Page 1

Measuring cycles

_

_

_

_

_

_

_

_

_

_

_

_

SINUMERIK

SINUMERIK 840D sl / 828D

Measuring cycles

Programming Manual

_________________

Preface

_________________

Description

_________________

Measuring variants

_________________

Parameter lists

Changes from cycle version

_________________

SW4.4 and higher

_________________

Appendix

1

2

3

A

B

Valid for:

SINUMERIK 840D sl / 840DE sl / 828D controls

Software CNC software, Version 2.7 SINUMERIK

Operate for PCU/PC Version 2.7

02/2011

6FC5398-4BP40-0BA0

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5398-4BP40-0BA0

Ⓟ 05/2011

Copyright © Siemens AG 2011.

Technical data subject to change

Page 3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific

machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

● www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

● www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

3

Page 4

Preface

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Target group

This programming manual is intended for machine tool programmers for the SINUMERIK

Operate software.

Benefits

With the programming manual, the target group can develop, write, test, and debug

programs and software user interfaces.

Standard scope

This documentation only describes the functionality of the standard version. Additions or

revisions made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

For the sake of simplicity, this documentation does not contain all detailed information about

all types of the product and cannot cover every conceivable case of installation, operation, or

maintenance.

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

Measuring cycles

4 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 5

Table of contents

Preface ...................................................................................................................................................... 3

1 Description................................................................................................................................................. 9

1.1 Basics.............................................................................................................................................9

1.2 General prerequi

1.3 Behavior on block search, dry run, prog

1.4 Reference points on the machine and workpiece........................................................................13

1.5 Definition of the planes, tool types ...............................................................................................15

1.6 Probes that can be used ..............................................................................................................18

1.7 Probe, calibration body, calibration tool

1.7.1 Measuring workpieces on milling machi

1.7.2 Measuring tools on milling machines, machining centers ...........................................................23

1.7.3 Measuring workpieces at the turning mac

1.7.4 Measuring tools at lathes .............................................................................................................28

1.8 Measurement princ

1.9 Measuring strategy for measuring workpi

1.10 Parameters for checking the meas

1.11 Effect of empirical value, mean value, an

1.12 Measuring cycle help programs

1.12.1 CYCLE116: Calculation of center point and radius of a circle.....................................................44

1.12.2 CUST_MEACYC: User program before/after measurements are performed

1.13 Miscellaneous functions...............................................................................................................46

1.13.1 Measuring cycle support in the program

1.13.2 Measuring result screens.............................................................................................................47

sites...................................................................................................................11

ram testing, simulation..................................................12

.......................................................................................22

nes, machining centers.................................................22

hines...........................................................................25

iple.................................................................................................................30

eces with tool offset....................................................35

urement result and offset ......................................................38

d tolerance parameters...............................................43

...................................................................................................44

..............................46

editor............................................................................46

2 Measuring v

2.1 General requirements

2.1.1 Overview of the measuring cycles ...............................................................................................49

2.1.2 Selection of the measuring variants

2.1.3 Selection of the measuring variants

2.1.4 Result parameters........................................................................................................................55

2.2 Measure workpiece (turning) .......................................................................................................56

2.2.1 General information .....................................................................................................................56

2.2.2 Calibrate probe - length

2.2.3 Calibrate probe - radius on s

2.2.4 Calibrate probe - c

2.2.5 Turning measurement - front edge (CYCLE974)

2.2.6 Turning measurement - inside diameter (CYCLE

2.2.7 Turning measurement - outside diameter (CYCLE974,

2.2.8 Extended measurement

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

ariants .................................................................................................................................. 49

..................................................................................................................49

via softkeys (turning) ..........................................................51

via softkeys (milling) ...........................................................53

(CYCLE973)..........................................................................................57

urface (CYCLE973)........................................................................60

alibrate in groove (CYCLE973) ......................................................................63

.........................................................................67

974, CYCLE994) ............................................71

CYCLE994) ..........................................76

...............................................................................................................81

5

Page 6

Table of contents

2.3 Measure workpiece (milling) ....................................................................................................... 83

2.3.1 Calibrate probe - length

2.3.2 Calibrate probe - radius in ring (CYCLE

2.3.3 Calibrate probe - radius on edge (CYCLE976)

2.3.4 Calibrate probe - c

2.3.5 Edge distance - set edge (CYCLE

2.3.6 Edge distance - align edge (CYCLE998)

2.3.7 Edge distance - groove (CYCLE977)

2.3.8 Edge distance - rib (CYCLE977)

2.3.9 Corner - right-angled corner (CY

2.3.10 Corner - any corner (CY

(CYCLE976) ......................................................................................... 83

976) .............................................................................. 86

........................................................................... 90

alibrate on ball (CYCLE976).......................................................................... 93

978)....................................................................................... 96

.................................................................................. 100

........................................................................................ 106

............................................................................................... 110

CLE961) ................................................................................ 114

CLE961) ............................................................................................. 118

2.3.11 Hole - rectangular pocket (CYCLE977) .................................................................................... 122

2.3.12 Hole - 1 hole (CY

2.3.13 Hole - inner circle s

2.3.14 Spigot - rectangular spi

2.3.15 Spigot - 1 circular spigot (CYCLE977)

2.3.16 Spigot - outer circle s

2.3.17 3D - align plane (CY

2.3.18 3D - sphere (CYCLE

2.3.19 3D - 3 spheres (CYCLE997)

2.3.20 3D - kinematic

CLE977) ........................................................................................................ 126

egment (CYCLE979).................................................................................. 130

got (CYCLE977)................................................................................... 134

...................................................................................... 138

egment (CYCLE979)............................................................................... 142

CLE998) ................................................................................................... 146

997).......................................................................................................... 150

..................................................................................................... 154

s (CYCLE996).................................................................................................... 159

2.4 Measure tool (turning)

............................................................................................................... 175

2.4.1 General information................................................................................................................... 175

2.4.2 Calibrate probe (CY

2.4.3 Turning tool (CYCLE

CLE982) .................................................................................................... 178

982).......................................................................................................... 182

2.4.4 Milling tool (CYCLE982)............................................................................................................ 186

2.4.5 Drill (CYCLE

2.4.6 Measure tool with toolholder that c

2.5 Measure tool (milling)

982)....................................................................................................................... 193

an be orientated ................................................................. 198

................................................................................................................ 200

2.5.1 General information................................................................................................................... 200

2.5.2 Calibrate probe (CY

2.5.3 Measure tool (CY

3 Parameter

lists....................................................................................................................................... 215

3.1 Overview of measuring cyc

3.1.1 CYCLE973 measuring cycl

3.1.2 CYCLE974 measuring cycl

3.1.3 CYCLE994 measuring cycl

3.1.4 CYCLE976 measuring cycl

3.1.5 CYCLE978 measuring cycl

3.1.6 CYCLE998 measuring cycl

3.1.7 CYCLE977 measuring cycl

3.1.8 CYCLE961 measuring cycl

3.1.9 CYCLE979 measuring cycl

3.1.10 CYCLE997 measuring cycl

3.1.11 CYCLE996 measuring cycl

3.1.12 CYCLE982 measuring cycl

3.1.13 CYCLE971 measuring cycl

CLE971) .................................................................................................... 202

CLE971)........................................................................................................ 208

le parameters................................................................................. 215

e parameters.................................................................................. 215

e parameters.................................................................................. 218

e parameters.................................................................................. 221

e parameters.................................................................................. 224

e parameters.................................................................................. 226

e parameters.................................................................................. 229

e parameters.................................................................................. 232

e parameters.................................................................................. 235

e parameters.................................................................................. 238

e parameters.................................................................................. 241

e parameters.................................................................................. 244

e parameters.................................................................................. 247

e parameters.................................................................................. 250

3.2 Additional parameters

3.3 Additional result param

Measuring cycles

............................................................................................................... 253

eters ..................................................................................................... 255

6 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 7

Table of contents

3.4 Parameter ..................................................................................................................................256

A Changes from cycle versi

A.1 Assignment of the measuring cycle para

A.2 Changes in the machine and s

A.3 Complete overview of the changed cycl

A.4 Comparing GUD parameters

A.5 GUD variables that can no longer be used

A.6 Changes to names of cycle program

on SW4.4 and higher ..................................................................................... 257

meters to MEA_FUNCTION_MASK parameters.......257

etting data from SW 4.4 ............................................................260

e machine and cycle setting data ...............................261

(regarding measuring functions).................................................263

................................................................................267

s and GUD modules ........................................................269

B Appendix................................................................................................................................................ 271

B.1 Abbreviations .............................................................................................................................271

B.2 Documentation overview............................................................................................................272

Glossary ................................................................................................................................................ 273

Index...................................................................................................................................................... 279

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

7

Page 8

Table of contents

Measuring cycles

8 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 9

Description

1.1 Basics

General information

Measuring cycles are general subroutines designed to solve specific measurement tasks.

They can be adapted to specific problems via parameter settings.

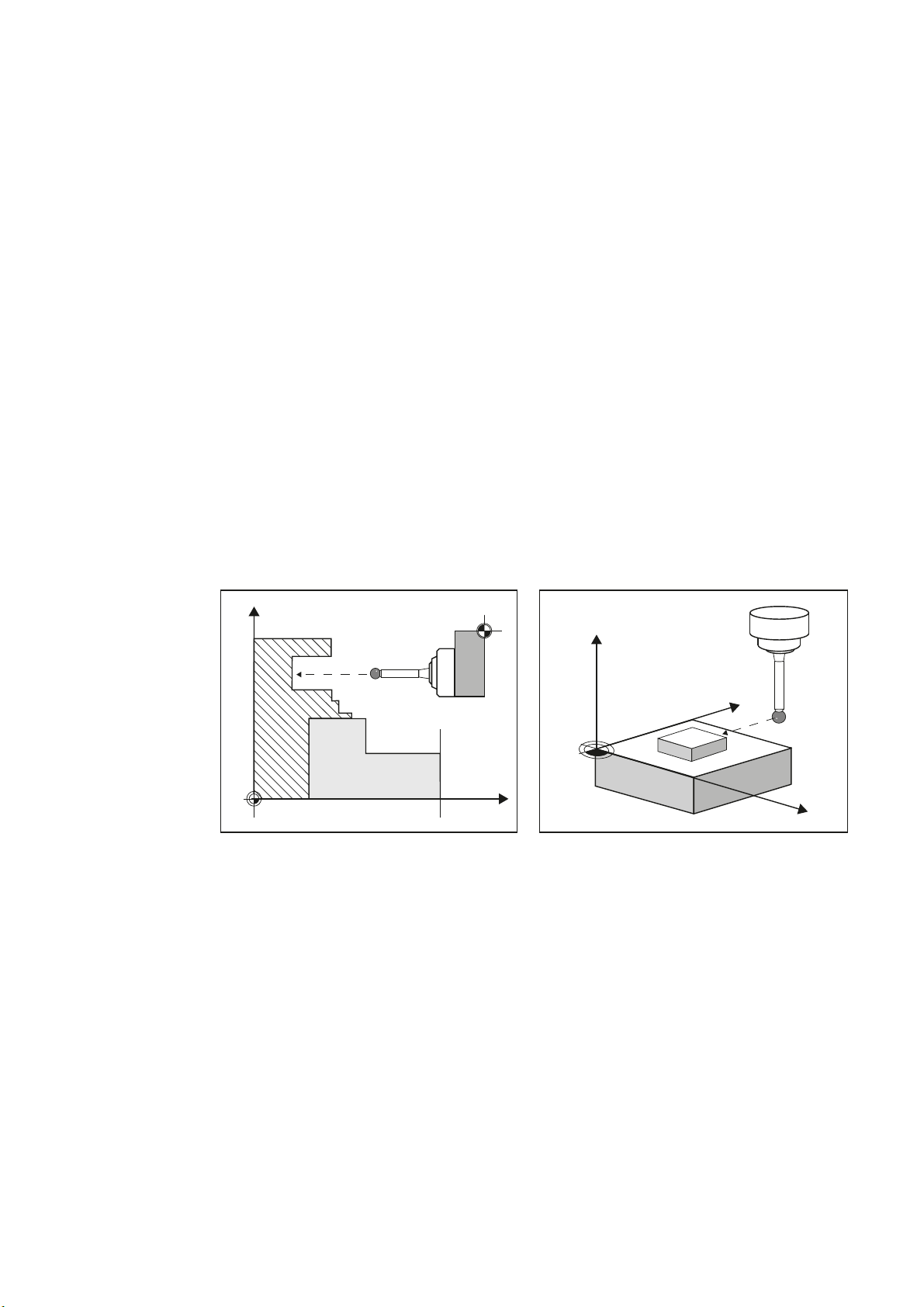

When taking general measurements, a distinction is made between

● Tool measurement and

● Workpiece measurement.

Workpiece measurement

;

1

)

=

<

:

:

