Edition

2019

SINUMERIK

Intelligent solutions

for machine tools

siemens.com/sinumerik

SINUMERIK | Content

Increased productivity

with SINUMERIK

Highly productive automation solutions are demanded

for workshops, jobshops and large series production –

that accompany and support users along the path to

digitalization. SINUMERIK CNC solutions always provide

companies, operating machine tools, with the optimum

solution to address their specific requirements.

Whether for individual parts or mass production –

basic or complex workpieces.

2

Content | SINUMERIK

Siemens Machine Tool Systems 4

CNC portfolio 6

Drives and motors 16

Industry solutions 18

Machining technologies 20

CNC performance 22

Operation and programming 26

Digitalization 30

Motion Control Services 34

3

SINUMERIK | Siemens Machine Tool Systems

Strong partner in the world

of machine tools

Digitalization is changing all areas of our lives.

Production and manufacturing companies must

satisfy some essential requirements: shorter market

launch times, higher degree of flexibility, higher

quality and increased efficiency – as well as suitable

and adequate safety measures. Sustainable competitiveness will only be able to be achieved by

taking a holistic approach, which encompasses

and digitizes the complete value-added chain. The

Digital Enterprise Portfolio combines automation

with all of the advantages provided by digital data.

Future of the machine tool industry

In close cooperation with machine builders,

we want to successfully shape the future of

the machine tool industry and master the

next phase of the digital transformation.

Trends and developments in the IT environment – such as artificial intelligence, machine

learning and digital marketplaces as well as

new forms of collaboration represent new

impetus and change workflows in industrial

landscapes.

4

Siemens Machine Tool Systems | SINUMERIK

The benefits of the digital twin

The digital twin simulates and optimizes all

areas of the value-added chain: Product, production and performance. This is the next

step in the digital transformation for machine

builders and users – allowing them to reach

the next level of productivity.

Productivity benchmark

This is why a SINUMERIK CNC is the first

choice when new, revolutionary machine

concepts must be implemented – and if

the absolute maximum productivity is

demanded for a machine tool application.

Siemens Machine Tool Systems – with the

power of innovation of a unique and experienced development team in the market – is

there to ensure that also in the future highly

productive machine concepts can be implemented based on SINUMERIK CNCs.

