the workpiece zero on all axis

to the

machine zero offset.

Programming

G54 to G59

————

—————————————————————————————

Absolute dimension G90

Function

With the G90 command

all dimensions are related from your active

zero offset.

Programming

G90

X

.. Y.. Z..

————

—————————————————————————————

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 6

C92

C92

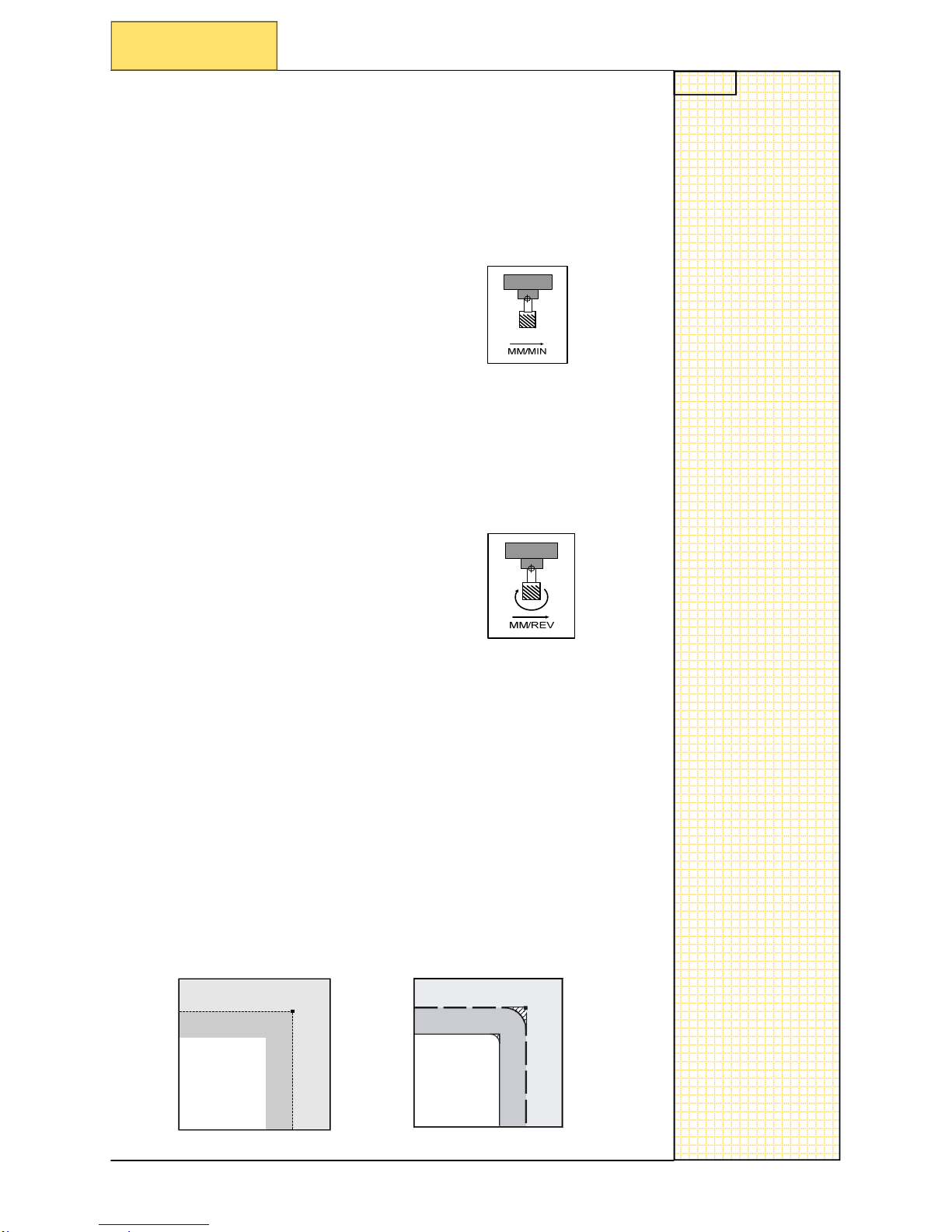

Feed rate G94

Function

This is how the feedrate will act to the axis that is moving in relationship to the spindle.

The spindle will be programmed in direct RPM and the feedrate will

be MM/MIN.

Note: the axis will move without the spindle rotating.

Programming

G94

S.. F..

Feed rate G95

Function

This is how the feedrate will act to the axis that is moving in relationship to the spindle.

The spindle will be programmed in direct RPM and the feedrate will

be REV/MIN.

Programming

G95

S.. F..

Section 2

G functions in detail

Exact stop/continuous-path control: G09, G60, G64

Function

Will set th

e block end behavior movement and to continue with the

next. E.g. G09/G60 the objective for

reaching the exact end position

is to dece

lerate the velocity to zero. With G64, the object is to avoid

deceleration

at the end of the block.