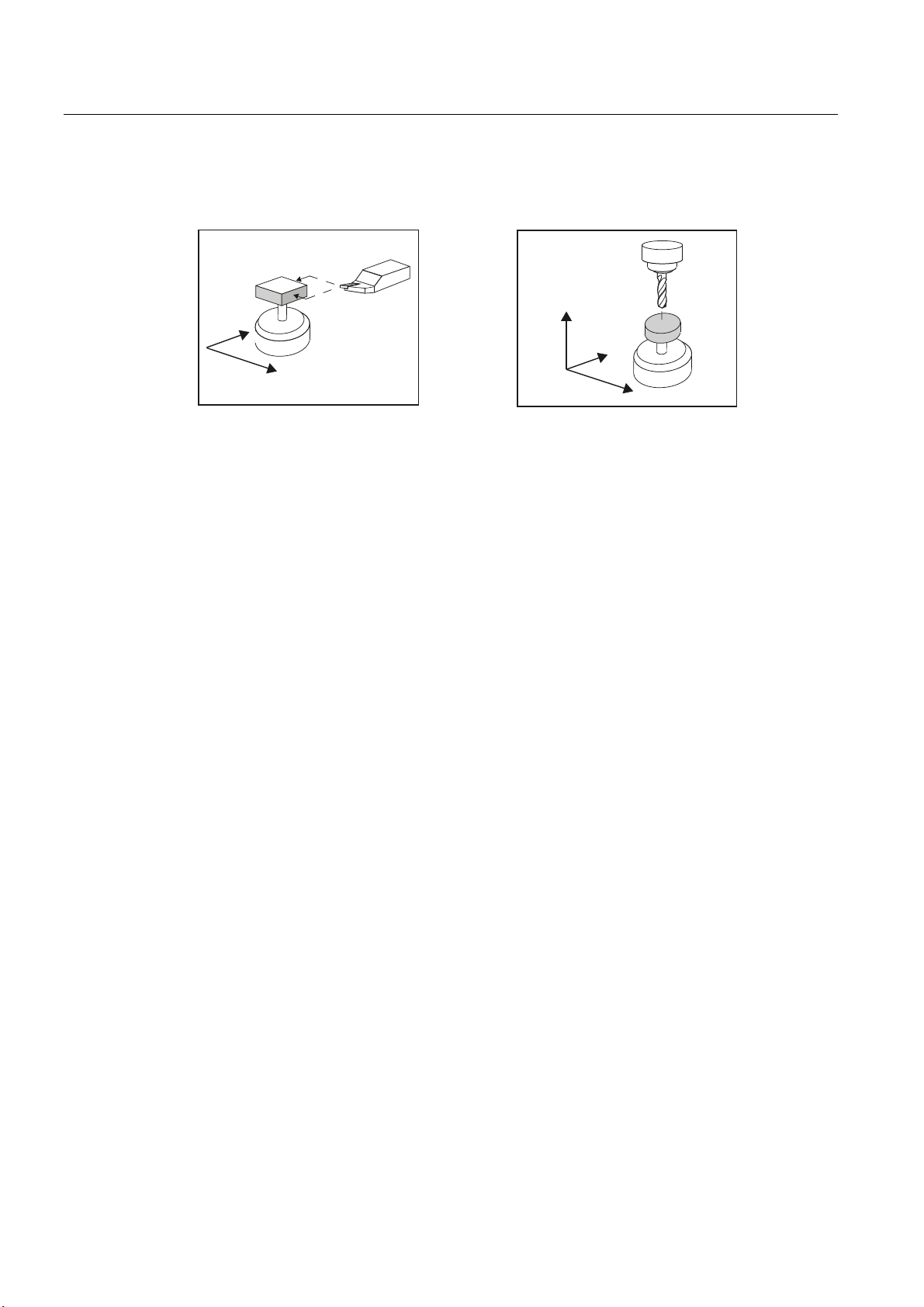

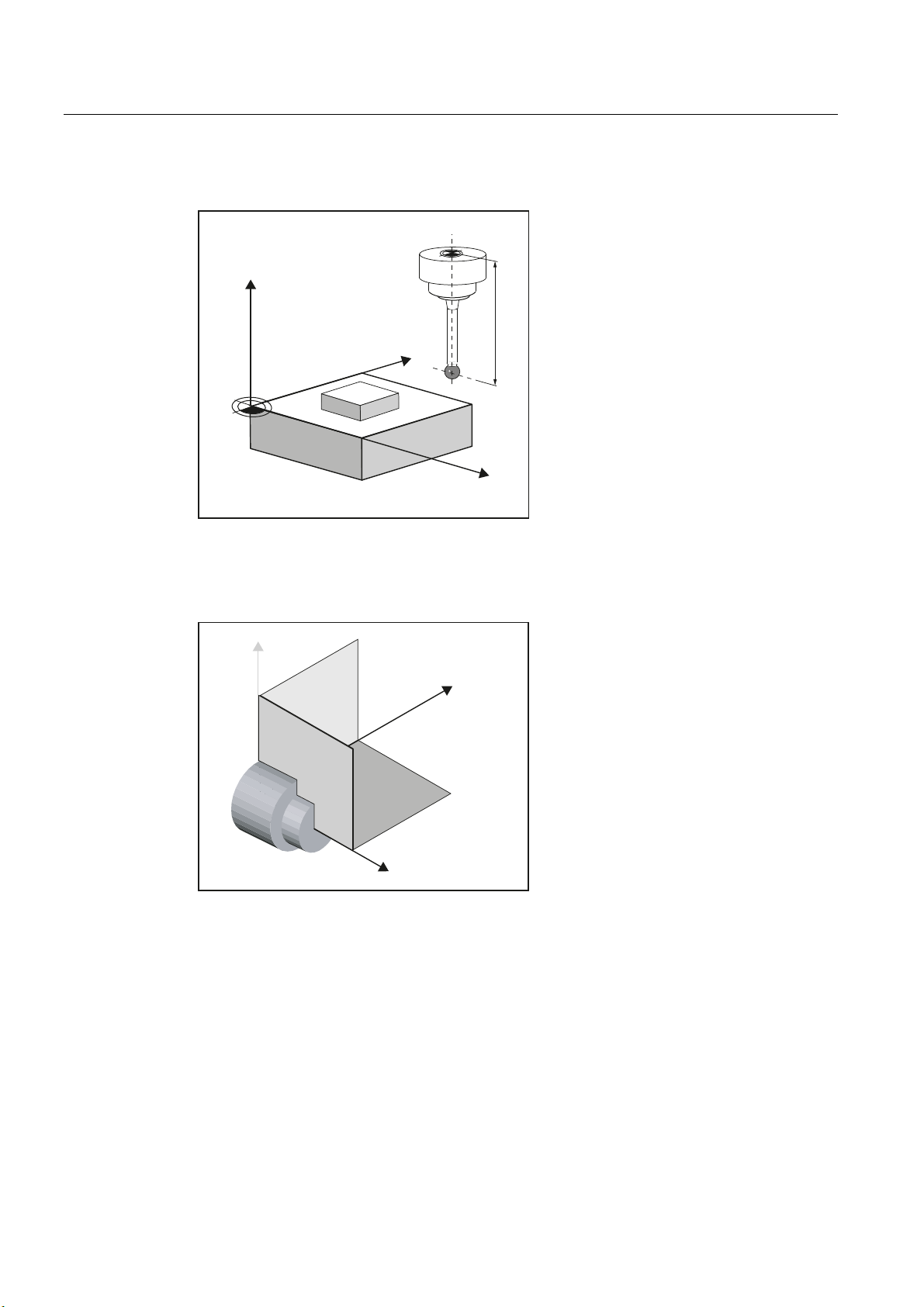

Workpiece measurement, turning example

In workpiece measurement, a probe is moved up to the clamped workpiece in the same way

as a tool and the measured values are acquired. The flexibility of measuring cycles makes it

possible to perform nearly all measurements required on a milling or turning machine.

The result of the workpiece measurement can be optionally used as follows:

● Compensation in the work offset

● Automatic tool offset

● Measurement without offset

=

Workpiece measurement, milling example

;

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

9

Page 10

Description

1.1 Basics

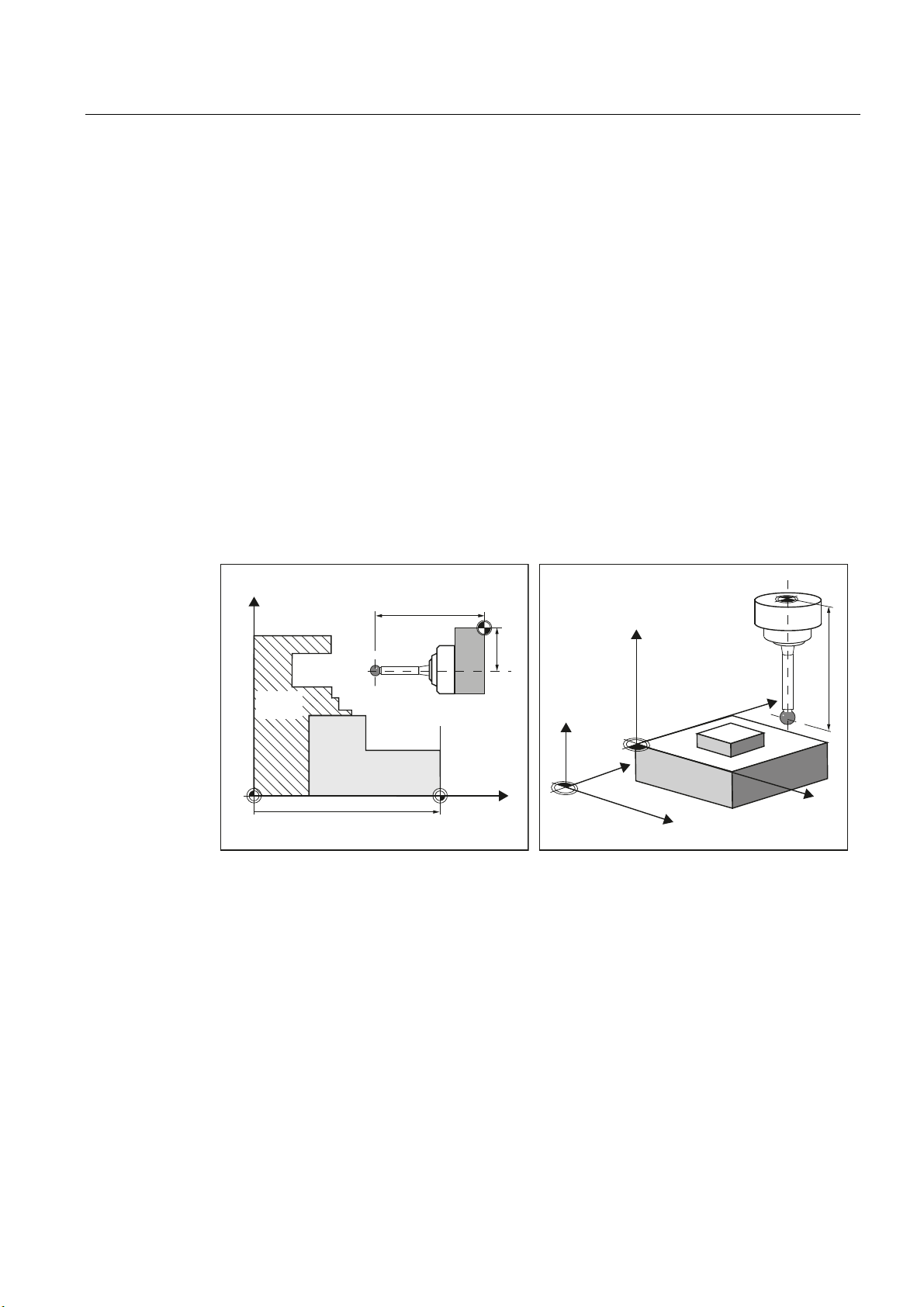

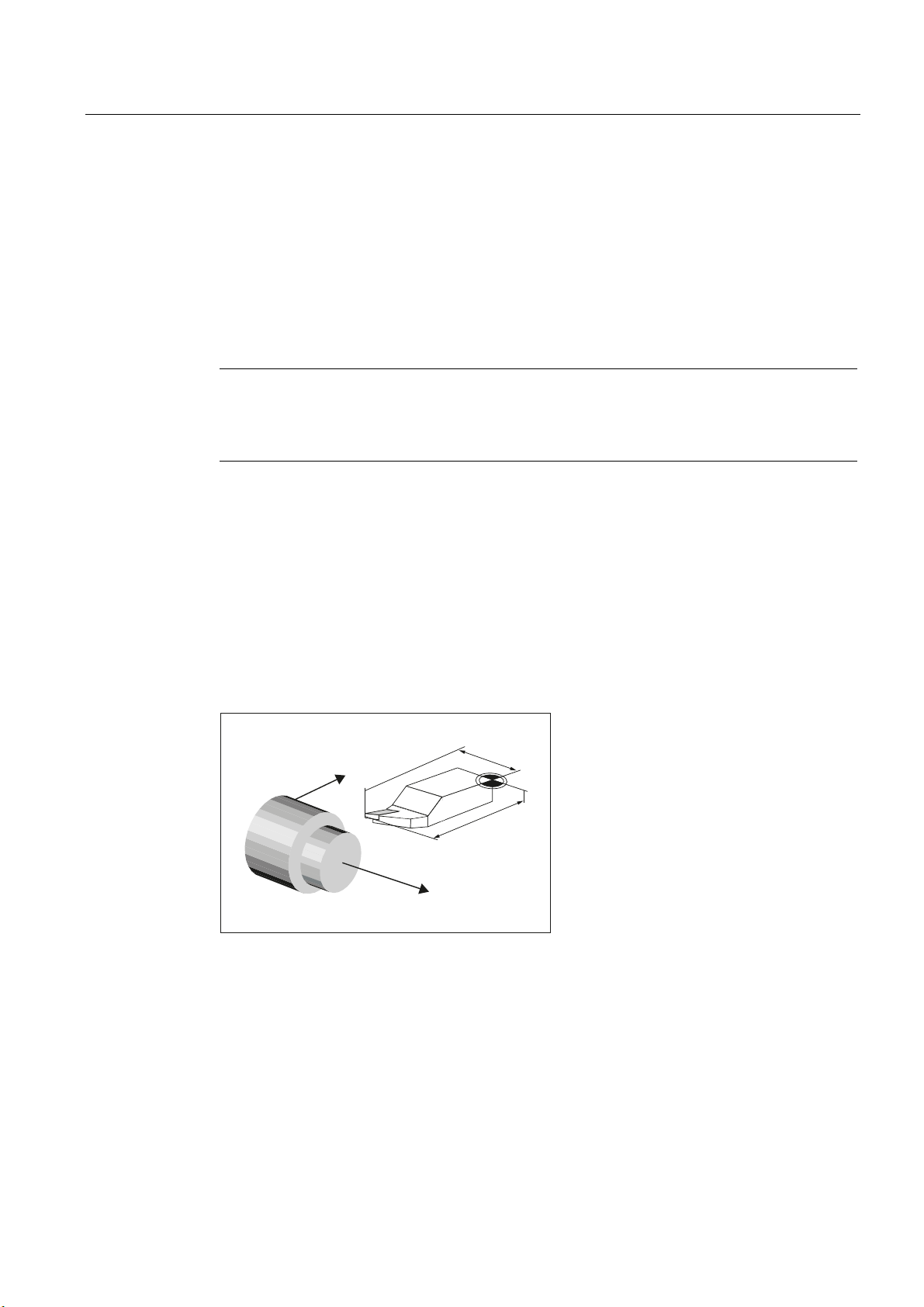

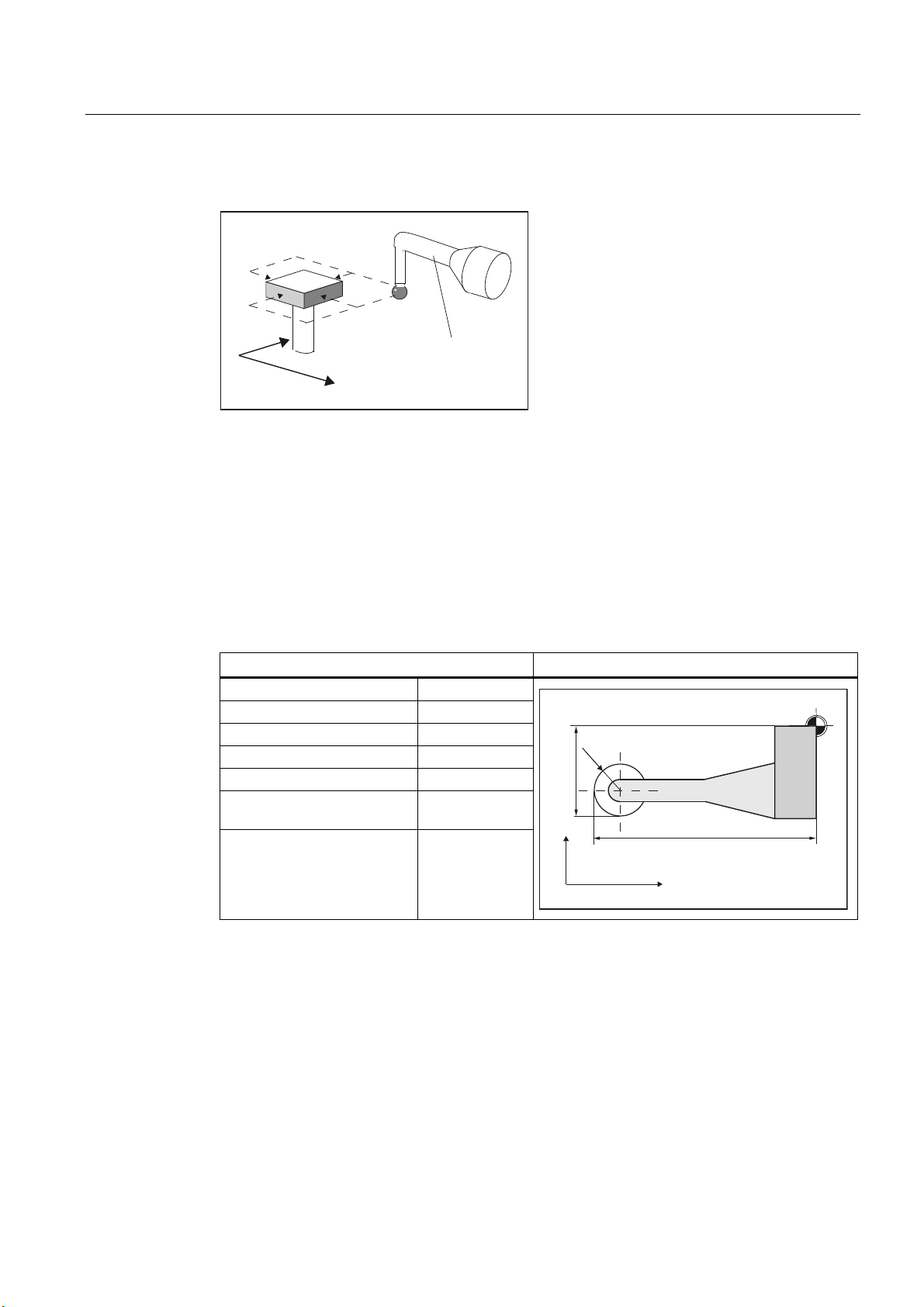

Tool measurement

;

=

Tool measurement, turning tool example

=

<

;

Tool measurement, drill example

In tool measurement, the selected tool is moved up to the probe and the measured values

are acquired. The probe is either in a fixed position or is swung into the working area with a

mechanism. The tool geometry measured is entered in the appropriate tool offset data set.