5

SINUMERIK | CNC portfolio

SINUMERIK –

the CNC portfolio

for the global machine tool market

SINUMERIK 808

The entry-level CNC for basic, standard machines

SINUMERIK 808

• Panel-based compact CNC

• Up to 6 axes/spindles

• 1 machining channel

• 8.4" color display

• SIMATIC S7-200-based PLC

SINAMICS V70

SIMOTICS S-1FL6

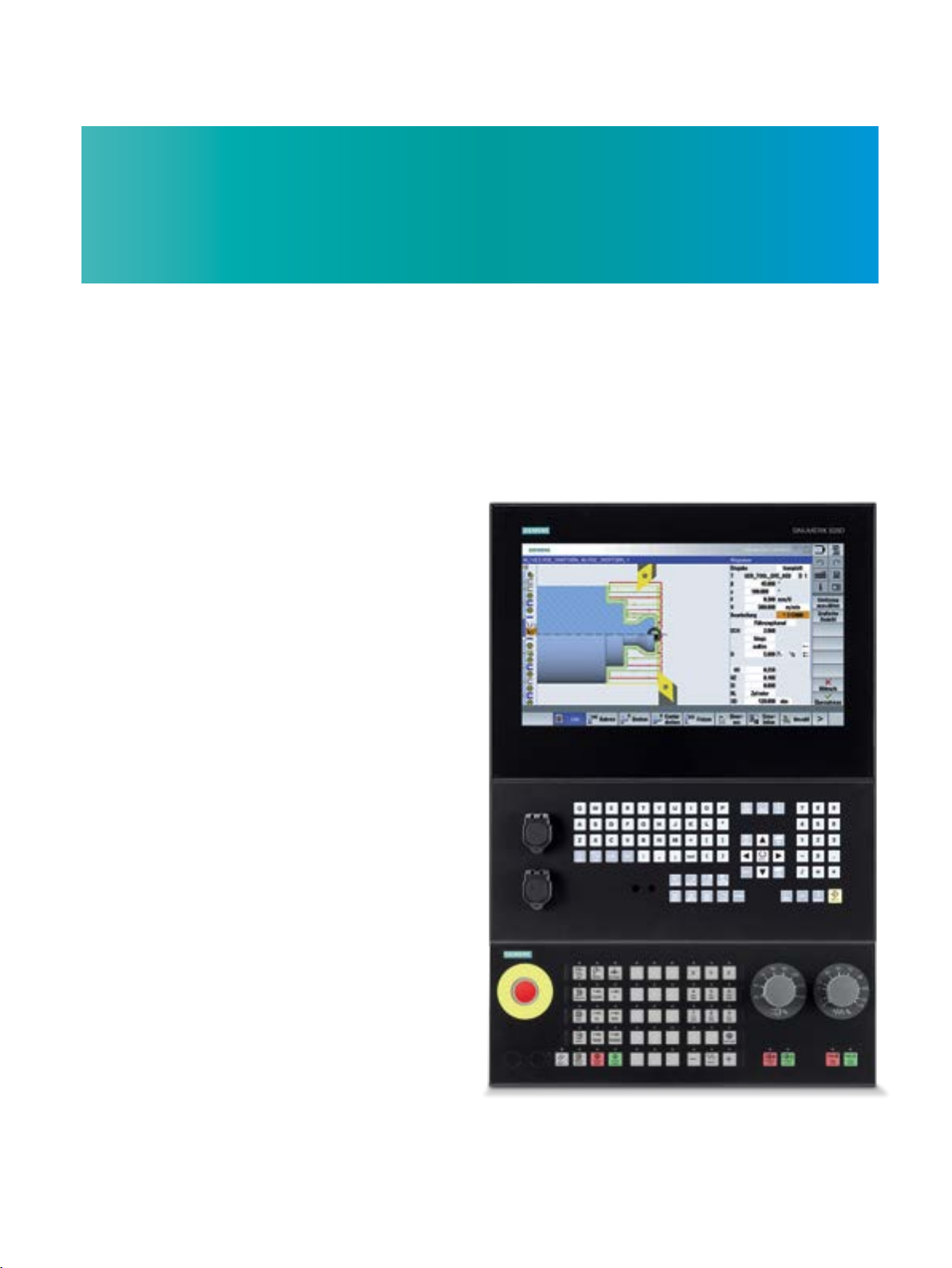

SINUMERIK 828

The compact CNC for standard machines

SINUMERIK 828

• Panel-based compact CNC

• Up to 10 axes/spindles and

2 auxiliary axes

• Up to 2 machining channels

T, M, G

• 10.4" display or

15.6" touch display

• SIMATIC S7-200-based PLC

SINAMICS S120/S120 Combi

SIMOTICS

The CNC for special machine tool technologies

SINUMERIK MC

• PC-based CNC

• Open user interface design based on WinCC or Run MyHMI

/3GL

• Up to 8 axes/spindles

• Up to 4 machining channels

• Modular panel concept

• SIMATIC S7-1500F PLC

SINAMICS S120 Booskize with CU320, SINAMICS S210

6

SINUMERIK MC

SIMOTICS

CNC portfolio | SINUMERIK

From basic, standard CNC machines through standardized machine tools up to

modular, high-end machine concepts – SINUMERIK CNCs offer the optimum

solution for each and every machine concept. Whether individual part or mass

production, basic or complex workpieces – SINUMERIK is the highly productive

automation solution across all production domains. These extend from prototype

and tool building through mold making up to large series production.

SINUMERIK 840

The open CNC for modular machine concepts

SINUMERIK 840

• Drive-based, modular CNC

• Multi-technology CNC

• Up to 31 axes/spindles per NCU*

and any number of PLC axes

• Up to 10 machining channels per

NCU*

• Modular panel concept up to

24" color display

• SIMATIC S7-300 PLC

*Up to 3 NCUs can be connected via NCU-Link

SINAMICS S120 Booksize/Combi/Chassis

SIMOTICS

SINUMERIK ONE

The digital native CNC – the next level of the digital transformation

SINUMERIK ONE

• Digital twin as integral component

of the CNC

• Drive and panel-based modular CNC

• Multi-technology CNC

• Up to 31 axes/spindles and

any number of PLC axes

• Up to 10 machining channels

• Modular panel concept up to

24" multitouch color display

• SIMATIC S7-1500F PLC

SINAMICS S120 Booksize/Combi/Chassis

SIMOTICS

7

SINUMERIK | CNC portfolio

SINUMERIK 808 –

outstanding performance, simply intelligent

SINUMERIK 808D ADVANCED brings impetus into basic turning and milling machines.

CNC technology from the global leader – teamed-up with a revolutionary operating concept

– make the SINUMERIK 808D ADVANCED the perfect entry point into the world of CNC.

Compact and rugged

Thanks to a panel-based CNC design with few interfaces

and an operator panel with IP65 degree of protection,

SINUMERIK 808D ADVANCED is the perfect answer for

applications in harsh environmental conditions. The

small dimensions of these units allow them to be used

in compact machines.

Optimized for basic turning and milling applications

As a result of its technology-specific versions, the

SINUMERIK 808D ADVANCED control is perfectly preconfigured for milling and turning. The range of applications

addressed extends from basic, standard milling machines or

simple machining centers through cycle-controlled lathes

up to basic full CNC lathes. Based on its hardware and software expansions, SINUMERIK 808D ADVANCED offers sufficient performance for moldmaking and toolmaking for

basic milling functions.

Ideal for entry-level machine operators

Based on the standard SINUMERIK operating and programming philosophy, SINUMERIK 808D ADVANCED is

the optimum partner when entering the world of CNC.

Commissioning is also explained interactively in a graphic

form.

8

CNC portfolio | SINUMERIK

SINUMERIK 828 –

the powerhouse in the compact class

With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it

comes to milling and turning on standard machines as well as functions to simply automate grinding

machines.

Rugged and maintenance free

Their die-cast magnesium operator panel fronts, the panelbased CNC design with just a few interfaces, as well as a

high degree of protection, make SINUMERIK 828 controls

a dependable partner even in harsh production environments. SINUMERIK 828D has no fan, no hard disk, and an

NV-RAM memory without a buffer battery, which makes

it a completely maintenance-free CNC.