Programming

G09

; Exact stop - non-modal

G60

; Exact stop - modally effective

G64

; Continuous path-control mode

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 7

C92

C92

Section 3

Example contour program

G00 G90 G94 G40 G17 ;Basic G-code commands

T1 D1

;call tool

G94 S2500 M03

F500 ;spindle speed in RPM feed MM/MIN

G00 G54 X5

5.0 Y55.0 Z50.0 ;rapid to safe position start of contour

Z0.0

;rapid to safe position

G01 Z-5.0

;feed onto workpiece

G01 G42 Y5

0.0

;apply cutter compensation

X-45

;coordinates for contour

G03 X-50.0

Y45.0 I0.0 J-5.0 ;arc using incremental start point

G01 Y-40.0

;coordinates for contour

G02 X-40.0

Y-50.0 CR=10.0 ;arc using circle radius

G01 X35.0

;coordinates for contour

G03 X50.0 Y-35.0 I=AC(35.0) J=AC(-35.0)

;arc using absolute start point

G01 Y55.0

;coordinates for contour

G00 G40 Z5

0.0 ;rapid to safe

height can

cel cut comp

X0.0 Y200.0 Z200.0

;safe tool change position

M30

;end of program

3.1

Example contour program

Note: G94 are being

used in this

contour

example

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 8

C92

C92

Section 3

Example contour program

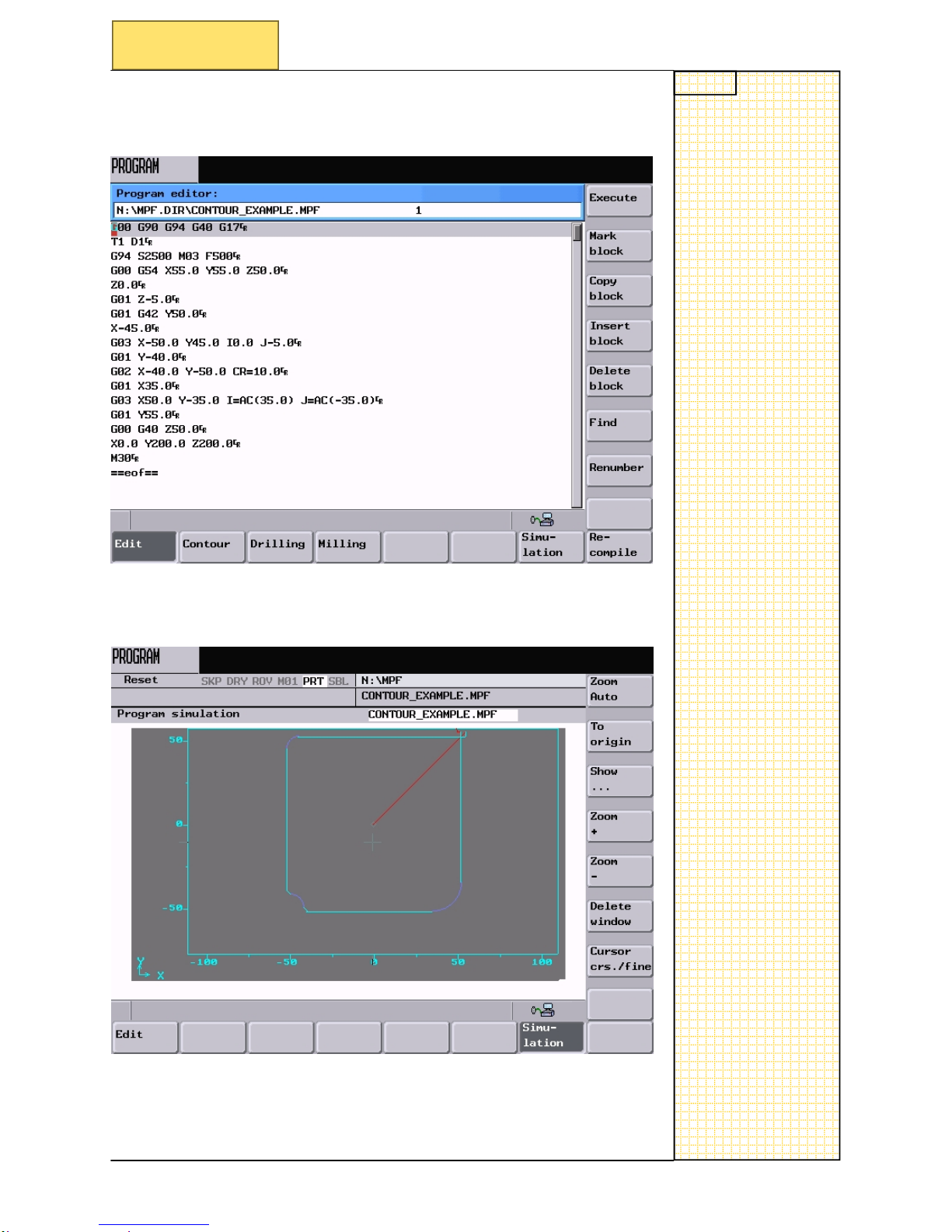

This is the same program typed into the control:

The same program run in simulation

:

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 9

C92

C92

Section 4

Example drilling program

4.1 Example drilling program

G00 G90 G95 G40 G17 ;basic G-code commands

T1 D1

;call tool

G95 S1500 M03

F0.15

;spindle speed in RPM feed MM/REV

G00 G54 X0

.0 Y0.0 Z50.0 ;rapid to safe position start of contour

Z2.0

;rapid to safe position

G01 Z-10.0

;feed onto workpiece

G04 F0.5

;dwell at bottom of hole

G00

Z2.0 ;

rapid out of

hole

X-50

;coordinates for drilling

G01 Z-10.0

;feed onto workpiece

G04 F0.5

;dwell at bottom of hole

G00

Z2.0 ;

rapid out of

hole

G00 G40 Z50.0 ;rapid to safe height

X0.0 Y200.0 Z200.0

;safe tool change position

M30

;end of program

Note: G95 are being

used in this

contour

example

Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 10

C92

C92

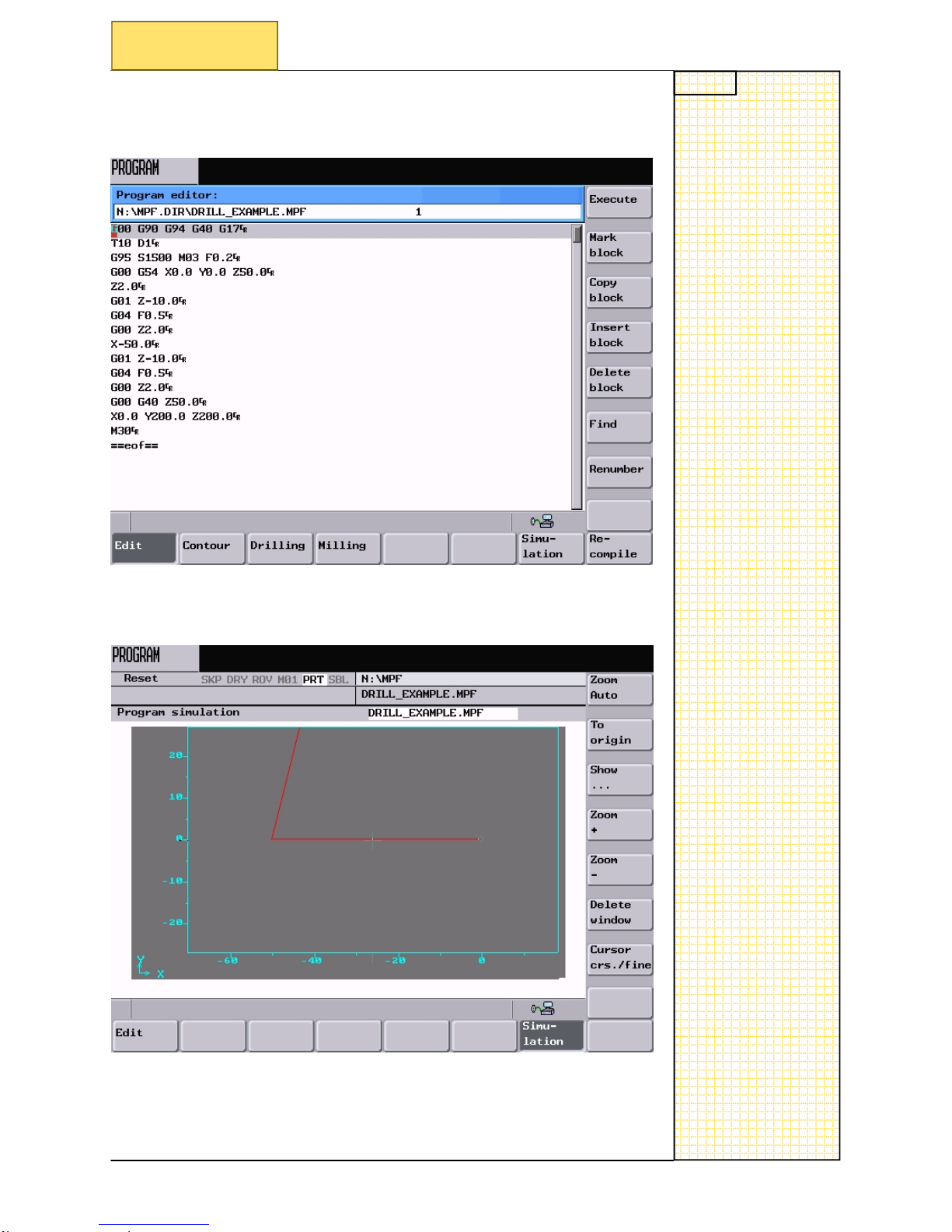

The same program run in simulation:

Section 4

Example drilling program

This is the same program typed into the control:

Loading...

Loading...