Measuring cycles

10 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 11

Description

1.2 General prerequisites

1.2 General prerequisites

Certain preconditions must be met before measuring cycles can be used. These are

described in detail in the

Check the preconditions using the following checklist:

● Machine

– All machine axes are designed in accordance with DIN 66217.

– Machine data has been adapted.

● Starting position

– The reference points have been approached.

– The starting position can be reached by linear interpolation without collision.

● Display functions of the measuring cycles

A HMI/PCU or HMI/TCU is required for showing the measuring result displays and for

measuring cycle support.

● Please observe the following when programming:

SINUMERIK 840D sl Base Software and Operating Software

.

References

– Tool radius compensation is deselected before it is called (G40).

– The cycle is called no later than at the 5th program level.

– The measurement is also possible in a system of units that differs from the basic

system (with technology data that has been switched over).

For metric dimension system with active G70, G700.

For inch dimension system with active G71, G710.

Supplementary information for this documentation is provided in the following manuals:

● Commissioning Manual

– /IM9/ SINUMERIK Operate

● /PG/, Programming Manual

● /FB1/, Function Manual

● /FB2/, Function Manual

● /FB3/, Function Manual

SINUMERIK 840D sl Base Software and Operating Software

SINUMERIK 840D sl / 828D Fundamentals

Basic Functions

Expanded Functions

Special Functions

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

11

Page 12

Description

1.3 Behavior on block search, dry run, program testing, simulation

1.3 Behavior on block search, dry run, program testing, simulation

Function

The measuring cycles are skipped during execution if one of the following execution modes

is active:

"Trial run"

($P_DRYRUN=1)

Simulation

"Program test"

"Block search"

The simulation of the measuring cycles is realized in the user interface (HMI) in the "Program

Editor" area.

Following settings are possible in the channel-specific setting data SD 55618:

● SD 55618 $SCS_MEA_SIM_ENABLE = 0

The measuring cycle is skipped, the HMI simulation shows no path motion of the probe.

● SD 55618 $SCS_MEA_SIM_ENABLE = 1

The measuring cycle is executed, the HMI simulation shows the corresponding path

motion of the probe.

No measurements, tool or work offsets are made.

Actived functions such as "measuring result display" or "travel with collision monitoring"

are not implemented.

($P_ISTEST=1)

($P_SEARCH=1), only if $A_PROTO=0.

Measuring cycles

12 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 13

Description

1.4 Reference points on the machine and workpiece

1.4 Reference points on the machine and workpiece

General information

Depending on the measuring task, measured values may be required in the machine

coordinate system (MCS) or in the workpiece coordinate system (WCS).

For example: It may be easier to ascertain the tool length in the machine coordinate system.

Workpiece dimensions are measured in the workpiece coordinate system.

Where:

● M = machine zero in the machine coordinate system

● W = workpiece zero in the workpiece coordinate system

● F = Tool reference point

Reference points

;

0

6SLQGOH

FKXFN

:RUNSLHFH

:2LQ=

/

)

/

;

:

==

=

0

=

<

:

<

;

)

/

;

The position of tool reference point F in the machine coordinate system is defined with

machine zero M as the machine actual value.

The position of the tip/cutting edge of the active tool in the workpiece coordinate system is

displayed with the workpiece zero W as workpiece actual value. For a workpiece probe, the

center or the end of the probe ball can be defined as the tool tip.

The work offset (WO) characterizes the position of the workpiece zero W in the machine

coordinate system.

Work offsets (WO) comprise the components offset, rotation, mirroring and scaling factor

(only the global basis work offset does not contain any rotation).

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

13

Page 14

Description

1.4 Reference points on the machine and workpiece

A distinction is made between the basis, work offset (G54 ... G599) and programmable work

offset. The basic area contains further subsections – such as the basic work offset, channelspecific basic work offset and configuration-dependent work offsets (e.g. rotary table

reference or basic reference).

The specified work offsets are effective together as chain and result in the workpiece

coordinate system.

Note

Scale factors with a scaling value unequal to "1" are not supported by the measuring cycles!

Mirroring functions are only permitted in conjunction with counterspindles on lathes.

The machine and workpiece coordinate system can be set and programmed separately in

the "inch" or "metric" system of units (G70/G71).

Note

Transformation

Measure workpiece

Workpiece measurements are always performed in the workpiece coordinate system. All

descriptions relating to workpiece measurement refer to it!

Measure tool

When measuring tools with kinematic transformation active, a distinction is made

between basic coordinate system and machine coordinate system.

If kinematic transformation is deactivated, this distinction is made.

All subsequent descriptions relating to tool measurement assume that kinematic

transformation is disabled and therefore refer to the machine coordinate system.

Measuring cycles

14 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 15

Description

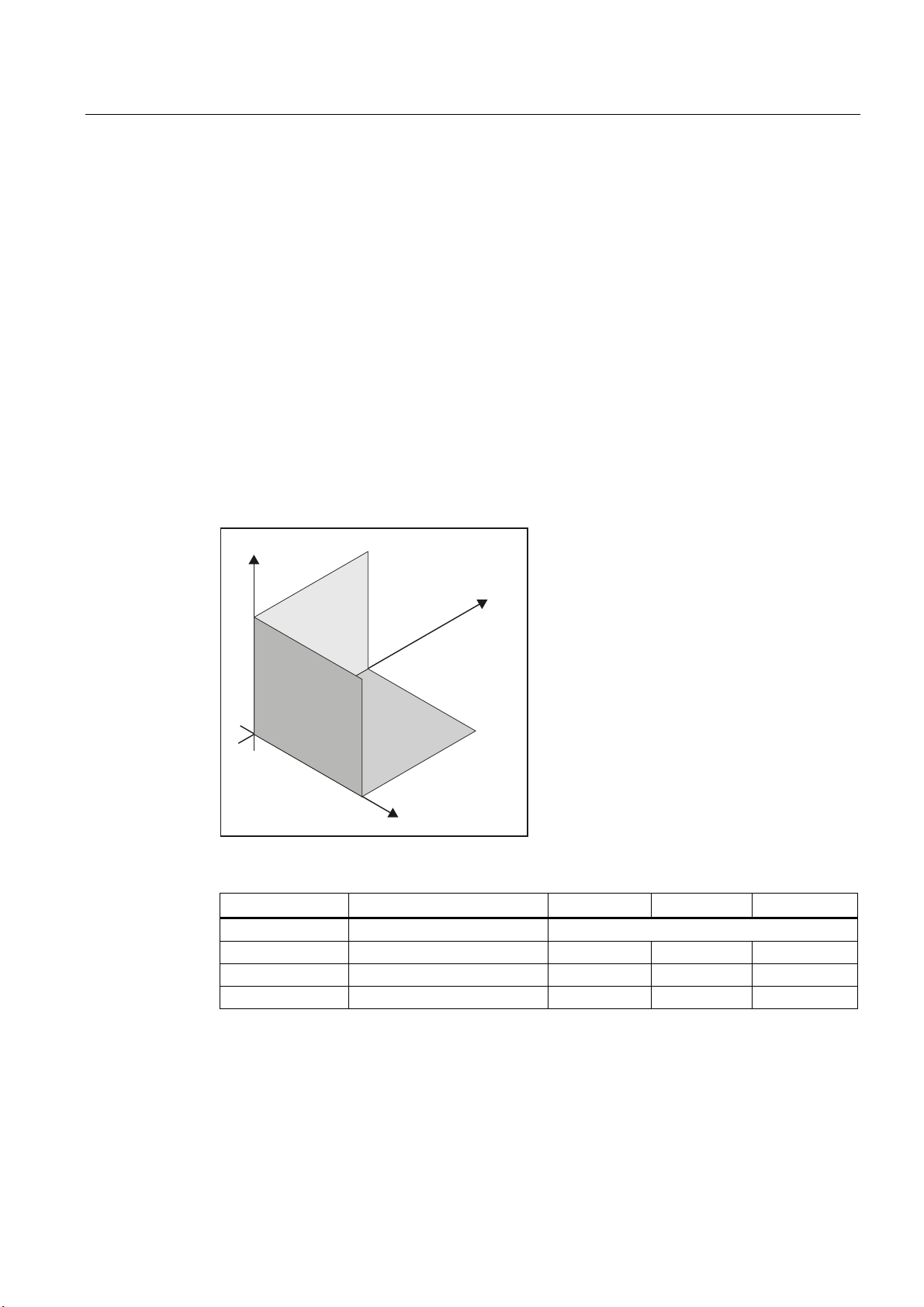

1.5 Definition of the planes, tool types

1.5 Definition of the planes, tool types

When measuring under milling, machining planes G17, G18 or G19 can be selected.

When measuring under turning, machining plane G18 must be selected.

For tool measurement, the following tool types are permitted:

● Milling, type 1..

● Drill, type 2 ...

● Turning tools, type 5 ...

Depending on the tool type, the tool lengths are assigned to the axes as follows:

● Workpiece probe, milling: Probe types 710, 712, 713, 714

● Workpiece probe, turning: Probe type, 580

Milling

=

*

<

*

*

;

Acts in ... G17 plane G18 plane G19 plane

Tool type: 1xy / 2xy / 710

Length 1 1. Axis of the plane: Z Y X

Length 2 2. Axis of the plane: Y X Z

Length 3 3. Axis of the plane: X Z Y

Lengths 2 and 3 are used in special cases, for example, if an angle head is attached.

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

15

Page 16

Description

1.5 Definition of the planes, tool types

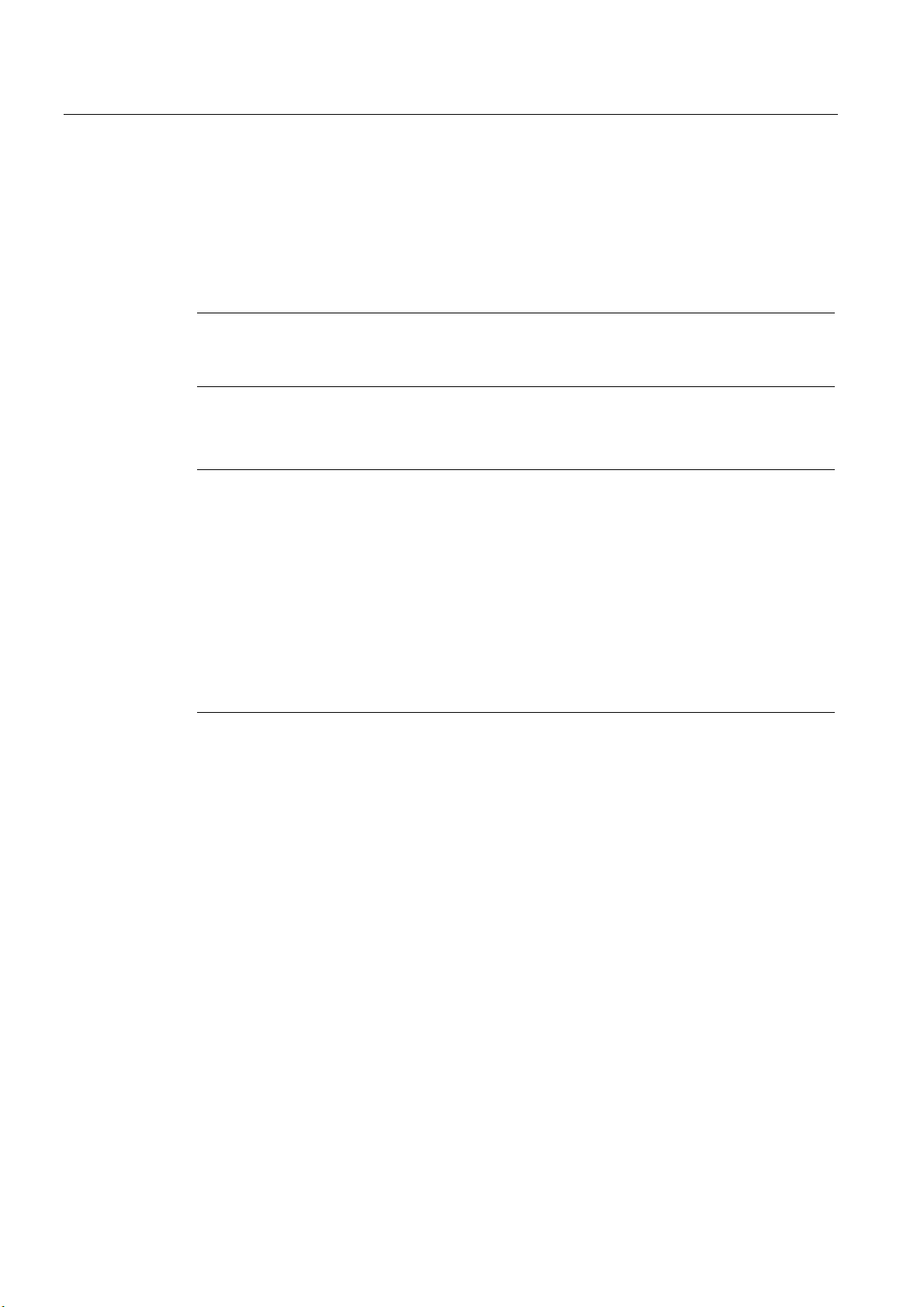

Example of plane definition for milling

)

=

Turning

<

/

:

;

Figure 1-1 Example: Milling machine with G17

<

;

*

=

Turning machines generally only use axes Z and X and therefore:

G18 plane

Tool type 5xy (turning tool, workpiece probe)

Length 1 Acts in X (2nd axis of the plane)

Length 2 Acts in Z (1st axis of the plane)

Measuring cycles

16 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 17

Description

1.5 Definition of the planes, tool types

G17 and G19 are used for milling on a turning machine. If there is no machine axis Y, milling

can be implemented with the following kinematic transformations.

● TRANSMIT

● TRACYL

In principle, measuring cycles support kinematic transformations. This is stated more clearly

in the individual cycles, measuring variants. Information about kinematic transformation can

be found in the Programming Manual

SINUMERIK 840D sl / 828D Fundamentals

or in the

documentation of the machine manufacturer.

Note

If a drill or milling cutter is measured on a lathe, in most cases, the channel-specific SD

42950 $SC_TOOL_LENGTH_TYPE = 2 is set: These tools are then length-compensated like

a turning tool.

SINUMERIK controls have other machine and setting data that can influence calculation of a

tool.

References:

● /FB1/, Function Manual

● /FB2/, Function Manual

● /FB3/, Function Manual

Example of plane definition for turning

;

Figure 1-2 Example: Lathe with G18

Basic Functions

Expanded Functions

Special Functions

/

)

/

=

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

17

Page 18

Description

1.6 Probes that can be used

1.6 Probes that can be used

General information

To measure tool and workpiece dimensions, an electronic touch-trigger probe is required

that provides a signal change (edge) when deflected with the required repeat accuracy.

The probe must operate virtually bounce-free.

Different types of probe are offered by different manufacturers.

Note

Please observe the information provided by the manufacturers of electronic probes and/or

the machine manufacturer's instructions on the following points:

Electrical connection

Mechanical calibration of the probe

If a workpiece probe is used, both the direction of deflection and transmission of

switching signal to the machine column (radio, infrared light or cable) must be taken into

account. In some versions, transmission is only possible in particular spindle positions or

in particular ranges. This can restrict the use of the probe.