User-friendly

Equipped with a full QWERTY CNC keyboard with shortstroke keys and a high resolution 10.4" TFT color display /

15.6" touch display, SINUMERIK 828 CNCs are extremely

simple to operate. Equipped with USB, CF card (for 10.4")

and RJ45 interfaces at the operator panel front, CNC data

is quickly and easily transferred.

Optimum scalability

Based on the three CNC performance versions (SW24x,

SW26x and SW28x) favorably-priced compact as well as

more complex machines with additional axes/spindles

and 2 machining channels can be implemented.

9

SINUMERIK | CNC portfolio

SINUMERIK 840 –

Well-proven performance

SINUMERIK 840D sl is considered to be the standard in premium class CNCs, which is certainly justified.

High CNC performance, along with a high degree of flexibility and openness, form the basis for almost

any machine concept.

Maximum performance

Thanks to the drive-based high-performance NCUs (Numerical Control Units), the SINUMERIK 840 D sl – equipped with

state-of-the art multicore processor technology – allows up

to 93 axes in 30 machining channels to be controlled in the

NCU link. Machine concepts with fewer axes benefit from

the performance of the SINUMERIK 840D sl as a result of

the highest degree of machining precision with the shortest

machining times.

Open and communicative at all levels

For instance, based on the system openness of

SINUMERIK 840D sl, operation can be supplemented and

adapted, or even robots and handling systems can be

integrated. SINUMERIK 840D sl is perfectly embedded in

the Siemens automation environment using PROFINET.

Totally Integrated Automation ensures optimum interoperability of all components within the automation solution –

allowing you to achieve maximum transparency and availability of your production landscape.

Intuitive and scalable

SINUMERIK panels make operation and visualization easier

for machine operators. With their touch screens, they pave

the way to create new and unique machine operating

philosophies. In addition to scalable NCU performance,

SINUMERIK 840D sl has a high degree of modularity when

it comes to the operating components. With a flexible M:N

operating concept, SINUMERIK 840D sl ideally fits the operating philosophy of any machine – from compact up to

high-end machine tools in the premium class.

10

CNC portfolio | SINUMERIK

1111

SINUMERIK | CNC portfolio

SINUMERIK ONE

The digital native CNC

With SINUMERIK ONE, Siemens has created the first CNC control system worldwide, which was developed from the ground up to master the challenges of digital transformation in the machine tool industry. This results in a paradigm change: The digital twin becomes an integral component of the control

system and the command variable for taking real action. Machining processes and machine behavior

can be simulated in detail in conditions close to those met in reality.

Maximize productivity

SINUMERIK ONE offers future-proof, state-of-the-art hardware and software platforms, which form the basis to

massively boost machine and machining performance.

Especially in the mold making domain - a process that is

extremely demanding - productivity has been boosted by

up to a double-digit percentage. Tasks such as collision

monitoring that take up a lot of CPU time can now be executed during machining without any restrictions.

Innovate faster

With SINUMERIK ONE virtual processes and digital twins

become the basis for taking real action. Based on the

SINUMERIK ONE digital twin, machine development and

commissioning, production planning and workpiece

machining, machine expansions and services achieve a

completely new level of quality and precision.

12

CNC portfolio | SINUMERIK

Excite digitalization

For the first time, SINUMERIK ONE is offering machine users

a true and consequential "Digital first" strategy. This means

that central processes in the production landscape (such as

programming, production planning and process optimization) are always simulated at the digital twin, providing a

detailed virtual image of the control system and machining

process. There, where previously these processes were performed at the machine, non-productive times have been

eliminated through virtualization and work executed offline

outside the actual production environment. This boosts

productivity.

Discover a new way of thinking

Can a part be produced at all? And if yes, how long will it

take? The digital twin responds to questions such as these

quickly and precisely. Production engineers check the suitability of the machine using the Run MyVirtual Machine

application. The program runtime for the workpiece is also

precisely calculated. These calculations are performed at a

PC in the office, remote from the production environment.

The digital twin makes it all possible in the first place –

faster communications with customers regarding pricing

and schedules, more precise planning, including production

planning – even with decreasing batch sizes and an increasing range of variants to be produced.

13

SINUMERIK | CNC portfolio

SINUMERIK MC

For special technologies

With integrated SINUMERIK CNC, SIMATIC controller as well as Windows® 10 operating system, the

SINUMERIK MC is the optimum solution for processing machines with customized user interface.

Application areas

Applications extend from wood, stone and glass processing

through applying adhesive up to basic grinding applications

and special machine tool technologies. These include sheet

metal cutting, laser and water jet cutting as well as Additive

Manufacturing, for example.

Maximum openness

With the integrated Windows® operating system, it is

simple to create customized user interfaces. The open

operating concept and extensive interfaces mean that

SINUMERIK MC is a seamlessly integrated and open

control system.

Excellent motion control and high automation

performance

SINUMERIK's well-proven CNC technology facilitates the

highest motion control precision, and – thanks to G code

programming – a high degree of flexibility and versatility

when it comes to the open-loop machine control. Further,

the short response times of the SIMATIC S7-1500F PLC

facilitate higher machining speeds and significantly boost

the automation performance.

Simple engineering

Symbolic programming, state-of-the-art programming

languages and comprehensive toolboxes to implement

standard applications mean that engineering in the TIA

Portal is both simple and efficient. This results in lower

commissioning times and costs.

14

CNC portfolio | SINUMERIK

15

SINUMERIK | Drives and motors

Drives and motors –

everything from a single source

SINAMICS V70 SINAMICS S120 Combi SINAMICS S120 Booksize SINAMICS S120 Chassis

Drives

SINAMICS V70 – small and powerful

The SINAMICS V70 with SINUMERIK 808D concept is simply

unbeatable when it comes to price-sensitive entry-level

machines. The compact design of the single-axis, fanless

motor modules ensures the highest degree of ruggedness.

The motor modules can be quickly adapted to the requirements of the feed axes by simply setting a few parameters.

SINAMICS S120 – providing the highest degree of

flexibility

SINAMICS S120 is synonymous with performance and

flexibility when it comes to equipping machine tools.

In addition to a wide range of Motor Modules, various

infeed options are available with functions such as energy

recovery and controlled DC link. This ensures the shortest

spindle acceler ation times and facilitates perfect reactive

power com pensation for the complete machine (cos φ = 1).

The SINAMICS S120 allows the power unit and control

module to be mounted separately, which means that this

drive system can be perfectly adapted to address the widest

range of drive applications.

SINAMICS S120 Combi –

the ideal drive for compact machines

SINAMICS S120 Combi (frame type A and B) combines the

performance of the modular SINAMICS S120 in a compact,

rugged design. One infeed and up to four motor modules

are integrated in one housing. This drive is the ideal basis

for compact standardized machine concepts with a spindle

power of up to 15 kW and can control up to five feed axes.

SINAMICS S120 Booksize –

minimal footprint for the control cabinet

The new SINAMICS S120 Booksize devices have a 300 percent overload capability and combine compactness with

power density. The width can be reduced for applications

that are dimensioned for maximum current with high

acceleration levels – or for positioning axes demanding a

high dynamic performance. The height required in a control

cabinet has also been reduced as a result of a new motor

connection/shield concept for the module.

SINAMICS S120 Chassis

The SINAMICS S120 converter in the chassis format has

been expanded up to high power ratings of 300 kW and

currents up to 490 A – allowing these devices to perfectly

address applications with the highest demands relating to

power and performance.

16

www.siemens.com/sinamics

Drives and motors | SINUMERIK

SINUMERIK control systems, in conjunction with SINAMICS drives and SIMOTICS motors,

are optimally designed to address the requirements of machine tools. The complete

SINAMICS drive family addresses all of the performance levels and sets itself apart as a

result of the highest degree of flexibility, functionality and efficiency.

SIMOTICS motors for motion control applications and SINAMICS drives are the driving

force for SINUMERIK CNCs, which sets the standard for maximum precision and speed.

SIMOTICS linear and torque motorsSIMOTICS servomotors

SIMOTICS motion control motors

SIMOTICS servomotors

High stall torques, high encoder accuracy and perfect

smooth-running operation make SIMOTICS servomotors

the optimum feed drive for machine tools.

For price-sensitive entry-level machines with SINUMERIK

808D control system, the SIMOTICS S-1FL6 motor with

enclosure ensures a rugged solution. For standard applications with the SINUMERIK 828D control system, the

SIMOTICS S-1FK2 is the optimum servomotor.

SIMOTICS S-1FK7 is synonymous for flexibility when it

comes to equipping machine tools, and is available with

various rated speeds, encoder types and moments of

inertia.

With 400 percent overload capability, SIMOTICS S-1FT7

motors offer the highest performance and are available

with various cooling methods.

Our portfolio of servomotors has been expanded to include

compact SIMOTICS S-1FG1 servo geared motors.

SIMOTICS linear and torque motors

Going beyond conventional rotary motor principles,

the SIMOTICS range also encompasses linear and torque

motors with a high dynamic performance. Using

SIMOTICS L-1FN3 linear motors, elasticity, backlash and

SIMOTICS main spindle motors

friction in the machine drive train can be almost completely

eliminated – and along with mechanical transmission

elements – allows the highest degree of precision to be

achieved. In addition to positioning tables with a high

dynamic performance, SIMOTICS T-1FW6 built-in torque

motors can also be used for rotary and swiveling tables

for precise 5-axis machining as well as new technology

domains such as turning on milling machines with the

SIMOTICS T-1FW6 High Speed torque motor.

www.siemens.com/motion-control-motors

SIMOTICS main spindle motors

An outstanding portfolio is obtained by teaming up the

high level of competence in spindle design and construction of Weiss Spindeltechnologie GmbH with Siemens

long tradition of building electric motors. This unique

portfolio supports all types of spindle solutions – from

classic mechanical spindles with SIMOTICS M-1PH8,

M-1PH3 or M-1PH1 mounted spindle motors, SIMOTICS M1FE1, M-1FE2 built-in synchronous spindle motors or

SIMOTICS M-1PH2 induction motors up to hybrid and

high-performance motor spindles.

www.siemens.com/spindles

17

SINUMERIK | Industry solutions

Solutions for every industry

that are fit for the future

Every sector has its own specific requirements. Whether standardized automation concepts for the

automotive sector or a holistic approach across all phases of the product and production lifecycle –

all the way up to aerospace. Siemens Machine Tool Systems has been a partner to the machine tool

industry for many years, and offers sector solutions that are deployed around the globe.

Many years of industry expertise is convincing

Based on our unique experience and the sector know-how

that we have built up over the years, we can provide optimum solutions for cost-effective component production

in the automotive, aerospace, power generation and

electronics domains.