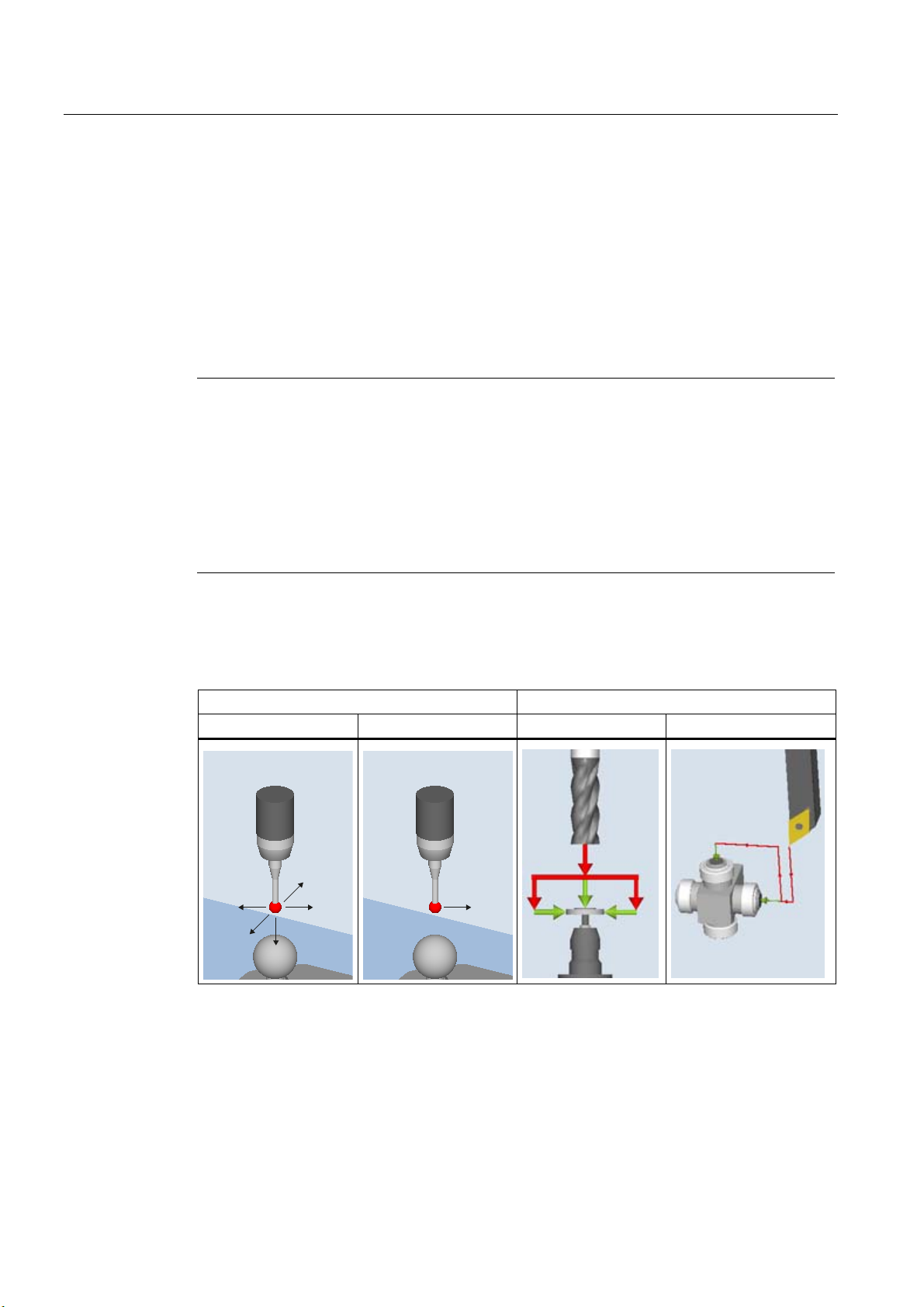

Probes are distinguished according to the number of measuring directions.

● Multi-directional (multi probe)

● Mono directional (mono probe)

Workpiece probe Tool probe

Multi-directional (3D) Monodirectional Milling machines Lathes

<

; ;

<

=

The probes also differ in the form of the stylus tip:

the measuring cycles support pin, L and star probes as autonomous tool types. The use of

the probe types is referenced in the individual measuring cycles. The multi probe is

universally applicable.

The use of probes requires a spindle that can be positioned. For a mono probe, the

switching direction is tracked for each measurement by turning the spindle. This can lead to

a longer program runtime.

Measuring cycles

18 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 19

Description

1.6 Probes that can be used

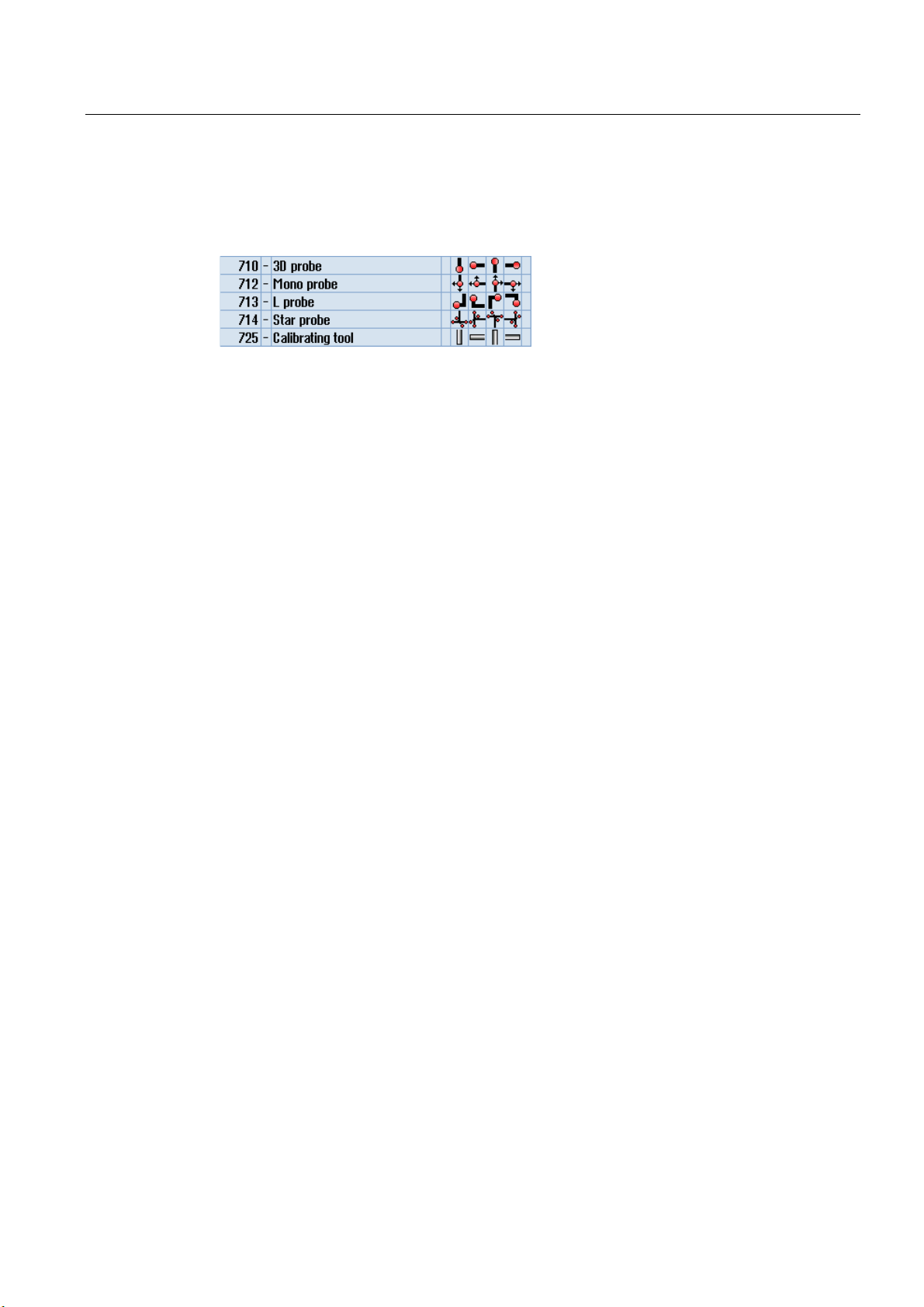

Workpiece probe types

The following probe types are provided in the tool management for measuring with

workpiece probes:

Figure 1-3 Probe types in the tool management

There is a calibration tool to calibrate tool probes (type 725) = cylindrical pin

Tool data from probes

The probes differ as a result of the tool type and the switching directions in tool parameter

$TC_DP25[ ] bit16 to bit 25. The switching directions are permanently coded when creating

the tool.

In the application, the probe can encompass several of the following tool types. In this case,

several cutting edges should be created for the probe (D1, D2, etc. ).

Example: Multi probe with a boom

D1 3D_PROBE Type 710

D2 L_PROBE Type 713

The user must take into account the geometry of the probe when pre-positioning. To do this,

you can read out individual tool data in the user program:

Example:

IF (($P_TOOLNO>0) AND ($P_TOOL>0))

R1= ($P_AD[6] ;Read tool radius of the actual tool

ENDIF

The probe is aligned in the + X direction using parameter offset angle.

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

19

Page 20

Description

1.6 Probes that can be used

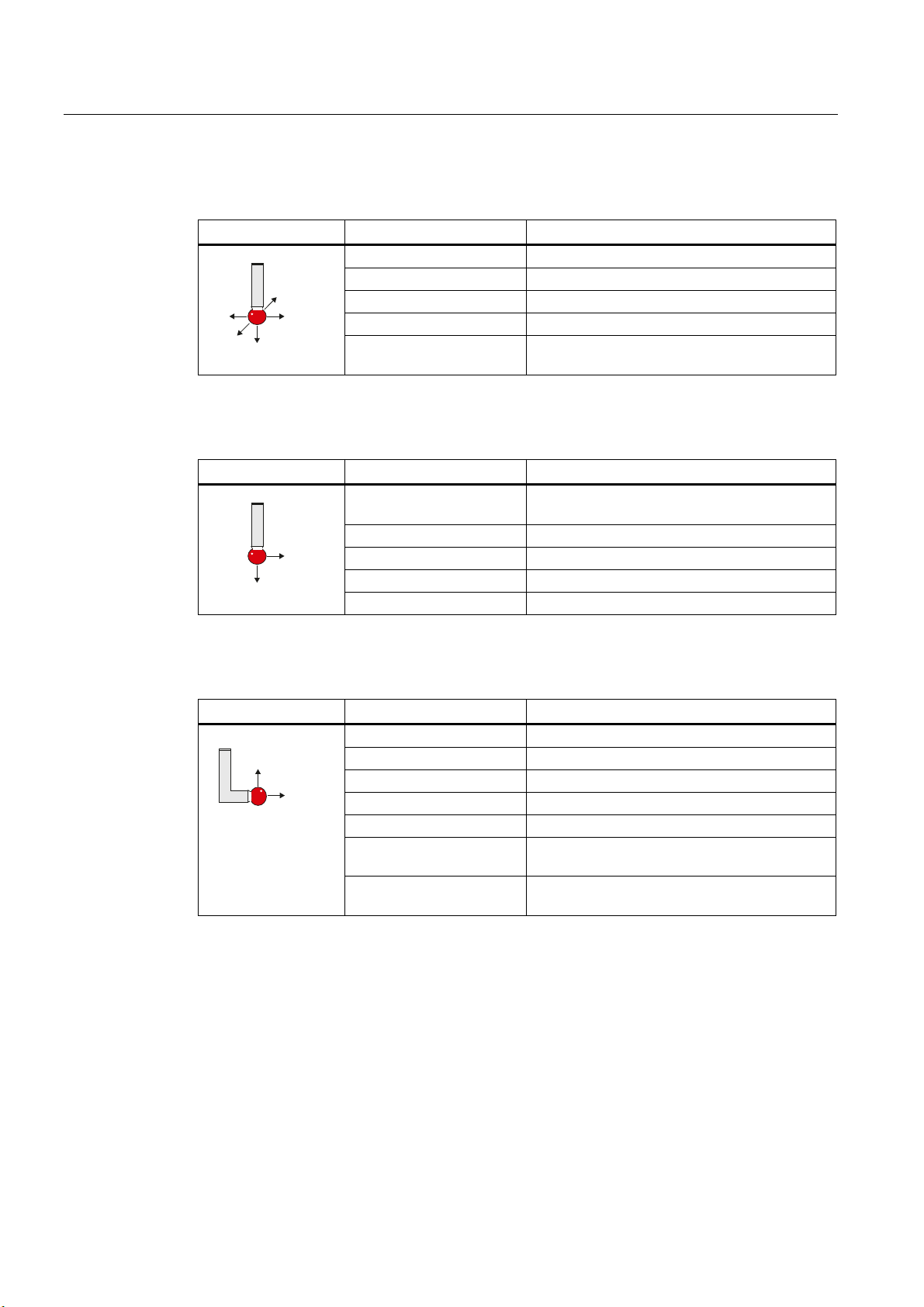

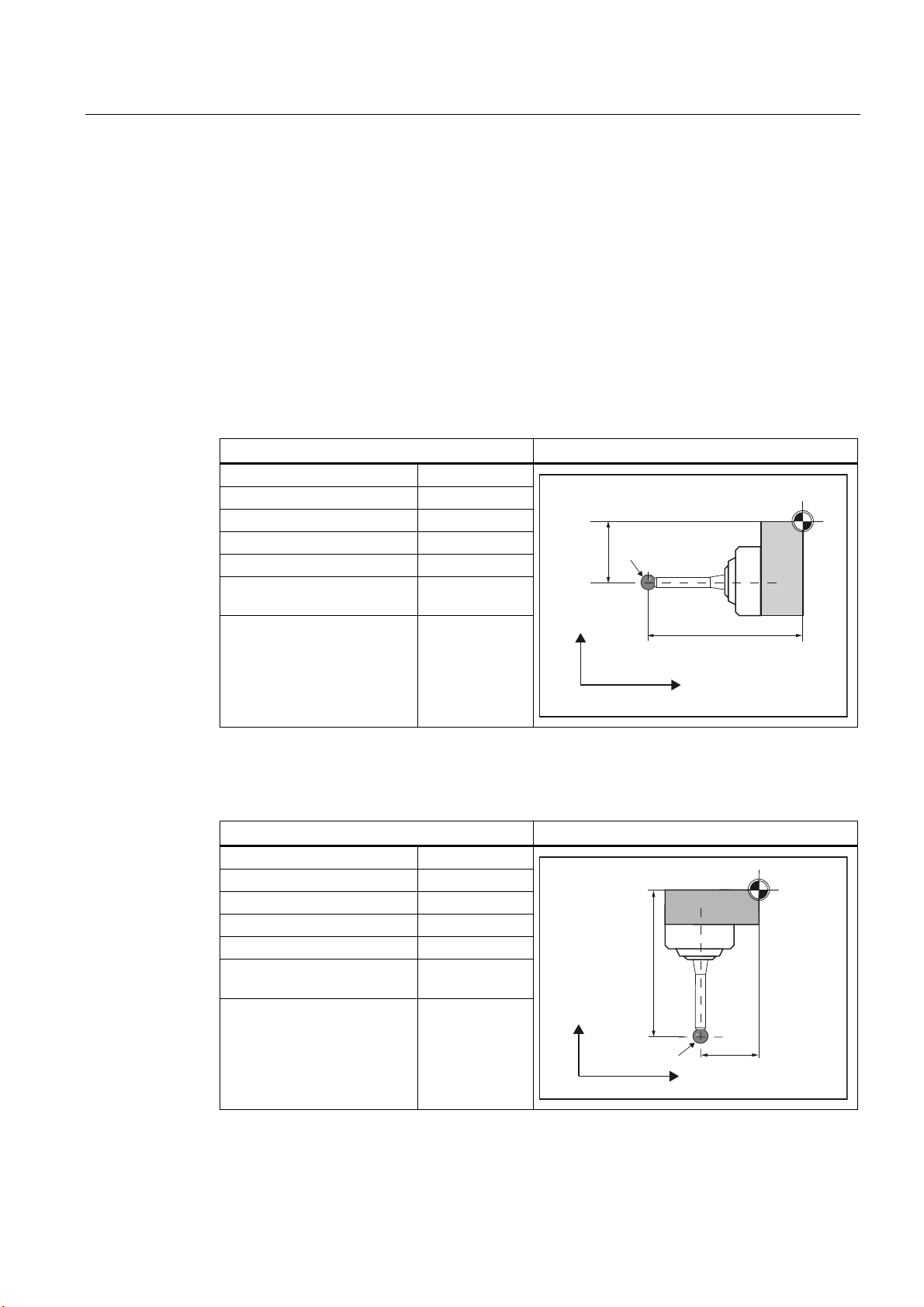

3D_PROBE (multi probe)

Representation Properties Feature

Application: Universal

Type: $TC_DP1[ ]=710

<

;

<

;

=

Tool length: in Z (for G17)

Offset angle: $TC_DP10[ ] = 0

Switching directions: $TC_DP25[ ] = hex 0x00000000

MONO PROBE

Representation Properties Feature

Application: Alignment of the switching direction when

measuring

Type: $TC_DP1[ ]=712

;

=

Tool length: in Z (for G17)

Offset angle: $TC_DP10[ ] = 0 to 359.9 degrees

Switching directions: $TC_DP25[ ] = hex 0x00120000

L_PROBE

Representation Properties Feature

Application: Towing measurement in +Z

=

Type: $TC_DP1[]=713

Tool length: in Z (for G17)

;

Offset angle: $TC_DP10[ ] = 0 to 359.9 degrees

Switching directions: $TC_DP25[ ] = hex 0x00220000

Radius in the plane

$TC_DP6[ ]

(length of the boom):

Radius of the probe ball in

$TC_DP7[ ]

the tool direction:

The tool length is the reference point of the tool holder with the equator of the probe ball.