Partner for automating machine tools

all the way up to complete production landscapes

Throughout decades of direct contact with end users in key

sectors, we clearly understand the requirements that are

placed on current generations of machines – and those in

the future. This know-how flows directly into our product

development. That ensures that SINUMERIK control systems

are closely aligned to address market requirements. As fullline supplier, in addition to automating machine tools,

Siemens can act as the general contractor for the manufacturing automation of your entire plant. Customers will

also benefit from this as a result of integrated and seamless

automation solutions from a single source – ultimately

helping you to achieve a highly-productive manufacturing

environment.

Setting trends in the production landscape

Siemens Machine Tool Systems is seen as innovation

leader in the machine tool market. The development

of innovative, cutting-edge solutions is a given for us.

Our digitalization solutions ensure maximum productivity, flexibility and availability.

www.siemens.com/machinetools

18

Industry solutions | SINUMERIK

19

SINUMERIK | Machining technologies

Leverage the bandwidth of

machining technologies

With SINUMERIK, every manufacturing environment is optimally equipped to address technological challenges – today and in the future. SINUMERIK is powerful when it comes to turning, milling, grinding – as well as nibbling, laser machining and gear wheel machining. Further,

it is open for new technological concepts, such as multitasking, Additive Manufacturing and

machining composites.

Turning

Highest precision and productivity

from cycle-controlled and standard

CNC turning through milling on

lathes up to multichannel and multitasking machining.

Nibbling, laser, water jet

and plasma machining

Going beyond standard technologies,

the openness of our SINUMERIK system allows nibbling, laser, water jet

and plasma machining solutions to

be engineered.

Grinding

SINUMERIK offers the optimum

solution – from basic up to

high-end grinding applications.

Milling

Superlative milling with SINUMERIK

Top Surface, Top Speed as well as

Collision Avoidance. From 3-axis

milling through 5-axis simultaneous

machining up to multitasking

machining.

Machining composites

When it comes to machining composites, the quality of the final product

is absolutely decisive. Depending on

the particular material, production

techniques such as laser machining,

milling or grinding are used – all of

which can be flexibly controlled by

SINUMERIK.

Gear machining

Machining gears is a complex process, that demands the highest

degree of precision. The advantages

of SINUMERIK controls are fully

leveraged when it comes to turning

a gear wheel, cutting gears with a

hobbing cutter – along with the final

beveling and chamfering.

Multitasking

Based on SINUMERIK Operate,

multitasking machining is seamlessly

supported across all technologies –

whether in series production or in a

workshop environment. For efficient

and highly productive CNC machining.

Additive Manufacturing

In additive techniques, such as material extrusion or laser cladding, the

5-axis technology of SINUMERIK –

in conjunction with the appropriate

SINAMICS drive system and SIMOTICS

motors - facilitates precise and dynamic motion control.

Automated cell

Robots must be able to be

simply integrated into machine tools

and production workflows. SINUMERIK

Run MyRobot offers solutions that

range from a simple connection

via the user-friendly integration for

handling tasks – up to high-precision

motion control of machines using

robot kinematics.

20

“My production?

Fit for the future.”

Machining technologies | SINUMERIK

With SINUMERIK, you can use

SINUMERIK

all machining technologies

Turning

Milling

Grinding

Multitasking

Additive Manufacturing

Gear machining

Nibbling, laser, water jet and

plasma machining

Machining composites

Automated cell

1) Option: CP-Comfort

SINUMERIK

808

✓ ✓ ✓ ✓ –

✓ ✓ ✓ ✓ –

– ✓ ✓ ✓ ✓

– – ✓ ✓ –

– – ✓ ✓ ✓

– ✓

– – ✓ ✓ ✓

– – ✓ ✓ –

– ✓ ✓ ✓ ✓

828

1)

SINUMERIK

840

✓ ✓ –

SINUMERIK

ONE

SINUMERIK

MC

21

SINUMERIK | CNC performance

22

CNC performance | SINUMERIK

Always achieve the maximum CNC performance

Productivity. Precision. Availability. These are the decisive drivers in the

machine tool market. Packed with special functions, SINUMERIK controls

precisely satisfy these requirements – helping to accomplish a high CNC

performance.

Wide ranging possibilities to

achieve high productivity

Robot integration, intelligent motion control as well as

continuous optimization are the relevant buzz words when

it comes to leveraging the wide-ranging possibilities of

boosting productivity.

All the facets of robot integration

The demand for automation solutions for machine tools

teamed up with high precision industrial robots is increasing

at a rapid pace. This applies equally to handling – as well

as high-precision and complex machining tasks. With

SINUMERIK, Siemens has a CNC system for robot integration:

From a simple connection via the user-friendly integration

for handling tasks – up to the complete integration of robot

kinematics in a system.

Optimum machining speed and quality

With the combination of the Top Surface and Top Speed

functions, SINUMERIK offers optimum path planning and

speed control for milling applications – providing the highest surface quality and machining speed.

Continuous optimization

Maximum machine dynamic performance is achieved by

automatically optimizing machine parameters as a function

of the load and axis positions using the Intelligent Load

Control and Intelligent Dynamic Control functions. As a

consequence, the best machining result is achieved for any

workpiece weight and at any position in the machining area

of the machine tool. The result – shorter machining times

and a higher machining quality.