Measuring cycles

20 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 21

Description

1.6 Probes that can be used

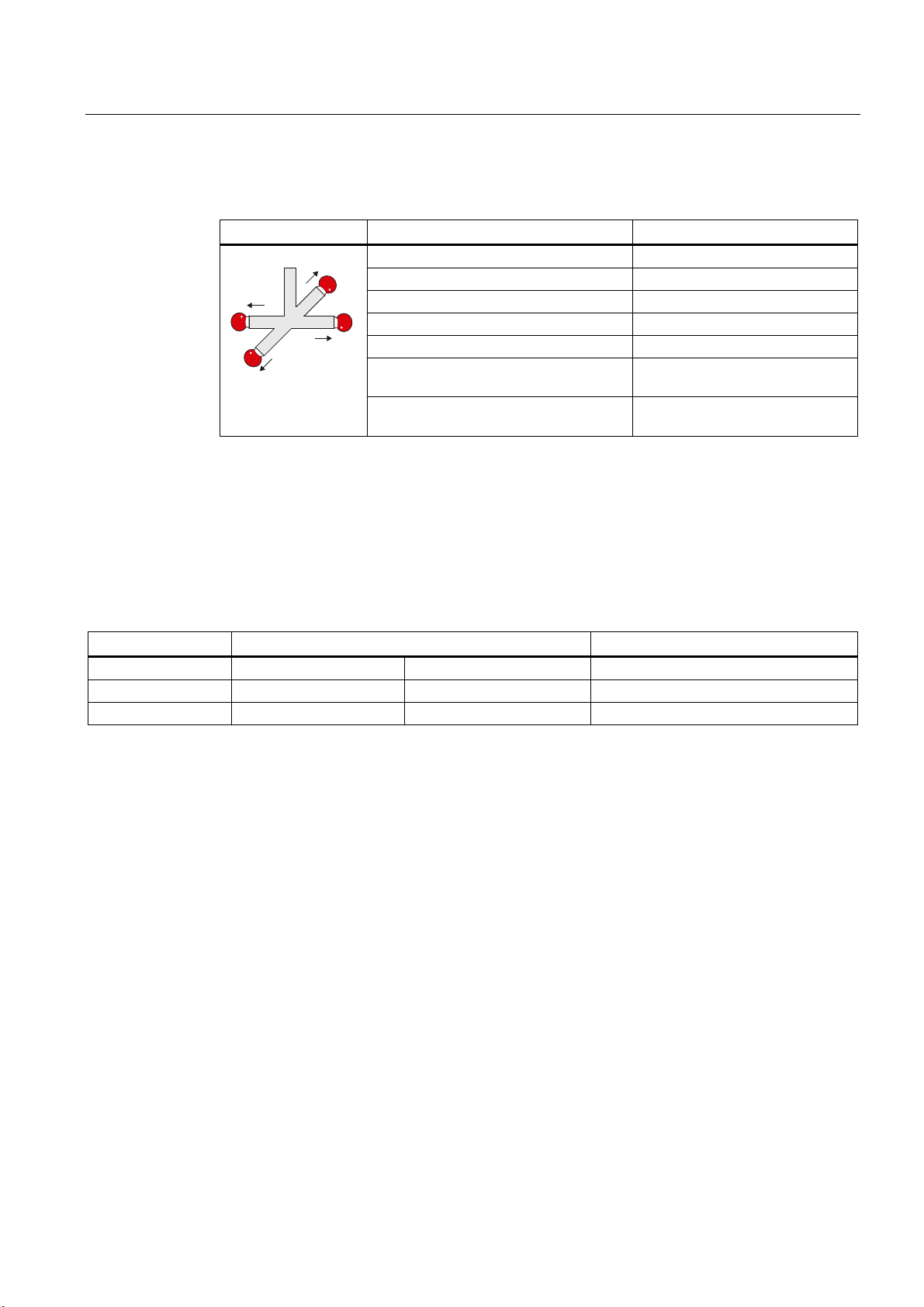

STAR PROBE

Representation Properties Feature

<

Application: Measure hole parallel to the axis

Type: $TC_DP1[ ]=714

;

Tool length: in Z (for G17)

Offset angle: $TC_DP10[ ] = 0 to 359.9 degrees

;

Switching directions: $TC_DP25[ ] = hex 0x000F0000

<

Radius in the plane

(diameter of the star parallel to the axis):

Radius of the probe ball in the tool

$TC_DP6[ ]

$TC_DP7[ ]

direction:

1)

The applications only refer to measurements in the plane (for G17 XY). Measurement in the tool

direction is not permitted using a star probe. If a measurement is to be made in the tool direction, a

star element (boom) must be declared as an L probe.

The tool length is the reference point of the tool holder with the equator of one of the probe

balls.

1)

Assignment of the probe types

Probe type Lathes Milling and machining centers

Tool measurement Workpiece measurement Workpiece measurement

Multidirectional X X X

Monodirectional -- -- X

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

21

Page 22

Description

1.7 Probe, calibration body, calibration tool

1.7 Probe, calibration body, calibration tool

1.7.1 Measuring workpieces on milling machines, machining centers

Probe calibration

All probes must be mechanically correctly adjusted before use. The switching directions

must be calibrated before they are used in the measuring cycles for first-time. This also

applies when changing the stylus tip of the probe.

When being calibrated, the trigger points (switching points), position deviation (skew), and

active ball radius of the workpiece probe are determined and entered into the data fields of

the general setting data SD 54600 $SNS_MEA_WP_BALL_DIAM . There are 12 data fields.

Calibration can be realized in a calibration ring (known bore), on a calibration ball or on

workpiece surfaces, which have an appropriate geometrical precision and low surface

roughness.

Use the same measuring velocity for calibrating and measuring. This applies in particular to

the feedrate overide.

See also

Measuring cycle CYCLE976 with different measuring versions is available to calibrate the

probe.

Calibrate probe - length (CYCLE976) (Page 83)

Calibrate probe - radius in ring (CYCLE976) (Page 86)

Calibrate probe - radius on edge (CYCLE976) (Page 90)

Calibrate probe - calibrate on ball (CYCLE976

) (Page 93)

Measuring cycles

22 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 23

Description

1.7 Probe, calibration body, calibration tool

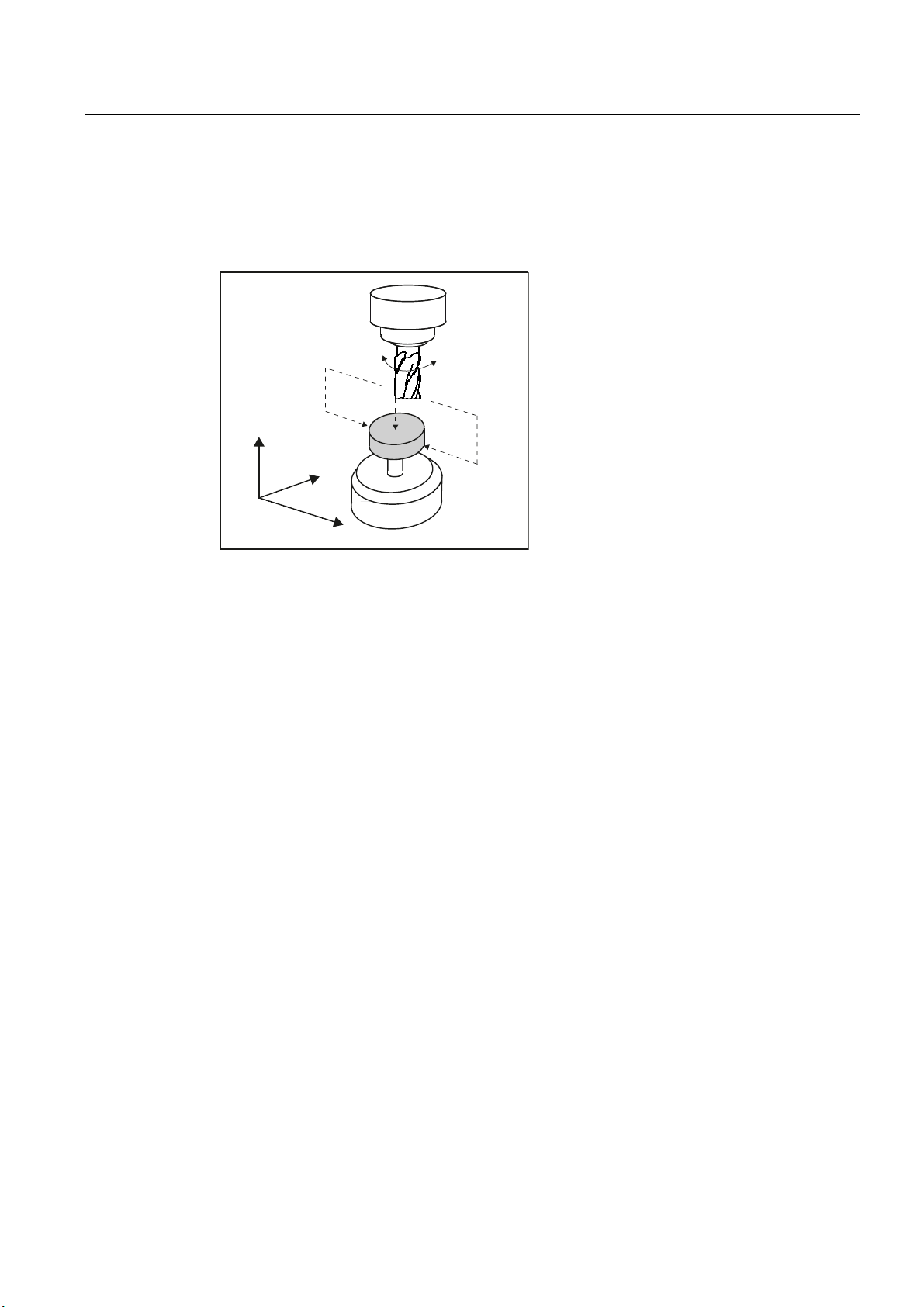

1.7.2 Measuring tools on milling machines, machining centers

Tool probe

=

<

;

Figure 1-4 Measuring a milling cutter

Tool probes have their own data fields in the general setting data:

● For machine-related measurement/calibration:

– SD 54625 $SNS_MEA_TP_TRIG_MINUS_DIR_AX1

– SD 54626 $SNS_MEA_TP_TRIG_PLUS_DIR_AX1

– SD 54627 $SNS_MEA_TP_TRIG_MINUS_DIR_AX2

– SD 54628 $SNS_MEA_TP_TRIG_PLUS_DIR_AX2

● For workpiece-related measurement/calibration:

– SD 54640 $SNS_MEA_TPW_TRIG_MINUS_DIR_AX1

– SD 54641 $SNS_MEA_TPW_TRIG_PLUS_DIR_AX1

– SD 54642 $SNS_MEA_TPW_TRIG_MINUS_DIR_AX2

– SD 54643 $SNS_MEA_TPW_TRIG_PLUS_DIR_AX2

The triggering points (switching points), upper disk diameter and edge length are entered

here.

Approximate values must be entered here before calibration – if cycles are used in automatic

mode. The cycle will then recognize the position of the probe.

The default setting has data fields for three probes. Up to 99 are possible.