23

SINUMERIK | CNC performance

Precision in the production landscape

The high degree of precision achieved using SINUMERIK

also comes from functions such as its 80-bit NANO computation accuracy. This is supplemented by innovative software-based compensation of various mechanical effects.

Precision

SINUMERIK CNCs and SINAMICS drives compute with

high-performance 80-bit NANO accuracy. This eliminates

rounding errors and results in an extremely high internal

computational accuracy in the complete controller circuit.

Nodding compensation

Nodding compensation is used to compensate dynamic position deviations that occur when machine axes accelerate.

This improves machining quality, and at the same time,

allows higher jerk and acceleration values to be reached.

Friction compensation

Friction-related path errors are even more effectively eliminated by compensating the effects of friction as a function of the velocity. This allows a consistently high contour

accuracy and workpiece precision to be achieved.

Volumetric compensation (VCS)

VCS allows geometrical deviations of linear and rotary axes

to be compensated regarding how they influence the tool

center point – directly resulting in higher machining precision.

Increasing the availability

High availability of machine tools is achieved through

collision avoidance and condition monitoring.

Collision avoidance

SINUMERIK collision avoidance functions offer extensive

collision protection for the machine, the workpiece,

clamping equipment and the tool. Using SINUMERIK Edge,

collision monitoring functionality can be shifted out, so

that the full SINUMERIK system performance can be

utilized.

Condition monitoring

SINUMERIK condition monitoring status information is

captured using machine fingerprints and the machine

condition evaluated. This allows valid statements to be

directly made about the machine quality and possible

hidden problems and issues.

24

CNC performance | SINUMERIK

Increasing security

Protecting intellectual know-how in the user program and

protecting against malware are two essential aspects when

it comes to the system integrity of SINUMERIK.

Know-how protection

Using the SINUMERIK Lock MyCycles function, user cycles

are saved to the control system so that they are protected.

Password-protected SIMATIC STEP 7 program blocks safeguard intellectual property and know-how.

Security

PC-based systems and the control level must be protected

against cyber attacks. Antivirus and whitelisting software

protect against manipulation – preventing malware from

influencing PC-based systems.

Optimizing processes using the digital twin

The digital twin plays a decisive role when it comes to optimizing the widest range of processes while the machine is

operational. With different digital twin variants, a range of

tasks can be shifted from the real world into the virtual

world.

Run MyVirtual Machine, the digital twin for machining,

optimizes the utilization levels of machine tools. Unproductive machine periods are reduced to a minimum and consequentially shifted into production planning. This makes

way for new business models.

www.siemens.com/sinumerik-digitaltwin

25

SINUMERIK | Operation and programming

User-friendly operation

and programming

Operation

A wealth of functions in SINUMERIK Operate ensure a high

degree of operator-friendliness of SINUMERIK controls.

These include state-of-the-art touch and gesture control

as well as working in several panes.

Touch and gesture operation

The SINUMERIK generation of touch panels with projected

capacitive touch technology offers the highest degree of

performance for demanding PC-based visualization tasks.

This comes along with an attractive front panel design. The

scratch-proof, non-reflecting surface with brilliant display

supports operation even in harsh ambient conditions.

Animated Elements

With its Animated Elements, SINUMERIK Operate makes it

very easy to enter parameters. Animated Elements with its

unique moving image sequences makes operation even

more user-friendly.

Display Manager

Using the Display Manager, the display area can be subdivided into three or four panes, allowing large screens to be

effectively used. Customized and flexible machine operation

is facilitated as additional information can be selected and

displayed.

26

Operation and programming | SINUMERIK

Zero points

Integrated measuring cycles ensure high workpiece precision during the machining process. Tool geometries

and work offsets are corrected automatically so that the

required production tolerances are maintained, even for

high batch quantities.

Setting-up

Based on an intelligent JOG mode and intuitive tool

management in SINUMERIK Operate, all of the typical setup

functions can be graphically and interactively supported.

This keeps unproductive times to an absolute minimum.

Measuring

The measurement of tools and workpieces is optimally supported in the intelligent JOG mode: It is sufficient to just

probe an edge, corner or hole to determine the clamping

position, including the basic rotation of the tool – even in

swiveled workpiece planes. The geometry is transferred

into the tool offset memory of the CNC by simply pressing

a button. Logging measurement results is simplified using

standard or user logs.

Tool management

Tool data and magazine location information are clearly

displayed on a screen. Selecting a suitable magazine

location is fully automatic: simply select a tool, press a key

and SINUMERIK CNC does the rest. It goes without saying

that the lifetime of each tool is monitored, and when

required, the appropriate replacement tool is loaded. This

reduces the amount of time required when setting up a

machine tool.

Protection for personnel

The intelligent SINUMERIK Safety Integrated system

functions allow user-friendly operation, with the highest

degree of safety for the operator and the machine itself.

For instance, when setting up the machine with the protective door opened. Users have an integrated F-PLC at their

disposal with SINUMERIK Safety Integrated plus. The safety

relevant logic is programmed in the TIA Portal. When commissioning the SINUMERIK 840D sl, application engineers

can use various innovative functions, for example, the ability to graphically configure safety functions and the transparent diagnostic screen forms. For Safety Integrated and

Safety Integrated plus, once commissioning has been completed, a prompted, partially automated acceptance test

can be performed in SINUMERIK Operate.

27

SINUMERIK | Operation and programming

Programming

SINUMERIK Operate offers the optimum programming for

each and every task: DIN ISO for large series production and

shortest cycle times – as well as graphic programming, so

that individual parts and components can be programmed

even faster.

High-level CNC language

The SINUMERIK high-level language means that the variance

associated with families of parts or special tools can be

simply mastered. The SINUMERIK high-level language

comes into its own precisely where graphic programming,

DIN ISO and cycle programming reach their limits. Quickly

programming workpieces with a wide range of variance

means that the complete range of workpieces can be

flexibly addressed – which is what makes it so unique.

DXF reader

The DXF reader supports the display of the CAD data format

and direct transfer into the CNC program. Programming

times can be slashed by up to 90 percent as the DXF reader

is used to transfer data. DXF files can be directly opened

on the CNC, and transferred to the CNC program with a

simple mouse click. The DXF reader can be called up in the

contour editor, and for positions, can also be called in programGUIDE as well as when programming machining steps

in ShopMill/ShopTurn.

ProgramGUIDE

In programGUIDE, G-code programs can be combined with

powerful SINUMERIK technology and measuring cycles in

a user-friendly fashion. Even classic ISO codes can be programmed. As a result, SINUMERIK is especially attractive

for machine operators who prefer this classic programming

method.

Machining step programming

Machining step programming (ShopMill/ShopTurn) ensures

that demanding and complex parts and components can be

quickly and simply programmed. Using the SINUMERIK contour computer, each contour can be directly entered and

programmed at the machine. This results in maximum productivity when it comes to programming and operating.

Diagnostics

Especially in large series production, machine downtimes

result in enormous production losses. SINUMERIK Operate

offers intelligent diagnostics if problems arise so that

machine operation can be resumed as quickly as possible.

In addition to bus diagnostic tools for drive, peripheral and

network components, there is also a powerful trace function. This is used to trace and troubleshoot NC, PLC and

drive signals

28

“My workpieces?

I can program them

myself.”

Operation and programming | SINUMERIK

29

“My machine? Highly

productive thanks to

the digital twin.”

SINUMERIK | Digitalization

30

Digitalization | SINUMERIK

On track to achieve higher

productivity with CNC Shopfloor

Management Software

Through digitalization, machine builders and companies operating machines

can respond more flexibly to market demands – and at the same time boost

their productivity.

CNC Shopfloor Management Software specifically addresses the requirements

in the machine tool domain. It facilitates the management, analysis and

optimization of machine tools – independent of the manufacturer of the

control system being used.

Digitalization for

machine builders

Higher engineering productivity

There are two main objectives when it comes to

machine construction. On one hand, a higher

degree of efficiency and flexibility in development, e.g. with consequential virtualization in

the development process. On the other hand,

supplementing portfolios to digitalize the customer production environments – all the way up

to new business models.

The digital twin – end-to-end development

and new business models

The closed-loop engineering allows machine

builders to create a seamless workflow from

the original idea through engineering up to

the virtual commissioning of the machine. As

a potential business model, the virtual image

of the machine can be made available to the

company operating the machine for production planning purposes.

www.siemens.com/

machine tool digitalization

Digitalization for

machine users

Higher productivity in production

Machine tools are intelligently integrated into

production processes. The precondition is that

production planning and production – along

with the various machines – are networked

on three different platforms depending on the

specific requirement. This allows programs

and data to be transferred error-free.

The digital twin in production

Programming and setting up operations are

virtually shifted from the real production environment into the office. The machine does not

have to be at a standstill to identify whether

components can be actually machined. CNC

programs can be tested in advance for potential collision of the tool with clamping equipment or machine parts. CNC programs for new

production orders can be run-in "off-line" as

long as the machine is still in productive operation. Further, new operating personal can be

trained without blocking the machine. Unproductive times at the machine are therefore

reduced to a minimum and consequentially

shifted into production planning. This boosts

the productivity and availability of the real

machine.

31

SINUMERIK | Digitalization

CNC Shopfloor Management Software –

ecosystem

A leading-edge IT architecture is created

based on the CNC Shopfloor Management

Software – and more specifically – at three

levels “In Cloud,” “In Line” and “In Machine.”

These levels correspond to the three plat forms – MindSphere, SINUMERIK Integrate

and SINUMERIK Edge with many customized

functions that extend from the field up

into the Cloud.

This is complemented by the opportunity of

creating new business models, in the service

domain, for instance. Leveraging digitalization,

potential for optimization, unknown up until

now can be tapped into so that productivity

and competitiveness can be sustainably

increased.

32

Digitalization | SINUMERIK

Links: Analyze MyMachine /Condition to determine the mechanical condition of the machine tool;

Right: Analyze MyWorkpiece /Toolpath to visualize and analyze workpiece data

MindSphere

Digitalization with cloud-based applications –

optimally networked

Cloud-based applications offer all of the advantages when

working with a common database. Intelligent tools network

design, production planning and machine tools across

various sites and locations to create seamless production

processes with the highest degree of effectiveness. Production and machines are continually analyzed. The captured

data is evaluated, creating a high degree of transparency.

This allows potential for optimization, unknown up until

now, to be identified and fully utilized.

SINUMERIK Edge

Capturing, analyzing and processing high-frequency

data close to the machine

SINUMERIK Edge is a reliable and high-performance

hardware and software solution for machine-related use

(Edge computing). This especially allows high-frequency

process data to be processed and analyzed essentially in

realtime in the field while production is running. Using

customized EdgeApps, processes are monitored and optimized.