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

23

Page 24

Description

1.7 Probe, calibration body, calibration tool

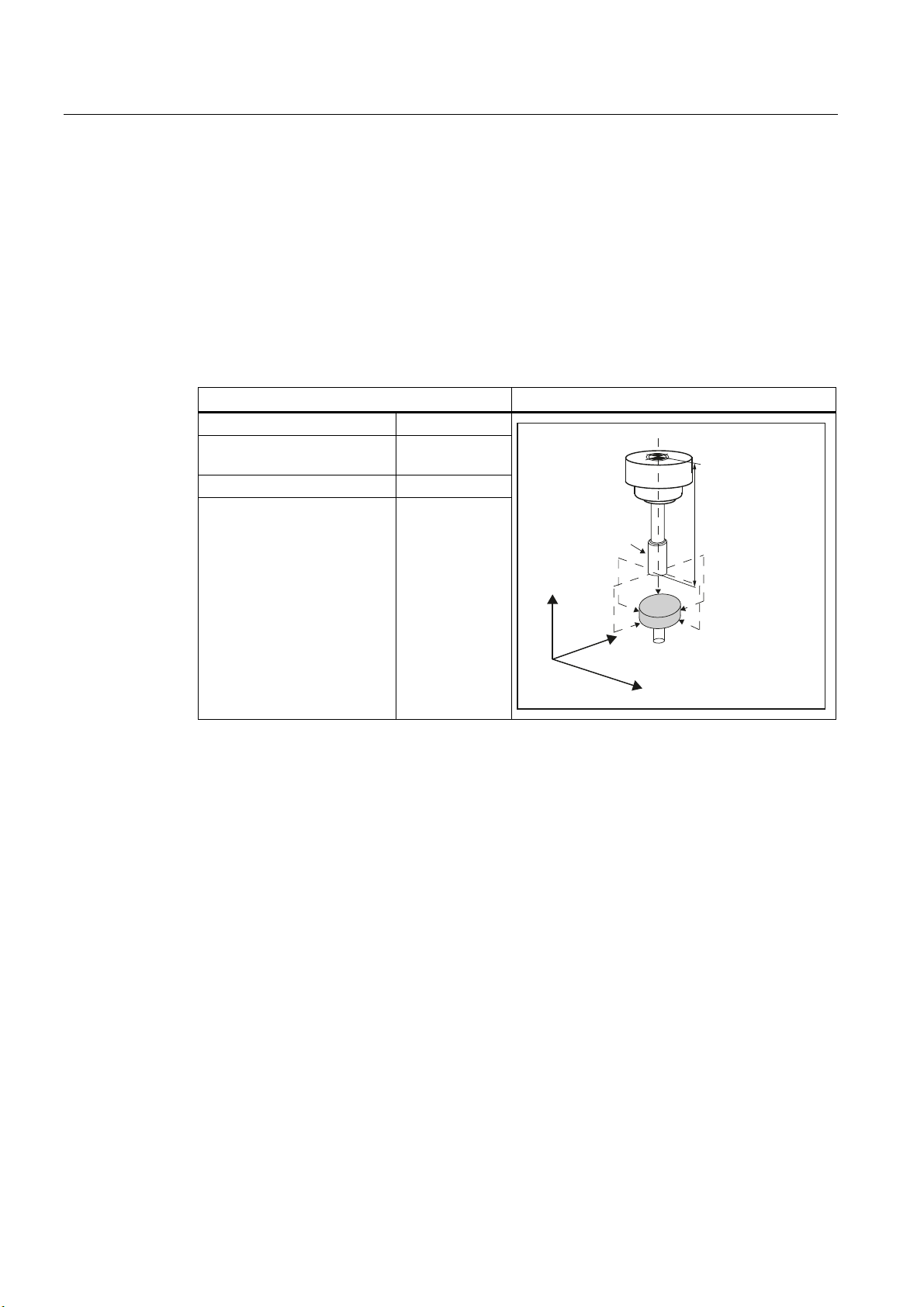

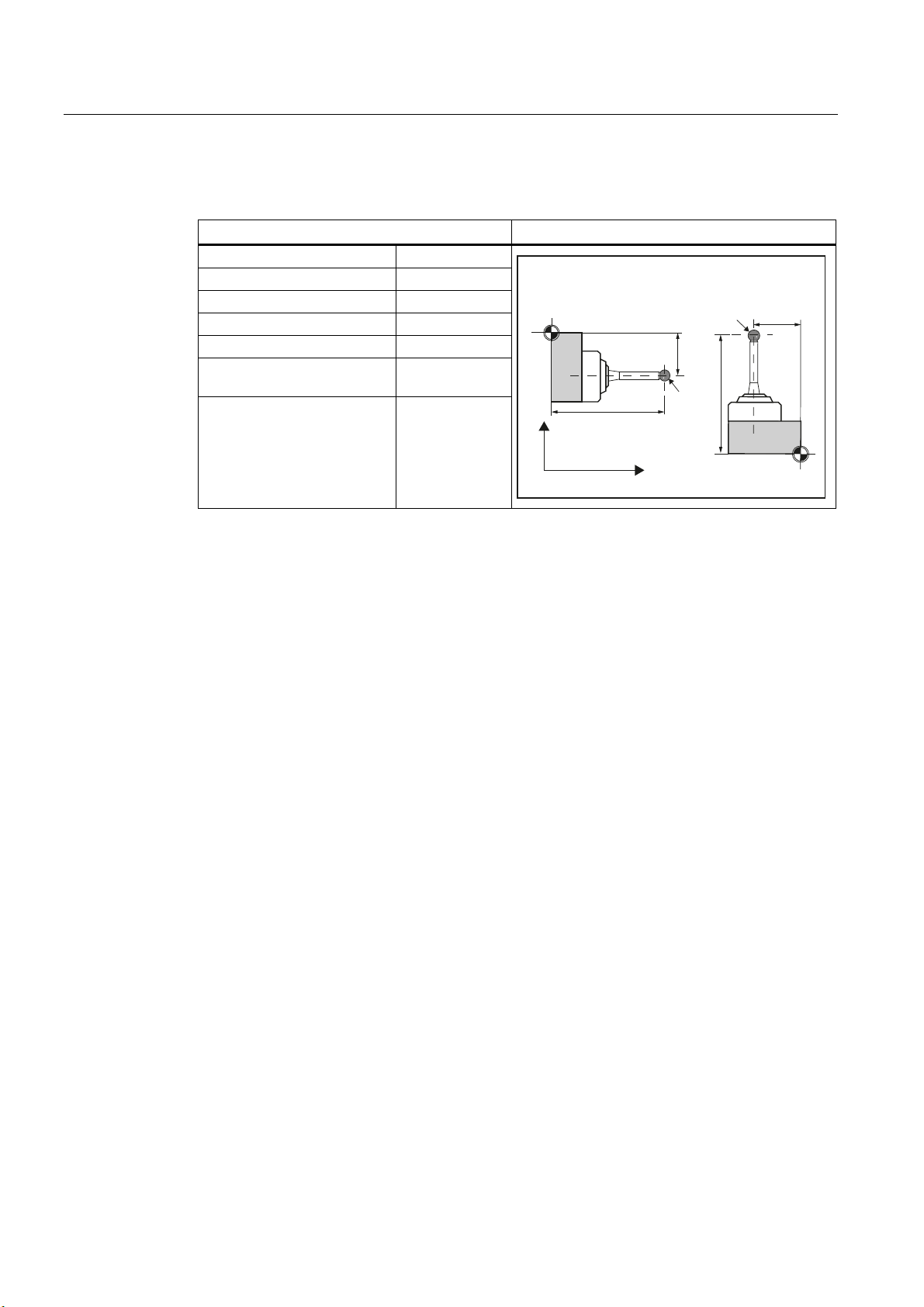

Calibration, calibration tool

A probe must be calibrated before it can be used. Calibration involves precisely determining

the triggering points (switching points) of the tool probe and entering them in special data

fields.

Calibration is performed with a calibration tool. The precise dimensions of the tool are

known.

Use the same measuring velocity for calibrating and measuring.

Measurement version Calibrate probe (CYCLE971) (Page 202) is ready for calibration.

Entry in tool memory Calibrating tool probes

Tool type ($TC_DP1[ ]): 1xy

Length 1 - geometry

($TC_DP3[ ]):

Radius ($TC_DP6[ ]): r

Length 1 - basic dimension

($TC_DP21[ ]):

L1

only if required

&DOLEUDWLRQWRRO

U

)

/

=

<

;

The wear and other tool parameters must be assigned the value 0.

7RROSUREH

Measuring cycles

24 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 25

Description

1.7 Probe, calibration body, calibration tool

1.7.3 Measuring workpieces at the turning machines

Workpiece probe

On turning machines, the workpiece probes are treated as tool type 5xy with permissible

cutting edge positions (SL) 5 to 8 and must be entered in the tool memory accordingly.

Lengths specified for turning tools always refer to the tool tip, except in the case of

workpiece probes on turning machines where they refer to the probe center.

Probes are classified according to their position:

Workpiece probe SL 7

Entry in tool memory Workpiece probe for a lathe

Tool type ($TC_DP1[ ]): 5xy

Cutting edge ($TC_DP2[ ]): 7

Length 1 - geometry: L1

Length 2 - geometry: L2

Radius ($TC_DP6[ ]): r

Length 1 - basic dimension

($TC_DP21[ ]):

Length 2 - basic dimension

($TC_DP22[ ]):

only if required

only if required

/

U

/

;

)

=

The wear and other tool parameters must be assigned the value 0.

Workpiece probe SL 8

Entry in tool memory Workpiece probe for a lathe

Tool type ($TC_DP1[ ]): 5xy

Cutting edge ($TC_DP2[ ]): 8

Length 1 - geometry: L1

Length 2 - geometry: L2

Radius ($TC_DP6[ ]): r

Length 1 - basic dimension

($TC_DP21[ ]):

Length 2 - basic dimension

($TC_DP22[ ]):

only if required

only if required

;

/

U

=

The wear and other tool parameters must be assigned the value 0.

)

/

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

25

Page 26

Description

1.7 Probe, calibration body, calibration tool

Workpiece probe SL 5 or SL 6

Entry in tool memory Workpiece probe for a lathe

Tool type ($TC_DP1[ ]): 5xy

Cutting edge ($TC_DP2[ ]): 5 or 6

/

6/

U

/

)

Length 1 - geometry: L1

Length 2 - geometry: L2

Radius ($TC_DP6[ ]): r

Length 1 - basic dimension

only if required

($TC_DP21[ ]):

Length 2 - basic dimension

only if required

($TC_DP22[ ]):

6/

)

/

U

/

;

=

The wear and other tool parameters must be assigned the value 0.

Measuring cycles

26 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 27

Description

1.7 Probe, calibration body, calibration tool

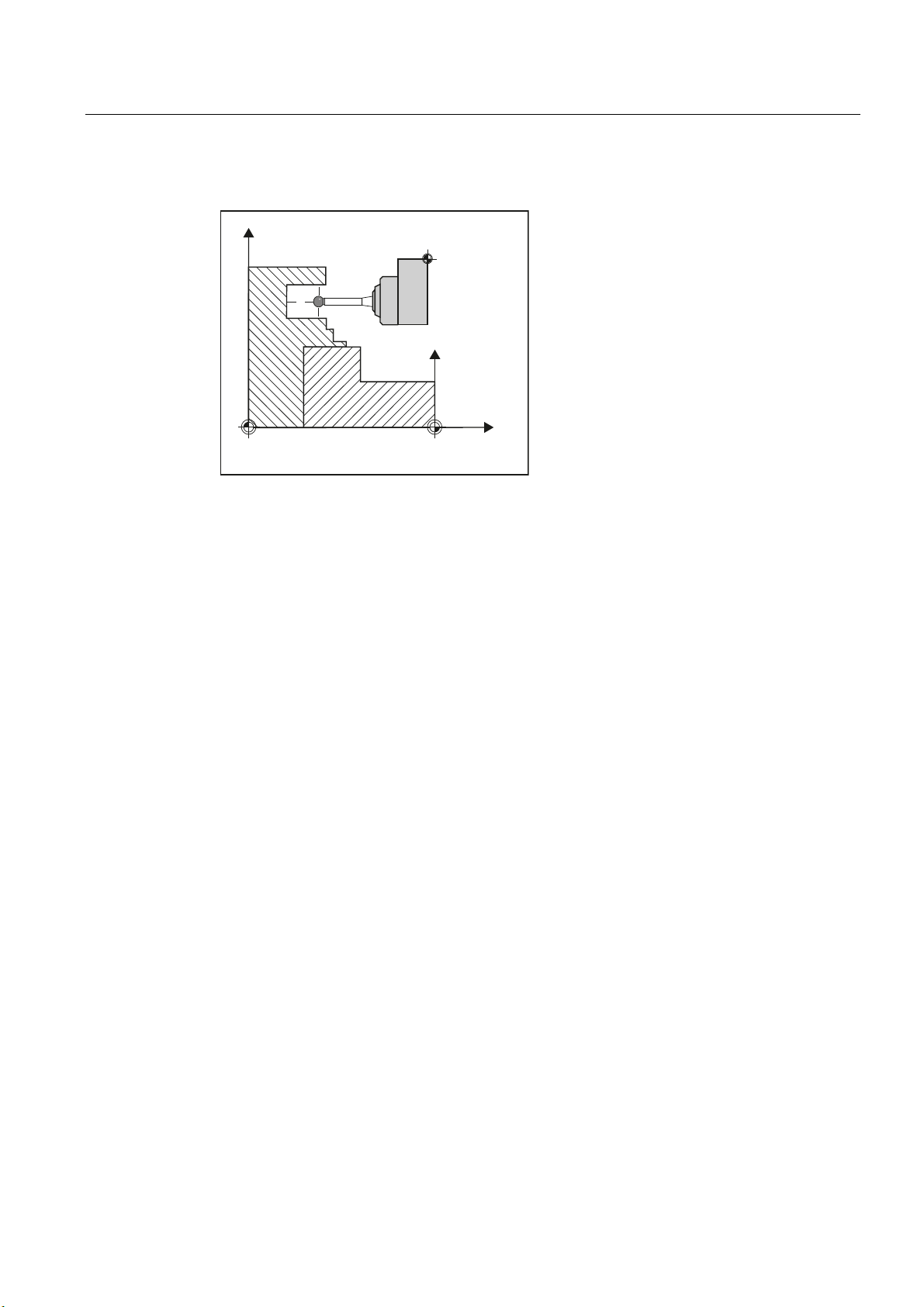

Calibration, gauging block

;

0

)

;

==

:

Figure 1-5 Calibrating a workpiece probe, example: Calibrating in the reference groove

A probe must be calibrated before it can be used. When being calibrated, the trigger points

(switching points), position deviation (skew), and precise ball radius of the workpiece probe

are determined and entered into the corresponding data fields of the general setting data

SD 54600 $SNS_MEA_WP_BALL_DIAM .

The default setting has data fields for 12 probes.

Calibration of the workpiece probe on turning machines is usually performed with gauging

blocks (reference grooves). The precise dimensions of the reference groove are known and

entered in the associated data fields of the following general setting data:

● SD54615 $SNS_MEA_CAL_EDGE_BASE_AX1

● SD54616 $SNS_MEA_CAL_EDGE_UPPER_AX1

● SD54617 $SNS_MEA_CAL_EDGE_PLUS_DIR_AX1

● SD54618 $SNS_MEA_CAL_EDGE_MINUS_DIR_AX1

● SD54619 $SNS_MEA_CAL_EDGE_BASE_AX2

● SD54620 $SNS_MEA_CAL_EDGE_UPPER_AX2

● SD54621 $SNS_MEA_CAL_EDGE_PLUS_DIR_AX2

● SD54622 $SNS_MEA_CAL_EDGE_MINUS_DIR_AX2

The default setting has data fields for three gauging blocks. In the measuring cycle program,

the selection is made using the number of the gauging block (S_CALNUM).

It is also possible to calibrate on a known surface.

Measuring cycle CYCLE973 with various measuring versions is ready for calibration.

See also

Calibrate probe - length (CYCLE973) (Page 57)

Calibrate probe - radius on surface (CYCLE973) (Page 60)

Calibrate probe - calibrate in groove (CYCLE973) (Page 63)

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

27

Page 28

Description

1.7 Probe, calibration body, calibration tool

1.7.4 Measuring tools at lathes

Tool probe

0HDVXUHOHQJWK

0HDVXUHOHQJWK

;

=

Figure 1-6 Measuring a turning tool

Tool probes have their own data fields in the general setting data:

● For machine-related measurement/calibration:

– SD 54626 $SNS_MEA_TP_TRIG_PLUS_DIR_AX1

– SD 54625 $SNS_MEA_TP_TRIG_MINUS_DIR_AX1

– SD 54627 $SNS_MEA_TP_TRIG_MINUS_DIR_AX2

– SD 54628 $SNS_MEA_TP_TRIG_PLUS_DIR_AX2

● For workpiece-related measurement/calibration:

– SD 54641 $SNS_MEA_TPW_TRIG_PLUS_DIR_AX1

– SD 54640 $SNS_MEA_TPW_TRIG_MINUS_DIR_AX1

– SD 54642 $SNS_MEA_TPW_TRIG_MINUS_DIR_AX2

– SD 54643 $SNS_MEA_TPW_TRIG_PLUS_DIR_AX2

The triggering points (switching points) are entered here. Approximate values must be

entered here before calibration – if cycles are used in automatic mode. The cycle will then

recognize the position of the probe.

The default setting has data fields for 6 probes.

In addition to turning tools, drills and mills can also be measured.

Measuring cycles

28 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 29

Description

1.7 Probe, calibration body, calibration tool

Calibration, gauging block

;

=

&DOLEUDWLRQWRRO

A probe must be calibrated before it can be used. Calibration involves precisely determining

the triggering points (switching points) of the tool probe and entering them in special data

fields.

Calibration is performed with a calibration tool. The precise dimensions of the tool are

known.

Measurement version Calibrate probe (CYCLE982) (Page 178) is ready for calibration.

For lathe

s, the calibration tool is treated like a turning tool with cutting edge position 3. The

lengths refer to the ball circumference, not to the ball center.

Entry in tool memory Calibration tool for a tool probe on a lathe

Tool type ($TC_DP1[ ]): 5xy

Cutting edge ($TC_DP2[ ]): 3

Length 1 - geometry: L1

Length 2 - geometry: L2

Radius ($TC_DP6[ ]): r

Length 1 - basic dimension

($TC_DP21[ ]):

Length 2 - basic dimension

($TC_DP22[ ]):

only if required

only if required

U

/

;

/

)

The wear and other tool parameters must be assigned the value 0.

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

=

29

Page 30

Description

1.8 Measurement principle

1.8 Measurement principle

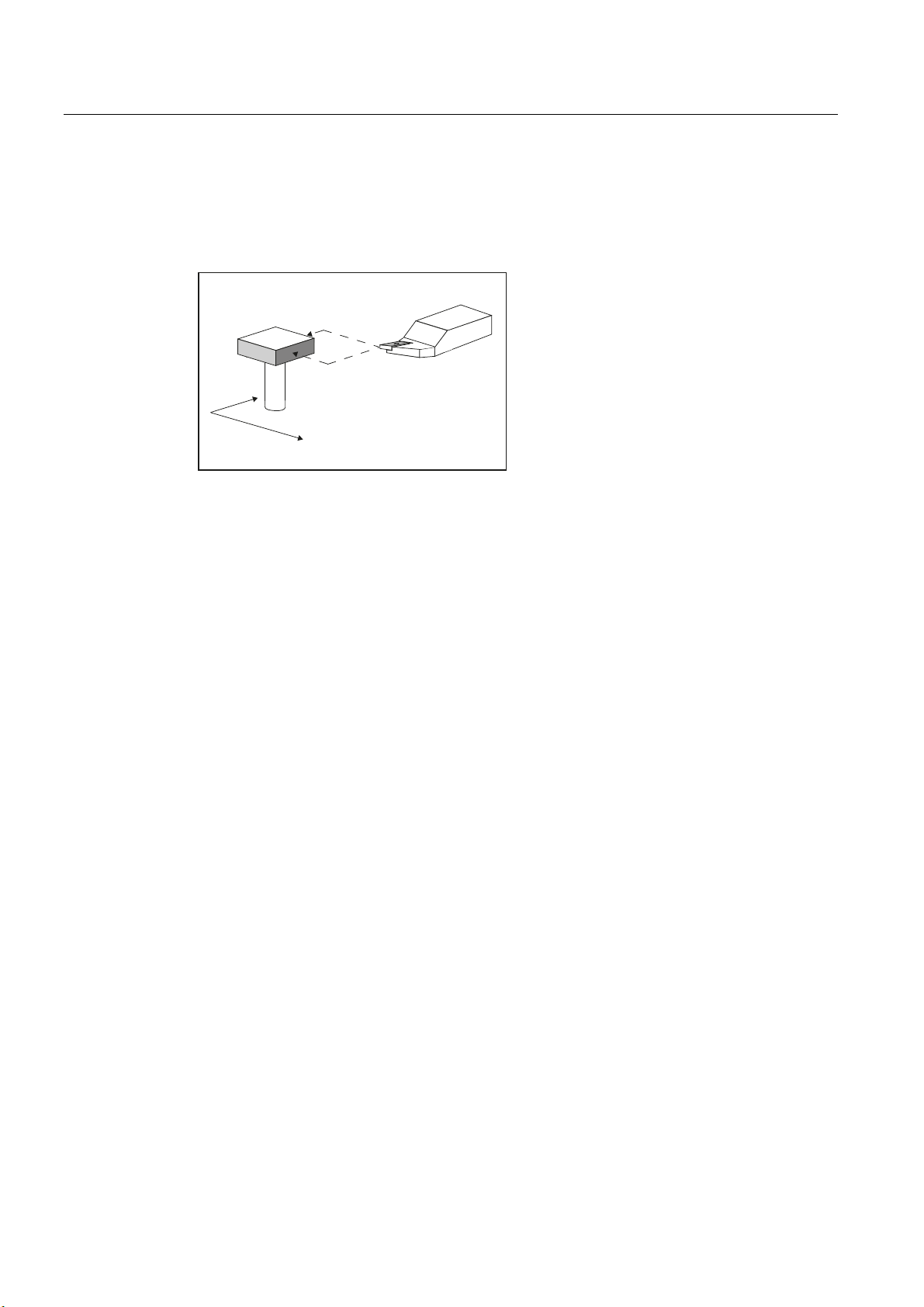

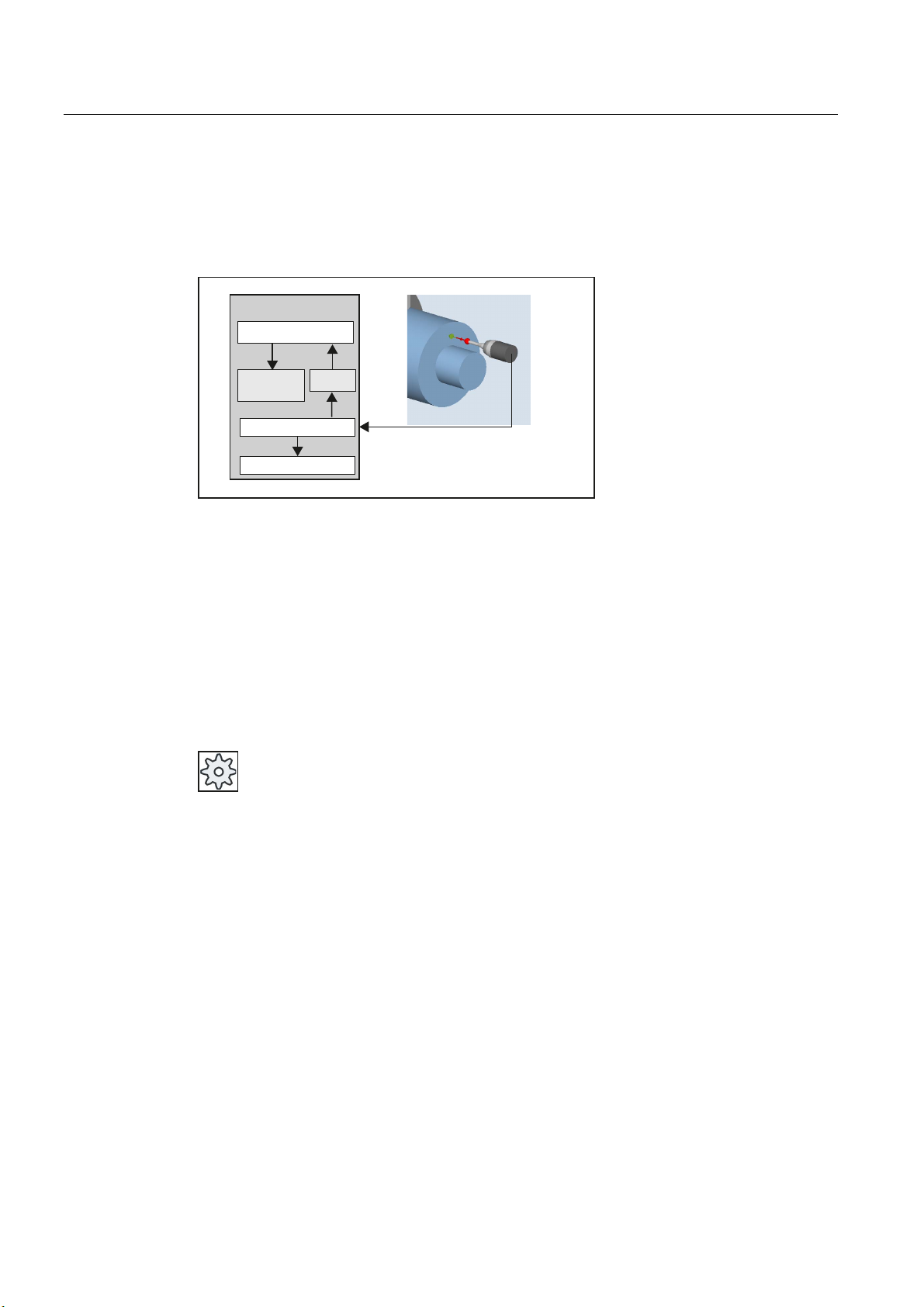

Flying measurement

1&

0HDVXULQJF\FOH

The principle of "flying measurement" is implemented in the SINUMERIK control. The probe

signal is processed directly on the NC so that the delay when acquiring measured values is

minimal. This permits a higher measuring speed for the prescribed measuring precision and

time needed for measuring is reduced.

Connecting probes

Two inputs for connecting touch trigger probes are provided on the I/O device interface of

the SINUMERIK control systems.

'HOHWH

GLVWDQFHWR

JR

$FWXDOYDOXHDFTXLVLWLRQ

3RVLWLRQFRQWURO

$FWXDO

YDOXH

Machine manufacturer

Please observe the machine manufacturer’s instructions.

Measuring cycles

30 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 31

Description

1.8 Measurement principle

Measurement operation sequence using the example set edge (CYCLE978)

Figure 1-7 Measurement operation sequence, example set edge (CYCLE978)

The sequence is described using the measuring version, set edge (CYCLE978). The

sequence is essentially the same for the other measuring cycles.

The starting position for the measuring procedure is the position DFA in front of the specified

set position (expected contour).

Figure 1-8 Starting position

The starting position is calculated in the cycle based on parameter entries and probe data.

The traversing distance from the pre-position, defined by the user program, to the starting

position of the measuring distance is either traversed with rapid traverse G0 or with

positioning speed G1 (depending on the parameter). From the starting position, the

measuring velocity is effective, which is saved in the calibration data.

The switching signal is expected along path 2 · DFA as from the starting position. Otherwise,

an alarm will be triggered or the measurement repeated.

The resulting maximum measuring position is available in the result parameters _OVR[ ] and

_OVI[ ] of the measuring cycle.

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

31

Page 32

Description

1.8 Measurement principle

At the instant the switching signal is output by the probe, the current actual position is stored

internally "on-the-fly" as the actual value, the measuring axis is stopped and then the "Delete

distance-to-go" function is executed.

The distance-to-go is the path not yet covered in the measuring block. After deletion, the

next block in the cycle can be processed. The measuring axis travels back to the starting

position. Any measurement repetitions selected are restarted from this point.

Measurement path DFA

Measurement path DFA defines the distance between the starting position and the expected

switching position (setpoint) of the probe.

Measuring velocity

As measuring feedrate, all of the measuring cycles use the value saved in the general

setting data SD54611 after the calibration of the workpiece probe. A different measuring

feedrate can be assigned for each calibration field [n].

To calibrate the measuring probe, either the measuring feedrate from the channel-specific

setting data SD55630 $SCS_MEA_FEED_MEASURE is used (default value: 300 mm/min) or

the measuring feedrate can be overridden in the input screen form at the calibration instant.

To do this, bit 4 must be set to 1 in the general setting data SD54760

$SNS_MEA_FUNCTION_MASK_PIECE.

The maximum permissible measuring velocity is derived from:

● The deceleration behavior of the axis.

● The permissible deflection of the probe.

● The signal processing delay.

Deceleration distance, deflection of probe

CAUTION

Safe deceleration of the measuring axis to standstill within the permissible deflection path

of the probe must always be ensured.

Otherwise damage will occur!

A delay t, typical for the control, is taken into account in signal processing (IPO cycle) for the

time between detection of the switching signal and output of the deceleration command to

the measuring axis: general machine data MD10050 $MN_SYSCLOCK_CYCLE_TIME and

MD10070 $MN_IPO_SYSCLOCK_TIME_RATIO). This gives the braking distance

component.

The following error of the measuring axis is reduced. The following error is velocity

dependent and at the same time dependent on the control factor of the measuring axis

(servo gain of the associated machine axis: servo gain factor).

The deceleration rate of the axis must also be taken into account.

Measuring cycles

32 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 33

Description

1.8 Measurement principle

Together they produce an axis-specific velocity-dependent deceleration distance.

The Kv factor is the axis MD 32200 $MA_POSCTRL_GAIN.

The maximum axis acceleration / deceleration rate a is saved in axis MD 32300

$MA_MAX_AX_ACCEL . It may have a lesser effect due to other influences.

Always use the lowest values of the axes involved in the measurement.

Measuring accuracy

A delay occurs between detection of the switching signal from the probe and transfer of the

measured value to the control. This is caused by signal transmission from the probe and the

hardware of the control. In this time a path is traversed that falsifies the measured value.

This influence can be minimized by reducing the measuring speed.

The rotation when measuring a milling tool on a rotating spindle has an additional influence.

This can be compensated using compensation tables.

The measurement accuracy that can be obtained is dependent on the following factors:

● Repeat accuracy of the machine

● Repeat accuracy of the probe

● Resolution of the measuring system

NOTICE

Precise measurement is only possible with a probe calibrated under the measurement

conditions, i.e. working plane, orientation of the spindle in the plane and measuring velocity

are the same for both measurement and calibration. Deviations result in measurement

errors.

Calculation of the deceleration distance

V>PP@

˂V

Y PPLQ

Y PPLQ

=HURVSHHGRIWKH

D[LV

6WDQGVWLOO

˂V

Y PPLQ

PVGHOD\VLJQDOSURFHVVLQJ

6WDQGVWLOO

Figure 1-9 Distance-time diagram at different measuring velocities according to the calculation

example

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

W>PV@

33

Page 34

Description

1.8 Measurement principle

The deceleration path to be considered is calculated as follows:

Y

VE YyW

˂V

D

˂V

˂V

sb Braking distance in mm

v Measuring velocity in m/s

t Delay signal in s

2

a Deceleration in m/s

Δs Following error in mm

Δs = v / Kv v here in m/min

Kv Servo gain in (m/min)/mm

Example of calculation:

● v = 6 m/min = 0.1 m/s measuring velocity

● a = 1 m/s

2

deceleration

● t = 16 ms signal delay

● Kv = 1 in (m/min)/mm

Intermediate steps:

Δs = v / Kv = 6[m/min] / 1[(m/min)/mm] = 6 mm Following error

= v²/2a = 0,1 [m/s]² / 2 · 1 [m/s²] = 5 mm Axis-specific component

Δs

2

= v · t = 0,1 [m/s] · 0,016 [s] = 1,6 mm Percentage due to signal delay

Δs

1

Overall result:

= Δs1 + Δs2 + Δs = 6 mm + 5 mm + 1,6 mm = 12,6 mm Braking distance

s

b

The deflection of the probe = braking distance to zero speed of the axis is 12.6 mm.

Measuring cycles

34 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 35

Description

1.9 Measuring strategy for measuring workpieces with tool offset

1.9 Measuring strategy for measuring workpieces with tool offset

The actual workpiece dimensions must be measured exactly and compared with the setpoint

values to be able to determine and compensate the actual dimensional deviations on the

workpiece. An offset value can then be ascertained for the tool used for machining.

Function

When taking measurements on the machine, the actual dimensions are derived from the

path measuring systems of the position-controlled feed axes. For each dimensional deviation

determined from the set and actual workpiece dimensions there are many causes which

essentially fall into three categories:

● Dimensional deviations with causes that are n o t subject to a particular trend, e.g.

positioning scatter of the feed axes or differences in measurement between the internal

measurement (probe) and the external measuring device (micrometer, measuring

machine, etc.).

In this case, it is possible to apply empirical values, which are stored in separate

memories. The set/actual difference determined is automatically compensated by the

empirical value.

● Dimensional deviations with causes that a r e subject to a particular trend, e.g. tool wear

or thermal expansion of the leadscrew.

● Accidental dimensional deviations, e.g. due to temperature fluctuations, coolant or slightly

soiled measuring points.

Assuming the ideal case, only those dimensional deviations that are subject to a trend

can be taken into account for compensation value calculation. Since, however, it is hardly

ever known to what extent and in which direction accidental dimensional deviations

influence the measurement result, a strategy (sliding averaging) is needed that derives a

compensation value from the actual/set difference measured.

Mean value calculation

Mean value calculation in conjunction with measurement weighting has proven a suitable

method.

When correcting a tool, it can be selected whether a correction is made based on the actual

measurement, or whether an average value of the measurement differences should be

generated over several measurements which is then used to make the correction.

The formula of the mean value generation chosen is:

-

DMi

-=

MiMi

altneu

Mv

Mean value new = amount of compensation

new

Mean value prior to last measurement

Mv

old

ialt

k

k Weighting factor for mean value calculation

Actual/set difference measured (minus any empirical value)

D

i

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

35

Page 36

Description

1.9 Measuring strategy for measuring workpieces with tool offset

The mean value calculation takes account of the trend of the dimensional deviations of a

machining series. The weighting factor k from which the mean value is derived is selectable.

A new measurement result affected by accidental dimensional deviations only influences the

new tool offset to some extent, depending on the weighting factor.

Computational characteristic of the mean value with different weightings k

0LWWHOZHUW

:RUNRIIVHW

6B7=/

&DOFXODWHG

PHDQYDOXHV

6HWSRLQW

N

1XPEHURIDYHUDJLQJV

QXPEHURIZRUNSLHFHV

N

N

&DOFXODWHG

PHDQYDOXH

N

/RZHUOLPLW

ZRUNRIIVHW

L

Figure 1-10 Mean value generation with influence of weighting k

● The greater the value of k, the slower the formula will respond when major deviations

occur in computation or counter compensation. At the same time, however, accidental

scatter will be reduced as k increases.