SINUMERIK Integrate

Wide-ranging applications to optimize availability

and productivity

However, the advantages of a digital landscape can be

utilized even without a connection to the cloud. The

SINUMERIK Integrate platform hosts a wide range of applications that provide functions adapted to engineering and

production, for example, tool and program management.

33

Mainten-

Spare

Parts

and

Repair

Services

Retrofit

Technical

Support

Service

Contracts

Productivity

Improvement

Upgrade

Services

SINUMERIK | Motion Control Services

Motion Control Services – digitalization of machine

tools and optimization of production landscapes

Digital services – the path to a digital

production environment

Based on the CNC Shopfloor Management Software, Motion

Control Services represents a partial or full digitalization

of the mechanical production workflow. We offer a complete solution from a single source. This extends from the

requirement analysis and the resulting concept through

installation up to implementation of optimization measures

and ensuring continuous system availability.

Consulting

Analysis and development of a digitalization strategy

tailored to address specific customer requirements within

the scope of professional consulting services.

Digitalization check as a service

This local service provides concrete recommendations

when it comes to networking machines in production

IT systems. Machine data are continuously captured and

evaluated in a standardized way while the machines

remain operational.

Digitalization preparation

Machine tools are updated to represent state-of-the-art

technology and made ready for digitalization. Irrespective

of whether greenfield or brownfield systems, using Brownfield Connectivity Services, software updates, hardware

upgrades or retrofits, machine fleets are made fit for digitalization.

Implementation

Specialists from Motion Control Services support you when

configuring and commissioning the various software

modules. This makes your production more efficient, more

profitable and increases your security of investment. Training programs ensure that your personnel know how to use

the application.

Data & Process Analysis

Data & Process

Analysis

Optimization

Implementation

Pre

paration

Digitalization

Consulting

Check

Optimization

Optimization measures are implemented to fully leverage

the potential of machine fleets. In addition to productivity

boosting measures, this also involves increasing the availability and leveraging cost-saving potential.

Maintenance

This service ensures that IT systems remain operational, to

secure operating time as well as resolve faults in the case

of non-scheduled downtimes.

ance

Individual measures and activities to optimize production

are derived based on captured and analyzed data.

34

Productivity

Improvement

Motion Control Services | SINUMERIK

Motion Control Services provide support to dealers or machine operators over

the complete lifecycle of production systems – for drives, motors, or controls.

The emphasis is on increasing transparency so that all types of resources and

machines can be used more efficiently, productively and flexibly – and of course

to increase machine availability.

Technical Support

Competent hotline experts answer every question related

to SINUMERIK – in your time zone and in your language.

Spare Parts & Repair Services

Upgrade

Services

A closely meshed, flexible spare parts and repair service

network ensures that spare parts are quickly available at

reasonable prices at over 150 service locations around the

globe. Not only this, for selected components, the Long

Life Repair option can extend service availability for up to

25 years.

Spare

Parts

and

Repair

Services

Technical

Support

Retrofit

Classic services – the basis for continuous

improvement

Service Contracts

Harmonized and aligned to specific requirements and business

objectives, our service contracts are modular and allow companies operating machines to create a customized service concept to reduce their machine downtimes. Here, customers can

integrate digital service options. These include remote access

and the use of service applications to achieve an even better

machine availability.

Upgrade Services

Component upgrades extend system and machine usage

times to secure investments over the long term.

Productivity Improvement

Especially when it comes to machine tools that are used

intensively with high utilization levels, fully leveraging the

machine capacity to its maximum has significant economic

benefits. With Productivity Improvement we optimize the

production potential for machine tools equipped with

SINUMERIK 840D sl or SINUMERIK 840D pl.

Retrofit

A CNC retrofit is the cost-effective alternative when compared to purchasing a new machine. This is the case if the

mechanical system of a machine tool is still in a good condition – however, the control or drive system no longer

represents state-of-the-art technology. As part of this

service, we upgrade specific components to reflect latest

state-of-the-art technology. Cycle times can be significantly reduced and quality optimized by just upgrading

the control system.

www.siemens.com/motioncontrolservices

35

More about SINUMERIK CNCs can be

found at:

siemens.com/sinumerik

Published by

Siemens AG 2019

Digital Industries

Motion Control

P.O. Box 31 80

91050 Erlangen

Germany

For the U.S. published by

Siemens Industry Inc.

100 Technology Drive

Alpharetta, GA 30005

United States

Article No. DFMC-B10020-01-7600

Printed in Germany

Dispo 06311

S&R/1000014988 WS 11192.0

Subject to change without prior notice.

The information provided in this brochure contains merely general

descriptions or characteristics of performance which in case of actual

use do not always apply as described or which may change as a result

of further development of the products. An obligation to provide the

respective characteristics shall only exist if expressly agreed in the

terms of contract.

All product designations may be trademarks or product names of

Siemens AG or supplier companies whose use by third parties for

their own purposes could violate the rights of the owners.

To secure plants, systems and machines as well as networks against

cyber attacks, a holistic industrial security concept must be implemented

(and continuously updated) corresponding to current state-of-the-art

technology. Products and solutions from Siemens are just one component

of such a concept. You can find additional information about industrial

security at siemens.com/industrialsecurity.

Loading...

Loading...