● The lower the value of k, the faster the formula will react when major deviations occur in

computation or counter compensation. However, the effect of accidental variations will be

that much greater.

● The mean value Mv is calculated starting at 0 over the number of workpieces i, until the

calculated mean value exceeds the work offset range (

S_TZL). From this limit on, the

calculated mean value is applied as an offset.

● Once the mean value has been used for the offset, it is deleted from the memory. The

next measurement then starts again with Mv

Measuring cycles

old

= 0.

36 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 37

Description

1.9 Measuring strategy for measuring workpieces with tool offset

Table 1- 1 Example of mean value calculation and offset

Lower limit = 40 µm

(S_TZL = 0.04)

i Di

[µm]

Mv

k = 3

[µm]

Mv

k = 2

[µm]

1. measurement 30 10 15

2. Measurement 50 23,3 32,5

3. Measurement 60 35,5

46,2 ③

4. Measurement 20 30,3 10

5. Measurement 40 32,6 25

6. Measurement 50 38,4 37,5

7. Measurement 50

42,3 ① 43,75 ④

8. Measurement 30 10 15

9. Measurement 70 30

10. Measurement 70

43,3 ②

42,5 ⑤

35

Characteristic of the mean value for two different

weighting factors

0HDQYDOXH

0HDQYDOXHV!6B7=/DUHH[HFXWHGDVWKHRIIVHW

1

3

L

N

N

4

5

1XPEHURIDYHUDJLQJVQXPEHU

RIZRUNSLHFHV

:RUNRIIVHW

2

For the measurements with marked fields, tool offset is performed with the mean value

(calculated mean value >S_TZL):

● If k=3 in the 7th and 10th measurement (

● If k=2 in the 3rd, 7th, and 9th measurement (

① and ②),

③, ④ and ⑤).

6B7=/

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

37

Page 38

Description

1.10 Parameters for checking the measurement result and offset

1.10 Parameters for checking the measurement result and offset

For constant deviations not subject to a trend, the dimensional deviation measured can be

compensated by an empirical value in certain measuring variants.

For other compensations resulting from dimensional deviations, symmetrical tolerance bands

are assigned to the set dimension which result in different responses.

Empirical value / mean value EVN (S_EVNUM)

The empirical values are used to suppress dimensional deviations that are not subject to a

trend.

Note

If empirical values are not to be applied, then S_EVNUM = 0 must be set.

The empirical values themselves are saved in channel-specific SD 55623

$SCS_MEA_EMPIRIC_VALUE.

EVN specifies the number of the empirical value memory. The actual/set difference

determined by the measuring cycle is corrected by this value before any further correction

measures are taken.

This is the case:

● For workpiece measurement with automatic tool offset.

● For single-point measurement with automatic WO correction.

● For tool measurement.

The mean value only refers to the workpiece measurement with automatic tool offset.

For an automatic tool offset, the mean value is generated from the measured difference of

the previous and the actual measurement. This functionality has special significance within a

machining series with measurements performed at the same measuring location.

The function does not have to be activated.

The mean values are stored in the channel-specific SD 55625

$SCS_MEA_AVERAGE_VALUE. The number of the mean value memory is transferred in

the measuring cycle using variable S_EVNUM.

Safe area TSA (S_TSA)

The safe area is effective for almost all measuring variants and does not affect the offset

value; it is used for diagnostics.

If this limit is reached then the following can be assumed:

● A probe defect, or

● An incorrect setpoint position, or

● An illegal deviation from the setpoint position can be assumed.

Measuring cycles

38 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 39

Description

1.10 Parameters for checking the measurement result and offset

Note

AUTOMATIC mode

AUTOMATIC operation is interrupted and the program cannot continue. An alarm text

appears to warn the user.

Dimension difference check DIF (S_TDIF)

DIF is active only for workpiece measurement with automatic tool offset and for tool

measurement.

This limit has no effect on generation of the compensation value either. When it is reached,

the tool is probably worn and needs to be replaced.

Note

An alarm text is displayed to warn the operator and the program can be continued by means

of an NC start.

This tolerance limit is generally used by the PLC for tool management purposes (twin tools,

wear monitoring).

Tolerance of workpiece: Lower limit (S_TLL), upper limit(S_TUL)

Both parameters are active only for tool measurement with automatic tool offset.

When measuring a dimensional deviation ranging between "2/3 tolerance of workpiece" and

"Dimensional difference control", this is regarded 100% as tool offset. The previous average

value is erased.

This enables a fast response to major dimensional deviations.

Note

When the tolerance limit of the workpiece is exceeded, this is indicated to the user

depending on the tolerance position "oversize" or "undersize".

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

39

Page 40

Description

1.10 Parameters for checking the measurement result and offset

2/3 tolerance of workpiece TMV (S_TMV)

TMV is active only for workpiece measurement with automatic tool offset.

Within the range of "Lower limit" and "2/3 workpiece tolerance" the mean value is calculated

according to the formula described in Section "Measuring strategy".

Note

Mv

is compared with the work offset range:

new

If Mv

is greater than this range, compensation is corrected by Mv

new

and the associated

new

mean value memory is cleared.

If Mv

is less than this range, no compensation is carried out. This prevents excessively

new

abrupt compensations.

Weighting factor for mean value generation FW (S_K)

FW is active only for workpiece measurement with automatic tool offset. The weighting factor

can be used to give a different weighting for each measurement.

A new measurement result thus has only a limited effect on the new tool offset as a function

of FW.

Work offset range TZL (S_TZL)

TZL active for

● Workpiece measurement with automatic tool offset

● Tool measurement and calibration for milling tools and tool probes

This tolerance range corresponds to the amount of maximum accidental dimensional

deviations. It has to be determined for each machine.

No tool compensation is made within these limits.

In workpiece measurement with automatic tool offset, however, the mean value of this

measuring point is updated and re-stored with the measured actual/set difference, possibly

compensated by an empirical value.

The tolerance bands (range of permissible dimensional tolerance) and the responses

derived from them are as follows:

Measuring cycles

40 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 41

Description

1.10 Parameters for checking the measurement result and offset

● For workpiece measurement with automatic tool offset

$ODUP6DIHDUHDYLRODWHG

76$

7',)

7//78/

709

6DIHDUHD

'LPHQVLRQGLIIHUHQFH

FKHFN

:RUNSLHFHWROHUDQFH

ZRUNSLHFHWROHUDQFH

$ODUP3HUPLVVLEOHGLPHQVLRQDOGLIIHUHQFH

H[FHHGHG

&RUUHFWWKHDFWXDOGHYLDWLRQ

$ODUP$OORZDQFHXQGHUVL]H

&RUUHFWWKHDFWXDOGHYLDWLRQ

0HDQYDOXHJHQHUDWLRQ(91):

DQGFRUUHFWPHDQYDOXH

7=/

:RUNRIIVHWORZHUOLPLW

6HWSRLQW

0HDQYDOXHJHQHUDWLRQLV

VDYHG

Note

In measuring cycles, the workpiece setpoint dimension is placed in the middle of the

permitted ± tolerance limit for reasons associated with symmetry.

● For tool measurement

$ODUP6DIHDUHDYLRODWHG

76$

7',)

6DIHDUHD

'LPHQVLRQGLIIHUHQFH

FKHFN

$ODUP3HUPLVVLEOHGLPHQVLRQDOGLIIHUHQFH

H[FHHGHG

7RROPHPRU\LVFRUUHFWHG

7=/

:RUNRIIVHWORZHUOLPLW

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

6HWSRLQW

7RROPHPRU\XQFKDQJHG

41

Page 42

Description

1.10 Parameters for checking the measurement result and offset

● For workpiece measurement with WO correction

$ODUP6DIHDUHDYLRODWHG

76$

6DIHDUHD

&RUUHFWLRQRIWKH:2PHPRU\

6HWSRLQW

● For workpiece probe calibration

$ODUP6DIHDUHDYLRODWHG

76$

6DIHDUHD

7=/

:RUNRIIVHWORZHUOLPLW

● For tool probe calibration

76$

7=/

6DIHDUHD

:RUNRIIVHWORZHUOLPLW

:RUNSLHFHSUREHGDWDDUHFRUUHFWHG

6HWSRLQW

:RUNSLHFHSUREHGDWD

XQFKDQJHG

$ODUP6DIHDUHDYLRODWHG

7RROSUREHGDWDDUHFRUUHFWHG

6HWSRLQW

7RROSUREHGDWDXQFKDQJHG

Measuring cycles

42 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 43

Description

1.11 Effect of empirical value, mean value, and tolerance parameters

1.11 Effect of empirical value, mean value, and tolerance parameters

The following flowchart shows the effect of empirical value, mean value, and tolerance

parameters on workpiece measurement with automatic tool offset.

0HDVXULQJF\FOH

0HDVXUH

&DOFXODWHDFWXDOVHWSRLQW

GLIIHUHQFH

'LIIHUHQFHPLQXV

HPSLULFDOYDOXH

'LIIHUHQFH!WRO

RIWKHZRUNSLHFH

6B709

&DOFXODWHFRUUHFWLRQYDOXH

WDNLQJLQWRDFFRXQW

ZHLJKWLQJIDFWRU6B.

&RUUHFWLRQYDOXH

1R

!ORZHUOLPLW

6B7=/

<HV

2IIVHWE\FRUUHFWLRQYDOXH

ZHDNHQHGRIIVHW

'HOHWHFRUUHFWLRQ

PHDQYDOXH

1R

2IIVHWE\

GLIIHUHQFH

RIIVHW

'HOHWHFRUUHFWLRQ

PHDQYDOXH

①

<HV

'LIIHUHQFH!WRO

RIWKHZRUNSLHFH

6B709

<HV

2IIVHWE\

GLIIHUHQFH

RIIVHW

'HOHWHFRUUHFWLRQ

PHDQYDOXH

1R

'LIIHUHQFH!7RO

RIWKHZRUNSLHFH

6B78/6B7//

,QWHUQDOSDUDPHWHU

SUHVHQWO\DOZD\V

<HV1R

'LIIHUHQFH!VDIH

1R

'LIIHUHQFH!

'LPHQVLRQDO

GLIIHUHQFHPRQL

WRULQJ6B7',)

<HV

&DOFXODWHPHDQRIIVHWYDOXH

WDNLQJLQWRDFFRXQWZHLJKWLQJ

IDFWRU6B.

1R

6DYHRIIVHW

DYHUDJHYDOXH

DUHD6B76$

<HV

'LVSOD\

$OORZDQFHRUXQGHUVL]H

<HV1R

0HDQRIIVHWYDOXH!

ORZHUOLPLW6B7=/

&RUUHFWLRQE\PHDQ

RIIVHWYDOXH

ZHDNHQHGRIIVHW

'HOHWHFRUUHFWLRQPHDQ

YDOXH

(QG

SD 54740 $SNS_MEA_FUNCTION_MASK, Bit 0

'LVSOD\

SHUPLVVLEOHGLPHQVLR

QDOGLIIHUHQFHH[FHHGHG

<HV1R

1R

2QO\H[LWWKHSURJUDP

'LVSOD\

6DIHDUHDYLRODWHG

5HSHDWPHDVXU

1R

,VVDIHDUHD

H[FHHGHG"

6B76$

<HV

ZLWK5(6(7

<HV

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

43

Page 44

Description

1.12 Measuring cycle help programs

1.12 Measuring cycle help programs

1.12.1 CYCLE116: Calculation of center point and radius of a circle

Function

This cycle calculates from three or four points positioned on one plane the circle they

inscribe with center point and radius.

To allow this cycle to be used as universally as possible, its data is transferred via a

parameter list.

An array of REAL variables of length 13 must be transferred as the parameter.

<

3

Programming

3

5DGLXV

03

3

3

;

Figure 1-11 Calculation of circle data from 4 points

CYCLE116 (_CAL[ ], _MODE)

Measuring cycles

44 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 45

Description

1.12 Measuring cycle help programs

Transfer parameters

● Input data

Parameters Data type Meaning

_CAL [0]

_CAL [1]

_CAL [2]

_CAL [3]

_CAL [4]

_CAL [5]

_CAL [6]

_CAL [7]

_CAL [8]

● Output data

Parameters Data type Meaning

_CAL [9]

_CAL [10]

_CAL [11]

_CAL [12]

_MODE

REAL Number of points for calculation (3 or 4)

REAL 1. Axis of the plane of the first point

REAL 2. Axis of the plane of the first point

REAL 1. Axis of the plane of the second point

REAL 2. Axis of the plane of the second point

REAL 1. Axis of the plane of the third point

REAL 2. Axis of the plane of the third point

REAL 1. Axis of the plane of the fourth point

REAL 2. Axis of the plane of the fourth point

REAL 1. Axis of the plane of the circle center point

REAL 2. Axis of the plane of the circle center point

REAL Circle radius

REAL Status for the calculation

0 = Calculation in progress

1 = Error occurred

INTEGER Error number (61316 or 61317 possible)

Note

This cycle is called as a subroutine by, for example, measuring cycle CYCLE979.

Example

%_N_Circle_MPF

DEF INT _MODE

DEF REAL _CAL[13]= (3,0,10,-10,0,0,-10,0,0,0,0,0,0) ;3 points specified P1: 0,10

P2: -10,0

P3: 0,-10

CYCLE116(_CAL[ ], _MODE) ;Result: _CAL[9]=0

_CAL[10]=0

_CAL[11]=10

_CAL[12]=0

_ALM=0

M0

STOPRE

M30

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

45

Page 46

Description

1.13 Miscellaneous functions

1.12.2 CUST_MEACYC: User program before/after measurements are performed

Function

The CUST_MEACYC cycle is called at the beginning of each measuring cycle.

It can be used by users to program sequences necessary before starting a measurement

(e.g. to activate probe).

In the as-delivered state, this cycle only contains one CASE statement that executes a jump

to a label with subsequent M17 (end of subroutine) for each measuring cycle.

Example

_M977: ;before measurement in CYCLE977

M17 ;end of cycle

From this label all actions to be executed on each CYCLE977 call must be programmed.

References

Commissioning manual

SINUMERIK 840D sl Basesoftware and Operating Software

1.13 Miscellaneous functions

1.13.1 Measuring cycle support in the program editor

The program editor offers extended measuring cycle support for inserting measuring cycle

calls into the program.

Prerequisite

Hardware TCU or PCU.

Function

This measuring cycle support provides the following functionality:

● Measuring cycle selection via softkeys

.

● Input screen forms for parameter assignment with help displays

● Retranslatable program code is generated from the individual screen forms.

Measuring cycles

46 Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

Page 47

Description

1.13 Miscellaneous functions

1.13.2 Measuring result screens

Function

Measurement result displays can be shown automatically during a measuring cycle. In the

channel-specific SD 55613 $SCS_MEA_RESULT_DISPLAY, you can select between the

following measurement result screens:

= 0 The measurement results screen is not displayed (default setting)

= 1 The measurement results screen is displayed for 8 seconds.

= 3 The measuring cycle stops at the NC command "M0", the measuring results screen is

statically displayed.

The measuring cycle is continued with NC Start, the measuring results screen is

deselected.

= 4 The measuring results screen is only displayed for cycle alarms 61303, 61304, 61305

and 61306.

The measuring cycle is continued with NC Start, the measuring results screen is

deselected.

The measuring cycles can display different measuring result screens depending on the

measuring variant:

● Calibrating tool probes

● Tool measurement

● Calibrating workpiece probes

● Workpiece measurement

Displaying measuring results screens

The measuring results screens contain the following data:

Calibrating tool probes

● Measuring cycle and measuring version

● Trigger values of axis directions and differences

● Probe number

● Safe area

Tool measurement

● Measuring cycle and measuring version

● Actual values and differences for tool offsets

● Safe area and permissible dimensional difference

● T name, D number

Measuring cycles

Programming Manual, 02/2011, 6FC5398-4BP40-0BA0

47

Page 48

Description

1.13 Miscellaneous functions

Calibrating workpiece probes

● Measuring cycle and measuring version

● Trigger values of axis directions and differences

● Position deviation (probe skew) when calibrating in the plane

● Probe number

● Safe area

Workpiece measurement